Cleaveland Controls RFS-4150 Quick Start Manual

·Cleveland Controls

Model·

Di-".ision~of

AIR PRESSURE SENSING SWITCH WITH ADJUSTABLE SET POINT

APPLICATION

Model RFS-4150 is a general purpose prov-

ing switch designed for HVAC and Energy

Management -applicatipns. This switch can

be used to sense positive, negative,

ferential air pressure.

GENERAL DESCRIPTION &

OPERATION

The

calibration spring, and a snap-acting switch.

The sample line connections located on

each side

and

connections are available.

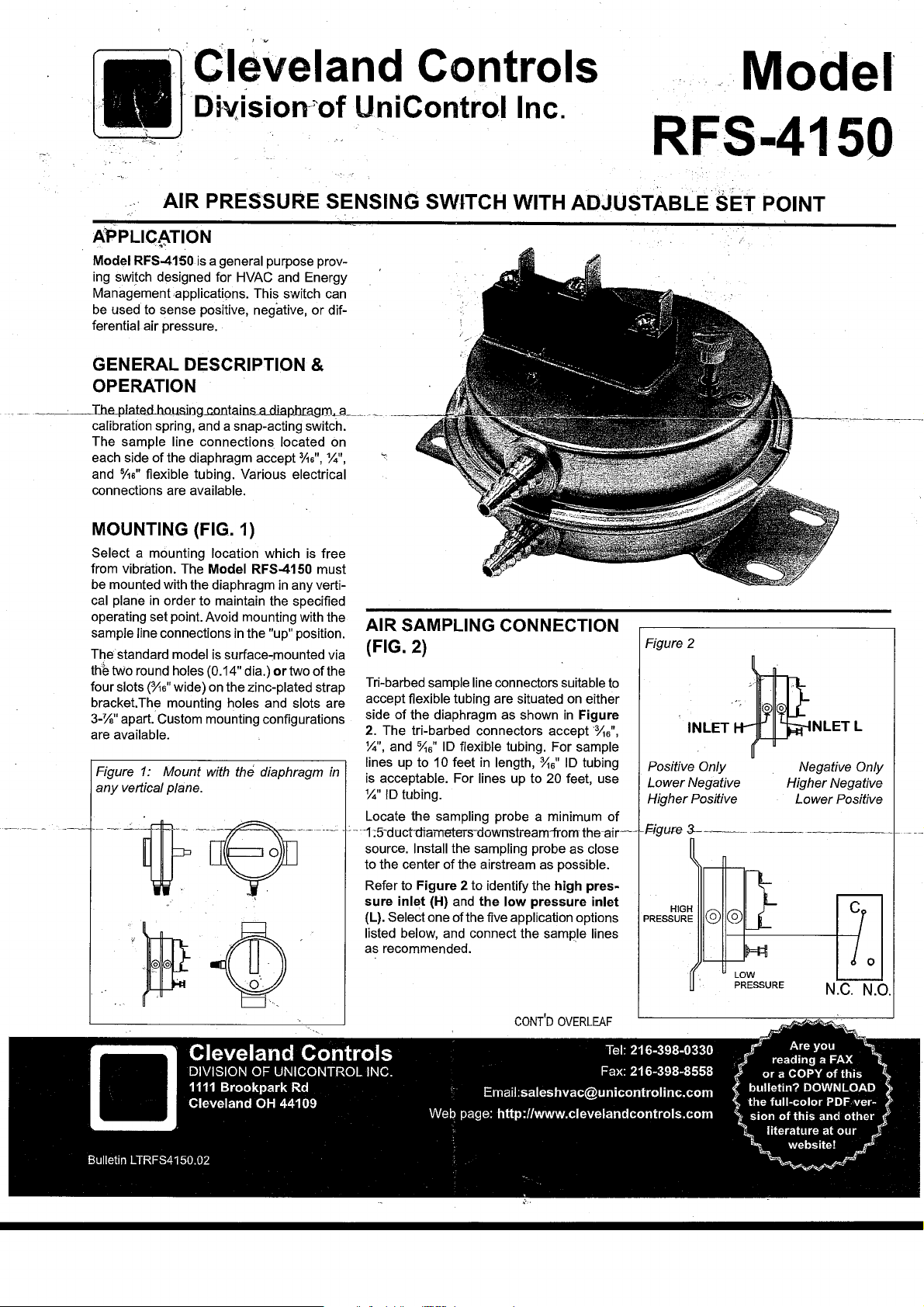

MOUNTING {FIG. 1)

