OPERATOR'S MANUAL

CLEAN BURN MODELS: CB-1400, CB-1800, and CB-2800

U.L. Listed Used Oil

Burning Appliance

#MH15393 (N)

U.L.-C Listed

#CMP217

MULTI-OIL FURNACES

with CB-525-S2 BURNER

PUBLICATION DATE: 12/15/01, Rev. 7 CLEAN BURN PART # 43081

WARNING: DO NOT assemble, install, operate, or maintain this equipment without first

reading and understanding the information provided in this manual. Installation and

service must be accomplished by qualified personnel. Failure to follow all safety precautions

and procedures as stated in this manual may result in property damage, serious personal injury

or death.

IMPORTANT FOR U.S. INSTALLATIONS: All installations must be made in accordance with state and local codes

which may differ from the information provided in this manual. Save these instructions for reference.

IMPORTANT FOR CANADIAN INSTALLATIONS: These instructions have been reviewed and accepted by

Underwriters' Laboratories of Canada as being appropriate for the installation of the ULC labelled products

identified herein. The use of these instructions for the installation of products NOT bearing the ULC label and

NOT identified herein may result in an unacceptable or hazardous installation.

IMPORTANT FOR CANADIAN INSTALLATIONS: The installation of this equipment is to be accomplished by

qualified personnel and in accordance with the regulation of authorities having jurisdiction and CSA Standard B 139,

Installation Code for Oil Burning Equipment.

WARRANTY INFORMATION

Clean Burn, Inc., MANUFACTURER, hereby warrants that MANUFACTURER's products shall be free from defect in

material and workmanship under normal use according to the provisions and limitations herein set forth. MANUFACTURER

warrants the heat exchanger/combustion chamber, excluding the ceramic flame target, for three (3) years from the date of

purchase by the purchaser and pro rata thereafter according to the following schedule: (a) If the defect occurs during the

fourth year, customer pays 60% of parts, replacement or repair. (b) If the defect occurs during the fifth year, customer pays

65% of parts, replacement or repair. (c) If the defect occurs during the sixth year, customer pays 70% of parts, replacement or

repair. (d) If the defect occurs during the seventh year, customer pays 75% of parts, replacement or repair. (e) If the defect

occurs during the eighth year, customer pays 80% of parts, replacement or repair. (f) If the defect occurs during the ninth

year, customer pays 85% of parts, replacement or repair. (g) If the defect occurs during the tenth year, customer pays 90% of

parts, replacement or repair. MANUFACTURER warrants all other Clean Burn products for a period of one (1) year from the

date of purchase by the purchaser.

LIMITATIONS:

The obligation of MANUFACTURER for breach of warranty shall be limited to products manufactured by MANUFACTURER (1) that are

installed, operated and maintained according to MANUFACTURER's instructions furnished and/or available to the purchaser upon

request; (2) that are installed according to all other applicable Federal, State and local codes or regulations; and (3) that the purchaser

substantiates were defective in material and workmanship notwithstanding that they were properly installed and correctly maintained as set

forth above and were not abused or misused.

The obligation of MANUFACTURER shall be limited to replacing or repairing the defective product, at the option of the

MANUFACTURER. MANUFACTURER shall not be responsible for any labor or costs of removal or reinstallation of its products and

shall not be liable for transportation costs to and from its plant at Leola, Pennsylvania.

Use of parts for modification or repair of the product or any component part thereof not authorized or manufactured by

MANUFACTURER specifically for such product shall void this warranty.

This warranty shall not apply to any damage to or defect in any of MANUFACTURER's products that is directly or indirectly caused by (1)

force majeure, Act of God or other accident not related to an inherent product defect; or (2) abuse, misuse or neglect of such product,

including any damage caused by improper assembly, installation, adjustment, service, maintenance or faulty instruction of the purchaser.

Other than as expressly set forth hereinabove, MANUFACTURER makes no other warranty, express or implied, with respect to any of

MANUFACTURER's products, including but not limited to any warranty of merchantability or fitness for a particular purpose.

And in no event shall MANUFACTURER be responsible for any incidental or consequential damages of any nature suffered by purchaser

or any other person or entity caused in whole or in part by any defect in any of MANUFACTURER's products. Any person or entity to

whom this warranty extends and who claims breach of warranty against MANUFACTURER must bring suit thereon within one year from

the date of occurrence of such breach of warranty or be forever barred from any and all legal or other remedies for such breach of warranty.

MANUFACTURER is not responsible for and hereby disclaims any undertaking, representation or warranty made by any dealer, distributor or other person that is inconsistent with or in any way more expansive than the provisions of this limited warranty.

This warranty grants specific legal rights and shall be read in conformity with applicable state law. In some jurisdictions, the applicable

law mandates warranty provisions that provide greater legal rights than those provided for herein. In such case, this limited warranty shall

be read to include such mandated provisions; and any provision herein that is prohibited or unenforceable in any such jurisdiction shall, as

to such jurisdiction, be ineffective to the extent of such prohibition or unenforceability without invalidating the remaining provisions and

without affecting the validity or enforceability of such provision in any other jurisdiction(s).

TRADEMARKS

The Clean Burn logo is a trademark of Clean Burn, Inc. All other brand or product names mentioned are the registered

trademarks or trademarks of their respective owners.

Copyright © 2001 Clean Burn, Inc. All rights reserved. No part of this publication may be reproduced, or distributed without

the prior written permission of Clean Burn, Inc. 34 Zimmerman Road, Leola, PA 17540. Subject to change without notice.

COPYRIGHT

TABLE OF CONTENTS

SECTION 1: INTRODUCTION.................................................................................... 1-1

Guide to this Manual ........................................................................................................ 1-1

For Your Safety... ............................................................................................................. 1-2

SECTION 2: UNPACKING ......................................................................................... 2-1

Removing the Shipping Pallet .......................................................................................... 2-1

Unpacking and Inspecting All Components..................................................................... 2-1

Furnace Component List ........................................................................................... 2-1

Warranty Registration ...................................................................................................... 2-2

SECTION 3: FURNACE ASSEMBLY ......................................................................... 3-1

Understanding Assembly ................................................................................................. 3-1

Required Tools and Materials ................................................................................... 3-1

Installing the Observation Port ......................................................................................... 3-4

Determining the Fan/Blower Assembly Configuration.................................................... 3-5

Unit Heater Models: Installing the Fan Assembly ........................................................... 3-6

Installing the Fan Assembly ...................................................................................... 3-6

Installing the Fan Brace (CB-1800/CB-2800 Only) .................................................. 3-6

Central Furnace Models: Installing the Blower Assembly ............................................. 3-7

Preparing the Furnace Cabinet for Blower Installation ............................................. 3-7

Installing the Blower Mount on the Furnace Cabinet................................................ 3-9

Installing the Blower on the Blower Mount ............................................................ 3-10

Installing the Motor on the Blower ......................................................................... 3-10

Installing the Motor Pulley ...................................................................................... 3-11

Installing the Blower Pulley and V-Belt .................................................................. 3-11

Installing the Belt Guard and the Blower Guard ..................................................... 3-12

Installing the Electrical Conduit .............................................................................. 3-12

Installing the Burner ....................................................................................................... 3-13

Checking the Burner Nozzle and Electrodes ........................................................... 3-13

Mounting the Burner on the Hinge Bracket ............................................................ 3-14

Installing the Connector Block, Oil Line Tubing, and Air Line Tubing ........................ 3-14

Installing the Connector Block on the Furnace Door .............................................. 3-14

Installing the Oil Line Tubing ................................................................................. 3-15

Installing the Air Line Tubing ................................................................................. 3-16

Locking the Burner into Firing Position .................................................................. 3-16

SECTION 4: FURNACE INSTALLATION................................................................... 4-1

Understanding Installation ............................................................................................... 4-1

Selecting a Location ......................................................................................................... 4-4

Guidelines for Selecting a Location .......................................................................... 4-4

Determining Air Flow from the Furnace ................................................................... 4-4

Mounting the Furnace ...................................................................................................... 4-5

Ceiling Mounting ...................................................................................................... 4-5

Raised Platform Mounting ........................................................................................ 4-5

Floor Mounting.......................................................................................................... 4-6

TABLE OF CONTENTS

SECTION 4: FURNACE INSTALLATION (continued)

Determining the Type of Oil Tank ................................................................................... 4-7

Specifications for Inside Above Ground Tank Installation ....................................... 4-9

Specifications for Outside Above Ground Tank Installation .................................. 4-11

Specifications for Underground Tank Installation .................................................. 4-13

Installing the Oil Pump .................................................................................................. 4-14

Wiring the Furnace and Pump ................................................................................. 4-16

Wiring to the Furnace .............................................................................................. 4-16

Wiring to the Oil Pump ........................................................................................... 4-16

Installing the Oil Lines ................................................................................................... 4-17

Installing the Suction Oil Line ................................................................................ 4-17

Installing the Pressure Oil Line ............................................................................... 4-18

Installing the Compressed Air Line ............................................................................... 4-18

Installing the Stack ......................................................................................................... 4-19

Installing the Interior Stack ..................................................................................... 4-22

Installing the Barometric Damper ........................................................................... 4-22

Installing the Stack Penetration ............................................................................... 4-23

Installing the Exterior Stack .................................................................................... 4-23

Installing the Stack Cap ........................................................................................... 4-23

Installing the Wall Thermostat ....................................................................................... 4-24

Inspecting the Furnace Installation................................................................................. 4-24

SECTION 5: OIL PUMP PRIMING ............................................................................. 5-1

Understanding Oil Pump Priming .................................................................................... 5-1

Required Tools and Materials ................................................................................... 5-1

Preparing the Canister Filter for Pump Priming............................................................... 5-2

Preparing the Pump for Pump Priming ............................................................................ 5-3

Preparing the Burner for Pump Priming .......................................................................... 5-4

Activating the Pump ......................................................................................................... 5-5

Establishing the Proper Oil Flow at the Pump ................................................................. 5-6

Flushing the Oil Lines ...................................................................................................... 5-6

Adjusting the Pump Pressure ........................................................................................... 5-6

SECTION 6: STARTING AND ADJUSTING THE BURNER ...................................... 6-1

Understanding Burner Startup and Adjustment ............................................................... 6-1

Preparing the Burner for Startup ...................................................................................... 6-1

Starting the Burner ........................................................................................................... 6-3

Checking the Operation of the Fan/Blower Motor........................................................... 6-4

SECTION 7: RESETTING THE OIL PRIMARY CONTROL ....................................... 7-1

Understanding the Oil Primary Control ........................................................................... 7-1

Using the Reset Button..................................................................................................... 7-1

TABLE OF CONTENTS

SECTION 8: ADJUSTING THE DRAFT OVER FIRE ................................................. 8-1

Checking for Correct Draft Over Fire .............................................................................. 8-1

Adjusting the Barometric Damper ................................................................................... 8-2

Solving Draft Overfire Problems ..................................................................................... 8-2

Understanding the Effect of Exhaust Fans on Draft .................................................. 8-3

Checking Draft Overfire to Determine Severity of Backdraft................................... 8-3

Installing a Make-up Air Louver ............................................................................... 8-5

SECTION 9: MAINTENANCE ..................................................................................... 9-1

Understanding Maintenance............................................................................................. 9-1

Annual Burner Tune-up ................................................................................................... 9-1

Cleaning the Canister Filter ............................................................................................. 9-2

Cleaning Ash from the Furnace ....................................................................................... 9-3

Cleaning the Check Valve ................................................................................................ 9-5

Cleaning the Tank ............................................................................................................ 9-6

End of Season Maintenance ............................................................................................. 9-6

APPENDIX A

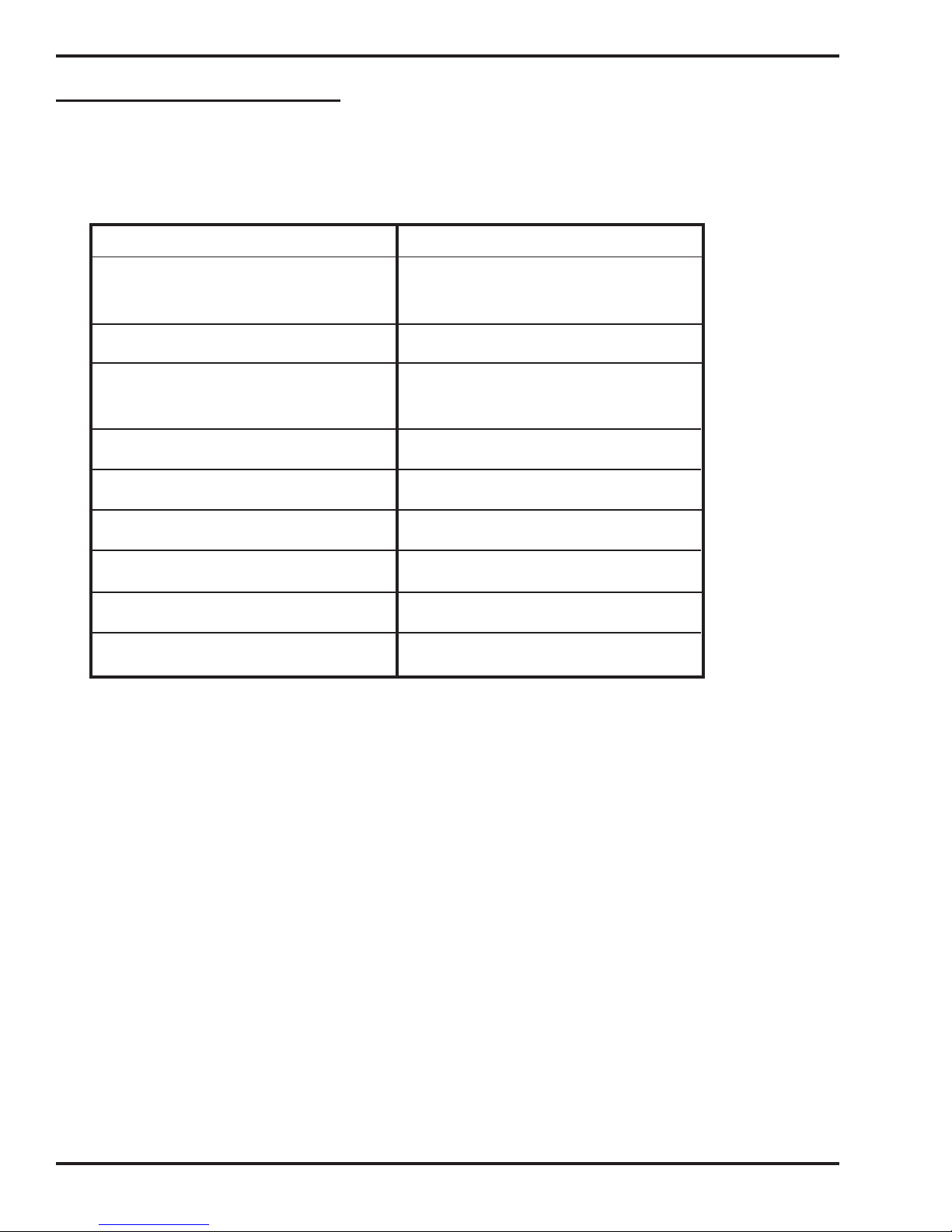

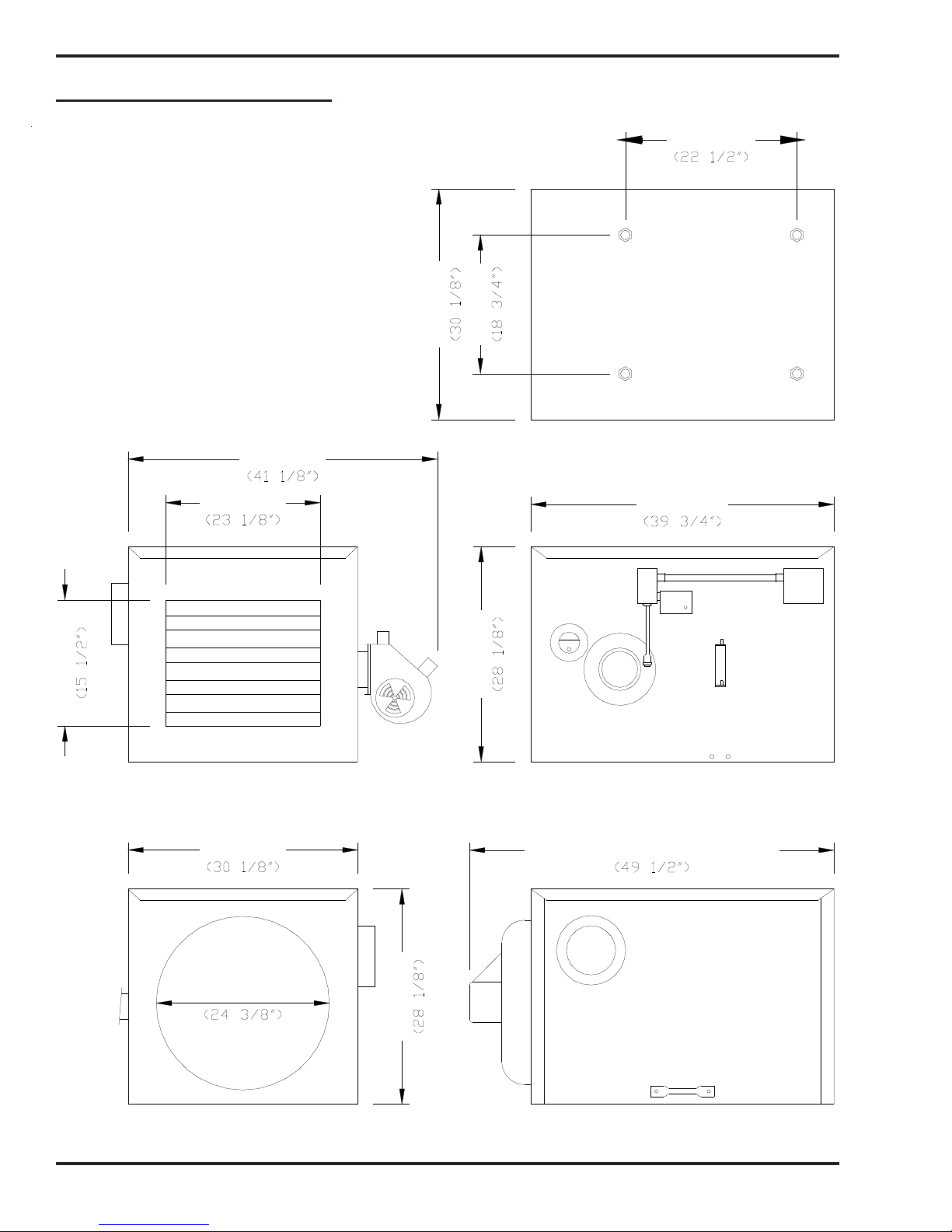

Detailed Furnace Specifications ...................................................................................... A-1

Furnace Technical Specifications ............................................................................. A-1

Burner Technical Specifications............................................................................... A-2

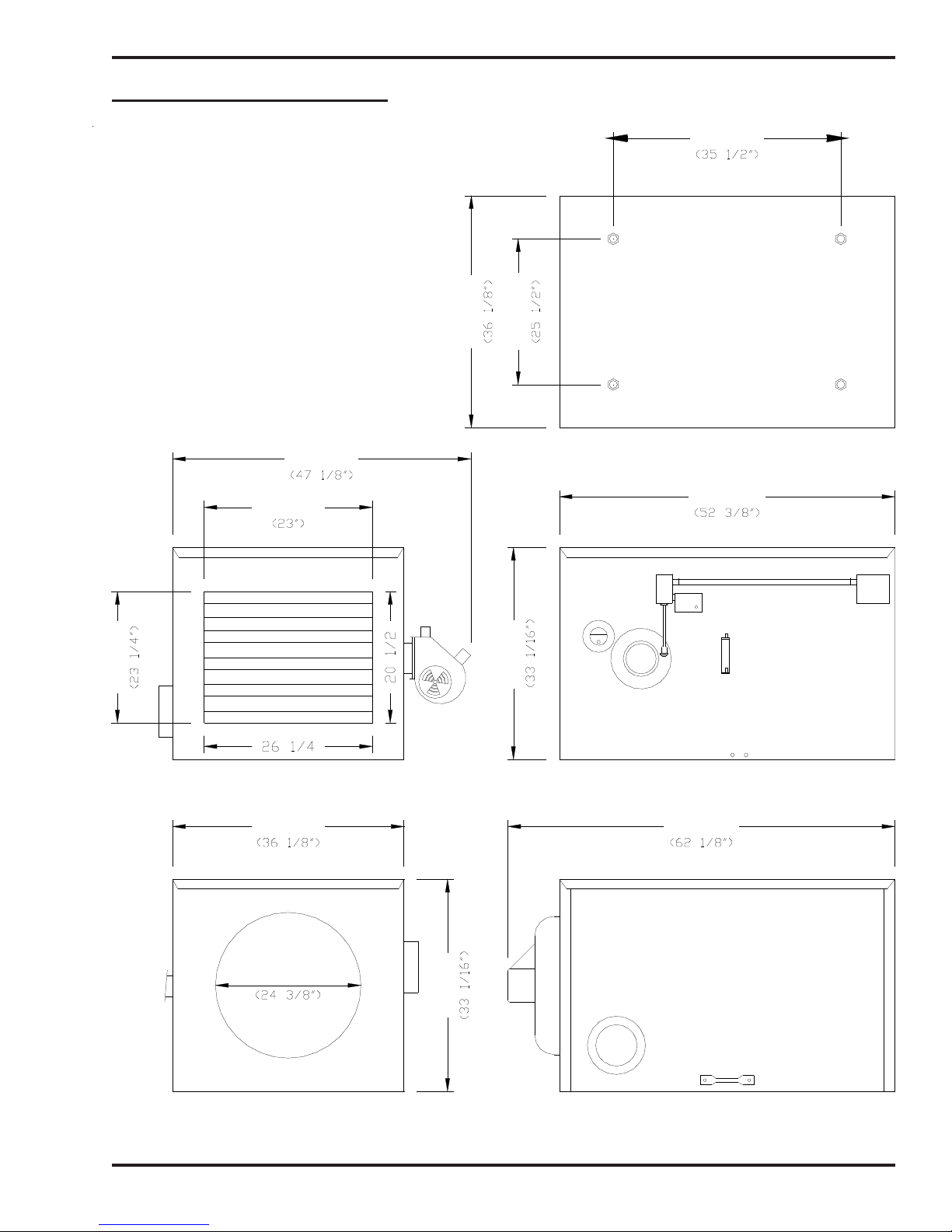

Furnace Dimensions (CB-1400) ............................................................................... A-3

