ClearWater HDO3-I, HDO3-III, HDO3-II Installation & Operation Manual

Ozone Systems

Installation & Operation Manual

HDO3 Series

High Dissolved Ozone Generation System

ClearWater Tech, LLC.

Integrated Ozone Systems

850-E Capitolio Way, San Luis Obispo, Ca 93401 • 805-549-9724 • Fax: 805-549-0306 • E-mail: service@cwtozone.com • www.cwtozone.com

Copyright © 2005 - ClearWater Tech, LLC • Reproduction of any kind is prohibited • LIT210 • REV121605

1

THEORY OF OPERATION/PRODUCT DESCRIPTION CHAPTER 1

The HDO3 Series systems are a complete, advanced ozone delivery system and engineered to efficiently produce high

levels of dissolved ozone in water of municipal quality or better. The HDO3 system takes water from a clean water

source, re-pressurizes it, injects ozone to the water, then allows contact time under pressure to achieve maximum ozone

solubility. Equipped with an integrated dissolved ozone monitor/controller, this system can be regulated to achieve most

desired dissolved ozone levels required. Each complete, integrated system includes the components required for reliable,

efficient ozone production and can be divided into four general segments:

• Air Preparation System • Ozone Generator • Ozone Injection/Contacting • Control Panel

Air Preparation System

ClearWater Tech HDO3 Series ozone generators require a source of clean, dry, oil-free, oxygen-enriched air for effective

ozone production. To meet that need, the built-in air preparation system employs pressure swing adsorption (PSA)

technology with oil-less compressor to increase the concentration of oxygen and reduce the moisture content in the feed

gas (the air supplied to the ozone generator). This substantially improves the output capability of the ozone generator and

prevents premature failure of key internal components. These air preparation systems deliver 90%+/-3% oxygen purity at

-100°F dew point and at very low pneumatic pressures, minimizing noise and reducing compressor wear.

The air preparation system affects ozone production in grams per hour and more importantly ozone concentration, also

known as “percent by weight.” Since ozone is produced with oxygen, the greater the percent of oxygen that enters the

ozone generator will produce more grams per hour and concentration of ozone. Since the HDO3 Series ozone generation

systems incorporate PSA oxygen concentrator they will yield the highest grams per hour at the highest concentrations.

Greater ozone concentration equates to higher solubility of the ozone gas in solution, which will yield a greater dissolved

ozone level.

Ozone Generator

HDO3-I and HDO3-II - Only:

The ClearWater Tech HDO3-I is equipped with a CD12 ozone generator where as the HDO3-II is equipped with CD2000

ozone generator. The oxygen feed gas produced by the air preparation system is supplied to the ozone generator at a

maximum pressure of 5 pounds per square inch (psi). It then flows into the built-in air flow meter; at this point, the feed

gas is mostly drawn through the ozone generator by the vacuum created at the ozone injector - rather than by the pressure

from the air preparation system compressors. A stainless steel needle valve, located on the control panel of the HDO3-I

and HDO3-II, is used to maintain optimum pneumatic parameters inside the ozone reaction chambers. The ozone

generator is equipped with vacuum switch, which prevents ozone production if vacuum is lost within the ozone reaction

chambers.

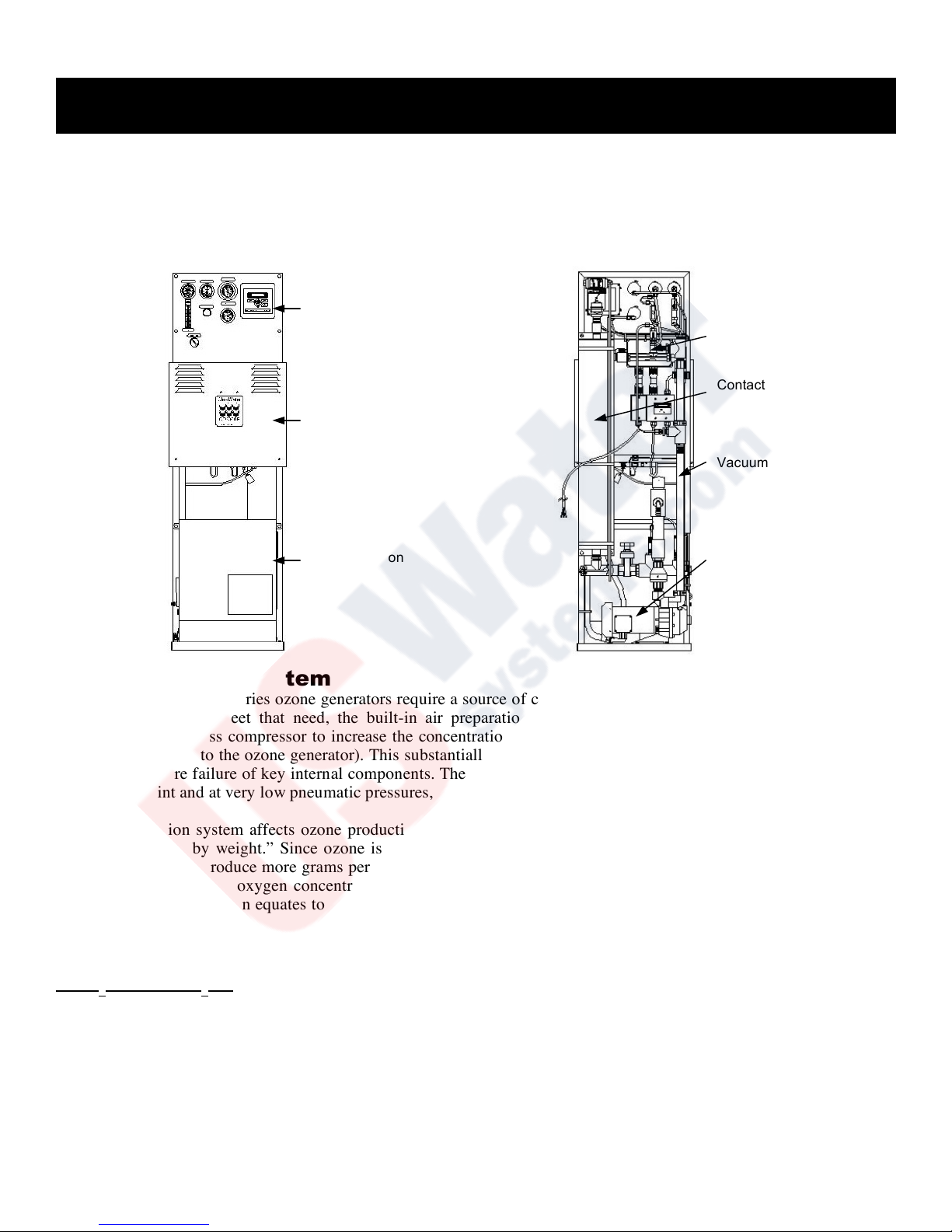

Control Panel

Ozone Generator

Air Preparation

Injector

Contact Tank

Vacuum Break

Booster Pump

Theory of Operation/Product Description (continued)

2

HDO3-III - Only:

The HDO3-III system is equipped with a ClearWater Tech CD2000P ozone generator designed to supply high

concentrations of ozone gas at 10 PSI. The oxygen feed gas produced by the air preparation system is supplied to the

ozone generator, which flows through the built-in flow meter. A stainless steel needle valve, located on the control panel

of the HDO3-III, is used to maintain optimum pneumatic parameters inside the ozone reaction chambers. After this point

the vacuum created at the ozone injector draws the ozone gas into the water line. The ozone generator is equipped with a

pressure switch, which prevents ozone production if pressure within the ozone reaction chambers drops below 9 PSI.

