CLEANTEC INNOVATION LIMITED

CARPET CLE AN ING MACHINE

INSTRUCTIO N MA NUAL

Model: GEN4

E

E00 -4-20 50 READ I NSTRU CTION S CAREF ULLY BEF ORE OP ERATIN G THE MA CHINE

TABLE OF CONTENTS

INTRODUC TI ON

How to use this Ma nual .............................................. 2.0

Machine Da ta L og/Overview....................................... 2 -1

SAFETY

Important Sa fety Instructions.................................... ...3-0

Hazard Inten sity Level ............................................ .. ..3-1

Earthing and G rounding Instructions ........................... 3-2

OPERATIONS

Product Technical Specificatio ns .................................4-0

How the Machin e Works........... ................................... 4-1

Machine Op er ation ............................................... .. ....4-2

Pre-run Insp ec tion............................................... 4-2

Starting Mac hi ne................................................. 4- 2

Machine Shut -d own and Storage.......................... 4-2

MAINTENA NC E

Brush Clea ni ng and Maintenance................................. 5-0

Machine Ma in tenance ............................................. ....5-0

Daily Mainte nance .............................................. 5-0

Periodic Mai ntenance.......................................... 5- 0

Annual Mainte nance ............................................5-0

Machine Tro ub leshooting....................................... .. ....5-1

Electrical D iagram............................................. .. ........5-2

WARRANTY

Cleantec Inn ovation Ltd Warranty Policy ............ .......... 6-0

Warranty Card................................... ......................... 6-1

Machine Warranty Request Form................... .. ............ 6-2

SPARE PARTS LIST... ............ ..... ..... ..... ............ ..... ..... ..... ...... 1-7

-1.1-

INTRODUCTION

This manual co ntains the following sections:

- HOW TO USE THIS MANUA L

- SAFETY

- OPERATIONS

- MAINTENANCE

the HOW TO USE TH IS M ANUAL section

will tell yo u ho w to find important information

for ordering c orrect spare parts.

Parts may be ord ered from authorized

envirodr i de alers. When placing an order for

parts, the mac hine model, and machine serial

number are i mp ortant, Refer to the MACHINE

DATA box which is filled out during the

installa ti on of your machine. Th e MACHINE

DATA box is located on the inside of the front

cover of this ma nual.

MOD EL

DATE O F PURCH ASE

SER IAL NUMB ER

SAL ES REPR ESENTATI VE #

DEA LER NAM E

OPE RATION S GUIDE N UMBER

The model an d se rial number of your

machine is o n th e operator’s left hand side

panel of bas e.

The SAFETY section is to familiari ze

the operator w ith the operation and function

of the machine .

The MAINTENA NCE section contains

preventive m aintenance to keep the machine

and its compon ents in good working condition.

-2-

Nam e:

Add ress:

MACHINE DATA LOG/OVERIEW

MOD EL

DATE O F PUR CHASE

SER IAL NUM BER

SAL ES REPR ESENTAT IVE #

DEA LER NAM E

OPE RATION S GUI DE NUMBER

YOUR DEALER

Pho ne Numb er:

OVERVIEW

The GEN 4 Carpe t Clean ing Machin e is desi gned to m aintain yo ur carp et usin g the enviro dri

Micro Spong es, dry c arp et clea ning sy stem. The ma chine has tw o count er rota ting brush es that e nable

the env irodr i Micro sponges to b e brush ed into t he carpet. The en virod ri Micr osponges e ncaps ulate t he

dirt wh en bein g brush ed into the ca rpet. The Mi croSp onges can th en be vac uumed u p leaving th e

carpe t dry. The brushes a lso hel p to rais e the pile of th e carpe t, givi ng it a lush gro omed ap peara nce.

-2.1-

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

This machine is for comme rc ial use.

WARNING

To reduce the risk o f fi re, electric shock, or inju ry:

Connect to a prope rly gro unded /earthed outle t. See Gr oundi ng and Earthing In struc tions .

Do not leave the mac hine un atten ded. Unplug mach ine fro m power o utlet when not in us e and

always before ma inten ance or s ervice.

Do not allow machi ne to be us ed as a toy. Close at tenti on is nec essary when used b y or near

children.

Use only as descri bed in th is manu al. Use only manuf actur er ’s reco mmend ed components an d

attachments.

Do not use damaged e lectr ical co rd or plug. Follow a ll inst ructi ons in this manual c oncer ning

grounding/ea rthin g the mac hine. If the machi ne is not w orkin g properly, has b een dro pped.

damaged, left ou tdoor s, or dro pped into water, re turn it t o an auth orized service c entre .

Do not pull or carry m achin e by elec trical cord, use a s a handl e, clos e a door on cord, or pul l cord

around sharp edg es or cor ners.

