Cleaver Scientific OmniPAGE Series, OmniPAGE Mini, omniPAGE Mini Wide, omniPAGE Maxi, omniPAGE VS30 Instruction Manual

Page 1

Version 1

OmniPAGE Vertical Electrophoresis Systems

OmniPAGE Mini

Instruction Manual

Catalogue No: CVS10D

CVS10DSYS

CVS10PRE

CVS10DSYS-CU

Page 2

Page 2

Table of Contents

Page

Section 1 Safety Information 3

1.1 Safety Precaution 3

Section 2 General Information 4

2.1 Introduction 4

2.2 Product Description 4

2.3 Packing Lists 5

2.4 Specifications 6

2.5 Care and Maintenance 7

Section 3 Operating Instructions 8

3.1 Setting up the omniPAGE Gel Tank 8

3.2 Gel casting 8

3.3 omniPAGE module assembly and Sample loading 13

3.4 Gel Running 14

3.5 Gel Removal 14

Section 4 Gel Preparation 14

4.1 Gel Selection 14

4.2 Volumes required per gel 15

4.3 Gel Preparation 16

4.4 Stacking Gel Preparation 16

4.5 Buffer Volume 17

4.6 Gel Running Conditions 17

4.7 Preparation of denatured protein samples for loading 18

4.8 Stock Solutions 19

Section 5 Trouble Shooting Guide 20

Section 6 Product Information 23

6.1 Catalogue numbers and product descriptions 23

6.2 Combs 24

6.3 Catalogue numbers and product descriptions for CSL Related products 26

Section 7 Warranty 27

Page 3

Page 3

Section 1 Safety Information

1.1 Safety Precaution

When used correctly, these units pose no health risk. However, these units can deliver dangerous levels of

electricity and are to be operated only by qualified personnel following the guidelines laid out in this

instruction manual. Anyone intending to use this equipment should read the complete manual thoroughly.

The unit must never be used without the safety lid correctly in position. The unit should not be used if there is

any sign of damage to the external tank or lid.

Acrylamide is a powerful neurotoxin in solution form. Polymerized gels can contain some unpolymerized

solution and protective gloves and clothing must be worn.

These units comply with the following European directives:

2006/95/CE Low Voltage Directive and 2014/30/UE (official Title 2004/108/EC) EMC Electromagnetic

Compatibility

By virtue of the following harmonised standards:

BS EN IEC 61010-1: 2010 Safety Testing of Lab Equipment

BS EN IEC 61326-1:2013 EMC Electro Magnetic Compatibility

Page 4

Page 4

Section 2 General Information

2.1 Introduction

Cleaver Scientifics’ omniPAGE range of Vertical Gel Units combines ease of use with high resolution

separations. Four sizes, Mini 10 x 10cm, Mini Wide 20 x 10cm and Maxi 20 x 20cm, VS 30 x 30cm share a host

of common features including a guaranteed leak proof seal required for trouble free, rapid and uncomplicated

gel casting. Utilising a built in gel running module eliminates time consuming transfer of glass plates during

casting, a process which can cause gel damage and misalignment. Glass plates with permanently bonded

spacers guarantee perfect spacer alignment. The glass plate sandwich is then simply inserted between

pressure bars and the new zero screw slide clamps clicked into position. This ensures fast set up times while

even pressure bars and ultra soft seals guarantee leak proof casting. Once the gel has polymerised, the gel

running module is just inserted into the gel tank for electrophoresis.

2.2 Product Description

Cleaver Scientifics’ vertical electrophoresis units comes as a complete package including Gel Tank, Safety Lid,

Gel Casting Inner Module, Glass plates with bonded spacers, Combs, Multipurpose Key, Power Cables and

Cooling pads. Detailed description of all the components is written below.

Gel Tank and Safety

Lid

Injection moulded gel tank and safety lid provides a sealed electrophoresis system

which is compatible with all major types of 8 X 10cm and 10 x 10cm precast gel. All

omniPAGE tanks are equipped with specially designed thumb locators for lifting up

the safety lid easily. All safety lids are designed to accommodate the polarity

design of the unit. They have special tapped holes which connect with the leading

edge of the power cables.

Inner Module

Injection moulded inner module gives a twofold effectiveness for gel casting and

running, thus no need of transferring the glass plates after casting the gel.

Glass Plates

2mm thick glass plates for the omniPAGE mini and 4mm thick glass plates for rest

of the range prevents breakage and have bonded spacers for convenience. All our

spacers are colour coded depending upon their thickness.

Multipurpose Key

CVS10KEY or the multipurpose key can be easily used to separate your notched

and plain glass plate to release the gel. The same key can be used to open the

CVS10 clamping doors.

Power Cables

Cleaver Scientifics’ power cables are designed with protective retractable

connectors which are compatible with most power supplies.

Cooling Pads

Rapid set up cooling packs enhance resolution eliminating the need of a chiller.

Combs with special

gel loading guides

Special combs (Combicombs) are designed with special oval shaped gel loading

guides on the other end of an ordinary comb which can be used.

Page 5

Page 5

2.3 Packing Lists

CVS10D, CVS10DSYS, CVS10PRE, CVS10DSYS-CU

Each unit includes a tank, lid, internal module, electrodes and the following accessories:

Glass Plates

Combs

Casting base

Cooling Pack

Cables

Screws

CVS10D

VS10NG – Notched,

Pk/2

VS10PGS1 – Plain with

bonded 1mm spacers,

Pk/2

VS10-DP – Dummy

Plate

2 of VS10-12-1

1mm thick, 12

sample

VS10ICB

CSL-CAB

VS10-SCREW x 4

CVS10DSYS

VS10NG – Notched,

Pk/2

VS10PGS1 – Plain with

bonded 1mm spacers,

Pk/2

VS10-DP – Dummy

Plate

2 of VS10-12-1

1mm thick, 12

sample

VS10DCAST

VS10DCASTM –

Mat

VS10ICB

CSL-CAB

VS10-SCREW x 4

CVS10PRE

VS10-DP – Dummy

Plate

VS10ICB

CSL-CAB

VS10-SCREW x 4

CVS10DYS-CU

See CVS10DYSYS

CVS10EXCASTER

See

CVS10DYSYS

See CVS10DYSYS

VS10ICB

CSL-CAB

VS10-SCREW x 4

Packing list checked by ________________________ Date ____________

The packing lists should be referred to as soon as the units are received to ensure that all components have

been included. The unit should be checked for damage when received.

