Page 1

Cleaver Scientific Thermal Cycler

Cleaver Scientific Thermal Cycler

GTC96S /GTC96S-230

Operation Manual

Ver.2.1

Cleaver Scientific

Page 2

Notice

This instrument is licensed for research and development and for uses

other than human in vitro diagnostics.

Page 3

Cleaver Scientific Thermal Cycler

Table of Contents

SAFETY PRECAUTIONS ................................................................................................ 1

GENERAL DESCRIPTION ............................................................................................. 2

2.1 FEATURES ........................................................................................................................ 2

2.2 PRODUCT OVERVIEW ....................................................................................................... 2

GETTING STARTED ........................................................................................................ 6

3.1 UNPACKING ..................................................................................................................... 6

3.2 INITIAL OPERATION ......................................................................................................... 6

3.3 HEATED LID .................................................................................................................... 6

3.4 LID OPENING/CLOSING ................................................................................................... 7

3.5 FUNCTION MAP ............................................................................................................. 10

3.6 KEY ENTRY SYSTEM ..................................................................................................... 11

3.7 LOADING THE REACTION VESSEL .................................................................................. 11

USER FOLDER MANAGEMENT ................................................................................ 12

4.1 VIEWING A USER FOLDER .............................................................................................. 12

4.2 CREATING A NEW USER FOLDER ................................................................................... 13

4.3 EDITING A USER FOLDER ............................................................................................... 13

4.4 DELETING A USER FOLDER ............................................................................................ 13

PROTOCOL MANAGEMENT ...................................................................................... 15

5.1 RUNNING A PROTOCOL .................................................................................................. 15

5.2 PAUSE A PROTOCOL ....................................................................................................... 16

5.3 VIEWING RUNNING PROTOCOL INFORMATION ............................................................... 16

5.4 TERMINATING A PROTOCOL ........................................................................................... 17

CREATING A NEW PROTOCOL ................................................................................. 18

6.1 CHANGING TEMPERATURE/TIME VALUES ...................................................................... 18

6.2 INSERTING/DELETING TEMPERATURE SEGMENT ........................................................... 19

6.3 CHANGING TEMPERATURE SEGMENT COUNT (TEMP) AND CYCLE COUNT (CYC) .......... 19

6.4 ADVANCED SETTINGS .................................................................................................... 19

6.5 SAVING A PROTOCOL ..................................................................................................... 23

EDITING(VIEWING) A PROTOCOL .......................................................................... 24

DELETING A PROTOCOL ........................................................................................... 24

SYSTEM SETUP ............................................................................................................. 25

Page 4

9.1 DATA LOG ..................................................................................................................... 26

9.2 DATE & TIME ................................................................................................................ 27

9.3 LID TEMPERATURE ........................................................................................................ 27

9.4 BEEPER ......................................................................................................................... 28

9.5 ADMINISTRATOR ........................................................................................................... 28

9.6 SERVICE MODE ............................................................................................................. 28

9.7 RAMPING SPEED ............................................................................................................ 28

9.8 TM CALCULATOR .......................................................................................................... 29

MAINTENANCE AND TROUBLESHOOTING ......................................................... 30

10.1 CLEANING THE UNIT .................................................................................................... 30

10.2 CLEANING THE HEATED LID ......................................................................................... 30

10.3 REPLACING A FUSE ...................................................................................................... 30

10.4 CHANGING THE THERMAL BLOCK ............................................................................... 30

TROUBLESHOOTING .................................................................................................. 31

1. OPERATING TEMPERATURE ENVIRONMENT MAY BE UNSUITABLE. ................................ 31

2. ELECTRONIC COOLING ELEMENT MAY BE DAMAGED OR AGED. .................................... 31

11.1 ERROR MESSAGES ....................................................................................................... 32

APPENDIX A: TECHNICAL SPECIFICATIONS ...................................................... 33

APPENDIX B: PROTOCOLS IN DEFAULT FOLDER ............................................. 34

APPENDIX C: CE DECLARATION ............................................................................ 36

Page 5

1

Safety Precautions

Before using the GTS96 thermal cycler for the first time, please read this entire operating

manual carefully. To guarantee problem free, safe operation of the GTS96 thermal cycler,

it is essential to observe the following points.

1. Do not use the machine in a potentially explosive environment or with potentially

explosive chemicals.

2. Install the machine in location free of excessive dust.

3. Avoid placing the machine in direct sunlight.

4. Choose a flat, stable surface capable of withstanding the weight of the machine.

5. Install the machine in the room temperature 15 ~ 30C, relative humidity 20

~80%.

6. DO NOT block the air vents.

7. Keep the side and rear of the machine at least 30cm from the wall or other

machine.

8. Make sure the power source conforms to the required power supply specifications.

9. To avoid electric shock, make sure the machine is plugged into a grounded

electrical outlet.

10. Do not allow water or any foreign objects to enter the various openings of the

machine.

11. Switch off the machine before cleaning or performing service on the machine,

such as replacing the fuses.

12. Repairs should be carried out by authorized service personnel only.

High Temperature Label: Please be aware of the heated block.

Warning Label: Please be aware of the danger of electric shock or other dangers.

Page 6

2

General Description

The GTS96 thermal cycler is a powerful, reliable and affordable thermal cycler. It is

equipped with a gradient function that enables the user to set a maximum 24 C

temperature gradient between the BLOCK#1 to BLOCK#6 (16 well/block).

2.1 Features

⚫ Easy-to-operate slide and lever type lid which prevents accidental skin burn

⚫ Large LCD panel enhances visibility and ease-of-operation.

⚫ Graphic display makes programming quick and simple.

⚫ Simple and easy to use graphical interface.

⚫ Extended Temperature return function that makes touchdown possible

⚫ Gradient function enables optimization of annealing temperatures.

⚫ Preset protocols that make starting amplification easier.

⚫ Air intake vents on the front and sides and exhaust vents on the rear that reduce

heat-based interference with other equipment.

⚫ Interchangeable blocks.

⚫ Automatically creates operating history and error logs.

⚫ Heated lid to prevent the formation of condensation.

⚫ Robust and attractive design.

⚫ Auto restart after power failure.