Furnace Dimensions (CB-1800) ............................................................................... A-4

Furnace Dimensions (CB-2800) ............................................................................... A-5

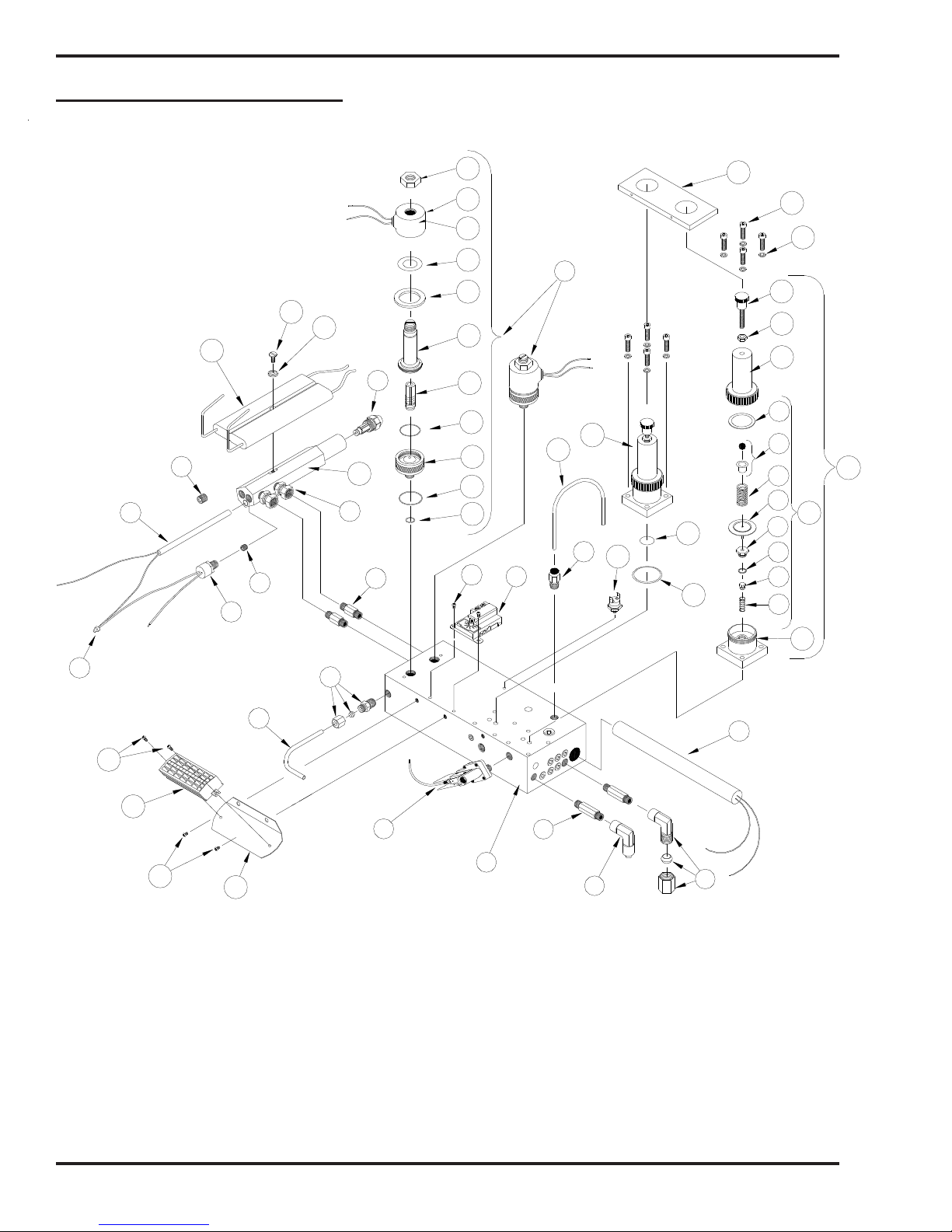

Burner Components .................................................................................................. A-6

Oil Pump Components ........................................................................................... A-12

Fan Limit Control ................................................................................................... A-14

APPENDIX B

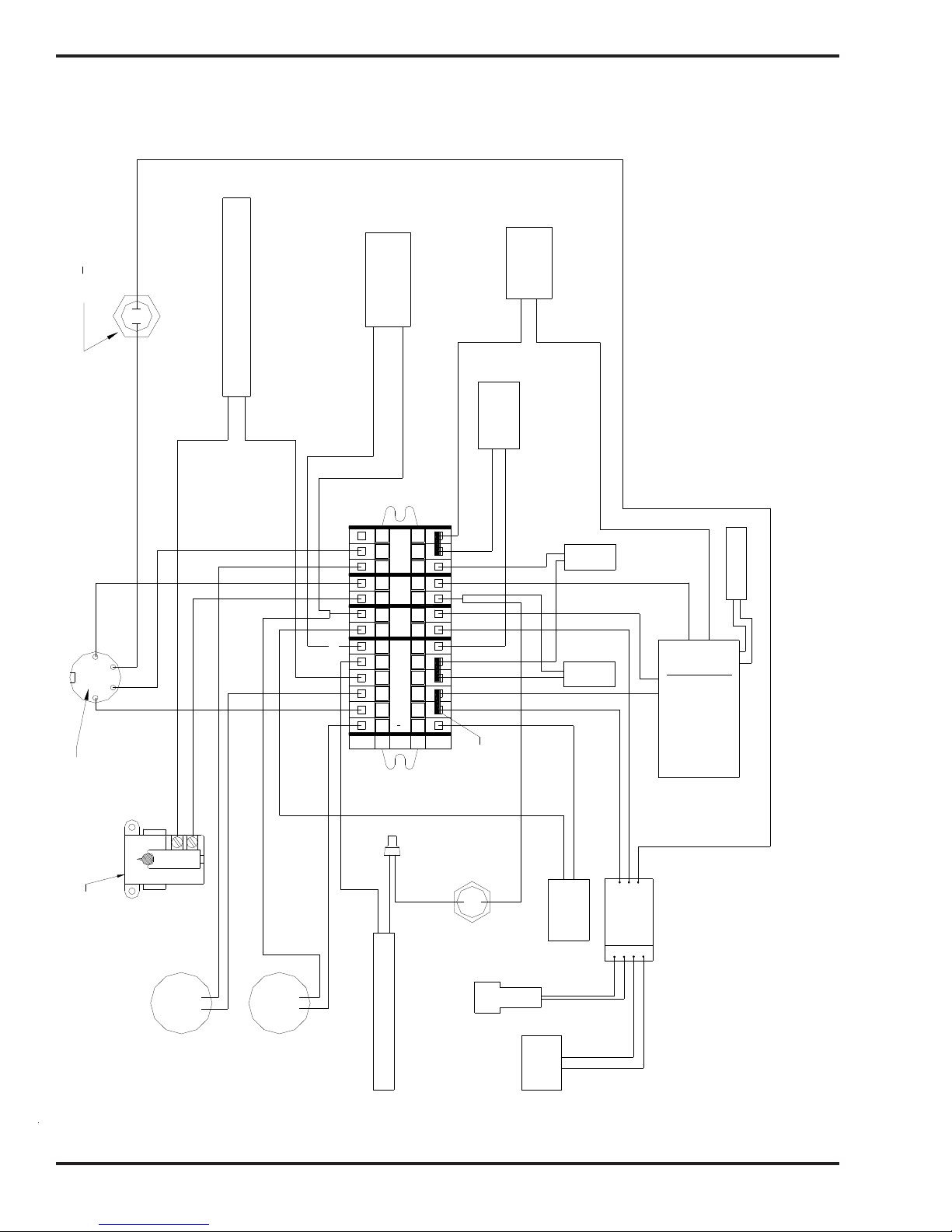

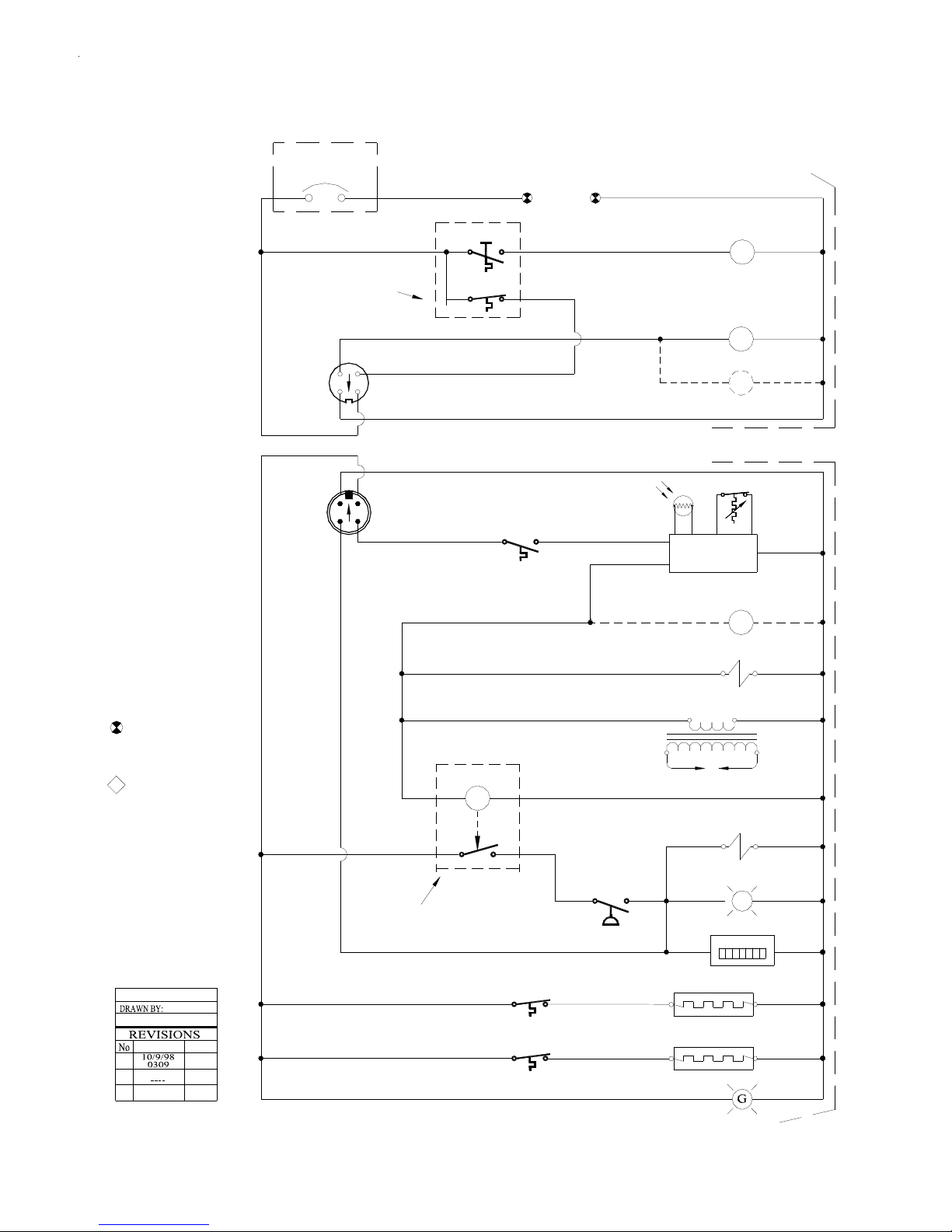

Wiring Diagrams ............................................................................................................. B-1

APPENDIX C

Furnace Service Record .................................................................................................. C-1

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

SECTION 1: INTRODUCTION

Guide to this Manual

This manual contains all the information necessary to safely install and operate the Clean Burn Furnace

Models CB-1400, CB-1800, and CB-2800. Consult the Table of Contents for a detailed list of topics

covered. You'll find this manual's step-by-step procedures easy to follow and understand. Should

questions arise, please contact your Clean Burn dealer before starting any of the procedures in this

manual.

As you follow the directions in this manual, you'll discover that assembling and operating your new

furnace involves five basic activities as outlined here:

• UNPACKING .................................................................................................... (Section 2)

• ASSEMBLY ...................................................................................................... (Section 3)

• INSTALLATION ............................................................................................. (Section 4)

• OPERATION

• Oil Pump Priming ................................................................................. (Section 5)

• Starting and Adjusting the Burner ..................................................... (Section 6)

• Resetting the Oil Primary Control ...................................................... (Section 7)

• Adjusting the Draft............................................................................... (Section 8)

• MAINTENANCE ............................................................................................. (Section 9)

The manual also contains important and detailed technical reference materials which are located at the

back of the manual in the Appendixes.

Please read all sections carefully--including the important safety information found in this section-before beginning any installation/operation procedures; doing so ensures your safety and the optimal

performance of your Clean Burn furnace.

1-1

For Your Safety...

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

For your safety, Clean Burn documentation contains the

following types of safety statements (listed here in order

of increasing intensity):

• NOTE: A clarification of previous

information or additional pertinent

information.

• ATTENTION: A safety statement

indicating that potential equipment damage

may occur if instructions are not followed.

CAUTION: A safety statement

that reminds of safety practices or directs

attention to unsafe practices which could

result in personal injury if proper

precautions are not taken.

WARNING: A strong safety

statement indicating that a hazard exists

which can result in injury or death if proper

precautions are not taken.

DANGER! The utmost levels of

safety must be observed; an extreme hazard

exists which would result in high probability

of death or irreparable serious personal

injury if proper precautions are not taken.

WARNING!

STOP

YOUR SAFETY IS AT STAKE!

DO NOT INSTALL, OPERATE OR

MAINTAIN THIS EQUIPMENT

WITHOUT FIRST READING

AND UNDERSTANDING THE

OPERATOR'S MANUAL!

In addition to observing the specific precautions listed

throughout the manual, the following general

precautions apply and must be heeded to ensure

proper, safe furnace operation.

WARNING: Never alter or modify your

furnace without prior written consent of

Clean Burn, Inc. Unauthorized

modifications or alteration can adversely

affect the proper, safe operation of your

furnace.

WARNING: The burner which is shipped

with your Clean Burn furnace is to be used

only with your furnace according to the

instructions provided in this manual. DO

NOT use the burner for any other purpose!

DO NOT ADD CHLORINATED

OILS, SOLVENTS, OR PAINT

THINNERS TO YOUR USED OIL!

BURNING ANY CHLORINATED

SUBSTANCES IS ILLEGAL AND

WILL DAMAGE YOUR FURNACE!

WARNING!

THIS BURNER IS TO BE

INSTALLED ONLY ON THE PROPER,

SPECIFIED, CLEAN BURN PRODUCT

DO NOT USE THE BURNER

FOR ANY OTHER PURPOSE

1-2

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

For Your Safety... (continued)

WARNING: The Best Operator is a Careful Operator! By using common sense,

observing general safety rules, and adhering to the precautions specific to the equipment, you,

the operator, can promote safe equipment operation. Failure to use common sense, observe

general safety rules, and adhere to the precautions specific to the equipment may result in

equipment damage, fire, explosion, personal injury and/or death.

WARNING: The installation, operation, and maintenance of this equipment in the U.S.

must be accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and with all national, state, and local codes or authorities

having jurisdiction over environmental control, building inspection and fuel, fire and

electrical safety and the following standards of the National Fire Protection Association.

NFPA 30 Flammable and Combustible Liquids Code

NFPA 30A Automotive and Marine Service Station Code

NFPA 31 Standard for the Installation of Oil Burning Equipment

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

NFPA88A Parking Structures

NFPA 88B Repair Garages

NFPA 70 National Electrical Code

The NFPA standards may be obtained from:

National Fire Protection Association (NFPA)

1 Batterymarch Park, P.O. Box 9101

Quincy, Massachusetts 02269-9101

Likewise, the installation, operation, and maintenance of this equipment in Canada is to be

accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and in accordance with the regulation of authorities having

jurisdiction and CSA Standard B 139, Installation Code for Oil Burning Equipment.

Failure to comply with these standards and requirements may result in equipment

damage, fire, explosion, personal injury and/or death.

• This furnace is listed for commercial and/or industrial use only; it is not listed for residential

use.

• This furnace is listed with Underwriters Laboratory and Underwriters' Laboratories of

Canada to burn the following fuels:

• Used crankcase oil up to 50 SAE

• Used transmission fluid

• Used hydraulic oils

• #2 fuel oil

1-3

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

For Your Safety... (continued)

WARNING: DO NOT add inappropriate or hazardous materials to your used oil, such as:

• Anti-freeze

• Carburetor cleaner

• Paint thinner

• Parts washer solvents

• Gasoline

• Oil additives

• Any other inappropriate/hazardous

material

WARNING: Burning chlorinated materials (chlorinated solvents and oils) is illegal, will

severely damage your heat exchanger, immediately void your warranty, and adversely affect

the proper, safe operation of your furnace. Instruct your personnel to never add hazardous

materials to your used oil.

DANGER! DO NOT create a fire or explosion hazard by storing or using gasoline or other

flammable or explosive liquids or vapors near your furnace.

DANGER! DO NOT operate your furnace if excess oil, oil vapor or fumes have

accumulated in or near your furnace. As with any oil burning furnace, improper installation,

operation or maintenance may result in a fire or explosion hazard.

• If your safety decals ever become worn, lost or painted over, please call your Clean Burn

dealer for free replacements.

• Make sure you comply with all EPA regulations concerning the use of your furnace. EPA

regulations require that:

• Your used oil is generated on-site. You may also accept used oil from

"do-it-yourself" oil changers.

• Hazardous wastes, such as chlorinated solvents, are NOT to be mixed with your

used oil.

• The flue gases are vented to the outdoors with an appropriate stack.

• Your used oil is recycled as fuel for "heat recovery". DO NOT operate your furnace

in warm weather just to burn oil.

Contact your Clean Burn dealer for current EPA regulations.

• If your furnace ever requires service, call your Clean Burn dealer. DO NOT allow

untrained, unauthorized personnel to service your furnace. Make sure that your furnace

receives annual preventative maintenance to ensure optimal performance.

1-4

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

SECTION 2: UNPACKING

Before assembling your furnace, you must accomplish the following activities described in this section:

• Removing the Shipping Pallet

• Unpacking and Inspecting All Components

• Warranty Registration

Removing the Shipping Pallet

ATTENTION: Your furnace cabinet is attached to the shipping pallet with two screws to keep the

cabinet from shifting during shipment. You must remove the shipping pallet prior to assembly and

installation of the furnace. DO NOT use the pallet as a platform for furnace installation!

1. Locate the shipping screws which attach the cabinet to the pallet by looking through the round

fan opening on the side of the furnace cabinet.

2. Remove and discard the two screws. Carefully lift the furnace off the shipping pallet with a fork

lift, and discard the pallet.

Unpacking and Inspecting All Components

Following is an itemized list of all components you should have received in your Clean Burn furnace

shipment. Open all shipping containers and inspect all components according to the list. Immediately

notify the freight company and your Clean Burn dealer in case of shipping damage or shortage(s). Keep

all components together so you will have them as needed for furnace assembly and installation.

