Cleco Tools BTSE series, mPro400GC-DGD, PDB-CPS3, PDB-CPS6, PDB-CPS9 System Handbook

...

For additional product information visit our Web site at http://www.apextoolgroup.com

mPro400GC-DGD-intelligent-spindle

BTSE series

System Handbook

P2077SB/EN

2011-09

2 P2077SB/EN 2011-09 77a_Deckblatt.fm, 06.09.2011

Notes on System Handbook

This System Handbook is the original system handbook – and

• provides important information on safe, correct and efficient operation of the system.

• describes the function and operation of the components.

• serves as a lexicon for technical data.

• It points out options.

Secondary information

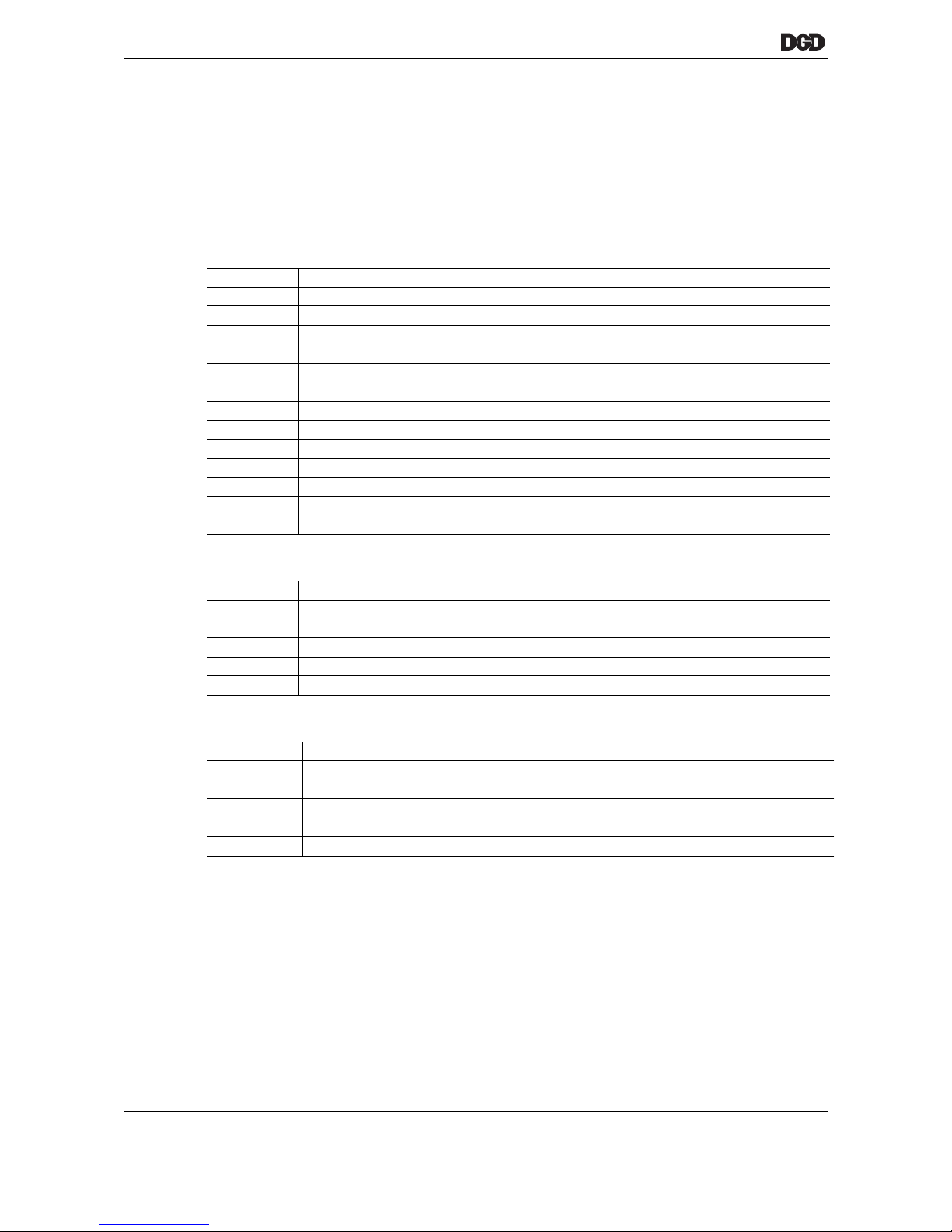

Symbols in text

Abbreviations

Copyright protection

Apex Tool Group reserves the right to modify, supplement or improve this document or the product without prior notice. This document

may not be reproduced in whole or in part in any way, shape or form, or copied to another natural or machine-readable language or to a

data carrier, whether electronic, mechanical, optical or otherwise, without the express permission of Apex Tool Group.

DGD is a trademark of Apex Tool Group Division.

P1908E Tightening torques – Assembling the DGD-intelligent-spindle components

P2074BA Operating instructions for telemetry system

P2075EL Data sheet: Transducer

P1913E Spare parts sheet: Gearing

P2080EL Spare parts sheet: Transducer

P1914E Spare parts sheet: Motor

P2085EL Tightening module spare parts sheet TSE/TUSE

P2076EL Spare parts sheet: Offset attachment

P2086MA DGD intelligent spindle assembly instructions

P2078MA Tightening module assembly instructions TSE/TUSE

P1919E Supply module assembly instructions CPS3

PL12DE-1001 Programming ManualmPro400GC

PL12DE-1004 Quick Start mPro400GC

P2079WA DGD intelligent spindle service manual

➔ Identifies instructions to be followed.

• Identifies lists.

italics Indicates menu items such as Diagnostics in software descriptions

<…> Identifies elements that have to be selected or deselected, such as buttons or control boxes, i.e. <F5>

Courier Indicates the name of paths and files, e. g. setup.exe

\ A backslash between two names indicates the selection of an item from the menu, e. g. file \ print

DGD-IS DGD intelligent spindles

PDB-CPS… Power distribution box

mPro400GC-M Nutsetter control unit

TSE/TUSE Tightening module

CP3-…-JH Transformer

CPS3 Supply module

P2077SB-EN_2011-09_m-Pro-400S-DGD-IS_BTSEIVZ.fm, 06.09.2011 P2077SB/EN 2011-09 3

Contents

1 Safety 7

1.1 Warnings and notes ....................................................................... 7

1.2 Basic requirements for safe working practices..................................... 7

1.3 Operator training................................................................................... 8

1.4 Personal protective equipment............................................................. 8

1.5 Designated use..................................................................................... 8

1.6 Ambient conditions ............................................................................... 9

1.7 EMC (Electromagnetic compatibility).................................................... 9

1.8 Noise................................................................................................... 10

2 Transport / Storage 10

3 System description 11

3.1 Components ....................................................................................... 11

4 First Operation 13

5 DGD intelligent spindles 15

5.1 General technical data........................................................................ 15

5.2 Catalogue data ................................................................................... 16

5.3 Component overview.......................................................................... 20

6 Tightening module TSE/TUSE 23

6.1 Description.......................................................................................... 24

6.2 General technical data........................................................................ 24

6.3 "Ready" LED....................................................................................... 25

6.4 Service panel...................................................................................... 25

6.5 Internal assemblies............................................................................. 27

7 Attachment 29

7.1 Centric Attachment............................................................................. 29

7.2 Offset attachment ............................................................................... 29

7.3 Angle head attachment....................................................................... 30

7.4 Spring collet – Optional....................................................................... 31

8 Transducer 33

8.1 Electrical Data..................................................................................... 34

8.2 Pin configuration of transducer........................................................... 34

4 P2077SB/EN 2011-09 P2077SB-EN_2011-09_m-Pro-400S-DGD-IS_BTSEIVZ.fm, 06.09.2011

9 Gearing 35

10 Motor 35

10.1 Technical data .................................................................................... 35

10.2 Electrical Data..................................................................................... 36

10.3 Thermal data....................................................................................... 36

10.4 Pin configuration motor connector ..................................................... 37

11 Power distribution box PDB-CPS… 39

11.1 Brief function description .................................................................... 39

11.2 General technical data........................................................................ 40

11.3 Electrical Data..................................................................................... 40

11.4 Installation........................................................................................... 41

11.5 Supply module CPS3.......................................................................... 42

11.6 Transformer........................................................................................ 47

11.7 General technical data........................................................................ 47

12 Instructions on laying cables 49

12.1 General............................................................................................... 49

12.2 Strain relief clamp............................................................................... 50

12.3 Shielding............................................................................................. 50

12.4 Laying "High-Flex Quality" cables in cable ducts................................ 51

12.5 Wiring of robot area »SuperhighFlex Quality«.................................... 52

13 Cable 53

13.1 HighFlex Quality, suitable for cable ducts........................................... 53

13.2 Super Highflex, suitable for robots...................................................... 58

14 Function description 61

14.1 Torque measurement ......................................................................... 61

15 Troubleshooting 63

15.1 Acknowledgment of Errors.................................................................. 63

15.2 DGD-IS............................................................................................... 64

15.3 Tightening module CPS3 in power distribution box PDB-CPS… ....... 65

15.4 Tightening module TSE/TUSE............................................................ 70

15.5 Nutsetter control unit mPro400GC-M ................................................. 70

16 Maintenance / Service 77

P2077SB-EN_2011-09_m-Pro-400S-DGD-IS_BTSEIVZ.fm, 06.09.2011 P2077SB/EN 2011-09 5

17 Disposal 77

6 P2077SB/EN 2011-09 P2077SB-EN_2011-09_m-Pro-400S-DGD-IS_BTSEIVZ.fm, 06.09.2011

77b_Sicherheit_bedingt-en.fm, 06.09.2011 P2077SB/EN 2011-09 7

Safety

1

1 Safety

1.1 Warnings and notes

1.2 Basic requirements for safe working practices

Only take the fastening system into service after you have read and completely understood the following

safety instructions and this document. Failure to observe the instructions below may result in electric shock,

fire and serious injuries.

WARNING!

A symbol combined with the word WARNING warns of a potentially dangerous situation for the health

of personnel, If this warning is not observed, death or serious injury may occur.

CAUTION!

A symbol combined with the word CAUTION warns of a potentially harmful situation for the health of

personnel or damage to property or the environment. If this warning is not observed, injuries, property

or environmental damage may occur.

DANGER!

A symbol combined with the word DANGER warns of an impending health risk or risk of fatal injury to

personnel. If this danger note is not adhered to, severest injury that may lead to the death of people, is

the consequence.

NOTE

This symbol indicates a general instruction.

General instructions include application tips and special useful information, but no warnings against

dangers.

DANGER!

High leakage current –

Fatal electric shock could occur!

➔ Establish a protective earth (PE) ground connection to the PDB-CPS… before taking into operation!

➔ Always disconnect the power supply before performing maintenance work on the DGD-IS and the

PDB-CPS….

➔ Always disconnect the system cable or motor cable from the PDB-CPS… or DGD-IS before making

throughput, resistance and short circuit measurements.

➔ Do not attempt to repair possible faults on the fastening system by yourself if you do not have the

required knowledge! Please consult your local service agent or the responsible Sales & Service Center

(see backside).

WARNING!

High temperature –

the motor on the DGD-IS may heat up and cause burns during removal. (max. engine temperature 80 °C).

