CleaverBrooks Q6-130, Q6-075, Q6-055, Q6-100, Q8-175 Installation Operation & Maintenance

...Page 1

Table Of Contents

ProFire Q

Full Modulation Burner

with UV flame detection

Installation

Operation

Maintenance

Manual Part No. 750-437 07/2019

Page 2

Page 3

Q SERIES

Linkageless Full Modulation Burner with UV Flame Detection

750-00516-000

Manual Number: 750-00437

Revision 07/2019

Information to be filled out by owner

Unit Serial Number:

Date of Installation:

Distributor Information

Name:

Address:

Phone Number:

Copyright © 2019 by Cleaver-Brooks

All rights reserved. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any means

without the prior written consent of Cleaver-Brooks.

Cleaver-Brooks

351 21st Street

Monroe, WI 53566

608-325-3141

cleaverbrooks.com

750-437

Q Series Full Modulation

i

Page 4

Q Series Installation, Operation, and Service Manual

Table of Contents

Preface iv

Specifications v

Dimensions vi

Spare Parts List vii

CHAPTER 1 Introduction 1-1

Description 1-1

Control Panel 1-2

Burner Control and Air Delivery 1-3

Direct Spark System 1-4

Firing Head 1-5

Gas System 1-6

CHAPTER 2 Installation 2-1

Burner Requirements 2-1

Factory and Field Wiring Overview 2-1

Draft Conditions 2-2

Combustion Air Supply 2-2

Combustion Chamber Recommendations 2-2

Firetube Refractory Front Plate Requirements 2-4

Support Bracket Installation 2-6

Gas Piping 2-6

Optional Ducted Combustion Air 2-7

Combustion Air Inlet Orifice Plate Installation 2-8

Installation Checklist 2-9

CHAPTER 3 Operation 3-1

Preparations for Starting 3-1

Burner Sequence Overview 3-2

Gas Pressure Regulator Setup 3-6

Gas Train Leak Test 3-6

Combustion Emissions and Efficiency 3-9

LMV3 Settings 3-10

Test and Set Gas Pressure Switches 3-19

Optional Heat Timer MCF Load Control 3-20

ii 750-437

Q Series Full Modulation

Page 5

CHAPTER 4 Adjustments 4-1

Overview 4-1

Gas System 4-1

CHAPTER 5

CHAPTER 6 Troubleshooting 6-1

Maintenance 5-1

Overview 5-1

Control System 5-2

Impeller 5-2

Firing Head Inspection 5-2

Ignition Electrode 5-3

Flame Scanner 5-3

Firing Rate Controls 5-4

Burner Mounting Inspection 5-4

Gas System 5-4

Electrical System 5-4

Extended Shutdown 5-5

Recommended Maintenance Schedule 5-6

Awareness 6-1

Emergency Shutdown 6-2

Troubleshooting - General 6-3

LMV3 Diagnostics 6-4

Restoring LMV3 Parameters 6-22

Default Settings 6-24

STARTUP/SERVICE REPORT

WARRANTY POLICY

750-437

Q Series Full Modulation

iii

Page 6

PREFACE

It is the responsibility of the owner of this equipment to post and maintain a legible copy of this

Installation, Operation and Maintenance manual while this equipment is in service.

Warning and caution references have been made in this manual and should be adhered to for smooth

operation of the burner.

Warning

!

This symbol precedes information which, if disregarded, may result in injury to the user of the burner or to

others.

Caution

!

This symbol precedes information which, if disregarded, may result in damage to the burner.

NOTE: This symbol precedes information which is vital to the operation or maintenance of the burner.

Model designations are based on the type of fuel(s) to be fired and the amount of furnace pressure to

be overcome. Burner size is based on firing rate (rated input in Btu/hr).

Model Standards Fuel

Q Gas

The equipment must be installed in accordance with applicable local, state, or Provincial Installation

Requirements including the National Electrical Code (NEC) and Associated Insurance Underwriters.

Where applicable, the equipment shall be installed in accordance with the Provincial Installation

Requirements, or in their absence, the Canadian Gas Association (CGA) B149.1 and B149.2 and

Canadian Standard Association (CSA) B140 and B139 (for oil burners) Installation Codes shall

prevail. Authorities having jurisdiction should be consulted before installations are made. Gas burning

equipment shall be connected to flues having sufficient draft at all times to assure safe and proper

operation of the burner.

Q Series burners are designed to burn gas only as defined by ASTM D396-2010 specifications.

iv 750-437

Q Series Full Modulation

Page 7

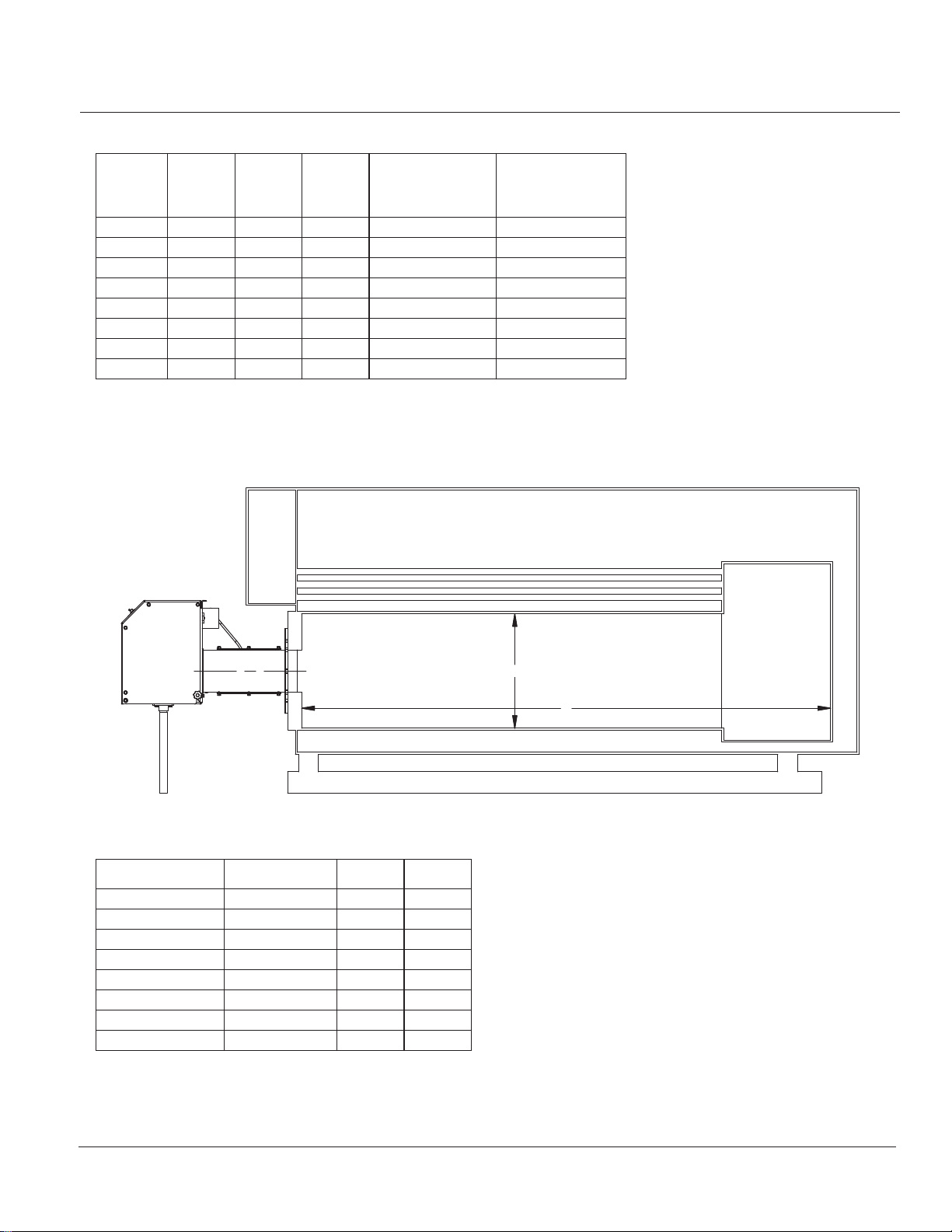

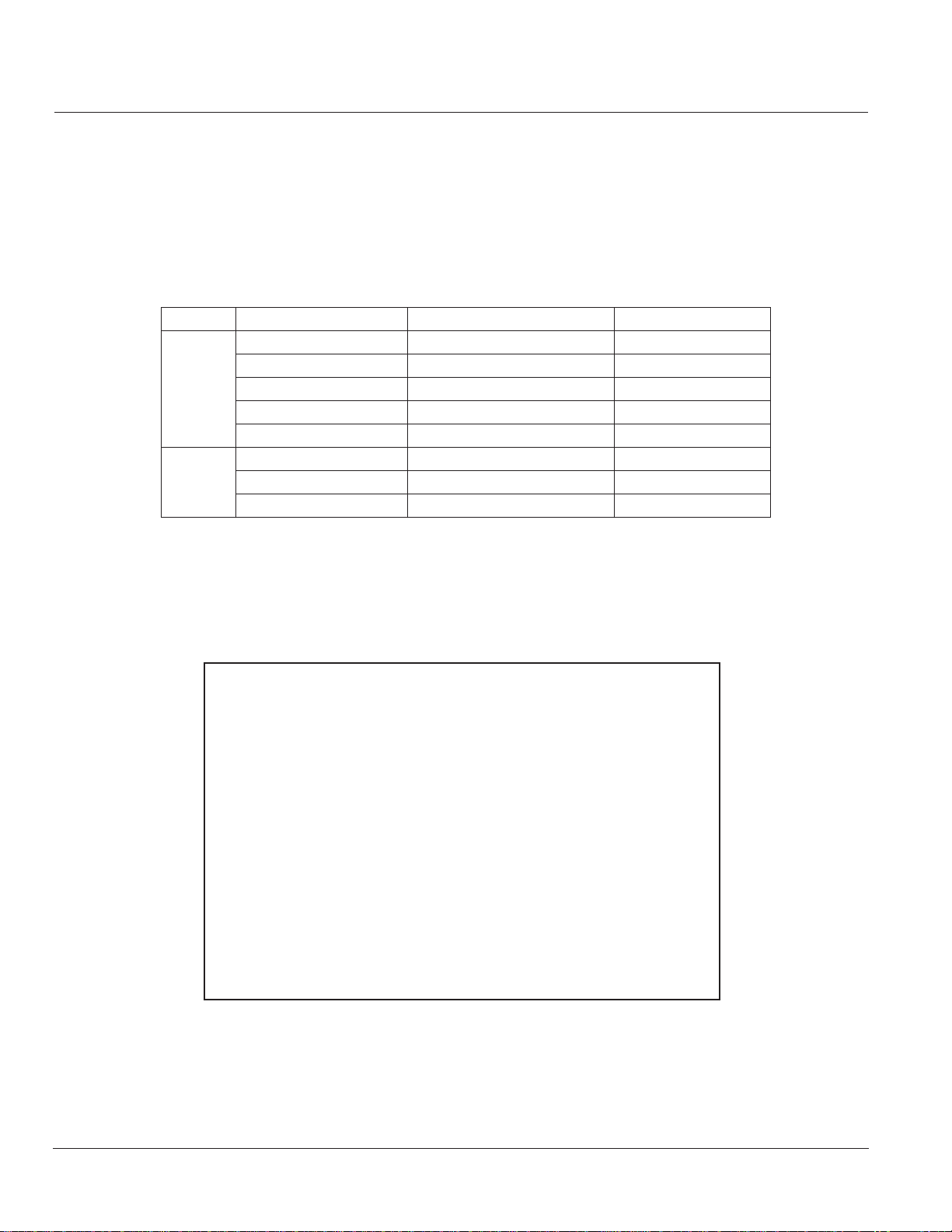

Q Series Full Mod Linkageless - Standard Specifications

Minimum Gas Pressure Required in Inches Water Column, by Gas Train

Burner

Gas Input

Model

Q6-055 550 13 1/2 1.0 1.50 2.10 - - 2.10 - -

Q6-075 750 18 1/2 1.0 1.80 3.60 1.70 - 3.80 2.00 -

Q6-100 1,000 24 1/2 1.0 2.25 6.40 2.90 2.60 6.60 3.40 2.60

Q6-130 1,250 30 1/2 1.0 2.95 10.10 4.20 3.50 10.60 5.20 3.70

Q6-150 1,500 36 1/2 0.75 * 13.60 5.70 4.80 14.20 7.00 5.10

Q8-175 1,750 42 3/4 1.0 3.45 15.50 4.80 3.50 16.30 6.60 3.90

Q8-200 2,000 48 3/4 1.0 3.80 19.80 5.70 4.10 20.80 8.10 4.60

Q8-250 2,500 60 3/4 0.75 * - 8.60 5.90 32.20 12.20 6.80

MBtu/hr

BHP

@80%

Eff.

Blower

Motor HP

Furnace

Pressure

(“w.c.)

Air Inlet

Orifice Size

7

(in.)

1 PSI Inlet Rated UL Trains 10 PSI inlet Rated UL Trains

1.00" 1.50" 2.00" 1.00" 1.50" 2.00"

*Orifice not required

NOTES:

1. Gas input based on natural gas at 1,000 Btu/cu. ft. and 0.60 gravity.

2. For total pressure at manifold, add furnace pressure.

3. Boiler overall efficiency of 80% estimated.

4. Blower wheel and motor HP is based on altitude up to 2,000 ft. above sea level. For higher altitude or 50 Hz.

applications, consult factory.

5. Firing at higher furnace pressures de-rates the burner by approximately 5% per 1/2” of additional pressure. Consult

factory.

