Page 1

ClearFire® Model CFV

Vertical Steam Boiler

Startup Guide

750-288

www.cleaverbrooks.com

Page 2

CFV Startup Guide

!

WARNING

DANGER

Improper installation, adjustment, service, or maintenance can cause equipment damage, personal

injury, or death. Refer to the Operation and Maintenance manual provided with the boiler.

!

WARNING

DANGER

To minimize the possibility of serious personal injury,

fire or damage to the equipment, never violate the following safety rules.

— Always keep the area around the boiler free of

combustible materials, gasoline, and other flammable

liquids and vapors

— Never cover the boiler, lean anything against it,

stand on it, or in any way block the flow of fresh air to

the boiler.

NOTE to equipment owners, operators, and maintenance

personnel: This guide is not a short-cut to safe and effi-

cient boiler operation. Operating an improperly commissioned boiler can result in increased fuel costs and may

shorten the life of the equipment or produce a hazardous

condition. All personnel involved in operating or maintaining the boiler should read the manual in its entirety.

!

WARNING

DANGER

Be sure the fuel supply which the boiler was designed to operate on is the same type as specified

on the boiler name plate.

!

WARNING

DANGER

Should overheating occur or the gas supply valve

fail to shut off, do not turn off or disconnect the

electrical supply to the boiler. Instead turn off the

gas supply at a location external to the boiler.

!

WARNING

DANGER

Do not use this boiler if any part has been under

water. Immediately call your Cleaver-Brooks service

representative to inspect the boiler and to replace

any part of the control system and any gas control

which has been under water.

!

WARNING

DANGER

The installation must conform to the requirements of

the authority having jurisdiction or, in the absence of

such requirements, to UL 795 Commercial-Industrial Gas Heating Equipment and/or the National Fuel

Gas Code, ANSI Z223.1

Refer to CFV Operation and Maintenance

Manual - CB Part Number 750-269

2 Part No. 750-288

!

WARNING

DANGER

The boiler and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

!

WARNING

DANGER

The boiler and its gas connection must be leak

tested before placing the boiler in operation.

Notice

Where required by the authority having jurisdiction, the installation must conform to the Standard

for Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1.

