CleanAIR® Pressure Flow Master

CleanAIR® Pressure

CleanAIR® Pressure Conditioner

NA-013-R03

GER X

NOR X

RUS X

SPA X

SWE X

ENG 3

CZE X

DUT X

FIN X

FRE X

PERSONAL RESPIRATORY PROTECTION SYSTEMS

USER MANUAL

3

1. Introduction

CleanAIR® Pressure systems are systems of

continuous flow compressed air line breathing

apparatus. The system is based on the principle of

overpressure of filtered air in the breathing zone.

The air is taken from the source of compressed air

(compressor) delivered to CA Pressure Conditioner where the solid particles, oil mists and

unpleasant odours are removed. Then is the air delivered to CA Pressure/CA Pressure Flow Master, which

allows to regulate the airflow delivered through the

hose into a protective mask or hood. The overpressure

in the breathing zone prevents from entering of contaminants. This mild overpressure at the same time

ensures the wearer’s comfort, even with long-term

use, as the wearer does not have to struggle in their

breathing to overcome the resistance of the filter.

The air supplied from the compressor directly

(without use of CAP Conditioner filter) to CA Pressure (Flow Master) must be hygienically clean and must

comply with the EN 12021 standard. If the air does not

comply with this requirement, install the CA Pressure

Conditioner filtration unit before the CA Pressure unit/

CAP Flow Master!

Apart from CA Pressure (CAP), CleanAIR® Pressure

Flow Master (CAP FM) is equipped with a pressure

gauge for the current check of the input pressure and

with warning whistle, which will warn the user in the

case of an inlet pressure decreases below the bottom

limit of operation pressure.

The air at the outlet of CA Pressure Conditioner

complies with EN 12021 if it is used within the range

of temperatures stated in Chapter 10 and the air from

the compressor complies with the requirements of

Chapter 1.1. CA Pressure Conditioner removes oil mist,

smells and flavours. There can be two users connected to the filtration station (CAP Conditioner).

CAP Conditioner does not remove carbon monoxide

(CO) and carbon dioxide (CO2) from the air!!!

1.1. Requirements for compressed air supplied

from the compressor

• CA Pressure Conditioner can only be connected to

compressor which supplies air at an oxygen concentration of 20 % to 22 % vol. The carbon dioxide

concentration must not exceed 500 ppm and the

carbon monoxide concentration must not exceed

15 ppm.

• The maximum concentration of water in the air

may be 50 mg/m³ at the rated pressure of 1 to

20 MPa. The humidity of the supplied air must be

controlled to prevent the unit from freezing.

2. Instructions for Use

Read this manual carefully and follow its instructions!!!

• The user must fully understand the instructions.

• During an extreme work load, the pressure in the

hood may reach negative values and the user may

feel air deficiency. In such case the protection of

air passages is reduced.

• The use of oxygen-enriched air and oxygen is

forbidden in the CleanAIR® system due to the risk

of explosion.

• The system may only be used in environments with a small probability of damage of the

supply hose and where the user’s movement is not

limited.

• If, apart from CleanAIR®, another accessory (e.g.

a spray gun) is connected to the compressed air

supply, the user must make sure that a sufficient

air flow to the hood is secured even at the maximum air consumption by this accessory.

• If the unit is used in environments with high temperatures, the supply hose must be resistant to

such effects.

• It is forbidden to use the unit in explosive

enviroments.

• Before every use of the unit, check that the air

flow is higher than the minimum value specified in

the technical parameters.

• If the unit stops supplying air for any reason, the

user must leave the contaminated area immediately.

• The unit, in a combination with a welding helmet

Contents:

1. Introduction

2. Instructions for Use

3. Unpacking / Assembly / Use and Functions

4. Before Use

5. Maintenance / Cleaning

6. Spare Parts and their Replacement

7. Storage

8. Warranty

9. Possible faults

10. Technical Data

11. List of Parts

EN

4

or a safety helmet, is not recommended for users

with beard or long hair extending to the respiratory

zone.

• Beware of a higher CO2 concentration in the airsupply, which may occur if the compressor does

not work properly, when the lubricating oil sometimes burns due to high temperatures.

• The supply air pressure must be within the range

between 400 - 1000 kPa.

• The supply pressure hoses may only be located in

such places of the workplace where they cannot

be damaged.

• Pressure hoses for CA Pressure (Flow Master) and

CAP Conditioner, order No. 61 00 30 and 61 00 46,

are not antistatic and the maximum temperature to

which they are resistant without damage is 70 °C.

