Clemas & Co TENNANT 7100 Operator's Manual

TENNANT 7100

SCRUBBER DRYER

OPERATOR MANUAL

Clemas & Co. Unit 5 Ashchurch Business Centre, Alexandra Way, Tewkesbury,

Gloucestershire, GL20 8NB.

Tel: 01684 850777 Fax: 01684 850707

Email: info@clemas.co.uk Web: www.clemas.co.uk

SAFETY PRECAUTIONS

3

7100 330699 (6--02)

SAFETY PRECAUTIONS

The following symbols are used throughout this

manual as indicated in their description:

WARNING: To warn of hazards or unsafe

practices that could result in severe

personal injury or death.

FOR SAFETY: To identify actions that

must be followed for safe operation of

equipment.

This machine is designed solely for scrubbing dirt

and dust in an indoor environment. Tennant does

not recommend using this machine in any other

environment.

The following information signals potentially

dangerous conditions to the operator or

equipment. Read this manual carefully. Know

when these conditions can exist. Locate all safety

devices on the machine. Then, take necessary

steps to train machine operating personnel.

Report machine damage or faulty operation

immediately. Do not use the machine if it is not in

proper operating condition.

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result. Keep

sparks and open flame away . Keep

covers open when charging.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

WARNING: Flammable materials or

reactive metals can cause explosion or

fire. Do not pick up.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operation manual is read and

understood.

-- In flammable or explosive areas unless

designed for use in those areas.

2. Before starting machine:

-- Make sure all safety devices are in

place and operate properly.

-- Check brakes and steering for proper

operation (if so equipped).

3. When using machine:

-- Go slow on inclines and slippery

surfaces.

-- Use care when backing machine.

-- Follow mixing and handling

instructions on chemical containers.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Set parking brake.

-- Turn off machine and remove key.

5. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves when

working on machine.

-- Block machine tires before jacking

machine up.

-- Jack machine up at designated

locations only. Block machine up with

jack stands.

-- Use hoist or jack that will support the

weight of the machine.

-- Wear eye and ear protection when

using pressurized air or water.

-- Disconnect battery connections before

working on machine.

-- Avoid contact with battery acid.

-- Use Tennant supplied or equivalent

replacement parts.

6. When loading/unloading machine

onto/off truck or trailer:

-- Turn off machine.

-- Use truck or trailer that will support

the weight of the machine.

-- Use winch. Do not drive the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

-- Set parking brake after machine is

loaded.

-- Block machine tires.

-- Tie machine down to truck or trailer.

SAFETY PRECAUTIONS

7100 330699 (12--00)

4

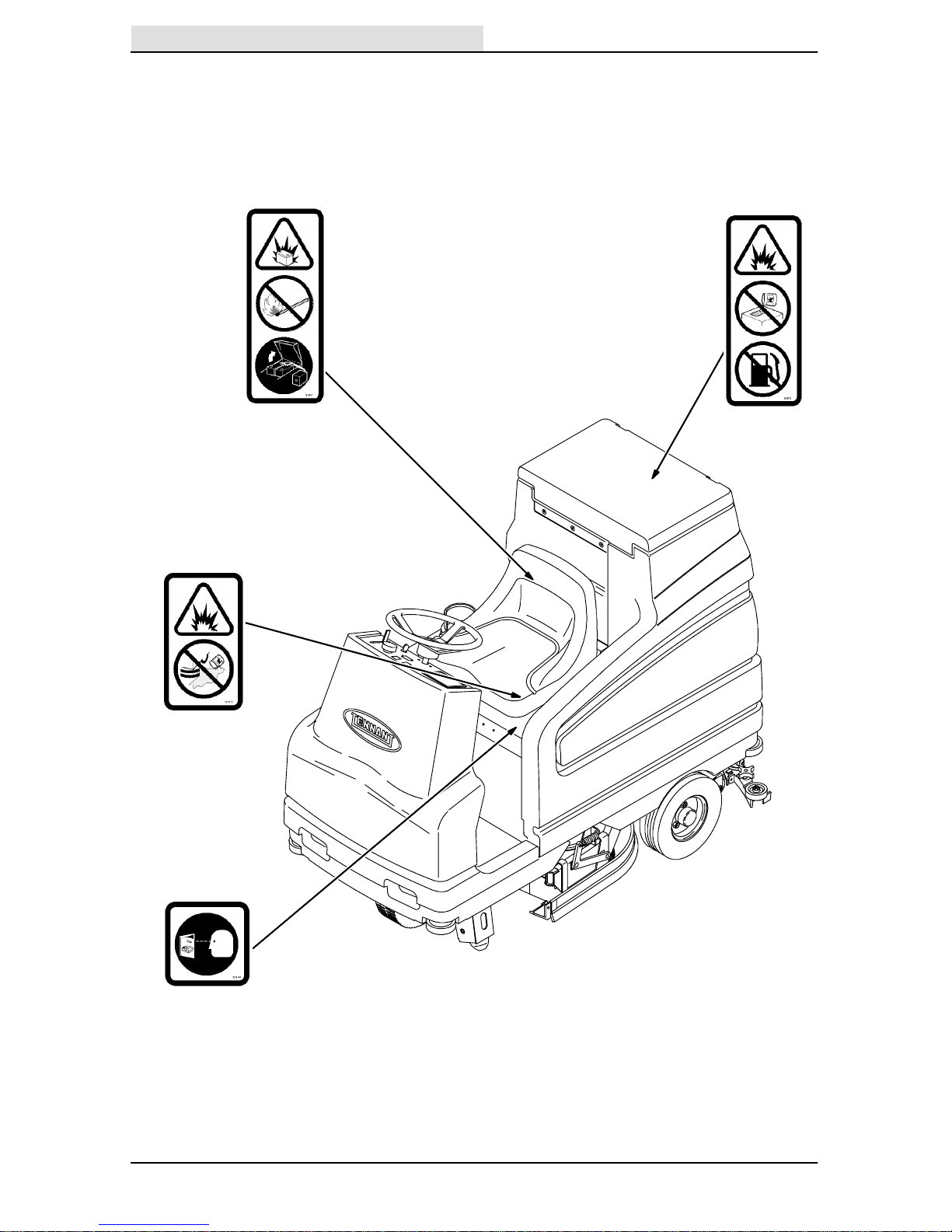

The safety labels appear on the machine in the

locations indicated. If these or any label becomes

damaged or illegible, install a new label in its

place.

BA TTER Y CHARGING LABEL -- LOCATED ON

AND UNDERNEATH THE SEAT SUPPORT.

FLAMMABLE SPILLS LABEL -LOCATED ON THE SEAT SUPPORT.

FOR SAFETY LABEL -- LOCATED ON THE

SEAT SUPPORT.

FLAMMABLE MATERIALS LABEL -- LOCATED

ON THE UNDERSIDE OF THE TANK COVER

AND ON THE LEFT SIDE OF THE OPERATOR

COMPARTMENT.

353450

OPERATION

5

7100 330699 (12--00)

OPERATION

OPERATOR RESPONSIBILITY

- The operator’s responsibility is to take care

of the daily maintenance and checkups of

the machine to keep it in good working

condition. The operator must inform the

service mechanic or supervisor when the

maintenance intervals are required as stated

in the MAINTENANCE section of this

manual.

