TENNANT 5680

SCRUBBER DRYER

OPERATOR MANUAL

Clemas & Co. Unit 5 Ashchurch Business Centre, Alexandra Way, Tewkesbury,

Gloucestershire, GL20 8NB.

Tel: 01684 850777 Fax: 01684 850707

Email: info@clemas.co.uk Web: www.clemas.co.uk

CONTENTS

1

5680 330459 (10--08)

CONTENTS

Page

SAFETY PRECAUTIONS 3.................

OPERATION 5............................

OPERATOR RESPONSIBILITY 5........

MACHINE COMPONENTS 6............

CONTROL PANEL SYMBOLS 7.........

CONTROLS AND INSTRUMENTS 8......

STEERING HANDLES 9.............

ON-OFF KEY SWITCH 10............

SCRUB SWITCH 11.................

SCRUB HEAD STRAP (DISC HEAD) 1 1

SQUEEGEE LEVER 11...............

HOURMETER 12....................

BATTERY DISCHARGE INDICAT OR 12

FaST SWITCH (OPTION) 12..........

ec--H2O SWITCH (OPTION) 13.......

POWER KILL SWITCH 13............

SOLUTION FLOW LEVER 14.........

CIRCUIT BREAKERS 14.............

SOLUTION TANK HOSE 15...........

RECOVERY TANK DRAIN HOSE 15...

SUPPORT ARM 15..................

STOP ARM 16......................

SQUEEGEE DOWN PRESSURE

CAMS 16.........................

PARKING BRAKE 16.................

HOW THE MACHINE WORKS 17.........

FaST SCRUBBING SYSTEM

(OPTION) 18......................

ec--H2O SYSTEM (OPTION) 19.......

PRE-OPERATION CHECKLIST 20........

INSTALLING FaST PAK AGENT

(OPTION) 21.......................

STARTING THE MACHINE 23............

FILLING THE T ANKS 23.................

SCRUBBING AND BRUSH

INFORMATION 25.....................

DOUBLE SCRUBBING 29................

STOP SCRUBBING 30...................

DRAINING AND CLEANING

THE TANKS 31........................

OPERATION ON INCLINES 35...........

STOP THE MACHINE 35.................

POST-OPERATION CHECKLIST 36.......

MACHINE TROUBLESHOOTING 37.......

MAINTENANCE 39.........................

MAINTENANCE CHART 39...............

LUBRICATION 41.......................

REAR CASTERS 41.................

TRANSAXLE 41.....................

BATTERIES 41.........................

CHARGING THE BATTERIES 43......

ELECTRIC MOTORS 44.................

Page

SCRUB HEAD 45.......................

DISK BRUSH SCRUB HEAD SKIRT 45.

CYLINDRICAL BRUSH SCRUB

HEAD SKIRTS 45..................

ADJUSTING THE SCRUB

HEAD SKIRTS 45..................

REPLACING THE SCRUB

HEAD SKIRTS 45..................

REMOVING OR REPLACING

THE SCRUB HEAD 46..............

LEVELING THE SCRUB HEAD 49.....

SCRUB BRUSHES AND PADS 50.........

DISK BRUSHES 50..................

REPLACING THE DISK BRUSHES

OR PADS 50......................

CYLINDRICAL BRUSHES 54..........

REPLACING THE CYLINDRICAL

BRUSHES 54......................

CHECKING AND ADJUSTING

CYLINDRICAL BRUSH PATTERN 55......

SOLUTION SYSTEM 57.................

RECOVERY TANK 57................

SOLUTION TANK 58.................

FaST SYSTEM (OPTION) 59.............

FaST SYSTEM MAINTENANCE 59....

FaST SYSTEM FILTER SCREEN 60...

FaST SUPPLY HOSE

CONNECTOR 60..................

ec--H2O SYSTEM (OPTION) 61...........

ec--H2O MODULE FLUSH

PROCEDURE 61..................

SQUEEGEE 62.........................

REMOVING THE SQUEEGEE

ASSEMBLY 62..........................

INSTALLING THE SQUEEGEE

ASSEMBLY 63..........................

LEVELING THE SQUEEGEE 63.......

ADJUSTING SQUEEGEE BLADE

DEFLECTION 64..................

SQUEEGEE BLADES 65.................

REPLACING OR ROTATING THE

REAR SQUEEGEE BLADE 65.......

REPLACING OR ROTATING THE

FRONT SQUEEGEE BLADE 67.....

BELTS AND CHAINS 68.................

BRUSH DRIVE BELT 68..............

STATIC DRAG CHAIN 68.............

TIRES 68...............................

PUSHING AND TRANSPORTING

THE MACHINE 69.....................

PUSHING THE MACHINE 69.........

TRANSPORTING THE MACHINE 69...

MACHINE JACKING 71..................

STORAGE INFORMATION 71............

FREEZE PROTECTION 71...........

CONTENTS

5680 330459 (10--08)

2

Page

SPECIFICATIONS 73.......................

GENERAL MACHINE

DIMENSIONS/CAPACITIES 73...........

FaST SYSTEM (OPTION) 74.............

ec--H2O SYSTEM (OPTION) 74...........

GENERAL MACHINE PERFORMANCE 74.

POWER TYPE 75.......................

TIRES 75...............................

MACHINE DIMENSIONS 76..............

SAFETY PRECAUTIONS

3

5680 330459 (10--08)

SAFETY PRECAUTIONS

The following symbols are used throughout this

manual as indicated in their description:

WARNING: To warn of hazards or unsafe

practices that could result in severe

personal injury or death.

FOR SAFETY: To identify actions that

must be followed for safe operation of

equipment.

This machine is designed solely for scrubbing dirt

and dust in an indoor environment. Tennant does

not recommend using this machine in any other

environment.

The following information signals potentially

dangerous conditions to the operator or

equipment. Read this manual carefully. Know

when these conditions can exist. Locate all safety

devices on the machine. Then, take necessary

steps to train machine operating personnel.

Report machine damage or faulty operation

immediately. Do not use the machine if it is not in

proper operating condition.

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result. Keep

sparks and open flame away. Keep

covers open when charging.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pickup.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operation manual is read and

understood.

-- In flammable or explosive areas unless

designed for use in those areas.

2. Before starting machine:

-- Make sure all safety devices are in

place and operate properly.

-- Check brakes and steering for proper

operation (if so equipped).

3. When using machine:

-- Go slow on inclines and slippery

surfaces.

-- Use care when backing machine.

-- Follow mixing and handling

instructions on chemical containers.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Set the parking brake.

-- Turn off machine and remove key.

5. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves when

working on machine.

-- Block machine tires before jacking

machine up.

-- Jack machine up at designated

locations only. Block machine up with

jack stands.

-- Use hoist or jack of that will support

the weight of the machine.

-- Wear eye and ear protection when

using pressurized air or water.

-- Disconnect battery connections before

working on machine.

-- Avoid contact with battery acid.

-- Wear protective gloves and eye

protection when handling white

vinegar.

-- Use Tennant supplied or equivalent

replacement parts.

6. When loading/unloading machine

onto/off truck or trailer:

-- Turn off machine.

-- Use truck or trailer that will support

the weight of the machine.

-- Use winch. Do not push the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

-- Set parking brake after machine is

loaded (option).

-- Block machine tires.

-- Tie machine down to truck or trailer.

SAFETY PRECAUTIONS

5680 330459 (10--00)

4

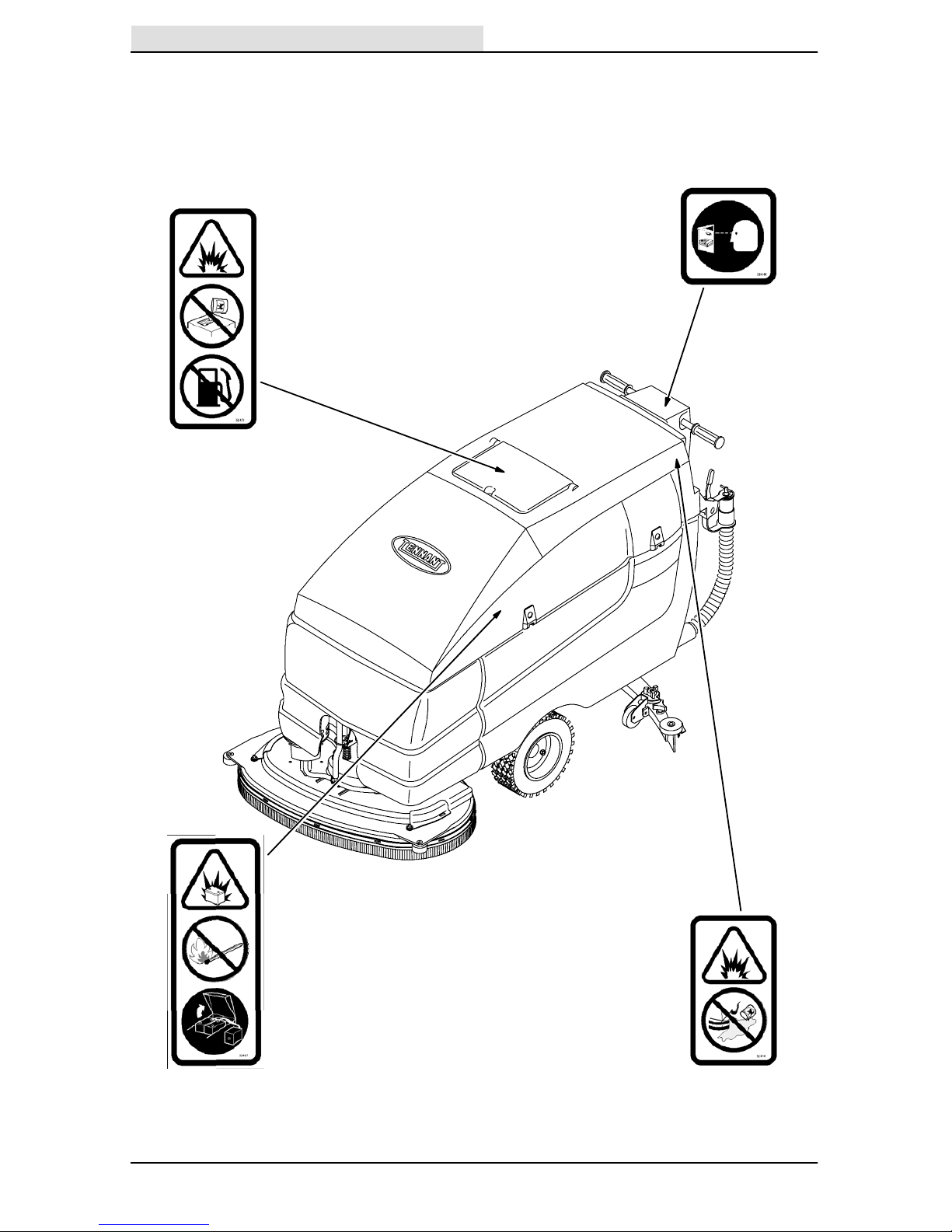

The safety labels appear on the machine in the

locations indicated. If these or any label becomes

damaged or illegible, install a new label in its

place.

BA TTER Y CHARGING LABEL -- LOCA TED ON

THE UNDERSIDE OF THE SOLUTION TANK.

FLAMMABLE SPILLS LABEL -- LOCATED

ON THE OPERATOR CONSOLE.

FOR SAFETY LABEL -- LOCATED ON

THE OPERATOR CONSOLE.

FLAMMABLE MATERIALS LABEL -LOCATED ON THE UNDERSIDE OF

THE SOLUTION TANK COVER.

