Electric Tool Control

TME Series

Version 2.5.2

Reference Document: PL12-1404 Parts manual

For additional product information visit our website at http://www.cooperpowertools.com

Programming Manual

PL12EN-1300

2008-03

2 PL12EN-1300 2008-03 en00d141.fm, 11.03.2008

Disclaimer:

The information and data in this document has been prepared to the best of our ability.

Nonetheless, differences between the information and the actual product cannot be

excluded with absolute certainty. Cooper

Power Tools does not assume any liability for

consequential errors and damages. We likewise do not assume liability for damages

resulting from defective circuitry inside the devices supplied. Cooper

Power Tools

reserves the right, to ammend, supplement or improve this document or the product with

-

out serving prior notice.

Without the express approval of Cooper Power Tools this document must not be reproduced in its entirity or in part by any means; it must not be converted to any type of natural or machine readable language or be saved on data storage media of electronic,

mechanic, optical or other type.

PL12EN-1300 TME-200 V2.5 .2 0108IVZ.fm, 11.03.2008 PL12EN-1300 2008-03 3

Contents

1 Getting Started 7

1.1 Safe Work Practices Symbol ................................................................ 7

1.2 Checking Your Unit ............................................................................... 7

1.3 Software................................................................................................ 7

1.4 Installing Unit ........................................................................................ 7

1.4.1 General ................................................................................................. 7

1.4.2 Mounting ............................................................................................... 8

1.4.3 Location Considerations ....................................................................... 8

1.4.4 Source Power ....................................................................................... 8

1.4.5 Intended Use ........................................................................................ 8

1.4.6 EMC Measures ..................................................................................... 9

1.5 Connecting Unit .................................................................................... 9

1.5.1 General ................................................................................................. 9

1.6 Energizing Unit ................................................................................... 10

2 Controller Specifications 13

2.1 Understanding the Keypad ................................................................. 13

2.2 Specifications...................................................................................... 14

2.2.1 Enclosure............................................................................................ 14

2.2.2 Display ................................................................................................ 14

2.2.3 Keypad Overlay .................................................................................. 15

2.2.4 Indicators ............................................................................................ 15

2.2.5 CPU with PC 104................................................................................ 15

2.2.6 AC Input Power................................................................................... 16

2.2.7 Inernal DC Power ............................................................................... 16

2.2.8 Input / Output Connectors................................................................... 16

3 Programming 21

3.1 Navigator Menu .................................................................................. 21

3.1.1 Basic Navigation Instructions.............................................................. 21

3.1.2 Work Cell ............................................................................................ 21

3.1.3 Password Function ............................................................................. 22

3.1.4 Print Screen ........................................................................................ 22

3.1.5 Two Channel Features: General Description

(2-Channel V2.xx.xx C2 only) ............................................................. 22