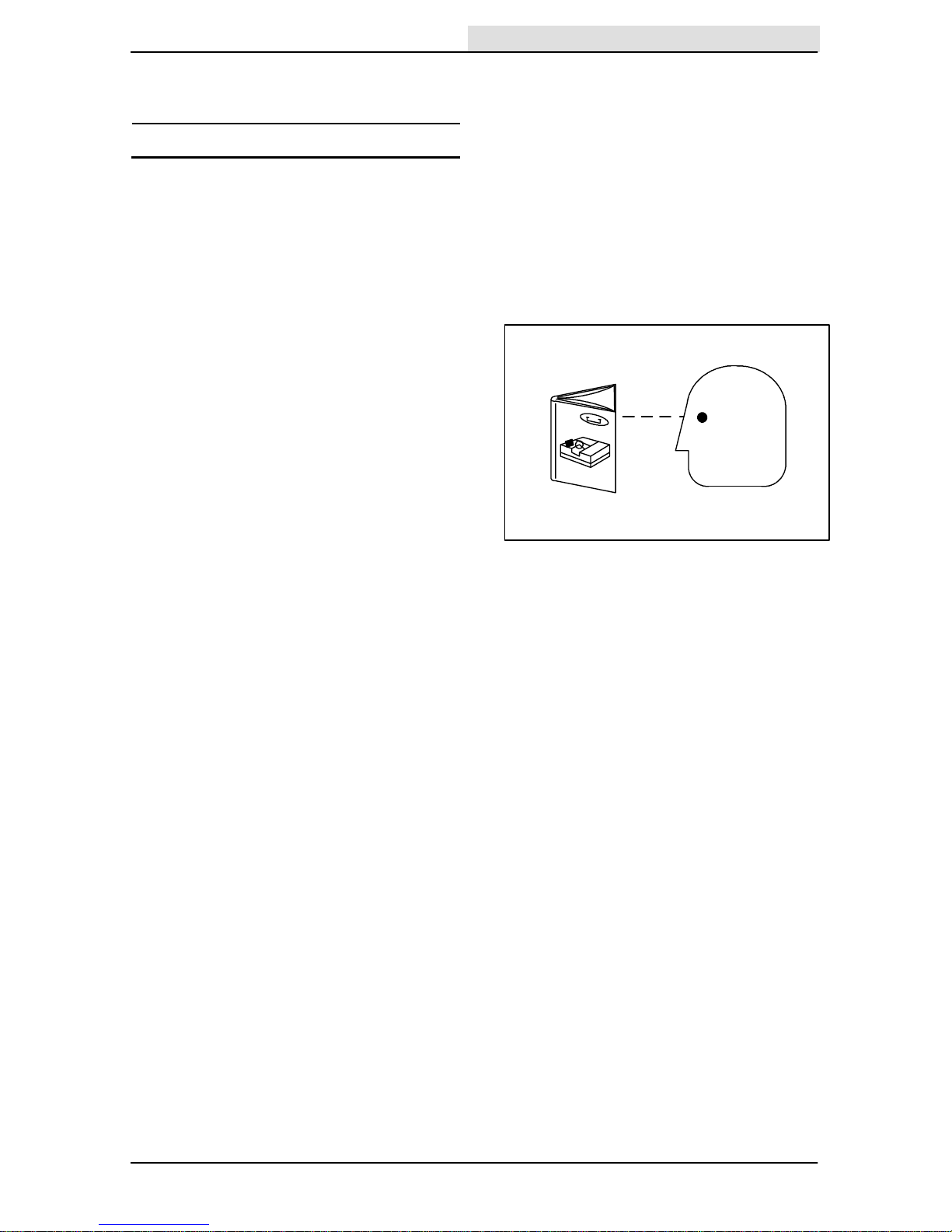

- Read this manual carefully before operating

this machine.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

- Check the machine for shipping damage.

Check to make sure machine is complete

per shipping instructions.

- Keep your machine regularly maintained by

following the maintenance information in this

manual. We recommend taking advantage of

a regularly scheduled service contract from

your TENNANT representative.

- Order parts and supplies directly from your

authorized TENNANT representative. Use

the parts manual provided when ordering

parts.

07324

OPERATION

7100 330699 (3--04)

6

MACHINE COMPONENTS

A

B

C

D

E

F

G

H

I

J

K

L

M

N

A. Vacuum fan inlet screen

B. Tank Cover

C. Solution tank

D. Operator’s seat

E. Batteries

F. Rear squeegee

G. Side squeegee

H. Scrub head

I. Front wheel

J. Operating lights

K. Steering wheel

L. Recovery tank

M. F aSTtttt PAK (option)

N. FaSTtttt solution system (option)

OPERATION

7

7100 330699 (3--04)

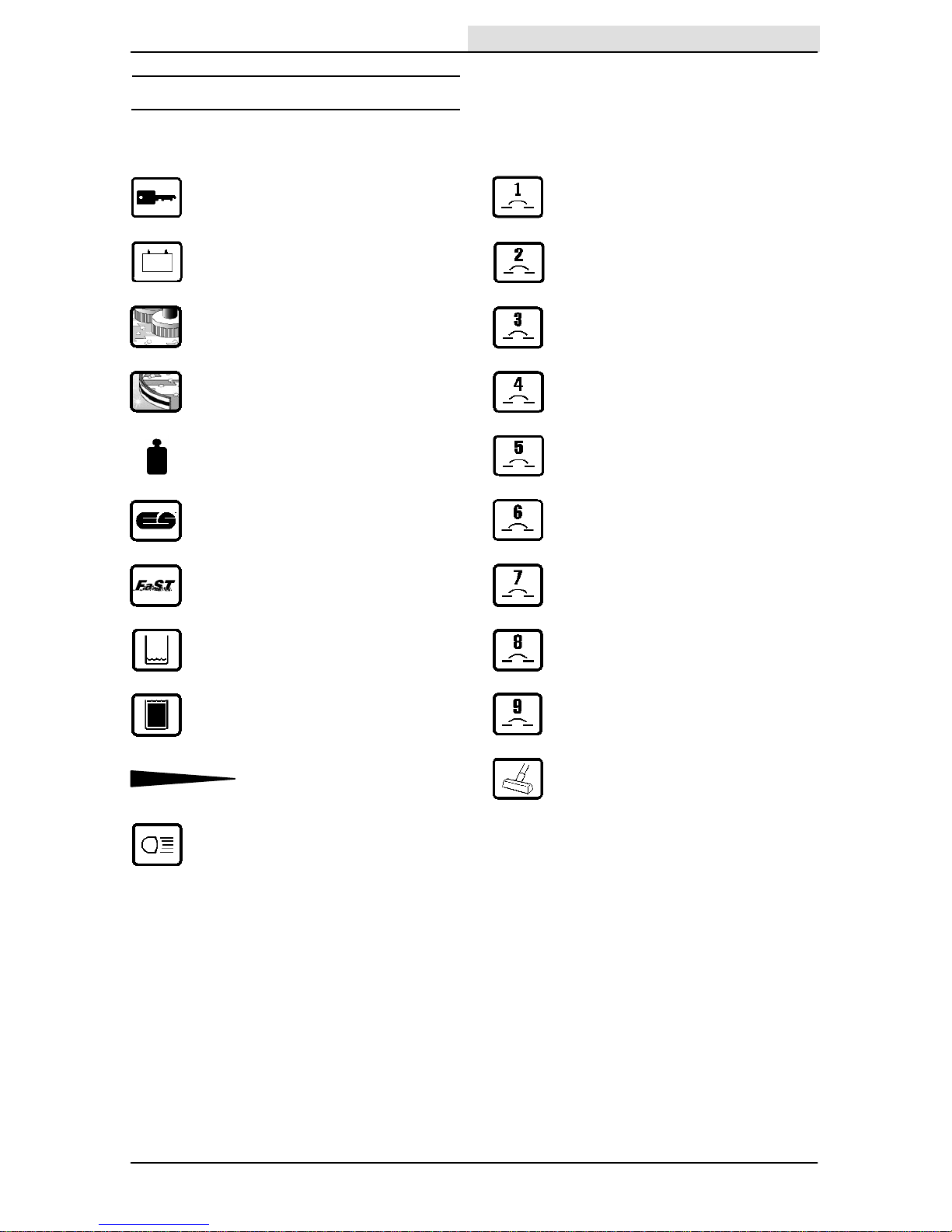

CONTROL PANEL SYMBOLS

These symbols identify controls and displays on

the machine:

Key switch Circuit breaker #1

Battery charge Circuit breaker #2

Scrub Circuit breaker #3

Squeegee Circuit breaker #4

Brush pressure Circuit breaker #5

ESt (Option) Circuit breaker #6

FaSTt (Option) Circuit breaker #7

Solution tank low Circuit breaker #8

Recovery tank full Circuit breaker #9

Solution flow Power wand switch (option)

Operating lights switch

OPERATION

7100 330699 (3--04)

