Page 1

Hawk 1000

Boiler Control

Operation Manual

750-366

07/2013

Page 2

TO: Owners, Operators and/or Maintenance Personnel

This operating manual presents information that will help to properly operate and care for the equipment. Study its contents carefully. The unit will provide good service and continued operation if proper operating and maintenance instructions are followed. No attempt should be made to operate the unit until the principles of operation and all of the

components are thoroughly understood.

It is the responsibility of the owner to train and advise not only his or her personnel, but the contractors' personnel who

are servicing, repairing, or operating the equipment, in all safety aspects.

Cleaver

and mechanical devices supplied as part of the unit were chosen because of their known ability to perform; however,

proper operating techniques and maintenance procedures must be followed at all times.

Any "automatic" features included in the design do not relieve the attendant of any responsibility. Such features merely

free him of certain repetitive chores and give him more time to devote to the proper upk

It is solely the operator’s responsibility to properly operate and maintain the equipment. No amount of written instructions can replace intelligent thinking and reasoning and this manual is not intended to relieve the operating personnel of

the responsibility for proper operation. On the other hand, a thorough understanding of this manual is required before

attempting to operate, maintain, service, or repair this equipment.

Operating controls will normally function for long periods of time and we have found that some operators become lax in

their daily or monthly testing, assuming that normal operation will continue indefinitely. Malfunctions of controls lead to

uneconomical operation and damage and, in most cases, these conditions can be traced directly to carelessness and

deficiencies in testing and maintenance.

The operation of this equipment by the owner and his operating personnel must comply with all requirements or regulations of his insurance company and/or other authority having jurisdiction. In the event of any conflict or inconsistency

between such requirements and the warnings or instructions contained herein, please contact Cleaver-Brooks before proceeding.

-Brooks equipment is designed and engineered to give long life and excellent service on the job. The electrical

eep of equipment.

Page 3

Cleaver-Brooks

HAWK 1000

Boiler Control

Operation Manual

Please direct purchase orders for replacement manuals to your local Cleaver-Brooks authorized representative

Manual Part No. 750-366

07/2013

Page 4

Page 5

CONTENTS

Section 1

General

Introduction .................................................................................. 1-2

System Description ........................................................................

Hawk 1000 System Features .......................................................... 1-4

Safety Provisions and Diagnostics .................................................... 1-5

Inputs and Outputs ......................................................................... 1-6

Section 2

System Components

Overview ...................................................................................... 2-2

Controller ......................................................................................

Human-Machine Interface (HMI) .....................................................2-3

Communications ............................................................................2-4

Sensor Inputs ................................................................................ 2-6

Section 3

Hardware Checkout

Control Panel Component Checks .................................................... 3-2

Modbus Actuator Checks ................................................................3-7

Section 4

System Configuration

Introduction .................................................................................4-2

Main Menu

Boiler Overview ............................................................................4-3

System Configuration ....................................................................4-4

..................................................................................

1-3

2-2

4-2

Section 5

Commissioning

Commissioning the Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting Combustion - P

Setting Combustion - Single Point Positioning . . . . . . . . . . . . . . . . . . 5-8

Setting Combustion - Low/High/Low. . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Firing Rate Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Alarms and Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

O2 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Drive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Two Boiler Lead Lag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Thermal Shock Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Diagnostics and T

System Monitoring and Diagnostics

PLC Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Hawk 1000 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

ositioning . . . . . . . . . . . . . . . . . . . . . 5-4

arallel P

Section 6

roubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Section 7

Parts

Page 6

Page 7

Section 1

General

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Hawk 1000 System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Provisions and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Burner Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Boiler Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

www.cleaverbrooks.com

Page 8

Section 1 — General Hawk 1000

1.1 Introduction

The Cleaver-Brooks HAWK 1000 is an exclusive Boiler Management and Control system specifically designed

to integrate the functions of a Programmable Boiler Controller and Burner Management Controller, as well as

other boiler operating and ancillary controls. The HAWK 1000 system incorporates a user-friendly, graphical

Human Machine Interface (HMI) that displays boiler parameters, fault annunciation and alarm history, as well

as providing access to boiler configuration and control functions.

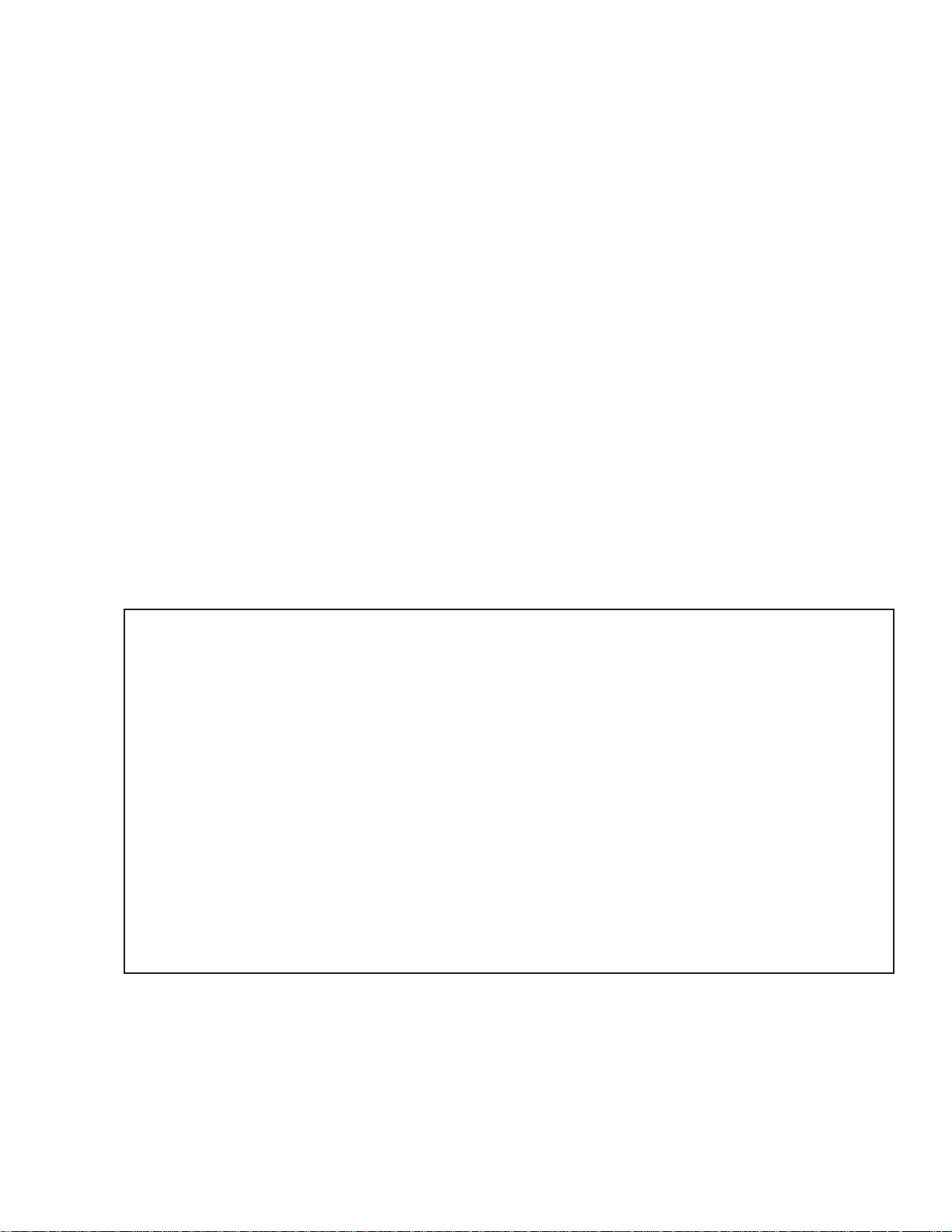

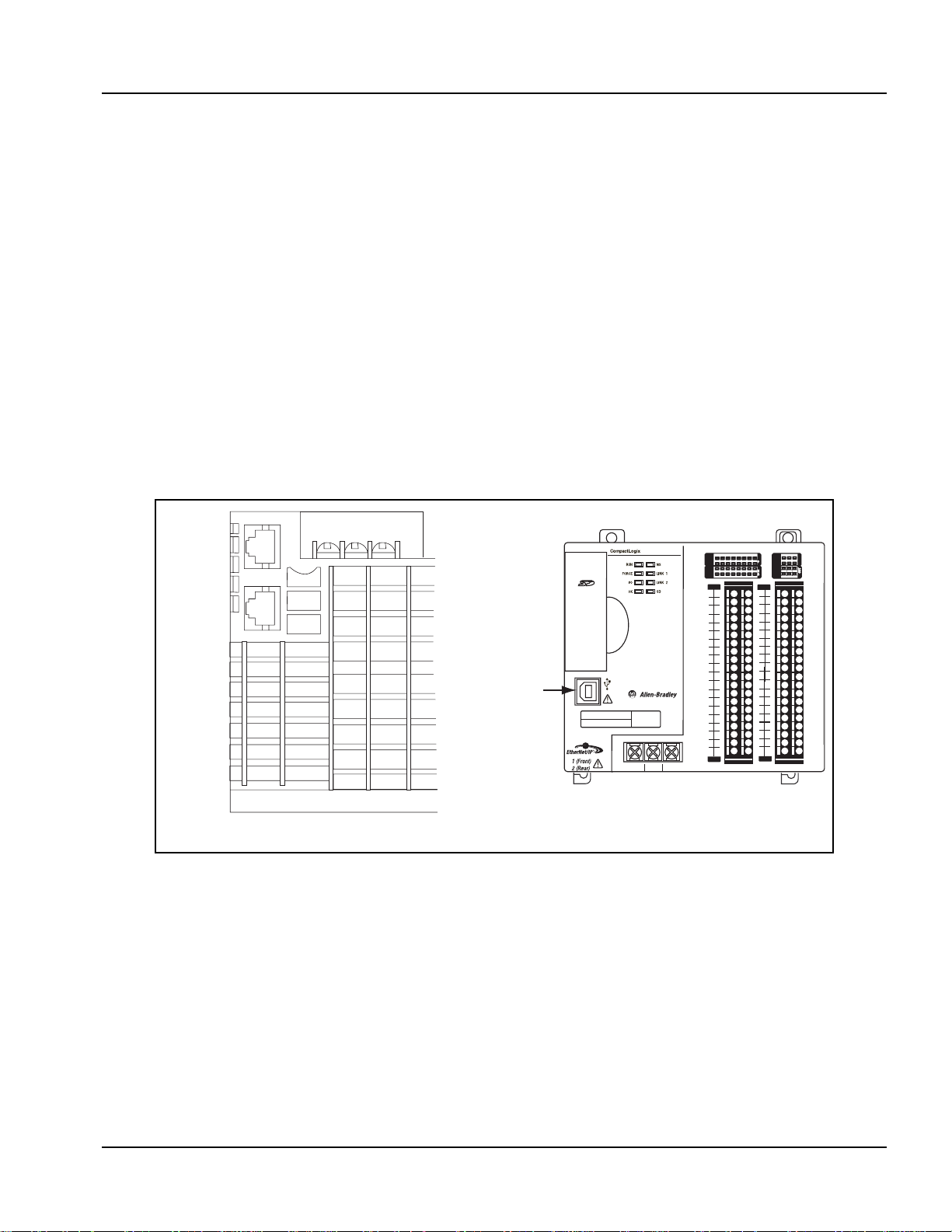

Figure 1-1. Boiler Overview Screen

Figure 1-2. Typical Panel Layout

1-2 Part No. 750-366

Page 9

Hawk 1000 Section 1 — General

1.2 System Description

The HAWK 1000 Boiler Control System provides boiler firing rate control to maintain steam pressure (or hot

water supply temperature) on set point. Final control element(s) are modulated via Modbus communications

network to insure that the optimum fuel/ air ratio is maintained throughout the firing range.