3.1.6 Navigator Menu .................................................................................. 23

3.1.7 Administration ..................................................................................... 24

3.2 Basic Application Builder .................................................................... 24

3.2.1 Basic Parameters for Torque Control / Angle Monitor ........................ 26

3.2.2 Basic Parameters for Angle Control / Torque Monitor ........................ 26

3.2.3 Basic Application Builder Parameters................................................. 26

3.2.4 Advanced Parameter Default Values.................................................. 27

4 PL12EN-1300 2008-03 PL12EN-1300 TME-200 V2.5.2 0108IVZ.fm, 11.03.2008

3.2.5 Backoff using Reverse Switch (Sequence 41 or Sequence 46) ......... 27

3.2.6 Basic Application Builder / Auto Program ........................................... 27

3.2.7 Basic Application Builder / Copy......................................................... 28

3.3 Standard Application Builder............................................................... 29

3.3.1 Standard Application Builder / View Stages........................................ 29

3.3.2 Standard Application Builder / View Stages / Copy ............................ 30

3.3.3 Standard Application Builder / Select Sequence ................................ 31

3.3.4 Standard Application Builder / Parameters......................................... 33

3.3.5 Standard Application Builder / Advanced Parameters........................ 38

3.4 Advanced............................................................................................ 40

3.4.1 Advanced Application Builder / Application Matrix.............................. 40

3.4.2 Advanced Application Builder / Inputs ................................................ 41

3.4.3 Advanced Application Builder / Outputs ............................................. 43

3.4.4 Advanced Application Builder / Fieldbus ............................................ 46

3.4.5 Advanced / Linking ............................................................................. 51

3.4.6 Advanced Application Builder / Signals .............................................. 52

3.4.7 Advanced Application Builder / System Settings ................................ 53

3.5 RUN Screen........................................................................................ 55

3.5.1 Run Screen / Tool 2 ............................................................................ 57

3.5.2 Run Screen / Split Screen................................................................... 57

3.5.3 Run Screen / TMEI ............................................................................. 58

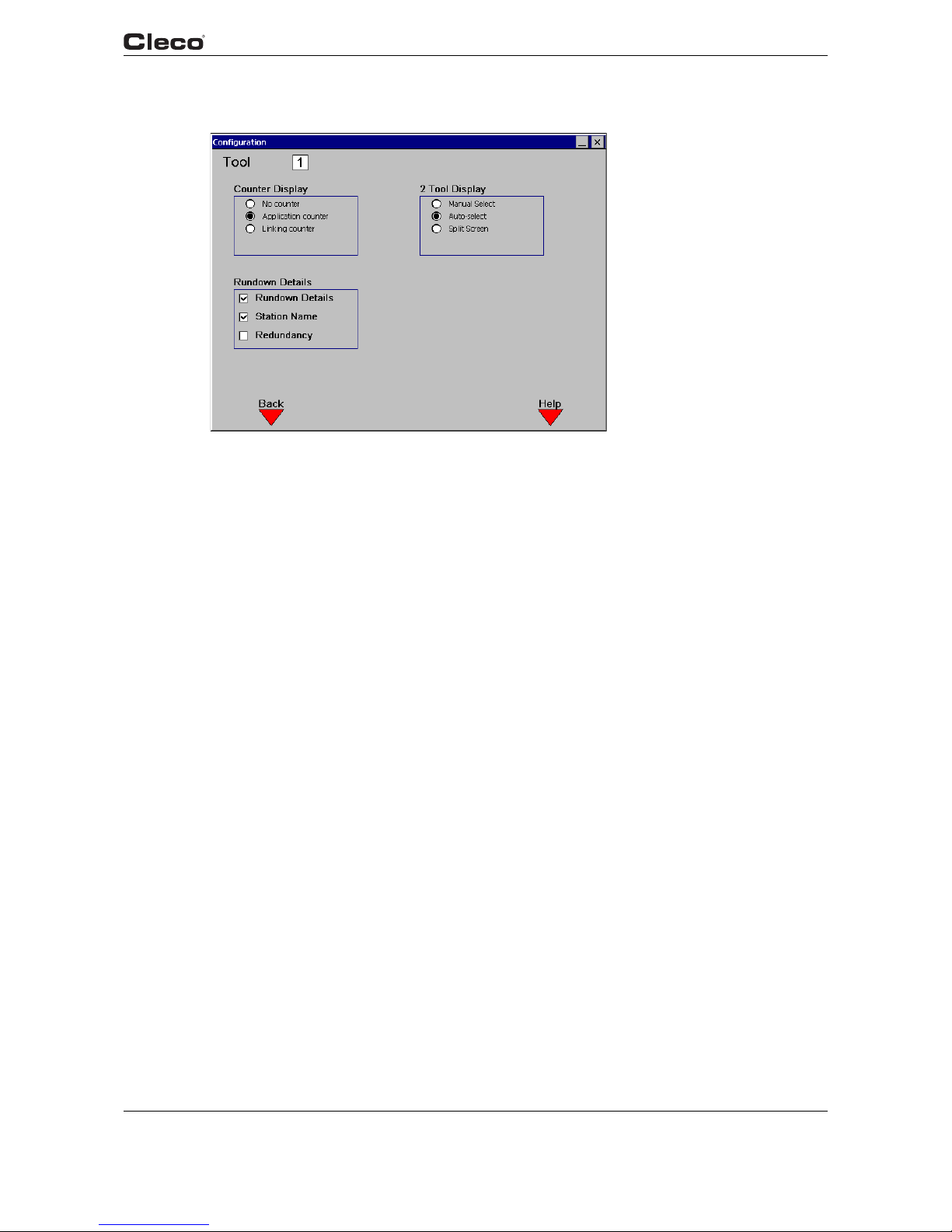

3.5.4 Run Screen / Configure ...................................................................... 59

3.6 Oscilloscope ....................................................................................... 60

3.7 Communication................................................................................... 61

3.7.1 Communications / Data Transmission ................................................ 61

3.7.2 Communication / Part ID..................................................................... 64

3.7.3 Communications / Printer ................................................................... 67

3.7.4 Communications / Work Cell .............................................................. 68

3.8 Tool Setup........................................................................................... 68

3.9 Tool Library ......................................................................................... 70

3.9.1 Tool Library ......................................................................................... 70

3.10 Statistics.............................................................................................. 71

3.10.1 Statistics / Chronological History ........................................................ 71

3.10.2 Statistics / Graphs............................................................................... 73

3.10.3 Statistic / Parameter............................................................................ 75

3.11 Diagnostics ......................................................................................... 76

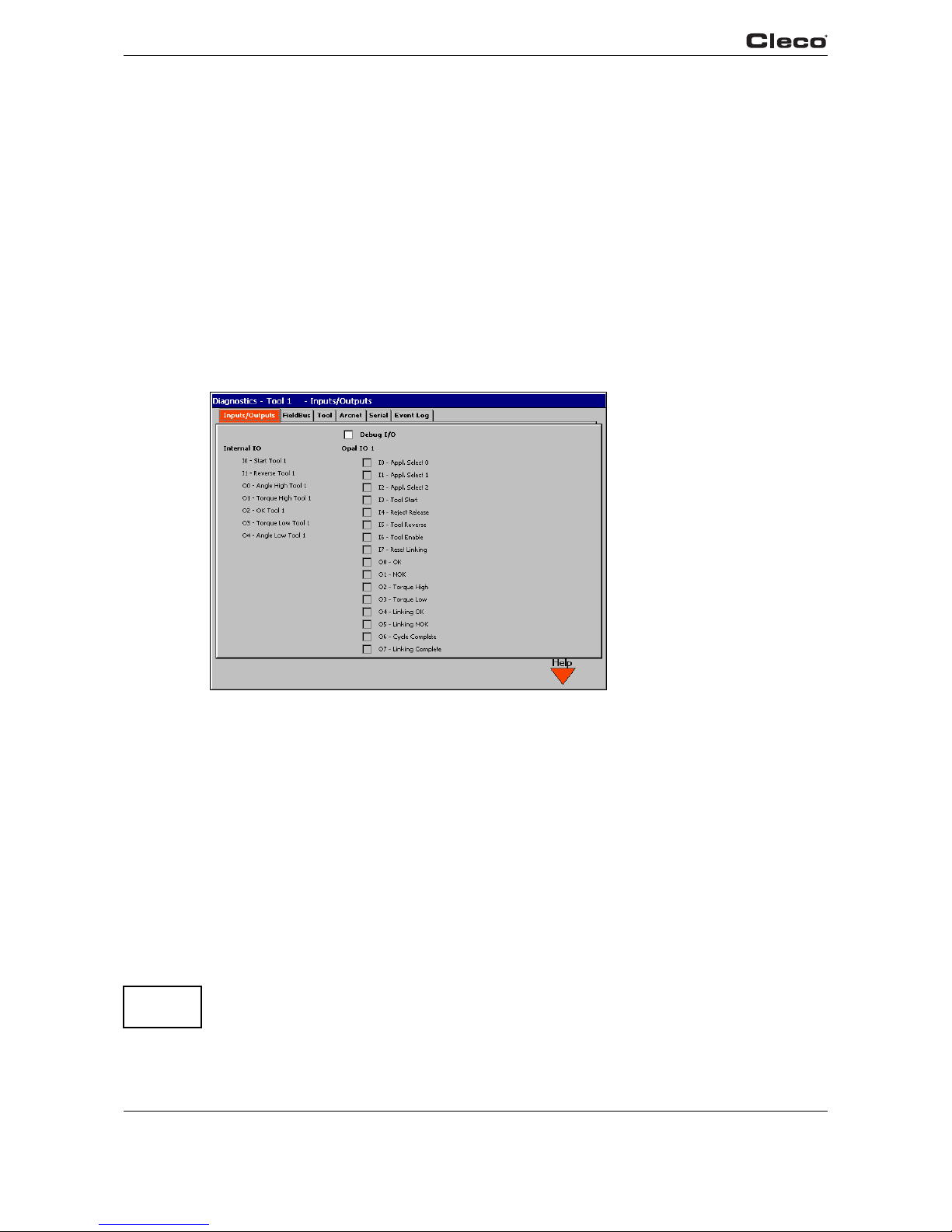

3.11.1 Inputs / Outputs .................................................................................. 76

3.11.2 Diagnostic / Fieldbus .......................................................................... 77

3.11.3 Tool / Calibration ................................................................................. 78

3.11.4 Tool / Angle Encoder........................................................................... 79

3.11.5 Tool / Voltages .................................................................................... 80

3.11.6 Tool / TQ Measurement ...................................................................... 81

3.11.7 Tool / Speed........................................................................................ 82

3.11.8 Tool / Tool Memory.............................................................................. 83

3.11.9 Arcnet / Map ....................................................................................... 83

3.11.10 Arcnet / Statistic.................................................................................. 84

PL12EN-1300 TME-200 V2.5 .2 0108IVZ.fm, 11.03.200 8 PL12EN-1300 2008-03 5

3.11.11 Serial................................................................................................... 85

3.11.12 Event Log............................................................................................ 86

3.12 Utilities ................................................................................................ 87

3.12.1 Utilities / Installed Versions................................................................. 87

3.12.2 Utilities / Software Update .................................................................. 88

3.12.3 Utilities / System Settings ................................................................... 90

3.13 Administration ..................................................................................... 91

3.13.1 Administration / Load/Save................................................................. 91

3.13.2 Administration / Print........................................................................... 92

3.13.3 Administration / Password .................................................................. 93

3.13.4 Administration / Date & Time .............................................................. 94

3.13.5 Administration / Language .................................................................. 95

3.13.6 Administration / Counter ..................................................................... 96

4 Statistics 97

4.1 Understanding Statistics ..................................................................... 97

4.1.1 The Nature of Variation....................................................................... 97

4.1.2 The Normal Curve .............................................................................. 98

4.1.3 The Procedure.................................................................................... 98

4.1.4 System Improvement........................................................................ 102

4.2 Statistic Symbols............................................................................... 102

5 Glossary 105

6 PL12EN-1300 2008-03 PL12EN-1300 TME-200 V2.5.2 0108IVZ.fm, 11.03.2008

en01d141.fm, 11.03.2008 PL12EN-1300 2008-03 7

Getting Started

1

1 Getting Started

1.1 Safe Work Practices Symbol

!

The signal word "Warning" identifies all notes on safe work practices in this operating

instruction, alerting to hazards for life and health of people. Observe these notes and proceed with special care in the cases described. Pass all safety instructions on to other

operators. In addition to the safety instructions in this operating instruction, the general

local safety and accident prevention rules must be observed.

CAUTION!

The signal word "Caution!" identifies all portions of this operating instruction meriting

special attention to ensure that guidelines, rules, hints and the correct work procedures

are observed; and, to prevent damage to and destruction of the machine and/or parts.

1.2 Checking Your Unit

Take the time to ensure you have the required peripheral equipment and cables necessary to

setup and run your unit. If you do not have all the necessary items, contact your distributor.

Refer to "Attachment A.1" on page12 for illustration of your unit.

1.3 Software

Your unit has been pre-loaded with software and requires no additional software to begin your

fastening process. If you are interfacing your unit with an external computer, interfacing software

is required. Contact your distributor for the interfacing software.

1.4 Installing Unit

1.4.1 General

!

It is mandatory that national, state and local safety and wiring standards be followed during installation. These standards would take precedence over any information presented

in this section.

To avoid the hazard of electrical shock or burn, the following instructions must be

adhered to. Failure to follow these instructions may also cause damage to your unit and

void existing warranties.

• Do not energize the unit until all connections have been properly made.

• Equipment must be properly grounded before applying power. Units energized by cord

and plug must be connected to an approved and properly grounded receptacle.

• All units must be energized by an isolated line.

• The unit door must always be closed and secured prior to energizing the unit.

• Ensure the power switch is in the "off" position prior to connecting the power cord.

CAUTION!

Though it is not mandatory, the following instructions are highly recommended for the

protected operation of your unit.

• Use an isolation transformer and surge arrestor on the incoming isolated line.

• Use oversized feeder lines to reduce electrical noise and voltage drop.

8 PL12EN-1300 2008-03 en01d141.fm, 11.03.2008

Getting Started

1

1.4.2 Mounting

Each unit is used primarily as a single tool process/controller/monitor installed in a work station

or work area. It may be wall mounted, table mounted, beam mounted, suspended overhead,

pedestal mounted or used without mounting. Always choose a stable location to avoid the possi

bility of unit damage and/or operator injury through hitting, falling, vibration or inconvenient

mounting. All cables attached to the unit should be located and secured in a manner to avoid

potential operator and passer-by injury. As with all electrical equipment, the unit will produce

some heat and should be located so that ambient air can freely circulate around the box.

Refer to Illustration Q of the parts manual, PL12-1400 for mounting hole dimensions.

1.4.3 Location Considerations

Your unit should be located to allow access to the front panel and connectors. The unit should be

installed for unrestricted and comfortable viewing of the LCD & LED's by the operator. The LCD

menu screen, key pad and side door connectors must be readily accessible for the setup.

Dependent on the peripheral equipment purchased, the unit may be located in a remote position

but should still be accessible.

Attachment of accessories and tools should also be considered with the installation locations.

Items to be considered are:

• Location of printer (10 ft. cable maximum for the parallel interface).

• Attachment of a data collection unit, if desired.

• Attachment of redundant master transducers (less than 50 ft. is desirable).

• Attachment of remote annunciators, socket nest, or remote parameter select.

• Attachment of the unit in a network to a computer.

• Operation convenience/safety - keep cables off the floor or dangling in operator areas.

1.4.4 Source Power

Your unit, which is used as the process control and power supply for the Cleco DC electric tools,

requires a power line with 10 amp capacity at 220-240 Volts AC (50/60 Hz) for the TME-XXX-30.

The TME-XXX-15 requires a power line with 15 amp capacity at 110-130 Volts AC (50/60 Hz).

