FILTERSCAN®

Reference Guide

Version 2.4

The information contained herein is proprietary and is not to be used for purposes other than as an aid in the

operation and/or maintenance of the of the product described herein and is not to be released or reproduced by

anyone without the written permission of CleanAlert, LLC.

Due to CleanAlert's constant strive for product improvement, minor discrepancies between the actual product, text

and illustrations may exist. All information contained herein is based on the latest specifications at the time of

publication and is subject to change without notice.

FILTERSCAN

®

is a registered trademark of CleanAlert, LLC.

Contents

Introduction ………………..…………………….………………………………………………………… 1

In The Box ..............................…………………………………………………………………………. 1

Tools Required ............…………………………………………………………………………………. 1

Safety ………………….…………………………………………………………………………………. 1

Application ………….……………………………............................................................................. 1

FCC Compliance ……………..………………………………………………………………………….. 1

IC Compliance ………………..………………………………………………………………………….. 2

Monitor Installation …………………..……………………..……………………………………. 2

Receiver Installation ……………..…………………………..……………………………………. 5

Operation …………………..……………….……………………………………………………………….. 7

System Monitoring ……….……………………………………………………………….…………….. 7

Alarm Modes ………..………………..………………………….……………………………………… 7

Clogged Air Filter …………...……….………………………………………………………………….. 7

Low battery ………………..…………………………..…………………………………………………. 7

Malfunction ……………..………………………………………………………………………..………. 7

Calibrating When Installing a New Air Filter ………………….………………………………………. 8

Automatic Adjustment ………….………………………….……………………………………………. 8

Specifications …………….…….…………………………………………………………………………… 8

Warranty ……………..……………………………………………………………………………………… 9

Wireless Option ……….………………….………….…………………………………..………………… 9

Transmitter ……………….……………………………………………………………………………… 9

Receiver ………………………………………………………………………………………………… 9

Learn Mode ………………………….…………………………….…………………………………….. 9

Low Battery Indicator …….…………..………………………………………………………………… 10

Identification Address …….…………………………………………………………………………….. 10

Revision History ………………....……………………………………………………………………… 10

Appendix ………………..…………..………………………….……………………………………. 11

Glossary ……………………………..……………..…………………………………………………….. 11

Indicators ………….…………………………..…………………………………………………………. 11

Battery Replacement ……..….……..……………………….………………………………………….. 11

Alarm Indications ………….………………………………..…………………………………………… 12

Disclaimer ……………………….……………….………………………………………………………. 12

Introduction

In The Box 1. FILTERSCAN

Tools Required 1. Drill

Safety WARNING! READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to

Application FILTERSCAN

If the wireless option has been installed, the FILTERSCAN® Monitor will

FCC Compliance This device complies with Part 15 of the FCC Rules. Operation is subject to the

Congratulations on your purchase of the CleanAlert FILTERSCAN® Air

Filter Clog Detection System. The CleanAlert FILTERSCAN® is

intended for continuous and automatic monitoring of the clogging of an air

filter installed into a household or commercial forced air heating, air

conditioning, or heat pump system. Please read all instructions carefully to

insure years of trouble-free operation. We're sure you enjoy outstanding

performance when the FILTERSCAN® is installed by a qualified HVAC

technician and properly operated.

®

Monitor

2. 4 "AA" Batteries (“B” models only)

3. Installation and Operation Guide

4. Template for attaching the FILTERSCAN

®

Monitor to an air duct

5. Mounting Screws

6. Packaging / box

7. External wall adapter power supply – Optional (“B” models only)

8. FILTERSCAN

®

Receiver – Optional (“W” models only)

9. 2 “AAA” Batteries (Receiver only)

2. 7/64” drill bit

3. 3/8” drill bit

4. Phillips Screwdriver

5. ½” drill bit (if Model CA-4DP Differential Pressure kit ordered)

follow all instructions may result in electrical shock and or serious personal

injury.

