CleanFreak 400BUCF Operator's Manual

Propane Burnisher

400BUCF

Operator’s Manual

Instructions For Use

Failure to read and understand this manual before operating this machine or performing service

on this machine may result in injury to the operator or nearby personnel or result in damage to the

machine or nearby property. Each operator must be trained in the operation of this machine before

being allowed to use it. Contact CleanFreak Customer Service at 1-888-722-5508 or

1-920-882-8453 to inquire about training or to request a replacement manual.

NOTICE

Proper maintenance is necessary with all propane powered floor

machines. Following the scheduled maintenance procedures found in

your operation manual will provide many years of uninterrupted service.

In addition to the scheduled maintenance procedures listed it is

recommended to have your machine serviced by certified service personnel

every three months. This service should include an emissions check.

DANGER! For your safety, if you smell

propane:

1. Extinguish any open flame.

2. Open window.

3. Do not touch electrical switches.

4. Immediately call your propane supplier.

Record This Important Information

Date of Purchase

Purchased From

Address

City State Zip

Phone Contact

DANGER! Do not store or use gasoline or

other flammable vapors and liquids in the

vicinity of this or any other appliance.

Machine Model

Machine Serial Number

Important Phone Numbers

Medical Emergency

Police

Fire Department

In this Operation Manual you will find three statements that you must read and observe to ensure

safe operation of this machine.

DANGER! indicates that the possibility of severe bodily injury or death can occur if DANGER!

statements are ignored. Read and observe all DANGER! statements included in the Operation

Manual and attached to the machine.

WARNING! indicates that the possibility of bodily injury to the operator and other people can occur

if WARNING! statements are ignored. Read and observe all WARNING! statements included in

the Operation Manual and attached to the machine.

CAUTION! indicates that the possibility of damage to the machine or other property can occur if

CAUTION! statements are ignored. Read and observe all CAUTION! statements included in the

Operation Manual and attached to the machine.

Table of Contents

Quick Reference Specifications..........................................5

Safety Precautions..............................................................6

Refueling and Storage of Fuel Cylinders............................8

Operator Responsibility.......................................................8

Machine Preparation.........................................................9

Unpacking the Machine........................................9

Filling the LP Cylinder...........................................9

Installing the LP Cylinder......................................9

Controls and Instruments.....................................10

Engine Ignition Switch..........................................11

Hour Meter/Tachometer........................................11

Fuse.............................................................11

Engine Throttle.....................................................11

Handle Adjustment...............................................11

Rok-Bak & Pad Change.......................................12

Wheel Adjustment................................................12

How the Machine Works...................................................13

Maintenance...............................................................17

Oil Level Inspection..............................................17

Oil Change...........................................................17

Oil Filter Replacement.........................................17

Air Filter Inspection and Replacement...............18

Spark Plug Inspection and Replacement............18

Engine Dust Filter................................................19

Valve Clearance & Re-torque Heads..................19

Valve Seating.......................................................19

Head Bolt Maintenance.......................................19

Cooling Fin Maintenance.....................................19

Inspect Pad and Padholders...............................19

Belt Maintenance.................................................19

Battery Maintenance............................................20

Machine Storage..................................................20

Repacking the Machine.......................................20

Transporting the Machine.....................................20

Pre-Operation Checklist....................................................13

LP Fuel Cylinder................................................................13

Installing the LP Fuel Cylinder..........................................13

Starting the Machine........................................................14

Idling and Stopping the Machine.....................................14

Burnishing..................................................................14

Machine Troubleshooting..................................................15

Scheduled Maintenance Chart........................................16

Machine Specifications.....................................................21

Electrical Schematic.............................................22

Connections......................................................23

Engine Assembly ...............................................26

Deck Assembly.....................................................28

Handle Assembly.................................................30

Main Assembly.....................................................32

Regulator & Solenoid Assembly...........................34

Small Off Road Engine Certification Warranty...............36

Manufacturer’s Warranty...................................................37

Safety Awareness Form...................................................39

4

Quick Reference Specifications:

Capacities:

lEngine Oil:

- Filter not removed: 1.6qt. (1.5L)

- Filter removed: 1.8qt. (1.7L)

- Engine Oil Type: SAE30 with API Service Classification SH or SJ

Routine Maintenance Parts:

l Sentinel Synthetic Oil: MP507700

l Engine Dust Filter: MP035200

l Engine Oil Filter: KA490657007

l Engine Primary Air Filter (Paper Element): KA110130752

l Engine Air Pre-Cleaner (Foam Element): KA110137046

l Spark Plug: KA920702112

l Battery: MP362200

l Drive Belt: MP8070 (21”)

MP272900 (28”)

l Fuses: SS2570 (20A)

l LP Cylinder: MP105900 (Steel)

5

Safety Precautions

Anyone operating the machine should read the

following carefully and be informed of potentially

dangerous operating conditions. Operators should

be familiar with the location and use of all safety

devices on the machine. Do not use the machine

if it is not in proper operating condition, and report

any damage or operation faults immediately.