353417

OPERAT ION

5

5680 330459 (10--00)

OPERATION

OPERATOR RESPONSIBILITY

- The operator’s responsibility is to take care

of the daily maintenance and checkups of

the machine to keep it in good working

condition. The operator must inform the

service mechanic or supervisor when the

maintenance intervals are required as stated

in the MAINTENANCE section of this

manual.

- Read this manual carefully before operating

this machine.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

- Check the machine for shipping damage.

Check to make sure the machine is

complete per shipping instructions.

- Keep your machine regularly maintained by

following the maintenance information in this

manual. We recommend taking advantage of

a regularly scheduled service contract from

your Tennant representative.

- Order parts and supplies directly from your

authorized Tennant representative. Use the

parts manual provided when ordering parts.

- After operation, follow the recommended

daily and hourly procedures stated in the

MAINTENANCE CHART.

07324

OPERAT ION

5680 330459 (10--08)

6

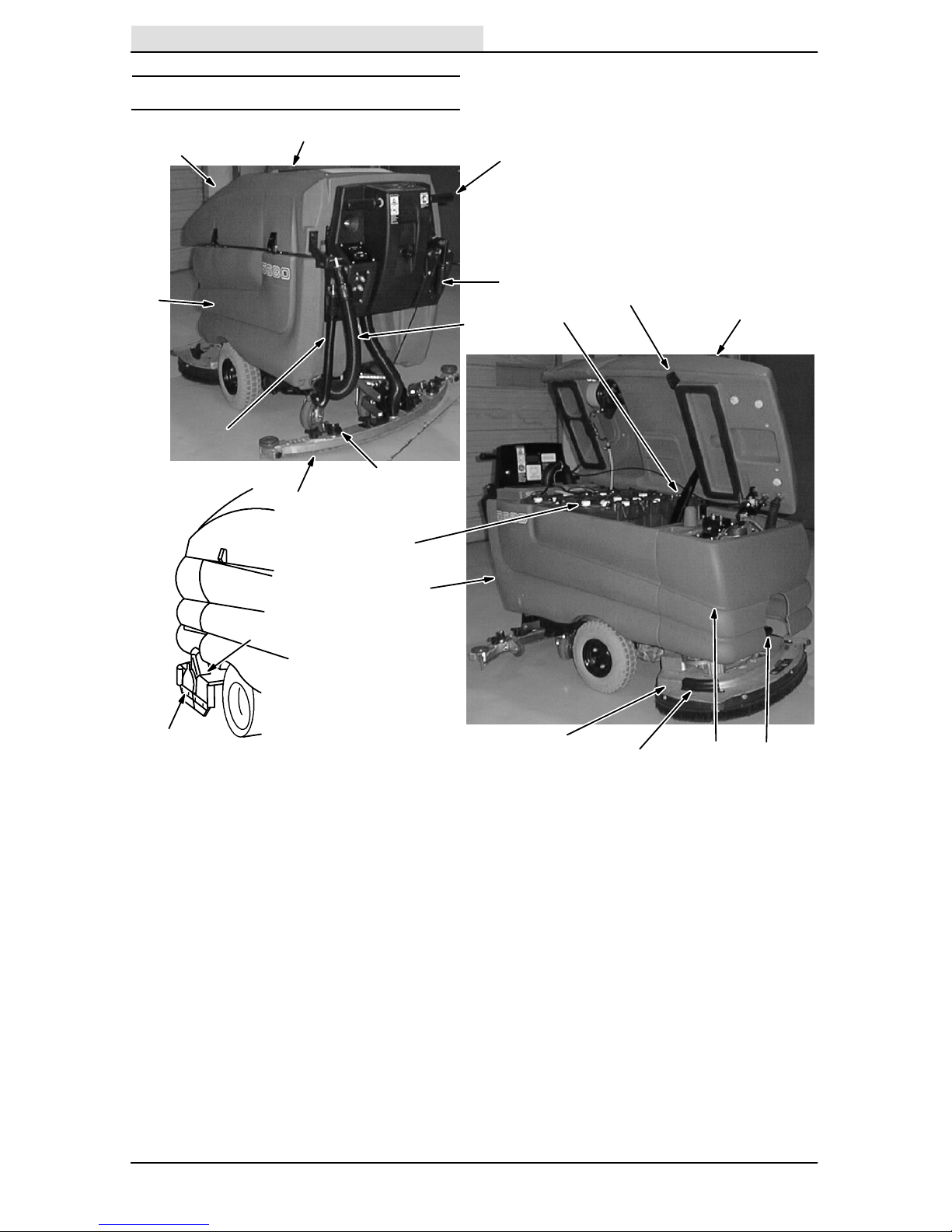

MACHINE COMPONENTS

A

D

E

F

G

H

I

K

C

M

L

A

B

C

J

N

O

P

Q

M

A. Solution tank

B. Solution tank fill opening

C. Recovery tank

D. Steering handles

E. Squeegee

F. Squeegee lever

G. Squeegee down pressure cams

H. Recovery tank drain hose

I. Solution tank hose

J. Support arm

K. Stop arm

L. Batteries

M. Scrub head

N. Scrub brush access cover

O. FaST solution system (option)

ec - H2O System Module (option)

P. Heavy duty scrub head strap

Q. Scrub brush idler door

OPERAT ION

7

5680 330459 (10--08)

CONTROL PANEL SYMBOLS

These symbols identify controls and displays on

the machine:

Key switch Circuit breaker #1--scrub head actuator

Variable flow or rate Circuit breaker #2--vacuum fan motor

Solution flow Circuit breaker #3--machine propel

Scrub brushes down and on Circuit breaker #4--left brush motor

Scrub brushes up and off Circuit breaker #5--right brush motor

Heavy scrub brush down pressure Circuit breaker #6--FaST

Circuit breaker #6--ec--H2O

OPERAT ION

5680 330459 (10--08)

8

CONTROLS AND INSTRUMENTS

CB1

CB2

CB3

CB4

CB5

B

D

G

I

J

K

B

L

M

C

A

H

CB6

K

N

F

O

E

10345

A. Operation label

B. Steering handles

C. On-off key switch

D. Scrub switch

E. Console height adjustment knob

F. Hourmeter

G. FaST system on/off switch (option)

ec- H2O system on/off switch (option)

H. ec- H2O system indicator light (option)

I. Battery discharge indicator

J. Solution flow lever

K. Circuit breakers

L. Squeegee lever

M. Recovery tank drain hose

N. Solution tank drain hose

O. Power Kill Switch

OPERAT ION

9

5680 330459 (10--00)

STEERING HANDLES

The steering handles control the machine speed

and direction.

Forward: Rotate the steering handles forward. The

further forward you rotate the steering handles,

the faster the machine will go.

Backward: Rotate the steering handles

backwards toward you.

Turning: Push the machine in the direction of the

turn with the steering handles. The machine will

turn on the swivel casters.

OPERAT ION

5680 330459 (10--00)

10

Stop: Release the steering handles.

The steering console height is adjustable.

Adjust: Turn the console adjustment knob

counterclockwise to loosen the knob. Move the

console up or down to the desired height. Then

turn the knob clockwise to tighten the knob, and

lock the console in position.