8

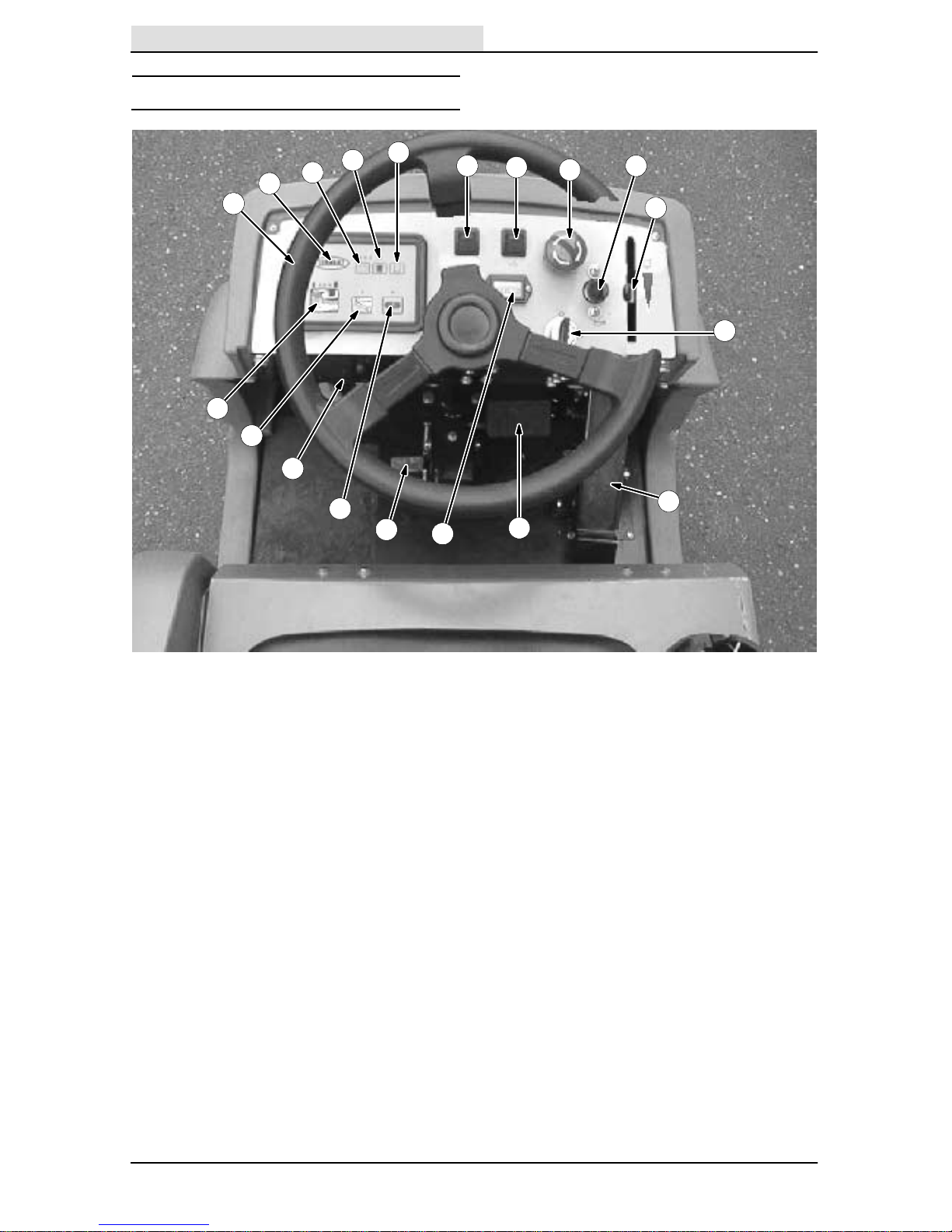

CONTROLS AND INSTRUMENTS

A

B

C

D

E

F

G

H

L

J

I

K

M

N

O

P

S

R

Q

A. Steering wheel

B. Control panel

C. Battery discharge indicator

D. Recovery tank full indicator

E. Solution tank empty indicator

F. Operating lights switch

G. Power wand switch (option)

H. Power kill switch

I. Horn button

J. Solution flow lever

K. On/Off key switch

L. Directional pedal

M. Brake pedal

N. Hourmeter

O. Parking brake pedal

P. E St switch (option)

or FaSTt switch (option)

Q. Circuit breaker panel

R. Rear squeegee switch

S. Scrub switch

OPERATION

9

7100 330699 (12--00)

OPERATION OF CONTROLS

BRAKE PEDAL

The brake pedal stops the machine.

Stop: Take your foot off the directional pedal and

allow it return to the Neutral position. Step on the

brake pedal.

PARKING BRAKE PEDAL

The parking brake pedal sets the front wheel

brake.

Set: Press the brake pedal down as far as

possible, then press on the parking brake pedal

with the toe of your foot to lock the parking brake

pedal in place.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, turn off

machine, and remove key.

Release: Press down on the brake pedal until the

parking brake releases.

DIRECTIONAL PEDAL

The directional pedal controls direction of travel

and the propelling speed of the machine. You

change the speed of the machine with the

pressure of your foot; the harder you press the

faster the machine travels.

When the machine is moving forward and the

directional pedal is reversed, the machine will

coast for a short distance before changing

direction. Use the brake pedal to stop the

machine.

OPERATION

7100 330699 (12--00)

10

Forward: Press the top of the directional pedal

with the upper part of your foot.

NOTE: The machine will not travel unless the

operator is sitting in the operator’s seat.

Reverse: Press the bottom of the directional

pedal with the heel of your foot.

When the directional pedal is placed into the

reverse position, the rear squeegee will

automatically raise. After a short delay, the

vacuum will stop.

Neutral: Take your foot off the directional pedal

and it will return to the neutral position.

When the directional pedal returns to the neutral

position, the scrub brushes will stop and after a

short delay, the scrub head will raise.

STEERING WHEEL

The steering wheel controls the machine’s

direction of travel.

Left: Turn the steering wheel to the left.

Right: Turn the steering wheel to the right.

OPERATION

11

7100 330699 (12--00)

