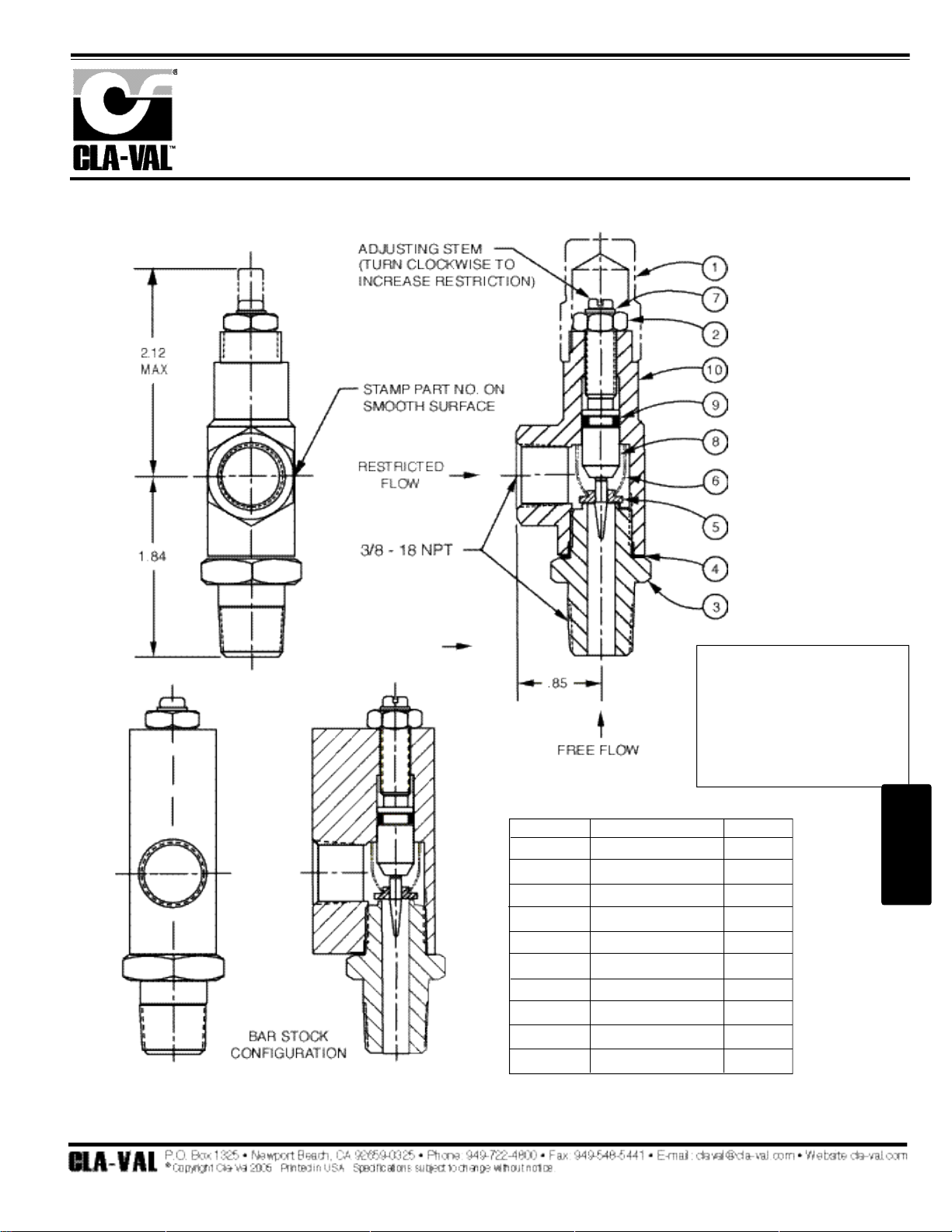

Page 1

Cla-Val

Section # 2

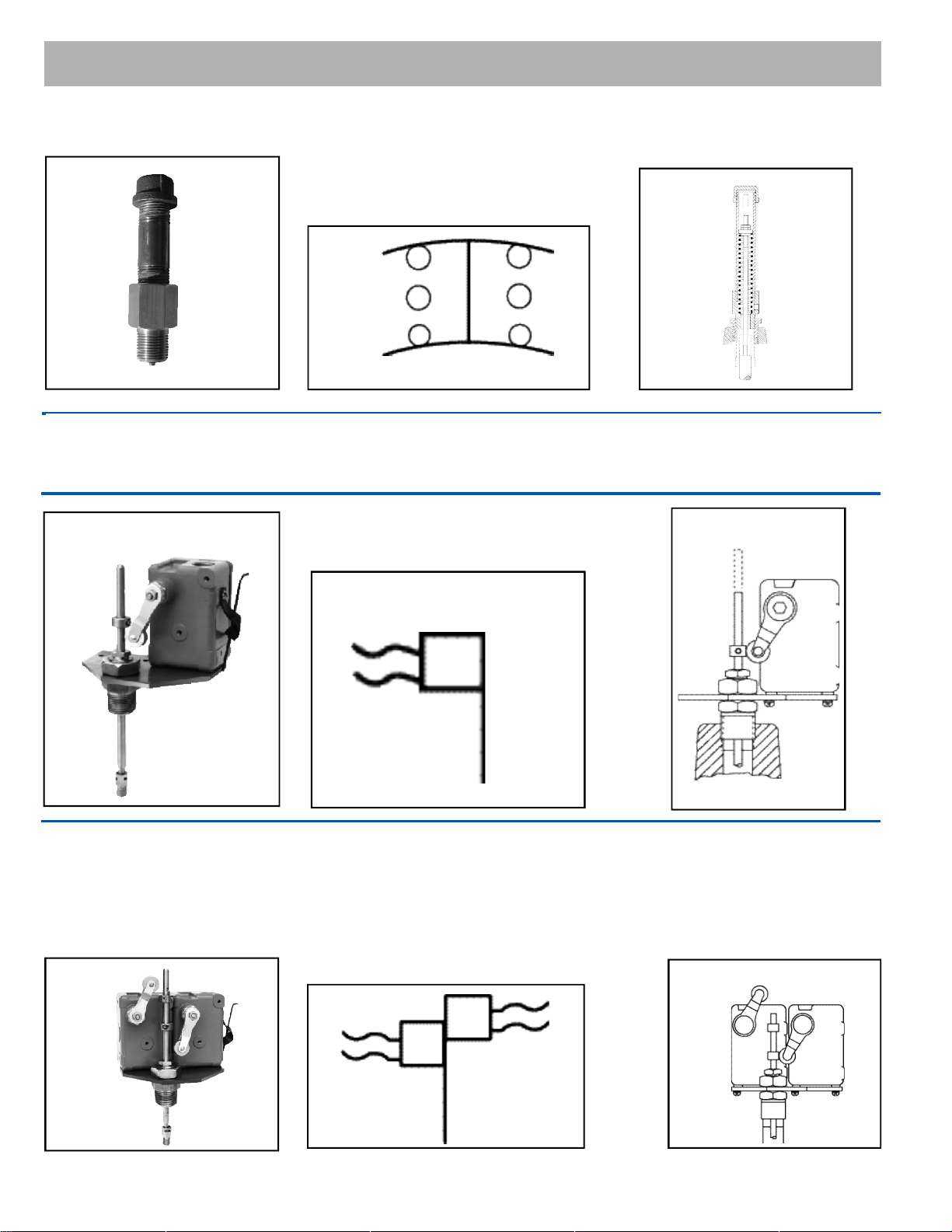

Pilots and Accessories

Service Training Manual

“Simple solutions plus learning with a purpose”

