Clemco Contractor Series, Contractor 4 CU. FT, Contractor 6 CU. FT Operational Instructions

Page 1

BLAST MACHINE WITH MILLENNIUM PNEUMATIC

CONTRACTOR SERIES 4 AND 6 CU. FT.

PRESSURE RELEASE REMOTE CONTROLS

O. M. 21941

DATE OF ISSUE: 01/96

REVISION: L, 03/17

WARNING

Do not use this

© 2017 CLEMCO INDUSTRIES CORP.

One Cable Car Dr.

Washington, MO 63090

Phone (636) 239-4300

AX (800) 726-7559

F

Email: info@clemcoindustries.com

www.clemcoindustries.com

equipment until you

have READ this

MANUAL and YOU

UNDERSTAND its

contents. *

These WARNINGS are

included for the health

and safety of the

operator and those in

the immediate vicinity.

*If you are using a Clemco Distributor

Maintenance and Parts Guide, refer to

the orange warnings insert preceding

the Index before continuing with the

enclosed instructions.

Electronic files include a Preface

containing the same important

information as the orange cover.

Page 2

PREFACE

• Employers are responsible for identifying all job site hazards, educating and training all persons who will operate and

maintain these products, and ensuring that all blast operators and their assistants understand the warnings and

information contained in these instructions relating to safe and proper operation and maintenance of this equipment.

• Serious injury or death can result from failure to comply with all Occupational Safety and Health Administration

(OSHA)regulations and all manufacturer’s instructions.

• This equipment is not intended for use in any area considered hazardous per National Electric Code NFPA 70 2011,

Article 500.

• Read this document and follow all instructions before using this equipment.

OSHA regulations relating to ab rasi ve bla sting are con tained in the Code o f Federal Regulation s, Title 29 (29 C FR 1910 Gene ral Indust ry ;

1915 Maritime; 1926 Con s truction). The most pertinent include: 1910.94 Ventilation, 1910 .95 Occupational Noise Exposure , 1 910.132

Personal Protective Equipment, 1910.133 Eye and Face Prote cti on, 191 0.134 Respiratory Protection, 1910 .1 35 Head Protection,

1910.244 (b) Remote Controls. Consult www.osha.gov for complete information.

NOTICE

PRODUCTS AND THIS INFORMATIONAL MATERIAL

TO

PURCHASERS

AND USERS OF

OUR

Clemco proudly provides products for the abrasive blast

industry and is confident that industry professionals will use

their knowledge and expertise for the safe and efficient use of

these products.

The products described in this material, and the information

relating to these products, are intended for knowledgeable,

experienced users.

No representation is intended or made as to: the suitability of

the products described here for any purpose or application, or

to the efficiency, production rate, or useful life of these

products. All estimates regarding production rates or finishes

are the responsibility of the user and must be derived solely

from the user’s experience and expertise, not from information

contained in this material.

It is possible that the products described in this material may

be combined with other products by the user for purposes

determined solely by the user. No representations are

intended or made as to the suitability of or engineering

balance of or compliance with regulations or standard practice

of any such combination of products or components the user

may employ.

Abrasive blast equipment is only one component of an

abrasive blasting job. Other products, such as air

compressors, air filters and receivers, abrasives, scaffolding,

hydraulic work platforms or booms, equipment for lighting,

painting, ventilating, dehumidifying, parts handling, or

specialized respirators or other equipment, even if offered by

Clemco, may have been manufactured or supplied by others.

The information Clemco provides is intended to support the

products Clemco manufactures. Users must contact each

manufacturer and supplier of products used in the blast job for

warnings, information, training, and instruction relating to the

proper and safe use of their equipment.

GENERAL INSTRUCTIONS

This material describes some, but not all, of the major

requirements for safe and productive use of blast machines,

remote controls, respirator systems, and related accessories.

All equipment and accessories must be installed, tested,

operated and maintained only by trained, knowledgeable,

experienced users.

The blast operator and all workers in the vicinity must be

properly protected from all job site hazards including those

hazards generated by blasting.

Work environments involving abrasive blasting present

numerous hazards. Hazards relate to the blast process from

many sources that include, but are not limited to, dust

generated by blasting or from material present on the surface

being blasted. The hazards from toxic materials may include,

but are not limited to, silica, cyanide, arsenic, or other toxins

in the abrasives or in the coatings, such as lead or heavy

metals. Other hazards from toxins include, but are not limited

to, fumes from coating application, carbon monoxide from

engine exhaust, contaminated water, chemicals or asbestos.

In addition, physical hazards that may be present include, but

are not limited to, uneven work surfaces, poor visibility,

excessive noise, and electricity. Employers must identify all

job site hazards and protect workers in accordance with

OSHA regulations.

Never modify Clemco equipment or components or

substitute parts from other manufacturers for any Clemco

components or parts. Any unauthorized modification or

substitution of supplied-air respirator parts violates OSHA

regulations and voids the NIOSH approval.

IMPORTANT

Contact Clemco for free booklets:

Blast Off 2 – Guide to Safe, Productive, and Efficient Abrasive

Blasting, and Abrasive Blasting Safety Practices – Guide to Safe

Abrasive Blasting.

Clemco Industries Corp. One Cable Car Drive Washington MO 63090

Tel: 636 239-4300 — Fax: 800 726-7559

Email: info@clemcoindustries.com

Website: www.clemcoindustries.com

[I]

Page 3

PREFACE

OPERATIONAL INSTRUCTIONS

OSHA regulation 1910.134 requires appropriate respiratory protection for blast operators and workers in

the vicinity of blasting. These workers must wear properly-fitted, properly-maintained, NIOSH-approved,

respiratory protection that is suitable for the job site hazards. Blast respirators are to be worn only in

atmospheres not immediately dangerous to life or health from which wearers can escape without use of

the respirator.

The employer must develop and implement a written respiratory protection program with required

worksite- specific procedures and elements for required respirator use. The employer must provide

effective training to employees who are required to use respirators. The training must be comprehensive,

understandable, and recur annually, and more often if necessary.

NEVER use abrasives containing more than one percent crystalline silica. Fatal diseases, such as silicosis,

asbestosis, lead or other poisoning, can result from inhalation of toxic dusts, which include, but are not

limited to, crystalline silica, asbestos, and lead paint. Refer to NIOSH Alert 92-102; and OSHA CPL 03-00-007:

“National Emphasis Program – Crystalline Silica”, in which OSHA describes policies and procedures for

implementing a national emphasis program to identify and reduce or eliminate health hazards from exposure

to crystalline silica. Numerous topics associated with the hazards of crystalline silica in silica blasting sand

can be found on http:// osha.gov/. Clemco urges users of silica blasting sand to visit this website, and read

and heed the information it contains.

Always make sure the breathing air supply (respirator hose) is not connected to plant lines that supply

gases that include, but are not limited to, oxygen, nitrogen, acetylene, or other non-breathable gas. Never

modify or change respirator air line connections without first testing the content of the line for safe

breathing air. Failure to test the line may result in death to the respirator user.

• Breathing air quality must be at least Grade D,

as defined by the Compressed Gas Association

specification G-7.1, per OSHA Regulation 29 CFR

1910.134. When compressed air is the breathing air

source, a Clemco CPF (suitable sorbent bed filter)

should be used. Respirator hose connecting the

respirator to the filter must be NIOSH approved.

Non- approved hose can cause illness from

chemicals employed to manufacture the hose.

• All workers must always wear NIOSH-approved

respirators when any dust is present. Exposure to

dust can occur when handling or loading abrasive,

blasting, cleaning up abrasive, or working in the

vicinity of blasting. Before removing the respirator,

test the air with a monitoring device to ensure it is

safe to breathe.

For additional information, consult:

Occupational Safety and Health Administration (OSHA) - www.osha.gov

Compressed Gas Association (CGA) - www.cganet.com

The Society for Protective Coatings (SSPC) - www.sspc.org

National Association of Corrosion Engineers (NACE) - www.nace.org

American Society for Testing and Materials (ASTM) - www.astm.org

National Institute of Occupational Safety and Health (NIOSH) - www.niosh.gov

American National Standards Institute (ANSI) - www.ansi.org

OPERATOR SAFETY EQUIPMENT

• Clemco respirators DO NOT remove or protect against

carbon monoxide or any other toxic gas. Monitoring

devices must be used in conjunction with the respirator to

ensure safe breathing air. Always locate compressors and

ambient air pumps where contaminated air will not enter

the air intake.

• Always use Clemco lenses with Clemco respirators;

installing non-approved lenses voids the NIOSH approval.

Respirator lenses are designed to protect the wearer from

rebounding abrasive; they do not protect against flying

objects, heavy high-speed materials, glare, liquids, or

radiation.

INDUSTRY ORGANIZATIONS

[II]

Page 4

PREFACE

BLAST MACHINES AND REMOTE CONTROLS

OSHA regulation 1910.169 describes the necessity of pressure relief valves on compressed air equipment. Do not

operate blast machines with air compressors that are no t equipped with properly functioning pressure relief valves.

OSHA regulation 1910.244(b) requires the use of remote controls on blast mach ines.

Serious injury or death can result from many sources, among them:

Involuntary activation of the remote controls. Never modify or substitute remote control parts; parts are not

compatible among different manufacturers. Welding hose is not suitable for remote control hose. Its ID and material

composition make it unsafe for remote control use.

Exceeding the maximum working pressure. Clemco blast machines are built to ASME-code and carry a ‘U’ or ‘UM’

stamp, and National Board/serial number. Every machine is marked with its maximum working pressure. Never

exceed the maximum working pressure limits of the blast machine.

Uncontrolled blast stream. High-velocity abrasive particles will inflict serious injury. Always point the blast nozzle

in the direction of the blast surface only. Keep unprotected workers out of the blast area.

Welding on the blast machine. Never weld on the blast machine; welding voids the Nation al Bo ard approval and

may affect the dimensional integrity of the vessel.

Moving the blast machine. Never manually move a blast machine contain ing abrasive, any machine containing

abrasive must be moved with appropriate mechanical lifting equi pment.

HOSES, COUPLINGS, AND NOZZLE HOLDERS

The inside diameter (ID) of air hoses, fittings, and connections

should be at least four times larger than the nozzle orifice size. Blast

hose ID should be three to four times the size of the nozzle orifice.

Example: a #6 nozzle (3/8” diameter orifice) calls for 1-1/2” ID blast

hose and 1-1/2” ID or larger compressor hose. All hose runs should be

kept as short as possible and run in as straight a line as possible to

reduce pressure loss.

