Page 1

CMS-4

IN-HELMET CARBON MONOXIDE MONITOR

O. M. 29872

DATE OF ISSUE: 07/2019

REVISION:

WARNING

Do not use this equipment

before READING this

© 2019 CLEMCO INDUSTRIES CORP.

One Cable Car Dr.

Washington, MO 63090

Phone (636) 239-4300

ax (800) 726-7559

F

Email: info@clemcoindustries.com

www.clemcoindustries.com

MANUAL and

UNDERSTANDING its

contents.

These WARNINGS are

included for the health

and safety of the operator

and those in the

immediate vicinity. Failure

to read and understand

these warnings can result

in injury or death.

Electronic files include a

preface containing the

same important

information as in the

orange cover.

Page 2

PREFACE

• Employers are responsible for identifying all job site hazards, educating and training all persons who will operate and

maintain these products, and ensuring that all blast operators and their assistants understand the warnings and

information contained in these instructions relating to safe and proper operation and maintenance of this equipment.

• Serious injury or death can result from failure to comply with all Occupational Safety and Health Administration

(OSHA)regulations and all manufacturer’s instructions.

• This equipment is not intended for use in any area considered hazardous per National Electric Code NFPA 70 2011,

Article 500.

• Read this document and follow all instructions before using this equipment.

OSHA regulations relating to ab rasi ve bla sting are con tained in the Code o f Federal Regulation s, Title 29 (29 C FR 1910 Gene ral Indust ry ;

1915 Maritime; 1926 Con s truction). The most pertinent include: 1910.94 Ventilation, 1910 .95 Occupational Noise Exposure , 1 910.132

Personal Protective Equipment, 1910.133 Eye and Face Prote cti on, 191 0.134 Respiratory Protection, 1910 .1 35 Head Protection,

1910.244 (b) Remote Controls. Consult www.osha.gov for complete information.

NOTICE

PRODUCTS AND THIS INFORMATIONAL MATERIAL

TO

PURCHASERS

AND USERS OF

OUR

Clemco proudly provides products for the abrasive blast

industry and is confident that industry professionals will use

their knowledge and expertise for the safe and efficient use of

these products.

The products described in this material, and the information

relating to these products, are intended for knowledgeable,

experienced users.

No representation is intended or made as to: the suitability of

the products described here for any purpose or application, or

to the efficiency, production rate, or useful life of these

products. All estimates regarding production rates or finishes

are the responsibility of the user and must be derived solely

from the user’s experience and expertise, not from information

contained in this material.

It is possible that the products described in this material may

be combined with other products by the user for purposes

determined solely by the user. No representations are

intended or made as to the suitability of or engineering

balance of or compliance with regulations or standard practice

of any such combination of products or components the user

may employ.

Abrasive blast equipment is only one component of an

abrasive blasting job. Other products, such as air

compressors, air filters and receivers, abrasives, scaffolding,

hydraulic work platforms or booms, equipment for lighting,

painting, ventilating, dehumidifying, parts handling, or

specialized respirators or other equipment, even if offered by

Clemco, may have been manufactured or supplied by others.

The information Clemco provides is intended to support the

products Clemco manufactures. Users must contact each

manufacturer and supplier of products used in the blast job for

warnings, information, training, and instruction relating to the

proper and safe use of their equipment.

GENERAL INSTRUCTIONS

This material describes some, but not all, of the major

requirements for safe and productive use of blast machines,

remote controls, respirator systems, and related accessories.

All equipment and accessories must be installed, tested,

operated and maintained only by trained, knowledgeable,

experienced users.

The blast operator and all workers in the vicinity must be

properly protected from all job site hazards including those

hazards generated by blasting.

Work environments involving abrasive blasting present

numerous hazards. Hazards relate to the blast process from

many sources that include, but are not limited to, dust

generated by blasting or from material present on the surface

being blasted. The hazards from toxic materials may include,

but are not limited to, silica, cyanide, arsenic, or other toxins

in the abrasives or in the coatings, such as lead or heavy

metals. Other hazards from toxins include, but are not limited

to, fumes from coating application, carbon monoxide from

engine exhaust, contaminated water, chemicals or asbestos.

In addition, physical hazards that may be present include, but

are not limited to, uneven work surfaces, poor visibility,

excessive noise, and electricity. Employers must identify all

job site hazards and protect workers in accordance with

OSHA regulations.

Never modify Clemco equipment or components or

substitute parts from other manufacturers for any Clemco

components or parts. Any unauthorized modification or

substitution of supplied-air respirator parts violates OSHA

regulations and voids the NIOSH approval.

IMPORTANT

Contact Clemco for free booklets:

Blast Off 2 – Guide to Safe, Productive, and Efficient Abrasive

Blasting, and Abrasive Blasting Safety Practices – Guide to Safe

Abrasive Blasting.

Clemco Industries Corp. One Cable Car Drive Washington MO 63090

Tel: 636 239-4300 — Fax: 800 726-7559

Email: info@clemcoindustries.com

Website: www.clemcoindustries.com

[I]

Page 3

PREFACE

OPERATIONAL INSTRUCTIONS

OSHA regulation 1910.134 requires appropriate respiratory protection for blast operators and workers in

the vicinity of blasting. These workers must wear properly-fitted, properly-maintained, NIOSH-approved,

respiratory protection that is suitable for the job site hazards. Blast respirators are to be worn only in

atmospheres not immediately dangerous to life or health from which wearers can escape without use of

the respirator.

The employer must develop and implement a written respiratory protection program with required

worksite- specific procedures and elements for required respirator use. The employer must provide

effective training to employees who are required to use respirators. The training must be comprehensive,

understandable, and recur annually, and more often if necessary.

NEVER use abrasives containing more than one percent crystalline silica. Fatal diseases, such as silicosis,

asbestosis, lead or other poisoning, can result from inhalation of toxic dusts, which include, but are not

limited to, crystalline silica, asbestos, and lead paint. Refer to NIOSH Alert 92-102; and OSHA CPL 03-00-007:

“National Emphasis Program – Crystalline Silica”, in which OSHA describes policies and procedures for

implementing a national emphasis program to identify and reduce or eliminate health hazards from exposure

to crystalline silica. Numerous topics associated with the hazards of crystalline silica in silica blasting sand

can be found on http:// osha.gov/. Clemco urges users of silica blasting sand to visit this website, and read

and heed the information it contains.

Always make sure the breathing air supply (respirator hose) is not connected to plant lines that supply

gases that include, but are not limited to, oxygen, nitrogen, acetylene, or other non-breathable gas. Never

modify or change respirator air line connections without first testing the content of the line for safe

breathing air. Failure to test the line may result in death to the respirator user.

• Breathing air quality must be at least Grade D,

as defined by the Compressed Gas Association

specification G-7.1, per OSHA Regulation 29 CFR

1910.134. When compressed air is the breathing air

source, a Clemco CPF (suitable sorbent bed filter)

should be used. Respirator hose connecting the

respirator to the filter must be NIOSH approved.

Non- approved hose can cause illness from

chemicals employed to manufacture the hose.

• All workers must always wear NIOSH-approved

respirators when any dust is present. Exposure to

dust can occur when handling or loading abrasive,

blasting, cleaning up abrasive, or working in the

vicinity of blasting. Before removing the respirator,

test the air with a monitoring device to ensure it is

safe to breathe.

For additional information, consult:

Occupational Safety and Health Administration (OSHA) - www.osha.gov

Compressed Gas Association (CGA) - www.cganet.com

The Society for Protective Coatings (SSPC) - www.sspc.org

National Association of Corrosion Engineers (NACE) - www.nace.org

American Society for Testing and Materials (ASTM) - www.astm.org

National Institute of Occupational Safety and Health (NIOSH) - www.niosh.gov

American National Standards Institute (ANSI) - www.ansi.org

OPERATOR SAFETY EQUIPMENT

• Clemco respirators DO NOT remove or protect against

carbon monoxide or any other toxic gas. Monitoring

devices must be used in conjunction with the respirator to

ensure safe breathing air. Always locate compressors and

ambient air pumps where contaminated air will not enter

the air intake.

• Always use Clemco lenses with Clemco respirators;

installing non-approved lenses voids the NIOSH approval.

Respirator lenses are designed to protect the wearer from

rebounding abrasive; they do not protect against flying

objects, heavy high-speed materials, glare, liquids, or

radiation.

INDUSTRY ORGANIZATIONS

[II]

Page 4

PREFACE

BLAST MACHINES AND REMOTE CONTROLS

OSHA regulation 1910.169 describes the necessity of pressure relief valves on compressed air equipment. Do not

operate blast machines with air compressors that are no t equipped with properly functioning pressure relief valves.

OSHA regulation 1910.244(b) requires the use of remote controls on blast mach ines.

Serious injury or death can result from many sources, among them:

Involuntary activation of the remote controls. Never modify or substitute remote control parts; parts are not

compatible among different manufacturers. Welding hose is not suitable for remote control hose. Its ID and material

composition make it unsafe for remote control use.

