ClearWater M-15/O2, P-20/O2, CD15/O2, CD20/O2 Installation & Maintenance Manual

Ozone Systems

Installation & Maintenance Manual

M-15/O2, P-20/O2

CD15/O2, CD20/O2

Corona Discharge Ozone Generator

850-E Capitolio Way, San Luis Obispo, Ca 93401 • 805-549-9724 • Fax: 805-549-0306 • E-mail: service@cwtozone.com • www.cwtozone.com

Copyright © 2006 - ClearWater Tech, LLC. • Reproduction of any kind is prohibited • LIT554 • REV012306

ClearWater Tech, LLC.

Integrated Ozone Systems

O

3

Introduction ............................................................................................................................

This Installation and Operation Man u al is

written to assist in the in stal la tion, operation

and main te nance of ozone delivery sys tems

man u fac tured by Clear Wa ter Tech, LLC. The

equip ment has been de signed using the most

mod ern ma te ri als and tech nol o gy available.

Please read this manual care ful ly and in its

entirety before pro ceed ing with any in stal -

la tion, op er a tion or main te nance pro ce dure

associated with this equip ment. Failure to

follow these instructions could result in

personal injury, damage to the equip ment or

reduced product performance.

In an ongoing effort to improve reliability

and operating ef fi cien cy, Clear Wa ter Tech

may fi nd it nec es sary to make chang es to its

prod ucts. Therefore, the in for ma tion con tained

in this man u al may not con form in ev ery

respect to earlier ver sions of ClearWaterTech

ozone systems found in the fi eld. If you have

any ques tions, please con tact your ClearWater

Tech deal er or the Clear Wa ter Tech ser vice

department.

1

OVERVIEW

How Ozone is Generated

Oxygen (O2)

Ozone (O3)

Ozone is generated by exposing oxygen molecules (O2)

in an air stream to a controlled, high energy electrical

field. As the air stream passes through the electri-

al field produced inside the ozone generator, some

c

oxygen molecules are split, forming single oxygen

atoms (O

other O

(O

3

). These oxygen atoms then recombine with

1

molecules in the air stream, forming ozone

2

).

Electrical Field

O

2

O

2

O1

O1

Properties of Ozone

Ozone is the most powerful oxidizer available that can be safely used in water treatment.1 It is used to treat drinking water, bottled water, swimming pool water, wastewater, food and beverage processing water, and in many other

applications. Ozone is effective in performing the following water treatment functions:

• Disinfection – Bacterial disinfection, inactivation

of viruses and cysts.

Molecular weight: 48

• Oxidation of Inorganics – Precipitates iron,

manganese, sulfides, nitrites and organically-bound

heavy metals.

• Oxidation of Organics – Including organics

causing color, taste and odor problems, some

detergents and pesticides, phenols, VOCs, turbidity

control and microflocculation of soluble organics.

Gas Density:

soluble than oxygen (at 68°F).

Odor:

Color:

Solubility:

Readily detectable at concentrations above 0.02 ppm in air

Bluish in ozone generator cell, but ozone/air mixture exiting

generator is invisible – even at high ozone concentrations.

2.144 grams/liter at 32°F (approx. 150% that of oxygen).

Only partially soluble in water, but about 10-20 times more

O

3

O

3

Benefits of Ozone Use

• Ozone is generated on site – no transportation or storage is required.

• The most powerful oxidizer commercially available – very effective for

disinfection and oxidation without handling problems.

• Ozone creates no potentially harmful by-products (such as THMs) – the only

by-product is oxygen.

• Ozone leaves no telltale taste or odor.

References

1. Water Quality Association, “Ozone for POU, POE and Small Water System Water Treatment Applications,” Lisle, IL, 1999.

2

SAFETY INFORMATION

SAFETY WARNINGS

Two aspects of ClearWater Tech ozone generators represent potential dangers – ozone gas and high voltage electricity.