1.4.5 Intended Use

The Electric Tool Control TME Series must be operated only if the following conditions are

met:

• Industrial environment, EMC (electromagnetic compatibility) class A

• Use only the cable types approved by Cooper Power To ol s .

• Use only accessory parts approved by Cooper Power Tools.

• Unauthorized remodeling, repairs, and modifications are forbidden for safety and product lia-

bility reasons.

en01d141.fm, 11.03.2008 PL12EN-1300 2008-03 9

Getting Started

1

1.4.6 EMC Measures

• The filters required to meet the EMC regulations are integrated.

• The closed control cabinet and the shielded cables result in very low noise radiation and high

immunity to interference.

• The following relevant EMC regulations are met:

-EN 61000-6-4: 08-2002

-EN 61000-6-2: 08-2002

-EN 61000-3-2: 2000

-EN 61000-3-3: 1995

• This is a class A device. In domestic areas, this device can cause radio interference. If

that is the case, the company operating it, can be obliged to introduce EMC measures

and cover the cost incurred.

• Operation without closed control cabinet is forbidden.

The properties of the shielding would be altered and the noise emission increase.

1.5 Connecting Unit

1.5.1 General

Connect all equipment to the correct input and output connectors. Refer to "Attachment A.1" on

page12 for proper port locations.

!

To avoid the hazard of electrical shock or burn the following instructions must be adhered

to. Failure to follow these instructions may also cause damage to your unit and void existing warranties.

• Ensure the power switch is in the "off" position and that the box cover is properly

secured prior to connecting power cord.

• Ensure equipment has been properly grounded before applying power.

10 PL12EN-1300 2008-03 en01d141.fm, 11.03.2008

Getting Started

1

1.6 Energizing Unit

!

To avoid the hazard of electrical shock or burn the following instructions must be adhered

to. Failure to follow these instructions may also cause damage to your unit and void existing warranties.

Upon application of power, the unit will initiate a self test. The initialization takes approximately

45 seconds.

The introduction screen shown below will be displayed for approximately 10 seconds and then

the Run Screen will be displayed.

c00276de.bmp

Fig. 1-1: Introduction Screen for TME-100

c00418de.bmp

Fig. 1-2: Introduction Screen for TME-200

c00407en.bmp

en01d141.fm, 11.03.2008 PL12EN-1300 2008-03 11

Getting Started

1

Fig. 1-3: Run Screen

Press the Ship‘s wheel to display the Navigator Menu. After the Navigator Menu is displayed,

verify the Tool Memory by entering Tool Setup. If Tool Memory is not active then select a tool

using the Tool Library. Press the ship's wheel to return to the Navigator Menu.

Once Tool Setup is complete the application needs to be programmed. To do this, go to Basic

Application Builder. From this screen torque, angle, and speed parameters must be entered for

the selected application. Press the ship's wheel to return to the Navigator Menu.

The controller is now ready to begin fastening cycles. The torque and angle data can be viewed

by pressing the Run Key. Tool and controller indicator lights will illuminate according to the

results.

12 PL12EN-1300 2008-03 en01d141.fm, 11.03.2008

Getting Started

1

Attachment A.1

Mounting Plate

Side Door Assembly

Connector Panel

Enclosure Key

(542818)

Indicator Lights

Keypad

Indicator Lights

LCD Display

a00254_1.bmp

Fig. 1-4: Controller

.1 .1

Tool Connectors

Floppy Drive

Power In

Fuse Holder

Ethernet Port

Keyboard Port

Printer Port

USB Port

Serial Ports

I/O Inputs

I/O Outputs

Power Disconnect

a00255_1.bmp

Fig. 1-5: Connector Box Detail

en02d141.fm, 11.03.2008 PL12EN-1300 2008-03 13

Controller Specifications

2

2 Controller Specifications

2.1 Understanding the Keypad

The following is a brief explanation of the keypad keys. You will need to become familiar with

these keys so you can smoothly program your unit.

Soft Keys (F1-F4) - used to select functions based on the screen displayed.

ESC Key - used at any time to return back one screen or exit the edit mode.

DEL Key - used to delete a numerical value on the LCD screen.

Arrow Keys - used to move the orange highlight around the screen.

ENTER Key - used to accept an answer/value on the LCD screen.

Ships Wheel - used at any time to return to the navigator menu.

Run - used at any time to return to Run Screen.

Soft Keys

Ship´s Wheel

14 PL12EN-1300 2008-03 en02d141.fm, 11.03.2008

Controller Specifications

2

2.2 Specifications

2.2.1 Enclosure

Model Weight* Width Height Depth

lb kg in mm in mm in mm

TME 80 36.4 16.5 419.1 17.5 444.5 12.3 312.4

* Mounting plate adds weight of 7 lbs / 3.2 kg and depth of 1.62 in / 41.1 mm

• Designed for NEMA 13/IP54 rating

• Lockable front door for customer specific key requirements

• Lockable 3-phase power switch

• Side door for connector/cable protection

• Removable Mounting Plate

• Removable, fully operational internal chassis (TME-100 only)

• Conductive front door gasket and lip to meet EMI regulations

• Orange textured powder coat

2.2.2 Display

• 7.7" in Passive Matrix Color LCD Module (TME-100);

6.5" in Passive Matrix Color LCD Module (TME-200)

• 640 x 480 resolution

• CCFT backlight

• Contrast and Brightness control

en02d141.fm, 11.03.2008 PL12EN-1300 2008-03 15

Controller Specifications

2

2.2.3 Keypad Overlay

Key Definitions

Key Description

0-9 Numbers 0-9

. Decimal point

DEL Delete

ESC Escape

Navigator Menu

RUN Run Screen

Up Arrow

Down Arrow

Left Arrow

Right Arrow

ENTER Enter

Orange Border 4 Soft Keys

2.2.4 Indicators

5 Highly visible indicators

• 2 red groupings

• 1 green grouping

• 2 amber groupings

• Each grouping contains 12 high intensity LED´s @ 30 mcd each

2.2.5 CPU with PC 104

Minimum Requirements

• Pentium 166 Mhz

• 32 MB DRAM

• 32 MB DiskonChip

• 2 serial ports

• 1 parallel port

• Ethernet 100-Base T

• PC Keyboard input

• PC/104 Bus

• Floppy interface

• LCD/Flat Panel controller

16 PL12EN-1300 2008-03 en02d141.fm, 11.03.2008

Controller Specifications

2

Arcnet PC/104 board

• Arcnet communication

• 4 +24 V inputs

• 12 +24 V outputs

• 24-position keypad decoder

• Battery-Backed SRAM, 1 MB

External I/O PC/104 board

• 8 optically isolated inputs

• 8 relay outputs

2.2.6 AC Input Power

• Selectable 115 VAC @15 A or 230 VAC @ 10 A, +/-5% on all voltages. External fuse should

be slow blow.

• Internal fuse

• Fault current circuit-breaker (10 mA)

• Isolation Transformer 4.5 kVA peak, meets VDA 0570 norm

Note: If necessary it's possible to connect two units to one 230 VAC power supply with a 16 A

slow blow fuse (C-Type).