2.2 Product Overview

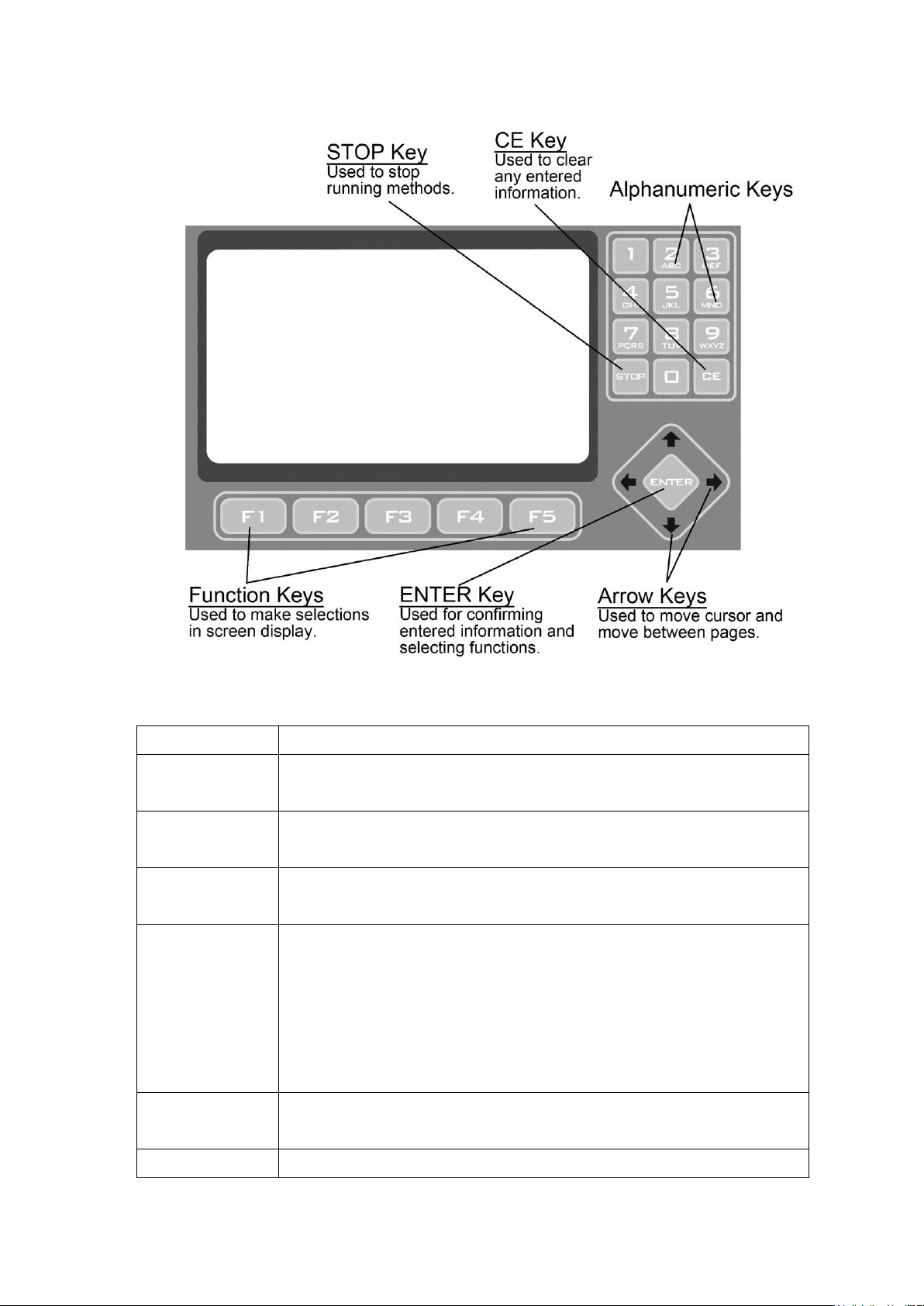

The front panel of GTS96 thermal cycler includes a display panel and 22-key keypad

which consists of function keys (F1-F5), alphanumeric keys, directional arrow keys and

the ENTER key.

Page 7

Cleaver Scientific Thermal Cycler

3

Figure 1. Front Panel Overview

Name

Function

Function Keys

(F1 to F5)

Use the function keys (F1 to F5) to activate the “button” displayed on

the screen above the key; for example, F1 for RUN.

Directional

Arrow Keys

The four Directional Arrow keys can move the cursor into different

directions.

ENTER key

The current selection is activated or accepted when the ENTER key is

pressed.

Alphanumeric

Keys (0~9)

The alphanumeric keys are usually used as number keys for the entry

of time, temperature, password and cycle numbers. When entering a

user name or protocol name, a small screen will pop out to display the

letters after pressing the Alphanumeric keys. Press the selected key

until the desired letter is highlighted. Press the ENTER key to select

the letter or wait 5 seconds.

CLEAR key

(CE)

Press CLEAR key will erase the entry in an input field.

STOP key

By pressing STOP, the Protocol current running will be terminated.

Page 8

4

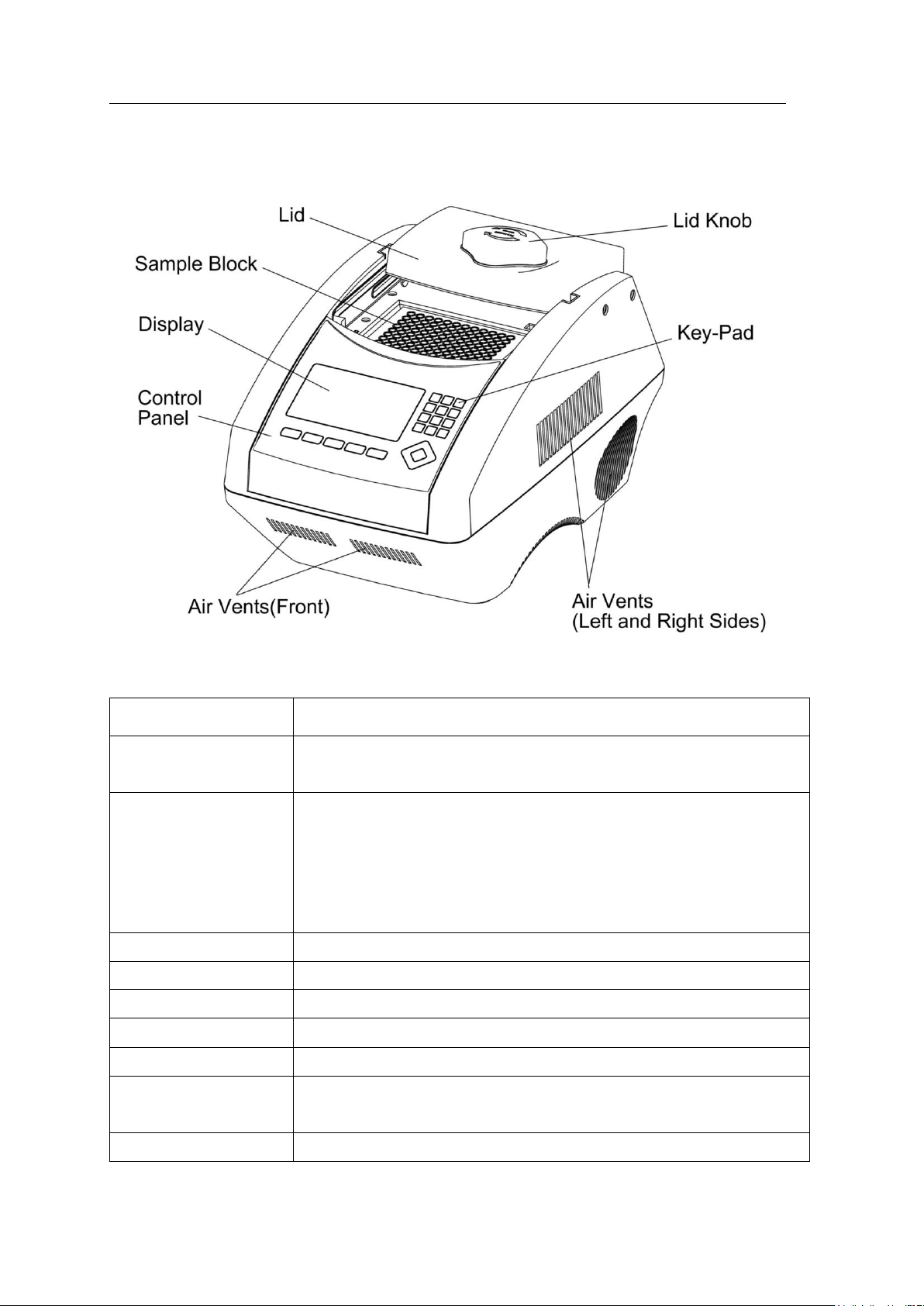

Figure 2. Front View

Name

Function

Lid

The lid with heating pad is designed to protect against evaporation

resulting from heating of the reaction tube and reaction plate.

Lid Knob

Rotate Lid Knob in clockwise will lower the heating plate to place

pressure on the cap of tubes. This forces the tubes to sit firmly in the

block for better contact. Rotate Lid Knob in counter-clockwise

direction until the Lid pops up. Only after the Lid pops, can users

slide the Lid to the rear.

Sample Block

Section of the unit in which sample tubes and plates are placed.

Key-Pad

Used to enter the various Protocols and settings.

Control Panel

which includes Display and Key-Pad

Display

Displays current status of the various system features and functions.