To install, squarely cut the end of the hose so that it fits snugly

against the coupling or hose end shoulder. Always use the screws

recommended by the manufacturer ensuring that they do not

penetrate the inner wall. Make sure the couplings tightly fit the hose.

Install cotter pins at ev ery conn ection or use couplings with built-in

lock-springs to prevent disengagement. Install safety cables at all

connections to prevent whipping if hoses disengage or blow out.

MAINTENANCE AND REPAIR

Completely read and follow all service instructions and recommended maintenance intervals. Always shut off compressor and

depressurize blast machine before performing any maintenance. At every service interval, clean all filters, screens, and alarm systems. If

spring-loaded abrasive valves are used, always cage spring before disassembly.

WARRANTY

The following is in lieu of all warranties, express, implied or statutory, and in no event shall seller or its agents, successors, nominees or

assignees, or either, be liable for special or consequential damage arising out of a breach of warranty. This warranty does not apply to any damage or

defect resulting from negligent or improper assembly or use of any item by the buyer or its agent or from alteration or attempted repair by any person

other than an authorized agent of seller. All used, repaired, modified, or altered items are purchased “as is” and with all faults. In no event shall seller

be liable for consequential or incidental damages. The sole and exclusive remedy of buyer for breach of warranty by seller shall be repair or

replacement of defective parts or, at seller’s option, refund of purchase price, as set forth below

:

1. Seller makes no warranty with respect to products used other than

in accordance hereunder.

2. On products seller manufactures, seller warrants that all products are to

be free from defects in workmanship and materials for a

period of one year from date of shipment to buyer, but no warranty is

made that the products are fit for a particular purpose.

3. On products which seller buys and resells pursuant to this order, seller

warrants that the products shall carry the then standard warranties of the

manufacturers thereof, a copy of which shall be made available to the

customer upon request.

4. The use of any sample or model in connection with this order is for

illustrative purposes only and is not to be construed as a warranty that the

product will conform to the sample or model.

5. Seller makes no warranty that the products are delivered free of the

rightful claim of any third party by way of patent infringement or the like.

6. This warrant y is conditioned upon seller’s receipt within ten (10)

days after buyer’s discovery of a defect, of a written notice stating in

what specific material respects the product failed to meet this

warranty. If such notice is timely given, seller will, at its option, either

modify the product or part to correct the defect, replace the product or

part with complying products or parts, or refund the amount paid for

the defective product, any one of which will constitute the sole liability

of the seller and a full settlement of all claims. No allowance will be

made for alterations or repairs made by other than those authorized

by seller without prior written consent of seller. Buyer shall afford

seller prompt and reasonable opportunity to inspect the products for

which any claim is made as above stated.

Except as expressly set forth above, all warranties, express, implied

or statutory, including implied warranty of merchantability, are

hereby disclaimed.

[III]

Page 5

PREFACE

r

p

r

as

e

Co

s

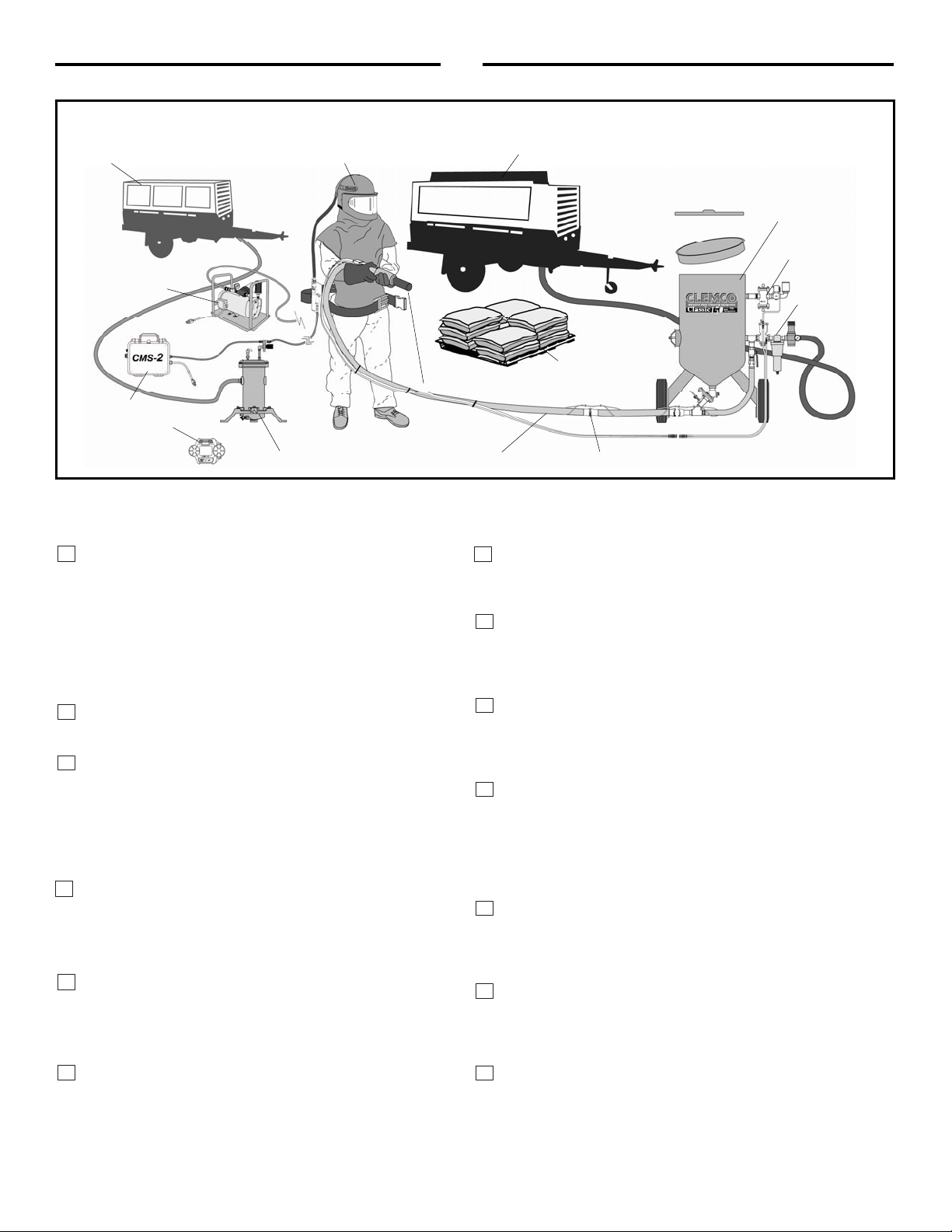

DAILYSET‐ UP CHECK LIST

2. Breathing Air Compressor for

High Pressure Respirators

or Ambient Air Pump for

Low Pressure Respirators

4. External or

Helmet Mounted

Carbon Monoxide

Monitor /Alarm

Make sure all blast operators are properly trained and suitably attired with a blast suit, safety boots, leather gloves, respiratory and hearing protection. Every day before start up,

check all equipment components, including piping, fittings, and hoses, and valves, for leaks, tightness, and wear. Repair or replace as needed. Use the following checklist.

1. PROPERLY-MAINTAINED AIR COMPRESSOR

sufficient volume (cfm) at given pressure for nozzle and other tools. ADD 50%

volume (cfm) reserve to allow for nozzle wear. Use large compressor outlet and

air hose (at least 4 times the nozzle orifice diameter). For oil-lubricated

compressors, the employer shall use a high- temperature or carbon monoxide

alarm, or both, to monitor carbon monoxide levels. If only high-temperature

alarms are used, the air supply shall be monitored at intervals sufficient to

prevent carbon monoxide in the breathing air from exceeding 10 ppm. Follow

the manufacturer’s checklist and maintenance instructions.

2. BREATHING-AIR COMPRESSOR

capable of providing Grade D quality air, located in a dust free area. Read # 1

above.

3. CLEAN, PROPERLY-MAINTAINED NIOSH-APPROVED SUPPLIED-AIR

RESPIRATOR

Make sure all respirator components are in place — all lenses, inner collar, and

cape. Thoroughly inspect all components for wear. The NIOSH approval (approval

number is listed in the owner’s manual) is for a complete assembly from point of

attachment on the CPF (sorbent bed) filter to the complete respirator. Substitution of

any part voids the NIOSH approval.

4. CARBON MONOXIDE MONITOR/ALARM

inside the supplied-air respirator for monitoring for the presence of deadly CO gas

and warning the operator(s) when the CO level reaches an unacceptable level.

When an ambient air pump is used for breathing air, a CO monitor provides a

measure of safety. Read # 1 above.

5. BREATHING-AIR FILTER (OSHA-REQUIRED

removal of moisture and particulate matter in the compressed air breathing-air

supply. Monitor the condition of the cartridge and replace when odor is detected or

at 3 month intervals, whichever comes sooner. The breathing air filter does NOT

detect or remove carbon monoxide (CO). Always install a CO monitor/alarm.

6. BLAST MACHINE

Maximum Working Pressure) sized to hold a 30-minute abrasive supply. Examine

pop-up valve for alignment. Check piping, fittings, screens, valves for tightness,

leaks, and wear. Always ground the machine to eliminate hazard of static shock.

Install a blast machine screen to keep out foreign objects. Use a blast machine

cover if left outdoors overnight. Never exceed the maximum working pressure of the

vessel.

worn by blast operators, and other workers exposed to blast dust.

(bearing U or UM stamp, National Board Number, and

3. NIOSH Approved

Supplied-Air Respirator

5. CPF Air Filter

sized to provide

(or oil-less ambient air pump)

installed at th e CPF filt e r or

sorbent bed filter) for

1. Air Compresso

12. Abrasive

11. Appropriately Sized Nozzle

9. Blast Hose

7. AIR LINE FILTER

blast machine inlet and sized to match the size of the inlet piping or larger air supply

line. Clean filter and drain often. Damp abrasive causes operational problems.

8. REMOTE CONTROLS

operating condition. Test and check all components to ensure all parts are present

and fully functional. Use genuine replacement parts. NEVER mix parts from different

manufacturers. Never use welding hose for remote control hose.

9. BLAST HOSE

The ID should be three to four times the size of the nozzle orifice diameter. Blast hose

should be arranged in as straight a line as possible from the blast machine to the

work area, avoiding sharp bends.

10. COUPLINGS AND NOZZLE HOLDERS

be installed with manufacturer recommended screws. Coupling lugs must snap firmly

into locking position. Gasket must always be used to form a positive seal, and cotter

pins must be installed. Replace gasket when wear, softness or distortion is detected.

Check nozzle holder for thread wear; replace at any sign of wear. Install safety cables

at all connections.