2.2.7 Inernal DC Power

• Input: 85 VAC-264 VAC

• Output: +5 VDC @ 5 A, +12 VDC @ 1 A, +24 VDC @ 3 A, +/-5% on all voltages

• 110 W capability without a fan

• MTBF->20,000 hours

2.2.8 Input / Output Connectors

Tool Connector Matrix MS83723R/2028N

Serial (2) 9-pin Male D-Shell

Parallel 25-pin Female D-Shell

Keyboard Mini 6-DIN

Inputs (+24 V) Phoenix MSTBV 2,5/12-GF-5,08 Order No. 1777170

Outputs Phoenix ICV 2,5/12-GF-5,08 Order No. 1825792

Floppy 3.5in 1.44 MB

AC Power Input Standard male receptacle

AC Power Output Standard female receptacle

Tool

Pin # Description Value

1 +Excitation +12 V +/- .05 V

2 -Excitation 0 V

3 + Torque signal 0 to +5 V

4 0 V Torque signal 0 V

5 Tool Memory TXD - -3 V to +3 V

6 Tool Memory TXD + -3 V to +3 V

7 Tool Memory RXD - -3 V to +3 V

8 Tool Memory RXD + -3 V to +3 V

9 Resolver Carrier R1 7 VAC

10 Resolver Carrier R2 0 VAC

11 Resolver Cosine S1 7 VAC

12 Red LED 0 to +24 V

13 Signal GND 0 V

14 Yellow LED 0 to +24 V

15 Motor PE 0 V

16 Start Switch 0 to +24 V

17 Reverse Switch 0 to +24 V

18 +24V +24 V

19 Motor Phase C 0 to 300 V

20 Transducer Calibration 0 to +5 V

21 Temperature Sensor + 0 to +5 V

22 Temperature Sensor - 0 to +5 V

23 Motor Phase B 0 to 300 V

24 Resolver Sine + S2 7 VAC

25 Resolver Cosine S3 0 VAC

26 Resolver Sine S4 0 VAC

27 Motor Phase A 0 to 300 V

28 Green LED 0 to +24 V

Housing PE 0 V

en02d141.fm, 11.03.2008 PL12EN-1300 2008-03 17

Controller Specifications

2

Serial

Pin # Description Value

1 DCD -25 V to +25 V

2 RxD -25 V to +25 V

3 TxD -25 V to +25 V

4 DTR -25 V to +25 V

5 GND 0 V

6 DSR -25 V to +25 V

7 RTS -25 V to +25 V

18 PL12EN-1300 2008-03 en02d141.fm, 11.03.2008

Controller Specifications

2

8 CTS -25 V to +25 V

9 RI -25 V to +25 V

Parallel

Pin # Description Value

1 Strobe 0 to +5 V

2 Data 0 0 to +5 V

3 Data 1 0 to +5 V

4 Data 2 0 to +5 V

5 Data 3 0 to +5 V

6 Data 4 0 to +5 V

7 Data 5 0 to +5 V

8 Data 6 0 to +5 V

9 Data 7 0 to +5 V

10 Acknowledge 0 to +5 V

11 Busy 0 to +5 V

12 Paper Out 0 to +5 V

13 Select Out 0 to +5 V

14 Auto Feed 0 to +5 V

15 Error 0 to +5 V

16 Initialize 0 to +5 V

17 Select In 0 to +5 V

18 Gnd 0 V

19 Gnd 0 V

20 Gnd 0 V

21 Gnd 0 V

22 Gnd 0 V

23 Gnd 0 V

24 Gnd 0 V

25 Gnd 0 V

Keyboard

Pin # Description Value

1 Data 0 to +5 V

2 N/C N/A

3 Gnd 0 V

4 Power 0 to +5 V

5 Clock 0 to +5 V

Serial

Inputs

Pin # Description Val ue

1 +24 V (Output) +24 VDC

2 Input 0 0 to +24 V

3 Input 1 0 to +24 V

4 Input 2 0 to +24 V

5 Input 3 0 to +24 V

6 Input 4 0 to +24 V

7 Input 5 0 to +24 V

8 Input 6 0 to +24 V

9 Input 7 0 to +24 V

10 Input Common (Input) 0 V

11 Signal Gnd (Output) 0 V

12 Spare N/A

en02d141.fm, 11.03.2008 PL12EN-1300 2008-03 19

Controller Specifications

2

For signal description please see chapter 3.4.2 Advanced Application Builder / Inputs, page 41.

Outputs

Pin # Description Val ue

1 +24 V (Output) +24 VDC

2 Output Common (Output) 0 to 30 V

3 Output 0 0 to 30 V

4 Output 1 0 to 30 V

5 Output 2 0 to 30 V

6 Output 3 0 to 30 V

7 Output 4 0 to 30 V

8 Output 5 0 to 30 V

9 Output 6 0 to 30 V

10 Output 7 0 to 30 V

11 Signal Gnd (Output) 0 V

12 Spare N/A

For signal description please see chapter 3.4.3 Advanced Application Builder / Outputs, page 43.

20 PL12EN-1300 2008-03 en02d141.fm, 11.03.2008

Controller Specifications

2

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 21

Programming

3

3 Programming

3.1 Navigator Menu

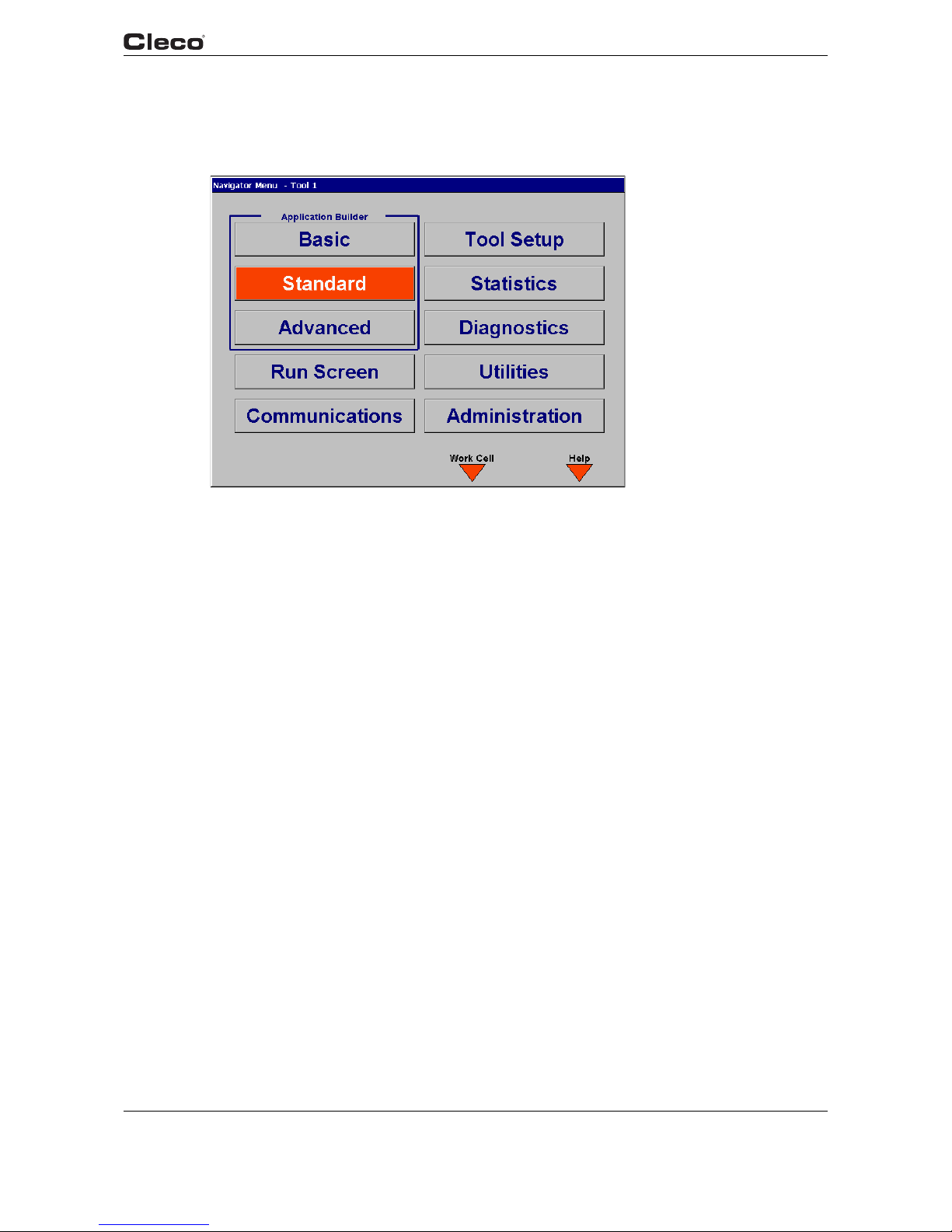

c00277en.bmp

Fig. 3-1: Navigator Menu

nav.txtS

3.1.1 Basic Navigation Instructions

Each field in a screen is selectable with an orange highlight using the 4 arrow keys and Enter.

Upon entering a screen the top left most field is always highlighted. The Navigator key (ship's

wheel) will always return the user to the Navigator Menu. At the bottom of the screen 4 soft keys

are available. These functions will change from screen to screen. In some cases the screen label

will contain the (>>) character to indicate more functions are available when the key is pressed.

To edit a textbox the user can use 0-9 or the DEL keys. To exit the edit mode the user can press

the arrow keys to move the highlight or press the ESC key. The ESC key will return the original

value.

In order to describe the soft key functions the left soft key is referred to as F1, center left soft key

F2, center right soft key F3 and right soft key F4. They are located in the orange display border.

F4 is always functions as Help for that screen.

Applications are selectable 1-255. When entering an application number of 1 or 2 digits (1-99), a

cursor blinks in the edit box. The number is accepted when the <ENTER> key is pressed, or after

3 seconds. A 3 digit application number (100-255) is accepted as soon as the third character is

typed.

Stages are selectable 1-6.

3.1.2 Work Cell

To connect to a remote unit configured in the work cell, press the <F3> "Work Cell" button from

the Navigator menu. From the "Work Cell List" dialog box, press the <ENTER> key do display

the droplist of configured units. Use the up or down arrow keys to select the desired unit, then

press the <ENTER> key again. Press the down arrow key to highlight the "OK" button and press

22 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

the <ENTER> key again. The user interface switches control to the selected unit. When a remote

unit is selected the IP address, station name, and station number of that unit are displayed in the

title bar of all screens.

To return control to the local unit, return to the Navigator menu and use the above procedure, this

time selecting "Local TM Unit" in the Work Cell List dialog.

To add units to the Work Cell List, use the Work Cell screen in Communications.

3.1.3 Password Function

Passwords can be configured to operate in one of two modes: Read Protected or not Read Protected. Refer to Administration / Password for configuration details

Read Protected: A password is required when selecting a section from the Navigator menu. It is

only required to enter the password once. If the user exits a section with programmable data

(Basic, Standard, Advanced, Communications, Tool Setup) that has been changed, then only the

confirm entry in the password dialog is displayed.

Not Read Protected: No password is required when selecting a section from the Navigator menu.

If the user exits a section with programmable data (Basic, Standard, Advanced, Communica

tions, Tool Setup) that has been changed, then the password entry dialog will be displayed. If no

password is activated, then only the confirm entry in the password dialog is displayed. Once the

password has been entered, it must be entered each time an appropriate screen is exited.

3.1.4 Print Screen

A Print Screen function is available on all screens. In some cases a Print Screen soft key has

been added that will allow the bitmap to be saved to the floppy disk, disk, or print directly to a

printer (Laser, Inkjet). On screens that do not have this soft key, the user can reach this function

by pressing the "0" key. A dialog box allowing the user to assign a filename will be displayed.

Using the arrow keys, highlight the filename and enter up to 8 characters, then activate Accept to

save to the floppy.