Exceeding the maximum working pressure. Clemco blast machines are built to ASME-code and carry a ‘U’ or ‘UM’

stamp, and National Board/serial number. Every machine is marked with its maximum working pressure. Never

exceed the maximum working pressure limits of the blast machine.

Uncontrolled blast stream. High-velocity abrasive particles will inflict serious injury. Always point the blast nozzle

in the direction of the blast surface only. Keep unprotected workers out of the blast area.

Welding on the blast machine. Never weld on the blast machine; welding voids the Nation al Bo ard approval and

may affect the dimensional integrity of the vessel.

Moving the blast machine. Never manually move a blast machine contain ing abrasive, any machine containing

abrasive must be moved with appropriate mechanical lifting equi pment.

HOSES, COUPLINGS, AND NOZZLE HOLDERS

The inside diameter (ID) of air hoses, fittings, and connections

should be at least four times larger than the nozzle orifice size. Blast

hose ID should be three to four times the size of the nozzle orifice.

Example: a #6 nozzle (3/8” diameter orifice) calls for 1-1/2” ID blast

hose and 1-1/2” ID or larger compressor hose. All hose runs should be

kept as short as possible and run in as straight a line as possible to

reduce pressure loss.

To install, squarely cut the end of the hose so that it fits snugly

against the coupling or hose end shoulder. Always use the screws

recommended by the manufacturer ensuring that they do not

penetrate the inner wall. Make sure the couplings tightly fit the hose.

Install cotter pins at ev ery conn ection or use couplings with built-in

lock-springs to prevent disengagement. Install safety cables at all

connections to prevent whipping if hoses disengage or blow out.

MAINTENANCE AND REPAIR

Completely read and follow all service instructions and recommended maintenance intervals. Always shut off compressor and

depressurize blast machine before performing any maintenance. At every service interval, clean all filters, screens, and alarm systems. If

spring-loaded abrasive valves are used, always cage spring before disassembly.

WARRANTY

The following is in lieu of all warranties, express, implied or statutory, and in no event shall seller or its agents, successors, nominees or

assignees, or either, be liable for special or consequential damage arising out of a breach of warranty. This warranty does not apply to any damage or

defect resulting from negligent or improper assembly or use of any item by the buyer or its agent or from alteration or attempted repair by any person

other than an authorized agent of seller. All used, repaired, modified, or altered items are purchased “as is” and with all faults. In no event shall seller

be liable for consequential or incidental damages. The sole and exclusive remedy of buyer for breach of warranty by seller shall be repair or

replacement of defective parts or, at seller’s option, refund of purchase price, as set forth below

:

1. Seller makes no warranty with respect to products used other than

in accordance hereunder.

2. On products seller manufactures, seller warrants that all products are to

be free from defects in workmanship and materials for a

period of one year from date of shipment to buyer , but no warranty is

made that the products are fit for a particular purpose.

3. On products which seller buys and resells pursuant to this order, seller

warrants that the products shall carry the then sta ndard warranties of the

manufacturers thereof, a copy of which shall be made available to the

customer upon request.

4. The use of any sample or model in connection with this order is for

illustrative purposes only and is not to be construed as a warranty that the

product will conform to the sample or model.

5. Seller makes no warranty that the products are delivered free of the

rightful claim of any third party by way of patent infringement or the like.

6. This warrant y is conditioned upon seller’s receipt within ten (10)

days after buyer’s discovery of a defect, of a written notice stating in

what specific material respects the product failed to meet this

warranty. If such notice is timely given, seller will, at its option, either

modify the product or part to correct the defect, replace the product or

part with complying products or parts, or refund the amount paid for

the defective product, any one of which will constitute the sole liability

of the seller and a full settlement of all claims. No allowance will be

made for alterations or repairs made by other than those authorized

by seller without prior written consent of seller. Buyer shall afford

seller prompt and reasonable opportunity to inspect the products for

which any claim is made as above stated.

Except as expressly set forth above, all warranties, express, implied

or statutory, including implied warranty of merchantability, are

hereby disclaimed.

[III]

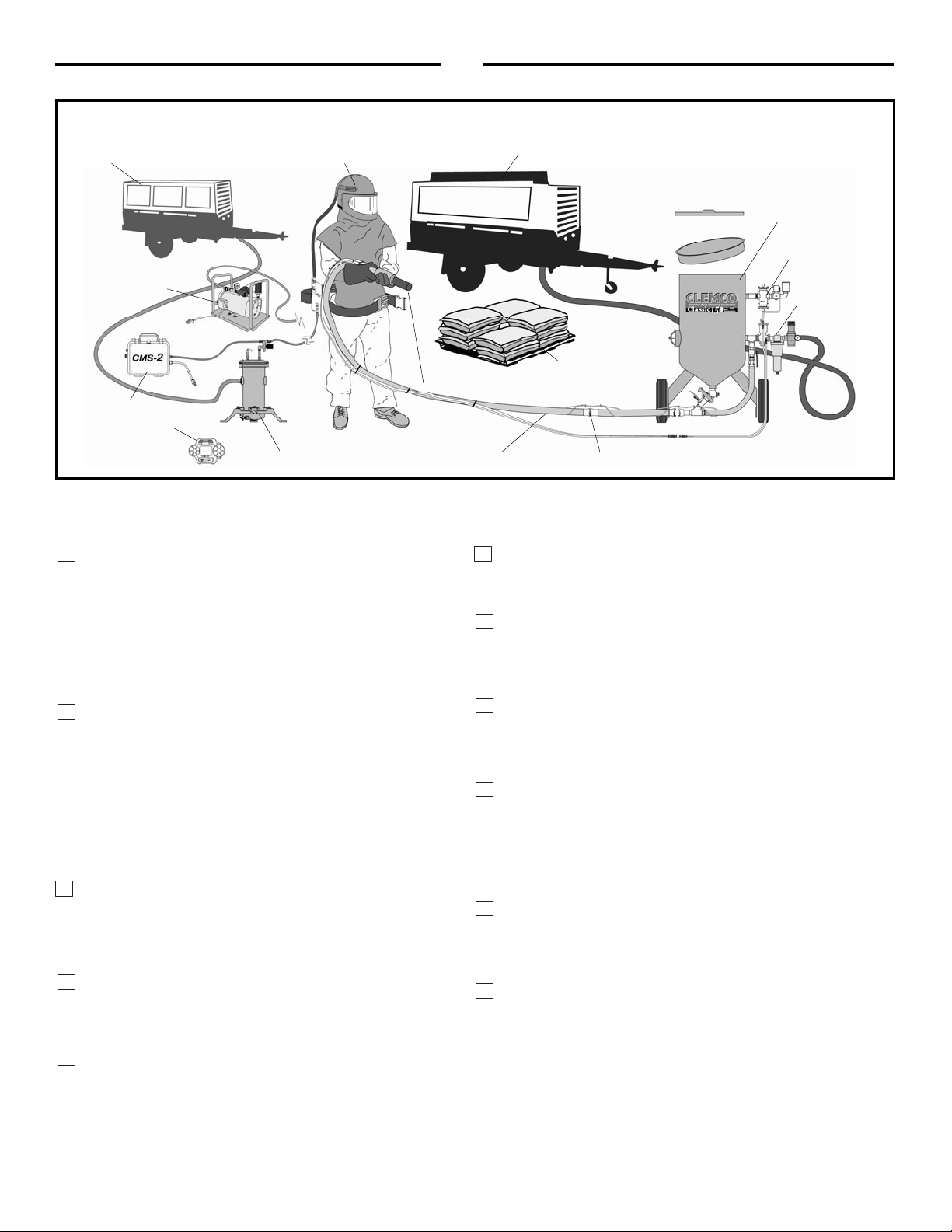

Page 5

PREFACE

r

p

r

as

e

Co

s

DAILYSET‐ UP CHECKLIST

2. Breathing Air Compressor for

High Pressure Respirators

or Ambient Air Pump for

Low Pressure Respirators

4. External or

Helmet Mounted

Carbon Monoxide

Monitor /Alarm

Make sure all blast operators are properly trained and suitably attired with a blast suit, safety boots, leather gloves, respiratory and hearing protection. Every day before start up,

check all equipment components, including piping, fittings, and hoses, and valves, for leaks, tightness, and wear. Repair or replace as needed. Use the following checklist.

1. PROPERLY-MAINTAINED AIR COMPRESSOR

sufficient volume (cfm) at given pressure for nozzle and other tools. ADD 50%

volume (cfm) reserve to allow for nozzle wear. Use large compressor outlet and

air hose (at least 4 times the nozzle orifice diameter). For oil-lubricated

compressors, the employer shall use a high- temperature or carbon monoxide

alarm, or both, to monitor carbon monoxide levels. If only high-temperature

alarms are used, the air supply shall be monitored at intervals sufficient to

prevent carbon monoxide in the breathing air from exceeding 10 ppm. Follow

the manufacturer’s checklist and maintenance instructions.

2. BREATHING-AIR COMPRESSOR

capable of providing Grade D quality air, located in a dust free area. Read # 1

above.