6. Blower motor power: 115V / single phase / 60 Hz

7. See spare parts list for orifice plate part numbers.

Pressure Rating and Pipe Size

750-437

Q Series Full Modulation

v

Page 8

12X R

ØN

ØM

E

L

60°6X

30°

45°

90°4X

ØK

F

J

G

H

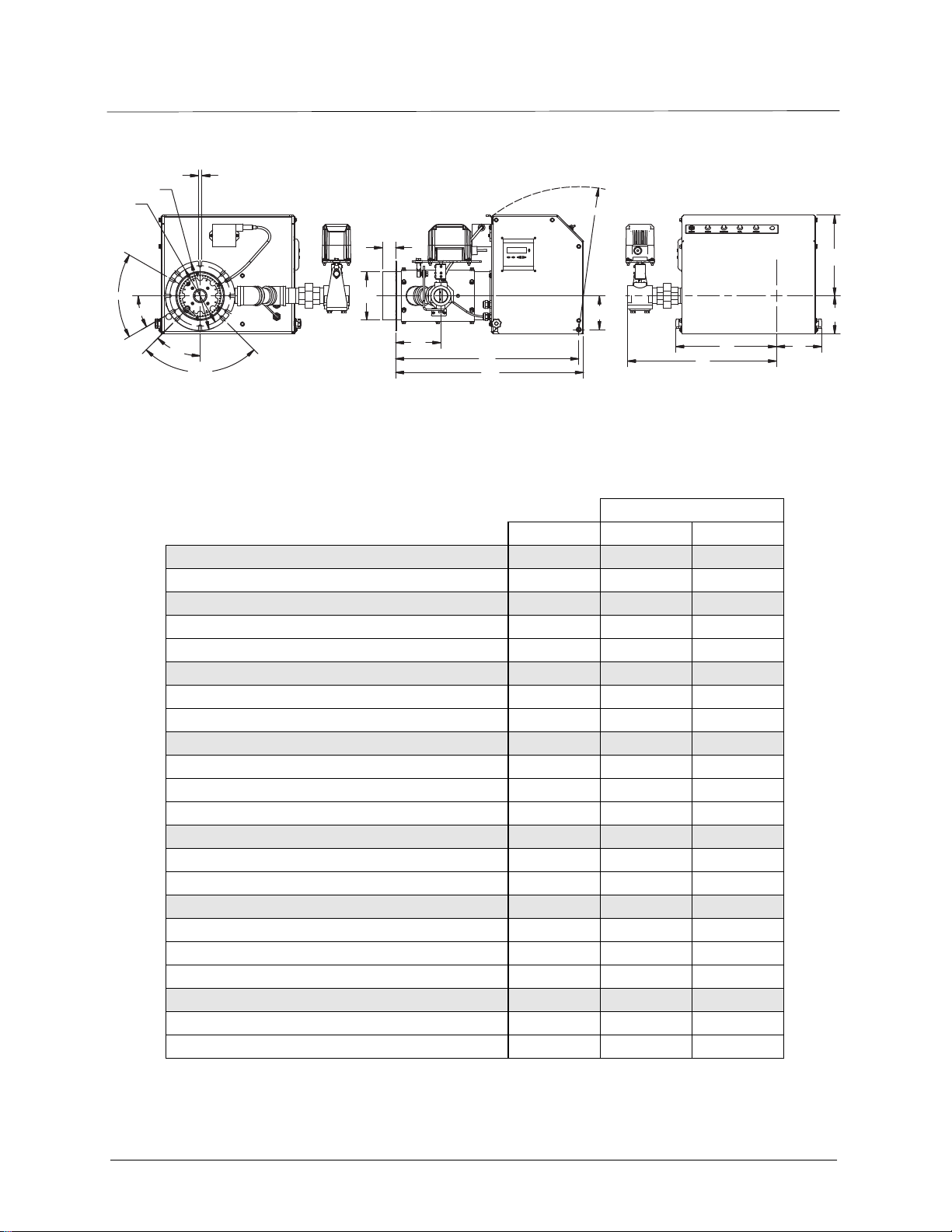

Q Series Full Modulation Linkageless Standard Dimensions

Accompanying dimensions are for layout purposes only.

Burner Model

DIM Q6 Q8

Length in inches

Overall burner length H 26 28 3/4

Width in inches

Center line to left side A 12 1/2 15 5/16

Center line to right side B 5 5/8 6 7/8

Height in inches

Center line to top D 10 11 7/8

Center line to bottom C 4 11/16 4 3/8

Hinge pivot point in inches

Mounting flange to hinge G 25 1/2 28

Hinge swing radius E 17 11/16 20 5/8

Center line to hinge F 4 3/16 3 7/8

Blast tube dimensions in inches

Extension L 3 1/2 3 1/2

Diameter K 6 8

Mounting flange dimensions in inches

Outer diameter of mounting flange N 12 14

Bolt circle diameter M 8 7/8 10 7/8

Mounting flange slot width R 5/8 5/8

Gas inlet dimensions in inches

Center line to main gas inlet P 18 1/2 19 1/2

Mounting flange to main gas inlet J 7 1/8 7 1/8

D

C

A

B

P

vi 750-437

Q Series Full Modulation

Page 9

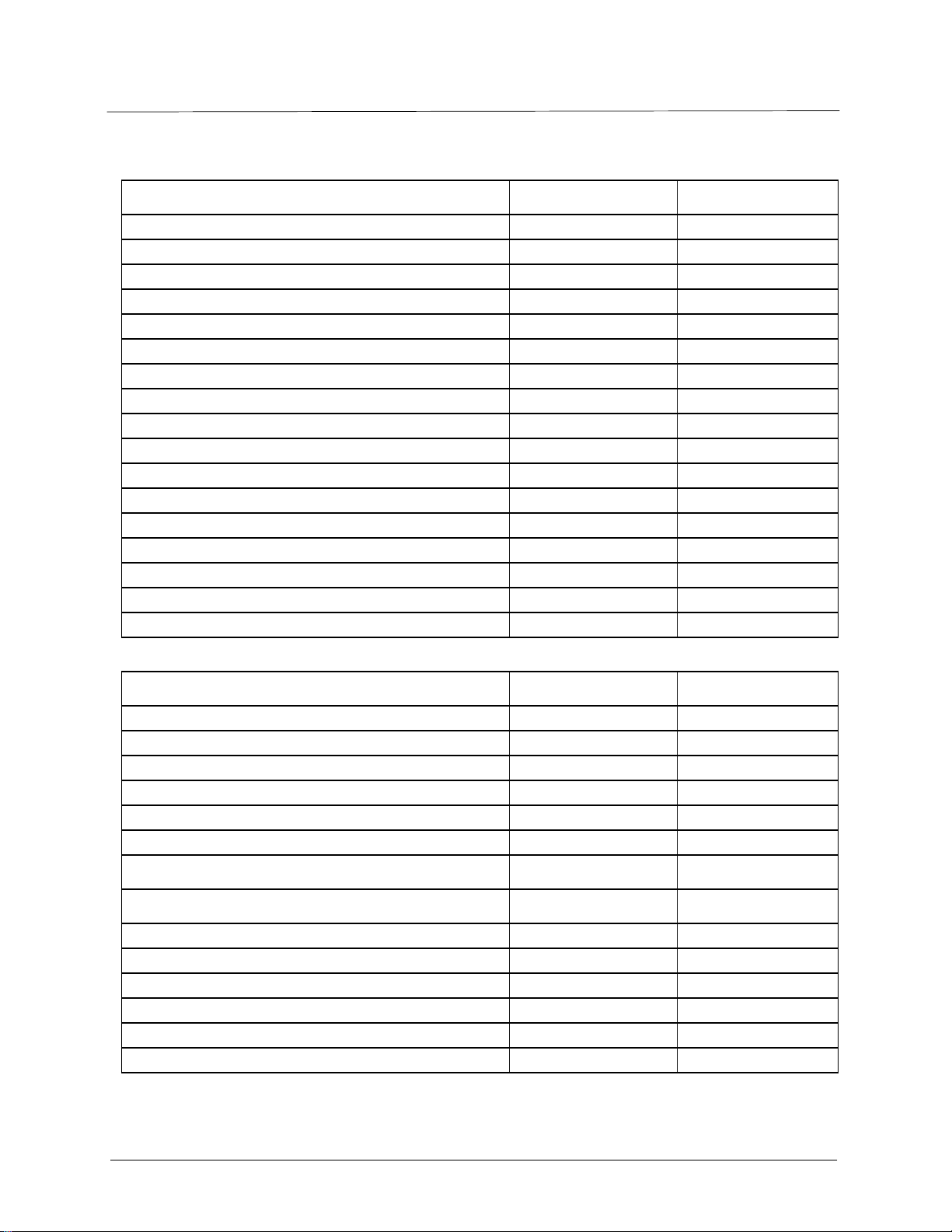

Q Series Spare Parts List

PART DESCRIPTION - COMMON PARTS BURNER SIZE PART NUMBER

Ignition Transformer Q6 & Q8 832-04117-000

Light Indicator, White Q6 & Q8 881-00136

Light Indicator, Red Q6 & Q8 881-00137

Light Indicator, Green Q6 & Q8 881-00138

Light Indicator, Amber Q6 & Q8 881-00139

Air Switch Q6 & Q8 836-01598-000

Electrode Q6 & Q8 435-00694-000

Ignition Cable Q6 & Q8 832-04118-000

Fuse, Blower Motor ATDR 6A Q6 832-01161

Fuse, Blower Motor ATDR 15A Q8 832-01168

Fuse, Control Circuit ATQR 6A Q6 & Q8 832-01210

PART DESCRIPTION - BURNER MODEL PARTS BURNER SIZE PART NUMBER

Baffle Weldment Q6 009-04280-000

Baffle Weldment Q8 009-04282-000

Burner Housing (Blast Tube) Q6 160-01003-000

Burner Housing (Blast Tube) Q8 160-01002-000

Flange Gasket Q6 853-02539-000

Flange Gasket Q8 853-02540-000

Fan/Blower Unit Q6 894-04076-000

Fan/Blower Unit Q8 894-04111-000

Cover Q6 019-02395-000

Cover Q8 019-02398-000

PART DESCRIPTION - CONTROL COMPONENTS BURNER SIZE PART NUMBER

Display, Siemens Q6 & Q8 833-05071-000

Cable, Display Siemens Q6 & Q8 826-00315-000

Controller, Siemens Q6 & Q8 833-09334-000

Valve, Butterfly, 1.5” Full Port Q6 & Q8 940-01254

Actuator, Fuel Valve Q6 & Q8 269-00166-000

Coupling Q6 & Q8 819-00337-000

UV Scanner Q6 & Q8 994-15597-000

750-437

Q Series Full Modulation

vii

Page 10

Q Series Spare Parts List Continued

PART DESCRIPTION - GAS TRAIN COMPONENTS GAS TRAIN OPTION PART NUMBER

Regulator, Maxitrol RV 1 1/2” All Standard Pressure 817-00622

Valve, Gas Diaphragm 1 1/2” All Standard Pressure 940-01090

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 1 1/2” All Standard Pressure 235-00368-000

Ball Valves 1 1/2” All Standard Pressure 941-00127

Regulator, Maxitrol RV 2” All Low Pressure 817-00617

Valve, Gas Diaphragm 2” All Low Pressure 940-01108

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 2” All Low Pressure 235-00369-000

Ball Valves 2” All Low Pressure 941-00128

Regulator, Maxitrol 210 1” All High Pressure 817-00674

Valve, Gas Diaphragm 1” All High Pressure 940-01103

Bleed, Used with Gas Diaphragm Standard on All 940-01373

Valve, Gas Solenoid 1” All High Pressure 940-01191

Ball Valves 1” All High Pressure 941-00594

Gas Pressure Switch, High Ventless Standard on All 817-00977

Gas Pressure Switch, Low Ventless Standard on All 817-00876

PART DESCRIPTION - AIR INLET ORIFICE PLATE BURNER SIZE PART NUMBER

550 MBTU Burner (1.5” diameter) Q6 059-11448-000

750 MBTU Burner (1.8” diameter) Q6 059-11449-000

1000 MBTU Burner (2.25” diameter) Q6 059-11450-000

1300 MBTU Burner (2.95” diameter) Q6 059-11452-000

1750 MBTU Burner (3.45” diameter) Q8 059-11457-000

2000 MBTU Burner (3.8” diameter) Q8 059-11458-000

PART DESCRIPTION - DUCTED AIR INLET PARTS BURNER SIZE PART NUMBER

Instruction Drawing Q6 880-06261-000

Ducted-Air Adapter, 4" ID Q6 001-01680-000

Panel Side Plate With Ducted-Air Adapter Cutout Q6 136-04096-000

Instruction Drawing Q8 880-06262-000

Ducted-Air Adapter, 6" ID Q8 001-01681-000

Panel Side Plate With Ducted-Air Adapter Cutout Q8 136-04097-000

viii 750-437

Q Series Full Modulation

Page 11

CHAPTER 1 Intr oduction

Q series burners are completely assembled, wired, and tested at the factory.

Caution

!

Only factory authorized burner service personnel should start up, adjust, or service this equipment.

The operator must be familiar with the individual functioning of all controls to understand the operations and

procedures described in this manual.

1.1 — Description

Q-series full modulation units are forced-draft, direct-spark ignited, linkage-less burners controlled by an LMV37

programmer. They include safeguard functionality to insure the burner always returns to the ignition light-off

position for startup.

The Q-series modulating burners provide 550 to 2,500 MBTU/hr (~13 to 60 boiler horse power) against

furnace pressures of 0.75" w.c. or less (refer to burner specifications, page v). The Q6 has a 6" diameter firing

head and can fire up to 1,500 MBTU/hr (~36 boiler horse power). The Q8 has an 8" diameter firing head and

can fire up to 2,500 MBTU/hr (~60 boiler horse power). A field-installed air inlet orifice plate is required on Q6

burners firing below 1500 MBTU/hr and Q8 burners firing below 2500 MBTU/hr. See page viii for orifice plate

part numbers.

Q series burners are designed for automatic unattended operation except for periodic inspection and

maintenance. The control panel components require little attention except for occasional cleaning.

