Page 1

Model CFC ClearFire Condensing Boiler

MODEL CFC FEATURES AND BENEFITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

MODEL CFC PRODUCT OFFERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

DIMENSIONS AND RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ENGINEERING DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

STACK/BREECHING SIZE CRITERIA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

CB FALCON CONTROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

AluFer Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Fireside Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

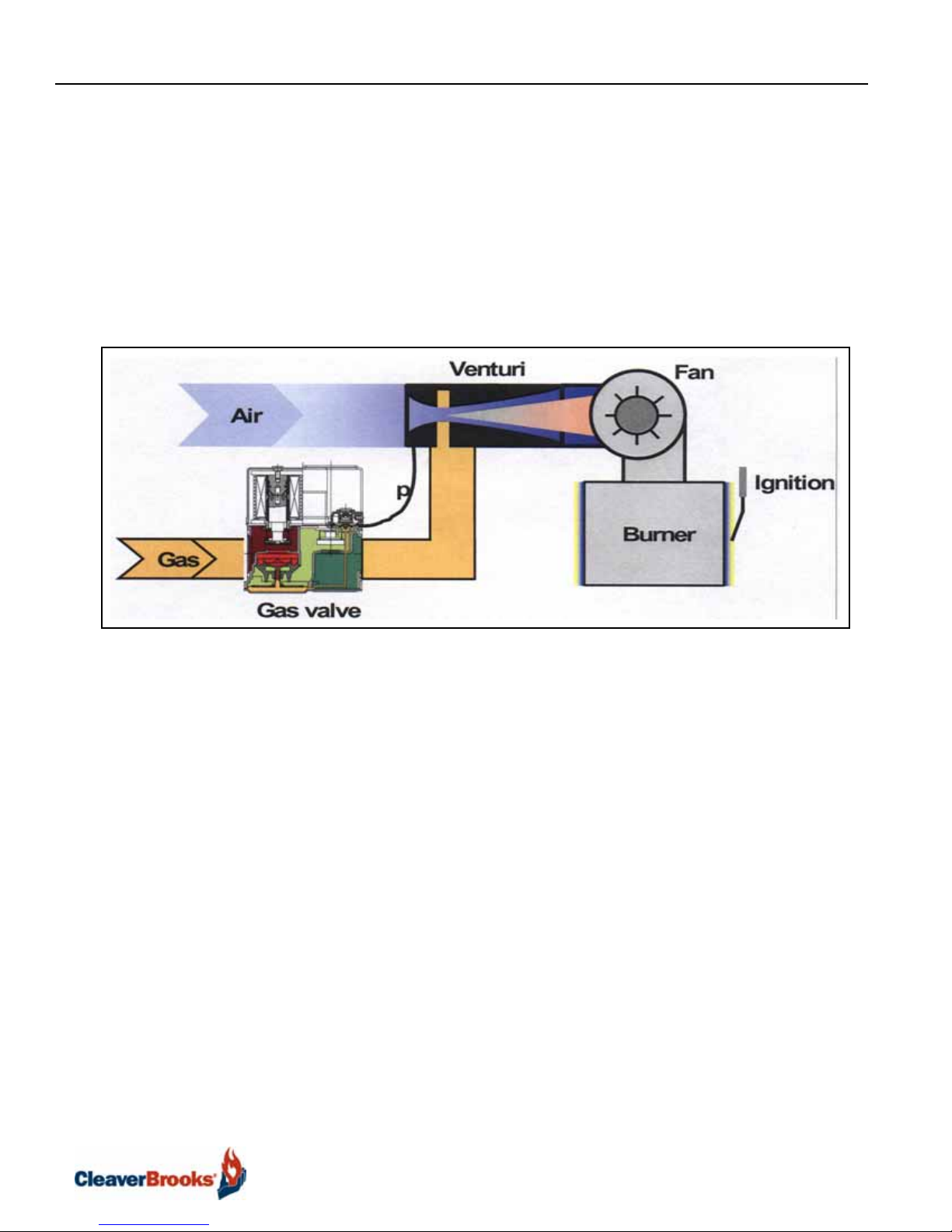

Premix Burner Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Model CFC Heat Flow and Component Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

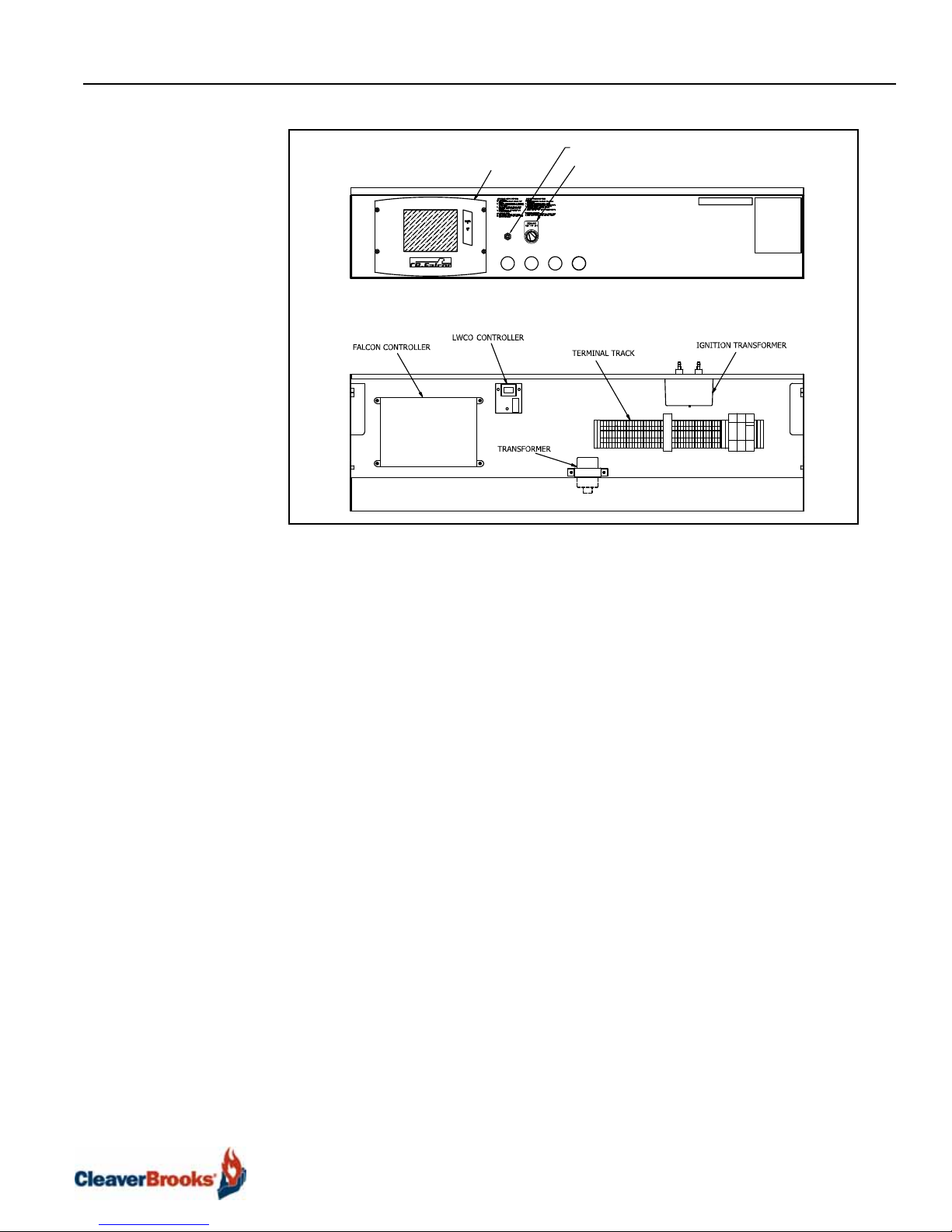

ClearFire Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

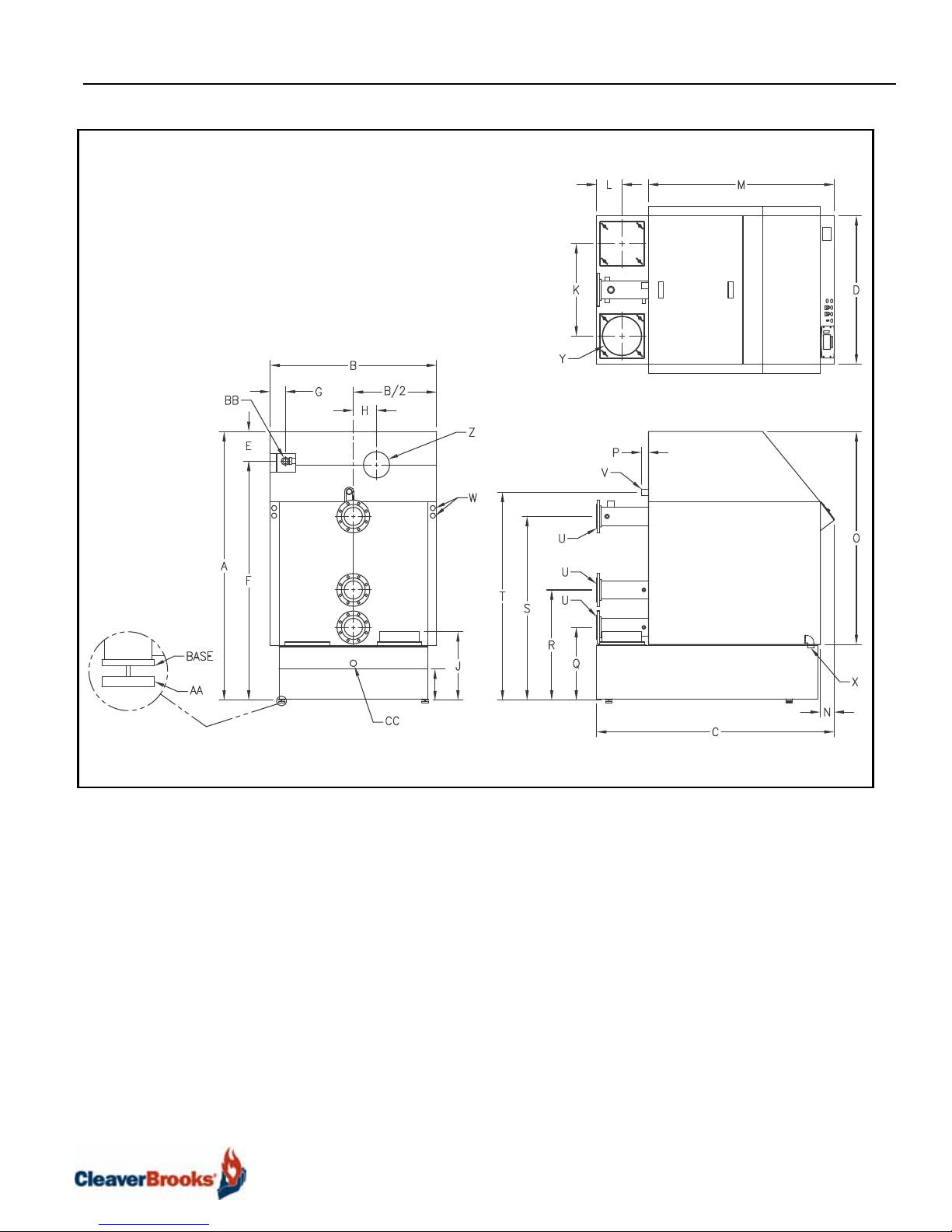

Model CFC Dimensional Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Competitive Condensation Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