Furnace Component List (CB-1400, CB-1800, and CB-2800)

ONE SKID containing:

• Furnace cabinet

ONE BOX containing:

• Burner

ONE SKID containing:

• Fan assembly (Unit Heater Models) OR Blower assembly (Central Furnace Models)

• Oil pump

• Canister filter

• Vacuum gauge

• Check valve and check valve screen

• Wall thermostat

• Barometric damper

• Assorted bolts/fittings for assembly/installation of furnace components

• Operator's Manual

• Burner Oil Line and Air Line Components

NOTE: You may have received additional boxes or skids if you ordered optional accessories.

2-1

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Warranty Registration

For proper warranty registration, Clean Burn requires that you fill out the provided warranty registration

card and return it within 30 days to:

CLEAN BURN WARRANTY REGISTRATION

Clean Burn, Inc.

34 Zimmerman Road

Leola, Pennsylvania 17540

2-2

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

SECTION 3: FURNACE ASSEMBLY

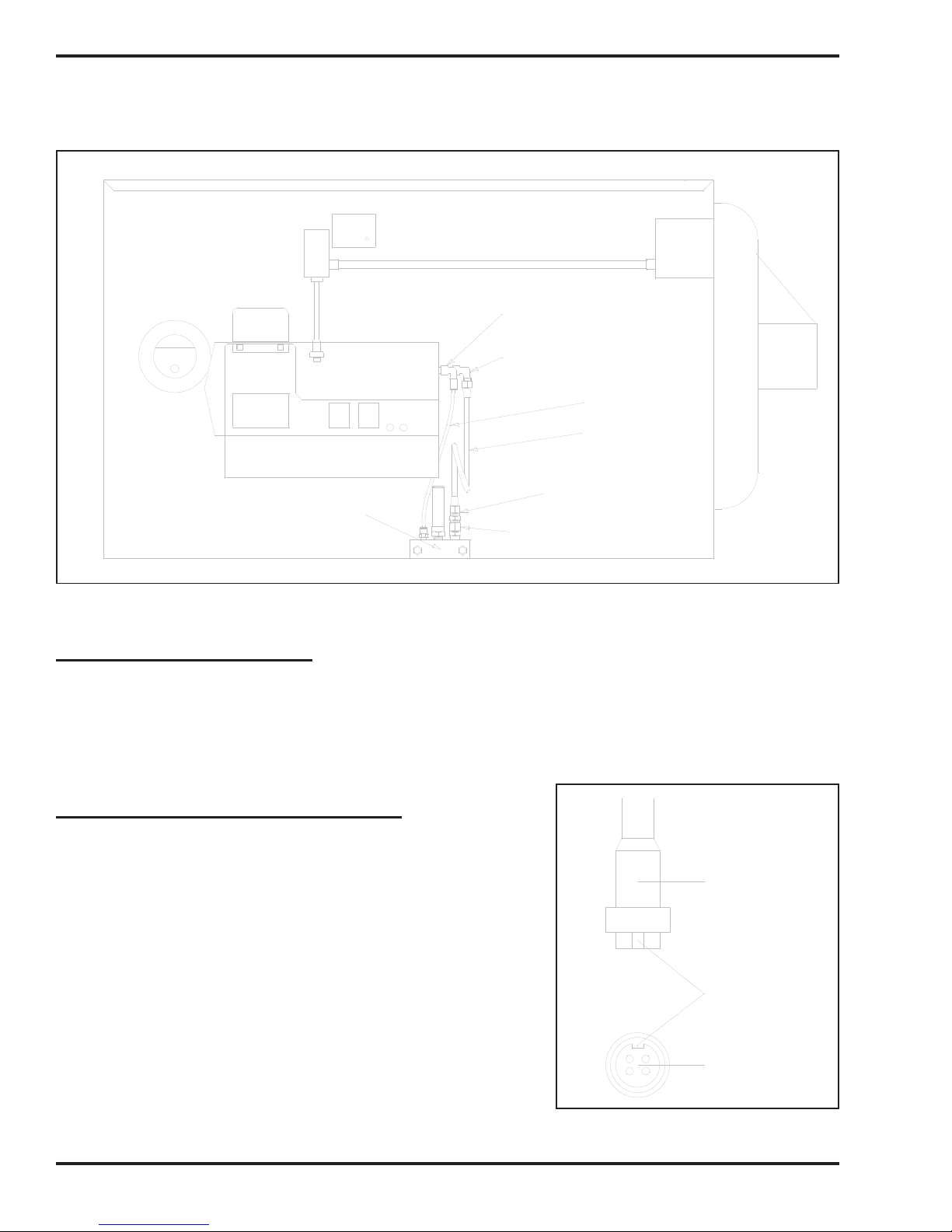

Understanding Assembly

Assembling your Clean Burn Furnace includes the following steps:

(1) Installing the Observation Port

(2) Determining the Fan/Blower Assembly Configuration

(3) Unit Heater Models: Installing the Fan Assembly

(4) Central Furnace Models: Installing the Blower Assembly

(5) Installing the Burner

(6) Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

Clean Burn recommends that you review all assembly procedures before proceeding, paying careful

attention to safety information statements. Please note that some assembly procedures apply only to

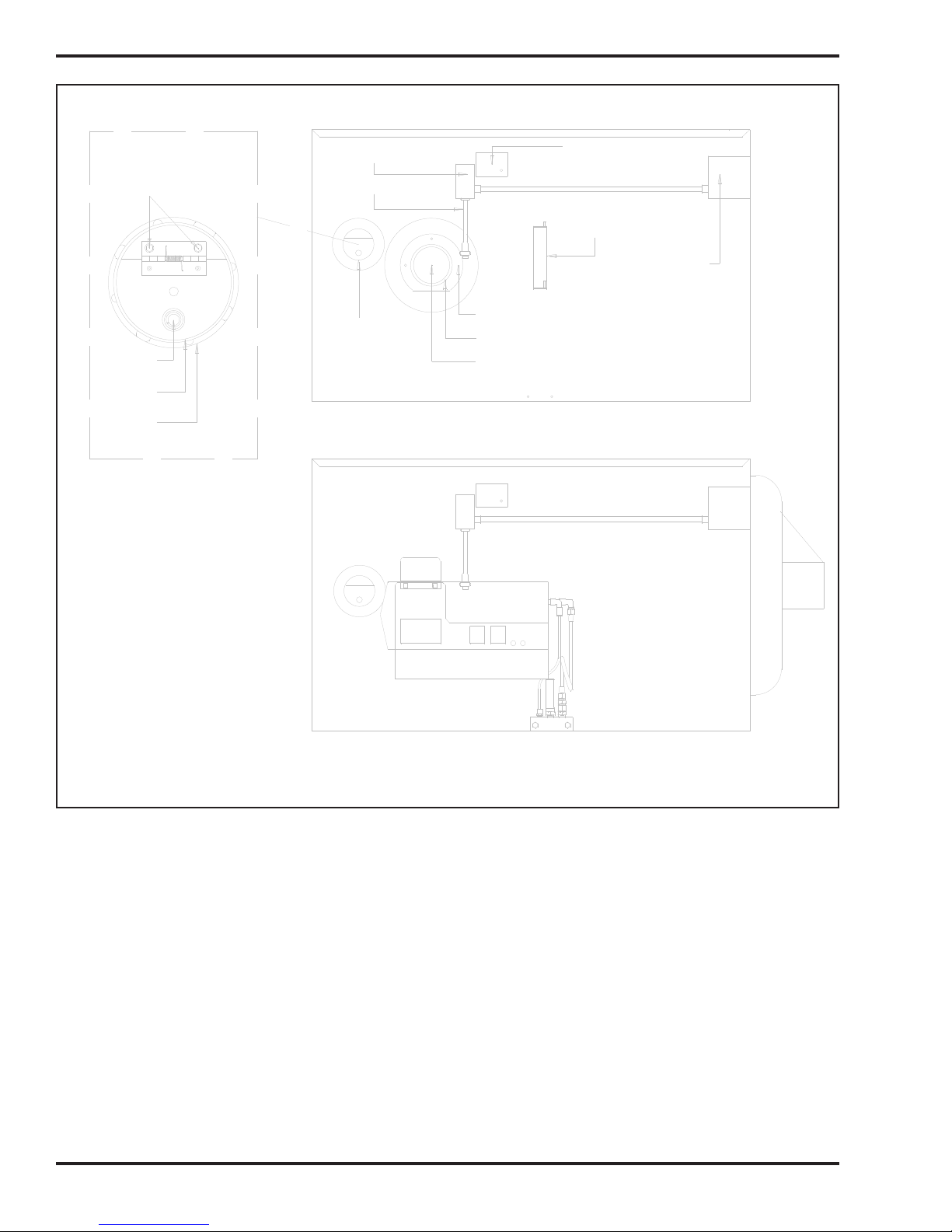

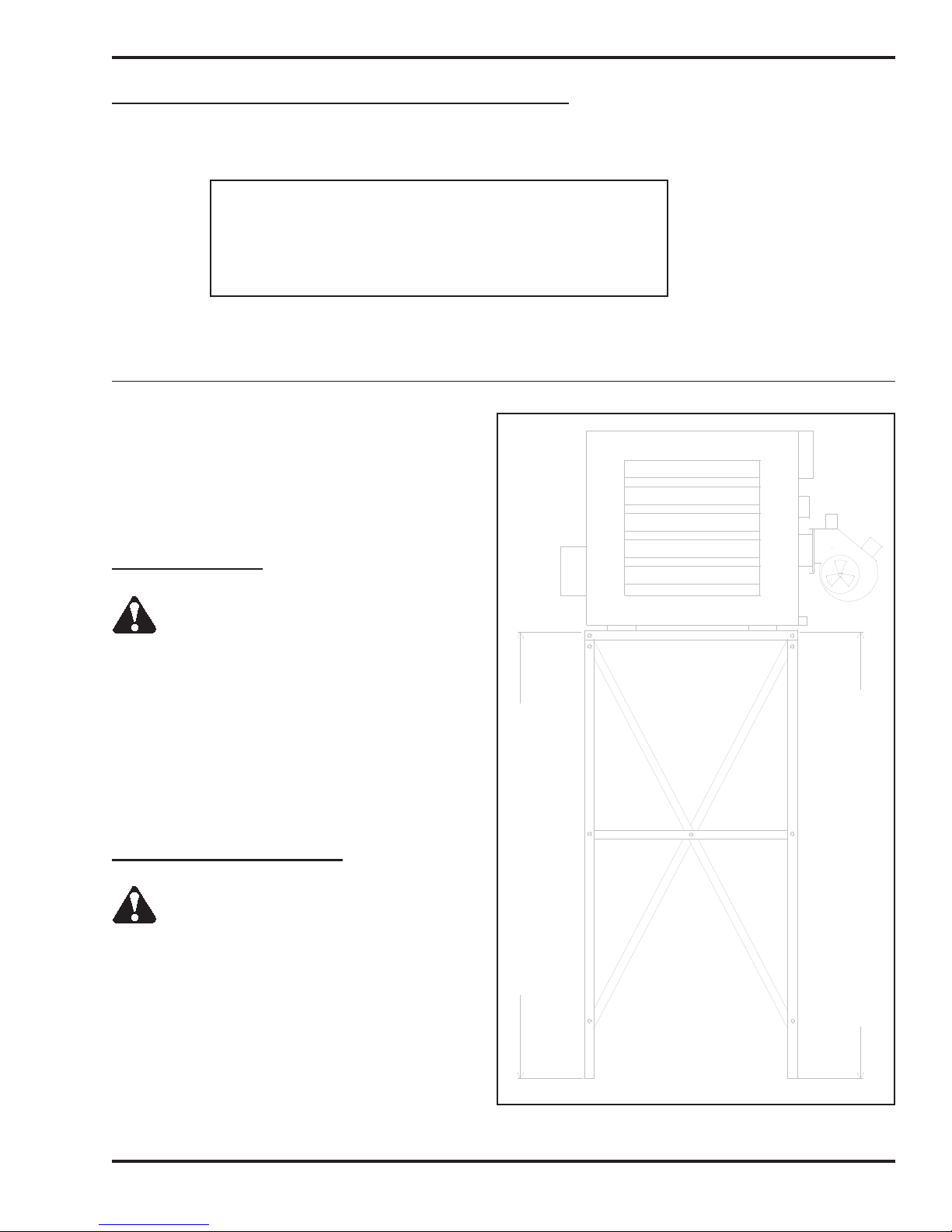

certain furnace models. Figures 3A, 3B, and 3C on the following pages provide a general overview of

the furnace components and their proper assembly and how the unit should look following proper

assembly.

Required Tools and Materials

The following tools and materials are required for furnace assembly and should be gathered before

starting any procedures:

• 9/16" open-end wrench

• Medium flat-blade screwdriver

• Medium adjustable wrench

3-1

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

DETAIL OF HINGED

OBSERVATION PORT

HEX HEAD

SCREWS

SPRING

HANDLE

FACE

PLATE

LOCKING

RING

JUNCTION BOX

BURNER CABLE

OBSERVATION

PORT

MOUNTING FLANGE

GASKET

FURNACE THROAT

FRONT VIEW OF CABINET

FAN LIMIT

CONTROL

HINGE

BRACKET

ELECTRICAL

JUNCTION

BOX

FRONT VIEW OF CABINET WITH BURNER,

CIRCULATING FAN, CONNECTOR BLOCK, AIR LINE

AND OIL LINE INSTALLED

FIGURE 3A - Overview of Furnace Assembly

NOTE: Furnace shown is CB-2800.

Assembly of CB-1400 or CB-1800 is similar.

3-2

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

ASSEMBLED

OBSERVATION PORT

OBSERVATION PORT

HALF-MOON

PIECE

FACE

PLATE

ASSEMBLY OF

OBSERVATION PORT

FIGURE 3B - Three-dimensional View - Unit Heater Completely Assembled

3-3

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

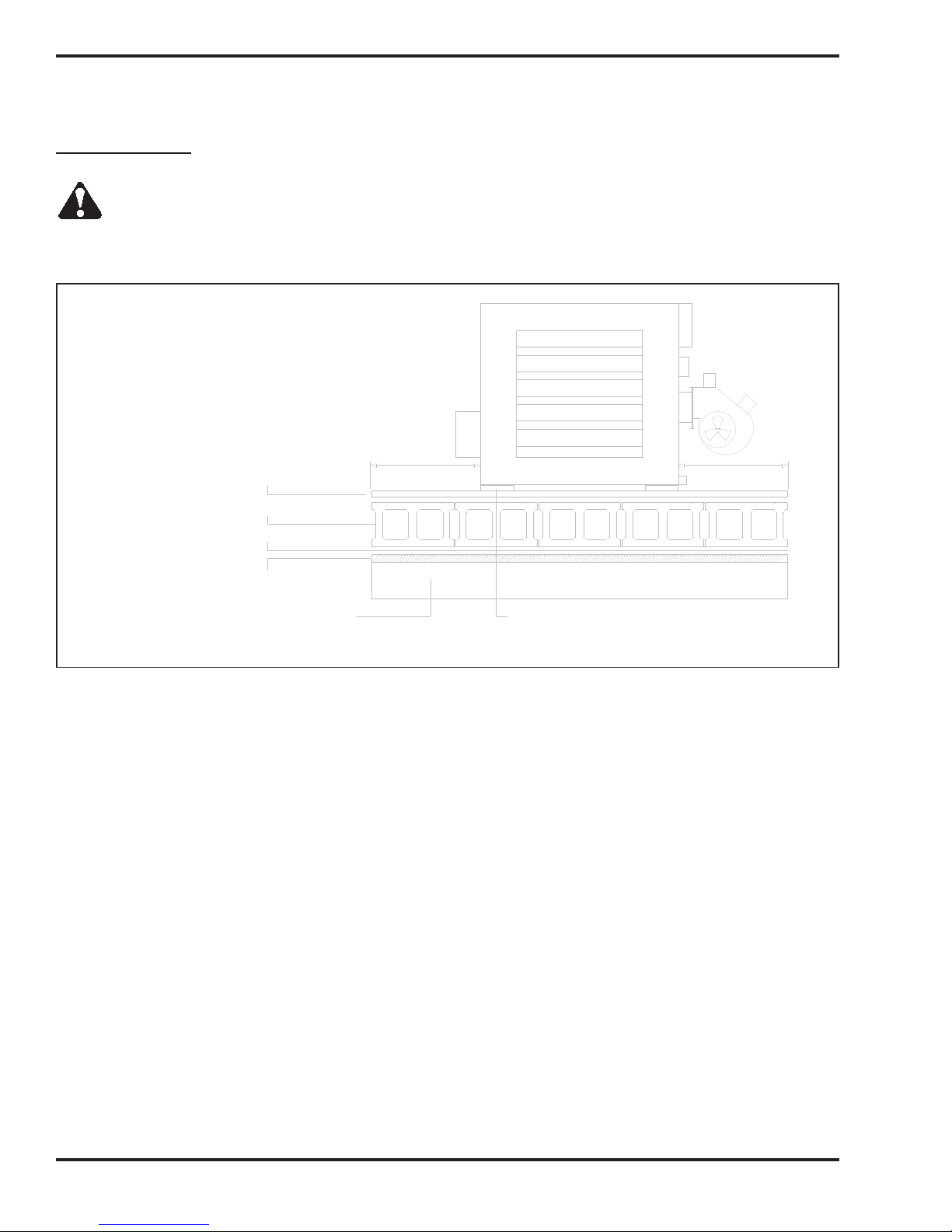

FIGURE 3C - Three-dimensional View - Central Furnace Completely Assembled

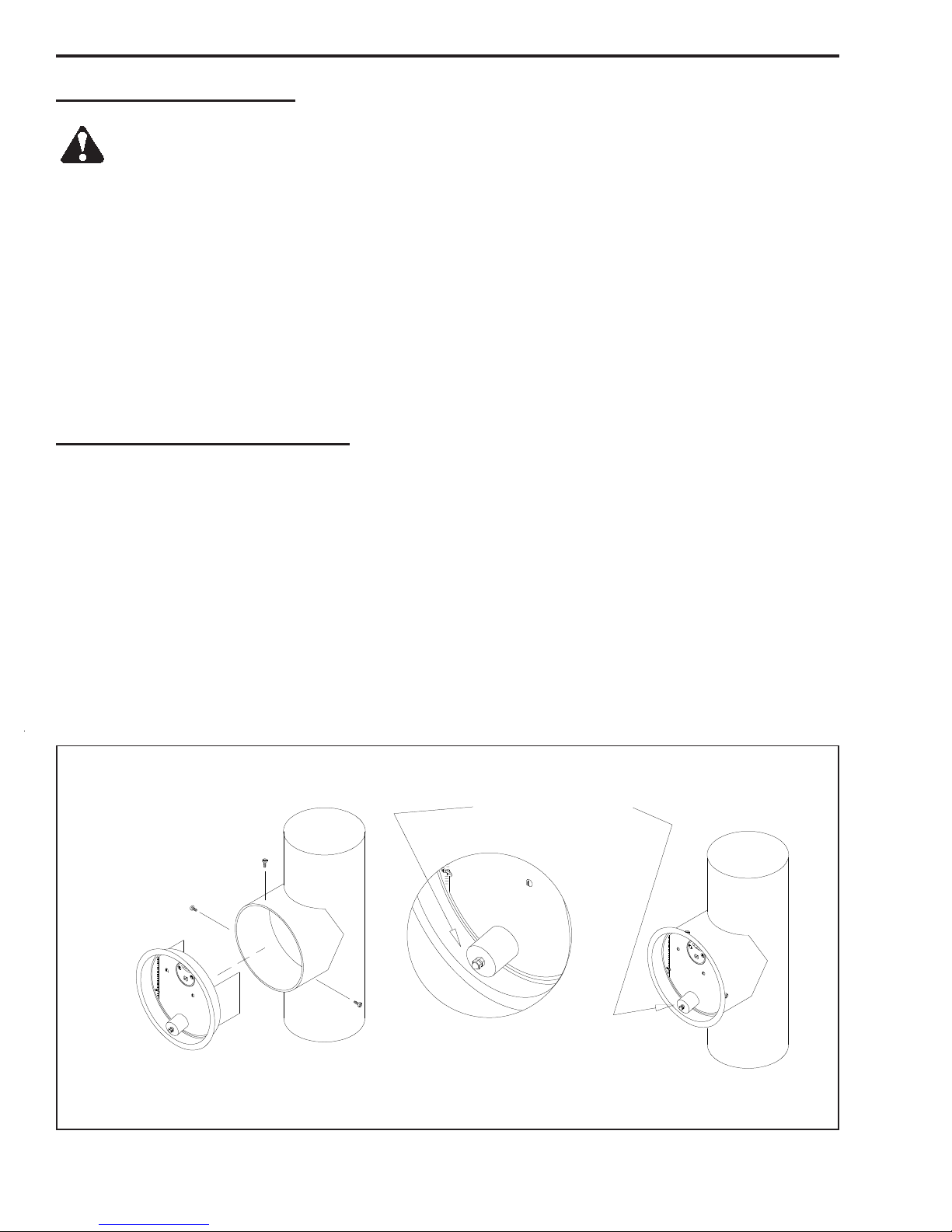

Installing the Observation Port

CAUTION: The observation port must be correctly installed according to the following

procedure to allow safe observation of the flame during furnace operation. Be sure to follow all

safety procedures as outlined in this manual when observing the flame through the port.