750-437

Q Series Full Modulation

1-1

Page 12

Introduction

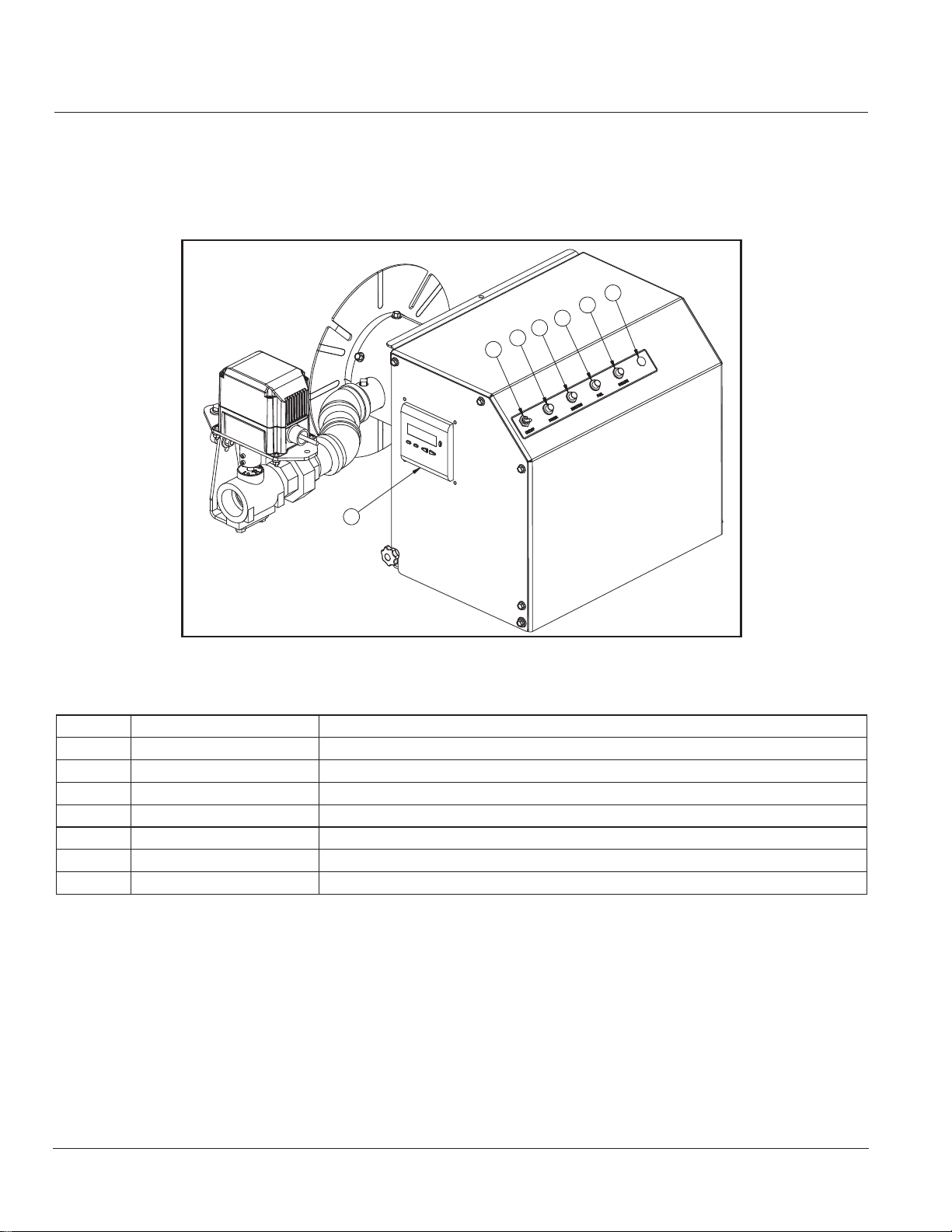

1.2 — Control Panel

The Q burner control panel has the control switch, status indicator lamps and LMV37 remote display mounted

on the panel exterior. The LMV37 control base, power supply, fusing and terminal strips are mounted on a

subbase inside the panel.

6

5

4

3

2

1

7

750-00532-000

FIGURE 1-1. Control Panel

Item Component Details

1 On/Off Control Switch Burner power switch

2 Power Light White lamp; illuminates when the control circuit is powered

3 Ignition Light Amber lamp; illuminates when the ignition transformer is powered

4 Fuel Light Green lamp; illuminates when the main fuel valves are powered

5 Failure Light Red lamp; illuminates when an LMV37 lockout fault occurs

6 Blank Blank lamp port

7 Control Display Control interface and status indicator

1-2

750-437

Q Series Full Modulation

Page 13

Introduction

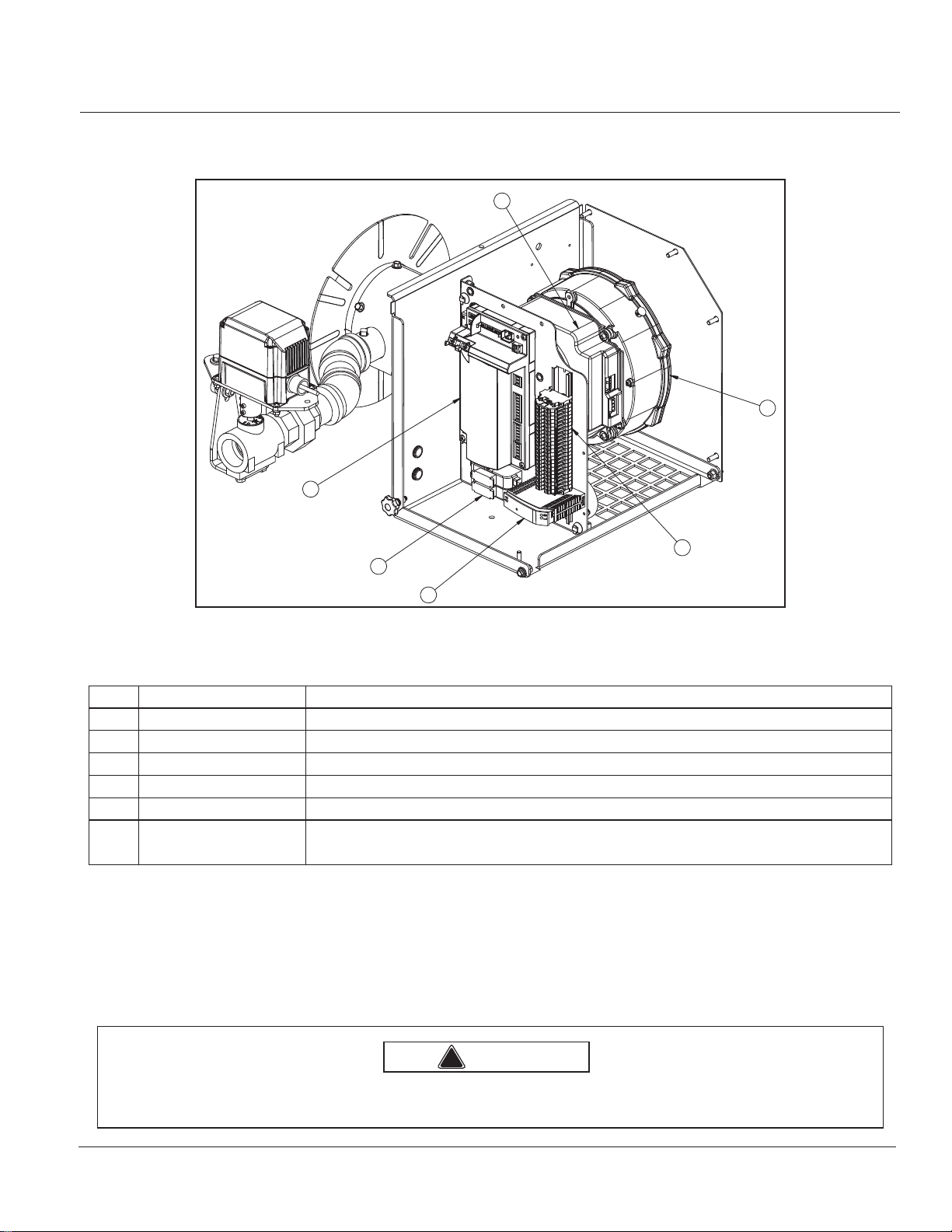

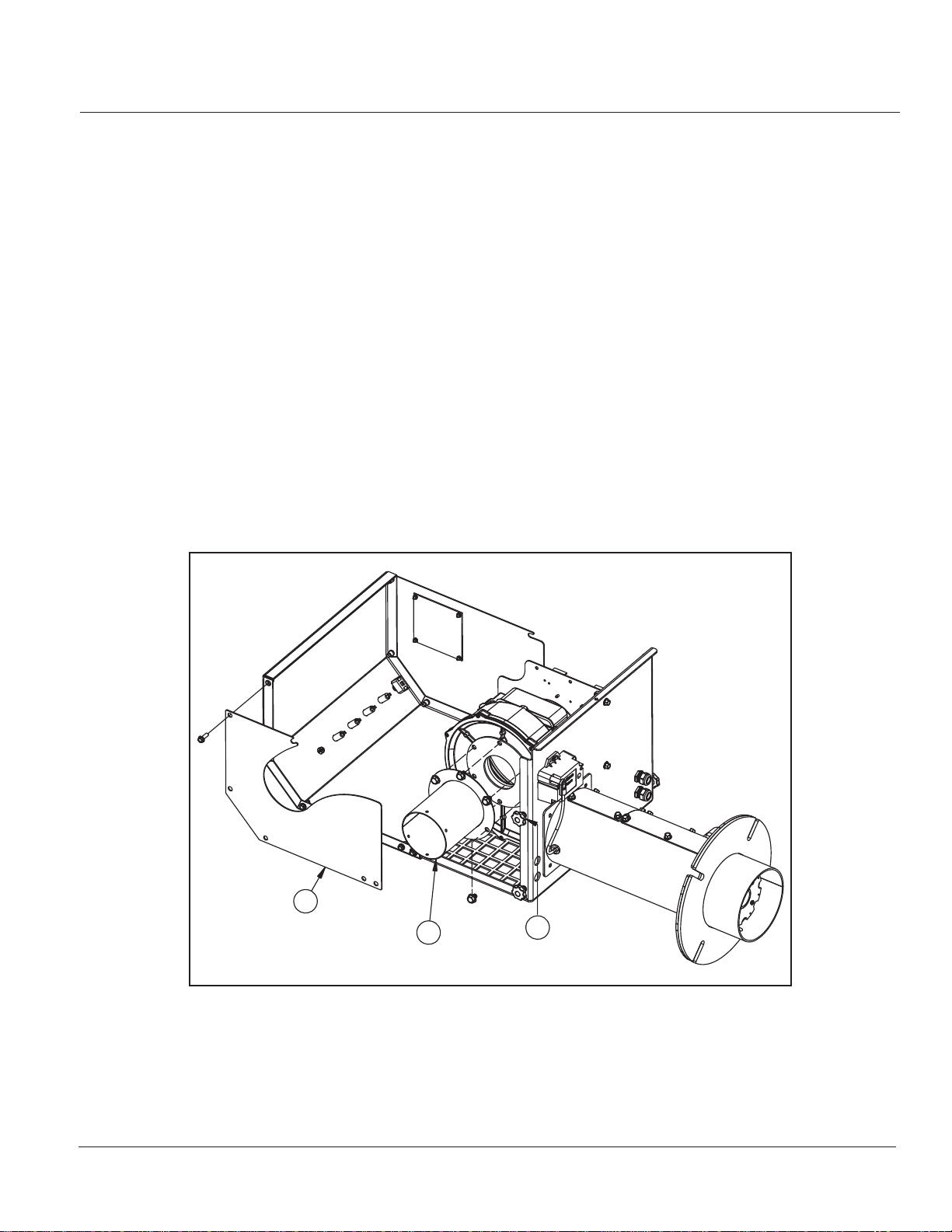

1.3 — Burner Control and Air Delivery

5

6

1

3

750-00533-000

2

4

FIGURE 1-2. Burner Control and Air Delivery

Item Component Details

1 LMV37 Control Combined flame-safeguard (FSG) and fuel-air-ratio-controller

2 Fuse holders Motor and control circuit fusing

3 Terminal Strip Field wiring interface

4 Power Supply 24Vdc for motor control speed input

5 DC modulation control The unit is fully modulated in response to the command signal sent from the LMV37.

6 DC (EC*) motor-fan

*Electronically Commutated

DC variable speed motor-fan unit with integral electronic controls. The unit is energized

by 115VAC power input.

1.3.1 — LMV37 Flame Safeguard and linkage-less fuel-air-ratio controller

The LMV37 incorporates burner sequencing functionality; flame detection; variable speed drive (VSD) control

and fuel-air-ratio control. Flame is detected by UV flame scanner. The LMV37 can modulate the burner from low

to high fire with servo control of the fuel metering valve and VSD electrical connection to the blower motor to

control fan speed (air volume).

Warning

!

Read the LMV37 manual and fully understand its contents before attempting to operate this equipment. Failure to do

so may result in serious personal injury or death.