3. CLEAN, PROPERLY-MAINTAINED NIOSH-APPROVED SUPPLIED-AIR

RESPIRATOR

Make sure all respirator components are in place — all lenses, inner collar, and

cape. Thoroughly inspect all components for wear. The NIOSH approval (approval

number is listed in the owner’s manual) is for a complete assembly from point of

attachment on the CPF (sorbent bed) filter to the complete respirator. Substitution of

any part voids the NIOSH approval.

4. CARBON MONOXIDE MONITOR/ALARM

inside the supplied-air respirator for monitoring for the presence of deadly CO gas

and warning the operator(s) when the CO level reaches an unacceptable level.

When an ambient air pump is used for breathing air, a CO monitor provides a

measure of safety. Read # 1 above.

5. BREATHING-AIR FILTER (OSHA-REQUIRED

removal of moisture and particulate matter in the compressed air breathing-air

supply. Monitor the condition of the cartridge and replace when odor is detected or

at 3 month intervals, whichever comes sooner. The breathing air filter does NOT

detect or remove carbon monoxide (CO). Always install a CO monitor/alarm.

6. BLAST MACHINE

Maximum Working Pressure) sized to hold a 30-minute abrasive supply. Examine

pop-up valve for alignment. Check piping, fittings, screens, valves for tightness,

leaks, and wear. Always ground the machine to eliminate hazard of static shock.

Install a blast machine screen to keep out foreign objects. Use a blast machine

cover if left outdoors overnight. Never exceed the maximum working pressure of the

vessel.

worn by blast operators, and other workers exposed to blast dust.

(bearing U or UM stamp, National Board Number, and

3. NIOSH Approved

Supplied-Air Respirator

5. CPF Air Filter

sized to provide

(or oil-less ambient air pump)

installed at th e CPF filt e r or

sorbent bed filter) for

1. Air Compresso

12. Abrasive

11. Appropriately Sized Nozzle

9. Blast Hose

7. AIR LINE FILTER

blast machine inlet and sized to match the size of the inlet piping or larger air supply

line. Clean filter and drain often. Damp abrasive causes operational problems.

8. REMOTE CONTROLS

operating condition. Test and check all components to ensure all parts are present

and fully functional. Use genuine replacement parts. NEVER mix parts from different

manufacturers. Never use welding hose for remote control hose.

9. BLAST HOSE

The ID should be three to four times the size of the nozzle orifice diameter. Blast hose

should be arranged in as straight a line as possible from the blast machine to the

work area, avoiding sharp bends.

10. COUPLINGS AND NOZZLE HOLDERS

be installed with manufacturer recommended screws. Coupling lugs must snap firmly

into locking position. Gasket must always be used to form a positive seal, and cotter

pins must be installed. Replace gasket when wear, softness or distortion is detected.

Check nozzle holder for thread wear; replace at any sign of wear. Install safety cables

at all connections.

11. NOZZLE

orifice size should be checked and nozzle replaced when worn

1/16” from original size. (No. 5 nozzle has 5/16” orifice diameter; replace when it

measures 3/8”). Threads should be inspected daily for wear and nozzle should be

replaced when wear is detected. Always use a nozzle washer.

12. ABRASIVE

should be properly sized for the job. Check material safety data sheet for freesilica, cyanide, arsenic, lead and other toxins and avoid use when these toxic,

harmful substances are present.

SURFACE TO BE BLASTED

Take appropriate protective measures as required by OSHA to ensure the blast

operator, other workers in the vicinity, and any bystanders are properly protected.

©Clemco Industries Corp., Stock No. 20954P, 0692 Rev. F, 06/12

6. ASME Code

t Machin

Bl

8. Remote

ntrol

7. Air Line

Moisture

arato

Se

10. Hose Couplings and Safety Cables

(moisture separator) installed as close as possible to the

are required by OSHA and must be in perfect

should have an inside diameter sized to suit the blast nozzle.

should fit snugly on the hose and

must be a material specifically manufactured for blasting. It

should be examined for hazardous substances.

[IV]

Page 6

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 1

W

1.0 INTRODUCTION

1.1 Scope of Manual

1.1.1 These instructions cover operation, maintenance,

troubleshooting and replacement parts for the CMS-4

Respirator-Mounted Carbon Monoxide Monitor.

1.1.2 The monitor detects the presence of carbon

monoxide (CO) inside Apollo supplied-air respirators,

where the maximum CO exposure limit in the United

States is 10 parts per million (ppm). This is the limit set

to meet the requirement for Grade D quality breathing air.

The monitor also displays the PEAK level of CO, shortterm exposure limit (STEL), and time-weighted average

(TWA). Instructions to toggle through the PEAK CO

concentrations, STEL, and TWA are explained in

Section 4.3.

1.1.3 All respirator users and those responsible for

maintenance and calibration of the monitor must read

and understand this manual before using the respirator

or operating the monitor.

1.2 Safety Alerts

1.2.1 Clemco uses safety alert signal words, based on

ANSI Z535.4-2011, to alert the user of a potentially

hazardous situation that may be encountered while

operating this equipment. ANSI's definitions of the signal

words are as follows:

This is the safety alert symbol. It is

used to alert you to potential physical

injury hazards. Obey all safety

messages that follow this symbol to

avoid possible injury or death.

NOTICE

Notice indicates information that is considered

important, but not hazard-related, if not

avoided, could result in property damage.

Caution indicates a hazardous situation that, if

not avoided, could result in minor or moderate

injury.

CAUTION

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

ARNING

Warning indicates a hazardous situation that, if

not avoided, could result in death or serious

injury.

DANGER

Danger indicates a hazardous situation that, if

not avoided, will result in death or serious

injury.

1.3 Table of Contents

Topic Page Section

INTRODUCTION ..........................................1 ........... 1.0

Scope of Manual ...........................................1 ........... 1.1

Safety Alerts .................................................1 ........... 1.2

Table of Contents .........................................1 ........... 1.3

Specifications .............................................. 2 ......... 1.4

Description of Operation .............................. 2 ......... 1.5

Ancillary Equipment Requirements ............. 3 ......... 1.6

Components and Functions ......................... 3 .......... 1.7

Case ......................................................... 3 ...... 1.7.1

Sensor Retainer ....................................... 3 ...... 1.7.2

Sensor ...................................................... 3 ...... 1.7.3

Sensor Gasket ........................................... 3 ...... 1.7.4

Charcoal Filter (black) .............................. 3 ...... 1.7.5

Hydrophobic Filter (white) .........................3 ....... 1.7.6

LCD (liquid crystal display) ........................ 3 ...... 1.7.7

Control Buttons ......................................... 4 ...... 1.7.8

Alarm-Lights ............................................. 5 ...... 1.7.9

Audible Alarm ........................................... 5 .... 1.7.10

Vibrating Alarm ......................................... 5 .... 1.7.11

Lithium Battery (a spare is included) ......... 5 .... 1.7.12

SETUP - INSTALLATION, STARTUP,

AND OPERATION .......................................5 ........... 2.0

Installation .....................................................5 ........... 2.1

