Clemas & Co C50, 50B Operator's Manual

C50 50B

SCRUBBER DRYER

OPERATOR MANUAL

Clemas & Co. Unit 5 Ashchurch Business Centre, Alexandra Way, Tewkesbury,

Gloucestershire, GL20 8NB.

Tel: 01684 850777 Fax: 01684 850707

Email: info@clemas.co.uk Web: www.clemas.co.uk

INDEX

1.

GENERAL INFORMATION

GENERAL INFORMATIONGENERAL INFORMATION

GENERAL INFORMATION

pag.

pag.pag.

pag.

4444

1.1. Used symbols…………………….…….........................……......………………..

4444

1.2. Notes................................................…………...…………..............…...….........

4444

1.3. Manual references......…………………………....….........………….…………

4444

1.4. Warranty..............................................................…………...…………...….…...........

4444

1.5. Conformity declaration........................................…...........………….…...………

6666

2.

SUPPORT FEATURES AND SPECIFICATIONS

SUPPORT FEATURES AND SPECIFICATIONSSUPPORT FEATURES AND SPECIFICATIONS

SUPPORT FEATURES AND SPECIFICATIONS

9999

2.1. Identification………………......…...............................….…………….….……...........

9999

2.2. Description and components….……………...……………………………….…….…....

9999

2.3. Specifications................................…........……………………….....…..........

11111111

3. SECURITY

SECURITYSECURITY

SECURITY

11115555

3.1. Correct use.…………..………....……………....…....……………….....…………........

11115555

3.2. Misuse…………………………………………………………………..…………..

11115555

3.3. Recommended equipment……………………………………………………………

11115555

3.4. Operators status..............……………….......……………...…………...............

11116666

3.5. Protection and alarm systems ……………..................…...…………............

11116666

3.6. Safety devices...............................................…………..….…....…………........

11117777

3.7. Residual dangers………………………….………………………………………………

11117777

3.8. Diagnostic signaling of safety……………………………………………………………

11118888

4.

ISTRU

ISTRUISTRU

ISTRUCTIONS FOR STARTING AND USE

CTIONS FOR STARTING AND USECTIONS FOR STARTING AND USE

CTIONS FOR STARTING AND USE

20

2020

20

4.1. Transport and handling.................….....................…....………….….….…........

20

2020

20

4.2. Storage..............................................…………….…………....................

21

2121

21

4.3. Instructions to un pack the machine...........................……………………........….....

21

2121

21

4.4. Handle the unpacked machine….….…..........………………………..……..........

21

2121

21

4.5. Installation…...............................................................………………..…….............

22

2222

22

4.5.1. Batteries installation……..........……..….......……………….…...….….........…......

22

2222

22

4.5.2. Charger installation ……………..……………………………………………

23

2323

23

4.6. Control devices………………………………………………………..

22224444

4.6.1. Control bridge version battery…………..…………………………………

22224444

4.6.2. Control bridge electric version……………………………………………………

4.7. Functionning……………………………………………………………………………..

25

2525

25

22226666

Congratulations for your choice!

FIORENTINI S.p.A. thanking you for the preference to our product, would like to remind you that

FIORENTINI’s S.p.A. production covers manufacture and marketing of industrial cleaning machines

and is currently a Leading industry in this sector .

Our tradition and competence guarantee technical quality of your choice; actually all our products are

being built first quality materials through criteria that can give reliability, solidity and functionality

satisfying every kind of customers. FIORENTINI has recently obtained the quality system certificate

conforming to the requirements of UNI EN ISO 9001:2000.

We wish therefore inviting you to contact us, unhesitatingly, for every kind of request, as technical or

commercial; we’ll be pleased to be at your disposal for any information you may need.

4.7.1. Start and preparation machine………………………………………………………...

4.7.2. Choise of detergent……………………………………………………………………..

26

2626

26

22226666

4.7.3. Regulation of driving position………………………………………………………….

22227777

4.7.4. Rudder pedal functions ……..…………………………………………………………

22225555

4.7.5. Regulation of detergent solution………………………………………………………

22226666

4.7.6. Squeegee adjustement…………………………………………………………………

22226666

4.7.7. Water discharge…………………………………………………………………………

22227777

4.7.8. Brushes replacement…………………………………………………………………..

22227777

4.7.9. Squeegee blades replacement……………………………………………………….

4.7.10 Adjust brush pressure………………………………………………………………...

33

3333

33

34

3434

34

5.