750-437

Q Series Full Modulation

1-3

Page 14

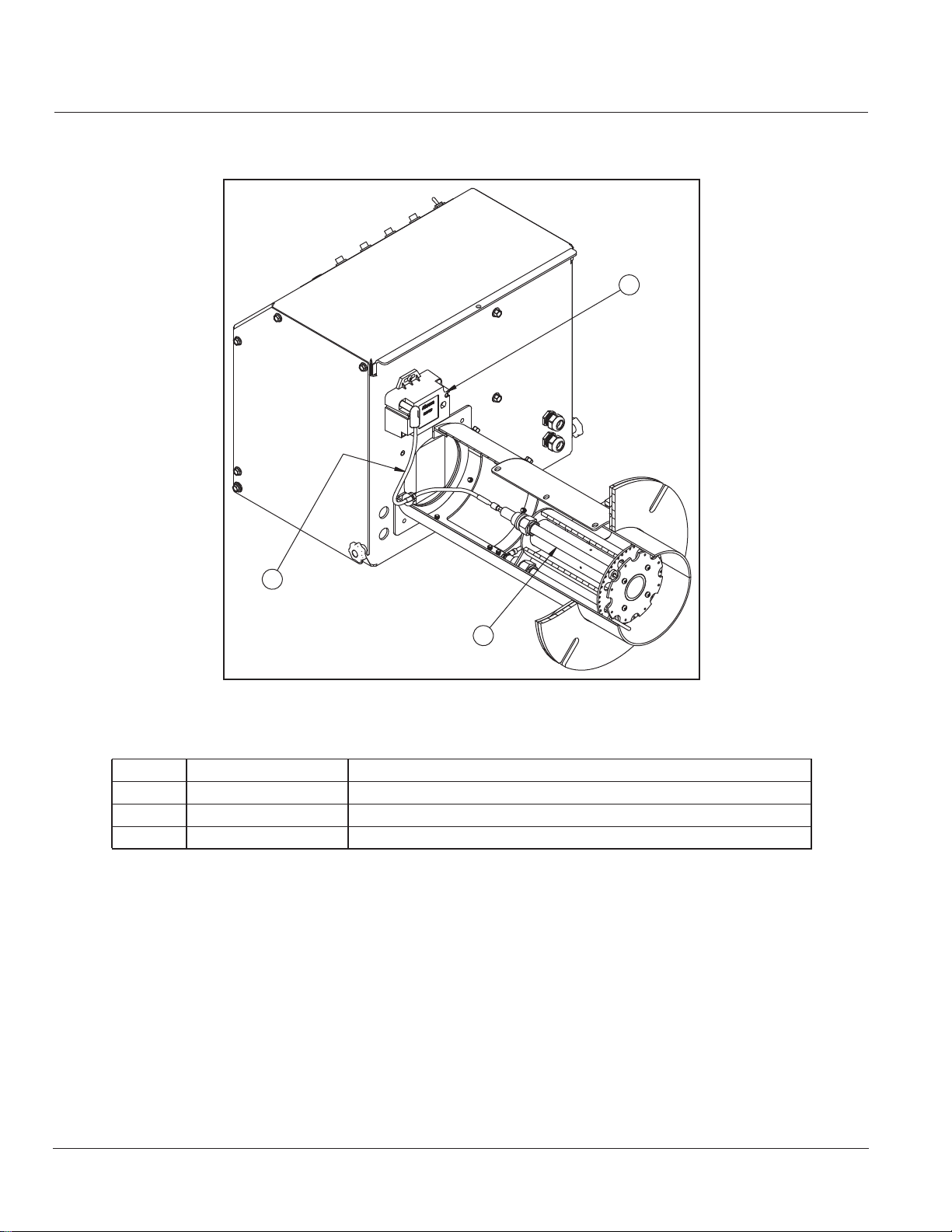

1.4 — Direct Spark System

Introduction

1

2

750-00531-000 3

FIGURE 1-3. Direct Spark System

Item Component Details

1 Ignition Transformer Step up secondary high voltage ignition transformer

2 Ignition Cable 25KV high tension ignition wire.

3 Igniter ø1/8" electrode with quick connect

1.5 — Firing Head

Access to the firing head is provided by the side access panel.

1-4

750-437

Q Series Full Modulation

Page 15

Introduction

R

UV SCANNER

BURNER HOUSING

NUT

LOCK WASHER

UV SCANNER

BAFFLE PLATE

ELECTRODE

GAS MANIFOLD

ELECTRODE

ORIFICE PLATE

FIGURE 1-4. Burner Housing with a UV Scanner

SPRING PIN

ORIFICE PLATE

LOCK WASHER

STAND OFF

750-00509-001

750-00517-001

750-437

Q Series Full Modulation

BAFFLE WELDMENT

LOCK WASHE

SCREW

SCREW

FIGURE 1-5. Burner Housing, Exploded View

1-5

Page 16

Introduction

R

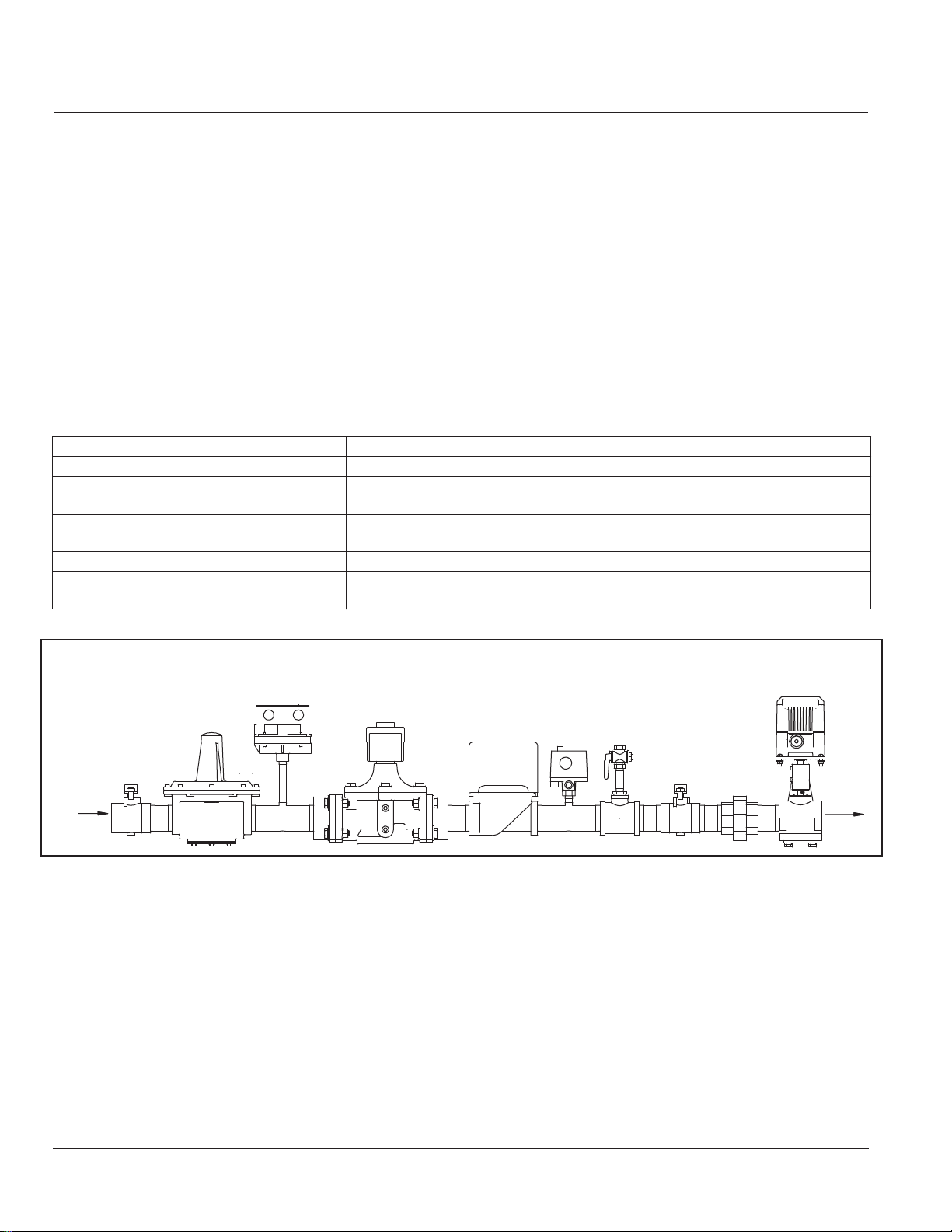

1.6 — Gas System

Gas is introduced into the combustion zone through multiple ports in the circular manifold. The full modulation

burner's LMV37 controls both the combustion air and fuel metering: it meters the fuel in proportion to fan speed

by adjusting the servo-driven gas metering butterfly valve.

Safety shutoff main gas valves are installed upstream of the gas-metering-butterfly valve and are controlled by

the LMV37 to open and close at the proper time in the operating sequence. The Safety shutoff valve models may

vary depending upon specific requirements.

1.6.1 — Main Gas Train Components

Depending upon the requirements of the regulating authority, the gas control system and gas train may consist of

some, or all, of the following items:

Component Description

Gas Metering Butterfly Valve A servo-driven butterfly valve that controls the gas flow rate.

Gas Automatic Safety Shutoff Valves (SSOV(s)) Electrically operated safety shutoff valve(s) that open to admit gas to the burner. Stan-

dard U.L. burners include one diaphragm gas valve and one solenoid gas valve.

Gas Regulator Regulates gas train pressure to specified pressure required at the inlet of the gas train.

Input is set by the main gas pressure regulator adjustment.

Main Manual Gas Shutoff Valve A manual gas shutoff valve located at the gas train inlet (upstream of the regulator).

Main Manual Leak Test Valve A second manual gas shutoff valve located between the SSOV(s) and metering butterfly

valve. It provides a means of testing for leakage through the SSOV(s).

SUPPLY GAS

INTO GAS TRAIN

INLET

MAIN

MANUAL

GAS

VALVE

GAS

REGULATOR

LOW

GAS

PRESSURE

SWITCH

GAS

AUTOMATIC

SAFETY

SHUTOFF

VALVE

GAS

AUTOMATIC

SAFETY

SHUTOFF

VALVE

HIGH

GAS

PRESSURE

SWITCH

750-00529-000

LEAK

TEST

VALVE

MAIN

MANUAL

LEAK TEST

VALVE

GAS METERING

BUTTERFLY

VALVE

TO BURNE

MANIFOLD

INLET

FIGURE 1-6. Main Gas Train for Full Modulation (Q6-055 to Q8-250)

1.6.2 — Typical Gas Operation

Upon a call for heat and before flame ignition, the LMV37 flame safeguard starts the combustion air fan and

confirms the gas metering butterfly valve is in the low-fire position. When the combustion air switch proves

sufficient air, the control opens the gas safety shutoff valves. Provided the gas supply is connected and manual

cocks are open, gas then flows through the main gas train and gas metering butterfly valve into the burner gas

manifold. The gas streams out of the manifold through the multiple ports of the orifice plate (see Figure 1-5) and

mixes with the fan-fed combustion air.

1-6

750-437

Q Series Full Modulation

Page 17

Introduction

The control then powers the ignition electrode and initiates flame. The UV scanner and control confirms flame

presence and the burner progresses to main-flame operation. Main flame continues while flame is proven; the

external limit switches confirm good operating conditions, and a call for heat exists.

During main flame, the LMV37 receives a modulation input signal from a separate modulating controller that

directs the LMV37 to provide more or less heat. When the call for heat is satisfied, the LMV37 moves the gas

metering valve to the low-fire position and deenergizes the safety shutoff valves thereby shutting down the

combustion process. A post-purge period follows, and the heat exchanger is purged with air. After post-purge, the

burner returns to standby mode.

750-437

Q Series Full Modulation

1-7

Page 18

Introduction

1-8

750-437

Q Series Full Modulation

Page 19

CHAPTER 2 Installation

2.1 — Burner Requirements

Proper installation requires the following:

• Sufficient air supply - allow enough clearance at the bottom of the burner to allow the burner's

fan to draw the high-fire air volume without difficulty.

Warning

!

• A gas-tight seal - for maximum safety, the burner/boiler mounting must be sealed to prevent the

escape of combustion products into the boiler room. When properly installed, the burner

mounting flange and flange gasket will provide this seal. Make sure the flange gasket is installed

uniformly flat between the burner flange and the boiler front plate. When the burner flange is

tightened to the boiler, the gasket should be consistently flat around the entire flange

circumference; an improperly installed gasket will not provide a seal.

• Proper burner support where needed - the front plates on many boilers, including some Scotch

Marine types, are not strong enough to support the burner's weight. The burner has provision

for vertical support as detailed in Section 2.7.

2.2 — Factory and Field Wiring Overview

Electrical motor power and control circuit power are 115 volt, single phase, 60 cycle. Refer to the electrical

schematic diagram shipped with the burner. The schematic is also attached to the inside of the control panel

cover. Installer power connections are made at the control panel. Wiring from the panel to burner mounted

components is completed at the factory. Field wiring from the burner panel to boiler controls, low water controls,

and remotely located fuel valves is completed by the installer.

Caution

!

It is important to provide support for the panel cover when in the open position to prevent damage to the burner

and enclosed components.

750-437

Q Series Full Modulation

2-1

Page 20

Installation

2.3 — Draft Conditions

Automatic over-fire draft control or barometric draft regulators are not usually required except where the system

has a tall chimney. The exact height of a chimney requiring draft control is indeterminate, but draft regulation is

seldom needed for chimneys less than 50 feet high, especially with Scotch Marine or sealed firebox boilers.

2.4 — Combustion Air Supply

The space in which a burner operates must be supplied with adequate fresh air for combustion and ventilation

purposes. Fresh air supply must meet or exceed all code requirements. Consult with insurance carrier and/or

local authorities for specific regulations.

Warning

!

The boiler room pressure must be at least equal to the outdoor atmospheric pressure. Where fan ventilation is used,

air must be forced into the boiler room. Never exhaust air from the boiler room. Adjoining areas having exhaust fans

must be positively isolated from the boiler room.

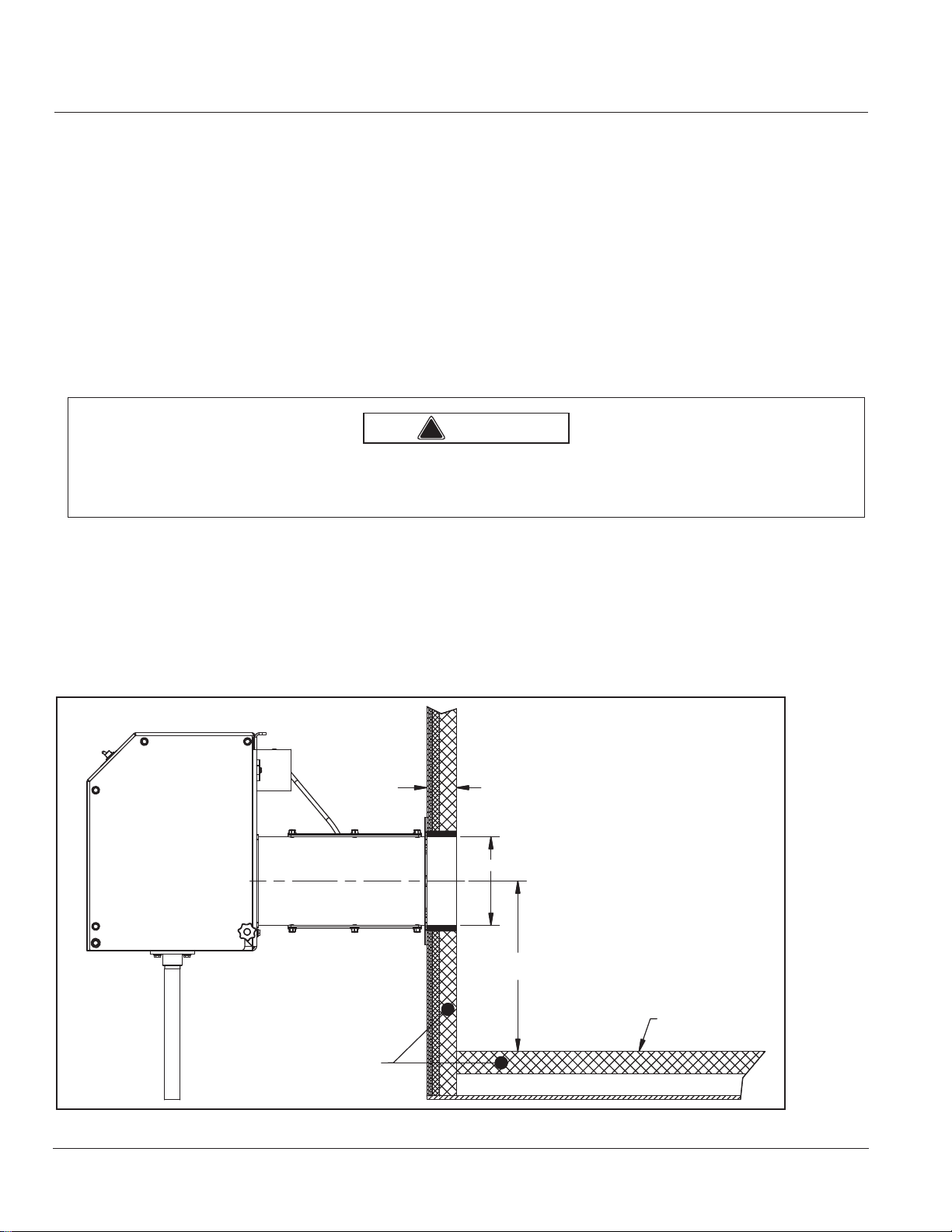

2.5 — Combustion Chamber Recommendations

The combustion chamber dimensions should be adequately sized to prevent flame impingements.