1. Refer to Figure 3B.

2. Use a 1/4" nut driver to remove the two (2) self-tapping screws from the half-moon piece.

3. Position the half-moon piece and the faceplate on the observation port, and install the two

self-tapping screws.

4. Open the port and make sure the faceplate moves and closes freely. If the faceplate hangs up,

loosen the hex-head screws slightly until the faceplate closes correctly.

3-4

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

STOP! READ THIS NOW.

The following information is critical to the proper assembly and installation of your

Clean Burn furnace; read this section carefully before starting any other procedures.

Determining the Fan/Blower Assembly Configuration

Before proceeding with the assembly of your furnace, it is important to determine the configuration of

the fan/blower assembly for your furnace model. There are two configurations to consider:

(1) Unit Heater CB-1400, CB-1800, and CB-2800 with propeller-type fan.

This configuration is for free air application only and may NOT be ducted.

CB-1800 and CB-2800 with blower assembly for free air applications.

You must install the correct blower motor pulley as described in the

blower assembly section in this chapter. Refer to the following chart for

proper specifications.

(2) Central Furnace CB-1800 and CB-2800 with blower assembly for ducting applications

from .2 to .3 static pressure.*

You must install the correct blower motor pulley as described in the

blower assembly section in this chapter. Refer to the following chart for

proper specifications.

Air Flow (CFM) and Static Pressure (SP) Specifications

for CB-1800 and CB-2800 Central Furnace Models

Static Pressure

"H20 in Outlet 0.20* 0.30*

CB-1800 Central Furnace CFM 2300 2200

CB-2800 Central Furnace CFM 3300 3100

*ATTENTION: A qualified electrician must check the blower motor amperage during operation of the furnace to ensure that

motor amperage does not exceed 85% of the maximum amperage on the motor label. DO NOT operate the blower motor

above 85% of maximum amperage or motor damage may occur.

IMPORTANT NOTE: It is essential that qualified HVAC personnel properly design the

ductwork for your furnace and determine the static pressure for your ducting application.

3-5

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Unit Heater Models: Installing the Fan Assembly

NOTE: The following information on the installation of the fan assembly applies to Unit

Heater Models (CB-1400 or CB-1800 or CB-2800) only. If you have a Central Furnace

Model, refer to the appropriate information later in this section for installation of the

blower assembly.

CAUTION: Ducting any Unit Heater Furnace is not

permitted. See Section 4 for additional information.

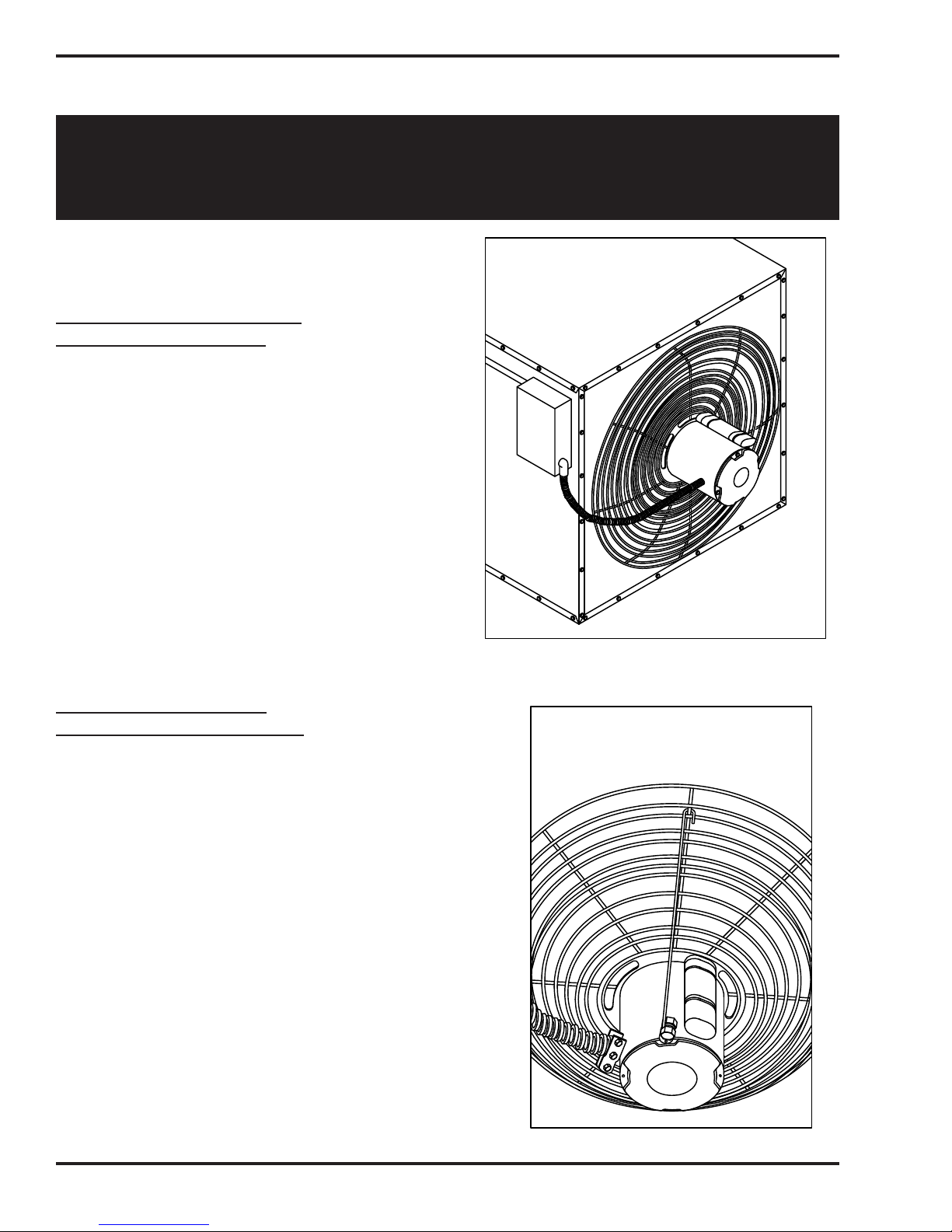

Installing the Fan Assembly

(All Unit Heater Models)

1. Refer to Figure 3D.

2. Attach the fan assembly to the furnace

cabinet using the six hex-head bolts.

3. Make sure that fan blade is centered in the

round opening on the cabinet. Spin the fan

blade to check that it spins freely.

4. Remove the cover of the electrical junction

box.

5. Attach the fan motor electrical cable to the

electrical junction box.

6. Connect the fan motor wires according to the

wiring schematic provided in Appendix B at

the back of the manual.

FIGURE 3D - Fan Installed on

Furnace Cabinet

Installing the Fan Brace

(CB-1800 and CB-2800 only)

NOTE: These instructions apply to Unit Heater Models

CB-1800 and CB-2800 only. Unit Heater Model CB-1400

does not require a fan brace.

1. Refer to Figure 3E.

2. Hook the fan brace end with the larger

loop over the fan guard strut.

3. Check that the fan brace lines up with the mounting

tab on the fan motor.

4. Attach the fan brace to the mounting tab using the

bolt and nut provided. Make sure the motor is

held firmly in place by the fan brace to prevent fan

vibration. DO NOT over-tension the motor.

5. Check that the fan blades spin freely.

FIGURE 3E - Fan Brace Installed

3-6

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Central Furnace Models: Installing the Blower Assembly

NOTE: The following information on the installation of the blower assembly applies to

Central Furnace Models (CB-1800 or CB-2800) only. If you have a Unit Heater Model

(CB-1400 or CB-1800 or CB-2800), refer to the appropriate information earlier in this

section for installation of the fan assembly.

NOTE: Ducting Central Furnace Models (CB-1800 or CB-2800) is permitted. Specifications for

ducting are provided in Section 4.

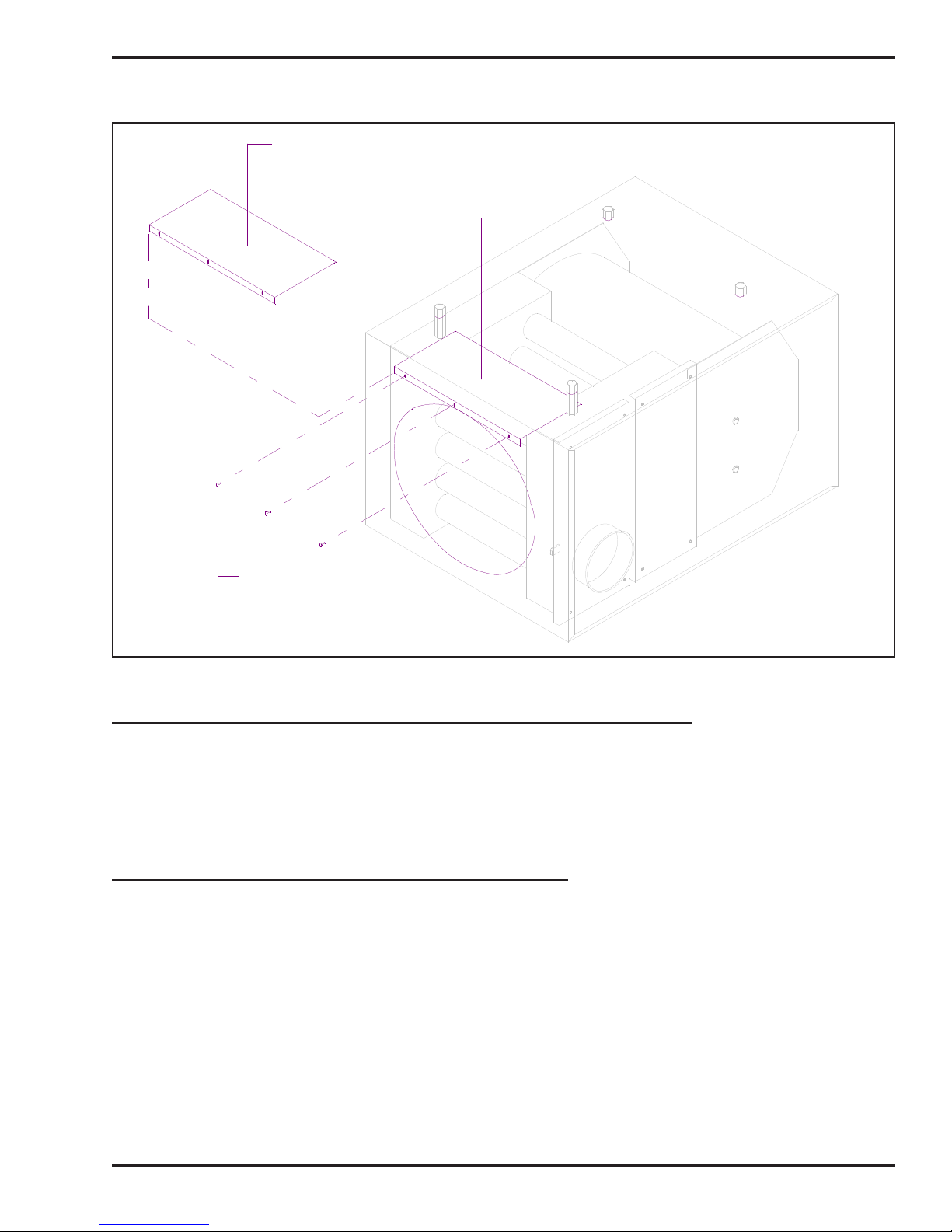

Preparing the Furnace Cabinet for Blower Installation

For Model CB-1800 Only:

1. Refer to Figure 3F.

2. Remove the six screws along the left edge of the cabinet so the side lip of the blower mount fits

snugly against the cabinet.

3. To remove the bottom screw, grab the screw head with a pair of vise grips and twist it out.

For Model CB-2800 Only:

NOTE: It is important that you install the air flow plate on Model CB-2800 which ensures that the air

flow from the blower is properly channeled over the heat exchanger.

1. Refer to Figures 3F and 3G.

2. Slide the air flow plate through the round opening on the fan side of the furnace cabinet.

3. Position the plate on top of the heat exchanger headers between the mounting lugs.

4. Pull the air flow plate snugly against the inside of the sheet metal on the fan side of the furnace

cabinet.

5. Use three self-tapping screws to mount the air flow plate in position.

NOTE: Most furnace cabinets are pre-drilled with three holes in the fan side sheet metal. If

these holes are not pre-drilled, mark the position of the lip of the air flow plate and carefully drill

three 1/8" holes to allow installation of the plate.

NOTE: Make sure the self-tapping screws are firmly tightened so that the air flow plate is held

tightly in place and cannot vibrate during blower operation.

For Ceiling-hung Furnaces Only:

1. Refer to Figure 3F and Section 4 (Installation), Figures 4A and 4B.

2. Install 5/8" all-thread rods in the four threaded mounting lugs on the top of the furnace cabinet.

Be sure to thread the rods into the four lugs on the furnace top until the rods are tight. Lock the

all-thread rods in place using double nuts as shown in Figure 3F.

