Programming Manual

PL12EN-TVP100

03/07/2013

TVP-100 Series

Pneumatic Torque Verier - Version 1.0

TVP-110-15

For additional product information visit our website at http://www.apextoolgroup.com

TVP-110-30

Cleco

®

PL12EN-TVP100

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

Disclaimer:

The information and data in this document has been prepared to the best of our ability.

Nonetheless, differences between the information and the actual product cannot be excluded

with absolute certainty. Apex Tool Group does not assume any liability for consequential errors

and damages. We likewise do not assume liability for damages resulting from defective circuitry

inside the devices supplied. Apex Tool Group reserves the right, to amend, supplement or

improve this document or the product without serving prior notice.

Without the express approval of Apex Tool Group this document must not be reproduced in

its entirety or in part by any means; it must not be converted to any type of natural or machine

readable language or be saved on data storage media of electronic, mechanic, optical or other

type.

Page 3

PL12EN-TVP100

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

Contents

1 Getting Started ..................................................................................................................6

1.1 Safe Work Practices Symbol .............................................................................................. 6

1.2 Transportation .....................................................................................................................6

1.2.1 Unpacking ...........................................................................................................................6

1.2.2 Checking Your Unit .............................................................................................................6

1.3 Software .............................................................................................................................6

1.4 Installing The Unit ............................................................................................................... 6

1.4.1 General ............................................................................................................................... 6

1.4.2 Mounting ............................................................................................................................. 7

1.4.3 Location Considerations ..................................................................................................... 7

1.4.4 Source Power ..................................................................................................................... 7

1.5 Connecting Peripherals ......................................................................................................7

1.6 Maintenance, Troubleshooting and Repair .........................................................................7

2 Operation - Quick Start Guide ......................................................................................... 8

2.1 Powering Up The Unit ........................................................................................................8

2.2 The Ship’s Wheel ...............................................................................................................8

2.3 Selecting Tool Type .............................................................................................................8

2.4 Calibration (AutoCal) ..........................................................................................................9

2.5 Setting Fasteners Per Batch .............................................................................................10

2.6 Running The Unit ..............................................................................................................10

3 Controller Specications ............................................................................................... 11

3.1 IP Protection Class ........................................................................................................... 11

3.2 Understanding The Keypad .............................................................................................. 11

3.3 Specications ...................................................................................................................12

3.3.1 Enclosure ..........................................................................................................................12

3.3.2 Display .............................................................................................................................. 12

3.3.3 Indicators .......................................................................................................................... 13

3.3.4 AC Input Power ................................................................................................................13

3.3.5 TVP-110-15 (115VAC) Input/Output Connectors .............................................................. 13

3.3.6 TVP-110-30 (230VAC) Input/Output Connectors ..............................................................15

3.4 Decommissioning of Unit .................................................................................................. 16

4 Programming ..................................................................................................................17

4.1 Run Screen .......................................................................................................................17

4.2 Navigation Menu ...............................................................................................................18

4.3 AutoCal ............................................................................................................................. 18

4.4 Viewing A Run ..................................................................................................................19

4.5 Statistics ...........................................................................................................................20

4.6 Options .............................................................................................................................20

4.6.1 Relay Options ................................................................................................................... 21

4.6.2 Beeper Options .................................................................................................................21

4.6.3 Application Select Input .................................................................................................... 22

4.6.4 Time and Date .................................................................................................................. 23

4.6.5 Tool Type ..........................................................................................................................24

4.6.6 Adjusting The Display ....................................................................................................... 24

4.7 Selecting Application ........................................................................................................25

4.8 Application Builder ............................................................................................................ 25

4.9 Sequencing .......................................................................................................................27

4.10 Administration ................................................................................................................... 27

4.11 I/O Schematic ................................................................................................................... 28

Page 4

Cleco

®

PL12EN-TVP100

Pneumatic Torque Verifier TVP-100 Series

Contents

A Appendix .........................................................................................................................29

A.1 Pneumatic Curves (Pulse Tool) ........................................................................................29

A.2 Pnuematic Curves (Direct Drive Tool) .............................................................................. 32

A.3 Box Dimensions ................................................................................................................35

A.4 Tool and Box Diagrams .................................................................................................... 35

B Appendix .........................................................................................................................36

B.1 Dip-Switch Settings ..........................................................................................................36

B.2 Test Modes .......................................................................................................................36

03/07/2013

Page 5

PL12EN-TVP100

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

1 Getting Started

1.1 Safe Work Practices Symbol

This“Warning”symbolidentiesallnotesonsafeworkpracticesinthisoperating

instruction, alerting to hazards for life and health of people. Please observe these

notes and proceed with special care in the cases described. Pass all safety

instructions on to other operators. In addition to the safety instructions in this operating

instruction, the general local safety and accident prevention rules must be observed.

The signal word “Caution” identies all portions of this operating instruction

meriting special attention to ensure that guidelines, rules, hints and the correct

work procedures are observed; and, to prevent damage to and destruction of

the machine and/or parts.

1.2 Transportation

This unit does not require any special transportation instructions.

1.2.1 Unpacking

This unit does not require any special unpacking instructions.

1.2.2 Checking Your Unit

Take the time to ensure that you have the required peripheral equipment and cables

necessary to setup and run your unit. If you do not have all the necessary items, please

contact your distributor.

1.3 Software

Your unit has been pre-loaded with its software and requires no additional software to

start monitoring your fastening process. If you are trying to interface this unit to an external computer, additional software may be required. Please contact your distributor with

inquires about interface software.

1.4 Installation Of The Unit

1.4.1 General

It is mandatory that national, state, and local safety and wiring standards

be followed during installation. These standards would take precedence

over any information presented in this section.

To avoid the hazard of electrical shock or burn, the following instructions must be

adhered to. Failure to follow these instructions may also cause damage to your

unit and void existing warranties.

Do not energize the unit until all connections have been properly made.•

Equipment must be properly grounded before applying power. Units energized •

by cord and plug must be connected to an approved and properly grounded

receptacle.

Ensure the power switch is in the “off” position before applying power.•

Page 6

Pneumatic Torque Verifier TVP-100 Series

1.4.2 Mounting

Each TVP-100 Series unit is intended to be used as a single tool process monitor in a

work station or work area. This unit may be wall mounted, table mounted, beam mounted,

suspended overhead, pedestal mounted, or used without mounting. Tabs have been

provided on the base of this unit to ease this mounting process. Please take care in

choosing a stable location for the unit to avoid the possibility of damage to the unit and/

or operator injury through hitting, falling, vibration or inconvenient mounting. All cables

attached to the unit should be located and secured in a manner to avoid potential operator

and passer-by injury. As with all electric equipment, the unit will produce some heat and

should be located so that ambient air can freely circulate around the box.

