Page 1

$30.00 U.S.

Compliments of Power Mechanical, Inc.

Used Boilers

Rental Boilers

CLEAVER-BROOKS

CBW

PACKAGED BOILERS

MODEL

Manual Part No. 75.0-150

Milwaukee, Wisconsin

Boilers and Accessories for the Complete

Service and Parts Coast

53201

to

Coast

Boiler Room

Page 2

Page 3

CLEAVER-BROOKS

MODELCBW

PACKAGED BOILERS

Operation, Service, and Part Manual

100 thru 400 HP

Fuel: Gas, Light Oil, Heavy Oil or Gas Combination

Cleave

Please direct purchase orders for replacement manuals

to your local Cleaver-Brooks representative

Manual

Part

No.

750-150

Printed

in

U.S.A.

Page 4

Page 5

DO NOT OPERATE, SERVICE,

ALL

APPLICABLE SECTIONS

WARNING

OR

REPAIR THIS EQUIPMENT UNLESS YOU FULLY UNDERSTAND

OF

THIS MANUAL.

DO NOT

ALLOW

OTHERS TO OPERATE, SERVICE,

OR

REPAIR THIS EQUIPMENT UNLESS

THEY

FULLY UNDERSTAND ALL APPLICABLE SECTIONS OF THIS MANUAL.

TO

FA.ll..URE

FOLLOW

VERE PERSONAL INJURY

TO:

This operating manual presents information that will help to properly operate

carefully. The unit will provide good service and continued operation

followed.

thoroughly understood. Failure to follow all applicable instructions and warning may result in severe personal injury or death.

It is the responsibility

servicing, repairing or operating the equipment, in all safety aspects.

Cleaver-Brooks equipment is designed

mechanical devices supplied as part

techniques and maintenance procedures must be followed at all times. Although these componesnts afford a

protection and safety, operation

firing

Any

him/her

It

replace intelligent thinking and reasoning and this manual

for proper operation.

maintain, service, or repair

Owners, Operators and/or Maintenance Personnel

No

attempt should be made to operate the tmit until the principles

of

fuel.

"automatic" features included in the design do not relieve the attendant

of

certain repetitive chores and give him/her more time tot devote to the proper upkeep

is solely the operator's responsibility to properly operate and maintain the equipment. No amount

On

ALL APPLICABLE WARNINGS

OR

DEATH.

of

the owner

the other hand, a thorough understanding

this equipment. ·

to

train and advise not only his or her personnel, but the contractor's personnel who are

and

engineered to give long life and excellent service on the job. The electrical

of

the unit were chosen because

of

equipment

is

not to be considered free from all dangers and hazards inherent in handling and

is

AND

INSTRUCTIONS MAY RESULT IN SE-

and

care for the equipment. Study its contents

if

proper operating and maintenance instructions are

of

operation and all

of

their know ability to perform; however, proper operating

of

any responsibility. Such features merely free

not intended to relieve the operating personnel

of

this manual

is

required before attempting to operate,

of

the components are

of

equipment.

of

written instructions can

high degree

of

and

of

the responsibility

Because

ably from one boiler to another. This manual contains information designed to show how a basic boiler operates.

Operating controls will normally

daily or monthly tesing, assuming that normal operation will continue

cal operation

and

It

activities

Most instances

for the operator to periodically check his/her low water controls and to follow good maintenance and testing practices.

connecting piping to low water devices must be internally inspected periodically to guard against any stoppages which could

obstruct the free flow

the presence

The waterside condition

check for the presence

The services

are essential.

The operation

of

such requirements and the warnings or instructions contained herein, please contact Cleaver-Brooks before proceeding.

of

state, local, or other applicable codes, there are a variety

fi.mction

and

damage and, in most cases, these conditions ca nbe traced directly to carelessness and deficiencies in testing

maintenance.

is recommended that a boiler room log or record be maintained. Recording

and

recording

of

of

foreign substances that would impede float ball movement.

of

a qualified water treating company or a water consultant

of

his/her insurance company and/or other authority having jurisdiction. In the event

of

any unusual operation will serve as a valuable guide

major boiler damage are the result

of

water to the low water devices. Float bowls

of

the pressure vessel is

of

any mud, sludge, scale or corrosion.

this equipment by the owner and his/her operating personnel must comply with all requirements or regulations

for

long periods

of

of

of

operation with low water. We cannot emphasize too strongly the need

extreme importance. Waterside surfaces should be inspected frequently to

of

electric controls and safety devices which vary consider-

~e

and we have found that some operators become lax in their

indefinitely. Malfi.mctions

of

daily, weekly, nonthly and yearly maintenance

to

any necessary investigation.

of

these controls must be inspected frequently to check for

to

recommend the proper boiler water treating practices

of

controls lead to uneconomi-

of

any conflict or inconsistency between

Cross·

Page 6

Safety precautions and Abbreviations

1.

Safety Precautions

It

is

essential to read and understand the following

safe.ty precautions before attempting

eqmpmenL

Failure

to equipment, serious personal injury

A complete understanding

_bef<:;~re

equtpmenL

The equipment should be

who have a working

the equipment.

to heed these precautions may result in damage

of

this manual

attempting to- startup, operate

o~rated

knowledge and understanding

to operate the

or

death!

or

main tam the

only by personnel

!WARNING

This symbol indicates a potentially

hazardous situation which,

avoided, could result in serious personal

in· or death.

CAUTION!

This symbol indicates a

ardous

could result

situation which,

in damage to the equip

ment.

~tentially

if

not avoided,

if

is

required-

not

haz-

BTU

·c

CFH

Cu.

Ft.

DC

OF

FM

FT

of

..

GPM

Hd

'HT

HTB

HZ

IRI

Lb

LWCO

:MFD

MR

NO

British Thermal Unit

Degrees Celsius

Cubic Feet per Hour

· Cubic Feet

Direct Current

Degrees Fahrenheit

Factory Mutual

Feet

Gallons per Minute

Head

Height

High Turndown Burner

Hertz

Industrial Risk Insurance

Pound

Low Water

Micro Farad

Manual Reset

Number

Cutoff

Note: This symbol indicates information that

is

vital to the operation

ment.

2.

Abbreviations

Following

acronyms, and symbols

AC

AR

ASME

ASThfD

BHP

is

an exP.lanation

Alternating Current

Automatic Reset

American Society

Engineers

American Society

Dimensions

Boiler Horsepower

of

used

in this manual.

of

this equip-

the abbreviations,

of

Mechanical

of

Tables, Measures,

ii

pH

PIN

PPM

PR

PSI

SAE

T

TC

11

v

we

WSI

Measure

base

Part Number

Parts Per Million

Program Relay

Pounds Per Square Inch (Gauge)

Society

Tern perature

Temperature Control

Temperature Gauge

Volt

Water Column

Watts

of

the degree

of

a sol uti

of

Per Square Inch

on

Automotive Engineers

of

acid

or

Page 7

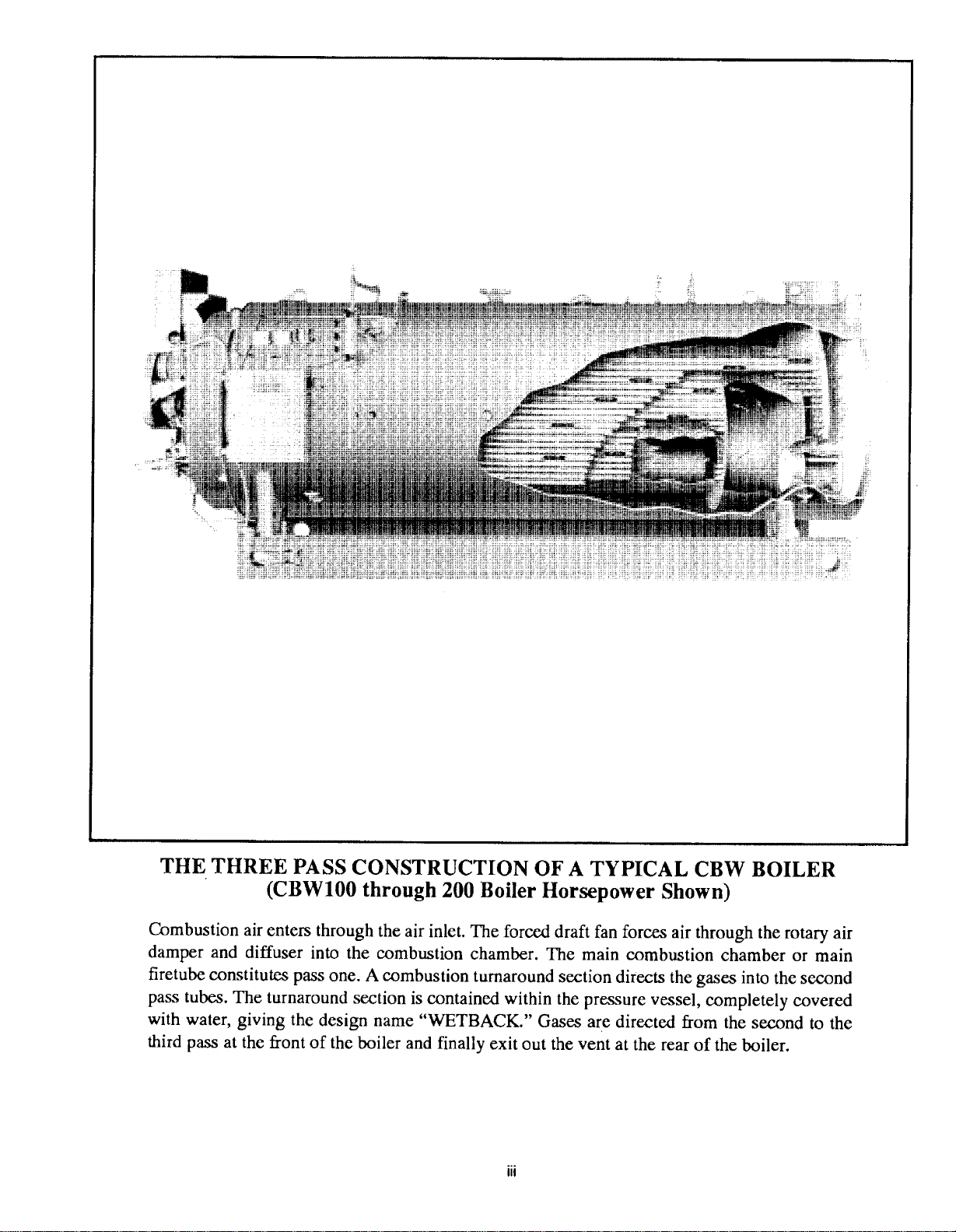

THE

Combustion air enters through the air inlet. The forced draft fan forces air through the rotary air

damper and diffuser into the combustion chamber. The main combustion chamber or main

firetube constitutes pass one. A combustion turnaround section directs the gases into the second

pass tubes. The turnaround section

with water, giving the design name

third pass at the front

THREE

(CBWlOO

PASS

CONSTRUCTION

through

of

the boiler and finally exit out the vent at the rear

200

Boiler Horsepower

is

contained within the pressure vessel, completely covered

"WETBACK." Gases are directed from the second to the

iii

OF

A TYPICAL

CBW

Shown)

of

the boiler.

BOILER

Page 8

Page 9

Table

of

Contents

CHAPTER 1

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION •

A

B.

C.

D.

E.

F.

G.

H.

I.

The

Boiler

The

Burner

Control

Controls Common to

Steam Controls

Hot Water Controls

Controls for Gas Firing

Controls Common to Oil Fired Boilers

(lncfuding

Additional Controls For Heavy Oil

and

Control System

and

Component Function

aJI

(AJI

Fuels)

(AJI

combination) ·

J. Controls for Combination Burners Only

K CombustionAir

L . Automatic Ignition

M.

N.

0.

P.

Q. Modulating Firing

Atomizing Air

Oil Fuel Flow - Ught Oil

Oil Fuel Flow - Heavy

Gas Fuel Flow

Boilers

Fuels)

Oil

1-1

.1·1

1-2

1·2

1-3

1-4

1-6

1-8

1-8

1-10

1-13

1-16

1-16

1-16

1-16

1-18

1-18

1-21

1-22

CHAPTER 2

THE PRESSURE VESSEL

A

B.

C.

D.

E.

F.

G.

H.

I.

J.

2-1

• • • •

General

Construction 2-2

Water Requirements 2-2

Water Treatment 2-6

Cleaning

Boil-out

Washing Out

SlowdownPeriodic Inspection 2-13

Preparation for Extended Lay-up

II

e • • • • a • • • • • • e • • 2·1

of

a New Unit 2-8

Steam Boiler

2-1

2-7

2-10

2-10

2-14

Page 10

CHAPTER

3

3-1

SEQUENCE OF OPERATION • • • • • • • • • • • • • • • • • • •

A General

CHAPTER

STARTING

4

B.

c.

D.

AND

OPERATING INSTRUCTIONS • • • • • • • • •

A General Preparation

B.

C.

D.

E.

F.

G. Firing Preparations For

H.

I.

Circuit and Interlock Controls

Sequence

Flame

For

Start-Up -

ControiSe~ngs-

Steam And

Gas Pilot

Atomizing Air 4-4

Firing Preparations for No. 2 Oil

(Sseries

Firing

(Series 400-600)

(Series 200-400-700) 4-8

Start-up, Operating and Shutdown

-

AJI

Control Operational Test and Checks

of

Operation - Oil

Loss Sequence 3-9

AJI

Fuels

Hot

Water

1 00-200) 4-5

Preparati~n

Fuels 4-9

For No. 6 Oil

gas

3-1

Or

Gas 3-7

4-1

3--1

3--6

4-1

4-2

4-3

4-6

4-11

CHAPTER

ADJUSTMENT PROCEDURES

5

A

B.

c.

D.

E.

F.

G.

H.

5-1

• • • • • • • • • • • • • • • • • .

Gene

raJ

Unkage-Modulating

and Air Damper

Modulating Motor

Modulating Motor Switches Low Fire and High Fire

Burner Operating Controls - General 5-5

Modulating Pressure Control (Steam) 5-7

Operating

(Steam)

High

Umit

Umit

Pressure Control (Steam)

Motor

Pressure Control

5-1

5-2

5-3

5-4

5-5

5-8

5-8

Page 11

I.

J.

K

L

M.

N.

0.

P.

a.

R.

s.

T.

u.

v.

w.

X.

Y.

z.

AA.

88.

cc.

DO.

Modulating Temperature Control

(Hot

Water)

Operating Umit Temperature Control

(Hot

Water)

High

Umit Temperature Control

(Hot

Water)

Low

Water Cutoff Devices

(Steam

Combustion Air Proving Switch

Atomizing Air Proving switch

Gas

Gas

Gas

Low

High

Fuel

General

Fuel

Burner Drawer Adjustment

Oil

Low

High

Low

Electric

(400

Steam

(No.6

Series Hot

400

(

Steam

(400

and

Hot

Water)

Pilot Flame Adjustment

Pressure

Fuel

Gas

Gas

Oil

Pressure

Oil

Combustion Adjustment 5-19

Drawer Switch

Oil

Temperature Switch

Oil

Temperature Switch (Optional) 5-24

Oii_Pressure

Oil

and

Oil

Oil)

Water

and

Heater Pressure Regulator

and

and

Flow Information 5-12

Combustion Adjustment

Pressure Switch 5-17

Pressure Switch

And

Temperature -

Switch (Optional)

Heater Thermostat

600

Series -Steam)

Heater Thermostat

(400

and

600

Steam)

Oil

Heater Thermostat

600

Series)

600

Series-

Steam)

5-8

5·8

5-9

5-9

5-9

5-9

5-10

5-15

5-18

5-18

5-23

5-23

5-23

5-24

5-24

5-24

5-24

5-25

Page 12

CHAPTER 6

6-1

TROUBLE SHOOTING

A

B.

c.