Page 3

CFV Startup Guide

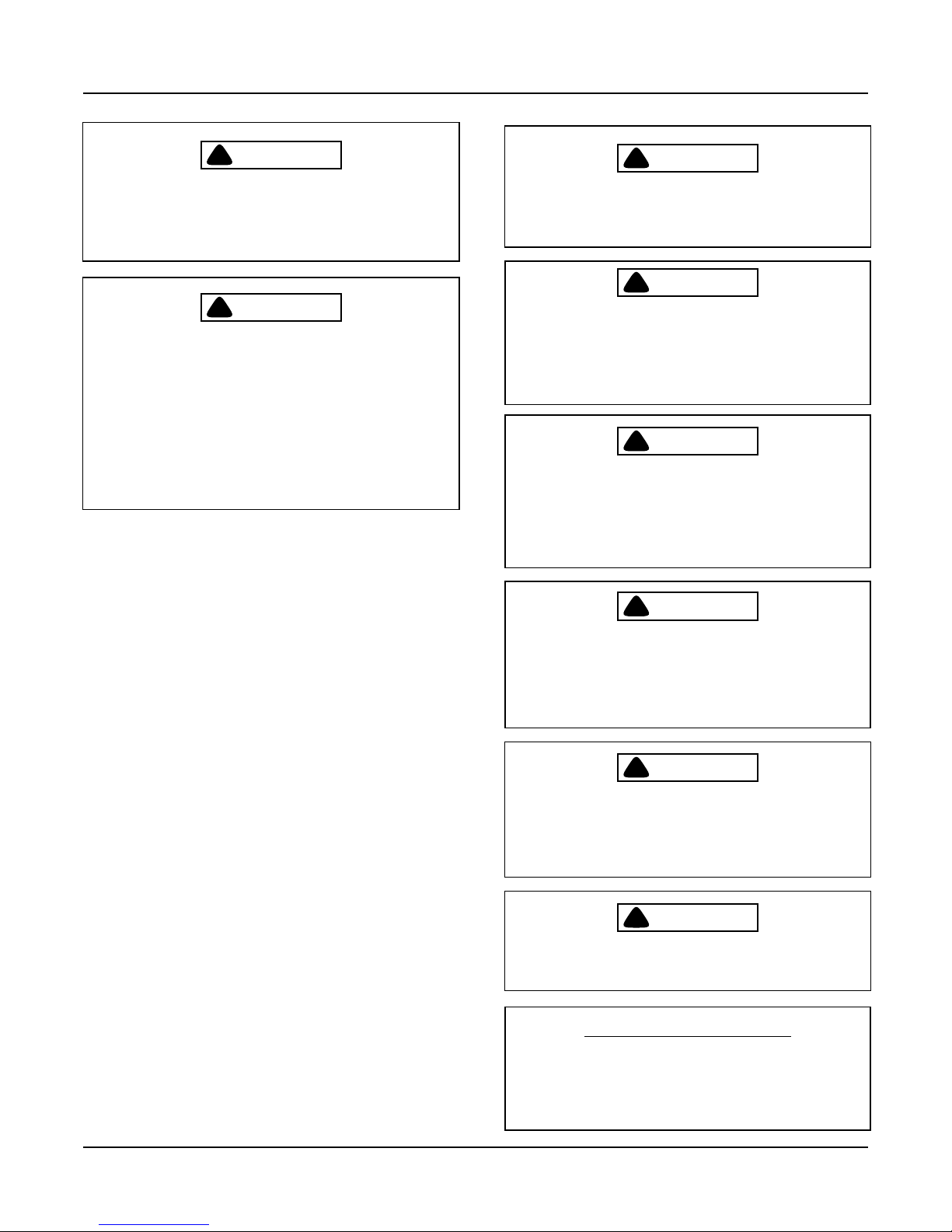

1 - BEFORE STARTUP

Your Cleaver-Brooks boiler has been factory fire-tested and the control system pre-configured for a troublefree startup. To help ensure a successful lightoff and reliable operation, certain initial conditions should be

observed.

Do not attempt to place the boiler into service without verifying that all connections - fuel, steam and

water piping, electrical connections, stack, and combustion air provisions - have been installed properly

and in accordance with any applicable codes or regulations.

COMBUSTION AIR INLET

RELIEF VALVE

STEAM

OUTLET

GAS SUPPLY

SURFACE

BLOWOFF

Figure 1 CFV Connections

1.1 Operating Conditions

• The installation site should be as free as possible from vibration,

dust, and corrosive media

• The controllers should be located as far as possible from sources of

electromagnetic fields, such as frequency converters or high-voltage

ignition transformers

• Control panel must be connected to earth ground. For electrical

wiring requirements, see wiring diagram provided with the boiler or

in the CFV manual.

GAUGE GLASS DRAIN

WATER COLUMN DRAIN

FEEDWATER

STACK

BLOWDOWN

!

CONDENSATE DRAIN

Warning

OUTLET

When using direct vent

combustion in cold climates,

special care must be taken to

observe combustion air

temperature limits. Failure to

follow this precaution may lead

to equipment damage or unsafe

operation.

Part No. 750-288 3

Page 4

CFV Startup Guide

Boiler room ambient conditions

Relative humidity

Ambient temperature range 0

Storage temperature range -20

Combustion air temperature 0

Specifications

Input power 115 VAC single phase 60Hz

Recommended operating steam

pressure

Gas pressure requirements See Table 1

< 85% non-condensing

o

C to 50 oC / 32oF to 122oF

o

C to 60 oC / -4oF to 140oF

o

C to 50 oC / 32oF to 122oF

75-135 psig

1.2 Gas Piping

A manually operated shut-off valve and pressure regulator are provided

as standard on the Model CFV boiler. It is recommended to install an

approved gas filter or strainer in the gas supply line to the boiler. Please

inquire with the local gas supply company.

The boiler shall be installed such that the gas ignition system

components are protected from water (dripping, spraying, etc.) during

appliance operation and service.

If building supply gas pressure is greater than 1 psig (27.8” WC), an

upstream regulator with overpressure protection and proper gas venting

will be required and must be piped to a safe point of discharge.

All gas piping and components to the boiler gas train connection must

comply with NFPA 54, local codes, and utility requirements as a

minimum. Only gas approved fittings, valves, or pipe should be used.

Standard industry practice for gas piping is normally Schedule 40

black iron pipe and fittings.

See Table 1 for CFV gas pressure requirements.

Table 1 CFV gas pressure requirements

Boiler HP Minimum pressure required

at gas train connection

9.5 7.2" w.c.

10 7.2" w.c.

15 7.3" w.c.

20 7.5" w.c.

25 7.7" w.c.

30 8.5" w.c.

40 11.0" w.c.

50 10.0" w.c.

60 10.0" w.c.

Max. pressure

28” w.c.

Note: To measure supply pressure

at the CFV gas valve, use the

test port on the valve inlet

flange (see below). Do not

use the leak test cocks to

measure gas pressure.

1.3 Flue Gas Connection

The flue gases from the ClearFire boiler are removed via a gas-tight, temperature and corrosion resistant flue

gas pipeline. Only flue gas systems approved and tested by the relevant region or province are to be connected

to the ClearFire boiler. Refer to flue piping manufacturer for proper installation and sealing instructions.

See also Chapter 3 in the CFV Operation and Maintenance manual.