Page 2

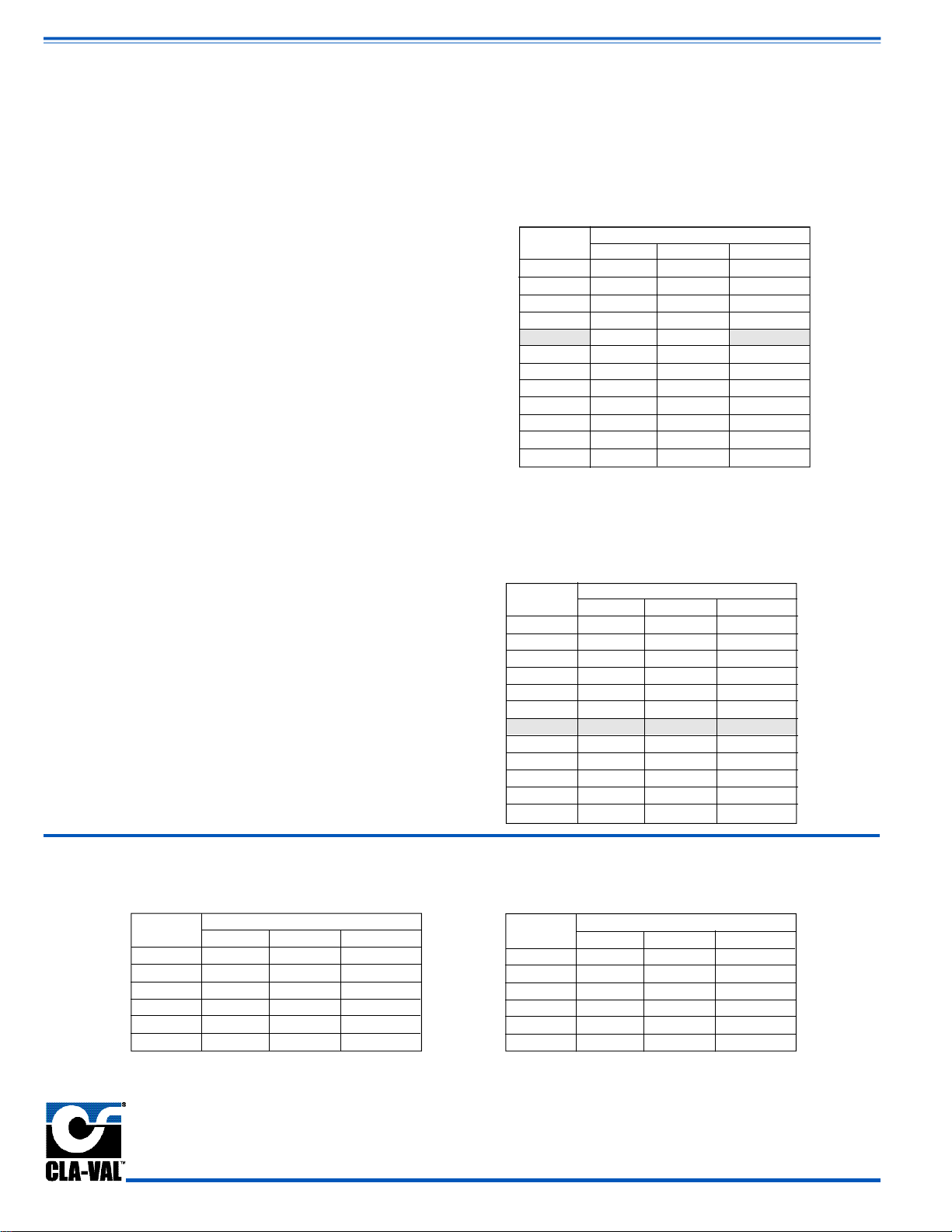

81

Section 2

Model Pilot Controls Section

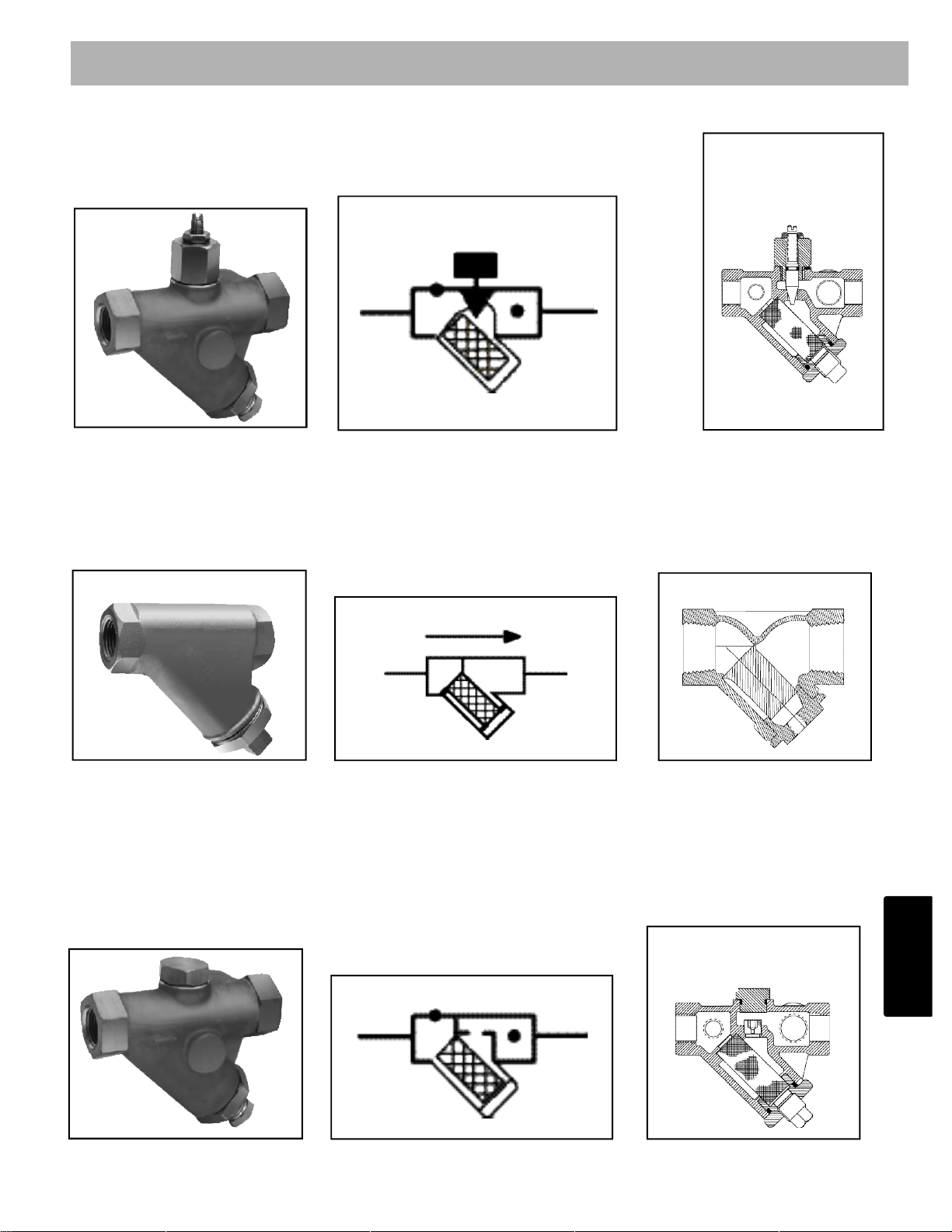

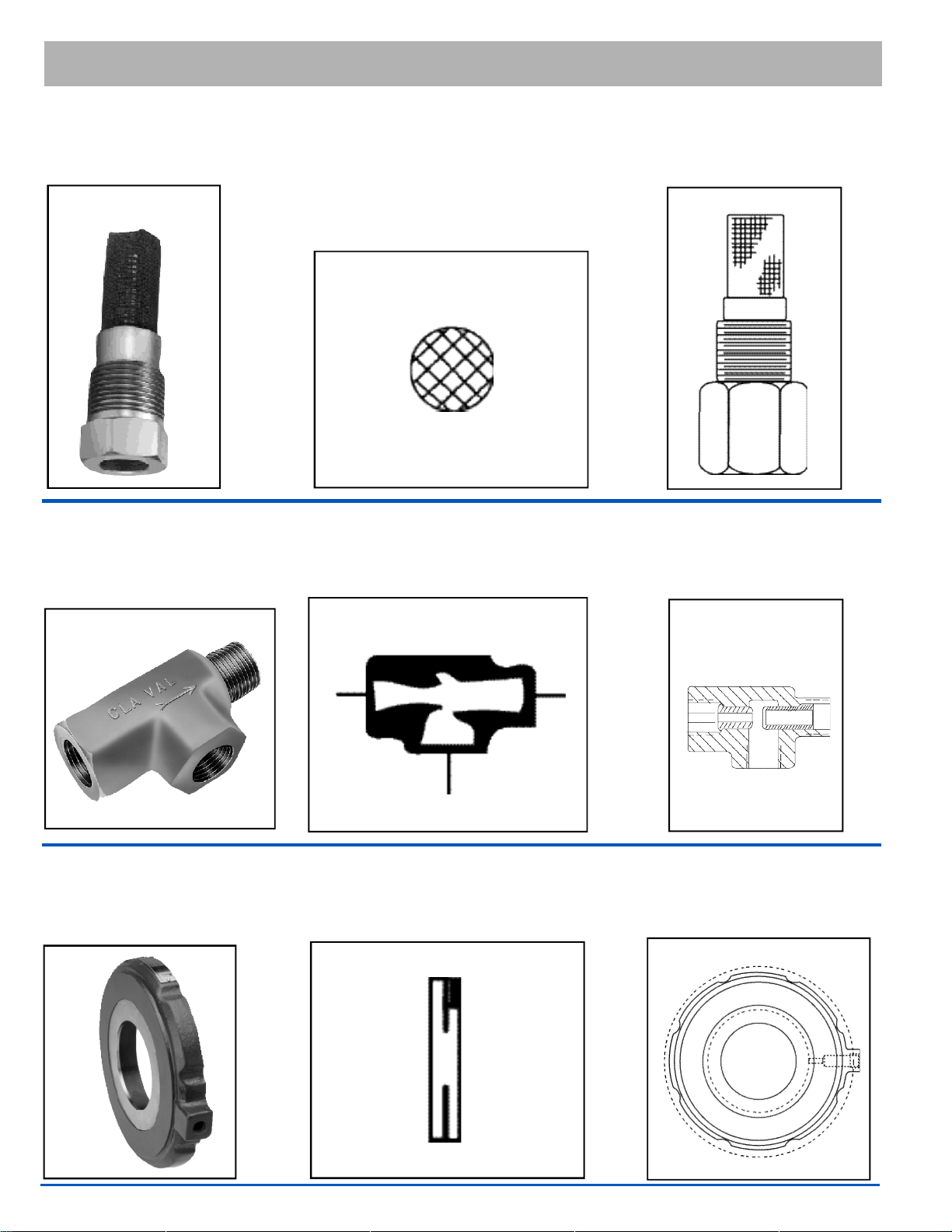

X42N-2 Strainer & Needle 2-2

Valve Assembly

X43 Y Strainer 2-2

