Clean Water Systems 5900-BT Tannin Filter Installation & Maintenance Manual

Clean Water Made Easy

www.cleanwaterstore.com

5900-BT Tannin Filter Installation

& Maintenance

Guide

Thank you for purchasing a Clean Water

System! With proper installation and a little

routine maintenance your system will be

providing softened water for many years.

Please review this start‐up guide entirely

before beginning to install your system and

follow the steps outlined for best results.

Minimum 30 PSI required. Maximum

pressure 90 PSI.

For indoor installation. Protect from sunlight,

rain, and freezing.

NOTE: Not for use on Hard Water. If your

water is over approximately 5 grains/gallon

hard (about 85 mg/L of calcium carbonate)

we recommend installing a water softener

ahead of the tannin filter to prolong the life

of the tannin resin.

Questions?

Call us toll‐free: 1‐888‐600‐5426 or 1‐831‐462‐8500

Email us: support@cleanwaterstore.com

See more information on our website: www.cleanwaterstore.com

5900-BT Tannin Filter Installation & Maintenance Guide

Table of Contents

Packing List for Different Size Tannin Filters ................................................................................................................. 3

How Your Tannin Filter Works ....................................................................................................................................... 4

Tannin Filter Installation Steps Overview ...................................................................................................................... 5

Pre‐Installation .............................................................................................................................................................. 5

Best Practices for Piping & Drain Installation ................................................................................................................ 6

Piping Diagram ............................................................................................................................................................... 7

Installation of Your Tannin Filter into Copper or Metal Piping Systems ........................................................................ 8

Add Tannin Resin and Install 5900‐BT Backwash Valve on Tank ................................................................................... 8

Attach the Bypass ........................................................................................................................................................ 10

Piping Installation ........................................................................................................................................................ 10

Attach the Brine Line Tubing to Brine Tank ................................................................................................................. 11

Brine Tank Set Up ........................................................................................................................................................ 12

Next: Program Your Valve ........................................................................................................................................... 13

Master Programming Mode ........................................................................................................................................ 14

See Historical Data and Real Time Flow Rate .............................................................................................................. 15

Start Up Your Tannin Filter .......................................................................................................................................... 15

Installing and Using the Optional Legacy View App .................................................................................................... 16

Normal Operation & Maintenance .............................................................................................................................. 19

How the Battery Back‐up Works ................................................................................................................................. 19

How to Start an Extra Regeneration Cycle .................................................................................................................. 19

How To Shut Down Tannin Filter For Extended Period of Non‐Use ............................................................................ 19

Troubleshooting Guide ................................................................................................................................................ 20

Brine Solution Not Being Sucked in During Regeneration ........................................................................................... 22

Error Codes .................................................................................................................................................................. 23

Service Instructions – Perform Before Doing Any Control Valve Service .................................................................... 23

How to Replace Powerhead ........................................................................................................................................ 24

How to Replace Piston Assembly ................................................................................................................................ 24

How to Replace Seals and Spacers .............................................................................................................................. 25

How to Replace Meter ................................................................................................................................................. 25

5900‐BT Powerhead Exploded View and Parts List ..................................................................................................... 26

5900‐BT Control Valve Body ........................................................................................................................................ 27

Warranty ...................................................................................................................................................................... 29

Page 2 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

Packing List for Different Size Tannin Filters

Every order includes: 5900‐BT control valve and Top Screen, Bypass assembly with 1” connector

yoke, Power supply (dual voltage 110‐230V 50/60hz), Hose Barb Adaptor (5/8” OD), Drain Line Flow

Control (DLFC), Media Funnel for adding resin to tank, Drain line tubing and Brine Tank.