The feed gas of the HDO3 systems enters the fused, thermally-protected reaction chambers inside the ozone generator;

some of the oxygen molecules are split while passing through the high voltage electrical field (the “corona”), forming

single oxygen atoms (O 1). These oxygen atoms then recombine with other oxygen molecules in the air stream, forming

ozone.

Ozone Injection/Contacting

The ozone injector serves two purposes: One, it creates the vacuum

required to safely draw the ozone gas from the ozone generator and

two, it provides a means by which the ozone gas can become

dissolved in water. A very dynamic injection process is required to

effectively dissolve ozone in water.

ClearWater Tech HDO3 systems use only Mazzei® injectors for

maximum mass transfer efficiency. The injector produces a

cavitation effect, enabling the ozone gas to join the water stream in

the form of extremely tiny bubbles. These bubbles must be as

small as possible in order to increase the ratio of bubble surface

area to the amount of ozone entering the water.

Incorporated on the HDO3 systems is a stainless steel contacting vessel and auto vent to provide sufficient contacting of

the ozone gas with the water and off-gas any residual ozone. By design, the operating water pressures of this system and

the ClearWater Tech engineered contacting system allows for high levels of dissolved ozone to be maintained in the water

in this single pass configuration.

The HDO3 systems incorporate a water pressure relief valve and positive atmospheric vacuum break as standard safety

equipment to protect the system. This water-pressure relief valve is located downstream of the dissolved ozone sensor and

is set to relieve at 55 PSI. If excessive backpressure is applied to the system this relief valve will open protecting the

dissolved ozone sensor. The vacuum break is located on the backside of the HDO3 system and is a positive atmospheric

break between the ozone injector and ozone generator. If the ozone injector check valve were to fail water would flow

back to the vacuum break and out to drain instead of back to the ozone generator.

Control Panel

The HDO3 systems incorporate a user-friendly instrumentation control panel, which includes; ozone generator oxygen

flow meter, ozone generator vacuum or pressure gauge, injector vacuum gauge, high water pressure gauge, low water

pressure gauge, stainless steel injector vacuum control valve and a dissolved ozone parts per million (PPM)

monitor/controller. This dissolved ozone monitor/controller can be used to monitor the dissolved ozone level produced

and can be set up control the ozone generator output via a 4-20mA output signal, other alarm relays are also available on

the monitor/controller.

Ozone Destruct

The ClearWater Tech off-gas destruct systems (offered separately), consists of two components the ozone destruct unit (a

heated chamber filled with manganese dioxide and copper oxide) and a water trap. Used in conjunction with a ClearWater

Tech off-gas vent, the ozone destruct system is an effective way to vent the contact vessel when it is impractical to send

the off gas to atmosphere or reintroduce it to the water. See the “Ozone Off-Gas Destruct” manual for installation and

maintenance procedures.

3

SAFETY INFORMATION

CHAPTER 2

SAFETY WARNINGS

Two aspects of ClearWater Tech dissolved ozone systems represent potential dangers – ozone gas and high voltage

electricity.

OZONE GAS -

WARNING: HIGH CONCENTRATIONS OF OZONE GAS ARE DANGEROUS

TO HUMANS. LOW CONCENTRATIONS CAN CAUSE IRRITATION TO THE

EYES, THROAT AND RESPIRATORY SYSTEM. DO NOT TAMPER WITH

OR DELIBERATELY BYPASS THE SAFETY SWITCHES BUILT INTO THE

OZONE GENERATOR.

The Cl earWat er Tech HDO3 Seri es co rona

discharge ozon e systems are designed to operate under

a vacuum or pressure condition. While safety precautions

have been taken, entering the equipment area should be

avoided if ozone gas is detected. Ozone has a very

distinctive odor and is detectable at very low

concentrations (0.02 ppm), which is far below OSHA’s

maximum permissible exposure level of 0.1 ppm.

HIGH VOLTAGE -

WARNING: CLEARWATER TECH OZONE GENERATORS OPERATE

AT HIGH VOLTAGE. DO NOT TAMPER WITH OR DELIBERATELY

BYPASS THE COVER OR SAFETY SWITCHES BUILT INTO THE

OZONE GENERATOR UNLESS INSTRUCTED TO DO SO BY THIS

MANUAL. IF CONTACT IS MADE WITH OPERATING HIGH VOLTAGE

COMPONENTS, ELECTRIC SHOCK WILL OCCUR.

ClearWater Tech HDO3 Series systems operate with line voltage. The incorporated corona discharge ozone generators

take line voltage and convert it DC current. A high voltage transformer then boosts the voltage. While each ozone

generator has a cover safety switch and other safety interlocks, proper care must be used by a qualified electrician when

making any internal adjustments or performing any maintenance procedures.

4

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should always be followed, including the

following:

1.

READ AND FOLLOW ALL INSTRUCTIONS.

2.

SAVE THESE INSTRUCTIONS.

3.

All electrical connections should be made by a licensed, qualified electrician.

4.

Before attempting any electrical connections, be sure all power is off at the main circuit breaker.

5.

Install all electrical equipment at least five feet from any open body of water using non-metallic plumbing.

6.

Install check valves to prevent water from contacting the electrical equipment.

7.

The electrical supply for this product must include a suitably rated switch or circuit breaker to open all

ungrounded supply conductors to comply with Section 422-20 of the National Electrical Code, ANSI/NFPA

70-1987. The disconnecting means must be readily accessible to the operator(s) but installed at least five

feet from any open body of water.

8.

Be sure to bond (ground) the system using the copper-bonding lug on the bottom front panel of the Ae

system. The system should be bonded with solid copper wire conforming to all local, state and national

electrical codes.

9.

The system should be sized appropriately for its intended use by a qualified professional familiar with the

application. This equipment must be validated by the manufacturer for its intended use; failure to do so

may void the warranty.

5

INSTALLATION PROCEDURES -

Getting Started

CHAPTER 3

Unpacking

Compare the ozone system equipment received to the packing list provided. Before beginning any

installation procedures, thoroughly inspect all components for damage. If damage is noticed,

promptly notify the freight carrier and request an on-site inspection. Inspect all packing materials for

small parts before discarding. Inspect all plumbing, fittings and tubing for packing material that may

have become lodged in openings.

Equipment Placement

• When placing the ozone system on the equipment pad, make sure to consider safety, maintenance requirements,

local building and fire codes, etc. The components should be easily accessible by the operators, including

equipment access doors and electrical hook-up boxes. All meters, gauges, indicator lights and switches should be

visible and accessible. Dimensional drawings of the HDO3 Series systems are included in Section A of the

Appendix.

• Like any electronic component, performance and longevity is enhanced by favorable operating conditions. Also,

since the air preparation system and ozone generator is air-cooled, a relatively dust-free, well-ventilated area is

required. No caustic chemicals should be stored in the area surrounding the equipment. A minimum clearance of

six inches from the vents on either side of the ozone generator is required.