®

designed to monitor the amount of dirt building on an air filter and alert the

user when the amount of clogging reaches a pre-determined threshold.

The FILTERSCAN® Monitor is compatible with most air filters ranging in

differential pressure drop from 0.10”wg to 4.0”wg and with single or multispeed blowers, but not compatible with VAV (Variable Air Volume)

systems.

transmit alarm conditions to a remote Receiver. The Receiver may be

located up to 100 feet from the Monitor depending upon line-of-sight and

obstacles located between the Monitor and Receiver.

following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

is an air filter clogging detection system. It has been

Formatted: Indent: Left: 1.94", Hanging:

0.28", Outline numbered + Level: 2 +

Numbering Style: 1, 2, 3, … + Start at: 2 +

Alignment: Left + Aligned at: 0.25" + Tab

after: 0.5" + Indent at: 0.5", Tab stops: Not at

0.5"

Formatted: Indent: Left: 1.94", Hanging:

0.28", Outline numbered + Level: 2 +

Numbering Style: 1, 2, 3, … + Start at: 2 +

Alignment: Left + Aligned at: 0.25" + Tab

after: 0.5" + Indent at: 0.5", Tab stops: Not at

0.5"

1

NOTE: This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and the receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

FCC ID Number: AUPFS-242

IC Compliance This Class B digital apparatus complies with Canadian ICES-003.

Model: FS-242-BW Modèle: FS-242-BW

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

This device complies with Industry Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Cet appareil est conforme à Industrie Canada exempts de licence RSS norme.

Opération est soumis aux deux conditions suivantes: (1) cet appareil ne peut pas

causer de brouillage et (2) cet appareil doit accepter toute interférence, y compris

les interférences pouvant causer un fonctionnement intempestif du dispositif.

Model: FS-242-CW Modèle: FS-242-CW

IC Certification/Registration Number IC: 10341A-FS242

Numéro de Certification / d'enregistrement les IC: 10341A-FS242

Monitor Installation

Although the CleanAlert FILTERSCAN® Air Filter Clogging Monitor and

Alarm, Model FS-242, may be installed upstream, downstream, or

differentially across the air filter (using optional tubing kit Model CA-4DP),

the best results will be found when installing downstream of the air filter

(that is, between the air filter and the system blower fan, usually located at

the return duct of the HVAC system).

WARNING! Ensure that the HVAC system blower motor/fan is turned OFF

until told to otherwise!

1. The FILTERSCAN® Monitor is to be attached to the external wall of

the air duct, either upstream or downstream from the air filter to be

Formatted: Indent: Left: 1.97", Outline

numbered + Level: 2 + Numbering Style: 1, 2,

3, … + Start at: 1 + Alignment: Left + Aligned

at: 2.08" + Tab after: 2.33" + Indent at:

2.33"

2

monitored. NOTE: The minimum distance for positioning the

FILTERSCAN

®

Monitor from the air filter is six (6) inches.

2. Locate an area on the return duct, preferably downstream from the air

filter (that is, between the air filter and the system blower), large

enough to place the Monitor template on a flat surface and where

there are NO obstacles inside the duct. There should be sufficient

clearance from the surrounding walls and from any components of the

air supply system.

3. Place the Monitor template at the location found in the previous step,

such that "TOP" is facing upward. NOTE: The FILTERSCAN®

Monitor front panel must be clearly visible when installed.

4. Using the template, drill one large hole, (3/8") for the sensor and four

small holes (7/64") for the mounting screws.

5. Attach the FILTERSCAN® Monitor by aligning its sensor tube with

the larger hole and secure the Housing using the mounting screws

supplied. The sensor tube does not extend into the duct.

6. Set the Upstream/Downstream switch so that it matches the

FILTERSCAN

®

Monitor position with respect to the air filter (that is,

OFF for upstream mounting or ON for downstream or differential

mounting). The switch can be accessed by removing the front cover

of the Monitor.