4 Part No. 750-288

Page 5

CFV Startup Guide

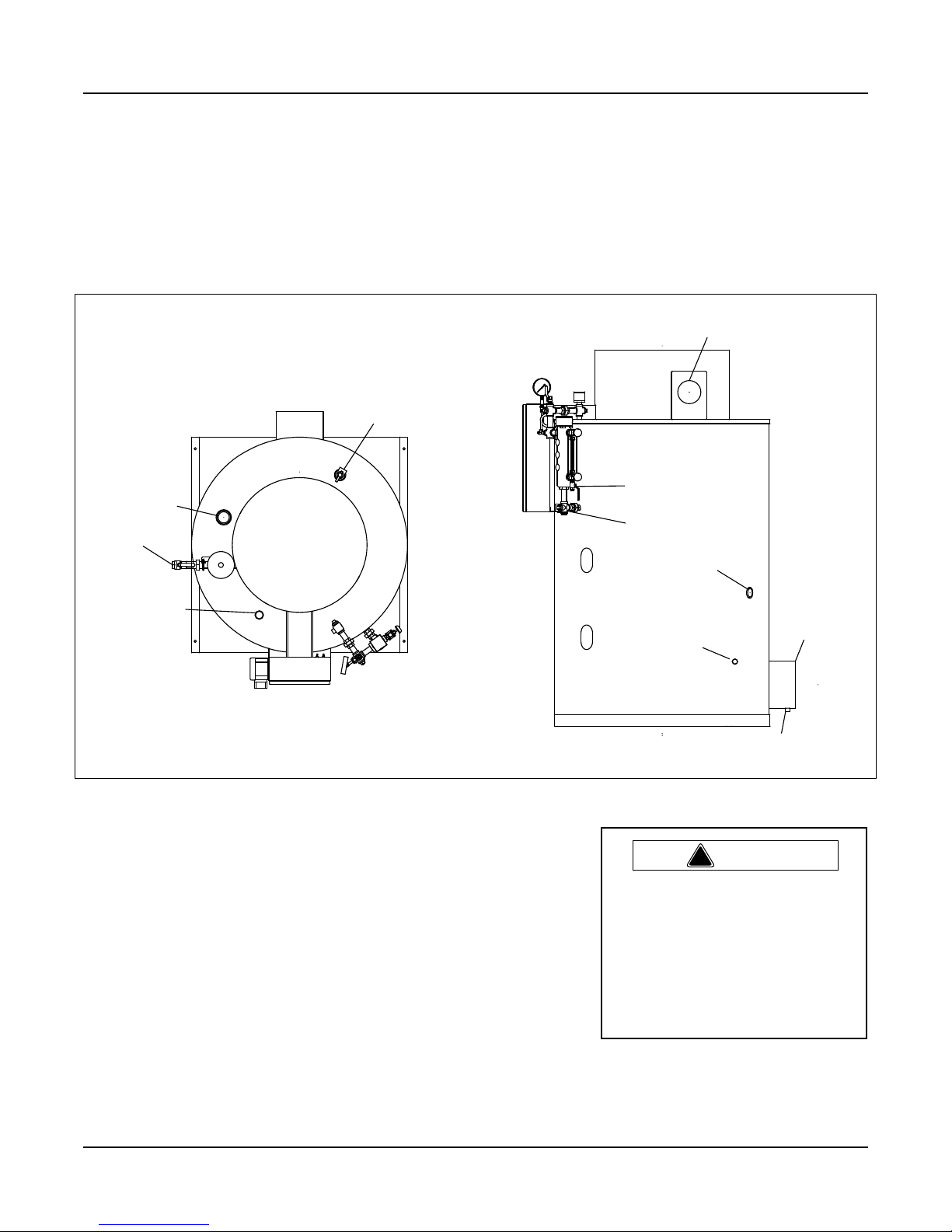

1.4 Boiler Water-Side Connections

A pressure relief valve (safety valve; Figure 2), provided with the

boiler, must be installed in the mounting provided and piped to a safe

point of discharge. Use pipe sealing compound and a flat sided

wrench when securing the safety relief valve. Do not use a pipe

wrench and do not over tighten the relief valve. The safety valve must

be mounted in a vertical position so that discharge piping and coderequired drains can be properly piped to prevent buildup of back

pressure and accumulation of foreign material around the valve seat

area.

Connection to the main steam header is made at the nozzle projecting

upward from the boiler shell.

Feedwater is introduced through the piping assembly installed on the

side of the boiler vessel.

