Page 1

Cleveland Range

REPAIR MANUAL

42CKEM24/36/48

42CKGM200/250/300

42CKDM

Model No. 42CKSM

UNITED STATES

1333 East 179th St

Cleveland. Ohio 44110

Phone:(216 )481-4900 • FAX: (216) 481-3782

Cleveland Range, Inc.

CANADA

Garland Commercial Ranges • 1777 Kamato Rd.

Mississauga, Ontario CN L4W 1X4

Phone: (416) 624-0260 • FAX: (416) 624-0623

Page 2

Installation, Use and Care Instructions

Convection Steamer

INSTALLATION

INSTALLATION SAFETY

WARNING

WARNING

INJURY TO PERSONNEL AND EQUIPMENT DAMAGE

may result from an improper dram connection.

Installation of this equipment must be

accomplished by qualified installation personnel,

working to all applicable local and national codes.

Improper installation at this product could cause

injury or damage.

D0 NOT store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

The flooring that will be directly under the boiler

must also be made of a noncombustible material.

Cleveland Range equipment is designed and built to

comply with applicable standards for manufacturers.

Included among those certification agencies which have

approved the safety of the equipment design construction

are: UL, A.G.A., NSF, ASME, CSA, CGA, and others.

Cleveland Range equipment is designed and certified for

safe operation only when permanently installed in

accordance with local and/or national codes. Many local

codes exist and it is this responsibility of the owner and

installer to comply with these codes.

In no event shall Cleveland Range assume any liability

for consequential damage or injury resulting from

installations which are not in strict compliance with our

installation instructions Specifically, Cleveland Range will

not assume any liability for damage or injury resulting

from improper installation of equipment including, but not

limited to, temporary or mobile installations.

INSTALLATION INSTRUCTIONS

1.These instructions must be retained by the owner/user

for future reference. Gas-fired boilers are only to be

installed in noncombustible areas that have provisions

for adequate air supply. The term "boiler'' will be used

synonymously with "steam generator"

2. Position: For proper operation and drainage, the

equipment must be level It should be placed next to

an open floor drain. DO NOT POSITION THE UNIT

DIRECTLY ABOVE THE FLOOR DRAIN. Observe all

clearance requirements to provide air supply for

proper operation. as well as sufficient clearance for

servicing. The surrounding area must be be free and

clear of combustibles. Dimensions and clearance

specifications are shown on the specification sheet.

3. Install in accordance with local codes and/or the

National Electric Code ANSI/NFPA No. 70-1987.

Installation in Canada must be in accordance with the

Canadian Electrical Code CSA Standard C22.1

Equipment that is connected to electricity must be

grounded by the installer. A wiring diagram is provided

inside the base cabinet.

4. The dram line outlet discharges exhaust steam and hot

condensate. Connect 1-1/2-inch. IPS piping (or larger) 10

extend the dram line to a nearby open floor dram. Up to

two elbows and six feet of 1-1/2-inch IPS (or larger)

extension pipe should be connected to the drain

termination. Drain piping extended six to twelve feet or

using three elbows, should be increased to 2-inch IPS No

more than two pieces of Cleveland Range equipment

should be connected to one common drain line. The

maximum length of extension from the dram

termination should not exceed six feet and use no

more than two elbows. The extension piping must

have a gravity flow and vent freely to the air. This

drain outlet must be free-vented to avoid the

creation of back pressure a the steamer cooking

compartments. To ensure a vented drain line, DO

NOT, UNDER ANY CIRCUMSTANCES, CONNECT

THE DRAIN OUTLET DIRECTLY TO THE FLOOR

DRAIN OR SEWER LINE. Do not run the drain line

discharge into PVC drain piping or any other drain

piping material not capable of sustaining 180 F

operation.

NOTE Direct steam connected pressure steamers do not

require a cold water connection, and therefore steps 5 and

6 do not apply. Refer directly to step 7. A kettle fin

faucet, if so equipped, requires a hot and/or cold water

connection. The data contained in step 5 for cold

water also applies to hot water.

5. Connect COLD water supply plumbing to the line strainer.

(Never connect hot water 10 the boiler-water fill line

strainer.) Constant flow pressure must he maintained

between 35 and 60 psi, and not experience a

pressure drop below 35 psi when other appliances

are used. If the water pressure exceeds 60 psi, a

pressure reducing valve must be installed in the

water supply plumbing 10 reduce the water

pressure 10 less than 60 psi. Locations and

pressure data are shown on the specification sheet,

1/4-inch IPS plumbing is sufficient for water supply

lines up to 20 feet in length, but water supply lines

longer than 20 feet should be at least 3/8-inch IPS.

Flush water supply lines thoroughly before

connecting them 10 the unit Use water which is low in

anal dissolved solids content and low in gas content to

prevent internal scaling, pitting and corrosion of the

steam generator, and carry -over of minerals into the

steam. Water which is fit to drink, can still contain highly

detrimental impurities.

NOTE: If equipped with a kettle and kettle water fin swing

spout, 3/8-inch (10mm) not and/or cold water

connections) win be required at the swing spout

valve.

6. Turn on the cold water supply to the unit. Ensure that the

manual water valve, inside this base cabinet, is open.

Page 3

Installation, Use and Care Instructions

7.

Connect the primary fuel supply in accordance with the

Convection Steamer

following instructions Location and other data are shown

on the specifications sheet.

For Gas-Fired Steam Generators: Post in a prominent

location, instructions to be followed in the event the user

smells gas. This information shall be obtained by

consulting the local gas supplier. Install a sediment trap

(drip leg) in the gas supply line then connect gas supply

piping to the boiler gas valve piping. GAS-FIRED

EQUIPMENT IS DESIGNED FOR INSTALLATION

ONLY IN NON-COMBUSTIBLE LOCATIONS. THIS

INCLUDES THE FLOORING THAT WILL BE

DIRECTLY UNDER THE EQUIPMENT. Location,

plumbing size, and pressure dataare shown on the

specifacation sheet. Boilers rated less that 225,000 BTU

require 3/4-inch IPS gas supply piping, and boilers rated

at 225,000 BTU or more require 1-inch IPS gas supply

piping. Natural gas pressure must be between 4''-14"

water column, and L.P. gas supply pressure must be

between I2'' - 14'' water column. NEVER EXCEED 14''

WATER COLUMN (1/2 psi) GAS PRESSURE. If the gas

supply pressure exceeds 14'' water column, a pressure

regulating valve most toe installed in the gas supply

plumbing to reduce the gas pressure 10 less than14''

water column. Installation must be in accordance with

local codes, or in the abcense of local codes, with the

National Fuel Gas Code, ANSI 2223.1 1984. Insallation

in Canada mast be in accordance with Installation codes

for Gas Burning Appliances and Equipment B149.1 and

B149.2 Use a gas pipe joint compound which is resident

to LP gas. Turn the gas valve control knob to ON (the

word "OB" on the knob will be opposite the index on the

valve's body). Test an pipe joints for leaks with soap and

water solution. Never obstruct the flow of combustion

and ventilation air. Observe an clearance requirements

to provide adequate air openings into the combustion

chamber The appliance and its individual shut -off valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 14" water column (1/2 psi or

3.45 kPa). The appliance must be isolated from the gas

supply piping system at test pressures equal to or less

than 14'' water column (1/2 psi or 3.45 kPa). A

permanent 115 volt electrical connection is required at

the junction box. The junction box location is shown OB

the specification sheet. The unit must be electricity

grounded by the installer.

For Electronic Powered Steam Generators: Connect

electric power: location and data are shown on the

specifications sheet Provide connection as required by

the unit; either directly to the single contactor, or to the

terminal block (when equipped with multiple contactors).

Electric supply must match power requirement s

specified on the data plate inside the base cabinet. The

copper wiring most be adequate to cany the required

current at the rated voltage. A separate fused

disconnect switch must be supplied and installed. The

unit must be electrically grounded by the installer.

For Steam Con Steam Generators: Connect Steam supply

piping to the input side of the steam coil. Location and

pressure data are shown on the specifacations sheet

Incoming steam pressure must be regulated between 35

and 45 psi A 3/4-inch strainer, equipped with a 20 mesh

stainless steel screen must be supplied and installed at the

incom ing steam connection point. Flush the steam line

thoroughly before connecting it 10 the boiler. To ensure an

adequate volume of steam, the branch steam supply line

must be 3/4-inch IPS minimum. Connect the inverted

bucket trap to the outlet end of the steam coil. Fill the

trap with water before installing it. A permanent 115 volt

electrical connection is required at the junction box. The

junction box location is shown on the specification sheet.

The unit must he electrically grounded by the installer.

For Direct-Steam Connected Steamers/Kettles: Connect

steam supply piping to the input side of the line strainer.

Location and pressure data are shown on the

specifacation sheet. Flush the stream line thoroughly

before connecting it to the steamer. To ensure adequate

of steam the branch steam supply line must be 3/4-inch

IPS minimum (Direct-steam -connected kettles require 1/2inch require IPS pipe if the kettle total capacity is 20

gallons or less, and 3/14-inch IPS pipe if the total capacity

exceeds 20 gallons.) A permanent 115 electrical

connection is required at the junction box. The junction

box location is shown OB the specification sheet. The

unit must be electronically grounded by the installer.

Installation Checks

Proper operation of the Cleveland Convection Steamer is

dependent upon proper installation. Alter the steamer has

been installed. A few quick checks could save unnecessary

service calls.

1. The unit must be level

2. The Convection Steamer requires a cold water connection

for proper, efficient operation. DO NOT USE HOT WATER

The cold water must be connected to the line strainer

located at the front lower-right of the steamer base

3. Check that the manual water supply valve is open

4. Check an water supply lines and valves for leaks

5. Check that the water supply pressure and water quality

meet the requirements of installation paragraph 5

6 On electric units, verify that the supply voltage meets the

voltage requirements on the rating plate 'inside the base

cabinet, and the •voltage shown on the packing slip Verify

that the unit is protected with a seperate fused disconnect.

and is properly grounded in accordance with the National

Electric Code

7. On gas, steam con, and diret -steam-connected units, verify

that there is a 115 Volt connection at the handi-box located

on the left side of the base at the bottom front.

2

Page 4

Installation, Use and Care Instructions

Range

3

Convection Steamer

8. On steam coil units, me incoming steam pressure

must be 35 10 50 psi Less than 35 pa will not

effectively operatethe unit. Pressure in excess of 50

psi must be reduced (with a a pressu re reducing

valve) to 35 to 50 psi.

WARNING

INJURY TO PERSONNEL AND EQUIPMENT DAMAGE

may result from an improper drain connection.

OPERATION

Operation of the Cleveland Range Convection Steamer is

very easy. Each operator should read and understand the

following procedures to effectively start, operate, and shut

down the steamer each day. The owner(s) and operator(s)

of this equipment should be aware that live steam can

cause serious injuries, and pay particular attention 10 the

WARN INGS in this text. These instructions are 10 be

retained by the owners) and operator(s)) for future

reference.

9. Check that the drain lines meet the installation

requirements specified in installation paragraph 4.

10. After completing checks 1 through 9, and correcting

any deficiencies, refer to the Start-Up and Preheat and

Preheat instructions in the Operation section. Verify

that the unit operates

properly, and make checks 11 and 12. and 12

11. Check ensure that the water the boiler sight gage

glass automatically says about 1/3 fan when the boiler

is started

12. Check to ensure that the stream pressure gage

registers 110 psi pa.

The steam pressure is factory -adjusted to provide the

proper pressure. In some cases, however,, the factory

set- may shift down 10 shaking and resetting win be

required after installation. Proper adjustments and

maintenance procedures are detailed on a separate

data sheet entitled "Steam Pressure Adjustments."