The Hawk 1000 supports two fuel types. Each fuel type can be fired in one of three possible methods: singlepoint combustion, parallel combustion, and LOW-HIGH-LOW (fuel 2 only). In parallel systems, the Hawk

1000 can also control a flue gas recirculation (FGR) damper.

The Hawk 1000 can be monitored by Building/ Plant Automation Systems via an optional CB-PT protocol

translator. EtherNet/ Internet communication also enables remote monitoring of the Hawk 1000 Boiler Control

System. (Additional software and/or hardware required).

The HAWK 1000 may be used on most types of steam and hot water boilers, including firetube, industrial

watertube, and commercial watertube. In addition to installation on new boilers, the HAWK 1000 can be

added as a retrofit to existing boilers. Call your local authorized Cleaver-Brooks representative for details.

Consult the following Cleaver-Brooks manuals for supplementary operating and maintenance information

regarding specific system options:

Level Master - 750-281

CB-PT Protocol Translator, CB-PTWS Protocol Translator with web server - 750-325

CB120E Burner Control - 750-264

CB780E Burner Control - 750-234

Variable Speed Drives - 750-198

O2 Trim - 750-224

Part No. 750-366 1-3

Page 10

Section 1 — General Hawk 1000

1.3 Hawk 1000 System Features

• Burner Control controls burner start and shutdown sequencing and flame and interlock monitoring

• Compatible with CB780E and CB120E Burner Controls and Flame Scanners

• Boiler Control monitors and displays connected boiler parameters (operating pressure or temperature, stack

temperature, shell water temperature, O2% etc.)

• 4" color touch/keypad Human Machine Interface (HMI)

• Optimized boiler firing rate control

• Alarm/Fault Indication and History -- first out annunciation with time stamp and displayed in order of fault

occurrence

• Dual set point capability

• Thermal shock protection (includes warm-up routine, low fire hold & hot stand-by operation)

• Available input for any ONE of the following: remote modulation, remote set point, or Level Master water level

interface

• Available input for any ONE of the following: water temp (Steam)

• Return Temp or Outdoor reset (hot water boilers)

• Remote Modulation by communications (EtherNet)

• Remote Set Point by communications (EtherNet)

• Boiler efficiency calculation

• Assured Low Fire Cut Off

• External Interlock with auxiliary devices (fresh air damper/louvers, circulating pumps, etc.)

• High stack temperature alarm and shutdown

• Built-in two-boiler lead/lag capability (local set point only)

• EtherNet communications

• Three firing modes: Single-point, parallel, or LOW-HIGH-LOW

• Revert to Pilot control function (requires CB120E burner control)

• Supports control of a flue gas recirculation (FGR) damper

• Supports the control of a 2nd gaseous fuel actuator (Both Gaseous Fuels)

• OPC server software for building/plant automation system interface

• Remote monitoring software

• O2 monitoring and O2 trim (Option)

• Variable Speed Drive on combustion air fan (with bypass) (Option)

• Combustion Air Temperature Monitoring (Option)

1-4 Part No. 750-366

Page 11

Hawk 1000 Section 1 — General

1.4 Safety Provisions and Diagnostics

1.4.1 Burner Management

• Utilizes CB780E or CB120E Burner Control

• Communicates with the PLC via Modbus

• Burner Control Status, Faults and Diagnostics displayed on HMI or panel mounted burner control

• Flame condition monitoring using either IR or UV Flame Scanner

Figure 1-3. CB 780E

1.4.2 Boiler Controls

• Operating and Modulating Controls

• Monitors Low Water Cut-Off

• Monitors Burner Control alarm terminal

• Non-Recycle Limit Relay de-energizes on PLC system errors or faults

• Transmitter input signal out of range alarms

• Actuator Modbus communication fault diagnostics

• Password protected system configuration and system set up screens

• Alarm Management incorporated into door-mounted HMI

• Password protection of Programmable Controller Logic

• Optional Variable Frequency Drive (VFD) fault shutdown

Figure 1-3. Burner Control Screen

Figure 1-4. Hawk 1000 Main Menu

Part No. 750-366 1-5

Page 12

Section 1 — General Hawk 1000

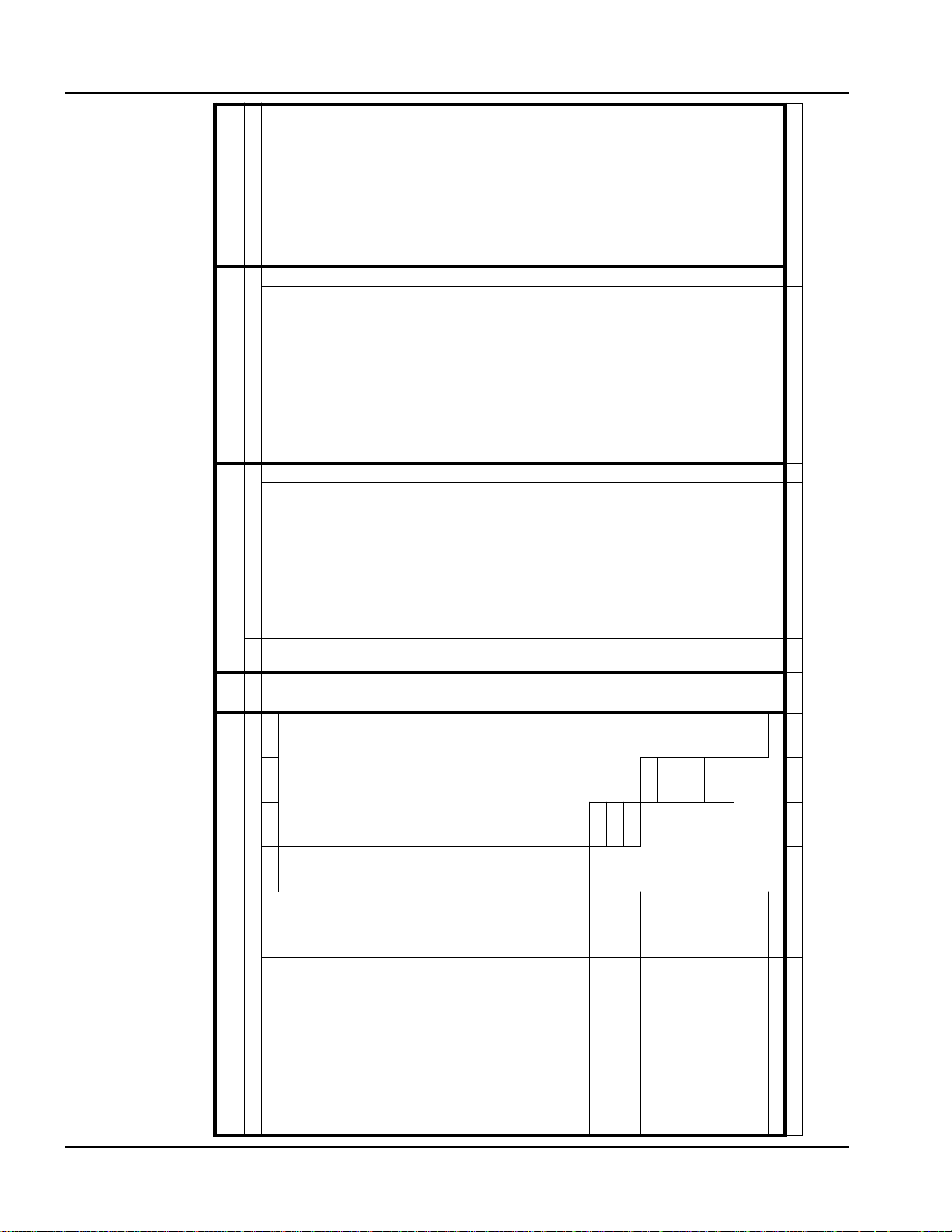

1.5 Inputs and

Outputs

with O2, VSD or Comb Air Temp)

1

1

CB120E only)

Fire Oil Valve 2

1

1769 IA16 Digital Input 1769 OW8I Isolated Digital Output 1769 IF4 Analog Input (Optional

SM2

Dig IN Dig OUT Ana IN Ana Out

SP

I2/2 1

I2/3 1

Processor 1769-L24ER-QBFC1B - Slot 0 1769

Embedded I/O - Slot 1-3 Slot 4 Slot 5 Slot 6 Slot 7

High Limit Control I1/0 1 I5/0 Blower Terminal 1 O6/0 Recycle Limit (RLR) 1 I7/0 VSD Feedback 1

ALWCO I1/1 1 I5/1 Purge 1 O6/1 Start Ext. Device (FAD) 1 I7/1 O2 Signal 1

Low Fuel 1 Pressure/Low Oil Temp I1/2 1 I5/2 O2 Analyzer Status (Yokogawa) 1 O6/2 Non-Recycle Limit (NRLR) 1 I7/2 Comb Air Temp 1

High Fuel 1 Pressure/High Oil Temp I1/3 1 I5/3 VSD Status 1 O6/3 Prove Low Fire 1 I7/3 Reserved * 1

Low Fuel 2 Pressure I1/4 1 I5/4 Force to Low Fire 1 O6/4 Revert To Pilot (Fireye

High Fuel 2 Pressure I1/5 1 I5/5 Ready To Start/ Limits Closed 1 O6/5 Prove High Fire / Open High

Oil Drawer Switch I1/6 1 I5/6 Ext. Device Start Interlock (FAD) 1 O6/6 Alarm Bell 1