2.5.1 — Non-Firetube Applications

A

B

C

(MIN)

FLOOR

2-2

STANDARD

FIREBRICK

BLOCK INSULATION

750-437

Q Series Full Modulation

Page 21

Installation

Combustion

Chamber Min.

Width (in.)

Chamber Min.

Burner

Size

A

(in.)

B

(in.)

C

(in.)

Q6-055 3.5 6 10 8 24

Q6-075 3.5 6 10 10 24

Q6-100 3.5 6 10 12 24

Q6-130 3.5 6 10 12 36

Q6-150 3.5 6 10 14 36

Q8-175 3.5 8 12 14 48

Q8-200 3.5 8 12 16 48

Q8-250 3.5 8 12 16 48

FIGURE 2-1. Non-Firetube Combustion Chamber Dimensions

2.5.2 — Firetube Applications

Combustion

Length (in.)

Burner Model Boiler HP A (in.) B (in.)

Q6-055 13 8 24

Q6-075 18 10 24

Q6-100 25 12 24

Q6-130 30 12 36

Q6-150 36 14 36

Q8-175 42 14 48

Q8-200 50 16 48

Q8-250 60 16 48

FIGURE 2-2. Firetube Combustion Chamber Dimensions

A

B

750-437

Q Series Full Modulation

2-3

Page 22

Installation

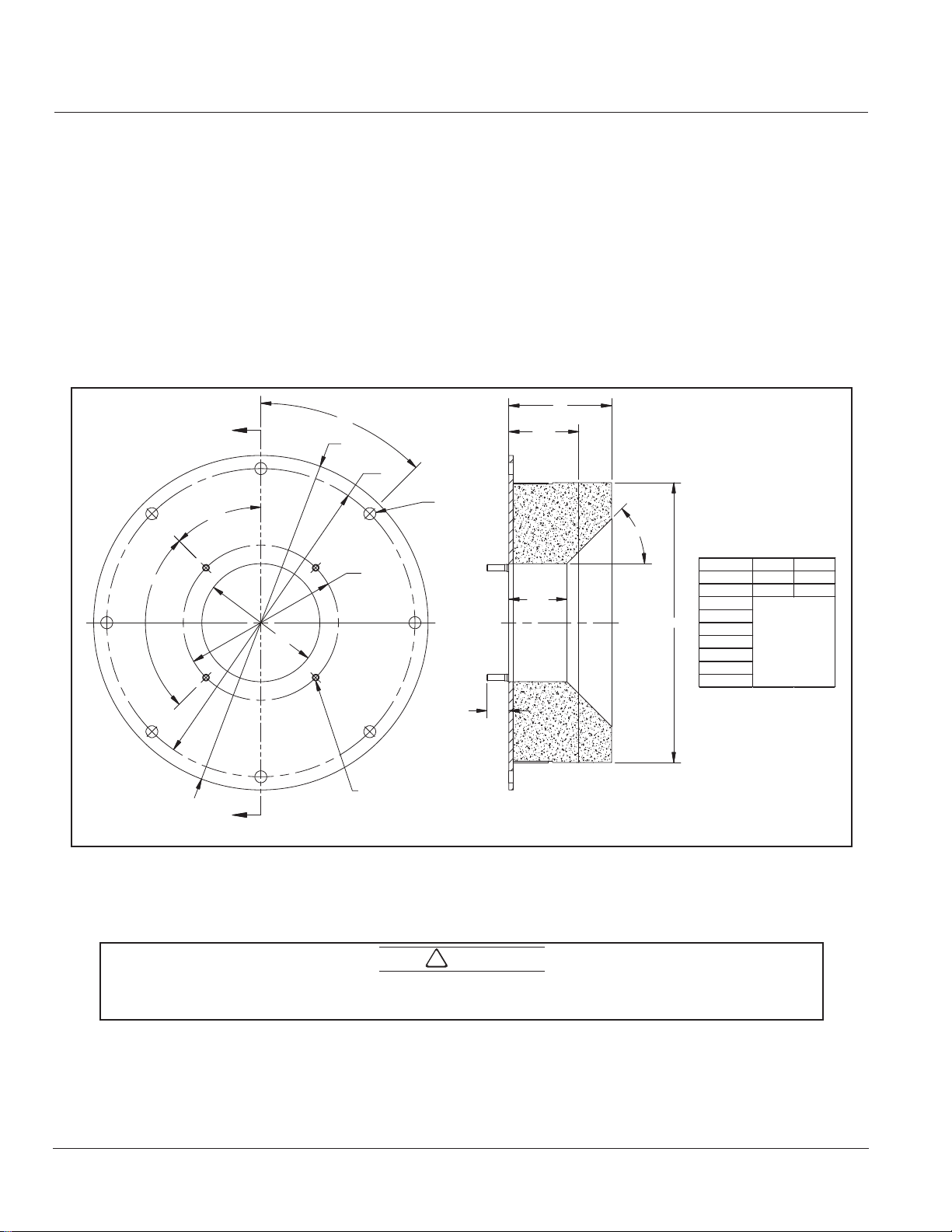

2.6 — Refractory Front Plate Requirements

A dry oven refractory is required only to protect surfaces not adequately protected by free circulating water. Basic

objectives of refractory installation include:

• Provide adequate combustion space

• Avoid flame impingement

• Protect surfaces not adequately water cooled

• Seal openings

Insulation should be provided between the refractory and the boiler base. Mineral wool or other material not

likely to settle is preferred. Insulation should be used between the refractory and front plate. Firebrick or

insulating firebrick should be set in high temperature bonding mortar with provision for expansion. Refer to

Figure 2-3 for refractory construction guidelines.

3.31

4.00

MIN.

"I"

45°

DIMENSION SIZE-6 SIZE-8

"A" 8.88 10.88

"B" 6.75 8.75

"C"

"C"

"D"

"E"

"F"

"G"

"H"

"I"

SIZED TO FIT BOILER

710-00897-000

A

45°

90°4X

"B"

"F"

"D"

"E"

"A"

P

3/8 STUDS

"G" x

1.25

P

"H"

A

FIGURE 2-3. Q Series Refractory Dimensions

To prevent leakage of combustion gases, the gasket must be resilient enough to seal any uneven areas

between the burner and the front plate.

2-4

Caution

!

750-437

Q Series Full Modulation

Page 23

Installation

Prepare the boiler front plate and burner insertion as follows:

1. Determine burner mounting height. Locate and scribe a level

horizontal centerline across the mounting face.

2. Locate and scribe a vertical centerline. Be sure stud locations

line up where studs will have full support. If they don’t, or if

the opening is too large, a steel adapter plate, 3/8” minimum,

may be welded or bolted in place. Suitable anchors should be

provided to hold the refractory in place. The adapter plate

must be properly sealed (using insulating rope gasket) to prevent leakage of combustion gases.

3. Insulate burner insertion as shown in Figure 2-4

•Apply tack spray on the insert portion of the firing head that

will be wrapped.

•Wrap the insertion part of firing head with ceramic fiber

blanket (Kaowool). The wrap should be installed such that it

fills the 3/8” gap between the burner head outside diameter

(OD) and the refractory internal diameter (ID).

•Wrap the Kaowool with masking tape-this makes the

assembly easier to insert into the refractory. The wrapped

Kaowool must provide a snug fit between the refractory and

burner head. Rework if there are gaps.

•Trim off excess Kaowool.

•Apply ceramic-fiber rigidizer to the exposed Kaowool lip (see

figure 2-5). Protect/mask off the burner head so the rigidizer

only contacts the Kaowool lip; do not allow rigidizer to contact

any other part of the burner head.

FIGURE 2-4. Insulate Insertion

Note: the tack spray and masking tape hold material in place while the burner is installed into the

refractory. Following installation, heat exposure will burn away the tacking spray and masking tape.

4. Using insulating rope gasket, wrap the rope on the inside of

the bolt circle, looping the rope around the mounting

studs.Set the burner into position for mounting and tighten

into place. Standard burners are equipped with a four-hole

mounting flange.

5. Permanently support the burner using the pipe support con-

nections.

FIGURE 2-5. Rigidize Exposed Lip

750-437

Q Series Full Modulation

2-5

Page 24

Installation

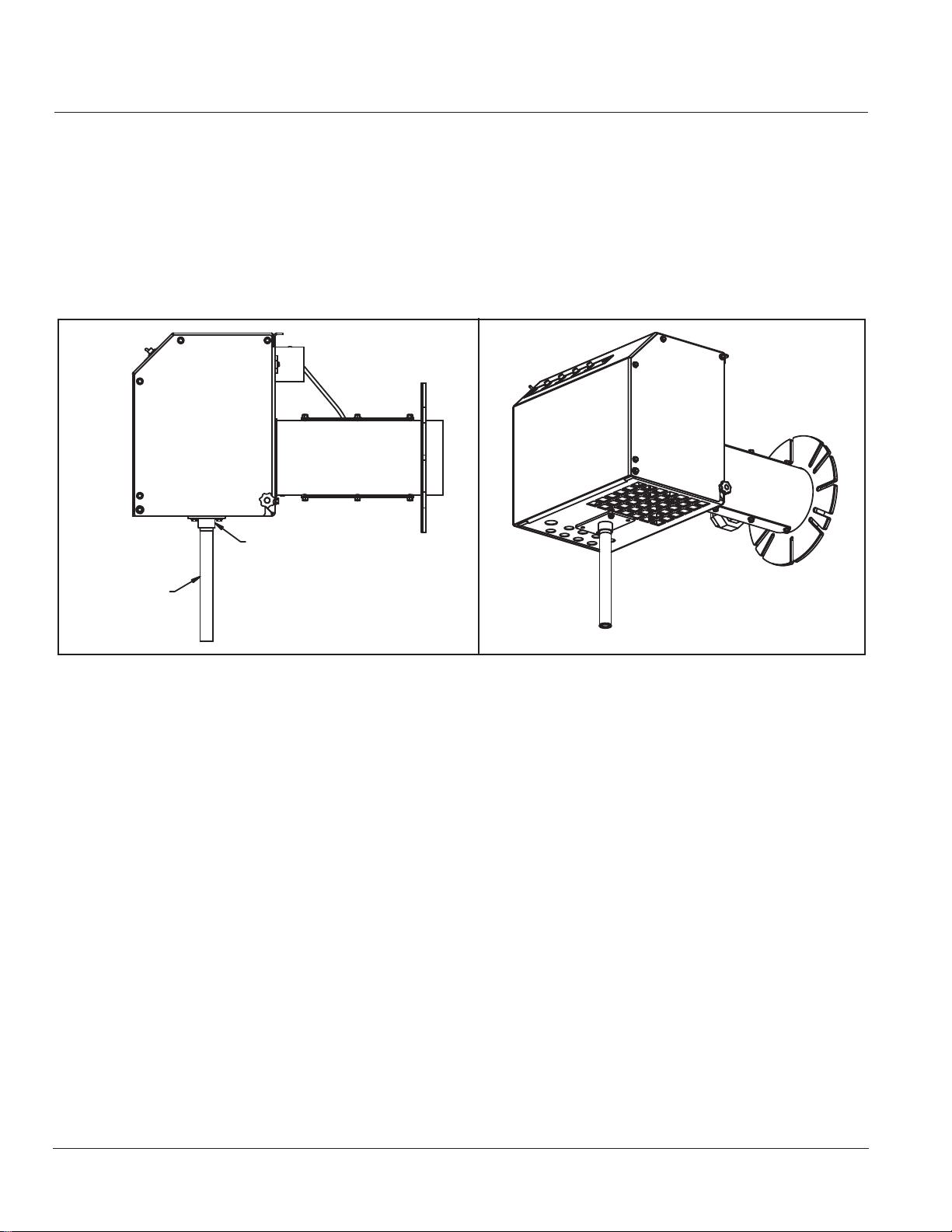

2.7 — Support Bracket Installation

Once the burner is installed, it must be supported by a suitable weight bearing surface. The burner is designed to

use the supplied support bracket kit number 880-06384-000. The bracket should be mounted to the burner

with the kit-supplied hardware.

A 3/4” NPS pipe, supplied by others, may then be cut to length and mounted so as to provide vertical support to

the burner.

