P1891E/EN 09/07

N O R T H A M E R I C A (N A)

Cooper Power Tools

P.O. Box 1410

Lexington, SC 29071-1410

E U R O P E (E U)

Cooper Power Tools GmbH & Co. OHG

Postfach 30

D-73461 Westhausen, Germany

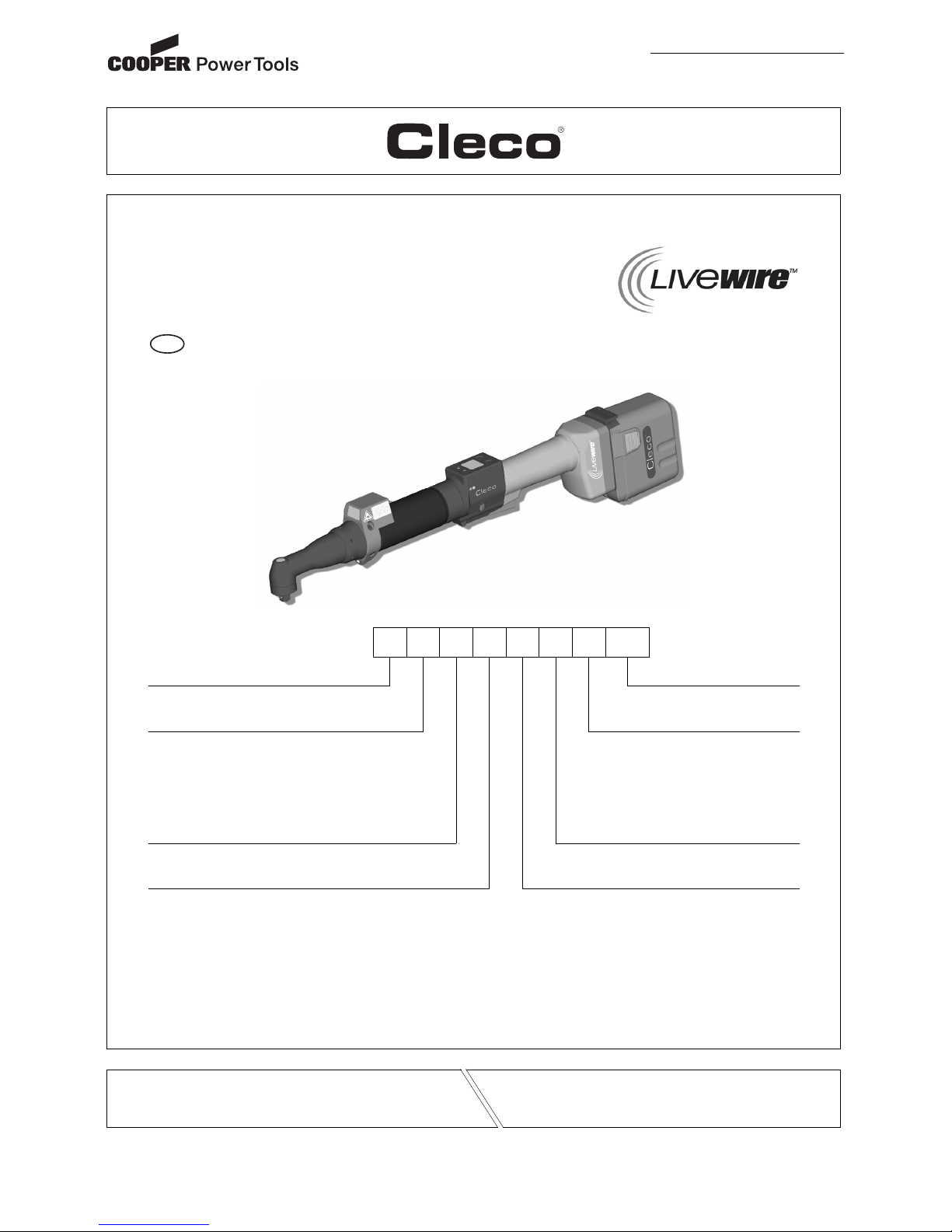

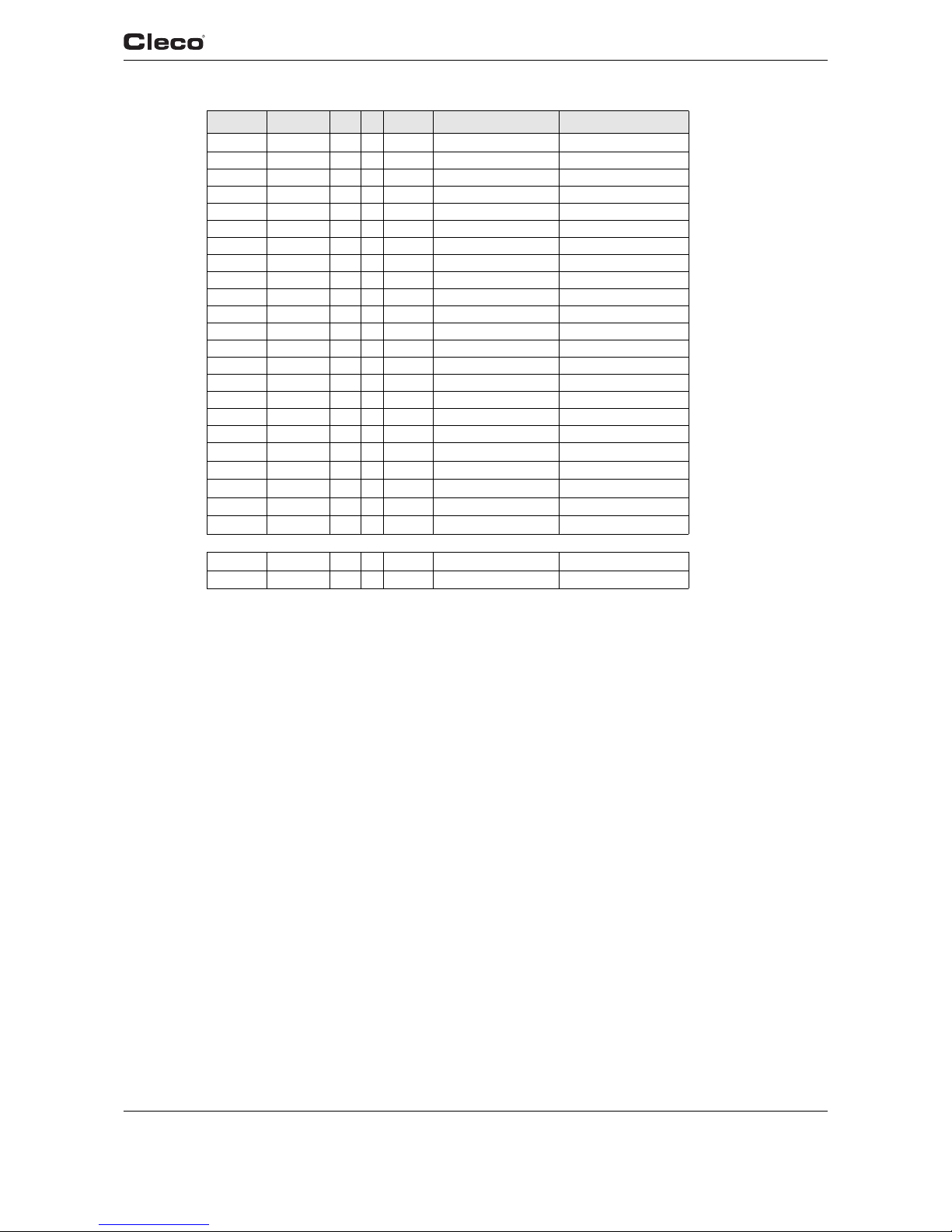

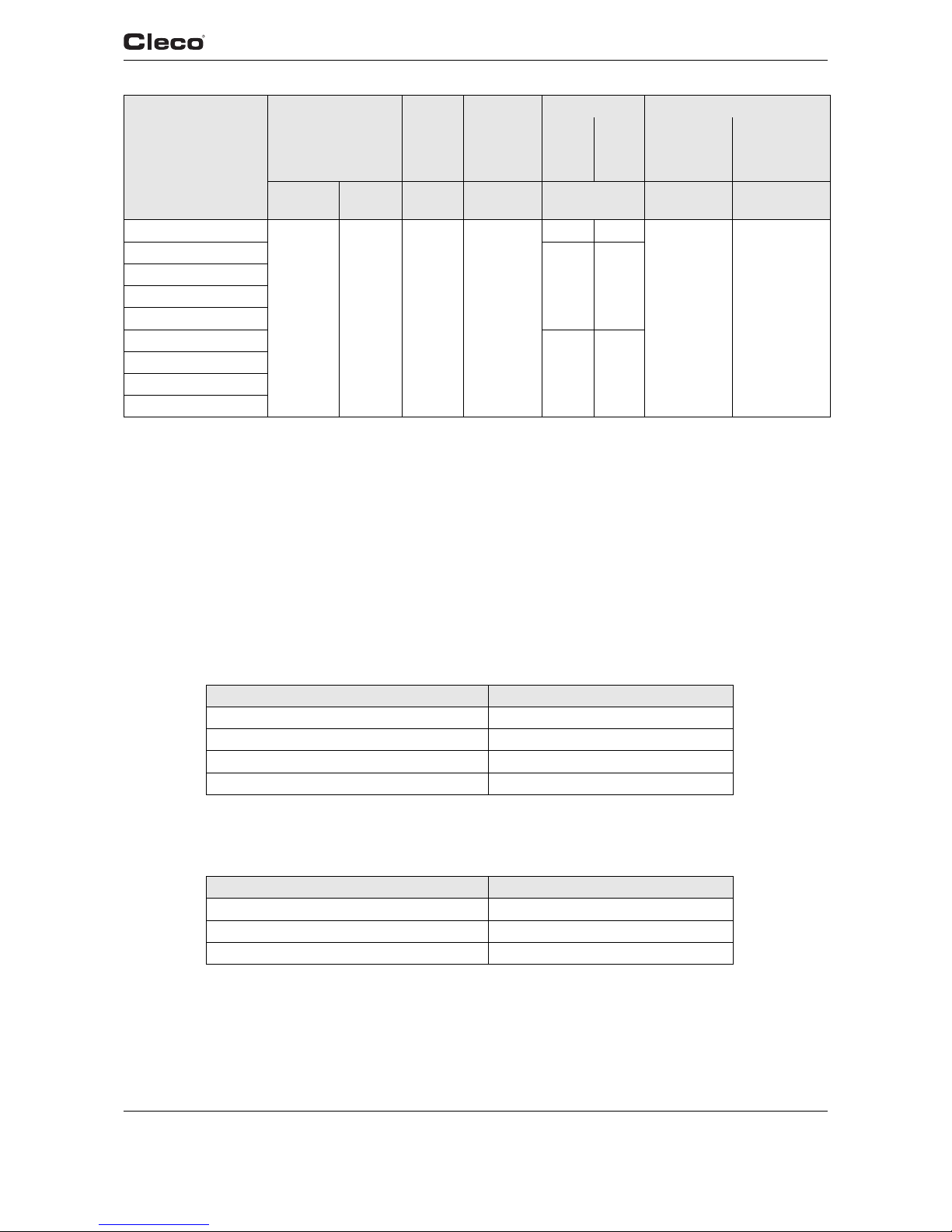

47BA…B…

Cordless EC angle nutrunner

47 B A … … B … AM3

Series Attachment

47 AM3 – Square 3/8"

Power Max. Torque

B – Battery 15 –- 15 Nm

21 – 21 Nm

28 – 28 Nm

35 – 35 Nm

50 – 50 Nm

Too l S ty le Battery

A – Angle B – 26 V

Feature 1 (Data Transmission) Feature 2 (Scanner)

– IrDA S – Barcode Scanner

F – RF915MHz – None

R – RF868 MHz

W – WLAN: WEP, WPA

X – WLAN: WEP, WPA/WPA2, 802.1x

EN

Retain for future reference!

For additional product information visit our website at http://www.cooperpowertools.com

Instruction Manual

2 P1891E/EN 09/07 91a_ Deckblatt en.fm, 24.09.2007

For this Instruction Manual

This Instruction Manual is intended for all persons who work with this tool but do not do any programming work.

The Instruction Manual

• provides important notes for safe and effective use.

• describes the function and operation of the cordless EC angle nutrunner.

• serves as a reference work for technical data, service intervals

and spare part orders.

• provides information on options.

For more information on the operation of the 47BA with the control electronics see

• programming manual controller TMEB-200, no. P1895E

• programming manual TMEB-COM, no. P1898E for PC application

In the text:

47BA represents all models of the

cordless EC angle nutrunner as described here.

➔ refers to required actions.

• refers to lists.

Identification text:

Identification graphic:

Copyright protection

Cooper Power Tools reserves the right to modify, supplement or improve the document or the

product without prior announcement. This document may not be reproduced in any way, shape

or form, in full or parts thereof, or copied to another natural or machine readable language or to a

data carrier, whether electronic, mechanical, optical or otherwise without the express permission

of Cooper Power Tools.

47BA represents all models of the cordless EC angle nutrunner as described here.

➔ refers to required actions.

• refers to lists.

kursiv refers menu items, i. e.: Diagnostics

<…> refers elements, that have to be selected or deselected, such as buttons or

control boxes, i.e.: <F5>

Courier refers names of paths and files are written in Courier font

i.e.: setup.exe

\ refers selection of an item from the menu i.e.: file \ print

refers a movement in one direction.

refers function and force.