D.

E.

F.

CHAPTER 7

INSPECTION AND MAINTENANCE

A

B.

G.

D.

E.

F.

G.

H.

I.

J.

K

L

M.

N.

0.

P.

a.

A.

s.

T.

• • • • • • • • • • • • • • • • • • • • • •

Burner

No Ignition

Pilot

Burner Stays

Shutdown Occurs During Firing

Modulating Motor

General

Fireside Cleaning

Water

Water

EJectriccU

Flame

Oil

Gas

Motorized

Sole~oid

Air

and

Forced

Safety

Fuel

Adjusting

The

Refractory

Opening

Lubrication

Oil

Electric,

Combustion

Does

Flame,

Level

Gauge

Safeguard Control

Bumer Maintenance

Bumer Maintenance

Control

Cam

Valves

Oil

Air

Heaters -

Not

Start

But

No

Main

In

Low

Fire 6-4

Does

• a • • a a e • e e • G • e e

Controls

Glass

Controls 7-4

Gas

Valve(s)

Valves

Damper,

Spring

Draft

Fan

Metering

and

Relief

Pump

and

And

Closing Doors

Steam,

Unkage

Valve,

Valves

Lubricating

Hot

Water

Flame

Not

Operate

8-1

7·1

7•1

System

6-2

6-2

6·3

6-4

6-5

7-2

7-3

7-3

7-4

7-6

7-7

7-9

7-9

7-9

7-12

7w12

7-13

7-13

7-15

7-16

7-20

7·20

7-22

7-22

CHAPTER 8

PARTS ORDER/UST INSTRUCTIONS

•.•.•.•••••.••

8-·1

8-1

Page 13

CHAPTERl

GENERAL

CHAPTER 1

DESCRIPTION

AND J?RINCIPLES

OF

OPERATION

GENERAL

DESCRIPTION

PRINCIPLES

A The Boiler

B.

C.

D.

E.

F.

G.

H. Controls For

I.

J. Controls For Combination Burners

K. Combustion Air

L. Automatic Ignition

M. Atomizing

N.

0.

P.

Q. Modulating Firing

AND

OF

The Burner And Control System

Control And Component Function

Controls Common To All Boilers

Steam Controls (All Fuels)

Hot Water Controls (All Fuels)

Controls For Gas Firing (Including Combination)

Co~trols

Oil Fuel Flow - Light Oil

Oil Fuel Flow - Heavy Oil

Gas Fuel Flow

OPERATION

Oil Fired Boilers

For Heavy Oil

Air

NOTE:

The general information

directly

Models in sizes ranging from 100 through 400

boiler horsepower for the following fuels:

750-150

If

your boiler

CB-HA

ment control system, refer to CB-

Hawk. Installation, Operating,

and Servicing Manual No.

133 for information regarding

controls discussed in this section.

to

Cleaver-Brooks

WK™

is

equipped with a

boiler

in

this manual applies

manage·

750-

"CBW''

Boiler

Series

Series

Series

Series

Series

NOTE:

100 - Light Oil (No. 2)

200 - Light Oil (No. 2) Or Gas

400 - Heavy Oil (No. 6) Or Gas

600700-

Although the Series 400

burner

to bum No. 6 oil, the burner will

handle grades

well

modifications. While this manual

contains peninent infonnation on

Heavy Oil (No. 6) Only

Gas Only

or

600

is

designed and designated

4 and 5 equally

with

some

possible

CHAPTER 1

..

1

Page 14

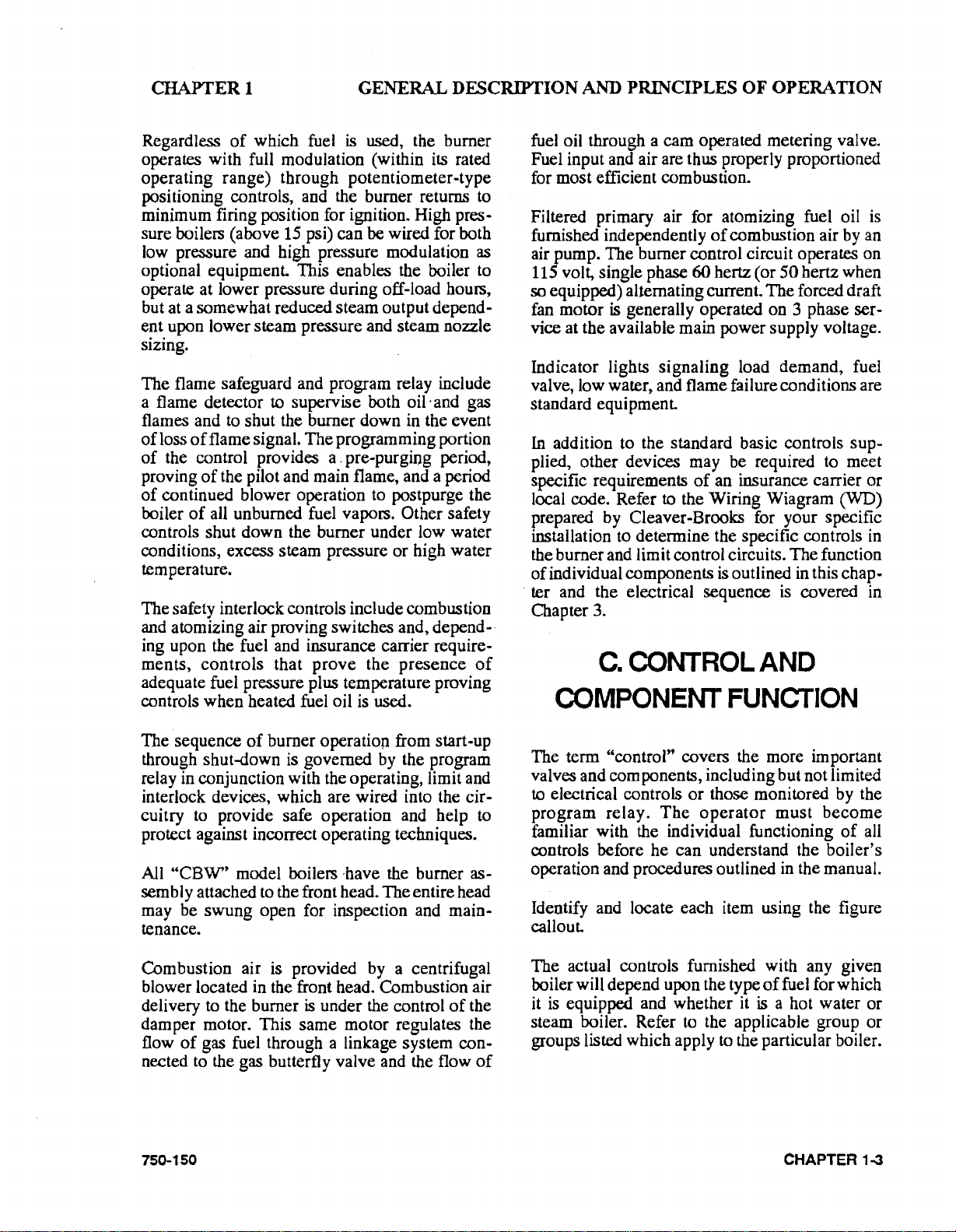

CHAPTER!

GENERAL

DESCRIPTION

AND

PRINCIPLES

OF

OPERATION

No. 6 fuel oil, all references

this fuel should

plicable

The boiler and related equipment installation, by

others,

of

stallation also should conform

codes governing such equipment.

lation, the proper authorities having jurisdiction

are to

boilers in the

equipped with optional equipment,

Risk Insurers (I.R.I.), Factory Mutual

other insuring underwriters requirements.

is

to

be

the National Board

be

consulted, permits .obtained, etc. All

A.

The "CBW" Boiler

of

welded steel construction and consists

pressure vessel, burner, burner controls, forced

draft

fan,

damper, air pump, refractory and ap-

propriate boiler trim.

to

in compliance with the standards

above

THE

is

be

considered ap-

all grades

of

series

of

heavy oil.

Fire Underwriters. In-

to

state and local

Prior to instal-

comply,

to

BOILER

a packaged :firetube boiler

to

when

Industrial

(FM), or

of

a

Burner (Oil)

Burner (Gas)

Air Damper . . . . . . . Rotary Type

Steam Trim . . . . . . . ASME Code

Water Trim . . . . . . . ASME Code

The horsepower rating

by

the numbers following the fuel series. Thus,

CBW700-200 indicates a gas fired 200 HP boiler.

B.

.......

......

THE

(Low Pressure)

Air Atomizing

Non-premix

Otificed Type

(Electrically

Modulated)

of

the boiler

BURNER

is

indicated

AND

Rated Capacity . .

Operating Pressure .Steam 15-250 psig,

Hot Water . . . . . . .

Fuel . .

Ignition

Firing . . . . . . . . . .Full Modulation

; . . . . . . . .Oil

.100 through 400)-IP

or higher if.specified

.30-250 psig

higher if specified

or

or Combination

.Automatic

Through Operating

Ranges

or

Gas

CONTROL

The oil burner

ing (nozzle) type. The gas burner

premix orifice type. The burners are ignited

spark ignited gas pilot. The pilot

rupted type and

is

flame

NOTE:

The burners equipped to burn oil and gas include

equipment for each distinct fuel.

uses only one type

selector switch

burner.

It

number, shown on the nameplate,

any correspondence

established.

is

important that the burner model and serial

is

of

is

A Series 100 boiler

equipped with a light oil pilot

though a gas pilot frequently

used.

is incorporated in a combination

SYSTEM

the low pressure, air

is

extinguished after the main

Since the burner

of

fuel at a time, a gas/oil

or

parts order.

atomiz~

is

of

the non-

of

the inter-

is

usually

be

included

by

al-

is

in

CHAPTER 1-2

750-150

Page 15

CHAPTER I

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

Regardless

operates with full modulation (within

operating range) through potentiometer-type

positioning controls, and the burner returns to

minimum firing position for ignition. High pressure boilers (above 15 psi) can be

low pressure and high pressure modulation

optional equipment. This enables the boiler to

operate at lower pressure during off-load hours,

but at a somewhat reduced steam output

ent upon lower steam pressure and steam nozzle

sizing.

The flame safeguard and program relay include

a flame detector

flames and to shut the burner down

ofloss

of

the control provides a . pre-purging period,

proving

of

continued blower operation to postpurge the

boiler

controls shut down the burner under low water

conditions, excess steam pressure or high water

tern

perature.

The safety interlock controls include combustion

and atomizing air proving switches and,

ing upon the fuel and insurance carrier requirements, controls that prove the presence

adequate fuel pressure plus temperature proving

controls when

of

which fuel is used, the burner

its

wired for both

depend-

to supervise both oil· and gas

in

the event

of

flame signal. The programming portion

of

the pilot and main flame, and a period

of

all unburned fuel vapors. Other safety

depend-·

heated fuel oil

is

used.

rated

as

of

fuel oil through a cam operated metering valve.

Fuel input and air are thus properly proportioned

for most efficient combustion.

Filtered primary air for atomizing fuel oil

furnished independently

air pump. The burner control circuit operates on

115 volt, single phase

so equipped) alternating current. The forced draft

is

fan motor

vice at the available main power supply voltage.

Indicator lights signaling load demand, fuel

valve, low water, and flame failure conditions are

standard equipment.

In addition to the standard basic controls

plied,

specific requirements

local code. Refer

prepared by Cleaver-Brooks for your specific

installation to determine the specific controls

the burner and limit control circuits. The function

of

individual components

ter and the electrical sequence

Chapter

generally operated on 3 phase ser-

other devices may be required to meet

to the Wiring Wiagram (WD)

3.

C.

CONTROL

COMPONENT

of

combustion air

60 hertz (or

of

an insurance carrier or

is

outlined

SO

hertz when

in

this chap-

is

covered

AND

FUNCTION

by

sup-

is

an

in

in

The sequence

through shut-down

in

relay

interlock devices, which are

cuitry to provide safe operation and help to

protect against incorrect operating techniques.

All "CBW" model boilers

sembly attached

may be swung open for inspection and

tenance.

Combustion air

blower located

delivery

damper motor. This same motor regulates the

flow

nected to the gas butterfly valve and the flow

750-150

conjunction with the operating, limit and

of

of

burner operatiop from start-up

is

governed

to

the front head. The entire head

is

provided

in

the front head. Combustion air

to

the burner

gas fuel through a linkage system con-

is

under the control

by

the program

wired into the cir-

·have the burner asmain-

by

a centrifugal

of

the

of

The term "control" covers the more important

valves and components, including but not limited

to electrical controls or those monitored by the

The

program relay.

familiar with the individual functioning

controls before he can understand the boiler's

operation and procedures outlined

Identify and locate each item using the figure

callout.

The actual controls furnished with any given

boiler will depend upon the type

it

is

equipped and whether

steam boiler. Refer to the applicable group or

groups listed which apply to the particular boiler.

operator

must become

in

the manual.

of

fuel for which

it

is

a hot water or

CHAPTER

of

all

1--3

Page 16

CHAPTER!

GENERAL DESCRIPTION

AND

PRINCIPLES OF OPERATION

LIMIT

ERATING, HIGH

LATING PRESSURE CONTROLS

AND

WATER

AND PUMP CONTROLS

COLUMN

GAS

CONTROL

VALVE

[FIGURE

OIL

FUEL

CONTROLLER

1-1

I TYPICAL STEAM

Boilers having optionally ordered features may

have control components not listed here.

D.