Do not run machine o ver cor d or allo w the rotating bru shes to c ome in co ntact with the cor d. Keep

cord away from hea ted sur faces .

Do not unplug mach ine by pu lling o n cord. To unplug, gras p the ele ctric al plug, not the ele ctric al cord .

Always use cable r estra int pro vided and wind the c able ar ound th e cable hol der on th e handl e. For

quick release of t he elec trica l cable rotate the c able ho lder 18 0 degrees.

Do not handle the el ectri cal plu g or machine with we t hands .

Do not operate the m achin e with an y openings block ed. kee p openi ngs free of debris t hat may

reduce airflow.

Machine is desig ned for i ndoor u se only and must not b e opera ted or st ored outdoors in w et

conditions.

Turn off a ll cont rols be fore unpluggin g.

Machine can caus e a fire wh en oper ating near flamm able va pours o r materials. Do no t opera te this

machine near fla mmabl e fluid s, dust or vapours .

Only the brushes p rovid ed with t he machine or thos e speci fied by t he manufacture r can be us ed.

The intended use o f the bru shes is s pecifically fo r the cle aning o f carpeting and sh ould no t be used

in any other way.

This machine is su itabl e for com mercial use, for e xampl e in hote ls, sch ools, hos pital s,

factories, sho ps and of fices .

Maintenance an d repai rs must b e done by qualifie d perso nnel.

SAVE THESE INSTRUCTIONS

-3-

HAZARD INTENSITY LEVEL

The following sy mbols a re used t hroughout this g uide as i ndica ted in their descr iptio ns:

HAZARD INTENSITY LEVEL

There are three le vels of h azard i ntensity ident ified b y signa l words -WAR NING an d

CAUTION and FOR SA FETY. The level of hazard i ntens ity is de termined by the fo llowi ng

definitions:

WARNING

WARNING - Hazards o r unsaf e pract ices which COULD r esult i n sever e personal injur y or

product or prope rty dam age

CAUTION

CAUTION - Hazard s or unsa fe prac tices which coul d resul t in mino r personal injur y or

product or prope rty dam age.

FO R SAFET Y: To identif y actio ns whic h must be f ollowed f or safe o perat ion of eq uipment .

Report machine d amage o r fault y operation imme diate ly. Do not use the ma chine i f it is not

in proper operat ing con ditio n. Following is in forma tion th at signals some po tenti ally

dangerous

conditions to th e opera tor or th e equipment. Rea d this in forma tion carefully. Know w hen

these

conditions can e xist. L ocate a ll safety device s on the ma chine . Please take the ne cessa ry

steps

to train the machi ne oper ating p ersonnel

FO R SAFET Y:

NO NOT OP ERATE MACHINE:

• Unless Trained an d Author ized.

• Unless Operati on Guid e is Read a nd understood.

• In Flammable or Ex plosi ve area s.

• In areas with poss ible fa lling o bjects.

• In wet or outdoor ar eas.

WH EN SERV ICING M AC HIN E:

Avo id movi ng parts. Do not wea r loose c lothi ng; jac kets, shi rts, or s leeve s when wo rking

on the machine. Us e envir odri ap proved replace ment pa rts.

-3.1-

EARTHING AND GROUNDING INSTRUCTIONS

THIS PRODUCT IS FOR COM MERCIAL

USE ONLY.

ELECTRICAL - USA:

In the USA this machi ne oper ates on a

standard 15 amp 115V, 60 Hz, A.C. powe r

circuit. The a mp, her tz, and voltage ar e liste d

on the data label fo und on ea ch mach ine.

Using voltages a bove or b elow th ose

indicated on the d ata lab el will c ause serious

damage to the moto rs:

EXTENSION CORD S:

If an extension co rd is use d, the wi re size

must be at least one s ize lar ger tha n the

power cord on the ma chine , and mus t be

limited to 50 feet ( 15.5m ) in leng th.

GROUNDING INST RUCTI ONS:

This appliance m ust be gr ounde d. If it should

malfunction or b reak do wn, gro unding

provides a path of l east re sista nce for electric

current to reduc e the ris k of elec tric shock.

This appliance i s equip ped wit h a cord having

and equipment- groun ding co nductor and

grounding plug . The p lug must be insert ed

into an appropri ate out let tha t is properly

installed and gr ounde d in acco rdance wi th all

local codes and or dinan ces.