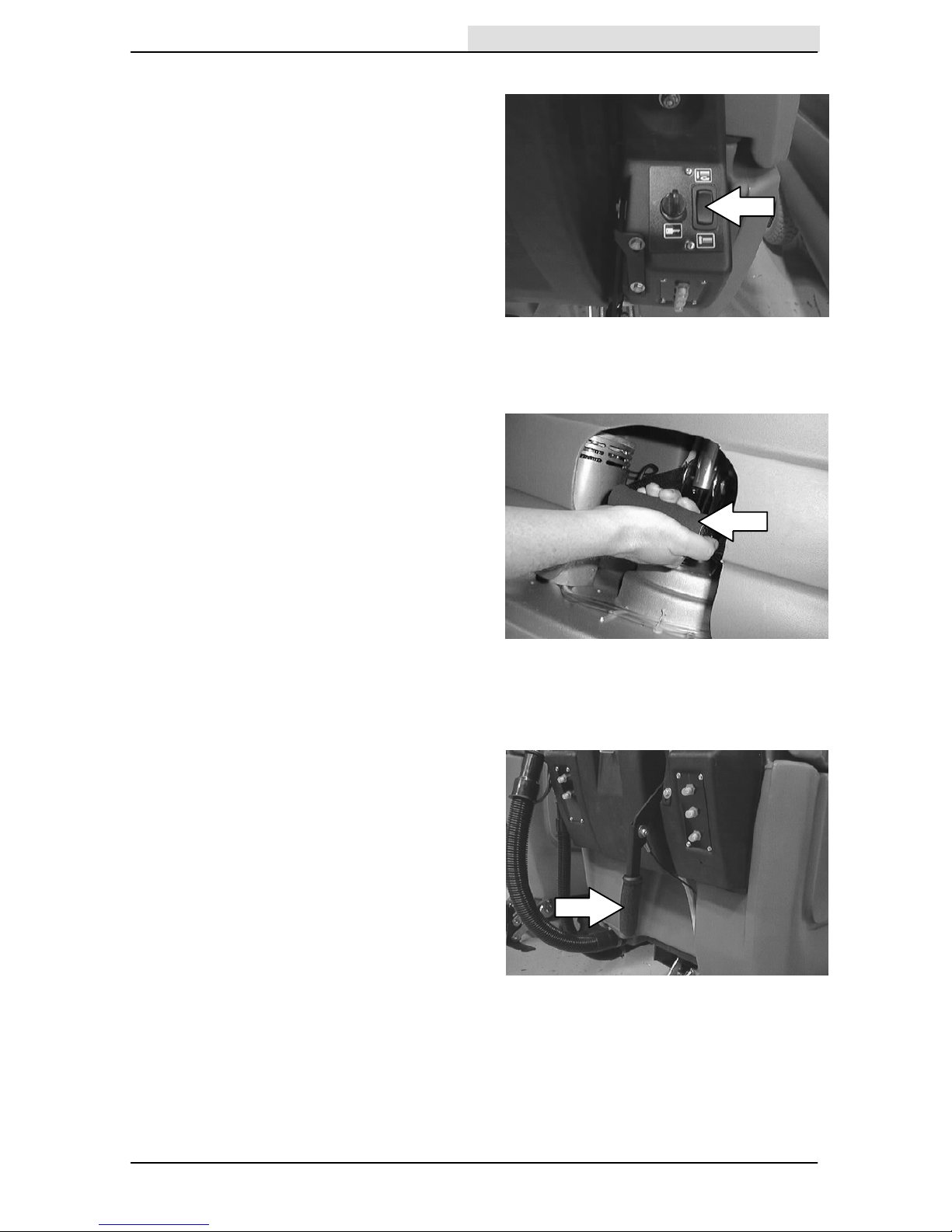

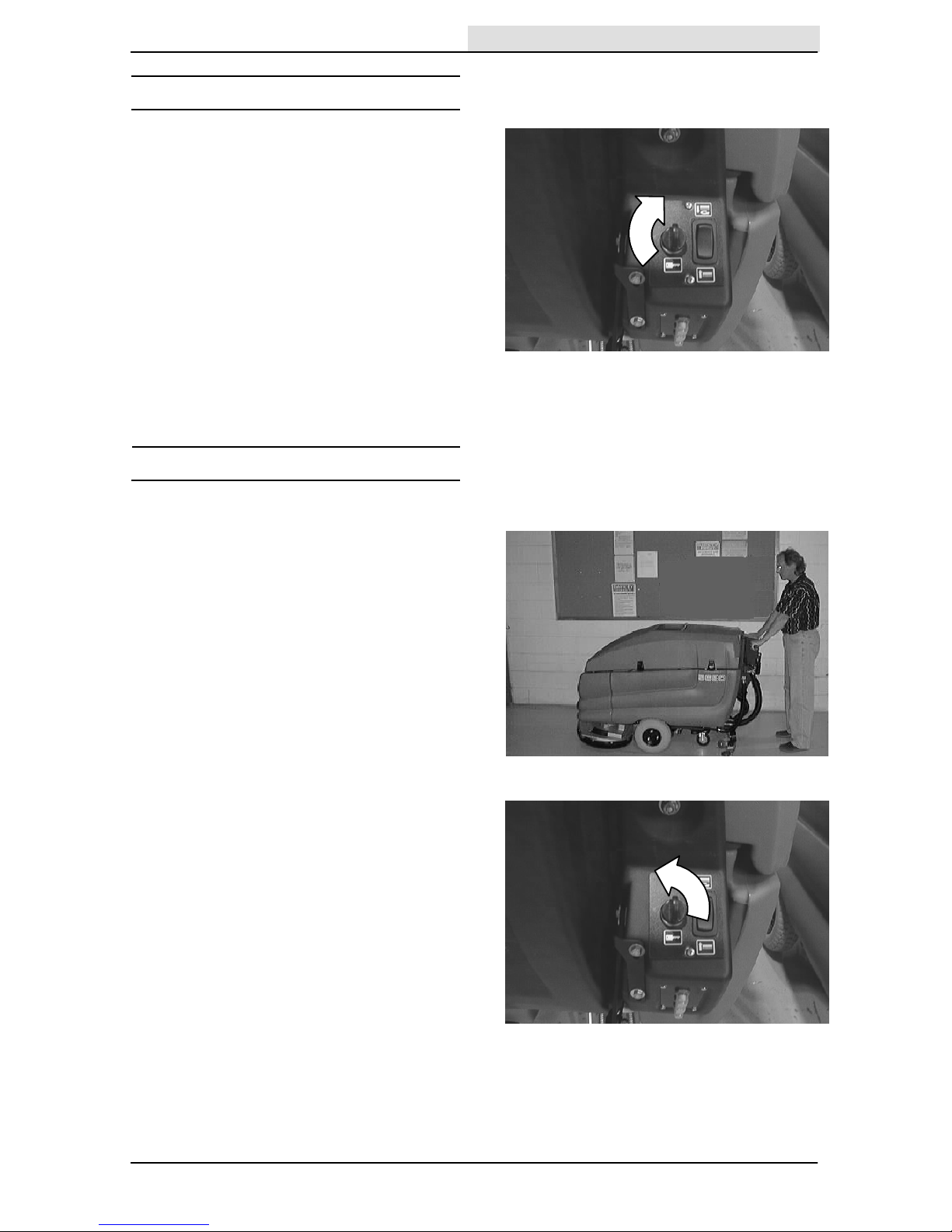

ON-OFF KEY SWITCH

The on-off key switch controls machine power with

akey.

On: Turn the key to the right.

Off: Turn the key to the left.

OPERAT ION

11

5680 330459 (10--08)

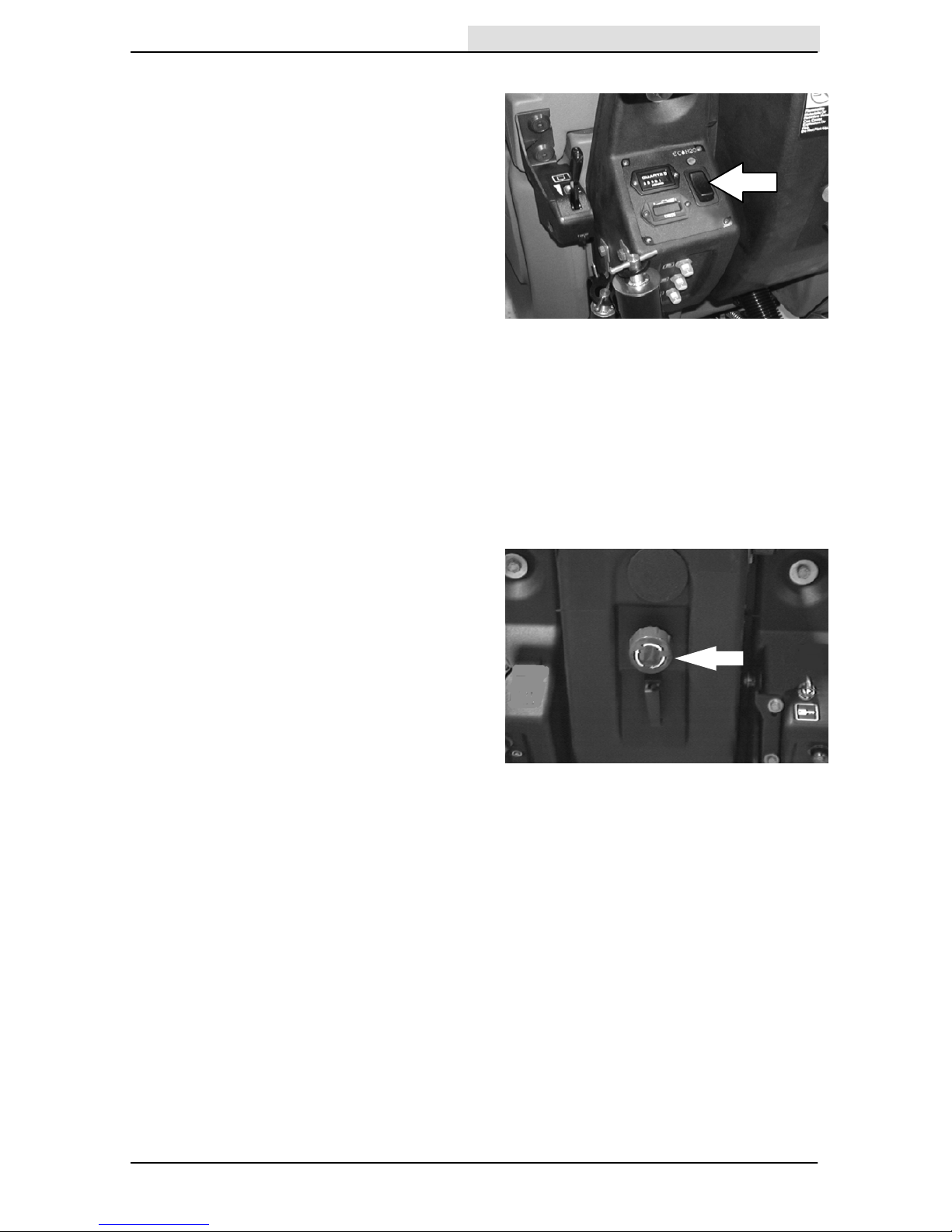

SCRUB SWITCH

The scrub switch controls the scrubbing

operations.

Lower brushes and start scrubbing: Press the top

of the switch.

Raise brushes and stop scrubbing: Press the

bottom of the switch.

NOTE: The scrub brushes do not start until the

steering handles are rotated forward or backward.

NOTE: The scrub switch also controls the

FaST/ec-H2O system (option) when the

FaST/ec-H2O system is enabled with the

FaST/ec-H2O switch.

SCRUB HEAD STRAP (DISC HEAD)

The scrub head strap increases the scrub head

pressure and puts the scrub head into heavy

scrub mode.

The heavy scrub mode is used when deep

scrubbing or floor stripping is necessary .

Start heavy scrub mode: With the scrub head in

the up position, pull out on the scrub head strap

until the scrub head drops into place. Lower the

brushes and start scrubbing.

Stop heavy scrub mode: Press the bottom of the

scrub switch. The scrub head will reset when it

raises and stops scrubbing. When it is started

again, the scrub head will operate at daily

scrubbing pressure.

SQUEEGEE LEVER

The squeegee lever controls the squeegee and

the vacuum system.

Lower squeegee and start vacuum: Move the

squeegee lever up and to the left to unlock it, and

then release the lever.

Raise squeegee and stop vacuum: Pull the lever

up and move it to the right to lock the lever in the

up position.

NOTE: Raise the squeegee before reversing the

machine.

OPERAT ION

5680 330459 (3--08)

12

HOURMETER

The hourmeter records the number of hours the

machine has been powered on. This information is

useful when servicing the machine.

BA TTER Y DISCHARGE INDICATOR

The battery discharge indicator shows the charge

level of the batteries.

When the batteries are fully charged, the indicator

on the far right is lit. As the batteries discharge,

the indicator will move along the display to the left.

Recharge the batteries when the indicator flashes.

NOTE: The battery discharge indicator will not

reset from the flashing indicator unless the

batteries have been fully charged.

FaST SWITCH (OPTION)

The FaST switch (option) enables the FaST

(Foam Scrubbing T echnology) system. When the

FaST system is enabled, it is turned on and off

with the scrub switch

Enable the FaST system: Press the top of the

FaST switch.

Enable conventional scrubbing: Press the bottom

of the FaST switch.

NOTE: Disable the FaST system before using the

machine for conventional scrubbing.

NOTE: The FaST system will not start until the

steering handles are rotated forward or backward.

NOTE: Do not enable the FaST system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the FaST

system. Conventional cleaning detergents/

restorers may cause failure to the FaST solution

system.

OPERAT ION

13

5680 330459 (10--08)

ec- H2O SWITCH (OPTION)

The ec--H2O switch (option) enables the ec--H2O

(electrically converted water) system. When the

ec--H2O system is enabled, it is turned on and off

with the scrub switch.

Enable the ec--H2O system: Press the top of the

ec--H2O switch.

Enable conventional scrubbing: Press the bottom

of the ec--H2O switch.

NOTE: Disable the ec--H2O system before using

the machine for conventional scrubbing.

NOTE: The ec--H2O system will not start until the

machine starts scrubbing.

NOTE: Do not enable the ec--H2O system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the ec--H2O

system. Conventional cleaning detergents/

restorers may cause failure to the ec--H2O

solution system.

POWER KILL SWITCH

The power kill switch halts all power to the

machine.

Halt: Hit the power kill switch.

Restart: Turn the power kill switch to the right to

release the switch. Turn off the machine power,

then turn on the machine power.

OPERAT ION

5680 330459 (10--08)

14

SOLUTION FLOW LEVER

The solution flow lever controls the amount of

solution flow to the floor.

Increase: Push the lever forward.

Decrease: Pull the lever backward.

NOTE: A solenoid valve dispenses the solution to

the scrub head. The valve opens when the

steering handles are rotated forward, and closes

when the steering handles are released in neutral

position.

NOTE: When using the FaST or ec--H2O system

(option), the solution flow lever is nonfunctional.

The FaST and ec--H2O system flow rates are

pre--set. The ec--H2O module has optional flow

rate settings. If solution flow adjustments are

required, contact an Authorized Service Center.