Formatted: Indent: Left: 1.97", Outline

numbered + Level: 2 + Numbering Style: 1, 2,

3, … + Start at: 1 + Alignment: Left + Aligned

at: 2.08" + Tab after: 2.33" + Indent at:

2.33"

3

Power Receptacle

7. Apply power:

a. Models FS-242-B and FS-242-BW - Insert the wall mount power

adapter into the FILTERSCAN® power receptacle, or install 4 AA

batteries and replace the Monitor front cover. See Appendix for

battery replacement.

Formatted: Indent: Left: 1.97", Outline

numbered + Level: 2 + Numbering Style: 1, 2,

3, … + Start at: 1 + Alignment: Left + Aligned

at: 2.08" + Tab after: 2.33" + Indent at:

2.33"

b. Models FS-242-C and FS-242-CW – These models should be

installed by a qualified electrician, and are powered from the HVAC

systems auxiliary 24 VAC/DC power supply. A typical installation

will have that power run through rigid conduit to the

FILTERSCAN

®

.

c. The STATUS LED should come on green momentarily then turn

and remain red. This indicates that the unit has not yet been

calibrated to the air filter and HVAC system upon which it is

installed.

4

8. Wait for approximately 15 seconds (warm up and stabilization time).

9. Install a clean, new air filter into the HVAC system.

10. Depress the ZERO/CLEAN button ONCE. The STATUS LED will

blink yellow for several seconds while the FILTERSCAN® records

the system’s FAN OFF condition, then turn to blinking green. This

Formatted: Indent: Left: 1.97", Outline

numbered + Level: 2 + Numbering Style: 1, 2,

3, … + Start at: 1 + Alignment: Left + Aligned

at: 2.08" + Tab after: 2.33" + Indent at:

2.33"

indicates proper operation and that you are ready to move to next

step. If the unit detects the zero air flow is out of limits, the STATUS

LED will blink red. In this case, check to see that the HVAC system

blower fan is OFF and no conditions exist during this part of the

calibration that would cause air to be moving within the HVAC ducts,

such as opening and closing of doors or windows. If no such

condition exists, contact the company that you purchased the

FILTERSCAN

®

from for repair information.

11. Adjust the thermostat temperature adjustment to either increase or

decrease the room temperature by at least four degrees, enough to

signal the HVAC system to turn on heating or cooling.

12. Once the HVAC system blower fan turns on, wait one minute for the

blower fan to stabilize.

13. Depress the ZERO/CLEAN button once. The STATUS LED should

turn from blinking green to blinking yellow for several minutes. This

indicates that the unit is calibrating itself to the air filter and HVAC

system into which it is installed. Once calibration is completed, the

STATUS LED will blink green a few times then turn off.

14. Return the thermostat to normal operating temperature. This

concludes the installation of the FILTERSCAN® Monitor.

15. The SERVICE FILTER control is a fine tuning adjustment that has

been calibrated to the mid-range, Recommended Setting at the

factory. This control allows the user to change the point at which the

clog alarm will be triggered. Turning the SERVICE FILTER adjustment

clockwise will cause the FILTERSCAN® to issue an alarm at a lower

level of filter clogging. Turning the SERVICE FILTER adjustment

counter-clockwise will cause the FILTERSCAN® to issue an alarm at a

higher level of filter clogging.

Receiver Installation – Wireless Option Only

1. Remove the front cover of the Receiver by depressing the latch at the

top of the Receiver housing, rotating the front cover downward, and

lifting the front cover out of the housing.

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.03" +

Tab after: 0.28" + Indent at: 0.28", Tab stops:

Not at 0.28"

5

2. Install two AAA batteries.

3. Your FILTERSCAN® Monitor and Receiver have been paired

(matched) at the time of manufacturing and should require no further

attention.