1.4.3 Location Consideration

Your unit should be located to allow access to the front panel and connectors. The unit

should be installed for unrestricted and comfortable viewing of the LCD and LED’s by

the operator. The LCD menu screen, key pad and side panel connectors must be readily

accessible for the setup. Depending on the peripheral equipment purchased, the unit may

be remotely mounted but should still be accessible.

Cleco

®

PL12EN-TVP100

03/07/2013

1.4.4 Source Power

This unit is capable of being run off of 115 or 230 VAC (both 50 and 60 Hz).

Before powering up the unit for the rst time, take care to notice which

voltage the unit is set up to accept. Damage to the unit may occur if the

voltage selection does not match the power that is supplied,

The TVP-100 is fused at 1 Amp for 115 V.•

The TVP-100 is fused at 5 Amp for 230 V.•

1.5 Connecting Peripherals

A pressure transducer was supplied with your unit. This transducer needs to be properly

connected to the tool that is being monitored and also to this unit. Other inputs and

outputs are available for communicating with devices such as PLCs and PCs. Make sure

these devices are connected to the proper ports before powering up the unit. Damage

can occur to the units if these inputs and outputs are used incorrectly.

To avoid the hazard of electrical shock or burn the following instructions

must be adhered to. Failure to follow these instructions may also cause

damage to your unit and void existing warranties.

Ensure the power switch is in the “off” position and that the box cover is properly •

secured before supplying power to the unit.

Ensure equipment has been properly grounded before applying power.•

1.6 Maintenance, Troubleshooting and Repair

Periodic maintenance of this equipment is not required. Repair is restricted to programming

issues.

Page 7

PL12EN-TVP100

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

2 Operation - Quick Start Guide

2.1 Powering Up The Unit

This quick-start guide assumes that the unit is set up properly, that the unit can be

powered up, and that the transducer is properly attached to the tool being monitored and

this unit. If you need more guidance in any of these areas, please refer to the in depth

directions found later in this manual.

2.2 The Ship’s Wheel

When the unit powers up, a splash screen will be displayed momentarily followed by the

main run screen. In order to set up any given tool, press the “ship’s wheel” key and go to

the navigation menu.

Torque Verier

TVP-110-15

F1.01 B2.96

Cleco

RUN SCREEN

Cycle Count:

ACCEPT

BATCH

ACCEPT

REJECT

SUSPEND UNLOCK

Cycle Accept

Batch Total:

RESET

BATCH

®

APPLICATION

of:

Run Screen

AutoCal

psi

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

2.3 Selecting Tool Type

With the navigation menu showing, use the arrow keys to highlight the “Options” icon and

then use the “Enter” key to select “Options”. You may be prompted to enter a password.

If so, enter it using the numeric keypad, the default is “0 1 0 4”. At this point, the Options

Screenwillappear.FromtheOptionsScreenselectthefthoption(ToolType)bypressing

the 5 key. The Tool Type screen will appear at this point. Threre are two options for Cleco

Pulse tools. Option 1 (Pulse Pneumatic) is typically for larger pulse tools, about 20Nm

and larger. Option 3 (7/11 PTH) is typically for smaller pulse tools. All other pneumatic

tools, Option 2 (Direct-drive Pneumatic) should be selected.

Pressing the “Ship’s Wheel” will return the user to the navigation menu.

Run Screen

AutoCal

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

5. Tool Type

Options

TOOL TYPE

1. Pulse Pneumatic

2. Direct-drive Pneumatic

3. 7/11 PTH

OPTIONS MENU

1. Relays

2. Beeper

3. Parameter Switch Type

4. Time / Date

5. Tool Type

6. Adjust Display

Save EXIT

5

Save EXITDownUp

Page 8

Pneumatic Torque Verifier TVP-100 Series

2.4 Calibration (AutoCal)

Before a tool can be monitored properly, the current application must be set up to monitor

that tool. The AutoCal option will do this for you automatically. In order to access the AutoCal

routine, press the “Ship’s Wheel” button and go to the navigation screen. From the navigation

screen, use the arrow keys to highlight the AutoCal option and then press enter.

Cleco

®

PL12EN-TVP100

03/07/2013

Run Screen

AutoCal

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

You may be prompted to enter a password. If so, enter it using the numeric keypad. The

default password is “0 1 0 4”.

Please enter your password

to contonue.

0 1 0 4

TherstscreenassociatedwiththeAutoCalprocesswillinformtheuserthatthetoolmust

be off and also that they should press the “Next” key. This screen also reminds the user

which application set is active. The calibration will only effect that application. At this

point, make sure the transducer is connected to both the tool and the box and also that

the tool is not running. Then press the “Next” softkey.

AUTOCAL

Tool must be OFF.

Press NEXT to continue

the AutoCalibration

for Application A.

NEXT

Select

EXIT

Application

NEXT

The second AutoCal screen will appear next. This screen will prompt the user to run a

typical fastener and then to press the “Next” softkey. After these steps are completed, the

result of the calibration will appear on the screen.

AUTOCAL

The Qualier will use the

last fastening cycle to

AutoCal.

OR

Run a sample fastener now.

Press NEXT to continue.

EXIT

NEXT

Run Typical

Fastener

NEXT

AUTOCAL

Auto Calibration was successful.

Press NEXT to continue.

EXIT

NEXT

If the calibration was not successful, you may need to check the tool connection to the

unit. On the “Run Screen” there is a portion of the window that shows the active pressure

within the tool. Check this pressure as the tool is running to see if a change is occurring.

Press the “Ship’s Wheel” to return to the navigation menu.

Page 9

PL12EN-TVP100

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

2.4 Calibration (AutoCal) - continued

With Pulse Tools, an oversized air regulator and air hose can cause pressure waves at the

signal port after the tool has shut off. This can hinder a successful AutoCal.

2.5 Setting Fasteners Per Batch

Thenalstepinsettingupanygivenapplicationistoprogramthenumberoffasteners

which will be in each batch or group. For example, if this unit is to monitor the fastening

Run Screen

AutoCal

View Run

Statistics

Options

ofvelugnutsintoacar’swheel,thebatchmightbesettove.

In order to set the batch, press the “Ship’s Wheel” and go to the navigation menu. From

the navigation menu select the “Application Builder” option.