CONTROLS COMMON

ALL

BOILERS

TO

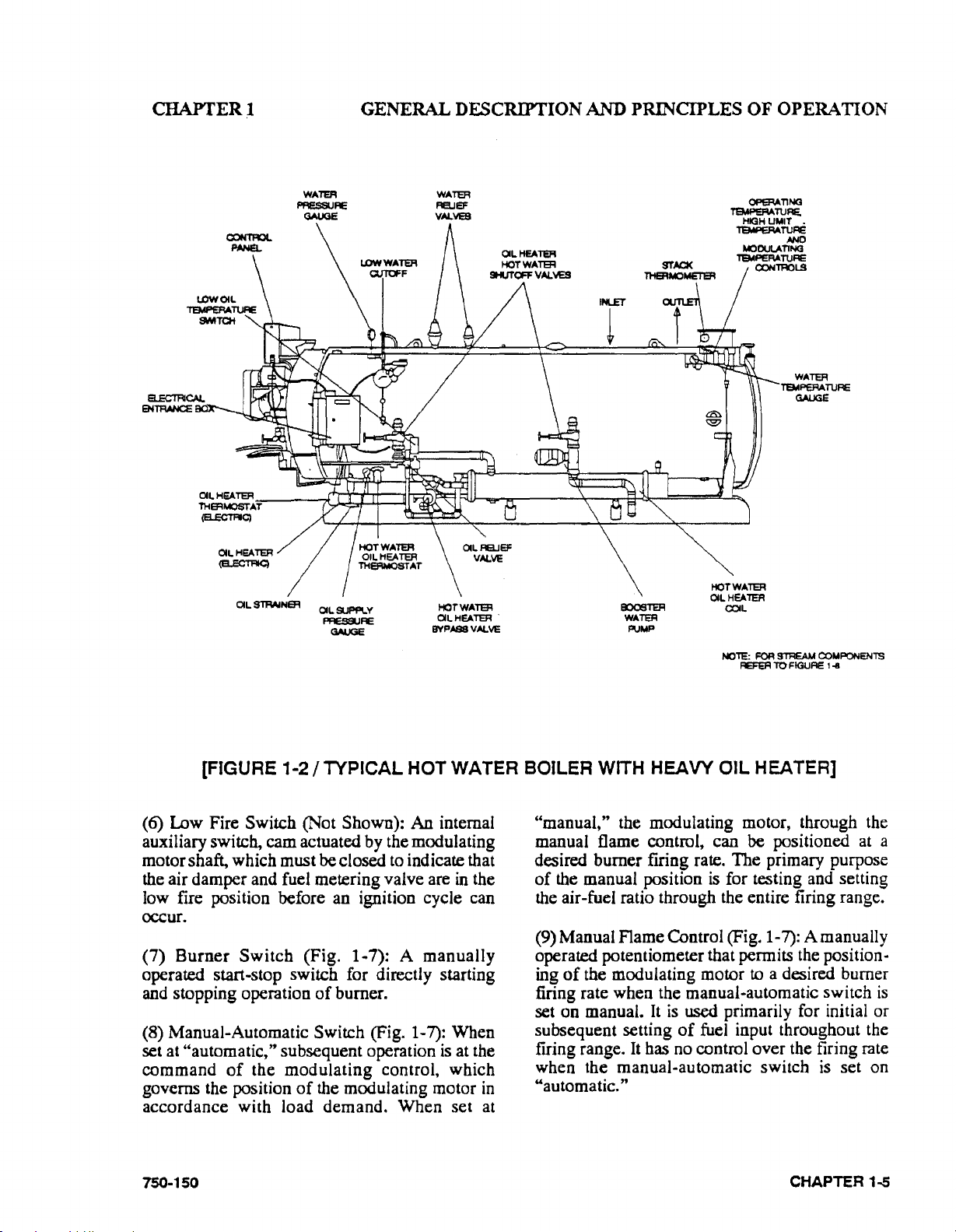

(1) Forced Draft Fan Motor (Fig. 1-1): Drives the

forced draft fan directly

air. Also referred

to

to

provide combustion

as a blower motor.

(2) Forced Draft Fan Motor Starter (Fig. 1-7):

Energizes the forced draft fan (blower) motor.

OIL

RELIEF VALVE

BOILER-

LIGHT OIL FIRED]

(3) Forced Draft Fan (Fig. 1-10): Furnishes all

of

air, under pressure, for combustion

pilot fuel

and main fuel, and for purging.

( 4) Ignition Transfonner (Fig.

high voltage spark for ignition

1-1

): Provides a

of

the gas pilot or

the light oil pilot.

(5) Modulating Motor (Fig. 1-1): Operates the

rotary air damper and fuel valves through a cam

and linkage system to provide proper air fuel

ratios under all boiler load conditions.

CHAPTER 1-4

750-150

Page 17

CHAPTER!

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

OIL

STRAINEfl

OIL

SUPPLY

PFESSUAE

GAUGe

WATER

FIEUEF

VALVES

HOTWA~

OILHEATER

BVP..a&VAL\IE

0Pe=IA11NG

TEMPeRATURE.

HIGHUMIT

T'EJIIFIEAA

MOOULA11NG

'T"EMP'ERA

CONTROLS

HOT

WATER

OIL

.

EI009"1"EF!

WATER

PUMP

HEATER

COIL

NOTE:

~TO

FOR

•

TURE

AND

TUAE

WATER

'T"EMPERA

GAUGE

STREAM

FIGURE 1-8

TUAE

COMPONENTS

[FIGURE 1-2 I TYPICAL HOT WATER BOILER WITH HEAVY

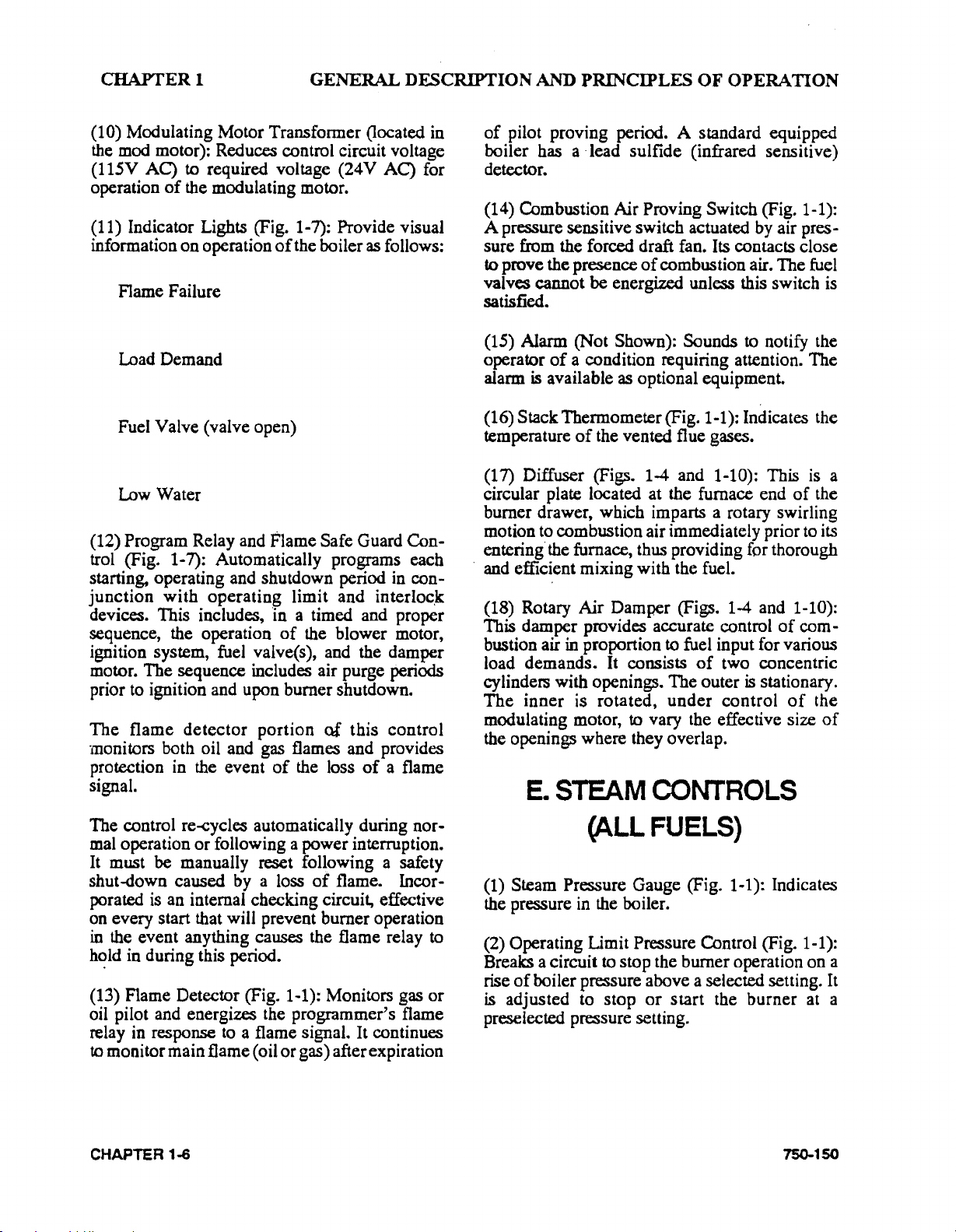

(6) Low Fire Switch (Not Shown): An internal

auxiliary switch, cam actuated by the modulating

motor shaft, which must be closed

the air damper and fuel metering valve are

to

indicate that

in

the

low fire position before an ignition cycle can

occur.

(7)

Burner

Switch

(Fig.

1·7): A manually

operated start·stop switch for directly starting

of

and stopping operation

(8)

Manual*Automatic Switch (Fig. 1-7): When

set at "automatic," subsequent operation

command

of

the

modulating

governs the position

accordance with load demand.

750-150

burner.

control, which

of

the modulating motor

When

is

at the

set at

in

OIL

HEATER]

"manual," the modulating motor, through the

manual flame control, can

desired burner

of

the manual position

firing rate.

be positioned at a

The

primary purpose

is

for testing and setting

the air-fuel ratio through the entire firing range.

(9) Manual Flame Control (Fig. 1-7): A manually

operated potentiometer that permits the

ing

of

the modulating motor to a desired burner

firing rate when the manual·automatic switch

set on manual.

subsequent setting

It

is

used primarily for initial or

of

fuel input throughout the

position-

is

frring range. It has no control over the firing rate

when the manual-automatic switch

is

set on

"automatic."

CHAPTER

1..5

Page 18

CHAPTER!

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

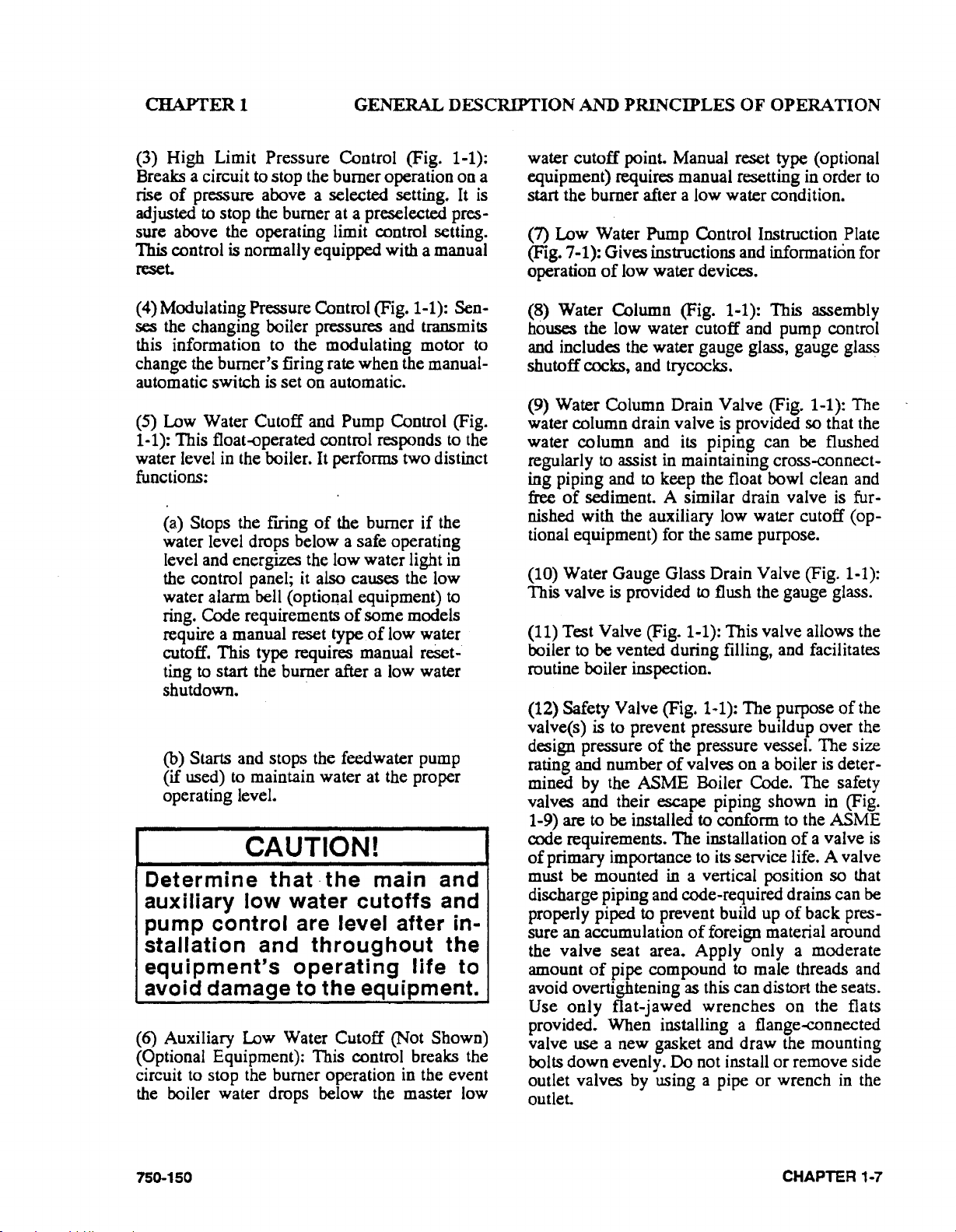

(10) Modulating Motor Transformer (located in

the mod motor): Reduces control circuit voltage

Aq

(115V

operation

(11) Indicator Lights (Fig. 1-7): Provide visual

information on operation

Flame Failure

Load Demand

Fuel Valve (valve open)

Low Water

(12) Program Relay and

trol (Fig.

starting, operating and shutdown period

junction

devices. This includes,

sequence, the operation

ignition system, fuel valve(s), and the damper

motor. The sequence includes air purge periods

prior to ignition and upon burner shutdown.

The flame

monitors both oil and gas flames and provides

protection

signal.

to required voltage (24V

of

the modulating motor.

of

the boiler

Flame Safe Guard Con-

1~

7): Automatically programs each

with

operating limit and interloc,k

in

a timed and proper

of

the blower motor,

detector

in

the event

portion

of

the loss

of

Aq

for

as

follows:

in

con-

this control

of

a flame

of

pilot proving period. A standard equipped

boiler has a

detector.

(14) Combustion Air

A pressure sensitive switch actuated

sure from the forced draft fan. Its contacts close

to

prove the presence

valves cannot

satisfied.

(15) Alarm (Not

operator

is

alarm

Stack Thennometer (Fig. 1-1): Indicates the

(16)

temperature

(17) Diffuser (Figs.

circular plate located at the furnace end

burner drawer, which imparts a rotary swirling

motion to combustion air immediately prior to its

entering· the furnace, thus providing for thorough

and efficient mixing with the fuel.

(18) Rotary Air Damper (Figs.

This damper provides accurate control

bustion air

load demands.

cylinders with openings. The outer

The

inner is rotated,

modulating motor,

the openings where they overlap.

E.

·lead sulfide (infrared sensitive)

Proving Switch (Fig. 1-1):

by

air pres-

of

combustion air. The fuel

be energized unless this switch is

Shown): Sounds

of

a condition requiring attention. The

available

in

STEAM

as

optional equipment.

of

the vented flue gases.

1-4 and 1-10): This

proportion to fuel input for various

It

consists

to vary the effective size

of

under

CONTROLS

to

notify the

1-4 and 1-10):

of

two concentric

is

stationary.

control

of

com-

of

is

the

the

of

a

The control

mal operation

It

must be manually reset following a safety

shut~own

porated

on every start that will prevent burner operation

in

the event anything causes the flame relay to

h~ld

in during this period.