• The equipment is heavy and requires proper support. Therefore, a clean, dry, level surface should be provided for

the HDO3 Series systems.

• The HDO3 Series systems are designed for specific voltage requirements and to withstand typical outdoor

elements, though should not be subjected to outdoor extremes including contact with water and/or temperature

extremes. Therefore, the equipment must be installed in an environment consistent with the following operating

parameters:

• Ambient temperature range: 20°F to 95°F continuous. If the temperature around the equipment

consistently exceeds 95°F, additional air-cooling must be provided.

• Humidity: 0 - 90% relative humidity, non-condensing environment.

• Line voltage: +/-10% of rated input

Note: Equipment installed in extreme environmental conditions will void manufacturer's warranty.

Water Quality

• For anticipated results the HDO3 Series systems require a source of clean water and free of any contaminate load,

which may include but not limited to:

- Bacteria

- Viruses

- Algae

- Iron

- Manganese

- Chlorine

- Hydrogen Sulfide

- Nitrates

- Nitrites

- pH below 7.0 or above 7.5

- No particulate matter – Pre-filtration is required for

any water supply that has particulate mater.

6

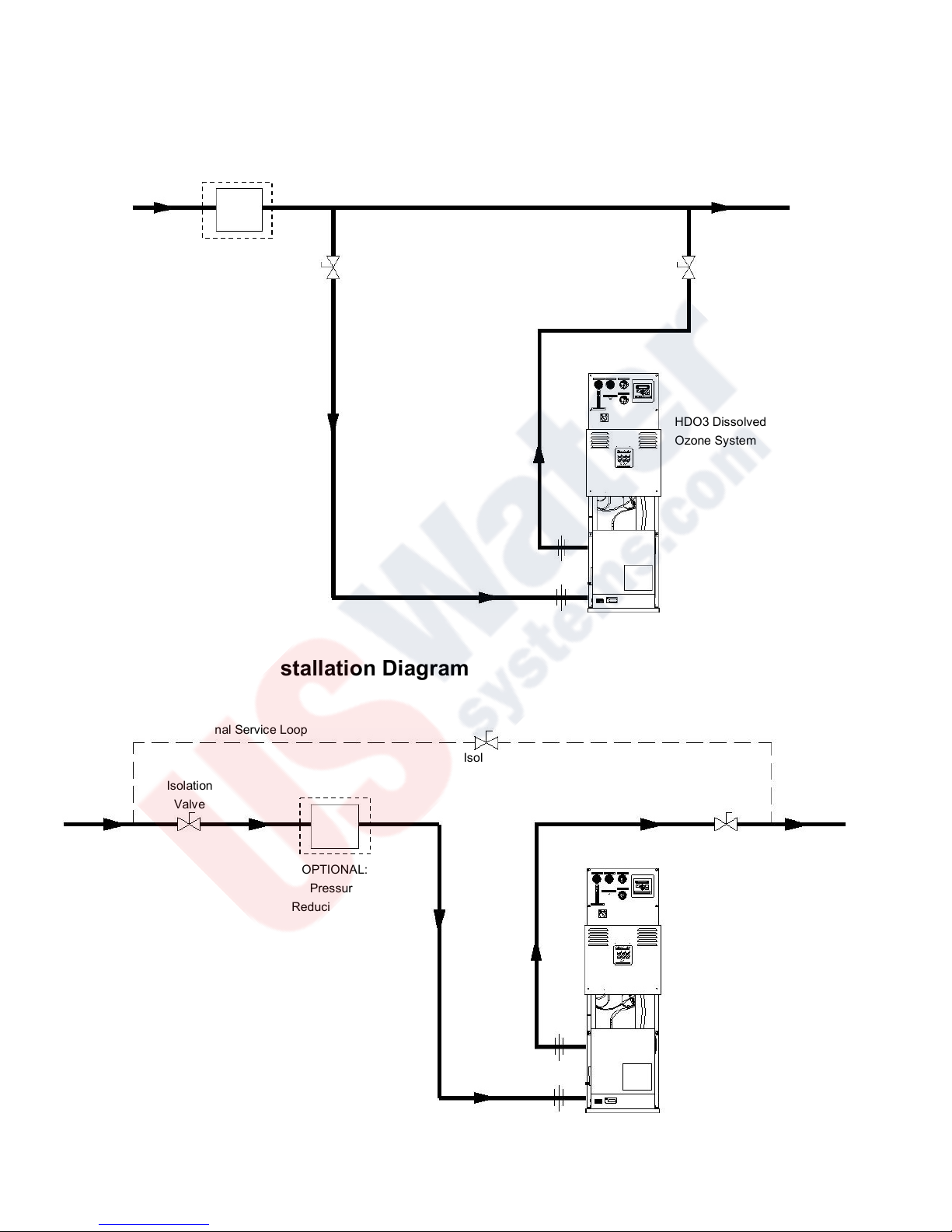

INSTALLATION PROCEDURES – Plumbing CHAPTER 4

The HDO3 system anticipated results are based on water quality and gallons per minute (GPM) flow rate

and water pressure. Based on desired dissolved ozone levels measured in parts per million (PPM), the

system should be plumbed using either a sidestream or full flow configuration, see Figure 4-1 for desired

ppm level at the suggested gpm flow rate. The sidestream method takes a portion of the water from the

main flow (see Figure 4-2) and diverts it into a sidestream through the HDO3 system, then returns the

water back into the full flow. In a full flow configuration, the water is simply plumbed into the HDO3 system, and then

out of the system to the point of use, see Figure 4-3. Note: The HDO3 Series systems have specific flow through rates

that must not be exceeded. If the full flow GPM flow rate exceeds the maximum flow through rate of the HDO3

system the sidestream configuration must be used, see Figure 4-1. Dissolved ozone levels may decline from the

anticipated result listed in Figure 4-1, if the system inlet water pressure is less than 20PSI.

NOTES:

• Adequate use of unions and isolation valves is

strongly recommended to facilitate maintenance

and repairs.

• Use Schedule 80 PVC for all plumbing connections

wherever possible. Plumbing size requirements

are dictated by the water flow characteristics of

the system.

• Make sure to use proper plumbing practices and

secure all plumbing and system equipment

according to local codes.