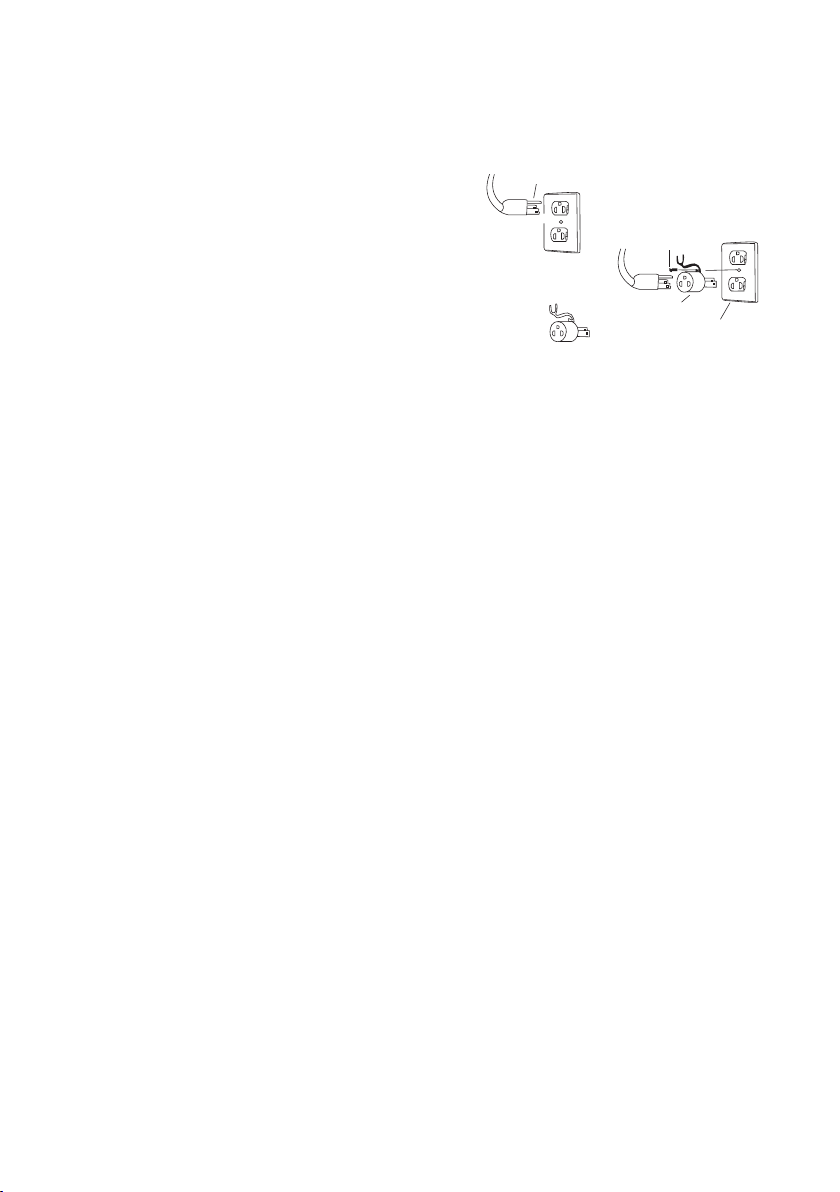

Gro undin g Pin

Grou nded

Outl et

Fig. A

Tab for Grounding

Screw

ADAPTOR

Note: Adaptors are not allowed in Canada.

GROUNDING CONNECTION

USING AN ADAPTOR

Fig. C

Meta l Screw

Adap tor

Grounded Outlet Box

Fig. B

Improper conne ction o f the equ ipment

grounding cond uctor c an resu lt in a ris k

of electric shoc k. Chec k with a qu alified

electrician or s ervic e perso n if you are in

doubt as to whethe r the out let is pr operl y

grounded. Do not m odify t he plug

provided with th e appli ance - if i t will no t

fit the outlet; ha ve a prop er outl et inst alled

by a qualified ele ctric ian.

This appliance i s inten ded for u se on a

nominal 120-vo lt circ uit, an d has a grounded

plug that looks li ke the pl ug in “Fi g.A.”A

temporary adap tor tha t looks l ike the adaptor

in “Fig.C” may be us ed to con nect th is plug

to a 2-pole recept acle as s hown in “ Fig.B,” if

a properly groun ded out let is no t available.

The temporary ad aptor s hould b e used only

until a properly g round ed outl et (Fig. A)can

be installed by a qu alifi ed elec trician. The

green colored ri gid ear, l ug, or wi re extending

from the adaptor m ust be co nnect ed to a

permanent grou nd such a s a prope rly

grounded outle t box cov er. Be sur e to fasten

the grounding ta b with a me tal fac eplate

screw, whenever t he adap tor is us ed

-3.2-

EARTHING AND GROUNDING INSTRUCTIONS

ELECTRICAL - UK:

In the UK this machi ne oper ates on a

standard 240 V, 50 Hz, A.C. po wer cir cuit.