(13) Flame Detector (Fig. 1-1): Monitors gas

oil pilot and energizes the programmer's flame

relay in response

to monitor main flame (oil

CHAPTER 1-6

re~ycles

or

caused by a loss

is

an internal checking circuit, effective

automatically during nor-

following a power interruption.

of

flame. lncor·

or

to

a flame signal. It continues

or

gas) after expiration

(ALL

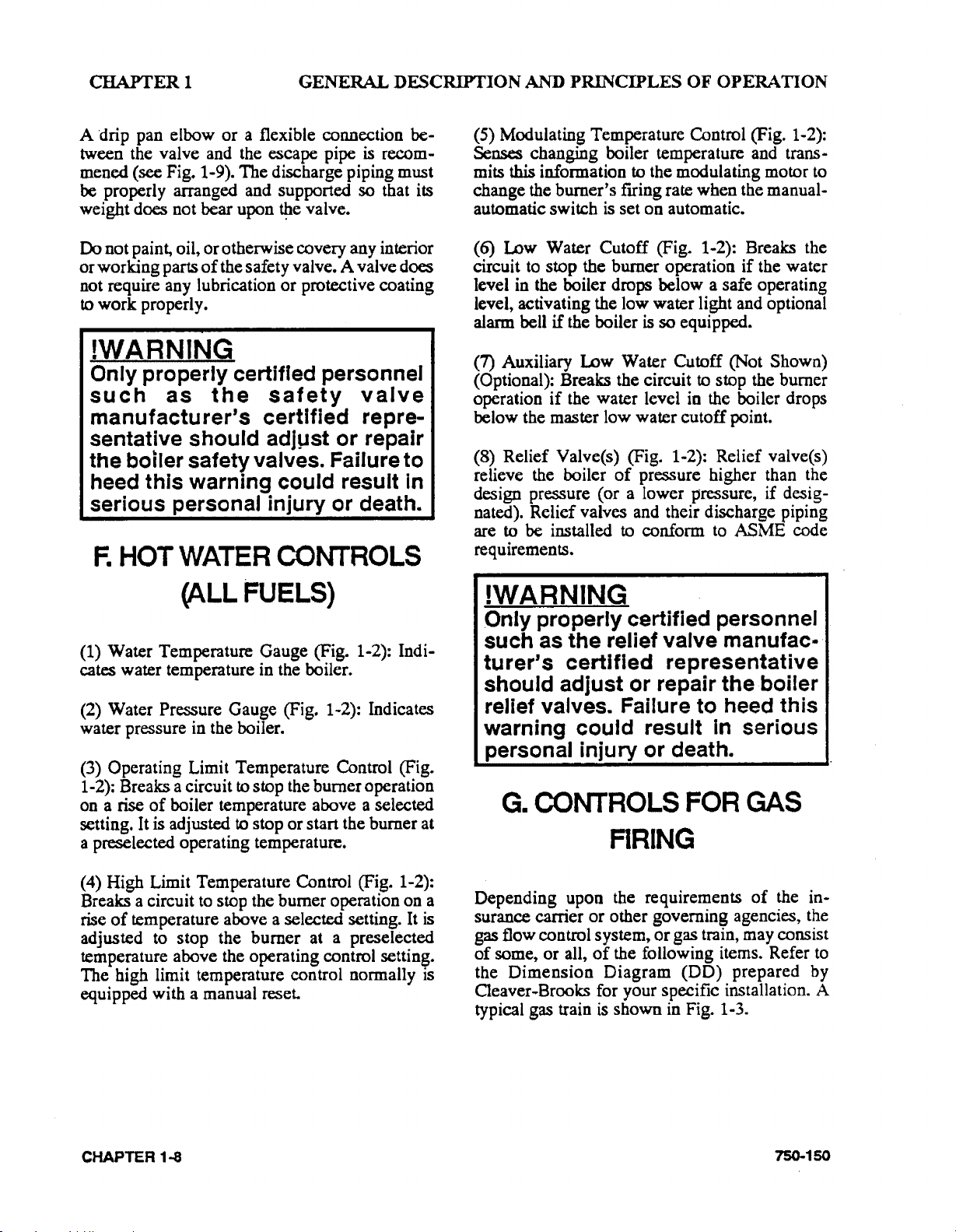

(1) Steam Pressure Gauge (Fig. 1-1): Indicates

in

the pressure

(2) Operating Limit Pressure Control (Fig. 1-1):

Breaks a circuit

rise

of

boiler pressure above a selected setting.

is

adjusted to stop

preselected pressure setting.

the boiler.

to

FUELS)

stop the burner operation on a

It

or

start the burner at a

750-150

Page 19

CHAPTER I GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

(3)

High

Breaks a circuit to stop the burner operation

rise

adjusted

sure above the operating limit control setting.

This control

reset.

Limit

of

pressure above a selected setting. It is

to

stop the burner at a preselected pres-

Pressure

is

normally equipped with a manual

Control (Fig. 1-1 ):

on

water

cutoff

a

equipment) requires manual resetting in order

start the burner after a

(7)

Low

(Fig. 7-1): Gives instructions and information for

operation

point. Manual reset type (optional

low

water condition.

Water Pump Control Instruction Plate

of

low water devices.

to

(4) Modulating Pressure Control (Fig. 1-1):

ses the changing boiler pressures and transmits

this information to the

change the

automatic switch is

Low

(5)

1-1): This float-operated control responds to the

water level in the boiler. It performs two distinct

functions:

(a)

water level drops below a safe operating

level and energizes the low water light in

the control panel; it also causes the low

water alarm bell

ring. Code requirements

require a manual reset. type.

cutoff. This type requires manual

ting to start the burner after a low water

shutdown.

(b) Starts and stops the feed water pump

(if

operating level.

burner's

Water

Stops the

used) to maintain water at the proper

Cutoff

fuing

modulating

firing rate

set

on

and Pump Control (Fig.

(optiOI~al

·

when

automatic.

of

the burner

equipment) to

of

some

the manual-

models

of

low water

Sen-

motor to

if

the

re8et-·

CAUTION!

Determine

auxiliary

pump

control

stallation

equipment's

avoid

(6) Auxiliary Low Water

(Optional Equipment): This control breaks the

circuit to stop the burner operation in the event

the boiler water drops below the master low

damage

that

low

and

·the

water

main

cutoffs

are level

throughout

operating

to

the

equipment.

Cutoff

and

and

after

in-

the

life

to

(Not Shown)

(8) Water Column (Fig. 1-1): This assembly

houses the low water

and includes the water gauge glass, gauge

shutoff

(9) Water Column Drain Valve (Fig. 1-1): The

water column drain valve is provided so that the

water

regularly

ing piping and

free

nished with the auxiliary low water cutoff (

tional equipment) for the

(10) Water Gauge Glass Drain Valve (Fig. 1-1):

This valve

(11) Test Valve (Fig. 1-1): This valve allows the

boiler

routine boiler inspection.

(12) Safety Valve (Fig. 1-1):

valve(s)

design pressure

rating and number

mined by the

valves and their escape piping

1-9) are to

code requirements.

of

must

discharge piping and code-required drains can be

properly piped

sure an accumulation

the

amount

avoid overtightening as this

Use

provided.

valve use a new gasket and draw the mounting

bolts

outlet valves by using a pipe

outlet

cocks, and trycocks.

column

of

sediment. A similar drain valve is fur-

to be vented during filling, and facilitates

is to prevent pressure buildup

primary importance to its service life. A valve

be

mounted in a vertical position

valve

of

only

down

and its

to assist in maintaining cross-connect-

to keep the float bowl clean and

is

provided to flush the gauge glass.

of

ASME

be installed to conform to the

to prevent build up

seat

pipe compound to male threads and

flatwjawed

When

evenly. Do not install

cutoff

the pressure vessel.

of

valves

Boiler Code.

The

of

area.

Apply

installing a flange-connected

and pump control

gl~

piping

same

installation

foreign material around

wrenches

can

be flushed

purpose.

The

purpose

on

a boiler is deter-

The

shown

of

a valve

of

back

only

a moderate

can

dis

toft

on

or

remove side

or

wrench

of

over

The

safety

in (Fig.

ASME

so

pres-

the seats.

the flats

in

op-

the

the

size

is

that

the

750-150

CHAPTER 1·7

Page 20

CHAPTER!

GENERAL

DESCRIPTION

AND

PRINCIPLES

OF

OPERATION

A drip pan elbow

tween the valve and the escape pipe

mened (see Fig. 1-9). The discharge piping must

be

properly arranged and supported so that its

weight does not bear upon

Do

not paint, oil,

or working parts

not require any lubrication

to work properly.

or

a flexible connection be-

is

recom-

~e

valve.

or

otherwise covery any interior

of

the safety valve. A valve does

or

protective coating

!WARNING

Only properly certified personnel

such

manufacturer's

sentative

the

heed

serious

F.

HOT

as

the

should

safety

certified

adj~st

or

valve

repre-

repair

boiler safety valves. Failure

this

warning could result in

personal

WATER

injury

or

death.

CONTROLS

to

(5) Modulating Temperature Control (Fig. 1-2):

Senses changing boiler temperature and transmits this information

change the burner's frring rate when the

automatic switch

low

(6)

circuit to stop the burner operation

level in the boiler drops below a safe operating

level, activating the low water light and optional

alarm bell

(7) Auxiliary

(Optional): Breaks the circuit

operation

below the master low water cutoff point.

(8) Relief Valve(s) (Fig. 1-2): Relief valve(s)

relieve the boiler

design pressure (or a lower pressure,

nated). Relief valves and their discharge piping

are

requirements.

Water Cutoff (Fig. 1-2): Breaks the

if

the boiler

low

if

the water level in the boiler drops

to

be installed

to

the modulating motor to

manual-

is

set on automatic.

if

the water

is

so equipped.

Water Cutoff (Not Shown)

to

stop the burner

of

pressure higher than the

if desig-

to

conform

to

ASME code

(ALL

(1) Water Temperature Gauge (Fig. 1-2): Indi-

water temperature in the boiler.

cates

(2) Water Pressure Gauge (Fig.

water pressure in the boiler.

(3) Operating Limit Temperature Control (Fig.

1-2): Breaks a circuit

on a rise

setting.

a preselected operating temperature.

(4) High Limit Temperature Control (Fig. 1-2):

Breaks a circuit

rise

adjusted

temperature above the operating control setting.

The high limit temperature control normally

equipped with a manual reset.

of

boiler temperature above a selected

It

is adjusted to stop

of

temperature above a selected setting. It

to

stop the burner at a preselected

i=UELS)

1-2): Indicates

to

stop the burner operation

or

start the burner at

to

stop the burner operation on a

is

is

!WARNING

.Only properly certified personnel

the

such as

turer's

should adjust

relief valves. Failure

warning

personal

G.

CONTROLS

relief valve manufac· ·

certified

representative

or

repair

the

to heed

could

injury

result In serious

or

death.

FOR

boiler

this

GAS

FIRING

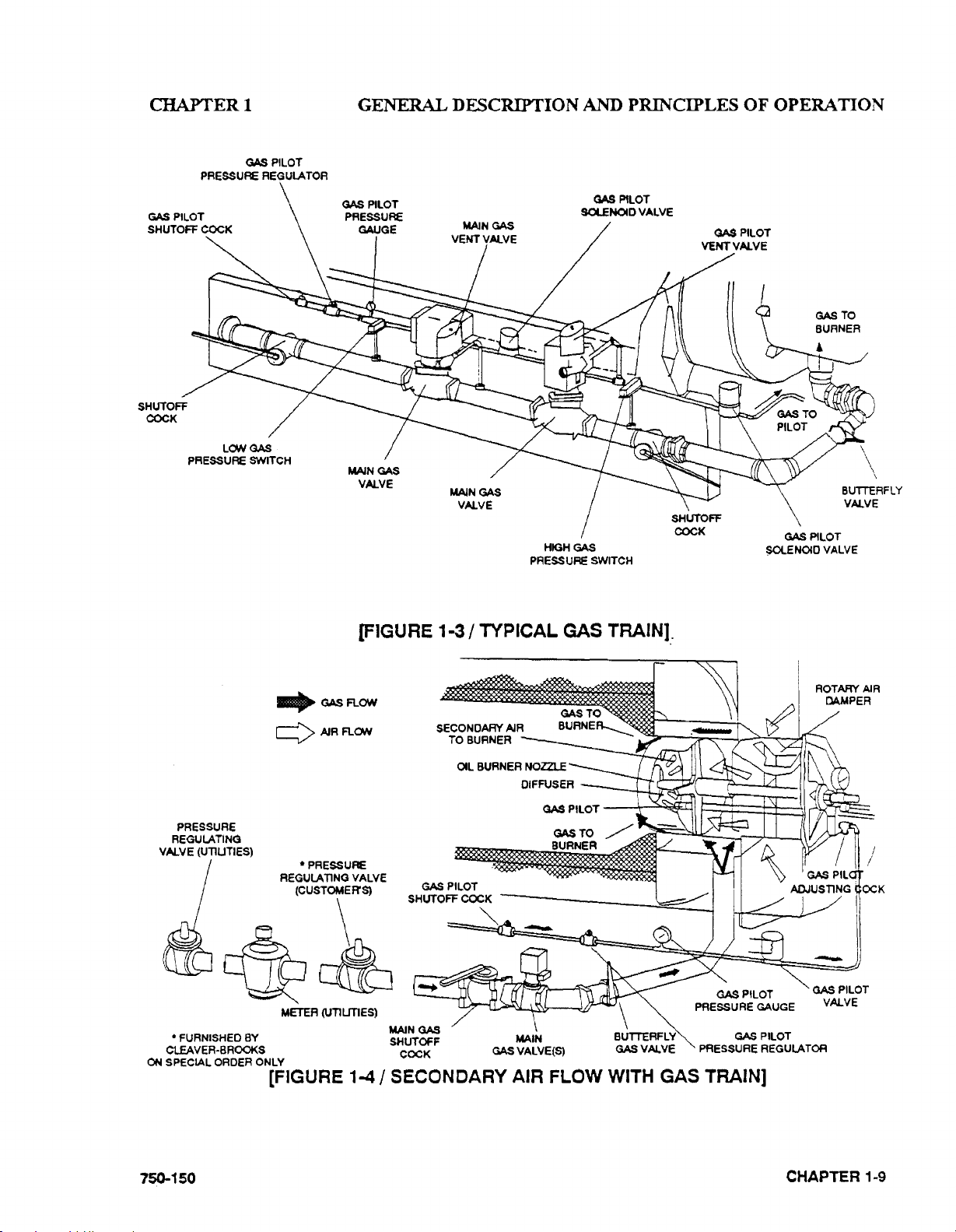

Depending upon the requirements

surance carrier

gas

flow control system,

of

some,

the Dimension Diagram (DD) prepared by

Cleaver-Brooks for your specific installation. A

typical gas train

or

or

other governing agencies, the

or

gas train, may consist

all,

of

the following items. Refer

is

shown

in

Fig. 1-3.

of

the in·

to

CHAPTER

1...S

750-150

Page 21

CHAPTER!

PRESSURE

GAS

PILOT

SHUTOFF COCK

LON

PRESSURE

GAS

PILOT

REGULA

GAS

SWITCH

TOR

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

GAS

GAS

PILOT

PRESSURE

GAUGE

PILOT

SOU:N040 VALVE

PRESSURE

REGULATING

VALVE (UTlUTIES)

[FIGURE

..