Select a mounting location which is free

from vibration. The Model RFS-4150 must

be mounted with the diaphragm

cal plane

operating set point. Avoid mounting with the

sample line connections

The standard model

th~

four slots

bracket.The mounting holes and slots are

3-Va"

are available.

Figure

any

-

•'

or

plated

hotJsiog_contains_a__dlapbLagm~<L~

of

the diaphragm accept

7'\s"

flexible tubing. Various electrical

in

order to maintain the specified

in

the "up" position.

is

surface~mounted

two round holes (0.14" dia.) or two

(o/is"

wide) on the zinc-plated strap

apart. Custom mounting configurations

1:

Mount with the diaphragm

vertical plane.

o/is",

in

any verti-

-~,-~

·~

\1)

UniControl Inc.

dif-

__

-------,

W',

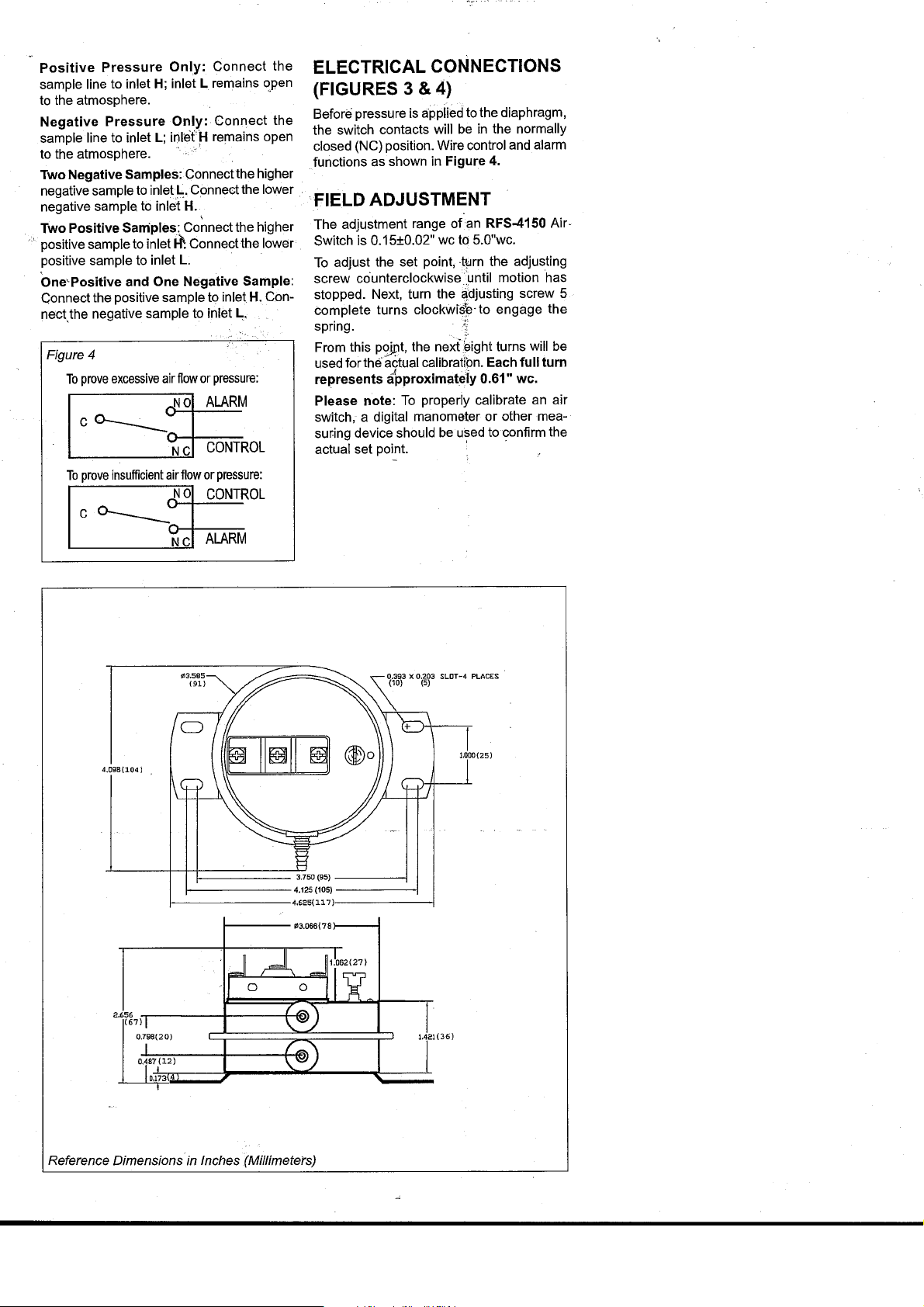

AIR SAMPLING CONNECTION

{FIG. 2)

via

of

the

Tri-barbed sample line connectors suitable

accept flexible tubing are situated on either

side

of

the diaphragm as shown

2.

The tri-barbed connectors accept

Y..",

and

o/;s"

ID

flexible tubing. For sample

lines up to 10 feet

in

is

acceptable. For lines up to 20 feet, use

Y.."

ID tubing.

Locate the sampling probe a minimum

--

-1;5-ductl:liameters-downstreamiromth.::.-.:H.·--+t=lctu.r:e

source. Install the sampling probe as close

to the center

Refer to Figure 2 to identify the high pres-

sure inlet (H)

(L).

Select one of the five application options

listed below, and connect the sample lines

as recommended.

of

the airstream as possible.

and

to

in

Figure

·o/is",

in

length,

11s"

ID

tubing

of

the low pressure inlet

RFS-4150

Figure 2

INLET

Positive Only

Lower Negative

Higher Positive

~---

HIGH

PRESSURE

---

LOW

PRESSURE

NLETL

Negative Only

Higher Negative

Lower Positive