Please contact your supplier if there are any problems or missing items.

Page 6

Page 6

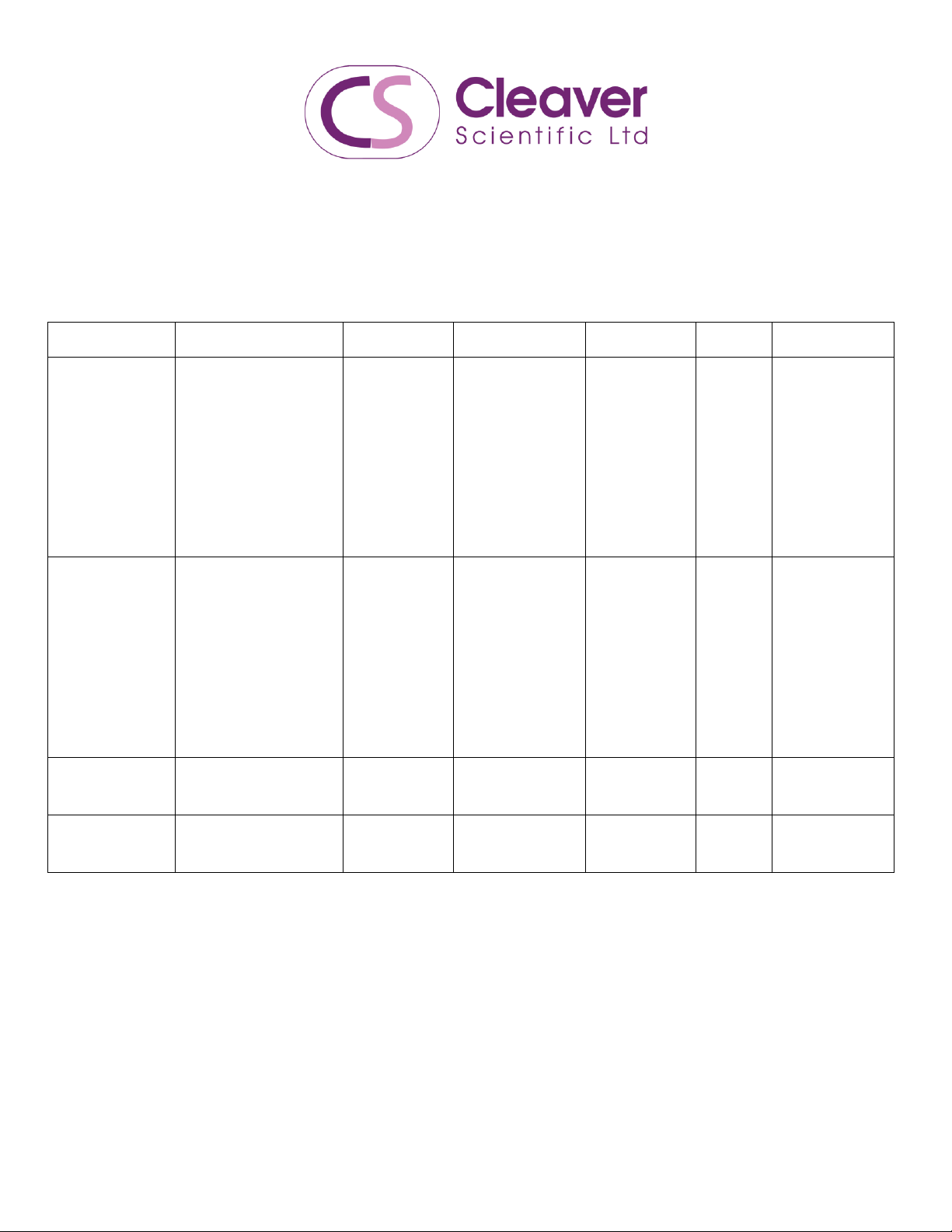

2.4 Specifications of OmniPAGE Vertical Electrophoresis Units

omniPAGE Mini

omniPAGE Mini

Wide

omniPAGE Maxi

omniPAGE VS30

Plate

Dimensions

Gel Dimensions

(WxL)

10x10cm

7.5x8cm

20 X 10cm

18 X 8cm

20 X 20CM

16 X 17.5CM

30 X 22cm

28 X 20cm

Unit Dimensions

19x13x15cm

(W x D x H)

26 X 16 X 16cm

(W X D X H)

26 X 16 X 28CM

(W X D X H)

36 X 33 X 18CM

(W X H X D)

Max Sample

Capacity

80 Samples

20 Samples per Gel

192 Samples

48 Samples per Gel

192 Samples

48 Samples per Gel

300 Samples per

Run

75 Samples per Gel

Buffer Volume

Min 250ml,

Max 1200ml

Min 600ml

Max 2800ml

Min 1200ml

Max 5600ml

Min1800ml

Max 8400ml

Combs Available

No. of Teeth

Thickness

1, 5, 8MC, 9, 10,

12, 16MC, 20

0.75, 1, 1.5, 2mm

1, 5, 10, 18MC, 24,

30, 36MC, 48

0.75, 1, 1.5, 2mm

1, 5, 10, 18MC, 24,

30, 36MC, 48

0.75, 1, 1.5, 2mm

1, 2, 4, 28MC,

56MC, 75

0.25, 0.35, 0.5, 1,

1.5, 2.0mm

Environmental

Operating

Conditions

Maximum Altitude

2,000 m

Temperature

Range 4°C - 65°C

Humidity

Upto 80%

Not for outdoor

Use

Maximum Altitude

2,000 m

Temperature

Range 4°C - 65°C

Humidity

Upto 80%

Not for outdoor

Use

Maximum Altitude

2,000 m

Temperature

Range 4°C - 65°C

Humidity

Upto 80%

Not for outdoor

Use

Maximum Altitude

2,000 m

Temperature

Range 4°C - 65°C

Humidity

Upto 80%

Not for outdoor

Use

This apparatus is rated POLLUTION DEGREE 2 in accordance with IEC 664.