Prepare Mounting Clip ...............................5 ........ 2.1.1

Installation in Apollo 20 .............................5 ........ 2.1.2

Installation in Apollo 60 and Apollo 600 ....6 ........ 2.1.3

Turning ON and Startup Procedure ..............6 .......... 2.2

Setting Date and Time ..................................6 ........... 2.3

Performing a Fresh-Air Adjustment ..............7 .......... 2.4

Turning OFF the CMS-4 ...............................7 .......... 2.5

ALARMS ......................................................8 ........... 3.0

Alarm Indications ..........................................8 ........... 3.1

Alarm Indications Table ................................8 ........... 3.2

Resetting CO Alarms ....................................8 ........... 3.3

Responding to CO Alarms ............................8 ........... 3.4

CO Alarm ...................................................8 ........ 3.4.1

Over Range Alarm .....................................8 ........ 3.4.2

Battery Alarms ...........................................8 ........ 3.4.3

Page 7

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 2

W

Sensor Failure Alarm .............................. 10 ......... 3.4.4

Clock Failure Alarm ................................. 10 ......... 3.4.5

System Failure Alarm .............................. 10 ......... 3.4.6

Alarm Setpoints .......................................... 10 ............ 3.5

MANEUVERING THROUGH MENU MODES 10 .............. 4.0

Measuring Mode ......................................... 10 ........... 4.1

Entering Measuring Mode ....................... 11 ......... 4.1.1

User Mode .................................................. 11 ............ 4.2

Entering User Mode ................................ 11 ......... 4.2.1

Tips for Using User Mode ....................... 11 ......... 4.2.2

Display Mode .............................................. 12 ............ 4.3

Entering Display Mode ............................ 12 ......... 4.3.1

Tips for Using Display Mode ................... 13 ......... 4.3.2

Display Mode Menu Item (Ref. Table) ........ 13 ......... 4.3.4

Displaying the PEAK Screen .................. 14 ......... 4.3.5

Displaying the STEL Screen ................... 14 ......... 4.3.6

Displaying the TWA Screen .................... 14 ......... 4.3.7

Maintenance Mode ..................................... 14 ............ 4.4

Return to Factory Default Settings ........... 14 ......... 4.4.1

Entering Maintenance Mode .................... 15 ......... 4.4.2

Performing a Default (M.DEF) ................. 15 ......... 4.4.3

CALIBRATION, FRESH-AIR ADJUSTMENTS,

BUMP TEST, and STORAGE ................... 15 ........... 5.0

Calibration Schedule ............................. 16 ............ 5.1

Performing Fresh-Air Adjustments ........ 16 ........... 5.2

Fresh-Air Adjustment with Ambient Air .. 16 ......... 5.2.1

Fresh-Air Adj. with 0 PPM CO Test Gas 16 ......... 5.2.2

Prepare Calibration Connector ................ 17 ............ 5.3

Connect Calibration Cup to Monitor ....... 17 ............ 5.4

Remove Calibration Cup from Monitor ... 18 ............ 5.5

Performing a Bump Test ........................ 18 ............ 5.6

Calibrating the CMS-4 ............................ 19 ............ 5.7

Storing the Calibration Kit and Test Gas .. 20 ............ 5.8

MAINTENANCE ......................................... 20 ............ 6.0

Replacing the Lithium Battery ............... 20 ........... 6 . 1

Replacing the Sensor ............................ 21 ........... 6.2

Replacing the Charcoal Filter ................ 22 ........... 6.3

Replacing the Hydrophobic Filter .......... 22 ........... 6.4

TROUBLESHOOTING ............................... 23 ........... 7.0

REPLACEMENT PARTS ............................ 24 ........... 8 . 0

System Replacement Parts .................... 24 ............ 8.1

Monitor Replacement Parts .................... 24 ............ 8 . 2

1.4 Specifications

Target Gas ................. Carbon Monoxide (CO)

Detection Range ...................... 0 to 1000 ppm

Display Increment 0 ‒ 500 .................. 1 ppm

0 ‒ 1000 ................ 5 ppm

CO Sensor ............................ Electrochemical

CO Test Gas ....................................... 25 ppm

Warning Alarm .................................... 10 ppm

Alarm Point, Low ................................. 10 ppm

Alarm Point, High ................................ 10 ppm

1.5 Description of Operation

ARNING

The CMS-4 detects carbon monoxide, which

can be life threatening. When using the CMS-4,

follow the instructions, maintenance,

calibration schedule, and warnings in this

manual to assure proper and safe operation of

the

monitor and to minimize the risk of personal

injury. Carbon monoxide poisoning can result

in death or serious injury.

1.5.1 The CMS-4 respirator-mounted carbon

monoxide monitor detects the presence of carbon

monoxide (CO) inside a supplied-air respirator.

1.5.2 CO is displayed in parts per million (ppm). The

current maximum exposure limit in the United States for

carbon monoxide in Grade D compressed breathing air

is 10 parts per million. If CO concentrations reach the

exposure limit, three alarms occur. The audible alarm

alternates between a high and low tone at about once

per second, the LED lights flash twice per second, and

the vibrator pulses twice per second. If an alarm occurs,

remove the respirator as soon as it is safe to do so.

1.5.3 The CMS-4 offers a full range of features,

including:

Digital liquid crystal display (LCD)

Visual, audible, and vibrating alarms that alert the

user to CO concentrations, malfunction, low

battery, and other conditions as noted within this

manual.

Low battery alarm

Sensor fail alarm

Current time display

Up to 4,000 hours of operation from one battery

* Peak is the highest CO concentration since the

monitor was last turned on. Refer to Section 4.3.5

for additional information on the PEAK screen.

* STEL is an acronym for short-term exposure

limit. It is the average reading over the last 15

minutes. Refer to Section 4.3.6 for additional

information on the STEL screen.

* TWA is the time-weighted average over the last

8 hours. Refer to Section 4.3.7 for additional

information on the TWA screen.

* Although some may find PEAK concentrations,

STEL, and TWA information useful, it is not pertinent

for supplied-air respirator use because the maximum

exposure limit for Grade D breathing air is 10 ppm.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 8

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 3

1.6 Ancillary Equipment Requirements

1.6.1 In addition to the monitor, the following

equipment is required to operate and maintain the CMS4 Monitor:

Calibration connector with 0.5 LPM fixed-flow

slide valve, tubing, and calibration cup: Stock

No. 29767.

25 ppm Test Gas: Stock No. 25573.

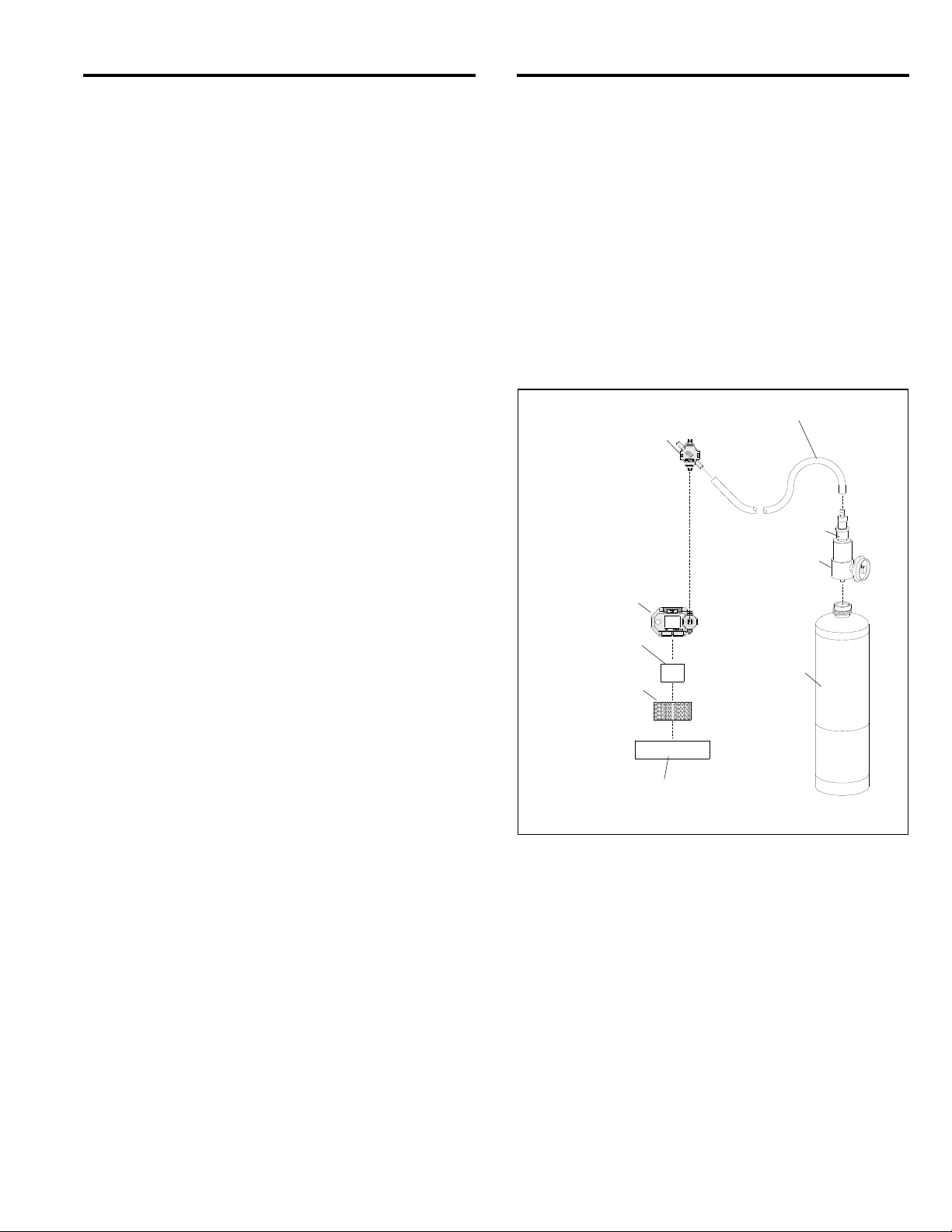

1.7 Components and Functions

Items included with the monitor package are shown in

Figure 1. Callouts shown in Figure 2 are items needed to

perform routine functions.

1.7.1 Case: The CMS-4’s sturdy, high-impact plastic

case is dust proof, water resistant, and .radio frequency

(RF) resistant.

The digital LCD is visible through the clear window on

the front of the case. During normal operation

(Measuring Mode), it displays

CO (Type of gas detection)

Remaining battery life

Current time

The heart symbol pulses, indicating the monitor is

in normal operating status.

In other modes, the LCD displays functions necessary to

operate and maintain the monitor. Refer to menu modes

in Section 4.0.

Below the LCD are two black control buttons: AIR and

POWER/MODE. The operator uses the buttons to make

selections and adjustments though various menus. Refer

to Section 1.7.8 for button functions

To the left of the LCD is the audible alarm opening,

which is located inside the case.