Adjustments be made only by qualified service

personnel The factory pressure settings shown in the

accompanying

chart should never be exceeded

Gage Pressure Reading with No Steam

Flow* (Static Pressure)

Self-Contained Steam Generator Steam , Gas or

Electric

Operating Pressure Switch 10 psi

High Limit Safety Pressure Switch

15psi

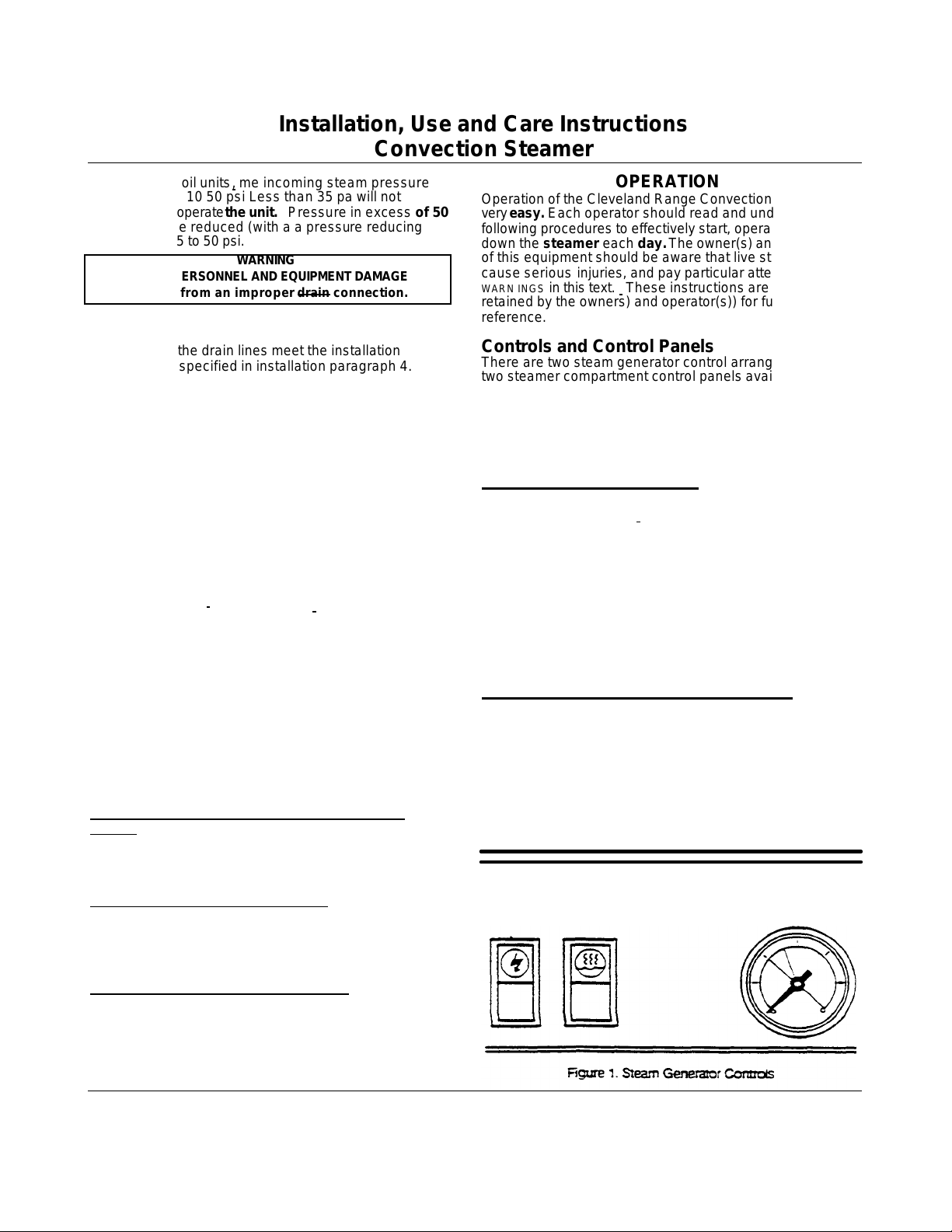

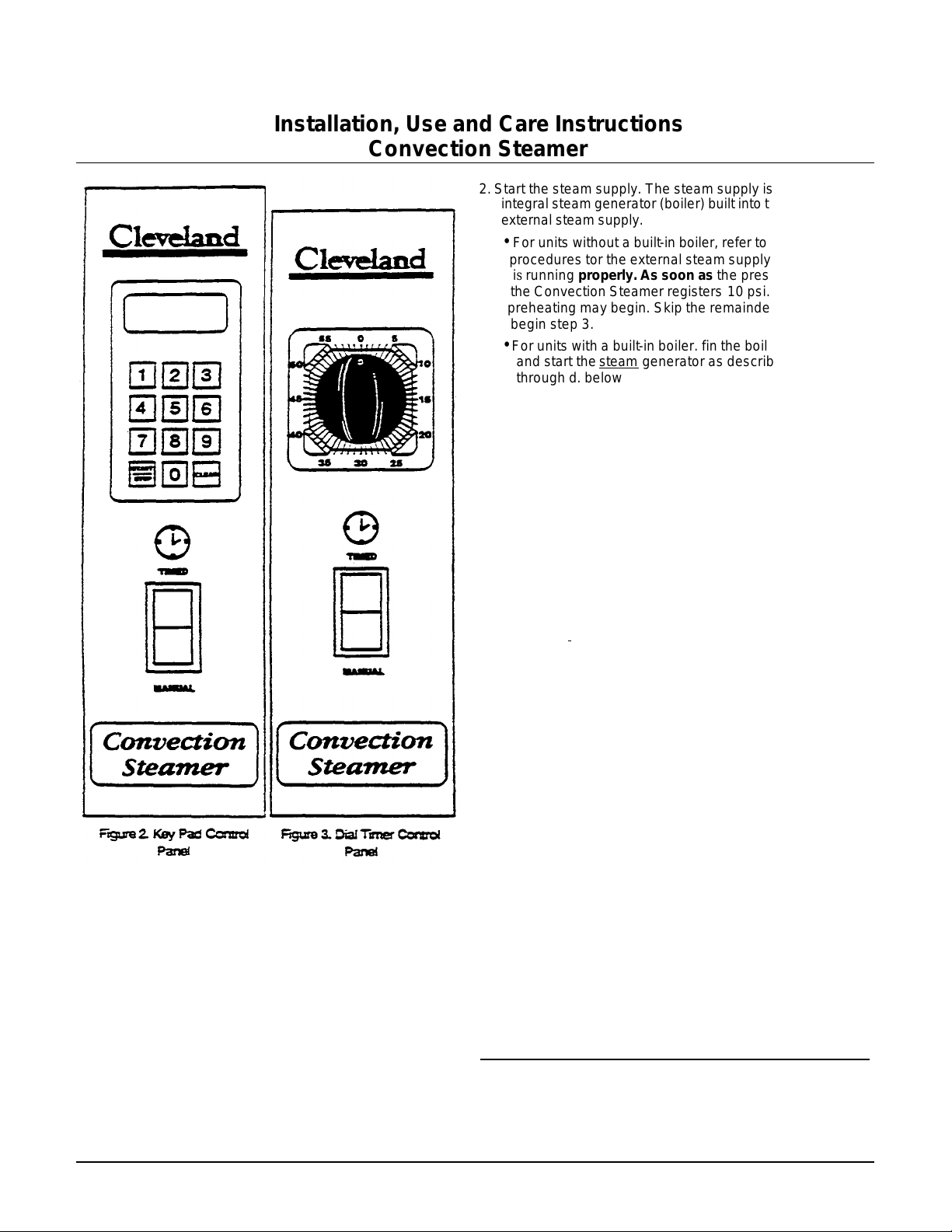

Controls and Control Panels

There are two steam generator control arrangements and

two steamer compartment control panels available for

Cleveland Range Convection Steamers. The steam

generator controls are illustrated The steamer compartment

control panels are illustrated in Figures 2 and 3. Compare

these figures with the equipment supplied, and identify

which control and panel combinations apply.

Steam Generator Controls

The steam generator controls are located on the front face

of the steamer base unit . The switches are 10 the left of the

pressure gage, as illustrated in Figure 1. Most Cleveland

Range<Convection Steamers have steam generator built

into the base unit which supplies steam to the cooking

compartments. However, an external steam supply may

also be used. Units with a built-in boiler have both the

POWER rocker switch and the STEAM mo mentary

switch next 10 the pressure gage. Units with an external

steam supply have the POWER rocker switch only.

They do not have the STEAM momentary switch.

Steamer Compartment Control Panels

Figure 2 illustrates the standard electronic controls: the Key

Pad Control Panel This panel has a rocker switch, a key

pad, and a digital timer. Figure 3 illustrates the optional

electromechanical controls: the Dial Timer Control Panel.

This panel] has a rocker switch and dial timer Steamer

functions are the same for both the standard and optional

panel configurations. Operating details are slightly different

especially when setting the automatic operating time. For

clarity, two sets of instructions are provided for cooking

operations.

Setf-Contained Steam Coil Generator

Operating Pressure Switch 10 psi High Limit

Safety Pressure Switch 15 psi Steam

Supply Pressure Range 3545 psi

Direct-Connect (to House Steam Supply)

Steamer Pressure Reducing Valve 10 psi Steam

Supply Pressure Range 15-45 psi

•with or without kettle

Page 5

Installation, Use and Care Instructions

Convection Steamer

Start-up and Preheat

WARNING

Do not attempt to start or operate the Convection Steamer

during a power failure are not energized, and serious injury

to personnel or damage to equipment may resu lt.

1. Inspect the steamer. Check: the cooking compartments 10

ensure that the steam tubes and drain screens are in

place and secure. Check inside the steamer base cabinet

10 ensure that the manual drain valve is closed and the

manual water supply valve is open.

2. Start the steam supply. The steam supply is either an

integral steam generator (boiler) built into the base unit. or

external steam supply.

• For units without a built -in boiler, refer to the startup

procedures tor the external steam supply and be sure it

is running properly. As soon as the pressure gage on

the Convection Steamer registers 10 psi. steamer

preheating may begin. Skip the remainder of step 2 and

begin step 3.

• For units with a built -in boiler. fin the boiler with water

and start the steam generator as described in steps a.

through d. below

a- Press the ON end of the POWER on-off rocker switch

located next 10 the steam pressure gage (Figure 1). The

red indicator light in the POWER rocker switch turns on

and the steam generator begins to fill with water. This

takes about 5 minutes

b. When the-water level in the steam generator reaches a

safe operating level, the amber light in the STEAM

momentary switch turns on. Whenever the amber light is

on, the heaters, steam su pply or burners arc off. and no

steam is being generated. The energy source (electric,

gas. etc..) cannot be activated until the boiler

contains sufficient water indicated by The amber light

c. Press the STEAM momentary switch to produce steam in

the boiler. This activates the energy source (electric

heaters, gas burners or steam solenoid valve) and

the amber light turn s off.

The STEAM switch must be pressed to re-start the

steamer after it is shut off for any reason (including a

brief power interuption). No attempt should be made to

operate the equipment during a power failure.

NOTE: For steamers with built-in gas-fired boiler:

If the burners fail 10 ignite m four seconds, a safety

circuit de- energizes the system. In this event, toggle

the POWER rocker switch to the OFF position and

back to the ON position. The amber light in the

STEAM momentary switch lights. Wait five minutes,

then press the STEAM momentary switch to start the

3. Preheat the Convection Steamer cooking compartments.

For accurate, efficient cooking times, the cooking com-

burner ignition cycle once again.

d. About20 minutes after starting the boiler in step c, the

e. steam pressure guage on the unit base should

register 10 psi.

partments should be preheated during startup.

NOTE: With a steamer/kettle combination, if both must

be used at the same time, always heat the kettle first,

When kettle contents begins to simmer, and steam

pressure returns, the steamer compartments may be

preheated.

a- Close the compartment door by gently swinging it

shut.

b. Refer to timer setting instructions under Automatic

Operation for the appropriate control panel Set the

Page 6

Installation, Use and Care Instructions

Convection Steamer

timer for each compartment to one minute, and start

the

cooking cycles Steaming begins in each compartment.

NOTE: On Convection Steamers equipped with

electronic key pad controls panels, the time r

does not begins counting down until the cooking

compartment reaches operating temperature.

This may take 2 or

3 minutes if the steamer has not been operting.

c. Steaming continues for the set one minute When

the preheating completed, the steam automatically

shuts off and a 3-second alarm sounds. The

Convection Steamer is ready for cookmg

operations.

COOKING OPERATIONS

The control panels mounted on the cooking

compartments regulate cooking operations. Although

cooking operations are similar for all Convection

Steamers, regardless of control panel configuration,

separate instructions are provided for each control panel

type.

Cooking Operations for

The Key Pad Control

Panel

The electronic key pad control panel is illustrated in

Figure 2.

The Cleveland Range Convection Steamer has two

cooking modes: Manual and Automatic. The Manual

Mode provides continuous steaming and is turned on and

off by the MANUAL/TIMED rocker switch. The Automatic

Mode monitors cooking time and temperature to provide

accurate, efficient, uniform steam cooking.

NOTE: Whether using timed or manual cooking mode,

optimum steam heat transfer, and therefore a

higher quality food product, is achieved when

shallow, perforated, uncovered pans are used.

WARNING LIVE STEAM may cause severe

burns. Use extreme caution when opening the steamer

door. Turn face away from the steamer when first

opening the door. Do not look into the cooking

compartment until steam has cleared. KEEP HANDS

OUT OF THE COOKING COMPARTMENT TO

PREVENT BURNS.

Manual Cooking Operation - Key Pad Controls

Use manual mode for a continuous supply of steam for

long periods, or if the required cooking time is unknown

and frequent inspection isrequired.

1. Place the pan(s) of food into the cooking

compartment.

2. To START the flow of steam, press the MANUAL end

of the MANUAL/TIMED rocker switch, located below

the timer. Steam immediately starts flowing into the

cooking compartment.

3. If food inspection is required during steaming, refer to

the LI VE STEAM WARNING above. Use extreme caution

when opening the steamer door during steaming

operations.

4. Although the timer cannot turn the steam off in manual

mode it can be used as a conventional cooking timer.

Refer to the timer setting instructions under Automatic

Operation and set the timer. The timer will count down

the set period and sound the buzzer, but IT WILL NOT

TURN OFF THE STEAM-AFTER THE ALARM

SOUNDS.

5. To STOP the flow of steam, press the Timed end of the

MANUAL/TIMED rocker switch. Steam stops flowing into

the cooking compartment.

Automatic Cooking Operation - Key Pad Controls

Each Convection Steamer cooking compartment is

equipped with an independent electronic digital timer, which

has a maximum setting of 99 minutes and 99 seconds.

Each timer is connected to a temperature sensing device in

the cooking compartment. THE SENSOR CIRCUIT

ALLOWS THE TIMER TO COUNTDOWN ONLY WHEN

THE COOKING COMPARTMENT IS AT THE PROPER

COOKING TEMPERATURE. This assures uniformity in the

cookmg times as the timer automatically compensates for

food product defrosting and/or heat -up time.

1. Place the pan(s) of food into the cooking compartment

2.Clear and reset the timer. The timer can be set only when

the COOKING TIME display is clear. Press the CLEAR

key on the number pad to zero the timer.

3. Set the Desired Cooking Time. The cooking time display

contains four digits. The left two digits are minutes, and

the right two digits are seconds. The display 12:34 is set

for 12 minutes and 34 seconds.

a. To set the cooking time: change the required cooking

time to minutes and seconds, press the number keys for

the minutes and then press the number keys for the

seconds, If the cooking time 99 seconds or less, only

press the number keys for seconds.

b. Example 1. To set the timer for 1 hour and 15 minutes:

Change 1 hour (60min) and 15 minutes to 75 minutes.