Atomizing Air Pressure I1/7 1 I5/7 ALFCO 1 O6/7 Open High Fire Oil Valve 1 1

Combustion Air Pressure I1/8 1 I5/8 Pilot Terminal 1

High Water (ST) or Flow Sw. (HW) I1/9 1 I5/9 Main Fuel Terminal 1

VSD Bypass I1/10 1 I5/10 Fuel 1 Selected 1

High Combustion Air I1/11 1 I5/11 Fuel 2 Selected 1

Spare I1/12 1 I5/12 Burner Control Alarm Terminal 1

Auxiliary Alarm 1 I1/13 1 I5/13 Low Water Alarm 1

Auxiliary Alarm 2 I1/14 1 I5/14 Lead Boiler / Sel Rem Mod / Sel

Auxiliary Alarm 3 I1/15 1 I5/15 Burner Switch 1

Reserved * O1/0 1

Ready for Lead/Lag O1/1 1

Spare(s) O1/2-O1/15 14

Steam Pres (ST) / Supply Temp (HW) I2/0 1

Stack Temp I2/1 1

Water Temp (ST) / Outdoor Temp

(HW) / Return Temp (HW)

Water Level (ST) / Rem Mod / Rem

Set Point

VSDControl O2/0 1

Firing Rate O2/1 1

High Speed Counter (NOT USED) Slot 3

Total 16 16 4 2 16 8 4

* Reserved for future add

1-6 Part No. 750-366

Page 13

Section 2

System Components

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Human-Machine Interface (HMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Steam Systems: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Hot Water systems: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

www.cleaverbrooks.com

Page 14

Section 2 — System Components Hawk 1000

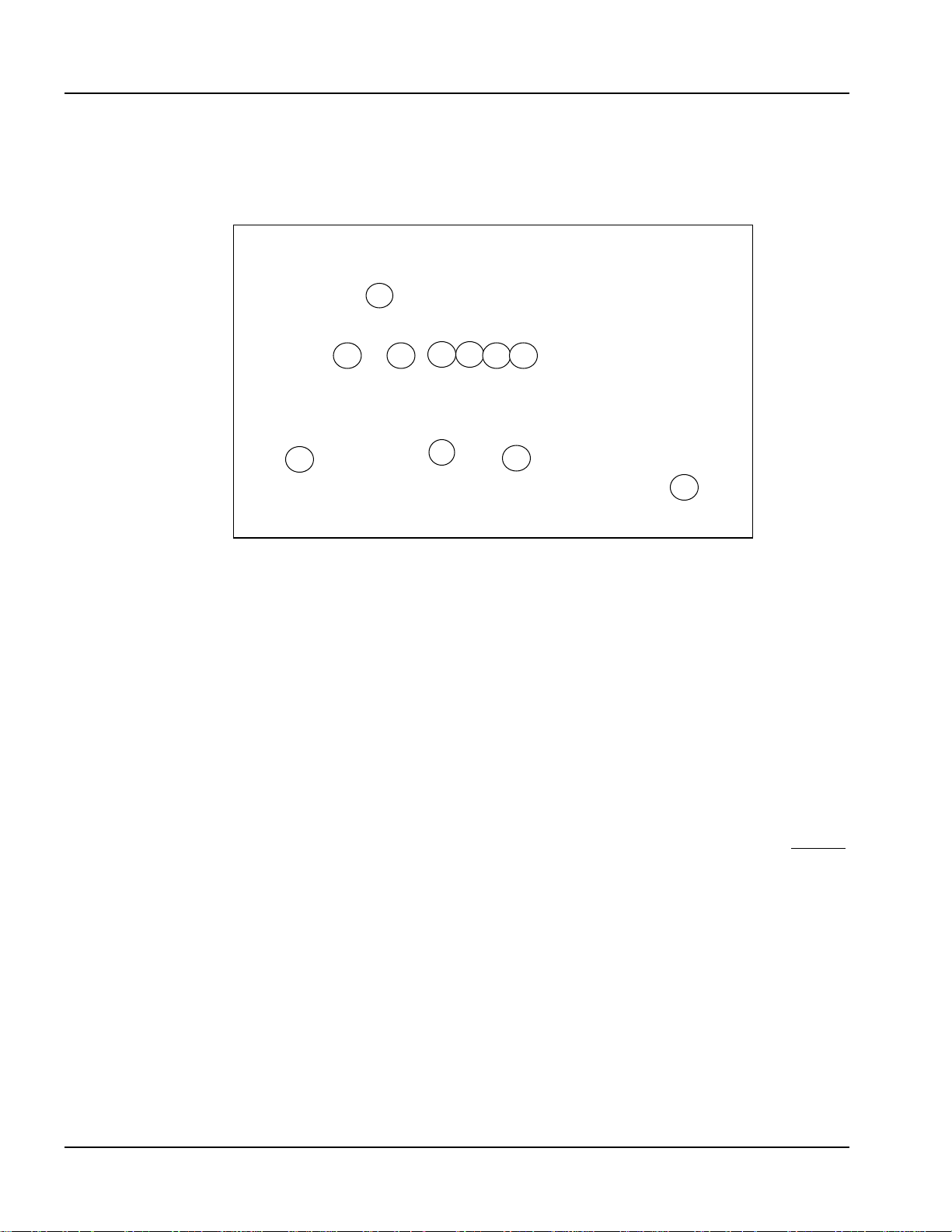

2.1 Overview

The principal components of the HAWK 1000 Boiler Control System are the Programmable Logic Controller

(PLC), Touch Screen Human Machine Interface (HMI), and the Flame Safety Control. The system also includes

24VDC power supplies and various relays and circuit breakers.

1

1a

686

1. Base Unit

1a. L24ER Programmable Logic Controller (PLC)

1b. Embedded I/O

2. SM2 Modbus Communications Module

3. Digital Inputs

4. Digital Outputs

5. Analog Inputs (optional)

6. Burner Control

7. Power supplies

8. Circuit breakers, relays, fuses,

9. ALWCO control

1b

Figure 2-1. Hawk 1000 Panel

etc.

2

7

4

3

5

9

The

HAWK

watertube boilers, yet allows easy configuration for specific boiler applications. The Boiler Controller

logic is password secured, ensuring tamper- proof controller operation. The Touch Screen HMI provides

friendly access to firing rate control functions, boiler diagnostics and alarm histor y, as well as

operating

Safety Control.

1000

parameters.

Boiler Controller is factory pre-programmed to work with most Cleaver-Brooks firetube

Burner

management

progra

conn

is handled by the proven CB780E or optional CB120E

Flame

2.2 Base Unit

The Base Unit consists of the Processor (CPU) which holds the program logic and configuration for the boiler

controller and embedded I/O modules which consist of discrete inputs, discrete outputs, and analog inputs.

The program logic is password-secured at the factory.

The SM2 module handles the Modbus communications between the PLC and other devices.

2-2 Part No. 750-366

and

m

user

ected

-

Page 15

Hawk 1000 Section 2 — System Components

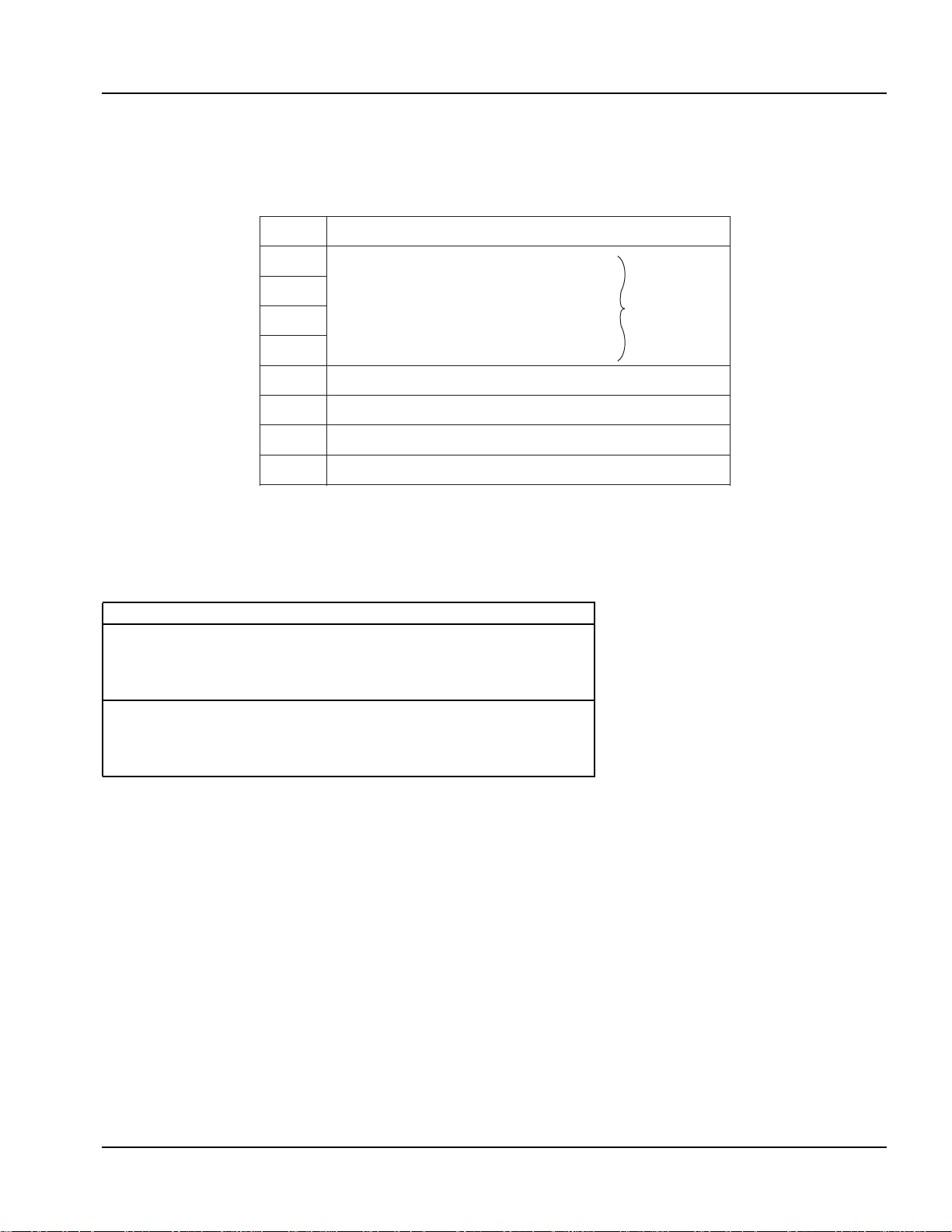

The Module Power Supply powers the Base Unit and the I/O modules. The remainder of the PLC rack is for

the discrete input and output modules, and for analog input module (optional).

I/O modules are used to send and receive control and communication signals to/from other parts of the system.

Slot Module

0

1

2

3

4

5

6

7

A Right End Cap Terminator is required to complete the modular communication bus. It attaches to the right

side of the last module in the rack.

An optional analog input module can be added to the PLC to provide additional functionality.