11. NOZZLE

orifice size should be checked and nozzle replaced when worn

1/16” from original size. (No. 5 nozzle has 5/16” orifice diameter; replace when it

measures 3/8”). Threads should be inspected daily for wear and nozzle should be

replaced when wear is detected. Always use a nozzle washer.

12. ABRASIVE

should be properly sized for the job. Check material safety data sheet for freesilica, cyanide, arsenic, lead and other toxins and avoid use when these toxic,

harmful substances are present.

SURFACE TO BE BLASTED

Take appropriate protective measures as required by OSHA to ensure the blast

operator, other workers in the vicinity, and any bystanders are properly protected.

©Clemco Industries Corp., Stock No. 20954P, 0692 Rev. F, 06/12

6. ASME Code

t Machin

Bl

8. Remote

ntrol

7. Air Line

Moisture

arato

Se

10. Hose Couplings and Safety Cables

(moisture separator) installed as close as possible to the

are required by OSHA and must be in perfect

should have an inside diameter sized to suit the blast nozzle.

should fit snugly on the hose and

must be a material specifically manufactured for blasting. It

should be examined for hazardous substances.

[IV]

Page 6

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 1

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

1.0 INTRODUCTION

1.1 Scope of manual

1.1.1 These instructions cover set-up, operation,

maintenance, troubleshooting, and replacement parts for

the Clemco Contractor Blast Machine with Millennium

pneumatic, pressure release remote controls.

20" diameter, 4 cu. ft. capacity

24" diameter, 6 cu. ft. capacity

1.1.2 These instructions contain important safety

information. All operators and personnel involved with

the abrasive blast process must read and understand

the contents of these instructions, including the orange

cover. It is equally important that the operator is trained

and qualified to safely operate the blast machine and

remote controls, and all other equipment used with the

blast machine.

1.1.3 All personnel involved with the abrasive blasting

process must be made aware of the hazards associated

with abrasive blasting. The Clemco booklet Abrasive

Blasting Safety Practices is included with every blast

machine; it contains important safety information about

abrasive blasting that may not be included in equipment

operation manuals. The booklet is available in both

English and Spanish; to request copies, email

info@clemcoindustries.com.

1.2 Safety Alerts

1.2.1 Clemco uses safety alert signal words, based on

ANSI Z535.4-2011, to alert the user of a potentially

hazardous situation that may be encountered while

operating this equipment. ANSI's definitions of the signal

words are as follows:

This is the safety alert symbol. It is

used to alert you to potential physical

injury hazards. Obey all safety

messages that follow this symbol to

avoid possible injury or death.

NOTICE

Notice indicates information that is considered

important, but not hazard-related, if not

avoided, could result in property damage.

CAUTION

Caution indicates a hazardous situation that, if

not avoided, could result in minor or moderate

injury.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

WARNING

Warning indicates a hazardous situation that, if

not avoided, could result in death or serious

injury.

DANGER

Danger indicates a hazardous situation that, if

not avoided, will result in death or serious

injury.

1.3 Components and Operating Principles

1.3.1 Components

1.3.1.1 The primary components of the Contractor

machines are shown in Figure 1. They include the blast

machine with Millennium remote controls, manuallyoperated Quantum abrasive metering valve, and frame

assembly. Blast machine systems also include optional

compressed air filter, and optional CPF particulate air

filter.

1.3.2 Instruction Maintenance Manuals

1.3.2.1 Individual manuals are included with optional

accessories: Manuals provided with blast machine

systems include:

CPF Particulate Air Filter

Apollo Respirator

Clem-Cool Air Conditioner

1.3.2.2 The front leg contains a storage area for

owner’s manuals. After reviewing all the manuals, and

startup and adjustments are completed, remove the

urethane cover plate and store manuals in the

compartment, for future reference.

1.3.3 Blast Machine

1.3.3.1 Clemco blast machines (pressure vessels) are

certified to conform to the ASME (American Society of

Mechanical Engineers) Boiler and Pressure Vessel

Code, Section VIII, Division 1. It is the owner’s

responsibility to maintain the integrity of the vessel in

accordance with the requirements of state regulations.

Regulations may include regular inspection and

hydrostatic testing as described in National Board

inspection code and jurisdictional regulations and/or

laws.

Page 7

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 2

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

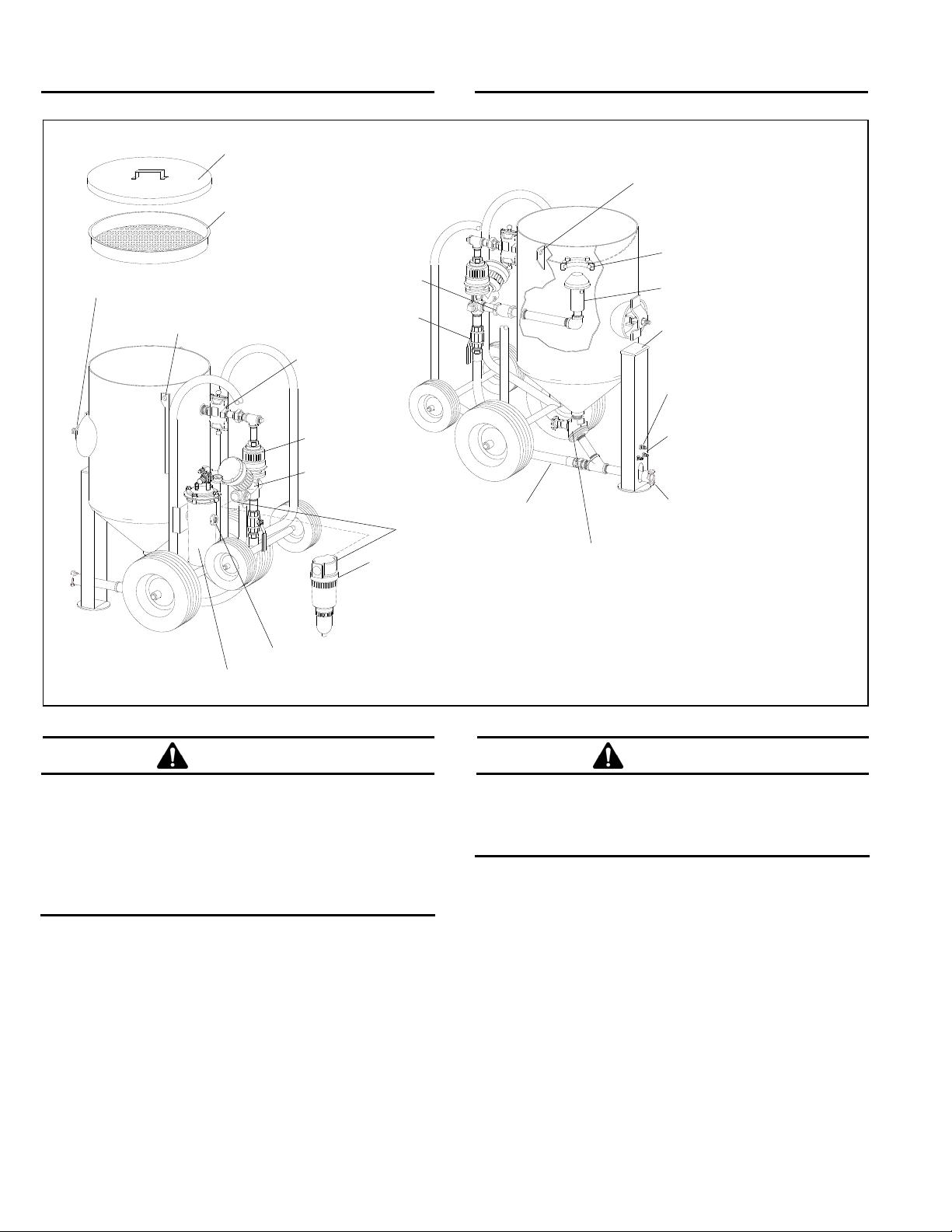

Cover

(Optional Accessory)

Lifting Eye

Screen

(**Optional Accessory)

Pop-up Seal

Inspection Door

Lifting Eye

Compression Coupling

Choke Valve

Abrasive Trap

Exhaust Muffler

Millennium Valve

Compressed Air Inlet

Air Filter (**Optional Accessory)

Pusher Line

Quantum Metering Valve

Pop-up Valve

Owner’s Manual

Storage Tube Cover

*Respirator Hose Connection

(Only with CPF Filter Option)

Bulkhead Fittings

(Control Hose Connection)

Quick Coupling

(Blast Hose Connection)

* Respirator hose connection is shown for

reference. Used only when the CPF Filter

is attached to the blast machine frame.

Breathing-Air Inlet

CPF Filter(**Optional Accessory)

** These accessories are included

with blast machine systems.

Figure 1

WARNING

Welding, grinding, or drilling on the blast

machine can weaken the vessel. Compressed

air pressure can cause a weakened blast

machine to rupture, resulting in death or

serious injury. Welding, grinding, or drilling on

the vessel, without a National Board R stamp,

voids the Clemco ASME certification.

1.3.3.2 All welding repairs to the vessel must be

performed by certified welders at shops holding a

National Board R Stamp. Welding performed by any

welder not properly qualified per the ASME code voids

the Clemco ASME certification.

1.3.3.3 This blast machine is rated for a maximum of

150 psi (pounds per square inch); do not exceed the

maximum working pressure. The maximum pressure

rating is also stamped into ASME nameplate which is

WARNING

Excessive compressed air pressure can cause

a blast machine to rupture. To prevent serious

injury or death, do not exceed the rated

pressure of the blast machine.

1.3.3.4 OSHA does not require pressure relief valves on

blast machines when air compressors supplying air to

the blast machines are built to ASME

with OSHA

(2)

regulations. OSHA regulation 1910.169

refers to the ASME code when describing the necessity

of pressure relief valves on compressed air equipment.

DO NOT operate blast machines with air compressors

that are not equipped with properly-functioning pressure

relief valves.

(1)

American Society of Mechanical Engineers, Boiler and Pressure

Vessel Code, Section VIII, Division 1,

(2)

Occupational Safety and Health Administration, 29 CFR 1910, 169.

(1)

code and comply

welded to the side of the vessel.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 8

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 3

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

1.3.4 Remote Controls

WARNING

Never modify or substitute remote control

parts. Parts from other manufacturers are not

compatible with Clemco equipment. If ANY part

of the remote control system is altered,

involuntary activation can occur, causing

serious injury.