The amp, herz, and v oltag e are lis ted on the

data label found o n each ma chine . Using

voltages above o r below t hose in dicated on

the data label wil l cause s eriou s damage to

the motors.

GROUNDING INST RUCTI ONS:

The UK machine is in tende d for use o n a

nominal 240 V, and it has a grounde d plug

with three recta ngula r prong s that form a

triangle, whic k looks l ike the p lug in “Fig D.”

This plug has been d esign ed to be pl ugged

into Power Outle ts simi lar to th e one shown

in “Fig E.” It compl ies wit h the BS 13 63

British Standa rd. The molded plug

incorporates a 1 0 Amps car tridg e Fuse.

The Wire colour co ding fo r the UK is a s

follows:

> Neutral: Blue Wi re

> Live: Brown Wire

> Earth: Green & Yellow

Fig.E

Fig.D

Neutral

(Blue)

Earth

(Green&Yellow )

Live

(Brown)

WARNING

Do not use the UK ‘G’t ype plu g in

conjunction wi th any ty pe of ada tors

Only operate the G EN4 env irodr i machine

with a Cord-set se rtifi ed and pr ovided by

the manufactur er

-3.2-

EARTHING AND GROUNDING INSTRUCTIONS

ELECTRICAL - EUROPE :

In Europe this mac hine op erate s on a

standard 230 V,50 Hz, A.C . power circuit.

The amp, herz, and v oltag e are lis ted on th e

data label found o n each ma chine . Using

voltages above o r below t hose in dicated on

the data label wil l cause s eriou s damage to

the motors.

GROUNDING INST RUCTI ONS:

The European mac hine is i ntend ed for us e on

a nominal 230 V, and it has a type‘F’ pl ug

with two round pro ngs and t wo grou nding

clips on the side of t he plug ( Fig F). T he

machine is inten ded to be p lugge d into ou tlets

that look like the o ne show n in “Fig . G.”

The Wir e colou r coding fo r Europ e is as

follows:

> Neutral: Blue Wi re

> Live: Brown Wire

> Earth: Green & Yellow

Live

(Brown)

Fig.F Fig.G

Earth

(Green&Yellow)

Neutral

(Blue)

WARNING

Do not use type ‘F’ plug in conjun ction w ith any t ype of adaptors.

Only operate the G EN4 env irodr i machine with a Cor d-set c ertif ied

and provided by th e manuf actur er.

-3.2-

PRODUCT TECHNICAL SPECIFICATIONS

1.SPECIFICATION OF U S MACHINES

ITEM

Electrical

Nominal Power

Rated Amper age

Brush Width

Brush RPM

Wheels

Dimensions - Weight

Dimensions - Hei ght wit h handl e

Dimensions - Dep th

Power Cord

2. SPECIFICATION OF UK AND EU ROPEA N MACHINES

ITEM

Electrical

Nominal Power

Rated Amper age

Brush Width

Brush RPM

Wheels

Dimensions - Weight

Dimensions - Hei ght wit h handl e

Dimensions - Dep th

Power Cord

DIMENSION/CA PACI TY

120V

650W

7.5 Amps

16 inches (40 cm)

550 RPM

2 inches (5 cm) non- marki ng blac k

46 lbs. (21 kg)

44 inches(112 c m)

12 inches (30 cm)

33 feet (10 m)

DIMENSION/CA PACI TY

230V

550W (Nikoda mot or: 3/4 H P)

3.5Amps

16 inches (40 cm)

500 RPM

2 inches (5 cm) non- marki ng blac k

46 lbs. (21 kg)

44 inches(112 c m)

Dimensions - Dep th 12 inc hes (30 c m)

33 feet (10 m)

-4-

EARTHING AND GROUNDING INSTRUCTIONS

Congratulati ons!

You ar e nowth e proud own er of the G EN4 Dry

Carpet Cleanin g Machi ne.

This machine is de signe d to main tain your carpet

using the enviro dri Dry C arpet C leaning System .

By using the envir odri Mi croSp onges you can

perform regula r light c leani ng and grooming of

your carpet very q uickl y, and have the car pet dry

and ready for use im media tely.

The GEN4 handle de tache s for eas y

transportati on and co mpact s torage. The ha ndle

has a 180 degree mov ement f or maxi mum

flexibility an d allow s the mac hine to clean unde r

low furniture. Ther e are foot operate d On/Off

Switches and a han dle loc k keepi ng the handle in

an upright posit ion whe n place d in the tray.

The tray is for mach ine sto rage wh en not in use

This will protec t the bru sh bris tles from being

crushed.

The brush guard pr otect s the mac hine

brushes by preve nting l oose th reads or wires

(telephone or el ectri cal)g etting caught- up in the

brushes.