POLLUTION DEGREE 2, states that: “Normally only non-conductive pollution occurs.

Occasionally, however, a temporary conductivity caused by condensation must be expected”.

Page 7

Page 7

2.5 Care and Maintenance

Cleaning Large Format Vertical Units

Units are best cleaned using warm water and a mild detergent. Water at temperatures above 600 C can cause

damage to the unit and components.

The inner module should be thoroughly rinsed with warm water or distilled water to prevent buildup of salts

but care should be taken not to damage the enclosed electrode and vigorous cleaning is not necessary or

advised. Air drying preferably before use.

The units should only be cleaned with the following:

Warm water with a mild concentration of soap or other mild detergent.

Compatible detergents include dishwashing liquid, Hexane and Aliphatic hydrocarbons. The units should not

be left in detergents for more than 30 minutes.

The units should never come into contact with the following cleaning agents, these will cause irreversible

and accumulative damage:

Acetone, Phenol, Chloroform, Carbon tetrachloride, Methanol, Ethanol, Isopropyl alcohol, Alkalis.

RNase Decontamination

This can be performed using the following protocol:Clean the units with a mild detergent as described above.

Wash with 3% hydrogen peroxide (H2O2) for 10 minutes.

Rinsed with 0.1% DEPC- (diethyl pyrocarbonate) treated distilled water.

Caution: DEPC is a suspected carcinogen. Always take the necessary precautions when using. RNaseZAP™

(Ambion) can also be used. Please consult the instructions for use with acrylic gel tanks.

Page 8

Page 8

Section 3 Operating Instructions

3.1 Setting up the omniPAGE Gel Tank

Note: Before setting up the Gel Tank please ensure that it has been properly cleaned and dried.

1. Note the position of the lid on the unit. This shows the correct polarity and the correct orientation of the

cables, black is negative and red positive.

2. Remove the lid from the unit.

Note: If the lid is not removed, fitting the cables may result in un-tightening of the gold plug and damage

the electrode.

3. Screw the cables into the tapped holes as fully as possible so that there is no gap between the lid and the

leading edge of the cable fitting.

4. Refit the lid and the unit is now ready to be used.

3.2 Gel casting

Cleaning the Glass Plates

Clean a set of glass plates for each gel first with distilled water and then with 70 % ethanol.

One set of glass plates constitutes one notched glass plate and one plain glass plate with bonded spacers.

When using a triple glass plate sandwich, two notched glass plates are required, one set of free spacers and a

set of plain glass plates with bonded spacers. The plain glass plate is positioned outermost, then a notched

glass plate, free spacers and second notched glass plate. Alternatively, accessory notch glass plates with

bonded spacers are available.

Note: All glass plates, gel casting modules, casting base and accessories must be completely dry before the

set – up. Wet components are more likely to miss-align and cause leaks.

Page 9

Page 9

Glass cassette Assembly

Assemble the glass plates so that the bottom of the glass plates and the spacers are perfectly aligned.

For triple plate sandwiches, the free spacers Need to be perfectly aligned which is best performed using a

small spacer or comb to push the spacers apart. Notched glass plates with bonded spacers do not need

manual alignment.

NOTE: The glass plates with bonded spacers have an arrow in the top of the spacers which are slightly

longer than the glass plate to indicate the top.

Casting Stand Assembly

Position the Slab Gel Insert on a flat surface.

Insert the glass plates into the Slab Gel Insert

between the pressure bar and the blue gasket.

The Slab Gel Insert contains pressure bars

which impart even pressure onto the glass plates

and allow even screw pressure transfer onto the

sealing edge of the glass plate, ensuring complete sealing. Ensure that the pressure bars are adequately open

for the thickness of spacer used. The bar can be opened by loosening the screws or by sliding the clamps.

When using a triple glass plate sandwich, the pressure bars will need to be in the completely open position.

Then fully tighten the pressure bar screws in the order top then bottom.

Page 10

Page 10

Fully tighten the screw for the Mini vertical and the screws sequentially and in an even manner for the maxi

vertical in the order middle two, top then bottom, making sure not to wobble the unit. When using the Slide

Clamp Mini version, simply slide both gates outwards until fully tightened. When only one gel is being run, the

dummy plate must be used in the second position and fully tightened.

NOTE: At this stage, check that the bottom edges of the spacers and glass plates are perfectly aligned.

Position the Slab Gel Insert in the casting base such that the Cam pins have handles pointing downwards and

are located in the insert holes. The top of the GRM may need to be pushed down very slightly to locate the

cam pins.

With the cam pin handles facing directly downwards, turn the cam pins fully through 1800 or until the insert has

tightened onto the silicone mat.

SCREW VERSION

SCREW VERSION

SLIDING CLAMP VERSION

SLIDING CLAMP VERSION

Page 11

Page 11

NOTE: It is best to turn the cams in opposite directions to each other. Do not overturn as this will cause the

glass plates to push upwards and the assembly will be more likely to leak. The unit is now ready for gel

preparation and pouring.

Always reverse the silicone mat after casting to avoid indentations from persisting. Never leave the casting

up-stand with glass plates tightened into the casting base for long periods of time as this will also cause

indentations in the silicone mat.