3-7

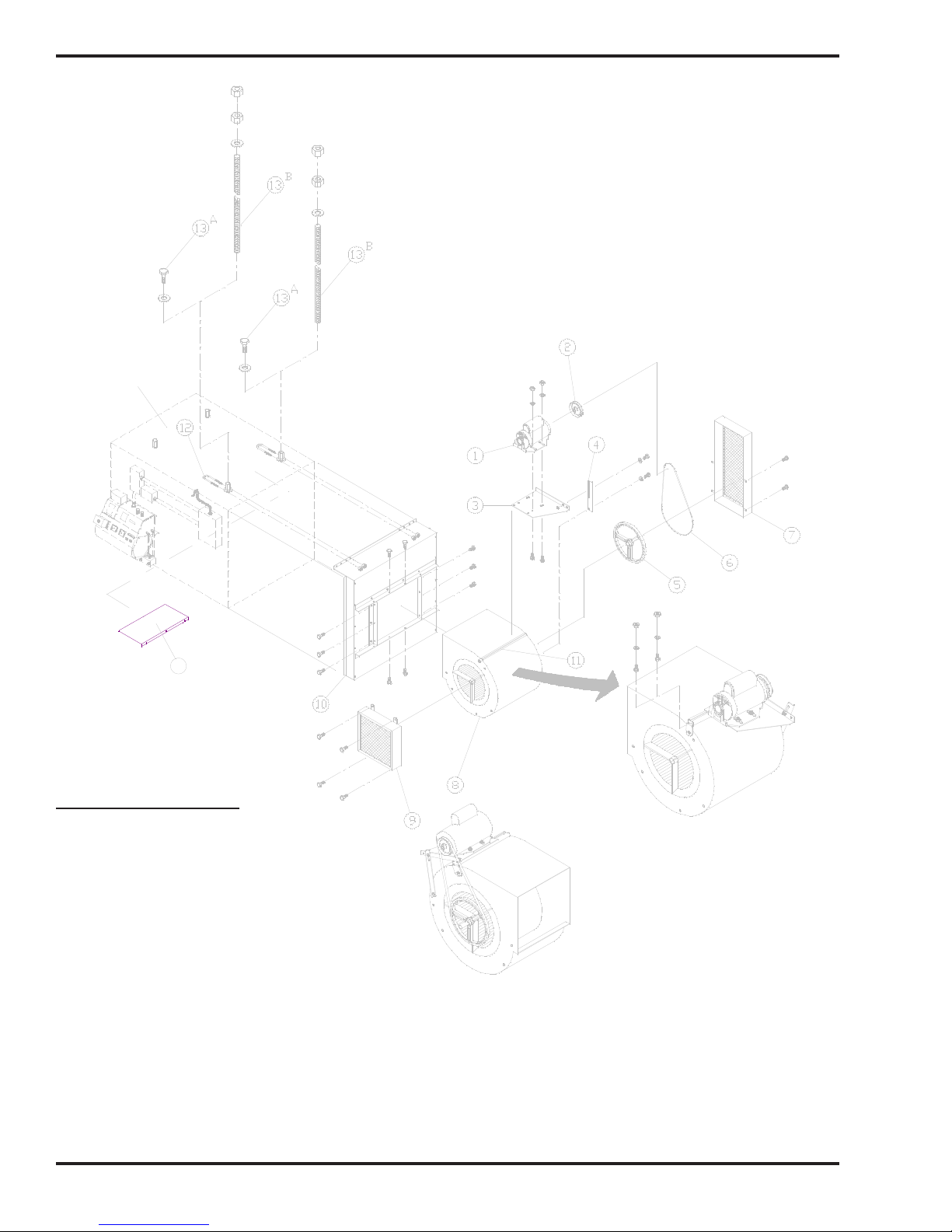

FURNACE ASSEMBLY

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

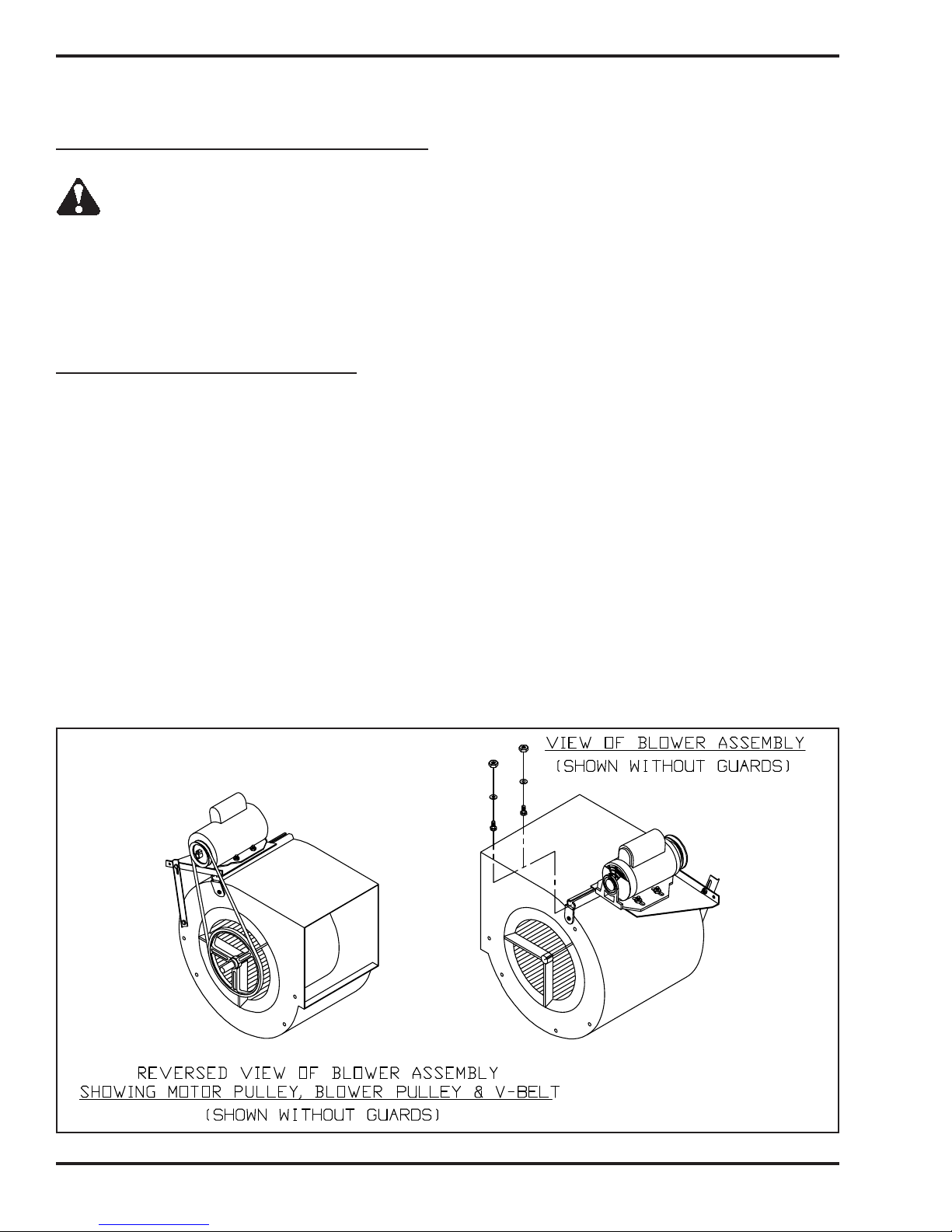

14

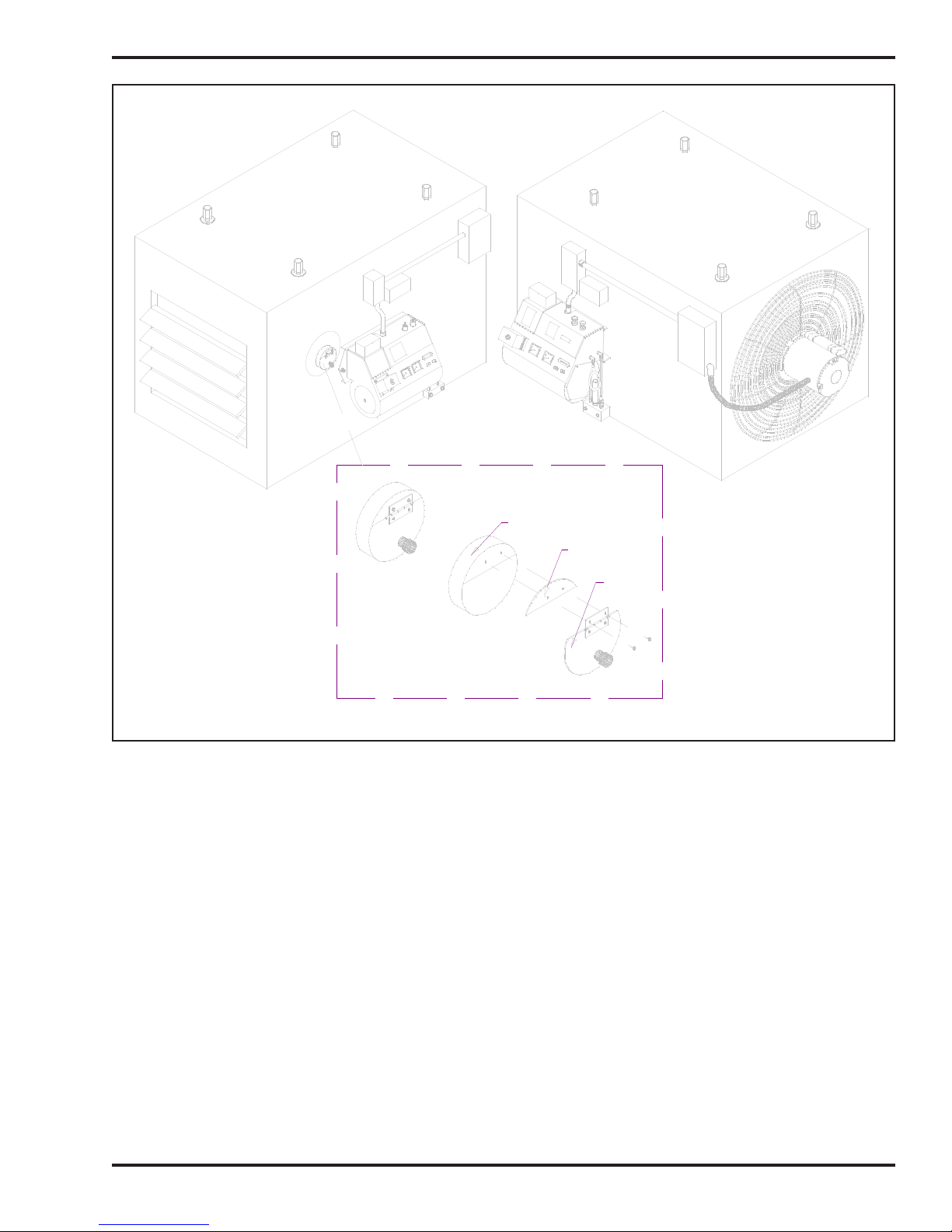

Blower Assembly Parts List

1 Blower Motor

2 Motor Pulley

3 Motor Mounting Plate

4 Motor Tensioning Bracket

5 Blower Pulley

6 V-Belt

7 Belt Guard

8 Blower

9 Blower Guard

10 Blower Mount

11 Top Mounting Bracket

12 U-Bolt

13A Platform Mounting: two bolts/washers

13B Ceiling Mounting: four all-thread rods with washers

and double locking nuts

14 Air Flow Plate (CB-2800 Central Furnace ONLY)

VIEW OF BLOWER ASSEMBLY

(SHOWN WITHOUT GUARDS)

REVERSED VIEW OF BLOWER ASSEMBLY

SHOWING MOTOR PULLEY, BLOWER PULLEY, & V-BELT

(SHOWN WITHOUT GUARDS)

Figure 3F - Detail of Blower Assembly and Installation of Blower on Furnace Cabinet

3-8

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Central Furnace Models: Installing the Blower Assembly (continued)

AIR FLOW

PLATE

AIR FLOW PLATE

INSTALLED ON

TOP OF HEADER

SELF-TAPPING

SCREWS

Figure 3G - Detail of Air Flow Plate Installation

Preparing the Furnace Cabinet for Blower Installation (continued)

For Platform-mounted Furnaces Only:

1. Refer to Figure 3F.

2. Install a washer and bolt in the two threaded lugs on the blower side of the furnace. Use the

washers and bolts which were supplied with the furnace.

Installing the Blower Mount on the Furnace Cabinet

1. Refer to Figure 3F.

2. For Model CB-2800 Only: Make sure the air flow plate has been installed as described earlier

in the Preparing the Furnace Cabinet section.

3. Position the blower mount over the fan opening on the furnace cabinet.

4. Install the two U-bolts over the mounting lugs and through the holes in the top lip of the blower

mount.

5. Tighten the nuts on the U-bolts until the blower mount fits snugly aginst the side of the furnace

cabinet.

6. Use sets of double nuts as shown in Figure 3F, and firmly tighten the nuts to securely lock the

blower mount in position.

7. Attach the side lips of the blower mount to the furnace cabinet using the self-tapping screws.

3-9

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Central Furnace Models: Installing the Blower Assembly (continued)

Installing the Blower on the Blower Mount

CAUTION: Follow the steps in this procedure carefully to ensure that the blower is installed

securely on the blower mount.

1. Refer to Figure 3F.

2. Slide the blower into position so that the blower outlet fits inside the mounting bracket on the

blower mount.

3. Install the top mounting bracket and firmly attach the blower using self-tapping screws as shown

in Figure 3F so the blower is safely supported.

Installing the Motor on the Blower

NOTE: The blower motor is non-reversible.

1. Refer to Figures 3F and 3H.

2. Use the self-tapping bolts to install the motor mounting bracket on the blower.

3. Slide the two square-head bolts upside-down in the channel of the motor mounting bracket.

4. Install the motor mounting plate on the mounting bracket using the two bolts in the channel to

hold the plate in position. DO NOT install the nuts on the bolts yet. Make sure the plate is flush

with the side of the blower.

5. Lift the motor into position on the motor mounting plate using the two bolts in the channel to

hold the motor in place. Now install the nuts on the two (2) bolts, and tighten the nuts.

6. Install the additional two (2) bolts and nuts through the lower holes in the motor mounting plate

and motor. Tighten the nuts to hold the motor firmly in position.

7. Lift up on the end of the motor mounting plate until the hole in the side of the plate is aligned

with the slot in the motor tensioning bracket. Push a bolt through the slot and install a nut to

hold the plate in position. DO NOT tighten the nut yet.

Figure 3H - Assembled View of Blower

3-10

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Central Furnace Models: Installing the Blower Assembly (continued)

Installing the Motor Pulley

CAUTION: It is essential that the correct motor pulley is installed for your specific ducting application.

Make sure that qualified HVAC personnel properly design the ductwork for your furnace and determine

the static pressure for your ducting application.

1. Refer to Figures 3F, 3H and the following charts.

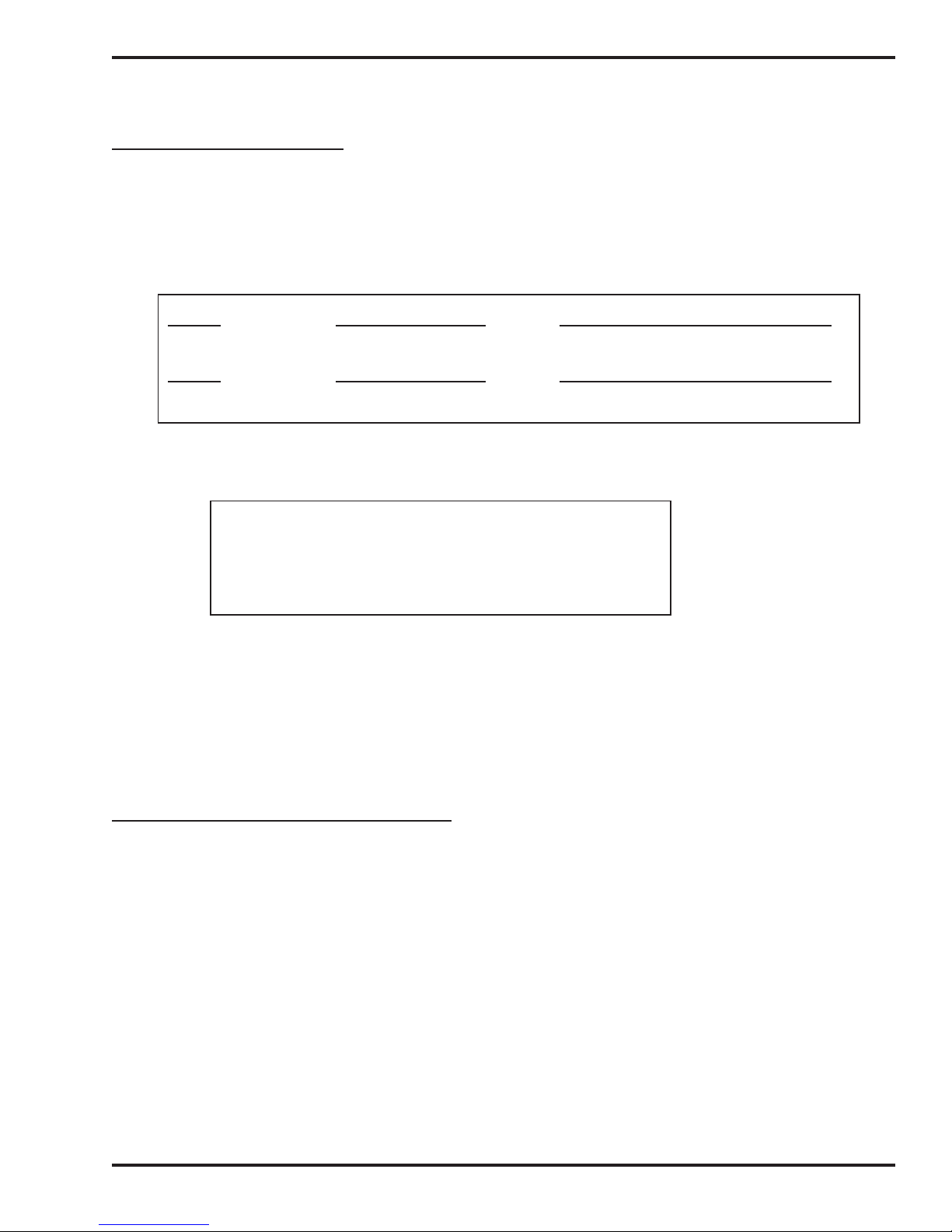

CB1800 Free Air (Unit Heater) .2 to .3 Static Pressure (Central Furnace)

Motor Pulley Size 3.75" O.D. 4.45" O.D.

5/8" Bore 5/8" Bore

CB2800 Free Air (Unit Heater) .2 to .3 Static Pressure (Central Furnace)

Motor Pulley Size 3.55" O.D. 3.95" O.D.

5/8" Bore 5/8" Bore

Air Flow (CFM) and Static Pressure (SP) Specifications

for CB-1800 and CB-2800 Central Furnace Models

Static Pressure

"H20 in Outlet 0.20* 0.30*

CB-1800 Central Furnace CFM 2300 2200

CB-2800 Central Furnace CFM 3300 3100

*CAUTION: A qualified electrician must check the blower motor amperage during operation of the furnace

to ensure that motor amperage does not exceed 85% of the maximum amperage on the motor label. DO NOT

operate the blower motor above 85% of maximum amperage or motor damage may occur.

2. Slide the motor pulley into position on the motor shaft.

3. Position the key in the slot on the motor shaft.

4. DO NOT tighten the locking screw in the motor pulley hub until instructed to do so.

Installing the Blower Pulley and V-Belt

1. Refer to Figures 3F and 3H.

2. Slide the blower pulley into position on the blower shaft.

ATTENTION: Ensure that you align the motor pulley and the blower pulley with a straight

edge, or vibration and bearing damage will occur.

3. Tighten the locking screw in the blower pulley hub against the flat on the blower shaft. Also

tighten the locking screw in the motor pulley hub.

4. Install the V-belt on the motor pulley and the blower pulley.

5. To tension the V-belt, lift up on the end of the motor mounting plate. Firmly tighten the nut and

bolt on the tensioning bracket.

6. Ensure that there is a 3/4" deflection in the tensioned V-belt. DO NOT overtension the V-belt.

Repeat step #5 if necessary to achieve the proper tension on the V-belt.

3-11

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Central Furnace Models: Installing the Blower Assembly (continued)

Installing the Belt Guard and the Blower Guard

1. Refer to Figures 3F and 3H.

2. Install the belt guard and blower guard as shown.

CAUTION: DO NOT operate the furnace without the belt and blower guards in place on the

blower assembly.

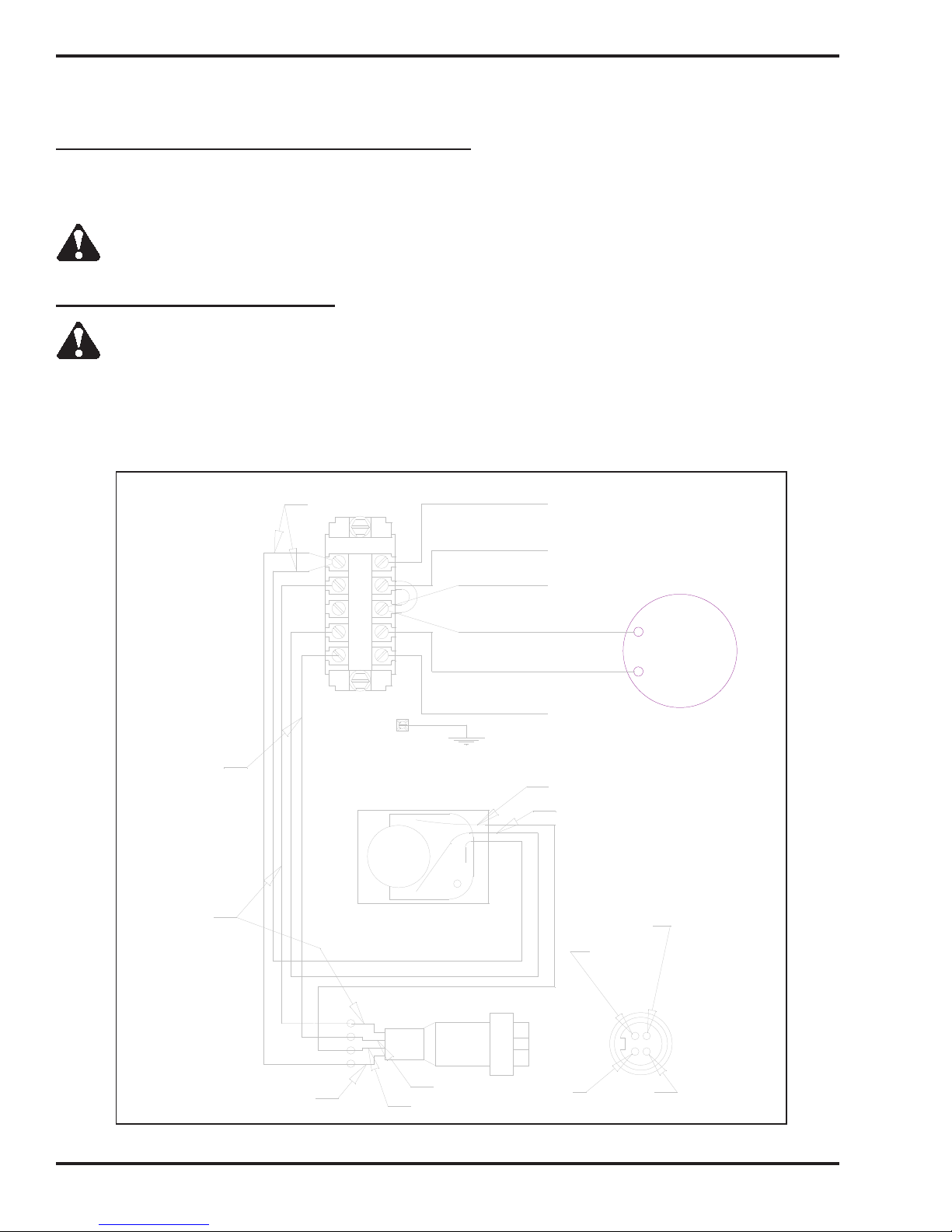

Installing the Electrical Conduit

WARNING: Ensure that the main power is turned OFF before wiring the blower motor.

1. Install an electrical connector in the electrical access holes on the blower motor and the electrical

junction box on the furnace cabinet.

2. Feed the electrical conduit assembly through the connectors.

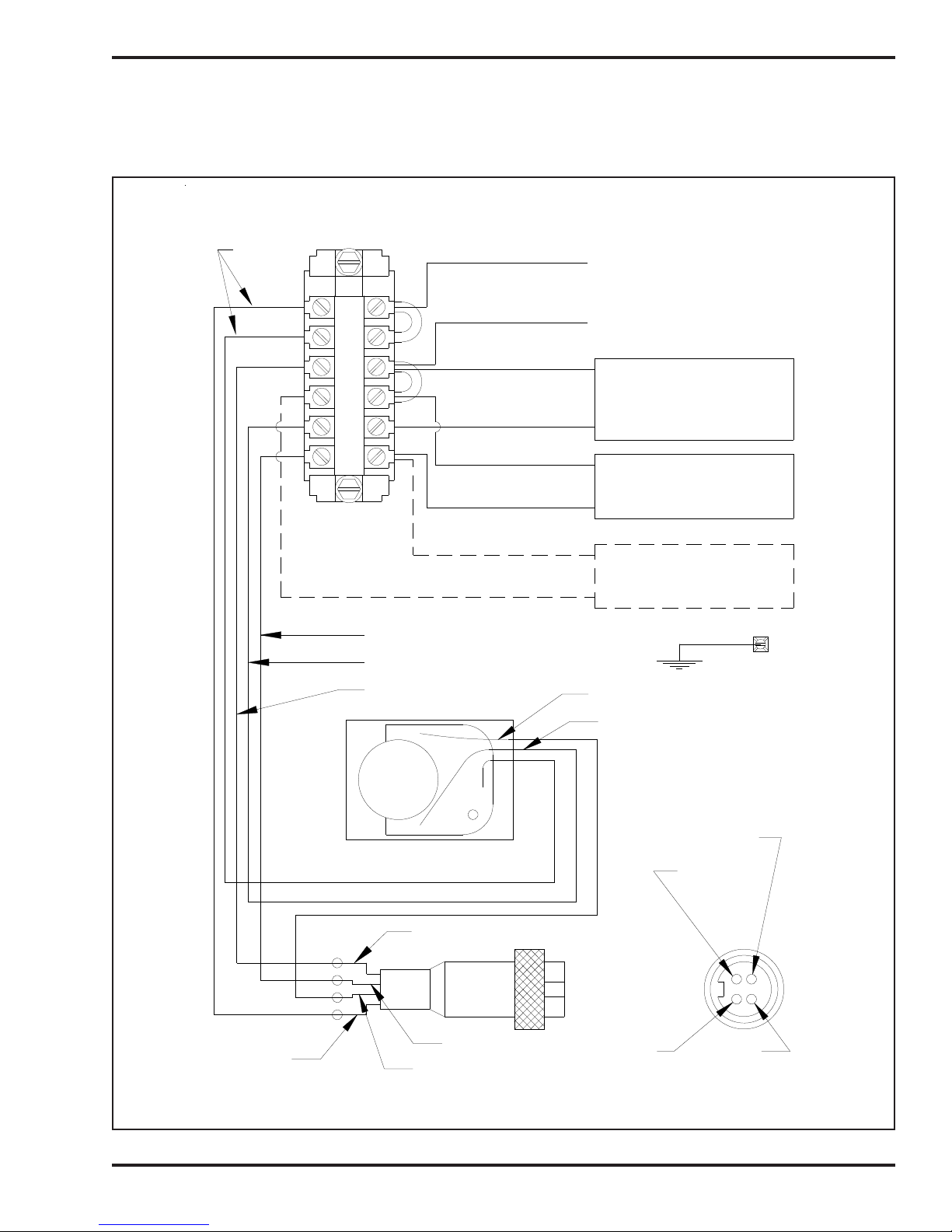

3. Connect the wires according to Figure 3I.

PURPLE

WHITE

BLACK

L1

L1

L2

L2

L2

L2

3

3

4

4

GREEN

GROUND

SCREW

FAN LIMIT SWITCH

(COVER REMOVED)