➔ Wear gloves.

CAUTION!

Risk of flying parts.

Components of the spindle may rotate, come loose and cause injury.

➔ Avoid speed increases of over 3

m

/s² on all axes.

8 P2077SB/EN 2011-09 77b_Sicherheit_bedingt-en.fm, 06.09.2011

Safety

1

➔ We do not claim that these safety notes are complete. Read and observe all applicable, general and

local safety and accident prevention rules.

➔ Follow a safety-conscious maintenance program which takes into account the local regulations for

maintenance and servicing in all phases of operation of the fastening electronics.

1.3 Operator training

• The fastening system may only be operated by personnel that have been trained and instructed

correspondingly and authorized by the operator.

• The tightening system must only be serviced by persons who have been instructed by qualified

representatives of DGD.

• The operator must make sure that all new operating and maintenance personnel are instructed in the

operation and maintenance of the fastening system to the same extent and with the same care and

attention.

• Personnel who are being trained may only work on the fastening system under the supervision of an

experienced operator.

1.4 Personal protective equipment

When working

• Wear the protective goggles to protect against spurting metal splinters.

Danger of injury by being wound up in and caught by machinery

• Wear close-fitting clothing.

• Do not wear jewelry.

1.5 Designated use

The owner is responsible for using the machine according to its designated use.

The fastening system may be used only under the following conditions:

• Industrial environment EMC limit class value A, DIN EN 55 0081-2.

• The DGD-IS is designed for stationary operation only and is intended exclusively for fastening and

loosening thread connections. Do not use as a hand-held tool.

• Only use the DGD-IS in conjunction with the power distribution box PDB-CPS… and the nutsetter

control unit mPro400GC-M.

• The DGD-IS must be fully assembled. Insert and lock all connecting cables.

CAUTION!

Work area

➔ Close all safety devices.

➔ Ensure that there is enough space in the work area.

➔ Keep the work area clean.

Electrical safety

➔ Only operate the tightening system indoors.

➔ Observe the safety notes on the DGD-IS.

Safe working with and around fastening tools

➔ Inspect screw bits and retaining ring for visible damage and cracks.

Replace damaged parts immediately.

➔ Always disconnect the power supply to the DGD-IS before changing screw bits.

➔ Only use screw bits for machine-controlled fastening tools.

➔ Make sure that the screw bits are retained securely.

77b_Sicherheit_bedingt-en.fm, 06.09.2011 P2077SB/EN 2011-09 9

Safety

1

• Secure the DGD-IS to an electroconductive mounting plate.

• Only cable types approved by DGD may be used.

• Only accessory parts approved by DGD may be used.

• Unauthorized alterations, repairs and modifications are prohibited for reasons of safety and product

liability.

• Only operate the tightening system indoors.

1.6 Ambient conditions

Do not operate the fastening system in an explosive atmosphere.

1.7 EMC (Electromagnetic compatibility)

• The tool complies with the following applicable EMC standards:

- DIN EN 61 000-3-2

- DIN EN 61 000-3-3

- DIN EN 61 000-6-2

- DIN EN 61 000-6-4

• The filters required to fulfill the EMC standards are integrated in the system components.

• Shielded cables offer protection against irradiating and radiating interference.

• All cable shields are connected to the shield terminals on the nutsetter control unit and the plug casing

on the DGD-IS.

NOTE

➔ Always remove the complete DGD-IS from a unit.

➔ A repair is only permitted by DGD authorized personnel. If repair is required, send the complete

DGD-IS to Sales & Service Center (see backside).

➔ Do not open the transducer, offset attachment or angle head attachment as this will void the

warranty. A repair is only permitted by DGD authorized personnel. If repair is required, send the

complete component to Sales & Service Center.

➔ Do not open the TSE/TUSE or CPS3 as this will void the warranty.

This does not include the service panel. A repair is only permitted by DGD authorized personnel. If

repair is required, send the complete component to Sales & Service Center.

➔ Read the following documents when replacing the DGD-IS

• This System Handbook (see 16 Maintenance / Service, page 77)

• Service Manual DGD-IS

• Assembly instructions DGD-IS

• Spare part sheets

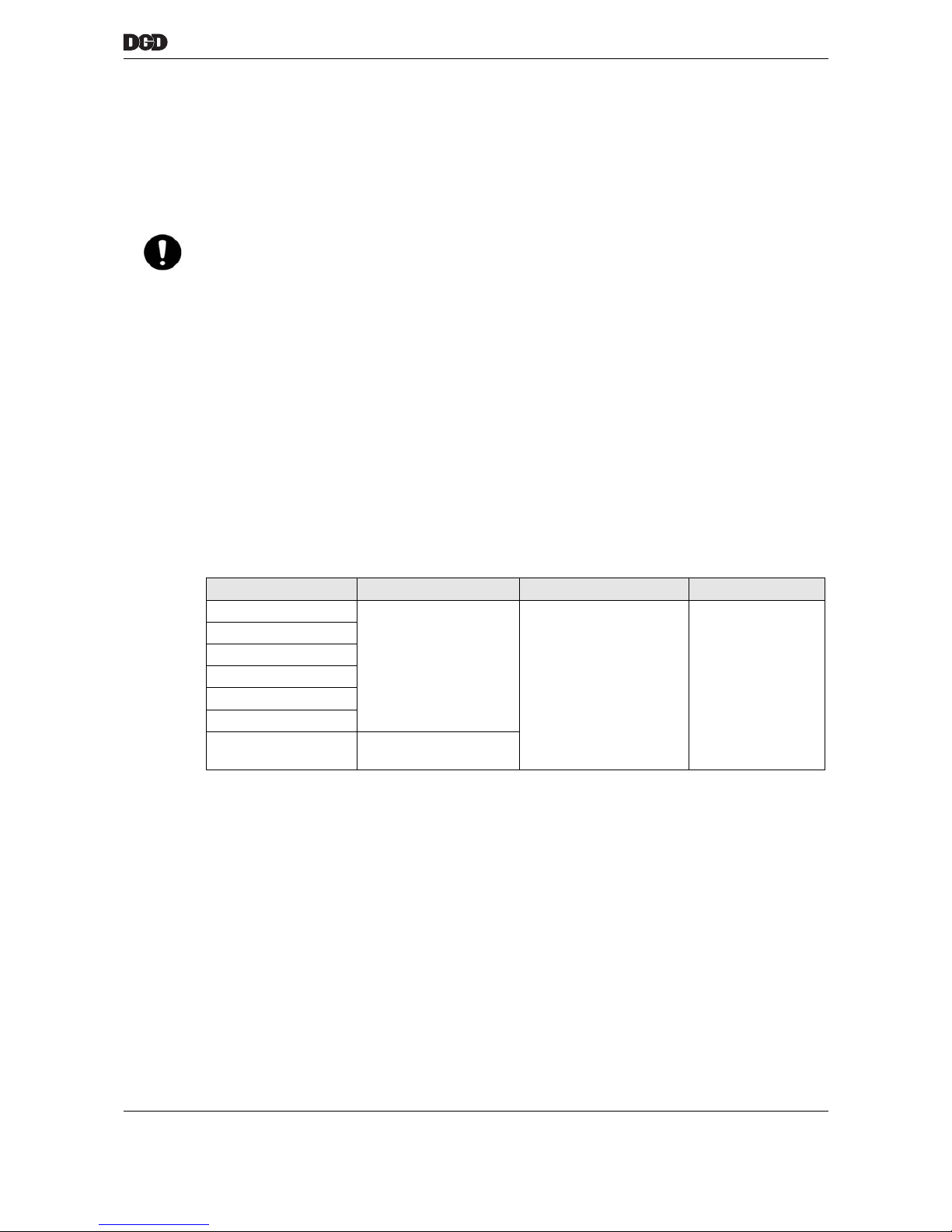

System components Ambient temperature Relative humidity Working height

DGD-IS

32 to 113 °F

(0 to 45 °C)

0 to 90 %

no condensation

up to 3000 m above

sea level

mPro400GC-M

PDB-CPS…

CP3-…-JH

TSE/TUSE

Motor

CPS3 32 to 158 °F

(0 to 70 °C)

10 P2077SB/EN 2011-09 77b_Sicherheit_bedingt-en.fm, 06.09.2011

Transport / Storage

2

1.8 Noise

Measured sound pressure level at idling speed (no load) / clockwise rotation in accordance with ISO 3744.

2 Transport / Storage

• Transport only in the original packing.

• If the package is damaged, check the part for visible damage.

Inform the carrier or DGD if necessary.

NOTE Equipment from EMC limit class value A, DIN EN 55 0081-2.

This equipment may cause radio interference in residential areas. Should this occur, you may request

that the operator pay for and implement relevant EMC measures.

DGD-IS dB(A)

1B(U)TSE-1B012A-… 72

1B(U)TSE-1B035A-… 72

1B(U)TSE-1B060A-… 67

2B(U)TSE-2B110A-… 71

2B(U)TSE-2B200A-… 67

3B(U)TSE-3B300A-… 66

4B(U)TSE-4B500A-… 66

4B(U)TSE-4B660A-… 66

System components Storage temperature Relative humidity

DGD-IS

-20 to 70 °C

0 to 90 %

no condensation

PDB-CPS…

TSE/TUSE

Motor

CPS3 -25 to 70 °C

77c_Systembeschreibung-en.fm, 06.09.2011 P2077SB/EN 2011-09 11

System description

3

3 System description

The system design is determined by the size and quantity of DGD-IS used and always varies depending on

the individual situation. These components can be combined with one another in various sizes.

This chapter includes a brief description of the components. Each respective chapter contains separate

technical details.

Special features of the fastening system mPro400GC-DGD-intelligent-spindle

In the mPro400GC-DGD-intelligent-spindle fastening system, the tightening modules are no longer installed

in a control cabinet, but directly on the built-in nutsetter, see system "m-Pro-400-tm" with single cable solution.

The intermediate circuit voltage was increased from 320 VDC to 380 VDC compared to the "TM" tightening

modules. This increased the maximum speed of the built-in nutsetter by 20 %.