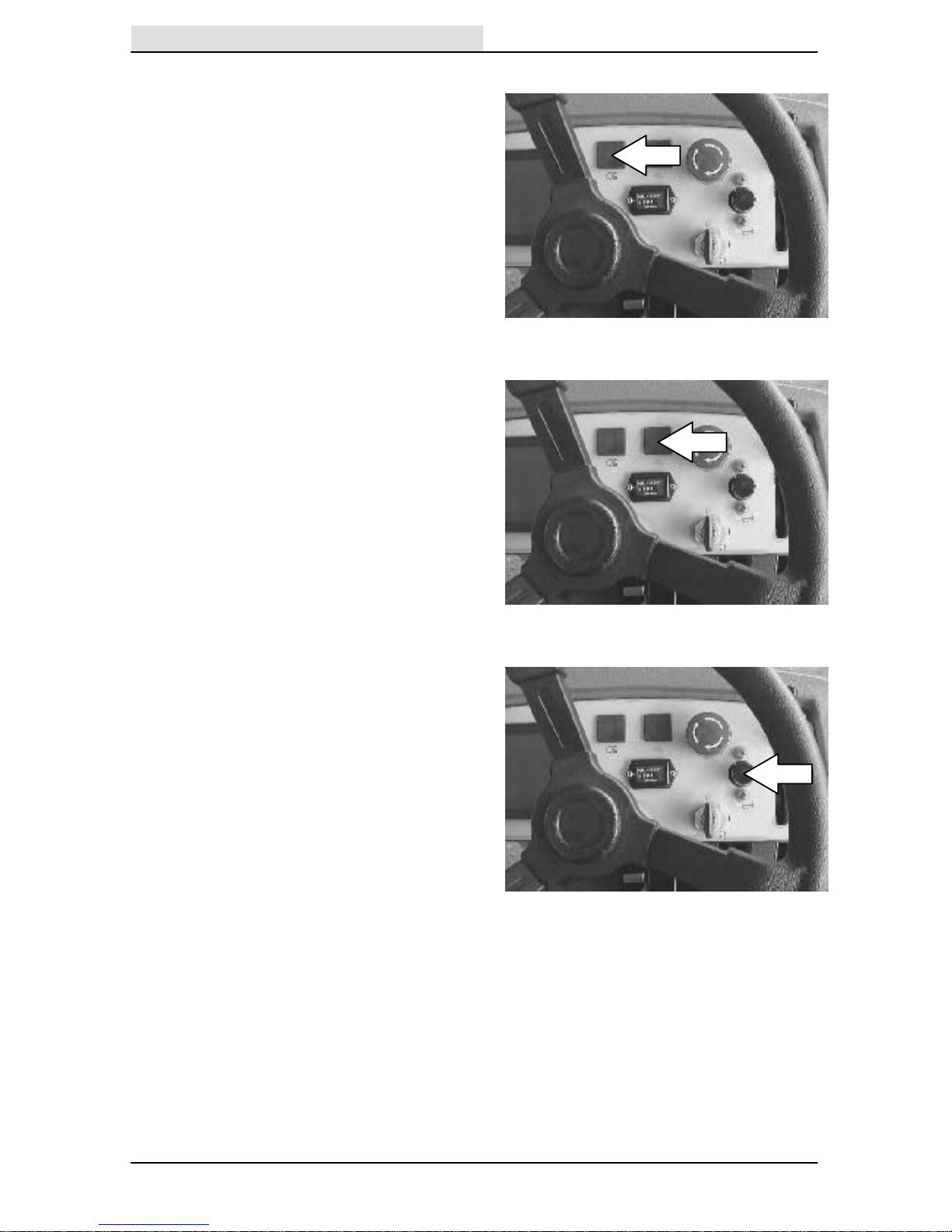

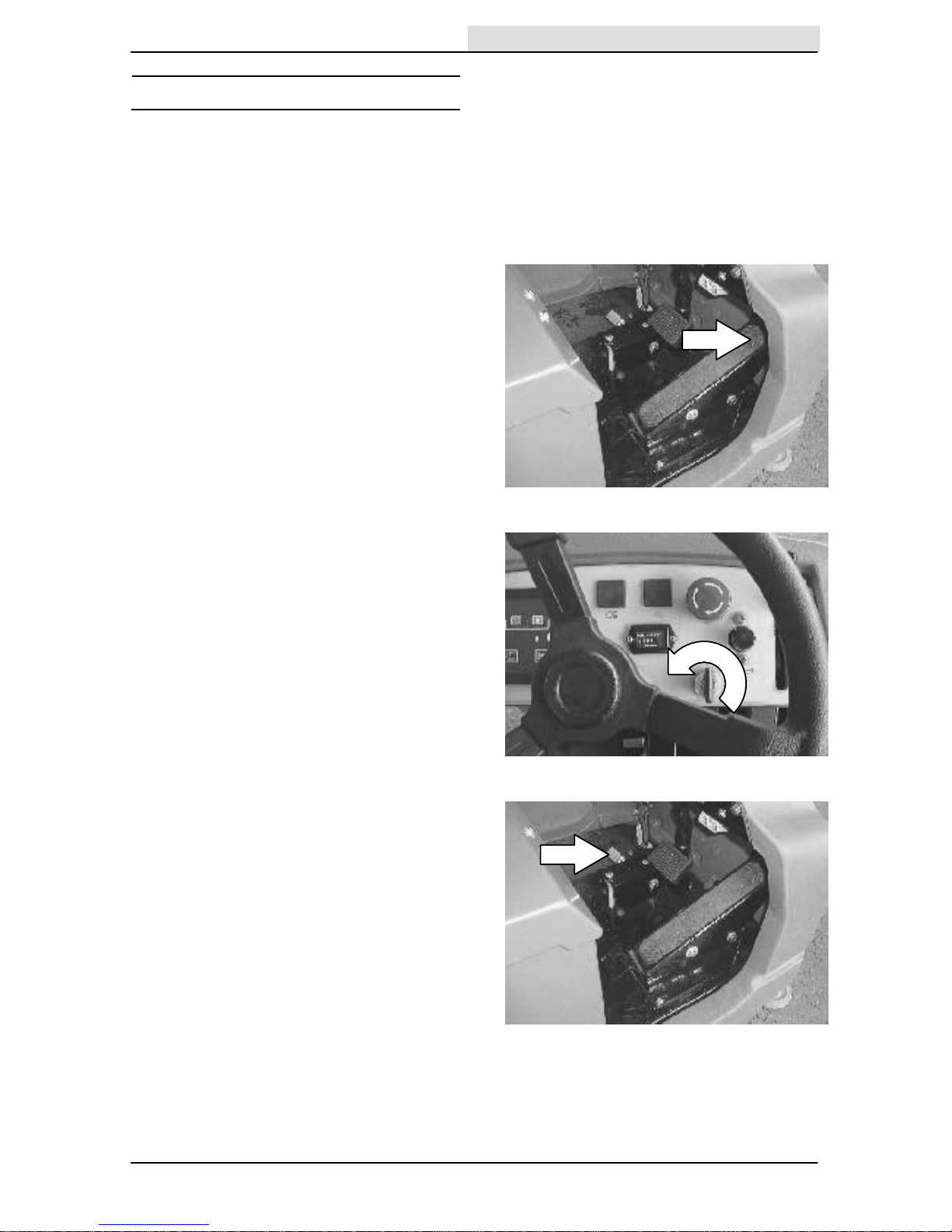

ON-OFF KEY SWITCH

The on-off key switch controls machine power with

akey.

FOR SAFETY: When starting machine,

keep foot on brake and directional pedal

in neutral.

On: Turn the key all the way clockwise and

release it to the on position.

Off: Turn the key all the way counterclockwise

until it clicks into the off position.

POWER KILL SWITCH

The power kill switch halts all power to the

machine.

Stop machine power: Press the power kill switch.

Restart: Turn off the machine with the on/off

switch. Turn the power kill switch to the right to

release the switch. Turn on the machine with the

on/off key switch.

HOURMETER

The hourmeter records the number of hours the

machine has been operated. Check the hourmeter

regularly; this information is used to determine

when to perform routine machine maintenance.

OPERATION

7100 330699 (12--00)

12

OPERATING LIGHTS SWITCH

The operating lights switch powers the headlights

and the hazard lights (option) on and off.

On: Press the top of the operating lights switch.

Off: Press the bottom of the operating lights

switch.

POWER WAND SWITCH (OPTION)

The power wand switch (option) powers the power

wand on and off.

On: Press the top of the power wand switch.

Off: Press the bottom of the power wand switch.

HORN BUTTON

The horn button operates the horn.

Sound: Press the horn button.

OPERATION

13

7100 330699 (12--00)

SCRUB SWITCH

The scrub switch controls the scrub head, scrub

brushes, squeegee, and vacuum fan. The scrub

switch is also used to set the scrub brush

pressure.

Start scrubbing: Press the scrub switch.The

indicator light will illuminate, the squeegee will

lower, and the vacuum fan will start. The

scrubbing system and solution flow will start when

the directional pedal is pressed and the machine

begins to move forward.

Stop scrubbing: Press the scrub switch.The

pressure indicator light will go out. The scrub

brushes will stop, the scrub head will raise, and

the solution flow will stop. After a short delay, the

rear squeegee will automatically raise. After

another delay, the vacuum will stop.

The brush down pressure indicators display the

pressure selection. The brush pressure indicator

has three positions. Brush pressure increases as

the indicator light moves to the right across the

display. Travel speed and floor conditions will

affect the scrubbing performance. Under normal

conditions, the brush pressure should be set in

one of the minimum settings. Set the brush

pressure in one of the maximum settings to scrub

a heavily soiled floor.

Change brush pressure: Press and hold the scrub

switch. T he pressure indicator light will cycle

through the three brush pressure settings. When

the switch is pressed and held, the brush pressure

will increase until it reaches the maximum setting.

The pressure will then return to the minimum

setting. Release the scrub switch when the

desired setting is indicated on the display.

NOTE: When the machine power is turned off, the

brush pressure will remain in the last setting used.

OPERATION

7100 330699 (12--01)

14

REAR SQUEEGEE SWITCH

The rear squeegee switch controls the vacuum

fan and the position of the rear squeegee. The

rear squeegee can be operated separately from

the scrub brushes for the purpose of picking-up

excess water without scrubbing, or double

scrubbing without water pick up

Lower squeegee and start the vacuum fan: Press

the rear squeegee switch. The indicator light

above the switch will illuminate.

Raise squeegee and stop the vacuum fan: Press

the squeegee switch. The indicator light above the

switch will go off. There will be a slight delay

before the vacuum shuts off.

NOTE: The rear squeegee lowers and the

scrubbing vacuum starts automatically, when the

scrubbing operations start.

NOTE: The rear squeegee will raise and the

scrubbing vacuum will shut off after a short delay

when the machine travels in reverse.

NOTE: The rear squeegee will raise and the

scrubbing vacuum fan will shut off after a short

delay when the scrubbing operations are shut off.

ESt SWITCH (OPTION)

The ES

t

(Extended Scrub) switch turns on and

off the solution recycling system. When the

scrubbing functions have started, the ESt will

default to the last setting used.

On: Press the ES

t

switch. The indicator light

above the switch will illuminate.

Off: Press the ES

t

switch. The indicator light

above the switch will turn off.

NOTE: The solution tank empty indicator light

will not illuminate with machines equipped with

the ES

t

option.

OPERATION

15

7100 330699 (3--04)

FaSTt SWITCH (OPTION)

The FaSTt switch (option) enables the FaSTt

(Foam Scrubbing Technology) system. When the

FaSTt system is enabled, it is turned on and off

with the scrub switch.

On: Press the FaST

t

switch. The indicator light

above the switch will illuminate.