Press the following number keys in sequence: 7500.

The display will read 75:00 when property set for 1

hour and 15 minutes.

c. Example 2. To clear the time numbers set in example

1. press the CLEAR key on the number pad. The

display returns to 00:00.

d. Example 3. To set the timer for 1-5 minutes: Change

the time to 1 minute and 30 seconds. Press the

following number keys in sequence: 1,3,0. The

display will read 01:30, when set for 1.5 minutes. AIl

seconds method: Change the 1.5 minutes to 90

seconds and press 9 0. The display will read 00:90,

when set for 1.5 minutes.

Page 7

Installation, Use and Care Instructions

Convection Steamer

4. Press the START/STOP key to start the timer. When the

START/STOP key is pressed, steam enters the cooking

compartment.

a. THE TIMER WILL BEGIN TO COUNT DOWN ONLY

AFTER THE COOKING COMPARTMENT

REACHES PROPER COOKING TEMPERATURE.

The timer automatically delays to compensate for

defrosting and/or food product heat -up time.

b. For example, a timer setting of 10 minutes may in

fact take 11 or 12 minutes for the timer to count

down and the alarm to sound. This is normal.

Heating the compartment and food to cooking

temperature uses the additional time.

c. To stop or reset the timer, press and hold the

START/STOP key. The cooking one display returns

to the last time setting.

• To restart the same time, press the

START/STOP key.

• To set a new time press the CLEAR key, and set

the new time.

5. When the timer counts down to zero, an alarm sounds

continuously. Press the START/STOP key to silence

the alarm. The cooking time display returns to the last

time setting. Either run this same setting again or clear

and reset the timer.

6. Example 4. To cook two 14 minutes cycles: Press the

CLEAR key to clear the timer. Press the following

number keys in sequence: 1,4,0,0. The display shows

14:00. Press the START/STOP key to start the timer.

When the display counts down to zero, the alarm

sounds. Press the START/STOP key, and the display

returns to 14:00. Press the START/STOP key to start

the second 14 minute cycle.

Cooking Operations for

The Dial Timer Control

Panel

The dial timer control panel is illustrated in Figure 3.

The Cleveland Convection Steamer has two cooking

modes:

Manual and Automatic. The Manual Mode provides

continuous steaming and is turned on and off by the

MANUAL/TIMED rocker switch. The Automatic Mode

monitors cooking time to provide accurate, efficient, steam

cooking.

NOTE: Whether using timed or manual cooking modes,

optimum steam heat transfer, and therefore a higher

quality food product, is achieved when shallow,

perforated, uncovered pans are used.

Manual Cooking Operation - Dial Timer Controls

Use Manual mode for a continuous supply of steam for

periods longer than the timer limits (99 minutes), or if the

required cooking time is unknown and frequent inspection is

required.

1. Place the pan(s) of food into the cooking compartment.

2. To START the flow of steam, press the MANUAL end of

the MANUAL/TIMED rocker switch, located below the

timer.

3. If food inspection is required during steaming, refer to the

LIVE STEAM WARNING above. Use extreme caution

when opening the steamer door during steaming

operations.

4. Although the timer cannot turn the steam off in manual

mode it can be used as a conventional cooking timer.

Refer to the timer setting instructions under Automatic

Operation and set the timer. The timer will count down the

set period and sound the buzzer, but IT WILL NOT TURN

OFF THE STEAM AFTER THE ALARM SOUNDS.

5. To STOP the flow of steam, press the Timed end of the

MANUAL/TIMED rocker switch.

Automatic Cooking Operation

Dial Timer Controls

Each Convection Steamer cooking compartment is equipped

with an independent dial timer. This timer controls the

cooking compartment steaming cycle. Use automatic mode

when an exact cooking time is required. Steam cooking

begins when the timer is set, and automatically stops when

the timer counts

down the set period.

1. Check that the MANUAL/TIMED rocker switch is in the

TIMED position. If it is not. press the TIMED end of the

MANUAL/TIMED rocker switch.

2. Place the pan(s) of food into the cooking compartment.

3. Set the Desired Cooking Time. Turn the dail until it points

to the desired cooking time. When the dial timer is set.

steam enters the cooking compartment.

4. When the timer counts down to zero, as alarm sounds for 4

seconds, and steam flow into the cooking compartment

stops.

Boiler Shutdown

The red-lighted power switch must be shut off for 3 minutes

a minimum of once every 8 hours to automatically drain

highly mineralized water from the boiler, which reduces the

formation of scale. See Step 1 in CARE AND CLEANING

instructions, which follow.

WARNING:

LIVE STEAM may cause severe bums. Use extreme caution

when opening the steamer door. Turn face away from the

steamer when first opening the door. Do not look into the

cooking compartment until steam has cleared. KEEP HANDS

OUT OF THE COOKING COMPARTMENT TO PREVENT

BURNS.

6

Page 8

Installation, Use and Care Instructions

Convection Steamer

CARE AND CLEANING

The Cleveland Convection Steamer must be cleaned

regularly to maintain its fast, efficient cooking

performance, and to ensure its continued safe, reliable

operation.

1. The boiler must be drained (Blowdown) after a

maximum of 8 hours of use. If the boiler feedwater

contains more than 60 pans per million of total

dissolved solids, the boiler must have a blowdown more

often, the frequency depending upon the mineral

content of the feedwater. Blowdown means the boiler

must be drained under pres-sure.

THE BOILER BLOWDOWN IS PERFORMED BY

SIMPLY SHUTTING OFF THE STEAMER'S REDLIGHTED POWER SWITCH WHILE THE BOILER IS

AT NORMAL 10 PSI OPERATING PRESSURE. WHEN

THE BOTTOM OF THE POWER ROCKER SWITCH IS

PRESSED, ITS RED LIGHT GOES OUT, AND THE

DRAIN VALVE AUTOMATICALLY OPENS, DRAINING

THE BOILER. AN AUTOMATICALLY-TIMED DRAIN

WATER CONDENSER WILL FLUSH THE DRAIN FOR 3

MINUTES, THEN SHUT OFF. AFTER 3 MINUTES THE

STEAMER IS READY TO BE RESTARTED.

When steam is produced, the water in the boiler is being

the boiler with the water, remain in the boiler as the

water boils away as steam. When allowed to

accumulate, the

water becomes highly mineralized, which results in erratic

operation, lime build-up corrosion, and premature

electric heater failures. In some cases, complete boiler

replacement becomes necessary, which is extremely

ex-pensive. By draining the boiler under pressure, most

sedi-meat present will be flushed down the drain.

2. The steamer is equipped with a drain in the back of the

cooking compartment. No compartment should be

operated without the drain screen in place. This screen

prevents large food particles from entering and possibly

plugging the drain line. Any restriction of the drain line

may cause a slight build-up of back-up pressure in the

compartment, resulting in steam leaks around the door

gasket. It also may adversely affect the convection

action of the steam in the compartment, which is critical

to optimum performance. Pouring USDA approved

drain cleaner through the compartment drains once a

week will help to ensure an open drain. A manual

(hand crank) drain auger, or "snake'', may be safely

used to clear obstructions in the compartment drains.

Do not use a power auger, as damage to the plastic

drain system will result.

With the steamer off open the cooking compartment

doors and allow the steamer to cool before cleaning the

cooking compartments and their compartments.

3. At the end of each day's operation, wash the pan

slide's, steam tubes, door gaskets, and compartment

interiors with mild detergent and warm water, either by

hand or in a dishwasher. Rinse thoroughly with clear

water. Rinse water should drain freely through the

compartment drain

opening. If it does not, the drain must be cleaned before

using the steamer.

4. Once a week, remove the steam robes and clean the

orifices. First, remove the pan slides by lifting upward

and toward the center of the compartment. Pressing

backward on the steam tube will allow its front eyelet to

clear the compartment stud. The tube is then angled

toward the center of the compartment just enough to

clear the stud and be pulled forward, out of its socket.

The orifices can be cleaned easily with a paper cap.

Then. thoroughly wash and rinse all steam tubes. This

can be done m a dishwasher. Lubricate each tube's

tapered end with cooking oil before replacing in the

steamers compartments. Be sure all four steam tubes

are securely in place before activating the compartment.

The tubes are interchangeable and may be placed m

any spot m either compartment.

5. To prolong door gasket always leave compartment door

ajar when not in use.

6. Exterior Care: Allow steamer to cool before washing. Use

the same cleaners and cleaning procedures as for other

kitchen surfaces of stainless steel and aluminum. Mild

soapy water, with a clear water rinse, is recommended.

Do not allow water to run into electrical controls. Always

turn off equipment power before using water to wash

equipment. Do not hose down the steamer.

WARNING

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity extras or any other appliance.

MAINTENANCE

Periodically, a qualified serviceman should be

summoned for routine preventive maintenance.

1. The blowdown procedure will not completely remove the

mineral deposits that adhere to the top of the boiler. A

chemical descaling should be done by a boiler treatment

specialist. This should be done once a year in average

water conditions, but in poor water areas it may be

needed two or three times a year.

2. Periodic boiler inspection should be made by a qualified

serviceman.

3- Once every three months, the cold water line strainer

should be cleaned.

Cleveland Ranges supports a comprehensive network of

Maintenance and Repair Centers (regional pans and

service distributors) throughout the United States and

Canada. Please contact your nearest distributor for the

name of an authorized service agency in your area, or for

replacement pans and information regarding the proper

maintenance and repair of Cleveland Range equipment. In

order to maintain the various agency safety certifications,

only factory -supplied replacement parts should be used.

The use of other than factory -supplied replacement parts

will void the warranty.

Printed 6/90 7 Cleveland Range. Inc.

Page 9

Page 10

CONVECTION STEAMER TIMER SETTINGS

(In Minutes)

Artichoke

12

Asparagus, spears

4 6

Beans, green

2"

cut 6 5 French cut

4 5"

whole 6 4

Broccoli, spears

3 2-3

flowerettes

2-3 2-3

chopped

6-8 Brussels sprouts

4-5 4

Cabbage

12-16 wedges/head

4 Cabbage.

whole

- to remove leaves

2

for cabbage rolls

Carrots. baby whole

10 6

sliced. crinkle cut

7-8 3

diced

2 Cauliflower, flowerettes

4-5 3-4

whole

10

Celery. diagnonal cut

1 1/2 3

diced

2 1

minced

1 Corn, yellow whole kernel

2 on

cob.

cobbettes

6

12" Eggptant. sliced, diced

1

Mixed vegetables

• 3-4

Mushrooms, whole (1 1/2"

3

sliced 1

Onions, diced, sliced

2-3 1

whole

4 2

Peas. green

2

Potatoes. whote 8

oz 30-35 peeled. quartered. fresh

12-19

peeled. diced

8-10

Potatoes, sweet whole

30-35

Spinach leaf

2 21-

chopped

21-

Squash, acorn halves

15 butternut. qu

artered

7 whipped*

20-

spaghetti squash, halves

15-18

Tomatoes, whole, sliced

1

Turnips, whole

20-25 Zucchini. sliced

2-4 2-4

SEAFOODS: Steam all seafoods on

a

perforated par

-

with

catch pan.

Cod fillets.

5

oz- portions

3 4

Crab legs. king

4-6 Snow crab

2-4

Crab. live,

4

oz 4

3/4 - 1 Ib. 12

Halibut. 6

-8

oz portions

4-6 6-8

Lobster, whole, 1 Ib.

7-9 Lobster tails.

8

oz 8-10

defrosted. butterflied

4-6 Mussels

in shell

2

Oysters in shell

2-4

Red snapper.

8

oz- 4-5 4-5

Salmon steak.

8

oz. 6 7 Shrimp,

10

ct. per Ib. lQF

3 4-6

5

Ib. block, peeled

&" deveined

30

ct. 6-8-

potatoe salad

10-12

Soft cooked

•a

Coddled

6

Poached in a cup

2-3

Fresh: Avocado

1

Apple. cored

1 Grapefruit

1

Orange

1 Apricot

1

Pineapple, whole

2

Dried': add water to re

-

hvdrate

Apple

10

Apricot

10

Peach

10

Pear 10

Prune

10

Timer settings are approximate due to the differences in food quality, age. shape and the degree of doneness desired 1: is no necessary to

add water- Perforated pans are recommended. Starred items (*) must be cooked in solid pans or- containers. Items marked with two stars

(**) require handling in two steps. First. steam for approximately 1/2 the time shown, remove from steamer separate thawed portion, or

stir and return to the steamer for the time remaining. The compensating feature of the timer allows the cooking compartment to reach

cooking temperature before the preset time starts to count up.

VEGETABLES: Fresh Frozen

(In Minutes)

Fresh Frozen

Clams in shell 3-5

5 Ib. block, green, 26-30 ct (nested pan) 10EGGS (Medium Sized):

Hard cooked for egg salad.