The slide clamp version CVS10 also includes screws. This system can be used either with the slide clamps or

screws as preferred by the user. For those that prefer to use the screws rather than clamps, the screws can

be simply inserted into the screw holes. The clamps can be removed by placing each clamp in the fully open

position and gently bending the clamp upwards from the slanted end. The holding pin will then slowly

release and the clamp can be removed.

Gel Pouring

Casting a gel with stacking layer

1. Place a comb into the gel cassette assembly with any gel and mark the glass plate below the comb teeth.

This is the reference level to which the resolving gel should be poured.

2. Prepare the resolving gel solution. Mix well and avoid generating air bubbles.

3. Fill the glass plates smoothly till the mark avoiding generating any air bubbles. Filling must be performed

quickly before the TEMED causes the gel to become too viscous.

4. Overlay the gel extremely carefully with 1 ml of Isobutanol, Isopropanol or distilled water. When using

distilled water extra care must be taken to ensure there is no mixing with the gel solution.

5. Let the resolving gel polymerize. Usually this takes around 15 to 30 minutes but this can vary due to the

freshness of the reagents used. If polymerization is taken a lot longer than this, use fresher stock solutions

or add more APS and TEMED.

Page 12

Page 12

6. Let the resolving gel polymerize. Usually this takes around 15 to 30 minutes but this can vary due to the

freshness of the reagents used. If polymerization is taken a lot longer than this, use fresher stock solutions

or add more APS and TEMED.

7. Prepare the stacking gel solution.

8. Before casting the stacking gel, insert a piece of filter paper to dry the area in between the glass plates

above the resolving gel. Take care not to touch the surface of the gel.

9. Carefully pour the stacking gel solution, avoiding generating air bubbles.

10. Carefully insert the comb making sure that no air bubbles get trapped under the ends of the comb teeth as

these will inhibit sample progression.

11. Allow the stacking gel polymerize.

12. Once the gel is polymerized it is ready for the electrophoresis run.

Casting a gel without stacking layer

1. Prepare the resolving gel solution. Mix well and avoid generating air bubbles.

2. Pour the solution smoothly into the glass plates avoiding any air bubbles until the top of the notched glass

plate is reached.

3. Carefully insert the comb making sure that no air bubbles get trapped under the ends of the comb teeth as

these will inhibit sample progression.

4. Let the gel polymerize. Usually this takes from 15 to 30 minutes but this can vary due to the freshness of

the reagents used. If polymerization is taken a lot longer than this, use fresher stock solutions or add more

APS and TEMED.

5. Once the gel is polymerized it is ready for the electrophoresis run.

Page 13

Page 13

Using Precast Gels

1. omniPAGE mini is compatible with all the precast gels available in the market.

2. Simply remove the precast gel from the storage pouch.

3. Gently remove the comb.

4. Keep the Inner module upstand on a flat surface and place the precast gel between the pressure bar and

the blue gasket.

3.3 omniPAGE module assembly and Sample loading

1. If desired, fit the cooling pack(s) into the end of the tank. These should be pre-frozen and fitted with the

longest side positioned sideways with the end(s) of the tank and pressed into the recess. Or these can be

fitted down the front of the tank.

Note: NEVER FIT THESE UNDERNEATH THE MODULE IN THE BOTTOM OF THE TANK AS THIS WILL PREVENT

THE FLOW OF CURRENT THROUGH THE GEL AND CAUSE SLOW RUNS AND OVER-HEATING.

Note one pack is supplied as standard. Additional packs can be purchased.

2. Transfer the Inner gel module containing cast gels into the main tank in the correct orientation as

indicated - +ve on the module aligned with +ve on the tank, -ve on the module aligned with –ve on the

tank.

3. Fill the outer tank with 1 x reservoir buffer. See Page 22 for recommended running buffer solution. Table 7 shows

the volume of buffer required.

4. Load the samples into the wells using a pipette tip taking care not to damage the wells or induce any air bubbles.

5. Fill any unused wells with 1 X sample buffer.

6. It is a good idea to note the orientation and order the samples were loaded in. This can be done by noting which

samples were loaded adjacent to each electrode.

Page 14

Page 14

3.4 Gel Running

1. Fit the lid and connect to a power supply.

2. Consult Table 8 for details on recommended power supply voltage settings.

3.5 Gel Removal

1. Turn the power supply off when the loading dye reaches the bottom of the gel, sooner if your proteins are

below 4Kd in size.

2. Remove the gel running module, first emptying the inner buffer into the main tank. Buffer can be re-used

but this may affect run quality if continued.

3. Unscrew the glass plates with the Screw version. To open the sliding door version insert the CVS10KEY into

the recess arch of the clamping door. Twist key applying pressure to both the clamping door and the

CVS10D side cheek. The door will now click open. Repeat this process until you have opened both the

doors.

4. Remove the glass plates. Then using CSLKEY separate notched and the plain glass plates. Place the wedged

end of the key between the two plates and gently twist until the plates pull apart. The gel will usually stick

to one of the plates and can be removed by first soaking in buffer and then gently lifting with a spatula.

5. The gel is now ready to be stained with Coomassie or silver stain or the proteins in the gel can be

transferred to a membrane by electroblotting for specific band identification and further analysis.

Section 4 Gel Preparation

4.1 Gel Selection

Care should be taken when selecting the pore size of the gel to be used. The pore size or % of gel determines

the resolving ability given different sizes of protein.

Page 15

Page 15

See Table 1 below explaining which percentage of gel to use to separate the sizes of proteins indicated.