DANGER! Operate this machine in a well-ventilated

area. It is the responsibility of the machine operator,

machine owner, and the site manager to ensure that the

air exchange system where the machine is to be used is

in compliance with local building codes and is operating

properly. Failure to operate this machine in a wellventilated area could lead to sickness, injury, or death

from carbon monoxide (CO) exposure.

DANGER! This machine emits CO, which is colorless,

odorless, non-irritating gas. The first symptoms of CO

exposure include headache, drowsiness, dizziness,

and nausea. If you should experience any of these

symptoms while operating the machine, shut off the

machine and go outside to get fresh air. Have the

machine tested for CO emissions by a qualified service

technician before using it again.

DANGER! Prolonged or high exposure to CO may

result in vomiting, confusion, and collapse in addition

to loss of consciousness and muscle weakness. If

such symptoms occur, call 911 for emergency medical

attention. If you have experienced these symptoms,

DO NOT operate this machine or any other propane

machine again until cleared by a physician. Excessive

exposure to CO can result in death.

DANGER! Propane is a highly flammable fuel. If you

smell propane, shut off the machine immediately and

take it outside the building. DO NOT use the machine

again until a qualified service technician has corrected

the propane leak. DO NOT use or allow another person

to use an ignition source such as a cigarette lighter

near the propane machine. DO NOT smoke near the

propane machine. DO NOT vent a propane cylinder

inside a building. DO NOT store propane cylinders

inside a building.

DANGER! Federal law and California State law

prohibits the following acts or the causing thereof: (1)

the removal or rendering inoperative by any person

other than for purposes of maintenance, repair,

or replacement, of any device or element of design

incorporated into any new engine for the purpose

of emission control prior to its sale or delivery to the

ultimate purchaser or while it is in use, or (2) the use of

the engine after such device or element of design has

been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are

the acts listed below: DO NOT tamper with the original

emission related part.