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Cleco

®

Application Builder

APPLICATION BUILDER

Application

Th1 Noise Floor

Th2 Run Start

Th3 Shut-off Threshold

T- Minimum Run Time

T+ Maximum Run Time

Tc Clutch Timer

Tb Bump Timer

Fasteners per Batch

Total Completed Batches:

Once inside the “Application Builder” menu you’ll want to use the up and down arrows on

the keypad to highlight the “Fasteners per Batch” option. When the “Fasteners per Batch”

option is highlighted, press Enter and a cursor will appear allowing you to edit the value

within the option.

Whilethecursorisashing,theleftandrightarrowkeyswillallowyoutohighlightanyof

the three active digits. The number keys will allow you to change any of those digits to

the desired value. The batch can be any value between 1 and 255.

Once the batch shows the desired value, press the Save soft-key to save that value.

Pressing the “Ship’s Wheel” button will return the unit to the navigation menu.

Run Screen

AutoCal

View Run

Statistics

Options

2.6 Running the Unit

In order to reach the “Run Screen” from the navigation menu, use the arrow keys to

highlight the “Run Screen” option and then press the Enter button.

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Run Screen

RUN SCREEN

Cycle Count:

ACCEPT

BATCH

ACCEPT

REJECT

SUSPEND UNLOCK

Cycle Accept

Batch Total:

RESET

BATCH

APPLICATION

of:

psi

The Run Screen will be the most useful source of information for the tool operator during

production.

Page 10

Pneumatic Torque Verifier TVP-100 Series

3 Controller Specications

3.1 IP Protection Class

TVP-110-15: This unit has an IP rating of 20.

TVP-110-30: This unit has an IP rating of 41.

3.2 Understanding the Keypad

Thefollowingisabriefexplanationofthekeypadkeys.Familiaritywiththekeyssimplies

the programming process.

Soft Keys (F1-F4) - used to select functions based on the screen display

ESC Key - used at any time to return to the previous screen or escape

an edit mode

DEL Key - used to delete numeric values

Arrow Keys - used to move highlighted or selected areas on the screen

ENTER Key - used to select or choose a value n the LCD screen

Cleco

®

PL12EN-TVP100

03/07/2013

Ship’s Wheel - used to return to the navigation screen

Run - used to return to the run screen from most other screens

Soft Keys

Ship’s Wheel

Torque Verier

TVP-110-15

Numeric Keypad

7 8 9

4 5 6

1 2 3

0

DEL

ESC

RUN

ENTER

Arrow Keys &

Enter Key

Page 11

PL12EN-TVP100

03/07/2013

3.3 Specications

3.3.1 Enclosure

8.00” (203) 9.13” (232)

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

8.75” (222)

Height 9.13 in. / 232 mm•

Width 8.75 in. / 222 mm•

Depth 4.13 in. / 105 mm•

Weight 6 lbs. / 2.72 kg•

Removable Fuse Compartment•

Settings for 115/230 VAC 50/60 Hz•

TVP-110-15: Exposed I/O Strip•

TVP-110-30: 12 pin I/O connector•

Mount with 4 M4x0.7 screws • (Disconnect power before mounting unit.)

3.3.2 Display

320 x 240 LCD•

LED Backlight•

Adjustable Contrast•

8.375” (213)

Page 12

3.3.3 Indicators

3 Highly Visible Indicators

Cycle Accept - Green

Batch Accept - Green

3.3.4 AC Input Power

Selectable 115 VAC or 230 VAC Power•

Fuse access in power entry module•

Spare fuses inside power entry module•

Unit fused at 1 Amp for 115 VAC power•

Unit fused at 5 Amp for 230 VAC power•

Peak power - 45VA•

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

Reject - Red

Torque Verier

TVP-110-15

PL12EN-TVP100

03/07/2013

Fuse Holder

Power

On/Off

Voltage

Selection

Window

Cover

Power Entry

Module

3.3.5 TVP-110-15 (115VAC) Input/Output Connectors

RS-232 Connection RJ12 (6-Conductor Phone)•

I/O Connector Phoenix 1757569•

Transducer Connection RJ12 (6-Conductor Phone)•

To change the selected

voltage, pull the cover

down and grasp the

fuse holder. Pull the

fuse holder out and

rotate it 180° to select

the desired 115 or 230

voltage.

Voltage Selection

Page 13

PL12EN-TVP100

Pin # Description Value

1

Unused N/A

2

Unused N/A

3

RX (Receive) -25V to +25V

4

TX (Transmit) -25V to +25V

5

GND 0V

6

Unused N/A

Pin # Description Value

1

Power Out +5 VDC

2

Analog Pressure IN 0V to 5V

3

RS-485+ -1V to 6.5V

4

RS-485- -1V to 6.5V

5

GND 0V

6

Unused N/A

Pin # Description Value

1

RS-485- -1V to 6.5V

2

RS-485+ -1V to 6.5V

3

Reject Relay Output +24VDC

4

Batch Relay Output +24VDC

5

Cycle Relay Output +24VDC

6

+24VDC OUT/Relay Common +24VDC

7

Ground/Opto Common 0VDC

8

Reset Optically Isolated Input 0V to 24V

9

Suspend Optically Isolated Input 0V to 24V

10

Parameter B Optically Isolated Input 0V to 24V

1 1

Parameter C Optically Isolated Input 0V to 24V

12

Parameter D Optically Isolated Input 0V to 24V

RS-232 Serial Port (RJ12)

Pressure Transducer Port

12-Pin Phoenix Input/Output Connector

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

3.3.5 TVP-110-15 (115VAC) Input/Output Connectors (continued)

RS-232 Serial

Connector

12-Pin I/O

Connector

Pressure Transducer

Connector

Page 14

Cleco

Pin # Description Value

1

Unused N/A

2

RX (Receive) -25V to +25V

3

TX (Transmit) -25V to +25V

4

Unused N/A

5

GND 0V

6

Unused N/A

RS-232 Serial Port

Pin # Description

1

Analog Signal In (from transducer)

2

GND

3

+5VDC (out to transducer)

4

Shield

Pressure Transducer Port

4 Pin Circular Amphenol Tuchel Pin Out

®

Pneumatic Torque Verifier TVP-100 Series

3.3.6 TVP-110-30 (230VAC) Input/Output Connectors

RS-232 Connection 9 pin D-SUB•

I/O Connector Amphenol 12 pin Circular Connector•

Transducer Connection Amphenol 4 pin Circular Connector•

PL12EN-TVP100

03/07/2013

12 Pin Connector Schematic

RS-232 Serial

Connector

12-Pin I/O

Connector

Pressure Transducer

Connector

RS 485 -

RS 485 +

Reject Relay

Batch Relay

Cycle Relay

+24VDC Relay Common

Ground / Opto Common

Reset

Suspend

Parameter B

Parameter C

Parameter D

RS 485

+24VDC

JP5

JP3

Press any key to continue.