MAINTENANCE

MAINTENANCEMAINTENANCE

MAINTENANCE

35

3535

35

5.1. Maintenance tabel……………..................….....…..…………..................................

35

3535

35

5.2. Battery maintenance………………………………………………………………………

36

3636

36

5.2.1. Hydrometry……………………………………………………………………………

33336666

5.2.2. Water filling up………………………………………………………………………....

33336666

5.2.3. Charging limits………………………………………………………………………….

33336666

5.2.4. Off duty or inactive batteries………………………………………….....................

33336666

5.2.5. Batteries disposal………………………………………………………………………

33336666

5.3. Maintenance of suction motor…………………………………………………………….

33337777

5.4. Electrical equipment checking…………………………………………………………….

33338888

5.5. Table about test sto be carried out……………………………………………………….

33338888

5.6. Maintenance register……………………………………………………………………….

40

4040

40

6.

TECHNICAL ASSISTENCE

TECHNICAL ASSISTENCETECHNICAL ASSISTENCE

TECHNICAL ASSISTENCE

44441111

6.1. Servicing addresses............…………..................……………..................

44441111

6.2. Verbal claim……………………………..…………...………………….…............

44441111

GENERAL INFORMATION

GIAMPY

Rev. 00

15/02/2012

Pag. 6/43

APPLICATION MODES

In order to establish anomalies causes, so that warranty could be applied, is necessary that defective

components must be sent to FIORENTINI. Repairing or substituting works under warranty will be, by

FIORENTINI’s opinion, made in its own workshop, or by third party on place. Works on place, are supplied

with customer’s energy sources and exceptional equipment to repairing if necessary.

INTERVENTION DEMANDS

Possible intervention demands have to be addressed to the technical assistance service of FIORENTINI Co.

in writing or by phone, just after a attentive analysis of fault and of causes, so that it would be necessary to

report to the agent the following data:

• Machine model, get from the relative label (point 2.1.);

• number, get from the relative label (point 2.1.);

• detailed description of defect and the way it happened;

• controls and/or regulations made;

• code number and position of possible defective component, deduced from spare parts list;

Components recognized under warranty are delivered ex works; those ones being substituted are property of

FIORENTINI Co..

The relative label missing will involve the loss of any kind of warranty.