• The maximum length of the hose from the

compressed air distribution or CAP Conditioner to

the unit must not exceed 10 m.

• The recommended temperature range of use is

10 - 40 °C; at lower temperatures, the use of the

protective hood or mask with air supply may be

unpleasant.

• Before connecting the unit to the air distribution, it

is necessary to check what medium is in the line

and what is its quality.

• For the CA Pressure (Flow Master) it is necessary

to provide breathable air according to EN 12021.

• The CA Pressure units can be combined with the

types of head parts shown in the pictorial annex.

It shows also classes for the respective combinations.

• Information on head parts are provided in the instructions for use of the CA head parts.

If any principles stated in this manual are breached,

the warranty becomes null and void!

3. Unpacking / Assembly /

Use and Functions

3.1. Unpacking CA Pressure

Check that the delivery is complete and no damage

occurred during transport.

Content of the CA Pressure (63 00 00), CA Pressure Flow Master (67 00 00) contain:

CleanAIR® Pressure (Flow Master) unit 1 pc

Belt for the unit 1 pc

Air flow indicator 1 pc

User manual 1 pc

Content of the CA Pressure Conditioner (61 00 50):

CA Pressure Conditioner unit 1 pc

Unit stand 1 pc

Screws for connecting the unit to the stand 2 pcs

Gasket 4 pcs

Instruction for Use 1 pc

3.2. Assembly

CA Pressure (Flow Master) + CAP Conditioner

• Check that all components are in good condition,

i.e. without apparent damage.

• Connect CAP Conditioner to the compressed air

distribution system or straight to a compressor.

The air source must be equipped with a safety

valve (if CA Pressure Conditioner is not used, the

compressed air supply is connected straight to CA

Pressure (Flow Master).

• It is recommended using only original hoses supplied by the manufacturer certified according to the

applicable standard.

• Check that the air pressure in the distribution system corresponds to the range 300 to 1000 kPa.

• Attach the unit onto your belt and fit the connecting hose to it.

• Using the quick coupling, connect the pressure

hose from the compressed air source to the CA

Pressure unit. The hose from CAP Conditioner to

CA Pressure must not be longer than 10 metres.

• Check the air flow according to Chapter 4.2. The

lowest allowable flow rate is 170 l/min.

3.3. Assembling CAP Conditioner (61 00 50)

Screw the pressure vessel body onto the stand; for

the procedure see pictorial annex 1A.

5

4. Before Use

4.1. Check before use

Check before every use:

• that individual parts, particularly the air hose and

sealing elements, are not apparently damaged,

• that the hose is fitted correctly to the unit and to

the head part connector,

• that the air pressure in the distribution system

is in the range 300 to 1000 kPa (for both CA

Pressure and CAP Conditioner),

• that the air flow in the hose is sufficient (using

the air flow indicator, see Chapter 4.2.),

• that air is supplied from the head part.

4.2. Air flow test (CA Pressure / CA Flow Master)

All units are pre-adjusted on the airflow of 170 liters/

min. When measuring the airflow, follow the instructions in the manual enclosed to the flow indicator. If

the flow rate is different, proceed as follows:

1. Pull the reducing valve, you will hear a click. see.

pictorial annex 2A.

2. To set the optimal airflow, rotate the reducing val-

ve clockwise or counter-clockwise (to check the

airflow, you may conect flow meter) see. pictorial

annex 2B.

3. Push the reducing valve, you will hear a click (see.

pictorial annex 2C).

WARNING:

The airflow should not drop below 160 liters/min!

5. Maintenance and Cleaning

CA Pressure (Flow Master)

Every time you finish work, it is recommended to clean the CA Pressure unit, to check individual parts and

to replace the damaged ones.

• Cleaning must be carried out in a well ventilated

room. Avoid inhaling the harmful dust settled on

individual parts of the unit and accessories!

• It is forbidden to use cleaning agents containing

solvents or abrasives. Detergents are recommended.

• The air hose can be rinsed with clean water.

• Use a damp cloth for cleaning. Each part must be

wiped dry after cleaning.

CA Pressure Conditioner

• Once a week, drain the condensate from the con-

tainer bottom by the cock located on the bottom

side. Before this operation, it is recommended

disconnecting the unit from the compressed air

supply.

• Replace the filter at least once in three months.

After this period, viruses and bacteria may proliferate in the unit filter and if it is used regularly,

the absorption capacity of the activated carbon

eliminating smells may be exhausted (if the air leaving CA Pressure Conditioner smells in any way,

replace the filter immediately).

