Page 1

Clemco

O W N E R’ S M A N U A L

Spin - XL

with pneumatic driven

blast-head

24407D

International GmbH Carl-Zeiss-Straße 21 Tel.: +49 (0)8062 – 9008-0

83052 Bruckmühl Mail: info@clemco.de

Germany Web: www.clemco-international.com

Revision 03

Page 2

INDEX

1 SHORTCUTS, DEFINITIONS, SYMBOLS AND ICONS ....................................... 3

2 PRODUCT DESCRIPTION ................................................................................... 4

2.1 CONVENTIONAL UTILIZATION AND RESTRICTIONS ............................................................................ 4

2.2 NO CONVENTIONAL UTILISATION – WARNINGS FOR MISUSE ............................................................. 4

2.3 OPERATING MODE OF COMPLETE SYSTEM ...................................................................................... 4

2.4 DESCRIPTION ............................................................................................................................... 4

2.4.1 Complete system ................................................................................................................ 4

2.4.2 Operating elements ............................................................................................................ 5

2.5 ENERGY CONSUMPTION ................................................................................................................ 5

2.6 EMISSIONS ................................................................................................................................... 5

3 SET-UP AND OPERATION .................................................................................. 6

3.1 TRANSPORT ................................................................................................................................. 6

3.2 UNPACKING AND DISPOSE OF PACKING MATERIAL ........................................................................... 6

3.2.1 Elimination, recycling, disposal of equipment ..................................................................... 6

3.3 STORAGE ..................................................................................................................................... 6

3.4 SET-UP FOR INITIAL INSTALLATION / OPERATION ............................................................................. 6

4 INSTRUCTION HANDBOOK ................................................................................ 7

4.1 OPERATION .................................................................................................................................. 7

4.1.1 Standard operation ............................................................................................................. 7

4.1.2 Shutdown ............................................................................................................................ 7

5 MAINTENANCE AND CLEANSE ......................................................................... 7

5.1 GENERAL ..................................................................................................................................... 7

5.2 MAINTENANCE CYCLES ................................................................................................................. 8

5.3 AFTER OTHER PERIODS OF TIME .................................................................................................... 8

6 TROUBLESHOOTING .......................................................................................... 8

7 ADMITTED MODIFICATIONS FOR USERS ......................................................... 8

8 REPLACEMENT PARTS ...................................................................................... 9

9 SUMMARY, REST HAZARD AND SAFETY PRECAUTIONS ............................ 11

9.1 NOISE POLLUTION .......................................................................................................................11

9.2 DUST POLLUTION ........................................................................................................................11

9.3 ESCAPE OF SPED BLAST MEDIA OF WEAR PARTS ...........................................................................11

10 APPENDIXES .................................................................................................. 12

10.1 MANUAL FOR AIR MOTOR TYPE MRD, STALL-PROOF, OIL FREE ..................................................12

Page 2 of 15

Page 3

1 Shortcuts, definitions, symbols and icons

Whipping

hose

Electrostati

c strokes

.

Noise > 85dB(A)!

Explosi

on hazard caused by

Explosion hazard!

Risk of injury!

Recycling

Garbage

Change within

Europ

e

Complete blast protective

Whipping hose!

Dangerous area!

Risk of escaping blast media.

Risk of whipping hose and escaping blast

Interlock coupling.

Wear ear protection.

Connect only max. admitted

pressure.

Ground!

dust!

Ground!

Discharge completely pressure

during maintenance jobs.

clothing.

Used pictograms

Hold tight end of hose.

X

X(m)= 10 x P(bar)

Mortal danger!

Wear blast helmet, protective clothing, cloves

media.

Mortal danger!

Interlock coupling.

Without protective clothing keep

out of area of 10x of pressure.

Page 3 of 15

Page 4

2 Product description

for inner

diameter

no

zzle-Ø Size of blast media (µ)

Min. air volume

8,0

9,5

2.1 Conventional utilization and restrictions

Parts to be blasted

- Inside of pipes

- Inside of cylindrical parts

Operating conditions

- indoor or outdoor

- acceptable temperature: -5° ... 40°C

- acceptable humidity: 0 ... < 100% (no rain!)

Compressed Air

- pressure: 6 to 8bar

- pressure air category 4, DIN ISO 8573

- air volume: see table 1

- air service unit for air motor:

max. part size: 15μm

max. part density: 8mg/m³

dry air: water content max. 6g/m³

oil free!