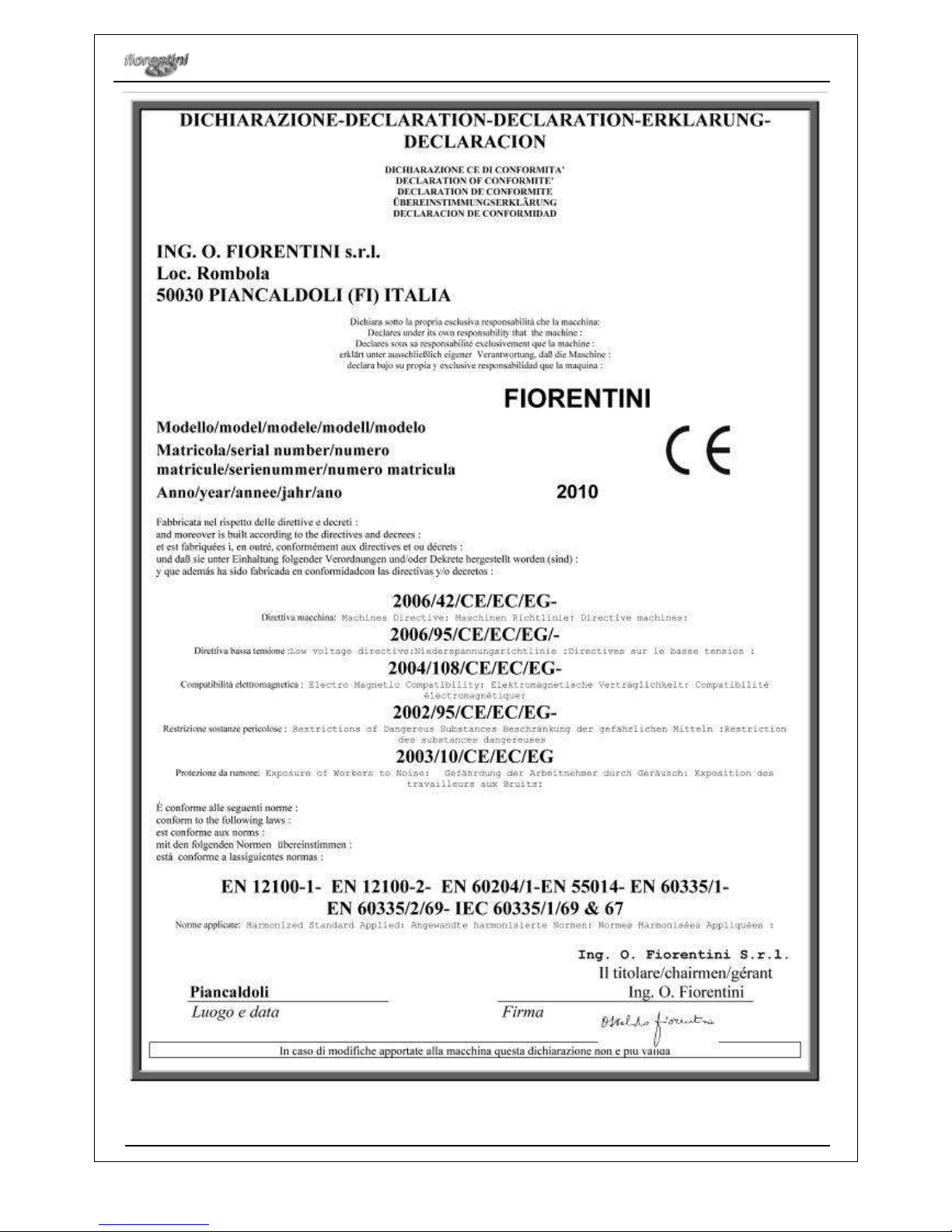

1.5. CONFORMITY DECLARATION

Conformity declaration is consigned with the support and the manual of operating and maintenance

instructions.