Page 15

PL12EN-TVP100

Supplied

Internal

Supplied

External

A Black RS 485- -1 - 6.5V

B White RS 485+ -1 - 6.5V

C Red/White Reject Relay +24VDC

D Black/White Batch Relay +24VDC

E Blue/Black Cycle Relay +24VDC

F Green/White +24VDC/Relay Common +24VDC

G Blue/White Ground/Opto Common 0VDC

H Blue Reset 0V to 24V

J White/Black Suspend 0V to 24V

K Red/Black Parameter B 0V to 24V

L Green/Black Parameter C 0V to 24V

M Orange/Black Parameter D 0V to 24V

Pin #

Description

12 Pin Circular Input/Output Connector

100 mA

2.4 W

3 A

(70 W)

Load Maximum

Value

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

3.3.6 TVP-110-30 (230VAC) Input/Output Connectors (continued)

3.4 Decommissioning of Unit

Disconnect the power source. No additional procedures are required.

Page 16

4 Programming

4.1 Run Screen

The Run Screen is the main screen that will be used while the tool is in operation. This

screen contains a wealth of information about what is occurring in the assembly process

at any given time. From this screen a user can ascertain how many fasteners have been

completed towards a batch, the current application, the last fastener status, the pressure

within the tool, whether the unit is locked or un-locked, and the total number of batches

that have been completed.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

PL12EN-TVP100

03/07/2013

LED Indicator

Function

LED Indicator

Function

LED Indicator

Function

Current

Status

Number Completed

Toward Batch

RUN SCREEN

Cycle Count:

ACCEPT

BATCH

ACCEPT

Batch Total:

REJECT

SUSPEND

Cycle Accept

RESET

BATCH

UNLOCK

Soft Key Functions

Number in Batch

APPLICATION

of:

psi

Application in Use

Lock State

Pressure Inside Tool

Number of

Complete Batches

This screen automatically appears at the end of the power up sequence. This screen may

also be reached by selecting the “Run Screen” option from the navigation menu.

Run Screen

AutoCal

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Run Screen

Page 17

RUN SCREEN

Cycle Count:

ACCEPT

BATCH

ACCEPT

REJECT

SUSPEND UNLOCK

Cycle Accept

Batch Total:

RESET

BATCH

APPLICATION

of:

psi

PL12EN-TVP100

03/07/2013

4.2 Navigation Menu

The Navigation Menu is the leaping off point to all functions within this unit. The Ship’s

Wheel key may be pressed at any time, and the Navigation Menu will appear. From

the Navigation menu, the user can go to the Run Screen, perform an AutoCal, view a

rundown, review statistics, set the units options, select the application in use, adjust any

given application, enable sequencing, perform administrative functions, and look at a

schematic that aids in external wiring.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

4.3 AutoCal

In order for this unit to function properly, the thresholds and timers within the application

need to be set appropriately with regards to the tool’s pneumatic signature. The AutoCal

feature provides a very quick and easy means of performing this set-up. To reach the

AutoCal function, select “AutoCal” from the navigation menu.The Navigation Menu

If the unit was locked prior to making this selection, you’ll be prompted to enter the

password. The default password is “0 1 0 4”.

Run Screen

AutoCal

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Run Screen

AutoCal

View Run

Statistics

Options

AutoCal

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Please enter your password

to contonue.

TherstscreenassociatedwiththeAutoCalprocesswillinformtheuserthatthetoolmust

be off and also that they should press the “Next” key. This screen also reminds the user

which application set is active. The calibration will only effect that application. At this

point, make sure the transducer is connected to both the tool and the box and also that

the tool is not running. Then press the “Next” softkey.

AUTOCAL

Tool must be OFF.

Press NEXT to continue

the AutoCalibration

for Application A.

EXIT

Select

Application

0 1 0 4

NEXT

NEXT

Page 18

Pneumatic Torque Verifier TVP-100 Series

4.3 AutoCal (continued)

The second AutoCal screen will appear next. This screen will prompt the user to run a

typical fastener and then to press the “Next” softkey. When running a “typical” fastener,

the user should start with the tool off and then run the fastener to its completion allowing

the tool’s clutch to turn the tool off. The tool’s trigger should then be released and left

alone until the “NEXT” softkey is pressed on the unit.

After these steps are completed, the result of the calibration will appear on the screen.

Cleco

®

PL12EN-TVP100

03/07/2013

AUTOCAL

The Qualier will use the

last fastening cycle to

Run a sample fastener now.

Press NEXT to continue.

EXIT

If the calibration was not successful, check the tool and transducer connections. The

transducer needs to be properly connected to both the tool and this unit in order for the

system to function correctly.

The Run Screen may be used to determine if a pressure change is occurring while the

tool is running. When the tool if off, the pressure should be near to if not 0 psi. While the

tool is running, the pressure will be around 50 or 60 psi. When the clutch shuts the tool

off, the pressure will rise almost to line pressure.

It’s also very important that the appropriate tool type is selected. Pulse tools and direct

drive tools are monitored differently. Be sure that the appropriate tool has been selected

under the Options screen.

4.4 Viewing A Run

A graph of the last run down may be viewed by selecting the “View Run” option from the

navigation menu. Once again, you may be prompted to enter a password if the unit has

not been un-locked.

AutoCal.

OR

NEXT

Run Typical

Fastener

NEXT

AUTOCAL

Auto Calibration was successful.

Press NEXT to continue.

EXIT

NEXT

Run Screen

AutoCal

View Run

Statistics

Options

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

While viewing a run, the “1” key may be pressed to draw and erase the thresholds and

timers. Pressing the “2” key will draw and erase the tool’s signature. If a new fastening

cycle is run, the “ENTER” key may be pressed to retrieve and view this new curve.

View Run

Page 19

AutoCal

Zoom

IN

Zoom

OUT

Application

Builder

PL12EN-TVP100

03/07/2013

4.5 Statistics

This unit will hold information pertaining to the last 1000 events. That information can

be viewed by going to the “Statistics” screen. In order to reach the “Statistics” screen,

highlight the Statistics option on the navigation menu and press “ENTER”.