Tannin Filter 16K Grain 0.5 cubic foot size

6” x 35” Tannin Filter tank with distributor tube

0.5 cubic foot of Tannin resin media; No Filter gravel needed with this size

Tannin Filter 32K Grain 1.0 cubic foot size

9” x 48” Tannin Filter tank with distributor tube

1.0 cubic foot of Tannin resin media; No Filter gravel needed with this size

Tannin Filter 48K Grain 1.5 cubic foot size

10” x 54” Tannin Filter tank with distributor tube

16 lbs. Filter gravel; 1.5 cubic foot of Tannin resin media

Tannin Filter 62K Grain 2.0 cubic foot size

12” x 52” Tannin Filter tank with distributor tube

20 lbs. Filter gravel; 2.0 cubic foot of Tannin resin media

Tannin Filter 80K Grain 2.5 cubic foot size

13” x 54” Tannin Filter tank with distributor tube

35 lbs. Filter gravel; 2.5 cubic foot of Tannin resin media

What to Do if Your Tank is Not Level Out of the Box:

Your black Tannin Filter tank base is not glued to the bottom of your tank. Occasionally tank

bases will become crooked during shipment.

If you find that that your tank does not sit level on the floor, you can easily adjust it by holding

the empty tank and rapping it on a concrete or solid floor once or twice to level it.