• Ozone is a powerful oxidizer and will degrade

certain materials. Use ozone-compatible

plumbing materials for section(s) of the system

that will come in contact with ozone dissolved in

water. The following is a list of materials that are

compatible with ozone:

• PVC • Stainless Steel (300 series)

• CPVC • Viton

• Kynar • EPDM

• Teflon • Concrete

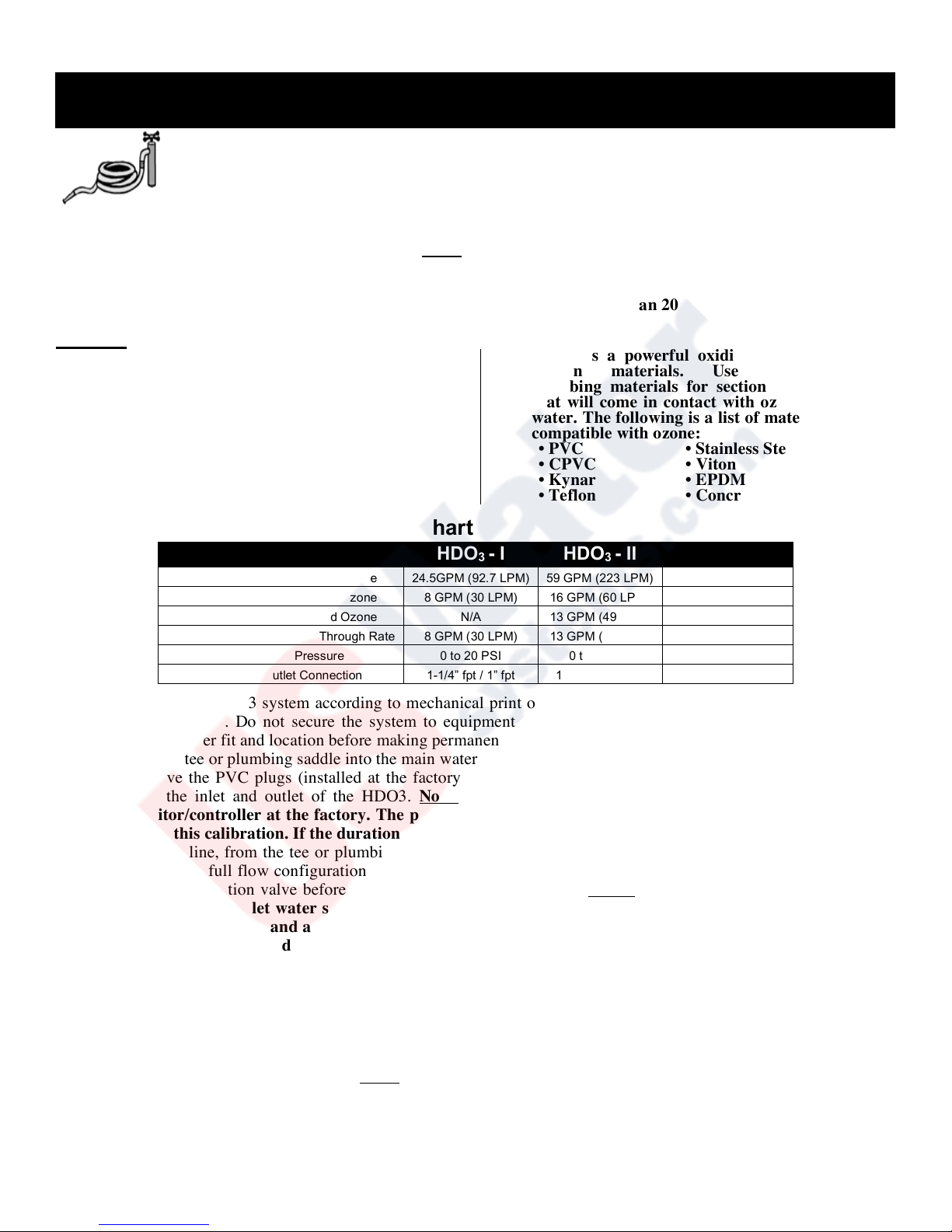

Hydraulic Specifications Chart Figure 4-1

HDO3 - I

HDO3 - II

HDO3 - III

GPM @ 1.0 PPM Dissolved Ozone

24.5GPM (92.7 LPM)

59 GPM (223 LPM)

150 GPM (568 LPM)

GPM @ 3.5 PPM Dissolved Ozone

8 GPM (30 LPM)

16 GPM (60 LPM)

50 GPM (189 LPM)

GPM @ 4.5 PPM Dissolved Ozone

N/A

13 GPM (49 LPM)

30 GPM (113 LPM)

Minimum & Maximum Flow Through Rate

8 GPM (30 LPM)

13 GPM (49 LPM)

13 GPM (49 LPM)

Min/Max Inlet Pressure

0 to 20 PSI

0 to 20 PSI

0 to 20 PSI

Water Inlet/Outlet Connection

1-1/4” fpt / 1” fpt

1-1/4” fpt / 1” fpt

1-1/4” fpt / 1” fpt

Step 1: Arrange the HDO3 system according to mechanical print or as dictated by equipment layout and serviceability

considerations. Do not secure the system to equipment pad at this point. Dry fit plumbing as appropriate to

insure proper fit and location before making permanent connections.

Step 2: Install a tee or plumbing saddle into the main water line for the sidestream configuration (see Figure 4-2).

Step 3: Remove the PVC plugs (installed at the factory to keep the dissolved ozone probe wet during transportation)

from the inlet and outlet of the HDO3. Note: The dissolved ozone probe is calibrated to the dissolved

monitor/controller at the factory. The probe must not be out of water for more than a 24-hour period to

retain this calibration. If the duration exceeds 24 hours re-calibration may be required.

Step 4: Plumb a line, from the tee or plumbing saddle for the sidestream configuration or from the main water supply

line for the full flow configuration, to the HDO3 booster pump. For serviceability of the equipment be sure to

install an isolation valve before the HDO3 system booster pump. Notes: A pressure reducing valve may be

required if the inlet water supply pressure is greater than 20PSI. The full flow configuration can also be

used to re-circulate and atmospheric vessel, although the HDO3 system must have a flooded suction to the

inlet of the integrated booster pump. If the HDO3 system operates with out water flow damage may

occur to the booster pump and warranty will be void.

Step 5: Using a tee or plumbing saddle, plumb from the outlet of the HDO3 back into the main water line for the

sidestream configuration or to the point of use for the full flow configuration. For serviceability of the

equipment be sure to install an isolation valve after the HDO3 system.

Step 6: Secure the HDO3 system to solid mounting surfaces using appropriate hardware and according to local codes.

Step 7: Depending on conditions, the vented gas from the contact tank off-gas vent may be directed to an ozone

destruct system or to atmosphere. Note: Do not direct the tubing to the suction side of a pump.

Step 8: The HDO3 system incorporates a water pressure relief valve (located on the water outlet line of the system) set

at 55 PSI, to protect the dissolved ozone probe. If the water pressure downstream of the probe reaches 55 PSI

the pressure relief valve will open. Plumb a line from the ½” fpt outlet port of the pressure relief valve to waste.