Figure 2 Pressure Relief Valve

Safety

Valve

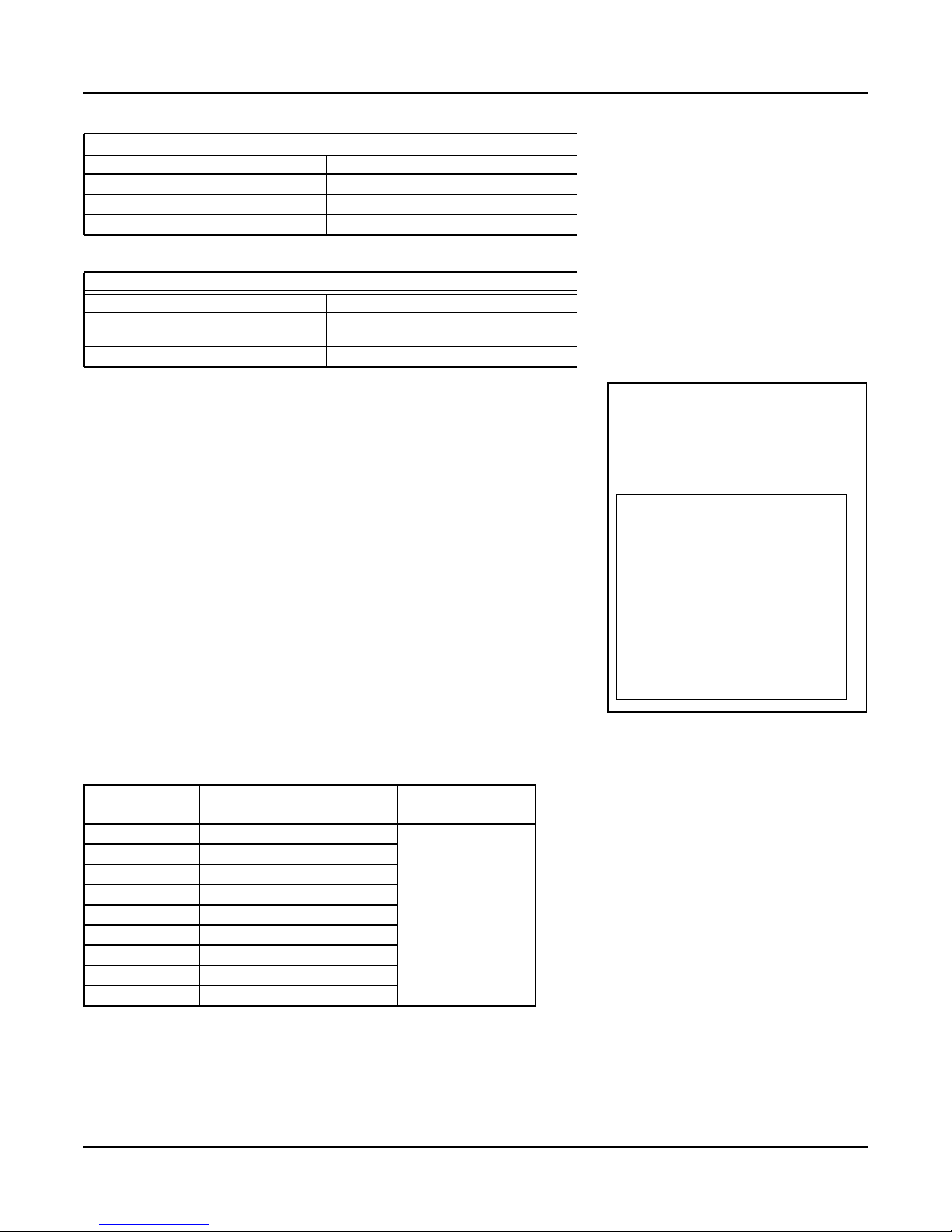

1.5 Electrical Connections

Refer to Figure 3 for CFV wiring and cable connections. See also wiring diagram on page 13.

A qualified electrician or service technician must make the electrical connections to the boiler; all local

electrical and building codes should be adhered to.

Refer to wiring diagram provided with the boiler or in the CFV manual. Ensure all required customer

connections are properly made. Main power (115 VAC single phase 60Hz) and any remote wiring should be

brought to the left side of the control panel and terminated at the appropriate terminals provided. Controls for

the boiler feed pump (or feedwater valve if applicable) should be wired to control panel terminals 6 and 7.