1.3.4.1 A remote control system is an OSHA-required

safety device; it is required when an operator mans the

nozzle. The remote controls allow the blast operator to

pressurize the machine to start blasting, and

depressurize it to stop blasting.

1.3.4.2 The control handle, located near the blast

nozzle, is the activator for the remote control system.

When the operator intentionally or unintentionally

removes hand-held pressure from the control handle, the

machine depressurizes and blasting stops. The remote

control system "fails to safe", which means when an

interruption in the control-air circuit occurs for reasons

such as a break in the line, the compressor stops

running, or the operator drops the blast hose, the remote

control deactivates the blast machine and blasting stops.

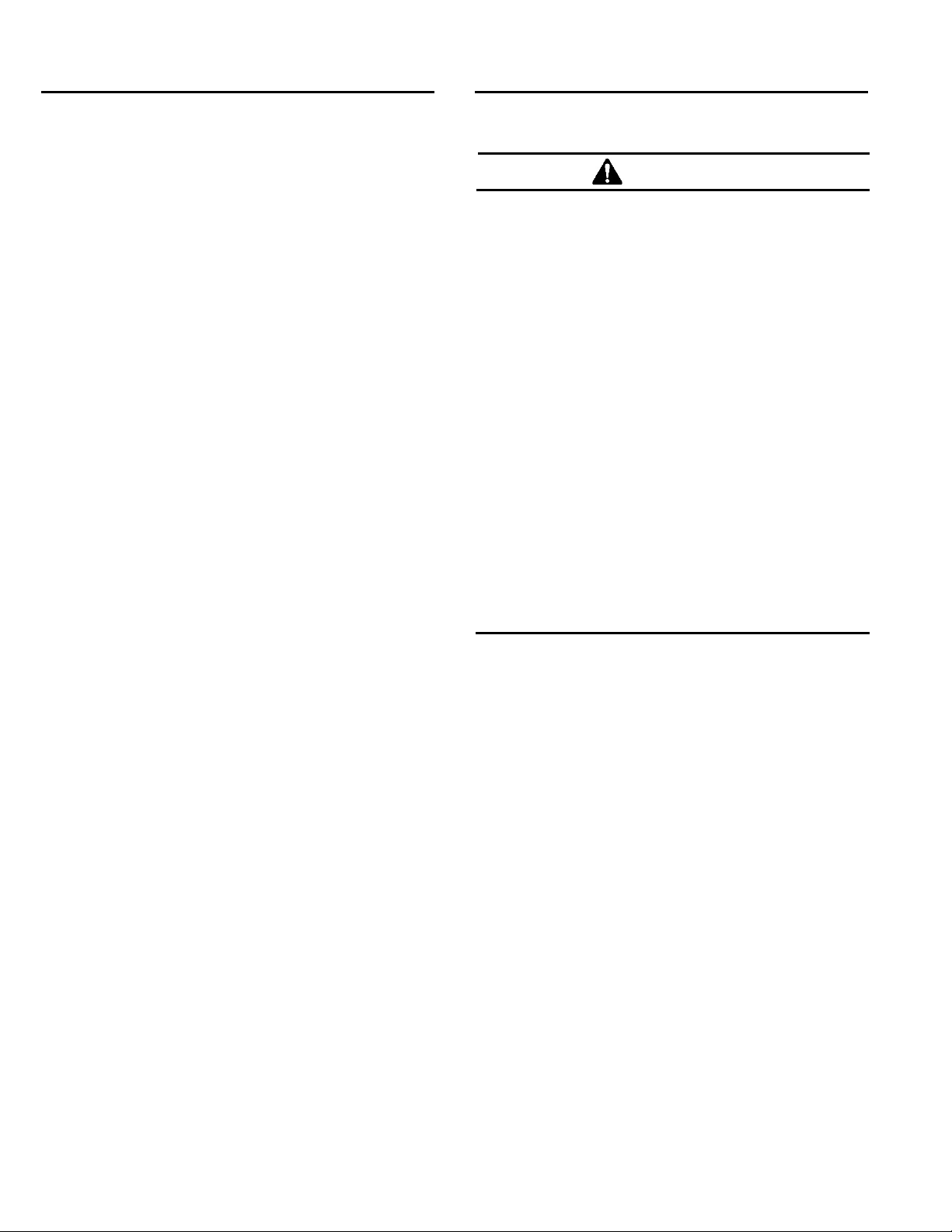

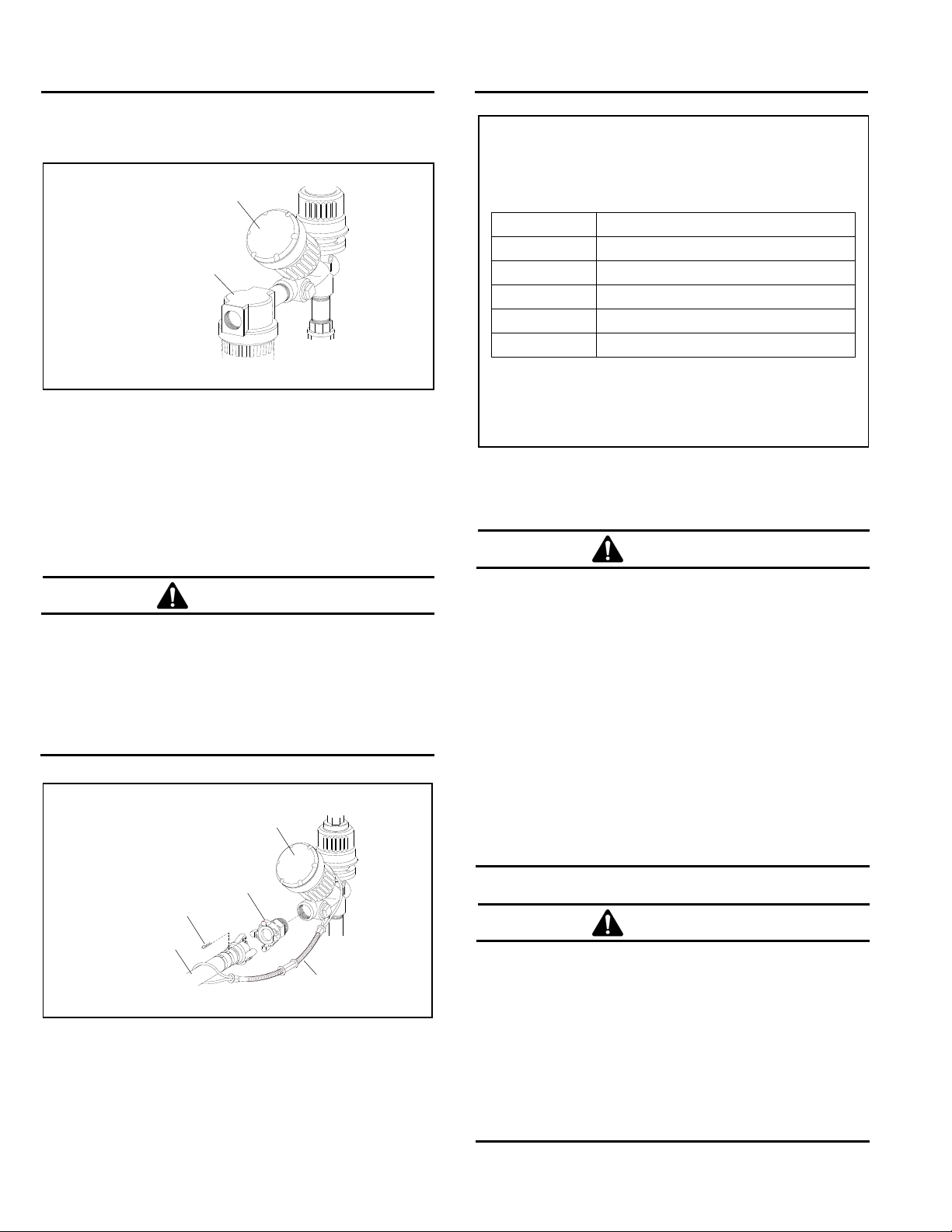

Safety Petcock

Orifice Fitting

Outbound Air Line

Millennium Valve Outlet Segment

Millennium Valve Inlet Segment

When using a regulator to reduce

blast pressure, relocate the orifice

upstream of the regulator, and p lug

the orifice port in the inlet valve.

Refer to Section 2.1.

Return Air Line

4-Ft. Twinline Hose

1.3.4.3 Components of the Millennium remote control

system are shown in Figures 1 and 2. They include the

Millennium inlet/outlet valve, RLX control handle, 50-ft.

and 4-ft. long twinline control hoses, and abrasive trap,

shown in Figure 1.

WARNING

Moist air that freezes can cause blockage at the

control handle or in the control lines. Blockage

can cause involuntary activation of the remote

controls, or prevent the controls from

deactivating upon release of the control handle.

This situation can result in serious injury or

death. If remote controls are operated in

freezing or near-freezing weather, install a

Clemco Anti-Freeze Injector, stock no. 05537,

on the remote control air-supply line.

1.3.4.4 Millennium remote controls are pressure-

release-style systems, which control the pressurization

and depressurization of the blast machine.

Pressurization, which starts blasting, occurs when the

control handle is pressed, and depressurization, which

stops blasting, occurs when the handle is released.

Pressure Regulator

Orifice Fitting

Blast Machine Front Leg

RLX Control Handle

1/4 NPT Adaptor

Bulkhead Fitting

Blast Machine Quick Coupling

50-Ft. Twinline Hose

Nylon Ties

Blast Hose

Figure 2

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 9

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 4

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

1.3.4.5 Clemco remote controls operate pneumatically

on a return-air principle. A stream of control air travels

from the orifice on the inlet valve, down the outbound

twinline (shown shaded in Figure 2) and escapes

through the opening located under the control handle

lever. The normally-closed inlet valve remains closed,

and the normally-open outlet valve remains open. As

long as air escapes through the hand le’s opening, the

remote control system remains inactive. When the

operator presses the control lever, a rubber button

seals the opening, and outbound air returns through

the inbound line to open the inlet valve and close the

outlet valve. This action pressurizes the blas t machine

and begins the blasting. Releasing the handle

exhausts the control air, which causes the inle t valve to

close, and the outlet valve to open to depressur ize the

blast machine and stop the blasting.

1.3.5 Electric Remote Control Option

1.3.5.1 Electric remote controls (electro-pneumatic) are

recommended when the nozzle and remote control

handle are farther than 100 feet from the blast machine.

Pressure drop of pneumatic systems over longer

distances increases actuation time, which prevents fast,

safe operation. Contact your local Clemco Distributor for

additional information.