3.1.5 Two Channel Features: General Description (2-Channel V2.xx.xx C2 only)

The user interface is identical to the single-channel configuration. On all screens, the data for the

currently selected tool is displayed. The current tool is selected by entering a 1 or 2 in the "Tool"

edit box. The Tool may be selected from the Run Screen, Basic Application Builder, Standard

Application Builder, or Statistics screens. On screens where there is no Tool edit box, the cur

rently selected tool is displayed in the blue title bar at the top of the screen. Both tools are always

operable regardless of which tool is currently selected by the user interface.

All editable parameters are set and saved individually for each tool, with the following exceptions:

• Language

• Date/Time

• Passwords

• Field Bus Parameters

• Torque Units

• Run Screen 2-Tool Display Configuration (Auto-select)

• Ethernet protocol, IP addresses and port number

• System Settings/General "Same for both tools" option

(See 3.4.7 Advanced Application Builder / System Settings, page 53)

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 23

Programming

3

The 2-channel model has the following limitations:

• Field Bus (DeviceNet/Profibus): When active, all inputs and outputs are only applicable to the

operation of Tool 1.

• The PFCS communications protocol uses a single Machine ID (MID) for both tools.

• The auto-select feature does not apply to the Oscilloscope screen.

3.1.6 Navigator Menu

Basic Application Builder

Basic Application Builder allows the user to graphically select and program a two-stage rundown

for Torque Control/Angle Monitor (Seq11+Seq30) or Angle Control/Torque Monitor

(Seq11+Seq50) for any of the 255 Applications. The user only enters Torque, Angle, and Speed

Setpoints in one screen. Other parameters such as timers, etc are automatically defaulted to predetermined values.

Standard Application Builder

Standard Application Builder allows the user to program up to a 6-stage rundown for any of the

255 Applications. Once the fastening sequences are selected for each stage, the associated

Torque, Angle, Speed, and Advanced parameters can be programmed.

Advanced Application Builder

Advanced Application Builder allows the user to View all Application setups at once, and perform

I/O Mapping. The Application Matrix shows an overview of Application and Stage programming

by displaying the selected Fastening Sequence for each stage. I/O Mapping lets the user select

from a list of functions and assign that function to a given input or output.

RUN Screen

The Run Screen button takes the user directly to the display for Torque, Angle, and Status Indicator Labels. The Oscilloscope function used for diagnosing torque traces is also located in the

Run Screen.

Communications

The Communications Setup allows the user to configure all communications for the Printer and

Serial Data Transmission. Appropriate communications settings for protocol, port, baud rate, etc

can be set in this screen.

Tool Setup

The Tool Setup displays the Tool Memory Data and allows the user to modify this information by

changing it directly or selecting from the Tool Library.

Statistics

Chronological History and associated statistics are viewable from this screen. Data can be

erased and printed as well.

Diagnostics

The System Diagnostics contains screens to determine if the system is functioning properly.

There are diagnostics for I/O, Arcnet, Tool and Tightening Module, Serial Communications, and

Transducer Calibration.

24 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

Utilities

Utilities contains functions for upgrading or changing the system software. From the Utilities

screen the user can update the TME application software, or install a new firmware version in the

Tightening Module.

3.1.7 Administration

From the Administration screen the user can load, save and configure system information.

Administration functions include loading and saving the system configuration to a diskette, set

ting date and time, setting password protection, and printing the system configuration, and

selecting the application software language

(English, German, Italian, Spanish, Czech, Portuguese, French, Polish, Dutch). From the Administration / Counter screen, the user may view, enable, disable, or reset any of the available

counters.

nav.txtE

3.2 Basic Application Builder

c00278en.bmp

Fig. 3-2: Torque Control / Angle Monitor

c00279en.bmp

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 25

Programming

3

Fig. 3-3: Angle Control / Torque Monitor

basic.txtS

The Basic Application Builder allows the user to select a typical two-stage rundown where the

first stage is a high speed rundown and the second stage is a lower speed rundown that controls

on either torque or angle.

Fastening Strategies Torque Control/Angle Monitoring (Sequence 11/Sequence 30) or Angle

Control/Torque Monitoring (Sequence 11/Sequence 50) are selectable from the dropdown listbox

in the upper right hand corner of the screen. Once a strategy is selected, the appropriate param

-

eters will be displayed for programming.

From the Basic Application Builder, the Auto Program feature is available by pressing the <F1>

soft key only when a tool is connected to the controller. The <F1> “Auto Program” button should

look disabled if there is no tool and <F1> should do nothing if there is no tool.

The <F1> soft key should be disabled if Angle Control/Torque Monitoring is selected. You can

input the Stage 2 target torque and select the units on this dialog. Pressing the <Cancel> button

exits the auto program screen without saving changes. Pressing the <OK> button causes the

auto calculations to be done and the results are displayed on the basic screen.

From the Basic Application Builder, the user can copy the parameters of an application to one or

more other applications by pressing the “Copy” <F3> soft key. From this dialog box, the user can

specify the source and target tool and application. When using “Copy” function from the Basic

Application Builder, all stages of the selected application are copied. Multiple target applications

may be specified by separating the application numbers with a period as shown.

Backoff using Reverse switch (Sequence 41 or Sequence 46)

The Backoff stage is automatically set to Sequence 46 for a tubenut tool and Sequence 41 for all

others. The automatic selection of a tube nut tool depends on a ‘T’ in the tool model number.

That means, if a ‘T’ appears in the model number a tube nut tool is expected. This fastening

sequence is selected when the tool runs in the reverse (untighten) direction. It is also used to

return a tubenut tool to the home position on every other trigger pull. The resolver integrated into

the nutrunner measures the angle during the untightening. The value is processed by the control

26 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

system. When the Turnoff angle is reached the nutrunner is shut off. For a tubenut tool, the Turnoff angle is programmed so that the attachment will always turn far enough to reach the home

position and stop based on the torque reaction against the pawl.

3.2.1 Basic Parameters for Torque Control / Angle Monitor

• Trigger Torque [Nm] - Torque to start collecting oscilloscope data.

• Turnoff Torque Stage 1 [Nm] - Torque to change from stage 1 to stage 2.

• Threshold Torque [Nm] - Torque to begin counting angle in stage 2.

• Torque Low Limit [Nm] - Minimum acceptable torque.

• Turnoff Torque Stage 2 [Nm] - Torque to turnoff the tool.

• Torque High Limit [Nm] - Maximum acceptable torque.

• Angle Low Limit [Deg] - Minimum acceptable angle.

• Angle High Limit [Deg] - Maximum acceptable angle.

3.2.2 Basic Parameters for Angle Control / Torque Monitor

• Turnoff Angle [Deg] - Angle to turnoff the tool.

• The rest of the Parameters are the same as Torque Control/Angle Monitor except Turnoff

Torque Stage 2 is eliminated.

Below are the acceptable ranges for each Parameter and its default value. For initial programming, the Parameters automatically use the default values.

3.2.3 Basic Application Builder Parameters

Parameter Name Range Typical

Fastening Strategy Torque Control/Angle Monitor

Angle Control/Torque Monitor

Torque Control/Angle Monitor

Trigger Torque [Nm] 0 to Tool Max 10% of Turnoff Torque

Turnoff Torque Stage 1 [Nm] 0 to Tool Max As appropriate

Threshold Torque [Nm] 0 to Tool Max 50% of Turnoff Torque

Torque Low Limit [Nm] -Tool Max* to Tool Max 90% of Turnoff Torque

Turnoff Torque Stage 2 [Nm] Low Limit to Tool Max As appropriate

Torque High Limit [Nm] Turnoff to 1.2 TQ-Cal. value 110% of Turnoff Torque

Angle Low Limit [Deg] 0 to 9999 90% of Turnoff Angle

Turnoff Angle [Deg] Low Limit to 9999 As appropriate

Angle High Limit Turnoff to 9999 110% of Turnoff Angle

Speed Stage 1 [RPM] 0 to Tool Max 80% of Tool Max

Speed Stage 2 [RPM] 0 to Tool Max 50

Backoff Speed 0 to Tool Max 50% of Tool Max

* Note: negative values may be entered by preceeding the value with two dots ".."

In the Basic Application Builder some parameters are not programmable and are also set to

default values. These values are located in the Standard Application Builder under Advanced

Parameters. However, if the parameters are changed using the Standard Application Builder,

then the Basic Application Builder does not reset them back to the default values.

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 27

Programming

3

3.2.4 Advanced Parameter Default Values

Parameter Name Stage 1 Stage 2

Start delay time [mS] 0 0

Start spike time [mS] 0 0

Max. Fastening time [mS] 10000 10000

End delay time [mS] 0 30

Torque Filter Factor 1 1

If NOK go to stage Stop Stop

Print None None

If an Application with more than two stages is required, or if a different Fastening Strategy has

previously been selected for the Application than described above, the Standard Application

Builder must be used.

3.2.5 Backoff using Reverse Switch (Sequence 41 or Sequence 46)

The Backoff stage is automatically set to Sequence 46 for a tubenut tool and Sequence 41 for all

others. The automatic selection of a tube nut tool depends on a ‘T’ in the tool model number.

That means, if a ‘T’ appears in the model number a tube nut tool is expected. This fastening

sequence is selected when the tool runs in the reverse (untighten) direction. It is also used to

return a tubenut tool to the home position on every other trigger pull. The resolver integrated into

the nutrunner measures the angle during the untightening. The value is processed by the control

system. When the Turnoff angle is reached the nutrunner is shut off. For a tubenut tool, the Turn

off angle is programmed so that the attachment will always turn far enough to reach the home

position and stop based on the torque reaction against the pawl.