Page 3 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

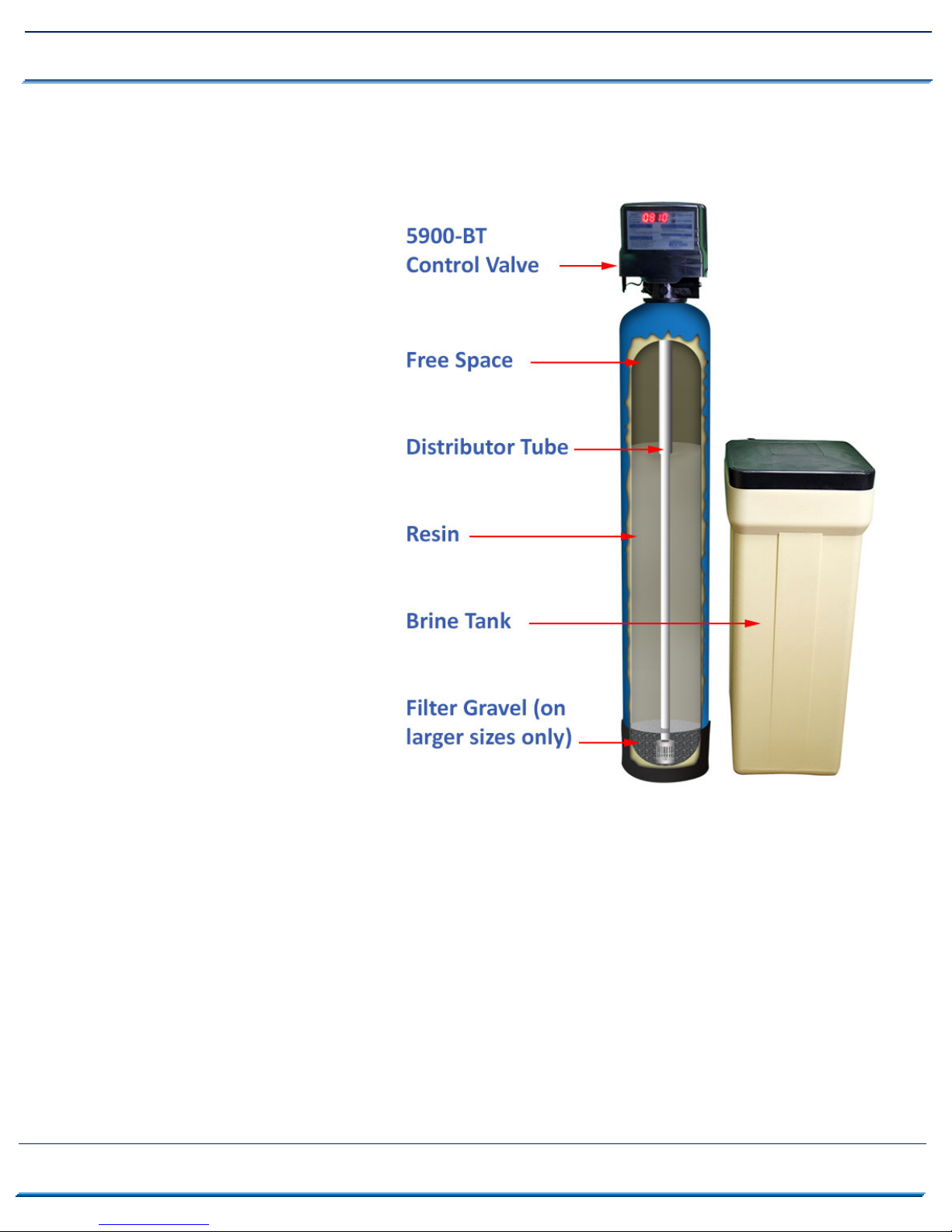

How Your Tannin Filter Works

In the Tannin Filter, water enters

the top of the tank and flows

down through the media and up

the distributor tube. Tannin

color is removed by the resin

beads in the Tannin Filter.

During regeneration the first

cycle in the process backwashes

and cleans the Tannin resin.

Water flow is reversed and

water flows down the distributor

tube and up through the media,

lifting and expanding the resin,

and removing any trapped

particles.

After the backwash stage, salt

brine is automatically drawn in

from the brine tank which then

slowly rinses through the resin

for 1 hour, allowing the color in

the water to be removed.

This entire automatic process,

called ‘regeneration’ takes

about 90 minutes.

Typically the Tannin Filter is set to regenerate based on gallons used and timed to occur during

the middle of the night when no water is being used.

Page 4 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

Tannin Filter Installation Steps Overview

1. Verify that you have received all parts and there are no damaged or missing parts.

2. If your size Tannin Filter uses gravel (48K grain and larger) add gravel first, then add

softening resin. Fill tank with clean water. OK to soak for 1 hour up to 24 hours while

doing piping.

3. Make the plumbing connections from your existing system to the bypass assembly,

installing extra valves, unions, pressure gauges and hose bibs as needed.

4. Attach the control head to the tank, and to the bypass assembly.

5. Install the Drain Line tubing

6. Plug in the power supply and program the valve.

7. Follow the instructions to put the Tannin Filter online and to verify the system is leak‐

free.

Pre-Installation

1. Review your packing list to make sure you have received all the parts before

installation.

2. If you are going to be turning off the water to the house and you have an electric

water heater, shut off the power to the water heater before beginning installation.

3. Pick a suitable location for your Tannin Filter on a dry level spot where it won’t be

exposed to freezing temperatures, direct sunlight, wind or rain.

4. Get all of your plumbing parts together before beginning installation.

5. After the system is installed and running, your water may be discolored, or full of

sediment or rust, especially if you have older or corroded piping. This typically clears

up over a day or two.