4. To test the pairing of the Monitor and Receiver:

a. Monitor and Receiver should be turned on and in close proximity to

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.03" +

Tab after: 0.28" + Indent at: 0.28", Tab stops:

Not at 0.28"

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.03" +

Tab after: 0.28" + Indent at: 0.28", Tab stops:

Not at 0.28"

each other.

b. Test the Receiver by inserting a paperclip through the small hole in

the front cover of the Receiver until the click of a switch is felt, then

immediately pressing the SEND button on the Monitor. This

transmits a signal to the Receiver, which turns on the Red LED

and Beeper.

5. To insure proper operation when Receiver is placed in a desired

remote location, retest the Receiver as described above. This remote

procedure may require two people.

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.03" +

Tab after: 0.28" + Indent at: 0.28", Tab stops:

0.25", List tab + Not at 0.28"

6

NOTE: Although the wireless transmission range is up to 100 feet,

it is greatest with no obstructions between the Monitor (transmitter)

and Receiver. Any obstructions, such as walls, floors, and ceilings

will reduce the range of transmission, and relocation of the

Receiver may be required. Retest with each location to ensure

proper operation

6. Mount the Receiver vertically by using the screws or adhesive strip

supplied.

7. Install the front cover by placing the bottom flanges into the housing

and rotating the cover upward until the top latches into the housing.

Operation

System Monitoring The STATUS LED will blink green approximately once per minute (called a

NOTE: Should there be a power failure the FILTERSCAN® will save all

Alarm Modes The FILTERSCAN

NOTE: The HVAC system blower fan must be running when the

Clogged Air Filter When the FILTERSCAN

Low Battery When the FILTERSCAN

Malfunction When the FILTERSCAN

heartbeat) to indicate that the unit is functioning properly. Usually the

FILTERSCAN

®

will be in the standby mode, conserving power. It wakes

up periodically to monitor air filter condition, battery level, and system

operation. If no alarm conditions are detected, the FILTERSCAN® goes

back to sleep after several minutes of monitoring.

parameters such as the clean air filter calibration and the current state of

the air filter. When power is restored, the FILTERSCAN® Monitor will

continue operation with no user action required. The same applies when

replacing depleted batteries.

®

provides both audible and or visual alarms indicating

a clogged air filter, a low battery, or a system malfunction. There is also a

wireless option which allows remote monitoring of system conditions.

FILTERSCAN

FILTERSCAN

®

Monitor attempts to check air filter condition. Since the

®

Monitor checks the air filter condition periodically, it may

take several days to detect, trigger, and alarm a clogged filter condition.

®

detects a clogged air filter, an alarm condition

is triggered. The red STATUS LED will illuminate, blinking five times

approximately every ten minutes until the alarm condition is reset. There

will also be an audio alert which corresponds to the visual alarm indication.

The clogged filter alarm is reset by installing a new, clean air filter,

depressing the CALIBRATE button, and then following the instructions in

the section "Calibrating When Installing a New Air Filter".

NOTE: A new air filter should always be installed whenever the

CALIBRATE operation is performed.

®

detects a low battery condition, an Alarm

condition is triggered. The STATUS LED will blink yellow approximately

once per minute to indicate a low battery in the Monitor. Replacing the

Monitor batteries (see the Appendix for instructions) will reset the alarm

condition.

®

detects an internal malfunction, an alarm

condition is triggered. The red STATUS LED will illuminate continuously

until the malfunction is corrected. In the unlikely event this should occur,

remove power from the FILTERSCAN® by removing the batteries,

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.03" +

Tab after: 0.28" + Indent at: 0.28", Tab stops:

Not at 0.28"

7

unplugging the optional AC Adapter, or in the case of conduit-powered

models (“C”) contacting your HVAC system electrician to have the power

to the Monitor cut. Wait for a minute and restore power. If your

FILTERSCAN

®

unit is operating with both AC Adapter and batteries

installed, both will need to be removed in order to reset the malfunction. If

this does not reset the malfunction alarm, contact the company that you

purchased the FILTERSCAN® from for repair information.

Calibrating When Whenever a new air filter is installed, the FILTERSCAN

®

clog detector

Installing a New Air Filter system must be calibrated. Calibration establishes the clogged air filter

detection threshold based upon the condition recorded for a new air filter.