3.2.6 Basic Application Builder / Auto Program

c00393en.bmp

Fig. 3-4: Basic Application Builder / Auto Program

28 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

From the Basic Application Builder, the Auto Program feature is available by pressing the <F1>

soft key only when a tool is connected to the controller and if the application is not already pro

grammed. The <F1> "Auto Program" button should look disabled if there is no tool or if the application is programmed or if Angle Control/Torque Monitoring is selected.

The Auto Program feature accepts the Stage 2 target torque and the torque units. Pressing the

cancel button exits the auto program screen without saving changes. Pressing the <OK> button

causes the auto calculations to be done and the results are displayed on the basic screen.

3.2.7 Basic Application Builder / Copy

c00362en.bmp

Fig. 3-5: Torque Control / Angle Monitor / Copy

From the Basic Application Builder, the user can copy the parameters of an application to one or

more other applications by pressing the Copy <F3> soft key. From this dialog box, the user can

specify the source and target tool and application. When using Copy function from the Basic

Application Builder, all stages of the selected application are copied. Multiple target applications

may be specified by separating the application numbers with a period as shown.

basic.txtE

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 29

Programming

3

3.3 Standard Application Builder

3.3.1 Standard Application Builder / View Stages

c00280en.bmp

Fig. 3-6: View Stages

viewstag.txtS

From View Stages, Stages 1-6 and a Backoff Stage are programmable for a given tool and application.

When the tool is started, each Stage having a programmed Fastening Sequence will be run in

succession based on the results from the previous stage. The Backoff Stage is used when the

tool is run in the reverse or untighten direction.

When the Counter Clockwise box is checked, each stage is run with the tool tightening in a

counter-clockwise direction. Sequence 41 (angle controlled backout) and the Backoff Stage are

run in the clockwise direction.

WARNING: When the Counter-Clockwise box is checked, the normal direction of rotation

is opposite from what is indicated by the label of the Reverse switch on the tool.

If a sequence has not been selected for a stage, then N/A is displayed for that stage. Otherwise

the Sequence number, description and icon are displayed. Sequences can be selected using the

Select Seq <F1> soft key. This key is only valid when stages 1-6 are highlighted. The Fastening

Sequence for the Backoff Stage is selected automatically.

The parameters for any stage can be programmed using the Parameters <F3> soft key. This key

is only valid when a Sequence has been selected for a given Stage.

30 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

3.3.2 Standard Application Builder / View Stages / Copy

c00366en.bmp

Fig. 3-7: View Stages / Copy

From the Standard Application Builder, the user can copy the parameters of an application or

stage to one or more other applications or stages by pressing the Copy <F2> soft key. From this

dialog box, the user can specify the source and target tool, application, and one or all stages. A

single stage can be copied to multiple applications and/or stages. Multiple target applications and

stages may be specified by separating the numbers with a period.

viewstag.txtE

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 31

Programming

3

3.3.3 Standard Application Builder / Select Sequence

c00281en.bmp

Fig. 3-8: Select Sequence

selectse.txtS

Fastening Sequences are selectable for a given Tool, Application and Stage by using the Control

and Monitor check boxes or selecting a Fastening Sequence directly from the drop down listbox.

The following Fastening Sequences or Fastening Strategies are available:

Sequence 41 or Sequence 46 Backoff using Reverse switch/Relax

Sequence 11 High Speed Rundown

Sequence 30 Torque Control/Angle Monitor

Sequence 50 Angle Control/Torque Monitor

Sequence 41 Angle Controlled Backoff

When a Sequence is selected the Control and Monitor check boxes and Fastening Sequence

listbox will both display the appropriate settings for the selected Sequence. An icon portraying

the selected Sequence is also displayed in the bottom right-hand corner.

The following table shows a matrix of the Control and Monitor schemes for each Sequence:

Sequence 11 Sequence 30 Sequence 50 Sequence 41

Control

Torque Control X X

Angle Control X

Angle Control Reverse X

Monitor

Torque Monitor X X

Angle Monitor X X X

The Parameters <F3> soft key allows the user to program all associated control parameters for

the selected Sequence. It is only valid when a Sequence has been selected.

32 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

The following is a detailed description of each Fastening Sequence:

Sequence 11

High Speed Rundown

This tightening method is generally used as a fast pre-tightening stage. The torque transducer

integrated into the nutrunner measures the torque during the tightening. The value is processed

by the control system. When the defined Turnoff Torque is reached the nutrunner is shut off.

Thereafter the peak torque is measured during a dwell time and is then processed as the tighten

ing torque of the bolt in the control system. This value is displayed on the Run Screen and can be

output to a printer or transmitted to other system components by data communication. When the

trigger torque is reached the torque curve is recorded and can be viewed and evaluated using

the oscilloscope function.

Sequence 30

Torque Control with Torque and Angle Monitoring

This tightening stage is normally preceded by a fast pre-tightening stage. The transducer integrated into the nutrunner measures the torque and the resolver measures the angle during the

tightening. The values are processed by the control system. When the threshold torque is

reached the angle count starts. When the Turnoff Torque is reached the nutrunner is shut off.

Thereafter the peak torque is measured during a dwell time and is then processed as the tighten

ing torque of the bolt together with the evaluation of the rundown in the control system. This

value is displayed on the Run Screen and can be output to a printer or transmitted to other sys

tem components by data communication. When the trigger torque is reached the torque curve is

recorded and can be viewed and evaluated using the oscilloscope function.

Sequence 50

Angle Controlled Tightening with Angle and Torque Monitoring

This tightening sequence is generally preceded by a fast pre-tightening cycle. The transducer

integrated into the nutrunner measures the torque and the resolver measures the angle during

the rundown. The values are processed by the control system. When the Turnoff angle is

reached the nutrunner is shut off. Thereafter the final angle and the peak torque are measured

during a dwell time, and these tightening values for the bolt are then processed together with the

evaluation of the rundown in the control system. These values are displayed on the Run Screen

and can be output to a printer or transmitted to other system components by data communica

tion. When the trigger torque is reached the torque curve is recorded and can be viewed and

evaluated using the oscilloscope function.

Sequence 41

Angle Controlled Back-off with Angle Monitoring

This fastening sequence is generally used to loosen a bolt a specified number of degrees. The

resolver integrated into the nutrunner measures the angle during the untightening. The value is

processed by the control system. When the Turnoff angle is reached the nutrunner is shut off.

Thereafter the final angle is measured during a dwell time and is then processed as the back-off

angle of the bolt together with the evaluation of the untightening in the control system. This value

is displayed on the Run Screen and can be output to a printer or transmitted to other system

components by data communication. In this stage the oscilloscope function is not supported.

Sequence 41 or Sequence 46

Backoff using Reverse switch/Relax

The Backoff stage is automatically set to Sequence 46 for a tubenut tool and Sequence 41 for all

others. The automatic selection of a tube nut tool depends on a 'T' in the tool model number. That

means, if a 'T' appears in the model number a tube nut tool is expected. This fastening sequence

is selected when the tool is run in the reverse or untighten direction. It is also used to return a

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 33

Programming

3

tubenut tool to the home position on every other trigger pull. The resolver integrated into the

nutrunner measures the angle during the untightening. The value is processed by the control

system. When the Turnoff angle is reached the nutrunner is shut off. For a tubenut tool, the Turn

off angle is programmed so that the attachment will always turn far enough to reach the home

position and stop based on the torque reaction against the pawl.

selectse.txtE

3.3.4 Standard Application Builder / Parameters

c00282en.bmp

Fig. 3-9: Parameters

paramete.txtS

Parameters are programmable for a given Tool, Application and Stage based on the selected

Fastening Sequence and only the appropriate parameters are displayed for the selected Fasten

ing Sequence.

The Next Stage <F2> key will increment to the next stage until it reaches the last stage having a

selected Sequence. It will then rollover to the first stage. In order to add a stage without a

selected Sequence the user must highlight the stage field and enter a number 1-6.

The following is a detailed description of each Fastening Sequence and associated Parameters:

Sequence 11

High Speed Rundown

This tightening method is generally used as a fast pre-tightening stage. The torque transducer

integrated into the nutrunner measures the torque during the tightening. The value is processed

by the control system. When the defined Turnoff Torque is reached the nutrunner is shut off.

Thereafter the peak torque is measured during a dwell time and is then processed as the tighten

ing torque of the bolt in the control system. This value is displayed on the Run Screen and can be

output to a printer or transmitted to other system components by data communication. When the

trigger torque is reached the torque curve is recorded and can be viewed and evaluated using

the oscilloscope function.

34 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

The following parameters are programmable from the Standard Application Builder:

• Fastening Sequence = 11

• Trigger Torque (Nm) = trigger torque, beginning of measurement for the graphic display.

• Turnoff Torque (Nm) = turnoff torque for the pre-tightening stage.

• Speed = max speed of the nutrunner during the pre-tightening stage.