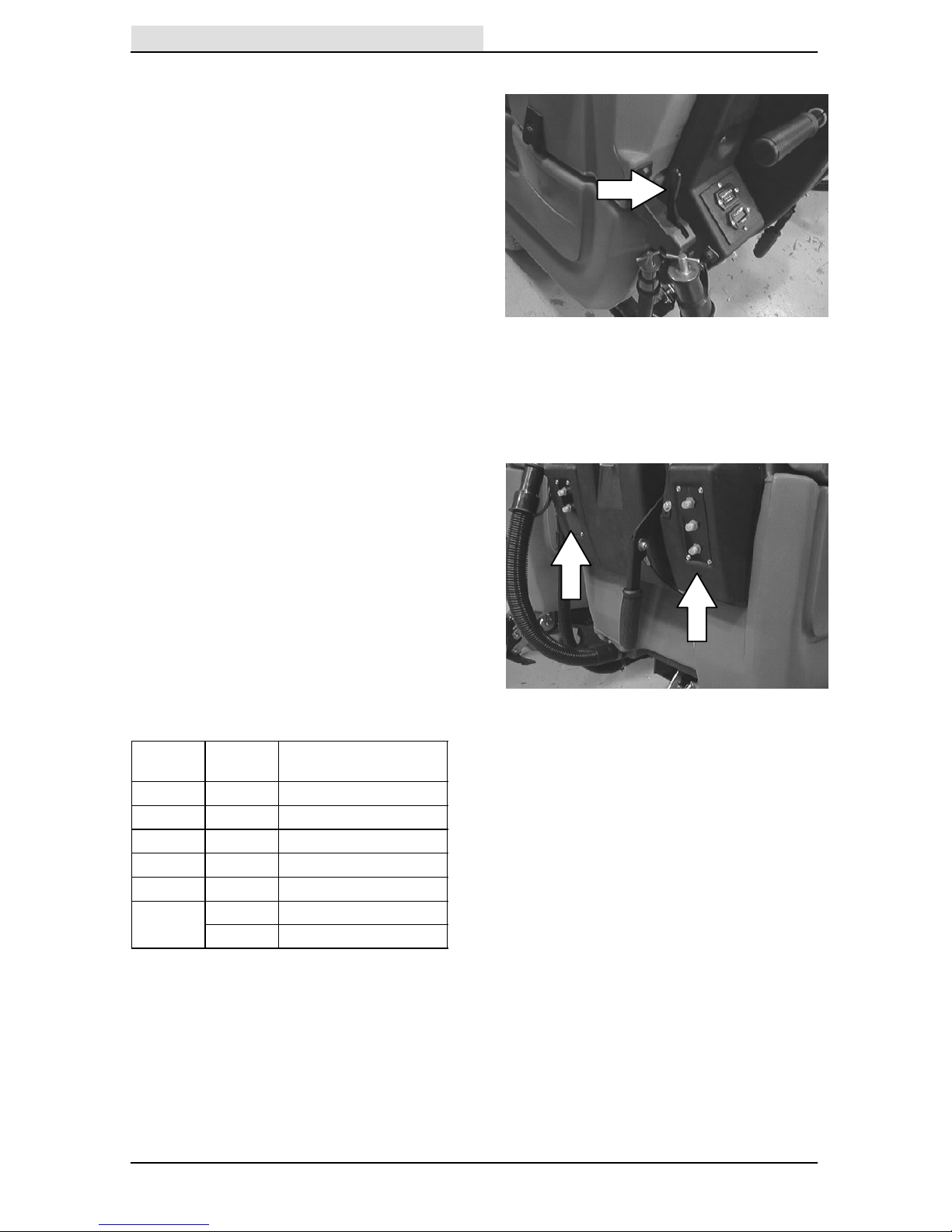

CIRCUIT BREAKERS

The circuit breakers are resettable electrical circuit

protection devices. They stop the flow of current in

the event of a circuit overload. Once a circuit

breaker is tripped, reset manually by pressing the

reset button after the breaker has cooled down.

If the overload that caused the circuit breaker to

trip is still there, the circuit breaker will continue to

stop current flow until the problem is corrected.

The circuit breakers are located on each side of

the operator console.

The chart shows the circuit breakers and the

electrical components they protect.

Circuit

Breaker

Rating Circuit Protected

CB1 10 A Machine power

CB2 25 A Vacuum fan motor

CB3 25 A Machine propel

CB4 30 A Right brush motor

CB5 30 A Left brush motor

CB6 10 A FaST (option)

10 A ec--H2O (option)

OPERAT ION

15

5680 330459 (10--00)

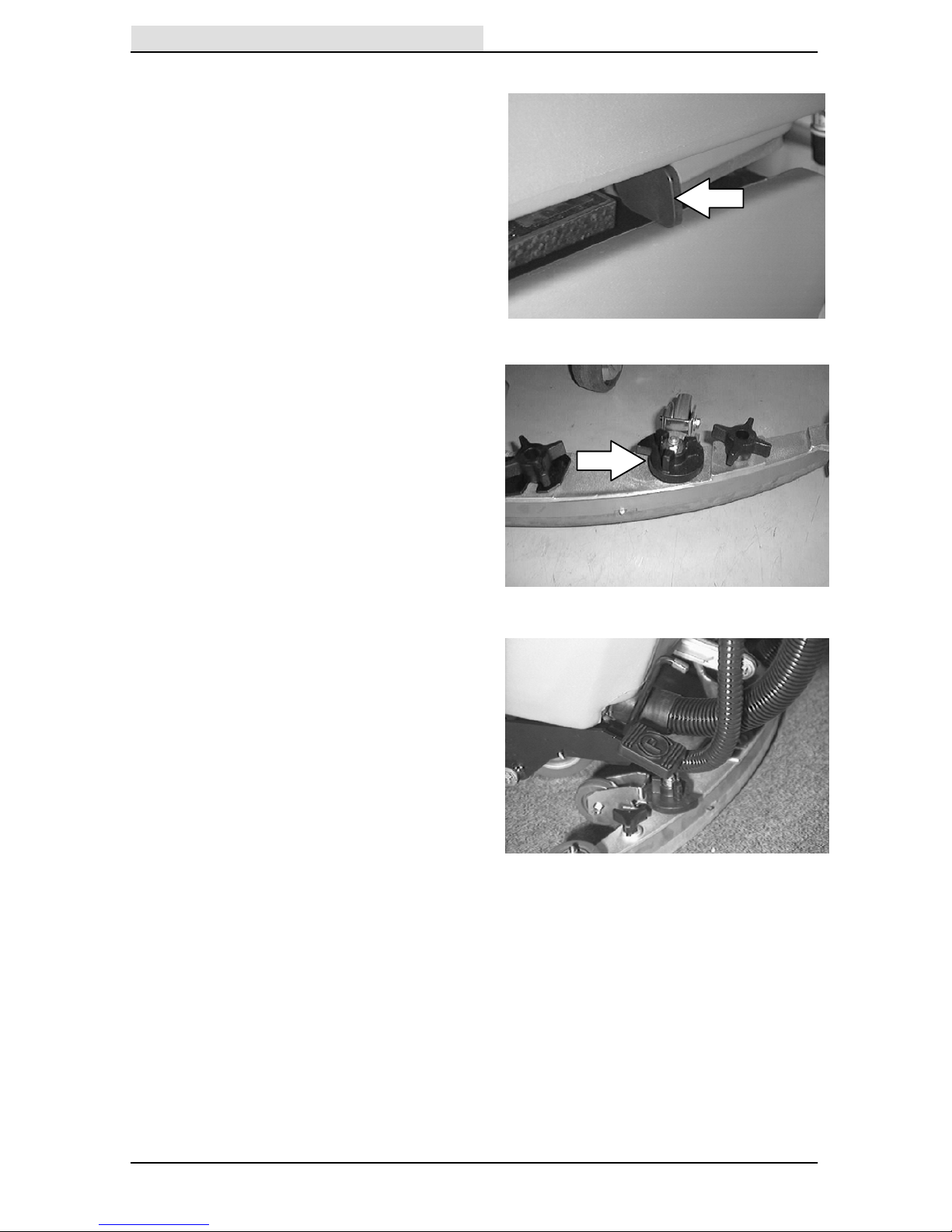

SOLUTION TANK HOSE

The solution tank hose is used to drain the

solution tank. The drain hose plug is removed by

turning the plug latch to loosen the plug and

pulling the plug out of the drain hose. The drain

hose is plugged by placing the hose plug in the

end of the hose and turning the plug latch to

tighten the plug.

RECOVERY TANK DRAIN HOSE

The recovery tank drain hose is used to drain the

recovery tank. The drain hose plug is removed by

turning the plug latch to loosen the plug and

pulling the plug out of the drain hose. The drain

hose is plugged by placing the hose plug in the

end of the hose and turning the plug latch to

tighten the plug.

SUPPORT ARM

The support arm holds up the solution tank when

the tank is lifted. The support arm engages when

the solution tank is lifted all the way open. The

arm is released by pulling up on it.

OPERAT ION

5680 330459 (10--00)

16

STOP ARM

The stop arm prevents the solution tank from fully

closing when the tank is lowered. Push the arm in

to lower the solution tank completely.

SQUEEGEE DOWN PRESSURE CAMS

The squeegee down pressure cams adjust the

squeegee deflection along the entire length of the

squeegee.

Increase: Turn the cams clockwise.

Decrease: Turn the cams counter-clockwise.

PARKING BRAKE

The parking brake is controlled with a foot pedal

and a release lever located by the squeegee.

Set: Push down on the foot pedal.

Release: Pull up on the release lever .

OPERAT ION

17

5680 330459 (6--05)

HOW THE MACHINE WORKS

The scrub components of the machine are a

solution tank, scrub brushes or pads, a squeegee,

a vacuum fan, and a recovery tank.

Water and detergent, from the solution tank, flow

to the floor through a solution valve to the scrub

brushes or pads. The brushes or pads scrub the

floor. As the machine is moved forward the

squeegee wipes the dirty solution off the floor,

which is then picked up and drawn into the

recovery tank.

The steering handles control the direction and

speed of the machine in forward or reverse. By

rotating the steering handles forward, the machine

propels forward. By rotating the handles towards

you, the machine propels backward.

Three different widths of scrub heads and

squeegees are available for the machine.

The scrub head widths are as follows; the model

700 (700 mm), the model 800 (800 mm), and the

model 900 (900 mm). The 700 mm squeegee is

used with the 700 model scrub head, as well as

the 800 mm with the model 800, and the 900 mm

with the model 900.

OPERAT ION

5680 330459 (3--08)

18

FaST SCRUBBING SYSTEM (OPTION)

The FaST (Foam Scrubbing T e chnology) system

operates by injecting the FaST PAK concentrate

agent (A) into the system with a small amount of

water and compressed air. This mixture creates a

large volume of expanded wet foam.

The expanded foam mixture is then dispersed

onto the floor (B) while the machine is scrubbing.

When the squeegee picks up the mixture, the

patented foaming agent has collapsed and is

recovered into the recovery tank.

The FaST system can be used with all double

scrubbing and heavy duty scrubbing applications.

Using the FaST system can increase

productivity by 30% by reducing your dump/fill

cycle. It will also reduce chemical usage and

storage space. One FaST PAK of concentrated

agent can scrub up to 1 million sq. ft.

NOTE: Do not enable the FaST system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the FaST

system. Conventional cleaning detergents/

restorers may cause failure to the FaST solution

system.

NOTE: Storage or transporting machines

equipped with FaST in freezing temperatures

requires special procedures. Check with a

TENNANT representative for advice.

B

A

The Safe Scrubbing Alternativer

OPERAT ION

19

5680 330459 (10--08)

ec- H2O SYSTEM (OPTION)

The ec--H2O (electrically converted water) system

operates by producing electrically activated water

for cleaning.

Normal water passes through a module where it is

oxygenated and charged with an electric current.

The electrically converted water changes into a

blended acidic and alkaline solution forming a

neutral pH cleaner. The converted water attacks

the dirt, breaks it into smaller particles, and pulls it

off the floor surface allowing the machine to easily

scrub away the suspended soil. The converted

water then returns to normal water in the recovery

tank.

The ec--H2O system can be used with all double

scrubbing applications.

NOTE: Do not enable the ec --H2O system with

conventional cleaning detergents in the solution

tank. Drain, raise and refill the solution tank with

clear cool water only before operating the ec--H2O

system. Conventional cleaning detergents/

restorers may cause failure to the ec--H2O

solution system.

NOTE: Storage or transporting machines

equipped with ec--H2O in freezing temperatures

requires special procedures. Check with a

TENNANT representative for advice.

OPERAT ION

5680 330459 (10--08)

20

PRE-OPERATION CHECKLIST

Check over this list of items before operating the

machine:

- Check under the machine for leaks.

- Check for wire, string, or twine wrapped

around the scrub brushes.