3.1 Components

77_system.png

1

Item Designation

1 Nutsetter control unit mPro400GC-M

2 ARCNET cable Order no. 960950-××× (××× = length in dm)

3 Mains cable, 3×480 VAC

4 Transformer CP3-…JH

5 Power distribution box PDB-CPS…

6 DGD-IS

7 ARCNET terminator

8 System cable, type A

9 System cable, type C

10 Power cable

6

3

5

4

7

9

8

2

10

12 P2077SB/EN 2011-09 77c_Systembeschreibung-en.fm, 06.09.2011

System description

3

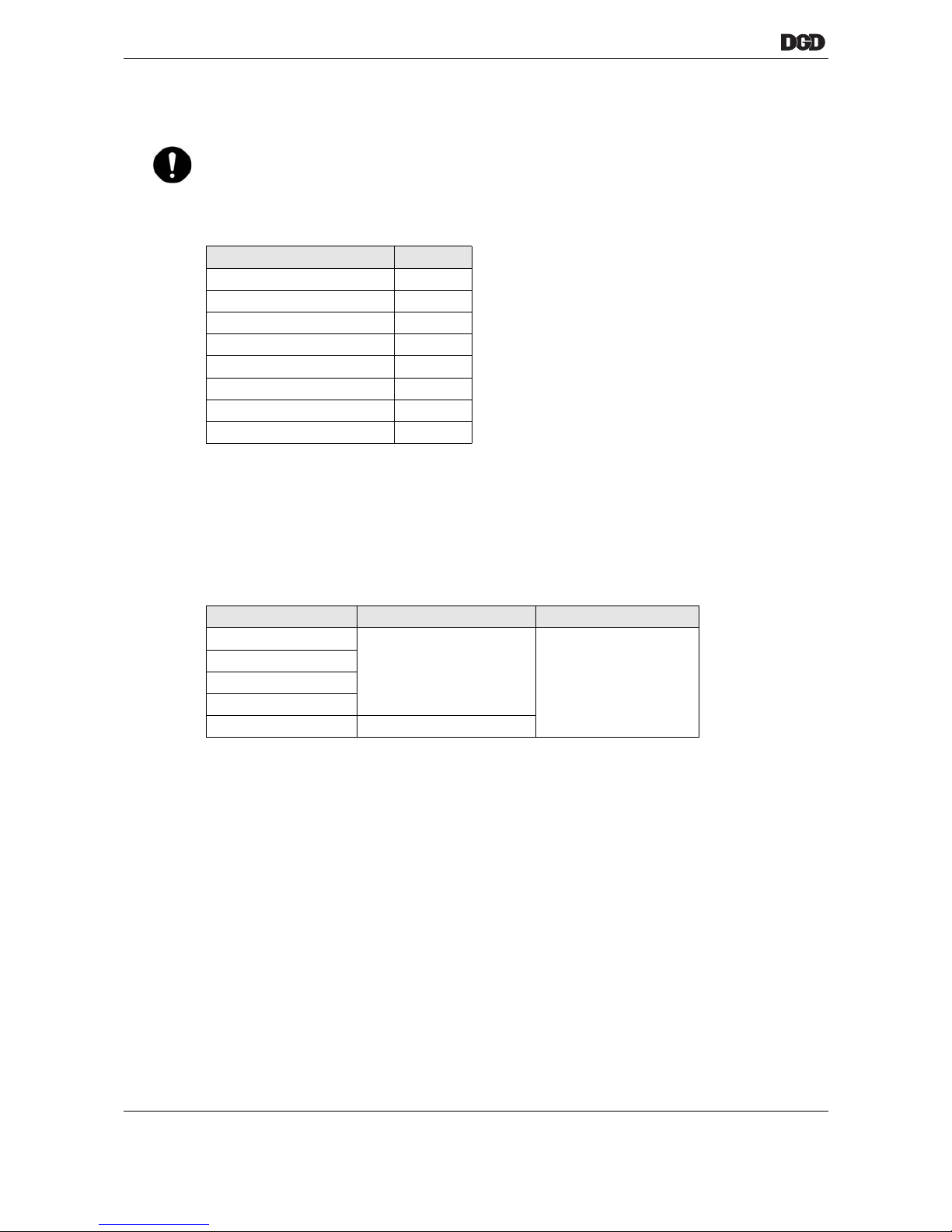

3.1.1 DGD-IS

The DGD-IS is available in sizes 1B(U)TSE…, 2B(U)TSE…, 3B(U)TSE… and 4B(U)TSE….

for a torque range of 2 to 1600 Nm.

3.1.2 Nutsetter control unit

Power and logic are supplied via the power distribution box PDB-CPS….

This is controlled by the nutsetter control unit mPro400GC-M.

• A single system cable (PDB-CPS… to the last DGD-IS) may have up to 16 DGD-IS units connected

(depending on the size and number).

• A single mPro400GC-M can have up to 32 DGD-IS units connected.

Available channel numbers

The maximum number of DGD-IS units per PDB-CPS… depends on load.

In order to guarantee the number stated, the following settings are to be made:

• Maximum speed at 20% of maximum torque (for 1BTSE, 2BTSE, 3BTSE and 4BTSE)

• Final tightening up to 500 Nm: Maximum speed 50

rpm at maximum torque (for 1BTSE, 2BTSE, 3BTSE

and 4BTSE- 4B500A...)

• Final tightening above 500 Nm: Maximum speed 20

rpm at maximum torque (for 4BTSE-4B660A...,

4BTSE-4B660A-4VK4MS, 4BTSE-4B360A-4Z1250A and 4BTSE-4B460A-4Z1600A)

If settings above those stated are selected, the number of channels must be reduced.

If using different types of spindle on one control unit, these must be individually defined.

Please consult your Sales & Service Center (see backside).

3.1.3 Cables

From PDB-CPS… to the last DGD-IS = 50 m maximum length.

3.1.4 ARCNET (System bus)

Communication between the mPro400GC-M and the DGD-IS is achieved via the serial, high-performance

field bus ARCNET, based on RS485.

• An ARCNET cable is connected between mPro400GC-M and PDB-CPS….

• ARCNET cables are integrated in the system cable between PDB-CPS… and DGD-IS, and between

DGD-IS and DGD-IS.

• Several system wiring harnesses meet at PDB-CPS6 and PDB-CPS9. An ARCNET bus amplifier

module (ARCNET HUB 1E3A order no. 961237) is installed for this purpose. The module allows a starshaped bus topology.

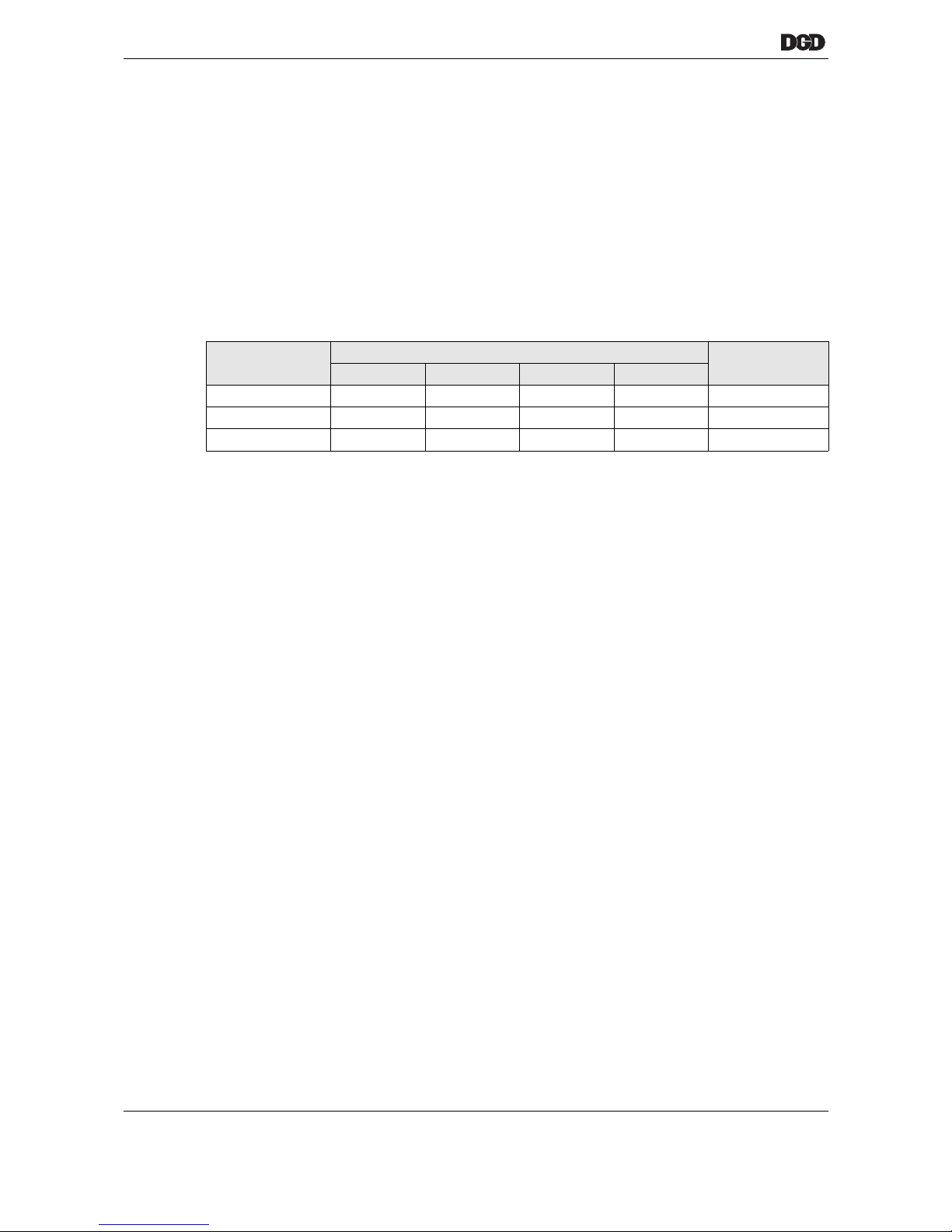

Code Maximum number of DGD-IS Quantity

System cable

1B(U)TSE… 2B(U)TSE… 3B(U)TSE… 4B(U)TSE…

PDB-CPS3 16 6 6 6 1

PDB-CPS6 32 12 12 12 2

PDB-CPS9 – 18 18 18 3

77d_Inbetriebnahme_bedingt-en.fm, 06.09.2011 P2077SB/EN 2011-09 13

First Operation

4

4 First Operation

For initial commissioning, the mPro400GC programming instructions must also be read and applied.

1 Position components of the DGD-IS so that they interlock at toothed interfaces, see Service Manual:

Turn size 1 in 15° increments.

Turn sizes 2 to 4 in 10° increments.

2 Connect all components, see (Chapter "3.1"Components starting on page 11).

3 Close all plug connectors and lock.

4 Connect the mains cable to the nutsetter control unit.

5 Preset the ARCNET address on each DGD-IS under the service panel,

see 6.4.1 ARCNET address preset, page 26.

6 Close the service panel.

7 Close the protective devices (i.e. safety grilles).

8 Switch on the machine control unit (PLC/SPS).

9 Switch on the nutsetter control unit.

If there are no faults pending after switching on the unit, the

"Ready" LED on the DGD-IS lights up green.

Otherwise, please refer to 15 Troubleshooting, page 63,

troubleshooting.

10 Enter parameters for torque / angle of rotation setting via

the mPro400GC-M….

The mPro400GC-M is programmed by DGD technical staff

during commissioning.

The first time the nutsetter control unit is switched on, the parameters for controlling fastening

sequences must be read in via the keyboard or a valid parameter file. For process programming of the

nutsetter control unit, see Programming Manual mPro400GC-M.

CAUTION!

Risk of tripping or falling over loose cables on the ground.

Lay all connected cables safely.

NOTE

The red ring around the outer diameter of plug connectors with a slide lock should not be visible.

NOTE

Always terminate the ARCNET with an ARCNET terminator at the bus end, i.e. at the last DGD-IS,

order no. 961127. This terminator is permanently installed in the nutsetter control unit mPro400GC-M (start

of bus).

DANGER!

High leakage current – Fatal electric shock could occur.

Establish a protective earth (PE) ground connection to the nutsetter control unit before taking into operation!