• When replacing the filter, clean the inner part of

the container with a dry cloth or detergent.

6. Spare Parts and their

Replacement

6.1. Filter for CA Pressure Conditioner

The filter plant CAP Conditioner contains a combined

filter which removes oil mist, smells and flavours from

industrially produced compressed air.

The filter does not remove CO and CO2!

Read the instructions for use and replacement.

Replacing CA Pressure Conditioner filter:

See pictorial annex 3A-3C

• Unscrew the top part of the filter pressure container (6 screws).

• Remove the contaminated filter, wipe the inside of

the container.

• Check the condition of the rubber seal in the top

cover. If the seal is damaged, replace it.

• Install a new filter, put the container cover on and

screw it back.

• Check the container for leakage. If the container is

not absolutely tight, tighten all screws that fasten

the top cover.

7. Storage

If any fault, sudden decrease or increase in air supply

occurs and the user is at a contaminated workplace,

it is necessary to leave the workplace and to check

the following:

• That the unit is assembled correctly.

• The filter condition in CA Pressure Conditioner.

• That the air hose is not damaged. It is necessary

to make sure that, during work, the hose is not got

caught at projecting objects and a crack cannot

occur.

• That the noise damper in CA Pressure is not

clogged.

• That the seal on the safety hood is in good condition. All components of CleanAIR® systems must

be stored in rooms with temperatures between

0 °C and 40 °C with relative air humidity between

20 % and 80 %. The storage time in closed containers is max. 2 years, except for the batteries!.

8. Warranty

Warranty for manufacturing defects is 12 months from

the date of sale to the customer. A claim must be filed

with the sales organization and the proof of sale (invoice or delivery note) must be submitted.

Warranty does not cover in particular defects caused

by a late replacement of the filter or by using a filter

damaged by cleaning or blowing.