GASFLCIN

YAIRFLON

*PRESSURE

REGULATlNG VALVE

MAIN

GAS

VALVE

HIGH

GAS

PRESSURE

1·3/

TYPICAL GAS TRAIN],.

SWITCH

SHUTOFF

COCK

BUTTERFLY

VALVE

GAS

PILOT

~ENOIOVALVE

ROTARY

DAMPER

AIR

*FURNISHED

CLEAVER-BROOKS

ON

SPECIAL

750-150

~ul

METER

(UT1UT1ES)

MAIN

GAS

SHUTOFF

COCK

ORDER

BY

ONLY

[FIGURE 1-4 I SECONDARY AIR

FlOW

GAS

PRESSURE

WITH GAS TRAIN]

PILOT

REGULATOR

CHAPTER 1-9

Page 22

CHAPTER!

GENERAL

DESCRIPTION

AND

PRINCIPLES

OF

OPERATION

(1) Gas Pilot Valve: A solenoid valve that opens

to

during the ignition period

It

pilot.

The sequence

controlled by the programming relay. A second

gas pilot valve may be required by insurance

regulations.

(2) Gas

pilot valve

valve

vent gas to the atmosphere, should any be present

in

The valve closes when the pilot valves are energized.

(3) Gas

ing

valve.

(4) Gas

Provided

flame.

(5) Gas

flow

(6) Gas Pressure Gauge: Indicates gas pressure

to the pilot.

(7) Gas Pressure Regulating Valve: Reduces in-

coming gas pressure

ment

(8) Butterfly Gas Valve: The pivoted disc

valve

gas modulating cam

flow to the burner.

closes after main flame

of

energizing and de-energizing

Pilot Vent Valve: When a secorid gas

is

required, a normally open vent

is

installed between them. Its purpose

the pilot line when the pilot valves are closed.

Pilot Shut

or

closing the gas supply to the gas pilot

Pilot Adjusting Cock (Fig. 5-10):

to

Pilot Aspirator (Fig. 5-10): Improves the

of

gas to the pilot.

of

between

is actuated by connecting linkage from the

...off

Cock: For manually open-

regulate the size

to

5"

to

10" W

to regulate the rate

admit fuel

is

of

the gas pilot

suit the pilot's require-

..

C.

to

the

established.

is

is

to

in

this

of

gas

(11) Main Gas Valves: Electrically actuated shut-

off

valves that open simultaneously to admit gas

to the burner. The downstream valve

with a "proof

into the pre-ignition interlock circuit.

(12) Main Gas

solenoid valve installed between the two main

gas valves

should any be present

the gas valves are de-energized. The vent valve

closes when the gas valves are energized.

(13) Low Gas

tuated switch that

line pressure

Should the pressure drop below this setting, the

switch contacts will open a circuit causing the

main gas valve(s)

from starting. This switch

with a device that must be manually reset after

being tripped.

(14) High Gas Pressure Switch: A pressure

tuated switch that

gas

line pressure

Should the pressure

switch contacts will open a circuit causing the

gas

main

from

starting~

with a device that must be manually reset after

being tripped.

(15) Leakage Connection: The body

valve has a plugged opening that

ever it

for possible leakage across the closed valve.

of

closure" switch that

Vent Valve: A normally open

to

vent the gas to the atmosphere

in

the main gas line when

Pressure Switch: A pressure ac-

is

closed whenever main gas

is

above a preselected pressure.

to

close,

or

prevent the burner

is

is

closed whenever the main

is

below a preselected pressure.

riSe

above this setting, the

valve(s)

is

necessary or desirous to conduct a test

to

close or prevent the burner

This switch

is

is

equipped

is

connected

usually equipped

ac-

usually equipped

of

the gas

is

used when-

An

(9) Gas Modulating Cam (Fig. 5-6):

of

a series

contour spring, providing for adjustment

input at any poirit in the modulating range.

(10) Main Gas Cock: For

closing the main fuel gas supply downstream

the main gas line pressure regulator. A second

shut-off cock, downstream

valve(s), may be installed

shutting

for leakage across the main gas valve.

CHAPTER

of

adjustable allen-head screws and a

m~nually

of

to provide a means

off

the gas line whenever a test

1-10

assembly

of

gas

opening and

of

the main gas

of

is

made

H.

CONTROLS

OIL

FIRED

QNCLUDING

The following items are applicable

or gas and oil fired boilers. Additional controls

for No. 6 oil are listed in Section

COMMON

TO

BOILERS

COMBINATION)

to

all oil fired

I.

75()..150

Page 23

CHAPTERl

OIL

BURNER

PRESSURE

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

OIL

MODULATING CAM

GAUGE

OIL

PRESSURE

REGULATOR

OIL

OIL

RETURN

SUPPLY

+ TO MAIN

OIL

[FIGURE 1-5 I OIL CONTROL VALVE

OIL

MODULATING

OIL

METERING

OIL

BURNER PRESSURE GAUGE

SOLENOID

VALVE

ASSEMBLY-

CAM

VALVE

PACKING

GLAND

OIL

PRESSURE REGULATOR

OIL

FOR LIGHT OIL]

RETURN PRESSURE GAUGE

OIL

FUEL

THERMOMETER

OIL

RETURN

750·150

OIL

ORIFICED

VALVE

TO

MAIN

SOLENOID

OIL

VALVE

BACK PRESSURE

MANUAL

VALVE

BY·PASS

SUPPLY

VALVE

[FIGURE 1-6 I OIL CONTROL VALVE ASSEMBLY- FOR HEAVY OIL]

CHAPTER

1-11

Page 24

CHAPTER!

GENERAL

DESCRIPTION

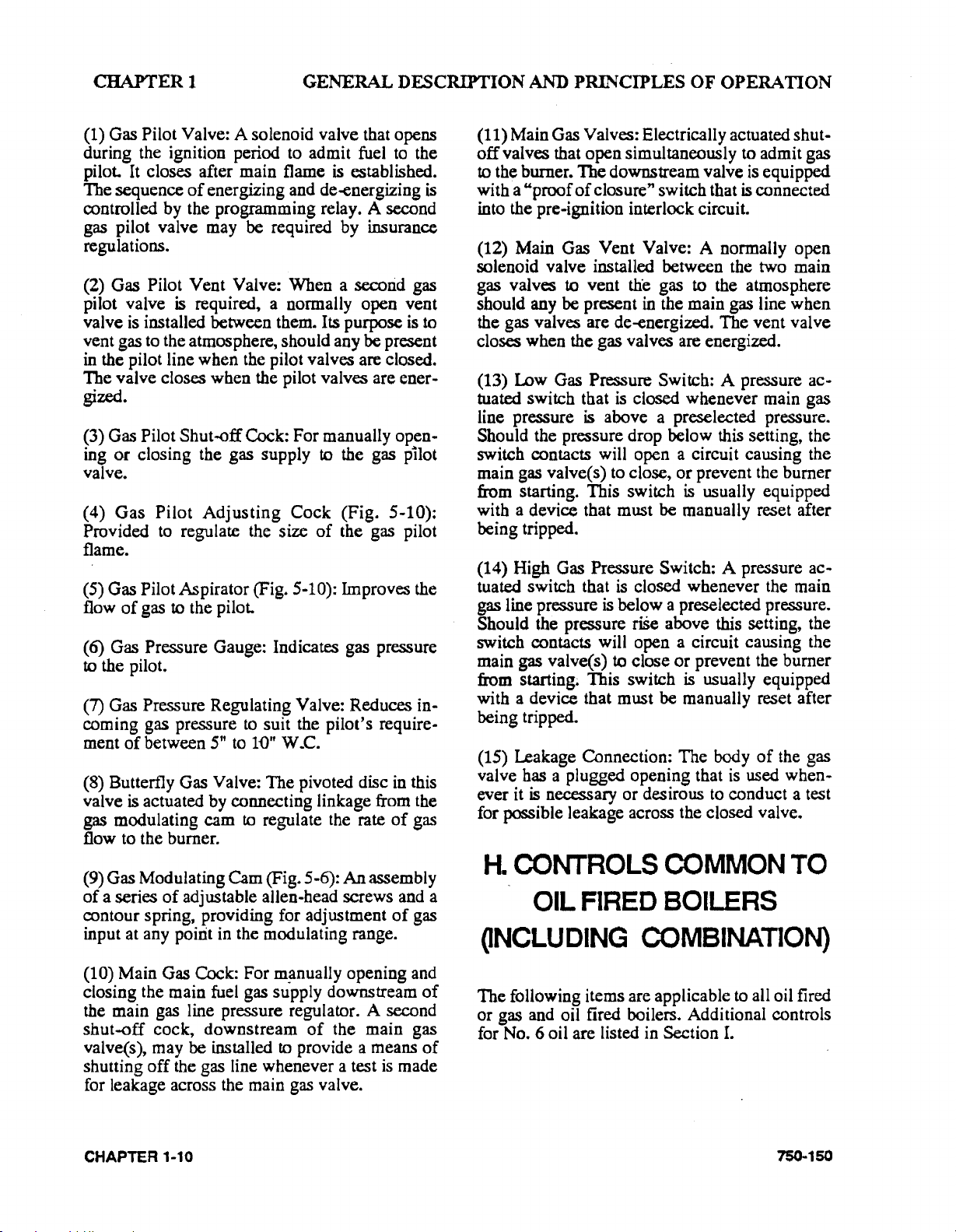

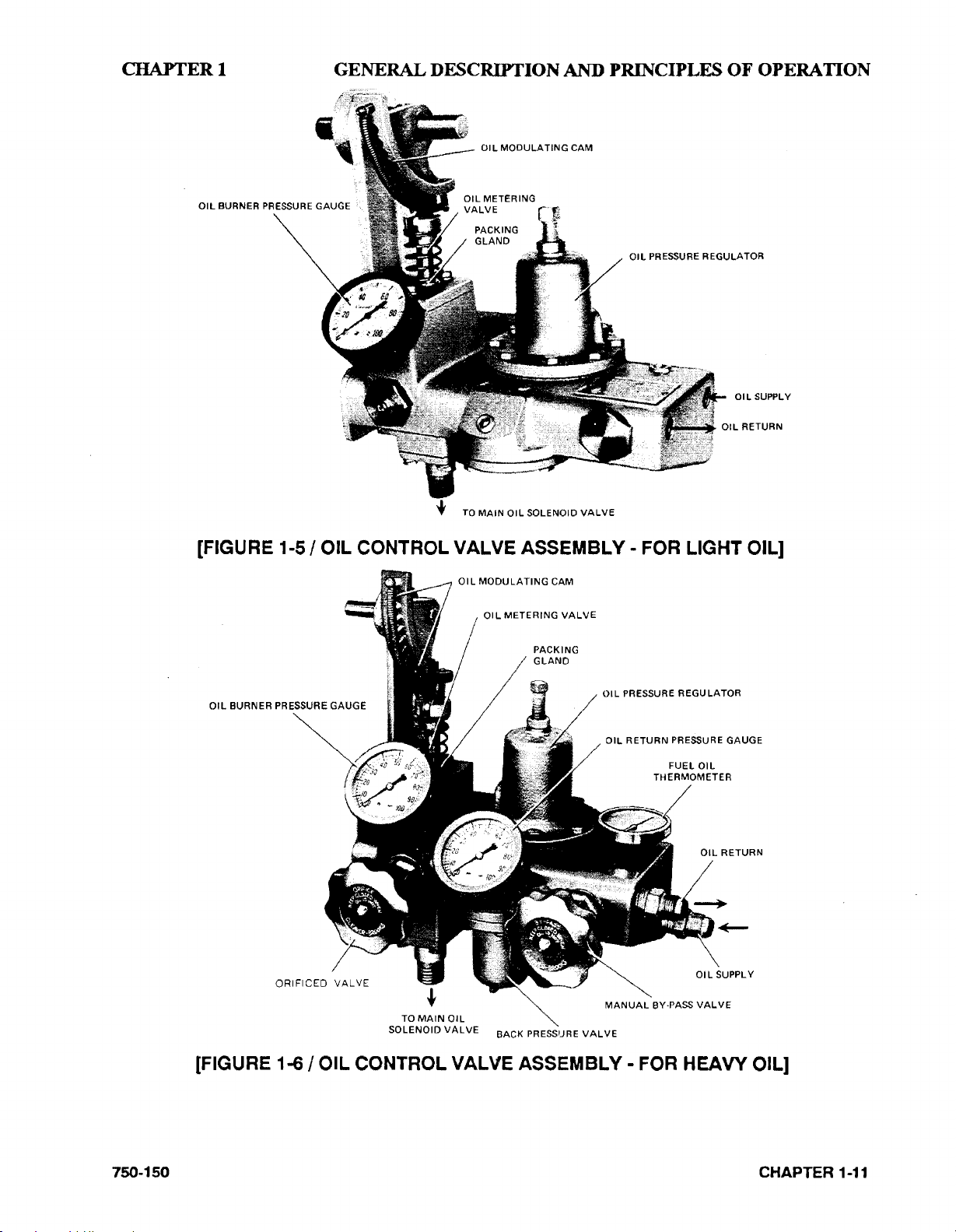

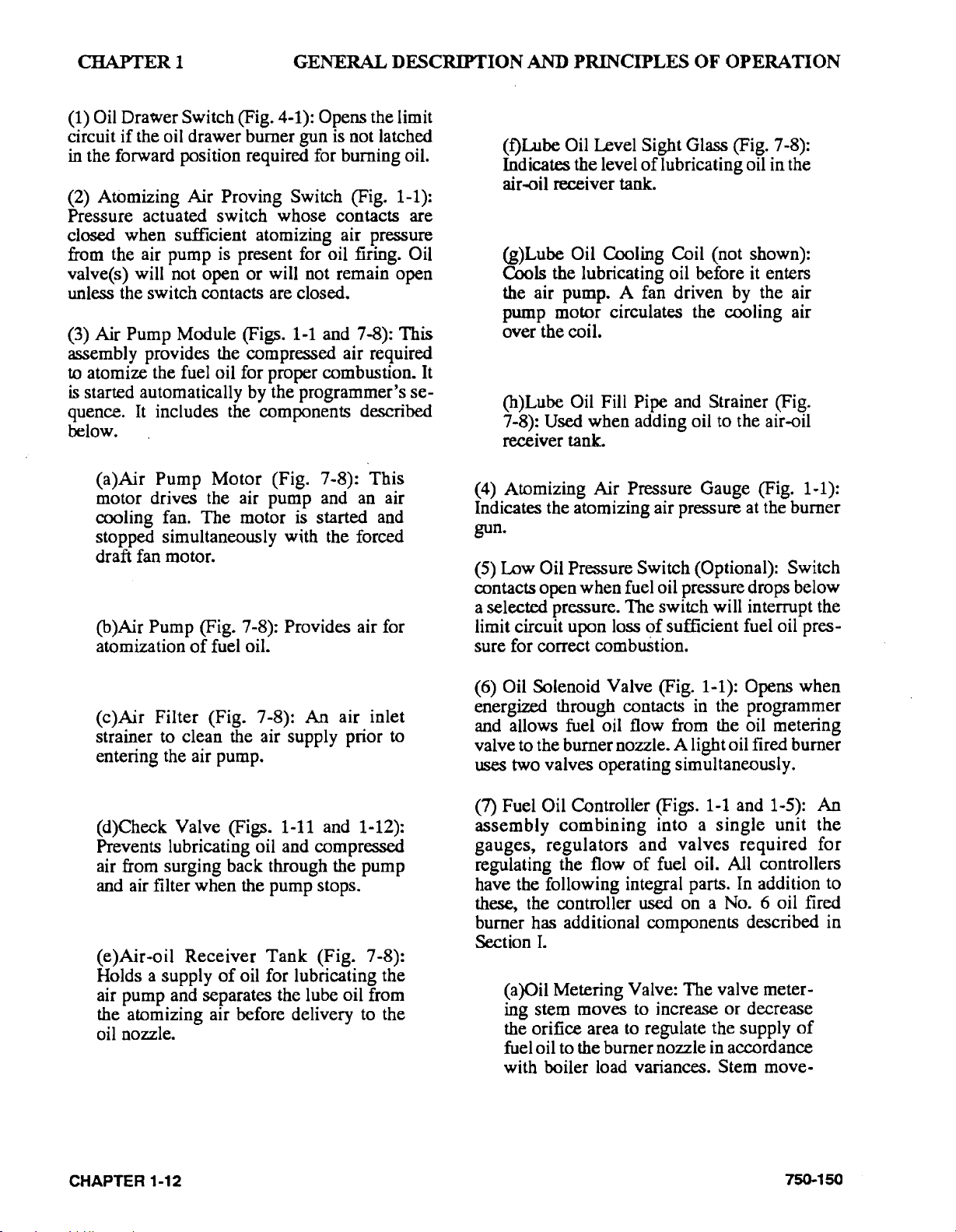

(1) Oil Dra'(ver Switch (Fig. 4-1): Opens the limit

circuit if the oil drawer burner gun

in

the forward position required for burning oil.

is

not latched

(2) Atomizing Air Proving Switch (Fig. 1-1):

Pressure actuated switch whose contacts are

closed when sufficient atomizing air pressure

is

from the air pump

present for oil firing. Oil

valve(s) will not open or will not remain open

unless the switch contacts are closed.