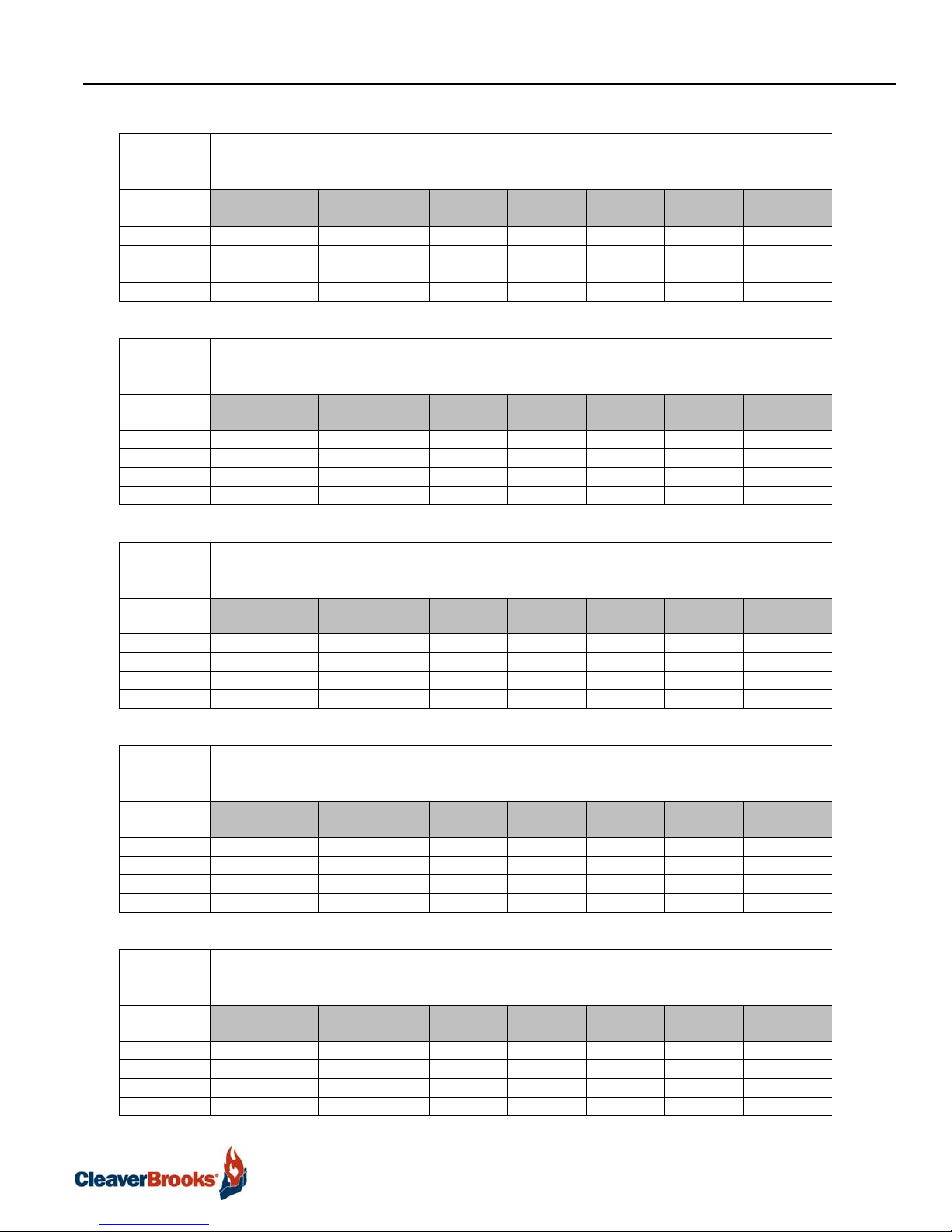

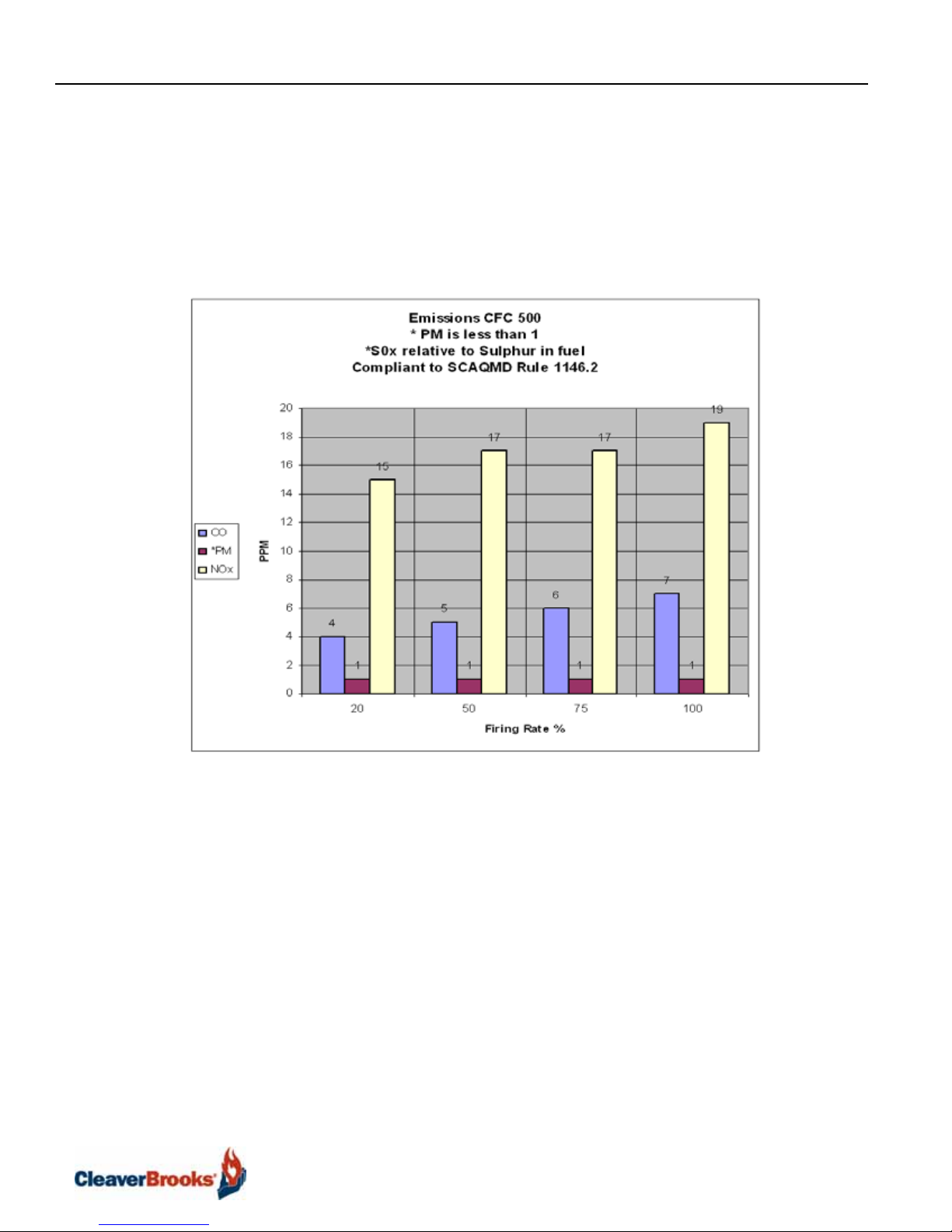

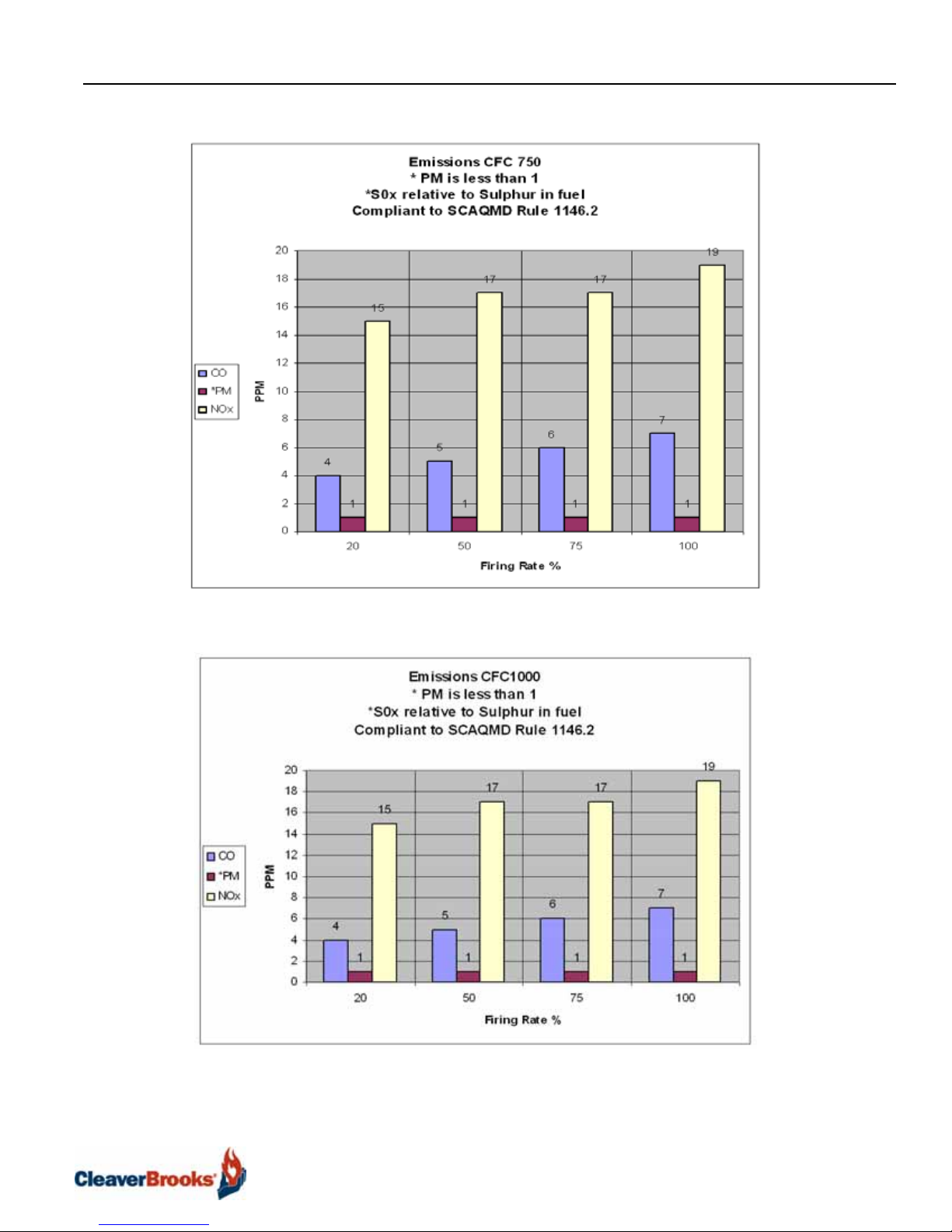

Emissions Data Clearfire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-19

Pressure Drop Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-25

Condensate Piping Direct To Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Optional Condensate Treatment Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Condensate Piping for Multiple Boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Condensate Treatment Tank for Multiple Boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Gas Piping Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Gas Header Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Model CFC Minimum Room Clearance Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

CFC Seismic Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

No Primary Loop with Domestic Water and 2-Way Divert Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Two Boilers and Three Variable Temperature Zones (No Primary Loop) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Two-Pipe Primary/Secondary Piping with Domestic Hot Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Two-Pipe Primary/Secondary Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

No Primary Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Domestic Water Heating, No Primary Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Domestic Water with On/Off and 3-Way Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Piping ‘Hybrid’ Boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

‘Hybrid’ Boilers with Domestic Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2 Pipe System, Typical (reverse-return) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table of Contents

List of Figures

1 Rev. 05-2012

Page 2

Model CFC ClearFire Commercial Boilers

Zoning with Zone Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Domestic Water with 2 Boilers and 2 Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Two Opening Outside Wall Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Two Opening Ducted Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

One Opening Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Two Opening Engineered Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Optional Direct Vent Combustion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Horizontal through the wall venting using inside air for combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Horizontal flue through-wall with direct vent combustion intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Inside Air - Vertical Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Vertical Stack with Direct Vent Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Electrical Connections CFC 500-2500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Electrical Connections CFC 3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