P1891E_EN 47BA_B 0907IVZ.fm, 24.09.2007 P1891E/EN 09/07 3

Contents

1 Safety 5

1.1 Warnings and notes.............................................................................. 5

1.2 Basic requirements for safe working practices ..................................... 6

1.3 Operator training................................................................................... 6

1.4 Personal protective equipment ............................................................. 6

1.5 Designated use..................................................................................... 7

1.6 Codes and standards............................................................................ 7

1.7 Noise and vibration ............................................................................... 8

2 Scope of supply, transport and storage 8

2.1 Items supplied....................................................................................... 8

2.2 Transport .............................................................................................. 9

2.3 Storage ................................................................................................. 9

3 Product description 10

3.1 General description............................................................................. 10

3.2 Operation and functional elements ..................................................... 11

3.3 System overview – optional accessories ............................................ 16

4 Before initial operation 17

4.1 Setting up tool holder.......................................................................... 17

4.2 Ambient conditions ............................................................................. 17

4.3 Charging the battery ........................................................................... 17

4.4 Replacing the battery.......................................................................... 18

5 First Operation 19

5.1 Carrying out the rundown ................................................................... 19

5.2 Operating status ................................................................................. 19

6LCD display 21

6.1 Result display ..................................................................................... 21

6.2 Status display...................................................................................... 22

6.3 Operating menu .................................................................................. 24

6.4 System error messages...................................................................... 32

7 Maintenance 35

7.1 Cleaning instructions .......................................................................... 35

7.2 Service schedule ................................................................................ 36

4 P1891E/EN 09/07 P1891E_EN 47BA_B 0907IVZ.fm, 24.09.2007

7.3 Lubricants ........................................................................................... 37

7.4 Disassembling gear ............................................................................ 37

7.5 Removing angle attachment 935313 .................................................. 38

7.6 Installing angle attachment 935313 .................................................... 39

8 Troubleshooting 41

9 Spare parts 47

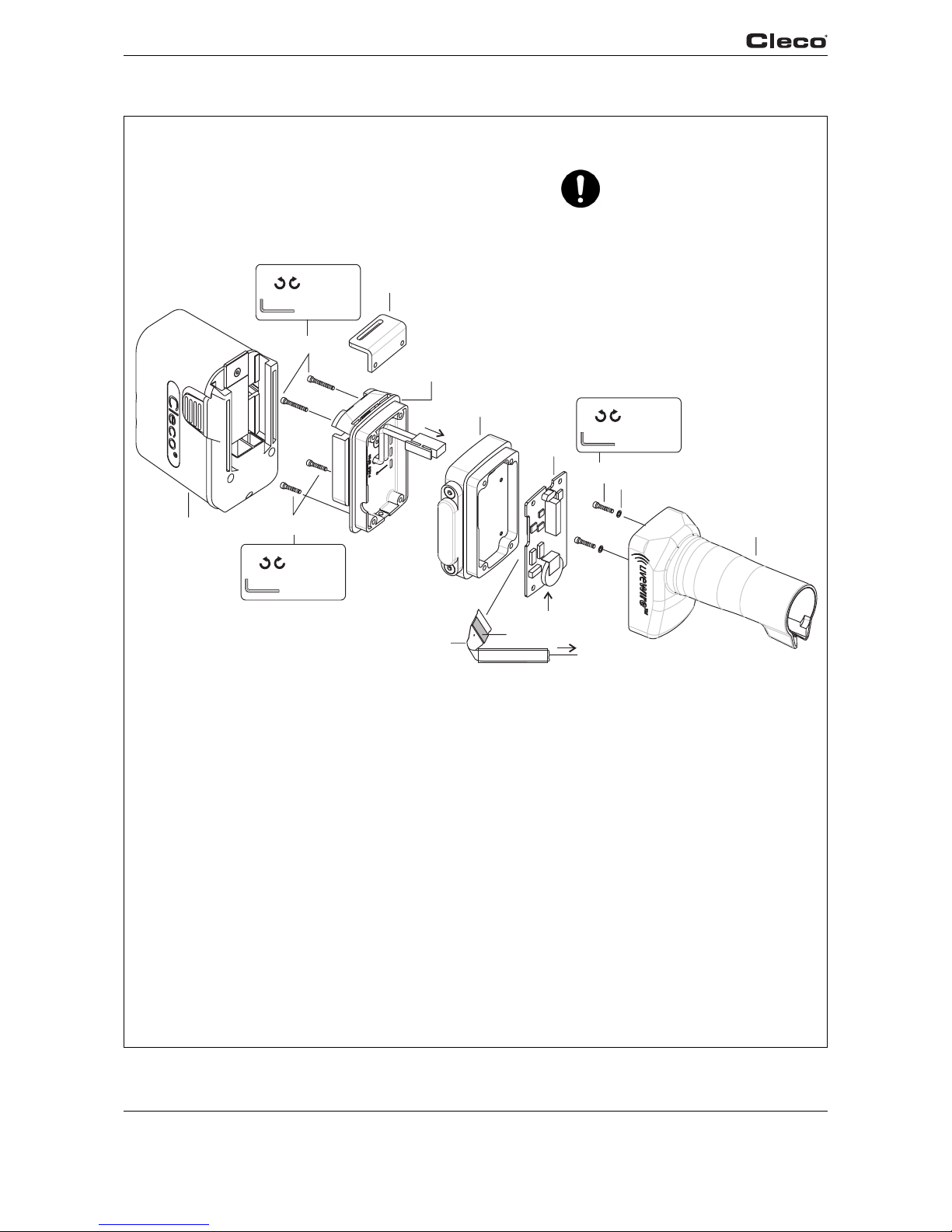

9.1 Handle ................................................................................................ 48

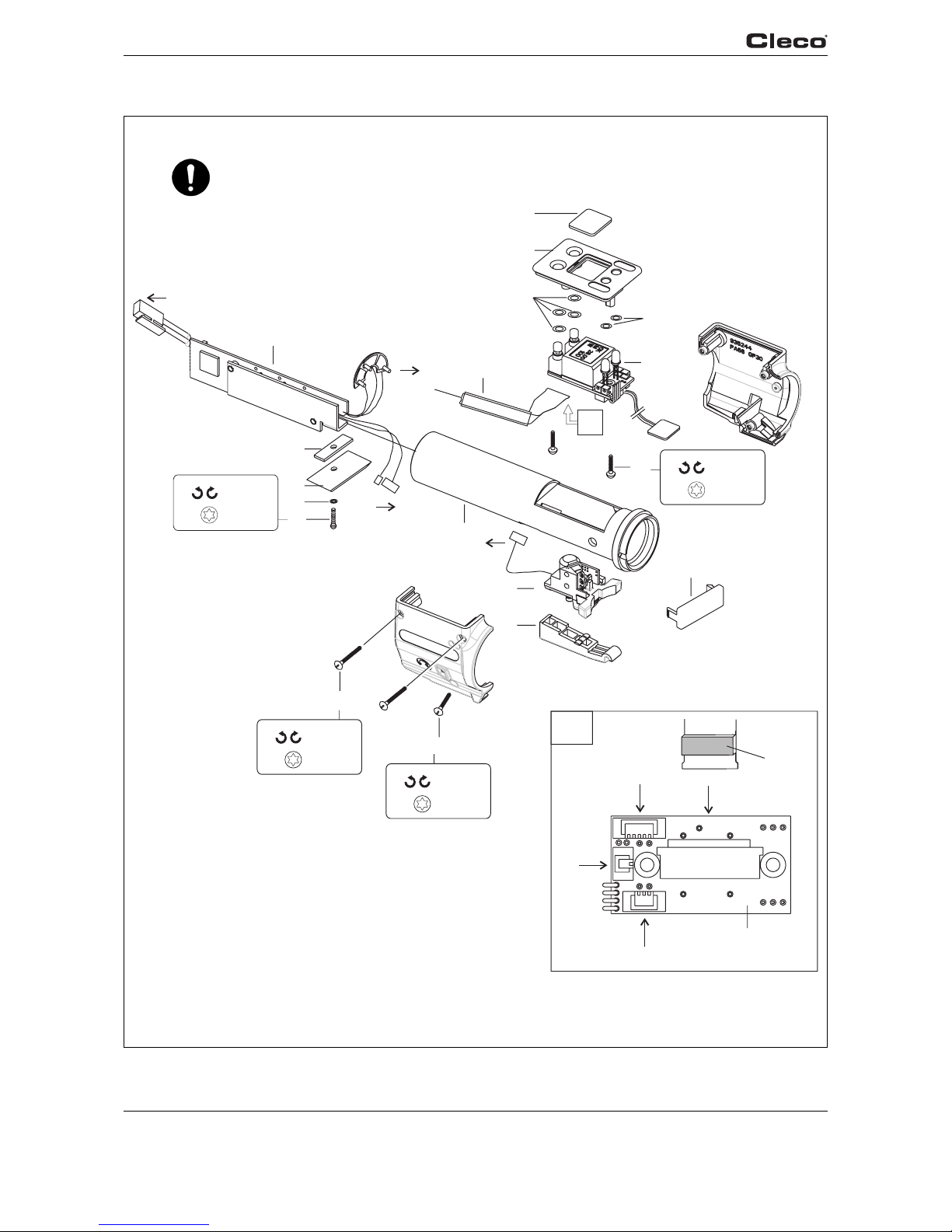

9.2 Servo bar, LCD bar & trigger components.......................................... 50

9.3 Motor................................................................................................... 52

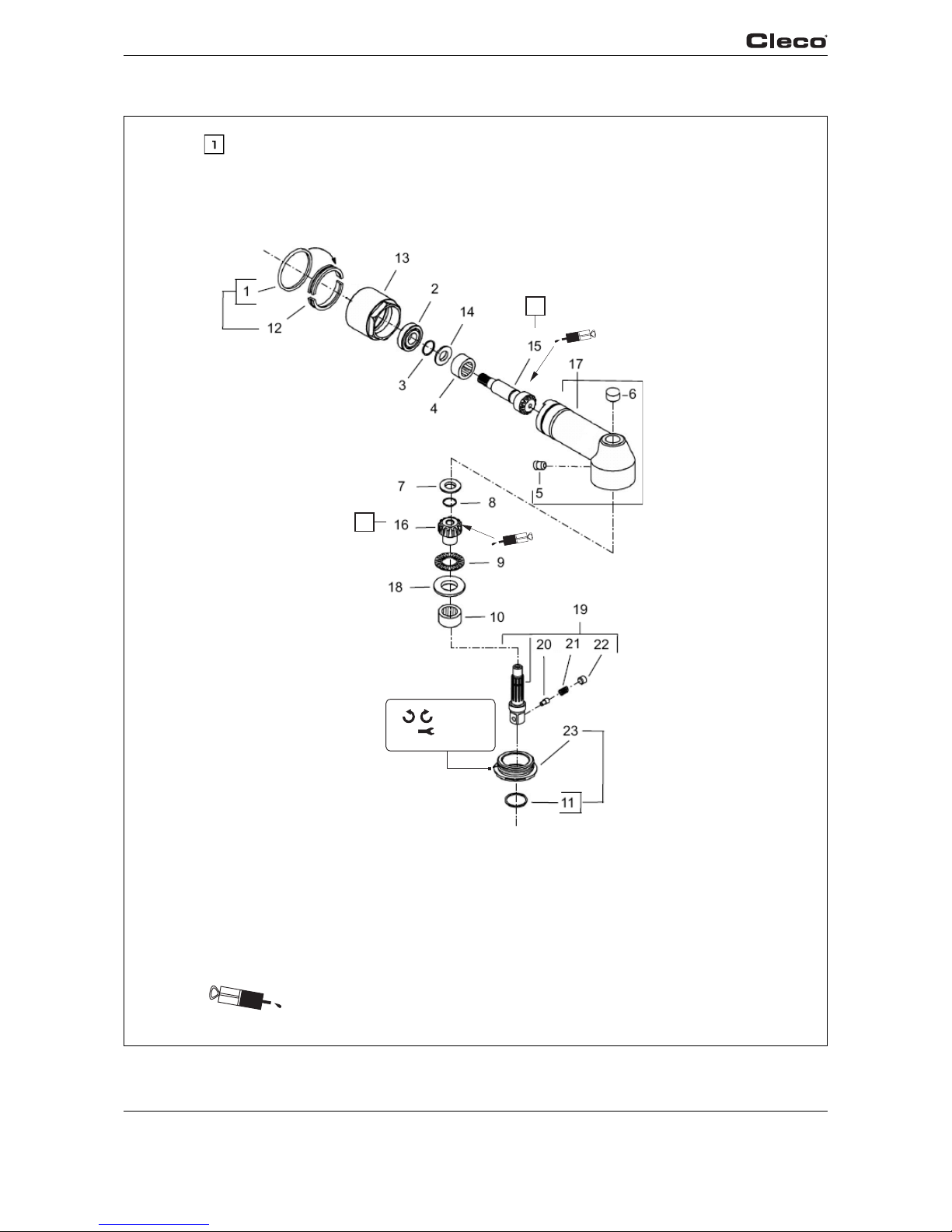

9.4 Gear + angle attachment .................................................................... 54

9.5 Angle attachment 935313................................................................... 56

9.6 Angle attachment 525943................................................................... 58

9.7 Tool holder 935290 with IrDA interface port / 935395 without ............ 60

9.8 Fixture order list for angle attachment 935313 ................................... 62

10 Technical data 63

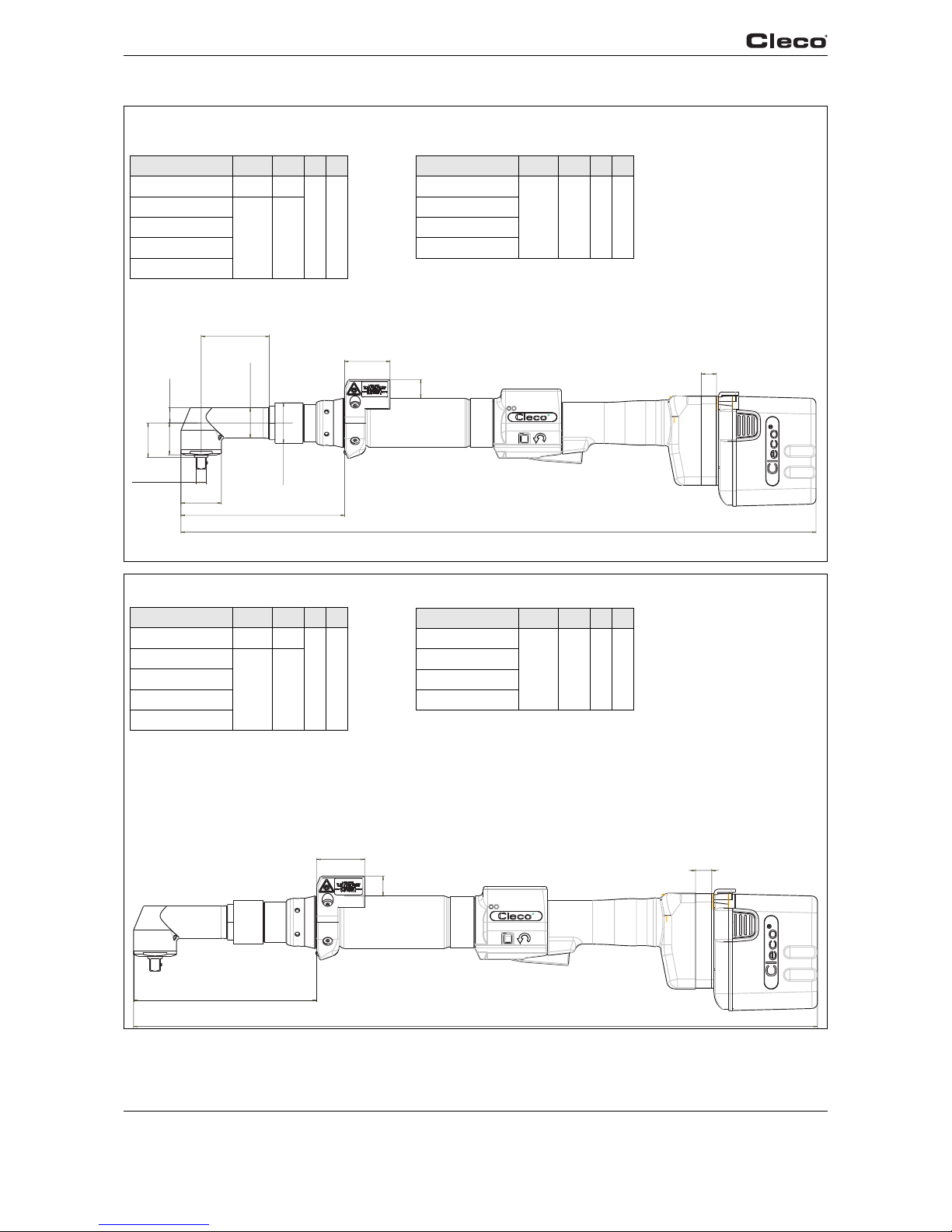

10.1 Dimensions ......................................................................................... 63

10.2 Dimensions of tool holder (Optional) .................................................. 65

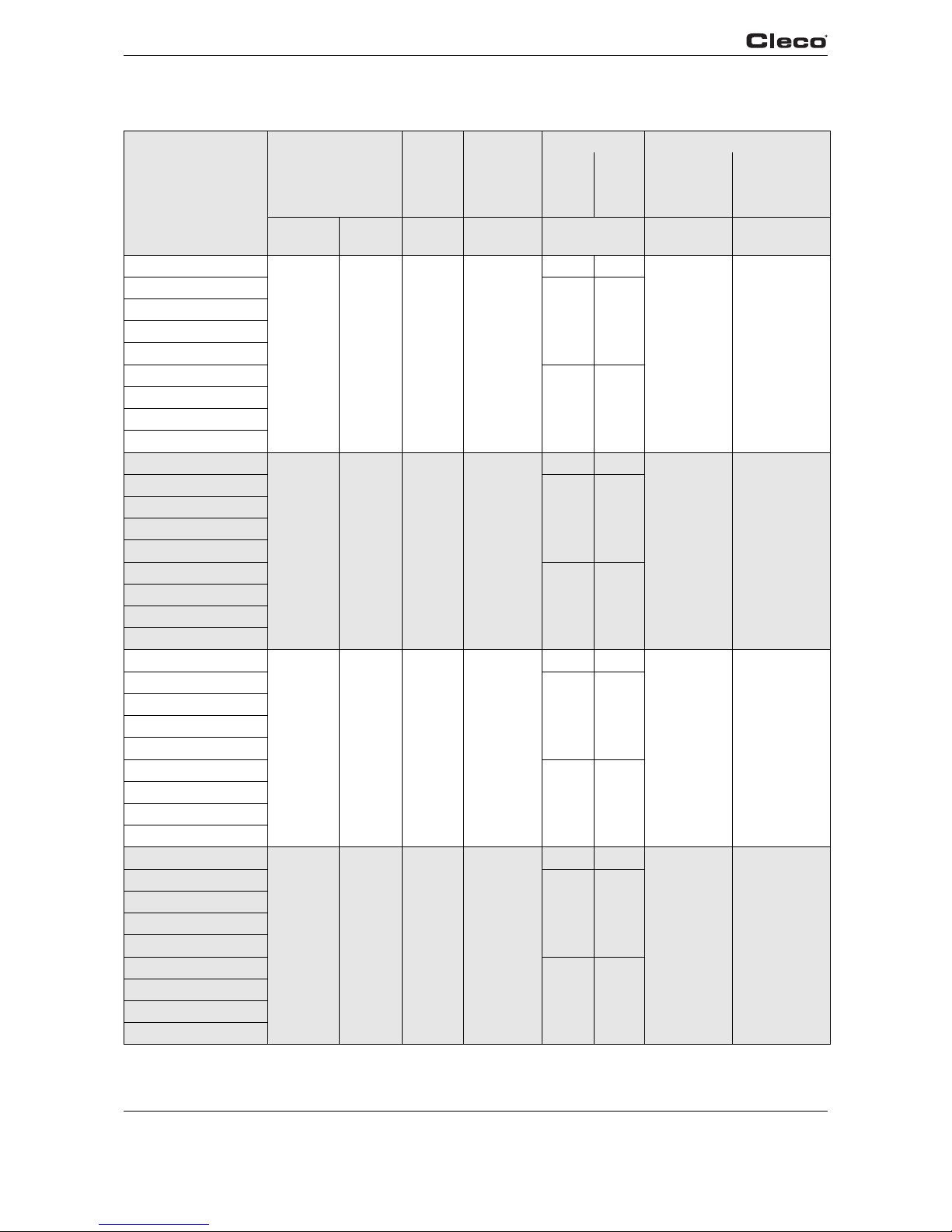

10.3 Performance Data............................................................................... 66

10.4 Electrical data ..................................................................................... 67

11 Service 71

11.1 Recalibration ....................................................................................... 71

12 Disposal 71

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 5

Safety

1

1Safety

1.1 Warnings and notes

Warning notes are identified by a signal word and a pictogram:

• The signal word describes the severity and the probability of the impending danger.

• The pictogram describes the type of danger.

WARNING!

Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION!

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or property and environmental damage. If this warning is not observed, injuries,