Air Vents (Front)

for air output

Air Vents (Left and

Right Sides)

for air output

Air Vents (Bottom)

for air intake

Page 9

Cleaver Scientific Thermal Cycler

5

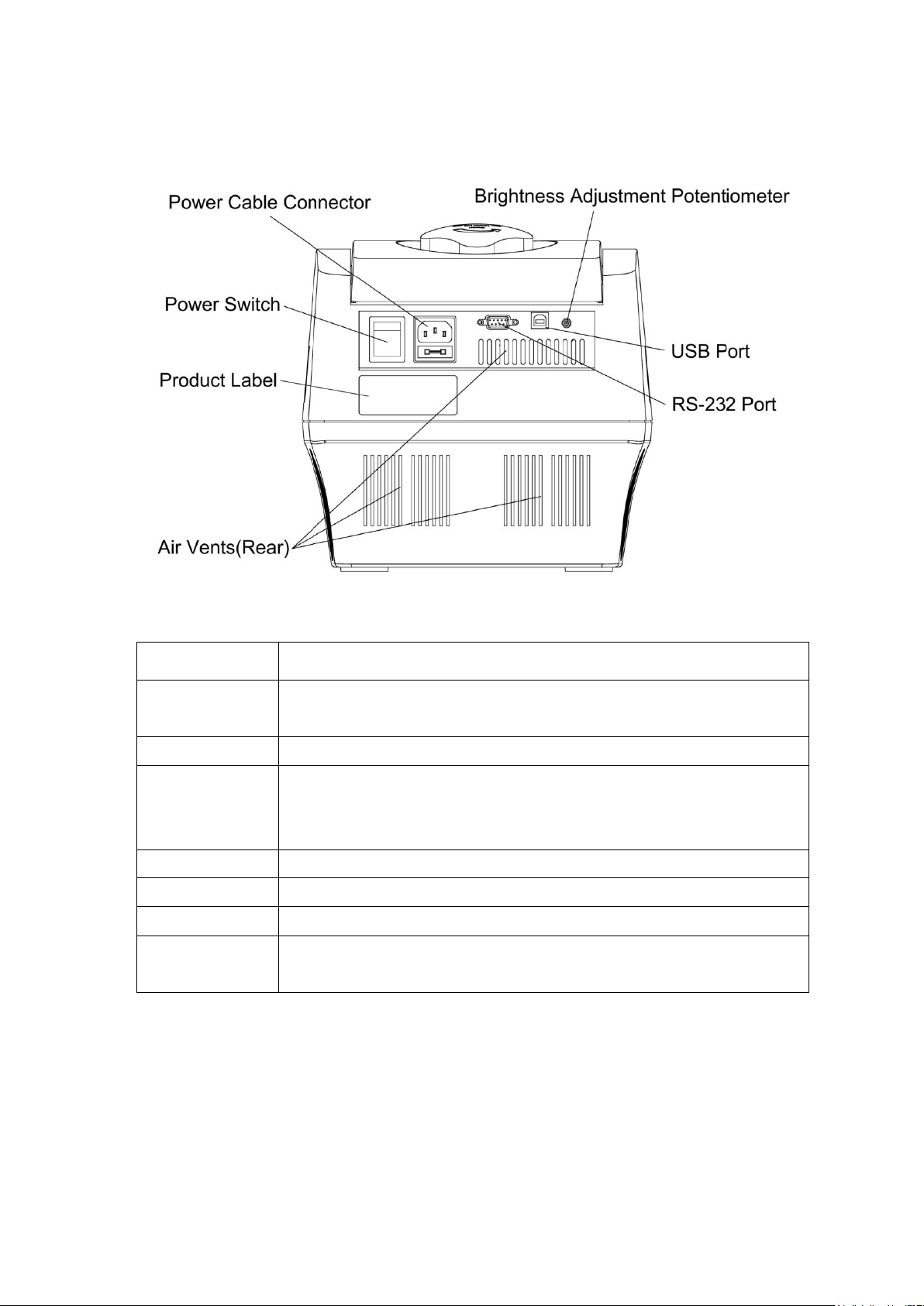

Figure 3. Rear View

Name

Function

Power Cable

Connector

Power cable socket and fuse.

Power Switch

Power On/Off switch

Brightness

Adjustment

Potentiometer

Control the brightness of LCD panel. Please use Philip-head screw

driver to adjust it.

USB Port

For run summary download to computer

RS-232 Port

For run summary download to computer

Air Vents(Rear)

For air output

Product Label

Indicate the model name, serial number, power specification, and

other important information

Page 10

6

Getting Started

3.1 Unpacking

Open the GTS96 thermal cycler package and confirm that all items below are included:

If there are any items missing, damaged, or incorrect items, please contact your

distributor or sales representatives immediately.

Note: Please use 7A fuse in power source 100~120/50~60Hz countries, while 3.15A fuse

is for power source 200~220V/50~60Hz countries.

3.2 Initial Operation

Place the machine on a steady, flat table. Please keep the machine at least 30cm from the

wall or other machine. Connect the power cord to the power socket in the rear of the

machine. Check the power source is compatible with your machine’s fuse rating input.

Press Power On/Off Button to switch on the machine. The screen will show the software

version for 10 seconds and then enter User Folder screen. Pressing any key will go to

User Folder screen immediately.

3.3 Heated Lid

The Heated Lid heats the air in the upper part of the sample vessels at higher temperature

than the reaction mixture. This prevents condensation of the evaporated water vapor on

the vessel walls, keeping the concentration unchanged during the heating and cooling

cycles. The top also places pressure on the caps of tubes and film on titer plates to prevent

vapor loss and cross contamination of samples.

When using full skirted plates it is highly recommended to use a Silicone Compression

Mat (to assist in placing even pressure on the plates.

Note:

1. If GTS96 is started cold, approximately two to three minutes will be required before

heated lid is at operating temperature.

2. To avoid heat dissipation, the Heated Lid should be closed and tighten during a

⚫ GTS96 thermal cycler unit

⚫ Operation manual

⚫ Electric fuses (7A & 3.15A)

⚫ AC power cord

⚫ Warranty card

Page 11

Cleaver Scientific Thermal Cycler

7

protocol run. Keeping the heated lid open during a protocol run might cause

“HEATER ERROR”, because the heated lid fails to reach the set temperature.

3. To evaporate the condensation water inside sample block, and to avoid “HEATER

ERROR”, users should turn off the Lid Temperature under SYSTEM mode before

heating the sample block and keeping the lid open.

3.4 Lid Opening/Closing

There are two ways to open the lid: 1) Slide the lid to the rear, 2) lift up the lid. The first

method is recommended for common operations and to prevent the skin burn from the

heated lid. The second method is used to clean up the heating plate of the lid.