------+

N.C.

/

0

N.O.

Positive

sample line to inlet

to the atmosphere. ·

Negative

sample line to inlet

to the atmosphere. · ·

Two Negative Samples: Connect the higher

negative sample

negative sample to inlet'

Two Positive Samples: Connect the higher

' positive sample to inlet

positive sample to inlet

\

One·Positive and One Negative Sample:

Connect the positive sample to inlet

nect, the negative sample to inlet

Figure 4

Pressure

Pressure

To

prove

excessive

c

e-_____-

~--------~~N~~c+-C-0-N-TROL

To

prove

insufficient

c

0--___:__""

~--------~N~C

Only:

Connect

H;

inlet L remains open

Only:

Connect

L;

inlefH

remains open

to

inlet L. Connect the lower

H.

\

~

Connect the lower

L.

H.

L,.

air

flow

or

pressure:

...,.NO

ALARM

air

flow

or

pressure:

JlO

CONTROL

.......

Q--1----

ALARM

the

the

Con-

ELECTRICAL CONNECTIONS

(FIGURES 3 &

Before pressure is applied to the diaphragm,

the switch contacts will be in the normally

closed (NC) position. Wire control and alarm

as

functions

shown

4}

in

Figure 4.

FIELD ADJUSTMENT

The adjustment range

Switch is 0.15±0.02" we to 5.0"wc.

To

adjust the set point,

screw

counterclockwise .until motion

stopped. Next, turn the adjusting screw 5

complete turns clockwis'll· to

spring.

From this

used forthei actual calibratibn.

represents

Please note:

switch, a digital manometer

suring device should be used to confirm the

actual set point. ' ·

p~t,

a~proximate'iy

To

of

an RFS-4150 Air-

t~rn

the adjusting

has

engage

;•

the next eight turns will be

Each full turn

0.61" we.

properly calibrate an air

or

the

other mea-

4.098(104)

1-----

Reference Dimensions in Inches (Millimeters)

.3.066(78)----1

Loading...

Loading...