property or environmental damage may occur.

Class 2 laser product

Class 2 laser scanners use a laser diode that produces a low-power visible light beam that is

comparable to a very bright source of light, such as the sun.

Do not look into the laser beam when the laser is on.

Doing so can cause damage to the eyes.

NOTE

General notes

include application tips and useful information but no hazard warnings.

LASER RADIATION

DO NOT LOOK INTO THE BEAM

CLASS 2 LASER

IN ACCORDANCE WITH

EN 60825-1:1994

P < 1mW;

λ = 630 nm

6 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Safety

1

1.2 Basic requirements for safe working practices

You should read all instructions.

Nonobservance of the instructions below may result in electrical shock, burns and serious

injuries.

1.3 Operator training

All operators must be trained and experienced before operating the 47BA.

The 47BA may be repaired by authorized technicians only.

1.4 Personal protective equipment

When working

• Wear the protective goggles to protect against spurting metal splinters.

Danger of injury by being wrapped up in and caught by machinery

• Wear a hairnet.

• Wear close-fitting clothing.

• Do not wear jewelry.

CAUTION! Work area

➔ Ensure there is enough space in the work area.

➔ Keep the work area clean.

Electrical safety

➔ Protect the 47BA from rain and moisture.

➔ Follow the safety instructions printed on the battery and charger.

Safety of persons

➔ Ensure a secure standing position. Maintain balance.

➔ Make sure that the battery is securely installed before operating the 47BA.

➔ Hold the 47BA tightly in the hand –

be prepared for high short-term reaction torques.

➔ Do not carry the 47BA with the finger on the start button –

prevent accidental operation.

➔ Do not open the battery. Contact with acid will cause injury.

➔ Do not look into the laser beam of tools with built-in barcode scanners.

➔ Follow generally valid and local safety and accident prevention rules.

Safe working with and around fastening tools

➔ Inspect sockets for visible damage and cracks.

Replace damaged sockets immediately.

➔ Dissconnect the 47BA from the battery before replacing the sockets.

➔ Only use sockets for machine-controlled fastening tools.

➔ Make sure that the sockets are securely inserted.

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 7

Safety

1

1.5 Designated use

The 47BA is designed exclusively for fastening and releasing threaded fasteners.

The communication with the controller TMEB-200 / TMEB-COM / TMEC is allowed only over the

following interface ports:

• Do not use it in areas where there is a risk of explosion.

• Do not open it or modify it structurally.

• Only use with accessory parts which are approved by the manufacturer

(see 3.3 System overview – optional accessories, page 16).

• Do not use as a hammer or for re-bending.

1.6 Codes and standards

It is mandatory that national, state and local codes and standards be followed.

1.6.1 FCC conformity

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate the equipment.

1.6.2 Canada conformity

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

1.6.3 EMC

Industrial environment EMC limit class A.

The tool complies with the following EMC standards:

DIN EN 61000-6-4 Emitted interference

DIN EN 61000-6-2 Interference immunity

Types Communications

All IrDA interface port of the tool holder, order no. 935290

47BAW...

47BAX...

WLAN standard IEEE 802.11b

47BAR… 868 MHz with base station, order no. 961300 (EU)

47BAF… 915 MHz with base station, order no. 961301 (NA)

8 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Scope of supply, transport and storage

2

1.6.4 Data transmission

WLAN

EN 50371:2002

EN 301489-17 V1.2.1

EN 300328 V1.6.1

FCC Part 15.247 / RSS-210

868 MHz

EN 301489-3 V1.4.1

EN 50371:2002

EN 300220 V1.1.1

915 MHz

FCC Part 15.249 / RSS-210

1.6.5 Barcode scanner

• 21CFR1040.10 and 1040.11

except for deviations in accordance with Laser Notice 50 of July 26, 2001.

• EN60825-1:1994+ A1:2002 +A2:2001

• IEC60825-1:1993+A1:1997+A2:2001

1.7 Noise and vibration

Noise level< 60 dB(A) free speed (without load) according to ISO 3744.

Vibration values < 2.5 m/s² according to ISO 5349.

2 Scope of supply, transport and storage

2.1 Items supplied

Check shipment for transit damage and ensure that all items have been supplied:

147BA

1 26 VDC Lithium-ion (Li-ion) interchangeable battery

1Marking foil

1 This instruction manual

1 Declaration of Conformity

1 Factory test certificate for transducers

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 9

Scope of supply, transport and storage

2

2.2 Transport

Transport and store the 47BA in the original packaging. The packaging is recyclable.

2.3 Storage

For short-term storage and for protection against damage.

➔ Place the 47BA in the tool holder.

For storage longer than 100 hours

➔ Disconnect battery from the 47BA.

The battery is discharged by the electronics integrated in the tool.

WARNING!

Danger of explosion from short circuit

➔ Protect the 47BA and the battery from moisture.

➔ Do not bring any electrically conducting objects such as paper clips, coins, keys, nails or

screws in contact with the battery contacts.

➔ When storing the battery outside the tool or the battery charger, cover the battery

contacts.