1.7.2 Sensor Retainer: The sensor retainer is located

on the right side of the case and allows access to the

filters, sensor gasket, and sensor.

1.7.3 Sensor: The sensor is held in its socket by the

sensor retainer. The CO sensor is an electrochemical

cell that consists of two precious-metal electrodes in a

dilute acid electrolyte. A gas-permeable membrane

covers the sensor face and allows gas to diffuse into the

electrolyte. The gas reacts in the sensor and produces a

current proportional to the concentration of the target

gas. The current is amplified by the CMS-4’s circuitry,

converted to a measurement of gas concentration, and

displayed on the LCD.

1.7.4 Sensor Gasket: The sensor gasket fits over

and seals around the sensor.

1.7.5 Charcoal Filter (black): A black charcoal filter is

placed into a recess in the filter gasket over the CO

sensor. The charcoal filter disk scrubs H2S and certain

hydrocarbons out of the sample to avoid false CO

readings. If false or elevated CO readings are noticed,

especially in the presence of H2S, change the charcoal

filter. Refer to Section 6.3: Replacing the Charcoal Filter.

1.7.6 Hydrophobic Filter (white): The white, circular

hydrophobic filter sits into the larger recess on the filter

gasket, on top of the charcoal filter.

Calibration Cup

CMS-4 Monitor

Velcro®

Loop Tape

Velcro®

Hook Tape

Transparent

Mounting Strip

Tubing 3/16" x 2 Ft

0.5 LPM Slide Valve

Calibration

Connector

CLEMCO

25 ppm CO

Test Gas

O

N

P

E

C

LES

O

Figure 1

1.7.7 LCD: A digital LCD (liquid crystal display) is

visible through the clear plastic window in the top of the

case. During normal operation in Measuring Mode, the

LCD displays CO concentrations, the time, remaining

battery life, and the heart symbol pulses, indicating the

monitor is in normal operating status. The LCD also

shows information for each of the CMS-4’s operating

modes. Once the monitor is ON, pressing the

Power/Mode or Air control button turns on the LCD

backlight for 30 seconds. NOTE: Except in dark places,

the display is easily seen without the backlight.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 9

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 4

CMS-4 callouts shown are items

needed to perform routine functions.

Cover Screw

Sensor Retainer

LED Alarm-Lens

Audible Alarm Opening

AIR Button

POWER/MODE Button

LCD Window

Sensor Retainer

CLEMCO

Hydrophobic Filter (white)

Charcoal Filter (black)

Sensor Gasket

Sensor Orientation Slots

Velcro® Loop Tape

Velcro® Hook Tape

Sensor

Mounting Clip

Figure 2

1.7.8 Control Buttons: Two control buttons, AIR and

POWER/MODE, are located below the LCD. The

functions performed by the control buttons are

summarized in the table in Figure 3.

They turn the CMS-4 ON and OFF. They control what is

displayed on the LCD, including time, gas

concentrations, as well as other messages. They also

allow for a fresh-air adjustment, change alarm points,

change the time, and calibrate the instrument.

NOTE: Important points to remember are:

1. The AIR button scrolls through items on the

menus much like a cursor. Once the menu

item is selected, use the POWER/MODE to

enter the selection into the microprocessor.

2. To reverse the direction of change (i.e. from

increasing to decreasing or vice versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE

and then release both buttons.

NOTE: Each screen displays for 20 seconds. If you

do not press a button within 20 seconds, the CMS-4

automatically returns to Measuring Mode.

Button Function

POWER/MODE

AIR

Turns the monitor ON and OFF.

Activates Display Mode.

Enters instruction into CMS-4’s

microprocessor.

Resets alarm after an alarm

condition.

Also

Turns the LCD backlight on

(when monitor is on).

.

Activates the Demand Zero

function (adjusts the CMS-4’s

fresh-air baseline).

Enters instructions into the

CMS-4’s microprocessor.

Increases the value of a

parameter available for

adjustment.

Scrolls through parameter

options.

Also

Turns the LCD backlight on

(when monitor is on).

Figure 3

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 10

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 5

1.7.9 Alarm-Lights: Two LED alarm-lights are located

above the LCD. The red alarm-lights show through

the reflective lenses. The LED’s alert the user to CO

gas, low battery, and failure alarms. The lights flash

once during the startup sequence.

1.7.10 Audible Alarm: An opening on the left side of

the top case allows the alarm’s sound to exit the case.

The alarm sounds for CO gas, unit malfunctions, low

battery voltage, and as an indicator during normal use of

various display options. It beeps once during the startup

sequence. Refer to Section 3.1 for alarm indications.

1.7.11 Vibrating Alarm: A vibrating motor mounted

inside the case vibrates for CO gas alarms, unit

malfunctions, and as an indicator during normal use of

the various modes of the CMS-4. It vibrates briefly

during the startup sequence.

1.7.12 Lithium Battery: A CR2450, 3.0-volt lithium

coin battery powers the CMS-4. The battery icon in the

upper right of the LCD shows remaining battery life.

When the CMS-4 detects a low battery voltage, a low

battery warning is activated. When battery power is too

low for Measuring Mode, the CMS-4 sounds a dead

battery alarm. (Gas reading disappears, FAIL appears in

the middle of the screen, BATTERY appears at the

bottom of the screen, LEDs flash once per second, and

audible alarm double pulses once per second.)

A spare battery is provided with the monitor; refer to

Section 6.1 for instructions on replacing the battery.

2.0 SETUP ‒ INSTALLATION, STARTUP AND

OPERATION

2.1 Installation

This section explains the initial installation of the CMS-4

to the inside of the respirator.

2.1.1 Prepare Mounting Clip

2.1.1.1 Adhere Velcro

Trim the Velcro

®

®

loop to CMS-4 mounting clip:

loop strip to 3/4" x 1". Remove the

backing and adhere it to the bottom of the monitors

mounting clip, as shown in Figure 4.

2.1.2 Installing Monitor in Apollo 20 Respirator

Refer to Section 2.1.3 for installing the monitor in Apollo 60

and Apollo 600 respirators.

2.1.2.1 If not already done, adhere the Velcro

CMS-4 mounting clip, per Section 2.1.1.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

®

loop to

3/4" x 1-1/4"

®

Velcro

Velcro

Loop Strip

Back of Monitor

3/4" x 1-1/4"

®

Loop Strip

Mounting Clip

End View of Monitor

Mounting Clip

Figure 4

2.1.2.2 Open the lens frame and remove the lenses.

2.1.2.3 Don (put on) the helmet and temporarily place the

monitor on one of the side walls of the window extension,

as shown in Figure 5. Make sure the monitor’s LED lights

are visible.

2.1.2.4

Mark the location and remove the monitor and helmet.

Make sure the monitor’s

LED lights are visible when

the helmet is donned, mark

its location inside of the

window extension, and

attach Velcro

®

hook tape.

Figure 5

2.1.2.5 Remove backing from the Velcro

®

hook tape and

adhere it at the marked location (the loop tape adheres to

the mounting clip on the monitor). Use the Velcro

attach the monitor to the hood, positioning it so the

control buttons face toward lenses and alarm-lights

toward the inside of the respirator. Don the helmet to

make sure the monitor’s alarm-lights are visible from

inside the helmet.

2.1.2.6 Remove the monitor and prepare it for operation,

per Section 2.2.

2.1.2.7 Replace the lenses and lens frame assembly.

2.1.2.8 After the initial setup is done, remove and

reattach the monitor using the Velcro

®

. Remove the

®

to

Page 11

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 6

W

W

W

monitor when doffing (taking off) the respirator at

the end of the shift and to do any service or

calibration, including turning the monitor on and off.

Do this to make sure the monitor is fully functional before

placing it inside the helmet.

ARNING

Remove the monitor at the end of the shift, turn

it off, and store it in a clean environment. At the

beginning of each shift, turn on the monitor and

make sure it is fully functional before installing it

in the helmet. Failure to do so could result in CO

poisoning and death.

2.1.3 Installing Monitor in Apollo 60 and Apollo

600 Respirators

Refer to Section 2.1.2 for mounting the monitor in Apollo 20

respirators.

2.1.3.1 If not already done, adhere the Velcro

CMS-4 mounting clip, per Section 2.1.1.

2.1.3.2 Place the transparent mounting strip on the

inside of the inner lens, and into the same window

gasket groove as the inner lens, as shown in Figure 6.

Position it so it is within peripheral vision toward the side

of the window opening.

As seen from inside the hood,

the strip is inserted into the

groove in the window gasket.

Attach Velcro

the inside of the strip. Make

sure the monitor’s LED lights

are visible when the helmet is

donned.

Figure 6

2.1.3.3 Remove backing from the Velcro

and adhere it to the mounting strip (the loop tape

adheres to the mounting clip on the monitor) making sure

the LED lights are visible from inside the helmet.

2.1.3.4 Attach the monitor to the strip, positioned so the

buttons face toward the outer edge of the window

opening and LED lights toward the center of the window

opening. Don (put on) the helmet to make sure the

monitor LED lights are visible from inside the helmet.