Run Screen

AutoCal

View Run

Statistics

Options

TherearevecolumnsworthofinformationontheStatisticsscreen.Columnoneholds

the event number. The second column displays the application the unit was using when

that event occurred. The date and time that the even occurred is displayed in column

threeandcolumnfour.Columnveholdsadescriptionofthe event itself. The event

description will be a Cycle OK, a Batch OK or a Reject.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

Select Application

Application Builder

Sequencing

Administration

I/O Schematic

Statistics

EVENT APP MM/DD/YYYY HH:MM.SS STATUS

17 A 12/15/2011 11:14.21 Cycle OK

16 A 12/15/2011 11:13.42 Batch OK

15 B 12/15/2011 11:12.25 Reject T14 A 12/15/2011 11:12.34 Cycle OK

13 A 12/15/2011 11:10.32 Cycle OK

12 A 12/15/2011 11:08.21 Cycle OK

11 A 12/15/2011 11:07.23 Cycle OK

10 A 12/15/2011 10:22.15 Batch OK

9 A 12/15/2011 10:21.12 Cycle OK

8 A 12/15/2011 10:20.20 Cycle OK

7 A 12/15/2011 9:44.26 Cycle OK

Page

Page

UP

DOWN

Most

Recent

EXIT

The Cycle OK status tells you that a single fastening was completed properly. A Batch OK

tells you that a single fastening was completed properly and that it was the last fastener

in the batch. A Reject status informs the user that for some reason that fastening was

rejected. Each Reject status is accompanied with a reason to help you discern why that

fastening was rejected.

The soft-keys provide functions that allow a user to view more statistics than can be

showed on the screen at one time. The “Page Up” and “Page Down” soft-keys can be

pressed to view events that occurred further back in time or more recently. Pressing the

“Most Recent” soft-key will place the most recent event at the top of the screen and the

events that preceded it directly below.

Pressing the “Exit” soft-key or the Ship’s Wheel will take the unit back to the navigation

menu.

4.6 Options

Several user adjustable features can be accessed from the “Options” menu. In order to

reach the “Options” menu, highlight the Options button on the navigation menu and press

the “ENTER” key.

Run Screen

AutoCal

View Run

Statistics

Select Application

Application Builder

Sequencing

Administration

Options

OPTIONS MENU

1. Relays

2. Beeper

3. Parameter Switch Type

4. Time / Date

5. Tool Type

6. Adjust Display

Options

I/O Schematic

Save EXIT

Page 20

4.6.1 Relay Options

TherstitemontheOptionsscreenlistisRelays.Byselectingthisoptiontheusercan

choose to set the relays to “latching” or “momentary”. To select “Relays” from the Options

screen list either press the “1” key or highlight the “Relays” option and press “ENTER”.

Once at the “Relays Options” screen you can choose how the relay outputs are going

to act. If the relays are set to momentary, each time an event occurs the corresponding

relay will turn on for 200ms and then turn back off. If the relays are set to latching, the

appropriate relay will turn on and remain on when an event occurs. That relay will turn off

at the beginning of the next cycle (the next time the tool starts).

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

RELAY OPTIONS

1. Momentary

2. Latching

Select EXITUp Down

PL12EN-TVP100

03/07/2013

To make a selection on this screen, the number key that corresponds with the selection

may be pressed. If you use this number key method, the selection will be made and

stored. The screen will also return to the “Options” menu.

A selection may also be made by using the arrow keys or the “UP” and “DOWN” soft-keys

to highlight the desired selection and then pressing the “Select” soft-key.

The “EXIT” soft-key, the “Ship’s Wheel”, or the “ESC” key may be pressed to return to the

“Options” screen without making and storing a new selection.

4.6.2 Beeper Options

The second item on the Options screen list is Beeper. The unit can be programmed to

double-beep or be silent upon the completion of a batch. In order to choose the Beeper

option either press the “2” key or highlight the Beeper option using the Arrow keys and

then press “ENTER”.

BEEPER OPTIONS

1. Double beep on Batch Accept

2. Beep on Reject only.

Select EXITUp Down

To make the box double-beep on a batch accept, either press the “1” key at the Beeper

Options screen or highlight the “Double Beep” option and press the “Select” soft-key.

If a double-beep is not desired either press the “2” key at the Beeper Options screen or

highlight the “Beeper on Reject” option and press the “Select” key.

Page 21

PL12EN-TVP100

Param D Param C Param B Application Application

INPUT INPUT INPUT (Binary) (Discrete)

OFF OFF OFF A A

OFF OFF ON B B

OFF ON OFF C C

OFF ON ON D C

ON OFF OFF E D

ON OFF ON F D

ON ON OFF G D

ON ON ON H D

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

4.6.3 Application Select Input

Applications can be selected through external inputs. These inputs can be used in two

different schemes. The inputs can either select one of four different applications. Or,

when set to “binary”, these three inputs can be used to select eight different inputs.

Binary(1of8)istherstoptiononthe“ApplicationsSelectInputs”screen.Inorderto

choose this option either press the “1” key at this screen or highlight the option and press

the “Select” soft-key.

Cleco

APPLICATION SELECT INPUTS

1. Binary, 1 of 8

2. Discrete, 1 of 4

®

Select EXITUp Down

If discrete (1 of 4) is how you would prefer to select applications either press the “2” key

or highlight this option and press the “Select” soft-key.

Page 22

4.6.4 Time and Date

This unit will keep track of the current time and date even when the unit is turned off.

Each time an event occurs (like an accept or reject), that event is stored in memory along

with a time and date stamp.

The time and date may be edited by pressing the “4” key at the Options screen or by

highlighting the “Time / Date” element and pressing the “Select” soft-key.

Once at the TIME / DATE edit screen, the left and right arrows may be used to select a

character within the time or date. Once the desired character is highlighted the number

keys may be used to alter its value.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

TIME / DATE

Enter the time and date in the

format: YYY/MM/DD HH:MM.SS

2011/06/16 13:41.24

The change will not occur

until the unit is powered down.

Save EXIT

PL12EN-TVP100

03/07/2013

Once the time and date are set to the desired value, either the “Save” soft-key or the

“ENTER” key may be pressed to save the new value. If a new value is saved, the unit will

have to be powered down and powered back up again before the changes take effect.

TIME / DATE

2011/06/16 13:41.24

Please turn the power switch OFF.

Save EXIT

To leave the TIME / DATE screen without making any changes either the “EXIT” soft-key

or press the “ESC” key.

Page 23

PL12EN-TVP100

03/07/2013

4.6.5 Tool Type

It is very important to select the correct tool type for the application. There are three

differentchoicesformonitoringtoolswithinthisunit.TherstchoiceisPulsePneumatic

and should be used for monitoring most Pulse Tools. When set to Pulse Pneumatic, this

unitwillnotonlyusethetimersandthresholds,thisunit willactuallycountandconrm

that pulses occurred.

The Direct-drive Pneumatic is used for monitoring pneumatic clutch tools that do not

pulse.

The 7/11 PTH mode is a combination of Pulse Pneumatic and Direct-drive Pneumatic.