BLACK

120 VOLTS

WHITE

WHITE

WHITE

BLUE

BLACK

MAIN

POWER

MAIN

NEUTRAL

OIL PUMP

BLOWER MOTOR

OIL PUMP

RED

ORANGE

WHITE

LINE 4

LINE 1

GREEN

BLACK

Figure 3I - Wiring Diagram for the Electrical Junction Box on the Furnace Front

RED

GREEN

3-12

BLACK

RED

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Installing the Burner

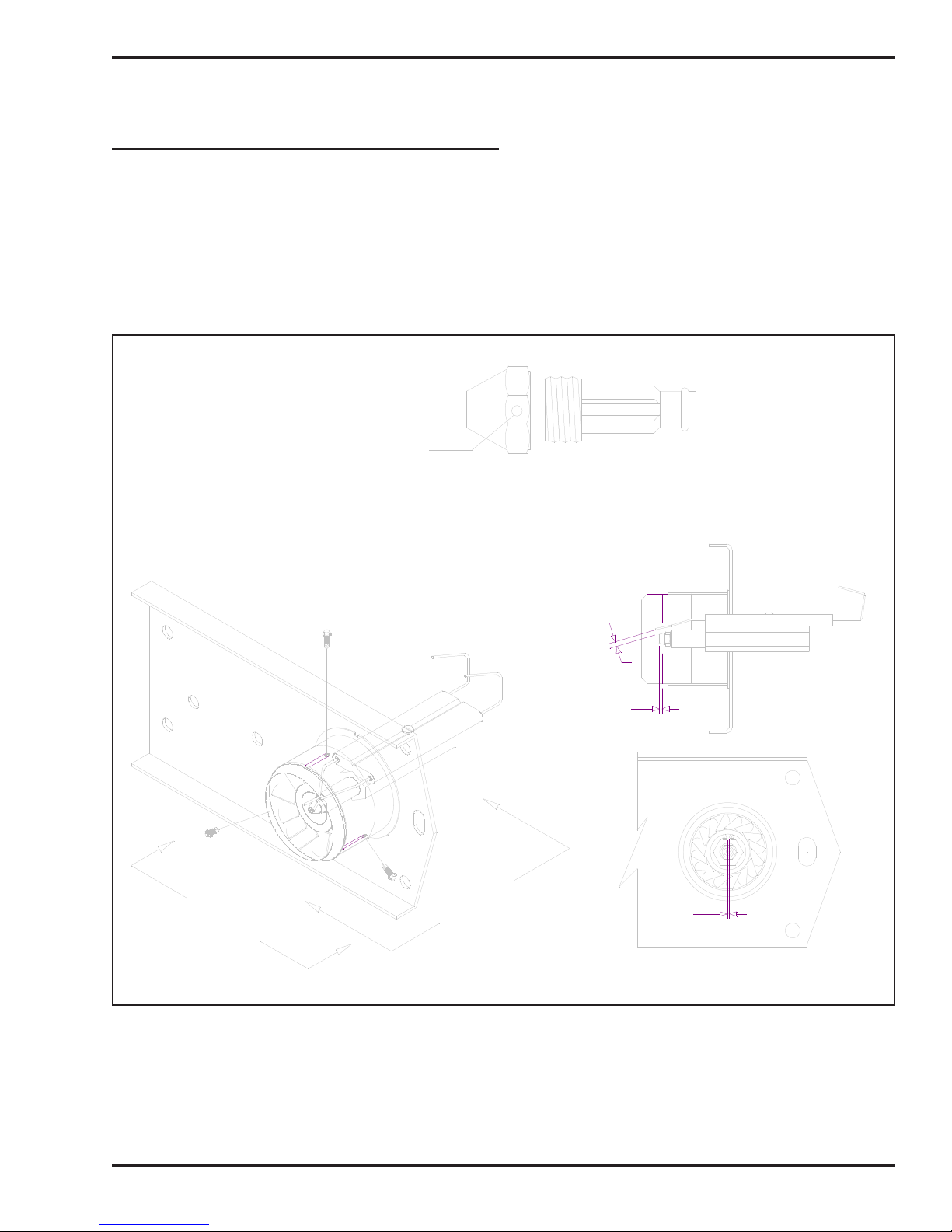

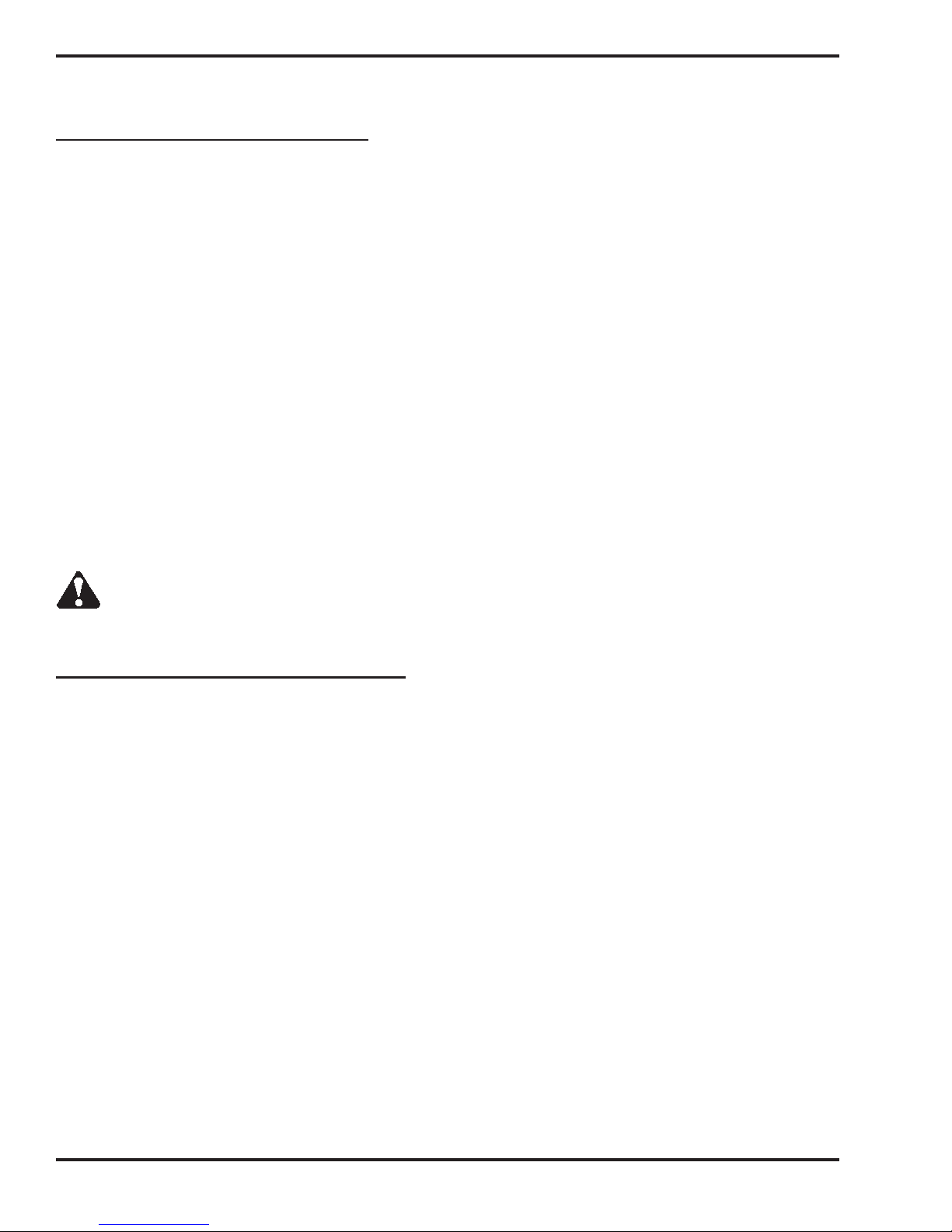

Checking the Burner Nozzle and Electrodes

NOTE: The burner nozzle is factory installed. All furnace models (CB1400, CB-1800 and CB-2800)

use a Delavan 9-5 nozzle. The nozzle size is indicated on the nozzle as shown in Figure 3J. Refer also

to Appendix A at the back of the manual for additional specifications/instructions on the burner nozzle.

ATTENTION: Check the electrode settings as specified in Figure 3J. The electrode settings must be

correct for your burner to operate properly.

BURNER NOZZLE

NOZZLE IS STAMPED EITHER 9-5

OR -5 ON FLAT OF NOZZLE HEAD

SIDE VIEW -- AA

3/16" GAP BETWEEN

3X

V

I

E

W

B

B

ELECTRODES & NOZZLE

A

-

A

W

E

I

V

CRITICAL DIMENSION:

NOZZLE MUST BE 1/8"

AHEAD OF THE DISK.

NOZZLE MUST NOT BE

BEHIND THE DISK.

1/8"

SPARK

GAP

FRONT VIEW -- BB

Figure 3J - Burner Nozzle and Electrode Specifications

3-13

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Installing the Burner (continued)

Mounting the Burner on the Hinge Bracket

ATTENTION: Burner tube components (e.g. electrodes and retention head) are factory set. Handle the

burner with extreme care so that burner components are not damaged.

1. Remove the nut from the bolt on the mounting flange of the furnace cabinet, and set it aside for

later use.

2. Lift the burner into position so the burner hinge plate is mounted on the hinge bracket on the

furnace cabinet.

3. Carefully swing the burner so the retention head enters the throat of the furnace.

4. Check the clearance between the retention head and the furnace throat. There must be at least

1/8" clearance, so the retention head is not "bumped" as you swing the burner into firing

position.

NOTE: If the retention head "bumps" the furnace throat, adjust the hinge bracket bolts

as follows:

• While supporting the burner, slightly loosen the two (2) hinge bracket bolts.

• Carefully re-position the burner so it swings freely into its firing position.

• With the burner in its firing position, re-tighten the hinge bracket bolts.

Installing the Connector Block, Oil Line Tubing, and Air Line Tubing

Installing the Connector Block on the Furnace Door

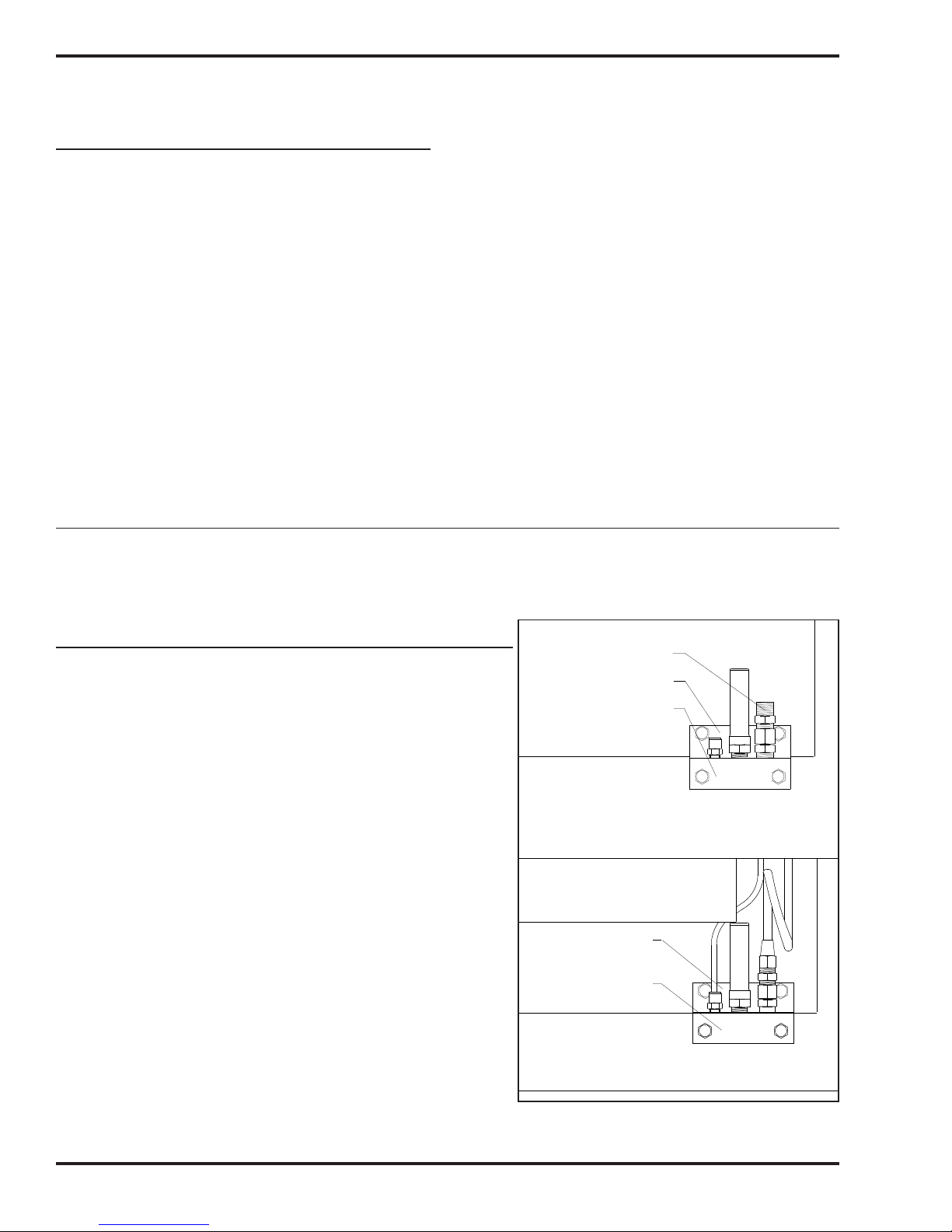

For Model CB-1400 Only:

1. Refer to Figure 3K.

2. Install the mounting bracket on the furnace cabinet

using the two (2) bolts supplied.

3. Install the connector block on the mounting bracket

using the two (2) carriage bolts supplied.

4. Remove and discard the red caps and plugs from the

fittings and ports on the connector block. DO NOT

allow any dirt/debris to enter these components

during furnace assembly.

For Models CB-1800 and CB-2800:

1. Refer to Figure 3L.

2. Use the two (2) bolts to install the aluminum

connector block onto the furnace cabinet.

3. Remove and discard the red caps and plugs from the

fittings and ports on the connector block. DO NOT

allow any dirt/debris to enter these components

during furnace assembly.

SWIVEL ASSEMBLY

MOUNTING BRACKET

CONNECTOR BLOCK

DETAIL OF MOUNTING BRACKET AND

CONNECTOR BLOCK ON CB-1400

MOUNTING

BRACKET

CONNECTOR

BLOCK

DETAIL OF OIL LINE, AIR LINE INSTALLED

ON CB-1400

Figure 3K - Installation of Connector

Block (CB-1400 only)

3-14

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Installing the Connector Block on the Furnace Door

(continued)

OIL LINE

OIL FITTING

ON BURNER

ATTENTION: The connector block includes an accumulator.

The accumulator functions like a shock absorber on the oil line

to prevent pressure buildup and protect vital burner

components. It is important that the connector block is

installed as shown so that the accumulator is in a vertical

CB-525 BURNER

position to prevent sediment from settling in the accumulator.

Never operate your furnace without the connector block and

accumulator properly installed on the furnace, or damage

may occur to vital burner components.

SWIVEL ASSEMBLY

CONNECTOR BLOCK

INSTALLED ON

FURNACE

FRONT VIEW OF FURNACE

ATTENTION: DO NOT use teflon tape on any fittings.

Teflon tape residues will plug vital burner components.

Installing the Oil Line Tubing

OIL LINE FITTING

ON BURNER LINED

UP WITH OIL LINE

NOTE: DO NOT disassemble the compression fitting from

the swivel fitting. To prevent leaks, the NPT threads of the

compression fitting have been sealed with hydraulic sealant

during assembly of the fittings at the factory.

OIL LINE

SWIVEL

ASSEMBLY

1. Remove and discard the red caps from the oil line

tubing.

CONNECTOR

BLOCK

2. Loosely install the oil line tubing into the oil line fitting

on the burner.

3. Use a wrench to slightly rotate the oil line fitting on the

burner counterclockwise so the tubing lines up with the

SIDE VIEW OF FURNACE

SHOWING OIL LINE INSTALLED

swivel assembly. Slightly bend the tubing as shown in

Figure 3L, if required, to "line up" the oil line.

4. If necessary, use a tubing cutter to cut the tubing to the

Figure 3L - Installation of

Connector Block and Oil Line

proper length.

ATTENTION: Due to adjustment of the burner hinge bracket, the oil line tubing may need to

be cut to fit properly. DO NOT lift up on the burner when installing the oil line tubing to

compensate for oil line tubing that is too long. This will place the weight of the burner on the

swivel fitting and result in leaks at the swivel fitting seal.

5. Make sure that the curl in the oil line is positioned as shown in Figure 3L so that the burner can

swing open correctly.

6. Install the oil line tubing and tighten the nuts on the compression fittings. DO NOT overtighten

these fittings to avoid damaging the ferrules.

NOTE: You may also check the positioning of the oil line according to Figure 3M on the next page

which provides a larger front view of the connector block assembly.

3-15

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Installing the Connector Block, Oil Line Tubing,

and Air Line Tubing (continued)

AIR LINE FITTING

ON BURNER

OIL LINE FITTING

ON BURNER

AIR LINE

OIL LINE

COMPRESSION

SWIVEL

FITTING

FITTING

CONNECTOR BLOCK

INSTALLED ON

FURNACE CABINET

Figure 3M - Installation of Connector Block, Oil Line and Air Line (Front View)

Installing the Air Line Tubing

1. Remove and discard the red caps from the air line tubing.

2. Refer to Figure 3M. Push the air line tubing into the swivel fitting on the connector block until

the tubing bottoms out in the fitting.

3. Repeat this procedure to connect the air line tubing to the air line fitting on the side of the burner.

Locking the Burner into Firing Position

1. Swing the burner into firing position.

2. Install and tighten the lock-down nut on the mounting

PLUG ON CAM

LOCK CABLE

plate bolt to secure the burner in its firing position.

3. Plug the burner electrical cable into the receptacle on the

top of the burner housing.

4. Tighten the locking ring to secure the electrical cable.

NOTE: Be sure to properly align the plug when plugging it into

SLOT IN PLUG

MUST ALIGN WITH

SLOT IN

RECEPTACLE

the receptacle. See Fig 3N.

RECEPTACLE ON

TOP OF BURNER

Figure 3N - Detail of Burner

Electric Receptacle

3-16

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

NOTE: Your furnace is now assembled and ready for installation. Install the furnace

as soon as possible so the burner and/or fan are not "bumped" or damaged. If you must

store the furnace for a period of time before installation, make sure it is located in a safe,

secure area.