CFC Rear Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

CB Falcon pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

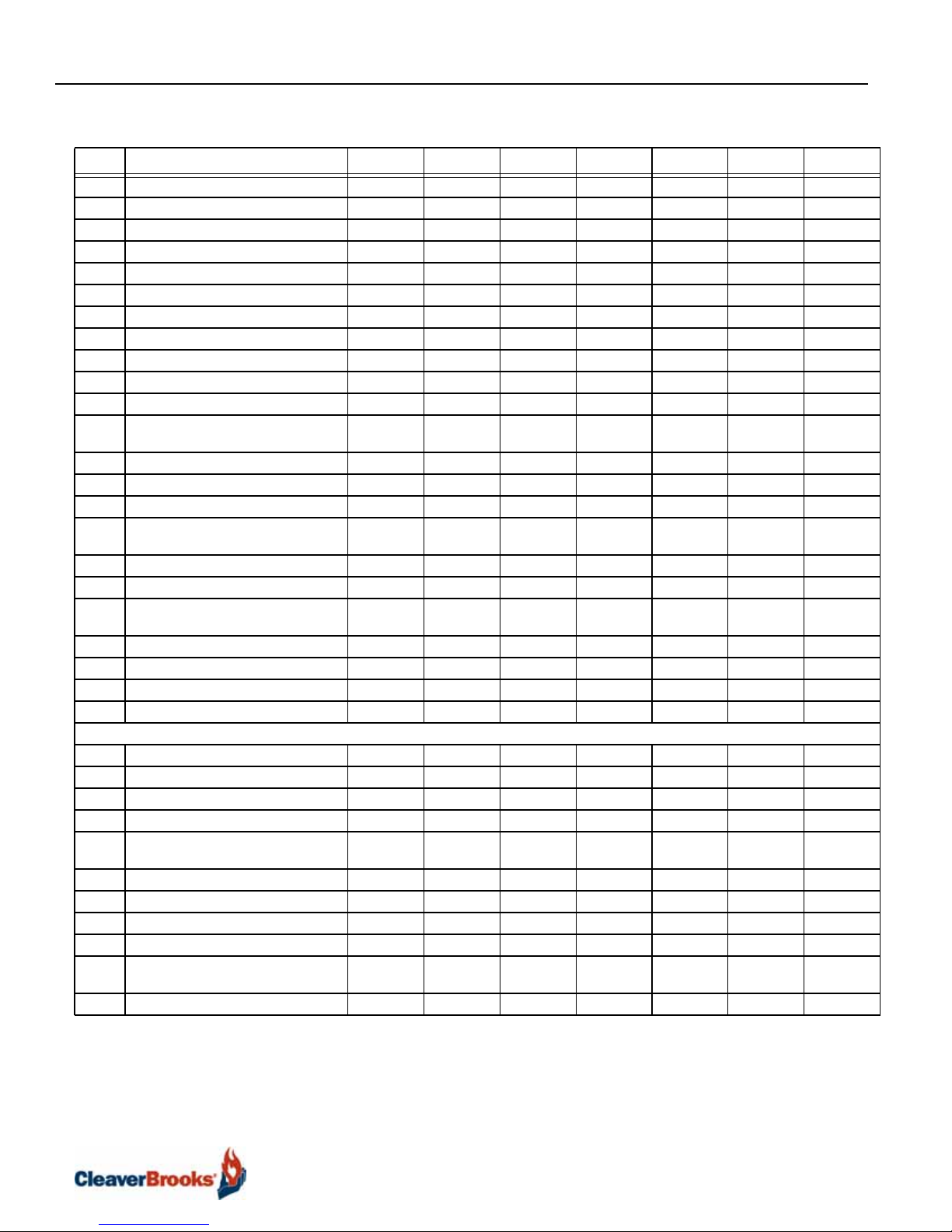

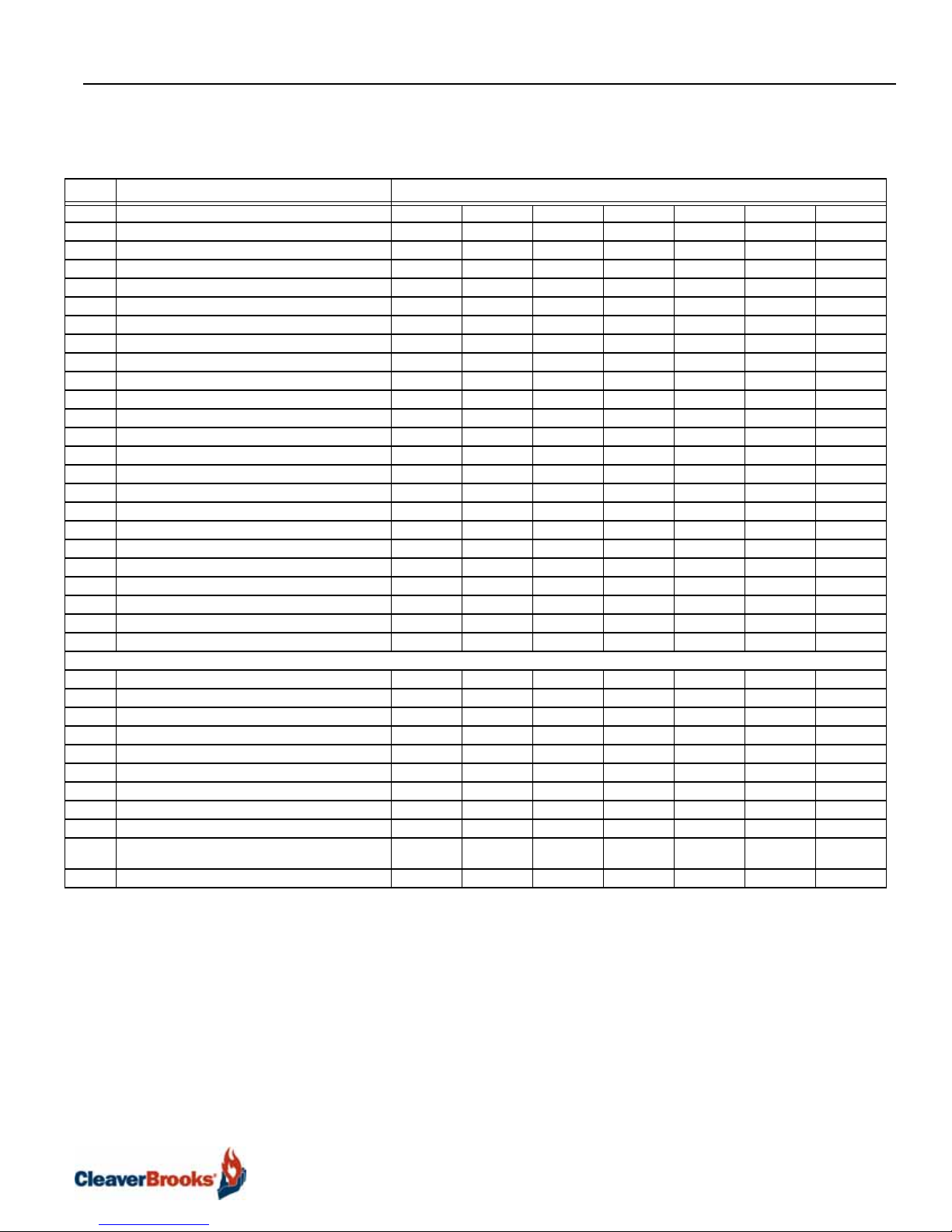

U.S. Standard Dimensions Model CFC Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Metric Dimensions Model CFC Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

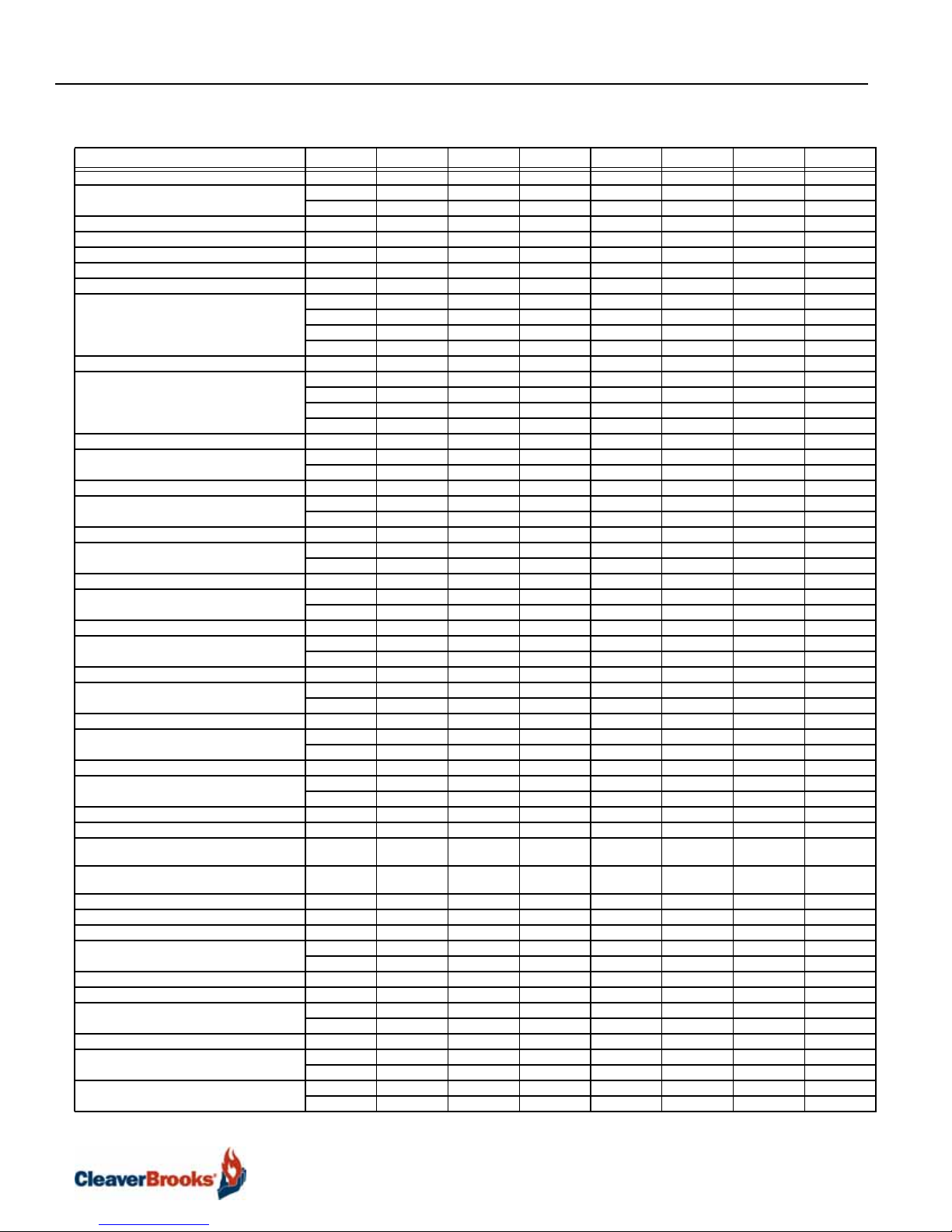

Model CFC Boiler Ratings (Sea Level to 2000 Feet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

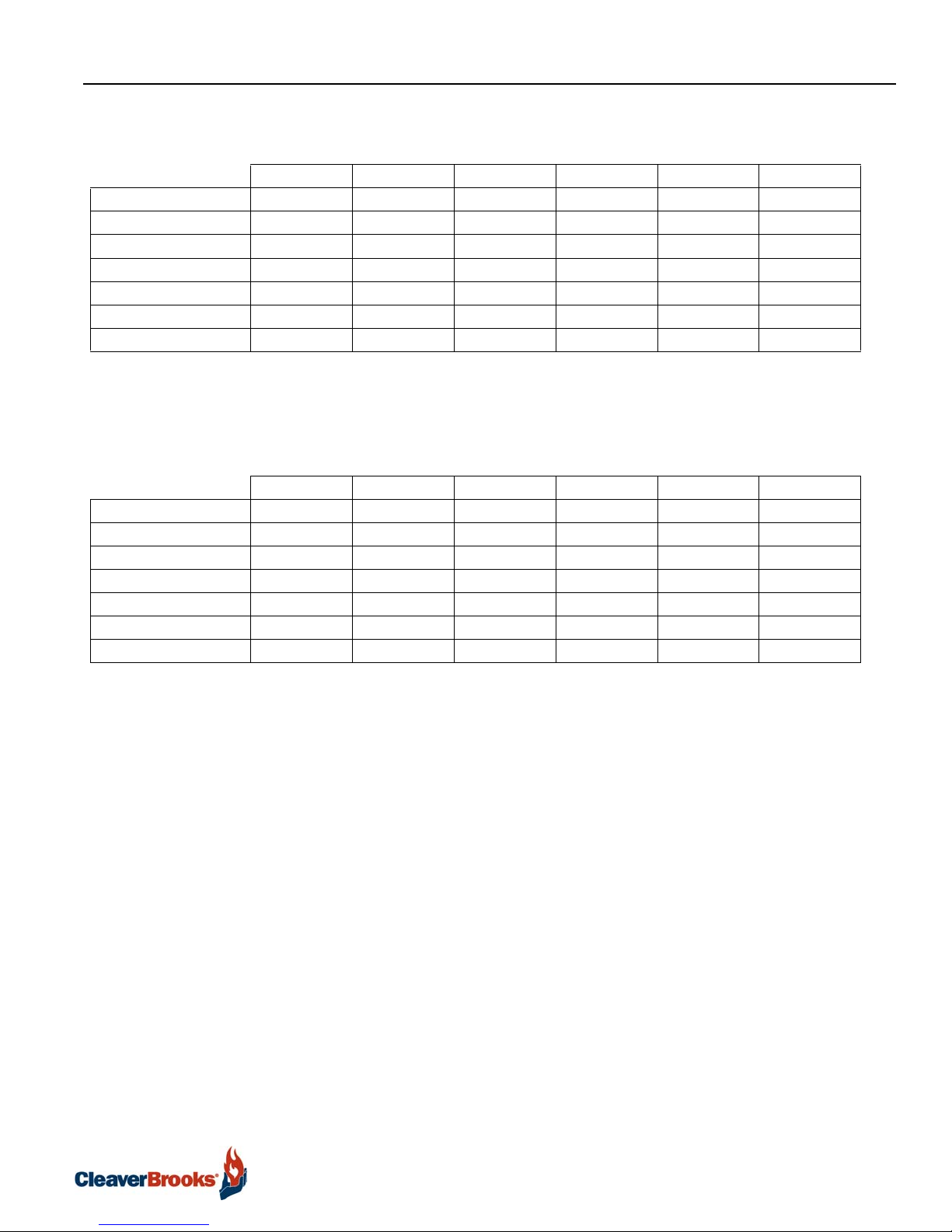

Altitude Correction for Input Capacity at Various Altitude Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