l Throttle body and internal parts

l Spark plugs

l Magneto or electronic ignition system

l Air cleaner elements

l Crankcase

l Cylinder heads

l Breather chamber and internal parts

l Intake pipe and tube

l Regulator

l Fuel lock-off

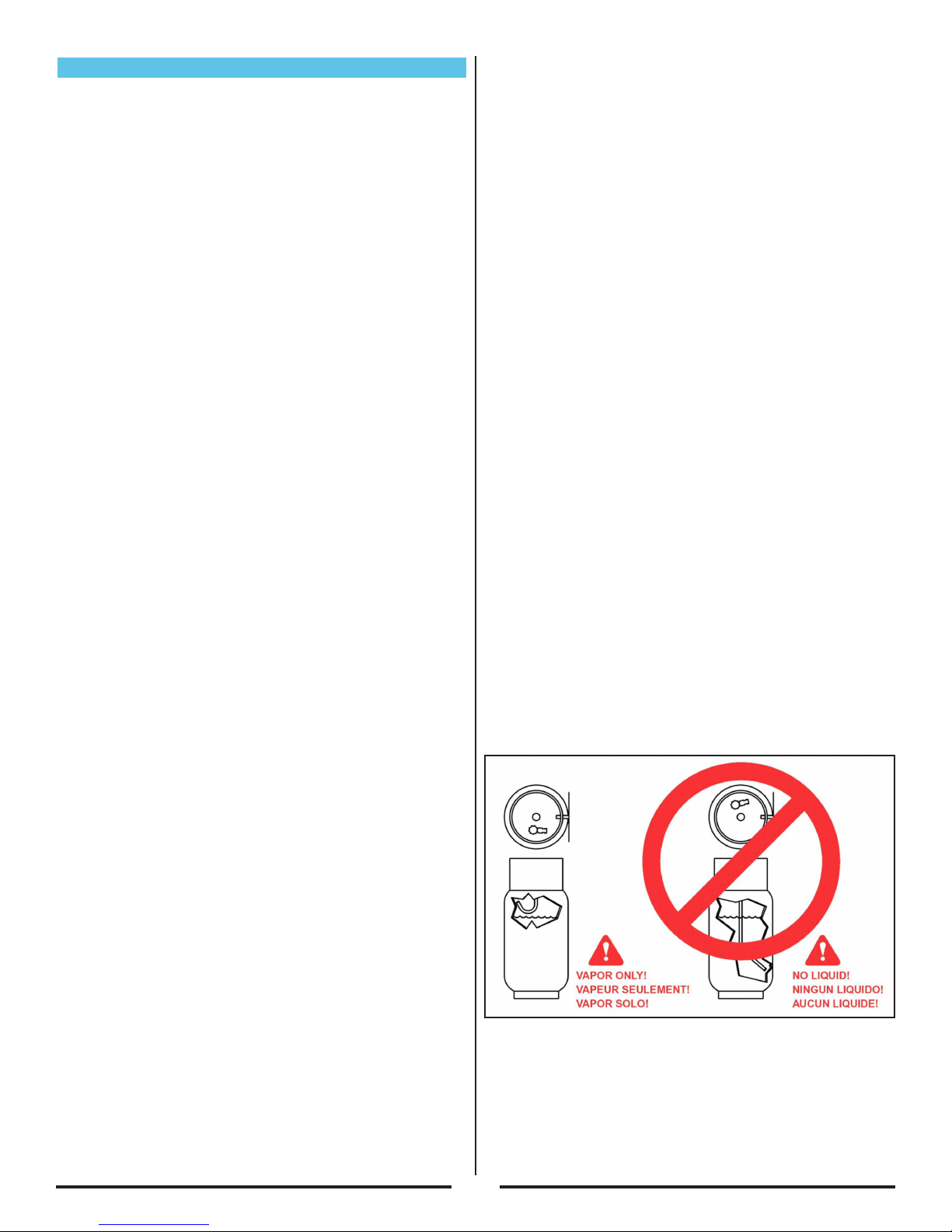

WARNING! Overfilled or liquid withdraw cylinders can

damage the fuel system and create a fire hazard. DO

NOT overfill the cylinder or use a liquid withdraw

cylinder on the machine. If the regulator freezes stop

the burnisher and take the cylinder outside. Inspect

cylinder, if a vapor withdraw cylinder, use gloves or

pliers to open bleeder valve and purge cylinder until

only vapor is escaping. If it is a liquid withdraw cylinder,

replace with a vapor withdraw cylinder. Both cylinders

are shown below.

DANGER! This machine has parts, including the pad

assemblies, that can cause severe injury if these parts

are contacted while they are moving. DO NOT allow

any part of the body or clothing to come in contact

with these parts while they are moving. DO NOT try

to change attachments while the machine is running.

DO NOT allow other people to come near the machine

while it is in operation. DO NOT allow the machine to

run unattended. DO NOT leave the machine in a place

where unauthorized or untrained personnel could use

the machine. DO NOT run the machine with the pad off

center, damaged or missing. DO NOT run machine with

unsecured guards and shields. DO NOT operate the

machine if the machine has loose parts.

6

WARNING! Modifications or alterations to this machine

can lead to personal injury or damage to the machine.

DO NOT make unauthorized modifications or alterations

to this machine. CleanFreak assumes no liabilities

for injury or damage resulting from an unauthorized

modification or alteration to the machine. Any

unauthorized modification or alteration to this machine

voids all warranties.

WARNING! The muffler and the engine become hot

enough while the machine is in operation, and for a

long time after the machine is shut off, to cause severe

burns. DO NOT touch these parts of the machine until

they have cooled.

WARNING! Injury can occur to the eyes and body while

using the machine. Safety goggles, safety shoes, and

safety clothing are recommended while operating the

machine.

WARNING! Continuous exposure to high noise levels can

cause hearing loss. Hearing protection is recommended

while the machine is in operation.

WARNING! Machine vibration may cause tingling

or numbness in the fingers or hands. Gloves are

recommended to reduce machine vibration. If tingling or

numbness persists, shut off the machine. If the vibration

is caused by loose parts, adjust or tighten these parts

before using the machine again.

CAUTION! A dirty engine filter can cause overheating.

Check and replace following recommended maintenance

schedule.

CAUTION! Overheating can be caused by insufficient or

low oil. Check oil before each use, and fill or change as

needed.