1.3.6 Air Filter, Optional

1.3.6.1 The optional filter removes particles and

condensed moisture from the compressed air before it

enters the machine. Water is drained through a manual

drain located at the bottom of the filter.

1.3.7 Frame and Cart

1.3.7.1 The frame assembly provides added protection

for the piping, valves and accessories. This protection

keeps the piping aligned and tight. The wheeled cart

assists in the mobility of the machine over smooth flat

surfaces. See transporting and moving in Section 3.1.

1.3.7.2 Use lifting eyes when raising, loading, and

unloading the blast machine. Do not use a sling around

the cart handles or piping.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

1.4 Abrasive

WARNING

Abrasives and dust from blasting may contain

toxic materials (e.g., lead paint, silica) that are

hazardous to workers. Before blasting, obtain a

safety data sheet (SDS) for the blast abrasive

and identify all substances removed by the

blasting process.

• Silica sand (crystalline) can cause silicosis,

lung cancer, and breathing problems in

exposed workers.

• Slags can contain trace amounts of toxic

metals such as arsenic, beryllium, and

cadmium and have the potential to cause

lung disease.

NO DUST IS SAFE TO BREATH. DUST

PRODUCED FROM ANY ABRASIVE OR FROM

THE BLASTING PROCESS CAN CAUSE

SERIOUS LUNG DISEASE AND DEATH WHEN

INHALED. It is the employer’s responsibility to

train employees to identify hazardous

substances and to provide suitable policies,

procedures, monitoring, recordkeeping and

personal protective equipment.

NOTE: Use only abrasives specifi call y manufa ctured

for blasting that are compatible with the surface

being blasted. Abrasives produced for other

applications may be inconsistent in size and shape

and produce an unsatisfactory finish, contain

particles that could jam the abrasive metering

valve, or cause irregular wear.

1.4.1 Selection of blasting abrasive can play a

significant part in worker health risk, job productivity,

and maintenance of the blast machine. DO NOT USE

abrasives containing more than one percent crystalline

(free) silica. Obtain safety data sheets (SDS) for the

blasting abrasive prior to blasting, paying particular

attention to worker health risks and presence of any

hazardous/toxic substances.

1.4.2 Abrasive Size

1.4.2.1 The choice of abrasive size depends on the

desired profile, cleaning rate, nozzle orifice size and

availability of clean dry air. Generally, larger, denser

abrasives provide a deeper profile, while smaller

abrasives clean faster. Most abrasive blasting is done

with abrasive sizes between 16 and 80 mesh. Larger

sizes may be used if the nozzle orifice is large enough to

Page 10

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 5

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

prevent particles to pass without jamming. Finer abrasives

are especially sensitive to moisture and requires very dry

air to prevent bridging in the metering valve.

1.4.3 Sand: Sand should never be used because of

the respiratory hazards associated with abrasives

containing free silica.

1.4.4 Slag: Slag abrasives are compatible with the

blast machine fitted with the MQV manual Quantum

metering valve. Obtain safety data sheet (SDS) to

identify hazardous substances.

1.4.5 Steel: Steel shot and steel grit may be used with

machines fitted with the MQV manual Quantum metering

valve. Shot applications may require the use of a

pneumatically-operated metering valve such as AQV

Auto-Quantum, to prevent surging at startup.

1.4.6 Silicon Carbide, Aluminum Oxide, and

Garnet: These are the most aggressive, high-volume

abrasives used in the blasting industry. These abrasives

may be used, but the service life of any equipment

components which come in contact with the abrasive will

be reduced. Use a nozzle lined with boron carbide with

these abrasives.

1.4.7 Glass Bead: Most beads are treated to ensure

free-flow operation even under moderately highhumidity. Glass beads subjected to excessive moisture

may be reused after thorough drying and breaking up of

any clumps. Clean, dry air is a necessity. Glass bead

applications may require the use of a pneumaticallyoperated metering valve, such as AQV Auto-Quantum,

which can help to prevent surging at startup.

1.4.8 Lightweight Media: Plastic media and most

agricultural media may be used occasionally in a

standard blast machine. Exclusive use of plastic, and

some other lightweight media, requires a blast machine

with a 60

o

conical bottom for continuous, uninterrupted

media flow.

2.0 INITIAL SET-UP

2.1 Installation of a Pressure Regulator to

Reduce Blast Pressure.

2.1.1 When Installing a pressure regulator to reduce

blast pressure below 60 psi, install a tee upstream of the

regulator as shown in the insert in Figure 2, relocate the

orifice to the tee, and plug the orifice port in the inlet

valve. This allows the pneumatic control circuit to

operate at line pressure.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

2.2 Set Up for Multiple Blast Machines Operating

From a Common Compressed Air Supply

NOTICE

If multiple machines are operating from a

common compressed air supply, and a

machine is under pressure, when another

machine is pressurized, the sudden, increased

demand for air can reverse air flow from the

machine that is under pressure, and

contaminate the compressed air supply with

abrasive-laden air. Install check valves at the

piping inlet to prevent the reversal of air.

2.2.1 Where multiple blast machines are operating

from a single air source, install a ball-cone check valve

at the air supply on each machine. Refer to the

illustration in Figure 3 to install the check valve.

2.2.2 If the machines are placed close together, use a

receiver tank or manifold and run separate air lines from it

to each machine. The check valves may be located on the

receiver tank outlets if the air line goes directly to the blast

machine and nowhere else.

2.2.3 Use a Clemco 1-1/2-NPT cone check valve, stock

no. 02296. A smaller size valve could restrict air

movement and reduce nozzle pressure. When installing

the valve, make sure the directional arrow is pointing in

the direction of the air flow, toward the machine. N OTE:

Do not use a swing check valve, as the swing gate may

break in blast machine applications.