Plumbing (continued)

7

Sidestream Plumbing Installation Diagram

Figure 4-2

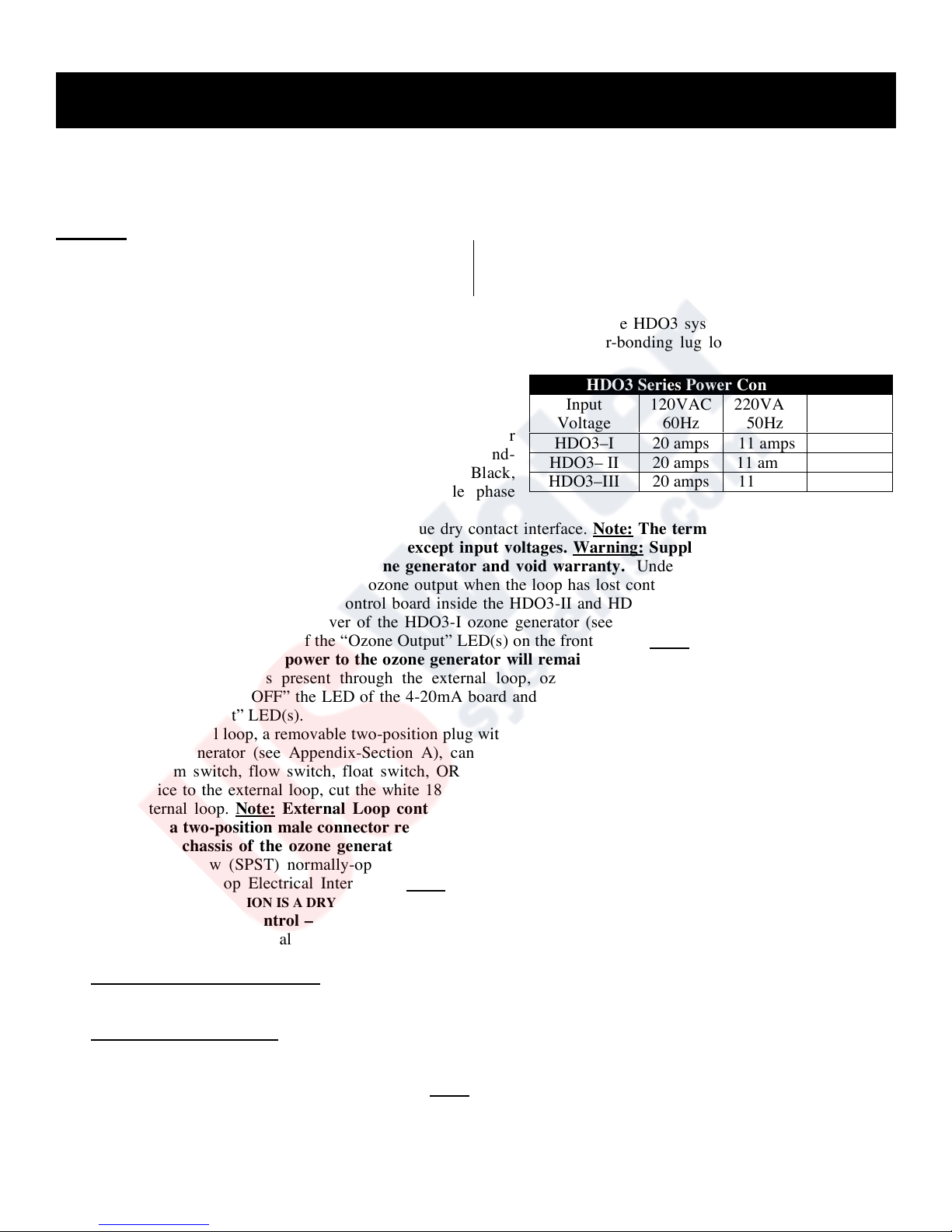

Full Flow Plumbing Installation Diagram

Figure 4-3

HDO3 Dissolved

Ozone System

OPTIONAL:

Pressure

Reducing Valve

Optional Service Loop

Isolation

Valve

Isolation

Valve

Isolation

Valve

Isolation

Valve

Main Water Line

Sidestream

Water Line

HDO3 Dissolved

Ozone System

Isolation

Valve

OPTIONAL:

Pressure

Reducing Valve

8

INSTALLATION PROCEDURES –

Electrical

CHAPTER 5

The HDO3 Series ozone generation systems are designed to be hard wired to the main power source with the specific

input voltage requirements. All possible pre-wiring has been completed at the factory. Logic schematics have been

provided in the Appendix - Section D.

NOTES:

• All electrical connections should be made by a

licensed, qualified electrician. All local, state and

national codes must be observed.

• Make sure all power is off at the main circuit

breaker before making any electrical connections.

Step 1: Conforming to all local, state and national electrical codes, ground the HDO3 system to a true earth ground.

Use solid copper bonding wire (usually #8 AWG) from the copper-bonding lug located on the base of the

HDO3 system.

Step 2: Main Power – The systems are equipped with a

12AWG 2-pole/3-wire cord 10 foot in length. Wire the

HDO3 system from the main power cord to the main

power source with specified input voltage, either

120VAC 60Hz (L1-Black, Neutral-White and Ground-

Green), 220VAC 50Hz or 220VAC 60Hz (L1-Black,

Neutral/L2-White and Ground-Green), single phase

(1ø), +/- 10% of rated voltage.