Off: Press the FaST

t

switch. The indicator light

above the switch will turn off.

NOTE: The FaST system will not start until the

directional pedal is pressed.

NOTE: To use the machine for conventional

scrubbing, disable the FaST

t

system by turning

the FaST

t

switch off.

NOTE: Do not enable the FaST

t

system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the FaST

t

system. Conventional cleaning detergents/

restorers may cause failure to the FaST

t

solution

system.

SOLUTION TANK EMPTY INDICATOR

The solution tank empty indicator will illuminate

when the solution tank is empty.

NOTE: Machines with the ES

t

option do not have

this feature.

RECOVERY TANK FULL INDICATOR

The recovery tank full indicator will illuminate

when the recovery tank is full.

NOTE: When the indicator illuminates, all

scrubbing functions will shut off automatically.

OPERATION

7100 330699 (12--00)

16

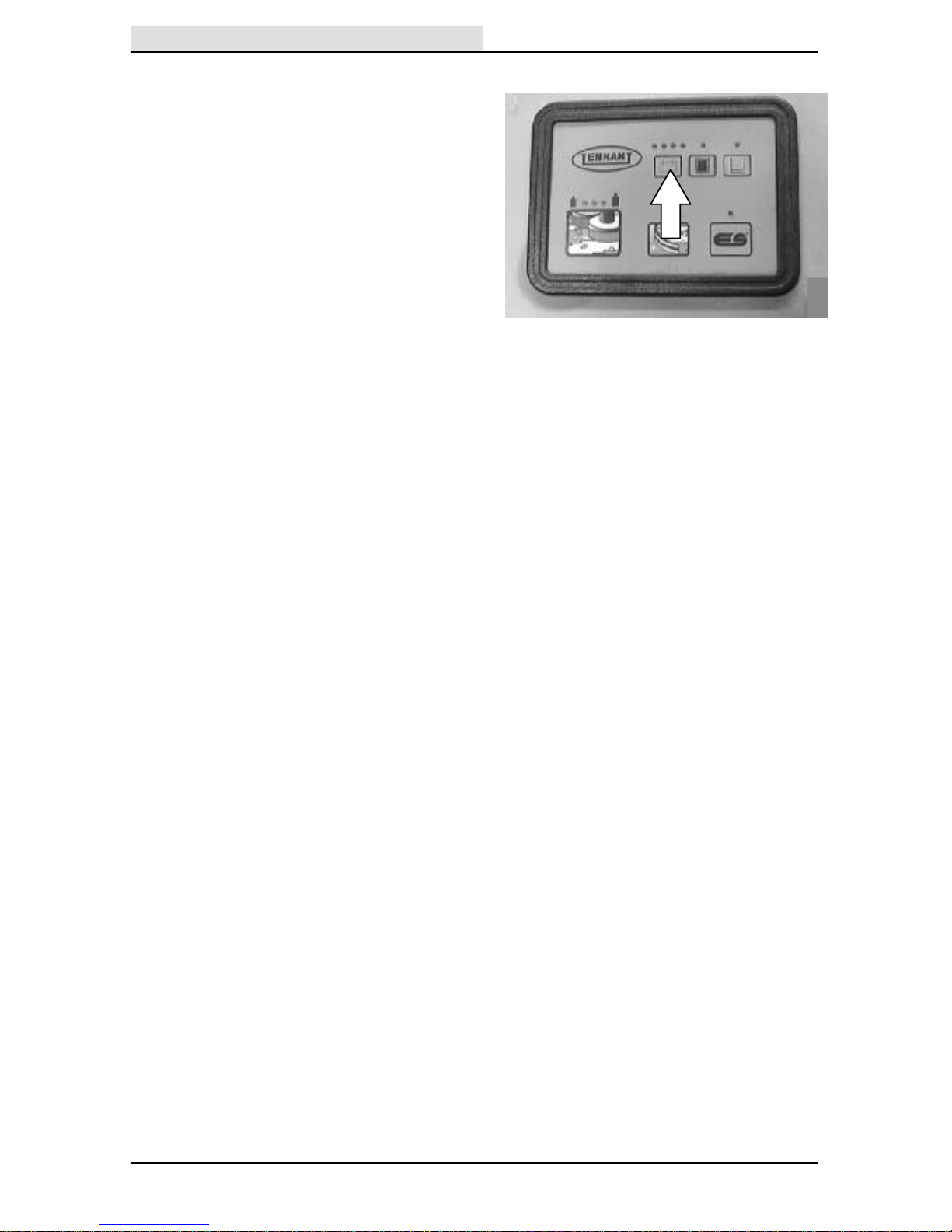

BA TTER Y DISCHARGE INDICATOR

The battery discharge indicator displays the

charge level of the batteries while the machine is

operating.

When the batteries are fully charged, all four

indicator lights are lit. As the batteries discharge,

the indicator lights will go out from right to left. The

batteries should be recharged when the indicator

on the left flashes. When the indicator flashes, all

scrubbing functions will shut off automatically.

Drive the machine to the battery charging area

and charge the batteries immediately after the

battery discharge indicator begins to flash.

NOTE: The battery discharge indicator will not

stop flashing until the batteries have been fully

charged.

NOTE: Do not charge the batteries more often

than is necessary to prolong the life of the

batteries. Do not charge the batteries with a “top

off” charge if there is enough remaining charge in

the batteries for the next machine use. Discharge

the batteries to a 20% level, when the battery

discharge indicator segments shut off, before fully

charging the batteries. Do not allow the batteries

to become completely discharged as this will also

damage the batteries. See BATTERIES in the

MAINTENANCE section.

OPERATION

17

7100 330699 (3--04)

CIRCUIT BREAKERS

Circuit breakers are resetable electrical circuit

protection devices designed to stop the flow of

current in the event of a circuit overload. Once a

circuit breaker is tripped, reset it manually by

pressing the reset button after the breaker has

cooled down.

If the overload that caused the circuit breaker to

trip is still present, the circuit breaker will continue

to stop current flow until the problem is corrected.

The circuit breakers are located on the operator

console.

Circuit

Breaker

Rating Circuit Protected

CB1 5A Machine power

CB2 10 A Lights

CB3 10 A Horn

CB4 10 A Power wand/

Back up alarm

CB5 10 A Control panel

CB6 20 A Vacuum Fan (single)

CB6 40 A Vacuum Fan (dual)

CB7 10 A ESt System (option)

FaSTt System (option)

CB8 25 A Left brush motor

CB9 25 A Right brush motor

The chart below shows the circuit breakers and

the electrical components they protect.

FUSE

The fuse is a one-time protection device designed

to stop the flow of current in the event of a circuit

overload.

NOTE: Always replace the fuse with a fuse of the

same amperage.

The fuse is located behind the operator console.

Access t he fuse by lowering the operator console.

Fuse

Rating Circuit Protected

FU-1 40 A Propelling

OPERATION

7100 330699 (3--04)