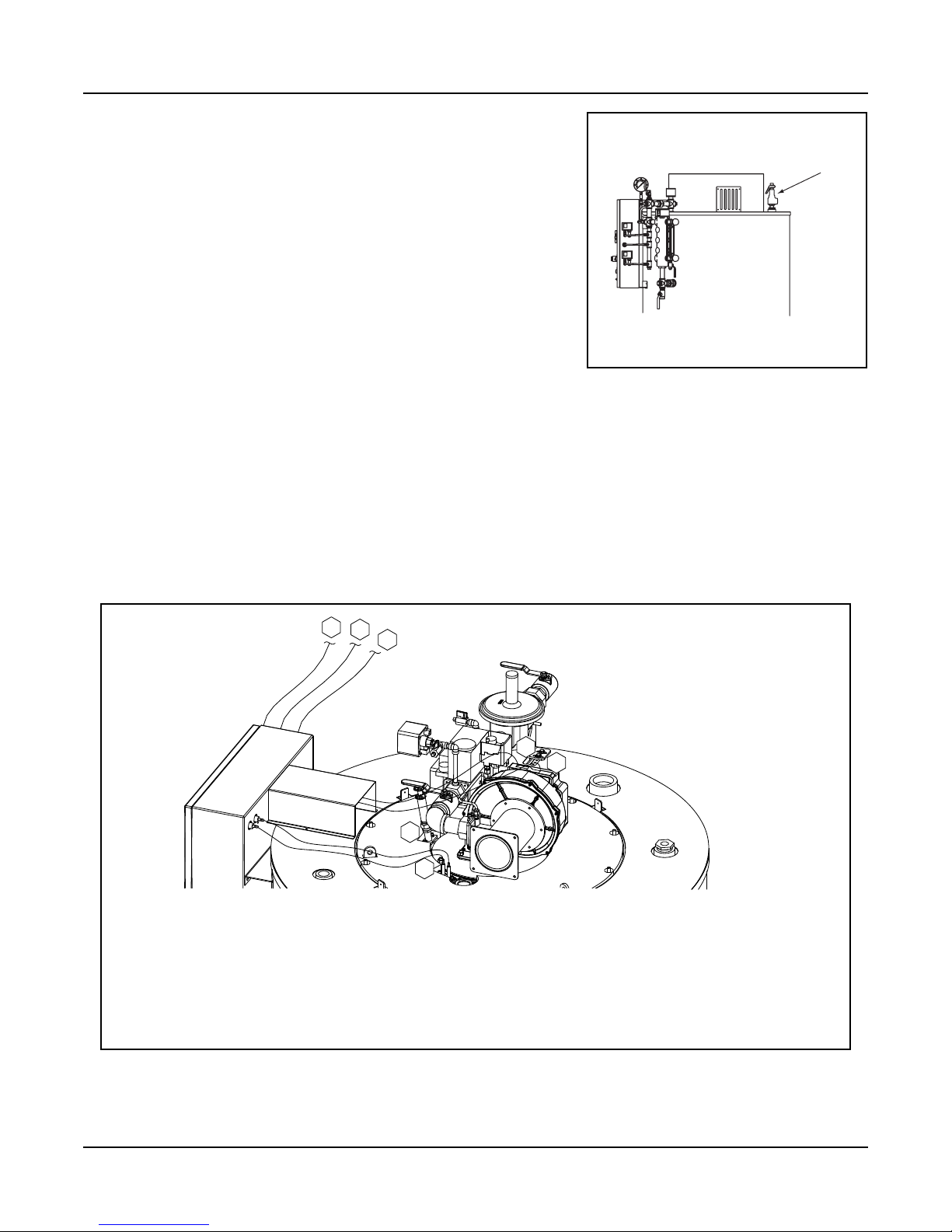

Figure 3 CFV wiring and cable connections

7

6

5

4

1

2

1. Connect UV Scanner to threaded connection on dry oven

2. Connect spark cables to dual electrode and ignition transformer

3. Plug AC pow er harnes s plug in to b lower

4. Plug D C blow er c ontrol harn es s pl ug in to blower

5. Connect incoming AC power per wiring diagram

6. Connect optional heat request inputs per wiring diagram

7. Connect pump controls per wiring diagram

The blower signal wiring must be isolated

from the blower power wiring and the

high voltage ignition cables.

3

Notice

Part No. 750-288 5

Page 6

CFV Startup Guide

1.6 Safety Controls

Users should take note of the safety controls installed as standard on the Model CFV. Minor adjustments to

the initial factory settings of some controls may be necessary for your particular installation.

It is required to test all controls for proper functioning prior to starting the boiler for the first time. Stepby-step procedures for testing the controls can be found in the CFV manual (Chapter 4 - Commissioning).

The primary flame safety control is the CB Falcon, which monitors the flame signal by means of an

ionization electrode installed in proximity to the burner canister.

Other Combustion Safety Controls (see Figure 4) include the following:

• Combustion Air Proving Switch

• Low Gas Pressure Switch

• High Gas Pressure Switch

• Dual Safety Shut-off Valve (SSOV)

Depress all manual reset buttons for all controls prior to starting the boiler.

Dual SSOV

Figure 4 Combustion Safety Controls at Burner

Warning

!

The Model CFV is factory tested. Nevertheless, all burner safety

controls should be checked upon installation, prior to initial firing.

Failure to verify burner control functioning could result in severe

bodily injury or death.

For detailed procedures on how to test the safety controls, see the

boiler Operation and Maintenance Manual.