OZONE GAS - WARNING: HIGH CONCENTRATIONS OF OZONE GAS ARE DANGEROUS

TO HUMANS. LOW CONCENTRATIONS CAN CAUSE IRRITATION TO

THE EYES, THROAT AND RESPIRATORY SYSTEM.

ClearW

are designed to operate under a vacuum condition.

While this would normally prevent ozone gas from

escaping into the atmosphere, entering the equip-

m

Ozone has a very distinctive odor and is detectable

at very low concentrations (0.02 ppm), which is far

below OSHA’s maximum permissible exposure level

of 0.1 ppm.

ater Tech corona discharge ozone generators

ent area should be avoided if ozone gas is detected.

CAUTION!

OZONE

GAS

HIGH VOLTAGE - WARNING: CLEARWATER TECH OZONE GENERATORS OPERATE

AT HIGH VOLTAGES. DO NOT TAMPER WITH OR DELIBERATELY

BYPASS THE DOOR OR SAFETY SWITCHES BUILT INTO THE

OZONE GENERATOR UNLESS INSTRUCTED TO DO SO BY THIS

MANUAL. IF CONTACT IS MADE WITH OPERATING HIGH

VOLTAGE COMPONENTS, ELECTRIC SHOCK WILL OCCUR.

ClearWater Tech corona discharge ozone generators take line voltage and convert it to 48 VDC. A transformer then

takes that current and boosts the voltage. While each ozone generator has a door switch and other safety interlocks,

proper care must be used by a qualified electrician when making any internal adjustments or performing any

maintenance procedures.

3

IMPORTANT SAFETY INSTRUCTIONS - When installing and using this

electrical equipment, basic safety precautions should always be followed, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

1.

2. SAVE THESE INSTRUCTIONS.

3. All electrical connections should be made by a licensed, qualified electrician.

4. Before attempting any electrical connections, be sure all power is off at the main circuit breaker.

5. Install all electrical equipment at least five feet from any open body of water using non-metallic plumbing.

6. Install check valves and a vacuum break to prevent water from contacting the electrical equipment.

7. The electrical supply for this product must include a suitably-rated switch or circuit breaker to open all

70-1987. The disconnecting means must be readily accessible to the operator(s) but installed at least five

feet from any open body of water.

8. Be sure to bond (ground) the system using the copper bonding lug on the bottom of the ozone generator. The

ungrounded supply conductors to comply with Section 422-20 of the National Electrical Code, ANSI/NFPA

system should be bonded with solid copper wire conforming with all local, state and national electrical codes.

9. The system should be sized appropriately for its intended use by a qualified professional familiar with the

application. This equipment must be validated by the manufacturer for its intended use.

4

CORONA DISCHARGE (CD) OZONE SYSTEMS

Ozone is manufactured in the CD ozone generator by drawing in air, which is composed of 20% oxygen (O2), and exposing

it to multiple high voltage electrical discharges. This causes a percentage of the oxygen molecules to dissociate and reassemble as ozone (O3). The ozone is drawn into the water by an injector/mixer, killing any bacteria, viruses or mold spores

it contacts. Ozone is generated on-site, eliminating the need to store toxic and corrosive chemicals. The corona discharge

method is the most efficient way to produce large amounts of ozone.

3 - O2 2 - O

Chemical Formula (simplified)

for Corona Discharge Ozone

In contrast to ultraviolet ozone generators, corona discharge systems produce a much higher concentration of ozone and

in much larger quantities. In addition, the annual expense of replacing lamps and checking ballasts is unnecessary with

corona discharge systems. Corona discharge ozone generation is the most economical and effective method to use on

most water treatment applications.

ClearWater Tech manufactures high output corona discharge systems capable of producing enough ozone to oxidize iron,

sulfide, manganese and act as an efficient sanitizer in a variety of applications. Ozone reacts to water-borne

contaminants significantly faster than other disinfectants and the primary by-product is pure oxygen.