CAUTION! Never over-fill engine with oil. Over-filling

could cause irreparable damage to the engine.

CAUTION! Do not engage starter for more than 5

seconds. Allow a 10 second cool-down period for

second failed start-up attempt.

CAUTION! Perform all recommended scheduled

maintenance. Regular maintenance of your propane

powered floor machine is necessary to keep it in safe

working condition.

CAUTION! DO NOT operate machine unless trained and

authorized. DO NOT operate machine unless you have

read and understand the operation manual. DO NOT

operate machine in flammable or explosive areas.

CAUTION! Before starting machine ensure all safety

devices are in place and functioning properly. Before

starting machine check for proper operation.

CAUTION! When using machine, go slowly on inclines or

slippery surfaces. Use care when operating machine in

reverse.

CAUTION! When servicing machine, stay clear of moving

parts. DO NOT wear loose clothing when working

on machine. Block machine wheels before raising or

jacking up machine. Use hoist stands that will support

the weight of the machine. Wear eye and ear protection

when using pressurized air or water. Disconnect

battery connections before servicing machine. Only use

replacement parts supplied by CleanFreak.

CAUTION! When loading or unloading machine onto or

off a truck or trailer, turn machine OFF. Only use a truck

or trailer that will support the weight of the machine

to transport. DO NOT push the machine onto or off a

truck or trailer unless the load height is 15 in (380mm)

or less from the ground. Block machine wheels when

transporting. Tie the machine down securely to truck or

trailer when transporting.

CAUTION! Overheating can be caused by dirty oil. Check

oil before each use and change regularly following

recommended maintenance schedule.

7

This machine is manufactured for

commercial use only

This machine is designed and manufactured for indoor

use in burnishing wax coated hard floor surfaces.

CleanFreak does not recommend use of this machine

in any environment other than an indoor environment.

This propane powered floor machine is designed and

manufactured for commercial floor burnishing only. This

machine is designed to burnish most modern types of

floors including composition tile, stone, marble, terrazzo,

and resilient floor covering, and some coated wood

floors. Even though NFPA 11.13.2.3 says...”the use

of floor maintenance machines in buildings frequented

by the public, including the times when such buildings

are occupied by the public, shall require the approval of

the authority having jurisdiction.” CleanFreak suggests

usage when occupancy of a given work area is minimal.

These machines should not be used

l In nursing homes, hospitals, day-care centers, etc.

that are occupied.

l By unqualified or untrained personnel.

l Unless properly maintained and adjusted.

l On areas with obstructions such as thresholds, floor

outlet boxes, etc.

l In areas where loose debris or other objects are

present.

l In rooms and areas without proper ventilation.

Refueling and Storage of Fuel Cylinders

This machine uses a 20lb (9.1kg) capacity aluminum or

steel cylinder, which meets the DOT 4E240 standards.

These cylinders are also listed by UL. In addition, the

steel cylinder meets European TPED specifications

and is CE compliant. Filling should be done ONLY

by a qualified propane dealer. FILL THROUGH THE

SERVICE VALVE ONLY. A properly filled cylinder should

not exceed 80% of the rated capapcity.

DO NOT attempt cylinder repair. Return the cylinder to

your propane dealer if repair is necessary. Please note

that DOT regulations prohibit shipping of cylinders after

the cylinder has been filled with propane. When not in

use, cylinders should always be stored outside in an

upright position in a secure, tamper-proof, steel mesh

storage cabinet. The cabinet may be located next to

the building, but with at least five feet (1.5 m) of space

between the cabinet and the nearest building opening

(door or window).

The cylinder to be used on this machine is a vapor

withdraw cylinder. A liquid withdraw cylinder is not

to be used with this machine. The use of a liquid

withdraw cylinder on a vapor withdraw system could

freeze the regulator and create a fire hazard. The

National Fire Protection Association (NFPA) Standard

for Storage and Handling of LP Gas is the appropriate

authority for safe propane use. A copy of this publication

is available through the National Fire Protection

Association (1-800-344-3555) or www.NFPA.org.

Operator Responsibility

The operator is responsible for performing the

recommended daily maintenance and checkups of

the machine to keep it in good working condition. The

operator must inform the service mechanic or supervisor

when recommended maintenance procedures are

required as described in the “MAINTENANCE” section

of this manual.

l Read this manual carefully before operating this

machine.

l FOR SAFETY: DO NOT operate machine before

reading and understanding the operation manual.

l Check the machine for shipping damage.