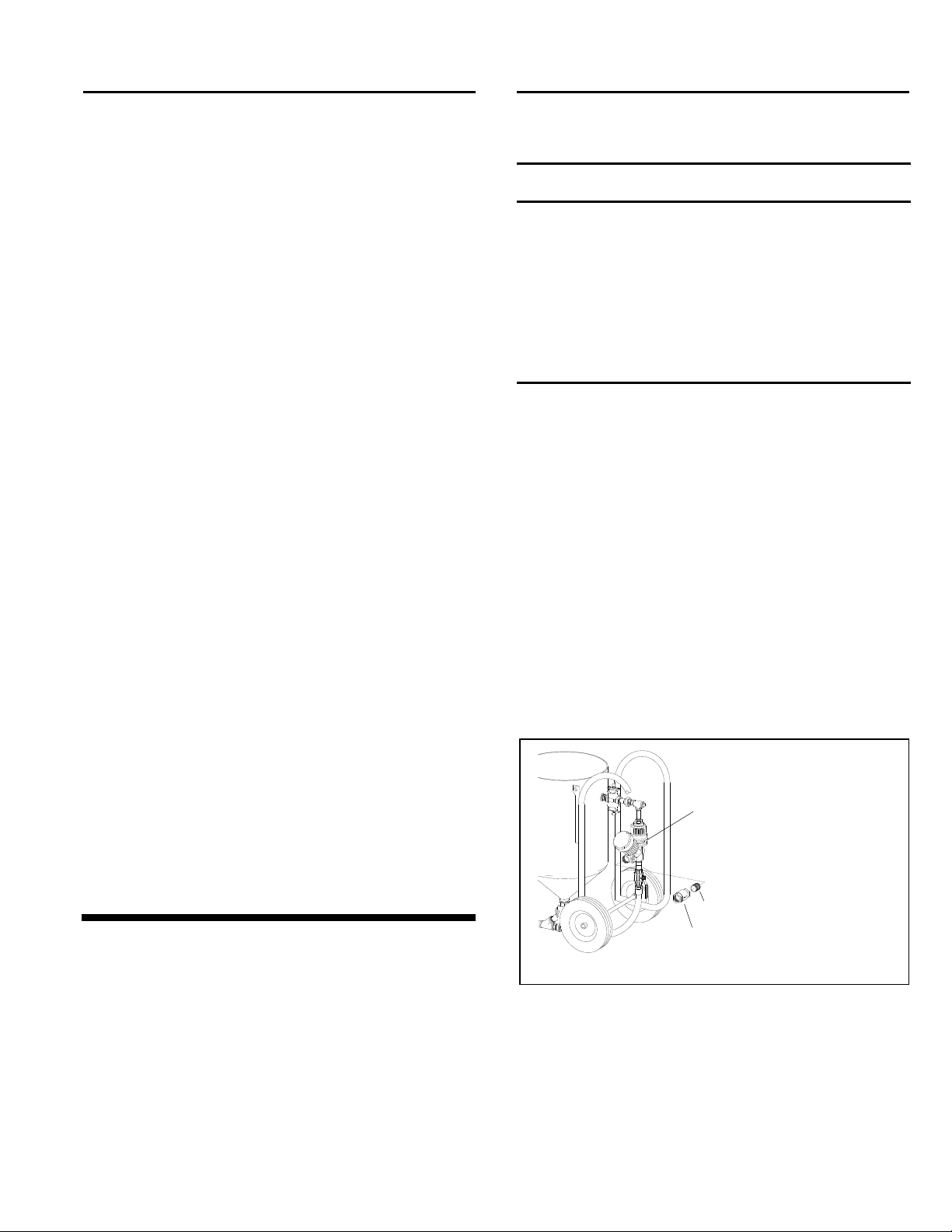

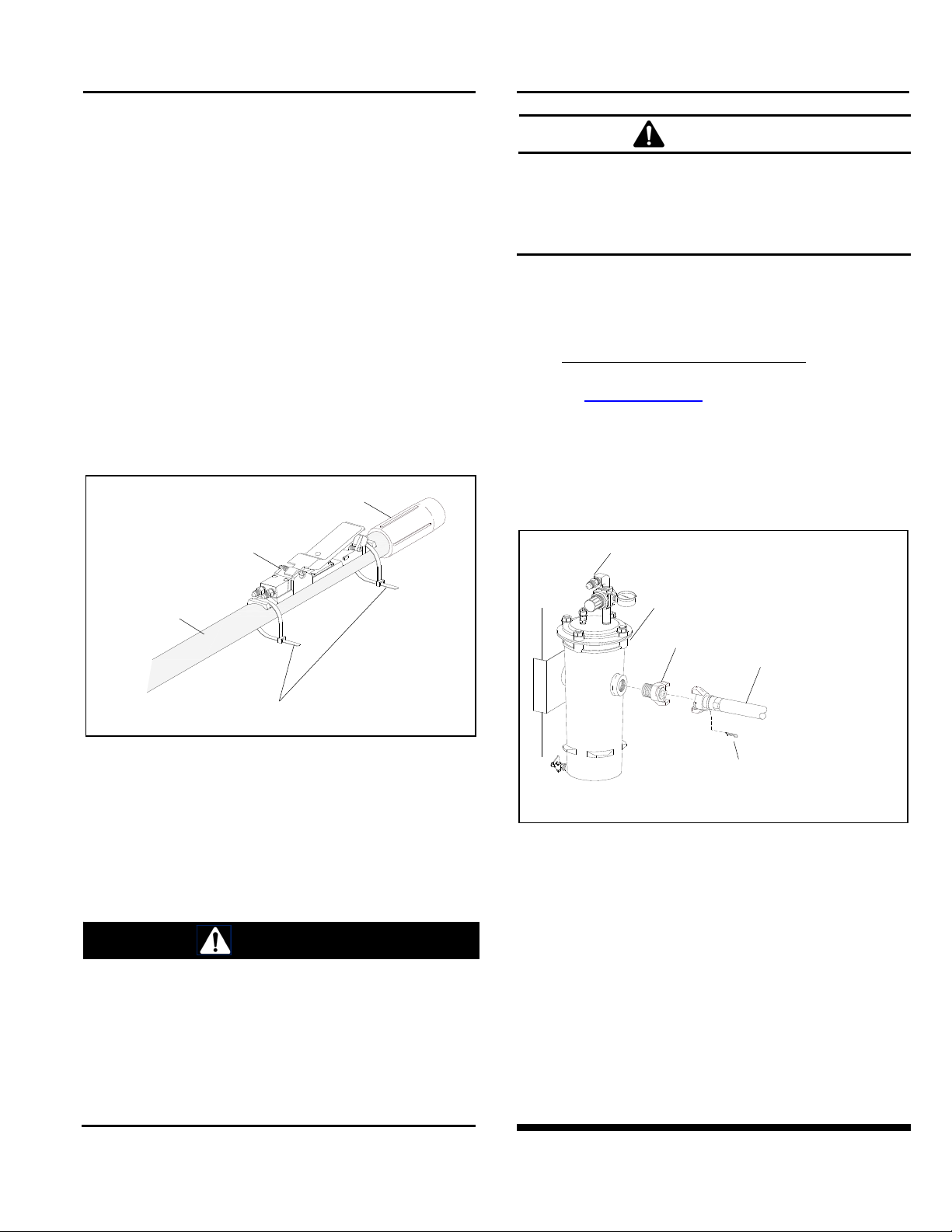

Millennium Valve

1-1/2-NPT Nipple

1-1/2-NPT Cone Check Valve

stock no. 02296

Figure 3

2.3 Install Optional Air Filter (Moisture

Separator) Figure 4, NOTE: The filter is included with

blast machine systems.

2.3.1 Install a compressed-air filter to the inlet valve

as shown in Figure 4. It is recommended that a filter be

installed at this location to remove moisture from air

before it enters the machine. If problems with moisture

Page 11

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 6

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

persists after installing the filter, a dryer or aftercooler

may be required in the air-supply line.

Millennium Valve

AIR LINE RECOMMENDATIONS

Nozzle

Orifice Size

BASED ON NOZZLE SIZE

Recommended Air Supply Line

No. 3, 3/16" 3/4" ID or larger

No. 4, 1/4" 1" ID or larger

Optional Air Filter

No. 5, 5/16" 1-1/4" ID or larger

No. 6, 3/8" 1-1/2" ID or larger

No. 7, 7/16" 2" ID or larger

Figure 4

2.4 Compressed-Air Supply Hose Connection

2.4.1 Apply thread sealant to the male pipe threads of

an air fitting that is compatible with the air supply hose

fitting, as noted in Section 2.4.2, and install it onto the

1-1/2 NPT optional air filter or the Millennium inlet valve,

as shown in Figure 5. Note that the style of

connection shown in Figure 5 is for reference only.

WARNING

Hose disconnection while under pressure can

cause serious injury or death. Use safety lock

pins or safety wire to lock twist-on (claw-type)

couplings together and prevent accidental

separation while under pressure, and safety

cables to prevent hose from whipping should

separation occur.

Millennium Valve

No. 8, 1/4" 2" ID or larger

Refer to the compressed air and abrasive

consumption table in Figure 9 for approximate air

consumption.

Figure 6

2.5 Prepare Blast Hose and Remote Control

Hose Connections, Figure 2.

WARNING

Where two or more blast machines are used,

carefully trace control lines and blast hose

when making connections. Cross-connecting

control hose or blast hose can lead to serious

injury, death, or property damage from

unintentional actuation of a blast machine. To

prevent cross connections, hoses should be of

equal lengths, and the hoses and blast machine

couplings clearly marked. Use optional hose

identification kits, stock no. 15890 for use with

two blast machines, or stock no. 15891 for up

to four machines. Mark each hose and

connection per the instructions supplied with

the kit, and carefully trace and verify each

Hose Fitting

Safety Lock Pin

connection before operating.

WARNING

Air Supply Hose

Safety Cable

Figure 5

2.4.2 Attach an air line from the compressor to the

hose fitting installed on the blast machine inlet. For best

blasting performance, refer to the table in Figure 6 for

the minimum recommended hose size based on the

nozzle orifice size. A smaller diameter hose could result

in a reduction in nozzle pressure.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Moist air that freezes can cause blockage at the

control handle or in the control lines. Blockage

can cause involuntary activation of the remote

controls, or prevent the controls from

deactivating upon release of the control handle.

This situation can result in serious injury or

death. If remote controls are operated in

freezing or near freezing weather, install a

Clemco Anti-Freeze Injector, stock no. 05537,

on the remote control air supply line.

Page 12

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 7

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

2.5.1 Uncoil the blast hose, and lay the 50-ft. twinline

hose alongside it. Hoses should be of equal lengths.

2.5.2 Band the control handle to the blast hose close

to the nozzle holder, as shown in Figure 7, using the two

nylon ties provided. Once the control is firmly attached,

clip the tie ends to avoid snags or interference with the

operation of the control handle.

2.5.3 Attach the 50-ft. twinline hose to the two fittings

on the control handle. Either side of the hose can be

attached to either fitting.

2.5.4 Working from the control handle back, band the

twinline hose to the blast hose every four to six feet, and

as close to the couplings as possible.

NOTE: Control hoses come with reusable hose ends.

Excess hose may be cut-to-fit and recoupled, refer to

Section 6.11.

Nozzle Holder

RLX Control Handle

WARNING

Air supply to the respirator system is critical to

the safety of the user. Read the CPF Filter and

Apollo Respirator manuals carefully. Poor

quality air will cause serious respiratory injury

or death to the user.

2.6.1 The employer is responsible for ensuring that

breathing air shall meet the requirements for Grade D or

higher quality, as described in Compressed Gas

Association Commodity Specification pamphlet G-7.1.,

titled Commodity Specification For Air, published by

Compressed Gas Association Inc., Chantilly, VA.

Website: www.cganet.com

2.6.2 Apply thread sealant to the male threads of an air

fitting that is compatible with the air supply hose fitting, as

noted in Section 2.6.3, and install it onto the 1-NPT port

located at the side of the filter, as shown in Figure 8. Note

that the style of connection shown is for reference only.

Respirator Lead Hose Fitting

(29 CFR 1910.134 (i)).

Blast Hose

Nylon Ties

CPF Filter

Air Fitting

Hose from

respirable air supply

Figure 7

2.5.5 Place the nozzle washer in the nozzle holder,

and screw the nozzle into the holder. The nozzle must

seat tightly against the nozzle washer.

2.6 Breathing Air Connection, Opt ional CPF Filter,

Refer to the CPF Owner’s Manual 04143 before

operating the filter.

DANGER

Do not connect the CPF Filter, or any other

regulator or filter, to bottled air or any other air

source that does not have a pressure-reducing

valve that reduces pressure to maximum of 150

psi. Failure to comply with this warning will

cause low-pressure devices to explode under

the high pressure of bottled air. Such an

explosion can cause severe injury or death.

Figure 8

2.6.3 Refer to the CPF air filter owner’s manual and

attach an air supply hose from an air source that meets

OSHA requirements for respirable air, to the fitting

installed on the CPF filter inlet, as shown in Figure 8 and

noted in the CPF air filter owner’s manual.

2.6.4 For models with CPF filter attached, Refer to

Page 27, Figure 35 and connect a hose union to one

end of the 5-ft. respirator lead hose and connect the

other end of the hose to the fitting at the top of the CPF

filter

2.6.5 Refer to the Apollo Respirator and CPF Filter

manuals for instructions concerning their operation.

Use safety lock pins

to secure couplings.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 13

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 8

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

3.0 OPERATION

3.1 Transporting and Moving

WARNING

Failure to observe the following warnings

before transporting or moving a blast machine

can result in serious injury or death.

Always empty the blast machine before

lifting or hoisting.

Never hoist the machine by the handle or

piping, or with a sling through the handle or

piping.

Always use lift equipment that is rated

higher than the weight of the machine and

accessories.

When transporting a machine on a pallet,

always securely attach the machine to a

sturdy pallet.

Always securely anchor the machine to the

transport vehicle.

Anyone using material handling equipment

to move, transport, or lift the machine must

be experienced, and able to recognize and

avoid hazards associated with handling this

type of machinery, and to safely operate the

equipment.

3.1.1 Transporting a blast machine

3.1.1.1 Always empty the machine before transporting.

Transporting the machine containing abrasive can

increase the weight to an unsafe handling limit, and

could cause abrasive to settle in the piping.

3.1.2 Moving a blast machine

WARNING

Do not manually move the machine on an

incline, or on a slippery or irregular surface that

can cause the operator to slip or lose balance.

Sudden weight shifts when the machine is tilted

on an incline, and slipping or tripping while

moving the machine will cause the operator to

lose control of the machine, causing severe

injury and property damage.

WARNING

Never attempt to manually move a blast

machine when it contains abrasive. An empty

machine may be moved manually in a forward

direction, on level flat surfaces.

3.1.2.1 An empty machine may be moved manually, on

level flat surfaces.

3.1.2.2 To avoid tripping hazards that may be out of

view, always move the machine by pushing it in a

forward direction. Do not back-up while moving the

machine,

3.1.2.3 Use the lifting eyes when lifting the machine. Do

not use a sling around the cart handles or piping.

3.1.2.4 If the machine contains any abrasive, keep the

machine upright. Laying down a machine containing

abrasive could cause abrasive to lodge in the piping,

machine to malfunction, or damaged valves.