DISCRETE and ANALOG Signal Types

Discrete inputs/outputs are used for signals taking on only one of two

possible states (on/off, open/close, etc.). The input state is represented

by a bit (0 or 1) in the control logic. Example:

Boiler Ready (yes/no)

Analog signals can assume almost infinite values within the fixed

analog input/ output current range of 4-20 mA. The Hawk 1000 PLC

converts this current value to a range in engineering units. Example:

Steam Pressure (0-150 PSI)

1769-L24ER-QBFC1B Processor

Embedded Discrete Inputs/Outputs

Embedded Analog Inputs/Outputs

Embedded High Speed Counter

SM2 Modbus Module

Digital Input Module

Relay Output Module

Analog Input Module (4 ch. - optional)

BASE

UNIT

NOTE: The PLC program expects each device to be in a specific slot location. The HAWK 1000 controls

will not function unless all devices are properly installed and configured.

2.3 Human-Machine Interface (HMI)

The HMI displays numerous boiler parameters at a glance and provides easy menu navigation for configuring

system parameters, setting of combustion, monitoring the boiler processes, and managing and annunciating

system alarms.

The HMI communicates with the PLC via Ethernet and is

Part No. 750-366 2-3

powered

by a 24

VDC

din-rail mounted power

supply.

Page 16

Section 2 — System Components Hawk 1000

Figure 2-2. Firing Rate screen

2.4 Communications

2.4.1 Modbus

Modbus is an open serial protocol used by the

commands,

communications

HAWK 1000 devices that communicate using Modbus include the burner flame safety control and the fuel, air,

and FGR actuators. The Modbus communication network allows burner control system status and fault

information to be transmitted to the PLC and displayed on the HMI screen, and in addition is used for actuator

control, feedback, and fault information.

position data, and diagnostic data between the

are managed by the SM2 module located to the right of the base unit in slot

Figure 2-3. SM2 Modbus Module

HAWK

1000 system

PLC

and attached

for sending and receiving control

devices.

Modbus

4.

2-4 Part No. 750-366

Page 17

Hawk 1000 Section 2 — System Components

2.4.2 Ethernet

The

HAWK

1000

uses Ethernet for several communication functions:

• Communication between the PLC and HMI. The Ethernet cable connecting the PLC and HMI can be either

a straight through or a crossover type.

• Connection of the boiler control system to an existing infrastructure, i.e. plant Local Area Network (LAN)

• Integration with a Building/Plant Automation System (BAS)

• Remote monitoring of boiler control system via the customer's Wide Area Network (WAN) or via the Internet

• Connection of a laptop for diagnostics

Ethernet/IP is also used for control functions. Individual boiler controllers may be networked to facilitate lead/lag

control, with a single BAS interface for multiple boiler systems.

2.4.3 USB

USB communications are used to connect a laptop computer for diagnostic purposes.

PORT 1

PORT 2

Ethernet ports (bottom of Base Unit)

Figure 2-4. L24ER Communication Ports

USB

PORT

00:00:BC:2E:69:F6

L24ER

QBFC1B

+24VDC COM FG

+24VDC C OM FG

01234567

01234567

8 9 10 11 12 13 14 15

SINK\

24VDC

SOURCE

SINK\

8 9 10 11 12 13 14 15

24VDC

SOURCE

01234567

24VDC

01234567

SOURCE

24VDC

SOURCE

8910

8910

DC IN

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

NC

NC

+V

+V

00

08

01

09

02

10

03

11

04

12

05

13

06

14

07

15

COM

COM

0

1

DC OUT

11 12 13 14 15

11 12 13 14 15

DC

DC

INPUT

DC

DC

OUTPUT

A0+

B0+

Z0+

A1+

B1+

Z1+

+V

OUT

OUT

COM COM

CJC

CJC

OUT

OUT

A0 B0 Z0

A0 B0 Z0

INOUT

A1 B1 Z1

INOUT

A1 B1 Z1

INPUT

COUNTER

0 2 FUSE

HIGH SPEED

COUNTER

0 2 FUSE

HIGH SPEED

13OK

OUTPUT

13OK

HSC

A0-

B0-

Z0-

A1-

B1-

Z1-

+V

OUT

2

0

0UT

1

3

V

V

in

in

0+

2+

I

I

in

in

0+

2+

V/I

V/I

in

in

0-

2-

V

in

+

3+

I

in

3+

V

V/I

in

in

1+

3V/I

I

in

in

1-

1+

V

V

OUT

0+

1+

I

I

in

0+

1+

COMCOM

ANALOG

Part No. 750-366 2-5

Page 18

Section 2 — System Components Hawk 1000

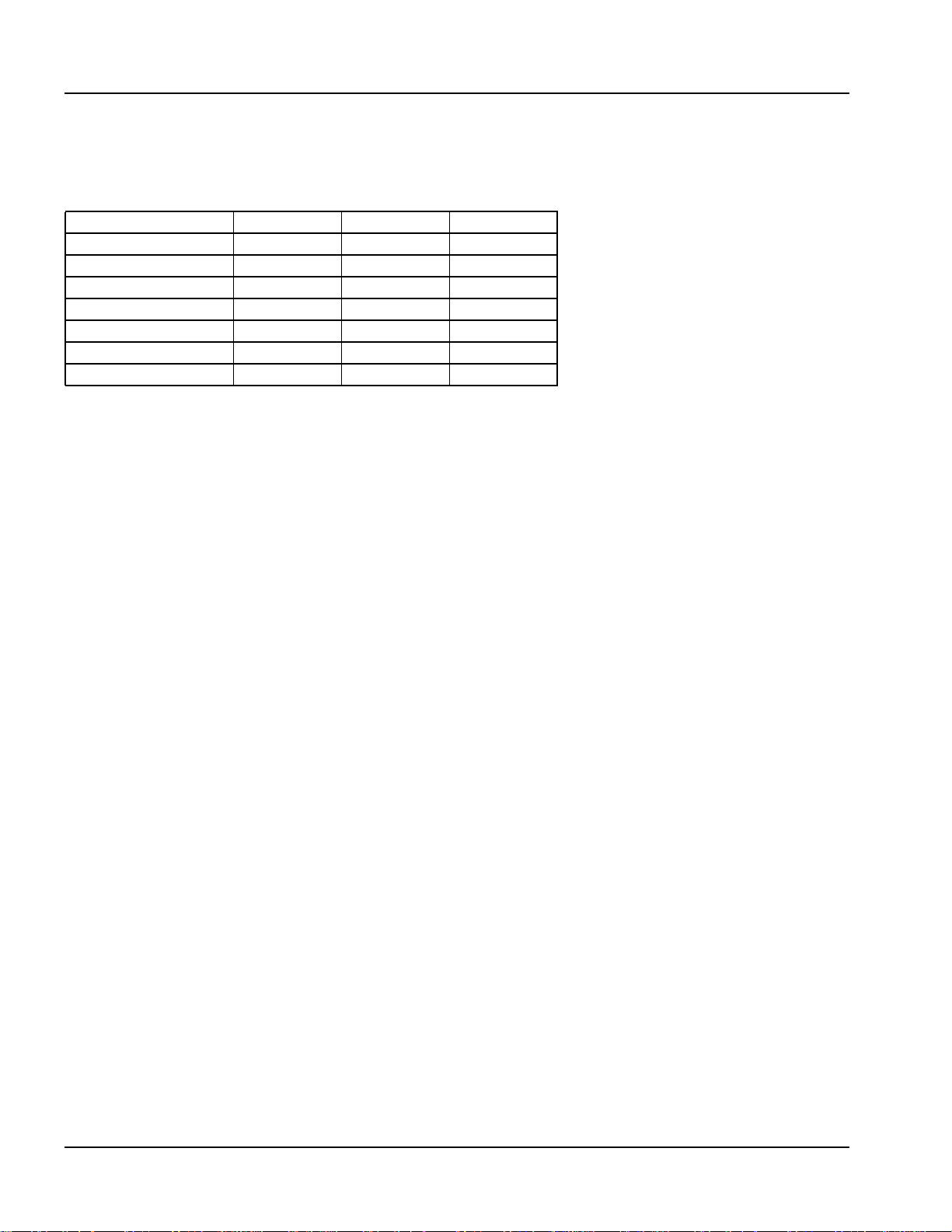

2.5 Sensor Inputs

The following table shows the sensors available as standard and as options for steam systems (ST) and for

hot water (HW) systems:

Sensor System Standard Optional

Steam Pressure ST Yes

Stack Temperature ST & HW Yes

Water Temperature ST Yes

Water Level ST Yes

Supply Temperature HW Yes

Outdoor Temperature HW Yes

Return Temperature HW Yes

All systems use RTDs with a transmitter to produce 4-20mA output for

temperature detection.

2.5.1 Steam Systems:

Steam Pressure is the primary sensor input to the HAWK 1000 Controller in a Steam System. It transmits a

4-20mA process variable signal to the Controller that is used to control Firing Rate and the Operating Limit

Control.

Stack Flue Gas Temperature is used for High Stack Temperature alarms and shutdown. It is also used in the

boiler efficiency calculation.

Water Temperature (mandatory on steam boilers) measures boiler-shell water temperature and is use d for

thermal shock protection and hot standby control on steam boilers. The standard location for the thermowell is

a 1/2” NPT coupling at the right-hand side center-line of the boiler shell. If this location is not available, an

unused feedwater connection may be used.

Water Level sensor is OPTIONAL on steam boilers, but must be a CB Level Master.

2.5.2 Hot Water systems:

Supply Temperature is the primary sensor input to the HAWK 1000 Controller in a Hot Water system. It

transmits a 4-20mA process variable signal to the Controller that is used to control Firing Rate and the

Operating Limit Control.

Outdoor Temperature is used in Hot Water Systems with the Outdoor Temperature Reset Option.

Return Temperature is used in Hot Water Systems with the Return Temperature option and is monitor only.

NOTE: The Outdoor Temperature and Return Temperature sensors use the same input. One or the other can

be used with the Hawk 1000, but not both.

2-6 Part No. 750-366

Page 19

Section 3

Hardware Checkout

Control Panel Component Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

DIN Rail Latch and Expansion I/O Module Locking Levers . . . . . . 3-2

Panel and Field Wiring Terminations . . . . . . . . . . . . . . . . . . . . . 3-3

SM2 Module DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Burner Control Modbus Address and Baud Rate - CB780E . . . . . 3-4

Burner Control Modbus Address and Baud Rate - CB120E . . . . . 3-6

PLC Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Modbus Actuator Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting The Modbus Node Address . . . . . . . . . . . . . . . . . . . . . . 3-9

Power/ Communications LED . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Moving The Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

www.cleaverbrooks.com

Page 20

Section 3 — Hardware Checkout Hawk 1000

Important

!

The base unit and expansion modules do not support removal and insertion under power. While the PLC

system is under power, any break in the connection between the power supply and the base unit (i.e.

removing the power supply, base unit, or an expansion module) will clear processor memory including the

user program. Ensure that the electrical power is OFF before removing or inserting any PLC device.

3.1 Control Panel Component Checks

This section will cover the initial system checkout to be done prior to configuring and commissioning the

system through the HMI menu system.

It is necessary to confirm that all of the integral components and interconnecting wiring are in place and

secure. Vibration and jarring from transport or installation may have loosened components or wiring terminals.