SUPPORT BRACKET

(SUPPLIED WITH BURNER)

PIPE, 3/4" NPS (TOE)

SUPPLIED BY OTHERS)

750-00520-000

FIGURE 2-6. Support Bracket Installation

2.8 — Gas Piping

Gas service and house piping must supply the burner-required gas volume and pressure to the burner gas train

inlet. All piping must be in strict accordance with applicable codes, ordinances, and regulations of the supplying

utility. In the absence of other codes, piping should be in accordance with the following standards: “National

Fuel Gas Code” NFPA No. 54, ANSI No. Z 223.1 (for Canada, the Canadian Gas Association (CGA) B149 and

Canadian Standards Association (CSA) B140 codes shall prevail).

Full modulation gas train components upstream of the butterfly valve that are shipped loose should be mounted

by the installer as close to the burner as practical. Normally, the gas train is ordered to suit a particular code or

insurance regulation, such as Underwriters Laboratories Inc., CGA, or Factory Mutual.

Arrange gas piping to the burner so that the burner is accessible for servicing without requiring train disassembly.

The gas piping must be internally clean and free of foreign material. Before using in service, a leak test must be

performed.

2-6

Q Series Full Modulation

750-437

Page 25

Installation

2.9 — Optional Ducted Combustion Air

An optional adapter port and slotted side panel allow combustion air to be ducted into the burner. The Q6

arrangement is a 4" OD inlet while the Q8 is a 6" OD inlet setup.

To equip the burner for ducted combustion air (item numbers refer to Figure 2-7):

• Change the side cover

1. Remove the cover lock-down thumb screw (Item 3).

2. Open the control cover (keep cover supported to prevent damage to it).

3. Remove the control panel side cover but retain the fasteners as they will be reused.

4. Install the slotted side cover (Item 2).

5. Replace the thumb screw (Item 3) to the position shown in Figure 2-7.

• Install the air inlet adapter

NOTE: If orifice plate required (Section 2.10) install between the blower and air inlet adapter.

1. Remove the (6) bolts from the fan-assembly inlet collar and air-pressure sensing line

2. Align the adapter (Item 1) and air-pressure sensing line bracket then replace and secure the 6 bolts. Use a

medium thread locker such as Loctite Blue to assure secure retention.

750-437

Q Series Full Modulation

2

1

FIGURE 2-7. Ducted Combustion Air

3

880-06262-000

2-7

Page 26

Installation

2.10 — Combustion Air Inlet Orifice Plate Installation

The Q burner size 6 and 8 use air-inlet-orifice plates to limit combustion air to the maximum firing rate needed

with respect to an application. The Q6 has a maximum rating of 1,500,000 BTU/HR. When used for the

maximum rate an air-inlet-orifice plate is not used. The same is true of the Q8 when used at its maximum rating

of 2,500,000 BTU/HR. For other firing rates, the chart below identifies the air-inlet orifice plate required:

TABLE 2- 1. Air Inlet Orifice Plate Application

Model Burner BTU/HR rating Air inlet Plate Part Number Orifice Diameter (in)

550,000 059-11448-000 1.50

750,000 059-11449-000 1.80

Q6

Q8

1,000,000 059-11450-000 2.25

1,300,000 059-11452-000 2.95

1,500,000 no orifice plate used -

1,750,000 059-11457-000 3.45

2,000,000 059-11458-000 3.80

2,500,000 no orifice plate used -

If an orifice plate is required, Install the provided plate to the blower assembly as shown in Figure 2-8 below.

Remove the existing (6) bolts from the fan-assembly inlet collar and air-pressure sensing line. Align the plate and

air-inlet sensing line then replace the (6) bolts. Use a medium thread locker such as Loctite Blue to assure

secure retention.

2-8

FIGURE 2-8. Inlet Orifice Plate Installation

750-437

Q Series Full Modulation

Page 27

Installation

2.11 — Installation Checklist

All burners are carefully assembled and tested at the factory, but before being placed in service, all connectors

should again be checked for looseness caused during shipment.

Check:

• Electrical terminals in the control panel and on all electrical components.

• Pipe fittings, unions and tube connections.

• Nuts, bolts, screws.

Before connecting electrical power to any component, be sure the supply voltage is the same as that specified on

component nameplates.

Before firing, make sure that the burner mounting flange is properly sealed to the boiler front plate.

It is the installer’s responsibility to identify the main electrical power disconnect and the manual shut-off valve on

the gas supply drop-line to the burner.

Make certain that the operator in charge is properly instructed in the operation and maintenance procedures.

Caution

!

Before opening the gas shutoff valves, read the regulator instructions carefully. Open the shutoff valve slowly to

allow inlet pressure to build up slowly in the regulator until it is fully pressurized. Opening the shutoff valve quickly

will damage the regulator.

Do not exceed the regulator pressure ratings.

750-437

Q Series Full Modulation

2-9

Page 28

Installation

2-10

750-437

Q Series Full Modulation

Page 29

CHAPTER 3 Operation

NOTE: Separate modulating load controller

required for operation.

3.1 — Preparations for Starting

The following items must be satisfied before any attempt is made to operate the burner:

• Electric, fuel, water, and vent stack connections are complete and all connections are confirmed tight.

• The operator is familiar with the boiler components and controls.

• The operator is familiar with the burner and understands: the burner components and controls (Chapter 1);

the LMV3 sequence of operation; and the burner wiring to the boiler controls per the burner wiring diagram.

In addition, the following checks must be made:

Item Check

Boiler

Burner

Boiler water level.

Be sure all boiler valves are installed correctly and positioned properly.

Set the high limit control slightly above the desired temperature.

Set the operating control to the desired temperature or pressure.

Set modulating controls at the desired temperature or pressure.

Check the electrical power supply to the burner in accordance with the nameplate voltage.

Check the fuel control actuator for proper movement of the fuel metering valve.

Refer to the Siemens LMV3 manual for additional information.

3.1.1 — Gas Supply

A representative of the gas utility should turn on the gas. Confirm sufficient pressure exists at the entrance to the

gas train (use test gauge upstream of the burner regulator). The gas pressure regulator must be adjusted to the

pressure required.

3.1.2 — Burner Settings

To ensure reliable and safe burner performance, the fan speed and gas settings must be checked and adjusted

prior to placing the burner into initial service, or after conducting any service work that may have altered the

settings. The modulating firing rate is controlled by a temperature or pressure sensor in conjunction with a

controller capable of generating a 4-20 mA output signal (minimum 500-ohm impedance) or a floating bumping

750-437

Q Series Full Modulation

3-1

Page 30

Operation

circuit. For optimal efficiency, the controller used should be capable of PID load control. The purge rate, ignition

position, minimum firing rate, maximum firing rate and fuel-air ratio throughout the firing range is determined by

settings made in the Siemens LMV37 display. Refer to the Siemens LMV37 operation manual for further

information.

3.1.3 — Combustion Settings

Fuel and air flow rates are individually adjusted at low fire and at high fire to achieve rated heat input, firing rate

turndown, optimum efficiency, and safe operation. Refer to the nameplate inside the control panel for fuel input

ratings and corresponding manifold pressures.

3.1.4 — Test Equipment

Combustion tests and pressure readings should be conducted on-site and typically requires equipment such as:

• Combustion analyzer with O2, CO2, and stack temperature indication.

• U-Tube manometer, or pressure gauge, to measure gas pressure.

• Manometer to measure draft pressures.

• Voltmeter/Ammeter.

Warning

!

Read the LMV37 manual and fully understand its contents before attempting to operate this equipment. Failure to observe this warning may result in serious personal injury or death.

3.2 — Burner Sequence Overview

Basic overview of the control's normal sequence of operation is provided herein. Refer to the LMV37 manual for

additional sequence-of-operation detail and the burner-wiring diagram to a better understanding of how the

boiler and burner limit devices impact sequence of operation.

3.2.1 — Normal Automatic Sequence of Operation

In automatic operation, the burner cycle proceeds through standby, pre-purge, ignition, main flame operation

(released to modulate and load controller is driving the firing rate), post-purge and return to standby.

During main-flame operation, the burner firing rate is modulated by a load controller in response to the heat

exchanger's pressure or temperature until the operating control* contacts open and end the call for heat.

*operating control contacts may be either an individual operating control device or in a controller which incorporates load controller capability.

The LMV3 operation should be tested when:

• the burner is initially placed into service;

• a control is replaced; or

• the scheduled maintenance program so indicates.

3-2

750-437

Q Series Full Modulation

Page 31

Operation

Normal automatic operation is detailed in Table 3.1 and the corresponding AZL indications are shown in Fig 3-1.

TABLE 3- 1. Normal Automatic Sequence Of Operation

LMV37

Sequence

Standby 12 Standby OFF No call for heat exists

Call for heat made 22 Fan motor on Ph 22

24 Air volume increased for pre-purge Ph 24

Pre-purge 30 Pre-purge Ph 30 _XX

36 Air volume adjusted for ignition Ph 36

Ignition 38 Ignition transformer energized Ph 38

Main fuel 40 Fuel valve Ph 40

42 Ignition Ph 42

Delay before

modulating

Released to

modulate

Call for heat ends 62 Fuel and air adjust to the low-fire rate Ph 62

70 After-burn time (confirms no flame) Ph 70

72

Post-purge 74 Mandatory post-purge time Ph 74 _XX

78 Optional post-purge time Ph 78

Low-fire position 10 Home run (fuel actuator referencing) Ph 10 Actuator self-check

Phase Action

44 Interval 1 pilot stabilization Ph44 _XX

Operation (LMV37 responding to

60

modulating control input)

Air volume is adjusted to the postpurge rate

oP: YY.Y where YY.Y = % firing rate

AZL DISPLAY

TEXT

Ph 72

INDICATOR

CMIVF

Gas press. switches must

Ignition/main flame

be made to progress to

ph24

where XX = countdown

timer in seconds

where XX = countdown

timer in seconds

where XX = countdown

timer in seconds

User added time (via

parameter)

Note

FIGURE 3-1. AZL Status Indications for Normal Operation

Note: In this manual, AZL display text is shown in brackets, e.g. “{OFF}.”

750-437

Q Series Full Modulation

3-3

Page 32

Operation

3.2.2 — Standby

The burner is in standby and ready to respond to a call for heat when

• All power supply switches are closed and power is present at the control panel as indicated by the burner's

illuminated white “power” light.

• The high limit control contacts are made. If the high limit has tripped (contacts open), it must be manually

reset.

• The burner's On/Off control switch is in the “ON” position.

• The AZL displays {OFF}.

3.2.3 — Startup

While burner is standby/{OFF}, and when the operating pressure/temperature falls below the operating control

set point the operating control contacts make/close. If all other devices in the limit string are made and the burner

switch is ON, the control sees a “call for heat” and then sequences through startup as follows (commentary in

italics)

{Ph22} = Fan motor on - The burner energizes the fan

{Ph24} = Traveling to pre-purge position - Airspeed ramps up to high-fire air delivery rate

{Ph30} = Pre-purge countdown timer (30 sec) - Control confirms combustion air pressure is proven and then

pre-purges the heat exchanger to rid it of any possible accrued flammable vapors. The control displays {Ph30

XX.X} where “XX.X” is the countdown in seconds.

{Ph36} = Traveling to ignition position - Airspeed and gas valve opening are positioned for ignition at the LMV's

P0 position.

{Ph38} = Pre-ignition Time - (ignition transformer ON) - Direct spark transformer energizes the electrode

{Ph40} = 1st Safety Time - (safety shutoff valves ON) - Gas delivered to the combustion zone.

{Ph42} = 1st Safety Time (ignition transformer OFF) - Direct spark period terminates and flame presence

confirmed.

{Ph44} = Interval 1 - Flame stabilization

3.2.4 — Operation - Automatic Modulation

• The Control is in phase 60 and burner modulation is released to the load controller. The AZL presents {oP:

YY.Y} where “YY.Y” indicates the percent firing rate.

• The “YY.Y” firing rate is typically proportional to the difference between the load controller's set point and the

currently measured temperature or pressure value: large differences result in high firing rates with the firing rate

diminishing as the measured value approaches the setpoint value.

3.2.5 — Automatic Shutdown

• When the call for heat is satisfied, the operating control contacts open and the LMV3 control enters phase 62

where it commands the airspeed and fuel valve position to the P1 low-fire position.

3-4

Q Series Full Modulation

750-437

Page 33

Operation

{Ph70} = The safety shutoff valves are de-energized/closed and the burner's "Fuel" lamp turns off.

{Ph72} = Traveling to post-purge position - Airspeed ramps up to high-fire air delivery rate

{Ph74} = Mandatory-post-purge time - High-fire air post-purges the heat-exchanger for the minimum-time

requirement. The display shows {Ph74 XX.X} where “XX.X” is the post-purge countdown timer in seconds.

{Ph78} = Optional-post-purge time - Additional post-purge time can be added via parameter adjustment.

{Ph10} = Home Run Position. Following post-purge, the burner motor stops. The gas actuator positions to home

which is the actuator's self-check of its optic position sensors.

• Burner returns to standby Phase 12, the AZL displays {OFF} and is ready for startup on the next call for heat.

Note: LOW WATER - If a low-water condition occurs, the burner shuts down as in “Automatic Shutdown” and the

AZL displays {OFF}. When the water level is restored and the low-water safety device resets. Provided all other

recycling limits are made and the burner switch is on, the burner will fire again when the operating control

contacts make (receives a new “call for heat”).

3.2.6 — Manual Shutdown

To manually shut off the burner:

• Turn the burner switch to OFF. The burner shuts down as in “Automatic Shutdown.”

• When the burner displays {OFF}, close the gas train's shutoff and main leak-test manual valves.

Automatic operation can not resume until the operator has determined it is safe to operate the system and

returns the gas valves to their open position and turns the burner switch to ON.

3.2.7 — Safety Shutdown

A safety-loop failure presents as an LMV3 error code 22 where the display alternates {Loc.c: 22} and {Loc.d:

X} (“x” being a diagnostic code value). A flame failure (loss of flame signal) presents as an LMV3 error code 93

where the display alternates {Loc.c: 93} and {Loc.d: X}. Either open safety-loop or loss-of-flame-signal

condition will cause the LMV3 to rapidly de-energize the safety-shutoff-fuel valves and the blower motor.

Shutdowns may result from motor overloading; low water; interruptions in either fuel or power supply; insufficient

combustion-air-pressure; tripped circuit breakers; blown fuses; or other interlock devices.

A safety shutdown will illuminate the burner's red “FAILURE” light and (if so equipped) energize an audible

alarm.

The failure's root cause must be determined and corrected before any attempt is made to restart the burner.