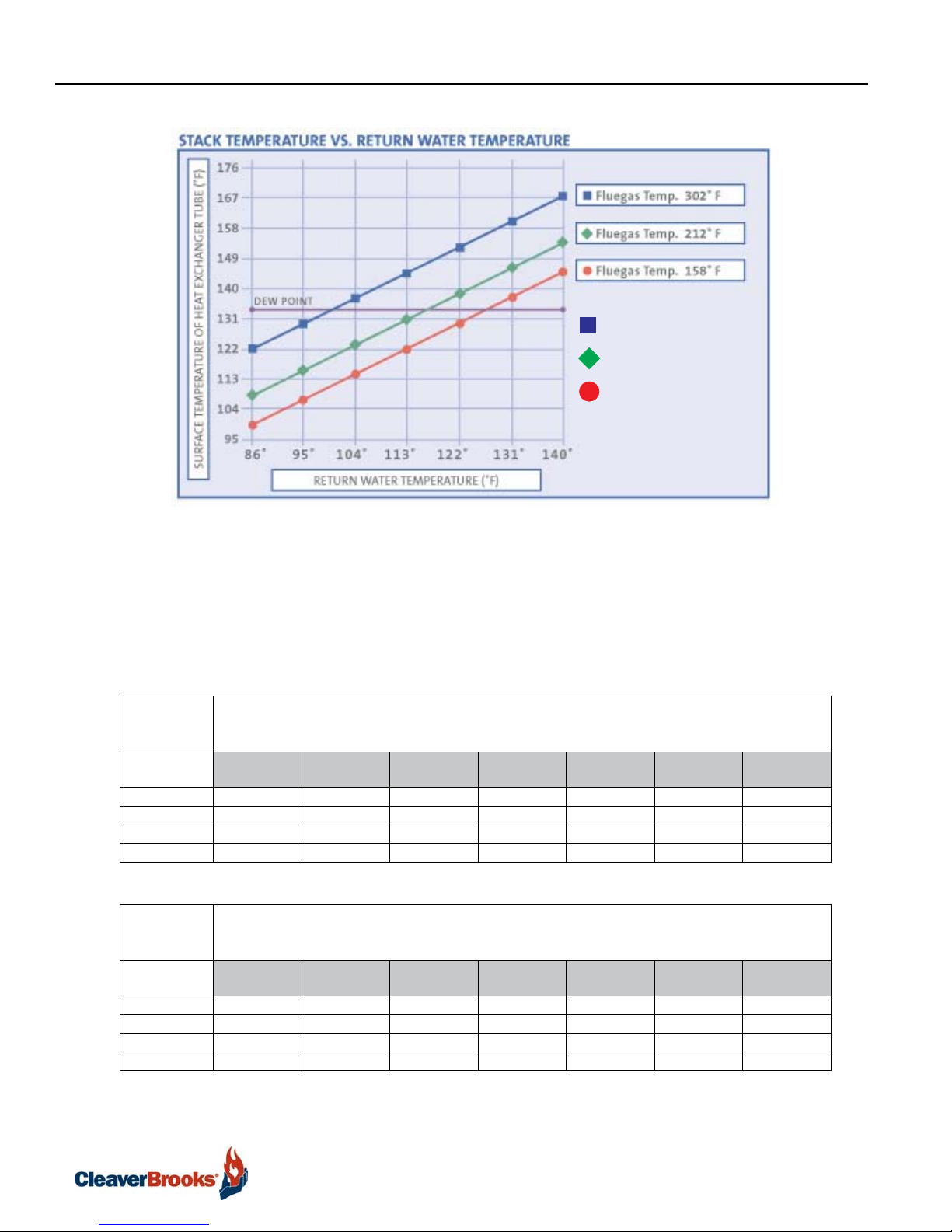

ClearFire Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 - 15

Noise Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CFC Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

CFC Flow Rates (Metric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Model CFC Minimum Over Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Model CFC Boiler Safety Valve Information @ 125 PSIG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Model CFC Boiler Safety Valve Information @ 60 PSIG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Model CFC Water Chemistry Requirements in accordance with ABMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Glycol Application Guidelnes - Model CFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Max Firing Rate vs. Glycol Concentration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

HF Speed Settings vs. Glycol Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Model CFC Maximum Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

CFC capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Model CFC Minimum and Maximum Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Model CFC Minimum Required Gas Pressure Altitude Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Stack design (single boiler) using room air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Stack sizing using outside air for combustion (direct vent combustion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Operating Conditions - Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Operating Conditions - Display/Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

CB Falcon burner sequence (Central Heat) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

List of Tables

2 Rev. 05-2012

Page 3

Model CFC ClearFire Commercial Boilers

MODEL CFC FEATURES AND BENEFITS

Compact Firetube

Design

The Model CFC boiler is a single pass,

vertical down fired durable firetube

boiler. The internal extended-heating

surface tubes provide very high levels of

performance in a compact space,

offering over 10 square feet of heating

surface per boiler horsepower, providing

many years of trouble free performance.

Figure B5-1. AluFer Inserts

Advanced

Technology

Advanced

Construction

Tubes and tube sheets are constructed from UNS S32101 duplex stainless steel.

Tubes feature AluFer tube inserts for optimal heat transfer.

The extended heating surface design provides the ideal solution for the demands of

a condensing boiler and helps to recover virtually all the latent heat of the flue gas.

Each tube consists of an outer stainless steel tube (waterside) and the AluFer

extended surface profile on the flue gas side.

High Efficiency With the extended heating surface tubes the CFC boiler will provide fuel to water

efficiency of up to 99% at low fire and 97% at high fire with 80 degrees F return

water temperature.

Ease of Maintenance The powder coated steel casing is designed for easy removal and re-assembly. As

shown in Figure B5-2, the burner is hinged and is provided with hydraulic pistons

for simple opening for service of the spark electrode, inspection of the burner

cylinder, tubes and tube sheet on Models CFC1000 and larger. (On the CFC500 and

750, the burner is hinged only). A front mounted service platform is provided for

easy access to the burner components and controls.

Figure B5-2. Fireside Access

Quality Construction ISO 9001:2001 certified manufacturing process ensures the highest degree of

manufacturing standards are always followed.

ASME Code construction ensures high quality design, safety, third party inspection,

and reliability, and is stamped accordingly.

Premix Technology The burner utilizes "Premix" technology to mix both gas fuel and combustion air prior

to entering the burner canister, with air "leading" during burner firing transitions.

3 Rev. 05-2012

Page 4

Model CFC ClearFire Commercial Boilers

Combined with a variable speed fan, this technology provides very low emission

levels, exceptionally safe operation, and nearly 100% combustion efficiency.

Full Modulation The variable speed fan provides modulated firing for reduced on/off cycling,

excellent load tracking, and reduced operating costs. The burner does not require

mechanical linkage connections between the fuel input valve and air control.

Instead, the microprocessor control positions the fan speed in accordance with

system demand, and this determines the fuel input without mechanical device

positioning - that is, linkage-less fuel/air ratio control. This eliminates linkage

slippage, minimizes burner maintenance, and provides control repeatability. This is

shown schematically in Figure B5-3.

Figure B5-3. Premix Burner Technology

Designed For

Heating

Applications

The pressure vessel is designed for 125 psig MAWP (Max. Allowable Working

Pressure) and is constructed of durable ASTM Grade Steel and Stainless Steel

materials. Figure B5-4 shows the counter flow heat exchanger design that gives

optimal heat transfer. The design also prevents hot spots, does not require a

minimum flow for thermal shock protection, and does not require a minimum return

water temperature. In fact, the design carries a 20-year thermal shock warranty.

Because of its design characteristics, the Model CFC is well suited for applications

utilizing indoor/outdoor reset controls, radiant floor heating, snow melt systems,

ground source heat pump systems and systems that utilize variable speed

circulating pumps. It may also be employed in standard hot water systems that

require higher heated water at colder outdoor temperatures but then require

minimum temperatures during warmer heating days, realizing fuel efficiency savings

over traditional hot water boilers.

While the design does not lend itself to the direct supply of potable water, a separate

storage tank with an internal heat exchanger can be employed, as the

microprocessor control permits domestic water programming. Therefore, the Model

CFC can service both hydronic heating and domestic water source heating.

Dual Return Two return pipes - high and low temperature - allow condensing performance with

as little as 10% return water at condensing temperature.

4 Rev. 05-2012

Page 5

Model CFC ClearFire Commercial Boilers

Combustion Fan and

Premix Gas Valve

Safety Relief Valve

Air Vent Connection

Hot Water

Outlet

High Temp.

Return

Assembly

Burner

Canister

Control

Panel

“Finned” High

Efficiency AluFer

Tubes

Low Temp.

Return

Flue Gas

Outlet

Figure B5-4. Model CFC Heat Flow and Component Orientation

MODEL CFC PRODUCT OFFERING

Information in this section applies to condensing hot water boiler sizes ranging from

500,000 Btu input through 3,300,000 Btu input for operation on Natural Gas or

LP Gas only. Installation is for indoor use only.

Dimensions, ratings, and product information may change to meet current market

requirements and product improvements. Therefore, use this information as a guide.

ASME Code

Pressure Vessel

5 Rev. 05-2012

Page 6

Model CFC ClearFire Commercial Boilers

Standard Equipment Equipment described below is for the standard boiler offering:

1. The Boiler

A. Each boiler size is designed for a Maximum Allowable Working Pressure

(MAWP) of 125 psig (8.6 Bar), constructed in accordance with the ASME

Code Section IV and bear the "H" stamp.

B. The insulated boiler is mounted on a base and powder coated steel casing

provided.

C. A drain valve connection is provided at the front bottom for field piping of a

boiler drain valve, which can be furnished as an option.

2. Boiler Trim and Controls

• The following items are furnished:

• Probe Type Low Water Cutoff control, manual reset.

• Excess Water Temperature Cutoff, manual reset.

• NTC (negative temp. coefficient) sensor for hot water supply temperature.

• NTC sensor for hot water return temperature.

• ASME Safety Relief Valve set @ 125 psig. (8.6 Bar)

• Combination Temperature/Pressure Gauge.

3. Burner Control

A. The CB Falcon is an integrated burner management and modulation control

with a touch-screen display/operator interface. Its functions include the

following:

• Two (2) heating loops with PID load control.

• Burner sequencing with safe start check, pre-purge, direct spark ignition (pilot

ignition CFC-3300), and post purge.

• Electronic ignition.

• Flame Supervision.

• Safety shutdown with time-stamped display of lockout condition.

• Variable speed control of the combustion fan.

• Supervision of low and high gas pressure, air proving, stack back pressure, high

limit, and low water.

• First-out annunciator.

• Real-time data trending.

• (3) pump/auxiliary relay outputs.

• Modbus communication capability.

• Outdoor temperature reset.

• Remote firing rate or setpoint control

• Setback/time-of-day setpoint

• Lead/Lag for up to 8 boilers

6 Rev. 05-2012

Page 7

Model CFC ClearFire Commercial Boilers

LWCO RESET

FALCON DISPLAY / OPERATOR INTERFACE

DEMAND SWITCH

Figure B5-5. ClearFire Control Panel (1500/1800 shown)

4. Forced Draft Burner

A. The burner is a "Pre-mix" design consisting of a unitized venturi, single body

dual safety gas valve, blower, and burner head.

B. Full modulation is accomplished with a variable speed fan for 5:1 turndown

ratio.

C. For near flameless combustion, the burner utilizes a Fecralloy-metal fiber

head.

D. Noise level at maximum firing is less than 70 dBA regardless of boiler size.

E. Operating on Natural Gas, NOx emissions will be less than 20 PPM

regardless of boiler size and the boiler is certified for California and Texas for

Low NOx emissions.

F. As an option, the burner is capable of direct vent combustion.

G. Ignition of the main flame is via direct spark, utilizing high voltage electrodes

and a separate electrode for flame supervision (CFC-3300 uses gas pilot

ignition and UV scanner for flame supervision).

H. To ensure adequate combustion air is present prior to ignition, and to ensure

the fan is operating, a combustion air proving switch is furnished.

I. A High Air Pressure Switch is provided to ensure burner lockout if excessive

back pressure due to a blocked stack occurs.

J. For ease of maintenance and inspection, the burner is furnished with

hydraulic rods and easy opening lockdown nuts, which permit the burner to

swing up (except 500 and 750, which are hinged only). This provides full

access to the burner and electrodes, as well, to the tube sheet and tubes.

5. Burner Gas Train

The standard gas train is equipped in accordance with UL certification and complies

with ASME CSD-1. Each burner gas train includes:

7 Rev. 05-2012

Page 8

Model CFC ClearFire Commercial Boilers

• Low Gas Pressure Interlock, manual reset.

• High Gas Pressure Interlock, manual reset.

• ASME CSD-1 Test Cocks.

• Downstream manual ball type shutoff cock.

• Single body dual safety shutoff gas valve.

Optional Equipment For option details, contact the local authorized Cleaver-Brooks representative. In

summary, here are some of the options that can be provided with the boiler:

A. Dual gas train for quick and easy fuel switchover.

B. Reusable air filter.

C. Condensate neutralization tank assembly - consists of neutralizing media, filter, and PVC

condensate holding tank with integral drain trap. This assembly can be mounted beneath

the boiler.

D. Outside air intake for direct vent combustion.

E. Outdoor temperature sensor for indoor/outdoor control.

F. Header temperature sensor for multiple boiler Lead/Lag operation.

G. Auxiliary Low Water Control (shipped loose) for field piping by others into the system piping.

H. Alarm Horn for safety shutdown.

I. Relays for output signal for burner on, fuel valve open.

J. Stack Thermometer.

K. Stack temperature limit-sensor.

L. Auto air vent.

M. Boiler drain valve.

DIMENSIONS AND RATINGS

For layout purposes, the overall dimensions for the Model CFC are shown in Table

B5-1 (US Dimensions) and Table B5-2 (Metric Dimensions) including the various

pipe connection sizes for supply and return water, drain, and vent. The performance

ratings for the boiler are shown in Table B5-3.

Altitude Relative to the ratings shown, installation of the boiler above 2000 feet elevation

will result in input capacity reduction. Please refer to Table B5-4 for input ratings of

the boiler at various elevations.

PERFORMANCE DATA

Efficiency The Model CFC is a "full condensing" boiler realizing efficiency gain at variable

operating conditions. It is designed to extract the latent heat of condensation over a

greater range than other designs. This can be seen in Figure B5-7, which depicts

nominal stack temperatures of the boiler versus other designs. The nominal point of

condensation is approximately 132

efficient heat transfer design and lower stack temperature, is able to capture the

latent heat of condensation over a broader range.

Fuel-to-water efficiency is relative to specific operating conditions. Operating

efficiency will be greater in the "condensing" mode of operation as noted above, yet

with its inherently greater heat transfer surfaces and superior pre-mix burner, the

ClearFire’s efficiency under "traditional" hot water conditions is also outstanding.

Table B5-6 through Table B5-9 show the guaranteed efficiencies at various

operating conditions and firing rates for Natural Gas. It should be noted that the

efficiency is exceptional at high fire and low fire versus other designs where high

efficiency is realized only with low fire or minimal firing rates and low temperature

returns.

