Cleaver Scientific powerPRO Series, powerPRO500, powerPRO300, powerPRO3AMP Instruction Manual

Page 1

POWERPRO

Page 2

Page 3

powerPRO Series

Power Supplies

Instruction Manual

Catalogue Numbers

powerPRO300

powerPRO500

powerPRO3AMP

Record the following for your records:

Model _____________________

Catalogue No. _____________________

Date of Delivery _____________________

Warranty Period _____________________

Serial No. _____________________

Invoice No. _____________________

Purchase Order No. _____________________

13/11/2018 Page 1

Page 4

Contents

Instruction Manual 1

Catalogue Numbers 1

Contents 2

Safety Information 3

Precautions 4

Environmental Conditions 4

Avoiding Electrical Shock 4

Avoiding Damage to the Instrument 4

Equipment Operation 5

Symbols 5

Potential Risk and Preventive Measures 6

Risk assessment table 6

Preventative measures 6

Packing List 7

Specifications 8

Operating Instructions 10

Installation 10

Control Interface 10

Operation 11

Constant Mode 11

Program Mode 13

Typical Running Conditions 14

Troubleshooting 16

Care and Maintenance 18

Replacing the Fuses 18

Maintenance 18

Ordering information 18

Warranty 19

13/11/2018 Page 2

Page 5

Safety Information

Cleaver Scientific powerPRO Power Supply has been tested and found to

comply with the limits for the CE regulation. Also, it is RoHS compliant to deliver

confident product which meets the environmental directive. These limits are

designed to provide reasonable protection against harmful interference when

the instrument series is operated in a commercial environment. This instrument

series used together with power supply unit generates, uses, and can radiate

radio frequency energy, and if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this instrument series in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference

at their expense. Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to operate

the equipment. It is strongly recommended for the user to read the following

points carefully before operating this equipment.

1. Read and follow the manual instructions carefully.

2. Do not alter the equipment. Failure to follow these directions could

result in personal and/or laboratory hazards, as well as invalidate

equipment warranty.

3. Use a properly grounded electrical outlet with correct voltage and

current handling capacity.

4. Disconnect from power supply before maintenance and servicing.

Refer servicing to qualified personnel.

5. Never use this instrument series without having the safety cover

correctly in position.

6. Do not use the unit if there is any sign of damage to the external tank

or cover. Replace damaged parts.

7. Do not use in the presence of flammable or combustible material;

fire or explosion may result. This device contains components which

may ignite such materials.

8. Refer maintenance and servicing to qualified personnel.

9. Ensure that the system is connected to electrical service according

to local and national electrical codes. Failure to make a proper

connection may create fire or shock hazard.

10. Use appropriate materials and operate correctly to avoid possible

hazards of explosion, implosion or release of toxic or flammable

gases arising from overheated materials.

11. The unit shall be operated only by qualified personnel.

13/11/2018 Page 3

Page 6

Precautions

Use high level of precaution against any electrical device. Before connecting

the electrical supply, check to see if the supply voltage is within the range

stated at the rating label, and see to it that the device be seated firmly. Place

the unit in a safe and dry location; it must NOT touch the surrounding. Follow

the safety precautions for chemicals / dangerous materials. If needed, please

contact qualified service representative or support@cleaverscientific.com

Environmental Conditions

Ensure the instrument is installed and operated strictly under the following

conditions:

1. Indoor use only

2. ≤95% RH

3. 75 kPa – 106 kPa

4. Altitude must not exceed 2000 meters

5. 4℃~ 40℃ operating temperature

6. Pollution degree: 2

7. Mains supply voltage fluctuations up to ±10% of the normal voltage

Avoiding Electrical Shock

Follow the guidelines below to ensure safe operation of the unit.

The powerPRO Power Supply has been designed to utilize shielded wires thus

minimizing any potential shock hazard to the user. Cleaver Scientific

recommends against the use of unshielded wires.

To avoid electrical shock:

1. In the event of solution spilling on the instrument, it must be dried out for

at least 2 hours and restored to NORMAL CONDITION before each

operation.

2. Never connect or disconnect wires loading from the power jacks when

the red indicator light of power switch is on.