This appliance c onfor ms with t he following

internationa l and nat ional s afety directiv es:

›ANSY/UL 561 STD;

›CAN/CSA STD C22. 2 NO 10-1 965, R 20 04;

›BS EN 60335 - 1:200 2;

›BS EN 60335 - 2 - 10:20 03.

The GEN4 Machine c omes wi th a one ye ar

warranty on all pa rts exc ept for c ords, switches ,

gears, capacit ors and b rushe s.

See envirodri Ne w Machi ne Wa rrant y Polic y.

-4.1-

MACHINE OPERATION

PRE-RUN MACHINE INSPECTION

Perform a pre-run inspection to find possible

problems that could cause poor performance or

lost time from breakdown. Check the rating plate

to confirm voltage and frequency is the same as

the power supply. NOTE: A 10% variation in

voltage is acceptable.

STARTING MACHINE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before stating machine, make

sure that all covers are in place and secured

properly.

After manually applying the envirodri

MicroSponges onto the carpet commence

cleaning following the steps below:

1. Take the machine out of the tray. Do this by

Leaning the machine back and applying

pressure on the end of the tray with your

foot. NOTE: Place the tray out of the way

when machine in use.

2. Connect the machine to a power supply.

3. Release the handle lock.

4. Depress the ‘ON’ foot switch to engage

machine as shown in the drawing provided.

5. Push and pull the machine slowing over the

carpet.

NB: Best results are obtained by moving the

machine in multiple directions and overlapping

strokes.

MAC HINE SHUT-DOWN AND STORAGE

1. Depress the ‘OFF’ foot switch to power off

machine as shown in the drawing provided.

2. Lock handle in the upright position.

3. Disconnect the power cord from the power

supply. Wind the power cord aro und the

cable holder on the handle.

4. Remove the brushes for cleaning. See Brush

Cleaning and Ma intenance section.

5. Once daily mai ntenance has been

Performed, place the machine back into the

tray.

The machine is no w ready for storage until the

nex t use. Make sure to store your equipment in

a dry place to prolong the life of your machine.

Sto rage outdoors or if left unprotected could

cau se damage to your machine or its internal

par ts, therefore voiding your warranty.

‘ON’ Foot

Switch

‘OFF’F oot

Switch

CAUTION

WARNING

Flammable materials can cause an explosion or

fire. Do not use near flammable or

combustible substances or hot ashes or burning

objects of any kind.

CAUTION

Always ensure that the handle lock is released prior

to switching on the machine.

-4.2-

When not in use or during interrupted cleaning,

the machine must always be placed in the tray

provided to prevent deformation of the brush

bristles. Deformation of brush bristles can

result in unbalanced running and excessive

vibrating or instability of the appliance.

MACHINE OPERATION

MACHINE SAFETY DEVICE:

The GEM4 machine incorporates a Safety

device which prevents its operation when the

handle falls below 0˚ and/or 180˚

Should the handle fall bellow these points, the

machine power will be cut off. The power will

not be reset simply by tilting the handle to the

upright position.

In order to restart the machine after the power

has been cut off, tilt the handle back to the 90˚

position and turn the machine on by pressing the

‘ON’ switch.

0

HandleLocked

90

180

HandleUnlocked

HANDLE LOCKING POSITION

The handle must be locked for transport and

storage.

Lock the handle in an upright position(90˚)

following the steps below:

1. After having completed the cleaning

process, tilt the handle back to the 90˚

position.

2. Turn the machine Locking Button

(clockwise until the green dot aligns with

the Locked arrow).

HANDLE UNLOCKING POSITION

Follow the steps below in order to unlock the

handle:

1. Turn the machine Locking Buttong

clockwise until the green dot aligns with

the Unlocked arrow

CAUTION

Do not use the GEN4 wheels to transport it

over uneven surfaces. Only wheel the

machine on even surface. The machine

wheels have been for internal transportation

‘only’ on carpeted areas. Do not transport the

machine downstairs.

-4.2-

MAINTENANCE

BRUSH CLEANING AND MAINTENANCE

After each session of carpet cleaning. the brushes and the brush housing should be

cleaned. Before

cleaning or changing the brushes, always unplug the machine from the power supply.

Brushes are removed without tools. Tilt and rest the machine on the handle. Push the brush shafts

through with your finger. Alternatively, use a screw driver. Once unlocked. pull the brush shafts through

the brushes and machine housings.

The brushes may be soaked in warm or hot water using mild detergent, and then rinsed with warm

water.

NOTE: Brushes with crushed bristles can often be restored to original condition by soaking in hot water.

