Clear Water CTA3 Installation Instructions Manual

INSTALLATION

INSTRUCTIONS

Crystal tall basin mixer

without pop up waste

● We recommend that this product is installed by a qualified professional contractor. Such as a plumber who is certified by NVQ

(National Vocational Qualification) or SNVQ (Scottish National Vocational Qualification) Level 3.

● Please check this product immediately to ensure that it has not been damaged and is complete. Before installation, please make

sure this product is the correct model and you have all the parts required for installation and using.

● All the taps should be supplied with hot and cold water at balanced pressure. If not, then the mixing function will not work correctly.

It is necessary to fit non-return valves on both hot and cold feeds pipe. These are not supplied.

● Please flush the water system to ensure that no metal swarf, solder, and other impurities can enter the taps.

●

Turn off water supply before commencing work, this should be done at the isolating valves of inlet feeds if fitted or main stopcock.

● Please read these instructions carefully and keep it for future reference.

Working pressure

The tap is suitable for both high and low pressure installation. To ensure that the tap works well under low water pressure, the

cold water storage tank must be at least 2 meters above the installed position. The maximum static pressure is 10 bar, and

operating water pressure is 5 bar. Where the operating water pressure above 5 bar, then a pressure reducing valve must be fitted.

Maintenance

We do NOT recommend you use any household cleaners to clean the product. Because these cleaners change substance or formula

too frequently. The product should be always cleaned only with soapy water and rinsed with clean water and dried with a soft cloth.

FLOW STRAIGHTENER

AERATOR

Straightener and aerator (alternative option)

Important

B

1 - 2

Cleaning

NOZZLE

Before use: Unscrew the filter and allow the water to run freely

for 5 minutes. Then screw the filter back in place.

Periodically: Unscrew the nozzle and remove. Rinse it with

running water until any loose debris is cleared.

Then replace the nozzle and tighten.

CTA3

Taps are all fitted with a flow straighter for use in low pressure installations.

An aerator is supplied in the box, and is an option that can be used in high

pressure installations. These can be interchanged by unscrewing the part,

and replacing with the alternate one. During the process do not loose the

washer, between the parts.

B

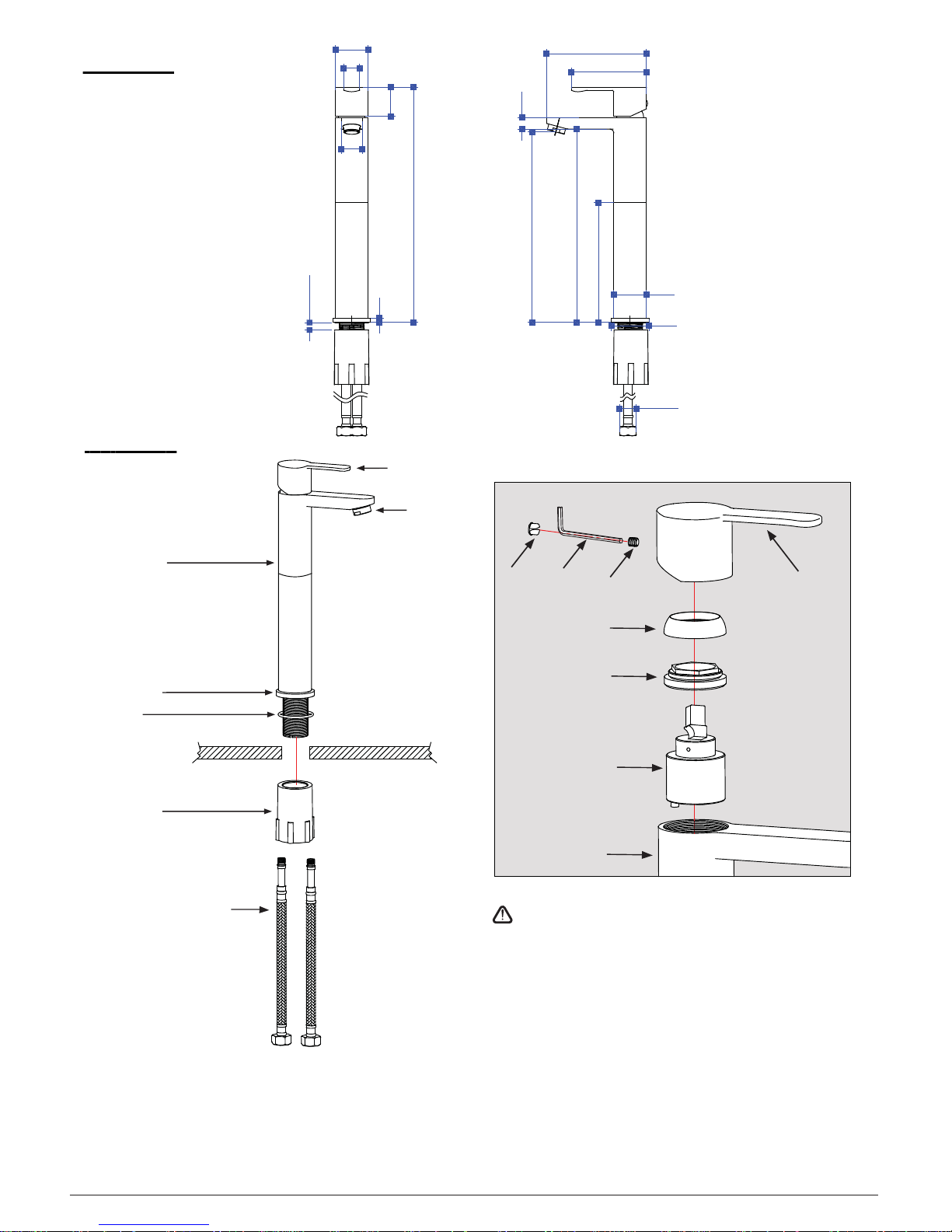

Installation

Dimension

2 - 2

To remove the cartridge.

First shut off the water supply to the tap.

1: Pull out the cap from the handle.

2: Loosen the grub screw in handle, but do not remove it.

3: Take off the handle, unscrew the cartridge cover.

4: Using a correct size spanner unscrew the retaining nut.

5: Pull the cartridge and wash it with clean running water.

6. Dry and lightly grease the seals (only use silicone grease)

7: Replace them in turn.

CAP

ALLEN

KEY

MIXER BODY

CARTRIDGE

RETAINING

NUT

CARTRIDGE

COVER

HANDLE

GRUB

SCREW

CAP

103

138

16

266

262

165

Ø52

Ø45

22

Ø45

29

324

40

6

2-G1/2

Max30

FLEXIBLE PIPES

LEFT: HOT FEED

RIGHT: COLD FEED

MIXER BASE

O’ RING

FIXING NUT

HANDLE

NOZZLE

MIXER BODY

1: Fit the O’ ring into the groove in the underside of the mixer body.

2: Screw the flexible pipes into the mixer body, and fully hand tighten.

3: Pass the tail of flexible pipes through the hole on the basin from above, and place the mixer in position on the basin, to see if any

alteration to the existing supply pipe work is necessary, make any necessary alterations to the pipe work.

4: Slide the fixing nut up the tails and onto the fixing bolt.

5: Check that the mixer body is correctly positioned, fully tighten the fixing nut.

6:

Connect the water supply pipe to the tail of flexible pipes with the hot water on the left and cold water on the right.

Loading...

Loading...