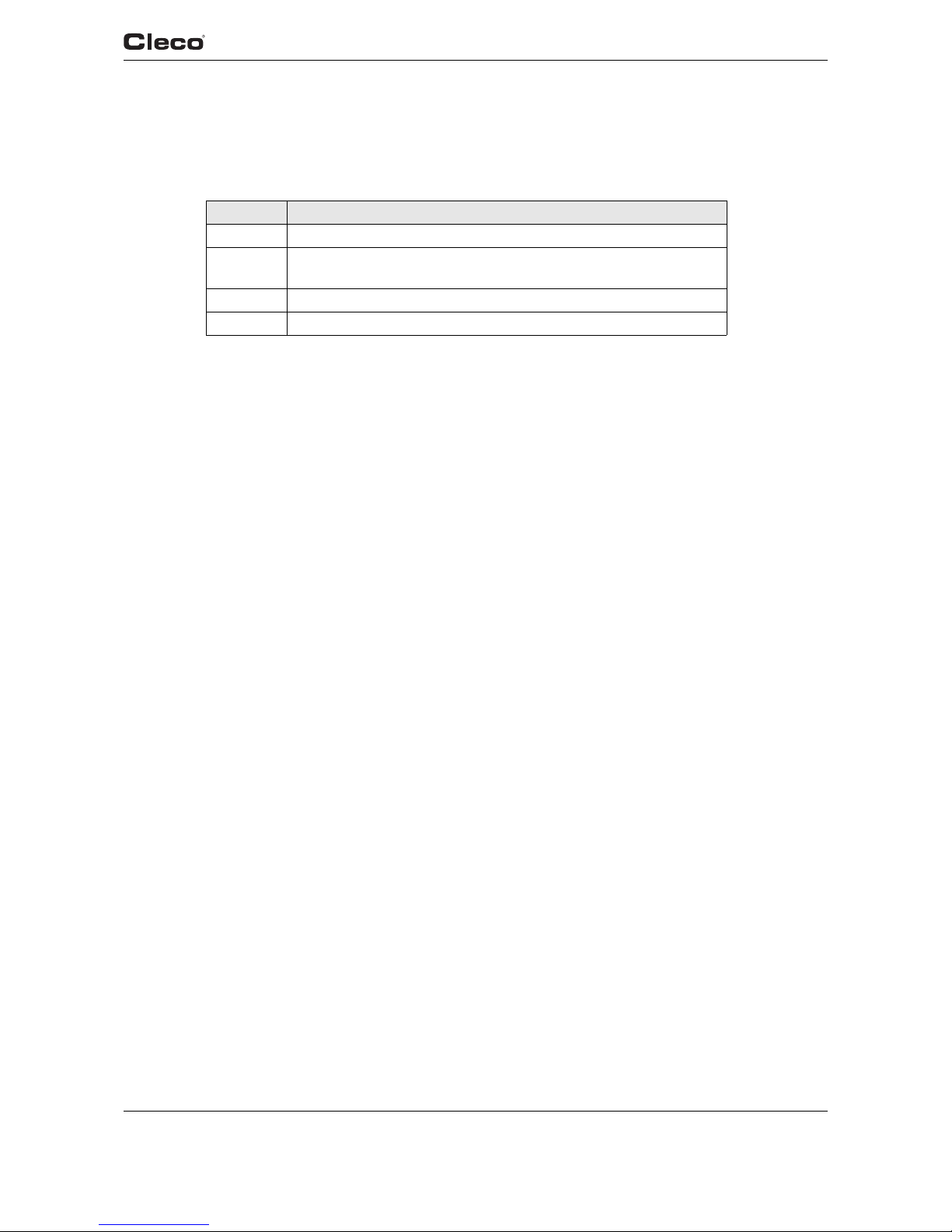

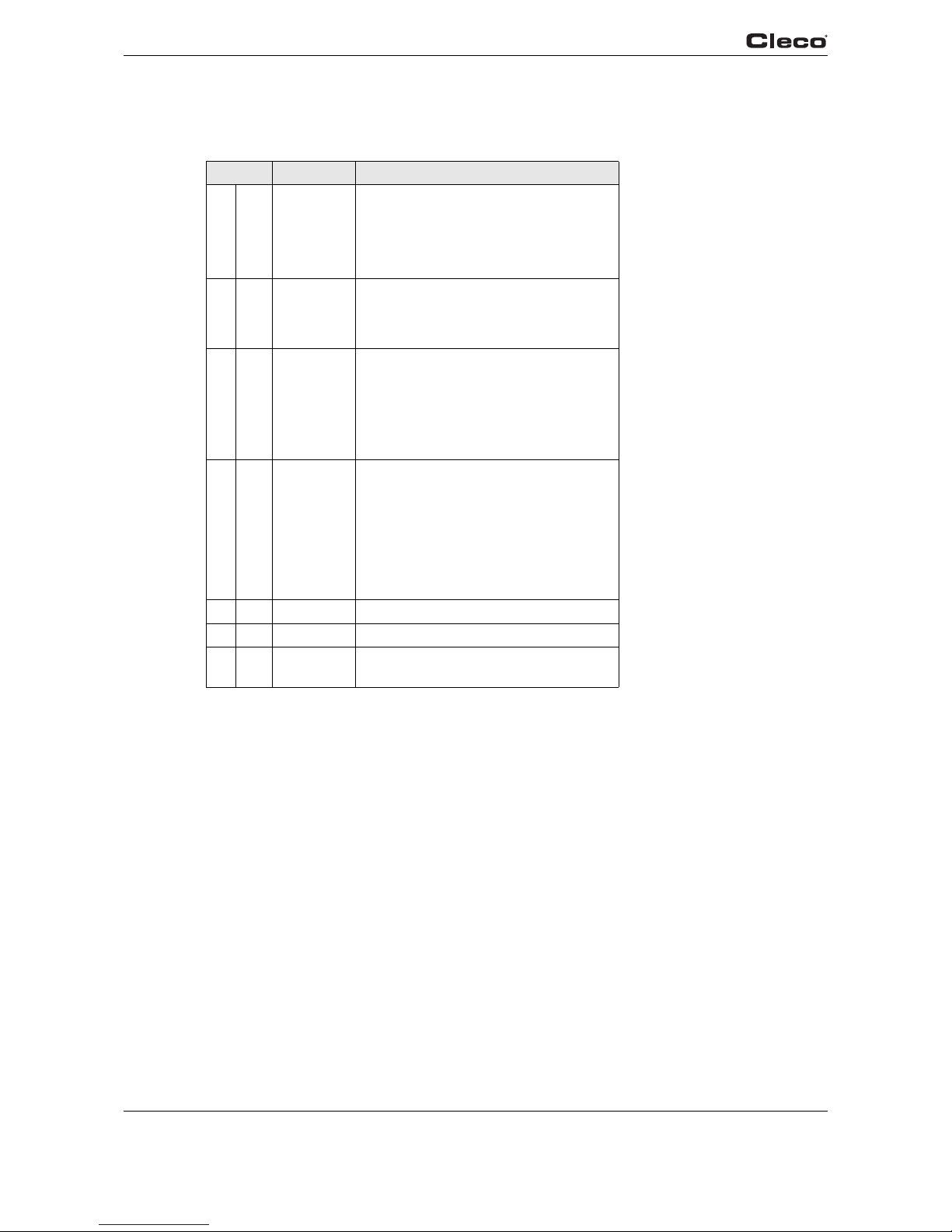

Object Time period Storage

temperature

Supplemental

information

47BA without battery No guideline -25 °C to +40 °C

(-13 to 104 °F)

Rechargeable battery Short-term -30 °C to +45 °C

(-22 to 113 °F)

Long-term, from

1year

-30°C to +30°C

(-22 to 86 °F)

30% – 50% store

charged.

Recharge after 1 year

to prevent deep discharging (< 17.5 V).

10 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Scope of supply, transport and storage

2

3 Product description

3.1 General description

• Sturdy, brushless motor with resolver.

Shutoff is torque/angle-controlled.

• LCD display with information on status, torque and angle.

• Green OK and red NOK LED display provides information

on the current fastening result.

• LED lighting makes it possible to find the screw point quickly.

• Clockwise/counterclockwise rotation

• Low vibration level

• Servo and fastening electronics are integrated in the 47BA.

• Fastening parameters are set with the TMEB-200 / TMEC controller or a PC.

• Data is transmitted between the controller and tool via infrared (IrDA) or, optionally, via WLAN

(IEEE 802.11b), 868 MHz or 915 MHz.

- Types with wireless transmission:

Parameters and rundown results are transmitted wirelessly.

- Types without wireless transmission:

Parameters and rundown results are transmitted to the TMEB-200 / TMEC control or to a

computer simply by placing the 47BA in the tool holder.

• Optionally, the tools are equipped with a 1D Linear barcode scanner.

• Built-in acoustic signal. The signal is activated after barcodes are scanned. It can also be

activated after NOK rundowns for a programmable time.

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 11

Scope of supply, transport and storage

2

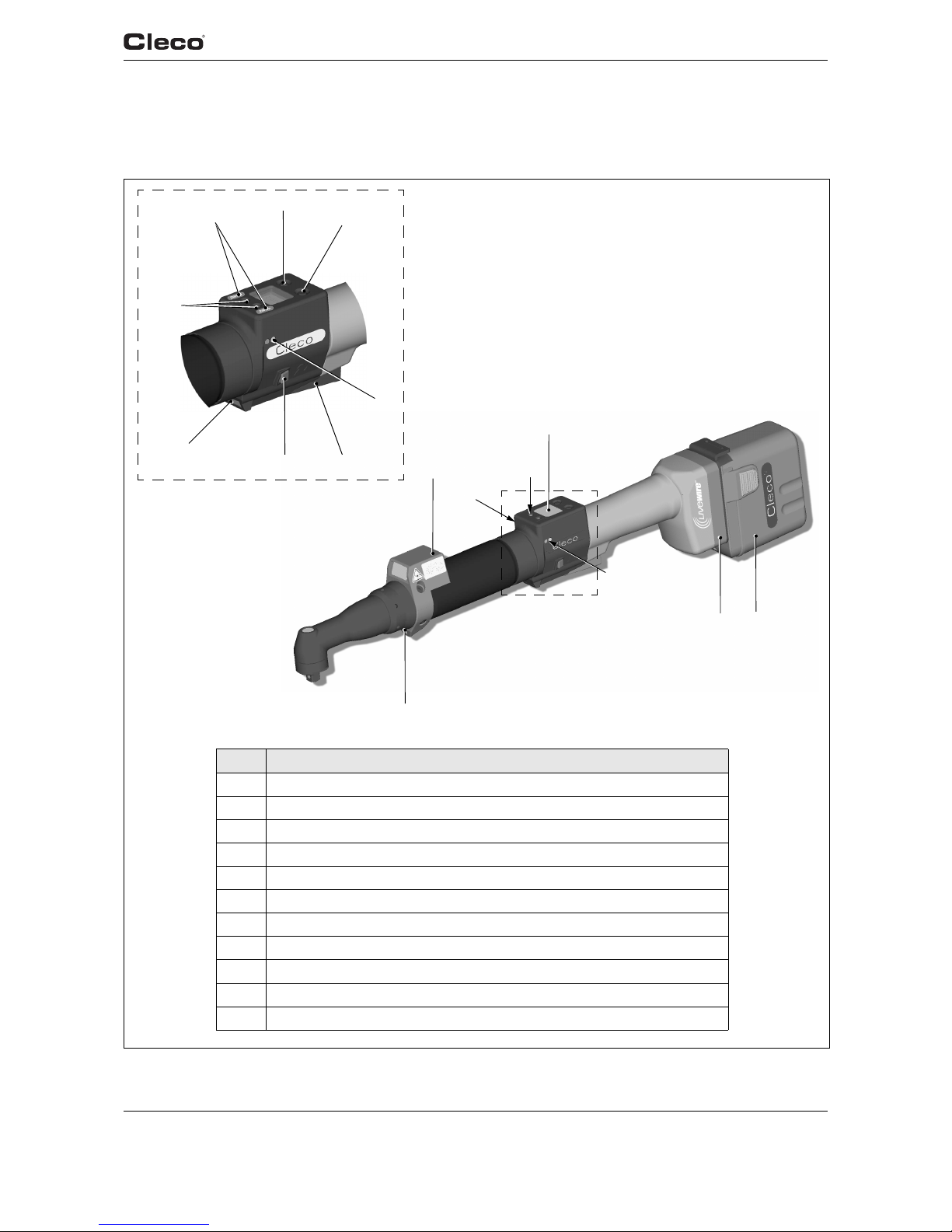

3.2 Operation and functional elements

This chapter describes operational and functional elements and their tasks in the order of their

respective item nos.

8

9

7

2

2

2

5

4

1 <F2>

2

6

3

2

Item Designation

1 Function keys <F1>, <F2>

2LED display

3 Start button

4 Reverse switch

5 IrDA (infrared interface port)

6 Set torque – stick-on marking foil

7 LED lights for fast location of the fastening position

8 Rechargeable battery

9 LCD display with information on torque, angle and status

10 Barcode scanner

11 Wireless module

11

10

1 <F1>

12 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Scope of supply, transport and storage

2

3.2.1 Function keys

Left function key <F1>

• Confirm error message

➔ Press once.

Programmable: Depending on how the key is programmed, actions can be carried out by

pressing it briefly.

•Exit menu

➔ Press for two seconds.

Right function key <F1>

• Activate menu

➔ Press until the display shows the Main menu (for additional information, refer to 6.3 Operating

menu, page 24).

• Select functions, if menu is activated

➔ Press for two seconds. Alternatively, the start button can be pressed.

3.2.2 LED display

The LED display shows the respective operating status and the result of the last fastening

sequence (see 5.2 Operating status, page 19):

Software update

During Software Update, the actual programming process is indicated by rapid flashing alternat-

ing at irregular intervals between red and green.

LEDs Operating status Result

after screwing cycle

Steady light Green Active OK

Steady light Red Active NOK

Flashing light Green –

low frequency

Energy saver mode

Off Sleep

If Linking is selected on TMEB-200 / TMEC:

Flashing light Green –

high frequency

Active / Settings: Linking Linking OK

Flashing light Red Active / Settings: Linking Linking NOK

NOTE

Do not interrupt programming by removing the battery during this phase.

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 13

Scope of supply, transport and storage

2

3.2.3 Start button

The start button has 3 functions (Standard for TMEB-200 / TMEC):

• It activates the LED lighting.

➔ Press the start button halfway down and hold it.

• It starts the motor, the LED light goes out.

➔ Press the start button all the way down.

• It activates the barcode scanner—only for types of the 47BA...S series.

➔ Press the start button all the way down.

3.2.4 Reverse switch

The reverse switch changes the rotation direction of the 47BA:

Clockwise rotation – for screwing in screws

Press reverse switch as far as it will go.

When the start button is pressed Active appears on the LCD display.

Counterclockwise rotation – for loosening or screwing out screws

Press reverse switch as far as it will go.

When the start button is pressed Left appears on the LCD display.

3.2.5 IrDA interface port

The 47BA communicates with the TMEB-200 / TMEC controller or a PC (TMEB-COM) via the

IrDA interface port. For secure data transmission and for programming the 47BA, place the 47BA

in the tool holder with IrDA interface port, Order no. 935290. Data transmission is possible in the

Active, Energy saver mode and Standby operating modes, but not possible in Sleep

(see 5.2 Operating status, page 19).

3.2.6 Identification – set torque

To identify the set torque on the 47BA, glue the corresponding marking foil to the right and the left

of the LCD display.

NOTE

If the data transmission has been interrupted, the 47BA reports Synch error on the LCD display.

Replace the 47BA in the tool holder. The complete data transmission is acknowledged on the

display with Remain 512.

Order No.

935759

Order No.

935330

14 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Scope of supply, transport and storage

2

3.2.7 LED lighting

LED lighting make it possible to quickly find the screw point.

3 different activation methods are possible. Define the method by programming

the TMEB-200 / TMEB-COM / TMEC correspondingly:

• Activation by pressing the start button halfway down (3.2.3 Start button, page 13).

• Time-controlled beginning at start

• You also have the option of disabling it.

The lighting distance is up to 4.7" (120 mm).

3.2.8 Rechargeable battery

For information on the battery, see

4.3 Charging the battery, page 17

4.4 Replacing the battery, page 18

10.4.1 Battery power supply, page 67.

3.2.9 LCD display

See 6 LCD display, page 21

3.2.10 Barcode scanner

For tools of the 47BA...S series, the built-in barcode scanner is a class 2 laser scanner with a

wavelength of 650 nm.

The barcode scanner reads one-dimensional linear barcodes:

Depending on how the TMEB-200 / TMEB-COM / TMEC is programmed, there are two different

operating modes:

Barcode as release for further rundowns

➔ Press the start button on the tool; this activates the barcode scanner.

The successful scan is acknowledged by an acoustic signal.

➔ Press the start button on the tool again; this starts the rundown.

If is necessary to read another barcode, proceed as follows.

CAUTION!

Eye injury from class 2 laser beam

➔ Do not look into the laser beam window when the laser is on.

➔ Repair any damage immediately.

Damage of the optical components can cause laser radiation.

➔ Modifications to the barcode scanner and procedures not outlined in these operating

instructions are strictly prohibited.

➔ Take defective devices out of operation immediately.

Scanning operation Acoustic signal

• Successful 50 ms long

•Faulty

• Not within 3 seconds

• Canceled by pressing the start button

3 times in rapid succession

LASER RADIATION

DO NOT LOOK INTO THE BEAM

CLASS 2 LASER

IN ACCORDANCE WITH

EN 60825-1:1994

P < 1mW;

λ = 630 nm

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 15

Scope of supply, transport and storage

2

Barcode not necessary as release for further rundowns

➔ From the Scanner tool menu, select Read barcode.

➔ Press the start button on the tool; this activates the barcode scanner.

The successful scan is acknowledged by an acoustic signal.

➔ Press the start button on the tool again; this starts the rundown.

Alternative: Assign the Read barcode function to the left function key <F1> on the tool.