Brushes should only be reassembled to the machine base when fully dry. Keep brushes clean and free

from debris. Rotate brushes regularly as this will increase the life span of the brushes and ensure even

wear.

Before reinstalling brushes, clean out machine brush housing by wiping with a clean damp cloth.

BRUSH ASSEMBLY

1- Push Components 4A and 4B towards component 2, until the ‘Internal Hex Profiles’ of both ends of

components 4A and 4B are aligned with the hex profiles of the ‘Top Brush Shaft

Housing’ and the Bottom Brush Shaft Housing’ of components 1 and 3. Assemble

components 4A and 4B following the illustration in image 1, which shows the position of the

bristles of components 4 A and 4B in relation to machine

2- Align components 5A and 5B with the ‘Top Brush Housing’

3- In order to complete the assembly of components 4A, 4B, 5A and 5B follow the steps below: Hold the

‘Brush Top’ with one hand and component 5A with the other.

Slowly push component %A through the ‘Top Brush Shaft Housing’ of component 1 until the ‘Locking

End’ of component 5A reaches the ‘Top Surface’ of component 4A.

Align component 5A with the ‘Top Internal Hex Profile’ of component 4A following the steps below:

> Slowly push component 5A into the ‘Top Internal Hex Profile’ of component 4A

-5-

MAINTENANCE

> As component 5 is being pushed into the ‘Top Internal Hex Profile’, move the ‘Brush Top’

away from and towards component 2 and simultaneously turn the ‘Brush Top’ clock and

anticlockwise. This will help to align and guide component 5A through the ‘Top Internal Hex

Profile’ of component 4A;

► Continue pushing component 5A through until it reaches the ‘Bottom Internal Hex Profile’ of

component 4A.

► Align component 5A with the ‘Bottom Internal Hex Profile’ of component 4A by following the

steps below:

►

> Slowly push component 5A towards th ‘Bottom Internal Hex Profile’ of component 4A.

> As component 5A is being pushed into the ‘Bottom Internal Hex Profile’, move the ‘Brush

Bottom’ away from and towards component 2 and simultaneously turn the ‘Brush Bottom’

clock and anticlockwise.

► Push component 5A through the ‘Bottom Internal Hex Profile’ once it has been properly aligned.

component 5A will reach the ‘Bottom Brush Shaft Housing’ as it goes through the ‘Bottom

Internal

Hex Profile’.

► Align component 5A(which has already been pushed through the ‘Top Brush Shaft Housing’,

the

‘Top Internal Hex Profile’ and the ‘Bottom Internal Hex Profile’) with the ‘Bottom Brush Shaft

Housing’ by following the steps below:

> Slowly push component 5A towards the ‘Bottom Brush Shaft Housing’ of component 4A

> As component 5A is being pushed into the ‘Bottom Brush Shaft Housing’, move the ‘Brush

Bottom’ away from and towards component 2 and simultaneously turn the ‘Brush Bottom’

clock and anticlockwise.

> Once component 5A is engaged with the ‘Bottom Brush Shaft Housing’, push it through the

Housing until the ‘Stop End’ of component 5A touches to surface of the ‘Top Brush shaft

Housing’.

► Repeat the previous steps for components 4B and 5B.

► Ensure the brushes are properly assembled by turning both brushes towards the direction of the

arrows shown in drawing 5.

Dra wing 1 Dra wing 2 Dra wing 3 Dra wing 4 Dra wing 5

-5-

MAINTENANCE

MACHINE MAINTENANCE

The GEN4 machine requires very little

maintenance. Wipe down the machine periodically

with a clean cloth and ensure motor air vents are

not obstructed. DO NOT spray water directly over

the top of machine.

During interruptions of the cleaning process,

always place the machine into the tray or lay it on

its side (gear housing) to prevent deformation of

the brush bristles.

CAUTION

Deformation of the brush bristles can result in

unbalanced running and excessive vibrating

or instability of the appliance.

The machine motor is fitted with a thermal cut out

In the unlikely event of overloading, the motor cut

out will automatically trip. It can be reset after

approximately 30 seconds (or when the machine

cools down) by pushing the ON switch.

DAI LY MAINTENANC E

1. Clean and insp ect brushes.

2. Clean and insp ect brush housing and

machine.

3. Inspect power cord for wear or damage.

To prevent electrical shock rep lace cords

that are frayed or have cracked insulation

immediately.

PER IODIC MAINTENANCE

1. Check all hand les, switches, knobs,

electrical cables and connections on your

machine for damage. Repair or replace

immediately.