Gas pressure fault - If a high or low gas pressure condition occurs during burner operation, the burner shuts down

as in “Automatic Shutdown.” The AZL presents a fault indication and error code 20 condition by alternating

{Loc.c: 20} and {Loc.d: X} in the display. The pressure condition must be corrected and the respective gas

pressure switch is manually reset before attempting a burner restart.

750-437

Q Series Full Modulation

3-5

Page 34

Operation

Reference the “LMV Troubleshooting” section duplicated in this manual for additional “{Loc. C}” error code and

“{Loc.d}” diagnostic information.

3.3 — Gas Pressure Regulator Setup

To determine the initial pressure setting of the gas pressure regulator

(for gas trains consisting of a regulator and two safety shut off valves) a

good rule of thumb is to adjust the regulator set point to twice the high

fire manifold pressure. If using a Siemens gas train, with the regulator

being the last component before the gas metering butterfly valve, set

the regulator set point to 1.5 times the high fire manifold pressure.

Fuel/air ratio curve setup may then proceed.

3.3.1 — Regulator Spring Selection

After determining the pressure setting as described above, use Table

3.3 to select the appropriate regulator spring.

TABLE 3- 3. Regulator Spring Selection

SPRING COLOR

Brown 1.0 - 3.5

Plated 3.0 - 6.0

Pink 3.0 - 8.0

Blue 5.0 - 12

Red 10 - 22

PRESSURE

RANGE (“WC)

TABLE 3- 2. Burner Manifold Pressure*

Manifold

Burner MBH

550 0.65

750 1.00

Q6

Q8

*Excludes furnace pressure. Add furnace

pressure to determine total manifold

pressure for your specific application.

1,000 1.70

1,300 2.25

1,500 3.10

1,750 2.30

2,000 2.50

2,500 3.50

Pressure

(“WC)*

Where possible, spring selection should be made so that the pressure setpoint falls within the upper 50% of the

spring range. For example, for a setpoint of 5.0”, the Plated spring (3-6” range) is preferable to the Pink spring

(3-8” range).

3.4 — Gas Train Leak Test

Note: In this section, AZL display text is shown in brackets, e.g. “{OFF}.”

A gas safety shutoff valve leak test (Bubble Test) must be performed prior to any initial commissioning or

subsequent maintenance of the burner and gas train system. This test should be performed periodically to ensure

no leakage of valves in their closed or de-energized position (refer to the valve manufacturer's procedures). The

unit should be taken out of service if the unit fails any part of the gas valve leak test. Any defective part must be

replaced prior to putting the equipment back into service.

Refer to Figure 3-2 when following this procedure:

3-6

Q Series Full Modulation

750-437

Page 35

Operation

[3]

[6]

[8B]

[4] [5]

[7]

TO

BURNER

GAS

TRAIN

INLET

[1]

[2]

8A

o

45

1/2”

FIGURE 3-2. Gas Train Leak Test

Caution

!

Before opening the manual gas shutoff valves, read the regulator instructions carefully. Open the shutoff valve

slowly to allow inlet pressure to build up slowly in the regulator until it is fully pressurized. Opening the shutoff

valve too quickly will damage the regulator.

1/2”

45

o

Do not exceed the regulator pressure ratings.

NOTE: for V48A equipped gas trains see 4.2.1 for additional information.

3.4.1 — Leak Test Procedure

Fill the gas train for leak testing (burner will go through startup with the blower running, but the burner is not

intended to be fired at this time as the closed leak-test valve blocks gas to the burner).

1. CONFIRM BURNER IS READY FOR LEAK-TESTING THE GAS TRAIN:

•Set burner control switch to OFF position.

•The AZL displays {OFF}

•CLOSE the main leak test valve [7] entirely.

•Minimize the chance that gas pressure switches will interfere with the initial setup:

Set the low gas pressure switch [3] to the lowest setting.

Set the high gas pressure switch [6] to its highest setting and press its reset.

NOTE: gas pressure switches will be tested and set following the LMV37 commissioning and tuning.

•Set the operating control so burner will run when the burner switch is turned ON.

•Partially open the manual shutoff cock [1].

•Reset the low gas pressure switch if required

750-437

Q Series Full Modulation

3-7

Page 36

2. TURN THE BURNER SWITCH ON.

If the burner blower does not start:

If the display continues to show {OFF} with the burner switch ON, then close the manual shutoff cock [1].

Troubleshoot the limit circuit and correct the situation so that the AZL “Heat request from controllers” LCD

bar beneath the icon turns solid with when the burner switch is turned ON. Repeat from Step 1.

FIGURE 3-3. Request for Heat

If the burner blower starts:

The burner will progress and display the following stages:

Operation

{Ph22} = Fan motor on

{Ph24} = Traveling to pre-purge position

{Ph30} = Pre-purge countdown timer (30 sec)

{Ph36} = Traveling to ignition position

{Ph38} = Pre ignition Time

Burner light off attempt at factory P0 setting

{Ph40} = 1st Safety Time (ignition transformer ON)

{Ph42} = 1st Safety Time (ignition transformer OFF)

{Ph44} = Interval 1

As the closed leak test valve [7] is blocking fuel delivery, the LMV37 will not detect flame during its trial for

main flame and will safety shutdown with the burner panel's red failure light illuminated. The LMV3 safety

shutdown should de-energize/close both safety shutoff valves [4] and [5]. If a safety-shutoff valve fails to

close, close the manual shutoff valve [1]. Do not proceed further until you correct the problem. If [4] and [5]

closed, pressurized gas should be trapped between [4] and [7] and you may proceed to the next step.

3. LEAK TEST THE DOWNSTREAM SAFETY SHUTOFF VALVE [5].

Release the gas trapped between and main gas safety shutoff valve [5] and manual cock [7] by opening the

leak test cock [8B]. After the trapped gas has been vented, continue to perform a bubble test for any leakage

through the safety shutoff valve [5]. Bubbles will appear if gas is leaking past [5]. If bubbles continue, close

the main shutoff valve [1], correct the valve [5] problem and retest 10 times before proceeding. If no leak,

close test cock [8B] and continue to the next step.

4. LEAK TEST THE UPSTREAM SAFETY SHUTOFF VALVE [4].

Release gas pressure at test cock [8A] and bubble test for any leaking through auxiliary safety shutoff valve

[4]. If you do not observe a leak, close test cock [8A] and go to the next step. If safety shutoff valve [4] leaks,

correct the problem and retest 10 times before proceeding.

Procede only when it is established there are no gas leaks.

3-8

Q Series Full Modulation

750-437

Page 37

Operation

5. RESET MANUAL VALVE OPEN/CLOSE POSITIONS BEFORE RESUMING NORMAL OPERATION.

Confirm:

•Manual-leak test valves [8A] and [8B] are closed.

•All safety shutoff valves are operating normally.

•Confirm manual cocks [1] and [7] are open.

3.5 — Combustion Emissions and Efficiency

The Q burner should be tuned so combustion results match the respective firing rate range in Table 3- 4:

TABLE 3- 4. Emissions Guidelines

Firing

Rate

HIGH

FIRE

MID

FIRE

LOW

FIRE

CO

O

2

3.0 15.0 10.0 11.7

3.5 18.0 9.6 11.5

4.0 21.0 9.4 11.2

4.5 24.5 9.1 10.8

5.0 28.1 8.8 10.4

5.5 31.9 8.5 10.0

6.0 35.9 8.3 9.8

6.5 40.3 8.0 9.5

7.0 44.9 7.7 9.2

8.0 55.6 7.5 8.5

Excess Air

Natural Gas

2

CO

2

Propane

3.5.1 — Carbon Monoxide

Warning

!

Carbon Monoxide is a colorless, odorless toxic gas resulting from incomplete combustion of gas. It can kill

quickly with no warning.

Know the signs: headaches, nausea, dizziness, breathlessness, collapse, loss of consciousness.

Carbon Monoxide Parts per Million (PPM) values should be kept to a minimum; it is reasonable to expect

attainable levels below 50 PPM. Certain heat exchanger characteristics such as furnace dimensions, vessel

construction, etc., can make low CO difficult to achieve; consequently, continued attention to levels is advised.

Most codes limit permissible CO amounts to below 400 PPM.

3.5.2 — Efficiency and Stack Temperature

A high net stack temperature indicates wasted heat. Net stack temperature is obtained by subtracting the

ambient air temperature from the flue gas temperature. Stack temperature should be as low as possible without

causing flue gas condensation.

750-437

Q Series Full Modulation

3-9

Page 38

Operation

Stack heat loss can be reduced by (a) decreasing stack temperature through improved heat transfer or (b),

decreasing the flue gas volume by decreasing excess combustion air. A certain amount of excess air is necessary

to complete combustion. See Table 3- 4 for excess air guidance.

Stack temperatures vary by system type but in clean, well-tuned vessels you may expect the following:

Hot Water Vessels: Stack temperature is typically 75-100° F above the water temperature.

Steam Pressure Vessels: Consult saturated steam tables to determine approximate stack temperature. Stack

temperature is normally 75 to 100°F over the saturated steam temperature. As an example, a 10 psig lowpressure steam system at 80° F ambient air, can indicate a stack temperature of approximately 320°F. A 125

psig system under the same conditions increases the stack temperature to approximately 453°F.

3.6 — LMV3 Settings

This section guides you through adjustment of the fan speed and gas valve setting for the LMV3’s ignition point,

P0, and the low to high-fire points P1 through P9. A combustion analyzer is required. A pen and paper should

be on hand to keep a written record of the settings. Final setting values should be recorded in the startup service

report found at the back of this manual.

Warning

!

The Q burner LMV3 has ignition point P0 and fuel-curve points P1 through P9 entered in the control. These points,

however, must be adjusted to the specific application the burner is being installed on. If reasonable care is not taken

to tune combustion points to the application, hazardous combustion conditions may result.

Note:

Read Section 3.6 in its entirety before making any adjustments.

The burner status is presented via the AZL and burner panel indication lights. Figure 3-4 shows how certain AZL indications are also indicated by the burner panel lights:

Display Representation - In this section, text on the AZL display is shown either graphically OR as text enclosed in

French brackets (example below).

Button References - The AZL panel has five buttons. This section uses parentheses to reference their single and combinational use as follows:

(F), (A), (-), (+), ( enter), (reset)

(ESC / - & +) = pressing (-) and (+) buttons simultaneously and,

(VSD / F & A) = pressing (F) and (A) buttons simultaneously.

Manual Lockout - In the case of an emergency, the installer can manually lockout the LMV3 by simultaneously pressing

( enter) in combination with any other button. Following lockout, the AZL will display {Loc:c: 167} {Loc:d: 2}.

Press (reset) until {rESET} appears.

3-10

Q Series Full Modulation

750-437

Page 39

Operation

FIGURE 3-4. AZL Display

3.6.1 — Password Entry / Login

With power on (panel's white indicator is illuminated) and Burner switch in the OFF position, the control

displays:

{OFF}

Reset any errors by holding the (reset) button for 1 to 3 seconds. To access LMV3 parameters, you'll need to

enter the password “YYYYY”.

Press and hold (VSD / F & A) until the control displays:

{CodE}

The display then changes and appears with a flashing bar at the bottom left and is ready to accept password

entry:

The (-) and (+) buttons will scroll the AZL through its character set. To enter the first “Y” of the password, press

(-) once; a blinking Y should appear:

750-437

Q Series Full Modulation

3-11

Page 40

Operation

Press ( enter) to accept the value. The display cursor position advances to accept the second character:

Press (-) then ( enter) four more times to enter “Y” five times; the sixth underscore will be flashing following

entry of the fifth “Y”:

Press ( enter) to enter the password. A successful login will briefly display

{PArA}

followed by:

{400: SEt} “400” flashing

An incorrect entry attempt will display:

{Error} then {OFF}

If the attempt fails, repeat the steps from the beginning of this section.

Note: The following conditions will exit you from AZL parameter entry (log out):

•Power to the LMV3 is disconnected or cycled.

•The AZL is unplugged from the LMV3.

•Timeout (AZL inactive for a time period greater than parameter 127 setting).

•While in a parameter group with {X00: SEt} (X = 1,2,3 etc.), hold (ESC / - & +) until {CLr CodE} displays.

To regain access after a log out, repeat the password entry steps.

3-12

750-437

Q Series Full Modulation

Page 41

Operation

3.6.2 — Initial Fuel-Curve Point Adjustments

Notes:

• You must be password entered to make changes to curve point values.

• The gas and air set values presented in this instruction are for example only.

• Air-fan speed is adjusted with the (VSD / F & A) buttons.

• Gas-valve actuator position is adjusted with the (A) button.

• Confirm curve-point emissions are within expected ranges per emission table 3.3 in section 3.6

Warning

!

Although the burner was fire tested at the factory, be certain to check fuel valve actuator coupling for tightness before

making any adjustments to fuel or air. Be certain the valve is fully closed when the control indicates “0” degrees open.

Caution

!

• The installer is responsible to ensure that safe fuel-to-air ratios are being maintained.

• If an AZL (+) or (-) button is held continuously when adjusting an actuator position value, the value will change at a

progressively faster rate.

• When increasing a setting, increase air and follow with fuel.

• When decreasing a setting, lower fuel first and then air.

Warning

!

Rapid temperature changes to the heat exchanger can cause major damage due to thermal shock.

It is imperative when starting a cold vessel for the first time the vessel be warmed slowly, either by allowing the burner

to cycle for intermittent periods or leaving at low fire. This should be done until the vessel is up to normal operating conditions.

A) Access parameter set 400

If the control displays

{400: SEt} “400” flashing

then go to B. Otherwise: Press (ESC / - & +) repeatedly until the display shows:

{OFF}

Press (VSD / F & A) until the control displays:

{400: SEt} “400” flashing

750-437

Q Series Full Modulation

3-13

Page 42

Operation

B) Advance control to standby PH12

From the {400: Set} screen, press ( enter) and the control displays:

{run}

Press ( enter) again and the control displays:

{Ph12} = Standby

Test P0 Ignition Point

NOTE:

The fan speed is measured in percentage. The gas metering valve is measured in degrees open. At P0 light off:

The Q-burner-fan speed should be approximately 20-30%

The gas-metering-valve angle should be between 2 - 12° open.