Table 1 Acrylamide percentages

Acrylamide Percentage

Separating

Resolution

5 %

60 - 220 KD

7.5 %

30 - 120 KD

10 %

20 - 75 KD

12%

17 – 65 KD

15 %

15 -45 KD

17.5%

12 – 30 KD

4.2 Volumes required per gel

Table 2 shows the total amount of gel solution required.

omniPAGE Mini

CVS10D, CVS10DSYS, CVSPRE, CVS10DSYS-CU

Number of gels

Gel Thickness

(mm)

Volume (ml)

Single – one gel, one

dummy plate

O.5

1.0

1.5

2.0

3.8

7.5

11.3

15.0

Double – two gels

O.5

1.0

1.5

2.0

7.5

15.0

22.5

30.0

Using a Triple Plate

sandwich – four gels

O.5

1.0

1.5

2.0

10.0

30.0

45.0

60.0

Page 16

Page 16

4.3 Gel Preparation

Prepare gel solutions as per tables below. These give the volumes of solutions from the standard stock

solutions. These should be gently mixed avoiding generation of bubbles which will inhibit polymerization by

removing free radicals.

Table 3 Preparation of the separating gel solution for two 10 x 10cm CVS10D gels using 1 mm spacers.

Solution

5 %

7.5%

10 %

12%

15 %

17.5%

Distilled Water

8.7ml

7.5ml

6.3ml

5.25ml

3.75ml

2.5ml

30 % Stock Acrylamide

Solution

2.5ml

3.75ml

5ml

6ml

7.5ml

8.75ml

4 X Resolving Tris Solution

3.75ml

3.75ml

3.75ml

3.75ml

3.75ml

3.75ml

10 % Ammonium Persulphate

150µl

150µl

150µl

150µl

150µl

150µl

Add 15µl of TEMED to the resolving gel solution for CVS10D sized gels.

4.4 Stacking Gel Preparation

Table 4 A guide to preparing the stacking gel

Solution

CVS10D

Distilled Water

4.2ml

30 % Stock Acrylamide Solution

0.65ml

4 X Stacking Gel Tris Solution

1.6ml

10 % Ammonium Persulphate

67µl

Page 17

Page 17

4.5 Buffer Volume

Table 5 Buffer Volumes

Buffer Volume

CVS10D

Minimum – Inner tank is filled to above the wells. Outer Tank is

filled to just flood the bottom of the glass plates. Cooling

potential is at a minimum which may affect resolution.

250ml

500ml

Maximum – Inner tank is filled to above the wells. Outer Tank is

filled to the maximum fill line. Cooling is high offering good

resolution of samples.

1200ml

2.8 Litres

Using the cooling packs – Inner tank is filled to above the wells.

Cooling packs are inserted behind the gels. Outer Tank is filled to

the maximum fill line. Cooling is at a maximum.

1000ml

2.3 Litres

4.6 Gel Running Conditions

Table 6 Gel Running Conditions

Recommended Voltages and Resultant Current for 1mm thick, 12%

gels.

CVS10D

One gel

90-225V

20-45mA

Two gels

90-225V

40-90mA

Three gels

90-225V

60-135mA

Four gels

90-225V

80-180mA

Page 18

Page 18

4.7 Preparation of denatured protein samples for loading

The instructions given below are for denatured samples. For Native samples, please consult a laboratory

handbook.

1. Prepare the protein samples for loading. The volume of sample depends on the capacity of the wells (See

Comb specifications section 6.2).

2. Using a 0.5 ml micro-centrifuge tube or other convenient receptacle, combine the protein sample and 4 X

sample buffer. It is always advisable to use protein markers in one of the end lanes to indicate sizes of

bands. These should be prepared according to the manufacturer’s instructions.

3. Heat the samples in a water bath or heating block for 2 minutes to denature the samples.

4. Centrifuge the samples in a micro-centrifuge for 20 seconds at 12,000 rpm. The protein samples are now

ready to load.

Page 19

Page 19

4.8 Stock Solutions (For SDS PAGE gels)

Stock 30% Acrylamide Gel Solution:

30.0 g acrylamide

0.8 g methylene bisacrylamide

Distilled Water to 100ml

Stock 4 X Resolving Gel Tris (1.5 M Tris.HCl pH8.8, 0.4 % SDS)

To 110ml Distilled Water add 36.4 g of Tris base

Add 8ml of 10 % SDS

Adjust pH to 8.8 with 1N HCl

Adjust the final volume to 200ml with Distilled Water.

Stock 4 X Stacking Tris (0.5 M Tris.HCL pH6.8, 0.4 % SDS)

To 110ml Distilled Water add 12.12 g of Tris base

Add 8ml of 10 % SDS

Adjust pH to 6.8 with 1N HCl

Add Distilled Water to a final volume of 200ml

Stock 4 X Tris-glycine tank buffer - SDS

36 g Tris base

172.8 g glycine

Distilled Water to 3 L

1 x Tris-glycine tank buffer - SDS

750ml of 4 X Tris-glycine reservoir buffer - SDS

30ml of 10 % SDS

Distilled Water to 3L

10 % AP (ammonium persulphate solution)

0.1 g ammonium persulphate

1ml Distilled Water

TEMED Stock 4 X Sample Buffer

4ml glycerol

2ml 2-mercaptoethanol

1.2 g SDS

5ml 4 X Stacking Tris

0.03 g Bromophenol blue

Aliquot into 1.5ml micro centrifuge tubes. Store at -20°C.

Page 20

Page 20

Section 5 Troubleshooting Guide

Problem: Sample Preparation

Cause

Solution

Laemmil sample buffer turns yellow

Sample buffer too acidic

Add Tris base until buffer turns blue again.

Sample very viscous

High DNA or carbohydrate content

Fragment DNA with ultrasonic waves during cell

lysis and protein solubilization.

Add endonucleases (for each benzonases).

Precipitate protein with TCA/acetone to diminish

carbohydrate content.

Problem: Gel casting and

sample loading

Cause

Solution

Poor well formation

Incorrect catalyst used

Monomer solution not degassed

(oxygen inhibits polymerization)

Prepare Fresh catalyst solution.

Increase catalyst concentration of stacking gel to

0.06% APS and 0.12% TEMED.

Degas monomer solution immediately prior to

casting stacking gel.