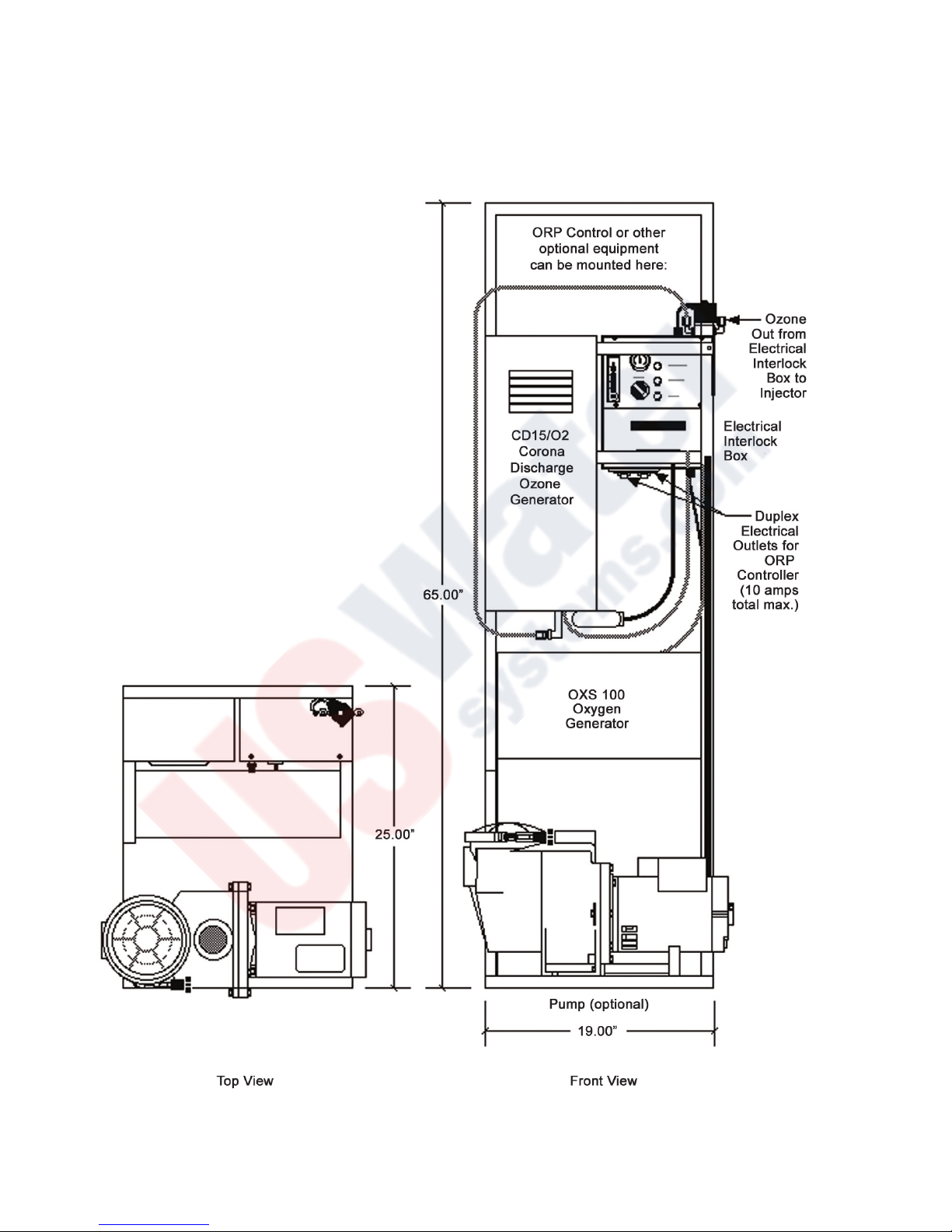

ClearWater Tech ozone systems are built with the finest components available. All are air cooled and are most efficient

when used with a venturi injection system to create the best possible contact and mixing of ozone while maintaining a

high level of safety. The CD15/O2 and CD20/O2 ozone generators have been tested and certified by the Water Quality

Association according to NSF/ANSI 50.