NOTE

Each address can be used only once in the system!

"Ready" LED

14 P2077SB/EN 2011-09 77d_Inbetriebnahme_bedingt-en.fm, 06.09.2011

First Operation

4

Blank page

77e_IntelligenteSpindel-en.fm, 06.09.2011 P2077SB/EN 2011-09 15

DGD intelligent spindles

5

5 DGD intelligent spindles

5.1 General technical data

• torque measurement with integrated pre-amplifier, resulting in greater signal noise spacing

• reverse voltage protected supply

• short-circuit proof outputs

• low voltage monitor

• watchdog for processor

• noise-protected input and output circuit

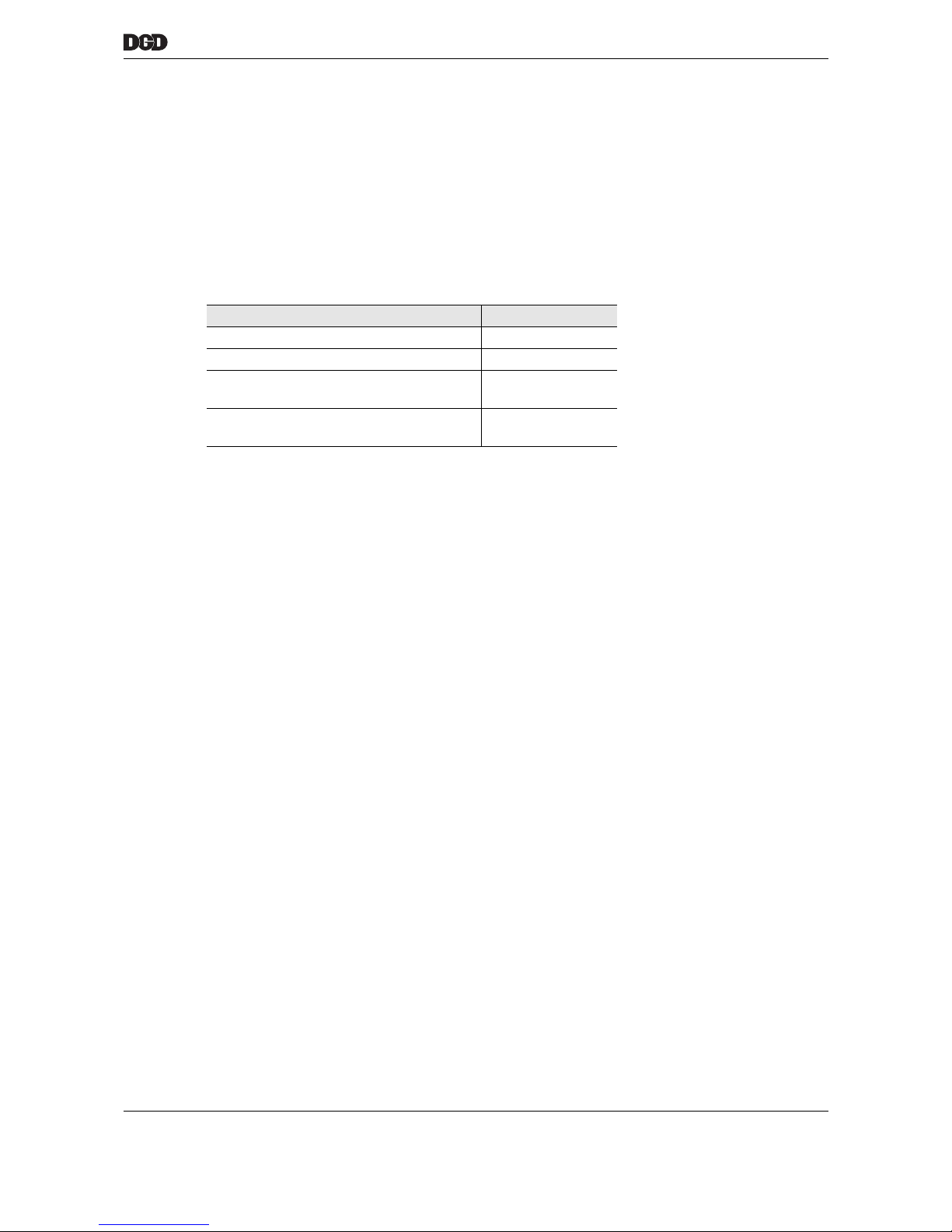

Features Data

Protection category IP54

Service life, operating 40,000 h

Load cycles

(min. at maximum torque)

1,000,000,

then recalibration

Mechanical overload capacity of the measuring shaft

100 %

16 P2077SB/EN 2011-09 77e_IntelligenteSpindel-en.fm, 06.09.2011

DGD intelligent spindles

5

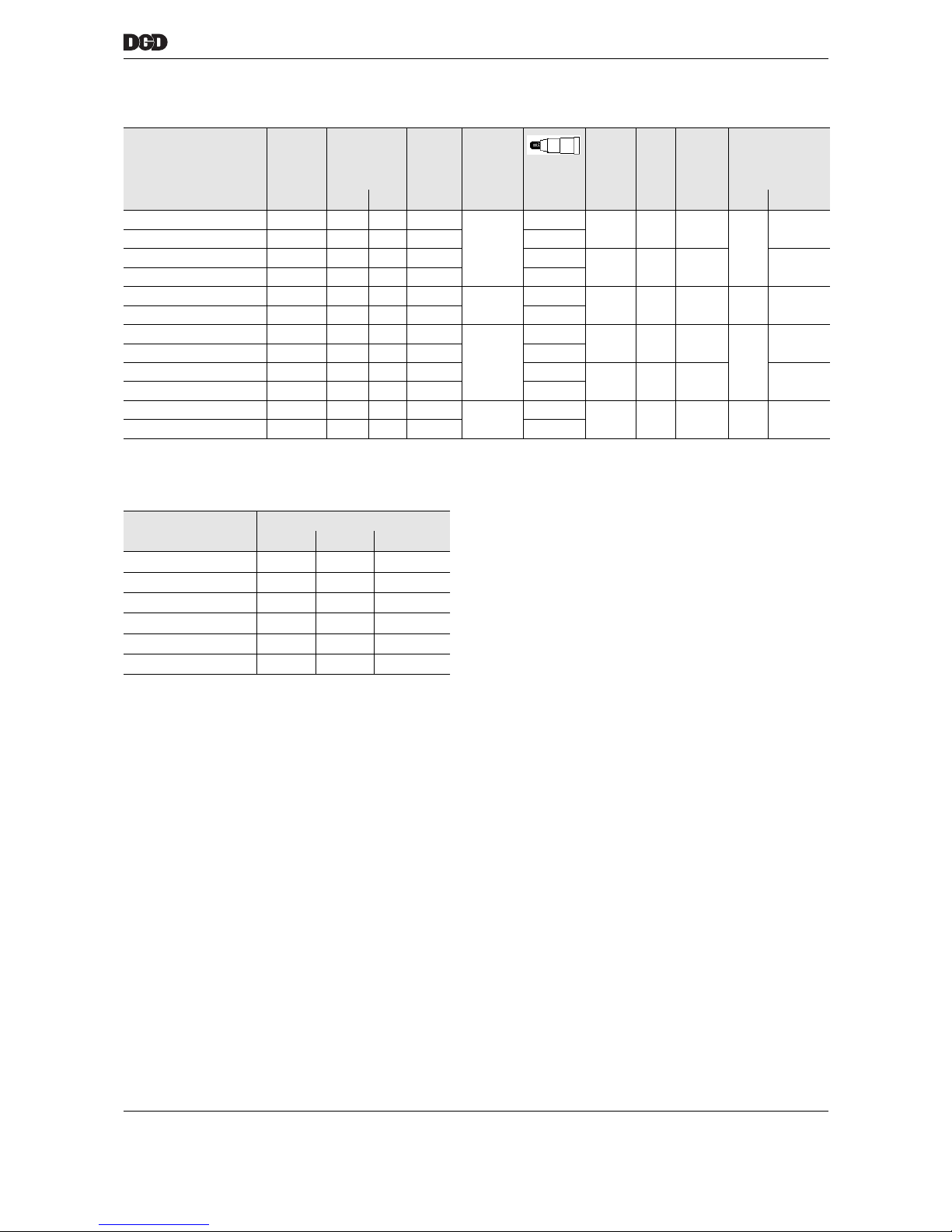

5.2 Catalogue data

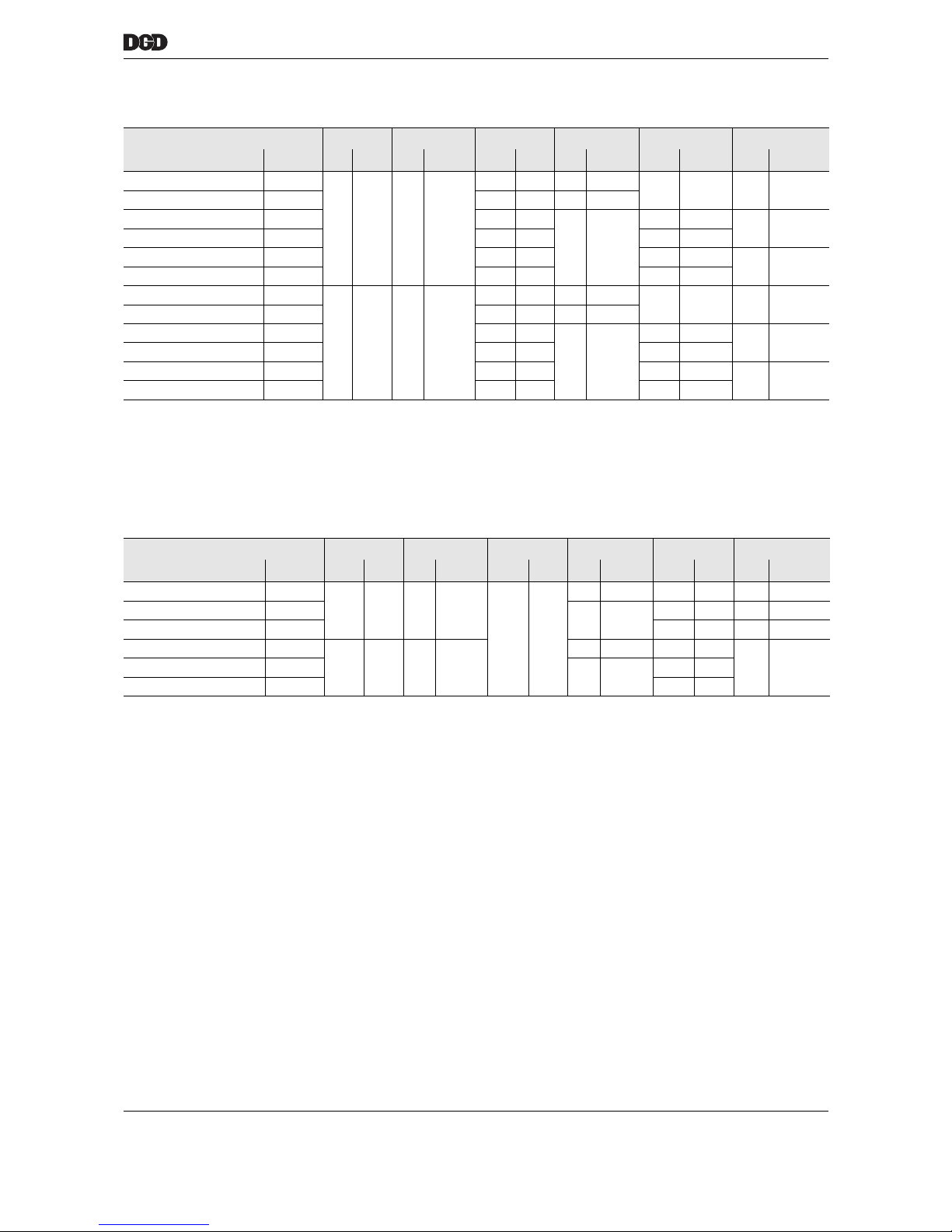

5.2.1 Size 1 – 1× transducer

Smallest scribed circle diameter in mm

Designation Order No. Torque

Nm

Speed Spring

travel

min.