Webbing; excess acrylamide behind

the comb

Incorrect catalyst concentration

Prepare fresh catalyst solution.

Increase catalyst concentration of stacking gel to

0.06% APS and 0.12% TEMED.

Gel does not polymerize

Too little or too much APS or TEMED

Failure to degas

Temperature too low

Poor quality acrylamide or bis

Old APS

Use 0.0.05% APS and 0.05% TEMED.

Degas monomer solutions 10-15min.

Cast at room temperature, warming glass plates if

necessary.

Use electrophoreses-grade reagents

Prepare fresh APS.

Swirls in the gel

Excess catalysts; polymerization time

< 10min

Gel inhibition; polymerization time

>2hr

Reduce APS and TEMED by 25% each.

Increase APS and TEMED by 50%; degas.

Gel feels soft

Low %T

Poor quality acrylamide or bis

Too little cross-linker

Use different %T.

Use electrophoresis- grade reagents.

Use correct %C.

Gel turns white

Bis concentration too high

Check solutions or weights.

Gel brittle

Cross-linker too high

Use correct % cross-linker

Sample floats out of the well

Sample is not dense enough

Pipetting, loading error

Induce 10% glycerol in sample to make it denser

than surrounding buffer.

Slowly pipet sample into well. Do not squirt sample

quickly into well as it may bounce off bottom or

sides and flow into next well. Do not pipet tip from

well before last of sample has left the tip.

Page 21

Page 21

Problem: Electrophoresis

Cause

Solution

Current zero or less than expected

and samples do not migrate into gel

Tape at the bottom of precast gel

cassette not removed

Insufficient buffer in inner buffer

chamber

Insufficient buffer in outer buffer

chamber

Electrical disconnection

Remove tape.

Fill buffer chamber with running buffer.

Fill inner and outer buffer chambers to ensure

wells are completely covered.

Check electrodes and connections.

Gels run faster than expected

Running buffer too concentrated and

gel temperature too high; incorrect

running buffer concentration or type

used

Running or reservoir buffer too

dilute

Voltage too high

Check buffer composition and type.

Check buffer protocol and concentrate if

necessary.

Decrease voltage by 25-50%.

Gels run slower than expected

Incorrect running buffer composition

or type

Excessive salt in sample

Check buffer composition and type.

Desalt sample.

Buffer leaking from inner chamber

Incomplete gasket seal

Set up again with sliding clamps tighter.

Problem: Total Protein

Staining

Cause

Solution

Bands not visible

No protein in gel

Imaging system malfunctioning

Incorrect imaging parameters were

used

Stain with another method to confirm there is

protein.

Check instrument manual for troubleshooting or

contact imaging instrument manufacturer.

Check Instrument manual.

Poor staining sensitivity

Dirty staining trays

Insufficient stain volume

Insufficient staining time

Reuse of staining solution

Clean staining trays and other equipment with

laboratory glassware cleaner.

Follow recommendations for stain volume

(appropriate to gel size).

Increase staining time.

Repeat staining protocol with fresh staining

solution.

High or uneven background staining

Staining trays or equipment dirty

Too much time in staining solution

Reagent impurities

Clean staining trays and other equipment with

laboratory glassware cleaner.

Restrict duration of incubation in staining solutions

as recommended in protocol.

Wash gel in water or retrospective destaining

solution for >30min.

Use high-purity water and reagents for staining.

Speckles or blotches in gel image

Particulate material from reagents,

staining tray, dust or gloves

Clean staining trays thoroughly.

Decrease time that gels and staining solution are

exposed to open air.

Use dust-free gloves and handle gels only by

edges.

Uneven staining

Insufficient shaking during staining

Agitate gel during staining.

Gel shrinkage

Gel dehyrated

Transfer gel to water for rehydration.

Page 22

Page 22

Problem: Evaluation of

Separation

Cause

Solution

Diffuse or broad bands

Poor quality acrylamide or bisacrylamide incomplete

polymerization

Old SDS or sample buffer

Gel temperature too high

Use electrophoresis-grade reagents.

Check polymerization conditions.

Prepare fresh solutions.

Use external cooling during run or run out a lower

voltage.

Bands ‘smile’ across gel, band

pattern curves upward at both sides

of gel

Excess heating of gel; center of gel

runs hotter than either end

Power conditions excessive

Insufficient buffer

Check buffer compostion; buffer not mixed well, or

buffer in upper chamber too concentrated.

Prepare new buffer, ensuring thoroughly mixing,

especially when diluting 5x or 10x stock.

Do not exceed recommended running conditions.

Decrease power setting from 200V to 150V or fill

lower chamber to within 1cm of top of short plate.

Fill inner and outer buffer chambers to ensure that

wells are completely covered.

Smiling or frowning bands with gel

lane

Overloaded proteins

Sample preparation/ buffer issues

Incorrect running conditions

Load less protein.

Minimize salts, detergents and solvents in sample

preparation and sample buffers.

Use correct voltage.

Skewed or distrorted bands, lateral

band spreading

Excess salt in samples

Ionic strength of sample lower than

that of gel

Insufficient sample buffer or wrong

formulation

Diffusion prior to turning on current

Diffusion during migration through

stacking gel

Uneven gel interface

Remove salts, from sample by dialysis or desalting

column prior to sample preparation.

Use same buffer in samples as in gel.

Check buffer composition and dilution

instructions.

Minimize time between sample application and

power startup.

Increase %T of stacking gel to 4.5% or 5%T.

Increase current by 25% during stacking.

Decrease polymerization rate.

Overlay gels carefully.

Rinse wells after removing comb to remove

residual acylamide.

Vertical streaking

Overloaded samples

Sample precipitation

Dilute sample.

Selectively remove predominant protein in sample

(fractionate).

Reduce voltage by 25% to minimize streaking.

Centrifuge samples to remove particulate prior to

sample loading.