➔ Press the left function key <F1> on the tool once.

➔ Press the start button on the tool again; this activates the barcode scanner.

Programming the barcode scanner is described in the programming manual of the TMEB-200 /

TMEB-COM / TMEC.

3.2.11 WLAN interface port

Tools of type 47BAW…/47BAX… are equipped with an IEEE 802.11b standard WLAN interface

port in addition to the IrDA interface port. The tool uses this WLAN interface port for continuous

communication with the controller. This interface port is used to transmit both the parameters and

the rundown results. Data transmission is possible in the Active, Energy saver mode and

Standby operating modes, but not possible in Sleep (see 5.2 Operating status, page 19). Programming and setting up the WLAN interface port are described in the programming manual of

the TMEB-200 / TMEB-COM / TMEC controller.

As the counterpart, an access point that complies with the IEEE 802.11b/g standard is required.

3.2.12 868 MHz interface port (EU)

Tools of the type 47BAR… have an 868 MHz interface port in addition to the IrDA interface port.

The tool uses this 868 MHz interface port for continuous communication with the controller. This

interface port is used to transmit both the parameters and the rundown results. Data transmission

is possible in the Active, Energy saver mode and Standby operating modes, but not possible in

Sleep (see 5.2 Operating status, page 19). Programming and setting up the 868 MHz interface

port are described in the programming manual of the TMEB-200 / TMEB-COM / TMEC controller.

The base station, Order no. 961300, is required as the remote station.

3.2.13 915 MHz interface port (NA)

Tools of the type 47BAF… have an 915 MHz interface port in addition to the IrDA interface port.

The tool uses this 915 MHz interface port for continuous communication with the controller. This

interface port is used to transmit both the parameters and the rundown results. Data transmission

is possible in the Active, Energy saver mode and Standby operating modes, but not possible in

Sleep (see 5.2 Operating status, page 19). Programming and setting up the 915 MHz interface

port are described in the programming manual of the TMEB-200 / TMEB-COM / TMEC controller.

The base station 961301 is required as the remote station.

NOTE

After the tool is switched on, it can take up to 25 seconds until the communication via WLAN is

active.

16 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Scope of supply, transport and storage

2

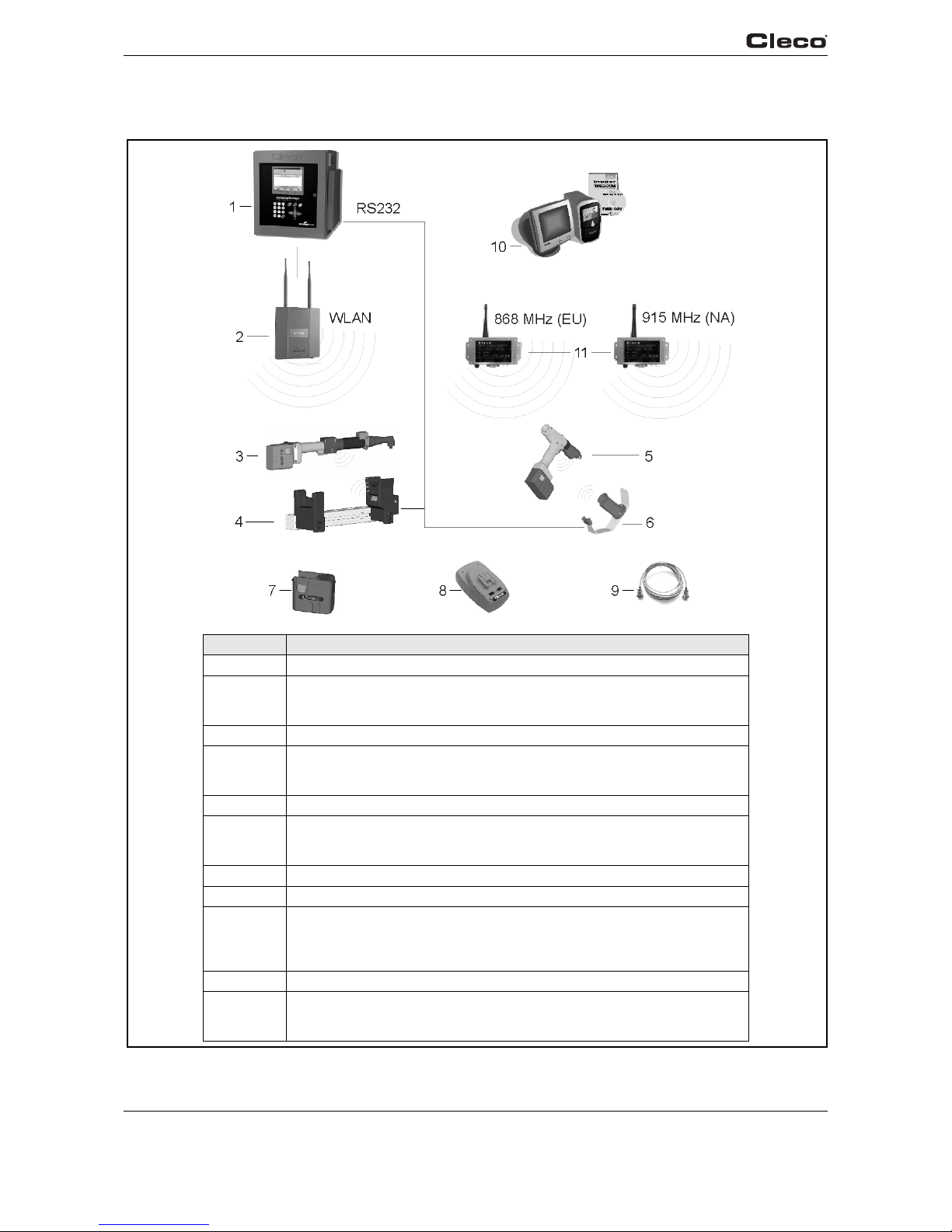

3.3 System overview – optional accessories

Overview EC tool_optional equipment

Alternatives

Item Designation

1 TMEB-200 / TMEC – Controller for electric nutrunner

2 Access point –

Order no. 543995 (NA)

Order no. 961323 (EU)

3 Tool series 47BA

4 Tool holder

Order no. 935290 – with IrDA interface, RS232 connection cable

Order no. 935395 – without IrDA interface, RS232 connection cable

5 Tool series 17BP

6 Tool holder

Order no. 935144 – with IrDA interface, RS232 connection cable

Order no. 935396 – without IrDA interface, RS232 connection cable

7 Interchangeable battery, Li-ion, 26 V – Order no. 935377

8 Battery charger, Li-ion, 26 V (110 – 230 VAC) – Order no. 935391

9 RS232 extension cable (IrDA)

Order no. 935154 – 9.84" (3 m)

Order no. 935155 – 19.7" (6 m)

Order no. 935157 – 32.8" (10 m)

10 TMEB-COM – Computer with PC software

11 Base station

Order no. 961301 – 915 MHz (NA)

Order no. 961300 – 868 MHz (EU)

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 17

Before initial operation

4

4 Before initial operation

The 47BA has been configured by Cooper Power Tools. A setting for your specific screw joint

needs must only be made with the TMEB-200 / TMEC controller or a PC by a qualified person.

For more information, refer to the TMEB-200 / TMEB-COM / TMEC programming manual.

4.1 Setting up tool holder

➔ Mount the tool holder on a stable base.

For tool holder with IrDA interface port:

➔ Select the location in such a way that no outside light shines onto the tool holder.

This can inhibit data transmission.

➔ Lay the connection cable in such a way that there is no danger that persons can trip.

4.2 Ambient conditions

4.3 Charging the battery

Charge fully before first use.

Battery is only partly charged when delivered.

➔ Fully charge before first use.

➔ Battery charging temperature: 5 °C to +45 °C (+41 °F to +113 °F)

➔ Follow the safety instructions printed on the battery and charger.

➔ Fully charge new batteries or those not used for a long time.

➔ Do not totally discharge the battery (< 17.5 V).

➔ Protect the battery from impact.

➔ Keep the charger and battery contacts clean and dry.

➔ Protect the battery from moisture.

➔ The battery can remain in the charger when not in use: the self-discharging is very low.

➔ Replace used batteries and recycle them (see 12 Disposal, page 71.)

Ambient temperature 0 °C (32 °F) to maximum +40° C (+104° F)

Humidity 0 to 80 %, not with dew

Working height up to 1000 m above sea level

WARNING!

Electrical shock, overheating or leakage of corrosive liquid from the battery can occur when

using incorrect chargers or batteries.

➔ Use only original CLECO batteries and chargers.

They are designed for use together.

NOTE

With proper use, the battery can be charged at least 800 (60% capacity) times.

Here, the following is important:

18 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

Before initial operation

4

4.4 Replacing the battery

Fig. 4-1:

Fig. 4-2:

Inserting the battery

➔ Insert the battery into the tool guide

until the catches securely engage.

Removing the battery

➔ Press the catches together and pull the

battery out of the handle.

1.

2.

91b_1_5 en bedingt.fm, 24.09.2007 P1891E/EN 09/07 19

First Operation

5

5 First Operation

5.1 Carrying out the rundown

Make sure that the battery is securely installed before operating the 47BA. The 47BA is now

ready for use. After you press and release the start button, the LCD display reads Ready.

Types with wireless transmission continuously communicate with the controller. The tool automatically receives the parameters and, when the rundown is complete, automatically sends the

rundown results to the control system. Programming and setting up the wireless interface port

are described in the programming manual of the TMEB-200 / TMEB-COM / TMEC controller.

Types without wireless transmission must be placed in the tool holder when the rundown is complete. The rundown results are transmitted and shown under the Run screen menu item.

5.2 Operating status

The operating modes change in the following order.

The following functions are available depending on the display:

Operating

status

LED

display

LCD display Function

Active Steady light:

Red – Rundown NOK

Green – Rundown OK

On Screws

Data transmission

Automatic switch to the following after 1 minute idle time:

Energy

saver mode

Flashing light Green Off Data transmission

Automatic switch to the following after further 10 minutes:

Sleep Off Off Data transmission not

possible

Manual switch from Sleep to Active:

Press down start button and hold down for approx. 1 second.

To switch off the 47BA manually, pull out the battery.

20 P1891E/EN 09/07 91b_1_5 en bedingt.fm, 24.09.2007

First Operation

5

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 21

LCD display

6

6 LCD display

The LCD display on the tool is divided into the result display, status display, operating menu and

system error messages.

6.1 Result display

First line – result:

The status is displayed in alternation with the Application being used.

The LCD display consists of a three lines, each with 6 characters,

to display the status, torque and angle. The result display is updated after the

rundown ends.

OK Result is OK

NOK Result is not OK

OFF Torque transducer offset error

CAL Torque transducer calibration error

ENC Angle encoder error

IP Current overload in output section

IIT Requested motor output is too high

TMAX Maximum fastening time exceeded

RC Rundown canceled by disabled start signal

TS Depth sensor signal was enabled at start or

was subsequently disabled during the rundown (only for 17BP series)

Tq< Torque too low

Tq> Torque too high

A< Angle too low

A> Angle too high

Error Error occurred

Second line – Shut-off torque in Nm:

T Final torque

Third line – Shut-off angle in degrees:

A Final angle

For types with wireless transmission, an interrupted data connection to the

TMEB-200 / TMEB-COM / TMEC is indicated by the symbol at the top right of

the LCD display.

OK

T 12.00

A 100

OK

T 12.00

A 100

22 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.2 Status display

The status display is divided into the "Standard" and "Linking" modes. "Standard" is selected if

"Linking" is not enabled on the TMEB-200 / TMEB-COM / TMEC (see Advanced Applica-

tion Builder\Linking). The application is selected at the Run Screen or via the App. selection inputs.

No other status messages take priority.

The tool is ready.

Number of remaining rundowns that can still be carried out until the rundown

data memory is full and the rundown data have to be transmitted to the

TMEB-200 / TMEB-COM / TMEC.

Emergency strategy active. Is displayed if emergency strategy is currently active

and with that no communication with TMEB-200/TMEB-COM/TMEC is necessary. On Tool are the latest 512 rundown results stored.

All fastening sequences have been completed.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC.

No fastening sequences have been initialized.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC.

No fastening sequence parameters have been set.

➔ Check the Application and Tightening group selected on the TMEB-200 /

TMEB-COM / TMEC to determine whether the tool settings and process

programming have been carried out.

Application locked.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC.

Reject Release active.

The tool has been programmed in Advanced Application

Builder\Reject Release.

➔ Depending on the programming, unlock the tool via the external input

NOK release or Release on Backoff. To unlock via the external input NOK

release, set the external input and synchronize it with the TMEB-200 /

TMEB-COM / TMEC.

Ready

Remain

512

Emerge

Strate

Job

comple

Sync

No

Job

Sync

Parame

not

set

App

locked

Sync

Reject

Releas

Sync

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 23

LCD display

6

Additional messages in "Linking" mode

Error in last data synchronization with the TMEB-200 / TMEB-COM / TMEC.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC again.

Tool has not yet been synchronized with a TMEB-200 / TMEB-COM / TMEC.

➔ Carry out initial synchronization of the tool with the TMEB-200 /

TMEB-COM / TMEC.

The Tool Enable input is missing.

➔ Set the Tool Enable input.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC.

This message can appear only if External Tool Enable has been activated

in Advanced Application Builder\System settings.

Tool disabled since no valid barcode data has been set.

➔ Send the barcode to the TMEB-200 / TMEB-COM / TMEC.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC once

again.

First line: The next position to be fastened.

Second line: Number of positions.

Third line: Number of repetitions at this position in case of an NOK rundown.

Linking has been cancelled without a batch result.

Not all of the positions in the tightening group have been programmed.

➔ Check the Application and Tightening group selected on the TMEB-200 /

TMEB-COM / TMEC to determine whether the tool settings and process

programming have been carried out.

Linking result OK.

Linking result NOK.

Sync

Error

Tool

not

Init

Input

Enable

Missin

Need

Part

ID

N.Pos1

of 3

Rpl 0

Linkin

No

Result

Linkin

OK

Linkin

NOK

24 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.3 Operating menu

6.3.1 General

The operating menu on the tool is divided into a main menu and submenus. You can navigate

through the menus using the two function keys below the LCD display. In the following description, <F1> is used for the left function key and <F2> is used for the right function key. The menu

is activated by pressing the right function key, <F2>. The menus can be disabled by configuring

appropriate parameter in the controller.

Basic functions:

➔ <F2>: Activate main menu.