axis

distance

Length

Weight Spring

chuck

max. min. RPM mm mm mm kg + flange

1BTSE-1B012A-1M3B-1ZB 947626A6

1)

1) On request

12 2 1921

50

3/8"

43 486 4.8

922325

S3084341BTSE-1B035A-1M1B-1ZB 947632A8 35 5 727

1BTSE-1B060A-1M2B-1ZB 947638A2 53 15 427

1BTSE-1B012A-1VM3B 947627A5

1)

12 2 1825

35 474 5.3 S3084371BTSE-1B035A-1VM1B 947633A7 35 5 690

1BTSE-1B060A-1VM2B 947639A1 53 15 405

1BTSE-1B012A-1WM3B 947628A4

1)

12 2 1801

25 52 542 5.7 – 9290411BTSE-1B035A-1WM1B 947634A6 35 5 681

1BTSE-1B060A-1WM2B 947640A8 53 15 400

1BUTSE-1B012A-1M3B-1ZB 947629A3

1)

12 2 1921

50

43 393 5.3

922325

S3084341BUTSE-1B035A-1M1B-1ZB 947635A5

1)

35 5 727

1BUTSE-1B060A-1M2B-1ZB 947641A7

1)

53 15 427

1BUTSE-1B012A-1VM3B 947630A0

1)

12 2 1825

35 382 5.8 S3084371BUTSE-1B035A-1VM1B 947636A4

1)

35 5 690

1BUTSE-1B060A-1VM2B 947642A6

1)

53 15 405

1BTSE-1B012A-1WM3B 947631A9

1)

12 2 1801

25 52 370 6.2 – 9290411BTSE-1B035A-1WM1B 947637A3

1)

35 5 681

1BUTSE-1B060A-1WM2B 947643A5

1)

53 15 400

Quantity Attachment

DGD-IS Centric Offset Angle head

2433552

3544060

4615074

5815889

6 99 70 105

7 116 85 120

77e_IntelligenteSpindel-en.fm, 06.09.2011 P2077SB/EN 2011-09 17

DGD intelligent spindles

5

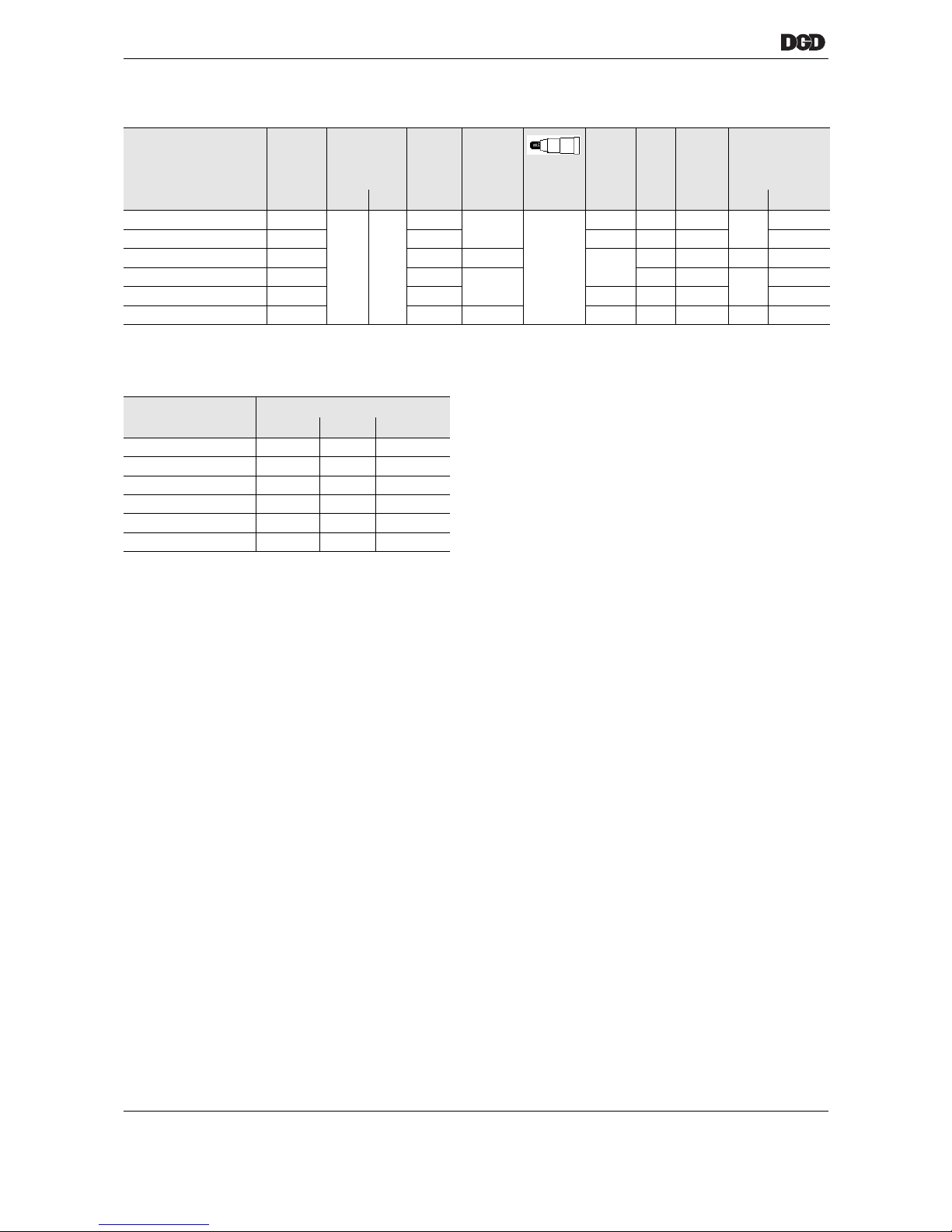

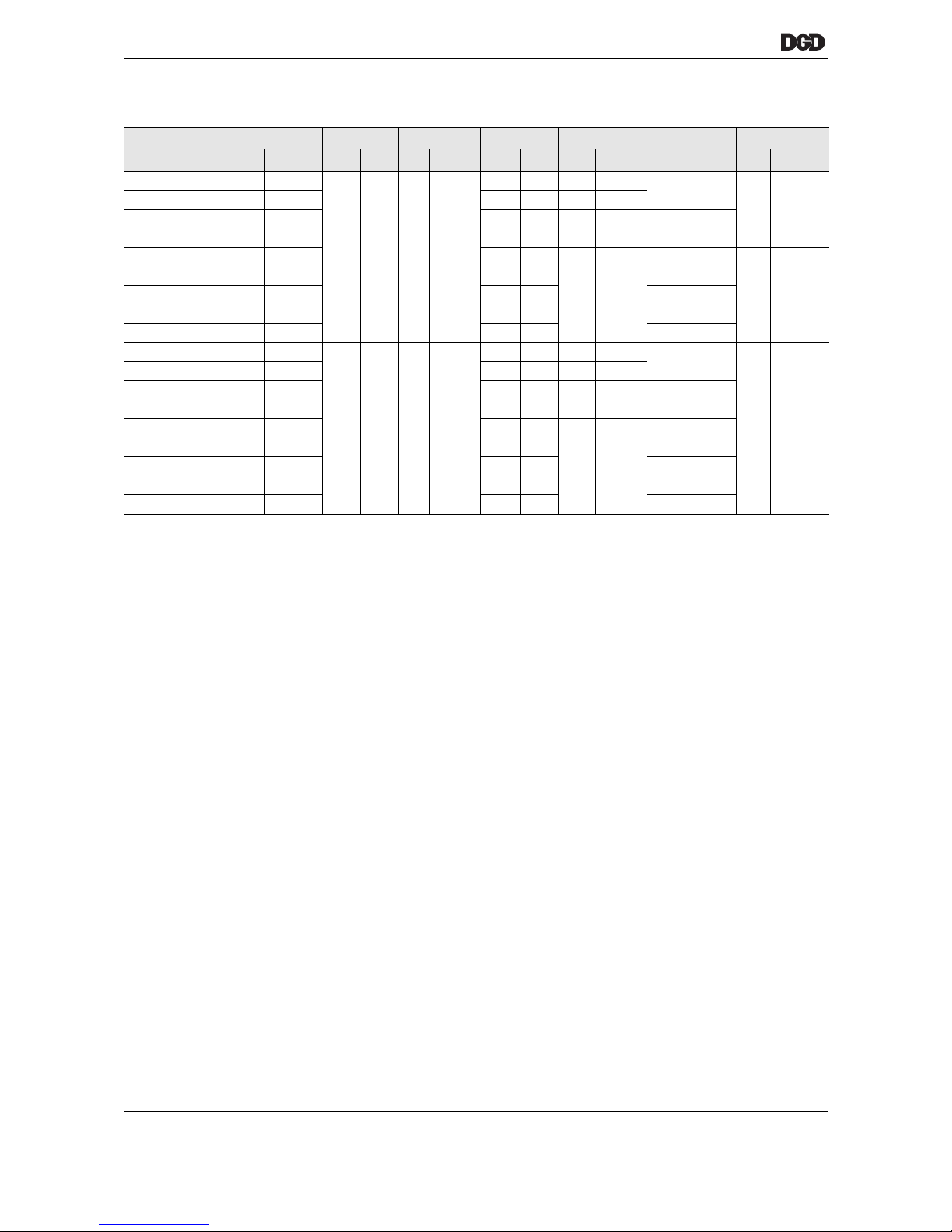

5.2.2 Size 2 – 1× transducer

Smallest scribed circle diameter in mm

Designation Order No. TorqueNmSpeed Spring

travel

min.

axis

distance

Length

Weight Spring

chuck

max. min. RPM mm mm mm kg + flange

2BTSE-2B110A-2M1B-2ZB 947644A4 110 25 890

50

1/2"

56 528 7.6

910609

S308435

2BTSE-2B200A-2M3B-2ZB 947650A6 200 40 502 3/4"

2BTSE-2B110A-2VM1B 947645A3 110 25 831 1/2"

44 551 9.2 S308438

2BTSE-2B200A-2VM3B 947651A5 200 40 468 3/4"

2BTSE-2B110A-2WM1B 947646A2 110 25 838

25

1/2"