Scrambled* 6-7-

FRUITS:

Blanch tor peeling

9

Page 11

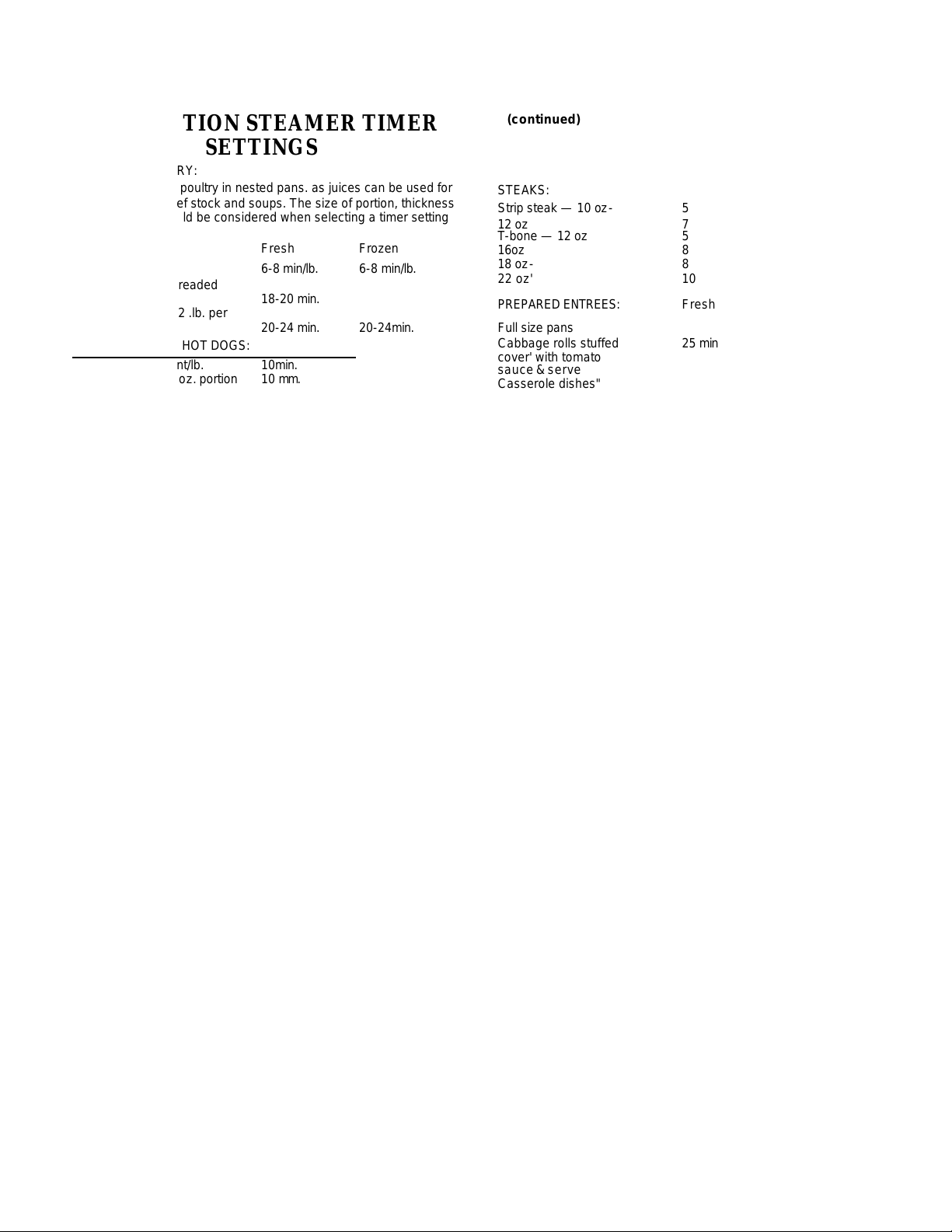

CONVECTION STEAMER TIMER

gravy, sauces. beef stock and soups. The size of portion, thickness

Chicken, 5

-

8 oz breaded

pieces

18-20

min. halves.

1 1/4 -

1 1/2 .l

b. per

Italian sausage.

4 oz.

portion

10

mm.

Ribs. 3 lb and down

20-26

min

Ground chuck

for chili

4-6 min/lb.

4-6

min/lb.

Pot roast, choice

8-12

min/lb.

Rump roast. choice

boned

-

rolled, tied

12

min/lb.

Meat loaf.

4

ib. loaf

5

min/lb.

Liver baby bee?.

8

oz- slice 2-4

min. 2-4 min.

Corned beef.

6-8

Ib.

'rare" stage

chopped.

8

Rioeye.

8

oz. Top butt steak.

6

oz. 8 oz. Filet Mignon, Butterflied

— 4

oz. 6 oz. 8

oz

10

oz

12 oz 7 min.

T-bone —

12 oz

5

min. 16oz 8 min 18 oz

- 8 min.

Full size pans

Cabbage rolls stuffed

25

min 20

min.

cover' with tomato

sauce

&

serve

Casserole dishes"

beef stew,

20-25 min.

25-30 min.

stroganoff

20-25 min.

25-30 min.

Lasagna". freshly prepared

20-25

min 25-30

mm.

Potatoes':

2 1-2 # random sliced

4

cups cold water/lb.

Beans*, pre

-

soaked over

-

night 1

lb. beans

+

1 1/4 qts. water

Beans*, unseated.

l to. beans

+

1 1/2 qts water

12

min.

Lasagna noodles

Maca

roni, shells. elbow

Rigatoni

Spaghetti, vermicelli

Spaghetti, regular

SETTINGS

MEATS & POULTRY:

Steam meats and poultry in nested pans. as juices can be used for

of cut, grade, should be considered when selecting a timer setting

for doneness.

POULTRY Fresh Frozen

Turkey, whole 6-8 min/lb. 6-8 min/lb.

half 20-24 min. 20-24min.

PORK, SAUSAGE, HOT DOGS:

Pork - Chop. 4 count/lb. 10min.

Hot dogs 8 count/lb. 2min

BEEF:

Cubes, 1 1/2" 6-7 min./lb. 6 min/lb.

add 1/2" water to pan 20-23 min/lb.

STEAKS:

Using a 3/4" to1" steak, the steaming time tested below produces a

"rare" steak. A "well done" steak is first steamed to the'

then broiled or grilled for 1 1/2 minutes on each side. This

"welldone" steak shrinks less is more tender and jucy and when

served, is the same SIZE as the '"rare" steak.

Sirloin patties

OZ

16 oz. whole (Chateaubrand)

CUT

4 min.

4 min.

4 min.

6 min.

3 min.

3-4min.

4.min.

5 min.

8 min

(continued)

STEAKS:

Strip steak — 10 oz- 5 min.

22 oz' 10 Min.

PREPARED ENTREES: Fresh Frozen

reheat each serving 4" 6-8 min. 12 min.

DEHYDRATED FOODS:

plus 5 cups cold water/lb.

RICE & BEANS:

Rice*. long again

Refried beans'. 2 #10 cans

PASTA:

Steam in nested pans. Place pasta on 2 1/2" perforated pan used

as a finer in a solid 2 1/2 pan. Cover pasta with cold water.

Egg noodles, 1 1/2" wide

4-6 min" 10-12min" 10-12 min" 10

Min" 8 min" 10 min."

10

Page 12

Page 13

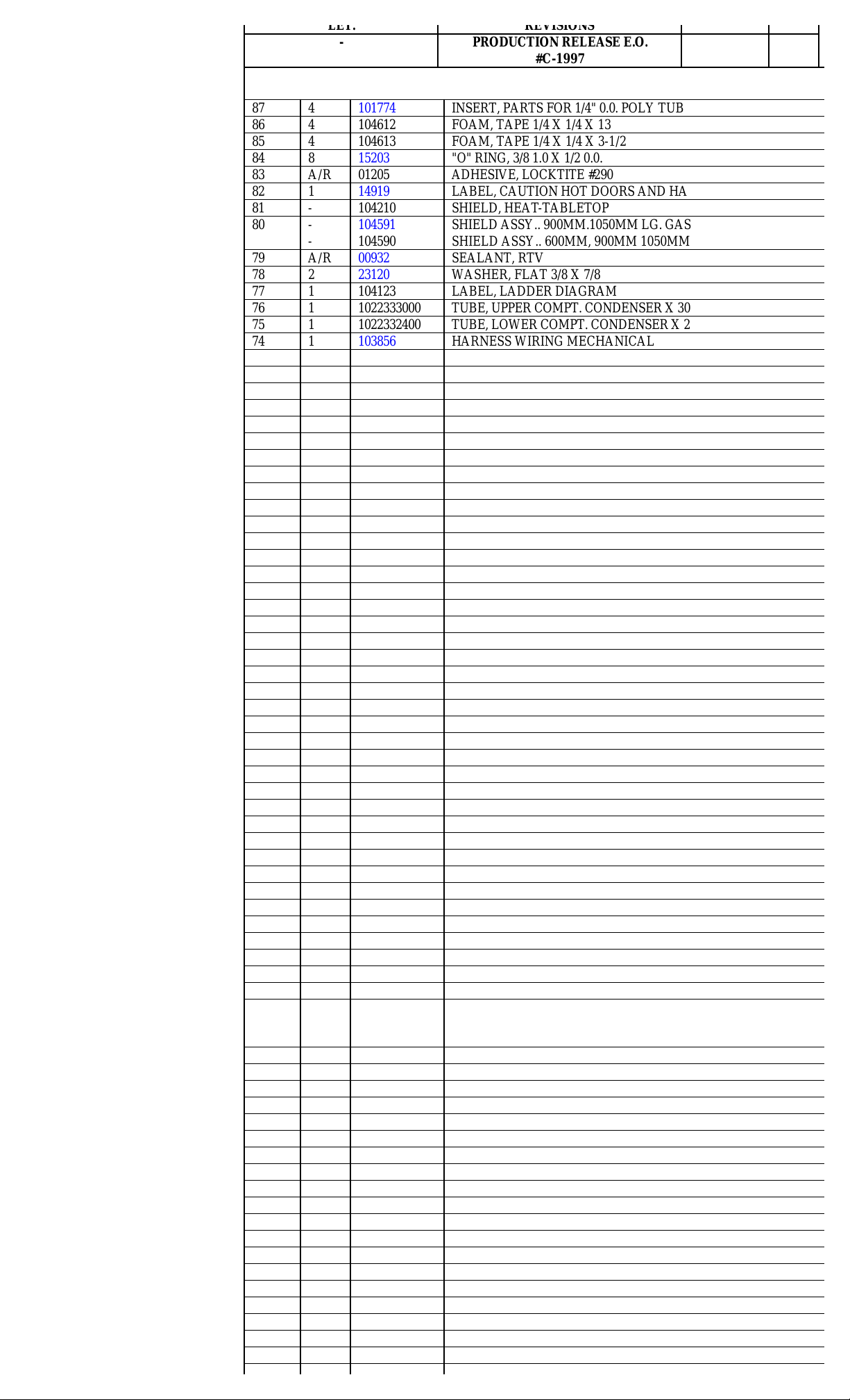

LET. REVISIONS

DATE

BY

- PRODUCTION RELEASE E.O.

#C-1997

09-30-91 PO

87 4 101774 INSERT, PARTS FOR 1/4" 0.0. POLY TUBE

86 4 104612 FOAM, TAPE 1/4 X 1/4 X 13

85 4 104613 FOAM, TAPE 1/4 X 1/4 X 3-1/2

84 8 15203 "O" RING, 3/8 1.0 X 1/2 0.0.

83 A/R 01205 ADHESIVE, LOCKTITE #290

82 1 14919 LABEL, CAUTION HOT DOORS AND HANDLES

81 - 104210 SHIELD, HEAT -TABLETOP

80

79 A/R 00932 SEALANT, RTV

78 2 23120 WASHER, FLAT 3/8 X 7/8

77 1 104123 LABEL, LADDER DIAGRAM

76 1 1022333000 TUBE, UPPER COMPT. CONDENSER X 30"

75 1 1022332400 TUBE, LOWER COMPT. CONDENSER X 24"

74 1 103856 HARNESS WIRING MECHANICAL

73 1 66014 PANEL, RIGHT SIDE CONV. STMR .

72 4 41423 RACK, PAN SLIDE, 20"

71 4 23149 WASHER-NYLON, TYPE 6/6

70 4 14649 NUT, HEX, 1/2 -12, ZINC PLTD

69 A/R 00908 LUBRICANT, "O" RING

68 1 102154 TUBE, COPPER TRAP TO DRAIN-LOWER

67 1 06190 FITTING, COMPRESSION 1/4 T X 1/8 MPT STRAIGHT

66 2 06233 FITTING, COMPRESSION 3/8 T X 1/8 MPT 90°

65 1 05227 ELBOW, 1" STREET BLACK 45°

64 2 56519 FITTING, COMPARTMENT DRAIN, 2 HOLE

63 2 02139 BEND, "Y", BLACK

62 2 06216 FITTING, COMPRESSION 1/4 T X 1/4 MPT STRAIGHT

61 2 06230 FITTING, COMPARTMENT DRAIN

60 2 14555 NOZZLE, SPRAY, BRASS 1/8" FULL JET

59 2 70732 TUBE, COPPER-DRAIN VENT

58 3 06192 FITTING, TUBE 1/4 T X 1/8 MPT 90°

57 1 70776 TUBE, COPPER, STEAMBOX TO TRAP -LOWER

56 1 70758 TUBE, COPPER, TRAP TO DRAIN-UPPER

55 2 20559 TRAP, 1/4 X 1/4 THERMOSTATIC

54 4 14661 NUT, COMPRESSION, FITTING, BRASS, 1/4" TUBE

53 1 70726 TUBE, COPPER, STEAM BOX TO TRAP -UPPER

52 1 06203 FITTING, COMPRESSION 1/2 T X 3/8 MPT 90°

51 1 104126 INSULATION, CONVECTION BODY REAR

50 1 69239 PANEL, REAR OUTER, SHEETING CONV. STMR.

49 7 19267 SCREW, TRUSS HEAD, SHT. METEL

48 1 70734 TUBE, STEAM SUPPLY-LOWER COMPARTMENT

47 1 06202 FITTING COMPRESSION 1/2 T XC 3/8 MPT ST

46 1 70735 TUBE, STEAM SUPPLY-UPPER COMPARTMENT

45 1 423951 STEAM, INL ET ASSEMBLY

44 1 03197 CLAMP, 1 HOLE 3/4"

43 1 44064 WATER VALVE ASSEMBLY NEW CONV. STMR.