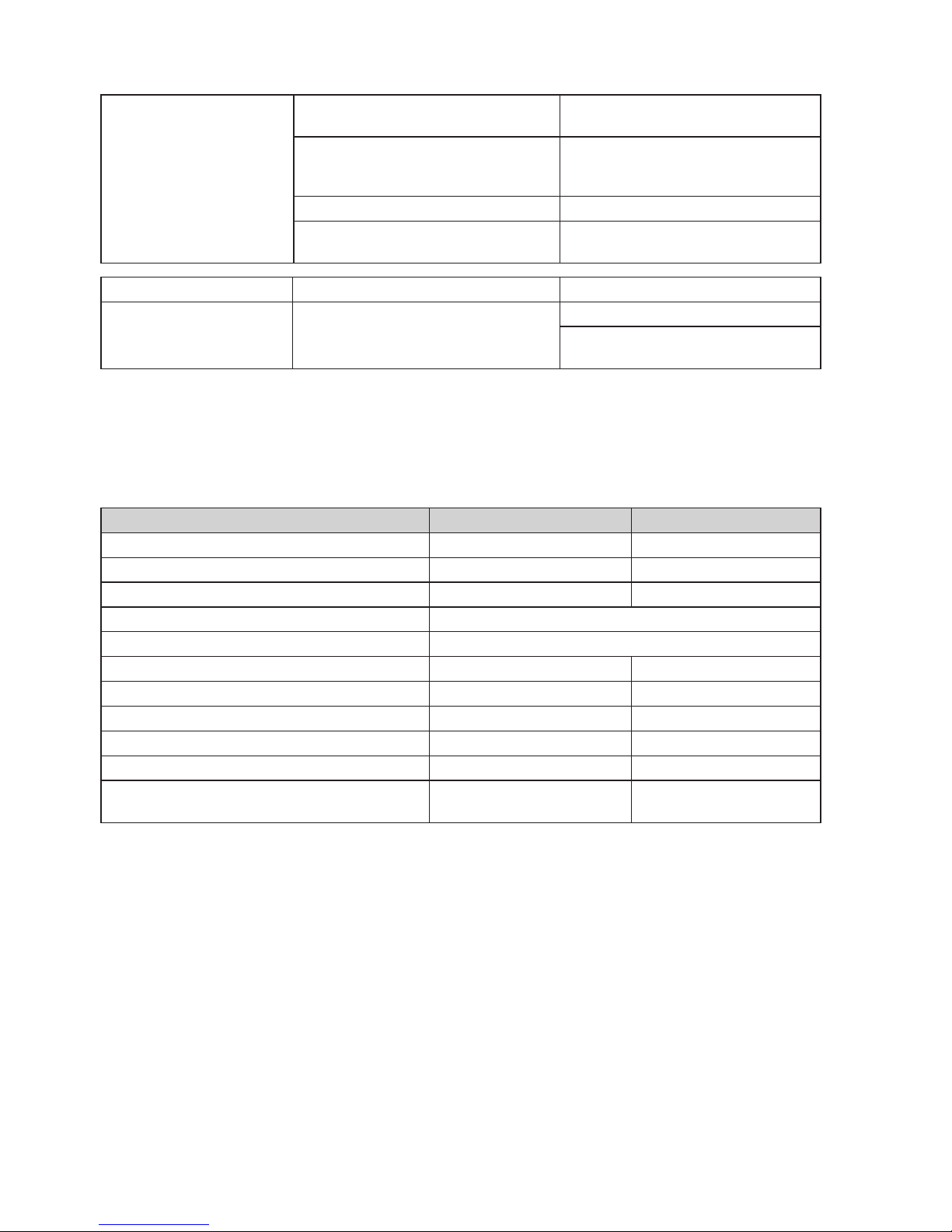

CA Pressure Pressure Pressure FM

Minimum air flow 170 lpm 170 lpm

Maximum air flow 400 lpm 250 lpm

Weight of unit 250 g 280 g

Inlet connection Compatible with RECTUS series 25, 26 and CEYN320

Outlet connection CA40x1/7“

Noise level of unit 61 dB 61 dB

Waist size 60 – 150 cm 60 – 150 cm

Supply pressure range 300 – 1000 kPa 400 – 1000 kPa

Recommended temperature range at work +10 to +60 °C +10 to +60 °C

Recommended air humidity range at workplace 20 % to 80 % Rh 20 % to 80 % Rh

Certification EN 14594 Class 2A EN 14594 Class 2A, 2B,

3A, 3B

10. Technical Data

Notified body for CE testing: Výzkumný ústav bezpečnosti práce, v.v.i. – ZL

Testing Laboratory No. 1024, Jeruzalémská 9, 116 52 Praha 1

Authorized Body 235 | Notified Body 1024

6

The unit does not supply

the sufficient amount of air.

Air hose or air channel blocked.

Check and remove the possible obstacle.

Air escapes through leakages.

Check all sealing elements and connections, check that the hose is not

damaged and without leaks.

The baffle is clogged. Replace the baffle in CA Pressure .

The filter in CA Conditioner is clogged. Replace the filter.

Fault Probable cause Recommendation

The unit does not work at

all.

Compressed air supply failure. Hose

damage.

Check the compressed air source.

Check that connecting hoses are not

damaged.

9. Possible Faults

CleanAIR® Pressure Conditioner

Maximum air flow 500 l/min

Weight without filter 6 300 g

Weight including filter 6 800 g

Inlet connection Compatible with RECTUS series 25,26 a CEYN320

Outlet connection Compatible with RECTUS series 25,26 a CEYN320

Recommended temperature range at work +10 to +60 °C

Recommended air humidity range at workplace 20 % to 80 % Rh

Certification If the requirements of TP-610050-1 are met, it com-

plies with EN 12021

11. List of Spare Parts:

CleanAIR® Pressure / CA Pressure Flow Master

Order No.: Description:

63 00 00 CA Pressure + belt

67 00 00 CA Pressure Flow Master + comfort belt

61 00 30 Standard hose 10 m for CAP

61 00 38 Standard hose 25 m for CAP

61 00 39 Standard hose 50 m for CAP

61 00 46 Spiral hose 10 m for CAP, mechanically resistant - mod.

63 00 10 CA Pressure - silencer

70 00 60 Light flexi hose CA40x1/7“ - CA40x1/7“

70 00 86CA Rubber hose CA40x1/7“ - CA40x1/7“

70 00 95 Belt for CA Pressure 155 cm

70 00 90RD Air flow indicator

CA PRESSURE CONDITIONER

Order No.: Description:

61 00 50 CleanAIR® Pressure Conditioner

61 00 10 Filter for CleanAIR® Pressure Conditioner

61 00 24 CleanAIR® Pressure Conditioner - sealing O-ring 139x3

61 00 28 CleanAIR® Pressure Conditioner - sealing O-ring 30x4

7

8

1. Úvod

CleanAIR® Pressure je systém umožňující kontinuální

zásobování dýchatelným vzduchem ze zdroje stlačeného vzduchu. Systém je založen na principu přetlaku

filtrovaného vzduchu v dýchací zóně. Vzduch je přijímán ze zdroje stlačeného vzduchu (kompresoru, či

tlakové láhve), přepraven do CA Pressure Conditioner

kde jsou následně odstraněny pevné částice, olejové

mlhy a nepříjemné pachy. Následně je vzduch přepraven do CA Pressure / CA Pressure Flow Master, který umožňuje regulovat množství vzduchu přicházející

hadicí do ochranné masky, či kukly. Přetlak v dýchací zóně zabraňuje vstupu kontaminantů. Tento mírný

přetlak ve stejné chvíli zajišťuje komfort uživatele i při

dlouhodobém používání, protože uživatel nemusí při

dýchání překonávat odpor filtru.

Vzduch přiváděný z kompresoru (bez použití CAP Conditioner filtru) přímo do CA Pressure (Flow Master)

musí být hygienicky čistý a musí vyhovovat normě

EN 12021. Pokud vzduch nevyhovuje těmto podmínkám, je nutné zařadit CA Conditioner mezi zdroj tlakového vzduchu a CA Pressure (Flow Master).

CA Pressure (Flow Master) je taktéž vybaven tlakoměrem pro kontrolu vstupního tlaku a současně i bezpečnostní píšťalkou, která varuje uživatele v případě,

že vstupní tlak poklesne pod spodní limit povoleného

provozního tlaku.

Vzduch na výstupu z CA Pressure Conditioner vyhovuje normě EN 12021 v případě je používán v rozsahu

teplot uvedených v kapitole 10 a vzduch z kompresoru vyhovuje požadavkům uvedeným v kapitole 1.1.

CA Conditioner odstraňuje olejové mlhy, pachy a chutě.

V jeden okamžik mohou být k filtrační stanici připojeni

dva uživatelé (CA Pressure Conditioner).

CAP Conditioner neodstraňuje ze vzduchu oxid uhelnatý (CO) and oxid uhličitý (CO2)!!!

1.1. Požadavky na stlačený vzduch přicházející z

kompresoru

• CA Pressure Conditioner může být připojen pouze

na kompresor distribuující vzduch s procentuelním

zastoupením vzduchu 20 % až 22 %. Koncentrace

oxidu uhličitého nesmí překročit 500 ppm a koncentrace oxidu dusného nesmí překročit 15 ppm.

• Koncentrace vody ve vzduchu by neměla překročit

50 mg/m³ při jmenovitém tlaku vzduchu v rozmezí

1 - 20 MPa. Vlhkost vzduchu přicházejícího z kompresoru musí být kontrolována jako prevence proti

zamrznutí jednotky.

2. Návod k použití

Čtěte tento návod pozorně a postupujte dle pokynů!!!

• Uživatel musí nejprve plně chápat pokyny.

• V případě extrémní pracovní zátěže může tlak v

kukle, či masce klesnout pod úroveň atmosferického tlaku a uživatel může pociťovat nedostatek

vzduchu. V těchto případech může být ochrana

uživatele snížena.

• Při použití systému CleanAIR® je kvůli hrozbě exploze zakázáno používat vzduch obohacený o kyslík.

• Systém může být použit pouze v prostředí s nízkou pravděpodobností poškození přívodní hadice,

prostředí v němž je systém využíván by zároveň

nemělo uživatele omezovat v pohybu.

• V případě, že je kromě systému CleanAIR® k přívodu stlačeného vzduchu připojeno další příslušenství (např. vzduchová pistole), uživatel se musí

ujistit, že je zajištěn dostatečný přívod vzduchu do

hlavového dílu i při maximálním využití připojeného

příslušenství.

• Pokud je zařízení používáno v prostředích s vysokými teplotami, přívodní hadice musí být vůči tomuto vlivu odolná.

• Je zakázáno používat zařízení ve výbušném prostředí.

• Před každým použitím zkontrolujte, že je skutečný

průtok vzduchu vyšší, nežli minimální hodnot uvedená ve technických parametrech.

Obsah:

1. Úvod

2. Návod k použití

3. Rozbalení / montáž / funkce a použití

4. Před prvním použitím

5. Údržba a čištění

6. Výměna náhradních dílů

7. Skladování

8. Záruka

9. Jak postupovat v případě selhání

10. Technické údaje

11. Seznam dílů

CZ

9

• Pokud z jakéhokoli důvodu jednotka přestane dodávat vzduch, uživatel musí neprodleně opustit

kontaminovanou oblast.