X44A Strainer and Orifice 2-2

Assembly

X46 Strainer 2-2

X47A Ejector 2-2

X52E Orifice Plate Assembly 2-2

X58C Restriction Assembly 2-2

X101 Position Indicator 2-2

X102 Flow Limiting Assembly 2-2

X103 Spring Lift 2-2

X105L Limit Switch Assembly 2-2

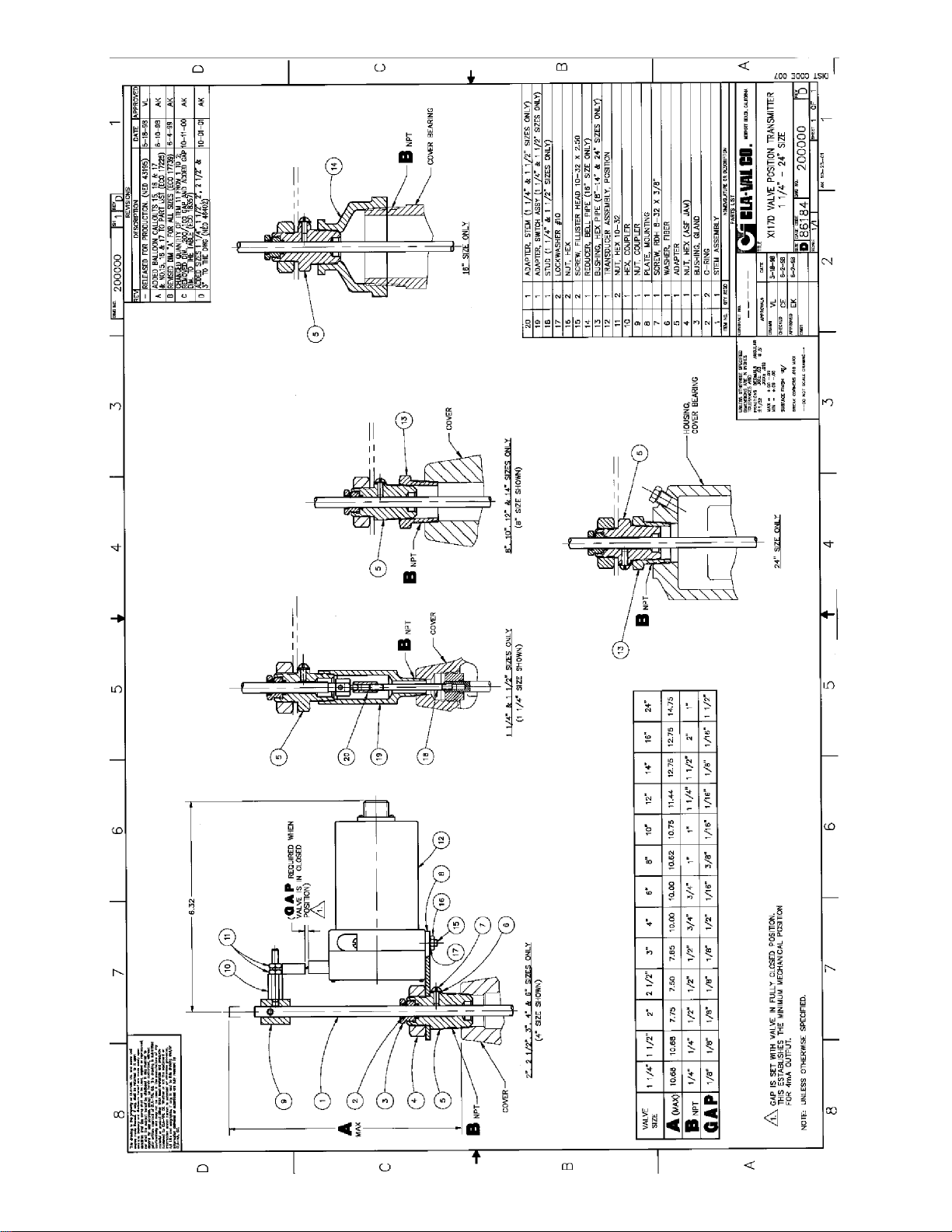

X117C/D Position Transmitter 2-2

Model Accessories

Section

CRD Pressure Reducing 2-1

CRA Reducing Pilot with 2-1

Remote Sensing

CRL Relief Pilot (55F & 55L) 2-1

CDHS-18 Differential Pilot 2-1