2.1.3.4 Remove the monitor and prepare it for operation.

®

hook tape to

®

loop to

®

hook tape

2.1.3.6 After the initial setup is done, remove and

reattach the monitor from inside the helmet. Remove

the monitor when doffing the respirator at the end of

the shift and to do any service or calibration,

including turning the monitor on and off. Do this to

make sure the monitor is fully functional before placing it

inside the helmet.

ARNING

Remove the monitor at the end of the shift, turn

it off, and store it in a clean environment. At the

beginning of each shift, turn on the monitor and

make sure it is fully functional before installing it

in the helmet. Failure to do so could result in CO

poisoning and death.

2.2 Turning ON and Startup Procedure

This section explains how to startup the CMS-4 and to

prepare it for operation.

2.2.1 Press and hold the POWER/MODE button until the

alarm beeps.

2.2.2 The monitor goes though the warm-up

sequence: all LCD segments turn on, backlight turns on,

and instrument beeps and vibrates. It then cycles

through calibration status, date/time, remaining battery

life, target gas, and alarm setpoint screens.

2.2.3 After the warm-up sequence, the monitor goes

into Measuring Mode (normal operating mode). It beeps,

the LCD screen (as shown in Figure 8) shows CO,

remaining battery life, a pulsing heart symbol (indicating

the monitor is in normal operating status), CO

concentrations (ppm), and the date and time (when set

per Section 2.3).

ARNING

If the monitor is in low battery warning, change

the battery as soon as possible. Do not use the

respirator if the dead battery warning is alarmed.

The monitor does not detect carbon monoxide

when it is in dead battery alarm, which can result

in death if carbon monoxide is present.

2.3 Setting the Date and Time ‒ Figure 7

NOTE: When using the CMS-4 for the first time, check

the current time and verify that it is correct for your time

zone. If it is not, set the time as follows:

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 12

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 7

O

0

2.3.1 With the instrument turned OFF, press and hold

AIR and POWER MODE. Release when you hear a

beep. BUMP is displayed.

2.3.2 Press and release the AIR button to scroll to

DATE.

2.3.3 Press and release POWER/MODE. The date

and time will be displayed with the year flashing.

2.3.4 Use AIR to display the desired year. To reverse

the direction of change (i.e. from increasing to

decreasing or vice versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then

release both buttons.

LCD Window

Year

Battery Icon

2019

Date

8.03

Time

12:34

Figure 7

2.3.5 Press POWER MODE to save it. The month

starts to flash.

2.3.6 Use AIR to adjust the month. Press POWER

MODE to save it. The day starts to flash.

2.3.7 Repeat the process to set the day, hour, and

minute. The time is shown in military format with the

hour going from 0 to 24.

2.3.8 Use AIR to scroll to START. Press and release

POWER MODE to begin the warm-up sequence. NOTE:

If no button is pressed within 20 seconds, the monitor

will automatically return to measuring mode.

2.4 Performing a Fresh-Air Adjustment

NOTE: Before using the CMS-4, set the fresh-air

baseline to ensure accurate gas readings.

Additional fresh-air adjustment information is in Section

5.2.

Heart Symbol

Pulses, indicating the

monitor is in normal

operating status.

2.4.1 Make sure the monitor is in a fresh-air

environment. This is an environment free of toxic or

combustible gases and of normal oxygen content

(20.9%).

2.4.2 Turn on the monitor by pressing and holding the

POWER/MODE button until the alarm beeps.

2.4.3 The monitor goes though the warm-up

sequence, as noted in Paragraph 2.2.2.

2.4.4 After the warm-up sequence, the monitor goes

into Measuring Mode (normal operating mode), it beeps,

and the LCD display is as shown in Figure 8.

2.4.5 Press and hold the AIR button. While pressing

the AIR button, the LCD displays HOLD, a prompt to

keep pressing the AIR button.

2.4.6 When the fresh-air baseline has been set, the

LCD displays Adj, and a prompt to RELEASE the AIR

button. The monitor beeps once and the screen displays

0 ppm, as shown in Figure 8.

2.4.7 The monitor is now in Measuring Mode (normal

operation). After an initial calibration per Section 5.7, the

CMS-4 is ready for monitoring.

LCD Window

C

Figure 8

2.5 Turning OFF the CMS-4

2.5.1 Remove the monitor after doffing (taking off) the

respirator at the end of the shift.

2.5.2 Press and hold the POWER/MODE button.

2.5.3 OFF will appear on the screen and the monitor

will beep for about five seconds. Release the button

when OFF disappears from the screen and the LCD is

blank. The monitor is off.

Time

Gas

ppm

12:34

Battery Icon

Heart Symbol

Pulses, indicating the

monitor is in normal

operating status.

Current Gas (CO)

Concentration

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 13

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 8

3.0 Alarms

This section covers alarm indications. It also explains

how to respond to an alarm condition and how to reset

the CMS-4 after an alarm has occurred.

3.1 Alarm Indications

3.1.1 Audible Alarms

Gas Alarms: Alternating high-low tone ‒ chirps occur

about once per second.

Fault Alarms: Double-pulsing beep occurring about

once per second.

In addition to the audible alarms, the monitor vibrates,

and the LEDs flash when any sort of alarm condition or

failure is encountered.

3.2 Alarm Indications Table: Refer to table in

Figure 9 on the following page for Alarm Type, Visual

Indications, and other alarm indications

3.3 Resetting CO Alarms

3.3.1 The CMS-4 remains in alarm until the alarm

conditions passes and POWER/MODE is pressed.

NOTE: Even though the gas concentration may have

fallen below the alarm point, the alarm indications will

continue until the alarm is reset using the

POWER/MODE button, as noted in the paragraph

below. A PEAK alarm display cannot be cleared until the

monitor is turned OFF. If a TWA or STEL alarm has been

activated, it cannot be reset unless the monitor is turned

OFF.

3.3.2 To reset a CO gas alarm, after the CO reading

falls below the low-alarm point (10 ppm), press and

release the POWER/MODE button once.

3.4 Responding to Alarms

This section describes responses to gas, over range,

battery, sensor failure, clock failure, and system failure

alarms.

3.4.1 Responding to CO Alarms

3.4.1.1 Follow an established procedure for responding

to CO gas alarms. It should include but not be limited to

removing the respirator as soon as it is safe to do so.

3.4.1.2 Reset the alarm by pressing and releasing the

POWER/MODE button once after the CO reading falls

below the low alarm point.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

3.4.2 Responding to an Over Range Alarm

An over range alarm could indicate CO gas is above the

detection limit of 1000 ppm. The CO concentration

reading is replaced by blinking brackets (ΠΠΠΠ).

WARNING

An over range condition may indicate an

extreme CO concentration. Remove the

respirator as quickly as possible when it is safe

to do so.

3.4.2.1 Follow an established procedure for responding

to CO gas alarms. It should include but not be limited to

removing the respirator as soon as it is safe to do so.

3.4.2.2 Reset the alarm using POWER/MODE once the

alarm condition has cleared.

3.4.2.3 Calibrate the CMS-4, as described in Section 5.7.

3.4.2.4 If the Over Range condition continues, the

sensor may need to be replaced.

3.4.2.5 If the Over Range condition continues after

replacing the sensor, contact the authorized Clemco

distributor the monitor was purchased through for further

instructions.

3.4.3 Responding to Battery Alarms

WARNING

The CMS-4 is not operational during a dead

battery alarm. Do not use the respirator until

the battery is replaced. Breathing compressed

air while a monitor is not operational can result

in death if carbon monoxide is present.

3.4.3.1 The CMS-4 is fully functional during a low

battery warning. However, only a limited amount of

operating time remains. The amount of time depends on

how often the LCD backlight is used and how often the

monitor responds to alarm conditions. Replace the

battery as soon as possible when a low battery warning

occurs. Refer to Section 6.1: Replacing the Lithium

Battery.

NOTE: Alarms and the LCD backlight consume

battery power and reduce the amount of operating

time remaining.

Page 14

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 9

ALARM TYPES AND INDICATIONS

ALARM TYPE VISUAL INDICATIONS OTHER ALARM INDICATIONS

WARNING

Concentration of CO

rises above the Warning

setting (10 ppm).

Alarm

Concentration of CO

rises above alarm

setting of 10 ppm.

Alarm H

Concentration of CO

rises above the high

alarm setting of 10 ppm.

TWA or STEL

Concentration of CO

rises above the TWA or

STEL alarm setting.

Over Range

An over range condition

indicates an extreme CO

concentration.

Low Battery Warning

Dead Battery Alarm

Sensor Failure

System Failure

Clock Failure

Gas reading flashes.

Warning appears at the bottom of the LCD.

Alarm LEDs flash.

Backlight turns on.

Gas reading flashes.

Alarm appears at the bottom of the LCD.

Alarm LEDs flash.

Alternating high-low tone ‒

chirps about twice per second.

Vibrator pulses once per second.

Alternating high-low tone ‒

chirps about twice per second.

Vibrator pulses once per second.

Backlight turns on.

Gas reading flashes.