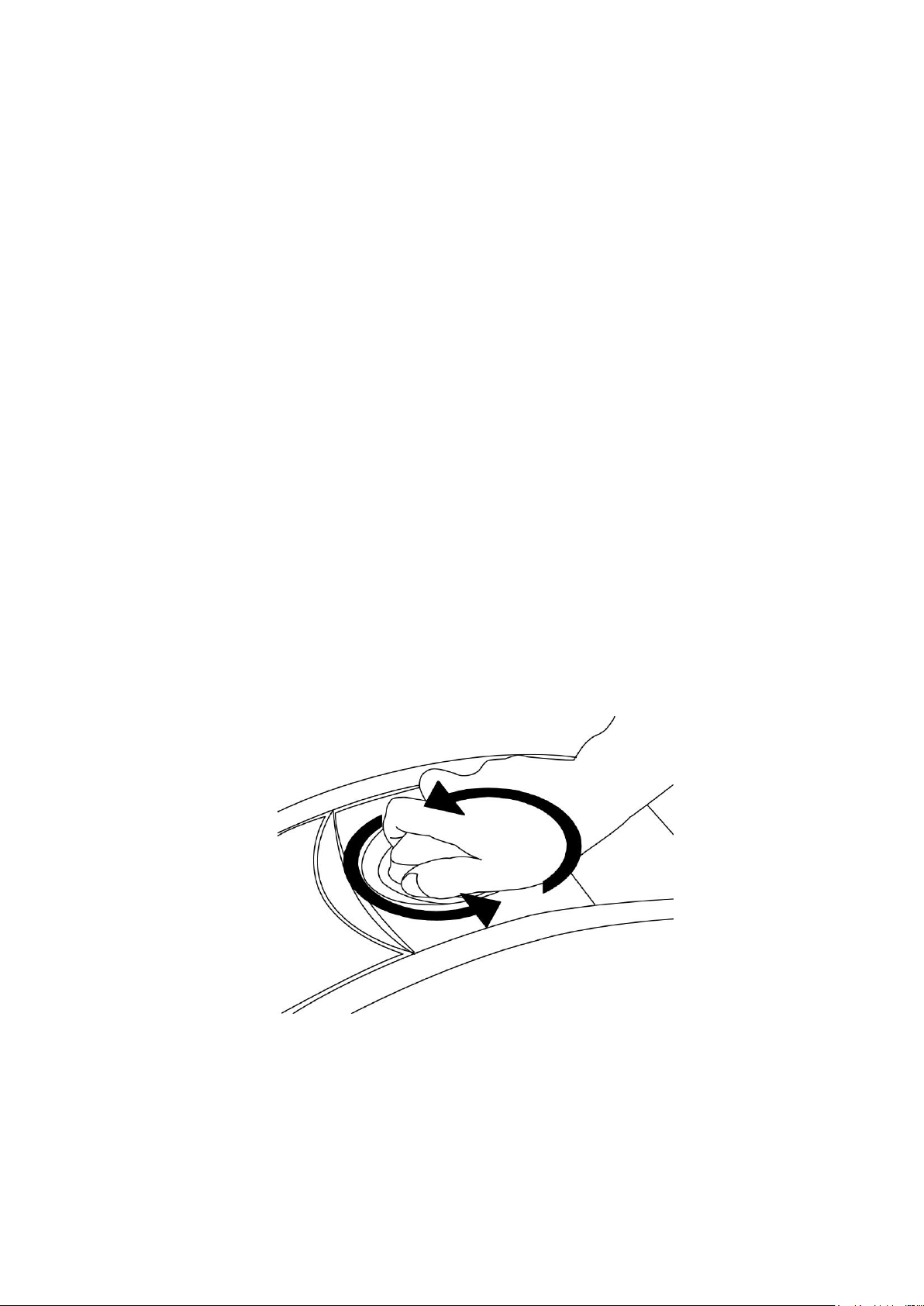

Rotate Lid Knob in a clockwise direction to lower down the heating plate and press down

on the cap of tubes, tighten until you feel resistance. This adjustment will provide better

contact between the tube or plates and the block for better performance. Rotate the Lid

Knob in counter-clockwise direction as shown in Figure 4 until the Lid pops out. Only

when the Lid pops out, users can slide the Lid to the rear as shown in Figure 5.

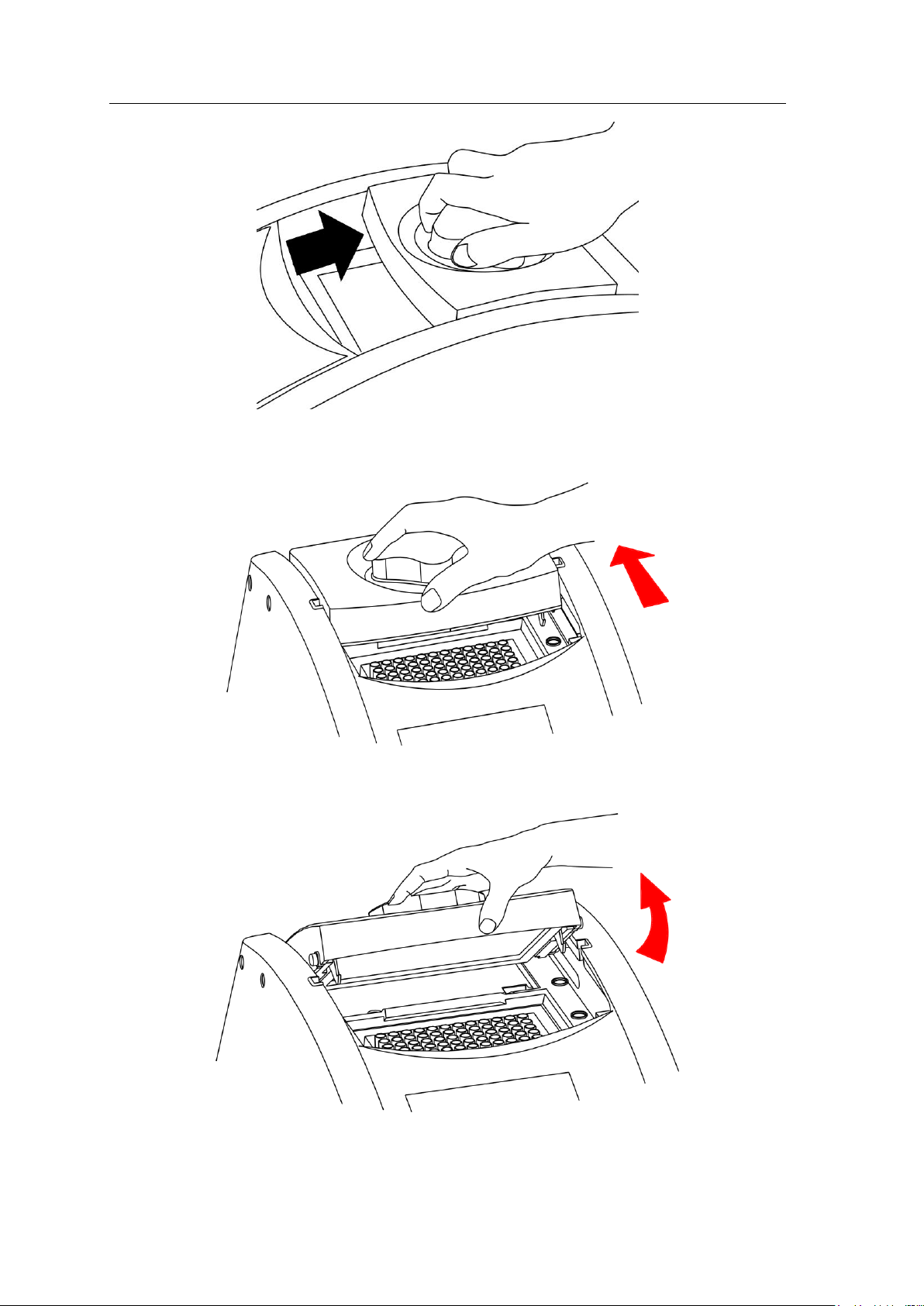

To lift up the lid for heating plate cleaning, please refer Figure 6 ~ 8.

Figure 4. Rotate Lid Knob to open the lid

Page 12

8

Figure 5. Slide the lid backward to access the block

Figure 6. Slide the lid to align the lid hinge with notches of top case

Figure 7. Lift the lid

Page 13

Cleaver Scientific Thermal Cycler

9

Figure 8. Rest the lid in vertical position

Page 14

10

3.5 Function Map

The User Screen includes 5 function options; 1) VIEW folders under selected User folder,

2) NEW(Create) a User, 3)EDIT a User, 4)DELETE a User, 5)SYSTEM. Once a user

folder is selected and the password is approved, users can; 1) RUN a Protocol,

2)NEW(Create) a protocol, 3) EDIT(VIEW) a Protocol, and 4) DELETE a Protocol.

The function map is shown in Figure 9. Various functions, including Gradient, can be

added to the selected/created Protocol.

Figure 9. Operation Flowchart

RUN

Protocol

NEW

Protocol

EDIT

(VIEW)

Protocol

DELETE

Protocol

EDIT

User

DELETE

User

SYSTEM

OPEN

User

User Folder

NEW

User

Insert

Delete

Advanced

Optimization

Increment

Pause

Data Log

Date &Time

Lid Temp.

Beeper

Administrator

Service Mode

Ramping Speed

Tm Calculator

Save

Main Menu

Page 15

Cleaver Scientific Thermal Cycler

11

3.6 Key Entry System

Note that the alphanumeric keys are assigned multiple characters, selectable by repeatedly

pressing the key to cycle through the available characters. The highlighted character or

number will automatically be entered into the name of a newly created or edited Protocol

(or User) after a very short period of time, if users don’t continue to press the key.

Key No.

Key Representation

0

0, space, +, =, <, >, &, (, ), %

1

1, . , , ,-, ?, ‘, #, : , ; ,/

2

A, B, C, a, b, c, 2

3

D, E, F, d, e, f, 3

4

G, H, I, g, h, i, 4

5

J, K, L, j, k, l, 5

6

M, N, O, m, n, o, 6

7

P, Q, R, S, p, q, r, s, 7

8

T, U, V, t, u, v, 8

9

W, X, Y, Z, w, x, y, z, 9

3.7 Loading the Reaction Vessel

For the optimal performance of the GTS96, we recommend Cleaver tubes and plates.