3

UNCRATING AND INSPECTION

Shipping Terms

Unless special arrangements have been made, the ozone equipment will be shipped FOB ClearWater Tech’s factory in

San Luis Obispo, CA. The freight charges will be prepaid and billed or shipped freight collect. Transfer of liability to the

freight company and the customer occurs as the equipment leaves the factory loading dock and is accepted by the freight

line.

Freight Inspection

All equipment should be thoroughly inspected immediately upon delivery. If any damage is noticed, promptly notify the

freight line and request an on-site inspection.

Unpacking

Typically, the equipment will arrive on a pallet. Compare the components with the packing list. Thoroughly inspect all

packing materials prior to discarding. Inspect all plumbing fittings and tubing for packing material inadvertently lodged in

any openings.

PRODUCT DESCRIPTION

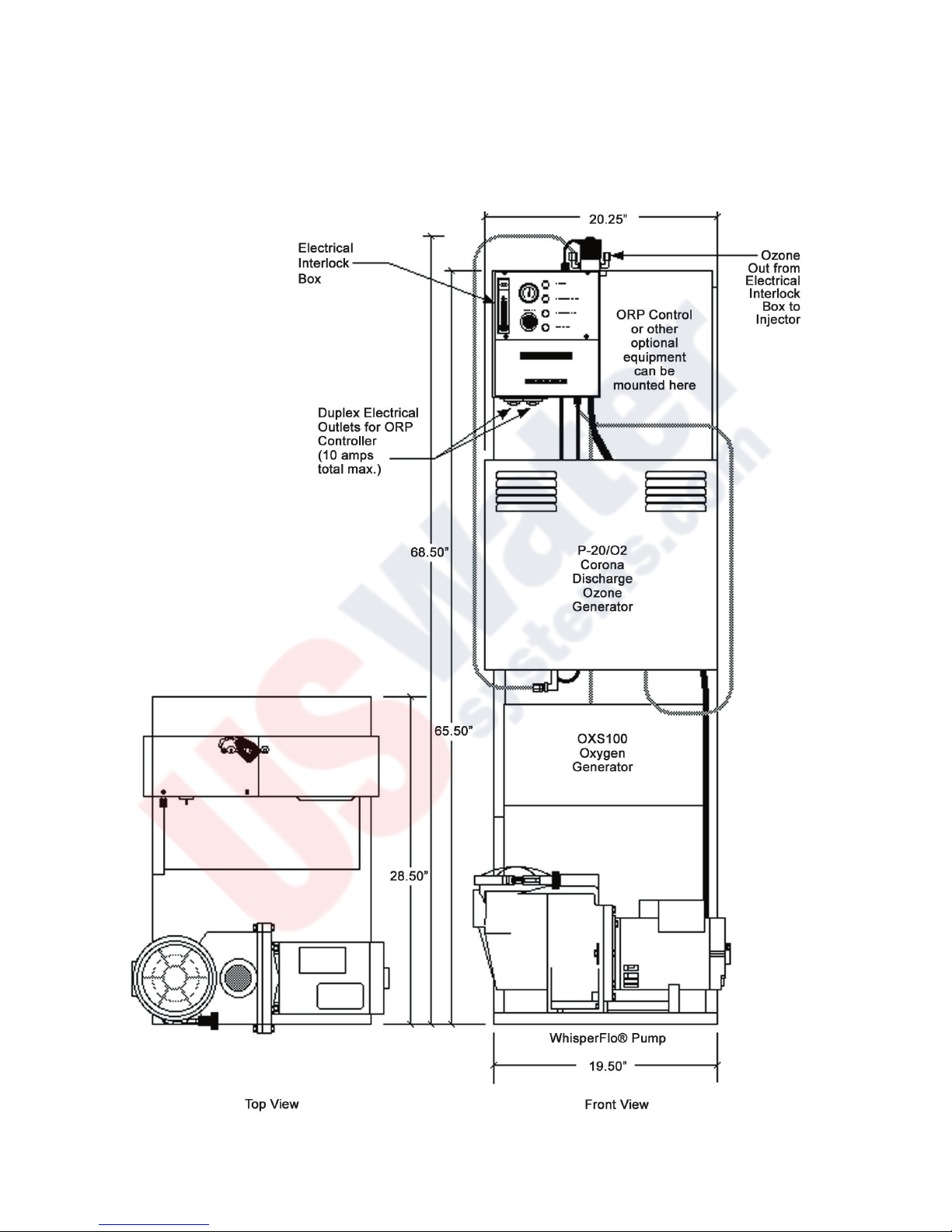

The complete systems are skid mounted and comprised of the ozone generator, air preparation system and an electrical

interlock box for the efficient production and control of ozone gas. The feed gas is approximately 55% dried oxygen at 20

standard cubic feet per hour (SCFH), supplied by the self-contained oxygen generator.

The ClearWater Tech System can be interlocked with an ORP controller, ozone monitor, booster pump or a variety of other

controls. The ozone generator will automatically shut down if the cooling system fails or if the vacuum to the unit is

interrupted.