Alarm H appears at the bottom of the LCD.

Alarm LEDs flash.

Alternating high-low tone ‒

chirps about twice per second.

• Vibrator pulses once per second.

Backlight turns on.

Gas reading flashes.

TWA or STEL appears at the bottom of the

LCD.

Alarm LEDs flash once per second.

Backlight turns on.

Gas reading is replaced with a flashing

ΠΠΠΠ.

Gas name and units flash.

OVER appears at the bottom of the LCD.

Alarm LEDs flash twice per second.

Backlight turns on.

The last bar in the battery icon disappears

and the battery icon starts flashing.

Alarm LEDs flash once per second.

Gas reading disappears.

FAIL appears in the middle of the screen

Alternating high-low tone ‒

chirps about twice per second.

•

Vibrator pulses once per second.

Alternating high-low tone ‒

chirps about twice per second.

Vibrator pulses once per second.

None.

Double pulsing beep occurring about

once per second

and BATTERY appears at the bottom of

the screen.

Alarm LEDs flash once per second

FAIL appears in the middle of the screen and

SENSOR appears at the bottom of the

Double pulsing beep occurring about

once per second.

screen.

Alarm LEDs flash once per second.

Gas reading replaced by FAIL.

Time replaced by SYS below FAIL.

• FAIL 050 CLOCK appears on the screen.

Alarm LEDs flash once per second.

Figure 9

Double pulsing beep occurring about

once per second.

Double pulsing beep occurring about

once per second.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 15

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 10

3.4.4 Responding to a Sensor Failure Alarm

3.4.4.1 Perform a calibration, as described in Section 5.7.

3.4.4.2 If the sensor failure alarm continues, replace the

sensor, as described in Section 6.2.

3.4.4.3 If the sensor failure alarm continues after

replacing the sensor, contact the authorized Clemco

distributor the monitor was purchased through for further

instructions.

3.4.5 Responding to Clock Failure Alarm ‒ Figure 10

A clock failure alarm occurs if the monitor’s internal clock

malfunctions.

FAIL

050

CLOCK

Figure 10

3.4.5.1 If the error code is 050, press and release

POWER/MODE to continue into Measuring Mode if the

instrument must be used temporarily.

3.4.5.2 Attempt to set the date using the DATE menu

item in User Mode. Refer to Section 2.3: Setting Date

and Time.

3.4.5.3 If the date cannot be set correctly, contact the

authorized Clemco distributor the monitor was

purchased through for further instructions.

3.4.6 Responding to a System Failure Alarm

3.4.6.1 If a system failure occurs, the system failure

screen will display an error code similar to that shown in

Figure 11.

3.4.6.2 If the System Failure error code is anything but

031, as shown in Figure 11, the instrument cannot be

used. Contact Clemco Industries as soon as possible.

If the error code is 031, press and release

POWER/MODE to continue into Measuring Mode if the

instrument must be used temporarily.

FAIL

031

SYSTEM

Figure 11

3.5 Alarm Setpoints

3.5.1 There are six alarm points. The alarm points and

their factory settings are summarized below. There are

no adjustments of alarm setpoints.

*F. S. (Full Scale): Is triggered when CO

concentrations go over the scale maximum of 1000

ppm.

WARNING: Is triggered when CO concentrations

reach 10 ppm, which is the maximum exposure limit

for Grade D compressed air in the United States.

Alarm: Is triggered when CO concentrations reach

10 ppm.

Alarm H: Because the maximum exposure limit for

grade D breathing air is 10 ppm of CO, the high

alarm is also set to alarm when CO concentration

reaches 10 ppm. This alarm is a rapid, twice per

second beep and stresses the urgency to remove

the respirator as soon as it is safe to do so.

*TWA Alarm: TWA is an acronym for time-weighted

average; it is the average reading of CO during the

last eight hours. The alarm triggers when TWA

reaches 25 ppm

*STEL Alarm: STEL is an acronym for short-term

exposure limit; it is the average reading of CO

during the last 15 minutes. The alarm triggers when

STEL reaches 200 ppm

* Although some may find Full Scale, TWA and STEL

information useful, it is not relevant for supplied-air

respirator use because the maximum exposure limit for

Grade D breathing air is 10 ppm.

4.0 MANEUVERING THROUGH MENU MODES

This section helps the user maneuver through CMS4 menu items. The menu item under each mode is

listed in sequential order.

4.1 MEASURING MODE ‒ Measuring Mode is the

normal operating mode used to detect CO and observe

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 16

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 11

W

W

O

0

any alarm indications. The monitor must be in measuring

mode before it is placed in the respirator.

The CMS-4 is not operational as a carbon

monoxide monitor unless it is Measuring Mode.

The monitor must be in Measuring Mode before

it is placed in the respirator. Failure to ensure

the monitor is in Measuring Mode can result in

death if carbon monoxide is present.

4.1.1 Entering Measuring Mode

4.1.1.1 Make sure the monitor is OFF. (Press and hold

POWER/MODE until the screen is blank.)

4.1.1.2 Turn on the monitor by pressing and holding the

POWER/MODE button until the alarm beeps.

4.1.1.3 After the warm-up sequence, the monitor goes

into Measuring Mode (normal operating mode) when the

alarm beeps and the LCD screen is as shown in Figure

12 and indicates the current gas concentration. After an

initial calibration per Section 5.7, the CMS-4 is ready for

monitoring.

LCD Window

C

Figure 12

4.2 USER MODE ‒ User Mode is used to do bump

tests, calibrate the monitor, and make minor screen

adjustments used primarily to calibrate the monitor.

The CMS-4 is not operational as a carbon

monoxide monitor while in User Mode. The

monitor must be in Measuring Mode before it is

placed in the respirator. Failure to ensure the

monitor is in Measuring Mode can result in

death from carbon monoxide poisoning.

Time

ARNING

Gas

Battery Icon

Heart Symbol

Pulses, indicating the

monitor is in normal

ppm

12:34

operating status.

Current Gas (CO)

Concentration

ARNING

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

4.2.1 Entering User Mode

Begin with the monitor OFF.

4.2.1.1 Press and hold the AIR button, then press and

hold the POWER/MODE button. Release both buttons

as soon as the monitor beeps.

4.2.2 Tips for Using User Mode

To scroll from one menu item to the next, press

AIR and release it as soon as the alarm beeps.

To reverse the scroll direction:

a. Press and hold AIR.

b. Immediately press POWER/MODE and then

release both buttons.

4.2.3 To cycle through each of the user mode menus,

press POWER/MODE and release it as soon as the

alarm beeps

4.2.4 The first screen to appear will be BUMP, as

shown in Figure 13.

BUMP

Figure 13

Refer to Section 5.6 to perform a bump test.

4.2.5 To scroll to the next menu item (GAS CAL),

press and release POWER/MODE. Continue to press

and release POWER/MODE to scroll through every

menu item.

4.2.6 Refer to the table in Figure 14 on the following

page for a sequential list of the items found in User

Mode, the page that the menu item’s instructions can be

found on, and a short description of the menu item.

4.2.7 Display Firmware Version.

4.2.7.1 Enter User Mode, per Section 4.2.1.

4.2.7.2 Press and release AIR and scroll to ROM/SUM.

4.2.7.3 Press and release POWER/MODE. The screen

will cycle through the boards and display the ROM as

the top value and SUM as the bottom value.

Page 17

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 12

W

SEQUENTIAL LIST OF USER MODE MENU ITEMS

Number of Times

POWER/MODE (beeps)

is pressed and released

to reach menu item.

ONE

TWO

THREE

FOUR

FIVE

SIX

SEVEN

EIGHT

NINE

TEN

ELEVEN

TWELVE

THIRTEEN

FOURTEEN

FIFTEEN

Figure 14

User Mode Menu Items Description Section in Which

Adjustments are Found

BUMP

GAS CAL

CAL SET

BUMP SET

ALARM-P

LUNCH

BEEP

BL TIME

KEY.TONE

DISP.SET

E-CAL

DATE

PASS W

ROM/SUM

START

Perform bump test.

Perform a calibration.

Changes parameters related to

calibration.

Changes setting related to bump testing.

Set and alarm points.

Resets TWA and STEL readings at

startup.

Sets confirmation beep parameters.

How long backlight stays on.

Sets whether or not alarm beeps when

button is pressed.

Sets user ID, Station ID, and Alarm

Volume.

A-CAL item appears in GAS CAL menu.

E-CAL. Factory setting is OFF.

Sets the Date and Time. Refer to Section 2.3.

When set to ON, password required

to enter User Mode.

Shows firmware version and

firmware checksum.

Enters Measuring Mode from User

Mode.

Refer to Section 5.6.

Refer to Section 5.7.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

Factory setting is ON.

Do not adjust.

Factory setting is ON.

Do not adjust.

Factory setting is OFF.

Do not adjust.

Factory setting is OFF.

Do not adjust.

Refer to Section 4.2.7

to display firmware.

Press and release

POWER/MODE.