Water Level Controls (see Figure 5)

The primary Low Water Cutoff and pump control level probes are mounted in an external water column.

The Auxiliary Low Water Cutoff is mounted in the boiler vessel or optional external column. Control boards

for the LWCO and ALWCO are located in the boiler control panel. The ALWCO includes a panel-mounted

reset/test switch.

6 Part No. 750-288

Page 7

CB FALCON

CONTROLLER

ALWCO CONTROLLER

Figure 5 Water level controls

Limit Controls (see Figure 6)

CFV Startup Guide

Control panel interior

LWCO CONTROLLER / PUMP CONTROL

The operating and high pressure limit controls are

externally mounted to the control trim piping. For

control settings and testing instructions, see the

boiler operation manual.

Figure 6 Limit Controls

1.7 Filling Boiler

Ensure that all feedwater equipment is properly installed and any feed

pumps, valves, etc. are in good working order.

Begin with the control panel DEMAND switch and CC/BLOWER switch (see

Figure 7) in the OFF position. Open the boiler vent valve (see Figure 8).

Turn the Control Circuit/Blower Switch ON to enable the feedwater control

circuit. If the CB Falcon icon does not appear on the display when the CC/

Blower switch is turned on, see STARTING THE BOILER below.

With the vent valve open, entrapped air will be allowed to escape while the

boiler fills with water. Do not close the vent valve until water is visible in

the gauge glass. The feed pump will shut off when water reaches the ‘Pump

Off’ probe level.

Check to ensure that no leaks appear at any pipe connections and correct

if water leaks are noticed.

Part No. 750-288 7

Figure 7 Control Panel Switches

Page 8

CFV Startup Guide

Important

!

The use of soft water is highly recommended. Failure to observe this recommendation can lead to dangerous

operating conditions, and may result in damage to the boiler. If necessary, your Cleaver-Brooks

representative can provide additional information regarding your water softening requirements.

Vent Valve

Gauge Glass

Figure 8 Filling the Boiler

2 - STARTING THE BOILER

Ensure boiler has been filled with water (see above - 1.7 Filling Boiler). The DEMAND switch should be in

the OFF position.

When the Control Circuit/Blower switch is turned ON, the Home page will appear on the CB Falcon display,

showing the boiler control icon. It may take a short time for the display/controller to initialize before the

Falcon icon appears.

If the Falcon icon does not appear, open the control panel and verify that the controller is receiving power.

The green ‘POWER’ LED should be lit (see Figure 9).

If the controller is powered on but still does not appear on the display, refer to manual. If unable to resolve

the problem, contact your CB representative.

Falcon

controller

icon

POWER

LED

HOME PAGE

Figure 9 Home Page; Falcon power indicator

8 Part No. 750-288

Page 9

CFV Startup Guide

2.1 Controller Configuration

The CB Falcon controller is factory pre-configured with default parameter

settings for the Model CFV. Prior to starting the boiler, verify that the

factory default settings are correct for your application. See the boiler

Note: The “Home” icon at the

upper left of the display

screen always returns to the

Home Page.

operation manual (Chapter 4 - Commissioning) for the parameter list and

parameter change procedure.

The “Back” icon at the upper

Changing the Setpoint

right displays the previous

screen.

The default steam pressure setpoint should be changed at this time to

suit your application. Press the CB Falcon icon on the Home page. The

Overview screen will appear. On the bottom row of screen buttons press

<Operation> to access the Operation screen (Figure 10).

Press the yellow highlighted setpoint display. A numeric keypad will appear. Press <Clear> to clear the

current value, enter the appropriate setting using the numeric keypad, and press <OK>.

Figure 10 Changing the setpoint

1

To change the steam pressure setpoint: 1. Press the yellow highlighted setpoint display window.

Note: Some features of the CB Falcon controls are password

protected. Service level password = 9220.

2.2 Initiating Burner Sequence

Before initial startup, check for blockages in the flue venting or vent terminations. Inspect the burner and furnace

for any contamination or blockages.

3

4

2. Clear the current value.

3. Enter the desired value.

4. Press <OK>.

Warning

!

2

When ready to start the boiler, navigate to the Operation screen (see “Changing the Setpoint” above).

Part No. 750-288 9

Page 10

CFV Startup Guide

BURNER

SWITCH

button

Figure 11 Operation screen

Turn the <Burner switch> screen button to ON. The burner is now

enabled.

Turn the control panel DEMAND switch to LOC (local). The burner

sequence should now begin. To verify that the sequence is in

Burner Sequence:

STANDBY (burner switch off or no demand)

SAFE STARTUP

progress, check the ‘Burner state’ display on the Operation screen.

If operating normally, the controller should advance through the

steps in the burner sequence (see Figure 12).