F (55.5 C). The ClearFire, due to its more

8 Rev. 05-2012

Page 9

Model CFC ClearFire Commercial Boilers

I

Figure B5-6. Model CFC Dimensional Views

9 Rev. 05-2012

Page 10

Model CFC ClearFire Commercial Boilers

Table B5-1. U.S. Standard Dimensions Model CFC Boiler

ITEM DIMENSIONS (inches) 500 750 1000 1500 1800 2500 3300

A Overall Height 71.8 71.8 75.7 81.6 81.6 82.2 85.0

B Overall Width 32.3 32.3 36.6 43.7 43.7 50.8 61.3

C Overall Depth 48.8 48.8 62.6 65.6 65.6 72.6 86.3

D Width Less Casing 26.8 26.8 31.1 38.2 38.2 45.3 55.5

E Gas Connection to Top of Casing 8.1 8.1 9.5 12.5 10.2 9.4 10.0

F Gas Connection to Floor 63.7 63.7 66.2 69.1 71.4 72.8 75.0

G Side of Casing to Gas Connection 2.3 2.3 4.3 3.4 5.2 4.7 5.1

H Boiler Centerline to Air Inlet Centerline 4.0 4.0 4.0 4.9 7.1 7.1 7.1

I Floor to Bottom of Base 10.3 10.3 10.3 10.3 10.3 10.3 10.3

J Floor to Top of Stack Connection 18.6 18.6 18.1 19.1 19.1 20.9 21.4

K Centerline to Centerline of Stack Stub 15.4 15.4 16.9 21.0 21.0 28.1 35.8

L Rear of Boiler to Centerline of Stack

Stub

M Front of Boiler to Rear of Casing 38.8 38.8 49.4 49.5 49.5 56.5 67.0

N Control Panel Projection 4.1 4.1 4.1 4.1 4.1 4.1 4.3

O Casing Height 56.2 56.2 60.0 65.4 65.4 65.4 67.0

P Air Vent Line Projection from Rear of

Casing

Q Floor to Centerline of Lower Return 19.5 19.5 19.6 20.7 21.3 22.4 24.1

R Floor to Centerline of Upper Return 28.2 28.7 30.5 20.3 32.3 33.8 35.5

S Floor to Centerline of Supply Connec-

tion

T Floor to Centerline of Air Vent 59.9 59.9 62.3 63.1 63.1 63.6 66.4

AA Boiler Adjustment Foot Height 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Height Above Boiler for Burner Service 14.0 14.0 14.0 14.0 14.0 14.0 18.0

5.4 5.4 7.5 8.1 8.1 8.6 10.0

7.8 7.8 7.3 8.1 8.1 8.7 4.7

54.3 54.3 56.2 57.1 56.2 56.2 59.1

CONNECTIONS

U Water Supply/Return, 150# RF Flg 2-1/2" 2-1/2" 2-1/2" 3" 4" 5" 5"

V Boiler Air Vent, NPT 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2"

W Electrical Conduit, left or right 1.6" 1.6" 1.6" 1.6" 1.6" 1.6" 1.6"

X Boiler Drain, NPT 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2"

Y Flue Gas Nominal OD, Left or Right

option

Z Combustion Air Option 4" OR 6" 4" OR 6" 4" OR 6" 6" OR 8" 6" OR 8" 8" 8"

BB Gas Connection, NPT 1" 1" 1" 1-1/2" 1-1/2" 1-1/2" 2"

CC Condensate Drain, FPT 3/4" 3/4" 3/4" 3/4" 3/4" 1" 1"

Relief Valve outlet @ 125 # Setting 1" 1" 1" 1" 1" 1" 1"

Voltage Fan Motor 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 208-240/

Voltage Control Circuit 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60

6" 6" 8" 10" 12" 12" 12"

10 Rev. 05-2012

3/60

Page 11

Model CFC ClearFire Commercial Boilers

Table B5-2. Metric Dimensions Model CFC Boiler

Boiler Size

ITEM DIMENSIONS (mm) 500 750 1000 1500 1800 2500 3300

A Overall Height 1824 1824 1923 2073 2073 2088 2159

B Overall Width 820 820 930 1110 1110 1290 1557

C Overall Depth 1240 1240 1590 1666 1666 1844 2192

D Width Less Casing 681 681 790 970 970 1151 1410

E Gas Connection to Top of Casing 206 206 241 318 259 239 254

F Gas Connection to Floor 1618 1618 1681 1755 1814 1849 1905

G Side of Casing to Gas Connection 58 58 109 86 132 119 130

H Boiler Centerline to Air Inlet Centerline 102 102 102 124 180 180 180

I Floor to Bottom of Base 262 262 262 262 262 262 262

J Floor to Top of Stack Connection 472 472 460 485 485 531 544

K Centerline to Centerline of Stack Stub 391 391 429 533 533 714 909

L Rear of Boiler to Centerline of Stack Stub 137 137 191 206 206 218 254

M Front of Boiler to Rear of Casing 986 986 1255 1257 1257 1435 1702

N Control Panel Projection 104 104 104 104 104 104 109

O Casing Height 1427 1427 1524 1661 1661 1661 1702

P Air Vent Line Projection from Rear of Casing 198 198 185 206 206 221 119

Q Floor to Centerline of Lower Return 495 495 498 526 541 569 612

R Floor to Centerline of Upper Return 716 729 775 516 820 859 902

S Floor to Centerline of Supply Connection 1379 1379 1427 1450 1427 1427 1501

T Floor to Centerline of Air Vent 1521 1521 1582 1603 1603 1615 1687

AA Boiler Adjustment Foot Height 64 64 64 64 64 64 64

Height Above Boiler for Burner Service 356 356 356 356 356 356 457

CONNECTIONS (inches)

U Water Supply/Return, 150# RF Flg 2-1/2" 2-1/2" 2-1/2" 3" 4" 5" 5"

V Boiler Air Vent, NPT 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2"

W Electrical Conduit, left or right 1.6" 1.6" 1.6" 1.6" 1.6" 1.6" 1.6"

X Boiler Drain, NPT 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2"

Y Flue Gas Nominal OD, Left or Right option 6" 6" 8" 10" 12" 12" 12"

Z Combustion Air Option 4" 4" OR 6" 4" OR 6" 6" 6" 6" OR 8" 8"

BB Gas Connection, NPT 1 "1 "1 "1-1/2 "1-1/2 "1-1/2 "2"

CC Condensate Drain, FPT 3/4 "3/4 "3/4 "3/4 "3/4 "3/4 "1"

Relief Valve outlet @ 125 # Setting 1 "1 "1 "1 "1 "1 "1"

Voltage Fan Motor 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 208-240/

Voltage Control Circuit 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60

3/60

11 Rev. 05-2012

Page 12

Model CFC ClearFire Commercial Boilers

Table B5-3. Model CFC Boiler Ratings (Sea Level to 2000 Feet)

Description Units 500 750 1000 1500 1800 2500 3300

Input Max. BTU/Hr. 500,000 750,000 1,000,000 1,500,000 1,800,000 2,500,000 3,300,000

KCAL/Hr. 126,000 189,000 252,000 378,000 453,600 630,000 831,600

Natural Gas (1000 Btu/ft3) FT3/Hr 500 750 1000 1500 1800 2500 3300

Propane (2500 Btu/ft3) FT3/Hr 200 300 400 600 720 1000 1320

Natural Gas M3/Hr 14.2 21.2 28.3 42.5 50.9 70.8 93.4

Propane M3/Hr 5.7 8.5 11.3 17.0 20.4 28.3 37.4

Output at 104/86 F [40/30 C] 100% Firing BTU/Hr. 480,000 720,000 960,000 1,440,000 1,728,000 2,400,000 3,168,000

KCAL/Hr. 120,960 181,440 241,920 362,880 435,456 604,800 798,336

BHP 14.3 21.5 28.7 43.0 51.6 71.7 94.6

KW 141 211 281 422 506 703 928

Output at 176/140 F [80/60 C] 100% Firing BTU/Hr. 435,000 652,500 870,000 1,305,000 1,566,000 2,175,000 2,871,000

KCAL/Hr. 109,620 164,430 219,240 328,860 394,632 548,100 723,492

BHP 13.0 19.5 26.0 39.0 46.8 65.0 85.8

KW 127 191 255 382 459 637 841

MAWP PSI 125 125 125 125 125 125 125

BAR 8.6 8.6 8.6 8.6 8.6 8.6 8.6

Operating Temp., Max. °F 194 194 194 194 194 194 194

°C 90 90 90 90 90 90 90

Water Content Gallons 51 51 90 113 99 126 209

Liters 193 193 341 428 375 477 791

Weight w/o Water Pounds 1,160 1,160 1,795 2,225 2,505 3,640 4,835

Kg 526 526 814 1009 1136 1651 2193

Operating Weight Pounds 1,585 1,585 2,545 3,165 3,325 4,685 6,570

Kg 719 719 1154 1436 1508 2125 2980

Weight, Shipping Pounds 1,210 1,210 1,850 2,300 2,600 3,725 5,000

Kg 549 549 839 1043 1179 1690 2268

Fireside Heating Surface ft2 185 185 307 445 596 937 1,258

m2 17.1 17.2 28.5 41.3 55.4 87.0 117

Standby Heat Loss BTU/Hr 1,206 1,639 1,912 2,459 2,561 3,415 4,620

Watts 353 480 560 720 750 1000 1353

Fan Motor Size Watts 335 335 335 750 1,200 1,200 2,200

Operating Voltage, Fan Volts/Ph/Hz115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 208-240/

Control Circuit Volts/Ph/Hz115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60 115/1/60

Current Draw, Fan Amperes 4 4 4 8.5 12 12 6.9

Current Draw Cont. Ckt. Amperes 1.5 1.5 1.5 1.5 2 2 2.3

Condensate Quantity Firing Nat. Gas & operating @ 104/86 F.

Condensate Value PH 4.5 - 5.5 4.5 - 5.5 4.5 - 5.5 4.5 - 5.5 4.5 - 5.5 4.5 - 5.5 4.5 - 5.5

Gal/Hr. 4 5 6.5 10 12 16.5 22

l/Hr. 15 19 25 38 45 62 83

3/60

Flue Gas Mass Flow @ 100% Firing (Natural

Gas)

Flue Gas Temp. Oper.

176/140 F [80/60 C]

Flue Gas Temp. Oper.

104/86 F [40/30 C]

lb/hr 557 835 1,113 1,670 2,004 2,783 3674

kg/h 253 379 505 758 909 1262 1667

°F 155 180 160 170 170 160 160

°C 68 82 71 77 77 71 71

°F 105 125 110 108 108 110 110

°C 41 52 43 42 42 43 43

12 Rev. 05-2012

Page 13

Model CFC ClearFire Commercial Boilers

Table B5-4. Altitude Correction for Input Capacity at Various Altitude Levels

Natural Gas

700' ASL 2000' 4000' 6000' 8000' 10000'

CFC 3300 3300 kBTU/h 3300 3300 3300 3057 2930

CFC 2500 2500 2418 2245 2083 1930 1850

CFC 1800 1800 1800 1800 1666 1544 1480

CFC 1500 1500 1500 1500 1415 1311 1257

CFC 1000 1000 1000 1000 943 874 838

CFC 750 750 750 750 707 655 628

CFC 500 500 500 490 454 421 404

Ratings assume 35% excess air, 80F combustion air.

Blower speed adjustments should be made to match performance and local conditions accordingly.

For minimum gas supply pressures see Table B5-24. Altitude corrections for supply pressure should be made per Table B5-25.

Natural gas heating value of 1000 BTU/SCF assumed.

LP Gas

700' ASL 2000' 4000' 6000' 8000' 10000'

CFC 3300 3300 kBTU/h 3300 3300 3300 3057 2930

CFC 2500 2500 2500 2339 2169 2010 1927

CFC 1800 1800 1800 1800 1704 1579 1514

CFC 1500 1500 1500 1500 1500 1390 1332

CFC 1000 1000 1000 1000 1000 926 888

CFC 750 750 750 750 750 695 666

CFC 500 500 500 500 481 445 427

Ratings assume 40% excess air, 80F combustion air.

Blower speed adjustments should be made to match performance and local conditions accordingly.

For minimum gas supply pressures see Table B5-24. Altitude corrections for supply pressure should be made per Table B5-25.

LP (propane) gas heating value of 2500 BTU/SCF assumed.

13 Rev. 05-2012

Page 14

Model CFC ClearFire Commercial Boilers

Competitor 1

Competitor 2

Clearfire

ClearFire

Efficiencies

Firing Rate

100 96.0 94.6 92.0 89.0 88.5 88.4 87.9

Firing Rate

100 94 92.7 90.5 88.5 87.8 87.0 86

Figure B5-7. Competitive Condensation Analysis

The Tables below depict the operating efficiencies of each size Model CFC boiler,

including radiation losses. As the Model CFC is a fully condensing boiler, maximum

efficiency is obtained when operating within the condensing mode, utilizing the latent

heat of condensation.