• Jednotka v kombinaci se svářecí kuklou, nebo bezpečnostní přilbou není doporučená pro uživetele s

bradkou, nebo s dlouhými vlasy přesahujícími do

dýchací zóny.

• Dejte si pozor na zvýšené koncentrace CO2 na

vstupní straně, které se mohou vyskytnout v případě, že kompresor nepracuje správně (v případě,

že mazací olej spalován díky vysokým teplotám).

• Vstupní tlak musí být v mezích 400 - 1000 kPa.

• Hadice přivádějící tlakový vzduch mohou být umístěny pouze na místech, kde nemohou být poškozeny.

• Tlakové hadice pro CA Pressure (Flow Master)

a CAP Conditioner, objednací číslo 61 00 30 a

61 00 46 nejsou antistatické a maximální teploty

vůči kterým jsou odolné bez poškození činí 70 °C.

• Maximální vzdálenost tlakové hadice vedoucí z

kompresoru, nebo z CAP Conditioner činí 10 m.

• Doporučený rozsah teplot pro použití je 10 - 40 °C;

při nižších teplotách může být používání ochranné

kukly, či masky nepohodlné.

• Před napojením jednotky k centrálnímu rozvodu

vzduchu je nutné zkontrolovat jaký plyn se nachází

v rozvodu a jaké je kvality.

• Jednotku CA Pressure (Flow Master) je nezbytné zásobovat dýchatelným vzduchem dle normy

EN 12021.

• Jednotky CA Pressure (Flow Master) mohou být

kombinovány s hlavovými díly uvedenými v obrázové příloze. Můžete zde nalézt taktéž ochranné třídy

pro dané kombinace.

• Návod k použití hlavových dílů je vždy přiložen ke

konkrétnímu produktu.

Pokud je kterýkoli z uvedených principů v tomto

manuálu porušen záruka zaniká!

3. Rozbalení / montáž / funkce a použití

3.1. Rozbalení CA Pressure

Zkontrolujte, že dodávka je kompletní a nedošlo k

žádnému poškození při přepravě.

Obsah balení CA Pressure (63 00 00) a CA Pressure

Flow Master (67 00 00) obsahuje:

Jednotka CleanAIR® Pressure (Flow Master) 1 ks

Opasek 1 ks

Indikátor průtoku vzduchu 1 ks

Návod 1 ks

Obsah balení CA Pressure Conditioner (61 00 50):

Jednotka CA Pressure Conditioner 1 ks

Stojan 1 ks

Šrouby k upevnění na stojan 2 ks

Podložky 4 ks

Návod 1 ks

3.2. Sestavení

CA Pressure (Flow Master) + CAP Conditioner

• Zkontrolujte, že jsou všechny komponenty v pořádku, tj. bez zjevného poškození.

• Připojte CA Pressure Conditioner k rozvodu stlačeného vzduchu, nebo přímo ke kompresoru. Zdroj

vzduchu musí být vybaven bezpečnostním ventilem. Pokud není CA Pressure Conditioner použit,

tlakový vzduch připojte přímo k CA Pressure (Flow

Master).

• Je doporučeno používat pouze originální hadice

dodávané výrobcem certifikované dle dané normy.

• Zkontrolujte, že tlak vzduchu v distribučním systému odpovídá rozsahu 300 - 1000 kPa.

• Upevněte jednotku na opasek a propojte pomocí

vzduchové hadice do hlavového dílu.

• Pomocí rychlospojky připojte tlakovou hadici ze

zdroje tlakového vzduchu k jednotce CA Pressure

(Flow Master). Hadice z CA Pressure Conditioner

nesmí být delší, než 10 metrů.

• Zkontrolujte skutečný průtok vzduchu indikátorem

průtoku vzduchu dle kapitoly 4.2. Nejnižsí povolený

průtok vzduchu je 170 l/min.

3.3. Sestavení CA Pressure Conditioner (61 00 50)

Sešroubujte jednotku CA Pressure Conditioner se

stojanem. Jako návod použijte obrazovou přílohu 1A.

10

4. Před prvním použitím

4.1. Zkontrolujte před použitím

Před každým použitím zkontrolujte:

• že nejsou jednotlivé díly (vzduchová hadice a

těsnění) poškozeny,

• že je vzduchová hadice správně připojena k

jednotce i k hlavovému dílu,

• že je tlak v rozvodu zlakového vzduchu v rozmezí 300 až 1000 kPa (pro CA Pressure (Flow

Master) i CA Pressure Conditioner),

• že je průtok vzduchu na výstupu z jednotky

dostatečný (dle indikátoru průtoku vzduchu, viz

kapitola 4.2),

• že je hlavový díl zásobován vzduchem.