Dilute sample in sample buffer.

Fuzzy or spurious artefactual bands

Concentration of reducing agent too

low

Use 5% BME or 1% DTT.

Protein bands do not migrate down

as expected

Bands of interest may be neutral or

positively charged in buffer used; pH

of bands must be -2pH units more

negative than pH of running buffer

Use SDS-PAGE or a different buffer system in

native PAGE or IEF.

Page 23

Page 23

Section 6 Product Information

6.1 Catalogue numbers and product descriptions

Catalogue No.

Product description

CVS10D

omniPAGE Mini, 10 x 10cm Dual, 2 sets of Glass Plates, 1mm thick bonded Spacers, 2 x 12

sample, 1mm thick combs. CLAMP VERSION

CVS10DSYS

omniPAGE Mini, 10 x 10cm Dual, 2 sets of Glass Plates, 1mm thick bonded Spacers, 2 x 12

sample, 1mm thick combs including caster. CLAMP VERSION

CVS10PRE

omniPAGE Mini, 10 x 10cm Dual. No accessories. CLAMP VERSION

CVS10DSYS-CU

omniPAGE Mini, 10 x 10cm Dual, 2 sets of Glass Plates, 1mm thick bonded Spacers, 2 x 12

sample, 1mm thick combs including caster. CLAMP VERSION, External casting upstand

CVS10EXCASTER

External Casting Stand - No Casting Base

CVS10EXCASTERSYS

External Casting System - Upstand+ Base

VS10DCAST

10 x 10cm Casting Base

VS10DCASTM

Replacement Silicone Mat for 10 x 10cm Casting Base

CVS10DIRM

Inner Running Module

VS10ICB

Mini Cooling Pack

VS10NG

10 x 10cm Notched Glass Plates 2mm thick (pk/2)

VS10PG

10 x 10cm Plain Glass Plates 2mm thick (pk/2)

VS10NGS0.75

10 x 10cm Notched Glass Plates with 0.75mm Bonded Spacers (pk/2)

VS10PGS0.75

10 x 10cm Plain Glass Plates with 0.75mm Bonded Spacers (pk/2)

VS10NGS1

10 x 10cm Notched Glass Plates with 1mm Bonded Spacers (pk/2)

VS10PGS1

10 x 10cm Plain Glass Plates with 1mm Bonded Spacers (pk/2)

VS10NGS1.5

10 x 10cm Notched Glass Plates with 1.5mm Bonded Spacers (pk/2)

VS10PGS1.5

10 x 10cm Plain Glass Plates with 1.5mm Bonded Spacers (pk/2)

VS10NGS2

10 x 10cm Notched Glass Plates with 2mm Bonded Spacers (pk/2)

VS10PGS2

10 x 10cm Plain Glass Plates with 2mm Bonded Spacers (pk/2)

VS10DP

Dummy Plate, 10 x 10cm

VS10S0.75

10cm Spacers - 0.75mm (pk/2)

Page 24

Page 24

VS10S1

10cm Spacers - 1mm thick (pk/2)

VS10S1.5

10cm Spacers - 1.5mm thick (pk/2)

VS10S2

10cm Spacers - 2mm thick (pk/2)

RPW-0.2

Replacement Platinum Wire - 0.2mm, 50cm

Multiple Minigel Casting

CSL-6CAST

6 gel caster for 8 x 10cm or 10 x 10cm gels

CSL-12CAST

12 gel caster for 8 x 10cm or 10 x 10cm gels

CSL-24CAST

24 gel caster for 8 x 10cm or 10 x 10cm gels

6.2 Combs – MC Denotes Multi Channel Pipette compatible

Code

Description

Sample Volume µl for a 5mm thick gel

VS10-1-0.75

Comb 1 Prep, 1 Marker, 0.75mm thick

500

VS10-5-0.75

Comb 5 sample, 0.75mm thick

70

VS10-8MC-0.75

Comb 8 sample MC, 0.75mm thick

40

VS10-9-0.75

Comb 9 sample, 0.75mm thick

35

VS10-12-0.75

Comb 12 sample, 0.75mm thick

25

VS10-16MC-0.75

Comb 16 sample MC, 0.75mm thick

20

VS10-20-0.75

Comb 20 sample, 0.75mm thick

15

VS10-1-1

Comb 1 Prep, 1 Marker, 1mm thick

650

VS10-5-1

Comb 5 sample, 1mm thick

100

VS10-8MC-1

Comb 8 sample MC, 1mm thick

60

VS10-9-1

Comb 9 sample, 1mm thick

50

VS10-10-1

Comb 10 sample, 1mm thick

40

VS10-12-1

Comb 12 sample, 1mm thick

35

VS10-16MC-1

Comb 16 sample MC, 1mm thick

25

VS10-20-1

Comb 20 sample, 1mm thick

20

VS10-1-1.5

Comb 1 Prep, 1 Marker, 1.5mm thick

1000

VS10-5-1.5

Comb 5 sample, 1.5mm thick

140

VS10-8MC-1.5

Comb 8 sample MC, 1.5mm thick

80

VS10-9-1.5

Comb 9 sample, 1.5mm thick

70

VS10-10-1.5

Comb 10 sample, 1.5mm thick

30

VS10-12-1.5

Comb 12 sample, 1.5mm thick

50

Page 25

Page 25

VS10-16MC-1.5

Comb 16 sample MC, 1.5mm thick

40

VS10-20-1.5

Comb 20 sample, 1.5mm thick

30

VS10-1-2

Comb 1 Prep, 1 Marker, 2mm thick

1300

VS10-5-2

Comb 5 sample, 2mm thick

200

VS10-8MC-2

Comb 8 sample MC, 2mm thick

120

VS10-9-2

2 Comb 9 sample, 2mm thick 100

100

VS10-10-2

Comb 10 sample, 2mm thick

80

VS10-12-2

Comb 12 sample, 2mm thick

70

VS10-16MC-2

Comb 16 sample MC, 2mm thick

50

VS10-20-2

Comb 20 sample, 2mm thick

40

Page 26

Page 26

6.3 Catalogue numbers and product descriptions for CSL Related Products

Catalogue No.