Keep your machine regularly maintained by following

the maintenance information in this manual. Order

parts and supplies only from CleanFreak Use the parts

illustration section of your manual when ordering parts.

During and after operation, perform the recommended

daily and hourly procedures outlined in the Maintenance

Chart.

8

Machine Preparation

Unpacking the Machine

The machine is shipped boxed on a wooden pallet. To

unpack machine:

1. Cut and remove bands holding the box to the pallet.

2. Remove staples attaching the box to the platform at

the bottom edge of the box.

3. With two people, one at either end of the box, lift box

straight up and off machine.

4. Cut and remove bands securing the machine to the

pallet.

5. Remove back brace.

6. Remove hex lock nut, bolt, and washer from handle.

7. Rotate handle to the user position. Then insert the

bolt through the handle bracket and handle top.

9. Check machine fluid levels (engine oil). See

Maintenance section.

NOTE: If machine was shipped by airfreight, add

engine oil.

10. Carefully back the machine off of the pallet.

Filling the LP Cylinder

This machine uses the 20 lb (9.1 kg) capacity cylinder,

which meets the D.O.T. 4E240 standards. These

cylinders are also listed by UL. In addition, the steel

cylinder meets European TPED specifications and is CE

compliant. Filling should be done ONLY by a qualified

propane dealer. A properly filled cylinder should not

exceed 80% of the rated capacity. Do not overfill the

cylinder or use a liquid withdraw cylinder on the

machine. The use of a liquid withdraw cylinder on a

vapor withdraw system could freeze the regulator and

create a fire hazard.

8. Place the washer and hex lock nut on the bolt. Adjust

the handle to the desired height and tighten the hex

lock nut.