When a new air filter is installed, its condition is recorded and saved in

nonvolatile memory.

1. Insure that the HVAC system is OFF at the thermostat.

2. Remove the dirty air filter from the HVAC system.

3. Install a new, clean air filter into the HVAC system.

4. Make sure the FILTERSCAN® Monitor power is ON via either AC

Adapter or Battery installation, making sure the low battery indication

is not being displayed.

5. Depress the ZERO/CLEAN button on the FILTERSCAN® Monitor.

6. Wait for the red STATUS LED to illuminate.

7. Depress the ZERO/CLEAN button again.

8. Wait several seconds for the STATUS LED to change from blinking

yellow to blinking green.

9. Turn the HVAC system ON at the system thermostat.

10. Set the thermostat temperature adjustment to either increase or

decrease the room temperature by four degrees, which should be

enough to signal the HVAC system to turn heating or cooling on.

11. Wait one minute for the HVAC system blower fan to turn on and

stabilize.

12. Depress the ZERO/CLEAN button again.

13. Wait several minutes for the STATUS LED to turn from blinking yellow

to blinking green. During this time, the unit is recording the condition

of a clean air filter.

14. Wait several seconds for the blinking green STATUS LED to turn

OFF.

15. Return the thermostat to normal operating temperature.

Your FILTERSCAN® Monitor is now calibrated to the type of air filter you

have installed. Depending on the air filter type and manufacturing

tolerances, you may need to calibrate the FILTERSCAN® air filter

clogging detector each time a new air filter is installed.

Automatic Adjustment ATTENTION - HVAC systems with two-speed blowers! Typical HVAC

systems will have different blower speeds for Heat and A/C. The

FILTERSCAN

blower speeds.

®

Monitor automatically adapts to the changes in HVAC

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 0.25" +

Tab after: 0.5" + Indent at: 0.5", Tab stops:

Not at 0.5"

Specifications

Pressure Differential Range 0.1 to 4.0 in H2O

Clog Filter Trigger Point 1.5 to 2 times initial differential pressure (at the recommended setting

on the SERVICE FILTER control)

Temperature Range 32o to +122o F (0o to +50o C) Operating

8

-40o to +257o F (-40o to + 125o C) Storage

Humidity 80% RH, non-condensing

Power Requirements (-B & -BW) 5.5 VDC at 25 mA Status LED on, 3 mA Transmitting, 60 uA Standby

Batteries, Monitor (-B & -BW) (4) AA 2400 mAH

Batteries, Receiver (2) AAA 1100 mAH

Battery Life Approximately 1 year

Power Requirements (-C & -CW) 24 VAC/DC at 25 mA Status LED on, 3 mA Transmitting, 60 uA

Insertion Depth into Duct Does not extend into duct

Clogged Air Filter Alarm Red STATUS LED & 2 KHz Beeper alternating ON & OFF five times

Low Battery Alarm Yellow STATUS LED blinking approximately once per minute

Malfunction Alarm Red STATUS LED continuously illuminated

Mounting 5 holes, 4 @ 7/64” and 1 @ 3/8"

Monitor Dimensions 6” x 4.625” x 1.5”

Receiver Dimensions 2.75” x 3.75” x 1.0”

Wireless Frequency 418 MHz

Transmission Range Up to 100 feet, depending upon line-of-sight and obstacles

FCC Identification # AUPFS-242

Industry Canada # 10341A-FS242

Standby

Warranty

One (1) year limited warranty Please refer to http://www.cleanalert.com/termsofsale.html for full warranty

text.

Wireless Option

Transmitter In a wireless system, the FILTERSCAN

transmitter, operating at a frequency of 418 MHz, which is activated

whenever there is an alarm condition. Transmissions are very short in

Each FILTERSCAN® Monitor is randomly assigned one of over 16

Receiver The FILTERSCAN

Learn Mode Each FILTERSCAN

duration and intermittent until the alarm condition is reset.

million identification addresses at the time of manufacture. This is

important in systems where neighbors have installed similar wireless

systems.