GENERAL INFORMATION

GIAMPY

Rev. 00

15/02/2012

Pag. 7/43

GENERAL INFORMATION

GIAMPY

Rev. 00

15/02/2012

Pag. 8/43

SUPPORT FEATURES AND SPECIFICATIONS

GIAMPY

Rev. 00

15/02/2012

Pag. 9/43

2. SUPPORT FEATURES AND SPECIFICATIONS

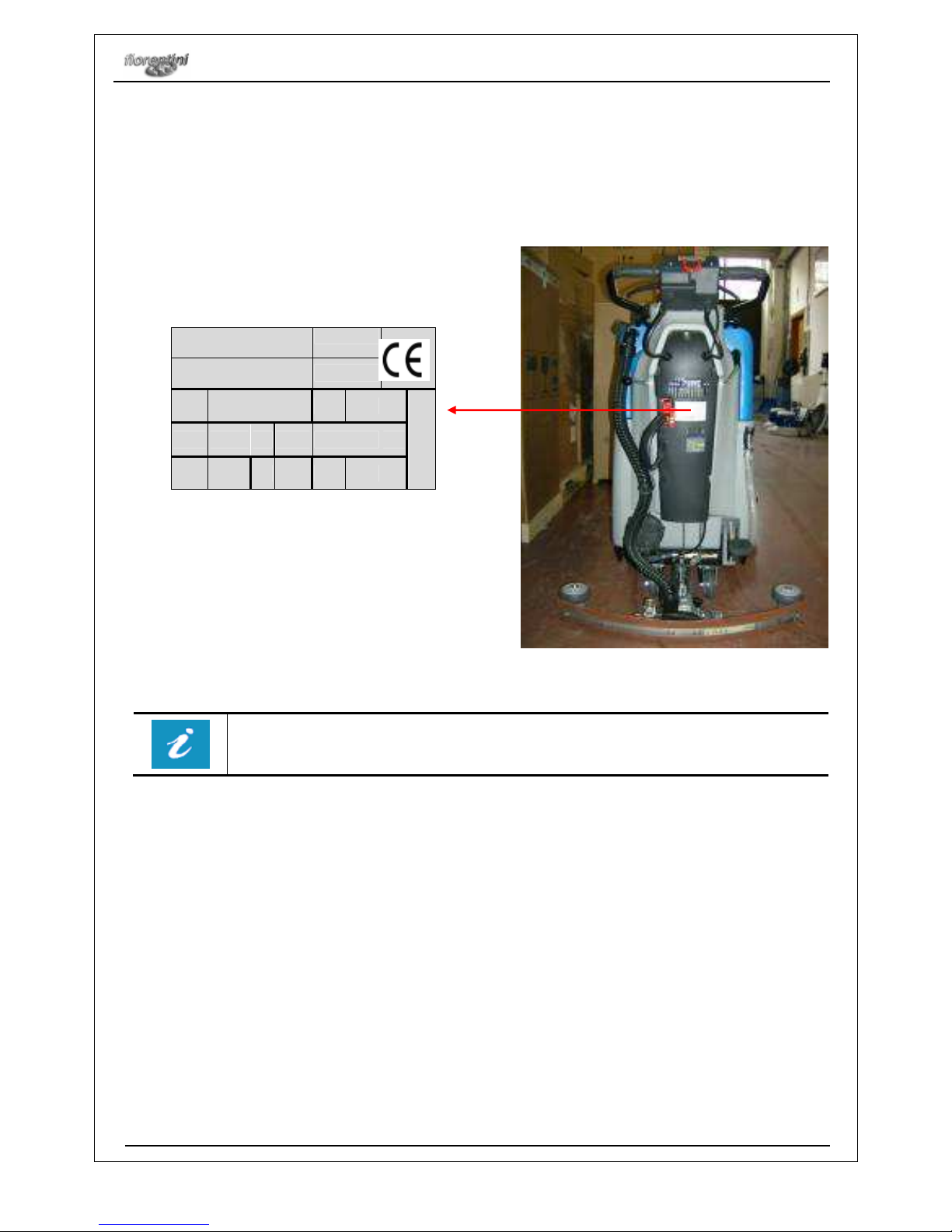

2.1. IDENTIFICATION

The autoscrubber machine can be identified with an adhesive label put on the protection carter in the

backside of the machine which will clearly report the data referring to “CE” marking.

The label has never to be removed and should be always kept legible. In case of

damaging it’s necessary to ask for a duplicate. The autoscrubber machine cannot be

commercialized without the label.

2.2. DESCRIPTION AND COMPONENTS

The autoscrubber machine Giampy has been designed for treatment of flat areas through washing and

following process of water drying. The power supply is furnished of a series of accumulator batteries, that

charge all the engines and the electrical controls.

The machine, depending on the model, can be supplied with one or two rotating brushes having in charge,

assisted by water and detergent action, to wash the areas. As the machine advances the brush in the back

(squeegee), touching the floor take the water that, at the same time, is aspired and piped in the recovery

tank.

The dashboard controls some of the functions of the machine and put at the operator’s disposal a signaling

system, through lighting leds, of the remaining charge of the battery. With the dashboard is possible to carry

out the following functions:

to start the washing brushes;

to start the suction motor;

to switch on and off the machine;

Ing. O.Fiorentini S.r.l.

MADE

50030 Piancaldoli (FI)

IN ITALY

Mod

GIAMPY

S.N.

2

0

1

2

V Hz

Kg A W

PICTURE N° 2.1

SUPPORT FEATURES AND SPECIFICATIONS

GIAMPY

Rev. 00

15/02/2012

Pag. 10/43

The bearing structure of the machine is made of a steel zinc-plated chassis or in stainless steel, so that to

avoid oxidation problems which could compromise the reliability of the machine.

The main components of the machine are:

steel zinc-plated chassis or stainless steel;

solution tank in plastic PE-HD;

recovery tank in plastic PE-HD complete with piping flexible system of suction and drainage;

a set of batteries placed in the recovery tank space;

rotating brushes;

suction system (squeegee);

one free caster-wheel;

two traction wheels;

driving unit;

FIORENTINI Co., taking care of new safety rules in CE community , has manufactured the machine following

safety and health rules of the CE normative. High quality material used, high technology and Fiorentini

experience allowed to have performing machine .

Each machine is inspected during the manufacturing time and the final check is done before shipping out the

machine.