3. WAIT at least 5 seconds after stopping a run before handling output leads

or any connected apparatus.

4. ALWAYS make sure that your hands, work area, and instruments are

clean and dry before making any connections or operating the power

supply.

5. ONLY connect the power cord to a properly grounded AC outlet.

Avoiding Damage to the Instrument

1. Do not attempt to operate the device if damage is suspected.

2. Protect this unit from physical damage, corrosive agents and

extreme temperatures (direct sunlight, etc.).

3. For proper ventilation and safety concerns, keep at least 10 cm of

13/11/2018 Page 4

Page 7

space behind the instrument, and at least 5 cm of space on each

Indicates an area where a potential shock hazard may

Consult the manual to avoid possible personal injury or

throw this unit into a municipal trash bin when

this unit has reached the end of its lifetime. To ensure

utmost protection of the global environment and

side.

4. Use high level of precaution against the damages on the unit.

5. Do not operate the unit out of environmental conditions addressed

above.

6. Do not operate the power supplies in high humidity environments (>

95%), or where condensation may occur.

7. To avoid condensation after operating the power supply in a cold

room, wrap the unit in a plastic bag and allow at least 2 hours for the

unit to equilibrate to room temperature before removing the bag

and operating the unit.

8. Prior to applying any cleaning or decontamination methods other

than manufacturer’s recommendation, users should check with the

manufacturer’s instruction to see if the proposed method will

damage the equipment.

Equipment Operation

Follow the guidelines below to ensure safe operation of the unit:

1. NEVER access dangerous chemicals or other materials to prevent

possible hazard of explosion and damage.

2. Do not operate the unit without lids or covers to prevent possible

hazards.

3. A temporary conductivity caused by condensation might occur

even though this series is rated Pollution Degree 2 in accordance

with IEC 664.

Symbols

Symbols used on the power supply are explained below.

exist.

instrument damage.

Indicates disposal instruction.

DO NOT

minimize pollution, please recycle this unit.