Table B5-5. CFC 500 ClearFire Efficiency

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99.0 98.8 97.5 94.8 92.0 88.5 88.0

50 97.4 96.2 95.0 92.2 90.5 88.5 88.0

75 97.0 95.6 93.0 90.5 89.0 88.5 88.0

Return Water Temperature F

0

(C)

Table B5-6. CFC 750 ClearFire Efficiency

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 98.3 97.1 93.6 91.7 90 88.0 87.5

50 96.5 95.3 91.8 89.9 88.5 88.0 87.5

75 96 94.9 91 89 88 87.5 86.5

Return Water Temperature F

0

(C)

14 Rev. 05-2012

Page 15

Model CFC ClearFire Commercial Boilers

Table B5-7. CFC 1000 ClearFire Efficiency

Firing Rate

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99 97.8 94.3 92.4 90.1 88.5 88

50 98.5 96.5 93.5 90.8 89.5 88.5 87.5

75 97.5 96.2 92.5 89.5 88.3 88 87.3

100 96.5 95.8 91.5 88.9 88 87.5 87

Return Water Temperature F

Table B5-8. CFC 1500 ClearFire Efficiency

Firing Rate

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99 98 96.2 94 91 88.7 88.2

50 98.2 97.5 94.3 92 90 88.5 88.2

75 98 96.5 92.1 91 89 88.5 88.2

100 97 95.3 91.5 90 88.1 87.8 87.5

Return Water Temperature F

0

(C)

0

(C)

Table B5-9. CFC 1800 ClearFire Efficiency

Firing Rate

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99 98 96.5 94 91 88.5 88

50 98.3 96 93.8 91 89.8 88.5 87.6

75 98 95 93 89.5 88.9 88.3 87.3

100 97.2 94 91.5 88.9 88 87.5 87

Return Water Temperature F

0

(C)

Table B5-10. CFC 2500 ClearFire Efficiency

Firing Rate

%

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99 99 97.5 95 92 88.5 88

50 99 98.5 96 93 91 88.3 88

75 98 97 95 92 89 88 87.5

100 98 97 94 91 88.5 87.6 87

Return Water Temperature F

0

(C)

Table B5-11. CFC 3300 ClearFire Efficiency

Firing Rate

%

Return Water Temperature F

0

(C)

68 80 100 120 130 140 160

(20) (27) (38) (49) (55) (60) (72)

20 99 98 95.7 93 90.2 88.5 88

50 98.6 97.5 94.1 92 89.6 88.5 88

75 98 96.5 93.5 91 89.2 88.5 87.9

100 97 95 93.1 89.8 89 88.3 87.8

15 Rev. 05-2012

Page 16

Model CFC ClearFire Commercial Boilers

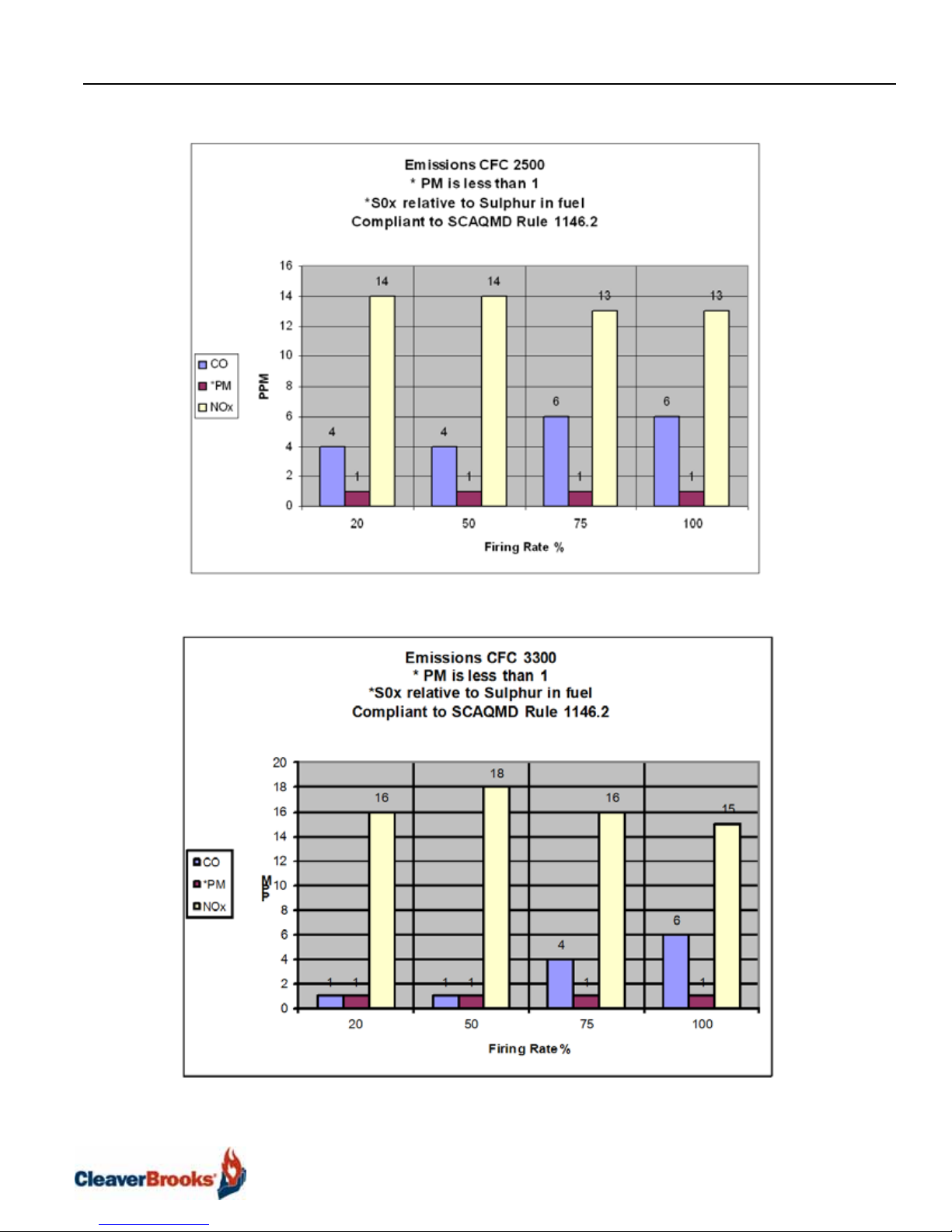

Emissions The Model CFC Boiler has been tested by an independent testing lab for Low NOx

certification in California under the requirements of South Coast Air Quality

Management District (SCAQMD) Rule 1146. Meeting the requirements of SCAQMD

also qualifies the boiler for meeting the NOx requirements in the state of Texas.

By means of the Pre-mix burner, the Clearfire boiler provides environmentally

friendly emissions when firing natural gas; emission data are shown in Figure B5-8

through Figure B5-13.

Figure B5-8. Emissions Data Clearfire Model CFC 500

16 Rev. 05-2012

Page 17

Model CFC ClearFire Commercial Boilers

Figure B5-9. Emissions Data ClearFire Model CFC 750

Figure B5-10. Emissions Data ClearFire Model CFC 1000

17 Rev. 05-2012

Page 18

Model CFC ClearFire Commercial Boilers

Figure B5-11. Emissions Data ClearFire Model CFC 1500

Figure B5-12. Emissions Data ClearFire Model CFC 1800

18 Rev. 05-2012

Page 19

Model CFC ClearFire Commercial Boilers

Figure B5-13. Emissions Data ClearFire Model CFC 2500

Figure B5-14. Emissions Data ClearFire Model CFC 3300

19 Rev. 05-2012

Page 20

Model CFC ClearFire Commercial Boilers

Noise Level The Model CFC is extremely quiet at all operating levels, does not require any sound

level modifications to provide ultra low noise levels, and is virtually vibration free.

Thus, it is very suitable in applications that demand low noise levels.

Table B5-11 shows the noise levels of the Clearfire at various firing rates.

20% Firing 60% Firing 100% Firing

CFC 500 39 48 60

CFC 750 41 51 62

CFC 1000 43 57 66

CFC 1500 40 50 64

CFC 1800 45 56 66

CFC 2500 45 57 68

CFC 3300 63 73 78

Table B5-11. Noise Level (dBA) measured 3 feet in front of boiler

ENGINEERING DATA

Boiler Information The Model CFC boiler is designed for service in any closed hydronic system and can

be used to augment any hot water system. It can be put into operation as a single

stand-alone unit with 5:1 turndown or in multiple units for larger turndown and

capacity.

Flow Rates and

Pressure Drops

System Operating

Parameters

Clearfire boilers may be utilized in water heating systems with temperatures from

40

F (4.4 C) to 195 F (90.5 C); ideal for ground water source heat pump

applications, etc. Because the Clearfire is a full condensing boiler, low water

temperature (below the dewpoint) restrictions do not apply. In fact, the lower the

return the better the fuel savings.

Variable temperature differentials can be designed to make use of changing outdoor

conditions and thus, the Clearfire is not restricted to a nominal 20

F (10 C)

differential. The boiler is designed to withstand thermal stresses with supply and

return temperature differences up to 100

F (55 C), without the use of a boiler-

circulating pump, blend pump or minimum water flow.

Note: The Clearfire does not require a minimum flow or continuous flow through it during operation.

However, the load imposed on the boiler must be considered when sizing the system flow so that

the flow does not exceed the capacity of the boiler or the demand.

To maintain rated capacity of the boiler, recommended flow rates should not be

exceeded as the flow will remove the heat beyond the capacity of the boiler. Table

B5-12 through Table B5-13 can be used to determine the full boiler output relative

to system temperature drop and the maximum recommended system pump flow.

Knowing the flow rate, the pressure drop through the boiler can be found in Figure

B5-14 through Figure B5-19.

To prevent water flashing to steam within the boiler or system, hot water boilers

must operate with proper over-pressure. System over-pressure requirements are

shown in Table B5-14.

Note: The ASME Code Section IV limits the maximum setting of the excess temperature control to

210 F (98.9 C) for boilers constructed with stainless steel. This is to ensure that water

temperature will not reach the boiling point (steaming) and therefore, so as not to exceed the

maximum limit of this control and in compliance with the Code, the operating limit of 195 F

20 Rev. 05-2012

Page 21

Model CFC ClearFire Commercial Boilers

(90.5 C) is set for normal boiler operation.

While proper overpressure is required, a means to relieve excess pressure at or

beyond the design pressure of the boiler must be provided. As boiler water is

heated, expansion occurs. And this expansion must be accounted for either with an

expansion tank (air filled) or with a bladder type tank. These devices permit the

water pressure to expand outside of the boiler and not impact the pressure vessel or

pressure relieving device. But, in accordance with Code, each boiler is equipped

with an ASME approved safety relieving device should pressure build-up occur (See

Table B5-16 and Table B5-15).

Air Venting The elimination of entrained air is required. It is recommended that each unit be

piped to an expansion tank. If this is not possible, then an auto air vent should be

provided on the vent connection of the boiler. The caveat in using an auto vent is

that free oxygen can be introduced to the vesel as the boiler cools, or in some

instances the vent can become plugged.

Table B5-12. CFC Flow Rates

System Temperature Drop 0 F

10 20 30 40 50 60 70 80 90 100 110 120

Boiler

Size

500 95 48 33 24 19 16 12 11 10.5 9 8 7

750 131 66 44 33 26 22 19 16 15 13 12 11

1000 176 88 59 44 35 29 25 22 20 18 16 15

1500 260 130 87 65 52 43 37 33 29 26 24 23

1800 351 176 117 88 70 59 50 44 39 35 32 30

2500 470 235 157 118 95 79 67 59 52 48 43 39

3300 620 310 207 155 124 103 89 78 69 62 56 52

Flow rate as a function of Delta T at 94% efficiency and maximum firing capacity

Flow Rate GPM

21 Rev. 05-2012

Page 22

Model CFC ClearFire Commercial Boilers

Table B5-13. CFC Flow Rates (Metric)

System Temperature Drop 0 C

5 1117222733384550556164

Boiler

Size

Flow Rate m

3

/hr.

500 21.6 10.9 7.5 5.4 4.3 3.6 2.7 2.5 2.3 2 1.8 1.6

750 29.75 15 10 7.5 6 5 4.3 3.6 3.4 2.9 2.7 2.5

1000 40 20 14 10 87654.543.63.4

1500 59 29.5 20 15 12 10 8.4 7.5 6.6 6 5.4 5.2

1800 80 40 27 20 16 13 11.3 10 9 8 7.3 6.8

2500 106.7 53.4 36.7 26.8 21.6 17.9 15.2 13.4 11.8 10.9 9.8 8.8

3300 141 70 47 35 28 23 20 18 16 14 13 12

Flow rate as a function of Delta T at 94% efficiency and maximum firing capacity

Figure B5-15. Pressure Drop Curve ClearFire Boiler Size 500

22 Rev. 05-2012

Page 23

Model CFC ClearFire Commercial Boilers

Figure B5-16. Pressure Drop Curve ClearFire Boiler Size 750

Figure B5-17. Pressure Drop Curve ClearFire Boiler Size 1000

23 Rev. 05-2012

Page 24

Model CFC ClearFire Commercial Boilers

Figure B5-18. Pressure Drop Curve ClearFire Boiler Size 1500

Figure B5-19. Pressure Drop Curve ClearFire Boiler Size 1800

24 Rev. 05-2012

Page 25

Model CFC ClearFire Commercial Boilers

Figure B5-20. Pressure Drop Curve ClearFire Boiler Size 2500\

Figure B5-21. Pressure Drop Curve ClearFire Boiler Size 3300

25 Rev. 05-2012

Page 26

Model CFC ClearFire Commercial Boilers

Table B5-14. Model CFC Minimum Over Pressure Requirements

Outlet Water Temperature 0 F (C)

80 - 180 (27 - 82) 12 (0.83)

181 - 185 (83 - 85) 15 (1.03)

186 - 195 (86 - 91) 18 (1.24)

Table B5-15. Model CFC Boiler Safety Valve Information @ 125 PSIG

Boiler Size

500 3/4” 1 1” 3364

750 3/4” 1 1” 3364

1000 3/4” 1 1” 3364

Valve Connection

@ Boiler

No. Valves Req'd Outlet Size

Minimum System Pressure PSIG (Bar)

Valve Setting 125 psig

Relie Valve

Capacity (MBH)

1500 3/4” 1 1” 3364

1800 3/4” 1 1” 3364

2500 3/4” 1 1” 3364

3300 3/4” 1 1” 3364

Table B5-16. Model CFC Boiler Safety Valve Information @ 60 PSIG

Boiler Size

500 3/4" 1 1" 1784

750 3/4" 1 1" 1784

1000 3/4" 1 1" 1784

1500 3/4" 1 1" 1784

1800 1" 1 1-1/4" 2788

Valve Connection

@ Boiler

Valve Setting 60 psig

No. Valves Req'd Outlet Size

Relief Valve

Capacity (MBH)

2500 1" 1 1-1/4" 2788

3300 1-1/2” 1 2” 5913

26 Rev. 05-2012

Page 27

Model CFC ClearFire Commercial Boilers

Water Treatment Even though hot water systems are "closed", some amount of make-up water (up to

10%) will be introduced. This more often than not happens from seal leaks of

pumps, or other minimal leaks from valves etc., that go unnoticed. Therefore,

proper water chemistry of a hot water boiler is necessary for good operation and

longevity, particularly to ensure that free oxygen is removed to prevent waterside

corrosion (see Table B5-17).