SUPPORT FEATURES AND SPECIFICATIONS

GIAMPY

Rev. 00

15/02/2012

Pag. 11/43

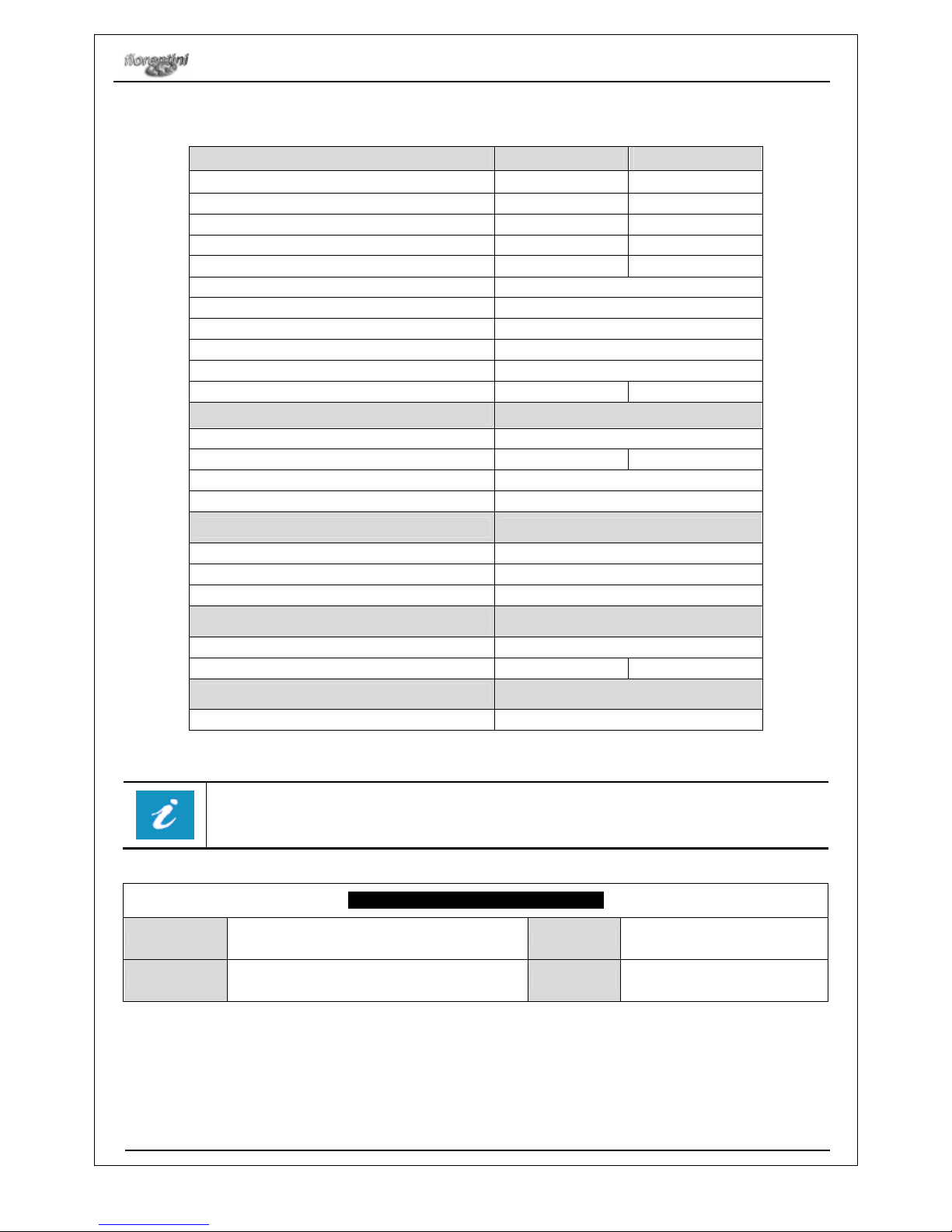

2.3. TECHNICAL DESCRIPTION

VERSION ELECTRIC AND ELETTRIC TRACTION GIAMPY20 :

DIMENSIONAL CHARACTERISTICS

GIAMPY20E GIAMPY20ET

LENGHT

1000 mm

WIDTH

550 mm

HIGHT

1080 mm

SCRUBBING BRUSH

N°1 Ø500 mm

SCRUBBING WIDTH

500 mm

SQUEEGEE WIDTH

750 mm

DRIVE

WALK-BEHIND

SOLUTION TANK CAPACITY

50 litres

RECOVERY TANK CAPACITY

50 litres

TRACTION (FRONT/REAR)

- FRONT

WEIGHT WITHOUT BATTERIES

80 Kg 85 Kg

ELECTRIC CHARACTERISTICS

VOLTAGE

220/230 V ~

BRUSH GEARMOTOR

N°1 x 230V 550W

TRACTION MOTOR

- N°1 x 24V 130W

SUCTION MOTOR

N°1 x 230V 350W

FUNCTIONAL CHARACTERISTICS

SQUEEGEE LIFT CONTROL

LEVER

VACUUM CONTROL

SWITCH

BRUSH LIFT CONTROL

SWITCH

PERFORMANCES

FORWARD RUNNING SPEED

- 0 / 4 km/h

HOUR SCRUBBING

- 2000 m²/h

ECOLOGIC CHARACTERISTICS

NOISE AT DRIVER’S EAR

72 dB

The above characteristics are not a must for the manufacturer so they can be changed

without any notice .In any case ING.O.FIORENTINI Co. Is always at disposal for any

information ( 6.1.).