(3) Air Pump Module (Figs. 1-1 and 7-8): This

assembly provides the compressed air required

to atomize the fuel oil for proper combustion.

is

started automatically by the programmer's se-

quence.

It

includes the components described

It

below.

AND

PRINCIPLES

OF

OPERATION

(f)Lube Oil Level Sight Glass (Fig. 7-8):

Indicates the level

of

lubricating oil in the

air-oil receiver tank.

(g)Lube

Oil Cooling Coil (not shown):

Cools the lubricating oil before it enters

the air pump. A fan driven by the air

pump motor circulates the cooling air

over the coil.

(h)Lube

7-8):

Oil Fill Pipe and Strainer (Fig.

Used when adding oil

to

the air-oil

receiver tank.

(a)Air

motor drives the air pump and

cooling fan. The motor

stopped simultaneously

Pump Motor (Fig. 7-8): This

an

air

is

started and

with the forced

draft fan motor.

(b)Air

atomization

(c)Air Filter (Fig. 7-8):

Pump (Fig. 7-8): Provides air for

of

fuel oil.

An air inlet

strainer to clean the air supply prior to

entering the air pump.

(d)Check Valve (Figs. 1-11 and 1-12):

Prevents lubricating oil and compressed

air from surging back through the pump

and air filter when the pump stops.

(e)Air·oil Receiver

Holds a supply

of

air pump and separates the

the atomizing air before delivery

Tank

(Fig. 7-8):

oil for lubricating the

1 ube oil from

to

the

oil nozzle.

(4) Atomizing Air Pressure Gauge (Fig. 1-1):

Indicates the atomizing air pressure at the burner

gun.

(5) Low

Oil Pressure Switch (Optional): Switch

contacts open when fuel oil pressure drops below

a selected pressure. The switch will interrupt the

of

limit circuit upon loss

sufficient fuel oil pres-

sure for correct combuStion.

(6) Oil Solenoid Valve (Fig. 1-1): Opens when

energized through contacts

in

the programmer

and allows fuel oil flow from the oil metering

valve to the burner nozzle. A light oil fired burner

uses two valves operating simultaneously.

(7) Fuel Oil Controller (Figs. 1-1 and 1-5): An

assembly

combining

into a single unit the

gauges, regulators and valves required for

regulating the flow

have the following integral parts.

these, the controller

burner has additional components described

of

fuel oil. All controllers

In

addition to

used

on a No. 6 oil fired

in

Section I.

(a

)Oil Metering Valve: The valve metering stem moves

the orifice area to regulate the supply

fuel oil to the burner nozzle

with boiler load variances.

to

increase or decrease

in

accordance

Stem move-

of

CHAPTER 1-12

750-150

Page 25

CHAPTER

I GENERAL DESCRIPTION AND PRINCIPLES

OF

OPERATION

ment

motor through linkage and the oil

ing cam.

(b)Oil Modulating

consisting

head screws and a contour spring

ing for adjustment

in

( c )Oil Burner Pressure Gauge:

pressure

valve.

(d)Oil Pressure Regulator: For

ment

valve.

(8) Fuel

oil from the storage tank and delivers it under

pressure to the burner system.

(9)

Oil Relief Valve (Fig. 1-1): Maintains a constant oil supply pressure to the fuel oil controller

by

bypassing excess fuel oil.

(10) Fuel Oil Strainer (Fig. 1-1): Provided

prevent foreign matter from entering the burner

system.

is

controlled by the modulating

Cam:

of

a series

of

the modulating range.

of

the fuel oil at the metering

of

the oil pressure at the metering

Oil Pump (Not

An

of

adjustable allen-

oil input at any point

~hown):

meter-

assembly

provid-

Indicates

adjust-

Transfers fuel

to

L ADDITIONAL

FOR

NOTE:

Oil Heater Switch (Fig. 1-7): Manually

(1)

provides power to the oil beater system.

(2)

Oil Heater (Electric) (Figs. 1-2 and 1-8):

Used for heating sufficient fuel oil for low fire

flow during cold starts before steam or hot water

is

available for heating. The heater must

turned

time that the fuel oil transfer pump

(3)

Oil Heater (Steam/Hot Water) (Figs. 1-2 and

1-8): Heats fuel oil through the medium

or

hot water. The electric heater

steam heater, but

water heater.

will operate at boiler pressure.

furnished on high pressure boilers are also

operated at less than 15 psi. This

through use

(4) Electric

1-8): Senses the fuel oil temperature and

gizes or de-energizes the electric oil heater

maintain the required temperature

Items 6 and 7 are applicable only

on a hot water boiler.

off

during extended boiler lay-up, or any

of

Oil Heater Thennostat (Figs. 1-2 and

HEAVY

is

Steam oil heaters on 15 psi boilers

a steam pressure regulator valve.

CONTROLS

OIL

be

is

stopped.

of

steam

is

housed

housed separately on a hot

Steam oil heaters

is

accomplished

of

in

the

to

be

ener-

to

the fuel oil.

(11) Gas

the various components.

(12) Light

a light oil. pilot

provided to control the flow

nozzle. It

tacts.

after main flame

(13) Back Pressure Orifice (Fig. 1-1): A

tion located

downstream

back pressure

750-150

Pilot: See Section G for description

Oil Pilot Valve (Not Shown): When

is

furnished, a solenoid valve

of

fuel to the pilot

is

energized through programmer con-

It

is

de-energized to shut

is

ignited and established.

in

the oil return line immediately

of

the fuel oil controller

(100 and 200 series only).

off

pilot fuel flow

restric-

to

create

of

is

Steam Oil HeaterThennostat (Fig. 1-8): Sen-

(5)

ses the fuel oil temperature and controls the

of

opening and closing

maintain the required temperature

(6) Hot Water

This control

the fuel oil temperature and control the starting

and stopping

hot water to the pre-heating assembly

the required temperature

(7) Booster Water

stopped by the hot water thermostat

the flow

heater

to

Oil Heater Thennostat (Fig. 1-2):

is

used on a hot water boiler

of

the booster water pump to supp I y

of

hot water through the hot water oil

maintain the temperature

the steam heater valve

of

the fuel oil.

to

maintain

of

the fuel oil.

Pump (Fig. 1-2): Started and

to

of

the fuel oil.

CHAPTER 1·13

to

to

sense

regulate

Page 26

CHAPTER I

GENERAL DESCRIPTION AND

PRINCIPLES OF OPERATION

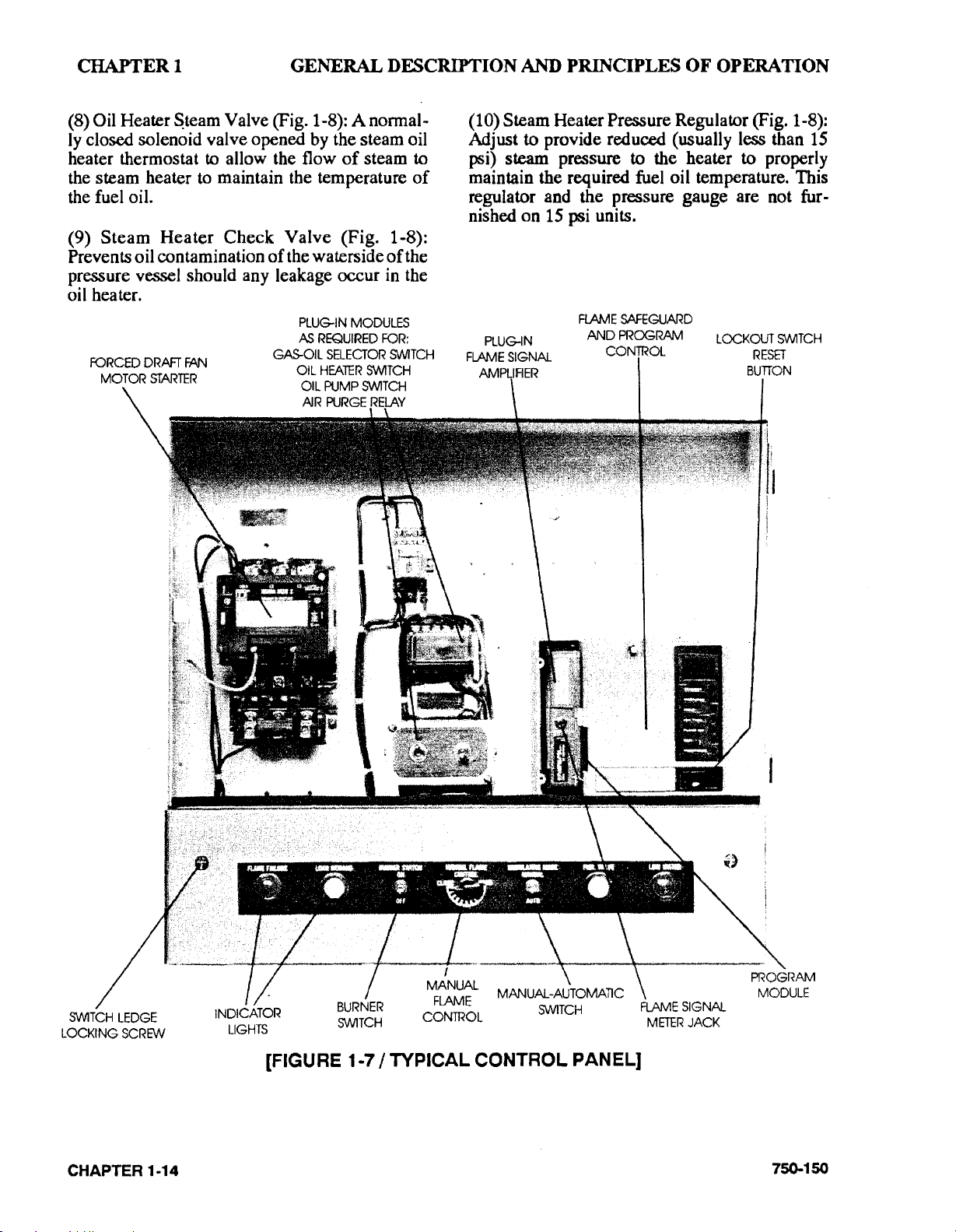

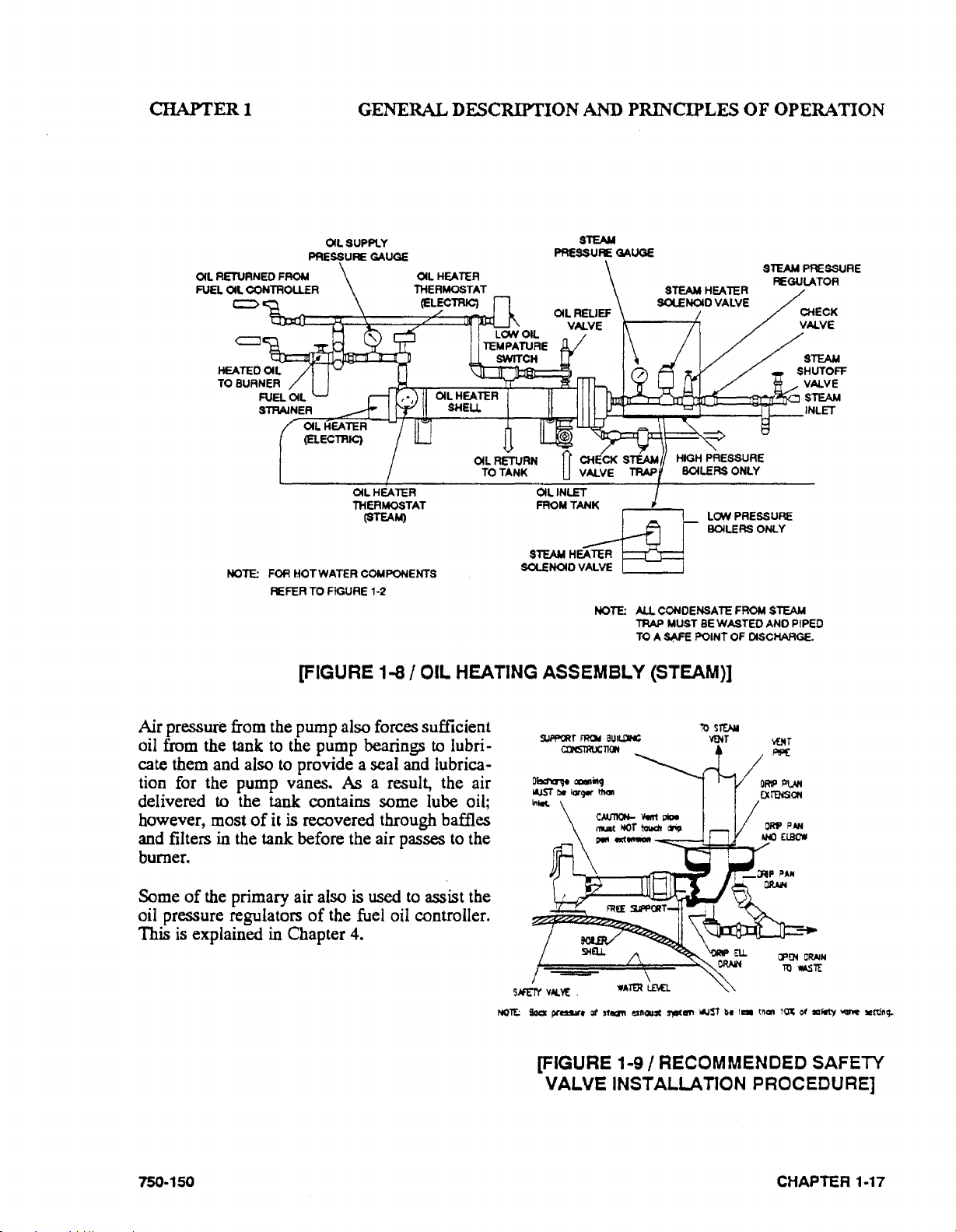

(8) Oil Heater

~team

Valve (Fig. 1-8): A normally closed solenoid valve opened by the steam oil

heater thermostat to allow the flow

the steam heater to maintain the temperature

of

steam to

of

the fuel oil.