It is good practice to check all system components for integrity and tightness prior to initial power-up of the

system. Any external interlock and remote signal wiring should also be connected to the boiler controller.

3.1.1 DIN Rail Latch and Expansion I/O Module Locking Levers

Before powering up the control system for the first time, check that all the DIN rail latches and expansion

module locking levers are in place (see Figure 3-1 and Figure 3-2).

Figure 3-1. DIN rail latches

Figure 3-2. Expansion I/O Module locking levers

The module locking levers should all be securely seated to the left.

3-2 Part No. 750-366

Page 21

Hawk 1000 Section 3 — Hardware Checkout

3.1.2 Panel and Field Wiring Terminations

Check that all factory wiring connections are tight and that field wiring terminations are completed and secure.

Figure 3-3. Check all wiring and connections

3.1.3 SM2 Module DIP Switch

Verify that the SM2 Module DIP switch setting is as shown below (the top switch is to the left, the bottom

switch is to the right).

DIP switch

settings: Top L,

Bottom R

Figure 3-4. SM2 module DIP switch setting

Part No. 750-366 3-3

Page 22

Section 3 — Hardware Checkout Hawk 1000

3.1.4 Burner Control Modbus Address and Baud Rate - CB780E

The CB780E Modbus node address should be set to 05 and the baud rate to 9600. Settings are made using

the 780E keypad display.

Press the left three buttons of the keypad display module for one second, then release.

DISPLAY Setup will appear.

Press the two ENTER buttons at the same time.

Press down arrow until MB ADDRESS is displayed.

Press ENTER buttons at the same time.

Press down arrow twice.

Set Modbus address to 05 by using up and down arrow keys.

Press ENTER buttons at the same time.

3-4 Part No. 750-366

Page 23

Hawk 1000 Section 3 — Hardware Checkout

Press down arrow key to save changes.

Press down arrow key until MB BAUD is displayed.

Press ENTER buttons at the same time.

Press down arrow to select.

Using up or down arrow key select 9600.

Press ENTER keys at the same time.

Part No. 750-366 3-5

Page 24

Section 3 — Hardware Checkout Hawk 1000

Press down arrow key to save changes.

Press ENTER buttons at the same time.

Press upper arrow key to exit.

3.1.5 Burner Control Modbus Address and Baud Rate - CB120E

The CB120E has built-in Modbus capability; for proper communications the ModBus baud rate and node

address need to be correctly set. To check the settings, the CB120E must be powered.

Press the <BACK> or <NEXT> key on the CB120E display until the screen displays PROGRAM SETUP>.

3-6 Part No. 750-366

Page 25

Hawk 1000 Section 3 — Hardware Checkout

Press the <MODE> then the <NEXT> key until the screen displays BAUD RATE.

Press <MDFY> and use the <BACK> or <NEXT> key to change to 4800. Press <MDFY> to save.

Press the <NEXT> key until UNIT ADDRESS # is displayed. To change the unit address, use the <BACK>

or <NEXT> key to change to 5. Press <MDFY> to save.

Press <MODE> to exit the menu.

3.1.6

Verify

The boiler will not operate if the switch is in the PROG

The boiler will immediately stop if the switch is moved to the

The switch must be in the PROG position and the Burner switch set to OFF before the PLC program

be copied to a blank SD card in “

The switch can be in either PROG or RUN position when copying a PLC program from a SD

a

3.2 Modbus

PLC

Switch

that the PLC switch is in the RUN

Logix

folder. No other files should be present on the SD

Actuator

Checks

position

Logix

folder” format.

.

position

.

PROG position.

can

card

containing

card.

3.2.1 Mounting

Fasten the actuator using bolts through the mounting bracket, threaded into the face of the actuator. Be

sure

that the mounting

surface

rests flat against the mounting bracket and is

secure.

The actuator output drive shaft should be connected to the valve shaft with a suitable coupling. The

coup

ling

may be connected with set screws and pinned in position or secured with a key.

It is recommended that the actuator drive shaft remain decoupled from

shaft (or damper level) until the actuator Modbus address is properly set, the wiring

is proven, and the direction of rotation to open the valve/ damper is determined.

the valve

3.2.2 Electrical Connections

(from

The actuators are intended to have one cable connection on the incoming side,

the previous actuator

or the Hawk panel) and one cable connection on the outgoing side, to the next actuator. The cable

connectors

align the

the cable.

movement of the

In some installations, codes or other requirements may call for the actuators to be hard wired. See Figure

Part No. 750-366 3-7

and mounting plugs are keyed to ensure that the pins all line up correctly. To connect the cable,

pins

and the key and push into place. Turn the threaded collar clockwise to tighten and secure

Secure

the cables such that the cables are not pinched and do not in

actuated

devi

ces.

terfere

with the mechanical

3-7.

Page 26

Section 3 — Hardware Checkout Hawk 1000

Figure 3-5. SM2 wiring to actuators

MODBUS ACTUATORS PLUG WIRED

FUEL 1

ACT. 1

Figure 3-6. Actuator daisy chain w/ plug connections

FUEL 2

ACT. 1

3-8 Part No. 750-366

Page 27

Hawk 1000 Section 3 — Hardware Checkout

MODBUS ACTUATORS HARD WIRED

FUEL 1

ACT. 1

FUEL 2

ACT. 1

Figure 3-7. Actuator daisy chain hard wired

3.2.3 Setting The Modbus Node Address

The actuators are required to have unique Modbus node addresses. The node address is set using a rotary

style switch located on the actuator front plate. Turn to the desired address using a small, flat bladed

screwdriver.

Part No. 750-366 3-9

Page 28

Section 3 — Hardware Checkout Hawk 1000

Rotary switch - set

node address

Power/Command LED

Figure 3-8. Modbus Actuator

Once the node address has been set, the actuator may be powered up.

Power must be cycled to the actuator before a new node address setting will be accepted by the actuator.

Actuator Node Address Table:

Actuator Address

Air Actuator 1

Fuel 1 Actuator 2

2nd Fuel 1 Actuator 3

Fuel 2 Actuator 5

2nd Fuel 2 Actuator 6

FGR Actuator 7

3.2.4 Power/ Communications LED

Each actuator has a green Power/ Communications LED. The LED can assume one of three states:

OFF - check that 24 VDC power is present. The LED is also OFF when pressing either the CCW or CW red

pushbutton.

ON Solid - power present but no commands received from PLC. ON Solid is the normal state for an actuator

not required by the PLC at the time - such as the Fuel 2 Actuator when the Fuel Selector is in the Fuel 1

position.

Rapid Flickering - actuator is responding to PLC commands and sending position data.

3-10 Part No. 750-366

Page 29

Hawk 1000 Section 3 — Hardware Checkout

3.2.5 Moving The Actuator

The actuator can be moved clockwise or counterclockwise by pressing either one of two red buttons

located

on the actuator (Figure 3-9). One red button moves the actuator shaft clockwise, and the other moves

the

actuator shaft counter-clockwise. The servo will automatically stop when it reaches the end of its

travel.

Moving of actuators manually should only be done when the main fuel valve is closed. Moving the actuators

manually while the main fuel valve is open will generate a fault.

Releasing the manual pushbutton will allow the PLC to automatically command the actuators to position;

therefore the buttons should not be used during commissioning, but only as a troubleshooting tool.

There are open/ close pushbuttons on the actuator calibration screen

should be used when calibrating the actuators.

Clockwise or counter-clockwise actuator shaft

Figure

3-9.

rotation

Counterclockwise (CCW)

is deduced

from

on the

the viewing perspective shown in

HMI. These pushbuttons

Clockwise (CW)

Figure 3-9. Actuator manual pushbuttons

Part No. 750-366 3-11

Page 30

Section 3 — Hardware Checkout Hawk 1000

3-12 Part No. 750-366

Page 31

Section 4

System Configuration

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Boiler Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Boiler Type and Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Fuel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Flame Safeguard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Remote Modulation/Remote Set Point . . . . . . . . . . . . . . . . . . . . 4-15

Actuator Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Variable Frequency Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Configuration Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-23

www.cleaverbrooks.com

Page 32

Section 4 — System Configuration Hawk 1000

4.1 Introduction

The Hawk 1000 is equipped with a 4" color touch screen Human Machine Interface (HMI). The HMI along

with the Burner Control display are the points of interface for the operator to monitor and control the boiler,

and for the technician to configure and set up the system.

This section describes the HMI screens and their functions.

For information on the Burner Control (Flame Safeguard), refer to one of the following CB publications:

CB120E Burner Control 750-264

CB780E Burner Control 750-234

Figure 4-1. Firing Rate Screen

A gray button on the HMI indicates that a password is required before user input is allowed. The Hawk 1000

employs three levels of security: Operator, Service, and Factory. Pressing a gray pushbutton will display the

login entry window.