➔ <F1>: Go to previous menu item.

➔ <F2>: Go to next menu item.

➔ Press <F1> longer than 2 seconds

to go to the next higher menu level. If the main menu is activated, the system goes into production mode.

➔ Press the start button or <F2> longer than 2 seconds

to activated the highlighted item or execute the highlighted action. Actions that start the tool

can be carried out only by pressing the start button.

➔ If the menu is enabled, no rundowns are possible.

➔ Each submenu has an entry for Back.

Linking disabled.

➔ Synchronize the tool with the TMEB-200 / TMEB-COM / TMEC.

Enables the main menu.

Linkin

locked

Sync

Back

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 25

LCD display

6

6.3.2 Structure

Main

Administration

Administration

Diagnostics Date / Time

Set position Counter display

Scanner Serial number

RF settings Software version

Back Emergency strategy

Back

Diagnostics

TQ calibration

TQ measurement

Angle encoder

Voltages

Speed

Back

Set position

Next position

Reset linking

Back

Scanner

Read barcode

Back

WLAN wireless transmission

47BAW…/ 47BAX… series

Wireless module version

MAC address

IP address

Subnet mask

Gateway

SSID

Signal strength

Back

868 / 915 MHz wireless transmission

47BAR…/ 47BAF… series

Wireless module version

Channel

Network ID

Tool ID

Power

Back

26 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.3.3 Main menu

6.3.4 Administration submenu

Administration – General items such as Date/Time, Counter display, etc.

Diagnostics – Diagnostic functions for the tool.

Position – Selects the position to be used next.

Scanner – Deletes a previously read barcode and activates a new read cycle.

RF settings – Displays the settings used for wireless transmission.

Date/Time

Displays the tool system time.

The system time can be displayed in US or European format.

➔ Refer to "Setting the system time on the TMEB-200 / TMEB-COM / TMEC

under Administration\Date\Time.

Counter display

The tool counter display is incremented after each rundown throughout the

service life of the tool.

➔ Refer to "Counter display on the TMEB-200 / TMEB-COM / TMEC under

Diagnostics\Tool\Tool Memory.

Serial number

Displays the tool serial number.

➔ Refer to "Serial number on the TMEB-200 / TMEB-COM / TMEC under

Tool or Diagnostics\Tool\Tool Memory.

>Main

Admini

strati

>Main

Diag-

nostic

>Main

Posi-

tion

>Main

Scan-

ner

>Main

RF-SET

Time

07:47

30.09

Counte

99

999999

S/N

000000

245

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 27

LCD display

6

Software version on controller board

Displays the installed software version.

Software version on servo

Displays the installed software version.Displays the installed software version.

NOTE

The emergency strategy can activated only if Emergency Strategy has been enabled on the

TMEB-200 / TMEB-COM / TMEC under Advanced Application

Builder\System settings.

Emergency strategy disabled.

➔ Enable the emergency strategy on the TMEB-200 / TMEB-COM / TMEC

under Advanced Application Builder\System settings\Enable emergency strategy.

Emergency strategy off.

If it has been enabled on the TMEB-200 / TMEB-COM / TMEC under Advanced

Application Builder\System settings\Enable emergency strategy,

you can switch the emergency strategy on and off using the tool start button or

by pressing <F2> for 2 seconds. The Emergency strategy is disabled automatically when the tool links to the TMEB-200 / TMEB-COM / TMEC

Emergency strategy on.

If the emergency strategy is enabled and Linking is disabled, the fastening

parameters of the last selected Application are used. For Linking operating

mode, all steps are used with the corresponding parameters of the last selected

Tightening Group.

The memory of the tool stores data from up to 512 rundowns. If more rundowns

than this are executed while the Emergency strategy is active, the oldest results

are always discarded once 512 rundowns have been recorded.

Emergency strategy active. Is displayed during fastening.

Ver s.

V1.00.

00

Servo

V:T108

N00015

Emerge

Strate

locked

Emerge

Strate

Off

Emerge

Strate

On

Emerge

Active

28 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.3.5 Diagnostics submenu

TQ calibration

This test function cyclically recalibrates the system with the values used immediately before the start of a rundown. For this, the tool must not be tensioned!

First line: Calibration test and status.

Second line: TQ calibration voltage.

Third line: Offset voltage. If a value lies outside the tolerance range, the corresponding error is displayed.

TQ measurement

In this test function, after the start button is pressed, the same calibration is

carried out as immediately before the start of a rundown. For this, the tool must

not be tensioned!

Then, the tool starts with speed "0". The torque is continuously measured and

displayed until the start button is released.

Second line: Current torque.

Third line: Peak value, highest value since the start button was pressed.

Angle encoder

The start button starts the tool at 30% of the maximum speed. After one revolution of the output shaft (nominal angle 360°), measured with the resolver, the tool

is stopped. During a fixed dwell time of 200 ms, any further angle pulses occurring are traced. The total result is shown as Actual Angle. If the test run is not terminated by a monitoring criterion and the batch result is greater than or equal to

360 degrees, it is evaluated and displayed as OK. Monitoring criteria are the

torque and a monitoring time.

If the torque exceeds 15 % of the calibration value (even during the dwell time),

or if the monitoring time of 4 seconds expires, the test run is terminated with a

TQ> or TMAX result. However, you specifically need to check whether the output

shaft has actually turned by the value indicated (e. g. by placing a mark on the

spindle). If the angle reached by the output shaft does not agree with the value

displayed, either the angle factor has been entered incorrectly or the resolver is

defective.

Voltag es

Second line: Current battery voltage. To ensure high utilization potential, this

voltage is monitored continuously during fastening operation. If the voltage drops

below limit, a warning output on the tool.

Third line: Programmed value. This can be changed using the TMEB-200 /

TMEB-COM / TMEC under Tool.

Cal OK

K 1.11

O 0.00

Value Rated

value

Tolerance

Calibration offset 0 V ± 45 mV

TQ calibration voltage: 1.122 V ± 32 mV

Torque

T 5.57

T 8.23

Angle

A 360

OK

Voltag e

V26.00

L18.00

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 29

LCD display

6

6.3.6 Set position submenu – only with Linking enabled

6.3.7 Scanner submenu – only for types of the 47BA...S series

Speed

The start button starts the tool at the maximum speed.

Second line: Current output shaft speed.

Third line: Current torque.

Rotational speed measurement is based on the angle information of the resolver.

If you release the start button, the tool stops. As a safety function the torque is

monitored by the tool transducer. If it exceeds 15 % of its calibrated value, the

speed measurement is terminated.

Selects the position to be used next.

You can skip the position.

You can select the position to be used next using the function keys:

➔ <F1>: Activate the previous position.

➔ <F2>: Activate the next position.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

Reset linking to position 1. The operator could terminate linking.

Scanner – Deletes a previously read barcode and activates a new read cycle.

➔ Press the start button or <F2> longer than 2 seconds.

Speed

Rpm466

T 0.02

<Posit

Change

Positi

Select

Positi

2/6

>Posit

Reset

Positi

<Scann

Activa

Scanne

30 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.3.8 WLAN wireless transmission submenu –

only for types of the 47BAW… / 47BAX… series

The WLAN RF settings submenu shows the settings being used.

If no actions are carried out, the menu is automatically exited after 60 seconds.

Programming the RF settings for WLAN data transmission is described in the programming

manual of the TMEB-200 / TMEB-COM / TMEC.

Displays the installed software version of the wireless module.

MAC address display

IP address display

Subnet display

Gateway display

SSID display. Only the first 12 characters are displayed.

When the start button is pressed, the current wireless signals are displayed.

17BPW… / 47BAW…:

N = Ratio of signal strength to ambient noise (dB)

S = Signal strength (dBm)

L = Ambient noise (dBm)

17BPX… / 47BAX…:

N = Signal strength (%)

S = Signal strength (dBm)

Ver sio

#27173

Dec 1

MAC

00302e

e162f8

IP 010

.122.0

77.110

Sub255

.255.2

40.0

Gat010

122.0

61.001

SSID

CPT

N: 34

S: -60

L: -94

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 31

LCD display

6

6.3.9 868/915 MHz wireless transmission submenu –

only for types of the 47BAR…, 47BAF… series

The 868/915 MHz RF settings submenu shows the settings being used. If no actions are carried

out, the menu is automatically exited after 60 seconds.

Programming the RF settings is described in the TMEB-200 / TMEB-COM / TMEC programming

manual.

Displays the installed software version of the wireless module.

Displays the radio channel being used and allows you to configure settings.

With 868 MHz, you can select channel 1 – 3.

With 915 MHz, you can select channel 1 – 8.

➔ <F1>: Activate a lower channel.

➔ <F2>: Activate a higher channel.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

NOTE

The channel must match the set channel of the base station.

Defines the network identification. You can operate no more than 4 tools per

network ID.

➔ <F1>: Activate a lower network ID.

➔ <F2>: Activate a higher network ID.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

NOTE

The network ID must match the set network ID of the base station.

Ver sio

B868

MC-tin

Chan-

nel

1/3

Networ

ID

1/16

32 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

6.4 System error messages

Displays the tool ID and allows you to configure settings.

You can select a tool ID from 1 – 4.

➔ <F1>: Activate a lower network ID.

➔ <F2>: Activate a higher network ID.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

NOTE

Each tool can be used only once for each base station.

Displays the transmission power and allows you to configure settings.

➔ <F1>: Activate a lower transmission power.

➔ <F2>: Activate a higher transmission power.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

For 868 MHz, the maximum transmission power depends on the selected channel. If channel 1 is selected, you can choose between 1, 5, 10, and 25 mW for

the transmission power. If channel 2 or 3 is selected, you can choose either 1 or

5 mW for the transmission power. For 915 MHz, you can choose between 1, 5,

10, and 25 mW.

➔ Press the start button or <F2> longer than 2 seconds

to accept the select and display the next menu item.

➔ Press <F1> longer than 2 seconds

to delete the selection and exit the menu.

NOTE

If a error is displayed, fastening is disabled until the error is acknowledged with the left-hand button on the tool. In the event of serious hardware errors, the tool is not enabled again even after

the error is acknowledged, and must be returned to the manufacturer for repair.

Initialization error in tool servo.

➔ Remove the battery and then re-insert it. If this does not help:

➔ Return tool to manufacturer for repair.

Tool

ID

1/4

Power

25 mW

Servo

Error

Init

91c_LCD en bedingt.fm, 24.09.2007 P1891E/EN 09/07 33

LCD display

6

Speed specification from the measuring board to the servo is faulty.

➔ Remove the battery and then re-insert it. If this does not help:

➔ Return tool to manufacturer for repair.

Too much power is being demanded from the tool.

➔ Switch the tool off for a time so that it can cool down.

➔ Increase the cycle time, reduce the fastening time or the torque.

The servo's current sensor is detecting a current offset error.

➔ Return tool to manufacturer for repair.

Collective servo error caused by hardware.

➔ Return tool to manufacturer for repair.

The current setpoint has been exceeded.

There may be a short circuit.

➔ Return tool to manufacturer for repair.

The servo has overheated.

➔ Switch the tool off for a time so that it can cool down.

➔ Increase the cycle time, reduce the fastening time or the torque.

The tool motor has overheated.

➔ Switch the tool off for a time so that the motor can cool down.

➔ Increase the cycle time, reduce the fastening time or the torque.

Operating voltage is outside the admissible range.

➔ Change the battery. If this does not help:

➔ Return tool to manufacturer for repair.

Current at servo output stage is too high.

There may be a short circuit.

➔ Return tool to manufacturer for repair.

Tool angle encoder is sending incorrect signals to the servo amplifier.

➔ Return tool to manufacturer for repair.

Servo

Error

PWM

Servo

Error

IIT

Servo

Error

IOFF

Servo

Error

Other

Servo

Error

IP

Servo

Error

Tem p >

Servo

Error

Tem pM>

Servo

Error

Voltag

Servo

Error

Curr>

Servo

Error

Angle

34 P1891E/EN 09/07 91c_LCD en bedingt.fm, 24.09.2007

LCD display

6

Warns that battery is running low.

➔ Recharge battery or replace it with one that is already charged.

The rundown counter could not be read or written to.

➔ Return tool to manufacturer for repair.

Tool memory could not be read.

➔ Return tool to manufacturer for repair.

Two-stage start button defective.

➔ Return tool to manufacturer for repair.

Transducer reference voltage error.

➔ Return tool to manufacturer for repair.

Transducer calibration voltage error.

Tool was not discharged at time of calibration.

➔ Allow tool to discharge and try again. If this does not help:

➔ Return tool to manufacturer for repair.

Transducer offset voltage error.

Tool was not discharged at time of calibration.

➔ Allow tool to discharge and try again. If this does not help:

➔ Return tool to manufacturer for repair.

General collective error.

➔ Return tool to manufacturer for repair.

Low

voltag

warnin

Tool

Error

Counte

Tool

Error

Ident

Tool

Error

Start

Transd

Ref.V.

Error

Trans

CAL

Error

Trans

Off

Error

Unknow

Error

91d_Wartung en.fm, 24.09.2007 P1891E/EN 09/07 35

Maintenance

7

7 Maintenance

7.1 Cleaning instructions

For tools with a built-in barcode scanner, the window must be free of dirt.

➔ Clean it regularly—or immediately, if it becomes dirty—using a damp cloth and a conventional

window cleaner. Do not use acetone for cleaning. A dirty window may make it impossible to

read barcodes.

36 P1891E/EN 09/07 91d_ Wartung en.fm, 24.09.2007

Maintenance

7

7.2 Service schedule

Regular maintenance reduces operating faults, repair costs and downtime. In addition to the following service plan, implement a safety-related maintenance program that takes the local regulations for repair and maintenance for all operating phases of the tool into account.

CAUTION!

Danger of injury due to unintentional activation

– before service - disconnect the 47BA from the battery.

After

… fastening cycles

1)

)

1) For the number of fastening cycles, refer to the counter display in 6.3.4 Administration submenu, page 26

Actions

100.000

➔ Check to ensure the battery adapter, scanner and radio

adapter are seated securely.

➔ Check the tool and battery for damage.

➔ Check to ensure scanner window is transparent.

➔ Check to ensure battery contacts are clean.

➔ Check to ensure battery charger is clean.

➔ Check the gearing and angle head for leaks

500,000

➔ Use grease-dissolving agent to clean the angle head

and gearing components and then regrease, see

9.4 Gear + angle attachment, page 54.

9.5 Angle attachment 935313, page 56

9.6 Angle attachment 525943, page 58

➔ Check the angle head and gearing components for wear

and replace if necessary.