®

operating at a frequency of 418 MHz, which is activated intermittently,

listening for an alarm condition. The Receiver listens for the

FILTERSCAN

transmissions originating from your system’s Monitor. This prevents

inadvertent activation when neighboring buildings also have

FILTERSCAN

FILTERSCAN

system, consisting of a Monitor and a Receiver, has had both components

identification addresses matched at the factory. In the event that a

replacement Receiver is introduced into your system, that Receiver must

learn the system Monitor’s identification address. In order to accomplish

Receiver contains a wireless receiver, also

®

transmitter's identification address and responds only to

®

systems in operation.

®

Receiver has the ability to learn and store a

®

Monitor's identification address. Your FILTERSCAN®

®

Monitor contains a wireless

9

Rev. #

Effective

Summary:

DRAFT

Initial draft for review and validation.

Version 1.1

2/2/12

Initial release for review.

Version 2.0

5/25/12

Initial printing release.

Version 2.1

6/4/12

Added Wireless Installation Section and Power failure statement in the System

Monitoring section. Revised the Indicator section.

Version 2.2

6/6/12

Added Copyright notice. Revised Figures & battery specification.

Version 2.3

6/12/12

Updated per comments, mostly grammar.

Version 2.4

6/13/12

Added Differential Pressure Mounting kit and Tools Required section.

this, both the Receiver and Monitor must be located close to each other.

The steps are:

1. Remove the Receiver front cover.

2. Depress the LEARN button located next to the batteries.

3. Within 5 seconds, depress the SEND button at the Monitor. After

several seconds, the Monitor will beep once. Then, after another

several seconds, the monitor will beep twice.

4. To confirm proper pairing of the Receiver to the Monitor,

a. After mounting the Monitor and Receiver, depress the LISTEN

pushbutton and insert a straightened paper clip through the small

hole located near the bottom of the Receiver cover.

b. Within 5 seconds, depress the SEND pushbutton on the Monitor.

This may require a second person.

c. The Red indicator should illuminate and the Beeper should sound

for approximately five seconds, indicating that the Receiver is

mounted within range of the Monitor.

NOTE: The best transmission range is obtained when a direct line-of-sight

between the Monitor and Receiver exists. Any obstructions, such as floors

and walls, will decrease the operating range of the system, and relocation

of the Receiver may be required.

Low Battery Indicator Receiver: When the FILTERSCAN

®

Receiver detects a low battery

condition, the Receiver's yellow STATUS LED will blink approximately

once per minute.

Monitor: When the FILTERSCAN® Receiver detects a low battery

condition at the Monitor, the Receiver's yellow STATUS LED will blink

three times every minute.

Identification Address Creating an identification address is performed by manually depressing the

SEND button on the Monitor. Wait about ten seconds until the first beep.

Depress the Create Address button on the Monitor. The green LED will

start flashing. After about one second, depress the Create Address button

again. The green LED will turn off. All of these steps must be completed

before the second set of two beeps. NOTE: The Create Address button is

accessible internally in the Monitor and intended only to be used by factory

technicians.

Formatted: Indent: Left: 1.97", Numbered +

Level: 1 + Numbering Style: 1, 2, 3, … + Start

at: 1 + Alignment: Left + Aligned at: 2.22" +

Tab after: 2.47" + Indent at: 2.47", Tab stops:

Not at 2.47"

Revision History

10

Appendix

Glossary

Dirty Air Filter ............... An air filter which has been in use and has collected some amount of dirt

Clogged Air Filter ......... An air filter which has collected a sufficient amount of dirt or dust particles

Monitor ......................... The sensor voltage detection and signal processing portion of the system,

Receiver ....................... The optional portion of the system containing a wireless receiver of data

Address ........................ One of 16 million randomly assigned identification numbers of each

Indicators

Green STATUS LED...... The blinking Green STATUS LED at the FILTERSCAN® Monitor or