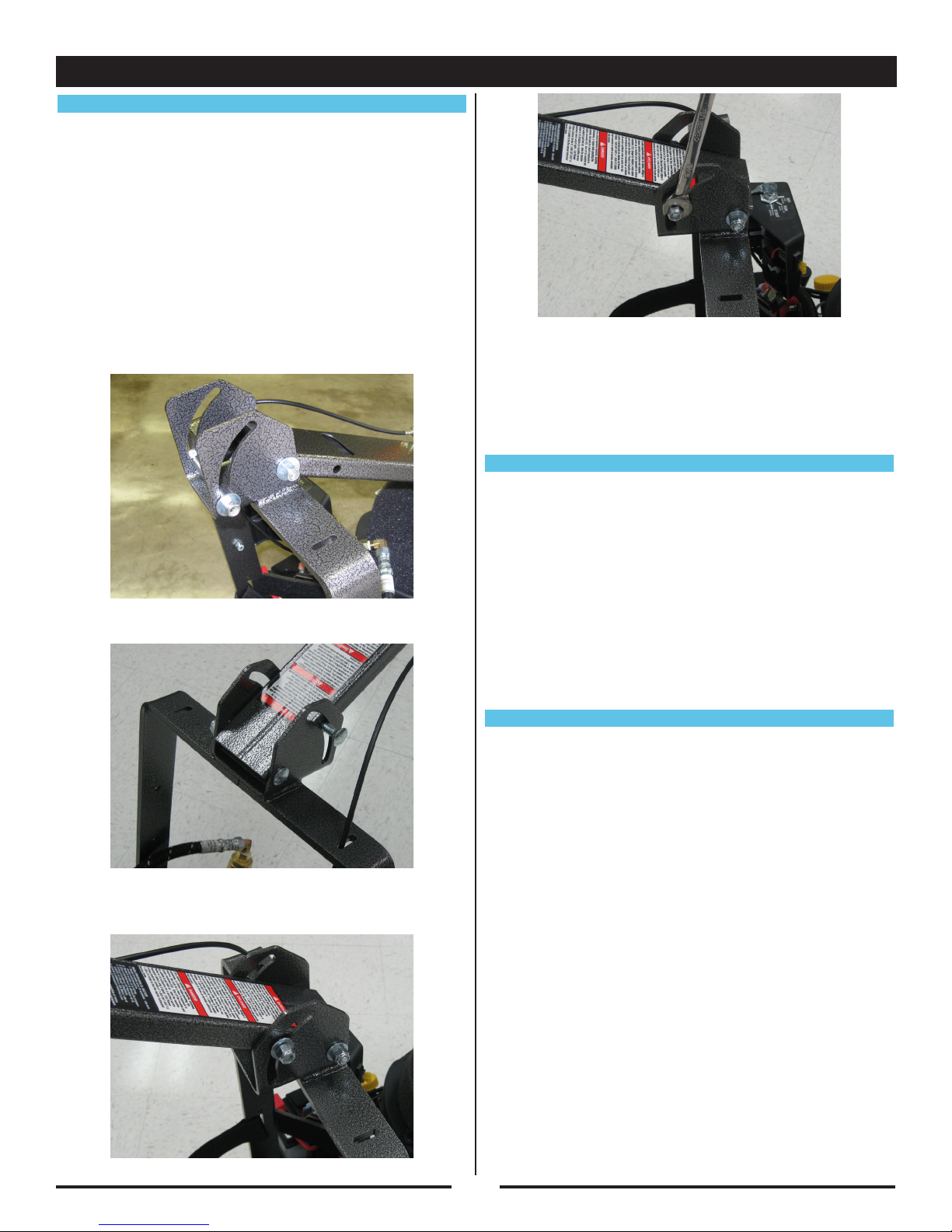

Installing the LP Cylinder

Place the cylinder on the cylinder platform at the back

of the machine. Connect the fuel hose coupling to the

service valve by turning to the right (clockwise). HAND

TIGHTEN ONLY! Make sure coupling is not cross

threaded and check for leakage by noting any propane

odors immediately after cylinder is connected. Finally,

secure the tank to the machine using the adjustable

strap. Remove slack by pulling on the loose end and

securing with the velcro.

TO REMOVE THE LP CYLINDER, reverse the above

procedure. Always connect or change cylinders in a

well-ventilated area.

9

Engine

Throttle

Machine Components

Controls and Instruments

Ignition

Switch

Hour Meter /

Tachometer

10

Ignition Switch

This machine features a key switch ignition.

Start: Turn the key all the way clockwise or START to

engage the engine starter motor. Once the engine

starts release the key.

NOTE: Always start this machine with the engine

throttle in the idle or “slow” position.

Run: This is the position of the key while the engine is

running.

Off: Turn the key to the “OFF” position to stop the

engine from running.

NOTE: For safety, always close the propane cylinder

valve to stop the engine and then turn the key switch

to the “OFF” position.

Fuse

The machine’s electrical circuit is protected by a fuse,

which stops the flow of current in the event of a circuit

overload. Once a fuse blows, it must be replaced. If

the overload that caused the fuse to fail is still present,

the new fuse will fail and the problem must be corrected.

DO NOT bypass any fuse. The ignition fuse is located

on the side of the starter switch panel.

Fuse

Engine Throttle

The engine throttle controls the engine speed. To

increase engine speed, move the hand lever forward.

For idle position, pull the lever back.

Hour Meter / Tachometer

The hour meter / tachometer records the number

of hours the machine has been powered ON. The

hour meter reading is used to mark recommended

maintenance intervals. It also displays the engine

speed. This meter displays hours when the machine

is turned OFF and engine speed when the machine is

turned ON.

Handle Adjustment

1. The height of the handle can be adjusted by raising

or lowering the handle.

2. If necessary, use a wrench to loosen the nut that

retains the handle in the adjustment bracket.

11

Rok-Bak & Pad Change

1. Close the valve on the propane cylinder, allow the

engine to stop and turn the machine OFF.

2. Remove the propane cylinder.

3. Raise the handle to the full-up position (about a 45°

angle).

4. Lift up on the front of the deck rocking the machine

back until it rests on the handle grips.

Wheel Adjustment

1. Close the valve on the propane cylinder, allow the

engine to stop and turn the machine OFF.

2. Remove the propane cylinder.

3. Raise the handle to the full-up position (about a 45°

angle).

4. Rock the machine by lifting up on the front of the

machine until it rests on the handle grips.

5. Remove the pin that retains each wheel and relocate

to the desired wheel position.

NOTE: To increase pad pressure (more aggressive)

move wheels to rear of machine. To decrease pad

pressure (less aggressive) move wheels toward the

front of machine.

5. Remove centering device and inspect pad. If pad

has worn to less than a 1/4” (6mm) thick, replace it.

CAUTION! Carefully inspect the pad holder for cracks

or damage. Replace if necessary.

WARNING! A damaged pad holder rotating at high

speeds may be an extreme hazard if it should come

apart.

6. When lowering the machine down, do not drop the

machine. Slowly lower the machine to the floor until

the wheels are on the ground.

12

Loading...

Loading...