Page 5 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

Best Practices for Piping & Drain Installation

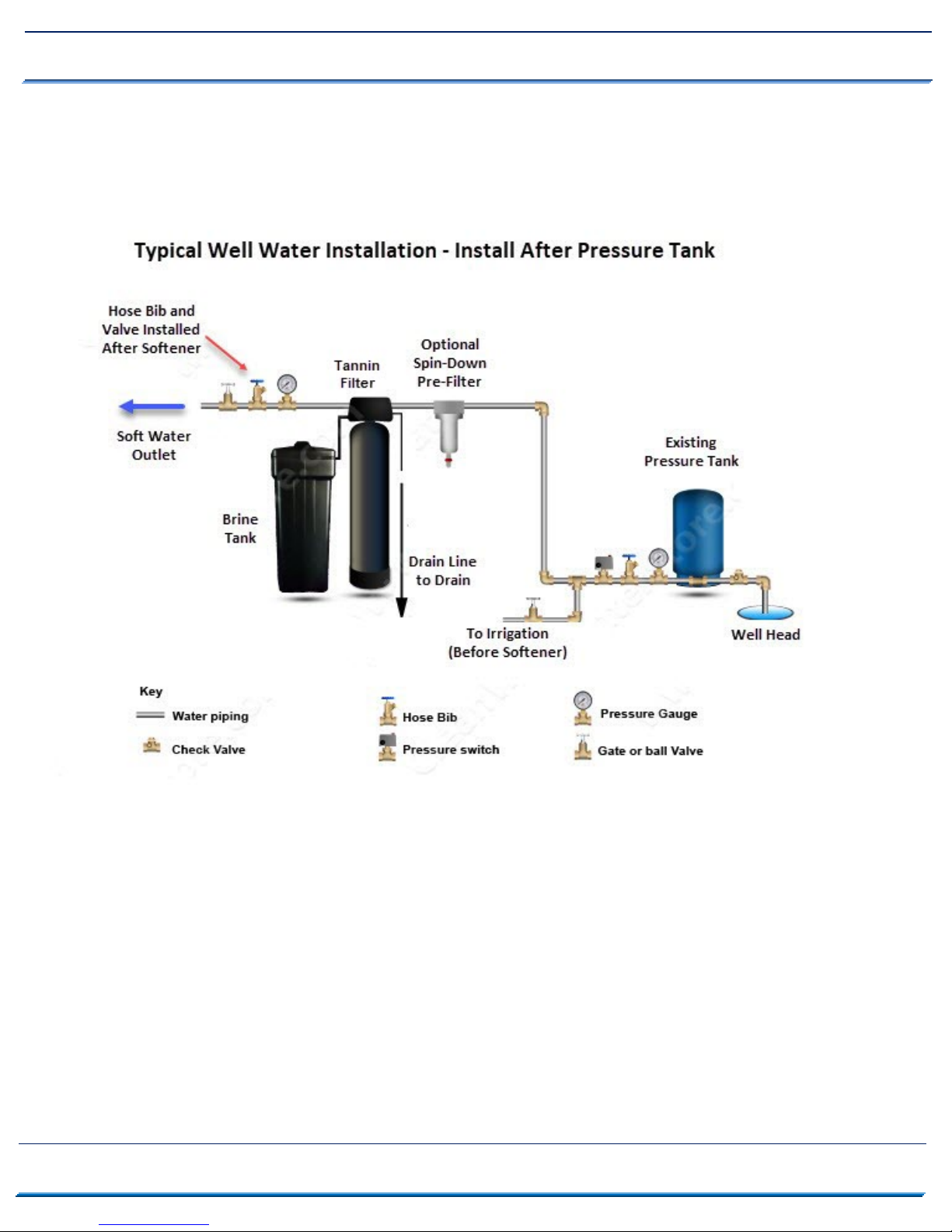

1. See typical installation Page 7. If on well water, Tannin Filter is installed after pressure tank.

2. Install on a level floor or surface.

3. Your new Tannin Filter must be installed at least 10 feet ahead of inlet to water heater to

prevent damage due to back‐up hot water or use a check valve to prevent hot water back‐

up.

4. DO NOT install the unit in an area of direct sunlight or expose to freezing.

5. Make sure brine tank is set on a smooth surface with no sharp objects, rocks etc.

6. Locate the unit near an unswitched, 120 volt / 60 Hz grounded electrical outlet.

7. Tannin Filter must be installed at least 10 feet ahead of inlet to water heater to prevent

damage due to back‐up hot water or use a check valve to prevent hot water back‐up.

8. DO NOT install the unit in an area of direct sunlight or expose to freezing.

9. Locate the unit near an unswitched, 120 volt / 60 Hz grounded electrical outlet.

10. Make sure to connect the IN pipe to the 5900‐BT inlet and the OUT pipe to the outlet.

11. Make sure there is a working gate or ball valve before the 5900‐BT Tannin Filter and also

one after as shown in Fig 2. The pressure gauges are optional. A hose bib (which is a faucet

that you can attach a garden hose to) is strongly recommended after the 5900‐BT Tannin

Filter and before the second ball valve, for rinsing and sampling water.