Yellow STATUS LED..... The blinking Yellow STATUS LED at the FILTERSCAN® Monitor

Red STATUS LED ........ The Red STATUS LED at the FILTERSCAN® Monitor and Receiver is

Beeper .......................... The audible beeper at the FILTERSCAN® Monitor and Receiver is an

Battery Replacement

Access ......................... Remove the front cover from the FILTERSCAN® Monitor or Receiver

Installation ................... Insert four (4) AA batteries in the battery holder of the FILTERSCAN®

or dust particles that discolor the filter fibers or element but do not

substantially affect the air flow through it.

to not only discolor the filter fibers or element but decrease the air flow

through the filter as well. The FILTERSCAN® typically identifies a filter

as clogged when the differential pressure within an HVAC system

increases to 1.5 to 2 times the initial differential pressure identified when

the unit was calibrated with a clean filter.

which may contain an optional wireless transmitter.

and indicates various alarm conditions.

monitor.

Receiver indicates normal operation.

indicates a process is occurring and can also indicate a low battery

condition at the Monitor or Receiver.

an alarm indicator which blinks whenever an alarm condition occurs.

alarm indicator which beeps whenever certain alarm conditions occurs.

housing. Remove the batteries.

Monitor, or insert two (2) AAA batteries in the battery holder of the

FILTERSCAN

recommends using DURACELL® COPPERTOP batteries.