- Check the squeegees for wear or damage.

- Check the squeegee suction hose for

obstructions.

- Check the recovery tank cover seals for

wear or damage.

- Check that the vacuum fan inlet filter is

clean.

- FaST Scrubbing: Check the FaST PAK

(option) concentrate agent level, replace

carton as needed. See the INSTALLING

THE FaST PAK AGENT section of the

manual.

- FaST or ec- H2O Scrubbing: Check that all

conventional cleaning agents/restorers are

drained and rinsed from the solution tank.

- FaST or ec- H2O Scrubbing: Check that

solution tank is filled with clear cool water

only.

OPERAT ION

21

5680 330459 (11--05)

INSTALLING FaST PAK AGENT (OPTION)

NOTE: Machine must be equipped with the FaST

option before the FaST PAK agent can be

installed.

1. Remove the perforated knock--outs from the

FaST PAK Floor Cleaning Concentrate

carton. Do not remove the bag from the

carton. Pull out the bag’s hose connector on

the bottom of the bag and remove the hose

cap from the connector.

NOTE: The FaST PAK Floor Cleaning

Concentrate is specifically designed for use

with the FaST system scrubbing application.

NEVER use a substitute, machine damage will

result.

FOR SAFETY: When using machine,

always follow the handling instructions

on chemical container.

2. Empty the solution tank. See the DRAINING

AND CLEANING THE TANKS section of the

manual.

NOTE: When scrubbing with the FaST system

option, use clean water only. Do not add cleaning

agents in the solution tank. Conventional cleaning

agents/restorers may cause failure to the FaST

solution system..

3. .Raise the solution tank and remove the front

cover to access the FaST PAK carton.

OPERAT ION

5680 330459 (10--08)

22

4. Place the FaST PAK carton in the carton

holder under the front cover of the machine.

Connect the supply hose to the FaST PAK

bag.

NOTE: If any dried concentrate is visible on the

supply hose connector or the on the FaST PAK

connector, soak and clean with warm water.

5. Make sure to connect the supply hose onto

the hose storing plug when the supply hose

is not connected to the FaST PAK. This will

prevent the FaST solution system from

drying out and clogging up the hose.

6. When replacing an empty FaST PAK carton,

allow the new FaST PAK detergent to gravity

feed into the system for several minutes

prior to operating the FaST system. If the

detergent does not flow out of the FaST

PAK, simply squeeze and release the hose

several times. If the previous FaST PAK was

run dry, it may take up to 3 minutes of

operation to remove any air pockets in the

system before you achieve maximum

foaming.

OPERAT ION

23

5680 330459 (3--08)

STARTING THE MACHINE

1. Turn the machine power on.

FILLING THE TANKS

1. Start the machine.

2. Drive the machine to the filling site.

3. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, turn off machine, and remove

key .

OPERAT ION

5680 330459 (10--08)

24

4. CONVENTIO NAL SCRUBBING: Open the

solution tank cover and partially fill the

solution tank with water. Pour the required

amount of detergent into the solution tank fill

opening. Continue filling the solution tank

with water 25 mm (1 in) below the bottom of

the solution fill opening channel.

FOR SAFETY: When using machine,

follow mixing and handling instructions

on chemical containers.

5. FaST or ec --H2O SCRUBBING: Open the

solution tank cover and fill the solution tank

with clear cool water only.

NOTE: When cleaning using the FaST or

ec- H2O option, USE CLEAR COOL WATER

ONLY. DO NOT add cleaning agents in

solution tank. Conventional cleaning

agents/restorers may cause failure to the

system.

NOTE: (For conventional scrubbing)

Floor conditions, water condition, amount of

soilage, types of soilage, and brush action all play

an important role in determining the type and

concentration of detergent used. For specific

recommendations, contact your Tennant

representative.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

OPERAT ION

25

5680 330459 (11--05)

SCRUBBING AND BRUSH INFORMATION

D Pick up oversized debris before scrubbing.

Pick up pieces of wire, string, twine, etc.,

which could become wrapped around the

scrub brush.

D Plan the scrubbing in advance. Try to

arrange long runs with minimum stopping

and starting. Do an entire floor or section at

one time.

D Try to scrub as straight a path as possible.

Avoid bumping into posts or scraping the

sides of the machine. When scrubbing dead

end aisles, start at the closed end of the

aisle and scrub your way out. Overlap the

scrub paths by a few centimeters (inches).

D If you see poor scrubbing performance, stop

scrubbing and refer to MACHINE

TROUBLESHOOTING.

Non-scuff polypropylene scrub brush -- T h i s

brush uses a softer, general purpose

polypropylene bristle to lift lightly compacted

soilage without scuffing high-gloss coated floors.

Nylon scrub brush -- Recommended for

scrubbing coated floors. Cleans without scuffing.

Super abrasive bristle scrub brush -- Nylon

fiber impregnated with abrasive grit to remove

stains and soilage. Strong action on any surface,

performing well on buildup, grease, or tire marks.

Heavy duty stripping pad -- This black pad is for

stripping floors. Cuts through old heavy finishes

easier, to prepare the floor for re-coating.

Stripping pad -- This brown pad is for stripping

floors. Quickly and easily cuts through old finish to

prepare the floor for re-coating.

Scrubbing pad -- This blue pad is for scrubbing

floors. Removes dirt, spills and scuffs, leaving a

clean surface ready for re-coating.

Buffing pad -- This red pad is for buffing floors.

Quickly cleans and removes scuff marks while

polishing the floor to a high gloss.

Polishing pad -- This white pad is for polishing

floors. Maintains a high gloss. Use for buffing very

soft finishes and lower traffic areas, or use for

polishing soft waxes on wood floors.

07218

OPERAT ION

5680 330459 (11--05)

26

Cylindrical polypropylene scrub brush -- T h i s

cylindrical brush uses a softer, general purpose

polypropylene bristle to lift lightly compacted

soilage without scuffing high-gloss coated floors.

Cylindrical nylon scrub brush -- This cylindrical

brush is recommended for scrubbing coated

floors. Cleans without scuffing.

Cylindrical super abrasive bristle scrub brush

-- Nylon fiber impregnated with abrasive grit to

remove stains and soilage. Strong action on any

surface, performing well on buildup, grease, or tire

marks.

NOTE: Cylindrical scrub brushes must be installed

with the herringbone patterns on the brushes

pointing towards each other for best debris pick

up.

1. Start the machine.

2. Drive the machine to the area to be

scrubbed.

3. Heavy Scrub Mode only: With the scrub

head in the up position, pull out on the scrub

head strap, until the scrub head drops into

place.

OPERAT ION

27

5680 330459 (10--08)

4. FaST SCRUBBING: Press the top of the

FaST switch to start the FaST system.

NOTE: Leave the FaST switch in the

CONVENTIONAL SCRUBBING position if not

using the FaST system.

ec--H2O SCRUBBING: Press the top of the

ec--H2O switch to start the ec--H2O system.

NOTE: Leave the ec--H2O switch in the

CONVENTIONAL SCRUBBING position if not

using the ec--H2O system.

NOTE: The ec--H2O system indicator light will not

turn on until the machine starts scrubbing.

ec--H2O SCRUBBING: If an alarm sounds and

the ec--H2O system indicator light begins to blink

red, the ec--H2O module must be flushed to

resume ec--H2O operation (See ec--H2O

MODULE FLUSH PROCEDURE)

NOTE: When the alarm sounds and the light

blinks red, the machine will bypass the ec--H2O

system. To continue scrubbing, turn the ec--H2O

switch off and change over to conventional

scrubbing.

ATTENTION: (ec - H2O model) Do not allow

solution tank to run dry. ec- H2O module

failure may result if operated without water for

an extended period.

ec- H2O SYSTEM

INDICATOR LIGHT

CODE

CONDITION

Solid green Normal operation

Blinking red Flush ec--H2O module

Solid red Contact Service Center

OPERAT ION

5680 330459 (10--08)

28

5. Press the top of the scrub switch to lower

the scrub head and begin scrubbing.

6. Lower the squeegee to the floor with the

squeegee lever .

7. Adjust the solution flow to the floor as

needed.

NOTE: When using the FaST or ec--H2O system

(option), the solution flow lever is nonfunctional.

The FaST and ec--H2O system flow rates are

pre--set. The ec--H2O module has optional flow

rate settings. If solution flow adjustments are

required, contact an Authorized Service Center.

8. Drive the machine forward and scrub as

required.

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pickup.

OPERAT ION

29

5680 330459 (10--08)

DOUBLE SCRUBBING

Double scrubbing is a method for removing heavy

floor accumulations. This is done by making two

passes over the area to be cleaned with the

machine.

Double scrubbing can be performed using the

FaST SCRUBBING SYSTEM (option),

ec--H2O SCRUBBING SYSTEM (option) or

CONVENTIONAL SCRUBBING methods.

1. First, make a pass over the area scrubbing

with the squeegee up. This dispenses the

solution/foam over the area allowing the

solution/foam to soak on the floor.

NOTE: When using the FaST or ec--H2O system

(option), the solution flow lever is nonfunctional.

The FaST and ec--H2O system flow rates are

pre--set. The ec--H2O module has optional flow

rate settings. If solution flow adjustments are

required, contact an Authorized Service Center.

FOR SAFETY: When using machine, go

slow on inclines and slippery surfaces.

2. Lower the squeegee to the floor with the

squeegee lever .

3. Then make a second pass scrubbing with

the squeegee down.

OPERAT ION

5680 330459 (9--02)

30

STOP SCRUBBING

1. Release the steering handles.

2. Press the bottom of the scrub switch to stop

scrubbing and raise the scrub brushes.

3. Propel the machine forward to pick up any

solution left on the floor.

4. Raise the squeegee with the squeegee lever.

OPERAT ION

31

5680 330459 (9--02)

DRAINING AND CLEANING THE TANKS

When you are finished scrubbing, or when the

vacuum fan shuts off, signalling a full recovery

tank, the recovery tank should be drained and

cleaned. The solution tank then can be filled again

for additional scrubbing.

1. Stop scrubbing.

2. Drive the machine next to a floor drain or

sink.

3. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, turn off

machine, and remove key.

4. Set the machine parking brake.

OPERAT ION

5680 330459 (9--02)

32

5. Remove the recovery tank drain hose from

the mounting clip.

6. Remove the recovery tank drain hose plug

while holding the hose up, then slowly lower

the drain hose to the floor drain or sink.

7. Check the solution tank, and empty any

remaining solution with the solution tank

drain hose.

8. Lift the solution tank to reach the recovery

tank.

OPERAT ION

33

5680 330459 (3--08)

9. Flush out the inside of the recovery tank with

clean water.

NOTE: DO NOT use steam to clean the tank.

Excessive heat can damage the tanks and

components.

10. Rinse off the float sensor on the side of the

recovery tank.

1 1.Remove and clean the vacuum fan filter

located in the recovery tank. Clean by

shaking dust or rinsing pleats with low

pressure water. Insert the filter back in to the

recovery tank when finished.

NOTE: Be sure the vacuum filter is dry before

reinstalling it in the machine.

OPERAT ION

5680 330459 (3--08)

34

12. An optional debris screen is available for the

recovery tank entry. If your machine is

equipped with this screen, remove and clean

it daily.

13. When the recovery, and solution tanks have

completely drained, replace the drain hose

plugs. Place the drain hoses back onto the

mounting clips on the machine.

14. Pull up on the support arm and lower the

solution tank. Push the stop arm in to

completely lower the solution tank.

15. Cylindrical scrub head: Remove and clean

the debris trough. Place the trough back in

the scrub head.

OPERAT ION

35

5680 330459 (6--05)

OPERATION ON INCLINES

Drive the machine slowly on inclines.

FOR SAFETY: When using machine, go

slow on inclines and slippery surfaces.