13/11/2018 Page 5

Page 8

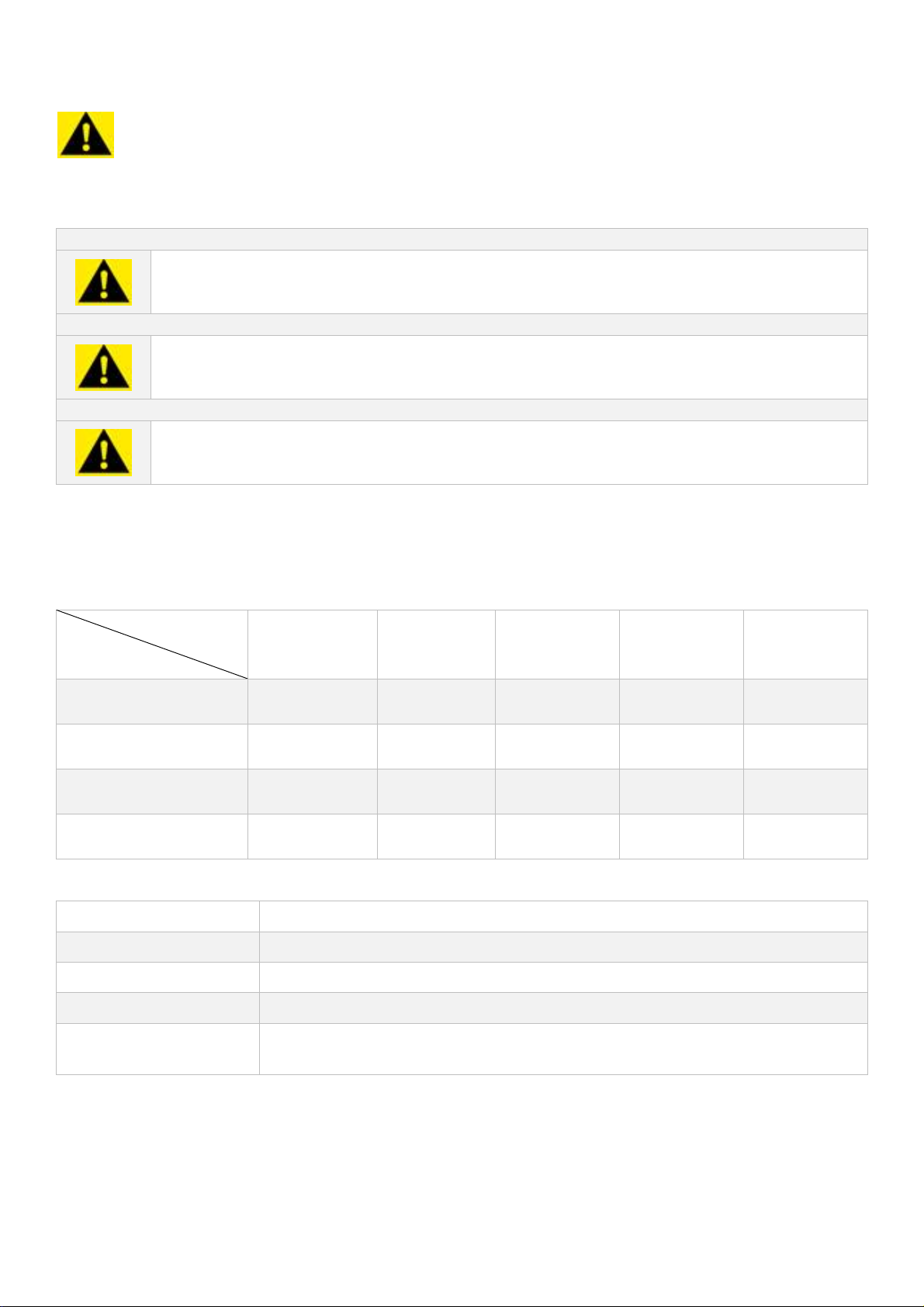

Caution/ Warning: Indicates a hazardous situation

which, if not avoided, could result in death or serious

injury.

powerPRO 300

Max. voltage: 300 V

Max. current: 700 mA

Max. watt: 150 W

powerPRO 3AMP

Max. voltage: 300 V

Max. current: 3000 mA

Max. watt: 300 W

powerPRO 500

Max. voltage: 500 V

Max. current: 800mA

Max. watt: 300W

Potential Risk and Preventive Measures

Risk assessment table

Frequency

Risk

Bruise √

Slash √

Electrical shock √

Power cord plug

wrong

Frequent Likely Possible Rare Unlikely

√

Preventative measures

Potential Risk Preventive measures

Bruise Do not put the machine near the table edge.

Slash Prevent hard impact on the case.

Electrical Shock Make sure that your hands, work area, and devices are clean and dry

Power cord plug

wrong

13/11/2018 Page 6

Observe correct adapter plug.

Page 9

Packing List

powerPRO 300

1x powerPRO 300 Power Supply

1x Power Cord

1x Instruction Manual

powerPRO 3AMP

1x powerPRO 3AMP Power Supply

1x Power Cord

1x Instruction Manual

powerPRO 500

1x powerPRO 500 Power Supply

1x Power Cord

1x Instruction Manual

Packing List Checked by: ________________________

Date: ________________________

The packing lists should be referred to as soon as the units are received to

ensure that all components have been included. The unit should be checked

for damage when received.

Cleaver Scientific is liable for all missing or damaged parts / accessories within

7 days after customer received this instrument package. Please contact

Cleaver Scientific immediately regarding this issue. If no response within such

period from consignee party, that will be consignee party’s whole

responsibility.

Please contact your supplier if there are any problems or missing items.