12. If you will be using copper piping, do not sweat the copper pipe directly on to the 5900‐BT

control valve. Avoid heating up the 5900‐BT control valve plastic with the torch.

13. You do not need unions to install your 5900‐BT control valve. If you need to remove it, the

5900‐BT has quick‐release couplings that make it easy to put the Tannin Filter on by‐pass

and remove the 5900‐BT Tannin Filter control valve from the piping.

14. The drain line tubing is connected to a drain from the drain outlet using flexible poly tubing.

The drain can run up above the control head and out to a drain, although this may require

installing a one way, flapper‐stlye check valve. Most plumbing codes require an air-gap

connection, so that if your sewer or septic tank backs up, it cannot cross connect with the

drain tubing (if running tubing into the washing machine drain pipe, for example)

Page 6 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

Piping Diagram

Page 7 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

Installation of Your Tannin Filter into Copper or Metal Piping Systems

If your new Tannin Filter is to be installed in a metal (conductive) plumbing system, i.e. copper

or galvanized steel pipe, the plastic components (bypass and connectors) will interrupt the

electrical continuity of the plumbing system.

As a result, any stray currents from improperly grounded appliances downstream or potential

galvanic activity in the plumbing system can no longer ground through contiguous metal

plumbing.

Some homes may have been built in accordance with building codes which encouraged the

grounding of electrical appliances through the plumbing system.

The installation of a bypass consisting of the same material as the existing plumbing, or a

grounded "jumper wire" bridging the equipment and reestablishing the contiguous conductive

nature of the plumbing system must be installed prior to your systems use.

A simple ground jumper wire with a pipe clamp can be purchased at any Home Center, or

hardware store etc. for a few dollars.