4.3 DISPLAY MODE ‒ Display mode is used to

view and change settings of menu items noted in the

table in Figure 15. Refer to the table for a list of the items

found in Display Mode, a short description of the menu

item’s function, and the section that the menu item’s

instructions can be found.

ARNING

The CMS-4 is not operational as a carbon

monoxide monitor while in Display Mode. The

monitor must be in Measuring Mode before it is

placed in the respirator. Failure to ensure the

monitor is in Measuring Mode can result in

death from carbon monoxide poisoning.

4.3.1 Entering Display Mode

4.3.1.1 Enter Display Mode using one of the two

following methods:

1. From Measuring Mode (normal operating mode)

press POWER/MODE and release it as soon as the

alarm beeps. The monitor is now in Display Mode.

2. If the monitor is OFF:

a. Press and hold POWER/MODE until the alarm

beeps.

b. After the warm-up sequence, the monitor goes into

Measuring Mode (normal operating mode). It beeps,

the LCD screen (as shown in Figure 12) shows CO,

remaining battery life, a pulsing heart symbol

(indicating the monitor is in normal operating status),

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 18

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 13

CO concentrations (ppm), and the date and time

(when set per Section 2.3). Review Section 2.2:

Turning On and Startup Procedure.

c. From Measuring Mode (normal operating mode),

press POWER/MODE and release it as soon as the

alarm beeps. The monitor is now in Display Mode.

4.3.2 Tips for Using Display Mode

To scroll from one menu item to the next, press

POWER/MODE and release it as soon as the

alarm beeps.

To enter an item, press and release AIR.

To reverse the direction of a flashing parameter,

(i.e. from increasing to decreasing or vice

versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then

release both buttons.

SEQUENTIAL LIST OF DISPLAY MODE MENU ITEMS

NOTE: Each screen displays for 20 seconds. If a

button is not pressed within 20 seconds, the CMS-4

automatically returns to Measuring Mode.

4.3.3 To cycle through each of the following display

mode menus, press POWER/MODE and release it as

soon as the alarm beeps. Refer to the Table in Figure 15

for additional information.

4.3.4 DISPLAY MODE MENU ITEMS (Reference

Table)

Menu items shown with "No Adjustment" have

factory settings that should not be adjusted. If

operator accidentally enters an unfamiliar menu, DO

NOT PUSH BUTTONS THAT COULD CHANGE THE

MONITORS FUNCTION. Refer to Section 4.4 to return

to factory settings.

Number of times

POWER/MODE (beeps)

is pressed and released

to reach menu item.

ONE

TWO

THREE

FOUR

FIVE

SIX

SEVEN

EIGHT HI (Alarm Beep Volume) Sets the buzzer volume. Factory set to

NINE Returns to measuring mode.

Figure 15

Display Mode Menu Items Description Sections In Which

Adjustments Are Found

PEAK

STEL

TWA

dISP (CAL DATA

LCD screen cycles

through CAL.DATA,

YES/AIR, and NO/MODE.

DATE and TIME

TEMP

dISP (ALARM-P

LCD screen cycles

through ALARM-P,

YES/AIR, and NO/MODE

Displays peak (highest) CO

concentration since the monitor was last

turned on.

Disp la ys short- term exposure limit. This

reading is the average reading over the

last 15 minutes.

Displays time-weighted average over the

last 8 hours.

Shows date of last calibration.

Factory set to ON.

Displays Year, Date, and Time. Set per Section 2.3.

Displays ambient temperature in Celsius. Not adjustable.

View alarm setpoints. No adjustment required.

high.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

No adjustment required.

Do not adjust.

Do not adjust.

No adjustment required.

Do not adjust.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 19

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 14

W

E

R

D

R

5

O

O

0

4.3.5 Displaying the PEAK Screen

4.3.5.1 The PEAK screen displays the highest CO

concentration detected since the CMS-4 was turned ON.

The PEAK reading is stored until a higher level is

detected, the PEAK reading is cleared, or the CMS-4 is

turned OFF.

4.3.5.2 PEAK readings are automatically cleared when

the monitor is turned OFF or cleared (as noted beginning

with Paragraph 4.3.5.3), and restarted when the monitor

is turned ON.

4.3.5.3 Make sure the monitor is in Display Mode, as

noted in Section 4.3.1.

4.3.5.4 Press and release POWER/MODE until PEAK

appears in the lower-left corner of the LCD screen, as

shown in Figure 16.

C

1

ppm

The number shown in the

illustration is for reference

only. The number shown

on the LCD screen will be

the actual peak reading.

PEAK

Figure 16

4.3.5.5 To clear the peak reading, do the following while

remaining in Display Mode:

1. While PEAK appears on the screen, press Air

and hold (as shown in the left image in Figure

17), and release it when prompted (as shown in

right image).

2. The peak reading will be reset and the display

will return to the Peak Screen.

3. After 20 seconds, the monitor will return to

Measuring Mode.

Figure 17

CL

HOL

CL

RELEAS

4.3.6 Displaying the STEL Screen ‒ Figure 18

4.3.6.1 The STEL Screen displays the short-term

exposure limit (STEL) reading. The STEL reading is the

average reading over the last 15 minutes. There are no

changes or resets on the STEL menu.

The number shown in

the illustration is for

C

ppm

STEL

Figure 18

4.3.7 Displaying the TWA Screen

4.3.7.1 The TWA Screen displays the time-weighted

average (TWA) reading. The TWA reading is the

average reading over the last 8 hours. If 8 hours have

not elapsed since the last time the TWA reading was

cleared, the average is still calculated over 8 hours. The

missing readings are assigned a value of 0.

4.3.8 TWA readings are automatically cleared when

the monitor is turned OFF and begins collecting new

TWA readings when the monitor is turned ON.

4.4 MAINTENANCE MODE

NOTE: Maintenance Mode Changes settings that

operationally affect the instrument.

Maintenance Mode settings affect the operation

of the monitor and should only be cautiously

changed. Changing settings on an impulse can

lead to false or no alarms, resulting in carbon

monoxide poisoning, death, or serious injury.

4.4.1 Return to Factory Default Settings: The only

function we advise using in Maintenance Mode is to

default to factory settings when menu items have been

unintentionally changed. These changes are identified

when menu items on the screen do not match menu

items in the instructions.

ARNING

reference only. The

number shown on the

LCD screen will be the

average STEL reading

over the last 15 minutes.

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 29872

Page 20

CMS-4 IN-HELMET CARBON MONOXIDE MONITOR Page 15

W

4.4.2 Entering Maintenance Mode

ARNING

The CMS-4 is not operational as a carbon

monoxide monitor while in Maintenance Mode.

The monitor must be in Measuring Mode before

it is placed in the respirator. Failure to ensure

the monitor is in Measuring Mode can result in

death if carbon monoxide is present.

4.4.2.1 Make sure the monitor is OFF. (Press and hold

POWER/MODE until the screen is blank.)

4.4.2.2 Press and hold AIR, then press and hold

POWER/MODE. Continue to hold the buttons down after

the first beep.

4.4.2.3 Release both buttons after the second beep.

The LCD screen should be as shown in Figure 19 with

the digit on the left flashing.

0 0 0 0

4.4.3 Performing a Default (M.DEF)

NOTE: Performing a default operation in Maintenance

Mode returns all parameters to their factory settings.

4.4.3.1 Enter Maintenance Mode, per Section 4.4.2.

4.4.3.2 Press and release AIR 16 times and scroll to

M.DEF.

4.4.3.3 Press and release POWER/MODE. The screen

will alternate between M.DEF, YES.MODE, and NO.AIR.

4.4.3.4 Press and release POWER/MODE to perform a

default operation.

4.4.3.5 The monitor will ask if you are sure you want to

perform a default operation by alternating between

SURE?, YES.MODE, and NO.AIR.

4.4.3.6 Press and release POWER/MODE. The monitor

will beep twice, briefly display PASS, and return to MDEF.

4.4.3.7 To return to Measuring Mode (normal operating

mode), press and release AIR once and press and

release POWER/MODE. The monitor will begin the

warm-up sequence and enter measuring mode.

PASS - W

Figure 19

4.4.2.4 The factory-set password is 3000.

4.4.2.5 Enter the password by using AIR to select each

password number and then press and release

POWER/MODE to save it and move on to the next

number until all of the numbers are entered. To reverse

the direction of change (i.e. from increasing to

decreasing or vice versa):

a. Press and hold AIR.

b. Immediately press POWER/MODE and then

release both buttons.

5.0 CALIBRATION, FRESH-AIR ADJUSTMENTS,

BUMP TEST, and STORAGE

This section covers:

Calibration Schedule

Performing Fresh-Air Adjustments

a) Setting the adjustment with ambient air.

b) Setting the adjustment with impurity-free test gas.

Prepare Calibration Connector for Calibration.

Connect Calibration Cup to Monitor

Remove Calibration Cup from Monitor

Performing a Bump Test

Calibrating the CMS-4

Storing the Calibration Connector and Test Gas

WARNING

Use a 0.5 LPM (liters per minute) fixed-flow,

calibration-connector regulator valve (Clemco