TosetToolType,fromtheOptionsScreenselectthefthoption(ToolType)bypressing

the 5 key or highlight the option and press “ENTER”. The Tool Type screen will appear

at this point. If a Pulse tool (20Nm or larger) is to be monitored, option one (Pulse

Pneumatic) should be selected. Select option three (7/11 PTH) for smaller pulse tools.

For all other pneumatic tools option two (Direct-drive Pneumatic) should be selected.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

TOOL TYPE

1. Pulse Pneumatic

2. Direct-drive Pneumatic

3. 7/11 PTH

Pressing the numeric key associated with the desired option (either “1”, “2” or “3”) will

select and write that option to memory. Alternatively, your option can be highlighted and

then “ENTER” can be pressed to make a selection.

4.6.6 Adjusting The Display

The unit’s display is set for optimal viewing at the factory. However, it may be necessary

at some point to make the display darker or lighter for easier viewing. If the display needs

adjusted, option six can be selected from the Options menu by either pressing the “6” key

or by highlighting the option and pressing “ENTER”.

The arrow keys are used to alter the display from the Adjust Display screen. Once the

display has the desired appearance, press the “EXIT” soft-key to return. The default

LCD values can be re-written if the “.” button is pressed during the power-up screen or at

the “Run” screen.

Select EXITUp Down

ADJUST DISPLAY

Less Contrast More Contrast

Light

Dark

highlighted text

selected text

EXIT

Page 24

Pneumatic Torque Verifier TVP-100 Series

4.7 Selecting Application

An application is a set of parameters that governs how a given tool is monitored. There

are two different ways to choose which application is in use. One way is through external

inputs. The other method can be accomplished through the keypad. A dip-switch inside

the box controls which method can be used.

If dip-switch one on the backboard is in the “ON” position, then applications can be selected

through the keypad. In order to change the application, go to the navigation menu and

choose “Select Application”.

On the “Select Application” screen, an arrow will point to indicate which application is

currently selected. To change this selection, you can press the number on the keypad

that is associated with the application you want to select. Or, you can highlight the desired

selection with the arrow keys and then press the “Select” soft-key.

Cleco

SELECT APPLICATION

1. A

2. B

3. C

4. D

5. E

6. F

7. G

8. H

®

Select EXIT

PL12EN-TVP100

03/07/2013

To leave this screen without making any changes, the “EXIT” soft-key can be pressed or

the “ESC” key can be pressed. The “Ship’s Wheel” has no effect at this screen.

4.8 Application Builder

An application is a set of timers, thresholds, and a batch value that are used in monitoring

the pneumatic tool. The best way to develop these values it to make use of the AutoCal

feature. By using AutoCal, the timers and thresholds will be generated automatically for

any given application.

A situation may arise where these values need to be manipulated manually. If so, select

the “Application Builder” option from the navigation menu. This action will take the unit to

the “Application Builder” screen.

APPLICATION BUILDER

Application

Th1 Noise Floor

Th2 Run Start

Th3 Shut-off Threshold

T- Minimum Run Time

T+ Maximum Run Time

Tc Clutch Timer

Tb Bump Timer

Fasteners per Batch

Total Completed Batches:

Page 25

PL12EN-TVP100

Application Element Description

Th1 Noise Floor

Pressure threshold that sets a pressure level for the unit to begin capturing

data

Th2 Run Start

Pressure threshold that sets a pressure level which after crossed a status

will be generated (either accept or reject).

Th3 Shut-off Threshold

Pressure threshold that sets a pressure level above which the tool is

considered to have "clutched" out. Th3 is a defined pressure increment

above the pulsing (or tightening) pressure.

Thd Dynamic Threshold

Th3 pressure level as it is displayed on oscilloscope. It is called

dynamic pressure because it rises/falls with line pressure.

T- Minimum Run Time

Minimum amount of time the tool must run before clutching out

without generating a reject.

T+ Maximum Run Time

Maximum amount of time tool can run before clutching out without

generating a reject.

Tc Clutch Timer

Amount of time user must hold tool trigger after tool clutches out

without generating a reject.

Tb Timer Bump

Timer used to cancel incidental runs in the case of a push to start

tool. If this timer is violated without the clutch firing, no status will be

generated. AutoCal sets this time to 0.

Fasteners per Batch

Number of fasteners associated with a batch. Every time this number

of fasteners is completed, a Batch Accept will be generated.

Total Completed Batches

This number represents the number of batches that have been

completed.

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

4.8 Application Builder (continued)

To edit an item from the Application Builder, highlight the item you want to edit and then

press “ENTER”. A cursor will appear. While that cursor is highlighting a digit, use the

numeric keypad to alter its value or use the left and right arrows to select a different

character.

Cleco

®

The“ESC”keywillstopthecursorfromashingandallowyoutoselectadifferentelement

to be edited.

The “SAVE” soft-key must be pressed in order to save any changes made within the

Application Builder. The “EXIT” soft-key will allow a user to leave the Application Builder

without making any changes.

The “Globalize” soft-key allows you to copy an application to all of the other applications.

The “Clear Total” soft-key sets the total back to zero.

Page 26

4.9 Sequencing

This unit has the ability to automatically switch from application to application if the

“Sequencing” feature is enabled. If Sequencing is enabled, the unit will start in Application

A. Once the batch is complete in Application A, the unit will automatically switch to

Application B. This switching from application to application will continue upon the

completion of each batch until the end application is reached.

Once the end application is reached and the batch is completed, a batch accept will be

generated and the unit will revert back to Application A. The batch accept output will only

begeneratedonthenalapplicationinthesequence.

In order to program the Sequence function, select the “Sequencing” item from the

navigation menu.

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

SEQUENCING

OFF

A-B

A-C

A-D

A-E

A-F

A-G

A-H

PL12EN-TVP100

03/07/2013

Using the arrow keys or the “UP” and “DOWN” soft-keys, you can highlight the type of

sequencing you wish to employ. Once the desired selection is highlighted, pressing the

“Select” soft-key will move the arrow to indicate that the selection has changed.

The “EXIT” soft-key, the “ESC” key, and the “Ship’s Wheel” will all take the unit back to

the navigation menu.

4.10 Administration

The unit’s password can be altered from the Administration screen. To alter the unit’s

password, choose “Administration” from the navigation menu. There are only two options

on the Administration screen, one is “Change Password” and the other is “Exit”. Choose

the “Change Password option by highlighting it and pressing the “ENTER key.

ADMINISTRATION

Change Password

EXIT

EXIT

Select EXIT

CHANGE PASSWORD

Please enter a new four-digit

password:

EXIT

CHANGE PASSWORD

Please conrm your new password.