59 581 8.7 – 929053

2BTSE-2B200A-2WM3B 947652A4 200 40 472 3/4"

2BUTSE-2B110A-2M1B-2ZB 947647A1

1)

1) On request

110 25 890

50

1/2"

56 367 8.6

910609

S308435

2BUTSE-2B200A-2M3B-2ZB 947653A3

1)

200 40 502 3/4"

2BUTSE-2B110A-2VM1B 947648A0

1)

110 25 831 1/2"

44 390 10.2 S308438

2BUTSE-2B200A-2VM3B 947648A0

1)

200 40 468 3/4"

2BUTSE-2B110A-2WM1B 947649A9

1)

110 25 838

25

1/2"

59 421 9.7 – 929053

2BUTSE-2B200A-2WM3B 947655A1

1)

200 40 472 3/4"

Quantity Attachment

DGD-IS Centric Offset Angle head

2564459

3755068

4806286

5 106 74 101

6 130 89 118

7 151 102 137

18 P2077SB/EN 2011-09 77e_IntelligenteSpindel-en.fm, 06.09.2011

DGD intelligent spindles

5

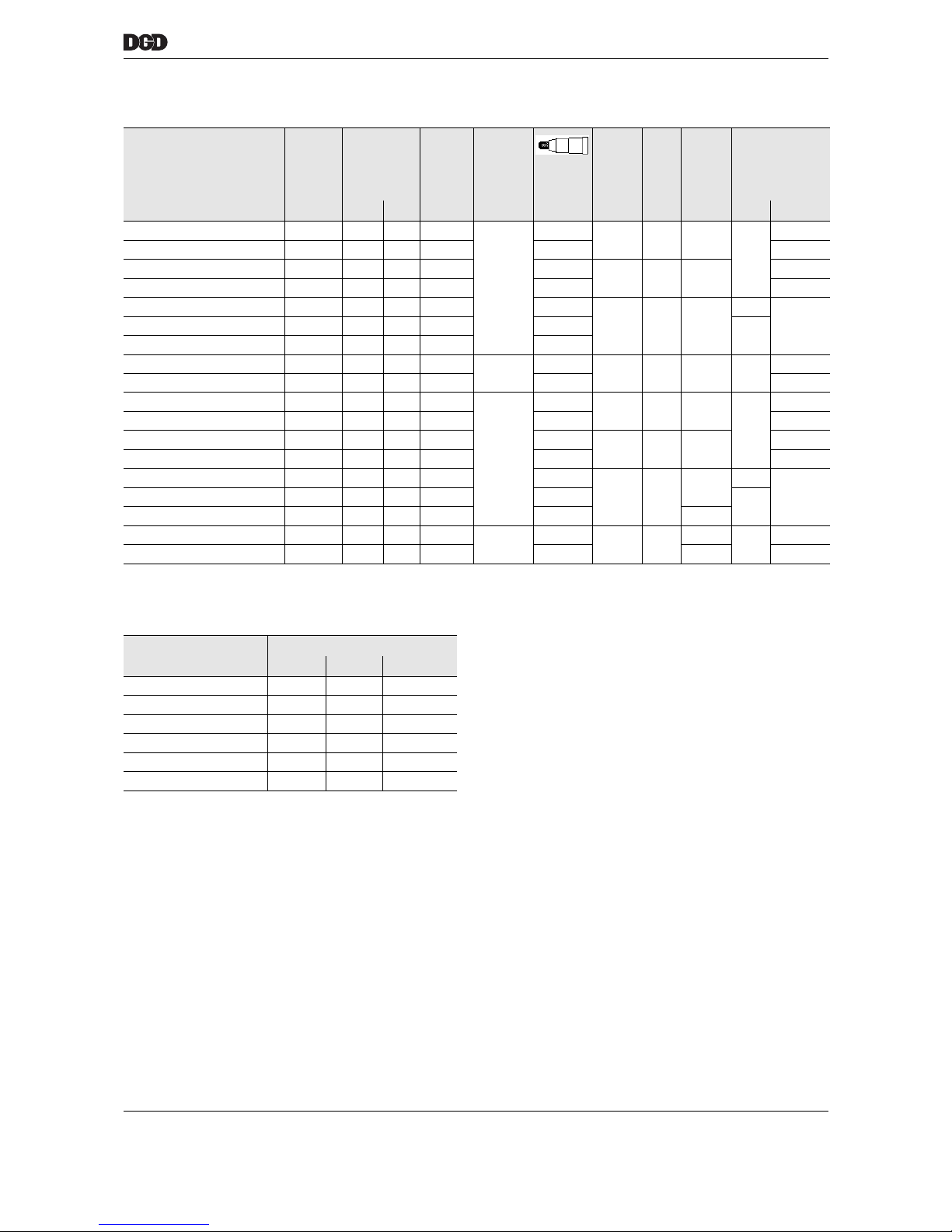

5.2.3 Size 3 – 1× transducer

Smallest scribed circle diameter in mm

Designation Order No. TorqueNmSpeed Spring

travel

min.

axis

distance

Length

Weight Spring

chuck

max. min. RPM mm mm mm kg + flange

3BTSE-3B300A-3M2B-3ZB 947656A0

300 50

453

50

3/4"

81 589 14.1

910613

S308436

3BTSE-3B300A-3VM2B 947657A9

1)

1) On request

421 59 584 15.2 S308439

3BTSE-3B300A-3WM2B 947658A8

1)

437 25

81

678 17.8 – 929065

3BUTSE-3B300A-3M2B-3ZB 947659A7

1)

453

50

417 16.1

910613

S308436

3BUTSE-3B300A-3VM2B 947660A4

1)

421 59 412 17.2 S308439

3BUTSE-3B300A-3WM2B 947661A3

1)

437 25 81 506 19.8 – 929065

Quantity Attachment

DGD-IS Centric Offset Angle head

2815981

3946994

4 116 84 116

5 139 102 139

6 164 122 164

7 189 138 189

77e_IntelligenteSpindel-en.fm, 06.09.2011 P2077SB/EN 2011-09 19

DGD intelligent spindles

5

5.2.4 Size 4 – 1× transducer

Smallest scribed circle diameter in mm

Designation Order No. TorqueNmSpeed Spring

travel

min.

axis

dis-

tance

Length

Weight Spring

chuck

max. min. RPM mm mm mm kg + flange

4BTSE-4B500A-4M2B-4ZA 947662A2 500 100 254

50

3/4"

91 719 21

–

916643

4BTSE-4B660A-4M3B-4ZA 947668A6 660 130 174 1" 916642

4BTSE-4B360A-4M1B-4Z1250A 947676A6 1250 320 86 1"

121 771 29

S976956

4BTSE-4B500A-4M2B-4Z1600A 947678A4

1)

1) On request

1600 400 68 1 1/2" S308441

4BTSE-4B500A-4VM2B 947663A1

1)

500 100 238 3/4"

76 684 22.5

912106

S3084404BTSE-4B660A-4VM3B 947669A5

1)

660 130 163 1"

912147

4BTSE-4B660A-4VM4B 947671A1

1)

750 160 135 1"

4BTSE-4B500A-4WM2B 947664A0

1)

500 100 245

25

3/4"

112 729 27.1 –

929077

4BTSE-4B660A-4WM3B 947670A2

1)

660 130 167 1" 929089

4BUTSE-4B500A-4M2B-4ZA 947665A9

1)

500 100 254

50

3/4"

91 546 22.5

–

916643

4BUTSE-4B660A-4M3B-4ZA 947672A0

1)

660 130 174 1" 916642

4BUTSE-4B360A-4M1B-4Z1250A 947677A5

1)

1250 320 86 1"

121 599 31

S976956

4BUTSE-4B500A-4M2B-4Z1600A 947679A3

1)

1600 400 68 1 1/2" S308441

4BUTSE-4B500A-4VM2B 947666A8

1)

500 100 238 3/4"

76 512

24

912106

S3084404BUTSE-4B660A-4VM3B 947673A9

1)

660 130 163 1"

912147

4BUTSE-4B660A-4VM4B 947675A7

1)

750 160 135 1" 24.5

4BUTSE-4B500A-4WM2B 947667A7

1)

500 100 245

25

3/4"

112 556

28.6

–

929077

4BUTSE-4B660A-4WM3B 947674A8

1)