Note: The <Burner switch> screen button enables the burner, but

will not by itself start the lightoff sequence. In order for the burner

to start, the following must be true:

• <Burner switch> screen button is ON

• All control circuit interlocks are satisfied

• A demand for steam exists (example: DEMAND switch is on LOC

PREPURGE DRIVE TO PURGE (prove fan

purge rate)

PREPURGE MEASURED PURGE TIME

(30 sec default)

PREPURGE DRIVE TO LIGHTOFF (prove

lightoff rate)

PREIGNITION TEST

DIRECT BURNER IGNITION

and steam pressure is below setpoint)

Once started, the boiler will continue running until demand is met,

RUN (release to modulating control)

an alarm condition occurs, or until manually shut down.

Before leaving the boiler unattended, ensure all safety controls

Figure 12 Burner Sequence

have been checked and boiler operational settings are properly

set,

As part of the initial safety checks, a flame failure test should also be performed to verify that the controls

are able to respond properly to a loss of flame: Disconnect the flame rod cable and attempt to start the

burner. The CB Falcon should lock out, indicating Lockout 109 Ignition Failure. Reconnect flame rod cable

after test.

The CB Falcon requires a manual reset to resume operation after a lockout.

3 - MANUAL OPERATION

Certain circumstances - such as setting combustion - require operating the boiler in manual mode. To enter

manual mode, use the following procedure:

10 Part No. 750-288

Page 11

1.On the CB Falcon Operation screen, press the Firing Rate

display in the Modulation section.

2. A numeric keypad will appear, showing the current firing rate

and operating mode.*

3. Under Firing rate control select Manual in Run.

4. Press <Clear> to clear the current RPM value.

5. Enter the desired RPM setting using the numeric

keypad.

6. Press <OK>. The display will return to the Operation

screen and the burner will modulate to the chosen firing

rate.

*Use Manual in Run for normal manual operation. In Manual in Run

and Standby mode, the burner will not operate. Use this mode for

testing blower operation without firing the boiler.

Notice

CFV Startup Guide

Figure 13

The CFV has been factory tested at 1000’ ASL and tuned for 5-6% excess

O2. To ensure optimum combustion throughout the firing range, the O2%

should be verified and if necessary adjusted to the proper levels. This

procedure involves manually firing the burner while using a combustion

analyzer to monitor O2%. Low and high fire adjustments are made at the

main gas valve. See the CFV Operation and Maintenance manual for a

detailed procedure.

Note: If an alarm or lockout occurs

during startup or operation, see

the boiler Operation and

Maintenance manual.

If any of the following conditions occur:

• Loss of flame

• Excessive or unusual noise

• Flame appears irregular when viewed through sight glass

• Frequent low water shutdowns

Cease boiler operation. See the Troubleshooting section in the CFV manual or consult your authorized CB

representative.

Repeated nuisance low water shutdowns may indicate a problem with the boiler feed system and/or water

level controls.

4 - POST STARTUP

• Review Chapter 4 - Commissioning in the CFV manual. Ensure all safety checks have been performed

according to instructions.

• Set high gas pressure switch to 50% higher than operating gas pressure at low fire. Set low gas pressure

switch to 50% lower than operating gas pressure at low fire.

• Check the draft on the outlet stack and compare to acceptable limits (-0.25 to +0.25 inches WC).

Operating outside of acceptable limits could result in light off and flame failure problems.

• Verify gas pressure remains within limits shown in Table 1.

• A new boiler should be cleaned by boil-out prior to being placed into service. See Chapter 4 of the CFV

manual for boil-out procedure.

Part No. 750-288 11

Page 12

CFV Startup Guide

5 - LOCKOUTS, HOLDS, AND ALERTS

To assist in monitoring boiler operation, the CB Falcon control system employs messages of three types:

Lockouts, Holds, and Alerts.

• Lockouts and Holds indicate interruptions in boiler operation, whether occurring as part of the normal

operating sequence or due to an abnormal condition. Lockouts require a manual reset to continue operation,

while Holds do not. A Hold will automatically clear when the hold condition is removed or satisfied.

The most recent Lockouts are stored in CB Falcon memory and may be accessed through the Lockout

History. Holds are not logged in memory.

Note: Before attempting to restart the boiler after a Lockout, identify and correct the Lockout condition.

• Alerts indicate conditions or events which, while not preventing boiler operation, may nevertheless be of

interest in evaluating boiler performance or operating conditions. Examples include certain operator actions,

out-of-range configuration data, controller internal status reports (e.g. timers, counters, memory read/write

activity), and recycle events. Alerts require no operator acknowledgment and are for informational purposes

only.

The most recently occurring message (Lockout, Hold, or Alert) is displayed in the alarm banner on the

Overview screen (see Figure 14). Press this banner to access the Alert or Lockout History, where a list of

the most recently occurring Alerts/Lockouts can be viewed.