Conrm:

EXIT

Page 27

PL12EN-TVP100

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

4.10 Administration (continued)

After “ENTER” is pressed, a screen will appear prompting you to enter a new four-digit

password. Use the numeric keypad to enter this new code or press the “Exit” soft-key to

escape without changing the password.

Once the new four-digit code is entered, the unit will prompt you to conrm this four

digit code. If you enter the same code the second time, the unit will politely ask you to

remember your new password. If for some reason the same code is not entered twice,

theunitwillinformyouthatyourconrmationfailed.

In either case, after a short delay, the unit automatically returns to the navigation menu.

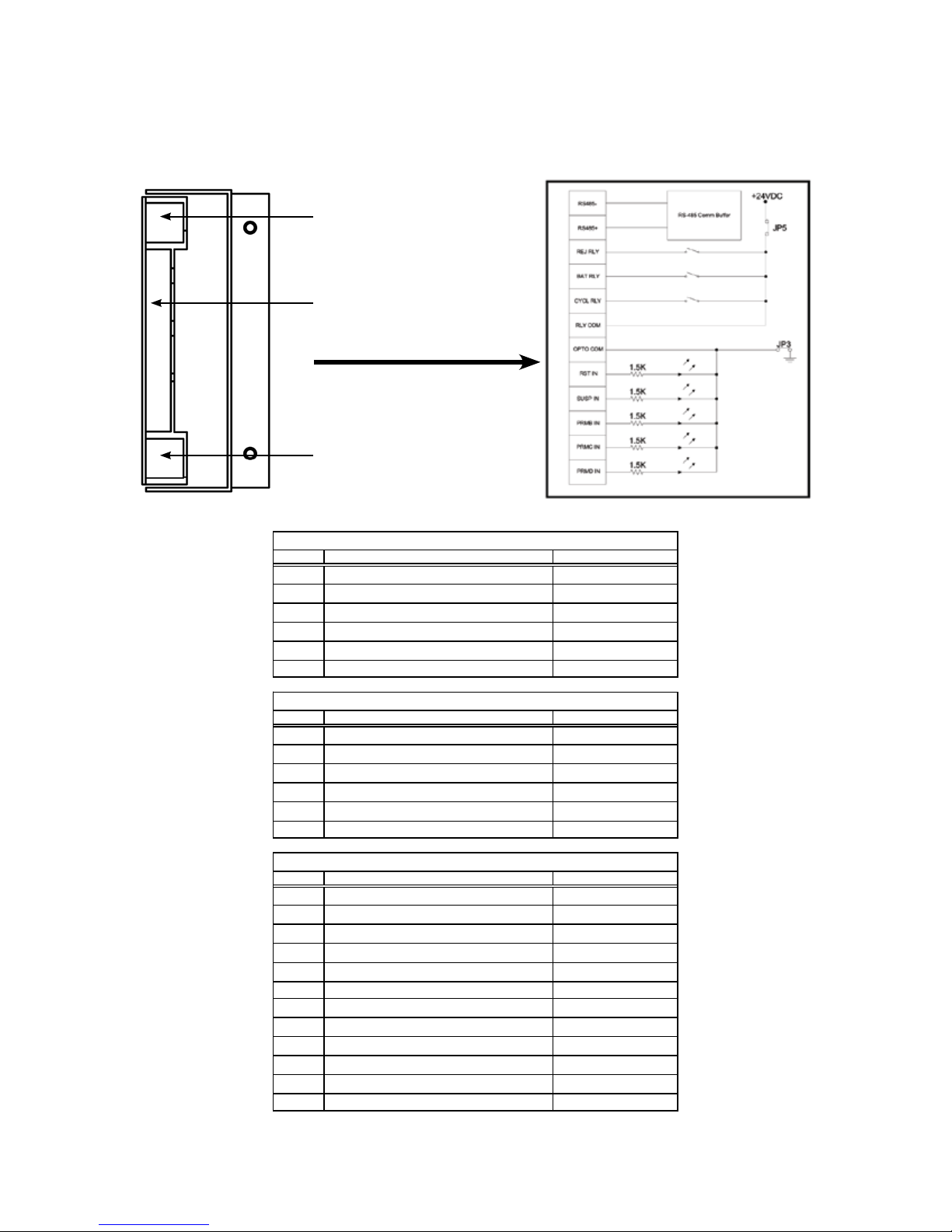

4.11 I/O Schematic

The nal option on thenavigation menuis “I/OSchematic” ifthis option is selected a

schematic appears on the screen which shows the function of the 12-pin I/O connector

and the circuitry behind it.

Pressing any key while the schematic is being displayed will return the unit to the navigation

menu.

Cleco

®

12 PIN CONNECTOR SCHEMATIC

+ RS485

- RS485

REJECT RELAY

BATCH RELAY

CYCLE RELAY

+24VDC/RLY COM

GND/OPTO COM

RESET INPUT

SUSPEND INPUT

PARAM B INPUT

PARAM C INPUT

PARAM D INPUT

PRESS ANY KEY TO CONTINUE

RS 485

+24VDC

JP5

JP3

Please note that jumpers JP3 and JP5 from the diagram above are not connected when

the unit ships.

Page 28

Pneumatic Torque Verifier TVP-100 Series

A Appendix

A.1 Pneumatic Curves (Pulse Tool)

Good Run Down:

Analog CH1 Analog CH2

Free Run

Pulsing Region

Cleco

®

Pulse Tool Good Run

PL12EN-TVP100

03/07/2013

Clutch-Out

Region

% Full Scale

Time (in seconds)

This picture shows the analog data from a good fastening process using a pulse tool.

There are a few hallmarks in this curve that are worth noticing. This tool was set up to

pulse at least four times. If the tool does not pulse at least four times, there is a good

chance that it will generate reject statuses.

Also, at the end of the pulsing phase, the pressure steps up almost to line level. This

region indicates the tool’s clutch shut the tool off when torque was achieved.

Page 29

PL12EN-TVP100

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

A.1 Pneumatic Curves (Pulse Tool) (continued)

Incomplete Run Down:

Pulse Tool No Clutch

Analog CH1 Analog CH2

% Full Scale

Time (in seconds)

This picture shows the curve generated by an incomplete fastening process. Notice how

the curve does not step up to line pressure at the end of the run. This indicates that the

clutch did not engage.

Page 30

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

A.1 Pneumatic Curves (Pulse Tool) (continued)

Double-Hit:

Pulse Tool Double Hit

Analog CH1 Analog CH2

% Full Scale

PL12EN-TVP100

03/07/2013

Time (in seconds)

This picture shows the curve generated by a double hit. Notice how the curve immediately

steps up to line pressure and stays there. There is little or no pulsing region. This curve

would be typical of a fastener being “hit” again after the fastener had already been

tightened to torque.