3-17

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

3-18

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

SECTION 4: FURNACE INSTALLATION

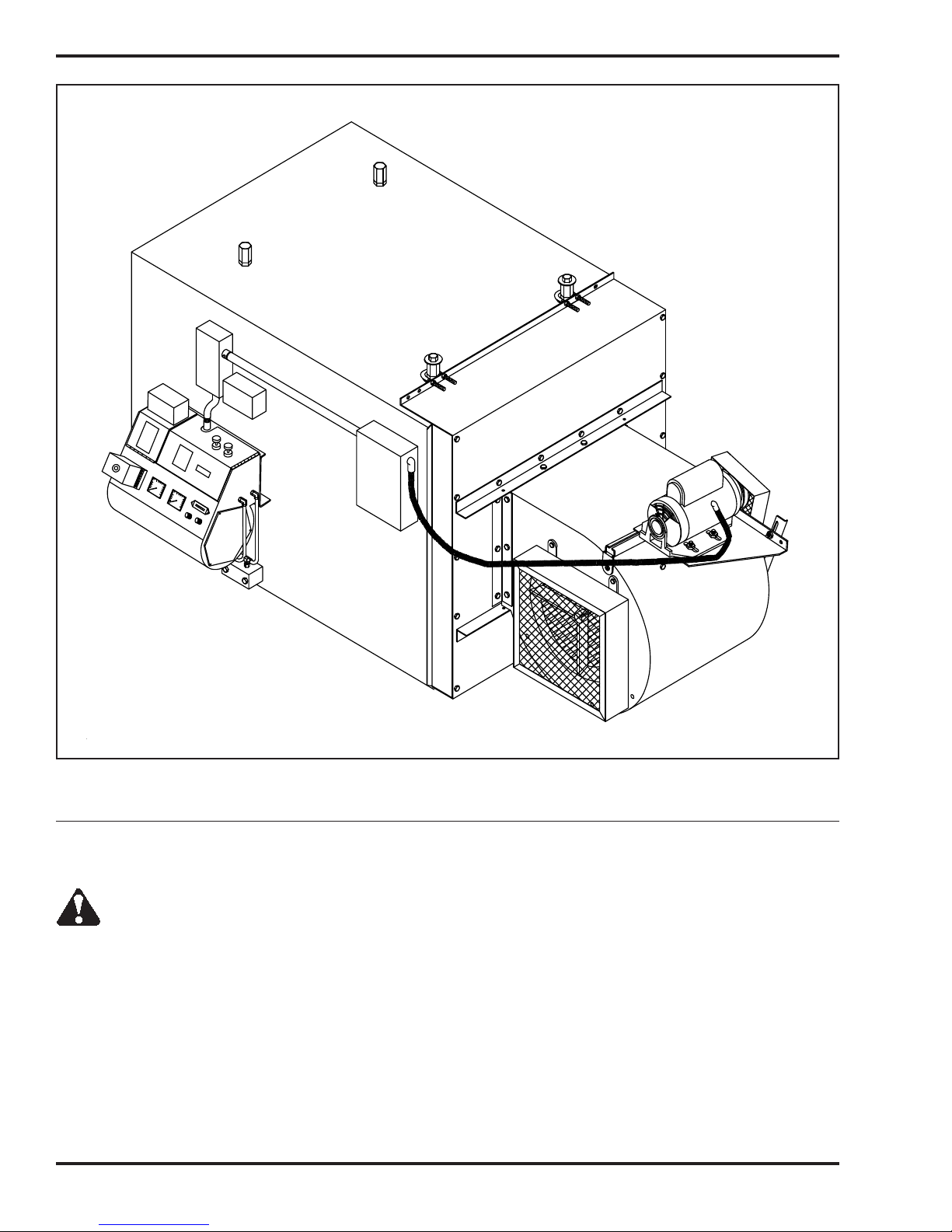

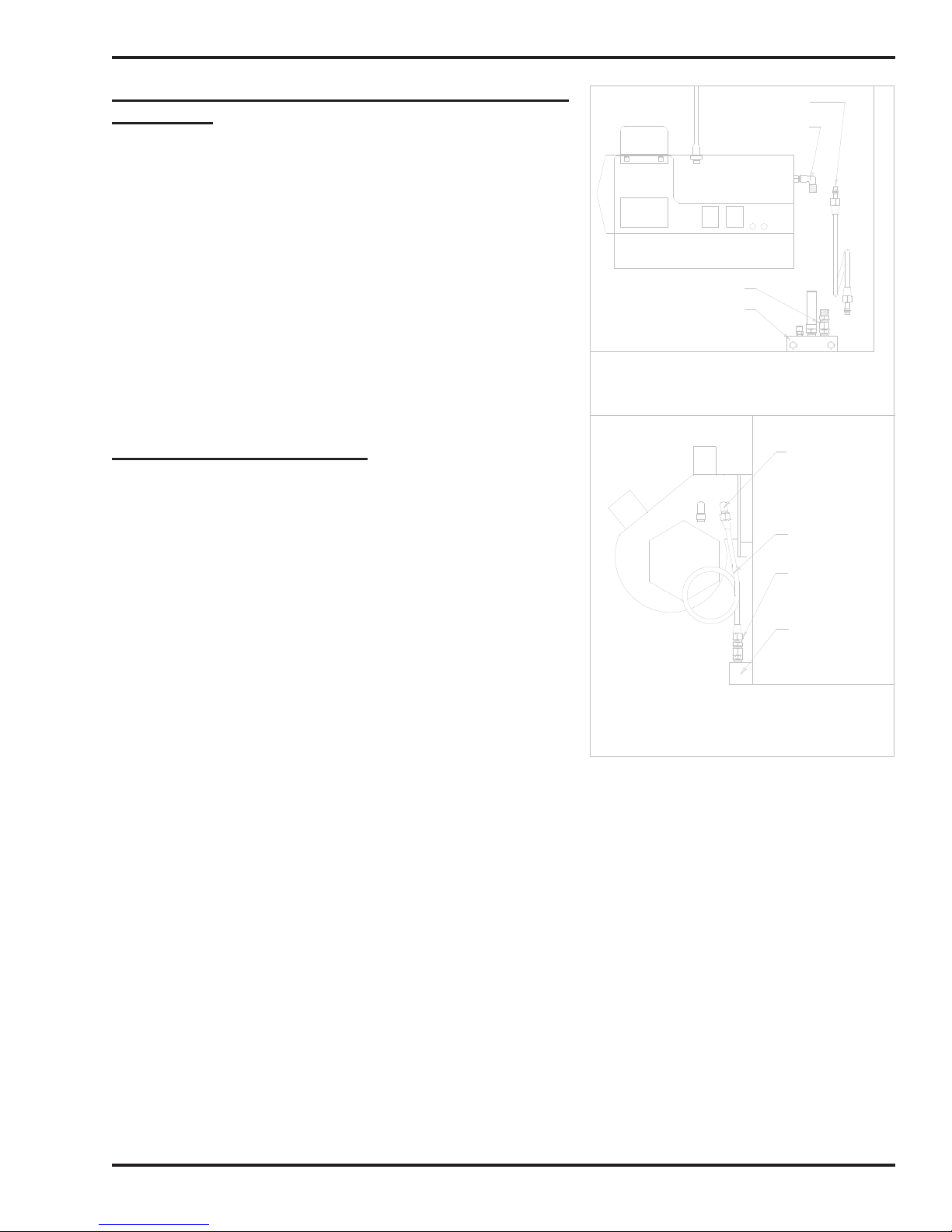

Understanding Installation

Installing your Clean Burn furnace is a multi-step process which includes:

(1) Selecting a Location

(2) Mounting the Furnace

(3) Determining the Type of Oil Tank

(4) Installing the Oil Pump

(5) Wiring the Furnace and Pump

(6) Installing the Oil Lines

(7) Installing the Compressed Air Line

(8) Installing the Stack

(9) Installing the Wall Thermostat

(10) Inspecting the Installation

Clean Burn recommends that you review all procedures before beginning installation, paying careful

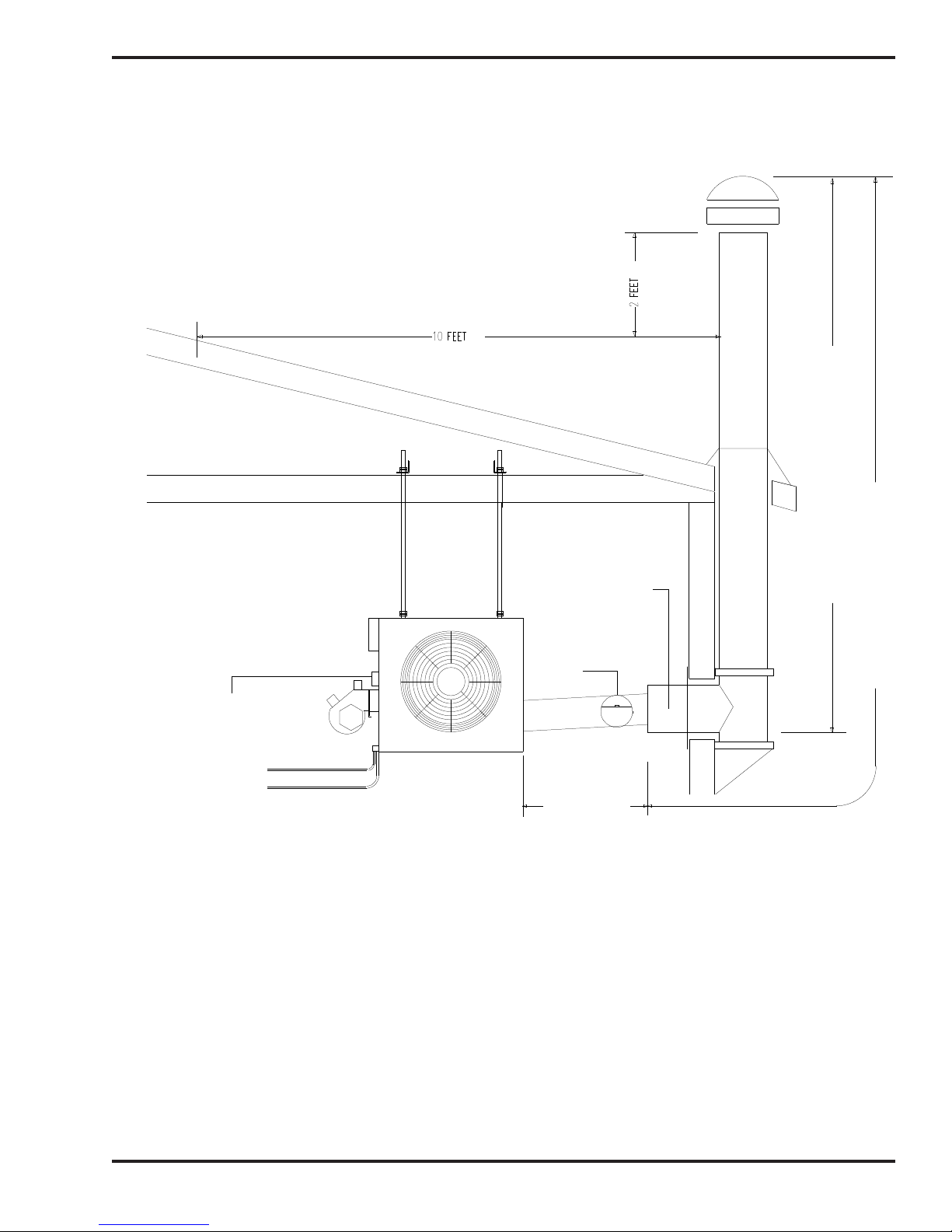

attention to safety information statements. Figures 4A and 4B provide a general overview of typical

furnace installations and should be reviewed closely before proceeding.

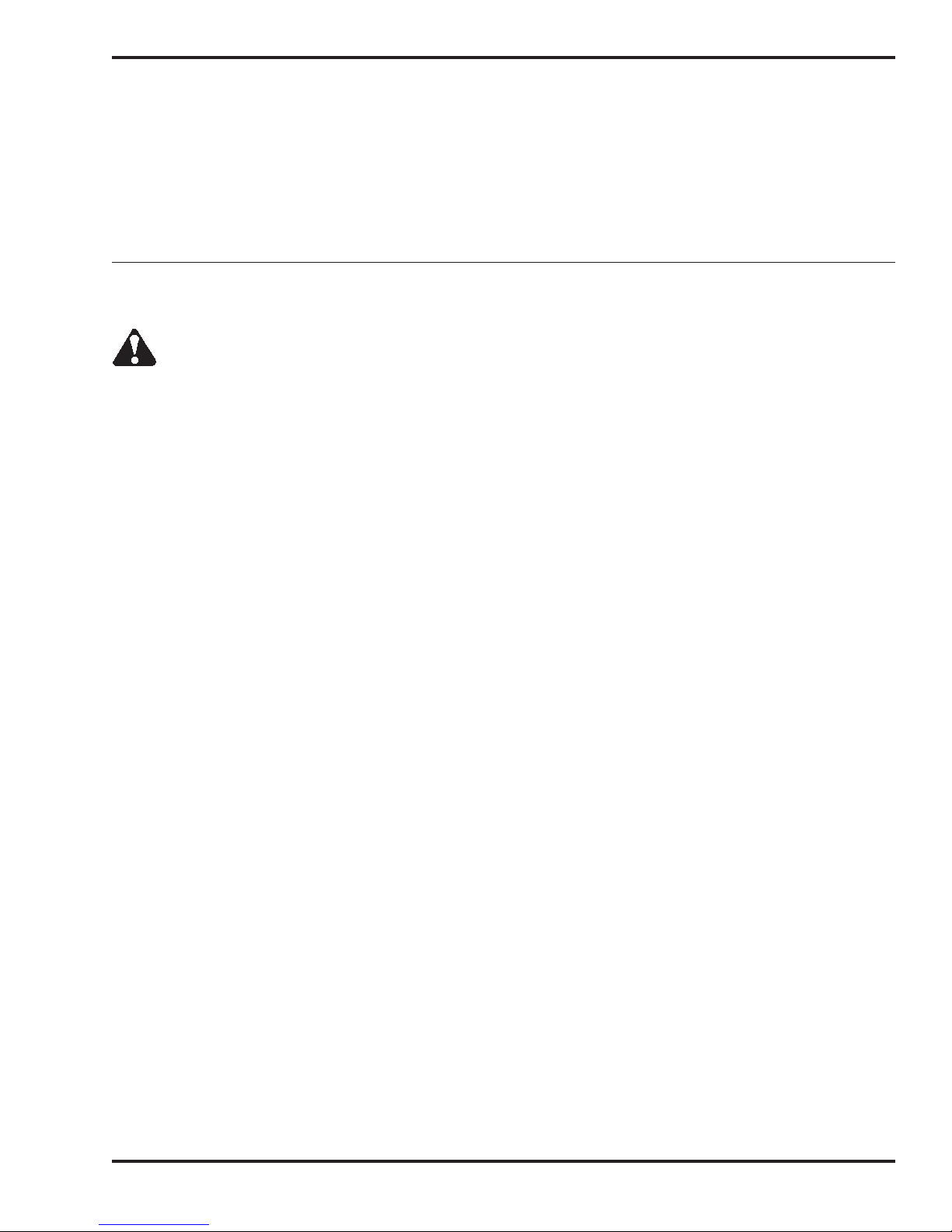

WARNING: The installation, operation, and maintenance of this equipment in the U.S.

must be accomplished by qualified personnel and in compliance with the specifications in the

Clean Burn Operator's Manual and with all national, state, and local codes or authorities having

jurisdiction over environmental control, building inspection and fuel, fire and electrical safety and the

following standards of the National Fire Protection Association.

NFPA 30 Flammable and Combustible Liquids Code

NFPA 30A Automotive and Marine Service Station Code

NFPA 31 Standard for the Installation of Oil Burning Equipment

NFPA 211 Chimneys, Fireplaces, Vents and Solid Fuel Burning Appliances

NFPA88A Parking Structures

NFPA 88B Repair Garages

NFPA 70 National Electrical Code

The NFPA standards may be obtained from:

National Fire Protection Association (NFPA)

1 Batterymarch Park, P.O. Box 9101

Quincy, Massachusetts 02269-9101

Likewise, the installation, operation, and maintenance of this equipment in Canada is to be accomplished

by qualified personnel and in compliance with the specifications in the Clean Burn Operator's Manual

and in accordance with the regulation of authorities having jurisdiction and CSA Standard B 139,

Installation Code for Oil Burning Equipment.

Failure to comply with these standards and requirements may result in equipment damage, fire,

explosion, personal injury and/or death.

WARNING: Improper installation can adversely affect the proper, safe operation of your

furnace. It is critical that your furnace installer reads and follows the instructions provided in

this manual.

4-1

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

NON-RESTRICTIVE

"CLASS A" STACK CAP

"CLASS A" STACK INSULATED STACK

WITH A STAINLESS STEEL LINER

WARNING! OUTSIDE STACK AND

STACK PENETRATIONS THROUGH

CEILING, ROOF, OR SIDEWALL MUST

BE "CLASS A" FOR FIRE SAFETY AND

TO MAINTAIN PROPER DRAFT.

EXTERIOR SINGLE WALL STACK

DOES NOT MEET CODE. EXTERIOR

SINGLE WALL STACK CHILLS THE

EXHAUST GASES RESULTING IN

POOR BURNER PERFORMANCE AND

BACK PRESSURE IN THE FURNACE.

WARNING! MAKE SURE TO INSTALL

ALL STACK COMPONENTS WITH

PROPER CLEARANCE FROM

COMBUSTIBLES.

WARNING! MAKE SURE TO INSTALL

THE PROPER ROOF SUPPORT

SYSTEM TO SAFELY SUPPORT THE

STACK.

WATERTIGHT ROOF FLASHING:

CLEAN BURN RECOMMENDS "DEKTITE"

FLASHING FOR A WATERTIGHT SEAL

"CLASS A" KIT FOR

INSTALLING

"CLASS A" STACK

THROUGH

CEILING

CLEAN-OUT TEE

OIL PUMP ELECTRICAL CIRCUIT

SINGLE WALL

STACK

BAROMETRIC

DAMPER

ELBOW OR

1/4" HOLE FOR

SETTING DRAFT AT

BREACH

PRESSURE OIL LINE

DOUBLE NUTS

DOUBLE NUTS

LOUVER SIDE

CB-2800 FURNACE

CEILING MOUNTING SYSTEM

WARNING! USE MINIMUM 2-1/2" x 2-1/2"

ANGLE IRON BEAMS, BRIDGED ACROSS

SUFFICIENT STRUCTURAL MEMBERS TO

SAFELY SUPPORT FURNACE.

(4) "ALL THREAD" SUPPORT RODS

5/8" (1.6 CM) DIAMETER FOR ALL MODELS

WARNING! MAKE SURE TO USE DOUBLE

NUTS TO SECURELY FASTEN SUPPORT

RODS.

ELECTRICAL

JUNCTION

BOX

CB-525

BURNER

COMPRESSED AIR LINE

INSTALLED TO ALUMINUM

CONNECTOR BLOCK

INSTALL 2" X 2" X 4"

ELECTRICAL BOX ON

OIL PUMP MOTOR

FILL PIPE WITH

RAINTIGHT CAP

VENT PIPE WITH

VENT CAP

OIL FLOW

CANISTER FILTER IN SUCTION LINE

FLARE FITTING

Figure 4A - Typical Furnace Installation

SUCTION OIL LINE

FLARE

FITTING

DOUBLE TAP BUSHING

REMOVABLE

STANDPIPE

INSTALL WITH ARROW UP

CHECK VALVE--

CHECK VALVE SCREEN

OIL STORAGE TANK

4-2

CAUTION: SUCTION OIL LINE

MUST BE 100% AIRTIGHT. AIR

LEAKS CAUSE THE BURNER TO

PERIODICALLY SHUT DOWN ON

SAFETY LOCK-OUT.

SEE TANK/PUMP

INSTALLATION DIAGRAM TO

PROPERLY INSTALL THE

SUCTION OIL LINE AND PUMP

CLEAN-OUT

24 VOLT WALL

THERMOSTAT

"2 WIRE" THERMOSTAT CABLE

ELECTRIC

SERVICE

DEDICATED ELECTRIC CIRCUIT

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

NOTE: THE LAST STACK SECTION SHALL EXTEND AT LEAST 2 FT. ABOVE THE HIGHEST

POINT AT WHICH IT COMES IN CONTACT WITH THE ROOF, AND AT LEAST 2 FT. HIGHER

THAN ANY RIDGE, PARAPET WALL OR ROOF STRUCTURE WITHIN 10 FT. OF IT.

MIN. CLEARANCES TO COMBUSTIBLES AND

MIN. SERVICE CLEARANCES:

TOP 18"

FRONT (BURNER SIDE) 24"

REAR (STACK SIDE) 36"

BOTTOM 24"

LOUVER END 60"

BLOWER END 24"

CHIMNEY CONNECTOR 18"

CIRCULATING FAN SIDE

10 FT. VERTICAL STACK HEIGHT OR

EQUIVALENT DRAFT SYSTEM TO MAINTAIN

-.02 W.C. DRAFT OVER FIRE.

COMPRESSED AIR LINE

DEDICATED ELECTRIC CIRCUIT

ELECTRIC

SERVICE

NOTE: LOCAL CODES MAY

REQUIRE ELECTRICAL

SHUT-OFFS AT OR NEAR

THE FURNACE AND PUMP.

"2 WIRE" THERMOSTAT CABLE

24 VOLT WALL

THERMOSTAT

OIL PRESSURE LINE SPECIFICATIONS:

LINE LENGTH MIN. LINE SIZE

LENGTH UP TO 50 FT. 1/2" O.D. COPPER TUBING

LENGTH UP TO 100 FT. 5/8" O.D. COPPER TUBING

LENGTH UP TO 200 FT. 3/4" O.D. COPPER TUBING

DIAMETER OF COPPER TUBING MUST BE MAINTAINED FOR FULL

LINE LENGTH.

OF VACUUM

VERTICAL SUCTION LIFT

OR NOT TO EXCEED 10" HG

CLEAN-OUT

CB-2800 FURNACE

STANDPIPE SPECIFICATIONS:

USE MIN. 1/2" I.D. STEEL PIPE OR

MIN. 5/8" O.D. COPPER TUBING

FOR INSIDE TANK.

FOR OUTSIDE/UNDERGROUND

TANK USE MIN. 3/4"

DRAFT READING PORT

DRAFT AT BREACH: -.04 W.C.

DRAFT OVER FIRE: -.02 W.C.

HORIZONTAL SUCTION LINE OR

NOT TO EXCEED 10" HG OF VACUUM

CAUTION: KEEP THE SUCTION LINE AS

SHORT AS POSSIBLE.