3.2 Set-Up for Operation

3.2.1 Locate the compressor upwind from the blasting

operation to prevent contaminated air from entering the

compressor intake.

3.2.2 Attach an air line from the compressor to the air

supply hose connector installed on the blast machine

inlet. For best blasting performance, use the minimum

recommended hose size as noted in Figure 6, Refer to

the compressed air and abrasive consumption table in

Figure 9 for approximate air consumption.

3.2.3 Make sure the coupling gaskets are in place

and in good condition before connecting the blast hose

to the quick coupling on the blast machine. NOTE:

When connecting a nylon coupling to a nylon

coupling, make sure the coupling spring lock pins

are at 180 degrees (Pins should enter the open hole of

the adjoining coupling). The spring lock pins prevent

accidental separation of hose couplings during blasting.

One lock pin is used when connecting nylon to metal

and two are used when connecting two metal couplings.

3.2.4 Make sure that all blast hose couplings and

compressed-air supply hose connections are secured

with safety lock pins to lock the couplings together and

prevent accidental separation while under pressure, and

safety cables to prevent hose from whipping should

separation occur. Lock pins and safety cables are listed

in Section 8.1 of this manual.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 14

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 9

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

Consumption rates are based on abrasives that weigh 100 pounds per cubi c foot

Pressure at the Nozzle (psi) Air, Power

Orifice and Abrasive

Size (in.) 50 60 70 80 90 100 125 140 Requirements

11 13 15 17 19 20 25 28 Air (cfm)

No. 2 67 77 88 101 112 123 152 169 Abrasive (lbs/hr)

1/8 2.5 3 3.5 4 4.5 5 5.5 6.5 Compressor (hp)

26 30 33 38 41 45 55 61 Air (cfm)

No. 3 150 171 196 216 238 264 319 353 Abrasive (lbs/hr)

3/16 6 7 8 9 10 10 12 14 Compressor (hp)

47 54 61 68 74 81 98 108 Air (cfm)

No. 4 268 312 354 408 448 494 608 676 Abrasive (lbs/hr)

1/4 11 12 14 16 17 18 22 24 Compressor (hp)

77 89 101 113 126 137 168 186 Air (cfm)

No. 5 468 534 604 672 740 812 982 1085 Abrasive (lbs/hr)

5/16 18 20 23 26 28 31 37 42 Compressor (hp)

108 126 143 161 173 196 237 263 Air (cfm)

No. 6 668 764 864 960 1052 1152 1393 1538 Abrasive (lbs/hr)

3/8 24 28 32 36 39 44 52 59 Compressor (hp)

147 170 194 217 240 254 314 347 Air (cfm)

No. 7 896 1032 1176 1312 1448 1584 1931 2138 Abrasive (lbs/hr)

7/16 33 38 44 49 54 57 69 77 Compressor (hp)

195 224 252 280 309 338 409 452 Air (cfm)

No. 8 1160 1336 1512 1680 1856 2024 2459 2718 Abrasive (lbs/hr)

1/2 44 50 56 63 69 75 90 101 Compressor (hp)

* For nozzle sizes 3/8 to 1/2, blast machines should be equipped with 1-1/4 or larger piping and inlet valve t o prevent

pressure loss.

* Air requirements were measured by a flow meter under actual blasting conditions, and are therefore lower than figures for

air alone, with no abrasive.

* Horsepower requirements are based on 4.5 cfm per horsepower.

* Figures are for reference only, and m ay vary for different working conditions. Several variables, including metering valve

adjustments, can affect abrasive flow.

* Figures show approximate compressed air and abrasive consumpt ion when nozzles are new. Consumption will incr ease as

the nozzle wears.

Figure 9

WARNING

Hose disconnection while under pressure can

cause serious injury or death. Use safety lock

pins or safety wire to lock twist-on (claw-type)

couplings together and prevent accidental

separation while under pressure, and safety

cables to prevent hose from whipping should

separation occur.

3.2.5 Attach the ends of the 50-ft. twinline hose to the

lower adaptors in the bulkhead fittings on the front leg as

shown in Figure 10. Either side of the tw inline hose can

be attached to either fitting.

Compressed Air and Abrasive Consumption

*Safety Lock Pin Blast Hose

* Safety lock pins are not used with nylon couplings,

refer to Section 3.2.3. One lock pin is used when

connecting nylon to metal. and two are used when

connecting two metal couplings

Figure 10

Twinline Hose Adaptors

Twinline Hose

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 15

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 10

r

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

3.2.6 Check all fittings to make sure they are wrench-

tight. Leaks will cause the system to malfunction.

3.2.7 Attach an air line between a source of respirable

breathing and the CPF filter inlet. Breathing air must

meet the requirements for Grade D or higher quality,

Refer to Section 2.6. The maximum inlet pressure for the

CPF Filter must not exceed 150 psi.

DANGER

Do not connect the CPF Filter, or any other

regulator or filter, to bottled air or any other air

source that does not have a pressure-reducing

valve that reduces pressure to a maximum of

150 psi. Failure to comply with this warning will

cause low pressure devices to burst from the

excessive pressure of bottled air. A rupture of

this nature can cause severe injury or death.

WARNING

If claw type air hose couplings are used, they

must be secured by safety pins or wires to

prevent accidental disconnection. Hose

disconnection while under pressure can cause

serious injury or death.

3.2.8 Make sure the choke valve is open; the valve is

open when the handle position is aligned with the piping,

as shown in Figure 14.

3.2.9 Close the abrasive metering valve; The valve is

closed when the metering knob is turned fully clockwise.

Refer to Section 4.1. NOTE: it is not neces sary to close

the metering valve after the initial startup and adjustment

per Section 4.1.

3.2.10 Make sure the safety petcock on the Millennium

valve. Open position is when the lever is aligned with the

petcock, as shown in Figure 11.

WARNING

To prevent severe injury from accidental

activation of the blast machine, open the safety

petcock when the blast machine is not in use.

Opening the petcock prevents unintentional

blasting. The control handle cannot activate the

machine when the petcock is open.

Millennium Valve

Closed

Figure 11

Open

3.2.11 Make sure the remote control handle lever is in

the up (no blast) position, as shown in Figure 12 and that

the handle lever and safety lock move freely.

The lever lock must be pulled down before the

control handle lever can be pressed.

Control Handle Leve

Shown in the UP non-blast position

Lever Lock

Prevents control handle

lever from being pressed

down to the blast position.

Figure 12

3.2.12 Make sure the rubber seal under the handle

lever does not seal the opening on the control handle,

unless the safety lever lock is intentionally pulled down

WARNING

.

Malfunctioning control handles can cause

unintentional actuation of a blast machine, or

prevent a machine from deactivating upon

release. Malfunctioning control handles must

be taken out of service immediately and be

repaired or replaced. Serious injury or death

can result from unintentional blasting.

3.2.13 Close the air valve on the compressor. Start the

compressor, and bring it to operating temperature and

pressure. The pressure must be more than 50 psi, but

not exceed 150 psi.

3.2.14 Slowly open the compressor air valve to

pressurize the air line. Listen for any open lines or air

leaks.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 16

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 11

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

3.2.15 Pressurize the breathing air supply line, and

adjust pressure on the CPF Filter outlet to the pressure

stated in the respirator manual.

3.2.16 Load abrasive into the machine according to the

instructions in Section 3.7.

3.2.17 Do not allow anyone near the blast machine

except machine tenders, who are appropriately attired in

approved protective equipment as noted in Section 3.3.

WARNING

Everyone except for the blast operator or blast

machine tender must stay clear of the blast

machine. The machine tender or blast operator

may pressurize or depressurize the machine at

any time, which can cause abrasive to vent

under pressure, causing dust and toxins to

become airborne. Noise is produced by the

sudden release of compressed air when the

machine is pressurized or depressurized. These

conditions can cause injury. Both the operator

and machine tender must wear suitable

personal protective equipment including an

approved respirator, plus approved eye, face,

and hearing protection.

3.3 Blasting Attire

WARNING

Before blasting, test the coating and substrate

for toxic materials (such as lead, other heavy

metals, or asbestos). These hazards require

special measures to protect the operators and

the environment.

Obtain a safety data sheet (SDS) for the blast

abrasive to identify hazardous substances.

Silica sand (crystalline) can cause silicosis,

lung cancer, and breathing problems in

exposed workers. Slag abrasives may contain

trace amounts of toxic metals

such as arsenic,

beryllium, and cadmium. Any abrasive dust has

potential to cause lung disease.

Abrasive blasting operations can create high

levels of dust and noise. No dust is safe to

breathe. Abrasive blasting can produce harmful

dust. Failure to wear NIOSH-approved

respirators can result in serious lung disease or

death. The respirators must be properly-fitted

and maintained NIOSH-approved, type-CE

supplied-air respirators approved for abrasive

blasting.

During abrasive blasting, abrasive particles and

dust in the area around the blast machine and

blast nozzle become airborne. Everyone

working in the vicinity of abrasive blasting must

wear properly-maintained, NIOSH-approved,

respiratory protection and eye protection

appropriate for the job site hazards.

Loud noise generated by the use of

compressed air can cause hearing damage.

Everyone in the blasting area must wear

approved hearing protection.

It is the employer’s responsibility to train

employees to identify hazardous substances

and to provide suitable policies, procedures,

monitoring, recordkeeping and personal

protective equipment.

3.3.1 Operators and anyone else that may be

exposed to the hazards generated by the blasting

process must wear appropriate protective gear,

including abrasive-resistant clothing, leather gloves, eye

and hearing protection, and a NIOSH-approved type CE

supplied-air respirator.

3.3.2 Don protective blasting attire outside the blast

area, in a clean non-hazardous environment, free of

contaminants, where the air is safe to breathe.

3.4 Pressurize Blast Machine to Start Blasting

3.4.1 Don all protective blasting attire per Section 3.3.

3.4.2 When the blast operator is ready to blast, either

the operator, or the machine tender, while standing back

and facing away from the concave filling head of the

blast machine and the exhaust muffler, closes the safety

petcock. Closing the petcock prepares the machine for

remote activation by the control handle. Air should be

heard escaping from the opening under the control

handle lever but from nowhere else. The air escaping at

the handle is an audible signal meaning air is supplied to

the blast machine, which will activate when the control

handle is pressed.

3.4.3 Hold the blast hose securely and point the

nozzle only toward objects intended to be blasted.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 17

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 12

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

3.4.4 Fold down the safety lever lock and press the

remote control handle as shown in Figure 13. Within a

few seconds, the pop-up valve will automatically close,

and the blast machine will pressurize to start blasting.