13/11/2018 Page 7

Page 10

Specifications

℃

powerPRO 300 powerPRO 3AMP powerPRO 500

Output Voltage / Inc 5 - 300V / 1V 5 – 300 / 1V 5 – 500 / 1V

Output Current / Inc 1 - 700mA / 1mA 10 – 3,000mA / 10mA 1 – 800mA / 1mA

Max. Watt 150W 300W 300W

Rated Voltages 100~ 240V; 47-60Hz,

200W: T2.5A/250V

Type of Output 1. Voltage or Current with automatic crossover

2. When target constant mode is set, system automatically adjusts the

two other parameter to maximum to allow constant run (later could be

changed by user)

Program Storage 30 programmed files

Program Multi-Step Up to 6 steps

Editable Program

Function

Display 2.4” TFT

Control Microprocessor controller

Safety Device No Load detect

1.Have typical running conditions program

2.Manual editable program

Leakage detect

Over temperature protection

100-240V: 4760Hz,410W: T4A/250V

100-240V: 4760Hz,400W: T4A/250V

Over load detection

Sudden load change detection (could be disabled by proper setting)

Shrouded plugs and sockets

Timer Constant: 1~999 mins with alarm, continuous

Program: 1~999 mins with alarm, continuous

Crossover Yes

Stackable Yes

Automatic Recovery

After Power Failure

IQ/OQ Protocols Yes, optional

Regulatory CE, ETL CE CE

Operating

Temperature

Construction Material Flame retardant ABS faceplate

Yes

4℃~ 40

13/11/2018 Page 8

Page 11

Unit Dimension 215 x 335 x 104 mm (W x L x H)

Weight approx. 2.1 kg

Cleaver Scientific powerPRO Series Power Supply are microprocessor

controlled and designed to meet most electrophoresis needs. This manual

describes the setup and operation of the powerPRO Series Power Supply

including important information on safety and maintenance of the unit. The

powerPRO Series Power Supply are capable of running horizontal & vertical

electrophoresis, SDS-PAGE, native PAGE applications, two-dimensional

electrophoresis, and electro-blotting. Furthermore, the powerful specifications

plus five terminal pairs can be used for multi electrophoresis units

simultaneously.

Cleaver Scientific powerPRO Series Power Supply provides Constant Voltage

or Constant Current or Constant Power to instruments used in electrophoresis.

5 terminal pairs and the powerful specification equipped enable the

maximum capability of powerPRO Series Power Supply compared to other

existing similar product on the market.

Features of powerPRO Series Power Supply:

Compact size

Microprocessor controller

Constant voltages, constant currents and constant power

Five terminal outlets

LCD display

Timer with alarm function

Advanced safety devices

Stackability

Wide applications for DNA, RNA and protein electrophoresis

13/11/2018 Page 9

Page 12

Operating Instructions

Installation

powerPRO Series Power Supplies require no complex installation. As long as

the unit is placed on a sturdy and level surface in a safe, dry place, and further

connects with well-prepared electrophoresis systems, it is ready for operation.

Control Interface

Start Key: Press to activate or stop

the unit

Pause Key: Press to temporarily

interrupt power to an operation in

progress; resume power after

pausing without resetting the timer

Settings Key: Press to select either

Constant/ Program Mode or

Constant Voltage or Constant

Current mode or Time

Enter Key: Press to enter the

numeric value set up

Press to move cursor left between

parameters

Press to move cursor right between

parameters

Press to move cursor up between

parameters and to increase

numeric values

Press to move cursor down

between parameters and to

decrease numeric values

13/11/2018 Page 10

Page 13

Operation

1. Place the unit on a sturdy and level surface in a safe, dry place,

away from laboratory traffic.

2. Ensure that the AC power switch is OFF, and then plug the threepronged power cord one end into a grounded three-prong AC

outlet with appropriate voltage (100V to 240V as indicated on the

rating sticker near the AC cord on the back of the unit) and plug the

other end into the main power socket.

3. Connect the DC output jacks from the electrophoresis unit; insert the

red lead (+) into the red output jack, and the black lead (-) into the

black output jack.

4. Power on the unit by pressing the ON/OFF switch on the back.

5. The screen will show a loading screen for few seconds then enter to

the mode-selecting page.

Constant Mode

Use the Constant Voltage / Current / Power Operation for applications that

require only one specific voltage limit, current limit, and power limit

continuously during the entire operation of electrophoresis.

Note: When target constant mode is set, system automatically adjusts the other two

parameters to maximum to allow constant run. For example, if constant voltage is set,

system will adjust current and power to the maximum value.

Users could later lower the other two values by themselves. System will hold the value either

at target constant value or the one which has been reached first

1. Use the up and down arrow keys to select

constant mode, then press the enter key to

move to the next page.