Product description

CSL-PPL

CSL Pink Plus Prestained Protein Ladder, 10-175kDa, with 10, 40 & 90kDa reference

bands, 1x 500μL vial.

CSL-BBL

CSL BLUE Wide Range Prestained Protein Ladder, 10-245kDa, with 25 & 75kDa

reference bands, 1x 500μL vial.

CSL-TGSDSP

Powdered Tris-Glycine-SDS Running buffer - 10 Pouches(10 litres/pk)

CSL-TGP

Powdered Tris-Glycine Running buffer - 10 Pouches(10 litres/pk)

CSL-TTSDSP

Powdered Tris-TRICINE-SDS Running buffer - 10 Pouches(10 litres/pk)

CSL-MSDSP

Powdered MOPS-SDS buffer Running buffer - 10 Pouches(10 litres/pk)

TG10X1L

Cleaver Buffer Tris-Glycerine 10 x 1litre

TG10x5L

Cleaver Buffer Tris-Glycerine 10 x 5litre

TG-SDS10X1L

Cleaver Buffer Tris-Glycerine SDS 10 x 1litre

TG-SDS10X5L

Cleaver Buffer Tris-Glycerine SDS 10 x 5litre

CSL-GELX4

4mm x 1mm, Gel Cutting Tips, 250/ bag

CSL-GELX4RACK

4mm x 1mm, Gel Cutting Tips, 5 racks of 48

CSL-GELX6.5

6.5mm x 1mm, Gel Cutting Tips, 250/ bag

CSL-GELX6.5RACK

6.5mm x 1mm, Gel Cutting Tips, 5 racks of 48

CS-300V

OmniPAC, MIDI 300V 700mA 150W - 110/230V

CS-500V

OmniPAC, MAXI 500V 400mA 200W - 110/230V

VS10BI

OmniBlot Mini Insert - including 4 cassettes, 16 foam pads

VS10DCi

omniPAGE Mini Tube Gel Insert - including 10 glass tubes

OMNIDOCIPROSAFE

OMNIDOC-i plus Blue LED Epi-illumination Module (OMNIDOC-BL), and 520, 560 & 580nm filters (OMNIDOCSYBR, -AF560 & -AF580); and White Light Table (OMNIDOC-WLT)

CVS10CBS

Complete system for Mini Vertical Electrophoresis & Blotting including: Vertical unit, Blotting insert &

accessories. CLAMP VERSION.

SB10

OmniBlot Mini, 10 x 10cm Blotting System, including 4 cassettes

SB20

OmniBlot Maxi, 20 x 20cm Blotting System, including 4 cassettes

CV20

Cleaver Pipette - Volume; 2 - 20ul

CSLVORTEX

Cleaver Vortex Mixer with general purpose head, 230V

CSLQSPIN

Mini Centrifuge complete with 1.5/2.0 ml rotor, strip tube rotor, 0.5 and 0.4 ml adapters, 230V, Purple lid

TCDB-01

The Cube Dry Bath Incubator (one block unit); without block 220V

CSL-UVCAB

UV sterilisation cabinet with timer, four UV lights and white light, no Tray - 230V

SD20

Semi Dry Maxi, 20 x 20cm System

VS10WD

omniPAGE Mini Wide, 20 x 10cm Dual, 2 sets of Glass Plates with 1mm thick bonded Spacers, 2 x 24 sample,

1mm thick combs, cooling pack

VS10WDSYS

omniPAGE Mini Wide, 20 x 10cm Dual, 2 sets of Glass Plates with 1mm thick bonded Spacers, 2 x 24 sample,

1mm thick combs, cooling pack including caster

VS10WDSYS-CU

omniPAGE Mini Wide, 20 x 10cm Dual, 2 sets of Glass Plates, 1mm thick bonded Spacers, 2 x 24 sample, 1mm

thick combs including caster, External casting upstand

VS20WAVESYS

VS20WAVE Maxi, 20 x 20cm Dual with Glass Plates with bonded 1mm thick spacers, 2x 24

sample combs, cooling coil, dummy plate and Casting Base

VS20WAVESYS-CU

VS20WAVE Maxi, 20 x 20cm Dual, 2 sets of Glass Plates, 1mm thick bonded Spacers, 2 x 24 sample, 1mm thick

combs, cooling coil, dummy plate;includes caster and External casting upstand

VS20WAVE-EC

VS20WAVE External Casting Stand - No Casting Base

Page 27

Page 27

Section 7 Warranty

The Cleaver Scientific Ltd. (CSL) Electrophoresis units have a warranty against manufacturing and material faults of

twelve months from date of customer receipt.

If any defects occur during this warranty period, CSL will repair or replace the defective parts free of charge.

This warranty does not cover defects occurring by accident or misuse or defects caused by improper operation.

Units where repair or modification has been performed by anyone other than CSL or an appointed distributor or

representative are no longer under warranty from the time the unit was modified.

Units which have accessories or repaired parts not supplied by CSL or its associated distributors have invalidated

warranty.

CSL cannot repair or replace free of charge units where improper solutions or chemicals have been used. For a list of

these please see the Care and Maintenance subsection.

If a problem does occur then please contact your supplier or CSL:

Cleaver Scientific Ltd.

Unit 41

Somers Road Industrial Estate

Rugby

Warwickshire

CV22 7DH

Tel: +44 (0)1788 565300

Fax: +44 (0)1788 552822

Email: info@cleaverscientific.com

Record the following for your records:

Model __________________________

Catalogue No. ____________________

Date of Delivery __________________

Warranty Period __________________

Serial No. _______________________

Invoice No. ______________________

Purchase Order No. _______________

Loading...

Loading...