Acceptable medias/ abrasives

- mineral and metallic blast media

- acceptable size see table 1

- dry and pourable

- use of Aluminium Oxide and Silicium Carbid causes high wear

Suggestion for parameters

see table 1

Table 1:

(mm)

400 - 700

700 - 1500

400-800 10,0 (353 CFM)

(400) 800-1200 15,0 (530 CFM)

2.2 No conventional utilisation – Warnings for misuse

Utilization is interdicted:

- in explosion hazard zones

- for blasting parts, where hazardous materials were released

o by explosion hazards

o which causes damages caused to somebody's health during a defective dust collector

2.3 Operating mode of complete system

- place Spin XL at the end of the pipe

- switch on system

- air motor turns blast head

- air-blast media mixture escapes radial

- pull back equipment manually: inner surface of pipe gets blasted/ cleaned

- blastmedia-dust mixture gets exhausted at end of pipe (option)

2.4 Description

(m³/min)

2.4.1 Complete system

To get the CE-conformance Clemco recommends the following components/ activities:

Page 4 of 15

Page 5

- Blast pot with

Where

Comment/ Func

tion

+ Remote control RMS 2000

+ Separate control of:

* Air for blasting

* Air for air motor

* Media metering

+ Diameter of hose or lance: 32 ... 38mm, length max. 20m

+ Pneumatic metering valve (e.g. PT)

- Spin-XL with carriage

- Air service unit for air motor, oil free!, (use included filter/ air service unit) with air hose (inner diam-

eter: min. 9mm, length max. 20m) for air supply

- Safety precautions for blast media emission, dust and noise exposure

Further description is based on above mentioned equipment configuration.

2.4.2 Operating elements

Pressure regulation of

air motor

Pressure regulation of

blast nozzle

Metering media Metering valve at pot ON/ OFF with slide valve at remote control handle

ON / OFF Remote control handle Activating:

Air service unit at blast

pot

Blast pot 4 - 7bar

3 … 6… max. 7bar

ON/ OFF at remote control handle

ON/ OFF with slide valve at remote control handle

air motor

blast air

metering blast media

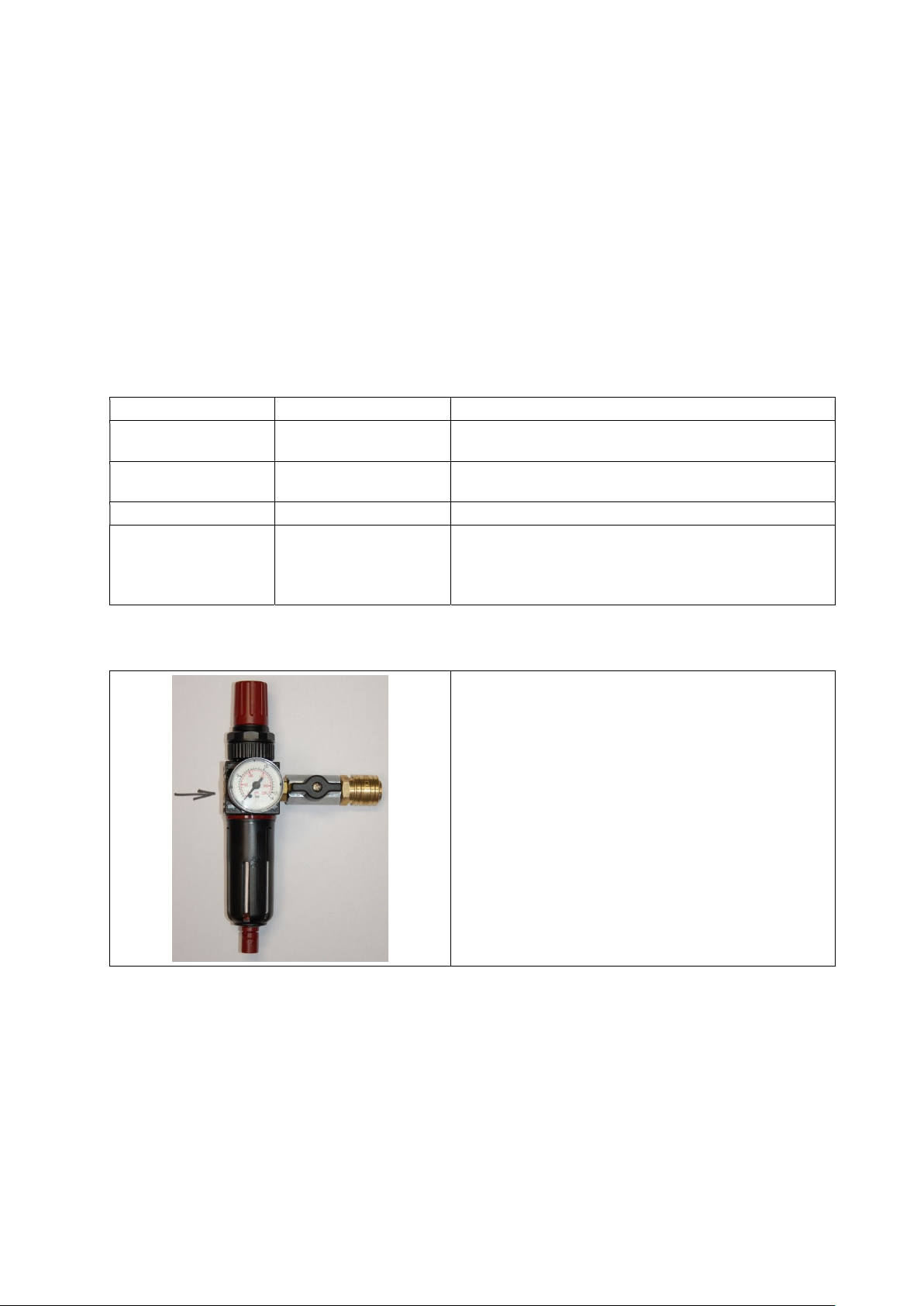

2.4.3 Air service unit for air motor

Mount included air service unit for air motor and connect it in vertical position with air supply.

Use green air hose to connect outlet with air motor.

2.5 Energy consumption

Pressure air consumption:

- nozzle see 2.1 table 1

- air motor: 5,6l/s at 6bar operating pressure

2.6 Emissions

- Noise: > 80dB(A)

- Dust: in unacceptable high concentration sanctions such as housing and aspiration

Page 5 of 15

Page 6

3 Set-up and operation

Recycling

Garbage

Change within Europe

Risk of whipping hose!

at motor

Risk of escaping blast media.

3.1 Transport

Weight app. 40kg

Protect from beats Observe instruction of complete system

3.2 Unpacking and dispose of packing material

3.2.1 Elimination, recycling, disposal of equipment

Disassemble equipment and

separate for materials

3.3 Storage

Storage in dry area Observe instruction of complete system

3.4 Set-up for initial installation/ operation

A1 Adjust carriage to pipe diameter See also chapter 8, table 2.

Mortal danger!

Interlock coupling.

A2

A3 Connect air motor with green air hose and

A4 Position Spin XL in pipe.

A5

A6

A7

A8

A9

Connect Spin XL with blast hose and pot.

upstream air service unit.

Function test without blast media.

Set air motor under pressure.

Adjust pressure of air motor (6bar at mo-

tor app. 90min-1)

Activate blast pot.

Function test with blast media.

Connection for

exhaust air

supply air

Blast head turns.

max. 7bar

of long hoses!)

Air comes out at nozzle.

(attend pressure drop

Page 6 of 15

Mortal danger!

Wear blast helmet, protective clothing,

gloves.

Page 7

X

Dangerous area!

Dangerous area!

Risk of escaping blast media.

X(m)= 10 x P(bar)

A6-8

A10

A11

Activate air motor and blast pot.

Open metering valve.

Adjust blast media at metering valve.

Without protective clothing keep out of

area of 10x of pressure.

Air and blast media mixture comes out at

nozzle

Blast media should only be visible as a

fine fog!

4 Instruction handbook

4.1 Operation

4.1.1 Standard operation

A1 Protect workplace. - Dust emission

- Noise

- Sped up blast media

X

X(m)= 10 x P(bar)

A2 Position Spin-XL.

A3 Switch on. First air of air motor

A4

A5 Switch off. First blast media

Pull back Spin XL.

Without protective clothing keep out of

area of 10x of pressure.

Mortal danger!

Wear blast helmet, protective clothing,

cloves

Than air of blast pot

At last blast media.

According to request of degree of purification.

Than air of blast pot

At last air motor.

4.1.2 Shutdown

4.1.2.1 After end of work

No special activity. Observe instruction of complete system

4.1.2.2 Shut down by longer interruption of work or moving equipment

No special activity. Observe instruction of complete system

5 Maintenance and cleanse

5.1 General

Blast equipment subjects to strong wear. Safety and high efficiency is only ensured

when maintained regularly!

Maintenance cycles are strongly regulated by operating parameters. Stated times are experiences, that

have to be reduced or extended in individual case.

Page 7 of 15

Page 8

5.2 Maintenance cycles

Maintenance

Risk of wear!