13/11/2018 Page 11

Page 14

2. Use the up and down arrows to select

which parameter should be kept constant.

Press the enter key to move to the next

page.

3. Use the up and down arrows to navigate

the parameters, press the enter key to start

parameter adjustment.

4. Use the up and down arrows to adjust

parameter values, then press the enter key

to confirm.

Note: If the time value is set “0,” it indicates the power

supplier will constantly operate until user manually stops it.

5. Press the start Key to begin electrophoresis.

The LED next to the start key will light,

indicating the power supply is active.

Parameter values can be viewed during the run.

6. Pressing the pause key will temporarily

pause the run and will allow parameter

values to be altered using the same

method outlined above.

Pressing the start key will resume the run

7. Upon completion of the run, an alarm will

sound, and the screen will display

“Complete”.

8. Press the start key to terminate the run and

press the setting key to return to the

settings screen.

13/11/2018 Page 12

Page 15

Program Mode

The Program Mode allows you to vary levels in voltage (V), current (mA), and

power (W) during specified time periods for up to 6 Steps, depending upon

your electrophoresis needs. The powerPRO Series power supply is capable of

having 30 different program files storages for user’s convenience. After starting

the operation, set the Program Mode as follow:

1. Use the up and down arrow keys to select

program mode, then press the enter key to

move to the next page.

2. Use the up and down arrows to select the

desired program. Press the enter key to

move to the next page.

3. Use the up, down left and right arrows to

navigate the parameters, press the enter key

to start parameter adjustment.

4. Use the up and down arrows to adjust

parameter values, then press the enter key

to confirm.

5. Navigate using the down arrow to set

parameters for step 5 and 6.

13/11/2018 Page 13

Page 16

6. Press the start Key to begin electrophoresis.

The LED next to the start key will light,

indicating the power supply is active.

Parameter values can be viewed during the run.

7. Pressing the pause key will temporarily pause

the run and will allow parameter values to

be altered using the same method outlined

above.

Pressing the start key will resume the run

8. Upon completion of the run, an alarm will

sound, and the screen will display

“Complete”.

9. Press the start key to terminate the run and

press the setting key to return to the settings

screen.

Typical Running Conditions

Besides Constant Mode and Program Mode, powerPRO Power Supply provide

a third option, Typical Running Condition. It is helpful for those users who are

not familiar with the parameter settings and is convenience for a quick start.

1. Use the up and down arrow keys to select

typical running conditions mode, then press

the enter key to move to the next page.

13/11/2018 Page 14

Page 17

2. There are 4 categories that can be selected. Choose the model

according to your experiment need.

3. After selecting model, the pre-set value will display. These values can

be adjusted as described previously.

4. Press the start button to begin electrophoresis.

13/11/2018 Page 15

Page 18

Troubleshooting

Many operating problems may be solved by carefully reading and following

the instructions in this manual accordingly. Some suggestions for

troubleshooting are given below. Should these suggestions not resolve the

problem, contact our service department or a distributor in your region for

assistance. If troubleshooting service is required, please include a full

description of the problem.

Problem Possible Causes Solution

No Display / lights No AC power Check if powerPRO power supply is

plugged, or AC power source has

problem.

AC power cord is not

connected

The fuse has blown Replace the fuse.

Repeated fuse broken Hardware failure Contact Cleaver Scientific service

Operation stops and

the screen displays

Operation stops with

alarm: The screen

displays

Communication wires on

circuit board have loosen

or broken.

Electrophoresis leads are

not connected to the

power supply or to the

electrophoresis unit(s), or

there is a broken circuit in

the electrophoresis cell

High resistance due to

tape left on a pre-cast

gel, incorrect buffer

concentration, or

incorrect buffer volumes

in the electrophoresis cell

Check AC power cord connections at

both ends. Use the correct cords.

department

It is recommended to send the machine

back to local distributor or our Service

Department for maintenance.

Check the connections to the power

supply and on your electrophoresis cell to

make sure the connection is intact; check

condition of wires in electrophoresis unit.

Close the circuit by reconnecting the

cables. Press START/STOP to restart the run.