660 130 167 1" 28.7 929089

Quantity Attachment

DGD-IS Centric Offset Angle head

29176112

3 122 88 130

4 130 108 160

5 174 130 192

6 217 153 224

7 246 180 263

20 P2077SB/EN 2011-09 77e_IntelligenteSpindel-en.fm, 06.09.2011

DGD intelligent spindles

5

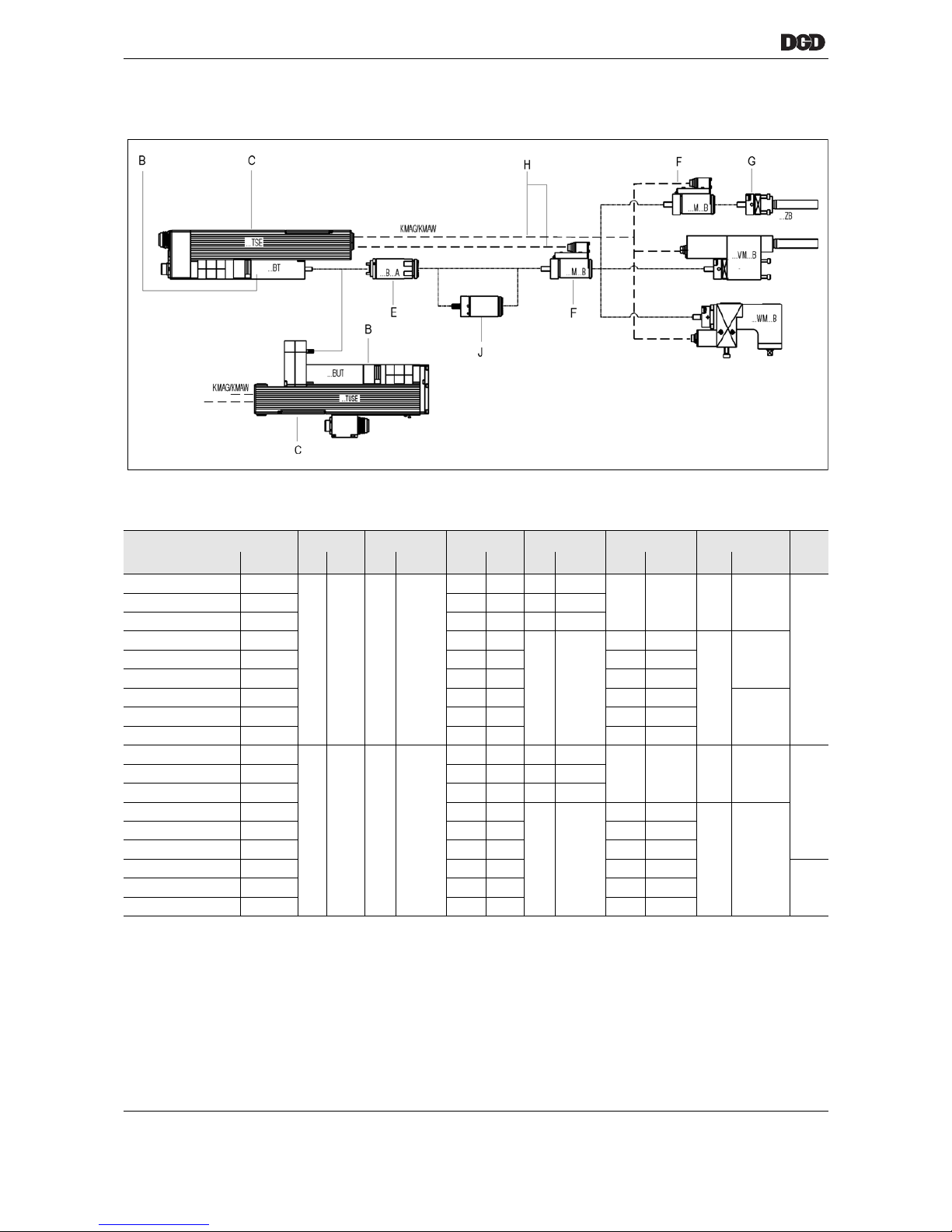

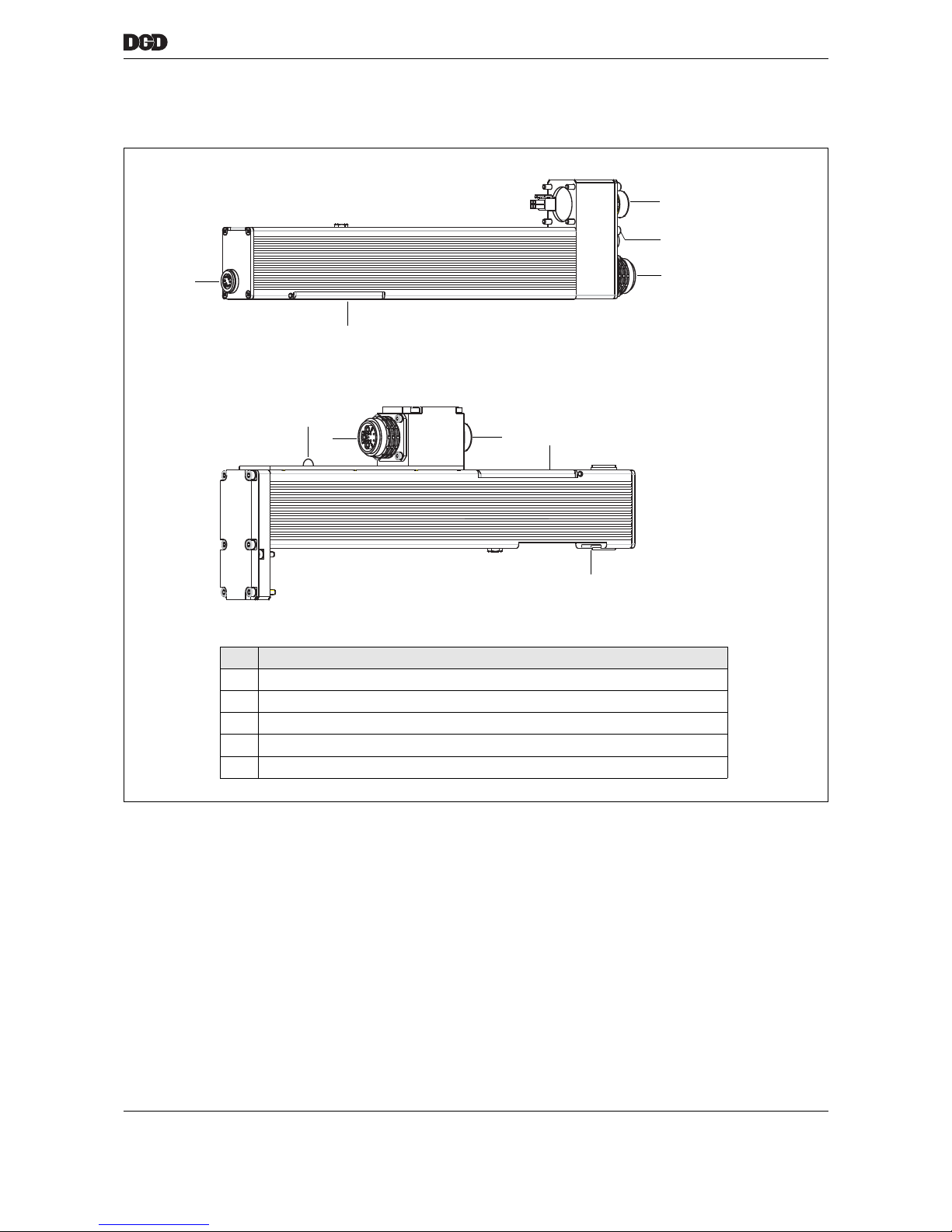

5.3 Component overview

5.3.1 Size 1 / 1× transducer

** Fit as spacer

DGD-IS B C E F G H J**

1)

1) Code

2)

2) Part no.

1) 2) 1) 2) 1) 2) 1) 2) 1) 2) 1) 2) 2)

1BTSE-1B012A-1M3B-1ZB

947626A6

1BT 935560 TSE 961446PT

1B012A 927346 1M3B 934288PT

1ZB 927222 KMAW 961089-002

–

1BTSE-1B035A-1M1B-1ZB

947632A8 1B035A 927344 1M1B 934286PT

1BTSE-1B060A-1M2B-1ZB

947638A2 1B060A 927345 1M2B 934287PT

1BTSE-1B012A-1VM3B

947627A5

3)

3) On request

1B012A 927346

––

1VM3B 935863PT

KMAG

961088-004

1BTSE-1B035A-1VM1B

947633A7 1B035A 927344 1VM1B 935865PT

1BTSE-1B060A-1VM2B

947639A1 1B060A 927345 1VM2B 935864PT

1BTSE-1B012A-1WM3B

947628A4

3)

1B012A 927346 1WM3B

3)

961088-003

1BTSE-1B035A-1WM1B

947634A6

3)

1B035A 927344 1WM1B 934367PT

1BTSE-1B060A-1WM2B

947640A8 1B060A 927345 1WM2B 934368PT

1BUTSE-1B012A-1M3B-1ZB

947629A3

3)

1BUT 936321 TUSE 961447PT

1B012A 927346 1M3B 934288PT

1ZB 927222 KMAG 961088-004

935796

1BUTSE-1B035A-1M1B-1ZB

947635A5

3)

1B035A 927344 1M1B 934286PT

1BUTSE-1B060A-1M2B-1ZB

947641A7

3)

1B060A 927345 1M2B 934287PT

1BUTSE-1B012A-1VM3B

947630A0

3)

1B012A 927346

––

1VM3B 935863PT

KMAG 961088-003

1BUTSE-1B035A-1VM1B

947636A4

3)

1B035A 927344 1VM1B 935865PT

1BUTSE-1B060A-1VM2B

947642A6

3)

1B060A 927345 1VM2B 935864PT

1BUTSE-1B012A-1WM3B

947631A9

3)

1B012A 927346 1WM3B

3)

–

1BUTSE-1B035A-1WM1B

947637A3

3)

1B035A 927344 1WM1B

3)

1BUTSE-1B060A-1WM2B

947643A5

3)

1B060A 927345 1WM2B 934368PT

77e_IntelligenteSpindel-en.fm, 06.09.2011 P2077SB/EN 2011-09 21

DGD intelligent spindles

5

5.3.2 Size 2 / 1× transducer

5.3.3 Size 3 / 1× transducer

DGD-IS B C E F G H

1)

1) Code

2)

2) Part no.

1) 2) 1) 2) 1) 2) 1) 2) 1) 2) 1) 2)

2BTSE-2B110A-2M1B-2ZB 947644A4

2BT 935561 TSE 961446PT

2B110A 935548 2M1B 934295PT

2ZB 927227 KMAW 961089-002

2BTSE-2B200A-2M3B-2ZB 947650A6 2B200A 935549 2M3B 934294PT

2BTSE-2B110A-2VM1B 947645A3 2B110A 935548

––

2VM1B 934336PT

KMAG 961088-004

2BTSE-2B200A-2VM3B 947651A5 2B200A 935549 2VM3B 934335PT

2BTSE-2B110A-2WM1B 947646A2 2B110A 935548 2WM1B 934357PT

KMAG 961088-003

2BTSE-2B200A-2WM3B 947652A4 2B200A 935549 2WM3B 934374PT

2BUTSE-2B110A-2M1B-2ZB 947647A1

3)

3) On request

2BUT 936322 TUSE 961447PT

2B110A 935548 2M1B 934295PT

2ZB 927227 KMAG 961088-004

2BUTSE-2B200A-2M3B-2ZB 947653A3

3)

2B200A 935549 2M3B 934294PT

2BUTSE-2B110A-2VM1B 947648A0

3)

2B110A 935548

––

2VM1B 934336PT

KMAG 961088-003

2BUTSE-2B200A-2VM3B 947648A0

3)

2B200A 935549 2VM3B 934335PT

2BUTSE-2B110A-2WM1B 947649A9

3)

2B110A 935548 2WM1B 934357PT

KMAG 961088-004

2BUTSE-2B200A-2WM3B 947655A1

3)

2B200A 935549 2WM3B 934374PT

DGD-IS B C E F G H

1)

1) Code

2)

2) Part no.

1) 2) 1) 2) 1) 2) 1) 2) 1) 2) 1) 2)

3BTSE-3B300A-3M2B-3ZB 947656A0

3/4BT 935562 TSE 961446PT

3B300A 935590

3M2B 934303PT 3ZB 927233 KMAG 961088-002

3BTSE-3B300A-3VM2B 947657A9

3)

3) On request

––

3VM2B 3) KMAG 961088-004

3BTSE-3B300A-3WM2B 947658A8

3)

3WM2B 3) KMAG 961088-003

3BUTSE-3B300A-3M2B-3ZB 947659A7

3)

3/4BUT 936323 TUSE 961447PT

3M2B 934303PT 3ZB 927233

KMAG 961088-0043BUTSE-3B300A-3VM2B 947660A4

3)

––

3VM2B 3)

3BUTSE-3B300A-3WM2B 947661A3

3)

3WM2B 3)

22 P2077SB/EN 2011-09 77e_IntelligenteSpindel-en.fm, 06.09.2011

DGD intelligent spindles

5

5.3.4 Size 4 / 1× transducer

DGD-IS B C E F G H

1)

1) Code

2)

2) Part no.