100% AIRTIGHT SUCTION OIL LINE

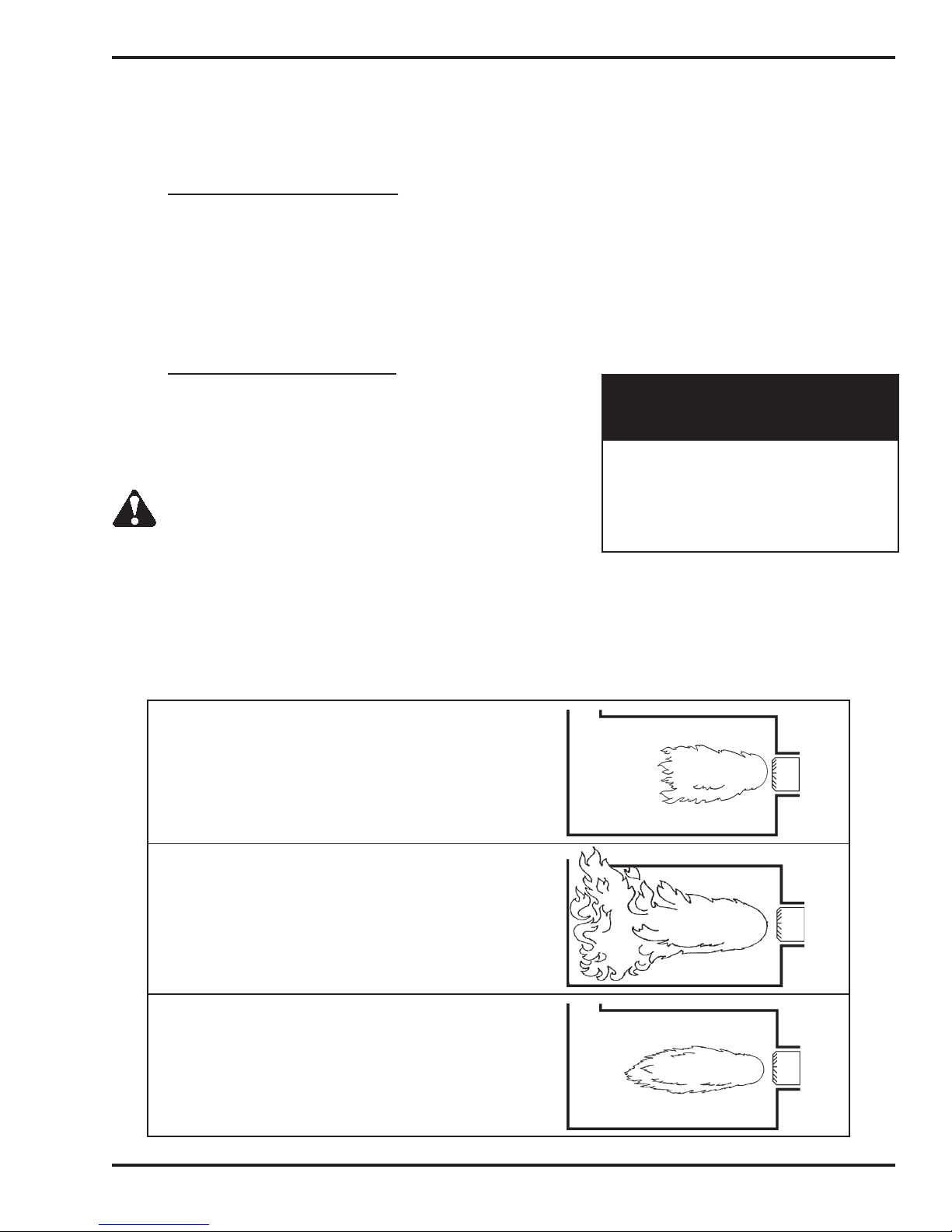

MIN. 12" FROM CHECK

VALVE TO TANK BOTTOM.

CB1400/1800/2800 REQUIRE MIN. 8 INCH

STACK COMPONENTS. DO NOT REDUCE

STACK SIZE.

OIL PUMP ELECTRICAL CIRCUIT

WARNING! MAKE SURE YOUR FURNACE

IS MOUNTED AT LEAST 5 FT. AWAY FROM

YOUR OIL STORAGE TANK. CHECK YOUR

LOCAL FIRE CODE.

WARNING! YOUR LOCAL CODES MAY REQUIRE THAT YOUR FURNACE IS MOUNTED A MIN.

OF 8 FT. OFF THE GROUND IF THERE IS THE POSSIBILITY OF GASOLINE FUMES OR

OTHER COMBUSTIBLE OR EXPLOSIVE FUMES IN YOUR SHOP. REFER TO NFPA-88B.

Figure 4B - Typical Furnace Installation - Detailed

4-3

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Selecting a Location

Guidelines for Selecting a Location

The location you select for your furnace must allow the following:

• Unobstructed, even heat distribution.

• Safe, easy access for servicing.

• Unobstructed passage for shop vehicles and equipment.

• Proper clearances from combustibles. Verify according to your local safety codes.

• Adequate combustion air per local codes.

• Proper stack installation.

Adhere to the following minimum clearances from combustible surfaces and to provide adequate clearance for servicing:

• TOP......................................................... 18"

• FRONT (burner side).............................. 24"

• REAR (stack side) .................................. 36"

• LOUVER END ....................................... 60"

• BLOWER/FAN END ............................. 24"

• BOTTOM ............................................... 24"

• CHIMNEY CONNECTOR .................... 18"

WARNING: Your local codes may require that your furnace is mounted a minimum of eight (8)

feet off the ground if there is the possibility of gasoline fumes or other combustible or explosive

fumes in your shop area. Refer to NFPA-88B.

Determining Air Flow From the Furnace

One important consideration in selecting the proper location for your furnace is heat distribution, i.e.

how the air (heat) will circulate from your furnace. Depending on the type of furnace you ordered (Unit

Heater or Central Furnace), you will use one of two air flow configurations:

• "Free air" circulation : this method is the easiest and most economical. In this case,

industrial-size ceiling fans may be installed to aid in efficient, even heat distribution.

NOTE: If the peak of your shop roof/ceiling is 14 feet or higher, Clean Burn recommends

the use of industrial-size ceiling fans to gently redistribute the heat from the furnace. A

minimum of one Clean Burn 56" Blade Industrial Ceiling Fan (C.B. part# 70003) or

equivalent is recommended for each 2000 square feet of heated shop space.

• Ductwork (central furnace ONLY ): this method is more complex and requires careful

planning and additional investment for proper installation. If you plan to duct your furnace,

it is essential that qualified HVAC personnel design and install the ductwork system

according to the specifications provided in this section.

4-4

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining Air Flow From the Furnace (continued)

Air Flow (CFM) and Static Pressure (SP) Specifications

for CB-1800 and CB-2800 Central Furnace Models

Static Pressure

"H20 in Outlet 0.20* 0.30*

CB-1800 Central Furnace CFM 2300 2200

CB-2800 Central Furnace CFM 3300 3100

*ATTENTION: A qualified electrician must check the blower motor amperage during operation of the furnace to ensure that

motor amperage does not exceed 85% of the maximum amperage on the motor label. DO NOT operate the blower motor

above 85% of maximum amperage or motor damage may occur.

Mounting the Furnace

After selecting a safe and appropriate location for

your furnace, construct the mounting system as

required by the location and the following

specifications.

Ceiling Mounting

CAUTION: Ensure that your furnace

mounting system can safely bear the

suspended weight of the furnace and allow safe

servicing of furnace components.

1. Refer to Figures 4A and 4B.

2. Follow the instructions as provided in the

diagrams.

3. Use a spirit level to make sure the cabinet

is level side to side and front to back.

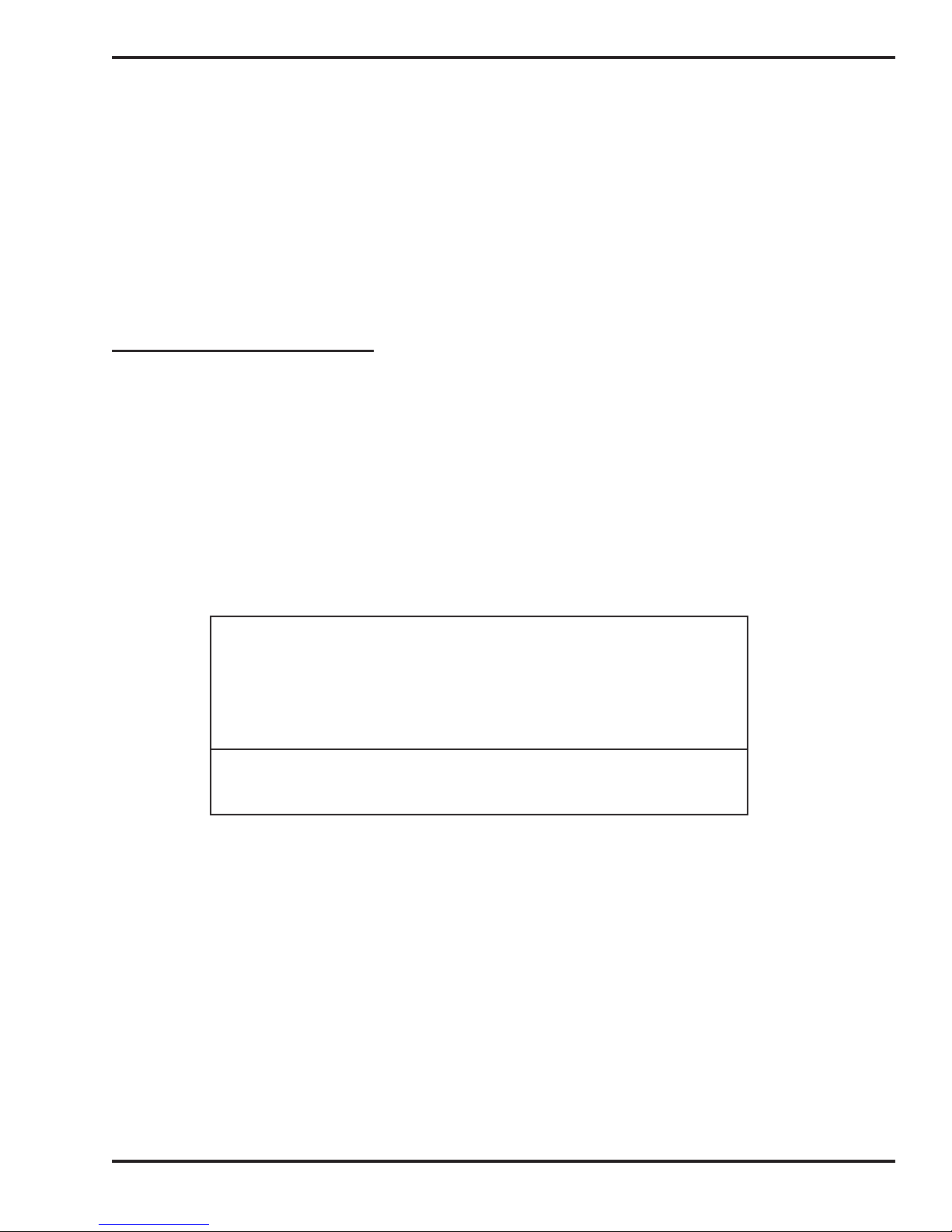

Raised Platform Mounting

CAUTION: Make sure the platform is

designed to safely bear the weight of the

furnace and allow safe servicing of furnace components. The platform must be constructed of

non-combustible materials (e.g. steel).

1. Refer to Figure 4C and follow the

instructions as provided in the diagram.

CB-2800 FURNACE

8 FOOT (2.5 METERS) MINIMUM FROM FLOOR

TO FURNACE IF THERE IS THE POTENTIAL FOR

GASOLINE FUMES IN YOUR SERVICE AREA

IF THERE IS NO POTENTIAL FOR GASOLINE FUMES

IN YOUR SERVICE AREA, YOU MAY MOUNT THE

FURNACE ON A RAISED PLATFORM WHICH IS

MINIMUM 2 FEET (61 CM) HIGH

FIGURE 4C - Furnace Installed on

Raised Platform

4-5

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Mounting the Furnace (continued)

Floor Mounting

CAUTION: If you are installing your furnace in an area with a combustible floor, you must

construct a non-combustible floor as shown in Figure 4D. Refer to NFPA-31 or CSA-B-139.

1. Refer to Figure 4D and follow the instructions as provided in the diagram.

MIN. 24 GA. STEEL PAN WITH MIN. 1 INCH

(2.5CM) LIP FOR OIL CONTAINMENT

8 INCH (20 CM) TALL CINDER BLOCK

MIN. 24 GA. STEEL

FIREGUARD SHEETROCK OR EQUIVALENT

COMBUSTIBLE MATERIAL

FIGURE 4D - Furnace Installed on Non-Combustible Floor

MIN. 18" (46 CM)

CB-2800 FURNACE

MIN. 2" (5 CM) TALL MASONRY BLOCKS TO

ALLOW CLEARANCE FOR INSTALLATION OF

FITTINGS ON THE CONNECTOR BLOCK

MIN. 18" (46 CM)

4-6

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank

It is very important that you determine which type of oil tank your furnace will be using, as this will

determine the correct method for installing your oil pump and oil lines. Oil tanks are classified in three

categories as follows:

(1) Inside Above Ground Tank

(2) Outside Above Ground Tank

(3) Underground Tank

Ensure that your tank installation adheres to the following safety guidelines:

• The tank installation must meet all national and local codes. Consult your Clean Burn dealer

and local municipal authorities for more information if necessary.

• Use a minimum 250-gallon tank. DO NOT use a 55-gallon drum as a substitute for an

appropriate tank. The tank must be large enough to allow water, sludge, etc. to settle out of

the used oil.

• The tank must have a manual shut-off type valve on the side of the tank to allow the water,

sludge, etc. to be drained from the bottom of the tank.

• All unused openings in the tank must be plugged or capped off.

• The tank must be vented to the outside of the building using iron or steel pipe and fittings

with an approved vent cap.

1. Review the following three figures (4E/4F/4G) which illustrate the different types of oil

tank/pump installations, and select the one which matches your site's tank installation.

2. Carefully review the appropriate tank/pump installation details, including the pump installation

and specifications for the oil line installation. (Procedures for installing these components can be

found in the following sections.)

4-7

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank (continued)

CAUTION: National and local codes govern the use and installation of

inside oil storage tanks. Your tank installation must comply with these codes.

MAX. 30 FT.

HORIZONTAL SUCTION LINE

OR NOT TO EXCEED 10" HG OF VACUUM

SUCTION OIL LINE

MAX. 10 FT.

10" HG OF VACUUM

OR NOT TO EXCEED

VERTICAL SUCTION LIFT

OIL FLOW

FILL PIPE WITH

RAINTIGHT CAP

VENT PIPE WITH

VENT CAP

MINIMUM 12 INCHES

(30.5 CM) FROM CHECK

CLEAN-OUT

VALVE TO TANK BOTTOM

Close-up of pump installation for inside above ground tank

PUMP ELECTRICAL CIRCUIT

FIGURE 4E - Inside Above Ground Tank Installation

4-8

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank (continued)

Specifications for Inside Above Ground Tank Installation (Figure 4E)

NOTE: Review the following specifications closely and fill-in as required. Procedures for oil pump

and oil line installation can be found in the sections following the tank illustrations/specifications.

Suction Line Specifications (Per Figure 4E)

(1) Horizontal length of suction line (NOT to exceed 30 ft.) __________ ft.

(2) Vertical lift of suction line (NOT to exceed 10 ft.) __________ ft.

(3) Use 5/8" O.D. copper tubing; DO NOT use steel pipe unions.

(4) Use only good flare fittings; DO NOT use compression fittings.

(5) Seal every threaded fitting with Permatex #2 non-hardening gasket sealer or equivalent;

DO NOT use teflon tape.

(6) Ensure that the suction line is 100% airtight.

Tank/Pump Installation Component Specifications (Per Figure 4E)

Number Quantity Description

(1) 1* Check valve

(2) 1* Check valve screen

(3) 1 1/2" I.D. steel pipe (standpipe)

(4) 1 2" x 1/2" tap double tap hex bushing

(5) _____ ft. 5/8" O.D. copper tubing

(6) 2 Flare fitting (5/8" flare x 1/2" NPT male)

(7) 1 1/2" stainless steel ball valve

(8) 1 1/2" close nipple

(9) 3** 3/4" x 1/2" hex bushing

(10) 1* Lenz canister filter

(11) 1* Vacuum gauge

(12) 1 1/2" street elbow

(13) 1 6" x 1/2" pipe nipple

(14) 1* Oil pump

(15) 1 1/4" close nipple

(16) 1 1/4" x 1/2" bell reducer

(17) 1 ___" x 1/4" NPT flare fitting (size correctly for pressure oil line)

(18) _____ ft. Pressure oil line (size according to chart in Oil Line Installation section)

(19) 1 1/2" close nipple

(20) 1 4" x 2" x 2" electrical box

(21) 3 Locking rings to attach box to pump motor

* Provided as stock part with furnace.

** Two bushings are provided with furnace.

4-9

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank (continued)

CAUTION: National and local codes govern the use and installation of

outside oil storage tanks. Your tank installation must comply with these codes.

MAX. 30 FT.

HORIZONTAL SUCTION LINE

OR NOT TO EXCEED 10" HG OF VACUUM

OIL PUMP ASSEMBLY

MOUNTED ON WALL INSIDE

BUILDING

MAX. 10 FT.

10" HG OF VACUUM

OR NOT TO EXCEED

VERTICAL SUCTION LIFT

BUILDING

Close-up of pump installation for outside

above ground tank

CAUTION: THE SUCTION LINE FOR AN OUTSIDE OIL STORAGE

TANK MAY REQUIRE HEAT TAPING TO ALLOW THE OIL TO FLOW

DURING COLD WEATHER. DO NOT INSTALL TANK OUTSIDE IF

WINTER TEMPERATURES ARE SEVERE. ADDING UNTREATED

FUEL OIL TO USED OIL DURING COLD WEATHER MAY CAUSE THE

OIL TO GEL.

FILL PIPE WITH

RAINTIGHT CAP

MINIMUM 12 INCHES

(30.5 CM) FROM CHECK

VALVE TO TANK BOTTOM

OUTSIDE OIL STORAGE TANK WITH CONTAINMENT

VENT PIPE WITH

VENT CAP

FIGURE 4F - Outside Above Ground Tank Installation

PUMP ELECTRICAL CIRCUIT

4-10

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank (continued)

Specifications for Outside Above Ground Tank Installation (Figure 4F)

NOTE: Review the following specifications closely and fill-in as required. Procedures for oil pump

and oil line installation can be found in the sections following the tank illustrations/specifications.

Suction Line Specifications (Per Figure 4F)

(1) Horizontal length of suction line (NOT to exceed 30 ft.) __________ ft.

(2) Vertical lift of suction line (NOT to exceed 10 ft.) __________ ft.

(3) Use 3/4" O.D. copper tubing; DO NOT use steel pipe unions.

(4) Use only good flare fittings; DO NOT use compression fittings.

(5) Seal every threaded fitting with Permatex #2 non-hardening gasket sealer or equivalent;

DO NOT use teflon tape.

(6) Ensure that the suction line is 100% airtight.

Tank/Pump Installation Component Specifications (Per Figure 4F)

Number Quantity Description

(1) 1* Check valve

(2) 1* Check valve screen

(3) 1 3/4" I.D. steel pipe (standpipe)

(4) 1 2" x 3/4" tap double tap hex bushing

(5) _____ ft. 3/4" O.D. copper tubing

(6) 2 Flare fitting (3/4" flare x 3/4" NPT male)

(7) 1 3/4" stainless steel ball valve

(8) 1 3/4" close nipple

(9) 1** 3/4" x 1/2" hex bushing

(10) 1* Lenz canister filter

(11) 1* Vacuum gauge

(12) 1 1/2" street elbow

(13) 1 6" x 1/2" pipe nipple

(14) 1* Oil pump

(15) 1 1/4" close nipple

(16) 1 1/4" x 1/2" bell reducer

(17) 1 ___" x 1/4" NPT flare fitting (size correctly for pressure oil line)

(18) _____ ft. Pressure oil line (size according to chart in Oil Line Installation section)

(19) 1 1/2" close nipple

(20) 1 4" x 2" x 2" electrical box

(21) 3 Locking rings to attach box to pump motor

* Provided as stock part with furnace.

** Two bushings are provided with furnace.

4-11

Operator's Manual: Models CB-1400, CB-1800, and CB-2800

Determining the Type of Oil Tank (continued)

CAUTION: National and local codes govern the use, installation, and monitoring of

underground oil storage tanks. Your tank installation must comply with these codes.

OIL PUMP ASSEMBLY

MOUNTED ON WALL INSIDE

BUILDING

MAX. 10 FT.

10" HG OF VACUUM

OR NOT TO EXCEED

VERTICAL SUCTION LIFT

MAX. 30 FT.

HORIZONTAL SUCTION LINE

OR NOT TO EXCEED 10" HG OF VACUUM

SUCTION OIL LINE

CONTAINMENT

WHEN USING AN UNDERGROUND TANK, YOU MUST CONSIDER

THE FOLLOWING:

CAUTION: BEFORE BURYING ANY LINES, MAKE SURE TO

THOROUGHLY TEST THE FURNACE SYSTEM. MAKE SURE THE