Make sure the tape is removed from the

pre-cast gel, buffers are prepared

correctly, and the recommended volume

of buffer is added to the electrophoresis

unit.

High voltage application

is set to run on a very low

current

Operation stops with

alarm. Display shows

13/11/2018 Page 16

Bad connections for

terminal connectors or

damaged wires or

damaged platinum wires

DISABLE No Load alarm on the Display

Screen

Check all the connections to terminators,

cables, wires, and gel tanks

Page 19

Operation stops with

alarm:

Display shows

Circuit is interrupted Verify that the running buffer is correct.

Verify the all cables are attached

correctly

Turn the Power switch off and on again;

restart application.

If you cannot restart the instrument, turn

off the power, disconnect the power cord

from the outlet, and contact Technical

Service.

Operation stops with

alarm:

Display shows

Operation stops with

alarm:

Display shows

Operation stops with

alarm:

Display shows

Circuit is interrupted Verify that the running buffer is correct.

Verify the all cables are attached

correctly

Turn the Power switch off and on again;

restart application.

If you cannot restart the instrument, turn

off the power, disconnect the power cord

from the outlet, and contact Technical

Service.

Ground leak detected

during run

Check the electrophoresis system for

improper grounding. Restart the power

supply by turning the Power switch off and

on.

Power supply is

overheating

Turn off power supply. Check for sufficient

airflow around the power supply fan. After

cooling down, restart the power supply by

turning the Power switch to the on

position.

If you cannot restart the instrument, turn

off the power, disconnect the power cord

from the outlet, and contact Technical

Service.

Warning message

displays with 5-second

beep sound.

The screen shows

The power once been cut

and now recover

User does not need to take extra action.

The warning sign and beep sound would

only last for 5 second; after that, the

machine will continue running the

unfinished project.

The sign indicates the machine has

been interrupted by sudden power off.

Press Enter Key to clear the sign.

13/11/2018 Page 17

Page 20

Care and Maintenance

Replacing the Fuses

1. Turn off the main power switch at the rear of Power Supply and

detach the power cord.

2. Open the fuses compartment located inside the Power Entry Module

by inserting a small flat blade screwdriver into the slot above the

ON/OFF switch. Turn the screwdriver to gently pry open the fuses

compartment.

Note: The fuses compartment will not open with the power cord in place.

1. Pull the fuses holder out of the compartment and inspect the fuses.

If the fuses are burned or there is a break in the fuses element,

replace the fuses with identical type of fuses.

2. Place the fuses holder back into the compartment.

3. Snap the cover closed.

For additional fuses, contact Cleaver Scientific

Maintenance

powerPRO Series Power Supply uses all solid-state components and should

require no maintenance or recalibration under normal use. If the unit must be

returned for repair, contact our service department or your local distributor for

shipping instruction.

Ordering information

Cat. No. Description

PowerPro300 300V, 700mA, 150W Power Supply

PowerPro3AMP 300V, 3000mA, 300W Power Supply

PowerPro500 500V, 800mA, 300W Power Supply

13/11/2018 Page 18

Page 21

Warranty

The Cleaver Scientific Ltd. (CSL) powerPRO units have a warranty against

manufacturing and material faults of twelve months from date of customer

receipt.

If any defects occur during this warranty period, CSL will repair or replace the

defective parts free of charge.

This warranty does not cover defects occurring by accident or misuse or

defects caused by improper operation.

Units where repair or modification has been performed by anyone other

than CSL or an appointed distributor or representative are no longer under

warranty from the time the unit was modified.

Units which have accessories or repaired parts not supplied by CSL or its

associated distributors have invalidated warranty.

CSL cannot repair or replace free of charge units where improper solutions or

chemicals have been used. For a list of these please see the Care and

Maintenance subsection.

If a problem does occur, then please contact your supplier or Cleaver

Scientific Ltd:

Cleaver Scientific Ltd.

Unit 41, Somers Road Industrial Estate

Rugby, Warwickshire, CV22 7DH

Tel: +44 (0)1788 565300

Email: info@cleaverscientific.com

13/11/2018 Page 19

Page 22

Page 23

Page 24

Loading...

Loading...