➔ Check battery guide, locking mechanism and contacts for

wear and replace if necessary.

1 million

➔ Use grease-dissolving agent to clean the angle head

and gearing components and then regrease, see

9.4 Gear + angle attachment, page 54.

9.5 Angle attachment 935313, page 56

9.6 Angle attachment 525943, page 58

➔ Check the angle head and gearing components for wear

and replace if necessary.

➔ Check battery guide, locking mechanism and contacts for

wear and replace if necessary.

➔ Recommendation: Recalibrate tool, see 11.1 Recalibra-

tion, page 71.

2.5 million

➔ General overhaul. Send it to Cooper Power Tools.

91d_Wartung en.fm, 24.09.2007 P1891E/EN 09/07 37

Maintenance

7

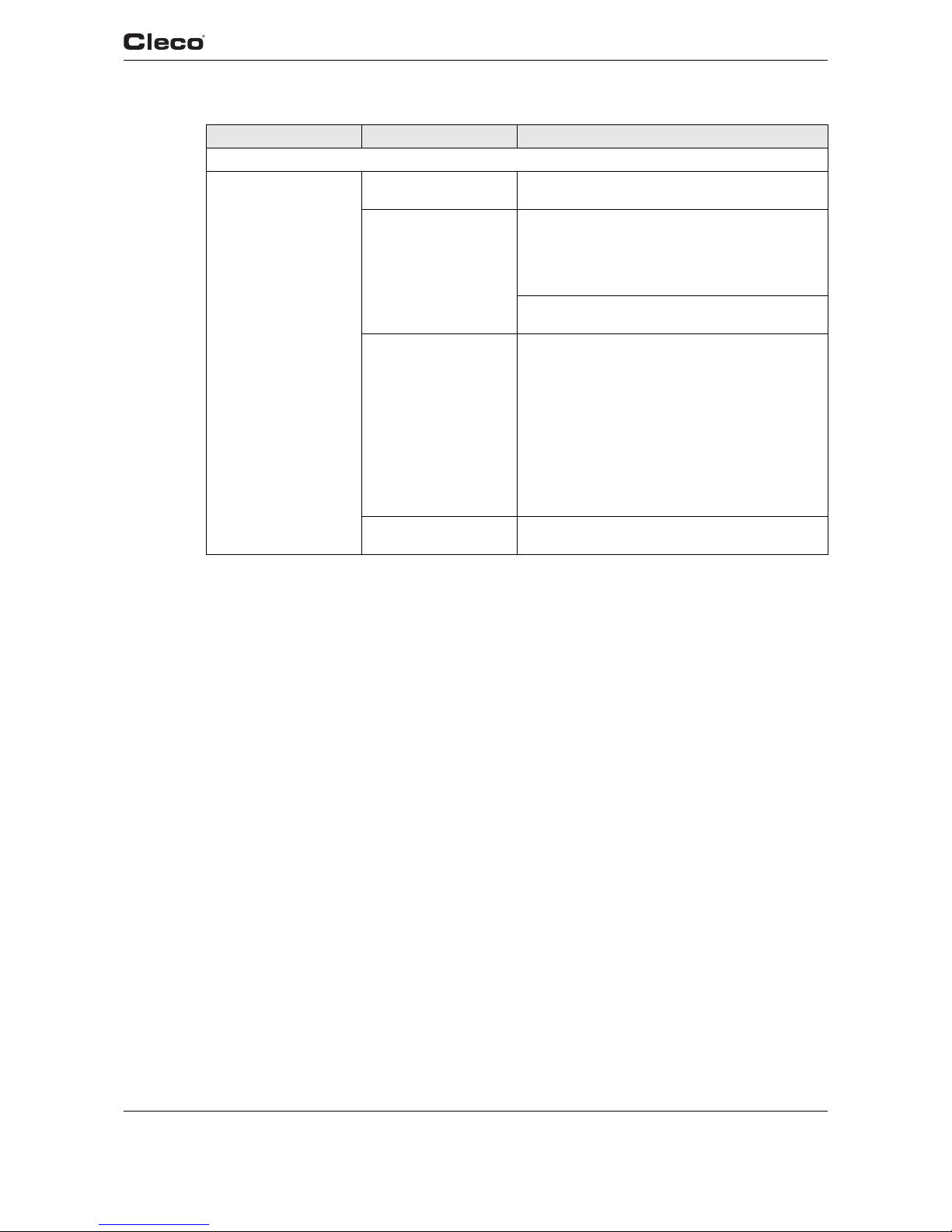

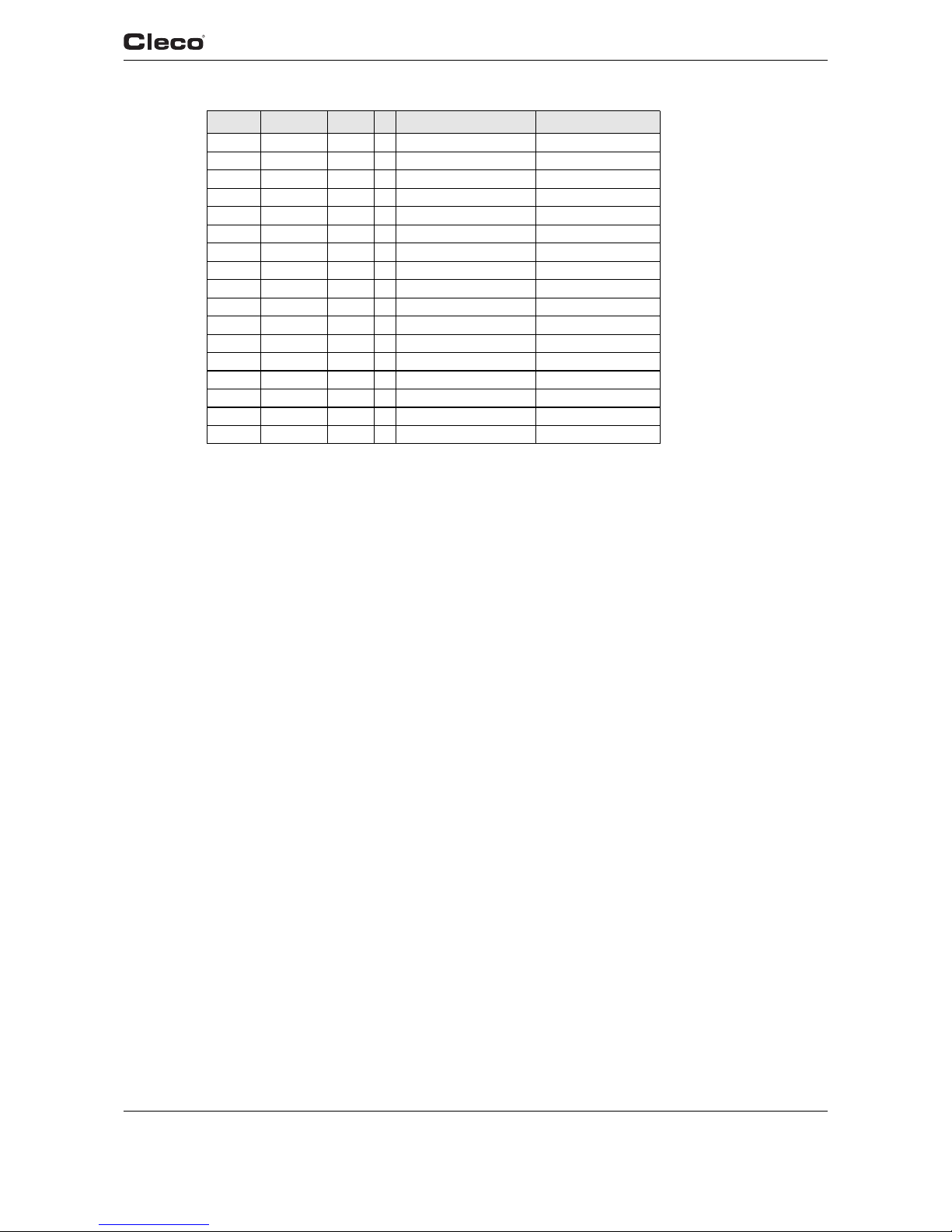

7.3 Lubricants

For smooth function and a long service life, use of the correct grease types according to the table

is essential.

Grease lubricants according to DIN51502 /ISO3498

7.4 Disassembling gear

NOTE

If the 47BA is opened, the warranty is voided. Only specialized technicians should be allowed to

open the gear for maintenance reasons.

Order no. Packing

unit

[ kg ]

DIN

51502

Nye

Lubricants,

Inc.

Dow

Corning

912554 15 G-POH

Aralub

FD00

Energrease

HTO

GA 0 EP

Expa 0

Mobilplex 44 –

Spec ial

Gear

H

–

933027 1 KP1K – – – –

Microlube

GL 261

––

912724 1 K-F2K – –

elf Multi

MoS

2

– UNIMOLY GL 82 –

Molykote

BR 2

541444 0.8 – – – – – – –

Rheolube

363AX-1

➔

Carefully tension the 47BA at the contact faces in a vise with plastic jaws

(max. 15 mm high).

➔ Release the Z by turning it counter-

clockwise.

Hook wrench, order no. 933336.

➔ Completely remove angle attachment.

➔ Pull gear completely off angle attach-

ment.

Z

38 P1891E/EN 09/07 91d_ Wartung en.fm, 24.09.2007

Maintenance

7

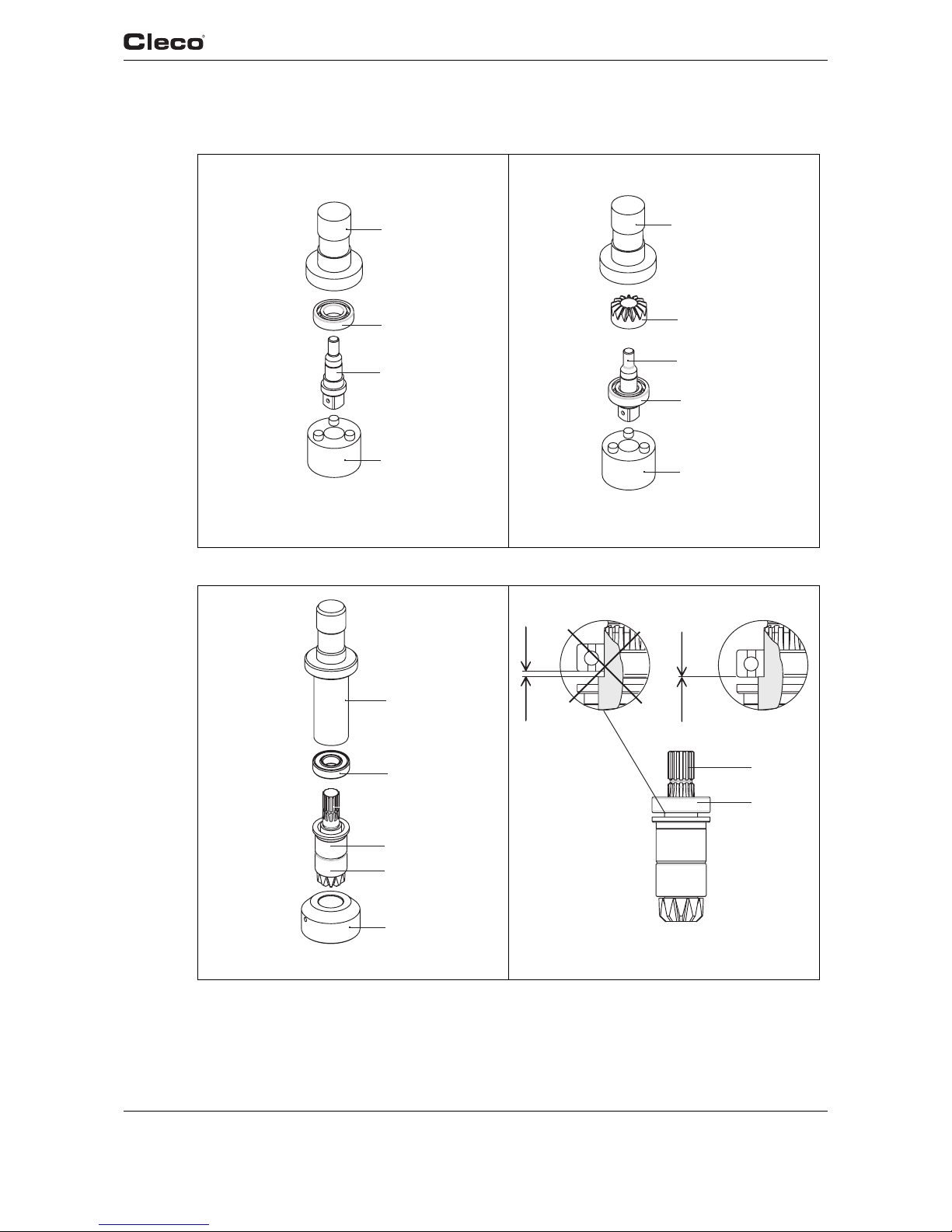

7.5 Removing angle attachment 935313

1.

2.

3. 4.

Index: See 9 Spare parts, page 47; 9.8 Fixture order list for angle attachment 935313, page 62

15 ohne 22 / 23

24

(29)

C2

25

F

1/2

D5

D4

(29)

C2

D5

D4

(29)

D5

D3

D2

D1

D5

91d_Wartung en.fm, 24.09.2007 P1891E/EN 09/07 39

Maintenance

7

7.6 Installing angle attachment 935313

Drive spindle

Bevel gear spindle

1.

2.

3.

4.

Index: See 9 Spare parts, page 47; 9.8 Fixture order list for angle attachment 935313, page 62

31

30

A2

A1

A3

(29)

A2

30

31

27

28

B2

B1

26

(29)

26

(29)

40 P1891E/EN 09/07 91d_ Wartung en.fm, 24.09.2007

Maintenance

7

Bevel gear and drive spindle in angle attachment

5. 6.

Index: See 9 Spare parts, page 47; 9.8 Fixture order list for angle attachment 935313, page 62

36

C3

B1

26

27

(29)

28

C2

F

1/2

OFF

18 22 Nm

13,3 16,3 lbf.ft

Loctite #242

OFF

10 - 14 Nm

7,4 - 10,4 lbf.ft

37

38

39

36

24

25

E

1/2

91e_Trouble shooting en bedingt.fm, 24.09.2007 P1891E/EN 09/07 41

Troubleshooting

8

8 Troubleshooting

Problem Possible cause Action

General – Tool

Tool does not start if

reverse switch is active.