18

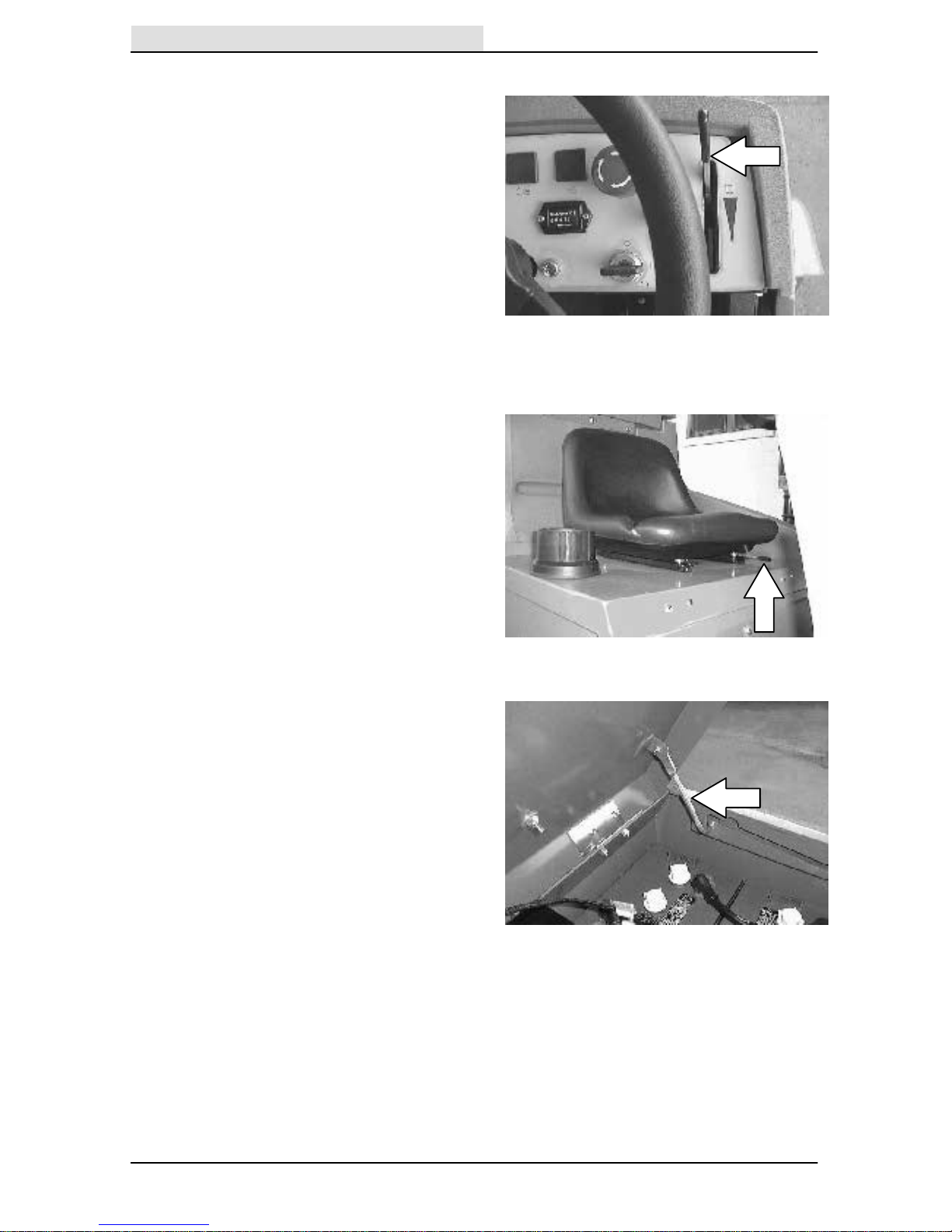

SOLUTION FLOW LEVER

The solution flow lever controls the amount of

solution that flows to the floor while scrubbing.

Increase solution flow: Push the lever forward.

Decrease solution flow: Pull the lever backward.

NOTE: The machine is equipped with a solenoid

valve that automatically stops the solution flow

when the directional pedal is in the neutral position

or when the scrub head is raised.

NOTE: When using the FaST

t

system (option),

the solution flow lever is nonfunctional. The

FaST

t

system flow rate is pre--set.

OPERATOR SEAT

The operator seat is a fixed back style with a

forward--backward adjustment.

Adjust: Pull the lever outward and slide the seat

to the desired position, then release the lever.

NOTE: The machine will not travel unless the

operator is sitting in the operator’s seat.

SEAT SUPPORT ARM

The seat support arm holds the seat up to allow

access to the batteries. The seat support arm

automatically engages when the seat is lifted all

the way up. Lower the seat support by slightly

raising it while pushing the support arm inward.

OPERATION

19

7100 330699 (12--00)

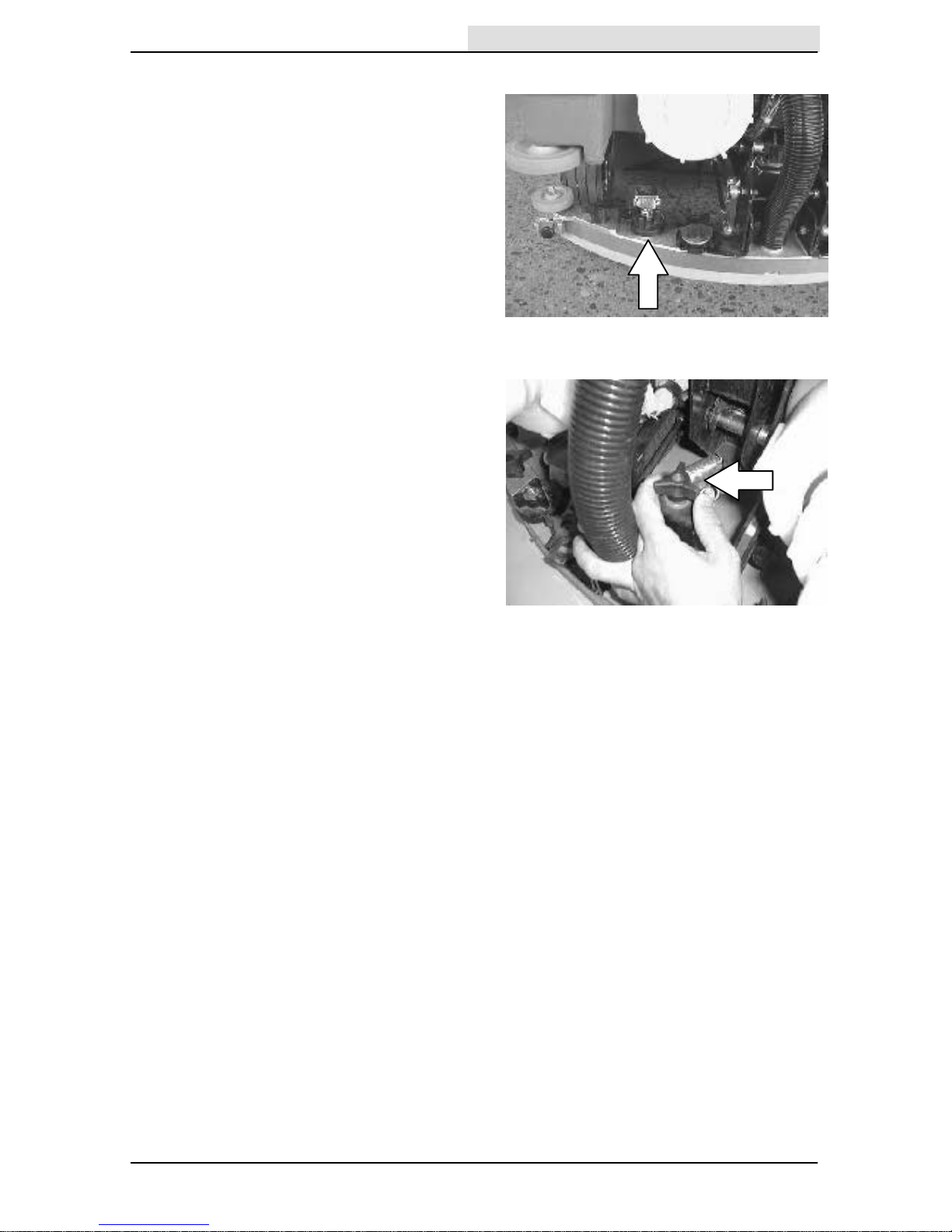

SQUEEGEE WHEEL CAMS

The squeegee wheel cams adjust the rear

squeegee deflection along the entire length of the

rear squeegee. There are wheel cams at either

end of the squeegee.

Increase deflection: Turn the cams

counterclockwise.

Decrease deflection: Turn the cams clockwise.

SQUEEGEE LEVELING KNOB

The squeegee leveling knob adjusts the deflection

at the ends of the rear squeegee.

The squeegee leveling knob is located directly

behind the squeegee suction hose. DO NOT

disconnect the suction hose from the squeegee

frame when leveling the squeegee.

Increase end deflection: Turn the squeegee

leveling knob counterclockwise to increase the

deflection at the end of the squeegees.

Decrease end deflection: Turn the squeegee

leveling knob clockwise to decrease the deflection

at the end of the squeegees.

OPERATION

7100 330699 (12--00)

20

HOW THE MACHINE WORKS

The following machine components work together

to effectively clean dirty floors: solution tank, scrub

brushes, squeegee, vacuum fan, and recovery

tank.

Water and detergent from the solution tank flow to

the floor through a solution valve. The brushes

use the detergent and water solution to scrub the

floor clean. As the machine propels forward, the

squeegee wipes the dirty solution from the floor.

The suction created by the vacuum fan then

draws the dirty solution from the squeegee into

the recovery tank.

The steering wheel controls the direction of

machine travel.The directional pedal controls the

speed and direction of the machine. The brake

pedal slows and stops the machine.

When using the ESt mode (option), the dirty

solution in the recovery tank is filtered and

returned to the solution tank to be reused for

extended scrubbing.

The four available scrub head types use disk or

cylindrical brushes.

Two different widths of scrub heads are available

for each type. Both the cylindrical and disk scrub

heads are available in 700 mm and

800 mm widths.