Article

replace (even without wear) after maximal

Problem

Probable cause

Remedy

cycles for

steel shot

(working

hours)

max. 8h Nozzles and blast head. Check and replace if necessary sealing of

max. 16h Plastic sealing. Check and replace if necessary.

Carbide insert head. Check and replace if necessary.

Shaft and felt seal. Check and replace if necessary.

max. 30h Ball bearings. Check and replace if necessary.

max. 50h Moisture separator. Clean only with soap and warm water.

Air and blast hoses. Gaskets of couplings for wear. Blast hose

Blast pot. Pop up valve for wear by hand.

max. 300h Air motor. Maintenance by Clemco or service man of

Demolition of equipment.

nozzles and blast head.

Shaft seal position: open side to back!

by hand for soft spots.

producer.

5.3 After other periods of time

Blast hoses 6 years

Remote control hoses 6 years

Air hoses – external air supply 6 years

O-rings 5 years

Pop up valve (blast pot) 5 years

Gaskets 5 years

6 Troubleshooting

Blast head

does not turn or

too slowly

Irregular blast

result.

Vibrations. 1. One nozzle blocked. Eliminate blockage.

1. Volume or pressure of air at motor is

too less.

2 Leakage/ bend in supply hose of air

motor.

3. Width/ length of supply hose unsuitable. Width of hose 6mm: max. 10m

4. Entered dust interlocks axle. Felt seal/ shaft seal/ ball bearing wear

1. Pulsing blast media. Reduce metering.

2. Moist blast media. Replace blast media with dry one.

2. Different sizes of nozzles. Use equal nozzles (length and diameter).

3. Fixture wheels loose. Tighten screws.

Increase volume/ pressure of air for air

motor.

Replace or place straight.

Width of hose 9mm: max. 20m

replace

7 Admitted modifications for users

Only with the improvement of the producer! Otherwise the installation will loose guarantee and CEcertification

Page 8 of 15

Page 9

8 Replacement parts

46

9

45

1

5

4

2

3

13 7 8 6 10 19 11 12 22 47

33

14

15

30

16 17 18 2021 23

16 27 28 29 31 32

41

18 26 25

40

38

22

37

36 35

39

42

43 44

34

24

Page 9 of 15

Page 10

Nr.

Art.

-

Nr. Bezeichnung

Description

24407D Basis Rohrinnenstrahlgerät Spin XL mit

pneumatisch angetriebenem Strahlkopf,

inkl. Spin XL Fahrgestell 400-580 (Art.

24443D), Filterregler und 10m Luft-

schlauch.

1 24439D Halterung Räder Fixture wheels

2 24440D Gestell Räder (ohne PU-Rollen) Frame wheels (without PU-wheels)

3 24445D Rohr 1" - 160mm (in "Fahrgestell 400-

580")

24449D Rohr 1" - 275mm (in "Fahrgestell 580-

800")

24452D Rohr 1" - 635mm (in "Fahrgestell 790-

1500")

24446D Kappe Cap

4 24441D PU-Rolle D80 PU-wheel D80

5 24453D Gestellverlängerung (ohne Rad) empfoh-

len für Ø > 800mm (enthalten in Fahrge-

stell 790-1500)

6 27192D DL-Motor, abwürgefest + ölfrei Air motor, stall-proof + oil free

7 24435D Stirnzahnrad Z20 Gear wheel Z20

8 90592D Madenschraube M4x6 Headless screw M4x6

9 24433D Elsa gerade 8-1/8 A Elsa straight 8-1/8 A

10 27224D PA-Schlauch 8/6 rot, pro Meter - 0,25m PA-hose 8/6 red, per meter - 0,25m

27225D PA-Schlauch 8/6 grün, pro Meter - 0,25m PA-hose 8/6 green, per meter - 0,25m

11 24434D Elsa gerade 8-1/4 A Elsa straight 8-1/4 A

12 27198D Schalldämpfer 1/4" Exhaust silencer 1/4"

13 24428D Deckel Antrieb Cap

14 24413D Mantelrohr Casing tube

15 90155D Zylinderkopfschraube M6x18 Hexagon bolt M6x18

16 24414D Kugellager Ball bearing

17 24415D Mantelrohr Einsatz Casing tube insert

18 24417D Wellendichtring 50x68x8 Shaft seal50x68x8

19 24416D Mantelrohr Distanzring Casing tube distance ring

20 24430D Dichtung Kunststoff Sealing plastic

21 24429D Anschlussflansch Connecting flange

22 24431D Zylinderkopfschraube M5x16 Hexagon bolt M5x16

23 24232D CFT-Kupplung 1 1/2" CFT-Coupling 1 1/2"