The recommended sample volume for 0.2 ml tubes or 96-well plates is 5-100ul. If using

the heated lid with full skirted 96 well plates it is highly recommended to use a Silicone

Compression Mat to assist in placing even pressure on the plates.

Note: To avoid deformation of the sample tubes or Strips, it’s important to load at least

one tube in each of the four corners and at least four tubes in the center of the block, this

will distribute the pressure evenly throughout the surface.

Page 16

12

User Folder Management

After the unit is turned on, the initial screen which contains software version and

manufacturer’s name will show up for 10 seconds and then enter User Folder screen.

Pressing any key will go to User Folder screen immediately.

A sample screen is shown below.

Users can use the function keys(F1~F4) above to view, create, edit and delete the User

folders. F5:SYSTEM is used for system settings.

Note:

1. The [ PRESET ] and [ PUBLIC ] folders are pre-registered folders which require no

Personal Identification Number(PIN) to enter.

2. The [ PRESET ] folder includes some frequently-used Protocols defined by vendor,

while the [ PUBLIC ] folder is open to all users.

4.1 Viewing a User Folder

All Protocols are stored inside the User folders. Use directional arrow keys to select a

User folder. Press F1:OPEN to view the names of all Protocols inside the selected folder.

To view the contents of the User, will require you to enter the 4-digit Personal

F 1

F 2

F 3

F 4

F 5

OOPPEENN

NNEEWW

EEDDIITT

UUSSEERR FFOOLLDDEERRSS 88//2211//22001111 1111::0000

PPRREESSEETT

PPUUBBLLIICC

LLaabb

MMiikkee

SSuussaann

JJeeffff

SSeelleecctt aa uusseerr ffoollddeerr

SSYYSSTTEEMM

DDEELLEETTEE

Directory

User Folder Name

Status Bar

Date & Time

Page 17

Cleaver Scientific Thermal Cycler

13

Identification Number(PIN) as shown in the screen below. After the PIN is entered,

press F1:ACCEPT or ENTER key to confirm the PIN. To run a Protocol, please refer

Section 5.1.

4.2 Creating a New User Folder

Under User Folder screen, press F2:NEW can create a new User folder. After entering the

new User name, press F1:ACCEPT to accept the new User folder name. The GTS96 will

prompt you to enter a 4 digit PIN. Pressing F1:ACCEPT will save the new folder name

and PIN.

Max. User folder name: 12 characters

Max. User folder no.: 50

4.3 Editing a User Folder

Under the User Folder screen, use directional arrow keys to select a User folder. Press

F3:EDIT to edit the User name. A PIN is required to edit the User folder name. After

editing the User folder name, press F1:ACCEPT to save the edited User name.

4.4 Deleting a User Folder

Use directional arrow keys to select a User folder. Press F4:DELETE to delete the

AACCCCEEPPTT

UUSSEERR FFOOLLDDEERRSS>>MMiikkee 88//2211//22001111 1111::0000

EEnntteerr PPIINN aanndd pprreessss AACCCCEEPPTT,, PPrreessss AACCCCEEPPTT iiff nnoott

PPIINN pprrootteecctteedd.

.

EEXXIITT

PPlleeaassee eenntteerr PPIINN::

F 1

F 2

F 3

F 4

F 5

Page 18

14

selected User folder. You are required to enter the PIN and press F1:ACCEPT or

ENTER . The screen will prompt “Do you want to delete”. Press F1:ACCEPT to

confirm the deletion. Press F5:EXIT to abort the deletion.

Note: User folders which contain any protocols can’t be deleted except by administrator.

Page 19

Cleaver Scientific Thermal Cycler

15

Protocol Management

After entering the selected User Folder, users can press F1~F4 keys to Run,

New(Create), Edit(View) and Delete a selected Protocol as shown below.

5.1 Running a Protocol

1. Press F1:RUN to run the selected Protocol under the User folder screen. The screen

will show as below.

MMiikkee>>PPRROOTTOOCCOOLL 88//2211//22001111 1111::0000

PPlleeaassee sseelleecctt aa pprroottooccooll aanndd pprreessss EENNTTEERR

TToouucchhddoowwnn 0077//2255//1111 0099::1100::2200

PPRROOTTOOCCOOLL DDAATTEE TTIIMMEE

LLaabb 0077//2288//1111 0033::2255::3300

RRUUNN

NNEEWW

EEDDIITT

EEXXIITT

DDEELLEETTEE

F 1

F 2

F 3

F 4

F 5

SSTTAARRTT

MMiikkee>>LLaabb>>RRUUNN 88//2211//22001111 1111::0000

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

11::TTuubbee CCoonnttrrooll 22::BBlloocckk CCoonnttrrooll

EEXXIITT

9944..00 9944..00 5555..00 7722..00 7722..0000 44..0000

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

F 1

F 2

F 3

F 4

F 5

Page 20

16

2. Users are required to select a Temperature Control Mode before running the Protocol.

Mode 1(Tube Control): Enable system operation with simulated temperature

control. If Mode 1 is selected, users are required to input the sample volume :

5-100ul. In this mode, temperature control is based on Block temperature and

an algorithm which estimates sample temperature based on the block

temperature and the sample volume. Recommended for more accurate

temperature control.

Mode 2(Block Control): Enable system operation with maximum temperature

control based on the actual block temperature. Recommended for normal

operation.

3. Press F1:START to run the Protocol.

Note:

1. The highlighted temperature (Temp) value represents the current block temperature

during Protocol running. The highlighted time (Time) value below represents the

remaining running time in the temperature segment. Once the countdown is completed,

the highlighted section will continue to move to the next temperature or cycle segment

and start counting down the time.

2. The Lid temperature will flash on the status bar when the Protocol starts and remain

on until it reaches 50ºC. When the lid reaches 50°C “HOT!” will appear in the right

hand corner and remain until the temperature falls below 40°C The sample block will

start to heat up when the lid temperature reaches its set temperature.

5.2 Pause a Protocol

During running of the Protocol, press F1:PAUSE will pause the running Protocol for 10

minutes. The Protocol will continue after the Pause stops. The Protocol won’t be paused

until set temperature is achieved. To resume running the Protocol, press F1:RESUME.

5.3 Viewing Running Protocol Information

Press F2:INFO to view the Protocol information screen as shown below during operation.

Press F5:RETURN to return the running Protocol screen. The Protocol information

screen will return to the running Protocol screen in 3 minutes, if F5:RETURN is not

pressed.

Page 21

Cleaver Scientific Thermal Cycler

17

5.4 Terminating a Protocol

1. Press F5:EXIT or STOP key in the bottom-left side of the Alphanumeric keypad to

terminate a running protocol.

2. The display will show message “Do you want to abort?” as below.

3. Press F1:YES or STOP key again to terminate the Protocol. Press F5:NO to return to

the running Protocol.

4. The display screen will return to Protocol screen.

LLaabb>>RRUUNN>>SSTTAARRTT 88//2211//22001111 1133::0000

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

RREETTUURRNN

94.0 94.0 55.0 72.0 72.00 4.00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

RRuunn ssttaarrtteedd:: 0088//2211//1111 1122::2200::5500

RRuunn wwiillll eenndd:: 0088//2211//1111 1133::5500::2200

F 1

F 2

F 3

F 4

F 5

YYEESS

MMiikkee>>LLaabb>>RRUUNN>>SSTTAARRTT 88//2211//22001111 1111::0000

EEssttiimmaatteedd RReemmaaiinniinngg:: 0011::2200

NNOO

9944..00 9944..00 5555..00 7722..00 7722..0000 44..0000

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

DDoo yyoouu wwaanntt ttoo aabboorrtt??

F 1

F 2

F 3

F 4

F 5

Page 22

18

Creating a New Protocol

A new Protocol can be created by going to the User Folder and selecting and editing a

basic Protocol format, and then assigning it a new name.

1. Select User name on User screen. Press F1:OPEN or ENTER button to enter User

Folder.