42 2 19147 SCREW, PAN HD STLD 8-32 S/S

41 2 100711 WASHER, INTERNAL TOOTH LOCK S/S #B

40 1 52598 BRACKET, VALVE, SUPPORT CONV. STMR.

39 2 104409 CLOSURE, THERMAL OPENING

38 - 14652 NUT, HEX 5/16-18 S/S

37 1 104398 LABEL, WIRING SCHEMATIC

36 2 23134 WASHER, FLAT 5/16"

35 1 40749 PEOSTAL, WELMENT HINGE-LEFT

34

33 - 19196 SCREW, HEX HD, 5/16 X 18 X 3/4

32 8 14679 NUT, ACORN 10-24 S/S

31 - 19148 SCREW, HEX WASH HD.. SHEET METAL

30 1 44168 TERMINAL BLOCK ASSEMBLY 2 POLE

29 2 104223 NUT, HEX 6-32 ELASTIC LOCK

28 A/R 101051 NEVER-SEEZ

27 6 14665 NUT, HEX 1/4 -20 ELASTIC LOCK W/ NYLON INSERT

26 7 23105 WASHER, LOCK S/S 1/4"

25 13 23116 WASHER, FLAT S/S 1/4"

24 5 19288 SCREW, HEX HEAD 1/4 -20

23 1 1025691 PANEL, FRONT FILLER

22 2 104501 TIMER ASSY, CONVECTION STEAMER MECHANICAL

21 2 103537 DOOR, OUTER ASSEMBLY HINGE LEFT

20 2 104101 DOOR, INNER ASSEMBLY

19 2 104046 CATCH, DOOR

18 4 14695 NUT, DOOR CATCH MOUNTING S/S

17 2 146771 NUT, ACRON 1/4 -20

16 2 69298 SCREEN, COMPARTMENT DARIN

15 2 102513 WASHER, FLAT S/S 5/15 X 3/4 X .080

-

-

-

-

-

104591

104590

70085

70082

70084

SHIELD ASSY.. 900MM.1050MM LG. GAS

SHIELD ASSY.. 600MM, 900MM 1050MM SM GAS

TABLETOP HINGE LEFT 900MM

TABLETOP HINGE LEFT 1050MM

TABLETOP, HINGE LEFT & RIGHT 600MM

Page 14

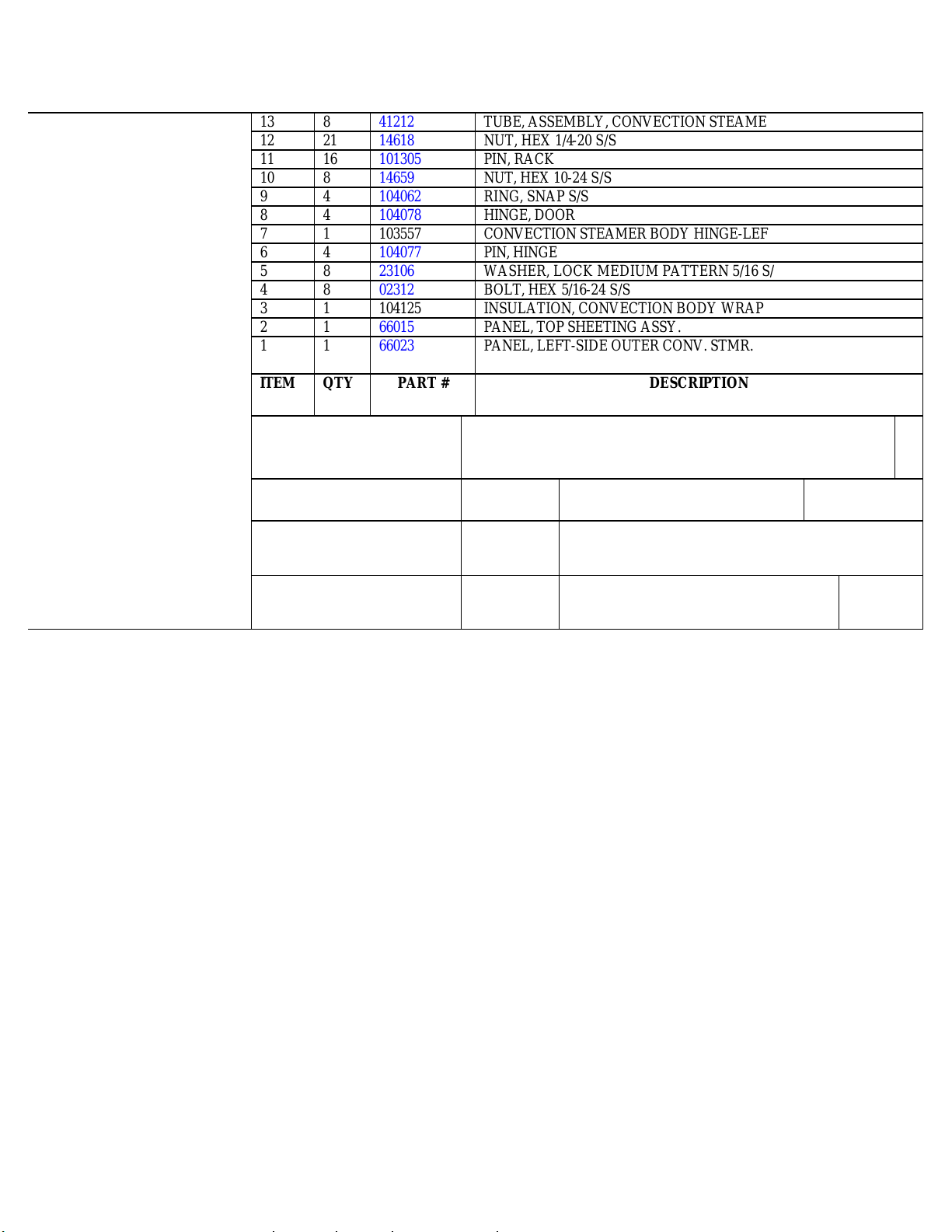

13 8 41212 TUBE, ASSEMBLY, CONVECTION STEAMER

12 21 14618 NUT, HEX 1/4-20 S/S

11 16 101305 PIN, RACK

10 8 14659 NUT, HEX 10-24 S/S

9 4 104062 RING, SNAP S/S

8 4 104078 HINGE, DOOR

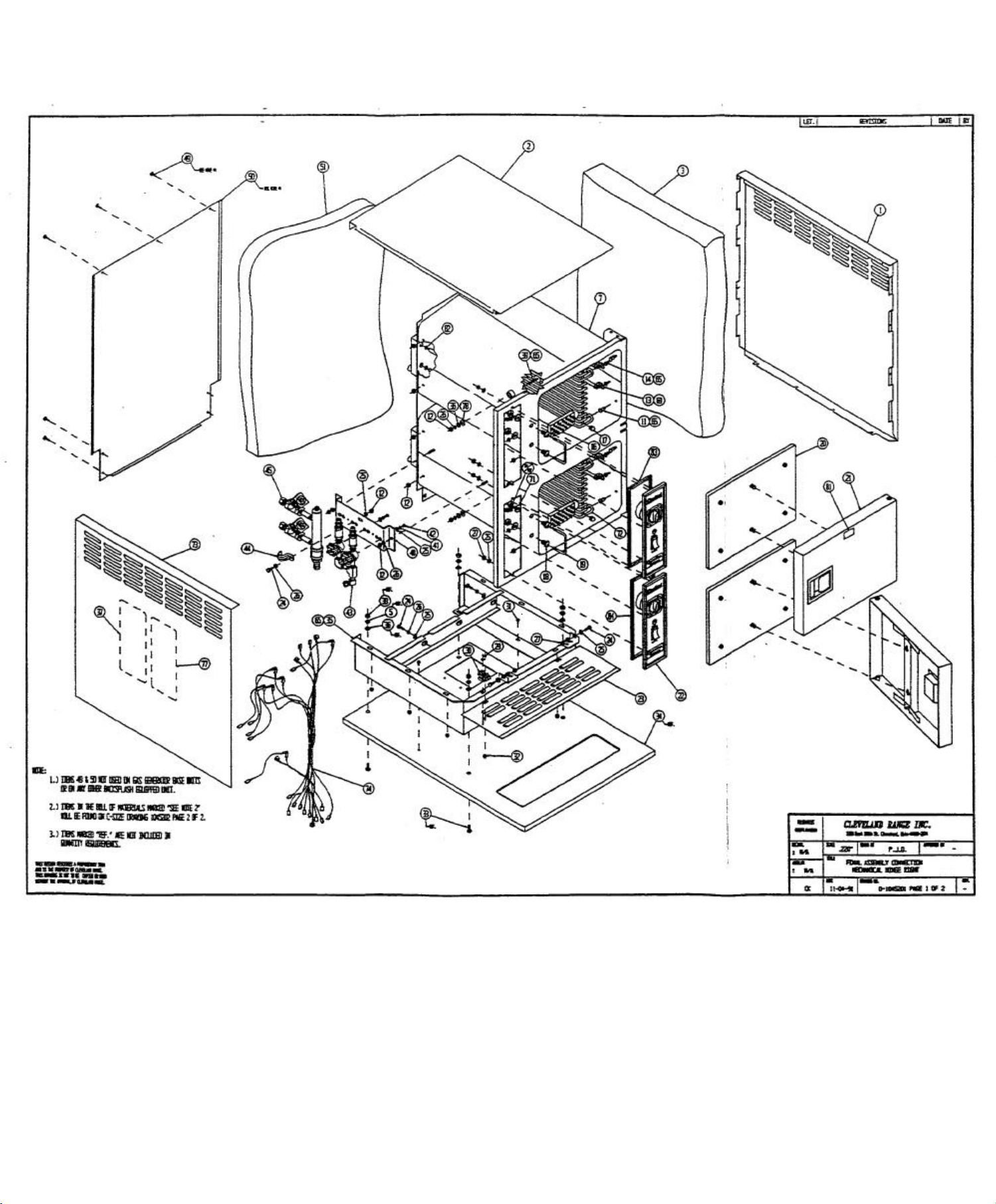

7 1 103557 CONVECTION STEAMER BODY HINGE-LEFT ASSEMBLY

6 4 104077 PIN, HINGE

5 8 23106 WASHER, LOCK MEDIUM PATTERN 5/16 S/S

4 8 02312 BOLT, HEX 5/16-24 S/S

3 1 104125 INSULATION, CONVECTION BODY WRAP

2 1 66015 PANEL, TOP SHEETING ASSY.

1 1 66023 PANEL, LEFT-SIDE OUTER CONV. STMR.

ITEM QTY PART # DESCRI PTION

TOLERANCES

(EXCEPT AS NOTED)

DECIMAL

1 N/A

ANGULAR

1 N/A

CK

1333 East 179th St. Cleveland, Ohio 44110-2574

SCALE

N/A

TITLE

DATE

07-15-91

CLEVELAND RANGE INC.

DRAWN BY:

P.J.D.

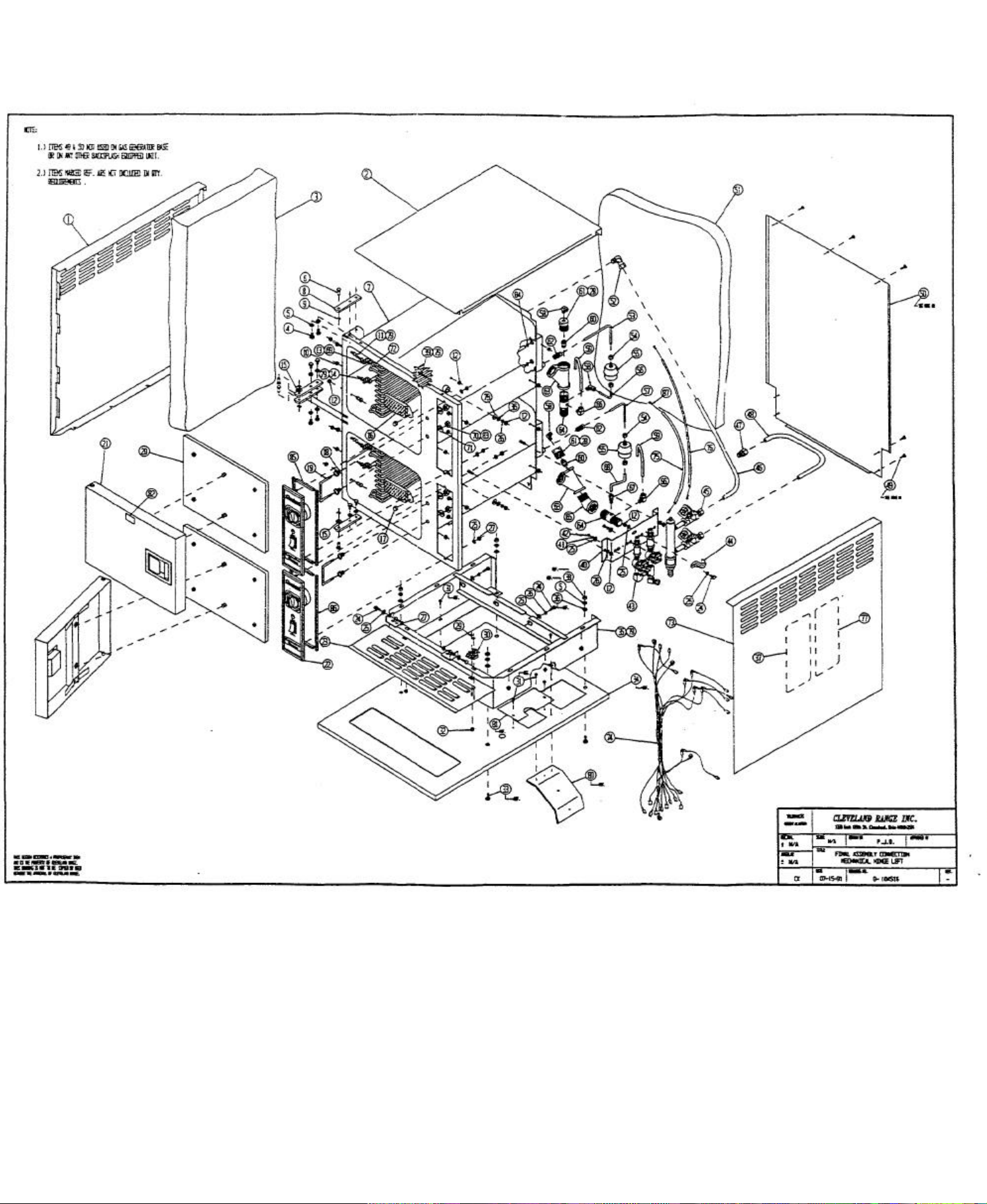

FINAL ASSEMBLY CONVECTION

MECHANICAL HINGE LEFT

DRAWING NO.