WARNING

Be prepared for the r eco il fr om t he bl ast hose .

Blasting should begin within a few seconds

after pressing the control handle lever.

Fold lever lock down

open; the valve is open is when the handle is vertical

and aligned with the piping as shown in Figure 14.

3.5.2 Closing the valve while blasting lowers pressure

in the pusher line from pressure in the vessel, forcing the

minor blockage through the metering valve. Closing the

valve is also used to rapidly empty the machine as noted

in Section 3.8.

NOTICE

Do not blast with choke valve closed or partially

closed. Prolonged blasting with the choke valve

partially closed will accelerate wear on the

metering valve.

Press control handle

down to begin blasting

Figure 13

WARNING

Choke Valve

Valve is shown open; handle

position is aligned with the piping.

OSHA requires the use of remote controls on all

blast machines when an operator controls the

nozzle. To comply with OSHA regulations, the

remote control handle, which starts and stops

the flow of air and abrasive, must be held down

manually. Never tie down the control handle

lever or attempt to bypass any part of the remote

control system. Doing so will defeat the purpose

of the fail-to-safe feature of the remote control.

Serious injury or death can result from

uncontrolled blasting. Ref. 29 CFR 1910.244 (b).

3.4.5 If the abrasive metering valve is closed as

instructed, only air will exit the nozzle. Adjust abrasive

flow per Section 4.1.

3.5 Operation and Function of the Choke Valve

Refer to Figure 14

3.5.1 Temporarily closing the choke valve while

blasting clears minor blockage caused from bridging and

damp abrasive. Always blast with the choke valve fully

Figure 14

3.6 Stop Blasting

3.6.1 To stop blasting, release the lever on the control

handle. The inlet segment of the Millennium valve

closes, the outlet segment opens, and the blast machine

depressurizes. The pop-up valve automatically drops

when air is expelled from the machine and pressure

equalizes.

3.6.2 When the control handle lever is released, the

safety lever-lock will flip up to lock the handle lever in the

up (no blast) position. Make sure the safety lever-lock is

up to prevent the handle lever from engaging.

3.6.3 Always open the safety petcock during work

breaks and before filling the blast machine. Opening the

petcock prevents unintentional blasting.

3.6.4 When finished blasting, shutdown per Section 3.9.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 18

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 13

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

3.7 Loading Abrasive into the Blast Machine

WARNING

When approaching an idle blast machine, and

before loading the blast machine with abrasive,

always check to make sure the safety petcock

is open. If it is closed, open it while standing

back and facing away from the concave head

and exhaust muffler. This step is especially

important if one worker (a machine tender)

loads the machine with abrasive while another

worker (the blast operator) controls the

blasting. The blast operator can pressurize the

machine before the machine tender has moved

away from the machine. During pressurization,

abrasive can be forced out of the top of the

machine, and cause injury.

WARNING

Obtain safety data sheets (SDS) for the blast

abrasive. Abrasive blasting with sands

containing crystalline (free) silica can lead to

serious or fatal respiratory disease. As NIOSH

recommends, do not use abrasives containing

more than trace amounts (more than one

percent) of free silica.

3.7.1 Load abrasive by pouring it into the concave

head. Use a screen (a screen comes with blast machine

system) placed over the filling head to prevent foreign

objects from falling inside. Foreign objects will jam the

machine. Abrasive flows through the filling port into the

machine. Keep the abrasive level below the top of the

pop-up valve to prevent abrasive from being forced up

and out of the machine when it pressurizes.

3.7.2 When ready to blast, the operator or machine

tender, while standing back and facing away from the

concave filling head and exhaust muffler, closes the

safety petcock.

3.7.3 Begin blasting or resume blasting per Section 3.4.

3.8 Emptying the Machine of Abrasive

3.8.1 Empty the machine of all abrasive when shutting

down for the day. Condensation dampens abrasive and

causes flow problems. When working in environments

subject to extreme temperature changes, or very humid

conditions, condensation may develop inside the machine.

Emptying the machine at the end of the work day

eliminates trouble caused from moist abrasive when

starting a new day's blasting . One way to avoid having to

empty the machine is to load on ly as much abr asive as w ill

be used during the work period. If the machine must be

purged of abrasive, do the followi ng:

3.8.2 With the blast machine OFF, turn the blast

pressure to approximately 50-55 psi, close the choke

valve and fully open the abrasive metering.

3.8.3 To prevent wear to the nozzle holder threads,

firmly attached the nozzle to the nozzle holder.

Removing the nozzle is not recommended. If

circumstances require the nozzle to be removed, also

remove the nozzle washer. Purging the machine without

a nozzle will eventually erode the thread area of the

nozzle holder. Thread wear could cause a hazardous

condition when the nozzle is reinstalled.

WARNING

The threads on the nozzle and nozzle holder

must be inspected each time the nozzle is

secured to the holder. A loose-fitting nozzle

may eject under pressure and can cause severe

injury. Check the threads for wear, and make

sure the nozzle holder securely holds the

nozzle. The nozzle washer must also be

inspected for wear. When nozzle washers are

worn, abrasive can erode nozzle threads.

3.8.4 Point the nozzle into a drum or suitable container,

or toward the direction where the abrasive is to be

disposed.

3.8.5 Hold the hose securely (do not leave the hose

unattended), and pressurize the machine by activating

the control handle. Be prepared for severe surging, or

recoil of the hose.

3.8.6 When the mach ine is empty, release the control

handle lever, open the safety petcock, and open the

choke valve.

3.8.7 If the nozzle was removed, thoroughly inspect

the nozzle holder threads for wear before installing the

nozzle washer and reattaching the nozzle.

3.9 Shutdown

3.9.1 Empty the blast machine per Section 3.8.

3.9.2 When finished emptying the machine and after

cleanup is completed, remove the respirator and

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

Page 19

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 14

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

protective clothing outside the respirator-use area, in a

clean environment where the air is safe to breathe.

3.9.3 Close the compressed-air supply valve at the

compressor.

3.9.4 Drain receiver tank, air filters, and water collecting

devices, and bleed the compressed-air supply hose.

3.9.5 Shutdown the compressor.

3.9.6 Cover the blast machine when not in use. Refer

to Section 8.1 for optional cover.

4.0 ADJUSTMENTS

4.1 Abrasive Metering, Figure 15

4.1.1 Abrasive flow is adjusted at the metering valve

located at the bottom of the blast machine. Use the

metering knob to adjust abrasive flow.

4.1.2 The hole in the knob enables the operator to

monitor its rotation and count turns as the knob is

turned. This helps to return the setting to its original

position, if temporary adjustments are required.

Rotation Reference

Clockwise to decrease flow

The air/abrasive mixture should be mainly air. As a rule,

the stream of abrasive coming out of the nozzle should

barely discolor the air when seen against a contrasting

background.

5.0 PREVENTIVE MAINTENANCE

5.1 Daily or More Frequent Inspection

5.1.1 With the air OFF, before blasting, do the

following:

Empty the abrasive trap and clean the abrasive trap

screen. Do this at least twice a day, or more often if

the machine is frequently cycled. Failure to clean the

abrasive trap on a regular basis is a major cause of

system malfunction. Refer to Section 6.7.

Make sure couplings are secure and lock pins and

safety cables are in place.

Inspect the RLX Control Handle; look for the

following:

The control handle lever must not seal the opening

on the control, unless the safety lever lock is

folded down.

The handle lever must return to the UP position

when released.

The safety lever lock must return to the UP

position when the handle lever is released.

Both the handle lever and safety lever lock must

move freely with no drag or binding.

WARNING

Malfunctioning control handles can cause

unintentional actuation of a blast machine, or

Counterclockwise to increase flow

Figure 15

4.1.3 The valve is closed when the knob is turned fully

clockwise. Begin with the knob set 1-1/2 turns from fully

closed. While the operator is blasting, the machine

tender turns the knob no more than 1/4 turn

counterclockwise to increase abrasive flow. Allow 10

to15 seconds for the flow to stabilize before readjusting.

Continue making adjustments as described until correct

flow is attained.

4.1.4 Optimum abrasive flow depends on the type and

size of abrasive and blasting pressure, and can best be

determined by experience. Use as little abrasive as

possible while maintaining the maximum cleaning rate.

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 21914, Rev. L

prevent a machine from deactivating upon

release. Malfunctioning control handles must

be taken out of service immediately and be

repaired or replaced. Serious injury or death

can result from unintentional blasting.

5.1.2 During blasting do the following:

Check the control handle for leaks.

Inspect all couplings and coupling gaskets for leaks.

Check the blast machine for leaks. If leaks are found

around the pop-up valve, inspection door, pipefittings

ports on the side of the machine or at the bottom of

the cone, stop blasting immediately and repair or

replace worn parts.

Page 20

CONTRACTOR SERIES BLAST MACHINE, 4 AND 6 CU. FT. Page 15

WITH MILLENNIUM PNEUMATIC, PRESSURE RELEASE REMOTE CONTROLS

NOTICE

If leaks are allowed to continue, abrasive

erosion can cause extensive or irreparable

damage to the blast machine.

Check all external piping, control hoses, and valves

for leaks. If leaks are found, stop blasting and repair.

Inspect blast hose, couplings, and nozzle holders for

leaks. At the first sign of a leak, stop blasting and

inspect all items for wear.

Leaks around couplings and nozzle holders

indicate worn or loose-fitting parts. Nozzle

holders and couplings that do not fit tightly on

hose, and nozzles that do not fit tightly in

nozzle holders can disconnect while under

pressure. Impact from objects (nozzles,

couplings, hoses, or abrasive) disconnected by

pressure during operation can cause severe

injury.

5.2 Weekly Inspection

5.2.1 With the air OFF, before blasting, do the

following:

Inspect the blast hose for wear; squeeze the hose

every two to three feet, looking for soft spots. Soft

spots mean the hose is worn. Replace the blast hose

before the tube wears as far as the fabric plies.

Worn blast hose can suddenly burst. Couplings

and nozzle holders may not adequately grip

worn hose causing them to blow-off under

pressure. Compressed air and abrasive

escaping from a burst hose, or disconnected

coupling or nozzle holder, can cause severe

injury.

Remove the nozzle for inspection. Replace with a

Make sure the nozzle washer is in good condition and

new nozzle if the orifice diameter is worn 1/16 or

more, or if the liner is damaged.

in place before reattaching the nozzle.

WARNING

WARNING

WARNING

The threads on the nozzle and nozzle holder

must be inspected each time the nozzle is

secured to the holder. A loose-fitting nozzle