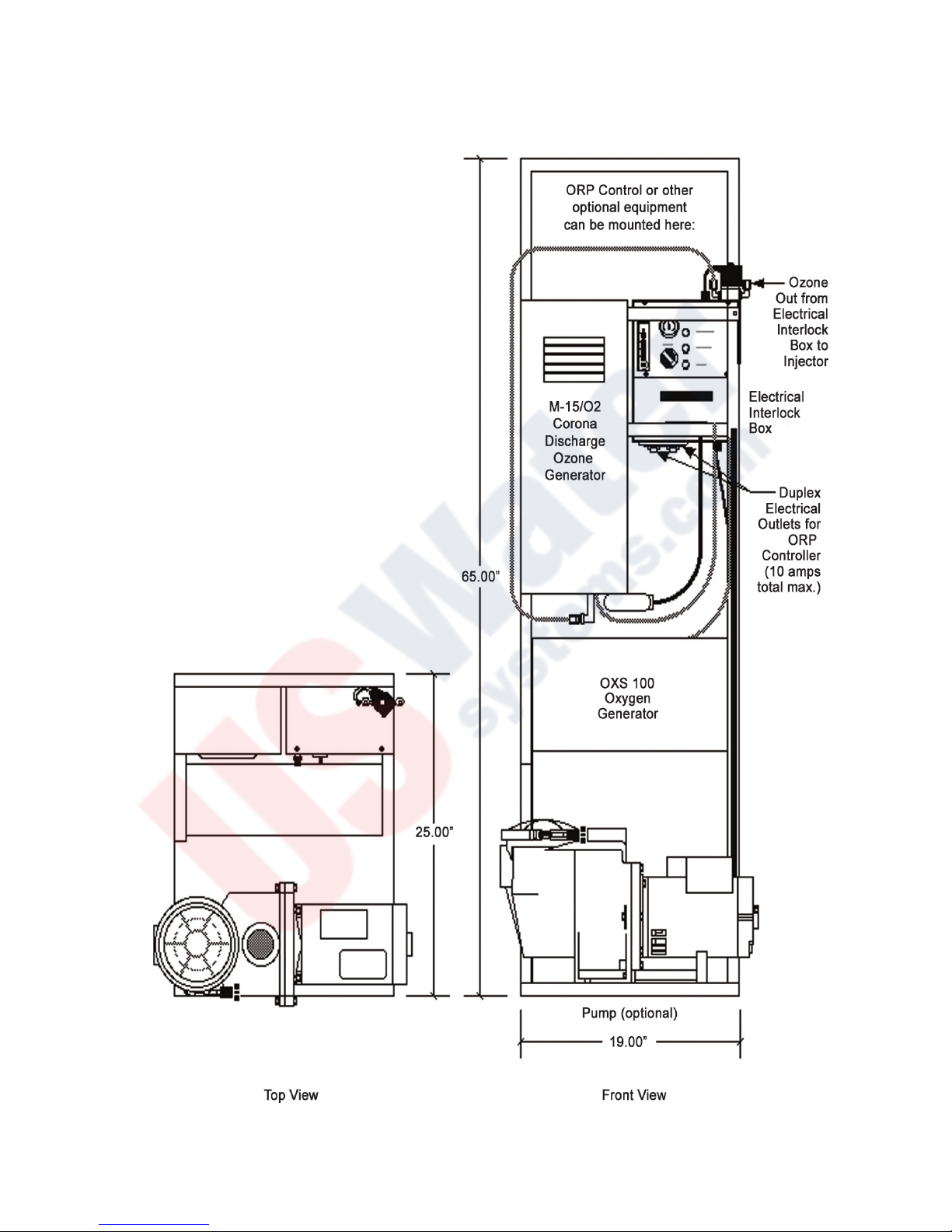

ClearWater Tech M-15/O2 & P-20/O2 corona discharge ozone systems consist of three main skid-mounted

components:

• Ozone Generator • Air Preparation Unit • Electrical Interlock Box

In addition to this basic unit, optional equipment includes:

• Ozone Injector Manifold • Contact Vessel(s) • Booster Pump • ORP Controller

5

Ozone Generator

The ozone generator houses the ozone reaction chamber(s), power supply and all electrical systems directly related to

the production of ozone. Ozone is produced when the feed gas is exposed to a high voltage electrical current inside the

reaction chamber.

Air Preparation

The ClearWater Tech ozone system is fed with oxygen enriched dry air. Corona discharge ozone generators are much

more effective, produce more ozone and require far less maintenance when the air preparation unit is included. The air

preparation system separates the majority of the nitrogen from the feed gas, creating oxygen enriched air while also lowering the dew point of the feed gas. Moist feed gas (air) will cause nitric acid to form inside the generator which decreases ozone production and if not removed, will cause corrosion and eventual failure of the generator’s internal components.

The ability of the ozone generator to produce ozone is drastically decreased when the dew point rises above -80°C.

Electrical Interlock Box

The electrical interlock box is a multifunction electrical enclosure. It houses the main terminal strip for the service disconnect, booster pump (or control switch), motor control interlock (MCI), ORP interlock (or optional ozone monitor interlock)

and the vacuum interlock. The enclosure also acts as the air preparation monitoring station, controlling the amount of

intake air and monitoring the vacuum.