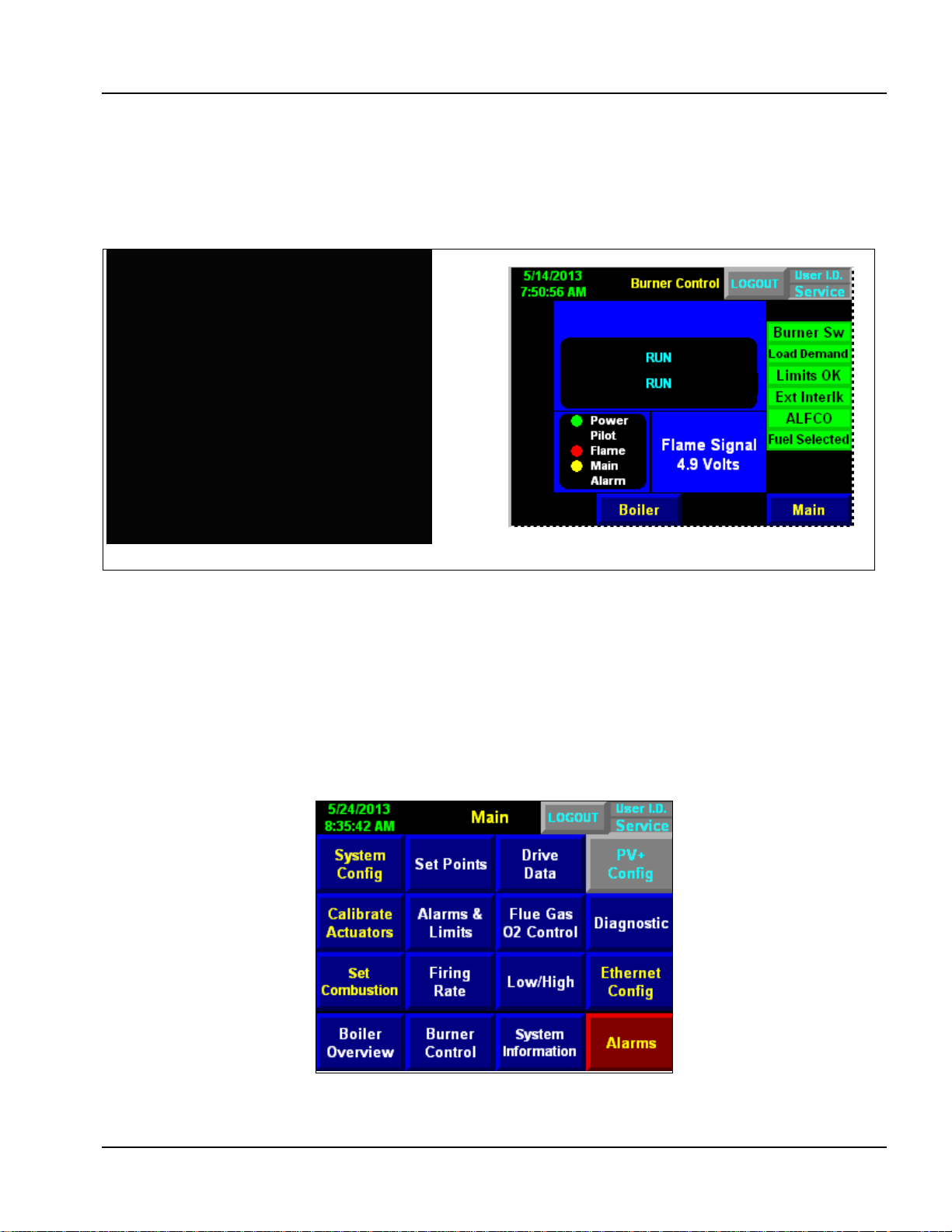

4.2 Main Menu

The Main Menu (Figure 4-2) is the first screen to appear when power is applied to the system. A header

section at the top of the screen shows the current date and time, the user login status, a logout button and

an alarm bell if an alarm is present. The rest of the screen consists of screen navigation buttons.

When the system is powered on for the first time (Figure 4-3), the <System Config>* button will indicate “System

Config Required”. The screen will indicate “Commissioning Not Done” until initial configuration and commissioning have

been completed. Note also that some screen buttons will not yet be available.

*In this manual, screen buttons

on

the HMI are identified by the

button

description with arrows on

either

side (e. g. <Main>

).

4-2 Part No. 750-366

Page 33

Hawk 1000 Section 4 — System Configuration

Figure 4-2. Main Menu (all possible screens)

Figure 4-3. Main Menu (initial startup)

4.3 Boiler Overview

The Boiler Overview display (Figure 4-4) serves as the main point of interface for the operator. The primary

purpose of the display is to monitor the current status of the boiler.

Part No. 750-366 4-3

Page 34

Section 4 — System Configuration Hawk 1000

Firetube

Model 4/5

Figure 4-4. Boiler Overview

4.4 System Configuration

The first step in commissioning the boiler is to

configure the control

Screen press <

System

system

options. On the Main

Config

>.

Flextube

A warning message is displayed:

Press <

System

Config

> again; a final warning

screen will appear:

Figure 4-5. Warning 1

4-4 Part No. 750-366

Page 35

Hawk 1000 Section 4 — System Configuration

Figure 4-6. Warning 2

Press <Next> to continue. The following items are configurable when in system configuration:

• Boiler Media Steam or Hot Water

• Boiler Type - Firetube, Flextube or M4/M5 boiler

• Safety Valve Setpoint

• NOx Level (PPM)

• Number of Fuels

• Fuel 1 Fuel Type

• Fuel 1 Control Type (Parallel or Single Point)

• Fuel 1 Turndown

• Fuel 2 Fuel Type

• Fuel 2 Control Type (Parallel, Single Point, or Low High)

• Fuel 2 Turndown

• Flame Safeguard Selection

• Revert to Pilot (CB120E Only)

• Revert to Pilot Signal Select (CB120E Only)

• Analog Input I:2.2

• Analog Input I:2.3

• Remote Modulation/Setpoint Signal Selection

• Dual Setpoint Selection

• Actuator Selection

• VFD Option Selection (requires additional analog input module Slot 7)

• VFD Bypass Option Selection

• O2 Analyzer (when this option is selected, type of analyzer must be specified - requires additional analog input

module Slot 7)

• O2 Trim

• Low O2 Shutdown Option

• Hot Standby Option Selection

• Combustion Air Temp Option Selection (requires additional analog input module Slot 7)

• Level Master Option selection (Steam Boiler)

• Return Water Temperature (hot water only)

• Outdoor Temp Reset Selection (hot water only)

• Selectable overview screen graphic - Firetube, Flextube, or M4/M5 boiler

Part No. 750-366 4-5

Page 36

Section 4 — System Configuration Hawk 1000

Note that if a configuration setting is marked with an asterisk and the setting is changed the Combustion

Curves will be erased.

Caution

!

If System Configuration is entered with the boiler running, a safety

shutdown will occur. Repeated shutdowns or nuisance shutdowns

can cause premature equipment failure.

Caution

!

The following screens should only be accessed by qualified

personnel. Selections should never be made while the boiler is in

operation.

Note: The boiler will not start while you are in the “System Config” screen.

Note: The firing rate will be put into manual mode upon entering the “System Config” screen.

4.4.1 Boiler Media and Type

The first step in the configuration procedure is to select the boiler media and type.

Figure 4-7. Select boiler media & type

Any time a gray button appears, a user I.D. and password are required for user input.

Pressing <Boiler Media> or <Boiler Type> will bring up the following screen:

4-6 Part No. 750-366

Page 37

Hawk 1000 Section 4 — System Configuration

Pressing <User> or <Password> will bring up an alphanumeric keypad. Use this (or the HMI hardware

keypad) to enter your user name and password. A USB keyboard may also be used.

Type the password (user name) followed by the Enter key.

When a valid user name and password are entered, the following screen will appear:

Part No. 750-366 4-7

Page 38

Section 4 — System Configuration Hawk 1000

Figure 4-8. System configuration

In this example, “Firetube” is selected as the boiler type. After selecting the boiler media (steam or hot water)

additional screen buttons will become available. Selecting “Steam” will bring up buttons for steam transmitter

span, safety valve setpoint, and NOx level. To change the default values, press the desired button and a keypad

will appear allowing user input.

Selecting boiler type and media will also bring up the <Next> button, allowing the user to advance to the

next configuration screen.

The user must be logged in at the appropriate password level to change configuration data. If the user tries to

change configuration data without having proper access rights, a pop-up window will appear and a password

will be requested.

Figure 4-9. Media selected

4-8 Part No. 750-366

Page 39

Hawk 1000 Section 4 — System Configuration

If a valid user name and password are entered, the operator will be allowed to change data. The current user

login status can be seen in the top right corner of each screen.

The color of the pushbutton will also indicate if the user has proper access rights.

Pressing the button of the value that needs modifying will pop-up a numeric keypad, allowing the operator to

enter the new value. Notice that there is a range of valid entries at the top of the numeric keypad. An out-ofrange entry will show up in red and require re-entering an acceptable value.

Enter the desired value and press the Enter key. If the entry is valid, the value will be accepted and the keypad

will disappear. Note that all entries can be made by touching the HMI screen or by using the HMI keypad.

Numerical values

may be entered

from here or from

the popup numeric

pad on the screen

Popup keypad Invalid entry

Boiler Media

Select Steam or Hot Water depending on the type of system.

Boiler Type

The Boiler Type will display the proper Boiler graphic on the Boiler overview screen

.

The three choices for

Boiler Type are: Firetube, Flextube and M4/M5

Boiler Type is also used to set limits on the maximum entry allowed for Safety Valve Setpoint (steam) or Max

Rated Temperature (hot water).

Safety Valve Setpoint Max

Firetube 400 psi

Flextube 250 psi

M4/M5 600 psi

Maximum Rated Temperature (Hot Water)

All Types = Between 200-400 Deg F

Part No. 750-366 4-9

Page 40

Section 4 — System Configuration Hawk 1000

Safety Valve Setpoint (steam)

On a steam boiler, the proper safety

safety

valve(s) on the boiler.

Warning

!

The safety valve setting is critical to the proper operation of

boiler. An incorrect setting could lead to unsafe

A

hot water boiler is configured similarly. The max rated temperature

number should not exceed

the

is 250º F. Contact your local Cleaver-Brooks representative if you do not know the maximum

rating of your

boiler.

valve

setting should correspond to the pressure setting of the steam

maximum design

operation

.

temperature

the

of the boiler should be entered. This

of the boiler. Default for hot

water

temperature

boilers

Steam Transmitter Span The span settings for the steam transmitter is adjustable. The Steam Transmitter

Span value cannot be set lower than the Safety Valve Setpoint and cannot be set higher than 1000. Initially

the Steam Transmitter Span is populated with a default value:

Safety Valve Setpoint Steam Transmitter Span

15.0 psi or less 15.0

15.1 to 150.0 150.0

150.1 to 300.0 300.0

300.1 to 500.0 500.0

500.1 to 600.0 600.0

In hot water systems the supply temperature transmitter is not scalable. The transmitters used must be rated

to accommodate the required range:

If the Max Rated Temperature > 250 Deg F the Supply Temp Transmitter is set to 50-300 Deg F.

If the Max Rated Temperature = 250.1 Deg F or greater the Supply Temp Transmitter is set to 50-500 Deg F.

NOx Level (PPM)

Enter the NOx Level for this specific job

.

NOx Level can range from 5-150 PPM and is initialized with a value of 60.0 PPM.

Note: On Steam Boilers If NOx Level is less than 60.0 PPM Remote Setpoint and Dual Setpoint Options

are Not Available

.

When all configurable items on this screen have valid entries, the <Next> button will appear, allowing System

Configuration to continue. The next screen is fuel configuration, where number and type of fuels, turndown,

and combustion control method are selected.

4-10 Part No. 750-366

Page 41

Hawk 1000 Section 4 — System Configuration

4.4.2 Fuel Configuration

Figure 4-10. Fuel configuration

Number of Fuels

Enter the Number of Fuels for this application

.

Acceptable values are either 1 or 2. High/Low control method MUST be fuel 2.

Fuel 1/Fuel 2 Type

Select the Fuel type for each fuel for this specific job

When pressing the Fuel Type push button a selector is displayed

The up/down arrows can be used to select the correct fuel. Press the enter key to accept the selection.

Fuel 1/Fuel 2 Turndown

Enter the Turndown for each fuel for this specific application.

The turndown entr y affects the boiler efficiency calculations - it has

turndown. Turndown ratio is established

Part No. 750-366 4-11

during burner commissioning by a qualified burner technician

no

impact on the burner's actual

.

Page 42

Section 4 — System Configuration Hawk 1000

Fuel 1/Fuel 2 Control Method

Select the type of control method for each fuel for this specific job.

Acceptable values for fuel 1 are Parallel Positioning or Single Point positioning.

Acceptable values for fuel 2 are Parallel Positioning, Single Point positioning or Low/High.

