Clean Water Systems Pro?OX 2510 Installation & Starting Manual

Clean Water Made Easy

hp://www.cleanwaterstore.com

Pro‐OX 2510 Manual Backwash Iron Filter

Installaon & Start‐Up Guide

Thank you for purchasing a Clean Water System! With proper installaon and a lile

roune maintenance your system will be providing iron water for many years.

Please review this start-up guide enrely before beginning to install your system, and

follow the steps outlined for best results.

PRO-OX MEDIA CONTAINS DUST.

USE PAPER MASK AND VENTILATE AREA TO AVOID BREATHING DUST DURING

INSTALLATION

Quesons?

Call us toll-free: 1-888-600-5426 or 1-831-462-8500

Email us: support@cleanwaterstore.com

See more informaon on our website: www.cleanwaterstore.com/resources

Pro‐OX 2510 Manual Backwash Iron Filter Installaon & Startup Guide

Table of Contents

Packing List ........................................................................................................................................................ 3

Pre-Installaon ............................................................................................................................ ...................... 4

Best Pracces for Piping & Drain Installaon ................................................................................................... 4

How Your Iron Filter Works .............................................................................................................................. 5

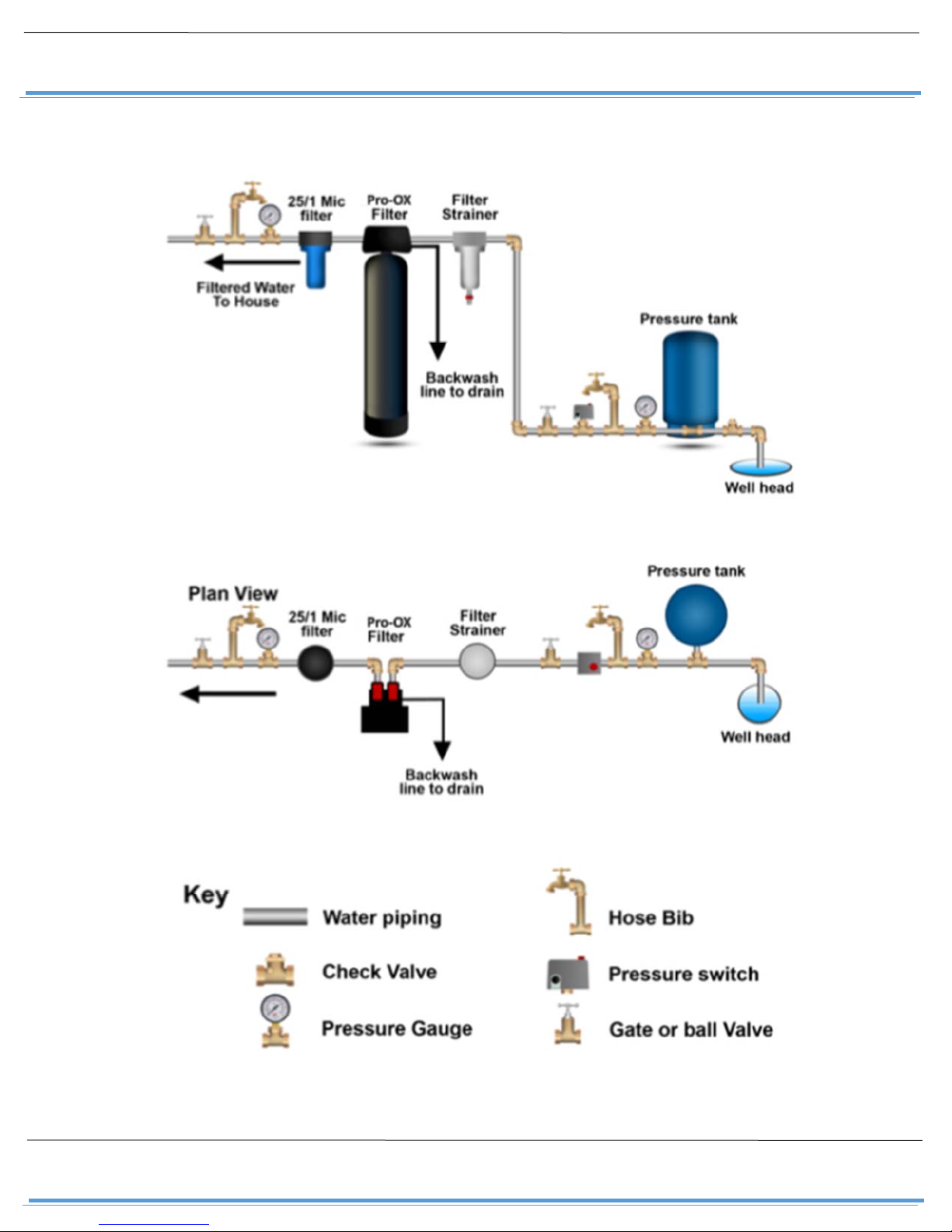

Fig. 1—Pro-OX iron Filter Diagram........................................................................................................ 5

Fig. 2—Typical Pro-OX Iron Filter Installaon ....................................................................................... 6

Fig. 3—Fleck 2510 Control Valve and Bypass Valve Rear View ............................................................ 7

Fig. 4—Fleck 2510 Control Valve and Bypass Valve Rear Side View .................................................... 7

Assembly and Installaon Instrucons ............................................................................................................. 8