®

Receiver, and replace the front cover. CleanAlert

11

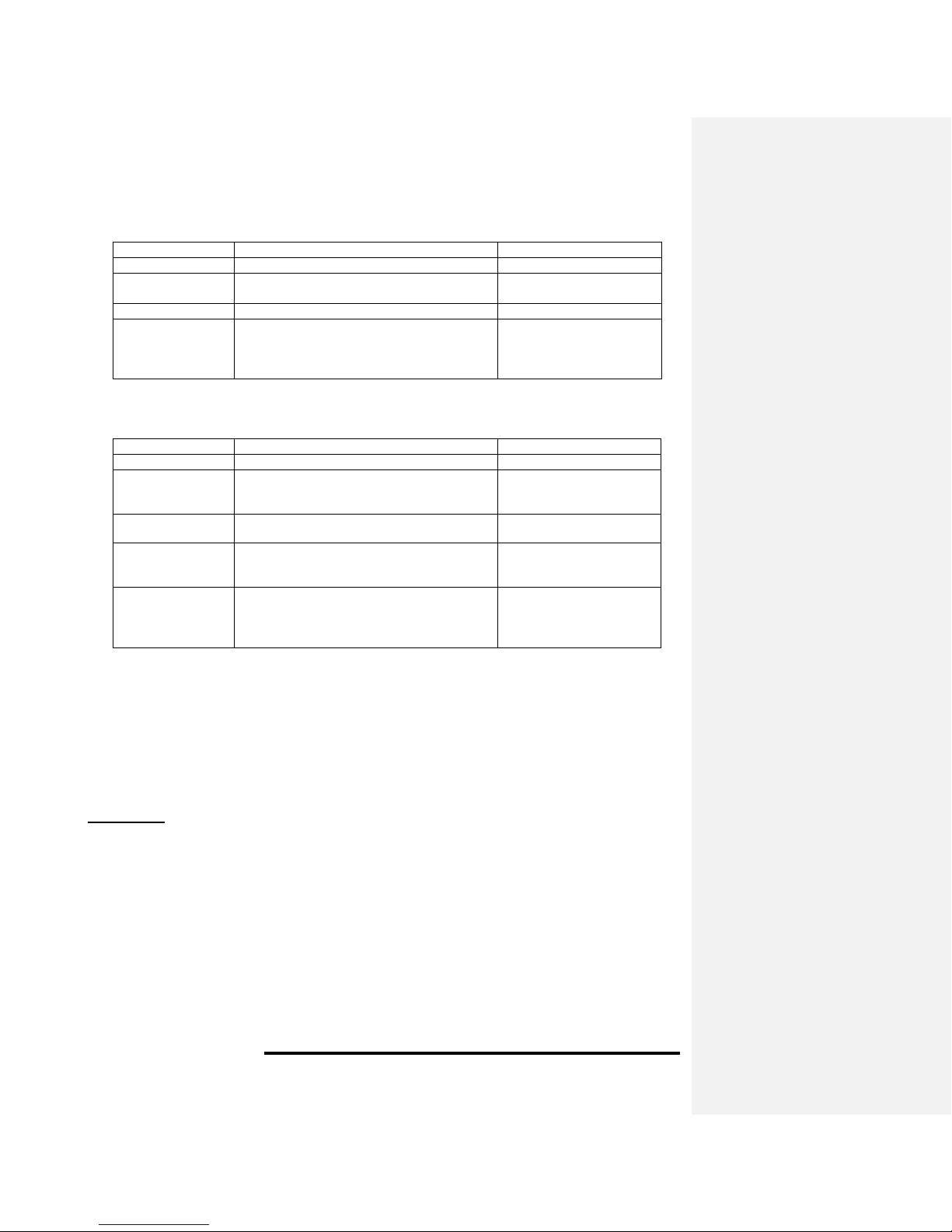

Alarm Condition

Alarm Indication

Clear Alarm Procedure

Normal Operation

STATUS LED flashes green every minute.

None

Clogged Filter

STATUS LED flashes red five times every

ten minutes. Beeper sounds with LED flash.

Replace Filter and

Recalibrate

Low Battery

STATUS LED flashes yellow every minute.

Replace Batteries

Sensor Failure

STATUS LED continuously on red.

Contact the company that

you purchased the

FILTERSCAN

®

from for

repair information

Alarm Condition

Alarm Indication

Clear Alarm Procedure

Normal Operation

STATUS LED flashes green every minute.

None

Clogged Filter

STATUS LED flashes red five times every

ten minutes. Beeper sounds with LED flash.

Supersedes the Heartbeat indication.

Replace Filter and

Recalibrate

Receiver Low

Battery

STATUS LED flashes yellow every minute.

Replace Receiver

Batteries

Transmitter Low

Battery

STATUS LED flashes yellow three times

every minute. Supersedes the Heartbeat

indication.

Replace Transmitter

Batteries

Sensor Failure

STATUS LED continuously on red.

Contact the company that

you purchased the

FILTERSCAN

®

from for

repair information

Alarm Indications

Monitor/Transmitter Alarm Indications

Receiver Alarm Indications

Disclaimer

The data contained herein are furnished for information only and are believed to be reliable. We cannot assume responsibility for

the results obtained by others over whose methods we have no control. It is the user's responsibility to determine suitability for the

user's purpose and to adopt such precautions as may be advisable for the protection of property and of persons. In light of the

foregoing, the warranty of CleanAlert, LLC on this product shall be exclusive and in lieu of any other warranties, including, without

limitation, any warranty of fitness for a particular purpose or warranty of merchantability or any other warranties which may be

claimed to arise by operation of law, custom, trade usage, or course of dealing between CleanAlert, LLC and the customer. In no

event shall CleanAlert, LLC be liable, whether in contract or tort (including negligence) for damages in excess of the purchase price

of the product(s), or for any indirect, incidental, special or consequential damages of any kind, or loss of revenue or profits, or other

financial loss arising out of or in connection with the ability or inability to use the product(s), to the full extent these damages may be

disclaimed by law. The discussion herein of various applications is not to be interpreted as representation that they are free from

domination of patents owned by others or as a license under any CleanAlert, LLC patents that may cover such applications. We

recommend that each prospective user test his proposed application before use, using this data as a guide.

CleanAlert products are manufactured under one or more of the following U.S. Patents: 7,178,410; 7,490,512; and others pending.

Specifications are subject to change without notice.

© 2012 CleanAlert, LLC

12

Loading...

Loading...