Table B5-17. Model CFC Water Chemistry Requirements in accordance with ABMA

Parameter Limit

Glycol 50%

pH 8.3 - 9.5

Nitrates 50 mg/liter

Sulphates 50 mg/liter

Chloride 30 mg/liter

Oxygen 0.1 mg/liter

Specific Conductivity

Total Hardness <10 ppm

3500 mmho/cm

Glycol The Model CFC boiler may be operated with a solution of glycol and water. Where

glycols are added, the system must first be cleaned and flushed. Correct glycol

selection and regular monitoring of the in-use concentration and its stability is

essential to ensure adequate, long-term freeze protection, as well as protection

from the effects of glycol-derived corrosion resulting from glycol degradation.

Typically, ethylene glycol is used for freeze protection, but other alternatives exist,

such as propylene glycol. Glycol reduces the water-side heat capacity (lower

specific heat than 100% water) and can reduce the effective heat transfer to the

system. Because of this, design flow rates and pump selections should be sized

with this in mind.

Generally, corrosion inhibitors are added to glycol systems. However, all glycols

tend to oxidize over time in the presence of oxygen, and when heated, form

aldehydes, acids, and other oxidation products. Whenever inadequate levels of

water treatment buffers and corrosion inhibitors are used, the resulting water glycol

mixture pH may be reduced to below 7.0 (frequently reaching 5) and acid corrosion

results. Thus, when pH levels drop below 7.0 due to glycol degradation the only

alternative is to drain, flush, repassivate, and refill with a new inhibited glycol

solution.

The following recommendations should be adhered to in applying ClearFire model

CFC boilers to hydronic systems using glycol:

1) Maximum allowable antifreeze proportion (volume %):

50% antifreeze (glycol)

50% water

27 Rev. 05-2012

Page 28

Model CFC ClearFire Commercial Boilers

2) The glycol concentration determines the maximum allowable firing rate and output

of the boiler(s). Please refer to the firing rate limitation and corresponding high fire

speed settings vs. glycol % in the charts below.

3) Maximum allowable boiler outlet/supply temperature: 185 deg F (85 deg C).

4) Minimum water circulation through the boiler:

a) The minimum water circulation must be defined in such a way that the

temperature difference between the boiler outlet/supply and inlet/return is a

maximum of 40 deg F (22 deg C), defined as DT (Delta T). A DT Limit

algorithm should be enabled in the boiler controller.

b) Independent from the hydraulics of the heating system, constant water

circulation through each boiler is required. (Requires a dedicated boiler

pump if in a primary/secondary loop arrangement.) Refer to table below for

minimum boiler circulation rates.

5) Minimum over-pressure at the boiler:

For outlet temperatures up to the maximum of 185 deg F (85 deg C), a minimum

operating pressure of 30 psig (2.1 bar) is required.

6) pH level should be maintained between 8.3 and 9.5

Table B5-18. Glycol Application Guidelnes - Model CFC

Minimum required boiler circulation rate (gpm) at maximum firing rate.

ClearFire System ΔT (˚F)

Model-Size ΔT = 10˚ ΔT = 20˚ ΔT = 30˚ ΔT = 40˚

CFC-500 88 44 29 22

CFC-750 131 66 44 33

CFC-1000 175 88 58 44

CFC-1500 263 131 88 66

CFC-1800 316 158 105 79

CFC-2500 438 219 146 110

CFC-3300 578 289 193 145

Notes/Limitations:

1. Maximum firing rate determined by ClearFire CFC - Glycol Firing Rate Limitation chart (below).

Maximum high fire blower speed should be set according to chart.

2. Glycol concentration limit of 25%-50%. Minimum required system operating pressure is 30

psig.

3. Maximum system operating temperature of 180 ˚F. Maximum ΔT of 40˚.

4. Circulation rates correlate with boiler output based on 92% nominal efficiency.

5. Standard altitude (<1000' ASL). Contact C-B for high altitude applications.

6. Pumps should be sized based on system design ΔT and minimum required flow rates.

7. At minimum firing rate, the minimum circulation rate should correspond to the boiler's turndown.

28 Rev. 05-2012

Page 29

Model CFC ClearFire Commercial Boilers

Table B5-19. Max Firing Rate vs. Glycol Concentration

Table B5-20. HF Speed Settings vs. Glycol Content

Condensation

As the Model CFC boiler is a full condensing boiler, condensation will develop during

startup of a cold boiler or at any time when the return water temperature is below

the dew point or approximately 132

The condensation collects in the lower portion of the boiler from the tube surfaces

and from the stack, and must be discharged to a drain. A Condensate trap must be

piped on the boiler and must be field piped to either a drain or to the optional

condensate treatment kit. Table B5-21 provides the amount of condensation that

will form when the boiler operates in the full condensing mode.

F (55.5 C).

29 Rev. 05-2012

Page 30

Model CFC ClearFire Commercial Boilers

Table B5-21. Model CFC Maximum Condensation

Boiler Size

500 3.5 (13.2)

750 5 (18.9)

1000 7 (26.5)

1500 9 (34)

1800 12 (45.4)

2500 17 (64.4)

3300 22 (83.3)

Boiler Operating @ maximum in full condensing mode.

Gallons Per Hour - GPH

(Liters Per Hour - L/H)

As prescribed by local codes, this condensate may be discharged directly to the

drain or treated using an optional treatment assembly. Figure B5-21 depicts piping

without the treatment assembly and Figure B5-22 shows the optional treatment

assembly.

Condensate Piping for Multiple Boilers

The number of condensate treatment tanks

required for multiple boiler installations depends

on the total amount of condensate produced by

the system. As a general rule, CB recommends

one tank per 5 million BTU/hr of boiler capacity

(5.0 MMBTU/hr). Model CFC capacities are in

Table B5-22.

See Figure B5-23 and Figure B5-24 for suggested

piping. A drain trap is built into the condensate

tank. Make-up water must be supplied at the

Table B5-22. CFC capacities

CFC Model BTU/hr

3300 3,300,000

2500 2,500,000

1800 1,800,000

1500 1,500,000

1000 1,000,000

750 750,000

500 500,000

connection shown in order to prevent flue gas from

entering an idle boiler. An internal float in the condensate tank activates the makeup water valve.

Figure B5-22. Condensate Piping Direct To Drain

3

1

2

1. Removable front

2. Min. 6” water trap

3. Plastic drain pipe

30 Rev. 05-2012

Page 31

Model CFC ClearFire Commercial Boilers

Condensate in

Figure B5-23. Optional Condensate Treatment Assembly

If a treatment kit is utilized, clearance at the front of the boiler must be provided for

servicing the assembly and for periodically adding the neutralizing granules.

Drain trap

Float valve for makeup water

Notice

Neutralization tank

To drain

Neutralization media

1/4" O.D. Make-up Water Supply

Figure B5-24. Condensate Piping for Multiple Boilers

Condensate Drain Trap

Neutralization Tank

To Drain

31 Rev. 05-2012

Page 32

Model CFC ClearFire Commercial Boilers

1" NPT Minimum Header Size

(Use PVC Pipe or other Nonferrous Material)

Condensate Drain Trap

Neutralization Tank

Neutralization Media

12” Minimum

Figure B5-25. Condensate Treatment Tank for Multiple Boilers

Cond. tank can be

mounted under boiler

To Drain

Gas Fuel

Connections

The local Gas Company should be consulted for the requirements for installation

and inspection of gas supply piping. Installation of gas supply piping and venting

must be in accordance with all applicable engineering guidelines and regulatory

codes. All connections made to the boiler must be arranged so that all components

are accessible for inspection, cleaning, and maintenance.

A drip leg should be installed in the supply line before the connection to the boiler.

The drip leg should be at least as large as the gas piping connection on the boiler.

See Figure B5-25, and Figure B5-26 for piping suggestions.

32 Rev. 05-2012

Page 33

Model CFC ClearFire Commercial Boilers

As required

As required

Same or larger than boiler gas connection

size

Drip leg required for any vertical run of

piping

Figure B5-26. Gas Piping Schematic

Gas header - size for boiler room

capacity and to minimize pressure loss

Consideration of volume and pressure requirements must be given when selecting

gas supply piping.

Connections to the burner gas train must include a union so that the burner may be

opened for inspection and maintenance.

A. Gas supply connection is at the rear of the boiler near the top. To permit

burner opening, gas piping must not traverse the top of the boiler.

B. Table B5-23 shows the gas pressure required at the inlet of the gas line.

Note: a pressure regulator is not furnished and if gas pressure exceeds 14"

W.C. a pressure regulator is recommended.

C. Table B5-24 shows the correction factors for gas pressure at elevations at

2000 feet and higher above sea level.

33 Rev. 05-2012

Page 34

Model CFC ClearFire Commercial Boilers

From

Meter

Header Pipe

Manual Shut Off

Gas Strainer

Regulator

See Note 1

Relief Valve

See Note 5

Model

CFC

Gas Header Piping, Typical

Model

CFC

Model

CFC

NOTES:

1. Dedicated gas pressure regulator required for each boiler.

2. Refer to local fuel gas codes when applicable.

3. Header to be sized for room capacity.

4. Provision required for measuring gas supply pressure at boiler.

5. Relief valve required if gas supply pressure >1 psig.

Figure B5-27. Gas Header Piping

Model

CFC

34 Rev. 05-2012

Page 35

Model CFC ClearFire Commercial Boilers

Table B5-24. Model CFC Minimum and Maximum Gas Pressure

Minimum pressure required at gas train connection

Boiler Model

500 7" w.c. 11" w.c.

750 7" w.c. 11" w.c.

1000 7" w.c. 11" w.c.

1500 10" w.c. 11" w.c.

1800 7" w.c. 11" w.c.

2500 9.5" w.c. 11" w.c.

3300 6.8" w.c. 11" w.c. 5 psi

Table B5-25. Model CFC Minimum Required Gas Pressure Altitude Correction

Altitude in Feet Correction Factor Altitude in Feet Correction Factor

1000 1.04 6000 1.25

2000 1.07 7000 1.3

Max. pressureNatural Gas LP Gas

28” w.c.

3000 1.11 8000 1.35

4000 1.16 9000 1.4

5000 1.21

To obtain minimum required inlet pressure, select altitude of installation and multiply the pressure

shown in Table B5-24 by the correction factor corresponding to the altitude listed above.

Boiler Room

Information

The boiler must be installed on a level non-combustible surface. If the surface is not

level, piers or a raised pad, slightly larger than the length and width of the boiler

base dimensions, will make boiler leveling possible. Installing the boiler on a raised

pad or piers will make boiler drain connections more accessible and will keep water

from splashing onto the boiler whenever the boiler room floor is washed.

Note: The pad or piers must be of sufficient load bearing strength to safely support the operating

weight of the boiler and any additional equipment installed with it. Approximate operating

weights are shown in Dimensions and Ratings.

Leveling Once the boiler is placed, it must be leveled side to side and front to back using the

supply and return nozzles for horizontal and vertical positions. If shims are required

to level the boiler, the weight of the boiler must be evenly distributed at all points of

support. The legs may also be used for leveling.

Clearances The boiler must be installed so that all components remain accessible; ensure no

overhead obstructions so the burner may be opened. Refer to Figure B5-28.

35 Rev. 05-2012

Page 36

Model CFC ClearFire Commercial Boilers

DIM Inches

Top Clearance A 14

Side Clearance B 20

Backway C 20

Front D 36

Between Boilers E 3

C

B

D

B

E

CFC 500-2500 CFC 3300

Figure B5-28. Model CFC Minimum Room Clearance Dimensions

Seismic Legs Seismic mounting details shown below.

Figure B5-29. CFC Seismic Mounting

36 Rev. 05-2012

Page 37

Model CFC ClearFire Commercial Boilers

Hot Water Piping Primary/secondary pumps are not necessary with the Model CFC boiler. As its

design is such that no minimum flow is required, variable speed or on/off pumps

may be employed in the piping scheme.

Typical piping arrangements are shown in figures B5-33 through B5-45.