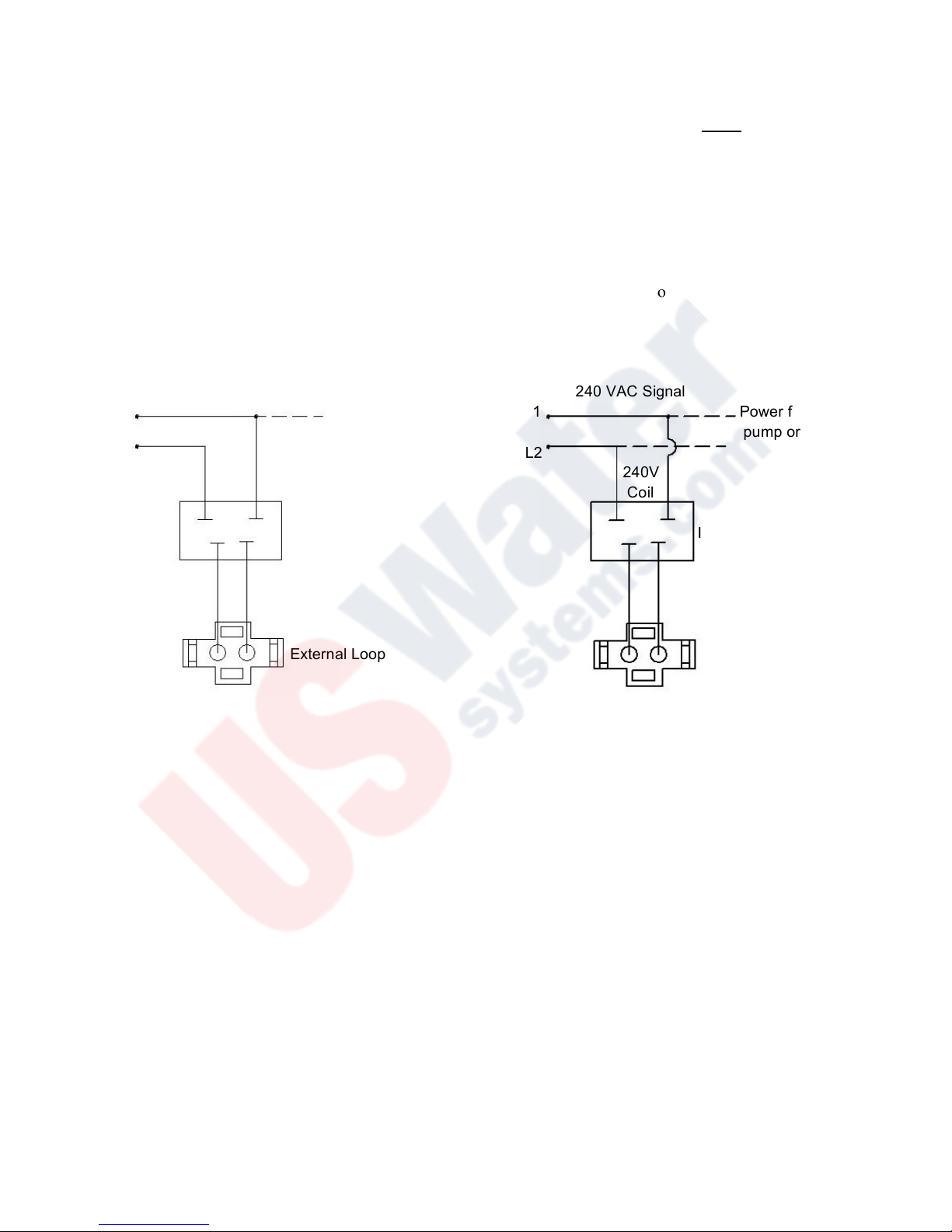

Step 3: External Loop: The external loop is a true dry contact interface. Note: The term ‘dry contact’ means that

this loop does not supply output nor except input voltages. Warning: Supplying voltage to the external

loop will cause damage to the ozone generator and void warranty. Under normal operation, the external

loop will effectively interrupt the ozone output when the loop has lost continuity; this will also illuminate the

LED located on the 4-20mA control board inside the HDO3-II and HDO3-III ozone generators and the EXT

LOOP LED on the front cover of the HDO3-I ozone generator (see Appendix-Section A, for location of 420mA board) and turn off the “Ozone Output” LED(s) on the front cover. Note: When the external loop has

lost continuity main power to the ozone generator will remain “ON” giving power to the cooling fan(s).

When continuity is present through the external loop, ozone output will continue. This continuity will

effectively turn “OFF” the LED of the 4-20mA board and the EXT LOOP LED and will again illuminate the

“Ozone Output” LED(s).

The external loop, a removable two-position plug with a white 18AWG wire located at the bottom panel of the

ozone generator (see Appendix-Section A), can be interfaced to any control device, i.e., pressure switch,

vacuum switch, flow switch, float switch, ORP controller, PPM controller, or timer. To interface a control

device to the external loop, cut the white 18AWG wire in half. Connect the control device to each leg of the

external loop. Note: External Loop control devices supplied by ClearWater Tech may come equipped

with a two-position male connector ready to be plugged into the female two-position connector mounted

to the chassis of the ozone generator. If the control device used supplies an output voltage, a single pole

single throw (SPST) normally-open relay may be used to create a dry contact interface (see Figure 5-1,

“External Loop Electrical Interface”). Note: Attached to the white 18AWG external loop is a warning,

“THIS CONNECTION IS A DRY CONTACT ONLY, DO NOT APPLY VOLTAGE”.

Step 3: Ozone Output Control – The HDO3 Series systems are equipped with two options for controlling the ozone

output, either a manual 0-100% ozone output control or a remote 4-20mA control input signal. See AppendixSection A for location.

1. Manual Ozone Output Control - Turning the control knob counterclockwise will decrease the ozone output down

to 0%, while turning the knob clockwise will increase the ozone output up to 100%. The “Ozone Output” is indicated

by the LED(s) on the front of the ozone generator, see Appendix-Section A.

2. Remote 4-20mA Control: The ozone generator will automatically sense the 4-20mA input signal and override the

setting of the manual ozone output control. Based on the 4-20mA signal, ozone output will increase or decrease,

4mA = 0% ozone output, 20mA = 100% ozone output. The “Ozone Output” is indicated by the LED(s) on the front

of the ozone generator, see Appendix-Section A. Note: If the remote 4-20mA signal fails or is missing, the system

will default to the manual ozone output setting. Check and adjust the manual ozone output control knob to

HDO3 Series Power Consumption

Input

Voltage

120VAC

60Hz

220VAC

50Hz

240VAC

60Hz

HDO3–I

20 amps

11 amps

10 amps

HDO3– II

20 amps

11 amps

10 amps

HDO3–III

20 amps

11 amps

10 amps

Electrical (continued)

9

avoid over-ozonation. The ozone generator 4-20mA control leads of the HDO3 system have been pre-wired at the

factory to the dissolved ozone monitor/controller. The negative (-) input signal to the Purple wire of the ozone

generator and the positive (+) input signal to the Orange wire of the ozone generator. Note: The dissolved ozone

monitor/controller has been pre-programmed at the factory to 20mA or 100% ozone output. Either reprogramming the dissolved ozone monitor/controller or removing the 3-position 4-20mA control connector

from the HDO3 ozone generator can override this function.

Step 4: Dissolved Ozone Monitor/Controller – The HDO3 series systems are equipped with an integral dissolved

ozone monitor/controller. This monitor/controller is equipped with alarm relays that can be used to interlock

other devices based on dissolved ozone levels. Main power and the 4-20mA control interface to the ozone

generator have been pre-wired at the factory. The unit has also been pre-programmed at the factory to supply a

constant 20mA (100%) ozone output signal to the ozone generator. The dissolved ozone monitor/controller

must be re-programmed for any other desired setting. See the dissolved ozone monitor/controller manual for

function and electrical hook-ups.

External Loop Electrical Interface

Figure 5-1

120 VAC Signal

L1 Power from ORP, PPM,

pump or timer

N

120V

Coil

Interface Relay

External Loop

240 VAC Signal

L1 Power from ORP, PPM,

pump or timer

L2

240V

Coil

Interface Relay

External Loop

10

START-UP & CALIBRATION

CHAPTER 7

The previous sections of this manual have involved comparatively static procedures – making

electrical connections and fitting pipe, etc. This section involves the dynamic process of starting up

and balancing the components of the system, including initiating water flow, making air and water

flow adjustments, etc.

Maximum performance and reliability is achieved when the prescribed air flow and vacuum or pressure levels are

maintained at the HDO3 system while the ozone injector is operating at a comparatively higher vacuum (measured in

inches of mercury, or “in.Hg”). Also, maintaining the correct water flow and hydraulic pressures will ensure the highest

possible level of dissolved ozone. The air from the air preparation system of the HDO3-I and HDO3-II flows toward the

ozone generator under pressure, and from the ozone generator under vacuum (created by the ozone injector). The change

from pressure to vacuum occurs at the SCFH meter of the air preparation system located on the bottom left side of the

HDO3 system. Where as, the air from the air preparation system of the HDO3-III is flowing through the ozone generator

under pressure, and from the ozone generator under a slight vacuum (created by the ozone injector). The change from

pressure to vacuum occurs after the stainless steel “Ozone Injector–Vacuum Control” needle valve located on the control

panel of the HDO3-III.

HDO3 Series – Dissolved Ozone Generation System

Warning: Disconnect the External Loop dry contact (see Appendix-Section A) from the ozone generator

while performing all start-up procedures. Failure to do so may result in ozone escaping to atmosphere.

Step 1: Make sure all isolation valves in the ozone water system are open (Figures 4-2 and 4-3 show recommended

isolation valve locations).

Step 2: The main power switch of the HDO3 system, located on the Control Panel (see Appendix-Section A), should

be in the “OFF” position. Main power should be available to the HDO3 system.