The maximum rated climb and descent incline with

empty tanks is 8_, with full tanks is 6_.

STOP THE MACHINE

1. Stop scrubbing.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, turn off

machine, and remove key.

3. Set the machine parking brake.

OPERAT ION

5680 330459 (11--05)

36

POST-OPERATION CHECKLIST

Check over this list of items after you have

finished scrubbing with the machine powered on:

- Check the battery charge level.

NOTE: The reading on the battery discharge

indicator may not be accurate when the machine

is first powered on. Operate the machine a few

minutes before reading the charge level of the

batteries.

Check over this list of items with the machine

powered off:

- Check for wire, string, or twine wrapped

around the scrub brushes.

- Check the squeegees for wear or damage.

- Check the squeegee suction hose for

obstructions.

- Drain and clean the recovery tank.

- Clean the vacuum fan inlet filter.

- Check under the machine for leaks.

- Check the service records to determine

maintenance requirements.

- FaST scrubbing: If FaST PAK is empty after

scrubbing, install the new FaST PAK or

connect the supply hose to the storage plug.

OPERAT ION

37

5680 330459 (3--08)

MACHINE TROUBLESHOOTING

Problem Cause Remedy

Trailing water -- poor or no water

pickup

Worn squeegee blades Rotate or replace squeegee blades

Squeegee out of adjustment Adjust squeegee

Vacuum hose clogged Flush vacuum hoses

Vacuum fan screen dirty Clean inlet screen

Debris caught on squeegee Remove debris

Vacuum hose to squeegee or

recovery tank disconnected or

damaged

Reconnect or replace vacuum hose

Solution tank not completely closed

Check for obstructions

Heavy duty batteries posts too tall,

file down posts

Machine front cover mounted too

high, mount cover lower

Torn seals on s olution tank Replace seals

Vacuum fan will not turn on Recovery tank full Drain recovery tank

Foam filling recovery tank

Empty recovery tank

Use less or change detergent

Use a defoamer

Recovery tank sensor dirty or stuck Clean or replace

Vacuum fan circuit breaker tripped Reset circuit breaker

Little or no solution flow to the floor Solution tank empty Fill solution tank

Solution control cable broken or out

of adjustment

Replace and/or adjust cable

Solution flow turned off Turn solution flow on

Solution supply lines plugged Flush solution supply lines

Solution supply line filter dirty Clean filter

Solution solenoid clogged or stuck Clean or replace

Poor scrubbing performance Debris caught on scrub brushes or

pads

Remove debris

Improper detergent, brush, or pad

used

Contact Service Center

Worn scrub brush(es) or pad(s) Replace scrub brush(es) or pad(s)

Scrub brush motor circuit breaker(s)

tripped

Reset circuit breaker(s)

Reduce scrub brush down pressure

Uneven brush pressure, level scrub

head

Contact Service Center

Low battery charge Charge batteries until the charger

automatically turns off

OPERAT ION

5680 330459 (10--08)

38

Problem Cause Remedy

Poor propelling traction

Tires slip on oily or waxed floors Contact Service Center

Uneven brush down pressure Level scrub head

FaST System (option) does not

operate

FaST switch is set for Conventional

scrubbing

Set the FaST switch for FaST

system scrubbing

FaST circuit breaker tripped Determine cause and reset the 10A

circuit breaker button

Clogged FaST PAK supply hose

and/or connectors

Soak connector and hose in warm

water and clean

FaST PAK carton is empty or not

connected

Replace FaST PAK carton and/or

connect supply hose

Clogged flow control orifice and/or

screen

Remove and clean orifice and/or

screen

Faulty pump or air compressor Contact Service Center

Clogged filter screen Drain solution tank, remove and

clean filter screen

FaST system is not primed To prime, operate the FaST solution

system for 3 minutes

ec - H2O Model:

ec--H2O system indicator light

blinking red

Mineral deposit build--up in module Flush module (See ec -- H2O

MODULE FLUSH PROCEDURE)

ec - H2O Model:

Alarm sounds

ec - H2O Model:

ec--H2O system indicator light solid

red

Defective module Contact Service Center

ec - H2O Model:

ec--H2O system indicator light does

not turn on

Defective light or module Contact Service Center

ec - H2O Model:

No water flow

Clogged module Contact Service Center

Defective solution pump Replace solution pump

MAINTENANCE

39

5680 330459 (3--08)

MAINTENANCE

1

2

3

4

5

6

7

8

9

10

11

6

8

353417

MAINTENANCE CHART

Interval Key Description Procedure

Lubricant/

Fluid

No. of

Service

Points

Daily 2 Squeegee

Check for damage and wear -- 1

Check deflection and leveling -- 1

8 Scrub brushes or pads Check for damage and wear -- 2

1 Recovery tank

Clean tank -- 1

Clean float sensor -- 1

Clean vacuum fan filter -- 1

Clean debris screen (option) -- 1

3 Solution tank Clean -- 1

3 Vacuum fan filter Clean -- 1

Machine Check for leaks -- 1

6 Disk scrub head skirt Check for damage and wear -- 1

6 Cylindrical scrub head

skirts

Check adjustment -- 4

Check for damage and wear -- 4

10 FaST PAK supply hose

and connector (option)

Clean and connect hose to storing plug when not in use

-- 1

50 Hours

10 FaST Filter screen

(option)

Clean -- 1

8 Cylindrical brushes Check taper and rotate front to

rear

-- 2

100 Hours

4 Rear casters Lubricate SPL 2

11 Cylindrical scrub brush

drive belts

Check tension -- 2

MAINTENANCE

5680 330459 (3--08)

40

Interval Key Description Procedure

Lubricant/

Fluid

No. of

Service

Points

500 Hours 9 Vacuum fan motor Check motor brushes -- 1

1000

Hours

10 FaST water and air filters

(option)

Replace -- 1

7 Scrub brush motors Check motor brushes -- 2

5 Propelling motor Check motor brushes -- 1

5 Transaxle Check lubricant level GL 1

SPL -- Special lubricant, Lubriplate EMB grease (TENNANT part no. 01433--1)

GL -- SAE 90 weight gear lubricant

MAINTENANCE

41

5680 330459 (9--02)

LUBRICATION

REAR CASTERS

The rear casters each have one grease fitting on

the caster swivel. Lubricate the caster with a

grease gun containing Lubriplate EMB grease

(TENNANT part no. 01433--1) every 100 hours of

machine operation.

TRANSAXLE

Check the transaxle lubricant level every

1000 hours of operation by removing one of the

orange filler plugs. If needed, add SAE 90 weight

gear lubricant.

BA TTERIES

The batteries are unique in that they hold their

power for long periods of time. The lifetime of the

batteries is limited by the number of charges the

batteries receive. To get the most life from the

batteries, charge them when all the battery

discharge indicator segments shut off (20%

charge left). Use an automatic charger with the

proper rating for the batteries.

Periodically clean the top surface of the batteries

and the terminals, and check for loose

connections. Use a strong solution of baking soda

and water. Brush the solution sparingly over the

battery tops, terminals, and cable clamps. Do not

allow any baking soda solution to enter the

batteries. Use a wire brush to clean the terminal

posts and the cable connectors. After cleaning,

apply a coating of clear battery post protectant to

the terminals and the cable connectors. Keep the

tops of the batteries clean and dry.

MAINTENANCE

5680 330459 (9--02)

42

Keep all metallic objects off the top of the

batteries, which may cause a short circuit.

Replace any worn or damaged wires.

Never add acid to the batteries, only distilled

water. Always keep the battery caps on, except

when adding water or taking hydrometer readings.

Check the electrolyte level in each battery cell

before and after charging, and after every

50 hours of operation. Do not charge the batteries

unless the fluid is slightly above the battery plates.

If needed, add just enough distilled water to cover

the plates. Never add acid to the batteries. Do not

overfill. Always keep the battery caps on, except

when adding water or taking hydrometer readings.

Measuring the specific gravity, using a

hydrometer, is a way to determine the charge level

and condition of the batteries. If one or more of

the battery cells test lower than the other battery

cells (0.050 or more), the cell is damaged,

shorted, or is about to fail.

NOTE: Do not take readings immediately after

adding distilled water. If the water and acid are not

thoroughly mixed, the readings may not be

accurate. Check the hydrometer readings against

the following chart to determine the remaining

battery charge level:

SPECIFIC GRAVITY

at 27_ C(80_F)

BATTERY

CHARGE

1.265 100% Charged

1.223 75% Charged

1.185 50% Charged

1.148 25% Charged

1.110 Discharged

NOTE: If the readings are taken when the battery

electrolyte is any temperature other than 27_ C,

the reading must be temperature corrected. Add

or subtract to the specific gravity reading 0.004,

4 points, for each 6_ C above or below 27_C.

04380

MAINTENANCE

43

5680 330459 (9--02)

CHARGING THE BATTERIES

1. Drive the machine to a flat, dry surface in a

well-ventilated area.

2. Turn the machine power off and set the

parking brake if your machine has this

option.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Lift up the solution tank to get access to the

batteries.

NOTE: The solution tank must be empty.

4. Check the water level in all battery cells. If

the level is low, add just enough distilled

water to cover the plates. DO NOT

OVERFILL. The batteries can overflow

during charging due to expansion.

NOTE: Make sure the battery caps are in place

while charging.

FOR SAFETY: When maintaining or

servicing machine, avoid contact with

battery acid.

5. Plug the charger connector into the battery

connector.

WARNING: Batteries emit hydrogen

gas. Explosion or fire can result. Keep

sparks and open flame away. Keep

covers open when charging.

6. Plug the battery charger into the wall outlet.

MAINTENANCE

5680 330459 (9--02)

44

NOTE: If the red “ABNORMAL CYCLE” lamp

lights when the TENNANT charger is plugged into

a wall outlet, the charger cannot charge the

battery and there is something wrong with the

battery.

7. The TENNANT charger will start

automatically. When the batteries are fully

charged, the TENNANT charger will

automatically turn off.

8. After the charger has turned off, unplug the

charger from the wall outlet.

9. Unplug the charger connector from the

battery connector on the machine.

FOR SAFETY: When maintaining or

servicing machine, avoid contact with

battery acid.

10. Check the electrolyte level in each battery

cell after charging. If needed, add distilled

water to raise the electrolyte level to about

12 mm below the bottom of the sight tubes.

1 1. Lower the solution tank.

12. Pull up on the support arm and rotate the

stop arm out of the way to allow the solution

tank to close completely.

ELECTRIC MOTORS

The carbon brushes on the vacuum fan motor

should be inspected after every 500 hours of

machine operation. The carbon brushes on the

scrub brush motors and propelling motor should

be inspected after every 1000 hours of machine

operation. The carbon brushes on the scrub brush

motors,and propelling motor should be inspected

after every 1000 hours of machine operation.

MAINTENANCE

45

5680 330459 (11--05)

SCRUB HEAD

The machine is equipped with a disk brush scrub

head. The scrub head contains skirts to control

over-spray from the scrub brushes.

DISK BRUSH SCRUB HEAD SKIRT

Make sure the scrub head skirt touches the floor

all the way around when the scrub head is

lowered. Check the skirt for damage or wear daily.

NOTE: Replace the scrub head skirt when it is

damaged or no longer is able to touch the floor.

CYLINDRICAL BRUSH SCRUB HEAD SKIRTS

The four head skirts should just touch the floor.

Check the skirts for damage or wear daily.

ADJUSTING THE SCRUB HEAD SKIRTS

1. Lower the scrub head on a level floor.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, and turn off machine.

3. Check to see if the scrub head skirts touch

the floor.

4. If any of the skirts needs adjusting, loosen

the retainer strip hardware and slide the skirt

to the proper adjustment. Tighten the

retainer strip hardware.