Tuning the P0 point may require repeated efforts to ignite the flame and find the required gas/air mix for consistent, stable ignition. If the burner fails to light, turn the burner switch off before resetting the control so you have the opportunity

to adjust the P0 setting.

In the sequence below, the burner executes trial for ignition/main flame during PH42 and PH44.

Turn the burner switch ON. The burner progresses through pre-ignition phases and trial for flame:

{Ph22} = Fan motor on

{Ph24} = Traveling to pre-purge position

{Ph30} = Pre-purge countdown timer (30 sec)

{Ph36} = Traveling to ignition position

{Ph38} = Pre ignition Time

Burner light off attempt at factory P0 setting

{Ph40} = 1st Safety Time (ignition transformer ON)

{Ph42} = 1st Safety Time (ignition transformer OFF)

{Ph44} = Pilot stabilization

If light off is successful, go to step e. Otherwise, continue to c.

C) Failed ignition - Reset LMV

Following a failed light off attempt, the burner locks out and displays alternating error/fault messages:

{Loc:c: X} and {Loc:d: Y}

Turn burner switch OFF

Press (reset) until display shows {rESET}

The control sequences to {Ph 10} home run, then

{OFF}

3-14

750-437

Q Series Full Modulation

Page 43

Operation

D) Access the P0 parameter

With the display showing {OFF}

Press (VSD / F & A) to enter parameters and the display shows:

{400: SEt} (“400” flashing)

press ( enter) and control displays: {run}

Press (ESC / - & +) and the control prompts you with the P0 setting:

{P0: : GG.c}

where “GG.c” = current fuel-valve open angle in degrees.

E) Adjust P0 setting:

AIR- Airspeed setting is typically between 20 and 30%. If airspeed needs adjusted, press and hold (VSD

/ F & A) and the display shows:

{0n: : SS.x} with “SS.x” value flashing

where “SS.x” = airspeed %. While holding (VSD / F & A), press (+) or (-) to adjust the setting.

When the intended value is reached, release all buttons.

GAS- The gas valve opening is typically between 2 - 12° open. If the gas valve position needs adjust-

ment, hold down (A) -the display shows:

{0A: : GG.c} with "GG.c" value flashing

Increase the gas value by an increment of 2.0 until clean ignition is achieved.

While holding (A), press (+) or (-) to adjust the setting. When the intended value is reached,

release all buttons and the display shows:

{P0: : GG.r}

where "GG.r" = revised fuel-valve setting in degrees.

Note: If the burner does not ignite by the value of 12, check regulator inlet and outlet pressure,

valve wiring, shut off valve positions and bleed gas line before continuing with additional adjustment.

Press (ESC / - & +) twice and the control prompts you with:

{OFF UPr}

Note: "OFF UPr" indicates the control will not start until the revised P0 is proven.

F) Test revised P0 ignition point by burner trial for ignition

With the display showing

{OFF UPr}

Press (VSD / F & A) to enter parameters and have control display:

750-437

Q Series Full Modulation

3-15

Page 44

{400: SEt} “400” flashing

press ( enter) display shows:

{run}

press ( enter) display shows:

{PH 12} = stand by

Turn the burner switch ON, and the burner progresses through pre-ignition phases and trial for flame:

{Ph22} = Fan motor on

{Ph24} = Traveling to pre-purge position

{Ph30} = Pre-purge countdown timer (30 sec)

{Ph36} = Traveling to ignition position

{Ph38} = Pre ignition Time

Operation

Progression stops at P0 setting: {P0: : GG.r} with "P0" blinking.

Press (+) to continue light off sequence:

{Ph40} = 1st Safety Time (ignition transformer ON)

{Ph42} = 1st Safety Time (ignition transformer OFF)

{Ph44} = Interval 1

If light off fails return and repeat from step d.

If light off is successful, the controller halts the sequence and displays:

{P0: : GG.G} “P0” is blinking

P0 may be adjusted further if desired. When satisfied with the P0 setting, press (+) to advance to P1.

G) Adjusting P1 through P9 points.

{P1: : GG.G} “P1” is blinking

Using the combustion analyzer, verify combustion for low-fire P1.

If adjustment is needed,

3-16

AIR- Press and hold (VSD / F & A) and the display shows:

{1n: : SS.S} with “SS.S” value flashing

Use (+) or (-) to adjust the setting. When the intended value is reached, release the keys.

GAS- Press and hold (A) and the display shows:

{1A: : GG.G} with “GG.G” value flashing

Use (+) or (-) to adjust the setting. When the intended value is reached, release the keys.

750-437

Q Series Full Modulation

Page 45

Operation

When the setting is satisfactory, wait for the setting value to flash: flashing verifies the LMV3 has entered and

saved the setting values.

Press (+) to advance to P2. Repeat this step for points P2 through P9- adjusting the air and gas at each point so

that combustion-analyzer results agree with table 3.3 in section 3.5.

Each point must be adjusted, combustion verified, and the point values internally saved by the LMV3 (point values

displayed until the “Px” flashed). Each point should also be recorded/written down. When completed continue to i.

H) High and Low-fire Load Limit optional limit settings

With the burner still running, the high and low fire limit parameters may be set in the following sequence. Press

(ESC / - & +) and the display shows the high-fire rate limit parameter:

{546: XXX} where “546” is flashing

This value is typically 100. To change it, press ( enter)) and adjust with (+) or (-). Press ( enter) to save the

new value and press (ESC / - & +) to return to

{546: XXX} “546” is flashing

Press (+) to advance to the low fire limit: {545: YYY} “545” is flashing

This value is typically blank. To adjust it, press ( enter) and adjust (+) and (-). Press (enter) to save the new

value and press (ESC / - & +) to return to

{545: YYY} “545” is flashing

Press (ESC / - & +) to return to the 400 parameter group.

I) Back up the LMV3 parameter settings to the AZL

With the display showing {400: Set} “400” flashing,

press (-) until the backup 000 parameter group displays as:

{000: Int} “000” flashing

Press ( enter) to select this parameter set.

Press (+) to advance to parameter 050 where display shows:

{050.00: 0} “050” blinking

Press ( enter) to select the parameter and the display shows:

{bAC_uP}

Press ( enter) to select the backup process and the display shows:

{ 0 }

Press (+) to enter backup mode. The display shows

{ 1 } with “1” flashing

750-437

Q Series Full Modulation

3-17

Page 46

Press ( enter) to perform the backup and the “1” shifts to the right edge and stops flashing:

{ 1}

Wait approximately 8 seconds and display changes to a non-flashing “0”.

{ 0}

Backup is complete.

Press (ESC / - & +): {bAC_uP}

Press (ESC / - & +): {050.00: 0} “050” blinking

Press (ESC / - & +): {000: Int } “000” flashing

Press (+) until control displays: {400: Set} “400” flashing

Commissioning and backup are complete.

Operation

J) Logout/exit Parameter Settings.

With the display showing: {400: Set} “400” flashing

Press and hold (ESC / - & +) until control displays:

{CLr CodE}

Password-parameter access is now off. The running burner returns to automatic operation and displays:

{oP XX.X} where XX.X is the firing rate value.

When the burner cycle is complete, the burner returns to standby and displays:

{OFF}

3-18

750-437

Q Series Full Modulation

Page 47

Operation

3.7 — Test and Set Gas Pressure Switches

Refer to the diagram below when following this procedure.

[6]

[8B]

[7]

TO

BURNER

GAS

TRAIN

INLET

[1]

[2]

[3]

[4] [5]

8A

o

45

1/2”

FIGURE 3-5. Gas Train

3.7.1 — Test the low-gas pressure switch [3].

Note: The low-gas pressure switch is typically set to 50% of the regulator set point.

1/2”

45

o

LGPS SETTING =

Open manual valve [7] and light the burner. While the burner is firing, gradually close

manual shutoff cock [1]. This simulates a low gas pressure condition. The low gas

pressure switch should trip causing the LMV to go into a safety shutdown closing the

safety shutoff valves and progressing the burner through a post-purge and shutdown with

burner's red FAILURE lamp illuminated. Turn the burner switch to “OFF”, reopen the main shutoff cock [1], reset

the low-gas pressure switch [3] and reset the LMV via the AZL reset button in preparation for the next step.

0.5 x REGULATOR

SETPOINT

3.7.2 — Test the high-gas pressure switch [6].

Note: The high-gas pressure switch is typically set to 1.5 times the manifold pressure.

HGPS SETTING =

Relight the burner. Reduce the high gas pressure switch [6] setting until it reaches the

operating gas pressure. This simulates a high gas pressure condition which should put

the LMV into a safety shutdown that closes the safety shutoff valves and progressing the

burner through a post-purge and shutdown with burner's red FAILURE lamp illuminated.

Return the high-pressure switch set point to 1.5 times the manifold pressure setting. Record the setting.

1.5 x MANIFOLD

PRESSURE

750-437

Q Series Full Modulation

3-19

Page 48

3.8 — Optional Heat Timer MCF Load Control

Sy

st

em

Decrea

se

3.8.1 — Electrical Connections:

Operation

SYSTEM TEMP SENSOR

834-00388-000

®

SYSTEM = 147oF

TARGET = 150

DECREASE SYSTEMINCREASE

T1 COM T2 COM T3+ T3- EXT+ EXT- P+ P- COM 24VAC

o

F

SystemDecrease

POWER

(BLACK)

BOILER ACTIVATION

(YELLOW)

COMMON (RED)

OPEN (WHITE)

CLOSE (BLUE)

120 VAC

OPERATING

CONTROL

X5-03.4

X5-03.3

X5-03.2

3-20

SHIELD

PRESSURE TRANSDUCER

996-31893-000

750-437

Q Series Full Modulation

Page 49

Operation

SET

3.8.2 — Initial Setup and Setpoint Adjustment

Startup Menus

HEAT-TIMER CORP.

V1.00 c 2008

------MAIN-----Set Point 150 F

<Out. Reset>

<Settings>

<Maintenance>

<Sys. Startup>

<Info>

<Back>

DIGI-SPAN ELITE

MCF

APPLICATION:

Heat-BreakOnRise

Cool-MakeOnRise

Default Screen

SYSTEM= 68 F

TARGET= 150

Loading Default

Values...

CONTROL MODE:

Outdoor Reset

Set Point

SENSOR FAULT:

Output On

Output O

SETUP COMPLETE!

PRESS SET

F

STANDARD

English

Metric

-SENSOR TYPE-Temp. 230F

Pres. 30psi

Pres. 100psi

Pres. 200psi

Pres. 300psi

100psiVacuum 30in

Humidity %RH

Temp. 110C

Pres. 0.250MPa

Pres. 0.600MPa

Pres. 1.000MPa

Pres. 1.600MPa

If <Pres. 30psi> is selected for SENSOR

TYPE, CONTROL MODE is not selectable

(automatically set to <Set Point>).

750-437

Q Series Full Modulation

3-21

Page 50

Operation

3-22

750-437

Q Series Full Modulation

Page 51

CHAPTER 4 Adjustments

4.1 — Overview

While each burner is tested at the factory for correct operation before shipment, variable conditions such as

burning characteristics of the fuel used and operating load conditions may require further adjustment after

installation to assure maximum operating efficiency.

Prior to placing the burner and heat exchanger into initial service, a complete inspection should be made of all

controls, connecting piping, wiring and all fastenings such as nuts, bolts and setscrews to be sure that no

damage or misadjustments occurred during shipping and installation.

A combustion efficiency analysis made during the initial start-up will help to determine what additional

adjustments are required in a particular installation.

4.2 — Gas System

4.2.1 — Honeywell V48A Gas Valve Adjustment

NOTE: If The gas train components ship loose, the bleed valve will need to be installed and adjusted in the field.

1. The bleed valve screw should be open one (1) turn counterclockwise from the fully closed position as a start-

ing point.

2. Adjust the bleed valve in 1/4 turn counterclockwise increments until the V48A gas valve opens at the desired

opening speed for a smooth main flame ignition.

3. The burner should be cycled between adjustments.

4.2.2 — Gas Pressure

Gas must be supplied at a pressure high enough to overcome the pressure loss in the burner gas train and

furnace pressure while running at full input. Refer to nameplate inside control panel for gas pressure

requirements at train inlet and manifold. The pressures listed are based on nominal 1000 Btu/cu ft. natural gas

at elevations up to 2000 feet above sea level.

750-437

Q Series Full Modulation

4-1

Page 52

Adjustments

4.2.3 — Gas Flow

The volume of gas is measured in cubic feet as determined by a meter reading. The gas flow rate required

depends on the heating value (Btu/cu ft.). The supplying utility can provide this information as well as pressure

correction factors. To determine the required number of cubic feet per hour of gas, divide burner input (Btu/hr) by

the heating value (Btu/cu ft).

Example:

Burner gas input = 1,000,000 Btu/hr

Natural gas heating value = 1,000 Btu/cu ft

1,000,000 Btu/hr

1,000 Btu/cu ft

NOTE: When checking the input rate, Make sure no other equipment is operating on the same meter.

=

1,000 cu ft

hr

4-2

750-437

Q Series Full Modulation

Page 53

CHAPTER 5 Maintenance

5.1 — Overview

Warning

!

Any cover plates, enclosures, or guards anchored to the burner, or any burner related equipment, must remain in

position at all times. Only during maintenance and service shutdown can these cover plates, enclosures, or guards be

removed. They must be replaced, and securely anchored before testing, adjusting, or running the burner or burner

related equipment.

Caution

!

It is important to provide support for the panel cover when in the open position to prevent damage to the hinges and

other components.

Warning

!

When doing refractory service or repair work, observe the following precautions:

• Ensure the area is well ventilated.

• Wear a respirator approved by the National Institute for Occupational Safety and Health (NIOSH).

• Wear gloves, eye protection, and long-sleeved, loose-fitting clothing.

Dispose of refractory waste material in an airtight plastic bag.

Vacuum clothing before leaving the work site. Wash work clothes separately from other laundry.

Wash all exposed body areas with soap and water.

A maintenance program avoids unnecessary down time, costly repairs, and promotes safety. It is recommended

that a record be maintained of daily, weekly, monthly, and yearly maintenance activities.

750-437

Q Series Full Modulation

5-1

Page 54

Maintenance

Electrical and mechanical devices require systematic and periodic inspection and maintenance. Any “automatic”