Steam

(9)

Prevents oil contamination

Heater

Check

Valve

of

the waterside

(Fig. 1-8):

of

the

pressure vessel should any leakage occur in the

oil heater.

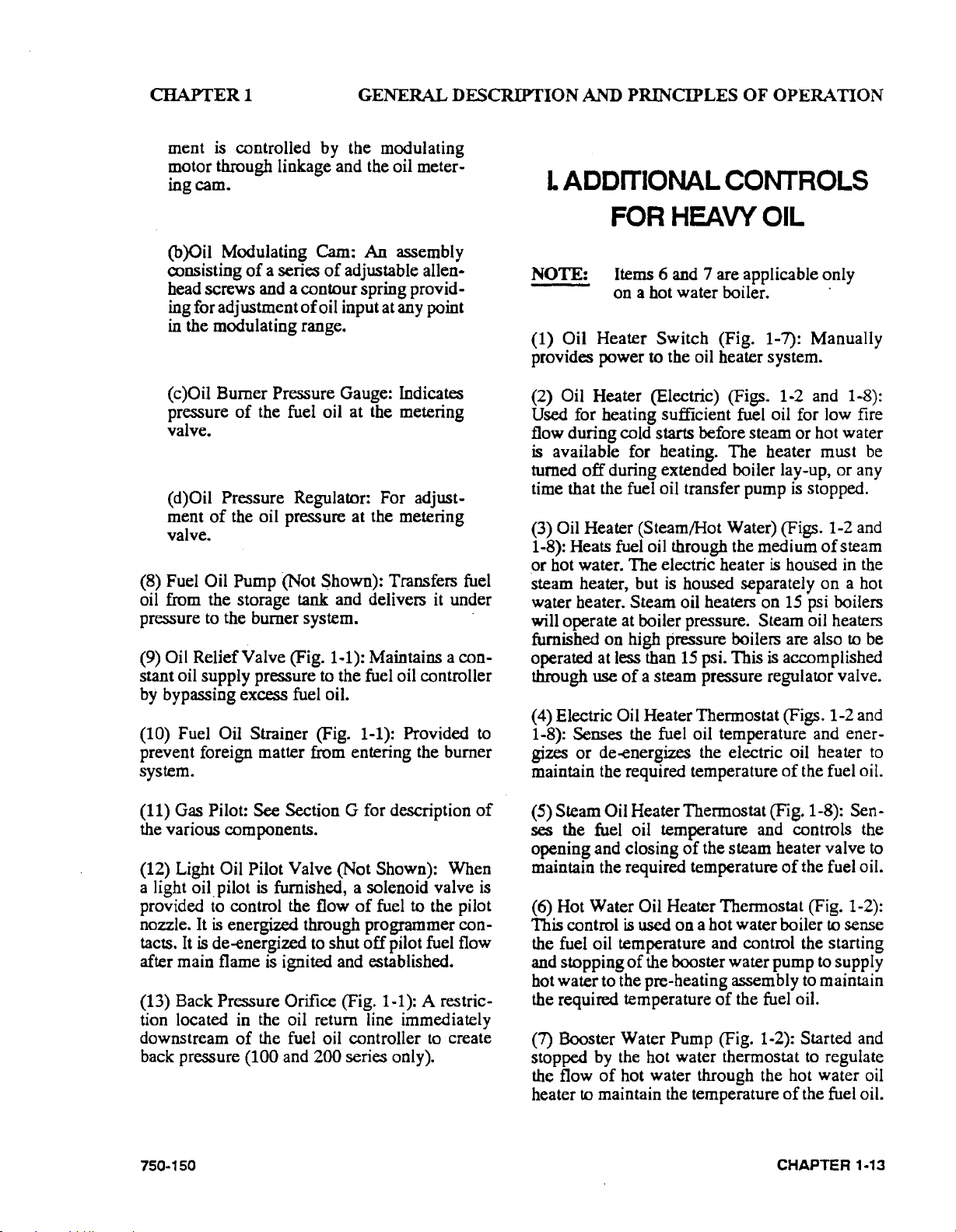

PLUG-IN

AS

GAS-OIL

OIL

OIL

AIR

MODULES

REQUIRED

SELECTOR

HEATER

SWITCH

PUMP

SWITCH

PURGE

FOR:

SvVlTCH

(10) Steam Heater Pressure Regulator (Fig. 1-8):

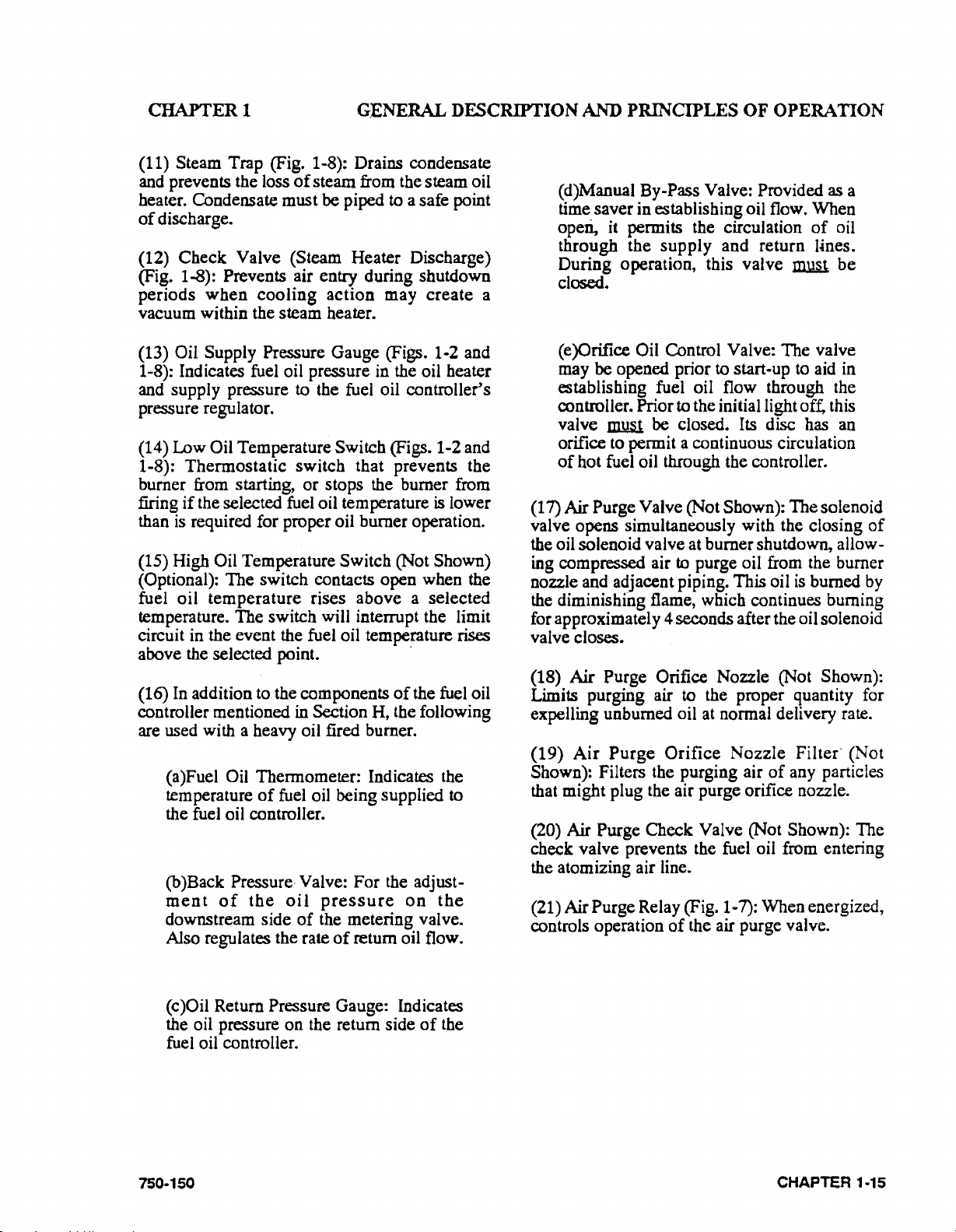

Adjust to provide reduced (usually less than 15

psi) steam pressure to the heater to properly

maintain the required fuel oil temperature. This

regulator and the pressure gauge are not

nished on

15

psi units.

Fl.Afv1E

SAFEGUARD

AND

PROGRAM

LOCKOUT

BUTTON

fur-

SvVlTCH

RESET

SWITCH

LOCKING

CHAPTER 1-14

LEDGE

SCREW

I

MANUAL

FLAME

CONTROL

[FIGURE 1·7 I TYPICAL CONTROL PANEL]

750-150

Page 27

CHAPTER!

GENERAL

DESCRIPTION

AND

PRINCIPLES

OF

OPERATION

(11) Steam

and prevents the loss

heater. Condensate must

of

discharge.

(12)

Check

Trap

(Fig. 1·8): Drains condensate

of

steam from the steam oil

be

piped

to

Valve

(Steam Heater Discharge)

a safe point

(Fig. 1-8): Prevents air entry during shutdown

periods

vacuum within the

(13)

when

cooling

steam

Oil Supply Pressure

action

heater.

Gauge

may

(Figs.

create

1·2

and

1-8): Indicates fuel oil pressure in the oil heater

and supply pressure

to the fuel oil controller's

pressure regulator.

(14)

Low

Oil Temperature Switch (Figs. 1-2 and

Thermostatic

1-8):

burner from starting,

firing

if

the selected fuel oil temperature

switch

or

that

prevents

stops the burner from

is

lower

the

than is required for proper oil burner operation.

(15) High

(Optional):

fuel

temperature.

Oil Temperature

The

oil

temperature

The

Switch

switch contacts

rises

(Not

Shown)

open

when the

above a selected

switch will interrupt the limit

circuit in the event the fuel oil temperature rises

above the selected point.

(16) In addition to the components

controller mentioned in Section

·

of

the fuel oil

H, the following

are used with a heavy oil fired burner.

(a)Fuel

temperature

Oil Thermometer: Indicates the

of

fuel oil being supplied to

the fuel oil controller.

(b)Back

ment

downstream

Also regulates the rate

Pressure· Valve:

of

the

oil

side

of

For

the adjust-

pressure

on

the

the metering valve.

of

return oil flow.

(d)Manual By-Pass Valve: Provided as a

saver

time

in establishing oil flow.

operi, it permits the circulation

through

During

a

closed.

(e)Orifice

may

the

supply

operation, this

Oil Control Valve:

be

opened prior to

and

return

valve

start·up

When

of

l-ines.

1IlJ.W.

The

valve

to aid in

oil

be

establishing fuel oil flow through the

controller. Prior

valve

~

to

the initial light off, this

be

closed. Its disc has an

orifice to permit a continuous circulation

of

hot fuel oil through the controller.

(17)

Air

valve

Purge Valve (Not Shown):

opens

simultaneously with the closing

The

solenoid

of

the oil solenoid valve at burner shutdown, allowing compressed air

nozzle and adjacent piping.

to purge oil from the burner

This

oil

is

burned by

the diminishing flame, which continues burning

for approximately 4 seconds after the oil solenoid

valve closes.

Air Purge Orifice Nozzle (Not Shown):

(18)

Limits purging air

to

the proper quantity for

expelling unburned oil at normal delivery rate.

(19)

Air

Purge

Shown): Filters the purging air

that

(20)

might

plug the air purge orifice nozzle.

Air

Purge

Orifice

Check

Nozzle

Filter·

of

any particles

Valve (Not Shown):

(Not

The

check valve prevents the fuel oil from entering

the atomizing air line.

Air

(21)

Purge

controls operation

Relay (Fig. 1-7):

of

the air purge valve.

When

energized,

(c)Oil Return Pressure Gauge: Indicates

on

the oil pressure

the return side

fuel oil controller.

750-150

of

the

CHAPTER 1-15

Page 28

CHAPTER I

J.

CONTROLS

COMBINATION

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

FOR

BURNERS

ONLY

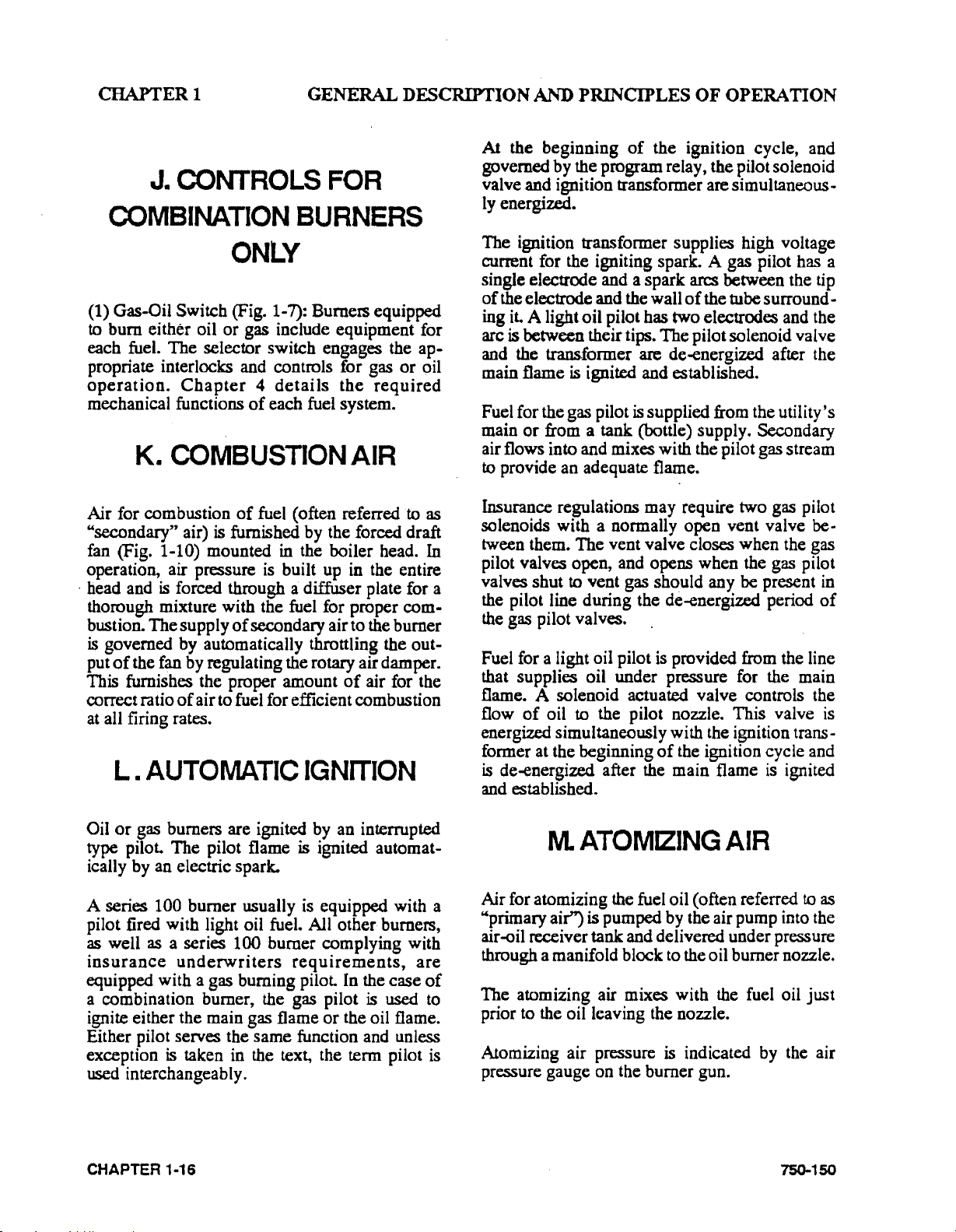

(1) Gas-Oil Switch (Fig. 1-7): Burners equipped

to

bum

either oil

~el..

each

propnate Interlocks and controls for gas

operation.

mechanical functions

The selector switch engages the ap-

K.