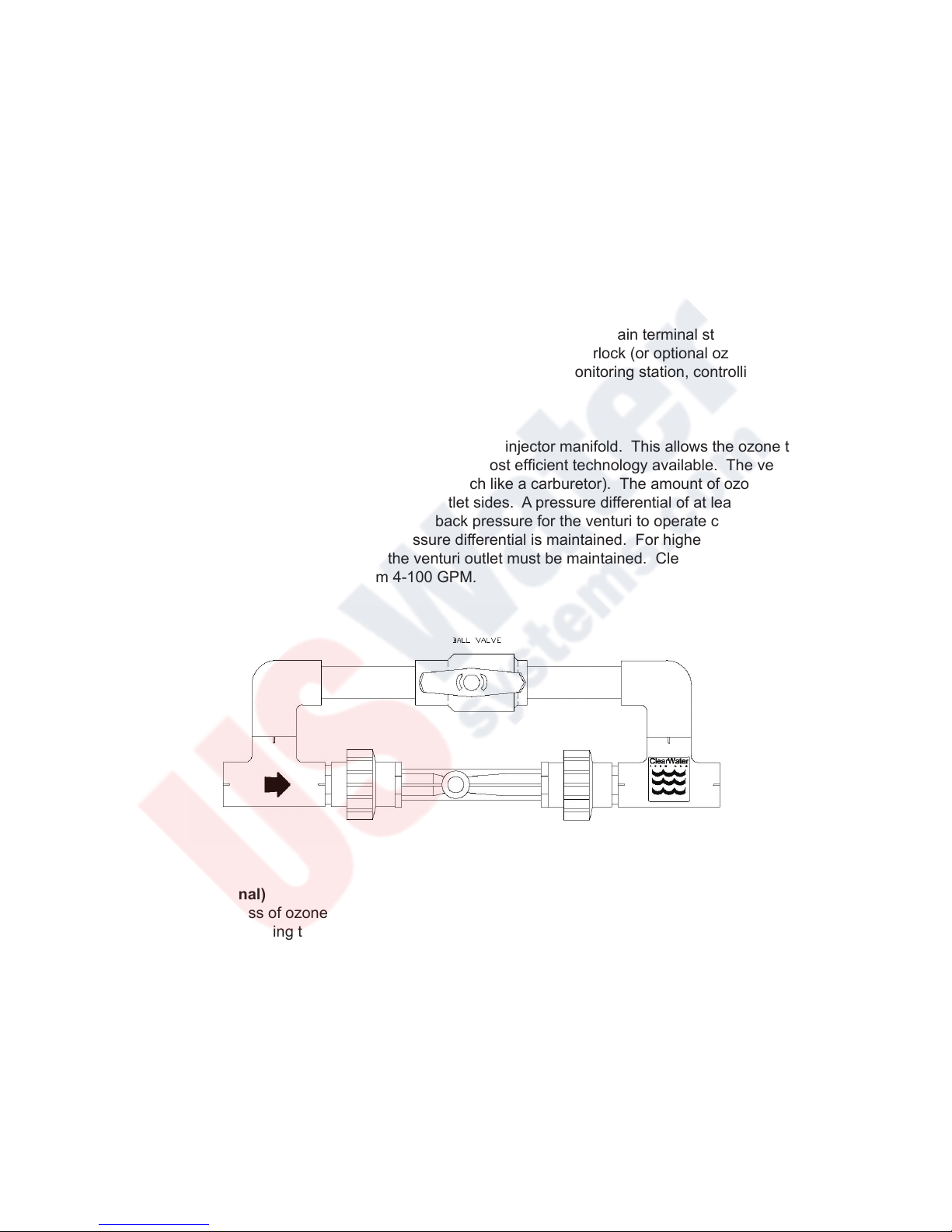

Injector Manifold (optional)

The ozone gas is drawn into the water line by means of a venturi injector manifold. This allows the ozone to be injected

into the water under a vacuum condition, which is the safest, most efficient technology available. The venturi utilized in

the injector manifold operates via a pressure differential (much like a carburetor). The amount of ozone drawn into it depends on the water flow and pressure on the inlet and outlet sides. A pressure differential of at least 25 psi must be maintained between the well (or booster pump) and system back pressure for the venturi to operate correctly. Proper function

of the venturi/ozone system will occur only if the pressure differential is maintained. For highest efficiency, at least 10” of

vacuum at the venturi suction port and 25 psi at the venturi outlet must be maintained. ClearWater Tech stocks a complete line of high-efficiency venturi injectors from 4-100 GPM.

Contacting Vessel (optional)

To maximize the effectiveness of ozone, it must be thoroughly mixed and have adequate time to react with the contaminants in the water before returning to usage or further processing. The contacting vessel is designed to achieve this

necessary mixing and contact time. A variety of contacting vessels are available for different applications from ClearWater

Tech.

Booster Pump (optional)

ClearWater Tech Model M-15/O2 and P-20/O2 ozone systems may include a booster pump. A variety of booster pumps

are available from ClearWater Tech to match different applications.