2. Key in PIN to enter the User’s folder.

3. Press F2:NEW to create a new Protocol by using a standard template, shown below.

Note: Users can create a new Protocol under Public folder without a PIN. Users can edit

a new Protocol inside Preset folder, BUT can not save these changes to the original

protocol settings.

6.1 Changing Temperature/Time Values

1. Press directional arrow keys to move cursor to the temperature or time settings

required to be changed.

2. Enter your desired values and press ENTER or to move cursor to other values to save

the settings.

MMiikkee>>PPRROOTTOOCCOOLL>>NNEEWW 88//2211//22001111 1111::0000

9944..00 9944..00 5555..00 7722..00 7722..0000 44..0000

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

SSAAVVEE

EEXXIITT

IINNSSEERRTT

DDEELLEETTEE

AADDVV..

3 Tmp. Segments

1 Tmp. Segment

Tmp./ Time Values

F 1

F 2

F 3

F 4

F 5

Page 23

Cleaver Scientific Thermal Cycler

19

The temperature and time ranges are shown below.

Temperature range: 4.0 to 99.9

◦

◦

C

Time range (minute: second): 00:01 to 99:59 ( 99:99 = ∞ )

6.2 Inserting/Deleting Temperature Segment

Temperature Segment can be inserted or deleted by selecting F2:INSERT or

F3:DELETE key. The inserted or deleted temperature segment is dependent upon the

location on the temperature segment where the cursor is positioned. If the cursor is

positioned inside the first multi-temperature/time segment, pressing F2/F3 will

insert/delete the whole Multi-Temperature Cycle. If the cursor is located in any other

Multi-Temperature/Time segment only the selected segment will be inserted/deleted.

6.3 Changing Temperature Segment Count (Temp)

and Cycle Count (Cyc)

The Temperature Segment Count(Temp) can be modified by entering a new value (1 to 20)

in the first Temperature position and pressing ENTER. When the Temperature Segment

Count is larger than one, the temperature Cycle Count (Cyc) will appear. The

Multi-Temperature Segment will cycle during this segment. The maximum temperature

segment per protocol is 12 segments. The temperature segment count and cycle count

ranges are shown below.

Temperature Segment Count(Temp.) range: 1 to 20

Cycle Count(Cyc) range: 1 to 99

6.4 Advanced Settings

Users can set up the following advanced functions: 1) Optimization, 2)

Temperature/Time Increment/Decrement, 3) Pause,.

F4:ADVANCE button, is used to enter these settings. The screen below will be

displayed.

Page 24

20

6.4.1 Optimization Temperature Setting

1. To enter an Optimization Temperature setting, place your cursor on the desired

Temperature Segment. Select F2:OPTI. to enter the screen below.

2. The temperatures of all BLOCK offset are based on BLOCK#1. If press F2:AUTO

to set gradient temperature, each BLOCK will add 4◦C automatically based on the

preceding BLOCK. Prior to press F3:AVG. users need to enter BLOCK#6 setting,

and the screen will show the calculated temperature gradient from BLOCK#1 to

BLOCK#6 as show in Figure 10. This reflects the variation of the temperature from

the BLOCK#1 (coolest) to the BLOCK#6 (hottest).

3. There are specially function in the optimization temperature setting. All temperatures

are based on BLOCK#1 and users can move the cursor to press any higher

temperature (Range:0.1~24.0◦C) on BLOCK#2 to BLOCK#6.

4. Press F5:EXIT to confirm the settings. Press F1:OFF to re-enter the settings. A

capital letter and High-temperature value; “G70.0”, will appear on the Temperature

Segment graph and Low-temperature value will be shown on the Temp value of the

section.

To remove the Optimization Temperature setting, place your cursor in the same

temperature segment with “G ” Gradient Temperature symbol. Press F2:OPTI. again.

The screen will show each BLOCK temperature settings. Press F1:OFF to clear the

Optimization Temperature setting. Press F5:EXIT will delete the Gradient Temperature

setting and its symbol.

MMiikkee>>PPRROOTTOOCCOOLL>>NNEEWW>>AADDVV.. 88//2211//22001111 1111::0000

9944..00 9944..00 5555..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp

EEnntteerr ddeessiirreedd tteemmpp,, ttiimmee oorr nnuummbbeerr..

F 1

F 2

F 3

F 4

F 5

EEXXIITT

OOPPTTII..

IINNCCRREE..

PPAAUUSSEE

Page 25

Cleaver Scientific Thermal Cycler

21

Figure 10. Block layout of 96-well model

The Optimization temperature ranges are shown below.

Temperature setting range: 30.0 to 99.0 ◦C

Temperature difference: 0.1 to 24.0 ◦C

MMiikkee>>PPRROOTTOOCCOOLL>>NNEEWW>>OOPPTTII.. 88//2211//22001111 1111::0000

BBlloocckk

TTeemmpp.

.

EEXXIITT

AAUUTTOO

BBlloocckk

TTeemmpp.

.

##11

50.0

AAllll OOffffsseett iiss bbaassee oonn BBLLOOCCKK ##11

##22

54.0

##33

58.0

##44

62.0

##55

66.0

##66

70.0

OOFFFF

AAVVGG..

F 1

F 2

F 3

F 4

F 5

BLOCK#1 BLOCK#2 BLOCK#3

BLOCK#4 BLOCK#5 BLOCK#6

Page 26

22

6.4.2 Incremental/Decremental Temperature and Time

Settings

To increase or decrease the dwell time or temperature after each repeat you must have

more than one cycle repeat. i.e. 55ºC and a dwell time 40 seconds, you could decrement

the second step by 5 seconds the second step would be 55ºC and a dwell time of 35

seconds.

1. Place the cursor at the Temperature or Time values. Press F3:INCRE.

2. To select increment/decremental values. The screen will ask to input the increment

values. Press F3: + or F4: - to choose increment or decrement.

3. Enter your desired values and press ENTER. The graph will show the

increment/decrement values.

4. Press F1:ACCEPT to accept the values or F2:CLEAR to re-enter the values.

To remove the Incremental/Decremental Temperature and Time settings, place the cursor

in the temperature segment with “Incremental/Decremental Temperature and Time

values”. Select F2:CLEAR to clear the values. Select F1:ACCEPT will remove the

incremental/ Decremental Temperature setting and its symbol.

Temperature Increment

Max. Temperature incremental value: +/- 9.9 ◦C

Max. Time incremental value (minute:second): +/- 9:59

BBBBBB>>PPRROOTTOOCCOOLL>>NNEEWW>>IINNCCRREE.. 88//2211//22001111 1133::0000

9944..00 9944..00 5555..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp

EEXXIITT

CCLLEEAARR

++ --

TTeemmppeerraattuurree IInnccrreemmeenntt::

++ 00..0

0

F 1

F 2

F 3

F 4

F 5

Page 27

Cleaver Scientific Thermal Cycler

23

Note:

1. Temperature limits 4.0ºC to 99.9ºC. DO NOT exceed.

2. Only Multi-cycle segments will have incremental/ decremental time or temperature

function.

Time Increment

6.4.3 Pause Setting

Position your cursor on desired temperature segment. Press F4:PAUSE to add a pause

action during operation. The “Pause” will appear on the Temperature Segment graph.

The pause will last for 10 minutes, then the Protocol will resume the operation.

To remove the Pause setting, place the cursor under “P.” Pause symbol. Press F4:PAUSE

again will remove the Pause setting and its symbol.

6.5 Saving a Protocol

After all settings are entered, press F1:SAVE will store the protocol. Screen will

Prompt “Please enter protocol name” A Protocol name is required to be entered.

Max. Protocol name: 12 characters

BBBBBB>>NNEEWW>>IINNCCRREE.. 88//2211//22001111 1133::0000

9944..00 9944..00 5555..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp

EEXXIITT

CCLLEEAARR

++

--

TTiimmee IInnccrreemmeenntt:: ++

00::000

0

F 1

F 2

F 3

F 4

F 5

Page 28

24

Editing (Viewing) a Protocol

An editing Protocol can be saved under a new name (newly created Protocol) or under the

same name (edited Protocol).

Under the User’s Folder, choose the Protocol to be edited. Select F3:EDIT to edit the

selected Protocol. This displays the existing Protocol and enables editing of the

temperature segment and numerical values as shown below.