Add Tannin Resin and Install 5900-BT Backwash Valve on Tank

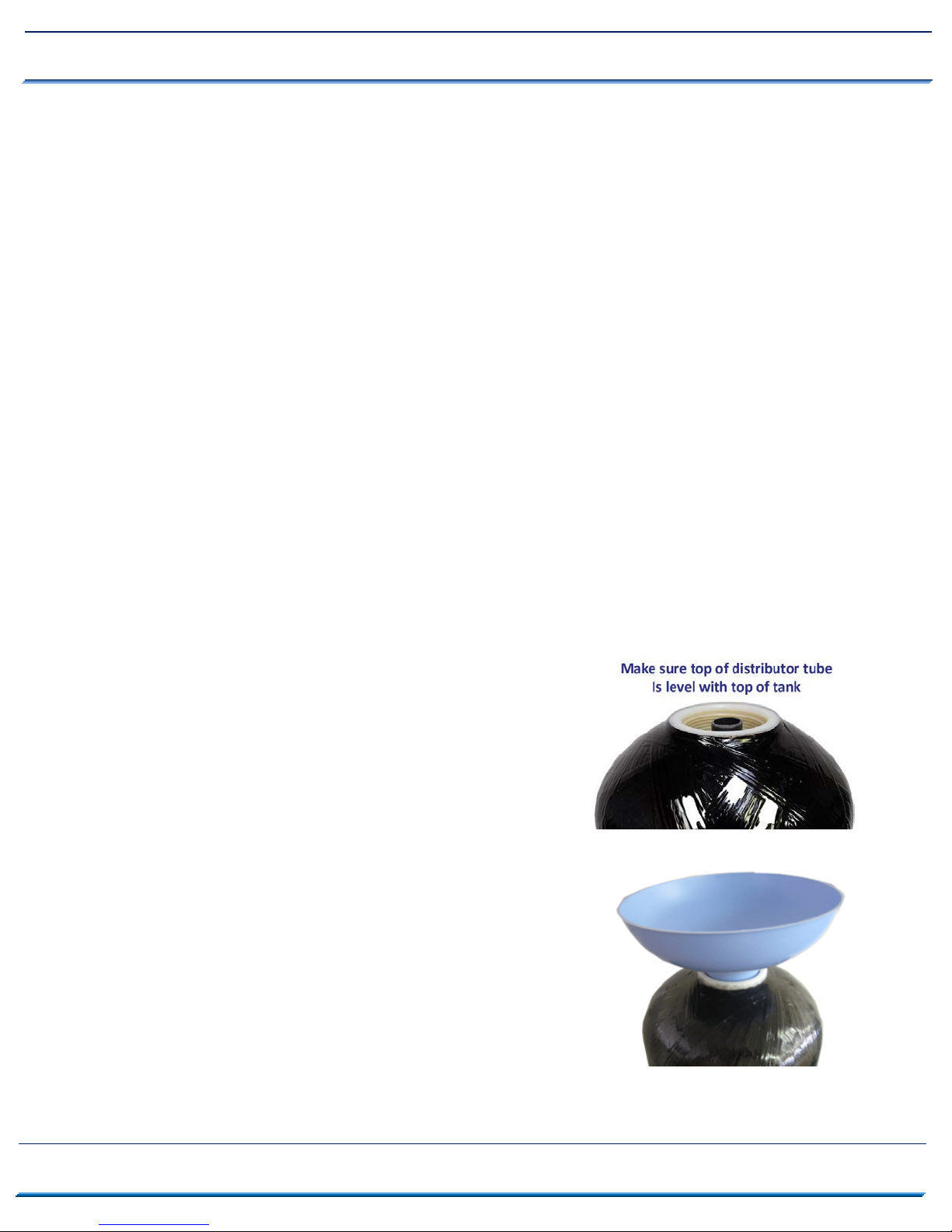

1. Make sure you “test fit” distributor tube, find divot that

keeps tube centered, before adding gravel so distributor

tube does not extend past top of tank.

2. There are two styles of funnel that we ship, depending on

availability; you get either the blue or black funnel.

3. If blue funnel, cover top of distributor tube with black

electrical tape, duct tape or masking tape so no gravel or

media will go down distributor tube when adding media.

4. Leave a folded tab of tape so you can easily pull off tape

after filling the tank.

5. Hold the tube center until there is enough gravel and media

to support the tube. The top of the distributor tube should

be level with the top opening of the Tannin Filter tank.

Page 8 www.cleanwaterstore.com Rev 071218

5900-BT Tannin Filter Installation & Maintenance Guide

6. Add the gravel (for 1.5 Cubic Foot 48K grain units and larger only) that came with your

order. The gravel should cover the bottom distributor screen before adding the Tannin

resin.

7. Next add the Tannin resin.

8. The tank should be about 2/3 to 3/4ths full of the resin.

9. Fill tank completely with water. Allow to soak for at least 1 hour up to 24 hours before you

hook it up to piping.

10. Remove tape from top of distributor tube. Be careful not to pull up distributor tube.

11. Attach plastic top screen to under‐side of the 5900‐BT control valve. It is a funnel‐shaped

plastic screen that snaps on to the control valve and prevents resin from being backwashed

out to drain during the regeneration cycles. It may twist on clockwise or counter‐clockwise.

12. Screw on Control Valve: Add small amount of silicone grease to both O‐rings (only O‐rings,

not tank thread) on bottom of control valve and screw on 5900‐BT control valve carefully.

13. Do not lubricate tank threads or any other fittings other than O-rings. Do not use pipe-

joint compound, vegetable oil, Teflon tape, or Vaseline or greases on tank threads.

14. If you accidentally pull distributor tube up after gravel and media are in tank (upon initial

install or any time after, for service, etc.), it must be re‐seated. It is usually possible to do

this by spraying water down distributor tube with a garden hose while pushing on end of

the tube. If this does not work, you must empty tank completely and start over.

15. Do not hard pipe the drain line with PVC or copper, use flexible tubing. If you use hard

PVC piping for the drain line, you must able to remove the hard drain piping and attach

flexible tubing for testing purposes.

Page 9 www.cleanwaterstore.com Rev 071218

Loading...

Loading...