Backoff speed parameter is set to 0 rpm.

¾ Adjust the backoff speed value in the Standard

Application Builder screen of the controller.

Tool light not active. Deactivated by param-

eter setting.

¾ Adjust the parameter for Tool light in the

Advanced Application Builder/System Settings

screen of the controller.

Operating menu of tool

not, or only partly,

enabled.

Disabled by parameter

setting.

¾ Activate the Enable Tool menu parameter in

the Advanced Application Builder/System Set-

tings screen of the controller.

Free speed parameter

value is not reached.

Battery voltage is too

low.

¾ Use a fully charged battery.

Could not reach the

expected number of

rundowns with one

battery charge.

Battery is not fully

charged.

¾ Use only fully charged batteries.

Low voltage warning is

not set to minimum

value.

¾ In the Tool Setup screen of the controller, set

the value for Low Level to 17.5 Volts.

During tightening

sequence, high torque

is required, for example

with coated screws.

¾ If high torque is required for a longer period of

time, e.g. for several turns, then the number of

rundowns with one battery charge is significantly reduced.

Battery has already

cycled too often.

¾ After 500 charge cycles the capacity is reduced

to about 80%.

Problem Possible cause Action

Infrared data communication between controller and tool

No infrared data

communication

between controller and

tool.

Wrong port is selected

for connection with the

controller.

¾ Check the port settings for infrared (IRDA)

communication in the Communication/Tool

screen of the controller.

Note: If the settings are changed, it is necessary

to press Accept <F1> in order to apply the settings.

¾ Check that the tool holder is connected to

selected port.

Selected port is used

for serial data transmission.

¾ In the Communication/Data Transmission

screen of the controller, check whether serial

data transmission is enabled (the protocol is

set to anything except NONE), and whether

the same port is being used. If so, select a dif-

ferent port or disable serial data transmission.

Check all available tools as necessary. The

same port cannot be used for serial data trans-

mission and infrared data communication with

the tool.

42 P1891E/EN 09/07 91e_Trouble shooting en bedingt.fm, 24.09.2007

Troubleshooting

8

Problem Possible cause Action

WLAN data communication between controller and tool

No WLAN

communication

between controller and

tool.

IP address of tool is not

entered correctly on the

controller.

¾ Check in the Communication/Tool screen of

the controller that the IP address of the tool is

entered in the RF Tool IP field. The IP address

of the tool is displayed on the tool in the WLAN

RF settings submenu.

Note: If the settings are changed, it is necessary

to press Accept <F1> in order to apply the settings.

Tool is not configured

with correct WLAN

parameter values.

¾ Configure the WLAN settings of the tool in the

Communication/Tool screen of the controller

via infrared communication.

WLAN network settings of the controller

and the access point

differ.

¾ In the Communication/Tool screen of the con-

troller, check that the settings of the access

point match the wireless network settings (Net-

work name, Security, Network key).

MAC address filter of

the access point is

active.

¾ Add the MAC address of the tool to the

address list of the access point. The MAC

address of the tool is displayed on the corre-

sponding label above the battery, and in the

WLAN RF settings submenu.

A firewall blocks port

4001.

¾ Reconfigure the firewall so that the specific IP/

MAC address of the tool can use port 4001.

The RF channel at the

access point is out of

the tool-supported

range.

¾ Change the channel setting of the access point

to a channel between 1 and 11.

Tool is already

assigned to a different

controller.

¾ Check whether any other controller has

already established a connection to this tool.

That means another controller use same IP

address.

WLAN communication

partly interrupted.

Distance between

access point and tool is

too great.

¾ Check the signal strength in the WLAN RF set-

tings submenu of the tool. For stable communi-

cation, the first value (N) should be greater

than 15. If the value is less than 15, move the

access point closer to the tool.

Tool is also assigned to

a different controller.

¾ Check whether this tool (IP address) is

assigned to any other controller. If so, delete

the assignment on the other controller. A tool

can only be assigned to one controller.

Too much traffic on the

wireless network.

¾ Reduce traffic on the wireless network.

Deactivate torque plot data transmission.

91e_Trouble shooting en bedingt.fm, 24.09.2007 P1891E/EN 09/07 43

Troubleshooting

8

Problem Possible cause Action

868 MHz data communication between controller and tool

No serial communication is possible

between the controller

and the base station.

(Error displayed after

Accept <F1> is pressed

in Communication/

Tool .)

Wrong serial cable is

used.

¾ Use a null modem cable (crossed).

Wrong port is selected

for connection with the

controller.

¾ In the Communication/Tool screen of the con-

troller, check the port settings for RF Serial.

Note: If the settings are changed, it is necessary

to press Accept <F1> in order to apply the settings.

¾ Check that the serial cable is connected to the

selected port.

Selected port is used

for serial data transmission.

¾ In the Communication/Data Transmission

screen of the controller, check whether serial

data transmission is enabled (the protocol is

set to anything except NONE), and whether

the same port is being used.

¾ If so, select a different port or disable serial

data transmission.

¾ Check all available tools as necessary. The

same port cannot be used for serial data trans-

mission and data communication with base

station tool.

Power outlet not active.

¾ Check the voltage at the outlet socket where

the base station is plugged in for power supply.

44 P1891E/EN 09/07 91e_Trouble shooting en bedingt.fm, 24.09.2007

Troubleshooting

8

No Ethernet communication is possible

between the controller

and the base station.

(Error displayed after

Accept <F1>) is

pressed in Communi-

cation/Tool.)

Wrong Ethernet cable

is used.

¾ A crossover cable is required if the base sta-

tion is directly connected to the controller. If the

base station is connected to a switch, a stan-

dard patch cable is required.

IP address of the base

station is not entered

correctly on the controller.

¾ In the Communication/Tool screen of the con-

troller, check that the IP address of the base

station is entered in the RF Base station field. If

the IP address of the base station is unknown

use the Network Enabler Administrator pro-

gram, which is included with each base station.

Note: If the settings are changed, it is necessary

to press Accept <F1> in order to apply the settings.

IP address and subnet

mask are not in the

same range.

Without network administration, it is necessary for

the IP address and subnet mask of the controller

to be in the same range as those of the base station.

¾ Enter the same subnet mask for both IP

addresses and use the same first three num-

bers for the IP addresses on both the controller

and base station.

E.g.:

IP address controller: 192.168.1.xxx

IP address base station: 192.168.1.xxx

Subnet mask: 255.255.255.000

A firewall blocks port

4001.

¾ Reconfigure the firewall so that the specific IP/

MAC address of the tool can use port 4001.

Base station is already

connected to a different

controller.

¾ Check whether any other controller has

already used the same IP address for RF com-

munication (RF Base station).

Power outlet not active.

¾ Check the voltage at the outlet socket where

the base station is plugged in for power supply.

No 868 MHz data communication is possible

between controller and

tool.

Settings are not configured correctly.

¾ In the Communication/Tool screen of the con-

troller, check that RF settings of the base sta-

tion correspond to the settings of the tool,

which are displayed in the 868MHz RF settings

submenu of the tool. The settings for Channel,

Network ID and Tool ID must match.

Distance between base

station and tool is too

great.

If channel 1 is selected, the distance can be up to

98.4 ft (30 m). If channel 2 or 3 is selected, the distance can be up to 32.8 ft (10 m).

¾ Increase output power on base station and on

the tool, or move the base station closer to the

tool.

Problem Possible cause Action

868 MHz data communication between controller and tool

91e_Trouble shooting en bedingt.fm, 24.09.2007 P1891E/EN 09/07 45

Troubleshooting

8

RF communication is

partly interrupted.

Distance between base

station and tool is too

great.

If channel 1 is selected, the distance can be up to

30 m. If channel 2 or 3 is selected, the distance

can be up to 10 m.

¾ Move the tool close to the base station to

check whether communication is successful. If

so, increase output power on base station and

on the tool, or move the base station closer to

the tool.

Output power is too

low.

¾ Increase the output power of the base station

and of the tool. If channel 1 is selected, you

can choose up to 25 mW for the output power.

If channel 2 or 3 is selected, you can choose 1

mW for the output power of the base station

and 5 mW for the output power of the tool.

Too much traffic on the

same channel.

¾ Reduce traffic on the wireless network. Deacti-

vate torque plot data transmission.

Too many tools on the

same channel.

¾ Use different channels for different base sta-

tions.

Other 868 MHz devices

on the same frequency.

¾ Use a different channel.

Distance for RF communication is too short

Antenna of the base

station is not tightened

securely.

¾ Manually tighten the base station antenna.

Output power is too

low.

¾ Increase the output power of both the base sta-

tion and the tool.If channel 1 is selected, you

can choose up to 25 mW for the output power.

If channel 2 or 3 is selected, you can choose 1

mW for the output power of base station and 5

mW for the output power of the tool.

Location of the base

station bad.

¾ Move the base station to a location where

there is an unobstructed line of view between

the base station and the tool.

Problem Possible cause Action

Barcode scanner on tool

Barcode scanner does

not activate when the

start switch is pressed.

Parameter for Part-ID is

not set to Enable Interlocked.

¾ In the Communication/Part-ID screen of the

controller, check that the Enable parameter is

set to Enable Interlocked.

Barcode has already

been read.

¾ Activate a further read cycle in the scanner

submenu.

¾ Press the left function key on the tool in order

to activate another read cycle.

Note: Only available if the parameter for <F1> button on Tool is set to Read barcode in the

Advanced Application Builder / System Settings

screen of the controller.

Problem Possible cause Action

868 MHz data communication between controller and tool

46 P1891E/EN 09/07 91e_Trouble shooting en bedingt.fm, 24.09.2007

Troubleshooting

8

Barcode is not read. Barcode scanner win-

dow is not clean.

¾ Clean the window by using a damp cloth and a

conventional window cleaner.

Barcode type is disabled by parameter setting.

¾ In the Communication/Part-ID screen, check

that parameter Barcode Type is set to the

appropriate barcode type.

Problem Possible cause Action

Barcode scanner on tool

91f_Ersatzteile en.fm, 24.09.2007 P1891E/EN 09/07 47

Spare parts

9

9 Spare parts

Note

Use only original CLECO spare parts. Failure to comply can result in reduced power and

increased service requirements. If spare parts not manufactured by us are installed, the tool

manufacturer is entitled to deny any warranty claims.

48 P1891E/EN 09/07 91f_Ersatzteile en.fm, 24.09.2007

Spare parts

9

9.1 Handle

2

4

3

1

5

6

7

(8)

11

9

10

12

22

36

OFF

1,2 - 1,6 Nm

0.9 - 1.2 lbf.ft

Loctite #242

931030 SW 2,5

OFF

2,7 - 2,9 Nm

1.9 - 2.0 lbf.ft

Loctite #242

913947 SW 3

OFF

0,9 - 1,0 Nm

0.6 - 0.7 lbf.ft

Loctite #242

931030 SW 2,5

!

NOTE: DO NOT OPEN!

Shown for reference only

91f_Ersatzteile en.fm, 24.09.2007 P1891E/EN 09/07 49

Spare parts

9

For information only. These parts are not user serviceable.

Refer to Section 11 Service.

2) Quantity

Index 2) Description

1 1 accupack

2 2 cap screw

3 2 cap screw

4 1 holding angle

5 1 adapter accu asm.

6 1 adapter asm.

7 1 measuring system asm.

8 1 flat flexible cable asm.

9 2 cap screw

10 2 retaining washer

11 1 handle asm.

50 P1891E/EN 09/07 91f_Ersatzteile en.fm, 24.09.2007

Spare parts

9

9.2 Servo bar, LCD bar & trigger components

X

13

16

17

14

12

15

26

27

18

19

22

25

23

28

24

20

21

5

31

31

22

8

7 (4 Pin)

39

(2 Pin)

26 (6 Pin)

X

22

(8)

OFF

1,1 - 1,3 Nm

0.8 - 1.0 lbf.ft

TX 10

OFF

1,1 - 1,3 Nm

0.8 - 1.0 lbf.ft

TX 10

OFF

1 - 1,25 Nm

0.7 - 0.9 lbf.ft

TX 08

OFF

1,1 - 1,3 Nm

0.8 - 1.0 lbf.ft

TX 10

!

NOTE: DO NOT OPEN!

Shown for reference only

91f_Ersatzteile en.fm, 24.09.2007 P1891E/EN 09/07 51

Spare parts

9

For information only. These parts are not user serviceable.

Refer to Section 11 Service.

2) Quantity

Index 2) Description

12 1 servo bar actuator

13 1 plate centre

14 1 plate holding

15 1 retaining washer

16 1 raised countersunk head

screw

17 1 handle sleeve asm.

18 1 LCD window

19 1 cover

20 2 o-ring

21 4 o-ring

22 1 card LCD asm.

23 2 raised countersunk head

screw

24 2 raised countersunk head

screw

25 1 raised countersunk head

screw

26 1 switch asm.

27 1 trigger

52 P1891E/EN 09/07 91f_Ersatzteile en.fm, 24.09.2007

Spare parts

9

9.3 Motor

32

33

34

35

38

36

40

(7)

39

37

29

30

31

12

22

22

22

OFF

1,8 - 2,4 Nm

1.3 - 1.8 lbf.ft

Loctite #242

931030 SW2,5

OFF

47 54 Nm

34,5 40 lbf.ft

Loctite #242

933339

Ø 4

NOTE: DO NOT OPEN!

Shown for reference only

91f_Ersatzteile en.fm, 24.09.2007 P1891E/EN 09/07 53

Spare parts

9

For information only. These parts are not user serviceable.

Refer to Section 11 Service.

2) Quantity

Index 2) Description

29 1 union nut

30 1 tension sleeve

31 1 electric motor

32 1 pinion gear

33 1 adapter shaft

34 1 spring washer

35 1 motor housing asm.

36 1 cover segment

37 4 countersunk screw

38 1 light housing

39 1 LED asm.

40 1 circlip

54 P1891E/EN 09/07 91f_Ersatzteile en.fm, 24.09.2007

Spare parts

9

9.4 Gear + angle attachment

7.3 Lubricants, page 37

13

15

1

2

3

4

5

6

8

9

10

11

12

14

7

17

16

ø4

OFF

54 - 68 Nm

40 - 50 lbf.ft

Loctite #242

31,8 (1.245)

ø4

OFF

40 - 42 Nm

29,5 - 31 lbf.ft

Loctite #242

933336

9×12