4.2. Test průtoku vzduchu CA Pressure (Flow Master)

Jednotky jsou přednastaveny na průtok vzduchu

170 l/min. V případě, že měříte průtok vzduchu, dbejte pokynů v návodu přiloženému k indikátoru průtoku

vzduchu. Pokud naměřený průtok neodpovídá, učinte

následující kroky:

1. Uvolněte tahem redukční ventil (uslyšíte cvaknutí).

Viz. obrazová příloha 2A.

2. Pro nastavení optimálního průtoku vzduchu otá-

čejte redukčním ventilem po směru, či proti směru

hodinových ručiček. Pro kontrolu průtoku vzduchu

připojte indikátor průtoku vzduchu (viz. obrazová

příloha 2B).

3. Zatlačte na redukční ventil a vraťte ho do původ-

ní pozice - uslyšíte cvaknutí (viz. obrazová příloha

2C)

VAROVÁNÍ:

Průtok vzduchu by neměl klesnout pod 160 l/min!!!

5. Údržba a čištění

CA Pressure (Flow Master)

Na konci každé směny je doporučené vyčistit

jednotku, zkontrolovat jednotlivé díly a vyměnit poškozené části.

• Čištění jednotky musí probíhat v dobře ventilované

místnosti. Vyhněte se vdechnutí škodlivého prachu usazeného na jednotlivých částech jednotky

a příslušenství!

• Je zakázáno používat čistící prostředky obsahující

rozpouštědla a abrazivní látky. K čištění lze doporučit běžné detergenty.

• Vzduchová hadice může být opláchována čistou

vodou.

• K čištění používejte vlhký hadr. Každá část musí

být utřena do sucha.

CA Pressure Conditioner

• Jednou za týden vypusťte zkondenzovanou vodu

vodu z nádrže za pomoci výpusti umístěné na

spodní části. Před tímto úkonem je doporučeno

odpojit jednotku od zdroje stlačeného vzduchu.

• Vyměňte tento filtr vždy alespoň jednou za

3 měsíce. Po uplynutí této doby se mohou v

jednotce začít velmi rychle množit viry a bakterie.

V případě, že je jednotka používána pravidelně,

absorbční kapacita aktivního uhlí eliminujícícho zápach může být vyčerpána (pokud vzduch vycházející z jednotky CA Pressure Conditioner jakkoli

zapáchá, vyměňte okamžitě filtr).

• Když měníte filtr, vyčistěte nejprve vnitřek jednotky suchým hadrem, nebo za pomoci běžného

detergentu.

6. Výměna náhradních dílů

6.1. Filter pro CA Pressure Conditioner

Zařízení CA Pressure Conditioner obsahuje

kombinovaný filtr odstraňující olejové mlhy, zápachy a

chutě z průmyslově vyráběného stlačeného vzduchu.

Filtr neodstraňuje CO and CO2!

Čtěte instrukce k použití a výměně.

Výměna filtru CA Pressure Conditioner:

viz. obrázková příloha 3A-3C

• Odšroubujte horní část jednotky (6 šroubů).

• Odstraňte filtr jednotky a vyčistěte její vnitřek.

• Zkontrolujte stav pryžového těsnění víka jednotky.

Pokud je poškozené, vyměňte ho.

• Vložte nový filtr, nasadtě víko filtru a našroubujte

ho zpátky.

• Zkontrolujte zdali z nádoby neuniká vzduch.

Pokud není nádoba naprosto těsná, utáhněte znovu všechny šrouby na horní straně.

7. Skladování

Všechny komponenty systému CleanAIR® musí být

skladovány v prostorách s teplotami v rozsahu 0 °C

až 40 °C s relativní vlhkostí 20 % až 80 %. Možná doba

skladování v uzavřených kontejnerech je maximálně

2 roky s výjimkou baterií.

8. Záruka

Záruka pro výrobní závady je 12 měsíců od data

prodeje koncovému zákazníkovi. Nárok musí být

uplatněn u prodávajícího při současném předložení

faktury, či dodejky.

Záruka ztrácí platnost v případě poškození

způsobeného pozdní výměnou filtru, nebo použitím

filtru poškozeného čištěním, nebo profukováním.