REPLACING THE SCRUB HEAD SKIRTS

1. Raise the scrub head.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, and turn off machine.

3. Remove the retainer strip and hardware.

4. Replace the old skirt with a new skirt and

mount in place with the retainer strip and

hardware.

MAINTENANCE

5680 330459 (6--05)

46

REMOVING OR REPLACING THE SCRUB

HEAD

The scrub heads are available in three widths.

NOTE: When you change to a different width

scrub head, be sure to install the appropriate width

squeegee and machine front cover.

1. Lower the scrub head.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Remove the machine front cover.

MAINTENANCE

47

5680 330459 (9--02)

4. Disconnect the solution line from the scrub

head tee fitting.

5. Disconnect the wire harness from each

scrub motor.

6. Disconnect the scrub head from the guide by

removing the clevis pin.

MAINTENANCE

5680 330459 (9--02)

48

7. Disconnect the lift arms from the scrub head

by removing the two clevis pins.

8. Mark the location of the actuator tube on the

actuator shaft before disconnecting the

actuator. Disconnect the actuator from the

scrub head by removing the clevis pin.

9. To install the scrub head, connect the lift

arms to the scrub head with the two clevis

pins.

10. Connect the scrub head to the guide with the

clevis pin.

1 1. Make sure the actuator tube lines up with the

mark made earlier on the actuator shaft. If

not, turn the actuator tube until it does.

Connect the actuator to the scrub head with

the clevis pin.

12. Connect the wire harness.

13. Connect the solution line to the scrub head

tee fitting.

MAINTENANCE

49

5680 330459 (11--05)

LEVELING THE SCRUB HEAD

1. Make sure the scrub head is lowered to the

floor.

2. Check the level of the scrub head by

measuring the distance from the top of the

scrub head, to the floor at all four corners.

The scrub head should measure the same

on all four corners.

3. If the scrub head is not level at all four

corners, loosen the jam nut on the

adjustment screw located on the top of the

scrub head. Turn the adjustment screw until

the scrub head measures level. Tighten the

jam nut.

4. Install the machine front cover.

5. Cylindrical scrub head: Check the brush

pattern as described in CHECKING AND

ADJUSTING CYLINDRICAL BRUSH

PATTERN.

MAINTENANCE

5680 330459 (9--02)

50

SCRUB BRUSHES AND P ADS

The scrub brushes should be checked daily for

wire or string tangled around the brush or drive

hub. The brushes should also be checked for any

damage and wear.

DISK BRUSHES

The disk brushes should be replaced if large

amounts of bristles are missing, or if the remaining

bristles’ length is less than 10 mm.

Cleaning pads must be placed on pad drives

before they are ready to use. The cleaning pad is

held in place by a pad holder.

Cleaning pads need to be cleaned immediately

after using with soap and water. Do not wash the

pads with a pressure washer. Hang dry pads, or

lie flat to dry.

NOTE: Be sure to replace brushes and pads in

sets. Otherwise one brush or pad will be more

aggressive than the other.

REPLACING THE DISK BRUSHES OR PADS

1. Raise the scrub head.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Open the access cover on either corner of

the scrub head.

MAINTENANCE

51

5680 330459 (9--02)

4. Turn the brush/pad driver until you can see

the brush spring clip.

5. Press the spring clip together with your

thumb and index finger. The brush/pad driver

will drop off the drive hub.

6. Pull the brush/pad driver out from under the

scrub head.

MAINTENANCE

5680 330459 (9--02)

52

7. PAD DRIVER ONLY: Turn the pad driver

over to access the spring clip underneath.

8. Press the spring clip together with your

thumb and index finger to remove the center

disk.

9. Flip or replace the scrub pad, center the

scrub pad on the pad driver.

MAINTENANCE

53

5680 330459 (6--00)

10.Replace the center disk to secure the pad in

place on the driver.

1 1. Place the new scrub brush/pad driver on the

floor in front of the scrub head. Push the

brush under the scrub head.

12. Line up the drive socket with the drive plug.

13. Lift the scrub brush/pad driver assembly into

the drive plug.

14. Check to make sure the brush/pad driver

assembly is securely mounted on the brush

drive hub.

15. Close the scrub head access cover.

16. Repeat for the other brush/pad driver.

MAINTENANCE

5680 330459 (11--05)

54

CYLINDRICAL BRUSHES

Check the brush taper and rotate the brushes

from front-to-rear every 50 hours of operation, for

maximum brush life and best scrubbing

performance.

The cylinder brushes should be replaced if large

amounts of bristles are missing, or if the remaining

bristles’ length is less than 10 mm

(0.38 in).

NOTE: Be sure to replace brushes in sets.

Otherwise one brush will be more aggressive than

the other.

REPLACING THE CYLINDRICAL BRUSHES

1. Raise the scrub head.

2. Turn the machine power off and set the

parking brake if your machine has this

option.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, and turn off machine.

3. Push down on the mounting spring and the

idler door, then pull out on the bottom of the

door. Push down on the spring until the door

releases from the scrub head. Pull the idle

plug off the brush.

4. Pull the brush out of the scrub head.

5. With the double row end of the brush

towards you, guide the brush onto the drive

hub.

NOTE: Use the double rows on the idler end of

the brush.

MAINTENANCE

55

5680 330459 (11--05)

6. Insert the Idler plug of the idler door into the

brush.

7. Push down on the door to catch the door in

the scrub head, then pull up on the door to

latch it in the spring.

8. Repeat for the other brush on the other side

of the scrub head.

NOTE: The idler doors have stamped letters that

correspond with letters on the scrub head. Make

sure the idler doors are placed back on the same

side of the scrub head that they were originally

removed from.

CHECKING AND ADJUSTING CYLINDRICAL

BRUSH PATTERN

NOTE: Check the tires for correct tire pressure

and make sure the solution tank is full before

checking or adjusting the brush pattern.

1. Apply chalk, or some other material that will

not blow easily away, to a smooth, level

floor.

2. Raise the scrub head. Position the scrub

head over the chalked area.

3. Set the parking brake if your machine has

this option.

4. Lower the scrub head for 15 to 20 seconds

while keeping the scrub head in one spot in

the chalked area.

NOTE: If chalk or other material is not available,

allow the brushes to spin on the floor for two

minutes. A polish mark will remain on the floor.

5. Raise the scrub head and move the machine

away from the chalked area. Turn the

machine power off.

MAINTENANCE

5680 330459 (11--05)

56

6. Observe the shape of the brush patterns. If

the brush patterns have parallel sides, the

brushes do not need taper adjustment.

If one or both of the brush patterns are

tapered, the brushes will have to be adjusted

to straighten the brush pattern.

A. Remove the idler door by pushing down

on the mounting spring and the idler

door, then pulling out on the bottom of

the door. Push down on the spring until

the door releases from the scrub head.

Pulltheidleplugoffthebrush.

B. While holding the flat end of the idler

shaft with a wrench, loosen the

mounting screw on the outside of the

idler door.

10355

10356

MAINTENANCE

57

5680 330459 (03--08)

C. Turn the idler shaft to raise or lower the

end of the brush as needed to

straighten the brush pattern. Tighten the

mounting screw.

D. Check the brush patterns again and

readjust as necessary.

The brush patterns should be the same

width. If one is narrower then the other,

loosen the jam nut on the adjustment screw

located on the top of the scrub head.

Turn the adjustment screw clockwise to

increase the front brush pattern width. T urn

the adjustment screw counter-clockwise to

increase the back brush pattern width.

Check the brush patterns again. Adjust until

the front and back patterns are the same

width.

Tighten the jam nut.

SOLUTION SYSTEM

RECOVERY TANK

The recovery tank stores recovered solution. The

recovery tank should be drained and cleaned

daily. The outside of the tank can be cleaned with

vinyl cleaner.

NOTE: DO NOT use steam to clean the tank.

Excessive heat can damage the tanks and

components.

MAINTENANCE

5680 330459 (3--08)

58

Rinse and wipe off the sensors daily on machines

with float sensors installed inside the recovery

tank.

A vacuum fan filter is located in the recovery tank.

Remove and clean this filter daily. Clean by

shaking dust or rinsing pleats with low pressure

water.

NOTE: Be sure the vacuum filter is dry before

reinstalling it in the machine.

An optional debris screen is available for the

recovery tank entry. If your machine is equipped

with this screen, remove and clean it daily.

SOLUTION TANK

The solution tank stores the cleaning solution.

The solution tank does not require regular

maintenance. If deposits form on the bottom of the

tank, rinse the tank with a strong blast of warm

water. The tank can be flushed through the fill

opening and top access hole.

The solution tank contains one standard solution

line filter. If the filter becomes dirty, the solution

flow will be reduced. Check and clean these filters

if necessary.

NOTE: DO NOT use steam to clean the tank.

Excessive heat can damage the tanks and

components.

MAINTENANCE

59

5680 330459 (3--08)

FaST SYSTEM (OPTION)

FaST SYSTEM MAINTENANCE

Every 1000 hours replace the water filter and air

filter located in the FaST detergent injector. Order

filter kit p/n 9003009.

To access the detergent injector assembly, lower

the scrub head and remove the front cover.

Remove the injector assembly from clamps.

Replace the water and air filter. An 8mm hex

wrench required to install new water filter.

Water Filter

(50 Mesh/Brown)

Air Filter

(50 Mesh/Brown)

MAINTENANCE

5680 330459 (3--08)

60

FaST SYSTEM FILTER SCREEN

The FaST system filter screen is located under

the solution tank and filters the water from the

solution tank as it flows into the FaST system.

Remove the filter screen bowl and clean the filter

screen after every 50 hours of machine operation.

Empty the solution tank before removing the filter.

FaST SUPPLY HOSE CONNECTOR

The FaST supply hose connector is located below

the FaST PAK holder. Soak the connector in warm

water if detergent buildup is visible. When a FaST

PAK carton is not installed, store the supply hose

connector on the storing plug to prevent the hose

from clogging.

MAINTENANCE

61

5680 330459 (10--08)