D-104516

APPROVED

BY:

REV.

-

Page 15

Page 16

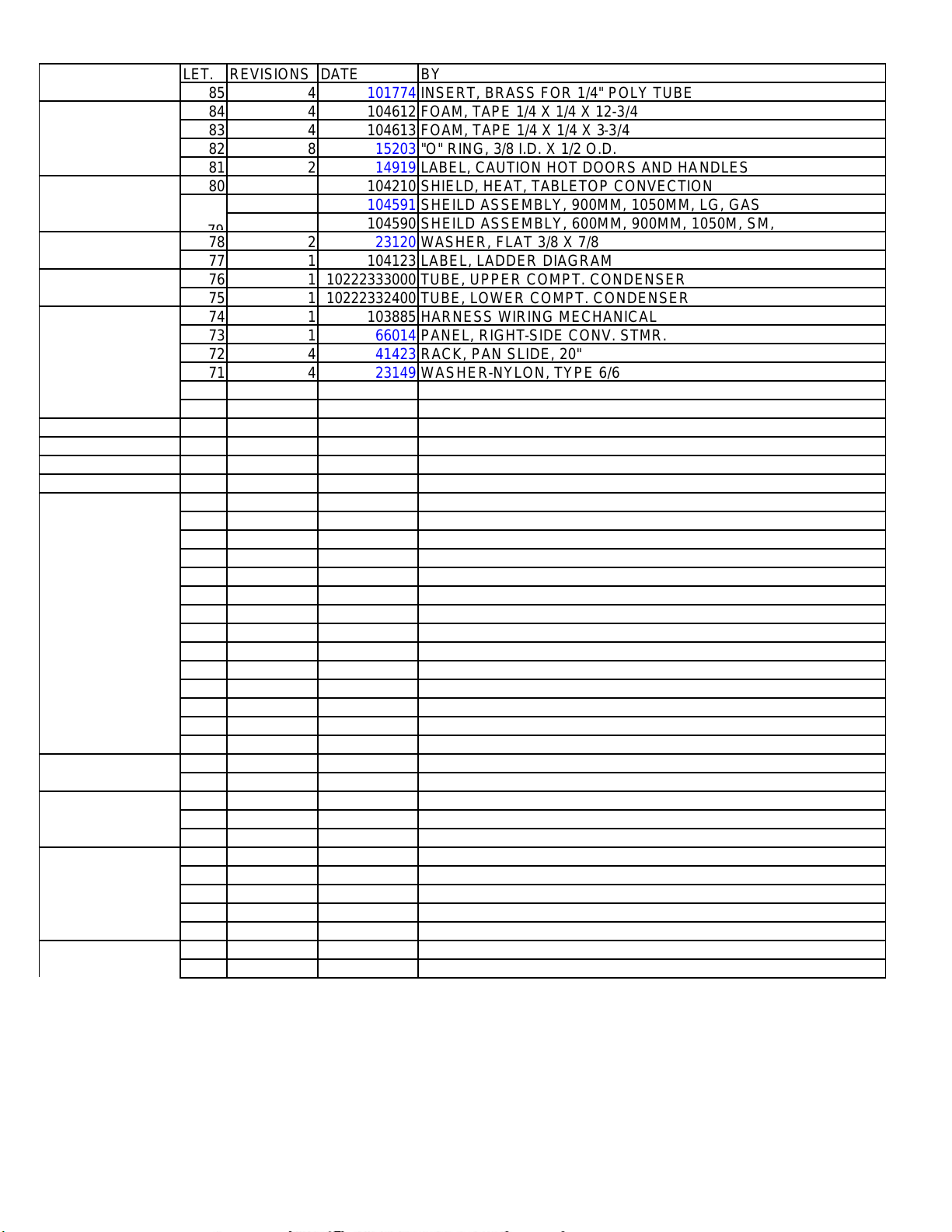

LET. REVISIONS

DATE

BY

SEE NOTE 2

85 4

101774

INSERT, BRASS FOR 1/4" POLY TUBE

84 4 104612

FOAM, TAPE 1/4 X 1/4 X 12

-

3/4 83 4

104613

FOAM, TAPE 1/4 X 1/4 X 3

-

3/4 82 8

15203

"O" RING, 3/8 I.D. X 1/2 O.D.

81 2 14919

LABEL, CAUTION HOT DOORS AND HA

NDLES

80 104210

SHIELD, HEAT, TABLETOP CONVECTION

104591

SHEILD ASSEMBLY, 900MM, 1050MM, LG, GAS

104590

SHEILD ASSEMBLY, 600MM, 900MM, 1050M, SM, GAS

78 2 23120

WASHER, FLAT 3/8 X 7/8

77 1 104123

LABEL, LADDER DIAGRAM

76 1

10222333000

TUBE, UPPER COMPT. CONDENSER

75 1 10222332400

TUBE, LOWER COMPT. CONDENSER

74 1 103885

HARNESS WIRING MECHANICAL

73 1 66014

PANEL, RIGHT

-

SIDE CONV. STMR.

72 4 41423

RACK, PAN SLIDE, 20"

71 4 23149

WASHER

-

NYLON, TYPE 6/6

70 4 14649

NUT, HEX, 1/2

-13 69 A/P 0908

LUBRICANT "O" RING

SEE NOTE 2

68 1

70769

TUBE, COPPER TRAP TO DRAIN

-

LOWER

67 A/P 01205

ADHESIVE, LOCKTITE #290

SEE NOTE 2

66 2

06233

FITTING, COMPRESSION 3/8 T X 1/8/ MPT 90°

65 A/P 00932

SEALANT, RTV

64 2

56519

FITTING, COMPARTMENT DRAIN

63 2

02139

BEND, "Y", BLACK

62 2

06216

FITTING, COMPRESSION 1/4 T X 1/4 MPT STRAIGHT

61 2

06230

FITTING, COMPARTMENT DRAIN

60 2

14555

NOZZLE, SPRAY, BRASS 1/8" FULL JET

59 2

70732

TUBE, COPPER

-

DRA

IN VENT

58 3

06192

FITTING, TUBE 1/4 T X 1/8 MPT 90°

57 1

70770

TUBE, COPPER, STEAMBOX TO TRAP

-

LOWER

56 1

70758

TUBE, COPPER, TRAP TP DRAIN

-

UPPER

55 2

20559

TRAP, 1/4 X 1/4 THERMOSTATIC

54 4

14681

NUT, COMPRESSION, FITTING, BRASS, 1/4" TUBE

53 1

70728

TUBE, COPPER, STEAMBOX TO TRAP

-

UPPER

52 1 06203

FITTING, COMPRESSION 1/2 T X 3/8 MPT 90°

51 1 104128

INSULATION, CONVECTION BODY REAR

50 1

69239

PANEL, REAR OUTER, SHEETING CONV. STMR.

49 7 19287

SCREW, TRUSS HEAD, SHEET ME

TAL 48 1 70734

TUBE, STEAM SUPPLY

-

LOWER COMPARTMENT

47 1

06202

FITTING, COMPRESSION 1/2 T X 3/8 MPT ST.

46 1 70735

TUBE, STEAM SUPPLY

-

LOWER COMPARTMENT

45 1 423951

STEAM, INLET ASSEMBLY

44 1 03197

CLAMP, 1 HOLE, 3/4"

43 1 44064

WATER VALVE ASSEMBLY NEW CONV. STMR.

42 2 19147

SCREW, PAN HD STLD 8

-

32 S/S

41 2 23114

WASHER, INTERNAL TOOTH LOCK S/S #10

40 1

52598

BRACKET, VALVE, SUPPORT CONV. STMR.

39 2 104409

CLOSURE, THERMAL OPENING

REF.

SEE NOTE 2

SEE NOTE 2

SEE NOTE 1

SEE NOTE 2

14.

Page 17

REF. 38

1

2

1

8

2

1

29 2

6

7

11

5

1

2

2

2

2

4

2

2

2

8

8

21

16

8

4

4

7 1

4

8

8

1

1

1

37

36

35

REF.

34

REF. 33

32

31

30

SEE NOTE 2- 28

27

26

25

24

23

22

21

20

19

18

17

16

SEE NOTE 2- 15

14

13

12

11

10

SEE NOTE 2-

SEE NOTE 2-

ITEM QUANTITY PART NO. DESCRIPTION

TOLERANCES

EXCEPT AS NOTED

DECIMAL

± N/A

14652 NUT, HEX 5/16-18 S/S

104398 LABEL, WIRING SCHEMATIC

23134 WASHER, FLAT 5/16"

407491 PEDESTAL, WELDMENT HINGE-RIGHT

70081 TABLETOP HINGE RIGHT 900MM

70083 TABLETOP HINGE RIGHT 1050MM

70084 TABLETOP HINGE LEFT AND RIGHT 600MM

19196 SCREW, HEX HD, 5/16 X 18 X 3/4

14679 NUT, ACORN 10-24 S/S

19148 SCREW, HEX,WASH HD

44168 TERMINAL BLOCK ASSEMBLY 2 POLE

104223 NUT, HEX 6-32 ELASTIC LOCK

101051 NEVER-SEEZ

101873 NUT, HEX 1/4-20 ELASTIC LOCK

23105 WASHER, LOCK S/S 1/4"

23118 WASHER, FLAT S/S 1/4"

19288 SCREW, HEX HEAD 1/4-20

1025691 PANEL, FRONT FILLER

104501 TIMER ASSY. CONVECTION STEAMER MECHANICAL

1035372 DOOR, OUTER ASSEMBLY HINGE RIGHT

104101 DOOR, INNER ASSEMBLY

104046 CATCH, DOOR

14695 NUT, DOOR CATCH MOUNTING S/S

146771 NUT, ACORN 1/4-20

69298 SCREEN, COMPARTMENT DRAIN

102513 WASHER, FLAT S/S 5/15 X 3/4 X .080

101471 PIN, STEAMTUBE SUPPORT

41212 TUBE, ASSEMBLY, CONVECTION STEAMER

14618 NUT, HEX 1/4-20 S/S

101305 PIN, RACK

14659 NUT, HEX 10-24 S/S

9

8

104062 RING, SNAP S/S

104076 HINGE, DOOR

103558 CONVECTION STEAMER BODY HINGE - RIGHT ASSEMBLY

6

5

4

3

2

1

104077 PIN, HINGE

23106 WASHER, LOCK MEDIUM PATTERN 5/16 8/9

02312 BOLT, HEX HEAD 5/16-24 S/S

104125 INSULATION, CONVECTION BODY WRAP

66015 PANEL, TOP SHEETING ASSY.

66023 PANEL, LEFT - SIDE OUTER CONV. STMR.

Cleveland Range inc.

1300 East 179th Street, Cleveland, Ohio 44110-2514

SCALE

.333”

DRAWN BY

DUTCHMAN

APPROVED BY

-

ANGULAR

± N/A

OK

TITLE

DATE

FINAL ASSEMBLY CONVECTION MECHANICAL – HINGE RIGHT

11-04-91

DRAWING NO.

D-104520 PAGE 1 OF 2

REV.

-

Page 18

Page 19

LET. Revisions Date BY

- PRODUCTION RELEASE E.O WC-1997 09-30-91 PD

86 4 101774 INSERT, BRASS FOR 1/4" 0.0. POLY TUBE

85 A/R

84 4 104612 FOAM, TAPE 1/4 X 1/4 X 13

83 4 104613 FOAM, TAPE 1/4 X 1/4 X 3 1/2

82 8 15203 "O" RING, 3/8 I.D. X 1/2 O.D.