CA Pressure Pressure Pressure Flow Master

Minimální průtok 170 l/min 170 l/min

Maximální průtok 400 l/min 250 l/min

Hmotnost jednotky 250 g 280 g

Vstupní konektor Compatible with RECTUS series 25, 26 and CEYN320

Výstupní konektor CA40x1/7“

Hlučnost jednotky 61 dB 61 dB

Délka opasku 60 - 150 cm 60 - 150 cm

Rozsah možného vstupního tlaku 300 – 1000 kPa 400 – 1000 kPa

Doporučený teplotní rozsah při práci +10 to +60 °C +10 to +60 °C

Doporučená relativní vzdušná vlhkost při práci 20 % to 80 % 20 % to 80 %

Certifikace EN 14594 Class 2A EN 14594 Class 2A, 2B,

3A, 3B

10. Technické údaje

Notifikovaná osoba pro testování CE: Výzkumný ústav bezpečnosti práce, v.v.i. – ZL

Testovací laboratoř č. 1024, Jeruzalémská 9, 116 52 Praha 1

Autorizovaná osoba 235 | Notifikovaná osoba 1024

11

Jednotka neposkytuje

dostatečné množství

vzduchu.

Hadice, nebo vzduchový kanál jsou ucpané.

Zkontrolujte a odstraňte případné

překážky.

Vzduch uniká díky netěsnostem.

Zkontrolujte všechny těsnící elementy

a spoje a prověřte zdali není hadice

poškozená a neobsahuje díry.

Tlumič hluku je ucpaný. Vyměňte tlumič hluku.

Filtr v CA Pressure Conditioner je ucpaný. Vyměňte filtr.

Závada Pravděpodobná příčina Doporučení

Jednotka vůbec nefunguje

Závada na straně zdroje tlakového

vzduchu, nebo poškozená hadice.

Zkontrolujte zdroj stlačeného vzduchu.

Ověřte, zdali jsou propojovací hadice

v pořádku.

9. Jak postupovat v případě selhání

CleanAIR® Pressure Conditioner

Maximální průtok vzduchu 500 l/min

Hmotnost bez filtru 6 300 g

Hmotnost včetně filtru 6 800 g

Vstupní konektor Compatible with RECTUS series 25,26 a CEYN320

Výstupní konektor Compatible with RECTUS series 25,26 a CEYN320

Doporučený teplotní rozsah při práci +10 to +60 °C

Doporučená relativní vzdušná vlhkost při práci 20 % to 80 % Rh

Certifikace Pokud jsou splněny požadavky uvedené v

TP-610050-1, pak odpovídá EN 12021

11. Seznam náhradních dílů:

CleanAIR® Pressure a CleanAIR® Pressure Flow Master

Objednací č.: Popis:

63 00 00 CA Pressure + belt

67 00 00 CA Pressure Flow Master + comfort belt

61 00 30 Standard hose 10 m for CAP

61 00 38 Standard hose 25 m for CAP

61 00 39 Standard hose 50 m for CAP

61 00 46 Spiral hose 10 m for CAP, mechanically resistant - mod.

63 00 10 CA Pressure - silencer

70 00 60 Light flexi hose CA40x1/7“ - CA40x1/7“

70 00 86CA Rubber hose CA40x1/7“ - CA40x1/7“

70 00 95 Belt for CA Pressure 155 cm

70 00 90RD Air flow indicator

CA PRESSURE CONDITIONER

Objednací č.: Popis:

61 00 50 CleanAIR® Pressure Conditioner

61 00 10 Filtr pro CleanAIR® Pressure Conditioner

61 00 24 CleanAIR® Pressure Conditioner - sealing O-ring 139x3

61 00 28 CleanAIR® Pressure Conditioner - sealing O-ring 30x4

12

13

CA Pressure conditioner assembly

1A

Airflow adjustment

CA Pressure, CA FM

2A 2B 2C

14

Filter change

3A 3B 3C

CA Pressure, CA FM

Exchangable silencer

Airflow regulation

(Reducing Valve)

Pressure hose connector

Headtop CA-1 CA-2 CA-3 CA-4 CA-10 CA-20 CA-40

/G/GW

CA-28

Euromaski

Unit

CA Pressure 2A 2A 2A 2A x x 2A 2A

CA FM 2A 2A 2A 3A 2A 3B 2B 2A

Possible combinations

Hose connector

15

16

MALINA - Safety s.r.o.

Luční 11,

466 01 Jablonec n. Nisou

Czech Republic

Tel. +420 483 356 600

Fax +420 483 312 106

export@malina-safety.cz

www.malina-safety.com

Loading...

Loading...