6

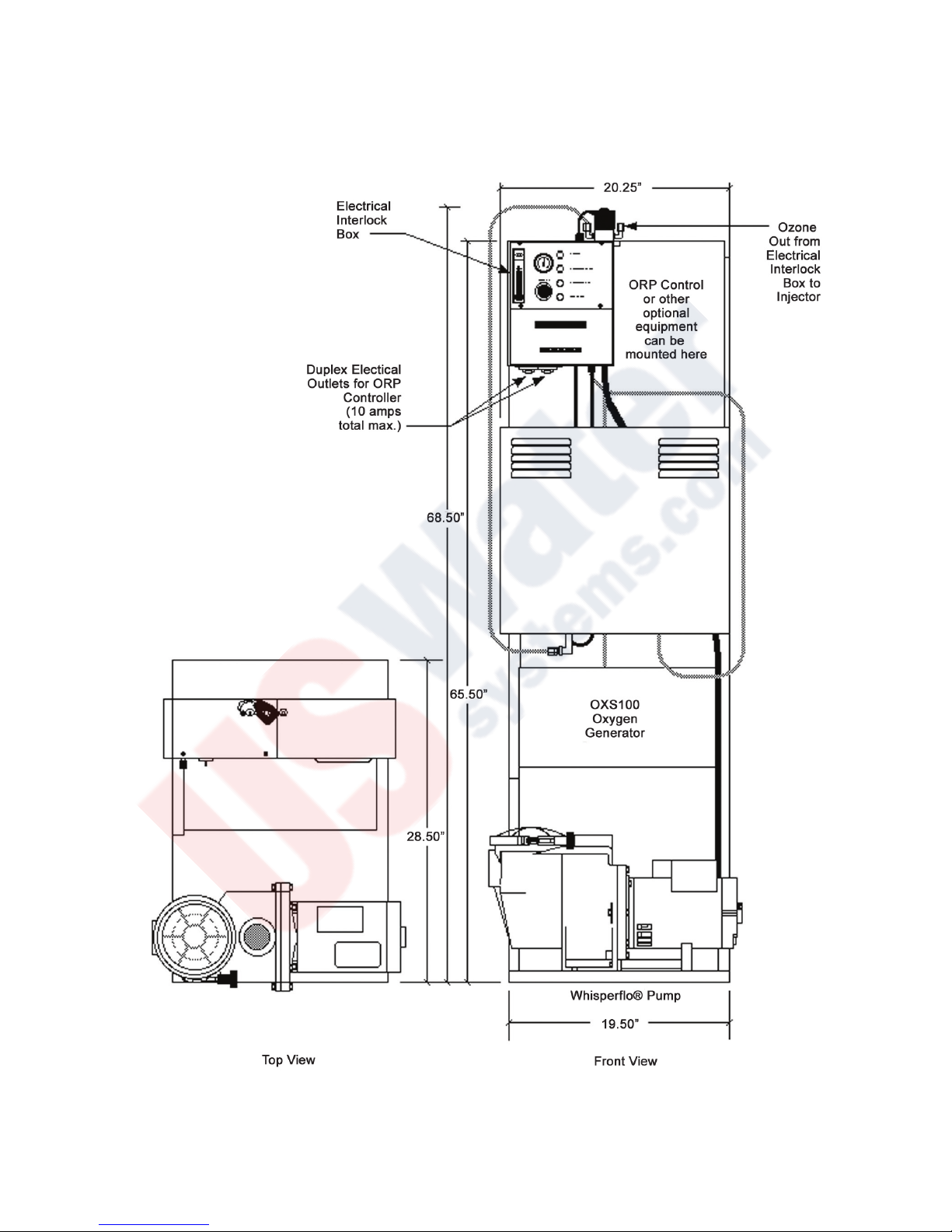

M-15/02 UNIT DIAGRAM

7

CD15/02 UNIT DIAGRAM

8

P-20/02 UNIT DIAGRAM

9

CD-20/02 UNIT DIAGRAM

10

Loading...

Loading...