81 A/R

80 1 14919 LABEL, CAUTION HOT DOORS AND HANDLES

REF

REF

{

REF

See

Note #1

REF. ------- 38 - 14652 NUT, HEX 5/16-18 S/S

REF. ------- 36 - 23134 WASHER, FLAT 5/16"

REF. ------- 34 - 70082 TABLETOP HINGE LEFT 1050MM

REF. ------- 33 - 19196 SCREW, HEX HD. 5/16 X 18 X 3/4

REF. ------- 31 - 19148 SCREW, HEX WASH HEAD, SHEET METAL

79 - 104210 SHIELD, HEAT - TABLETOP

78 - 104591 SHIELD, ASSY., 900MM, 1050MM, LG, GAS

- 104590 SHIELD, ASSY., 600MM, 900MM, 1050MM SM. GAS

77 1 104124 LABEL, LADDER DIAGRAM

76 1 1022333000 TUBE, UPPER COMPT. CONDENSER X 30'

75 1 10223332400 TUBE, LOWER COMPT. CONDENSER X 24'

74 1 104189 HARNESS WIRING NCC TIMER

73 1 66014 PANEL, RIGHT-SIDE CONV, STMR

72 4 41423 RACK, PAN SLIDE, 20'

71 4 23149 WASHER-NYLON, TYPE 6/6

70 4 14649 NUT, HEX 1/2-13, ZINC PLTD

69 A/R

68 1 102154 TUBE, COPPER TRAP TO DRAIN - LOWER

67 1 06190 FITTING, COMPRESSION 1/4 T X 1/8 MPT STRAIGHT

66 2 06233

65 1 05227 ELBOW, 1" STREET BLACK 45

64 2 56519 FITTING, COMPARTMENT DRAIN, 2 HOLE

63 2 02139 BEND, 'Y', BLACK

62 2 06216 FITTING, COMPRESSION 1/4 T X 1/8 MPT STRAIGHT

61 2 06230 FITTING, COMPARTMENT DRAIN

60 2 14555 NOZZLE, SPRAY, BRASS 1/8" FULL JET

59 2 70732 TUBE, COPPER - DRAIN VENT

58 3 06192

57 1 70776 TUBE, COPPER, STEAMBOX TO TRAP - LINER

56 1 70758 TUBE, COPPER, TRAP TO DRAIN - UPPER

55 2 20559 TRAP, 1/4 X 1/4 THERMOSTATIC

54 4 14661 NUT, COMPRESSION, FITTING, BRASS, 1/4" TUBE

53 1 70726 TUBE, COPPER, STEAMBOX TO TRAP - UPPER

52 1 06203

51 1 104126 INSULATION, CONVECTION BODY REAR

50 1 69239 PANEL, REAR OUTER, SHEETING CONV. STNR.

{

49 7 19267 SCREW, TRUSS HEAD, SHT. METAL

48 1 70734 TUBE, STEAM SUPPLY - LOWER COMPARTMENT

47 1 06202 FITTING, COMPRESSION 1/2 T X 3/8 MPT ST

46 1 70735 TUBE, STEAM SUPPLY - UPPER COMPARTMENT

45 1 423951 STEAM, INLET ASSEMBLY

44 1 03197 CLAMP, 1 HOLE, 3/4"

43 1 44064 WATER VALVE ASSEMBLY NEW CONV. STNR.

42 2 19147 SCREW, PAN HD STLD 8-32 S/S

41 2 100711 WASHER, INTERNAL TOOTH LOCK S/S #8

40 1 52598 BRACKET, VALVE, SUPPORT CONV. STNR.

39 2 19972 SWITCH, THERMAL

37 1 104397 LABEL, WIRING SCHEMATIC

35 1 40749 PEDESTAL, VELOMENT HINGE-LEFT

- 70085 TABLETOP HINGE LEFT 900MM

- 70084 TABLETOP, HINGE LEFT & RIGHT 600MM

32 8 14679 NUT, ACORN 10-24 S/S

30 1 44168 TERMINAL BLOCK ASSEMBLY 2 POLE

29 2 104223 NUT, HEX 6-32 ELASTIC LOCK

28 A/R

27 6 14665 NUT, HEX 1/4-20 ELASTIC LOCK W/ NYLON INSERT

00932 SEALANT, RTV

01205 ADHESIVE, LOCKTITE #290

00908 LUBRICANT, "O" RING

FITTING, COMPRESSION 3/8 T X 1/8 MPT 90°

FITTING, TUBE 1/4 X 1/8 MPT 90°

FITTING, COMPRESSION 1/2 T X 3/8 MPT 90°

101051 HEVER - SEEZ

Page 20

TOLERANCES

(Except as noted)

DECIMAL

N/A

MODULAR

N/A

CK

26 5 23105 WASHER, LOCK S/S 1/4"

25 13 23116 WASHER, FLAT S/S 1/4"

24 5 19288 SCREW, HEX HEAD 1/4-20

23 1 1025691 PANEL, FRONT FILLER

22 2 104500 TIMER ASSY. CONVECTION STEAMER ELECTRICAL

21 2 103537 DOOR, OUTER ASSEMBLY HINGE LEFT

20 2 104101 DOOR, INNER ASSEMBLY

19 2 104046 CATCH, DOOR

18 4 14695 NUT, DOOR CATCH MOUNTING S/S

17 2 146771 NUT, ACORN 1/4-20

16 2 69298 SCREEN, COMPARTMENT DRAIN

15 2 102513 WASHER, FLAT S/S 5/15 X 3/4 X .000

14 8 101471 PIN, STEAMTUBE SUPPORT

13 8 41212 TUBE, ASSEMBLY, CONVECTION STEAMER

12 21 14618 NUT, HEX 1/4-20 S/S

11 16 101305 PIN, RACK

10 8 14659 NUT, HEX 10-24 S/S

9 4 104062 RING, SNAP S/S

8 4 104076 HINGE, DOOR

7 1 103557 CONVECTION STEAMER BODY HINGE-LEFT ASSEMBLY

6 4 104077 PIN, HINGE

5 8 23106 WASHER, LOCK MEDIUM PATTERN 5/16 S/S

4 8 02312 BOLT, HEX HEAD 5/16-24 S/S

3 1 104125 INSULATION, CONVECTION BODY WRAP

2 1 66015 PANEL, TOP SHEETING ASSY.

1 1 66023 PANEL, LEFT-SIDE OUTER CONV. STNR.

ITEM QTY

PART # DESCRIPTION

CLEVELAND RANGE INC.

1333 East 179th St. Cleveland, Ohio 44110-2574

SCALE

TITLE

DATE

N/A

DRAWN BY

FINAL ASSEMBLY CONVECTION

ELECTRICAL HINGE LEFT

DRAWI NG NO.

07-16-91

P.J.O.

D-104517

APPROVED BY

REV.

-

Page 21

Page 22

Page 23

Page 24

84 4 101774 INSERT, BRASS 1/4" POLY TUBE

83 4 104812 FOAM, TAPE 1/4 X 1/4 X 12-3/4

82 4 104813 FOAM, TAPE 1/4 X 1/4 X 3-3/4

81 A/R 101051 NEVER-SEEZ

80 8 15203 "O" RING, 3/8 I.D X 1/2 O.D.

79 2 14919 LABEL, CAUTION HOT DOORS AND HANDLES

78 - 104210 SHEILD, HEAT, TABLETOP CONVECTION

77

76 1 1022333000 TUBE, UPPER COMPT. CONDENSER

75 1 1022332400 TUBE, LOWER COMPT. CONDENSER

74 1 104189 HARNESS WIRING NOC TIMER

73 1 66014 PANEL, RIGHT-SIDE CONV. STMR.

72 4 41423 RACK, PAN SLIDE, 20"

71 4 23149 WASHER-NYLON, TYPE 6/8

70 4 14549 NUT, HEX, 1/2 -13

69 A/R 00908 LUBRICANT "O" RING

68 1 102154 TUBE, COPPER TRAP TO DRAIN-LOWER

67 A/R 01205 ADHESIVE, LOCKTITE #290

66 2 06233 FITTING, COMPRESSION 3/8 T X 1/8 MPT 90°

65 1 104224 LABEL, LADDER DIAGRAM

64 2 58519 FITTING, COMPARTME NT DRAIN

63 2 02139 BENS, "Y" BLACK

62 2 06216 FITTING, COMPRESSION 1/4 T X 1/4 MPT STRAIGHT

61 2 06230 FITTING, COMPARTMENT DRAIN

60 2 14555 NOZZLE, SPRAY, BRASS 1/8" FULL JET

59 2 70732 TUBE, COPPER-DRAIN VENT

58 3 06192 FITTING, TUBE 1/4 T X 1/8 MPT 90°

57 1 70770 TUBE, COPPER, STEAMER TO TRAP -LOWER

56 1 70758 TUBE, COPPER, TRAP TO DRAIN-UPPER

55 2 20559 TRAP, 1/4 X 1/4 THERMOSTATIC

54 4 14881 NUT, COMPRESSION, FITTING, BRASS, 1/4" TUBE

53 1 70728 TUBE, COPPER, STEAM BOX TO TRAP -UPPER

52 1 06203 FITTING, COMPRESSION 1/2 T X 3/8 MPT 90°

51 1 104128 INSULATION, CONVECTION BODY REAR

50 1 69239 PANEL, REAR OUTER, SHEETING CONV. STMR.

49 1 19287 SCREW, TRUSS HEAD, SHEET METN.

48 1 70734 TUBE, STEAM SUPPLY-LOWER COMPARTMENT

47 1 06202 FITTING, COMPRESSION 1/2 T X 3/8 MPT ST

46 1 70735 TUBE, STEAM SUPPLY-UPPER COMPARTMENT

45 1 423951 STEAM, INLET ASSEMBLY

44 1 03197 CLAMP, 1 HOLE, 2/4"

43 1 44064 WATER VALVE ASSEMBLY NEWCONV. STMR.

42 1 18147 SCREW, PAN HD STLD 8-32 S/S

41 2 23114 WASHER, INTERNAL TOOTH LOCK S/S #10

40 1 52598 BRACKET, VALVE, SUPPORT CONV. STMR

39 2 104409 CLOSURE, THERMAL OPENING

38 - 14852 NUT, HEX 5/18-18 S/S

37 1 104398 LABEL, WIRING SCHEMATIC

36 2 23134 WASHER, FLAT 5/16"

35 1 407491 PEDESTAL, WELDMENT HINGE-RIGHT

34

33 - 19198 SCREW, HEX HD. 5/18 X 18 X 3/4

32 8 14879 NUT. ACORN 10-24 S/S

31 - 18148 SCREW, HEX WASH HD.

30 1 44168 TERMINAL BLOCK ASSEMBLY 2 POLE

29 2 104223 NUT, HEX 6-32 ELASTIC LOCK

28 A/R 101051 NEVER-SEEZ

27 6 101873 NUT, HEX 1/4-20 ELASTIC LOCK

26 5 23105 WASHER, LOCK S/S 1/4"

25 11 23118 WASHER, FLAT S/S 1/4"

24 5 19288 SCREW, HE X HEAD 1/4-20

23 1 1025891 PANEL, FRONT FILTER

22 2 104501 TIMER ASSY, CONVECTION STEAMER MECH.

21 2 1035372 DOOR, OUTER ASSEMBLY HINGE RIGHT

20 2 104101 DOOR, INNER ASSEMBLY

19 2 104048 CATCH DOOR

18 4 4695 NUT, DOOR CATCH MOUNTING S/S

17 2 46771 NUT, ACORN 1/4 -20

16 2 69298 SCREEN, COMPARTMENT DRAIN

15 2 102513 WASHER, FLAT S/S 5/15 X 3/4 X .080

14 8 101471 PIN, STEAMTUBE SUPPORT

13 8 41212 TUBE, ASSEMBLY, CONVECTION STEAMER

12 21 14816 NUT, HEX 1/4-20 S/S

11 16 101305 PIN, RACK

-

-

-

-

-

104591

104590

70081

70083

70084

SHEILD ASSEMBLY, 900MM, 1050MM, LG GAS

SHEILD ASSEMBLY, 600MM, 900MM,1050MM SM

GAS

TABLETOP HINGE RIGHT 900MM

TABLETOP HINGE RIGHT 1050MM

TABLETOP HINGE LEFT & RIGHT 600MM

Page 25

10 8 14659 NUT, HEX 10-24 S/S

9 4 104062 RING, SNAP S/S

8 4 104078 HINGE, DOOR

7 1 103558 CONVECTION STEAMER BODY HINGE-RIGHT ASS.

6 4 104077 PIR. HINGE

5 8 23106 WASHER, LOCK MEDIUM PATTERN 5/16 S/S

4 8 02312 BOLT, HEX HEAD 5/18-24 S/S

3 1 104125 INSULATION, CONVECTION BODY WRAP

2 1 66015 PANEL, TOP SHEETING ASSY.

1 1 66023 PANEL, LEFT-SIDE OUTER CONV. STMR.

ITEM QTY PART

DESCRIPTION

NO.

TOLERENCES

(EXCEPT AS

NOTED)

DECIMAL

N/A

ANGULAR

N/A

CK

DATE

11-05-91

1130 East 179th St. Cleveland, Ohio 44110-2574

SCALE

N/A

TITLE FINAL ASSEMBLY CONVECTION

ELECTRICAL HINGE RIGHT

DRAWN BY:

P.J.D.

DRAWING NUMBER

0-104521 PAGE 1 of 2

CLEVELAND RANGE INC.

APPROVED BY:

-

REV.

-

Page 26

DIRECT STEAM KETTLE

OPERATION

Ensure that there is an adequate steam supply

to the kettle.

Turn the steam control valve to the fall open

position by turning the knob counter-clockwise,

then allow the kettle to pre-heat.

NOTE: "When cooking egg and milk products,

the kettle should NOT be preheated, as products

of this nature adhere to hot cooking surfaces.

These types of foods should be placed in the

kettle before hearing is begun.

Fill kettle with product to desired level

"When the produce has reached the desired

temperature, regulate the heat, as required, by

turning the steam control valve for less steam

and therefore, a lower temperature.

When cooking is complete, dose the steam

control valve by turning the knob.

For kettle/steamer combinations: If the boner in a

steamer is supplying steam to a kettle, always

heat the kettle first. After the kettle contents are

heated, and the boiler's steam pressure returns

to normal the steamer may be used. Pressure

steamer compartments should be sequentially

started, and preheated before cooking.