Note - Single Point positioning cannot be selected in conjunction with parallel positioning.

When fuel configuration is complete, press <Next> to go to Flame Safeguard configuration.

4.4.3 Flame Safeguard

Figure 4-11. FSG screen

Flame Safeguard

Select the type of Flame Safeguard used for the specific job.

The CB780E and CB120E are the two selections available on the Hawk 1000

If CB120E is selected the Revert to Pilot Option is available (not available on the CB780E).

Revert to Pilot

The Revert to Pilot selection is made by pressing the <Revert to Pilot> push button until “Yes” is displayed

on the pushbutton.

If Revert to Pilot is selected there are two ways to initiate the Revert to Pilot sequence - either by Process

Variable (Steam Pressure/Supply Temperature) or by Digital Input.

If Process Variable is selected the setpoint for Revert to Pilot must be entered from the Setpoint Screen - see

Section 5 E - Setpoints for more details.

If Digital Input is selected, when discrete input I:5.7 ALFCO is turned off, Revert to Pilot will be initiated.

4-12 Part No. 750-366

Page 43

Hawk 1000 Section 4 — System Configuration

Caution

!

Revert to Pilot modes are to be determined in the field

after

careful

analysis of the load conditions that necessitate the use of these mode

r

of ope

Care should be taken to avoid

boiler equipment.

ation.

unnecessary

recycling and damage to the

4.4.4 Analog Inputs

Figure 4-12. Analog Inputs (steam)

Analog Input I:2.2

For Steam systems it is mandatory that Analog Input I:2.2 is Water Temperature

For Hot Water systems Analog Input I:2.2 can be selected as None, Outdoor Temperature, or Return

Temperature.

Part No. 750-366 4-13

Page 44

Section 4 — System Configuration Hawk 1000

Figure 4-13. Analog Inputs (hot water)

Analog Input I:2.3

For Steam systems Analog Input I:2.3 can be selected as None, Water Level, Remote Modulation, or Remote

Set Point. If Water Level is selected it is mandatory that the Level Master is the sensor used to measure the

water level. Remote Set Point is not available on Low Emission boilers <60ppm.

750-281

Level

Master

For Hot Water systems Analog Input I:2.3 can be selected as None, Remote Modulation, or Remote Setpoint

If Analog Input I:2.3 is used for Remote Modulation or Remote Set Point then neither Remote Modulation by

communications or Remote Setpoint by communications are available.

4-14 Part No. 750-366

Page 45

Hawk 1000 Section 4 — System Configuration

4.4.5 Remote Modulation/Remote Set Point

Signals for Remote Modulation or Remote Setpoint can be provided by either an analog input signal or written

directly into the PLC by communications (Ethernet).

Figure 4-14. Remote Mod/Setpoint by Communications

Remote Modulation by Analog Input

This configures the Boiler Controller

rate of the

boiler.

receive a remote 4-20mA signal on input I:2.3 to control the

firing

to

The signal is scaled from 0-100%, (4ma = Low Fire and 20ma = High Fire).

Remote Modulation by Analog Input Signal Selection

The user can select between HMI or digital input to enable Remote Modulation.

Select <Digital In> if another control system will enable Remote Modulation by isolated contact input signal

(120 VAC) on digital input I:5.14. When that input is de-energized, the Boiler Controller will revert back to

local firing rate control. If Remote Modulation operation will be enabled manually, select <HMI Input>.

Remote Modulation can then be enabled, by selecting the <Remote> button on the Firing Rate Screen.

If the PLC detects a bad analog signal, an alarm “Remote Modulation Signal Failure” is activated and the Firing

Rate revert to the LOCAL setting on the HMI.

Part No. 750-366 4-15

Page 46

Section 4 — System Configuration Hawk 1000

Figure 4-15. Remote Modulation signal select

Remote Modulation by Communications

This configures the Boiler Controller

to

receive a Remote Modulation signal directly by Communications

(Ethernet). Modulation units range from 0-100%. Communication integrity is determined by a Communication

Heartbeat signal between the Control System and the Building Management System. If a Communications

failure is detected, an alarm message “Remote Communications Failed” is displayed on the HMI and

Modulation reverts back to the LOCAL setting on the HMI

Remote Set Point by Analog Input

This configures the Boiler Controller

receive a remote 4-20mA signal on input I:2.3 to vary the

set

point

to

of the boiler.

Note: Remote Setpoint is not allowed for low emission steam boilers

.

With Remote Setpoint selected, the analog signal can be scaled to the engineering units on the “Alarm and

the

Limits” Screen, by setting the Remote Setpoint Scaling values (zero and span) of

remote 4-20mA signal

Remote Set Point by Analog Input Signal Selection

The user can select between HMI or digital input to enable Remote Set Point.

Select <Digital In> if another control system will enable

VAC) on digital input I:5.14.

(120

local

setpoint control. If Remote Set point operation will be

Remote Setpoint can then be

When

that

enabled,

input is de-energized, the Boiler Controller will revert back to

by selecting the

R

emote

Set Point by isolated contact input signal

enabled

<Remote>

manually, select <HMI

button on the Firing Rate

Input>.

Screen

.

If the PLC detects a bad analog signal, an alarm “Remote Setpoint Signal Failure” is activated and the Set

point revert to the LOCAL setting on the HMI.

Remote Set Point by Communications

This configures the Boiler Controller

to

receive a Remote Set Point signal directly by Communications

(Ethernet). Setpoint is written in engineering units. Communication integrity is determined by a

Communication Heartbeat signal between the Control System and the Building Management System. If a

4-16 Part No. 750-366

Page 47

Hawk 1000 Section 4 — System Configuration

Communications failure is detected, an alarm message “Remote Communications Failed” is displayed on the

HMI and Setpoint reverts back to the LOCAL setting on the HMI

Warning

!

Remote Set Point control should not be used on certain Low

Emission boiler systems. Low Emission boilers can be

changing operating set points. Contact your Cleaver-Brooks

representative

your boiler. Failure to follow these precautions may result in

damage to equipment, serious personal

Dual Set Point

Dual Set Point control - traditionally referred to as night setback - allows the Boiler Controller to easily switch

from the primary set point (Set Point 1) to the setback set point (Set Point 2). Set Point 1 is the primary set

point for the Controller and is the only set point available if the Dual Set Point option is disallowed (see below).

Setback can be initiated manually (through the HMI on the Firing Rate screen) or remotely (by energizing an

isolated contact input signal (120 VAC) on digital input I:5.14. Press the button to the right of “Dual Set Point

Selection By” to toggle between <HMI Input> and <Digital In>.

to determine if Remote Set Point

injury,

control

or

sensitive

is

death.

allowed

to

on

The Dual Set Point option is not allowed when Remote Modulation, or Remote Set Point options are enabled.

Selecting <Yes> to Dual Setpoint enables dual Set Point control. This option is not allowed for low emission

steam boilers (<60 ppm).

Warning

!

Dual Set Point control should not be used on certain Low Emission

boiler systems. Low Emission boilers can be sensitive to changing

operating set points. Contact your Cleaver-Brooks representative to

determine if Dual Set Point control is allowed on your boiler. Failure

to follow these precautions may result in damage to equipment,

serious personal injury, or death.

4.4.6 Actuator Selection

FGR Actuator

The FGR actuator should be selected as “Yes” if it is present on this system. This actuator is only available for

parallel positioning control.

Fuel 1 Actuator 2

The Fuel 1 Actuator 2 should be selected as “Yes” if it is present on this system. This actuator is only available

for parallel positioning control.

Fuel 2 Actuator 2

Part No. 750-366 4-17

Page 48

Section 4 — System Configuration Hawk 1000

The Fuel 2 Actuator 2 should be selected as “Yes” if it is present on this system. This actuator is only available

for parallel positioning control.

Figure 4-16. Actuator selection

4.4.7 Variable Frequency Drive

VFD Type

Select the appropriate VFD Type for this specific job.

The available options are None, PowerFlex, and Other Mfg.

Selecting <PowerFlex> assumes you are using either the PowerFlex 400, PowerFlex 70 Enhanced, or

PowerFlex 700 Vector drive.

All drives types use 4-20mA command and feedback.

VFD Bypass

VFD Bypass should be selected “Yes” if VFD Bypass is on this specific job.

An Air/Fuel curve must be configured for each fuel while in bypass mode.

VFD bypass allows the boiler system the ability to keep the combustion blower motor running even if the

Variable Frequency Drive is taken out of the loop for any reason.

4-18 Part No. 750-366

Page 49

Hawk 1000 Section 4 — System Configuration

Figure 4-17. VFD screen

Variable Frequency Drive for Combustion Air Fan Motor

Variable frequency drives (VFDs) offer many benefits to reduce energy costs and extend the life of mechanical

equipment.

The optional Variable Frequency Drive (VFD; see Figure 2-7) controls the speed of the combustion air fan

motor for the purposes of improving boiler efficiency and reducing electrical energy consumption.

4.4.8 Options

Oxygen Analyzer

The Oxygen (O2) Analyzer (See Figure 2-8) is available for monitoring stack flue gas oxygen concentration. The

O2 Analyzer transmits an analog signal to the controller. The O2 signal is used for Low O2 alarms, Low O2

Shutdown and in calculating boiler efficiency. O2 concentration is displayed on the Boiler Overview and Firing

Rate screens.

Figure 4-18. O2 Analyzer

Part No. 750-366 4-19

Page 50

Section 4 — System Configuration Hawk 1000

O2 Trim

02 trim control is an integral part of the HAWK 1000 system. This feature affords additional control over fuel-toair ratios in the event of adverse atmospheric conditions or fluctuating fuel heating values.

The HMI has an 02 trim screen that displays O2 Actual concentration and O2 Setpoints. The Screen allows for

viewing and calibrating the Cleaver Brooks O2 Sensor (CB) and also

allows for adjustment of PID tuning. The

Flue Gas O2 Control Screen can be accessed from the HMI Main screen.

Figure 4-19. Flue Gas O2 Control Screen

Low O2 Shutdown

Low 02 Shutdown is a feature that allow the boiler to be shutdown if O2 concentrations become too low.

Low O2 Shutdown can be enabled or disabled b y

screen)

between

<Yes> and <No>

.

toggling “O2 Shutdown” (on the System Configuration

If enabled the Low O2 Shutdown Setpoint and Low O2 shutdown time delay can be adjusted on the alarms

and limits screen.

Hot Standby

The Hot Standby function maintains a minimum water temperature to keep the boiler in a state of readiness

for a load demand. While operating, the boiler

remains at the minimum firing rate and cycles on-and-off

relative to the Hot Standby water temperature set point. This set point is configured on the Setpoints screen

(accessed from the Main Screen).

Hot Standby can be enabled or disabled by Pressing the “Hot Standby” button to toggle between <Yes> and

<No>. The boiler overview and firing rate screens will indicate when the boiler is in hot standby.