Please refer Chapter 6 Creating a New Protocol to edit the temperature segment and

numerical values, and other advanced functions. Press F1:SAVE to save the edited

Protocol under the original name or F2:SAVE A to as a new protocol.

Deleting a Protocol

1. An existing Protocol can be deleted under a User’s Folder.

2. Under the User’s Folder screen, choose a Protocol. Select F4:DELETE to delete the

selected Protocol.

3. If F4:DELETE is selected the screen will prompt you “Are you sure you want to

delete?” Press F1:YES to confirm the deletion. Press F5:NO to abort the deletion.

SSAAVVEE

AA>>MMiikkee>>EEDDIITT 88//2211//22001111 1111::0000

MMaaxxiimmuumm:: 1122 cchhaarraacctteerrss

EEXXIITT

PPrrooggrraamm nnaammee::AA

SSAAVVEEAASS

CCLLEEAARR

KKeeyy00((00++==<<>>&&(())%%))

KKeeyy11((11..,,--??’’##::;;//))

F 1

F 2

F 3

F 4

F 5

Page 29

Cleaver Scientific Thermal Cycler

25

Note: Protocols in the Preset Protocols Folder can’t be deleted, while Protocols in the

Public Folder can be deleted by any user if not password protected.

System Setup

System Setup contains 6 functions:

1. Data Log: contains the history of the latest-run Protocol.

2. Date & Time: Users can change the Date and Time settings.

3. Lid Temperature: Users can choose the preferred lid temperature as default setting

during running a Protocol.

4. Beeper: Users can turn on/off the audible beep.

5. Administrator: Users can delete unwanted Usernames and their Protocols.

6. Service Mode: is reserved for Service engineers.

7. Ramping Speed: Users can choose the High Ramping Speed or Low Ramping

Speed.

8. Tm Calculator: Press A, T, C, and G number of sequence, then users can get the

Tm value.

MMIIKKEE>>PPRROOTTOOCCOOLL 88//2211//22001111 1111::0000

AArree yyoouu ssuurree yyoouu wwaanntt ttoo ddeelleettee??

TToouucchhddoowwnn 0077//2255//1111 0099::1100::2200

PPRROOTTOOCCOOLL DDAATTEE TTIIMMEE

LLaabb 0077//2288//1111 0033::2255::3300

YYEESS

NNOO

F 1

F 2

F 3

F 4

F 5

Page 30

26

9.1 Data Log

The Data Log records a log of activity for the most recently run Protocol. Executing a

new Protocol updates the history log by overwriting previous log. To export log to a PC a

Hyper Terminal communication protocol must be installed. Hyper Terminal

communication protocol comes free with Windows.

Please refer Appendix D: Hyper Terminal and USB Driver Setup.

SSYYSSTTEEMM>>DDaattaa LLoogg 88//2211//22001111 1111::0000

FFOOLLDDEERR:: MMiikkee

PPRROOTTOOCCOOLL:: LLaabb

TTuubbee CCoonnttrrooll,, VVoolluummee:: 5500 uull

PPrroottooccooll ccoommpplleetteedd ssuucccceessssffuullllyy..

RRuunn :: 1133::2200::1100 ttoo 1144::2255::0000

EExxiitt

PPCC

F 1

F 2

F 3

F 4

F 5

F 1

F 2

F 3

F 4

F 5

SSEELLEECCTT

SSYYSSTTEEMM 88//2211//22001111 1111::0000

DDaattaa LLoogg

DDaattee&&TTiimmee

LLiidd TTeemmppeerraattuurree

BBeeeeppeerr

AAddmmiinniissttrraattoorr

SSeerrvviiccee MMooddee

RRaammppiinngg SSppeeeedd

TTmm CCaallccuullaattoorr

PPrreessss EEnntteerr oorr FF11 ttoo sseelleecctt yyoouurr SSyysstteemm..

EEXXIITT

Page 31

Cleaver Scientific Thermal Cycler

27

9.2 Date & Time

Users can change the date type, default date and time of this unit by selecting Date

&Time screen as shown below under SYSTEM screen. Please remember to press

F1:ACCEPT to store your settings.

9.3 Lid Temperature

Users can change the temperature of lid of this unit by selecting Lid Temperature screen

as shown below under SYSTEM screen. Please remember to press F1:ACCEPT to store

your settings. Two temperature segments: 60~65 ◦C and 100~115 ◦C are available.

AACCCCEEPPTT

SSYYSSTTEEMM>>DDAATTEE&&TTIIMMEE 88//2211//22001111 1111::0000

DDaattaa TTYYPPEE:: 22

((11.. YY//MM//DD 22..MM//DD//YY 33..DD//MM//YY))

DDeeffaauulltt DDaattee :: 0088//2211//1111

DDeeffaauulltt TTiimmee :: 1111::0000::3333

PPrreessss FF11 ttoo ssaavvee yyoouurr sseettttiinnggss

EEXXIITT

F 1

F 2

F 3

F 4

F 5

AACCCCEEPPTT

SSYYSSTTEEMM>>LLIIDD TTEEMMPPEERRAATTUURREE 88//2211//22001111 1111::0000

LLiidd TTeemmppeerraattuurree FFuunnccttiioonn:: 11

((11::OONN 22::OOFFFF))

LLiidd TTeemmppeerraattuurree:: 110055

◦

◦

CC

((6600----6655 )),,((110000----111155)

)

◦

◦

CC

PPrreessss FF11 ttoo ssaavvee yyoouurr sseettttiinnggss

EEXXIITT

F 1

F 2

F 3

F 4

F 5

Page 32

28

9.4 Beeper

Users can turn ON or OFF the sound of this unit by selecting the Beeper screen as shown

below under SYSTEM screen. Please remember to press F1:ACCEPT to store your

settings.

9.5 Administrator

The password of Administrator is “9610”. The Administrator of this unit has rights to

delete any User Folder and any Protocols inside a User’s Folder.

9.6 Service Mode

Only authorized service personnel have the password to enter Service Mode and perform

necessary maintenance and repairs.

9.7 Ramping Speed

Users can choose the Ramping Speed. High Ramping Speed heating rate about 4◦C/sec

and cooling rate about 3◦C/sec. Low Ramping Speed heating rate about 3◦C/sec and

cooling rate about 2◦C/sec. Please remember to press F1:SAVE to store your settings.

AACCCCEEPPTT

SSYYSSTTEEMM>>BBEEEEPPEERR 88//2211//22001111 1111::0000

BBeeeeppeerr FFuunnccttiioonn:: 22

((11::OONN 22::OOFFFF))

PPrreessss FF11 ttoo ssaavvee yyoouurr sseettttiinnggss

EEXXIITT

F 1

F 2

F 3

F 4

F 5

Page 33

Cleaver Scientific Thermal Cycler

29

9.8 Tm Calculator

Users can press the number of the bases of A, T, C and G in the sequence, then press

F1:RUN to get the Tm value of the sequence.

SSAAVVEE

SSYYSSTTEEMM>>RRAAMMPPIINNGG SSPPEEEEDD 88//2211//22001111 1111::0000

RRaammppiinngg SSppeeeedd:: 11

11 :: HHiigghh RRaammppiinngg SSppeeeedd

22 :: LLooww RRaammppiinngg SSppeeeedd

PPrreessss FF11 ttoo ssaavvee yyoouurr sseettttiinnggss

EEXXIITT

F 1

F 2

F 3

F 4

F 5

RRUUNN

SSYYSSTTEEMM>>TTMM CCAALLCCUULLAATTOORR 88//2211//22001111 1111::0000

AA == 00

TT == 00

CC == 00

GG == 00

PPrreessss FF11 ttoo CCaallccuullaattee

EEXXIITT

F 1

F 2

F 3

F 4

F 5

Page 34

30

Maintenance and Troubleshooting

10.1 Cleaning the unit

Please ensure that no liquid is spilled onto or into the unit. In addition, periodically wipe

it clean of dust and other residue that comes with normal operation of the unit. Use a soft,

lint-free cloth and deionized water. Air vents should be vacuumed to remove dust.