NOTE: As with cleaning food soil from any

cookware, an important pan of kettle cleaning is

to prevent foods from drying on. For this reason,

cleaning should be completed immediately after

cooked foods arc removed. Please refer to the

"Care and Cleaning instructions for detailed

kettle washing procedures.

CARE AND CLEANING

Your kettle must be cleaned regularly to maintain

its fast, efficient cooking performance, and to

ensure its continued safe, reliable operation.

WARNING: Do not use chlorine base detergent.

1. Prepare a warm water and mild detergent

solution in the kettle.

2. Remove food son inside- die kettle using a

nylon brush, Do not use a metal bristle

brush, as this may permanently damage the

kettle's stainless steel surface.

3. Loosen food which is stuck to the kettle by

allowing it to soak at a low temperature

(simmer or low boil).

4. Tilt kettle forward to drain the •wash water.

5. Rinse the kettle interior thoroughly, then

drain rinse water.

6. Leave the cover and draw-off valve open

when the kettle is not in use.

7. Using mud soapy water and a damp

sponge, wash the exterior of the kettle,

rinse, and dry.

NOTE: For more difficult cleaning applications, one

of die following can be used: alcohol, baking soda,

vinegar, or a solution of ammonia in water. Avoid

the use of chloride cleansers, which may damage

the kettle's stainless steel surface.

WARNING: Steel wool should never be used for

cleaning the cooking chamber of the kettle.

Particles of steel wool become embedded in the

cooking surface and rust, and may corrode the

stainless steel.

234-03TE

Page 27

STEAM CONTROL

Page 28

PARTS LIST - STEAM CONTROL

ITEM NO. PART NO. DESCRIPTION QTY.

1. KE50458 End cap, condensate return 1

2. KE50455-1 Trunnion, condensate return 1

3. KE50456 Trunnion, housing 2

4-10. SE00011 Steam inlet Trunnion assy. 1

4. FA00017 "O" Ring 2

5. FA00117 "O" Ring 4

6. KE50460-1 Trunnion, steam inlet 1

7-10. SE00029 Operating stem assy. stainless steel 1

7. FA11089 Screw, 8-32x1/4- 1

8. KE51713 Washer, operating stem 1

9. FA00110 "0"Ring 1

10. KE50459

11. KE50457 End cap, steam inlet 1

12. FA11054 Screw, 6-32 x 3/8" 2

14. SE00028 Steam inlet knob assy. 1

15. FA11092 Screw, 8-32 x 1/2" 1

16. KE00200 Leg weldment ( 1 gal model) 2

KE00197 Leg weldment ( 6 gal model) 2

17. KE50465 Service pipe ( 1 gal model) 2

18. KE50467 Washer, foot 2

19. FA30502 Washer, satin coal 2

20. KE51898 Washer, lock 2

21. FI00222 Lock nut, 1/2 NPS 2

22. KE50475 Plug button 1

23. KE50886 Handle ( 1 gal model) 1

24. KE50151 Knob 1

25. KE50474 Foot 1

KE00198 Leg weldment (12 gal model) 2

KE00199 Leg weldment (20 gal model) 2

KE52030 Service pipe ( 6 gal model) 2

KE50463 Service pipe (12 gal model) 2

KE50464 Service pipe (20 gal model) 2

SK50051 Handle ( 6,12 gal model) 1

KE50803 Handle (20 gal model) 1

Operating stem, stainless steel 1

Page 29

OPERATING CONTROLS

For your better understanding and confidence, the following explanation of the control system on this

kettle is offered.

ITEM NO. DESCRIPTION FUNCTION

14 Steam Inlet Knob Toms the steam on or off to the kettle.

23-24 Tilting Handle Used for tilting the kettle.

Page 30

SERVICING GUIDE

This section contains information intended for use by Authorized Service Personnel only.

A/ PROBLEM : Kettle heats too slowly or does not come to a boil.

Probable Cause Remedy

1. Inadequate steam flow. Check for correct steam using chart below.

If kettle is connected to a -steamer and

powered by a generator the units should be

operated sequentially (kettle boiling first,

then start steamer).

2. Steam trap not operating property. The trap should open periodically to dump

condensate, then close, If it does not open

or dose it should be cleaned or replaced.

3. Food batches are not always the same. When checking make certain that the

original state (ie. fresh or frozen) and

quantity of food product is the same.

B/ PROBLEM : The trunnion housing leaks steam.

Probable Cause Remedy

1. Trunnion "O" rings are worn. Replace "O" rings.

STEAM FLOW RATING

OF STEAM GENERATORS

GAS INPUT STEAM OTJTPCT BOILER

BTU/HOOR LB&/HOUR

100,000 60 1.7

160,000 95 2£

200.000 325 3.6

250000 150 4.4

300,000 ISO

ELECTRIC

KW INPUT

18 KW 60 1.7

24 KW 70 20

27 KW 90 26

36 KW 320 35

48 KW 250 43

BS.

52

Capacity Fast Medium Speed

GaL./Lit. Cooking

REQUIREMENTS FOR KETTLES

5/17 11 9 6

10/42 22 18 11

25/95 55 44 28

40/151 88 70 44

60/227 132 105 66

Note: Above shows lbs. per hour with 10-15 psig

steam at the kettle. The use of higher steam

pressures (20-25 psig) will reduce heat-up time

5 to 20 %.

STEAM FLOW RATE

Cooking

Studs.

Kettle

Page 31

ELECTRIC STEAM GENERATOR (BOILER) ASSEMBLY - 2 PROBE TYPE

flanged heater elements

10

07128 Heater Gasket:

441

49 Electric Boiler Shell (43894) above, also incl

uding 16546 3"

Block-Off Plate

07108 Fiber Washer

(2

required)

20

20478 Interval Timer.

3

minute

9 08235 Heater. 9 KW.

208

volt. 3 phase 23 03276 1/4" Ball Valve, water supply shut

-

off

08237 Hea

ter. 9 KW.

440/480

volt. 3 phase 25 19870 Line Strainer, 1/4"

18 KW, 27 KW, 36 KW, & 48 KW (2, 3, & 4 HEATER ELEMENTS)

(OPTIONAL)

REFERENCE

NUMBER

1 43894 Electric Boiler Shell only, with legs , hand hole

2 40421 Hand Hole Plate Assembly including bar. nut. 13 19947 Pressure Switch

23 43748 Hand Hole Plate only

3 07106 Hand Hole Gasket. 4'" x 6" oval 15 23198 Control Board. water level and LWCO

4 40462 Probe 16 03524 Relay

5 101466 Probe Extension Set (set of two) 17 03525 Relay Socket

6 52305 Probe Cover Box 18 44168 Terminal Block. 2 pole

7 40445 Water Gauge Set with Glass 19 03202 Circuit Breaker, 1 amp

8 07302 Gauge Glass Only. 6" long 22 22102 Cheek Valve. 1/4"

PART

NUMBER

23132 Gauge Glass Washer (2 required) 21 20535 Transformer. 150 VA

08236 Heater. 9 KW. 220/240 volt 3 phase 24

08234 Heater. 9 KW. 600 volt 3 phase 26 03277 1/4" Ball Valve, manual drain

08241 Heater. 9 KW. 208 won. 1 phase 27 22221 Solenoid Valve, boiler drain

08242 Heater. 9 KW. 220/240 volt. 1 phase 28 13252 Drain Manifold

08243 Heater. 9 KW. 440/480 volt. 1 phase 29 45006 Low Water Cut-Off Assembly (California only)

08244 Heater. 9 KW. 600 volt. 1 phase 30 41943 LWCO Mounting Plate (California only!

08165 Heater. 12 KW. 208/220 vott. 3 phase 31 05253 Brass Street Elbow (California only)

08166 Heater. 12 KW. 230/240 volt. 3 phase 32 02623 Reducing Bushing. 1/2' • 1/4" (California only)

08167 Heater. 12 KW. 440/480 volt. 3 phase 33 19995 Float Switch. LWCO (California only)

08163 Heater. 12 KW. 600 volt 3 phase 34 19993 DPDT Power switch

08214 Heater. 12 KW. 208/220 volt. 1 phase 35 19994 SPST Momentary contact reset switch

08215 Heater. 12 KW. 230/240 volt. l phase 36 07167 Pressure gauge. 0-30 psi. 1 1/2 "

DESCRIPTION REFERENCE

sight gauge, two probes and extensions with 12 22131 15 psi Safety Valve

cover box.

and gasket. 14 03509 Contactor. 50 amp

NUMBER

PART

NUMBER

08216 Heater. 12 KW. 440/480 volt 1 phase

22130 8 psi Safety Valve

03506 Contactor. 75 amp

22223

DESCRIPTION

Solenoid Valve, water feed

Manufacturer reserves right of design improvement or modification as warranted.

Page 32

HEATER AND CONTACTOR WIRING SCHEMATICS FOR SOLID

STATE ELECTRIC STEAM GENERATORS

Manufacturer reserves right of design improvement or modification, as warranted.

Page 33

Page 34

Electric Models with Secondary Low Water Cutoff Built to California Code

Page 35

Page 36

GAS STEAM GENERATOR (BOILER) ASSEMBLY - 2 PROBE TYPE SMALL: 100,000

O

BTU (2 Burners) & 200,000 BTU (4 burners) LARGE: 250,000 BTU (5 burners) &

300,000 BTU (6 burners)

REFERENCE

NUMBER

1 43898 Small boiler shell only (100.000/200. 000 BTU). with

2 40421 Hand hole plate assembly including bar. nut, and

2a 43748 Hand note Plate only

3 07106 Hand hole gasket. 4' x 6' oval

4 40462 Probe

5 101466 Probe extension set (set of two)

6 52305 Probe cover box

7 40445 Water gauge set with glass

8 07302 Gauge glass only 6' long

9 44043 Left side insulation panel assembly

10 44042 Right side insulation panel assembly

11

13 44134 2-burner front baffle assembly - natural gas

14 44153 2-bumer rear burner support

PART

NUMBER

43899 Large boiler shell only (250.000/300.000 BTU), with

44173 Small boiler shell (43898) above, also including

44172 Large boiler shell (43899) above, also including

07108 Fiber washer (2 required)

23132 Gauge glass washer (2 required)

440431 Left side insulation panel assembly for LP. gas -

440421 Right side insulation panel assembly for LP. gas -

42398 Top flue collector with insulation, for small boiler

42399 Top flue collector with insulation, for large boiler

42360 Internal flue riser assembly for small boiler

42361 Internal flue riser assembly for large boiler

44135 4-burner from baffle assembly - natural gas

40840 5-burner front baffle assembly - natural gas

40842 6-bumer front baffle assembly - natural gas

44150 Front burner baffle assembly for LP. gas -

44170 Right side burner baffle assembly for L.P. gas

44171 Left side burner baffle assembly for L.P. gas

44155 4-bumer rear burner support

DESCRIPTION

legs. studs. Hand hole plate assembly and top flue

bracket.

legs. studs. hand hole plate assembly. and top flue

bracket.

insulation panels, top flue collector with insulation,

sight gauge, two probes and extensions with cover

box.

insulation panels, top flue collector with insulation.

sight gauge, two probes and extensions with cover

box.

gasket.

100.000/200.000 BTU boiler only

100.000/200.000 BTU boiler only

(100.000/200.000 BTU)

(250.000/300.000 BTU)

(100.000/200.000 BTU)

(250,000/300.000 BTU)

100.000/200.000 BTU boiler only (not shown)

100.000/200.000 BTU boiler only (not shown)

100.000/200.000 BTU boiler only (not shown)

REFERENCE

NUMBER

15 22130 Safety valve. 6 psi

16 19947 Pressure switch

17 22228 Gas control valve, natural gas. small boiler

PART

DESCRIPTION

NUMB

44156 5-burner rear burner support

44157 6-burner rear burner support

22131 Safety valve. 15 psi

(100.000/200.000 BTU)

22230 Gas control valve. natural gas. large boiler

(250/300.000 BTU)

22231 Gas control valve. L.P. gas. small and large boilers

(100.000/200.000 and 250,000/300.000 BTU)

18 44169 Igniter cable

19 44096 Igniter box assembly with ignitor

20 05101 Igniter electrode

21 40918 Gas manifold. 2-burner

40920 Gas manifold. 4-burner

40921 Gas manifold. 5-timer

40922 Gas manifold. 6-burner

22 52602 Manifold alignment bracket

23 19632 Orifice holder

26 03546 Spark ignition control module

27 20528 24 volt transformer

28 20478 Internal time 3 minute

29 44164 Terminal block- 4 pole

30 03525 Relay socket

31 03524 Relay

32 23198

33 22102 Check valve. 1/4"

34 03276 1/4" Ball valve, water supply shut off

35 22223 Solenoid valve, water feed

36 19870 Line strainer. 1/4"

37 03277 1/4" Ball valve, manual drain

38 22221 Solenoid valve, boiler drain

39 13252 Drain manifold

40 45006 Low water cut-off assembly (California only)

41 41943 LWCO mounting plate (California only)

42 07128 Gasket (California only)

43 05253 Brass street elbow (California only)

44 02623 1/2"-1/4" Brass reducing bushing (California only)

45 19995 Float switch. IWCO (California only)

46 19993 DPOT Power switch

47 19994 SPST Momentary contact reset switch

48 07167 Pressure gauge. 0-30 psi. 1 l/2"

Burner orifice, natural gas 24 25 15453

15450

02497

Burner orifice. L.P. gas Burner

Control board, water level and IWC

Manufacturer reserves right of design improvement or modification, as warranted.

Page 37

Page 38

Page 39

Page 40

STEAM COIL GENERATOR (BOILER) ASSEMBLY 2 PROBE

TYPE

REFERENCE NUMBER PART NUMBER DESCRIPTION

1 43977 Steam Coil Boiler Shell with Legs, Sight Gauge, Steam