Hot Stand-By can be initiated manually by pressing <Force Hot Standby> on the Firing Rate screen. The

boiler will remain in standby until the button is again pressed.

See Section 5 - Commissioning for more on Hot Standby.

4-20 Part No. 750-366

Page 51

Hawk 1000 Section 4 — System Configuration

Overview - Hot Standby Force Hot Standby

Figure 4-20. Hot Standby

Outdoor Temperature Reset (Hot Water units only) With

outdoor

temperature

required on Analog Input 2.2

Input 2.2 outdoor

will be applied to the operating set point. An outdoor

for

this feature. When the outdoor

temperature

is displayed on

the

this

option selected, a correction based on the

temperature

boiler overview

screen

temperature

transmitter is

is selected for Analog

.

Figure 4-21. Options

When Outdoor Reset is selected, the outdoor temperature and water temperature setpoints should be entered

from the Setpoints screen (See Section 5.5 - Setpoints) after system configuration is completed.

Combustion Air Temperature

The Combustion Air Temp Sensor transmits a 4-20mA signal to the controller. The Combustion Air Temp signal

is used in the boiler efficiency calculation, and is displayed on the Boiler Overview screen. Analog input

module required (Slot 7).

Part No. 750-366 4-21

Page 52

Section 4 — System Configuration Hawk 1000

Boiler Information

The customer name, boiler ID, and boiler serial number and can be entered. This information is displayed on

the System Information Screen. To enter this information, press the text display button beneath the

description. An alphanumeric keypad pop-up window appears.

Figure 4-22. Boiler information

Once all the information is entered, press the carriage return button. The Boiler ID and Serial Number are each

limited to 20 characters, including spaces.

If a Master Panel is being used in this system the customer name, boiler ID, and boiler serial number must be

entered again in order for this information to appear on the Master Panel HMI

Auxiliary Alarm 1-3

If the system has auxiliary alarms the text that is displayed when the alarm is triggered can be entered. To

enter this information, press the text display button beneath the description. An alphanumeric keypad pop-up

window appears.

Once all the information is entered, press the carriage return button. The auxiliary alarms are each limited to

20 characters, including spaces.

Auxiliary alarm 1 must be wired to Slot 1 Input 13

Auxiliary alarm 2 must be wired to Slot 1 Input 14

Auxiliary alarm 3 must be wired to Slot 1 Input 15

For example: If Auxiliary Alarm 1 is entered as Low Water Flow and Discrete Input I:1.13 is “On” the alarm

displayed on the HMI for Auxiliary Alarm 1 will read “Aux 1 - Low Water Flow”.

4-22 Part No. 750-366

Page 53

Hawk 1000 Section 4 — System Configuration

Figure 4-23. Aux inputs

4.4.9 Configuration Summary

Once the System Configuration settings have been entered the entries can be viewed from the System

Configuration Summary screens.

Note: The “Confirm Options” push button is only visible if this is a new system configuration or a system

configuration parameter marked with an asterisk has been changed.

Page 1 Page 2

Figure 4-24. Configuration summary

To complete system configuration, press the <Confirm Options> pushbutton on the Options Summary Screen.

The Configuration selections may be changed after the HAWK 1000 is installed. However, for many of the

options, additional hardware is required to make the function work. Please refer to the parts section for the

required hardware.

Part No. 750-366 4-23

Page 54

Section 4 — System Configuration Hawk 1000

4-24 Part No. 750-366

Page 55

Section 5

Commissioning

Commissioning the Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting Combustion - Parallel Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Store Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Store Lightoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Curve Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Setting Combustion - Single Point Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

VFD or O2 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

No VFD or O2 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Setting Combustion - Low/High/Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Firing Rate Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Alarms and Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Low O2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Low Steam Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Mod. Rate Limiter, Max. O2 Correct, Remote Shutdown by Comms. . . . . . . . . . . . . 5-12

Stack Low Temp. Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Operating Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Outdoor Temperature Reset (Hot Water only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Revert to Pilot (CB 120E only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

O2 Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Drive Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Ethernet Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Two Boiler Lead Lag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Thermal Shock Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

www.cleaverbrooks.com

Page 56

Section 5 — Commissioning Hawk 1000

5.1 Commissioning the Actuators

When system configuration is complete, the <Calibrate Actuators> button will be available on the Main

screen and will indicate “Required”.

Figure 5-1. Actuator calibration required

Press <Calibrate Actuators> for the Actuator Commissioning screen, where air, fuel, and FGR actuators can

be individually selected for commissioning. On this screen, press <Commission Actuator> for the desired

actuator and read the warning screen which follows. In this example we will be commissioning the air

actuator.

Actuator Commissioning Screen

Warning

Figure 5-2. Actuator commissioning

NOTE: Any combustion curves previously stored for the current fuel will be erased once the actuator

commissioning process has begun. Press <Enable Air Actuator Commissioning> on the warning screen to

continue.

First select the direction of rotation of the actuator shaft. This is the direction of rotation to open the actuator

when looking at the actuator from the perspective of the actuator circuit board (or circuit board cover).

5-2 Part No. 750-366

Page 57

Hawk 1000 Section 5 — Commissioning

Figure 5-3. Actuator rotation

The default direction of rotation is counterclockwise for air and all fuels, and clockwise for FGR.

This screen also indicates the actuator torque rating (read via Modbus by the PLC).

Press <Next> after confirming the actuator direction of rotation. Next store the open and closed positions of

the actuator. Using the <Actuator Close (Open)> buttons, move the actuator to its fully open or closed

position (either position may be stored first). With the actuator fully open (closed), press <Store Open

(Close)>.

Figure 5-4. Actuator stroke

Note: CCW rotation means the closed position will be greater than the open position.

CW rotation means the open position will be greater than the closed position.

The actuator position is given in units of degrees x 10.

Valid range is 0 - 1100 units (0-110 degrees). Open and closed positions must be greater than 100 units (10

degrees) apart. If these conditions are not met, a “Configuration Invalid” error will result, and reconfiguration

of the actuator will be required.

When valid data have been entered, the <Save Air Actuator Configuration> button will appear. Press to save

data, then press <Next Actuator> and repeat the above steps.

Part No. 750-366 5-3

Page 58

Section 5 — Commissioning Hawk 1000

Invalid Data

Save Data

Figure 5-5. Verify actuator calibration

5.2 Setting Combustion - Parallel Positioning

When actuators for the currently selected fuel have been calibrated, the <Set Combustion> button will be

available on the Main screen. To begin the procedure, press <Set Combustion> and observe the warning that

follows.

Main Screen

Warning

Figure 5-6. Begin combustion setup

Press <I READ THE WARNING - I AM QUALIFIED> to continue. An

additional warning screen will appear, notifying the user that the

boiler Operating Limit Relay will be de-energized during combustion

setup.

Press <Confirm Combustion Setup> to continue.

2nd Warning

5-4 Part No. 750-366

Page 59

Hawk 1000 Section 5 — Commissioning

5.2.1 Store Purge

The first step is to store the Purge position. A help screen is available to guide the user through storing the

Purge (and Lightoff) positions:

Figure 5-7. Purge/Lightoff help

For a valid Purge position the air actuator must be greater than 80% open. To position the actuators in setting

combustion, first press the button for the desired actuator on the Combustion Setup screen.

Press to

adjust

actuator

Figure 5-8. Combustion Setup

Next, use the <Dec> and <Inc> buttons to move the air actuator to the desired position.

Part No. 750-366 5-5

Page 60

Section 5 — Commissioning Hawk 1000

Figure 5-9. Adjust actuator

When purge position is set, press <Store Purge>. When prompted with “Store Current Values?”, press <Store

Purge> again to confirm or <Cancel> to re-adjust.

Figure 5-10. Store Purge

Note: If a VFD is present, the VFD purge value is automatically set at 100%.

5.2.2 Store Lightoff

When the purge position has been set, the <Store Lightoff> button will be available on the Combustion Setup

screen. After positioning the actuators in the lightoff position press <Store Lightoff>. A confirmation prompt

will appear as when storing the purge position. When both purge and lightoff have been set, the <Curve

Setup> button will be available.

All values except VFD must be less than 25% to store lightoff.

5-6 Part No. 750-366

Page 61

Hawk 1000 Section 5 — Commissioning

Figure 5-11. Store Lightoff

5.2.3 Curve Setup

A help screen is available to guide the user through the steps of setting the combustion curve:

Figure 5-12. Combustion setup help

To set the combustion curve, the burner must be on. If all conditions to start the boiler have been met, the

<Burner Start> pushbutton will appear on the Combustion Setup screen. Press <Burner Start>; the purge

sequence will run and the actuators will return to the lightoff position. Press <Lightoff>. The Flame Safeguard

will sequence through pilot trial and main flame and the burner will ignite. The actuators can now be

positioned for the first point.

• 8 points minimum must be stored for a valid curve (16 maximum allowed)

• Points can not be skipped

• Values for Air and Fuel Actuator 1 must be greater than previous values for a valid point to be stored.

• Pressing <New Profile> at any time will erase the current curve.

• When the combustion curve is complete (8 valid points are stored) the <Firing Rate> button will appear,

replacing the <Main> button.

• Pressing <Pt Adv Enable> will allow stepping through the combustion curve using <Next> and <Prev>.

With Points Advance disabled, the actuators will not move when <Next> or <Prev> is pushed.

Part No. 750-366 5-7

Page 62

Section 5 — Commissioning Hawk 1000

Figure 5-13. Combustion curve complete

5.3 Setting Combustion - Single Point Positioning

5.3.1 VFD or O2 Trim

If VFD or O2 Trim is selected, combustion setup is identical to parallel positioning, with the exception that

only the air actuator will be active. 8 points minimum are required for the combustion curve, with 16 points

maximum.

5.3.2 No VFD or O2 Trim

The combustion curve consists of 2 points. Only the air actuator will be active. Point 1 will be low fire; Point

2 will be high fire.

5.4 Setting Combustion - Low/High/Low

Low/High/Low combustion is only available with Cleaver-Brooks Model 4/Model 5 boilers.

Low/High/Low is only available for Oil (as Fuel 2). The combustion curve consists of 2 points; only the air

actuator is active. Point 1 will be low fire; Point 2 will be high fire.

A View/Adjust Setpoints screen is provided.

Figure 5-14. View/Adjust Setpoints

When using Low/High/Low combustion the boiler firing rate will be either 0% or 100%. The oil valves open

and close based on the air actuator feedback percent. The high fire and low fire setpoints are limited by the

Boiler On and Boiler Off points.

5-8 Part No. 750-366

Page 63

Hawk 1000 Section 5 — Commissioning

When steam pressure is greater than the low fire point, the firing rate will go to 0%.

When steam pressure is less than the high fire point, the firing rate will go to 100%.

5.5 Firing Rate Screen

From the Firing Rate screen the boiler controls can be toggled between manual and automatic operation. With

<Manual> selected, the actuators will remain in their current positions until moved manually by the operator

using the Control Output <Decrease> and <Increase> buttons.

Figure 5-15.