COMBUSTION

or

gas include equipment for

Chapter 4 details

of

each fuel system.

the

AIR

or

oil

required

At

the beginning

governed by the program relay, the pilot solenoid

valve and ignition transformer are

ly

energized.

The ignition transformer supplies high voltage

current for the igniting spark. A gas pilot has a

single electrode and a spark arcs between the tip

of

the electrode and the wall

ing

it..

A light oil pilot has two electrodes and the

arc

is between their tips. The pilot solenoid valve

and the transformer are de-energized after the

main flame

Fuel for the gas pilot

~ain

or

a1r

flows

to provide an adequate flame.

is

~om a ta~

10to

of

the ignition cycle, and

simultaneous-

of

the tube surround-

ignited and established.

is

supplied from the utility's

and

(bott~e)

m1xes

supply. Secondary

w1th

the pilot gas stream

Air for combustion

"secondary" air)

fan (Fig.

operation, air pressure

· head and

thorough mixture with the fuel for proper

bustion. The supply

is

governed by automatically throttling the out-

put

of

This furnishes the proper amount

correct ratio

at all firing rates.

L.

Oil

type

ically by an electric spark.

A series

pilot fired with light oil fuel. All

as

well

insurance

equipped with a gas burning pilot. In the case

a combination burner, the gas pilot

ignite either the main gas flame

Either pilot serves the same function and unless

exception

used interchangeably.

1-1 0) mounted in the boiler head. In

is

forced through a diffuser plate for a

the fan by regulating the rotary air damper.

of

AUTOMATIC

or

gas burners are ignited by an interrupted

pilot..

The pilot flame is ignited automat-

100 burner usually

as

a series 100 burner complying with

underwriters

is

taken

of

fuel (often referred to

is

furnished by the forced draft

is

built up

of

secondary air to the burner

air to fuel for efficient combustion

in

the entire

of

air for the

com-

IGNITION

is

equipped with a

other

burners,

requirements,

is

used

or

the oil flame.

in

the text, the term pilot

as

are

of

to

is

Insurance regulations may require two gas pilot

is

ignited

to

be-

in

of

is

as

solenoids with a normally open vent valve

~een

ptlot valves open, and opens when the gas pilot

valv~

the pilot hoe

the gas pilot valves.

Fuel for a light oil pilot

that supplies oil under pressure for the main

flame. A solenoid actuated valve controls the

flow

energized simultaneously with the ignition trans-

~ormer

IS

and established.

Air for atomizing the fuel oil (often referred

"primary

air-oil receiver tank and delivered under pressure

through a manifold block to the oil burner nozzle.

The atomizing air mixes with the fuel oil just

prior to the oil leaving the nozzle.

Atomizing air pressure

pressure gauge on the burner gun.

them. The vent valve closes when the gas

sh~t

to

ve~t

gas should any be present

dunng

of

oil to the pilot nozzle. This valve

at the beginning

de-energized after the main flame

M

ATOMIZING

air") is pumped by the air pump into the

the de-energized period

is

provided from the line

of

the ignition cycle and

AIR

is

indicated by the air

CHAPTER 1-16

750-150

Page 29

CHAPTER!

GENERAL

DESCRIPTION

AND

PRINCIPLES

OF

OPERATION

NOTE:

PAESSUFE

FOR

HOT

FEFERTO

[FIGURE

OIL

SUPPLY

WATER

FIGURE

GAUGe

COMPONENTS

1·2

1-8/

OIL

STEAM

SOLENOIOV

HEATING

STEAM

PRESSUFE

OIL

INLET

FROM

GAUOE

~~=C~~l===~~aSTEAM

1..-'-_._-"""'"'"..,..,_

TANK

HEA

NOTE:

ASSEMBLY

AU

CONOENSA

TRAP

MUST

TO A SAFE

POINT

(STEAM)]

__

LOW

BOflERS

TE

BE

WASTED

STEAM

FEGULATOR

-i.-.f

__

PRESSURE

ONLY

FROM

STEAM

AND

OF

DISCHARGE.

PRESSURE

STEAM

SHUTOFF

VALVE

INLET

PIPED

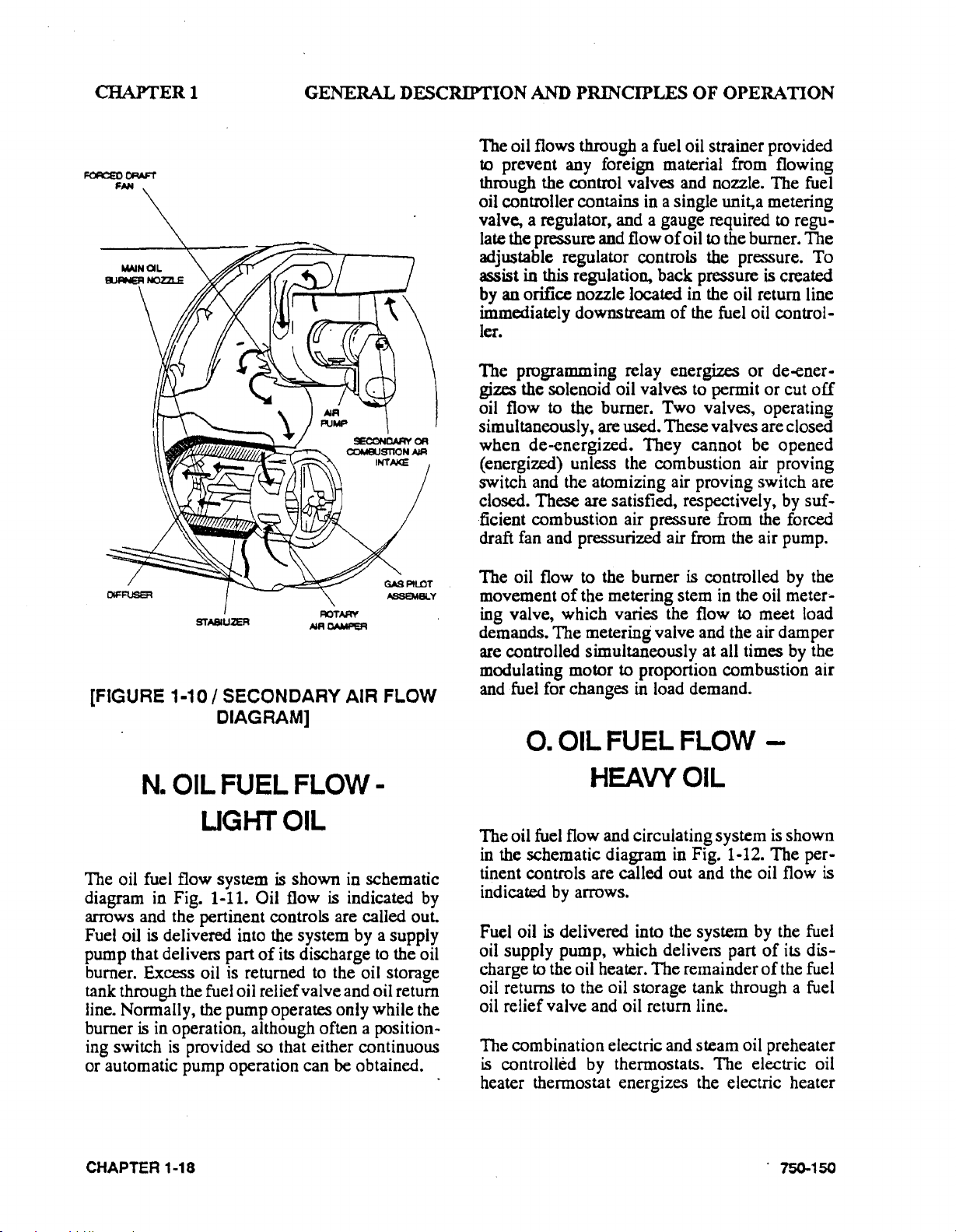

Air pressure from the pump also forces sufficient

oil from the tank

cate them and also

tion for the pump vanes.

delivered

to the tank contains some lube oil;

however, most

and filters

in the tank before the air passes

to

the pump bearings to lubri-

to

provide a seal and lubrica-

As a result, the air

of

it is recovered through baffles

to

the

burner.

Some

of

the primary air also is

oil pressure regulators

is

This

explained in Chapter 4.

of

used

to

assist the

the fuel oil controller.

SIJIIfii(.Jtf

F'RCII

a::lNS't'RUCTia.

[FIGURE

VALVE

ro

aUIU'IHC

1·9/

RECOMMENDED SAFETY

sro.M

~T

INSTALLATION PROCEDURE]

750-150

CHAPTER 1-17

Page 30

CHAPTER!

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

The oil flows through a fuel oil strainer provided

to

prevent any foreign material from flowing

through the control valves and nozzle. The fuel

oil controller contains in a single unit,a metering

to

is

created

regu-

valve, a regulator, and a gauge required

late the pressure and flow

adjustable regulator controls the pressure. To

in this regulation, back pressure

assist

by an orifice nozzle located in the oil return line

immediately downstream

ler.

of

oil to the burner. The

of

the fuel oil control-

[FIGURE

N.

1·1

0 I SECONDARY AIR FLOW

CIA

GRAM]

OIL FUEL

FLOW-

The programming relay energizes or

gizes the solenoid oil valves to permit or cut

oil flow to the burner. Two valves, operating

simultaneously, are used. These valves are closed

when de-energized. They cannot be opened

(energized) unless the combustion air proving

switch and the atomizing air proving switch are

closed.

·ficient combustion air pressure from the forced

draft fan and pressurized air from the air pump.

The oil flow

movement

ing valve, which varies the flow to meet load

demands. The metering valve and the air dam per

are controlled simultaneously at all times

modulating motor to proportion combustion air

and fuel for changes

These are satisfied, respectively,

to

the burner is controlled

of

the metering stem

in

load demand.

0.

OIL FUEL FLOW -

HEAVY

in

OIL

de-ener-

off

by

suf-

by

the

the oil meter•

by

the

UGI-ITOIL

The oil fuel flow system is shown in schematic

diagram in Fig. 1-11.

arrows and the pertinent controls are called out.

is

Fuel oil

pump that delivers part

burner. Excess oil

tank through the fuel oil relief valve and oil return

line. Normally, the pump operates only while the

burner

ing switch

or automatic pump operation can

CHAPTER 1-18

delivered into the system by a supply

is

in operation, although often a position-

is

provided so that either continuous

Oil flow is indicated by

of

its

discharge

is

returned

to

the oil storage

be

obtained.

to

the oil

The oil fuel flow and circulating system

in the schematic diagram in Fig. 1-12. The

tinent controls are called out and the oil flow

indicated

Fuel oil

oil supply pump, which delivers part

charge to the oil heater. The remainder

oil returns

oil relief valve and oil return line.

The combination electric and steam oil preheater

is

controlled by thermostats. The electric oil

heater thermostat energizes the electric heater

by

arrows.

is delivered into the system by the fuel

to

the oil storage tank through a fuel

is

shown

per-

of

its dis-

of

the fuel

. 750-150

is

Page 31

CHAPTER!

~A

oo---

STRAINER

swiNo

CHECK

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

·

NOZZL.E

PRESSURE

VAlVE

AIR

GAUGE

LUBE

OIL

STRAINER

ATOMIZING

PROVING

SWITCH

AIR

ATOMIZING

FEED

CONTROLLER

OIL

METERING

VAlV

~OIL

0

~=================='

MODULATING

CAM

0 D

BACK

FUEL

AIR

PRESSURE

CONTROl

OIL

TUBING

0

750

..

150

OIL

RETURN

PRESSURE

ORIFICE

==========================~~~~~

PRIMING

TEE

VACUUM

GAUGE

NOT

SUPPUED

CLEAVER-BROOKS

BY

SHUTOFF

VALVE

FUEL

OIL

STRAINER

BACK

rl~====~~

FUEL

SUPPLY

C'

01

PUMP

(FIGURE 1·11 I SCHEMATIC DIAGRAM FOR LIGHT OIL FLOW]

0

......_.....

CHAPTER 1-19

Page 32

CHAPTER!

STRAINER

@II

NOTE: DIAGRAM SHOWS COMPO·

NENTS USED WITH STEAM

ATO~S.

FOR CORRESPONDING

HEATING COMPONENTS.

WBE

OIL

~EFE~

SWING

CHECK

£=.=:=:::l

wee

OIL

8;;;::£D

TO

FIGU~E

GENERAL DESCRIPTION AND PRINCIPLES OF OPERATION

VN..VE

ATOIIMZING

0

AIR

PURGE

ORIFlCE

NOZZLE

I

AIR

c:::::====l

ou

LOWOIL

TEMPERATURE

SWITCH

D

[3

GENEA-

1·2

HOT WATER

OIL

~FE

OIL

HEATER

(B..ECTRq'

•

THESE

fiFIESSURE

SUPA. Y

CXLHEATER

THe:IMOSTAT

ll"E1o6

OIL

HEA

113=1

THEMOSTAT

(S...ECTRiq

OILHEATCR

.

SH8.J..

(STEAM)

ARE

USED

GENERATOFB

ON

ONLY

OIL

VN..VE

HIGH

REUEF

NOTE: CONCENSA TE FROM STEAM

MUST BE WASTED ANC PIPED

TFIAP

TO A

SAFE POINT OF DISCHARGE.

VACUUM

GAUGE

SHUTOFF

VN..VE

CHAPTER 1

[FIGURE

~20

1-12/

SCHEMATIC DIAGRAM FOR

(STEAM-ELECTRIC HEATER))

NO.6

HEAVY OIL FLOW

750-150

Page 33

CHAPTER!

that

is

provided to supply heated oil on cold

starts. The steam heater thermostat controls the

operation

flow

able.

A hot water boiler

hot water from the boiler unless other pre-heating

equipment

is

housed separate! y, is sized to provide heated

oil on a cold start. The hot water thermostat

controls the operation

water

able.

The heated oil flows through a fuel oil strainer to