MEASUREMENT UNIT CONVERSION

Lenght

1 inch = 1” = 25,4 mm

Power

1 kW = 1,36 CV = 1,34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1,8 t (°C) + 32

Pressure

1 bar =100 kPa = 14,5 psi

SUPPORT FEATURES AND SPECIFICATIONS

GIAMPY

Rev. 00

15/02/2012

Pag. 12/43

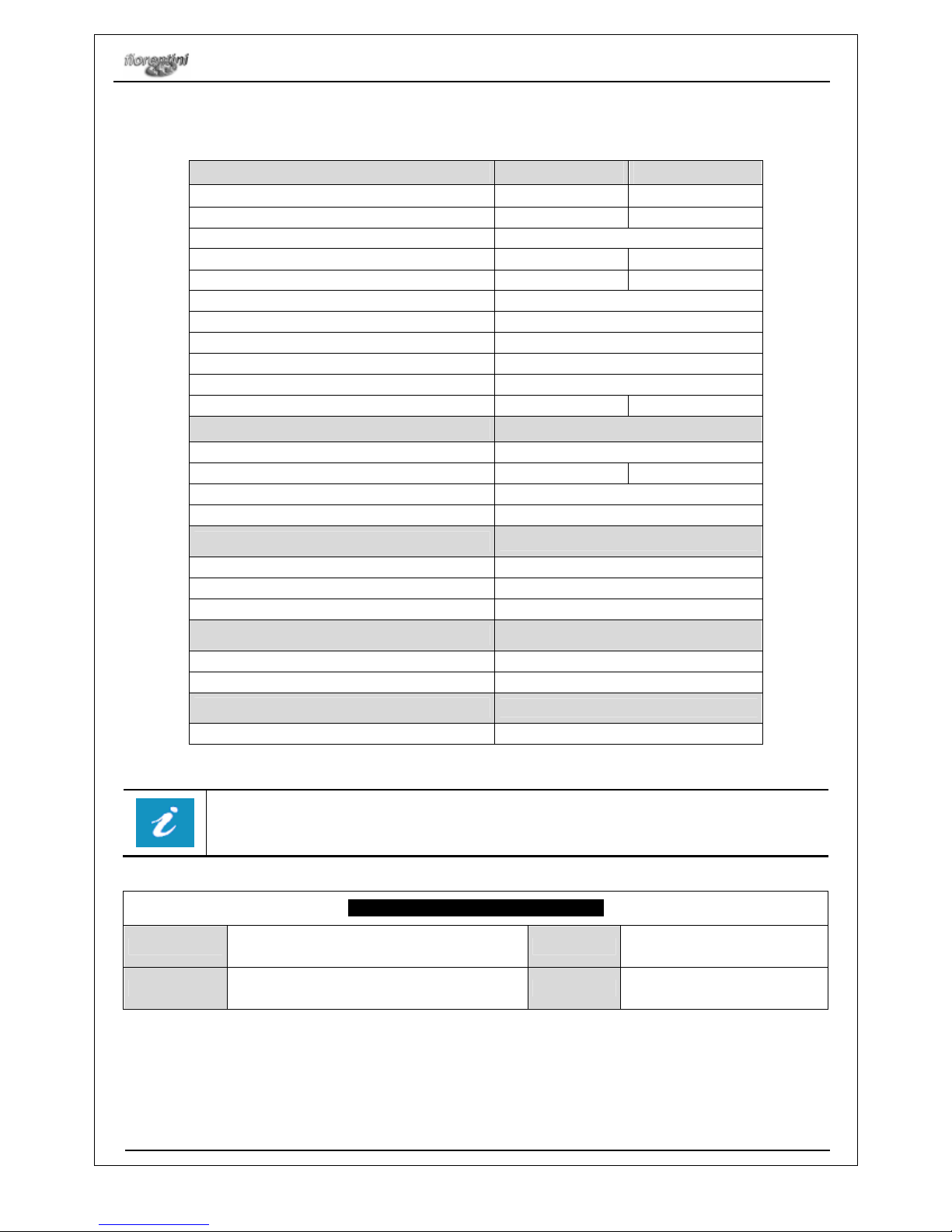

BATTERY VERSION GIAMPY20/24:

DIMENSIONAL CHARACTERISTICS

GIAMPY20B GIAMPY24B

LENGHT

1000 mm 1300 mm

WIDTH

550 mm 710 mm

HIGHT

1080 mm 1040 mm

SCRUBBING BRUSHES

N° 1 x Ø 500 mm N° 2 x Ø 305 mm

SCRUBBING WIDTH

500 mm 610 mm

SQUEEGEE WIDTH

750 mm

DRIVE

WALK-BEHIND

SOLUTION TANK CAPACITY

50 litres

RECOVERY TANK CAPACITY

50 litres

TRACTION (FRONT/REAR)

FRONT

WEIGHT WITHOUT BATTERIES

91 Kg 105 Kg

ELECTRIC CHARACTERISTICS

VOLTAGE

24 V

BRUSH GEARMOTOR

N°1 x 24V 400 W N°1 x 24V 850 W

TRACTION MOTOR

N°1 x 24V 130W

SUCTION MOTOR

24 V 550 W

FUNCTIONAL CHARACTERISTICS

SQUEEGEE LIFT CONTROL

LEVER

VACUUM CONTROL

SWITCH

BRUSH LIFT CONTROL

SWITCH

PERFORMANCES

FORWARD RUNNING SPEED

0 / 4 km/h

HOUR SCRUBBING

2000 m²/h 2400 m²/h

ECOLOGIC CHARACTERISTICS

NOISE AT DRIVER’S EAR

72 dB

The above characteristics are not a must for the manufacturer so they can be changed

without any notice .In any case ING.O.FIORENTINI Co. Is always at disposal for any

information ( 6.1.).

MEASUREMENT UNIT CONVERSION

Lenght

1 inch = 1” = 25,4 mm

Power

1 kW = 1,36 CV = 1,34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1,8 t (°C) + 32

Pressure

1 bar =100 kPa = 14,5 psi

SUPPORT FEATURES AND SPECIFICATIONS

GIAMPY

Rev. 00

15/02/2012

Pag. 13/43

BATTERY VERSION GIAMPY22 WITH 1 OR 2 BRUSHES:

The above characteristics are not a must for the manufacturer so they can be changed

without any notice .In any case ING.O.FIORENTINI Co. Is always at disposal for any

information ( 6.1.).

MEASUREMENT UNIT CONVERSION

Lenght

1 inch = 1” = 25,4 mm

Power

1 kW = 1,36 CV = 1,34 BHP

Temperature

T (K) = t (°C) + 273 / t (°F) = 1,8 t (°C) + 32

Pressure

1 bar =100 kPa = 14,5 psi

DIMENSIONAL CHARACTERISTICS

GIAMPY22/1 GIAMPY22/2

LENGHT

1350 mm 1300 mm

WIDTH

595 mm 815 mm

HIGHT

1040 mm

SCRUBBING BRUSHES

N° 1 x Ø 550 mm N° 2 x Ø 285 mm

SCRUBBING WIDTH

550 mm 550 mm

SQUEEGEE WIDTH

750 mm

DRIVE

WALK-BEHIND

SOLUTION TANK CAPACITY

50 litres

RECOVERY TANK CAPACITY

50 litres

TRACTION (FRONT/REAR)

FRONT

WEIGHT WITHOUT BATTERIES

91 Kg 105 Kg

ELECTRIC CHARACTERISTICS

VOLTAGE

24 V

BRUSH GEARMOTOR

N°1 x 24V 550 W N°2 x 24V 200 W

TRACTION MOTOR

N°1 x 24V 130W

SUCTION MOTOR

24 V 550 W

FUNCTIONAL CHARACTERISTICS

SQUEEGEE LIFT CONTROL

LEVER

VACUUM CONTROL

SWITCH

BRUSH LIFT CONTROL

SWITCH

PERFORMANCES

FORWARD RUNNING SPEED

0 / 4 km/h

HOUR SCRUBBING

2200 m²/h

ECOLOGIC CHARACTERISTICS

NOISE AT DRIVER’S EAR

72 dB

Loading...

Loading...