2. Inspect and/or replace brushes

3. Inspect and clean (if necessary) brush

guard of any outside debris

ANN UAL MAINTENANCE

1. Check all bear ings for noise and wear.

2. Check motor for operation.

3. Check overall machine for operation.

-5-

MAINTENANCE

PROBLEM

No power to machine Dead electrical circuit breaker

Electrical Shock

Nuisance tripping of circuit

breaker

Brush not turning or scrubbing

Worn bearings

CAUSE

in fuse box

Faulty power cord

Power switch failure

Faulty circuit breaker

Equipment not grounding Follow earthing and

Receptacle not grounded

Faulty circuit breaker Replace circuit breaker

Mechanical problem

Faulty motor Replace motor

Gears worn

Brushes worn

Bearing squealing or grinding

in brush housing

SOLUTION

Check building circuit breaker

Replace power cord

Replace power switch

Replace circuit breaker

grounding instructions

Have an electrician inspect

the building’s wiring

Test circuit breaker for

continuity. Higher amp draw

may indicate faulty parts. Find

parts not moving freely and

repair or replace

Replace gears not functioning

Replace brushes

Replace worn bearing

-5.1-

ELECTRICAL DIAGRAM

16uF

CAPACITOR

60u F

CAPA CITOR

STAR T

RUNNI NG

10m Cord-Set

220~240V 50Hz

MOTOR

(Niko da Mo tor )

RED

BLAC K

BROW N

BUTT SPLICE

BROW N

POWER CABLE

GREE N

W

ExternalWi ring

PCB

HITE

BLAC K

220~2 40V,

BLAC K (13)

BLAC K (12)

BLAC K (11)

Internal Wi ring

BLAC K (10)

(Nor mally O pened )

Push Button Sta rt

Push Button Sto p

(Nor mally C losed )

Micro Switch

BLAC K (14)

WHIT E

BLAC K

WHIT E

ORAN GE

YELL OW

BLUE

10

11

12

13

14

15

L2

1

4

3

-5.2-

BLAC K (15)

CLEANTEC INNOVATION LTD WARRANTY POLICY

CLEANTEC INNOVATION LTD -Li mited Warr anty

Cleantec Innovation Ltd warrants to the original purchaser only (ʺBuyerʺ) that each new envirodri Machine

shall be free from defect in material and workmanship upon delivery. Cleantec Innovation Ltd’ liability is

limited to repair or replacement of parts at the discretion of Cleantec Innovation Limited and/or the factory

authorised service centre.

A warranty registration card is to be completed and returned within 14 days of purchase to register the

purchases of your machine. Failure could result in any warranty claims not being undertaken.

Items not covered by warranty include, but are not limited to:

► Damage resulting from accidents abuse, misuse or acts of God(lightning/flood etc,)

► Damage in transit

► Rental units

► Failure due to lack of proper maintenance or care

► Relatively minor adjustments such as tightening of screws or bolts, etc. not connected with the

placement of parts.

► Repairs or alterations by a person or organisation other than the factory or authorised repair

centre.

► Normal wear items, handles, wheels, brushes**, gears**, power cords.

Cleantec Innovation Ltd equipment used in commercial applications has limited warranty of one year with

exception of electric motors with carbon brushes, being subject to wear, their durability depends on the

number of hours of use. It does not depend on the years of life of the machine. Example: In commercial

application, The eventual substitution of the motor under warranty will therefore be effected only in case

of tatal wear. If, after inspection of the returned machine or any part or parts, Cleantec Innovation Ltd in

connection with the replacement or repair or any parts there of shall be at the buyer’s responsibility.

Any parts returned to Cleantec Innovation Ltd for replacement shall become the property of Cleantec

Innovation Ltd. In no Event shall cleantec Innovation Ltd be liable for any indirect, special, incidental,

consequential or other damages including but not limited to damage or loss of property or equipment,

lost revenues or profits, claims of customers, or harm to goodwill or business reputation directly or

indirectly arsing from the safe, handling or use of the envirodri Machine, or from any other costs

relating thereto and Cleantec Innovation Ltd liability hereunder. Cleantec Innovation Ltd shall not be

liable to the buyer for any claims, damages, injuries, actions or causes of action whatsoever based on

negligence or strict liability. Cleantec Innovation Ltd Limited makes no warranty that its envirodri

Machines shall be merchantable or that such machine shall be fit for any particular purpose. Moreover,

Cleantec Innovation Ltd makes no expressed or implied warranties except for the limited warranty set

forth herein. In addition no representation or warranty, expressed or implied, made by any dealer, sales

representative, or field agent or Cleantec Innovation Ltd which is not specifically set forth herein shall

be binding on Cleantec Innovation Ltd.

Genuine envirodri replacement parts shall be free from defects in material and workmanship for a period of 90

days after ″installation″ and shall be subject in all respects to the limitations and exclusions of this limited

warranty.