Troubleshoong the Pro-OX 2510 Iron Filter ................................................................................................... 9

Low Water Pressure .............................................................................................................................. 9

Filter Tank Does Not Sit Level on the Floor ........................................................................................ 10

Page 2

www.cleanwaterstore.com

Rev 032114

Pro‐OX 2510 Manual Backwash Iron Filter Installaon & Startup Guide

Packing List

1.0 Cubic Foot System

Quanty Descripon

1 Fleck 2510 manual backwash control valve and bypass valve

1 Pipe connector kit (1” or 3/4”)

1 Enpress filter tank with distributor tube

1 Media funnel

1 12 lbs. gravel

2 1/2 cubic foot boxes of Pro-OX filter media

1.5 Cubic Foot System

Quanty Descripon

1 Fleck 2510 manual backwash control valve and bypass valve

1 Pipe connector kit (1” or 3/4”)

1 Enpress filter tank with distributor tube

1 Media funnel

1 16 lbs. gravel

3 1/2 cubic foot boxes of Pro-OX filter media

2.5 Cubic Foot System

Quanty Descripon

1 Fleck 2510 manual backwash control valve and bypass valve

1 Pipe connector kit (1” or 3/4”)

1 Enpress filter tank with distributor tube

1 Media funnel

1 20 lbs. gravel

5 1/2 cubic foot boxes of Pro-OX filter media

Page 3

www.cleanwaterstore.com

Rev 032114

Pro‐OX 2510 Manual Backwash Iron Filter Installaon & Startup Guide

Pre‐Installaon

1. Review your packing list and make sure you have received all the parts before beginning installaon.

2. If you are going to be turning off the water to the house and you have an electric water heater, shut off

the power to the water heater before beginning installaon in case water heater is accidentally drained.

3. Pick a suitable locaon for your filter system on a dry level spot where it won’t be exposed to freezing

temperatures. A minimum of 20 PSI is required. Maximum pressure is 90 PSI.

4. Get all of your plumbing parts together before beginning installaon. Installaon typically takes 3 to 5

hours. However aer installaon the iron filter must be allowed to run through a complete backwash and

rinse cycle (also called "regeneraon"). You don’t have to be present for this first backwash necessarily,

but it does take 90 minutes.

5. Aer the system is installed and running, your water may be discolored, or full of sediment or rust, parc-

ularly if this is older piping that has been exposed to iron or manganese for some me. Typically this

clears up over a day or two, but can persist for weeks if the pipe is old, galvanized iron pipe that has been

corroded.

Best Pracces for Piping & Drain Installaon

1. See typical installaon (see Fig. 2, page 6). The iron filter is installed aer the pressure tank.

2. Make sure to connect the inlet pipe to the Fleck 2510 control valve inlet and the outlet to the outlet (see

Fig. 3, page 7). Water enters on the right and exits on the le when facing the control valve from the

front. From the back (Fig. 3) the water enters on the le. The inlet and outlet are aached to the bypass

valve which is marked with arrows as well.

3. Make sure there is a working gate or ball valve before the filter and also one aer as shown in Fig. 2 on

page 6. The pressure gauges are oponal and not necessary but a hose bib (which is a faucet that you can

aach a garden hose to) is strongly recommended aer the filter before the second ball valve. This makes

it easy to rinse your new filter on start-up and gives you a place to test the water before it enters your

household plumbing.

4. If you will be using copper piping, do not sweat the copper pipe directly on to the control valve. Avoid

heang up the control valve plasc with the torch.

5. You do not need unions to install your Fleck 2510control valve. If you need to remove it, the valve has

quick-release couplings that make it easy to put the filter on bypass and remove it from your piping.

6. The drain line tubing (not supplied) is connected to a drain from the rain outlet using flexible 1/2” ID tub-

ing. Note that the drain line can run up above the control valve and into a drain—it does not need to

drain down, as the filter backwashes under line pressure from your well pump. Most plumbing codes require an air-gap connecon, so that if your sewer or sepc tank backs up it cannot cross-connect with the

drain tubing.

Page 4

www.cleanwaterstore.com

Rev 032114

Pro‐OX 2510 Manual Backwash Iron Filter Installaon & Startup Guide

How Your Iron Filter Works

See Fig. 1. Water enters the top of your Pro-OX iron filter tank and flows down through the media and up the

distributor tube. Iron and manganese in the water turns to an oxidized parcle upon contact with the media and

is trapped in the media. During backwash, the water flow is reversed and water flows down the distributor tube

and up through the media, liing and expanding the Pro-OX filter media, and removing all the iron and rust

trapped in the filter. Aer the backwash stage, potassium permanganate soluon is automacally drawn in from

the potassium permanganate soluon tank and slowly rinsed through the Pro-OX filter for 1 hour, aer which

the Pro-OX media is thoroughly rinsed-to-drain. This enre automac process, called “regeneraon” takes about

90 minutes. Typically the Pro-OX filter is set to regenerate every 3 to 7 days, during the middle of the night when

no water is being used.

Fig. 1—Pro‐OX Iron Filter Flow Diagram

Page 5

www.cleanwaterstore.com

Rev 032114

Pro‐OX 2510 Manual Backwash Iron Filter Installaon & Startup Guide

Fig. 2—Typical Pro‐OX Iron Filter Installaon

Page 6

www.cleanwaterstore.com

Rev 032114

Loading...

Loading...