Step 3: Remove the Fill Port Cap of the vacuum break located on the backside of the HDO3 system and fill the Riser

Tube with clean water (no particulate matter) to the fill level, see Appendix-Section A

Step 4: Re-install the Fill Port Cap, hand tight. Note: Do not over tighten as damage to PVC fittings may occur.

Step 5: Completely open the contact tank backpressure valve, located towards the bottom backside of the HDO3

system (see Appendix-Section A), by turning it counter-clockwise.

Step 6: Start-up hydraulics. Allow the water in the system to reach hydraulic equilibrium (contact vessel full, off-gas

vent operating, etc.) and observe for plumbing leaks. If the inlet water supply is not under pressure be sure the

HDO3 booster pump is flooded with water so that the booster pump will prime. Notes: Water flow must be

established through the HDO3 system booster pump before operation. If the inlet water supply to the

HDO3 system is not under pressure the system may not completely fill with water until the HDO3

system is operational.

Step 7: If the inlet water supply to the HDO3 system is pressurized, using a water pressure regulator with a pounds

per square inch (PSI) gauge, regulate the inlet water supply pressure to 20PSI maximum. Note:

Backpressure downstream of the HDO3 system could affect this PSI reading.

Step 8: Disconnect the green oxygen delivery line from the oxygen concentrator, located on the bottom left-hand side

of the HDO3 system.

Step 9: Turn the main power switch of the HDO3 to the “ON” position. The HDO3 should energize giving power to

the booster pump, oxygen concentrator, ozone generator and dissolved ozone monitor/controller.

Step 10: Adjust the oxygen concentrator flow meter located on the bottom left-hand side of the HDO3 system. This

standard cubic feet per hour (SCFH) air flow meter must be set to atmospheric pressure. See the “Air

Preparation Air Flow” line of the Operating Parameters chart Figure 7-2 for the set point of each HDO3

system. Note: When the system is in normal operation the SCFH flow meter setting may drop due to

backpressure through the system. Do not re-adjust the flow meter.

Step 11: Reconnect the green oxygen delivery line to the oxygen concentrator, which was removed in Step 7 above.

Step 12: Switch the ozone generator power switch to the “ON” position located on the bottom of the ozone generator,

see Appendix-Section A.

Step 13: If the inlet water supply to the HDO3 system is under pressure, slowly close the contact tank backpressure

valve until the needle of the “Low Pressure – Side Water” gauge reaches 20PSI. If the inlet water supply is

not under pressure slowly close the contact tank backpressure valve until the needle of the “Low Pressure –

Side Water” gauge is between 1-5PSI.

Step 14: Adjust the feed gas flow meter, located on the Control Panel (see Appendix-Section A), of the HDO3 system.

See the “Feed Gas Flow Rate” line of the Operating Parameters chart Figure 7-2.

Start-Up and Calibration (continued)

11

Step 15: HDO3-I and HDO3-II – only: Adjust the “Ozone Injector – Vacuum Control” knob, located on the Control

Panel (see Appendix-Section A), until the “Ozone Generator – Vacuum” gauge achieves -5 inHg. Due to the

vacuum switch installed, the “Ozone Generator – Vacuum” gauge must achieve -3inHg before ozone will

begin production (once the External Loop is re-connected). Note: Re-adjustment of the “Feed Gas Flow

Rate” meter and the “Ozone Injector – Vacuum Control” knob may be required to correctly set the

normal operating parameters of both the feed gas flow rate and the ozone generator vacuum.

Step 16: HDO3-III – only: Adjust the “Ozone Injector – Vacuum Control” knob, located on the Control Panel (see

Appendix-Section A), until the “Ozone Generator – Pressure” gauge achieves 10PSI. Due to the pressure

switch installed, the PSI gauge must achieve a minimum of 9 PSI before ozone will begin production (once

the External Loop is re-connected). Note: Re-adjustment of the “Feed Gas Flow Rate” meter and the

“Ozone Injector – Vacuum Control” knob may be required to correctly set the normal operating

parameters of both the feed gas flow rate and the ozone generator pressure. The ozone generator flow

meter and pressure gauge on the front cover of the ozone generator will match the readings of the

“Feed Gas Flow Rate” meter and the “Ozone Generator – Pressure” gauge.

Step 17: Check that the “Low Pressure – Side Water” and “High Pressure – Side Water” gauges match the normal

operating parameters outlined in Figure 7-2. Note: It is typical for the “High Pressure - Side Water” gauge

to be about 40PSI greater than the “Low Pressure – Side Water” gauge.

Step 18: The dissolved ozone monitor/controller should be registering 0.00PPM of dissolved ozone at this time. If it is

not the dissolved ozone probe should be “Zeroed” or re-calibrated. Follow the calibration steps of the Quick

Reference Guide located in Figure 7-3 or the “Calibration” section of the monitor/controller I/O Manual.

Step 19: Re-connect the External Loop dry contact that was removed before starting these start-up procedures.

Production of ozone should now begin. Note: If bubbles are observed in the vacuum break, do NOT reconnect the External Loop dry contact. See Troubleshooting Guide.

Step 20: Approximately 20 seconds after the External Loop has been re-connected, the dissolved ozone

monitor/controller should begin registering a steady increase in the dissolved ozone level. Adjust the

dissolved ozone level by either, setting the dissolved ozone controller to a desired set point or remove the 420mA control 3-position connector (with orange and purple wires) from the bottom of the ozone generator

(see Appendix-Section A), then adjust the “Manual Ozone Output Control” knob located at the bottom of the

ozone generator (see Appendix-Section A) to manually adjust ozone output.

Step 21: Perform a final check of all pneumatic connections from the air preparation system to the ozone injector

manifold. Repair leaks as required. Check all system water connections. Repair leaks as required. Note: The

check valve at the ozone injector may make a humming noise. This is normal.

Step 22: Observe indicating LED(s), on the front cover of the HDO3 systems ozone generator. See Figure 7-1 A-C and

Appendix-Section A for proper function and location.

Step 23: Make final adjustments to the dissolved ozone monitor/controller. For information regarding the dissolved

ozone monitor/controller use the Quick Reference Guide Figure 7-3 or see the monitor/controller I/O Manual.

HDO3-I - Ozone Generator LED Function Figure 7-1 A

LED

Function

Display

OZONE

OUTPUT

The ten LED’s represent 0-100%, minimum to maximum ozone output. Each LED is equal to 10%

output. These LED’s can be adjusted with the manual output control knob located at the bottom of

the ozone generator or automatically with a remote 4-20mA control signal.

POWER

Main Power is ‘ON’ to the ozone generator, when LED is illuminated.

HV DRIVE

Power is being sent to the high voltage drive board, when the LED is illuminated.

EXT LOOP

The External Loop has continuity through it when the LED is not illuminated, which indicates

ozone is being produced. The External Loop does not have continuity, when the LED is

illuminated, which indicates no ozone production.

HIGH TEMP

The High Temp LED will not be illuminated during normal operation. If the ozone generator’s

internal temperature is in excess of 150˚F the High Temp LED will illuminate, which will

discontinue ozone production.