10.2 Cleaning the heated lid

Make sure the GTS96 is unplugged and cooled down. To clean the heated slide the lid

back on the tracks until the front black pins align with the two slots, taking care that the

rolleiflex cable is clear. Lift the lid from the front, (be careful of sharp edges) and flip up.

Use mild detergents to clean material from the lid. A Kimwipe™ dipped in 70% ethanol

will help remove and residue from sealing tape. Make sure the lid is dry prior to

lowering it into the tracks. Once the lid in secure in the tracks make sure the lid easily

slides forward.

10.3 Replacing a Fuse

The fuse is located in the power socket module, just below the power connector. If the

unit does not turn on when the power switch is turned on, then replace the fuse.

To replace the fuse:

1. Disconnect the power cord from the unit.

2. Remove the fuse drawer with a small-blade screwdriver.

3. Pull the fuse out of the fuse socket and replace the fuses with one having the

correct current rating.

4. For 100V-120V operation: Use 7.0A, 5 x 20mm, Glass Tube.

5. For 220 V- 240 V operation: Use 3.15A, 5 x 20 mm, Glass Tube.

6. Reinsert fuse into the fuse socket. Reinsert the fuse drawer.

10.4 Changing the Thermal block

1. Slide the lid to the furthest point back.

2. Remove the two plastic plugs and two screws holding the face plate.

3. Flip the face plate forward to gain access to the block.

4. Remove the two set screws holding the heating block.

5. Gently slide the Thermal block forward, once clear of the frame remove it from

Page 35

Cleaver Scientific Thermal Cycler

31

the unit.

6. Slide the new block into place and connect the plug.

7. Gently slide the block until the two screw holes are lined up.

8. Replace the two screws and plugs.

9. Shut the face panel and secure it with two screws.

Troubleshooting

Problem

Cause

Action

The display is off even when

power is switched on.

1. Power is not reaching the

system.

2. Power cord is not

plugged into the socket

properly.

3. Power fuse is blown out.

4. Block fuse is blown out.

1. Check power source

voltage.

2. Reconnect the power

cord.

3. Replace the power fuse.

4. Return the unit for

service.

Can’t reach 4C.

1. Operating temperature

environment may be

unsuitable.

2. Electronic cooling

element may be damaged

or aged.

1. Operate the unit in a

environment temperature

between 15 to 30 C.

2. Return the unit for

service.

Cycle time is too long

1. Operating environment

temperature may be

unsuitable.

2. Electronic cooling

element may be damaged

or aged.

3. Faulty temp. sensor.

1. Operate the system in a

temperature environment

between 15 to 30 C.

2. Return the unit for

service.

3. Return the unit for

service.

Lid heater does not work.

1. Lid heater is set off.

2. Lid sensor problem

1. Check Lid Temperature

setting in System Mode.

2. Return the unit for

service.

No key entry sound.

1. Sound may currently be

set off.

2. Faulty keys or keypad

wiring.

1. Check Beeper setting in

System Mode.

2. Return the unit for

service.

The display goes off.

1. Faulty backlight.

1. Check the LCD contrast.

Page 36

32

2. Faulty LCD panel

2. Return the unit for

service.

Display is too dark or light

Backlight brightness is not

adjusted properly.

Adjust Display Brightness

Potentiometer.

Lid will not close.

1. Foreign matter, between

lid heater and sample

block.

2. Faulty lid lock

mechanism.

Remove the foreign object or

matter.

Error message appears.

Refer to list of error

messages below.

Check the nature of the error

and take the suggested

actions.

11.1 Error Messages

Message

Cause

Action

HEATER ERROR!

⚫ Lid temperature sensor problem.

⚫ Lid temperature exceeds 132 °C.

⚫ Lid temperature can’t reach the set

temperature.

Reboot the unit.

BLOCK ERROR!

⚫ Block temperature sensor or heating

element problems.

⚫ The unit can’t reach the set

temperature, because the room

temperature is too high.

⚫ The block temperature exceeds 108

°C.

Cool down the room

temperature. Reboot the unit.

ROOM ERROR!

⚫ Room temperature sensor problem.

Reboot the unit

ROOM > 30 °C

⚫ The room temperature exceeds 30

°C.

⚫ Two running units are too close to

each other.

Cool down the room

temperature. Reboot the unit.

Remove any objects

blocking the vents.

Keep two running units at

least 30cm from each other.

Page 37

Cleaver Scientific Thermal Cycler

33

Appendix A: Technical specifications

Model Name

TC9610/TC9610-230V

Sample Capacity

0.2ml x 96 tubes

Temperature Ranges

4 ~ 99.9 C

Temperature Accuracy

+/- 0.5C ( 30 to 99.9 C)

Temperature Uniformity

+/- 0.5C

Max. Temp. Increment/Decrement Rate

4C / 3 C

Gradient Temperature

30 ~ 99 C (Max. temp. difference: 24 C)

Max. Lid Temperature

60~65/ 100~115 C

Protocol Capacity

200 sets

Operating Temperature

15 ~ 30 C

Operating Humidity

20 ~ 80% RH

Networking

1 x RS-232, 1 x USB

Power Supply

100 to 240V AC, 50/60 Hz, 750VA

Dimensions (W x D x H)

24 x 25 x 42cm

Weight (Net)

9 Kg

Page 38

34

Appendix B: Protocols in Default Folder

⚫ 2-Step

⚫ Gradient

SSTTAARRTT

PPRREESSEETT>>22--SSTTEEPP>>RRUUNN 88//2211//22001111 1111::0000

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

11::TTuubbee CCoonnttrrooll 22::BBlloocckk CCoonnttrrooll

EEXXIITT

9944..00 9944..00 5555..00 5555..0000 44..0000

55::0000 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 22 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

F 1

F 2

F 3

F 4

F 5

PPRREESSEETT>>GGRRAADDIIEENNTT>>RRUUNN 88//2211//22001111 1111::0000

9944..00 9944..00 5555..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2255 CCyycc 22 TTmmpp 11 CCyycc

SSTTAARRTT

EEXXIITT

G.

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

11::TTuubbee CCoonnttrrooll 22::BBlloocckk CCoonnttrrooll

F 1

F 2

F 3

F 4

F 5

Page 39

Cleaver Scientific Thermal Cycler

35

⚫ Touch down

⚫ Time Increment

PPRREESSEETT>>TToouucchh ddoo..>>RRUUNN 22001111//88//2211 1133::0000

9955..00 9955..00 6655..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2200 CCyycc 22 TTmmpp

SSTTAARRTT

EEXXIITT

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

11::TTuubbee CCoonnttrrooll 22::BBlloocckk CCoonnttrrooll

-- 00..55

F 1

F 2

F 3

F 4

F 5

PPRREESSEETT>>TTiimmee iinncc..>>RRUUNN 22001111//88//2211 1133::0000

9955..00 9955..00 6655..00 7722..00 7722..00 44..00

55::0000 00::3300 00::3300 00::3300 1100::0000

TTeemmpp

TTiimme

e

11 TTmmpp 33 TTmmpp 2200 CCyycc 22 TTmmpp

SSTTAARRTT

EEXXIITT

MMooddee::11((11--22)) VVoolluummee:: 5500uull((55--110000uull))

11::TTuubbee CCoonnttrrooll 22::BBlloocckk CCoonnttrrooll

-- 00::0055

F 1

F 2

F 3

F 4

F 5

Page 40

36

Cleaver Scientific Ltd.

Unit 41

Somers Road Ind. Est.

Rugby

Warwickshire

CV22 7DH

Declaration of Conformity

Product Name: GTS96 Thermal Cycler

Model Names: TC9610 /TC9610-230

All models comply with the following European standards:

EMC: EN 61326 (Group 1, Class B)

Safety: EN 61010-1 and EN 61010-2-010

To the best of my knowledge and belief, these units conform to these

standards.

Name: Deb Cleaver

Position: Quality Assurance

Issue Date: 2016/08/04

Appendix C: CE Declaration

Page 41

Cleaver Scientific Thermal Cycler

37

Cleaver Scientific Ltd.

Unit 41 Somers Road Industrial Estate

Rugby

Warwickshire

CV22 7DH

Loading...

Loading...