Making a Claim

With each new machine sold a warranty card and Warranty Request Form will be supplied with the instruction

manual of the new machine, this is standard practice.

PLEASE RETURN YOUR CARD AS FAILURE TO DO SO COULD INVALIDATE YOUR WARRANTY.

Upon finding a fault with your machine which you believe to still have warranty the″envirodri Machine Warranty

Request Form(1)″ should be completed in full and faxed to 08707 337734.

Once we have received your form a representative from Cleantec Innovation Ltd will call you within 24 hours

to discuss the problem and arrange for collection of your machine if required. Bookings for collections are

normally made for the same day but you will be advised when to expect a courier.

-6-

SPARE PARTS LIST

MODEL GEN4

CONFIGURATIONS:

E00-4-9001-US Model

E00-4-9002-UK Model

E00-4-9003-Europe Model

E00-4-9004-China Model

NB:

▪ The Bearing Pack(Item 29) is composed of 5 of 35x17x10(6003) Bearings and 2 of

32x12x10 (6201) Bearings.

▪ The Machine Base Label Set (Item 43) is composed of the “ON” and “OFF” labels,

the LOCKED/UNLOCKED label and the CAUTION label.

▪ Item 47 refers to the Wiring Harness that connects the “ON” and “OFF” Switches to the

PCB.

▪ The Micro-Switch (Item 6) is cold with its Wiring Harness.

SHEET 1 OF 7

Handle

Spare Parts List

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

ITEM NO.

1,2,3

1

2

3

4

PART NO.

E00-4-1002

E00-4-1010

E00-4-1003

E00-4-1004

E00-4-1005

E00-4-4002

E00-4-4001

E00-4-1013

E00-2-2004

E00-4-1049

E00-4-1008

E00-4-1009

E00-2-1005

E00-4-4014

E00-0-3054

E00-0-3040

E00-0-3041

E00-0-3042

E00-0-3043

E00-2-1010

See Below

E00-0-3053

E00-0-3046

E00-4-4012

DESCRIPTION

Lower Handle Assembly

Upper Handle Assembly

Handle Linking Shaft

Connecting Bar Gen 4

Handle Linking Shaft

Cross Bar Assembly

Carry Handle Assembly

Locating Bush Top Handle

Handle Grip

Frontal Top Handle Cover

Frontal Bottom Handle Cover

Back Handle Cover

Cable Holder

Bottom Cable Holder Assembly

Screw M5 x 25 Stl Skt Cap

Screw M8 x 25 Stl Skt Cap

Screw M6 x 50 Stl Skt Csk

Screw M4 x 16 Self Tapping

Screw M5 x 10 Stl Skt Butt

Thumb Wheel

10m Cord Set

Screw M6 x 35 Stl Skt Cap Hd

Nut Nylon Insert M6

Handle Label Set

Handle Assembly & Sub Assemblies

PART NO.

E00-4-4008*

E00-4-5005

E00-4-5007*

E00-4-5006

E00-4-4011

DESCRIPTION

Complete Handle (With Labels)

Top Handle Assembly (With Label)

Lower Handle Assembly(With Label)

Handle Kit

Cross Bar Assembly

QTY PER PACK

1

1

2

2

1

1

1

2

2

1

1

1

1

1

2

2

2

16

4

2

1

2

2

1

QTY PER PACK

1

1

1

1

1

Machine Twinning Parts

PART NO.

E00-4-4009

E00-4-4017

E00-4-4010

E00-4-4015

DESCRIPTION

Twinning Bar Assembly 115V

Twinning Bar Assembly 230V

Y Junction Adapter 115V

Y Junction Adapter 230V

QTY PER PACK

The twinning bar Assemblies contain one Junction Adapter

SHEET 2 OF 7

1

1

1

1

Brushes

PART NO.

GEN 4G

GEN4GW

GEN4W

GEN4BW

GEN4B

DESCRIPTION

Gold Brush

Gold and White Brush

White (Standard) Brush

Black and White Brush

Black Brush

10m Cord Set

USITEM NO

21 E00-4-2021 E00-4-2023

* Please specify your Cord Set requirements when ordering these components

UK

EUROPE CHINA

E00-4-2022 E00-4-2032 E00-4-2033 E00-4-2033

JAPAN 50HZ

QTY PER PACK

2

2

2

2

2

JAPAN 60HZ

SHEET 2 Cont. OF 7

Handle

SparePartsExplodedDiagram-1

9 17

13

22

18

12

14

23

21

5

8

10

24

2

4

19

24

1

3

20

15

6

7

16

GEN4Machine-SpareParts

SHEET3OF7

GEN4Machine-SpareParts

SHEET 4OF7

Loading...

Loading...