Start-Up and Calibration (continued)

12

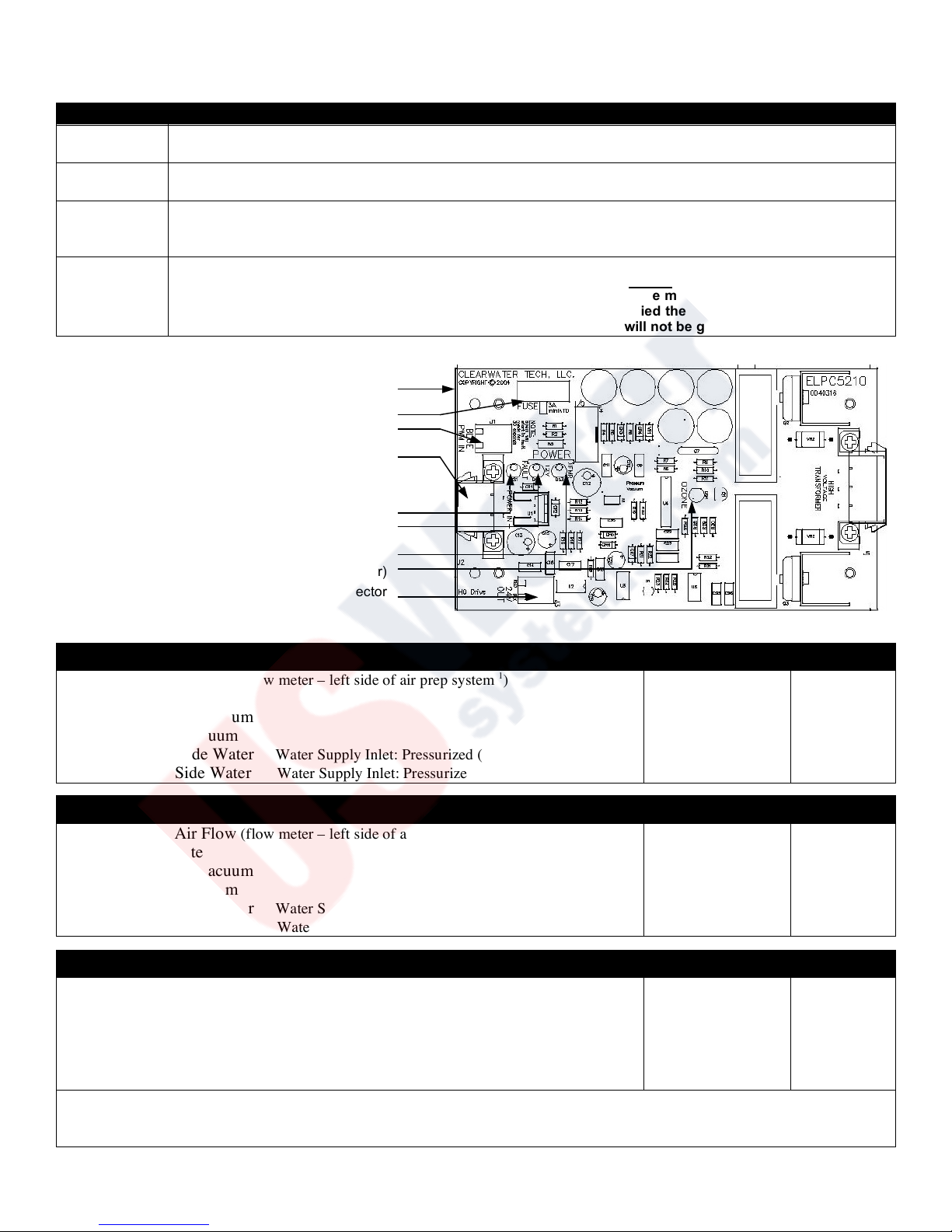

HDO3-II and HDO3-III - Ozone Generator Drive Board LED Function Figure 7-1 B

LED

Function

12V MAIN

POWER

When illuminated, this “Green” LED indicates that main power is supplied to the drive module up to the “on board”

fuse of the drive board.

XFMR

POWER

When illuminated, this “Green” LED indicates that 48V Buss power is available to the drive module transformer

(XFMR) from the “on board” fuse to the drive transformer.

OZONE

OUTPUT

The “Amber” ozone output LED will illuminate when ozone is being generated. The LED will also pulse as the

output increases or decreases with either the Manual Ozone Output Control located on the bottom of the ozone

generator (see Appendix-Section A), or from a Remote 4-20mA signal (see “Installation Procedures – Electrical”).

FAULT

When illuminated, this “Red” LED indicates that there is a fault with the drive module or the Ozone Reaction

Chamber. If this LED is illuminated, refer to the Troubleshooting Guide. Notes: Upon startup, the fault LED will

remain illuminated for 30 seconds before ozone is produced. If the drive module goes to a fault condition,

the drive board will restart every 30 seconds. If the fault is not remedied the drive module will continue to

go into a fault mode. When the drive module is in fault mode ozone will not be generated.

HDO3-II and HDO3-III Drive Board

Figure 7-1 C

Operating Parameters Figure 7-2

HDO3 - I Operating Range Optimum

Air Preparation Air Flow (flow meter – left side of air prep system

1

)

Feed Gas Flow Rate

Ozone Generator - Vacuum

Ozone Injector - Vacuum

High Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

Low Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

6 to 8 scfh

6 to 8 scfh

-3 to -8 in.Hg.

-5 to -25 in.Hg.

55-65 (35-45) PSI

15-25 (0-5) PSI

8 scfh

8 scfh

-5 in.Hg.

-15 in.Hg.

60 (40) PSI

20 (5) PSI

HDO3 - II Operating Range Optimum

Air Preparation Air Flow (flow meter – left side of air prep system

1

)

Feed Gas Flow Rate

Ozone Generator - Vacuum

Ozone Injector - Vacuum

High Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

Low Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

10 to 15 scfh

10 to 15 scfh

-3 to -8 in.Hg.

-5 to -25 in.Hg.

55-65 (35-45) PSI

15-25 (0-5) PSI

15 scfh

14 scfh

-5 in.Hg.

-15 in.Hg.

60 (40) PSI

20 (5) PSI

HDO3 - III Operating Range Optimum

Air Preparation Air Flow (flow meter – left side of air prep system

1

)

Feed Gas Flow Rate (Control Panel and Ozone Generator)

Ozone Generator – Pressure (Control Panel and Ozone Generator)

Ozone Injector – Vacuum

High Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

Low Pressure – Side Water Water Supply Inlet: Pressurized (Non-Pressurized

2

)

10 to 12 scfh

4 to 6 cfh

9 to 12 PSI

-5 to -25 in.Hg.

55-65 (35-45) PSI

15-25 (0-5) PSI

12 scfh

6 cfh

10 PSI

-15 in.Hg.

60 (40) PSI

20 (5) PSI

1 This flow meter is set at atmospheric pressure. See, “Start-Up and Calibration” steps 8-11. The flow rate will be reduced

when in normal operation.

2 The pressure range is based on possible head pressure and may vary by installation.

Drive Board

Fuse

Variable Input Connector

DC Power Input Connector

Fault LED

Drive Board Main Power LED

Transformer – XFMR LED

Ozone Output LED (illuminates through cover)

24VDC Output Connector

Loading...

Loading...