Alarm Banner

Figure 14 Alarm Banner

To obtain more information for a particular message, press that item in its respective history list. For Alerts,

burner cycle and hours of operation at the time of occurrence will be displayed. For Lockouts, in addition

to cycle and hours the screen will show on/off status of all interlocks at the time of the lockout. This

information can be used to help pinpoint the cause of a particular Lockout.

If the boiler is left unattended after a startup, the Alert/Lockout History can be consulted to determine

whether the boiler has been running normally or if operation has been interrupted due to a fault condition.

12 Part No. 750-288

Page 13

1

E

2

115V/1PH AC FUSED

POWER SUPPLY W/

GROUNDED NEUTRAL

BLOWER MOTOR FUSE SELECTION

CFV HP

10 - 30

40

50 - 60

3

CNTRL

CIRC

FUSE

50

DISPLAY

PS FUSE

1 AMP

LL1

57

N

BLOWER

FUSE

80

(8)

(L1)

(COM)

(6)

49

4

5

RESET

PB

(MOM)

ALWCO

(L2)

(7)

(NO)

(NC)

(G)

81

POWER

OFF

(REF. 8)

ON

4

LWCO DF16

PROBE

(A)

PROBES

(L1)

(COM)

54

55

(B)

(C)

56

(H)

(COM)

6 7

51

FW PUMP

4

RLY1

(LLCO)

(L)

RLY2

(NO)

(NC)

(G)

(NO)

(REF. 8)

13

4

(L2)

PS

(L)

(V+) (V-)

(N)

(G)

12 VDC

NOTES:

DASHED LINES INDICATE CUSTOMER CONNECTIONS

ALL CONTROL WIRE IS #18 AWG UNLESS OTHERWISE NOTED

DENOTES CONTROL PANEL TERMINAL

4

5

6

7

5 AMP

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

(REF. 8)

25

26

27

28

29

30

Figure 15 CFV Wiring Diagram

BLOWER MODEL RATING, CLASS CC

G1G170-AB05-20 6 A

G3G200-GN26-01 12 A

G3G250-GN39-01 15 A

4

W

W

(REF. 8)

(3)

R

R

3

B/R

B/R

(4)

HGPS

9

PR BL BL

(2)

MODBUS RS485 J3-MB2 - A,B,C

MR

(REF. 15)

OLC

(REF. 15)

HLC

8

(1)

MR

14

CUSTOMER CONNECTIONS:

FW PUMP ON/OFF 6 & 7

REMOTE ALARM 15 & 16

REMOTE ON-OFF 24 & 25

REMOTE 4-20MA INPUT 26 & 27

(2)

REMOTE

ALARM

52

53

GAS

VALVE

(1)

10

8

CFV Startup Guide

IGNITION

TRANSFORMER

2

BL

(REF. 14)

IONIZATION

ELECTRODE

C1

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

1

26,27,

BURNER

CANISTER

GROUND

TRANSFORMER

5

BK

(REF. 9)

(R)

24

23

BK

(V-) (V+)

BR

(REF. 25)

24 25

(REF. 7)

IGNITION

ELECTRODES

W

(C)

24 VAC

-

PRESS

XMTR

+

+

26

REMOTE ON-OFF

(24V 1A)

(REF. 8)

REM

AC POWER

CONNECTOR

G

G

W

1

BK

G

G

LGPS

BK

MR

16

CAPS

OR

GY

(REF. 15)

8

9

(REF. 15)

10

11

3C 18AWG

SHIELDED

14 GAUGE

2

3

11

15

12

N

L

RED

+-

Y

LOCAL

DISPLAY

BLOWER

12

11

10

9

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

7

6

5

4

3

2

1

9

ACB

MB1

BLK

G

DC CONTROL

CONNECTOR

G

G

J4

C2

J2

J1

J8

FALCON

J5

EXT IGN

FUEL VALVE

INTLK

J6

ALARM

PRE-IGN INTLK

LCI

ANNUN #1/IAS

ANNUN #2/LWCO

J7

ANNUN #3/ALWCO

ANNUN #4/HLC

ANNUN #5/HGPS

ANNUN #6/LGPS

J3

ACB

WH

J9

J10

J11

COMMS

MB2

COMMON

DATA DATA +

GLOBAL MODBUS

CONNECTIONS

TERMINALS: LL1,N,G,1,2,3,4-4-4,5-5-5,6,7,8,9,10,11,12,13,14,15,16,

23,24,25,

4

DEMAND

OFF

W

LOC

REMOT

4-20MA

27

4

(REF. 8)

25

-

(REF. 8)

CFV STEAM

Part No. 750-288 13

Page 14

CFV Startup Guide

14 Part No. 750-288

Page 15

CFV Startup Guide

Part No. 750-288 15

Page 16

e-mail: info@cleaverbrooks.com

Web Address: http://www.cleaverbrooks.com

Loading...

Loading...