Parameter Name Range Typical

Fastening Strategy Sequence 11 High Speed Rundown

Trigger Torque [Nm] 0 to Tool Max 10% of Turnoff Torque

Turnoff Torque [Nm] Trigger to Tool Max As appropriate

Speed Stage 1 [RPM] 0 to Tool Max 80% of Tool Max

Sequence 30

Torque Control with Torque and Angle Monitoring

This tightening stage is normally preceded by a fast pre-tightening stage. The transducer integrated into the nutrunner measures the torque and the resolver measures the angle during the

tightening. The values are processed by the control system. When the threshold torque is

reached the angle count starts. When the Turnoff Torque is reached the nutrunner is shut off.

Thereafter the peak torque is measured during a dwell time and is then processed as the tighten

ing torque of the bolt together with the evaluation of the rundown in the control system. This

value is displayed on the Run Screen and can be output to a printer or transmitted to other sys

tem components by data communication. When the trigger torque is reached the torque curve is

recorded and can be viewed and evaluated using the oscilloscope function.

The following parameters are programmable in the Standard Application Builder:

• Sequence input value = 30

• Trigger Torque (Nm) = trigger torque, beginning of measurement for the graphic display.

• Threshold Torque (Nm) = threshold torque, beginning of angle counting

• Turnoff Torque (Nm) = shut-off torque for the stage.

• Torque High Limit (Nm) = max torque, high limit for torque reached.

• Torque Low Limit (Nm) = min torque, low limit for torque reached.

• Angle High Limit (deg) = maximum angle, high limit for angle reached. The nutrunner will stop

if this value is exceeded

• Angle Low Limit (deg) = minimum angle, low limit for angle reached.

• Speed = max speed of the nutrunner during the tightening stage.

Parameter Name Range Typical

Fastening Strategy Sequence 30 Torque Control/

Angle Monitor

Trigger Torque [Nm] 0 to Tool Max 10% of Turnoff Torque

Threshold Torque [Nm] 0 to Tool Max 50% of Turnoff Torque

Torque Low Limit [Nm] -Tool Max* to Tool Max 90% of Turnoff Torque

Turnoff Torque [Nm] Low Limit to Tool Max As appropriate

Torque High Limit [Nm] Turnoff to 9999 110% of Turnoff Torque

Angle Low Limit [Deg] 0 to 9999 70% of Final Angle

Angle High Limit Low Limit to 9999 130% of Final Angle

Speed [RPM] 0 to Tool Max 50

* Note: negative values may be entered by preceeding the value with two dots ".."

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 35

Programming

3

Sequence 50

Angle Controlled Tightening with Angle and Torque Monitoring

This tightening sequence is generally preceded by a fast pre-tightening cycle. The transducer

integrated into the nutrunner measures the torque and the resolver measures the angle during

the rundown. The values are processed by the control system. When the Turnoff angle is

reached the nutrunner is shut off. Thereafter the final angle and the peak torque are measured

during a dwell time, and these tightening values for the bolt are then processed together with the

evaluation of the rundown in the control system. These values are displayed on the Run Screen

and can be output to a printer or transmitted to other system components by data communica

tion. When the trigger torque is reached the torque curve is recorded and can be viewed and

evaluated using the oscilloscope function.

The following parameters are programmable in the Standard Application Builder:

• Sequence input value = 50

• Trigger Torque (Nm) = trigger torque, beginning of measurement for the graphic display

• Threshold Torque (Nm) = threshold torque, beginning of angle counting

• Turnoff Angle (deg) = shut-off angle for the stage

• Angle High Limit (deg) = maximum angle, high limit for angle reached

• Angle Low Limit (deg) = minimum angle, low limit for angle reached

• Torque High Limit (Nm) = max torque, high limit for torque reached and safety shut-off

• Torque Low Limit (Nm) = min torque, low limit for torque reached

• Speed = max speed of the nutrunner during the tightening stage

Parameter Name Range Typical

Fastening Strategy Sequence 50 Angle Control/

Torque Monitor

Trigger Torque [Nm] 0 to Tool Max 10% of Turnoff Torque

Threshold Torque [Nm] 0 to Tool Max As appropriate

Torque Low Limit [Nm] -Tool Max* to Tool Max 70% of Final Torque

Torque High Limit [Nm] Low Limit to Tool Max. 130% of Final Torque

Angle Low Limit [Deg] 0 to 9999 90% of Turnoff Angle

Turnoff Angle [Deg] Low Limit to 9999 As appropriate

Angle High Limit Turnoff angle to 9999 110% of Turnoff Angle

Speed Stage [RPM] 0 to Tool Max 50

* Note: negative values may be entered by preceeding the value with two dots ".."

36 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

Sequence 41

Angle Controlled Back-off with Angle Monitoring

This fastening sequence is generally used to loosen a bolt a specified number of degrees. The

resolver integrated into the nutrunner measures the angle during the untightening. The value is

processed by the control system. When the Turnoff angle is reached the nutrunner is shut off.

Thereafter the final angle is measured during a dwell time and is then processed as the back-off

angle of the bolt together with the evaluation of the untightening in the control system. This value

is displayed on the Run Screen and can be output to a printer or transmitted to other system

components by data communication. In this stage the oscilloscope function is not supported.

The following parameters are programmable in the Standard Application Builder:

• Sequence input value = 41

• Turnoff Angle (deg) = shut-off angle, back-off angle

• Angle High Limit (deg) = maximum angle, high limit for angle reached.

• Angle Low Limit (deg) = minimum angle, low limit for angle reached.

• Speed = max speed of the nutrunner during the back-off stage.

Parameter Name Range Typical

Fastening Strategy Sequence 41 Angle Control in Reverse

Angle Low Limit [Deg] 0 to 9999 90% of Turnoff Angle

Turnoff Angle [Deg] Low Limit to 9999 As appropriate

Angle High Limit Turnoff angle to 9999 110% of Turnoff Torque

Speed [RPM] 0 to Tool Max 80% of Tool Max

Backoff Using Reverse Switch (Sequence 41 or Sequence 46)

The Backoff stage is automatically set to Sequence 46 for a tubenut tool and Sequence 41 for all

others. The automatic selection of a tube nut tool depends on a "T" in the tool model number.

That means, if a "T" appears in the model number a tube nut tool is expected. This fastening

sequence is selected when the tool is run in the reverse or untighten direction. It is also automat

ically used to return a tubenut tool to the home position on every other trigger pull. The resolver

integrated into the nutrunner measures the angle during the untightening. The measured angle

value is processed by the control system. When the Turnoff angle is reached the nutrunner is

shut off. For a tubenut tool, the Turnoff angle is programmed so that the attachment will always

turn far enough to reach the home position and stop based on the torque reaction against the

pawl.

The following parameters are programmable in the Standard Application Builder:

• Speed [rpm] = Max speed of the nutrunner during the backoff stage

Parameter Name Range Default

Speed [RPM] 0 to Tool Max 500 or 30% of Tool Max

(tubenut)

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 37

Programming

3

The backoff parameters that are not displayed are set to values as in the table below.

Parameter Name Sequence 41 Sequence 46

Start delay time [mS] 0 0

Start spike time [mS] 0 0

Max. Fastening time [mS] 10000 10000

End delay time [mS] 30 30

Torque Filter Factor 1 1

Tor q u e Ta r ge t --- 3,5% of Tool max. Torque

Torque High Limit --- 10% of Tool max. Torque

Angle Low Limit 0 0

Angle Target 9999 370

Angle High Limit 9999 380

For at tube nut tool the maximum speed for backoff is 30% of Tool Max Speed. It is not possible

to enter a higher value.

Relax

This sequence is generally used at the end of a rundown to prevent mechanical locking of the

tool without loosening the joint.

The relax parameters are set to values as in the table below. These parameters cannot be programmed.

Parameter Name Value

Fastening strategy Sequence 46

Start delay time [ms] 0

Start spike time [ms] 0

Max. fastening time [ms] 3000

End delay time [ms] 0

Torque filter factor Used from preceding stage

Tor q u e t a r g e t 1/6 of Torque low limit from preceding stage

Torque high limit 1/3 of Torque low limit from preceding stage

Angle low limit 0

Angle target 3

Angle high limit 6

Speed stage [RPM] Used from preceding stage

The results are not displayed on the Run Screen unless the relax stage was NOK.

paramete.txtE

38 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

3.3.5 Standard Application Builder / Advanced Parameters

c00283en.bmp

Fig. 3-10: Advanced Parameters

advparam.txtS

The user can enter the Advanced Parameters using the Advanced <F3> soft key from the

Parameter screen. These parameters are identical regardless of the selected Fastening

Sequence.

The Next Stage <F2> key will increment to the next stage until it reaches the last stage with a

selected Sequence. It will then rollover to the first stage. In order to add a stage without a

selected Sequence the user must highlight the stage field and enter a number 1-6.

Timers

Start delay time [mS] time delay before the stage will start

Start spike time [mS] time delay for the control system to start measuring torque after the stage

starts

Max. Fastening time [mS] max time for the tool to run during the stage.

End delay time [mS] time delay from tool turn off until shut-off of measured value recording.

Other

Torque Filter Factor used for torque averaging

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 39

Programming

3

Speed Ramp-up, Beginning of Stage

Ramp-up time [ms]: Time to accelerate to tool max speed.

Speed Ramp-down, End of Stage

Deactivate Ramp-down: Allows the user to deactivate the ramp-down.

Begin Ramp-down [%]: Percentage of turn off torque (seq 11, 30) or high limit torque (seq 50),

where speed ramp-down begins.

Use Default for Target

Speed:

Default value for target speed is used. The default value depends on

parameter of the next stage. Refer to the programming manual for more

information.

Target Speed [RPM]: Target speed after ramp-down at turn off. From beginning of ramp down,

speed is reduced in 30 steps to target speed.