Note: These diagrams are generic and are not intended for use in a specific design without

consultation with your local Cleaver-Brooks sales representative

37 Rev. 05-2012

Page 38

Figure B5-33. No primary Loop with Domestic Water and 2-Way Divert Valve

ClearFire Full

Condensing

ClearFire Full

Condensing

To Condensate Drain

To Sanitary Drain

System Returns

Domestic Cold

Water In

Domestic

Water

Domestic

Water Pump

Return Header

Boiler Drain

Domestic

Water Supply

Heating System

Pumps

System Supply & Returns

System Supply

Header

Expansion

Tank

Water

Makeup

2-Way Diverting

Valve

On/Off Valve

Page 39

Figure B5-36. Two Boilers and Three Variable Temperature Zones (No Primary Loop)

ClearFire

ClearFire

P P

T T

BV1 B1

T T

BV1 B1

T T

BV1 B1

CWS

Filling Loop

Removable

Tank

Expansion

Return

Return

Run condensate drain to

adjacent drain (or via optional

condensate pumping unit)

Drain

Flow

Prefabricated

Header

Back Pressure

Radiant

Heating Load

Valve

Page 40

Figure B5-37. Two-Pipe Primary/Secondary Piping with Domestic Hot Water

Boiler

Heating Load

A

Heating Load

B

Heating Load

C

1

BOILER OUTLET (SUPPLY)

2

BOILER INLET (RETURN)

3

SECONDARY CONNECTION

4

ISOLATION VALVES

5

PURGE COCKS

6

AIR SEPARATOR WITH AUTOMATIC AIR VENT

7

DIAPHRAGM EXPANSION TANK WITH FILL VALVE

8

BALANCING VALVES (SQUARE HEAD COCKS)

9

SYSTEM CIRCULATOR

10

SECONDARY CIRCULATORS INJECTION PUMP

11

FLOW/CHECK VALVES (TO PREVENT GRAVITY

10

11

8

10

5

8

8

3

5

10

3

11

10

5

8

3

5

1

2

6

9

4

7

(FIXED OR VARIABLE SPEED)

OR PRESSURE-DROP-INDUCED FLOW IN

SECONDAY CIRCUITS)

12" MAX APART AT ALL SECONDARY CONNECTIONS

TO PREVENT FORCED FLOW IN SECONDARY

CAUSED BY PRESSURE DROP THROUGH PIPING

BETWEEN CONNECTIONS

TEMPERATURE CONTROL BY SECONDARY

CIRCULATION ONLY

TEMPERATURE CONTROL USING MIXING

VALVE

TEMPERATURE/HEAT INPUT CONTROL

USING INJECTION PUMPING

A

B

C

13

12

12

DOMESTIC PUMP

13

DOMESTIC WATER TANK

4

Page 41

Figure B5-38. Two-Pipe Primary/Secondary Piping

Boiler

Heating Load

A

Heating Load

B

Heating Load

C

1

BOILER OUTLET (SUPPLY)

2

BOILER INLET (RETURN)

3

SECONDARY CONNECTION

4

ISOLATION VALVES

5

PURGE COCKS

6

AIR SEPARATOR WITH AUTOMATIC AIR VENT

7

DIAPHRAGM EXPANSION TANK WITH FILL VALVE

8

BALANCING VALVES (SQUARE HEAD COCKS)

9

SYSTEM CIRCULATOR

10

SECONDARY CIRCULATORS INJECTION PUMP

11

FLOW/CHECK VALVES (TO PREVENT GRAVITY

10

11

8

10

5

8

8

3

5

10

3

11

10

5

8

3

5

1

2

6

9

4

7

(FIXED OR VARIABLE SPEED)

OR PRESSURE-DROP-INDUCED FLOW IN

SECONDAY CIRCUITS)

4

12" MAX APART AT ALL SECONDARY CONNECTIONS

TO PREVENT FORCED FLOW IN SECONDARY

CAUSED BY PRESSURE DROP THROUGH PIPING

BETWEEN CONNECTIONS

TEMPERATURE CONTROL BY SECONDARY

CIRCULATION ONLY

TEMPERATURE CONTROL USING MIXING

VALVE

TEMPERATURE/HEAT INPUT CONTROL

USING INJECTION PUMPING

A

B

C

4

Page 42

Figure B5-39. No Primary Loop

ClearFire Full

Condensing

ClearFire Full

Condensing

To Condensate Drain

To Sanitary Drain

System Returns

Return Header

Boiler Drain

Heating System

Pumps

System Supply & Returns

System Supply

Header

Expansion

Tank

Water

Makeup

Y10.2

Y10.1

VK-1

VK-2

Y10.1 Motorized Shutoff

Y10.2 Motorized Shutoff

VK-1 3-Way Mixed Circuit

VK-2 3-Way Mixed Circuit

Back Pressue

Valve

Page 43

Figure B5-40. Domestic Water Heating, No Primary Loop

ClearFire Full

Condensing

ClearFire Full

Condensing

To Condensate Drain

To Sanitary Drain

System Returns

Boiler Drain

Expansion

Tank

Water

Makeup

Air Vent Line

Primary

Pump

Standby

Pump

Surge Tank

Page 44

Figure B5-41. Domestic Water with On/Off and 3-Way Valves

ClearFire Full

Condensing

ClearFire Full

Condensing

To Condensate Drain

To Sanitary Drain

System Returns

Domestic Co

l

Water In

Domestic

Water

Domestic

Water Pump

Return Header

Boiler Drain

Domestic

Water Supply

Heating System

Pumps

System Supply & Returns

System Supply

Header

Expansion

Tank

Water

Makeup

On-Off

Valves

Page 45

Figure B5-42. Piping ‘Hybrid’ Boilers

CFC

1

BOILER OUTLET (SUPPLY)

2

BOILER INLET (RETURN)

3

ISOLATION VALVES

4

PURGE COCKS

5

AIR SEPARATOR WITH AUTOMATIC AIR VENT

6

DIAPHRAGM EXPANSION TANK WITH FILL VALVE

7

FLOW/CHECK VALVES

8

SYSTEM CIRCULATOR

3

4

5

8

6

Supply Retur

n

FLX

2

3

1

7

3

130 F

150 F

Sensor

3

3

3

3

3

3

7

Page 46

Figure B5-43. ‘Hybrid’ Boilers with Domestic Water

CFC

1

BOILER OUTLET (SUPPLY)

2

BOILER INLET (RETURN)

3

SECONDARY CONNECTION

4

ISOLATION VALVES

5

PURGE COCKS

6

AIR SEPARATOR WITH AUTOMATIC AIR VENT

7

DIAPHRAGM EXPANSION TANK WITH FILL VALVE

8

FLOW/CHECK VALVES

9

SYSTEM CIRCULATOR

5

6

9

7

3

12" MAX APART AT ALL SECONDARY CONNECTIONS

TO PREVENT FORCED FLOW IN SECONDARY

CAUSED BY PRESSURE DROP THROUGH PIPING

BETWEEN CONNECTIONS

Supply

Retur

n

FLX

2

4

1

8

4

130 F

150 F

Sensor

Hot Water

Outlet

Cold Water

Supply

10

DOMESTIC PUMP

4

4

4

4

4

1

2

8

10

4

3

Page 47

Figure B5-34. 2 Pipe System, Typical (reverse-return)

CFC

2

1

1

PRIMARY ZONE (WITH THERMOSTAT)-

THERMOSTAT CONTROLS BOILER AND CIRCULATOR.

2

HEATING UNITS WITH

THERMOSTATIC VALVES.

Page 48

Figure B5-35. Zoning with Zone Valves

CFC

1

BOILER OUTLET (SUPPLY)

2

BOILER INLET (RETURN)

4

5

11

6

3

4

1

2

8

5

4

9

7

3

SECONDARY CONNECTION (BOILER CIRCUIT)

4

ISOLATION VALVES

5

PURGE COCKS (HOSE BIBB)

6

AIR SEPARATOR WITH AUTOMATIC AIR VENT

7

DIAPHRAGM EXPANSION TANK

8

COMBINATION FILL VALVE

9

ZONE VALVES

10

ZONE CIRCULATORS (CIRCULATOR ZONING)

11

SYSTEM CIRCULATOR (ZONE VALVE SYSTEM)

Page 49

Figure B5-44. Domestic Water with 2 Boilers and 2 Coils

To

Boilers

RTD

120V or

24V

Control

Two Stage

Cold In

Recirc Pump

Drain

Tank

Thermal Expansion

Hot Out

Thermometer

Pipe To

Safe Location

Top Relief

Pipe Per Code

Cold In

Air Purger with Vent, PRV

and Expansion Tank

Reducers

Auto Air Vent

It High Point

(Reverse Return For

Balanced Flow)

Boiler 2

Boiler 1

Circulators

Tube Bundles Can Be

In Any Location Exc

e

On Top Of Each Oth

e

Supply

Supply

Return

Heating Domestic Water with (2) Boilers and (2) Coils

Return

Page 50

Model CFC ClearFire Commercial Boilers

Boiler Room

Combustion and

Ventilation Air

Combustion Air

Supply - Unconfined

Spaces (For U.S.

Installations Only)

The boiler(s) must be supplied with adequate quantities of uncontaminated air to

support proper combustion and equipment ventilation. Air shall be free of chlorides,

halogens, fluorocarbons, construction dust or other contaminants that are

detrimental to the burner/boiler. If these contaminants are present, we recommend

the use of direct vent combustion provided the outside air source is

uncontaminated.

Combustion air can be supplied by means of conventional venting, where

combustion air is drawn from the area immediately surrounding the boiler (boiler

room must be positive pressure), or with direct vent (direct vent combustion) where

air is drawn directly from the outside. All installations must comply with local Codes

and with NFPA 54 (the National Fuel Gas Code - NFGC) for the U.S. and for

Canada, CAN/CGA B 149.1 and B 149.2.

Note: A boiler room exhaust fan is not recommended as this type of device can cause a negative

pressure in the boiler room if using a conventional air intake.

In accordance with NFPA54, the required volume of indoor air shall be determined

in accordance with the "Standard Method" or "Known Air Infiltration Rate Method.

Where the air infiltration rate is known to be less than 0.40 Air Changes per Hour,

the Known Air Infiltration Rate Method shall be used. (See Section 8.3 in the

NFPA54 Handbook for additional information.)

A. All Air From Inside the Building - If additional combustion air is drawn from

inside the building (the mechanical equipment room does not receive air

from outside via louvers or vent openings and the boiler is not equipped with

direct vent combustion) and the boiler is located in a unconfined space, use

the following guidelines:

1. The mechanical equipment room must be provided with two permanent

openings linked directly with additional room (s) of sufficient volume so

that the combined volume of all spaces meet the criteria for an

unconfined space. Note: An "unconfined space" is defined as a space

whose volume is more than 50 cubic feet per 1,000 Btu per hour of

aggregate input rating of all appliances installed in that space.

2. Each opening must have a minimum free area of one square inch per

1,000 Btu per hour of the total input rating of all gas utilizing equipment

in the mechanical room.

3. One opening must terminate within twelve inches of the top, and one

opening must terminate within twelve inches of the bottom of the room.

4. Refer to the NFGC, Section 8.3 for additional information.

50 Rev. 05-2012

Page 51

Model CFC ClearFire Commercial Boilers

GAS

VENT

CLEARFIRE

BOILER

GAS

VENT

WATER

HEATER

Figure B5-45. Two Opening Outside Wall Method

12" MINIMUM

FRESH AIR OPENING

INTERIOR WALL

FRESH AIR OPENING

12" MINIMUM

B. All Air From Outdoors - If all combustion air will be received from outside the building (the mechanical

room equipment is linked with the outdoors), the following methods can be used:

1. Two Opening Method (Figure B5-45) - The mechanical equipment room

must be provided with two permanent openings, one terminating within

twelve inches from the top, and one opening terminating within twelve

inches of the bottom of the room.

2. The openings must be linked directly or by ducts with the outdoors.

3. Each opening must have a minimum free area of one square inch per

4,000 Btu per hour of total input rating of all equipment in the room,

when the opening is directly linked to the outdoors or through vertical

ducts.

4. The minimum free area required for horizontal ducts is one square inch

per 2,000 Btu per hour of total input rating of all the equipment in the

room.

51 Rev. 05-2012

Page 52

Model CFC ClearFire Commercial Boilers

GAS

VENT

GAS

VENT

CLEARFIRE

BOILER

WATER

HEATER

Figure B5-46. Two Opening Ducted Method

12" MINIMUM

OUTLET AIR DUCT

INTERIOR WALL

EXTERIOR WALL

FRESH AIR

INLET DUCT

12" MINIMUM

C. One Opening Method (Figure B5-47) - One permanent opening,

commencing within 12 inches of the top of the enclosure, shall be provided.

1. The equipment shall have clearances of at least 1 inch from the sides and

back and 6 inches from the front of the appliance.

2. The opening shall directly communicate with the outdoors and shall have

a minimum free area of 1 square inch per 3000 BTU's per hour of the

total input rating of all equipment located in the enclosure, and not less

than the sum of the areas of all vent connectors in the confined space.

3. Refer to the NFGC, Section 8.3 for additional information.

52 Rev. 05-2012

Page 53

Model CFC ClearFire Commercial Boilers

GAS

VENT

CLEARFIRE

BOILER

GAS

VENT

12" MINIMUM

FRESH AIR OPENING

EXTERIOR WALL

WATER

HEATER

Unconfined Space/

Engineered Design

Figure B5-47. One Opening Method

When determining boiler room air requirements for unconfined space, the size of the

room, airflow, and velocity of air must be reviewed as follows:

1. Size (area) and location of air supply openings in the boiler room.

A. Two permanent air supply openings in the outer walls of the boiler room are

recommended. Locate one at each end of the boiler room, preferably below

a height of 7 feet. This allows air to sweep the length of the boiler. See

Figure B5-48.