Page 31

PL12EN-TVP100

03/07/2013

Cleco

Pneumatic Torque Verifier TVP-100 Series

A Appendix

A.2 Pneumatic Curves (Direct Drive Tool)

Good Run Down:

Direct Drive Good Run-Down

Analog CH1 Analog CH2

Free Run

®

Clutch-Out

Region

% Full Scale

Time (in seconds)

This picture shows the analog data from a good fastening process using a direct drive

tool. There are two hallmarks in this curve worth noticing. First, during free run the tool

runs at a constant pressure which is lower than the shut-off or clutch-out pressure. Then,

after the tool’s clutch engages the pressure steps up to near line pressure.

Page 32

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

A Appendix

A.2 Pneumatic Curves (Direct Drive Tool) (continued)

Incomplete Run Down:

Direct Drive No-Clutch

Analog CH1 Analog CH2

PL12EN-TVP100

03/07/2013

% Full Scale

Time (in seconds)

This picture shows the curve generated by an incomplete fastening process. Notice how

the curve does not step up to line pressure at the end of the run. This indicates that the

clutch did not engage.

Page 33

PL12EN-TVP100

03/07/2013

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

A Appendix

A.2 Pneumatic Curves (Direct Drive Tool) (continued)

Double-Hit:

Direct Drive Double-Hit

Analog CH1 Analog CH2

% Full Scale

Time (in seconds)

This picture shows the curve generated by a double hit. Notice how the curve immediately

steps up to line pressure and stays there. There is no free run region. This curve would

be typical of a fastener being “hit” again after the fastener had already been tightened to

torque.

Page 34

A Appendix

A.3 Box Dimensions

Cleco

®

Pneumatic Torque Verifier TVP-100 Series

8.75” (222)

PL12EN-TVP100

03/07/2013

8.00”

(203)

4.00” (102)

A.4 Tool and Box Diagram

Tool

Air Signal

(from Porting)

(includes cable and air hose)

Main Air

Transducer

207237 - 115V

207238 - 230V

Air Hose

9.125”

(232)

8.375” (213)

To Compressor

Phone Cable

Page 35

PL12EN-TVP100

Position ON Off

1. Parameter Selection Software Select External Input Selection

2. No Function

3. No Function

4. Test Mode Test Mode ON Normal Operation

5. Test Selection 1 See Below See Below

6. Test Selection 2 See Below See Below

7. Beeper Beeps ON Beeps OFF

8. RS-485 Terminator Termination ON Termination OFF

DIP5 DIP6 FUNCTION

OFF OFF Digital Outputs Test (each output is turned on one at a time)

OFF ON Digital Inputs Test (digital input will appear as a segment on bar LED)

ON OFF Analog Test CH0 (analog input on CH0 will appear as % on bar LED)

ON ON Analog Test CH1 (analog input on CH1 will appear as % on bar LED)

1 2 3 4 5 6 7 8

ON

Dip-Switch Settings

03/07/2013

Pneumatic Torque Verifier TVP-100 Series

B Appendix

B.1 Dip-Switch Settings

The dip-switch (located in the corner on the CE2731 board) controls certain aspects of

the units functionality. Those functions are listed below.

Cleco

®

B.2 Test Modes

When dip-switch four is in the ON position, the backboard (CE2731) enters a test mode.

The possible tests are as follows:

Page 36

Sales & Service Centers

Note: All locations may not service all products. Please contact the nearest Sales & Service Center for

the appropriate facility to handle your service requirements.

Detroit, MI Houston, TX Lexington, SC Los Angeles, CA

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center 670 Industrial Drive Sales & Service Center

2630 Superior Court 6550 West Sam Houston Lexington, SC 29072 6881 Stanton Avenue

Auburn Hills, MI 48326 Parkway North, Suite 200 Tel: 800-845-5629 Unit B

Tel: 248-393-5640 Houston, TX 77041 Tel: 803-951-7544 Buena Park, CA 90621

Fax: 248-391-6295 Tel: 713-849-2364 Fax: 803-358-7681 Tel: 562-623-4457

Fax: 713-849-2047 Fax: 562-802-1718

Seattle, WA York, PA Canada Germany

Apex Tool Group Apex Tool Group Apex Tool Group Apex Tool Group

Sales & Service Center Sales & Service Center Sales & Service Center GmbH & Co. OHG

2865 152nd Avenue N.E. 3990 East Market Street 5925 McLaughlin Road Industriestraße 1

Redmond, WA 98052 York, PA 17402 Mississauga, Ont. L5R 1B8 73463 Westhausen

Tel: 425-497-0476 Tel: 717-755-2933 Canada Germany

Fax: 425-497-0496 Fax: 717-757-5063 Tel: 905-501-4785 Tel: +49 (0) 73 63 81 0

Fax: 905-501-4786 Fax: +49 (0) 73 63 81 222

England France China Mexico

Apex Tool Group Apex Tool Group S.N.C. Cooper (China) Co., Ltd. Cooper Tools

GmbH & Co. OHG 25 rue Maurice Chevalier a company of de México S.A. de C.V.

C/O Spline Gauges B.P. 28 Apex Tool Group, LLC a company of

Piccadilly, Tamworth 77831 Ozoir-La-Ferrière 955 Sheng Li Road, Apex Tool Group, LLC

Staffordshire B78 2ER Cedex, France Heqing Pudong, Shanghai Vialidad El Pueblito #103

United Kingdom Tel: +33 1 64 43 22 00 China 201201 Parque Industrial Querétaro

Tel: +44 1827 8741 28 Fax: +33 1 64 43 17 17 Tel: +86-21-28994176 Querétaro, QRO 76220

Fax: +44 1827 8741 28 Fax: +86-21-51118446 Mexico

Tel: +52 (442) 211-3800

Fax: +52 (442) 103-0443

Brazil Hungary

Cooper Tools Industrial Ltda. Apex Tool Group

a company of Hungaria Kft

Apex Tool Group, LLC Platànfa u.2

Av. Liberdade, 4055 9027 Györ

Zona Industrial - Iporanga Hungary

18087-170 Sorocaba Tel: +36 96 66 1383

SP Brazil Fax: +36 96 66 1135

Tel: +55 15 2383929

Fax: +55 15 2383260

Apex Tool Group, LLC

1000 Lufkin Road

Apex, NC 27539

Phone: 919-387-0099

Fax: 919-387-2614

www.apextoolgroup.com

PL12EN-TVP100/Printed in USA 03/2013/Copyright © Apex Tool Group, LLC

Loading...

Loading...