1) 2) 1) 2) 1) 2) 1) 2) 1) 2) 1) 2)

4BTSE-4B500A-4M2B-4ZA

947662A2

3/4BT 935562 TSE 961446PT

4B500A 935780 4M2B 934319PT

4ZA 927236

KMAG 961069-002

4BTSE-4B660A-4M3B-4ZA

947668A6

3)

3) On request

4B660A 935781 4M3B 936496PT

4BTSE-4B360A-4M1B-4Z1250A

947676A6 4B360A 929541 4M1B 934318PT 4Z1250A S976950

4BTSE-4B500A-4M2B1-4Z1600A

947678A4

3)

4B500A 935780 4M2B1 3) 4Z1600A S976951

4BTSE-4B500A-4VM2B

947663A1

3)

4B500A 935780

––

4VM2B 3)

KMAG 961069-004

4BTSE-4B660A-4VM3B

947669A5

3)

4B660A 935781 4VM3B 3)

4BTSE-4B660A-4VM4B

947671A1

3)

4B660A 935781 4VM4B 3)

4BTSE-4B500A-4WM2B

947664A0

3)

4B500A 935780 4WM2B 3)

KMAG 961069-003

4BTSE-4B660A-4WM3B

947670A2

3)

4B660A 935781 4WM3B 3)

4BUTSE-4B500A-4M2B-4ZA

947665A9

3)

3/4BUT 936323 TUSE 961447PT

4B500A 935780 4M2B 934319PT

4ZA 927236

KMAG 961069-005

4BUTSE-4B660A-4M3B-4ZA

947672A0

3)

4B660A 935781 4M3B 936496PT

4BUTSE-4B360A-4M1B-4Z1250A

947677A5

3)

4B360A 929541 4M1B 934318PT 4Z1250A S976950

4BUTSE-4B500A-4M2B1-4Z1600A

947679A3

3)

4B500A 935780 4M2B1 3) 4Z1600A S976951

4BUTSE-4B500A-4VM2B

947666A8 4B500A 935780

––

4VM2B 3)

4BUTSE-4B660A-4VM3B

947673A9

3)

4B660A 935781 4VM3B 3)

4BUTSE-4B660A-4VM4B

947675A7

3)

4B660A 935781 4VM4B 3)

4BUTSE-4B500A-4WM2B

947667A7

3)

4B500A 935780 4WM2B 3)

4BUTSE-4B660A-4WM3B

947674A8

3)

4B660A 935781 4WM3B 3)

77f_Schraubmodul-en.fm, 06.09.2011 P2077SB/EN 2011-09 23

Tightening module TSE/TUSE

6

6 Tightening module TSE/TUSE

2

3

Item Designation

1 "XS1A" supply input

2 "XS1B" supply output

3 Service panel

4 "XS3" transducer plug connector

7 "Ready" LED, ready for operation (green) or fault (red)

TSE

Order no. 961446PT

TUSE

Order no. 961447PT

2

1

1

3

4

7

7

4

77_tse_tuse.eps

24 P2077SB/EN 2011-09 77f_Schraubmodul-en.fm, 06.09.2011

Tightening module TSE/TUSE

6

6.1 Description

The tightening module TSE/TUSE controls the DGD-IS.

The servo amplifier (output section) and the measuring section (measuring board) are integrated in the

tightening module.

Both circuit boards are linked to the connections via cables and plug connectors.

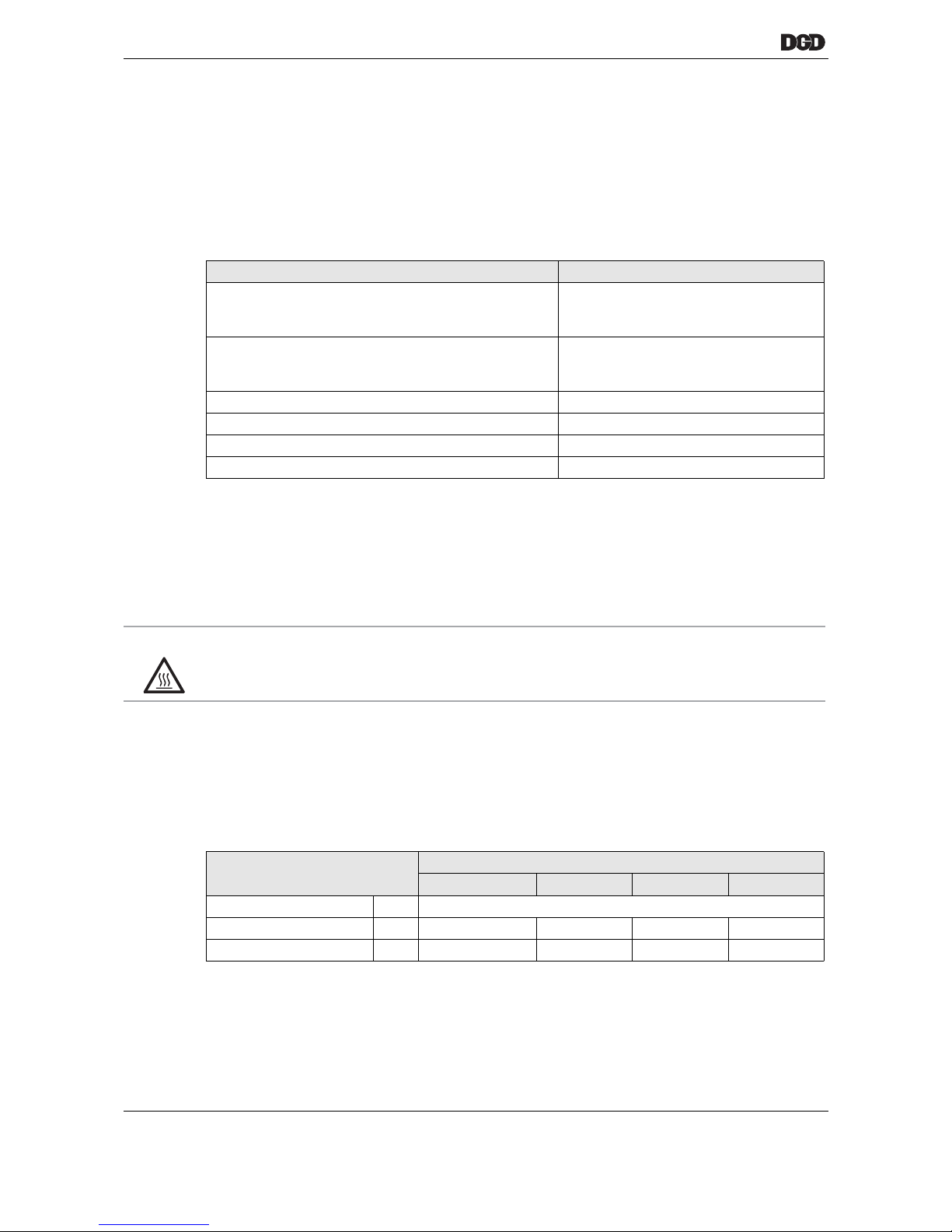

6.2 General technical data

6.2.1 Power loss

Low-loss components generate minimal heat.

Extremely good heat dissipation. Overall housing serves as a cooling element.

6.2.2 Power supply 380 VDC

Intermediate power circuit (380 VDC) and logic power (24 VDC) are supplied separately by the

PDB-CPS…. In the event of an emergency stop the intermediate power circuit is switched off separately

by the PDB-CPS…. The logic section remains connected to the power.

Performance data DGD-IS different

Features Data

Weight:

TSE

TUSE

1480 g

1500 g

Protection category – is attained

when all connectors are plugged in

and the service panel is closed.

IP54

Cooling type Convection (self-cooling)

Service life, operating 40,000 h

Usability period if stored 100,000 h (approx. 11 years)

Acceleration of each axis max. 100 m/s²

Standby 9 A

Operation max. 40 W

WARNING!

High temperature –

the tightening module TSE/TUSE may heat up and cause burns during removal

(max. temperature 70 °C). Wear gloves.

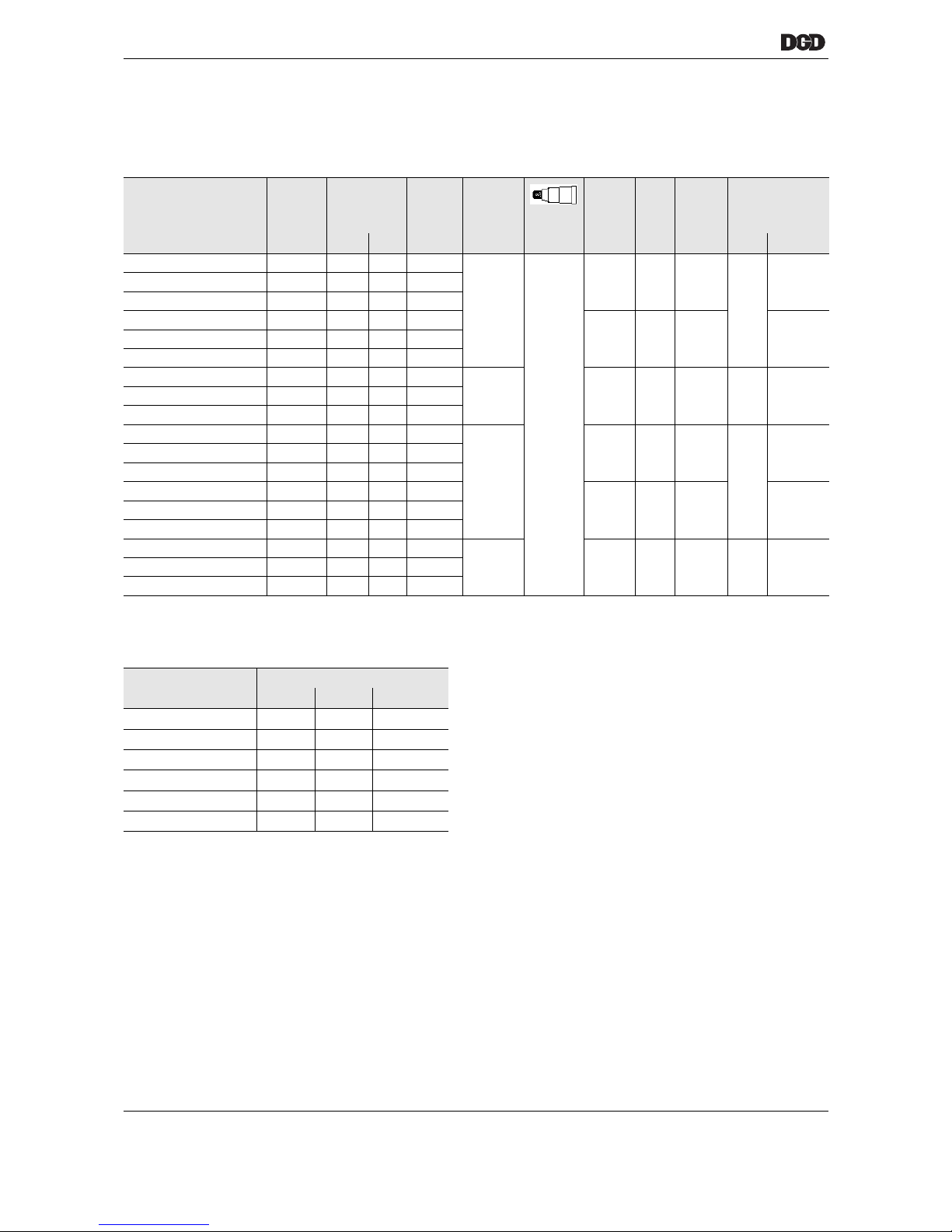

Features Data

1B(U)TSE… 2B(U)TSE… 3B(U)TSE… 4B(U)TSE…

Supply voltage VDC 380 ±10 %

Rated supply current A 0.5 1 2 2

Peak supply current A 6 15 15 15

Loading...

Loading...