NOTE: The amount and type of soilage play an

important role in determining the type of brushes

to be used. For specific recommendations, contact

your Tennant representative.

When finished scrubbing, clean the recovery tank.

If using the ESt system, drain and clean the

solution tank, and clean the ESt filter.

OPERATION

21

7100 330699 (3--04)

FaSTtttt SCRUBBING SYSTEM (OPTION)

Unlike conventional scrubbing, the FaSTt (Foam

Scrubbing Technology) system operates by

injecting the FaSTt PAK concentrate agent into

the system with a small amount of water and

compressed air. This mixture creates a large

volume of expanded wet foam.

The expanded foam mixture is then dispersed

onto the floor while the machine is scrubbing.

When the squeegee picks up the mixture, the

patented foaming agent has collapsed and is

recovered into the recovery tank.

The FaSTt system can be used with all double

scrubbing and heavy duty scrubbing applications.

Using the FaSTt system can increase

productivity by 30% by reducing your dump/fill

cycle. It will also reduce chemical usage and

storage space. One FaSTt PAK of concentrated

agent can scrub up to 1 million sq. ft.

NOTE: Do not enable the FaST

t

system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the FaST

t

system. Conventional cleaning detergents/

restorers may cause failure to the FaST

t

solution

system.

The safe scrubbing alternative

tttt

OPERATION

7100 330699 (3--04)

22

PRE-OPERATION CHECKLIST

Check over this list of items before operating the

machine:

- Check under the machine for leaks.

- Check the brakes and steering for proper

operation.

- Check for wire, string, or twine wrapped

around the scrub brushes.

- Check the squeegees for wear or damage.

- Check the squeegee suction hose for

obstructions.

- Cylindrical brushes: Check that the debris

tray is empty and clean.

- ESt machines. Check that the ESt filter is

clean.

- Check the recovery tank cover seals for

wear or damage.

- Check that the vacuum fan inlet filter is

clean.

- FaSTt Scrubbing: Check the FaST PAK

(option) concentrate agent level, replace

carton as needed. See the INSTALLING

THE FaSTt PAK AGENT section of the

manual.

- FaSTt Scrubbing: Check that all

conventional cleaning agents/restorers are

drained and rinsed from the solution tank.

- FaSTt Scrubbing: Check that solution tank

is filled with clear cool water only.

OPERATION

23

7100 330699 (3--04)

INSTALLING FaSTtttt PAK AGENT (OPTION)

NOTE: Machine must be equipped with the FaST

option.

1. Remove the perforated knock--outs from the

FaSTt PAK Floor Cleaning Concentrate

carton. Do not remove the bag from the

carton. Pull out the bag’s hose connector on

the bottom of the bag and remove the hose

cap from the connector.

NOTE: The FaST

tttt

PAK Floor Cleaning

Concentrate is specially designed for use with

the FaST

tttt

system scrubbing application.

NEVER use a substitute, machine damage will

result.

FOR SAFETY: When using machine,

always follow the handling instructions

on chemical container.

2. Empty the solution tank. See DRAINING

AND CLEANING THE TANKS section of the

manual.

NOTE: When scrubbing with the FaST

t

system

option, use clean water only. Do not add cleaning

agents in the solution tank. Conventional cleaning

agents/restorers may cause failure to the FaST

solution system..

3. Place the FaSTt PAK carton in the carton

holder located next to the seat. Connect the

supply hose to the FaSTt PAK bag.

NOTE: If any dried concentrate is visible on the

supply hose connector or the on the FaST

t

PAK

connector, soak and clean with warm water.

OPERATION

7100 330699 (3--04)

24

4. Make sure to connect the supply hose onto

the hose storing plug when the supply hose

is not connected to the FaSTt PAK. This

will prevent the FaSTt solution system from

drying out and clogging up the hose.

5. FIRST TIME USE: The FaSTt solution

system is protected against freezing during

shipment. You must operate the FaSTt

system for 10 minutes to disperse the

mixture of RV anti--freeze/FaST detergent

before you achieve maximum foaming.

6. When replacing an empty FaSTt PAK

carton, allow the new FaSTt PAK detergent

to gravity feed into the system for several

minutes prior to operating the FaSTt

system. If the detergent does not flow out of

the FaSTt PAK, simply squeeze and

release the hose several times. If the

previous FaSTt PAK was run dry, it may

take up to 5--10 minutes of operation to

remove any air pockets in the system before

you achieve maximum foaming.

STARTING THE MACHINE

1. You must be in the operator’s seat with the

directional pedal in neutral, and your foot on

the brake pedal or with the parking brake

set.

FOR SAFETY: When starting machine,

keep foot on brake and directional pedal

in neutral.

2. Turn the machine power on.

3. Release the machine parking brake.

4. Drive the machine to the area to be cleaned.

NOTE: The machine will not travel unless the

operator is sitting in the operator’s seat.

OPERATION

25

7100 330699 (12--00)

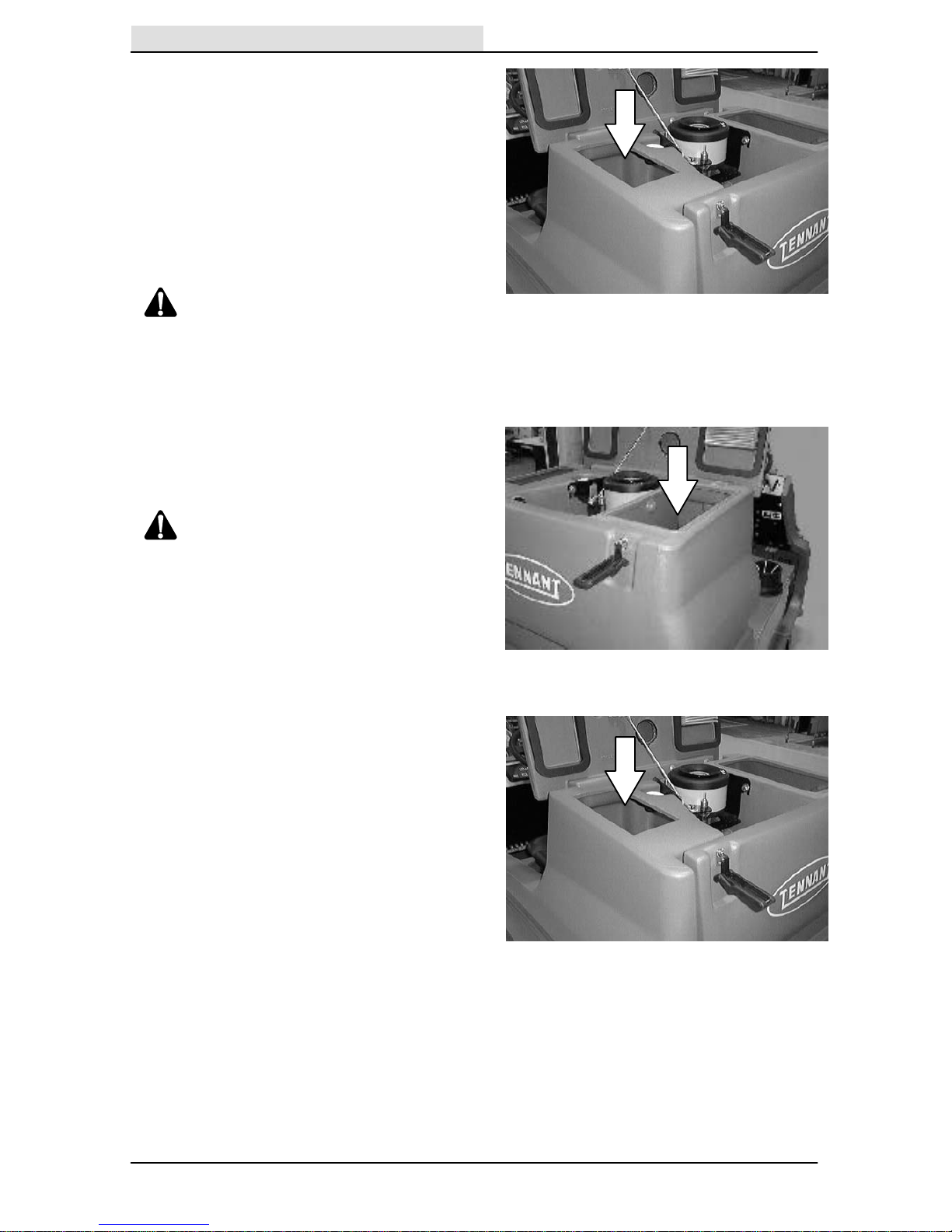

FILLING THE TANKS

1. Turn the machine power on. See the

STARTING THE MACHINE section of the

manual.