24 08416D Dichtung CQG 32 Sealing CQG 32

25 24426D Kopf Antrieb Head

26 24427D Filzdichtung 6x6-177 Felt seal 6x6-177

27 24424D Hülse Feder Bushing spring

28 24425D Druckfeder Spring

29 24421D Stirnzahnrad Z80 Gear wheel Z80

30 24420D Paßfeder 6x6x14 Flat key 6x6x14

31 24419D Sicherungsring 50x2 Snap ring 50x2

32 24418D Welle Axle

33 24412D Dichtung Kopf Eingang PU Sealing head entrance PU

34 24408D Strahlkopf Blast head

35 24409D HM-Einsatz Kopf Hardened insert head

36 24410D Dichtung Kopf PU Sealing head PU

37 24411D Blindstopfen 1 1/4" mit M8 Blank plug 1 1/4" with M8

38 100956 Anschlagpunkt Attachment point

39 91025D Düsendichtung NW32 Sealing blast nozzle NW32

91023D Düsendichtung NW25 Sealing blast nozzle NW32

40 24444D Düsenhalter 25 Nozzle holder 25

41 *) Kurzdüse mit NW25 Short nozzle with NW25

42 90437D Rohr 1 1/4" - 95 (in "Fahrgestell 790-

1500")

90435D Rohr 1 1/4" - 285 (in "Fahrgestell 790-

1500")

43 24451D Muffe 1 1/4" (in "Fahrgestell 790-1500") Pipe coupling 1 1/4" (in carriage 790-1500

Spin XL basic with pneumatic driven blast

head, incl. Spin XL carriage 400-580 (part

24443D), filter regulator and 10m air

hose.

Rod 1" - 160mm (in carriage 400-580

incl.)

Rod 1" - 275mm (in carriage 580-800

incl.)

Rod 1" - 635mm (in carriage 790-1500

incl.)

Frame extension (without wheel) recommended for Ø > 800mm (in carriage 7901500 incl.)

Tube 1 1/4" -95mm (in carriage 790-1500

incl.)

Tube 1 1/4" -285mm (in carriage 790-1500

incl.)

Page 10 of 15

Page 11

incl.)

Inner diameter of pipe

Extension no

z-

Kind

of nozzle

Length of rod

Spin XL

carriage

400-580

Spin XL carriage

580-800

790-1500

790-1500

44 24448D Düsenhalter 32 (in "Fahrgestell 790-

1500")

45 *) Strahldüse mit NW32 Blast nozzle with NW32

46 27194D Kontermutter 1 ½“ Lock nut 1 ½”

47 27200D Vorfilter DL-Motor Prefilter air motor

24438D Filterregler 5µm, G1/4" für DL-Motor Filter regulator 5µm, G1/4" for air motor

90381D Luftschlauch 9mm x 10m, inkl. Kupplun-

gen

90073D Luftschlauch 9mm x 20m, inkl. Kupplun-

gen

*) Auswahl Strahldüsen siehe Preisliste oder fragen Sie Ihren Händler. Range of blast nozzles see price list or ask your

distributor.

Tabelle 2

Nozzle holder 32 (in carriage 790-1500

incl.)

Air hose 9mm x 10m, incl. couplings

Air hose 9mm x 20m, incl. couplings

[mm]

400 … 580 (15,5" - 23")

580 … 800 (22,5“-

31,5“)

790 ... 1200 (31“ - 47“) 95mm (90437D) Long nozzle with

1200 ... 1500 (47“ - 59“) 285mm (90435D)

zles

/ Short nozzle with

NW25

/ Long nozzle with

NW32

NW32

Long nozzle with

NW32

for frame [mm]

160

275

635

635

9 Summary, rest hazard and safety precautions

9.1 Noise pollution

Noise levels > 80dB(A) can occur use ear protection.

9.2 Dust pollution

Adequate methods have to be chosen to meet the acceptable contamination.

…

(24443D)

extensions

(24447D)

(24450D)

(24450D)

9.3 Escape of sped blast media of wear parts

Blasting subjects to strong wear that can cause hazards. Therefore the required maintenance cycles of chapter 5 have to be followed exactly!

Especially the blast hose has to be checked to reduce existing hazard.

Page 11 of 15

Page 12

10 Appendixes

10.1 Manual for air motor type MRD, stall-proof, oil free

Page 12 of 15

Page 13

Page 13 of 15

Page 14

Page 14 of 15

Page 15

Page 15 of 15

Loading...

Loading...