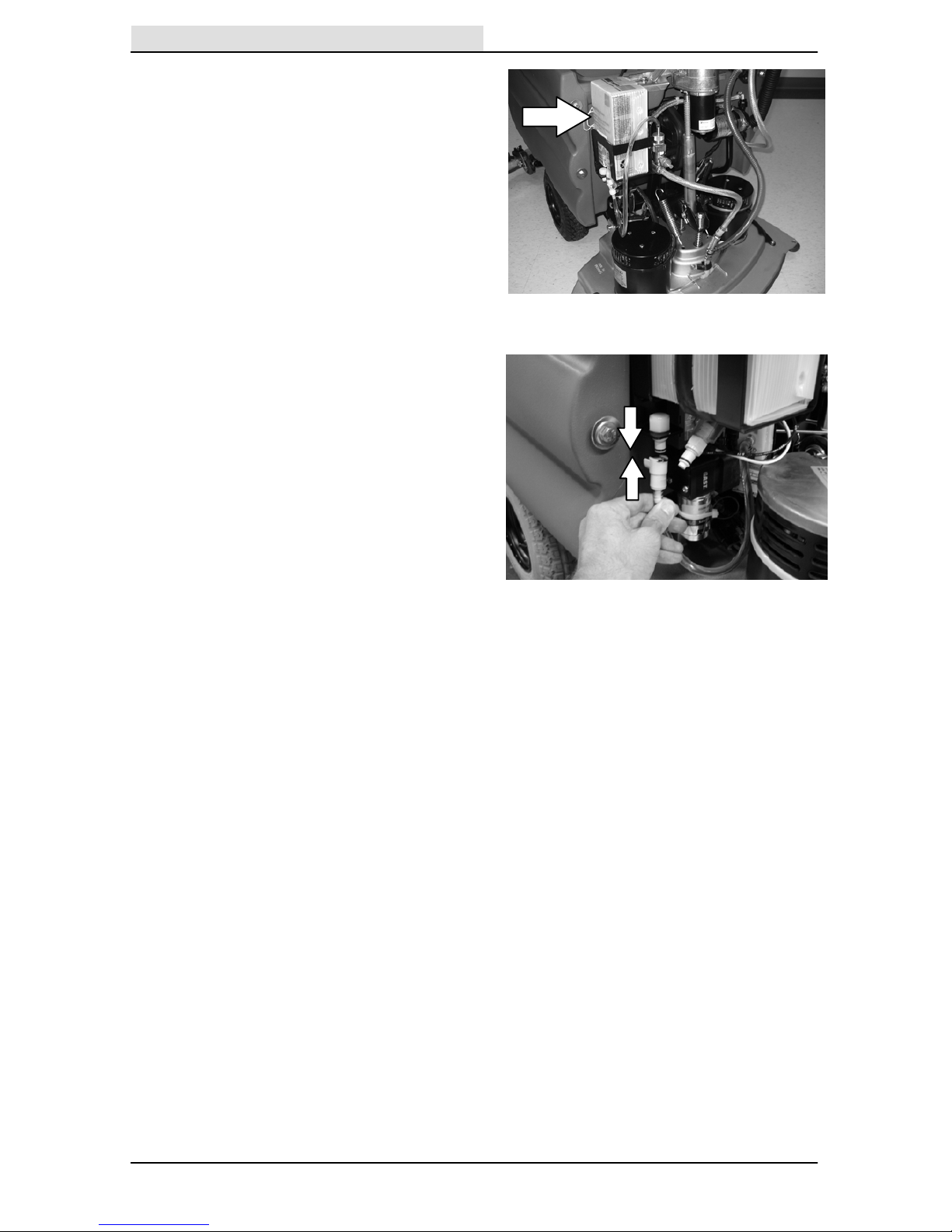

ec- H2O SYSTEM (OPTION)

ec- H2O MODULE FLUSH PROCEDURE

This procedure is only required when an alarm

sounds and the ec--H2O system indicator light

begins to blink red.

1. Drain the solution tank and recovery tank of

all water .

2. Pour 2 gallons (8 liters) of white or rice

vinegar into the solution tank at full strength.

Do not dilute.

(p/n 1050552 -- Vinegar, 2.5 gals/10 ltrs)

NOTE: Use white or rice vinegar only. The

acidity level should be between 4--8%. Do not use

other acids for this procedure.

FOR SAFETY: When servicing machine, wear

protective gloves and eye protection when

handling vinegar.

3. Disconnect the black connector fitting at the

scrub head and place the hose into a bucket.

To access the connector fitting, you may

have to remove the front cover from the

machine.

4. Turn the key to the on position.

5. Press and release the ec--H2O module flush

switch to start the flush cycle. The module is

located behind the front cover.

NOTE: The module will automatically shut off

when the flush cycle is complete (approx. 7

minutes). The module must run the full 7 minute

cycle in order to reset the system indicator light

and alarm.

Repeat flush procedure if the ec-- H2O

module does not reset. If module fails to

reset, contact an Authorized Service Center.

MAINTENANCE

5680 330459 (9--06)

62

SQUEEGEE

The squeegee assembly channels water into the

vacuum fan suction. The front blade channels the

water, and the rear blade wipes the floor.

Check the squeegee blades for damage and wear

daily. Rotate or replace either of the squeegee

blades if the leading edge is torn or worn half-way

through the thickness of the blade.

The squeegee can be adjusted for leveling and

deflection. The deflection and leveling of the

squeegee blades should be checked daily, or

when scrubbing a different type of floor.

The squeegee assembly can be removed from the

squeegee pivot to prevent damage during

transport of the machine, or when changing to a

different squeegee width. The squeegees are

available in three widths to be used with the three

different model scrub heads; model 700 (700 mm),

model 800 (800 mm), and model 900 (900 mm).

REMOVING THE SQUEEGEE ASSEMBLY

1. Raise the squeegee.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Remove the squeegee suction hose from the

squeegee.

MAINTENANCE

63

5680 330459 (9--06)

4. Loosen the two mounting knobs.

5. Pull the squeegee off the machine.

INSTALLING THE SQUEEGEE ASSEMBLY

1. Make sure the squeegee is raised.

2. Place the squeegee under the squeegee

pivot.

3. Slide the squeegee frame onto the squeegee

pivot.

4. Tighten the mounting knobs.

5. Push the squeegee suction hose on the

squeegee.

LEVELING THE SQUEEGEE

Leveling of the squeegee assures even contact

the length of the squeegee blade with the surface

being scrubbed. Make sure this adjustment is

done on an even, level floor.

1. Turn the machine power on.

2. Lower the squeegee.

3. Drive the machine forward, then turn the

machine power off.

4. Look at the deflection of the squeegee blade,

over the full length of the squeegee blade.

MAINTENANCE

5680 330459 (9--06)

64

5. If the deflection is not the same over the full

length of the blade, turn the squeegee

leveling bolt counter-clockwise to increase

the deflection at the ends of the squeegee.

Turn the squeegee leveling bolt clockwise to

decrease the deflection at the ends of the

squeegee blade.

6. Drive the machine forward again with the

squeegee down to check the squeegee

blade deflection.

7. Readjust the squeegee blade deflection if

necessary.

ADJUSTING SQUEEGEE BLADE DEFLECTION

Deflection is the amount of curl the squeegee

blade has when the machine moves forward with

the squeegee lowered to the floor. The best

deflection is when the squeegee wipes the floor

just dry with a minimum amount of deflection.

1. Turn the machine power on.

2. Lower the squeegee.

3. Drive the machine forward, and look at the

deflection of the squeegee blade. The

correct amount of deflection is 12 mm for

scrubbing smooth floors and 15 mm for

rough floors.

4. Turn the machine power off.

5. To adjust the amount of deflection, turn the

squeegee deflection cams counter-clockwise

to decrease the blade deflection.

Turn the squeegee deflection cams

clockwise to increase blade deflection.

6. Drive the machine forward again to check

the squeegee blade deflection.

7. Readjust the squeegee blade deflection if

necessary.

03719

12 mm

MAINTENANCE

65

5680 330459 (9--02)

SQUEEGEE BLADES

The squeegee has two squeegee blades, the front

and back. Each blade has four wiping edges. To

use them all, start with one wiping edge. To use

the next wiping edge, rotate the blade end-for-end.

To use the next wiping edge, rotate the top edges

down, bottom edges up. To use the last edge,

rotate the blade end-for-end.

Replace any worn or damaged squeegee blades.

REPLACING OR ROT ATING THE REAR

SQUEEGEE BLADE

1. Make sure the squeegee is raised off the

floor.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Loosen the two retention knobs, one at each

end on the squeegee.

MAINTENANCE

5680 330459 (9--02)

66

4. Pull off the rear retaining band.

5. Pull off the rear squeegee blade.

6. Insert the rotated or new squeegee blade

and then insert the retainer band.

7. Tighten the two retention knobs until the

ends of the front and rear squeegee blades

touch. Do not overtighten.

MAINTENANCE

67

5680 330459 (6--05)

REPLACING OR ROT ATING THE FRONT

SQUEEGEE BLADE

1. Make sure the squeegee is raised off the

floor.

2. Turn the machine power off.

FOR SAFETY: Before leaving or

servicing machine, stop on level

surface, set parking brake, and turn off

machine.

3. Remove the squeegee from the machine.

See REMOVING THE SQUEEGEE

ASSEMBLY.

4. Remove the rear squeegee blade and

retainer. See REPLACING OR ROTATING

THE REAR SQUEEGEE BLADE.

5. Loosen the two remaining knobs on top of

the squeegee assembly.

6. Pull the retainer plate back and pull out the

front squeegee blade of the squeegee frame.

7. Insert the rotated or new squeegee blade in

the squeegee frame, lining up the slots in the

blade with the tabs on the retainer plate.

8. Push the retainer plate forward. Tighten the

two outside knobs on top of the squeegee

assembly.

9. Insert the rear squeegee blade and retainer.

Tighten the two rear blade retention knobs

until the ends of the front and rear squeegee

blades touch. Do not overtighten.

10. Install the squeegee assembly on the

squeegee pivot. See INSTALLING THE

SQUEEGEE ASSEMBLY.

1 1. Adjust the squeegee blade leveling and

deflection as stated in LEVELING THE

SQUEEGEE and ADJUSTING SQUEEGEE

BLADE DEFLECTION.

MAINTENANCE

5680 330459 (11--05)

68

BELTS AND CHAINS

BRUSH DRIVE BELT

The two brush drive belts are located on the

cylindrical brush scrub head. The belts drive the

cylindrical brushes. Proper new belt tension is a 3

mm (0.1 in) deflection from a force of 1.37 to 1.48

kg (3.0 to 3.26 lb) at the belt midpoint.

When reusing an old belt, measure and record the

belt tension before removal, so that the belt can

be reinstalled at the same tension.

If the old belt tension was not recorded, the

recommended force per old belts is

1.03 to 1.14 kg (2.28 to 2.52 lb) with a deflection

of 3 mm (0.1 in).

Check the belt tension and wear every 100 hours

of operation.

STATIC DRAG CHAIN

A static drag chain prevents the buildup of static

electricity in the machine. The chain is attached to

the transaxle.

Make sure the chain is always touching the floor.

TIRES

The standard front tires are foam filled.

The front wheel lug nuts should be tightened to

102 to 115 Nm.

MAINTENANCE

69

5680 330459 (9--02)

PUSHING AND TRANSPORTING THE

MACHINE

PUSHING THE MACHINE

If the machine becomes disabled, it can be

pushed if necessary.

Unplug the drive motor from the electrical harness

before attempting to push a disabled machine.

The machine will become easier to maneuver

when it is unplugged.

ATTENTION! Do not push the machine

for a long distance and without

unplugging the drive motor or damage

may occur to the propelling system.

Only push a disabled machine for a very short

distance and do not exceed 3.2 kp/h. It is NOT

intended to be pushed for a long distance or at a

high speed.

TRANSPORTING THE MACHINE

1. Position the rear of the machine at the

loading edge of the truck or trailer.

FOR SAFETY: Use truck or trailer that

will support the weight of the machine.

NOTE: Empty the recovery and solution tanks

before transporting the machine.

2. If the loading surface is not horizontal or is

higher than 380 mm from the ground, use a

winch to load machine.

If the loading surface is horizontal AND is

380 mm or less from the ground, the

machine may be pushed onto the truck or

trailer.

3. To winch the machine onto the truck or

trailer, attach the winching chains to the rear

tie down locations on either side of the

machine frame by the rear casters.

MAINTENANCE

5680 330459 (9--02)

70

4. Unplug the drive motor from the electrical

harness before attempting to winch the

machine. The machine will become easier to

maneuver when it is unplugged.

5. Position the machine onto the truck or trailer

as far as possible. If the machine starts to

veer off the centerline of the truck or trailer,

stop and straighten the machine.

6. Lower the scrub head with the brushes or

pad drivers installed, lower the squeegee

when transporting the machine. Block the

machine tires and tie down the machine to

the truck or trailer before transporting.

NOTE: Do not use the steering handles to

secure the machine for transport.

Secure a strap over the top of the machine

to prevent the machine from tipping.

The rear tie-down locations are on either

side of the machine frame by the rear

casters.

7. If the loading surface is not horizontal or is

higher than 380 mm from the ground, use a

winch to unload machine.

If the loading surface is horizontal AND is

380 mm or less from the ground, the

machine may be pushed off the truck or

trailer.

FOR SAFETY: When unloading machine

off truck or trailer, use winch. Do not