FOR SAFETY: When starting machine,

keep foot on brake and directional pedal

in neutral.

2. Drive the machine to the tank filling site.

3. Turn the machine power off. See the STOP

THE MACHINE section of the manual.

4. Set the machine parking brake.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, turn off

machine, and remove key.

OPERATION

7100 330699 (3--04)

26

5. CONVENTIONAL SCRUBBING: Open the

solution tank cover. Measure and pour in the

correct amount of detergent. Fill the rest of

the solution tank with water up to the FULL

line near the top of the tank.

NOTE: Floor conditions, water condition, amount

of soilage, type of soilage, and brush pressure all

play an important role in determining the type and

concentration of detergent used. For specific

recommendations, contact your Tennant

representative.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

FOR SAFETY: When using machine,

follow mixing and handling instructions

on chemical containers.

6. ESt (option): Fill the recovery tank with

water and detergent up to the lower sensor

float to extend scrub time. Make sure the

ESt system is on.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

FOR SAFETY: When using machine,

follow mixing and handling instructions

on chemical containers.

NOTE: If you DO NOT want to use the ESt

mode (option), DO NOT put water in the recovery

tank and make sure the ESt system is off.

7. FaSTt SCRUBBING (option): Open the

solution tank cover and fill the solution tank

to the FULL line near the top of the tank with

cool clear water only. Do not add cleaning

detergents.

NOTE: When cleaning using FaST

tttt

option,

USE CLEAR COOL WATER ONLY. DO NOT add

cleaning detergents in solution tank.

Conventional cleaning detergents/restorers

may cause failure to the FaST

tttt

solution

system.

8. Lower the tank cover.

OPERATION

27

7100 330699 (12--00)

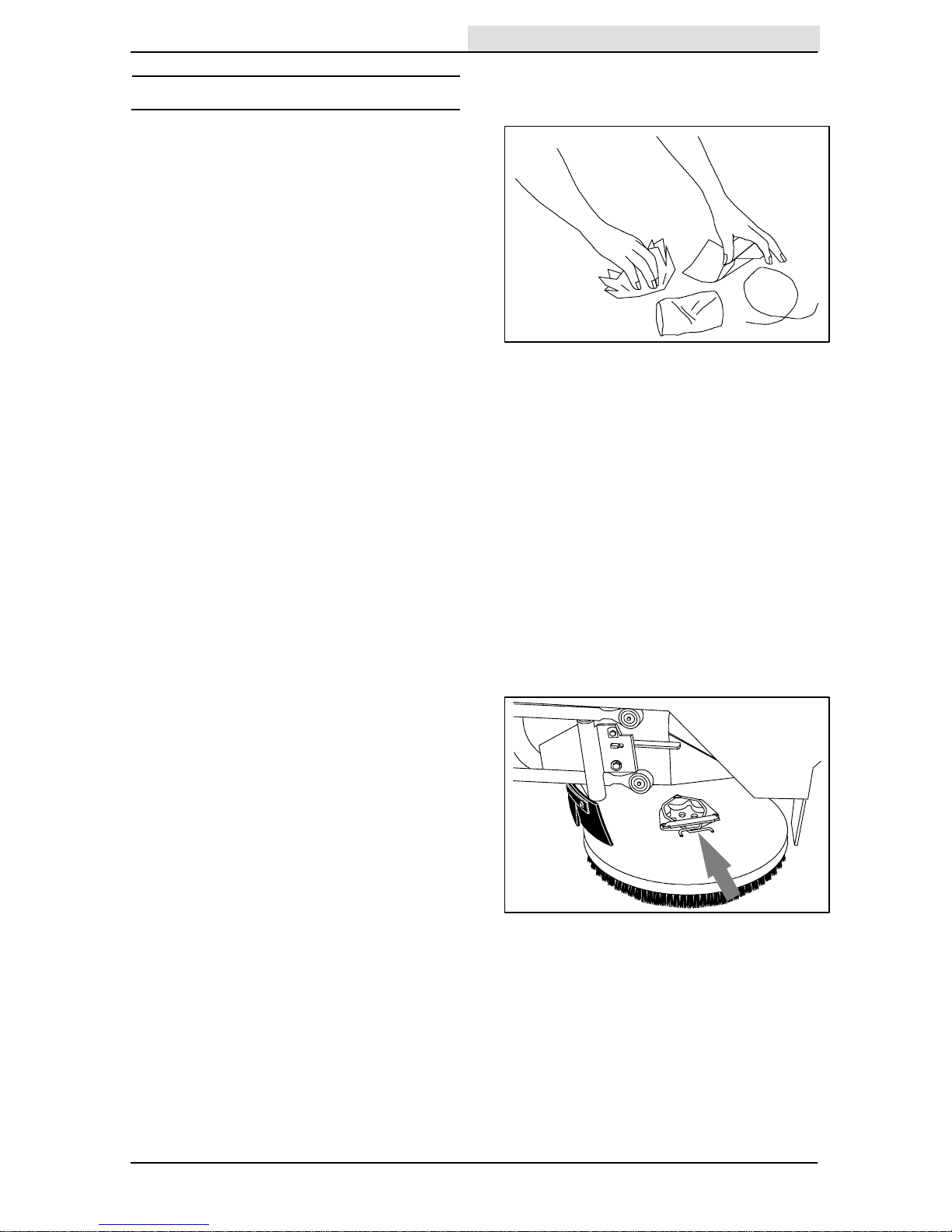

SCRUBBING AND BRUSH INFORMATION

Pick up oversized debris before cleaning. Pick up

pieces of wire, string, twine, etc., which could

become wrapped around the scrub brushes.

Plan the scrubbing in advance. Try to arrange long

runs with minimum stopping and starting. Do an

entire floor or section at one time.

Drive as straight a path as possible. Avoid

bumping into posts or scraping the sides of the

machine. Overlap the scrub paths by several

centimeters.

Avoid turning the steering wheel too sharply when

the machine is in motion. The machine is very

responsive to the movement of the steering wheel.

Avoid sudden turns, except in emergencies.

When scrubbing dead end aisles, start at the

closed end of the aisle and scrub your way out.

Adjust the machine speed, scrub brush pressure,

and solution flow as required when scrubbing. Use

minimum scrub brush pressure and solution flow

required for the best results.

If you see poor scrubbing performance, stop

scrubbing and refer to MACHINE

TROUBLESHOOTING.

For best results, use the correct brush type for

your cleaning application. The following are

recommended brush applications.

Non-scuff polypropylene scrub brush -- T h i s

brush uses a softer, general purpose

polypropylene bristle to lift lightly compacted

soilage without scuffing high-gloss coated floors.

Nylon scrub brush -- Recommended for

scrubbing coated floors. Cleans without scuffing.

Super abrasive bristle scrub brush -- N y l o n

fiber impregnated with abrasive grit to remove

stains and soilage. Strong action on any surface,

performing well on buildup, grease, or tire marks.

07218

05939

OPERATION

7100 330699 (12--00)

28

Heavy duty stripping pad -- This black pad is for

stripping floors. Cuts through old heavy finishes

easier, to prepare the floor for re-coating.

Stripping pad -- This brown pad is for stripping

floors. Quickly and easily cuts through old finish to

prepare the floor for re-coating.

Scrubbing pad -- This blue pad is for scrubbing

floors. Removes dirt, spills and scuffs, leaving a

clean surface ready for re-coating.

Buffing pad -- This red pad is for buffing floors.

Quickly cleans and removes scuff marks while

polishing the floor to a high gloss.

Polishing pad -- This white pad is for polishing

floors. Maintains a high gloss. Use for buffing very

soft finishes and lower traffic areas, or use for

polishing soft waxes on wood floors.

Cylindrical polypropylene scrub brush -- T h i s

cylindrical brush uses a softer, general purpose

polypropylene bristle to lift lightly compacted

soilage without scuffing high-gloss coated floors.

Cylindrical nylon scrub brush -- This cylindrical

brush is recommended for scrubbing coated

floors. Cleans without scuffing.

Cylindrical super abrasive bristle scrub brush

-- Nylon fiber impregnated with abrasive grit to

remove stains and soilage. Strong action on any

surface, performing well on buildup, grease, or tire

marks.

NOTE: Cylindrical scrub brushes must be installed

with the herringbone patterns on the brushes

pointing towards each other for best debris pick

up.

Loading...

Loading...