Flex-Stop, After Turn-off

Deactivate Flex-Stop: Allows the user to deactivate the flex-stop.

Flex-Stop [%]: Percentage of duration of flex-stop. The higher the percentage the longer it

takes to relieve torque after shut-off. The absolute time depends on the run

-

down parameter and the joint.

Max Flex-Time [ms]: Max time for flex-stop to relieve torque after shut off

Advanced Parameters Default Range of Values

Start delay time [mS] 0 0 - 60000

Start spike time [mS] 0 0 - 999

Max. Fastening time [mS] 10000 1 - 60000

End delay time [mS] 30 0 - 999

Torque Filter Factor 1 1, 2, 4, 8, 16, 32

Ramp-up time [ms] 1000 100 - 2000

Begin Ramp-down [%] 90 1 - 100

Target Speed [RPM] (*) 1 - speed of stage

Flex-Stop [%] 50 10 - 100

Max Flex-Time [ms] 1000 1 - 2000

.

(*) The default value depends on parameter of the next stage. Refer to manual for more information.

advparam.txtE

40 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

3.4 Advanced

3.4.1 Advanced Application Builder / Application Matrix

c00284en.bmp

Fig. 3-11: Application Matrix

appmatri.txtS

The Application Matrix is a display matrix of 255 Applications vs. 6 Stages showing the selected

Sequence number for each stage. It gives the user an overview of controller programming in a

single screen. The arrow following the sequence number for a stage indicates the direction of

rotation (> for clockwise; < for counter-clockwise).

appmatri.txtE

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 41

Programming

3

3.4.2 Advanced Application Builder / Inputs

c00285en.bmp

Fig. 3-12: Inputs

Tool

Start

Tool Stop

in Final

Stage

Tool

Start

Inp uts

I0. Application Select 0

I1. Application Select 1

I2. Application Select 2

I3. Tool Start

I4. Re ject R eleas e

I5. To ol Re vers e

I6. Tool Enable

With Linking:

I7. Reset Linking /

Synchronization In

With Tool Synchronization:

I7. Reset Linking /

Synchronization In

Start

Stage2

c00288en.bmp

Fig. 3-13: Input Timing Diagram

inputs.txtS

42 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

Eight optically isolated, +24 V inputs are available at the Phoenix input connector under the right

side door and are defined as follows:

PIN 1 +24 VDC

PIN 2 Input 0

PIN 3 Input 1

PIN 4 Input 2

PIN 5 Input 3

PIN 6 Input 4

PIN 7 Input 5

Pin 8 Input 6

PIN 9 Input 7

PIN 10 Input Common

Pin 11 Signal Ground

Pin 12 Spare

Each of the physical inputs 0 - 7 can be programmed to have one of the following definitions:

Not Used Unused

Too l E nable When active, allows the tool to run in conjunction with Tool Start

Too l Sta r t Starts the tool. Works in parallel with the start switch on the tool.

Too l R everse When active, causes the tool to run in the counter-clockwise direc-

tion using the Backoff strategy. Works in parallel with the reverse

actuator on the tool

Too l R eady Prepares the controller for a new rundown. When active, the previ-

ous outputs are cleared, and the yellow LEDs flash

Appl. Select 0 Application Selects 0-7 are used to select Applications 1-255

using a binary count of 0-254 where Appl. Select 0 is the

least significant bit. This feature overrides application

changes from the keypad. When Linking is activated, the

Tightening Group is selected with these inputs.

Appl. Select 1

Appl. Select 2

Appl. Select 3

Appl. Select 4

Appl. Select 5

Appl. Select 6

Appl. Select 7

Synchronization Input If enabled from Advanced / System Settings, the tool is prevented

from continuing to the next stage until this input is active

Reset Linking When active, Linking (batch counting) is reset to position one

Reject Release Used when Reject Release is enabled from System Settings, and

the Release Method is "Release Input Toggle". When the tool is

disabled due to the reject limit being reached, it is re-enabled after

this input is toggled

Socket Tray Enable Socket Tray Enable is used along with Socket Tray Sel 0-2 to indi-

cate to the worker which socket to use.

Socket Tray Sel 0

Socket Tray Sel 1

Socket Tray Sel 2

Acknowledge When this signal is ON, the "results" output signals should be

cleared and the tool cannot be started; however, the tool LEDs

should still indicate the status of the previous rundown until

cleared by another tool start or the tool ready signal.

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 43

Programming

3

All inputs are active high. They are referenced to an isolated Input Common (pin 10). When using

the internal +24 V (pin 1) to activate these inputs, you must connect Input Common (pin

10) and

GND (pin 11). For hardware pin location please see

page 19.

Note:

When active, the Fieldbus has the priority. Refer to help page for Advanced / Fieldbus.

inputs.txtE

3.4.3 Advanced Application Builder / Outputs

c00286en.bmp

Fig. 3-14: Outputs

Tool

Start

Tool Stop

in F inal

Stage

Tool

Start

Outputs

O0. Cycle OK

O1. Cycle NOK

O2. Torque High

O3. Torque Low

O4. Linking OK

O5. Linking NOK

O6. Cycle Complete

With Linking:

O7 . Linkin g C om plete /

Synchronization Out

With Tool Synchronization :

O7 . Linkin g C om plete /

Synchronization Out

As appropriate

As appropriate

As appropriate

As appropriate

As appropriate

As appropriate

As appropriate

End

Stage1

Start

Stage2

c00287en.bmp

44 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

Fig. 3-15: Output Timing Diagram

outputs.txtS

Eight relay outputs are available at the Phoenix output connector under the right side door and

are defined as follows:

PIN 1 +24 VDC

PIN 2 Output Common

PIN 3 Output 0

PIN 4 Output 1

PIN 5 Output 2

PIN 6 Output 3

PIN 7 Output 4

PIN 8 Output 5

PIN 9 Output 6

PIN 10 Output 7

PIN 11 Signal Ground

PIN 12 Spare

Each of the physical outputs 0-7 can be programmed to have one of the following definitions:

Not Used Unused

OK Active if Torque / Angle / Yield are within programmed limits

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 45

Programming

3

All relay outputs are active high. One side of all of the relay contacts is tied to a common point

called Output Common (pin 2). When using the internal +24 V (pin 1) as a source for these out

puts, you must connect Output Common (pin 2) and +24 V (pin 1). The outputs will then be referenced to GND (pin 11). For hardware pin location please see page 19.

Note:

When active, the Fieldbus inputs have priority. Refer to help page for Advanced / Fieldbus.

outputs.txtE

NOK Active if Torque / Angle / Yield are outside limits or some

other error has occurred

Torque Low Active if Peak Torque < Torque Low Limit

Torque High Active of Peak Torque > Torque High Limit

Angle Low Active if Angle < Angle Low Limit

Angle High Active of Angle > Angle High Limit

Torque OK Active if Peak Torque is within limits

Angle OK Active if Angle is within limits

Tool Running Active when the tool is running

Cycle Complete Active when a rundown has ended in the last stage

Linking Complete Active when rundowns of all positions of the selected batch

group are complete

Linking OK Active if all positions of Linking were OK

Linking NOK Active if one or more positions of Linking were NOK

Confirm App. Sel 0 Confirm application Selects 0-7 are used to indicate the

currently selected applications 1-255 using a binary count

of 0-254 where Appl. Select 0 is the least significant bit

Confirm App. Sel 1

Confirm App. Sel 2

Confirm App. Sel 3

Confirm App. Sel 4

Confirm App. Sel 5

Confirm App. Sel 6

Confirm App. Sel 7

Sync Output If enabled from Advanced / System Settings it is active at

the end of each stage to allow for synchronization with

other controllers

Tool In Reverse Indicates that a tool reverse input or actuator is set

Socket Tray Enable Pass-through of Socket Tray Enable input signal

Socket Tray Sel 0 Pass-through of Socket Tray select 0-2 input signals

Socket Tray Sel 1

Socket Tray Sel 2

Fault (Active Low) Indicates the servo module has detected an error (trans-

ducer, resolver etc)

46 PL12EN-1300 2008-03 en03d141.fm, 11.03.2008

Programming

3

3.4.4 Advanced Application Builder / Fieldbus

c00400en.bmp

Fig. 3-16: FieldBus

fieldbus.txtS

From the FieldBus Screen the user is allowed to choose from four options for fieldbus connections: None, DeviceNet, Profibus, or Ethernet/IP.

For selection of DeviceNet or Profibus additional hardware is required.

en03d141.fm, 11.03.2008 PL12EN-1300 2008-03 47

Programming

3

Field Bus Configuration

Node Address Defines the address of the TME controller. DeviceNet (1-63),

Profibus (2-125), Ethernet/IP uses the controller IP address

configured in Communications / Data Transmission.

Baud Rate Defines the rate at which information is sent/received from the

TME controller. For DeviceNet three choices are available:

500KBits, 250 KBits, or 125 KBits. The rate should be set to

match the fieldbus system available. For Profibus and Ether

net/IP, this option is not available. The Baud Rate is automatically set to the master settings.

Part ID A checked box enables the Part ID function.

Disable on disconnect A checked box that disables further rundowns and displays a

"Check Cable" Message on Run Screen as long as the field

-

bus doesn't work.

Format Determines how the 32-bit Part ID is converted into readable

characters. When "Decimal" is selected, the resulting Part ID

is 10 characters in length. When "Hexadecimal" is selected,