CDS6 Altitude Control 2-1

CFI-C1 Float Control 2-1

CFC2 External Float Control 2-1

CFM2 Modulating Float Control 2-1

CSM11 Solenoid Control 2-1

CV Speed Control 2-1

Pilot Regulator Spring Color Chart 2-1

Page 3

82

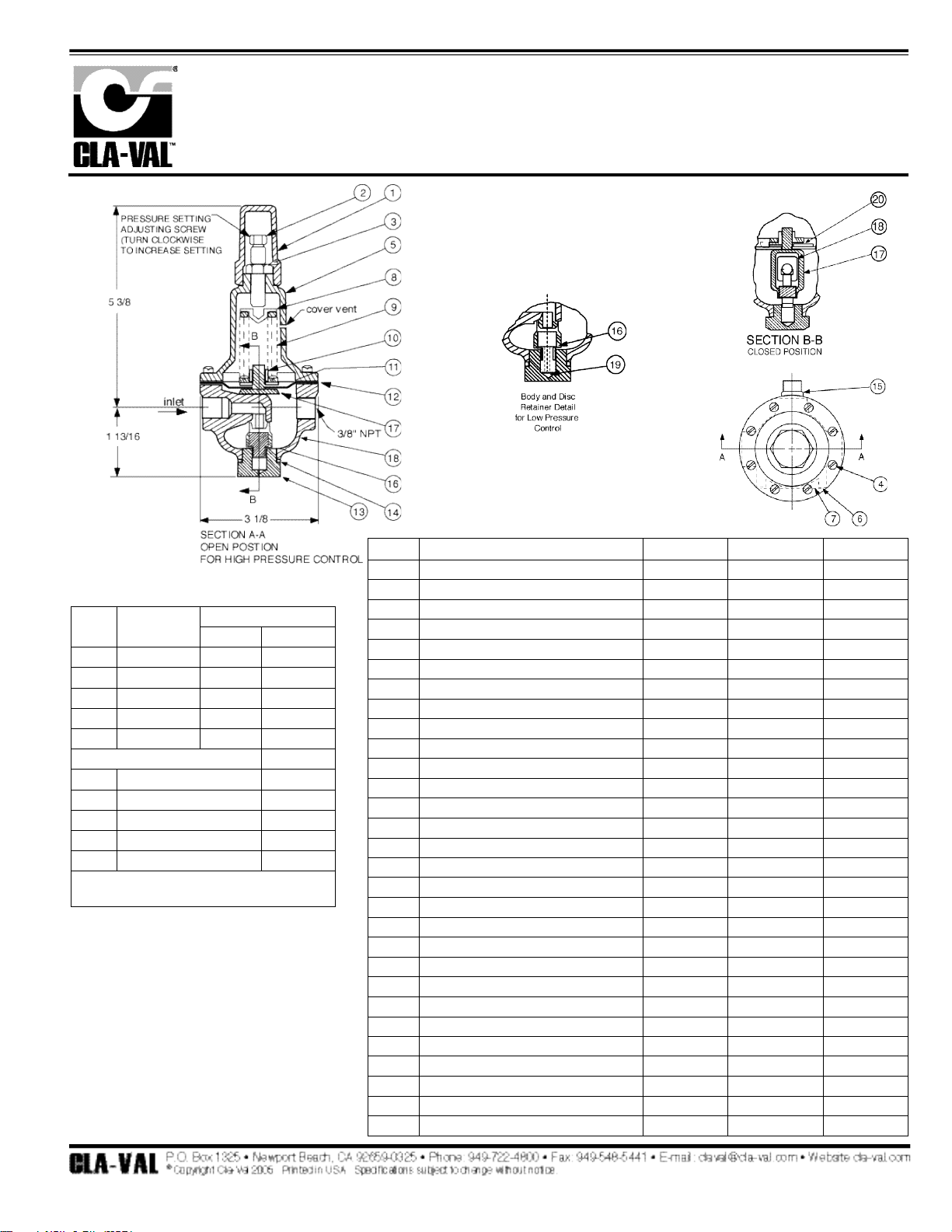

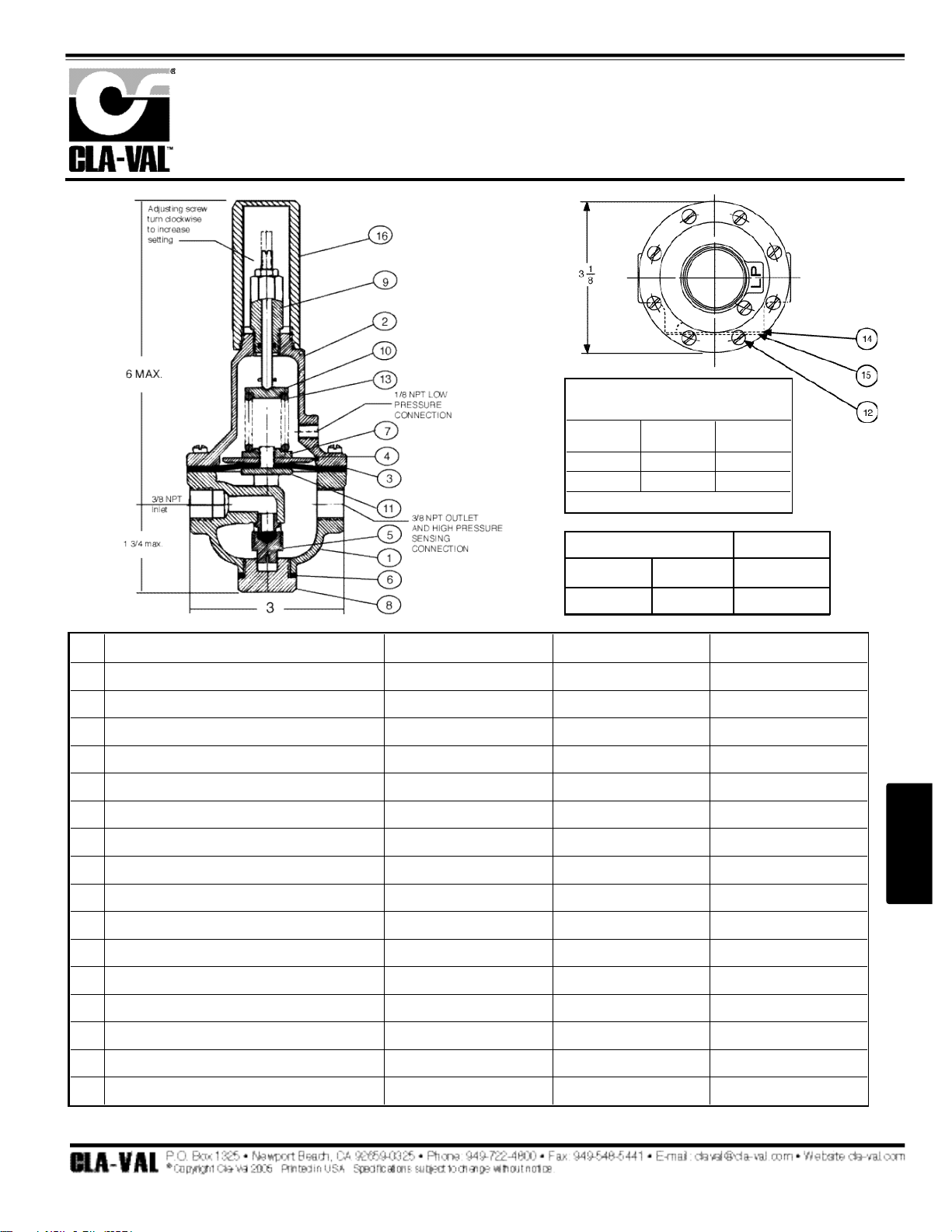

CRD – Cla-Val Reducing Pilot

The CRD is a Normally Open pilot and will shift to close on rise in outlet pressure. The CRD pilot is

used for most pressure reducing applications.

Normally Open – Shifts to closed on rise in

sensed pressure

Adjustment Ranges – 2-30, 15-75, 30-300 psi

Maximum Working Pressure 400 PSI

Pilot Controls

OUTIN

CRD

CRD

CRD

90-01/690-01

CRD

Schematic Symbol

Page 4

83

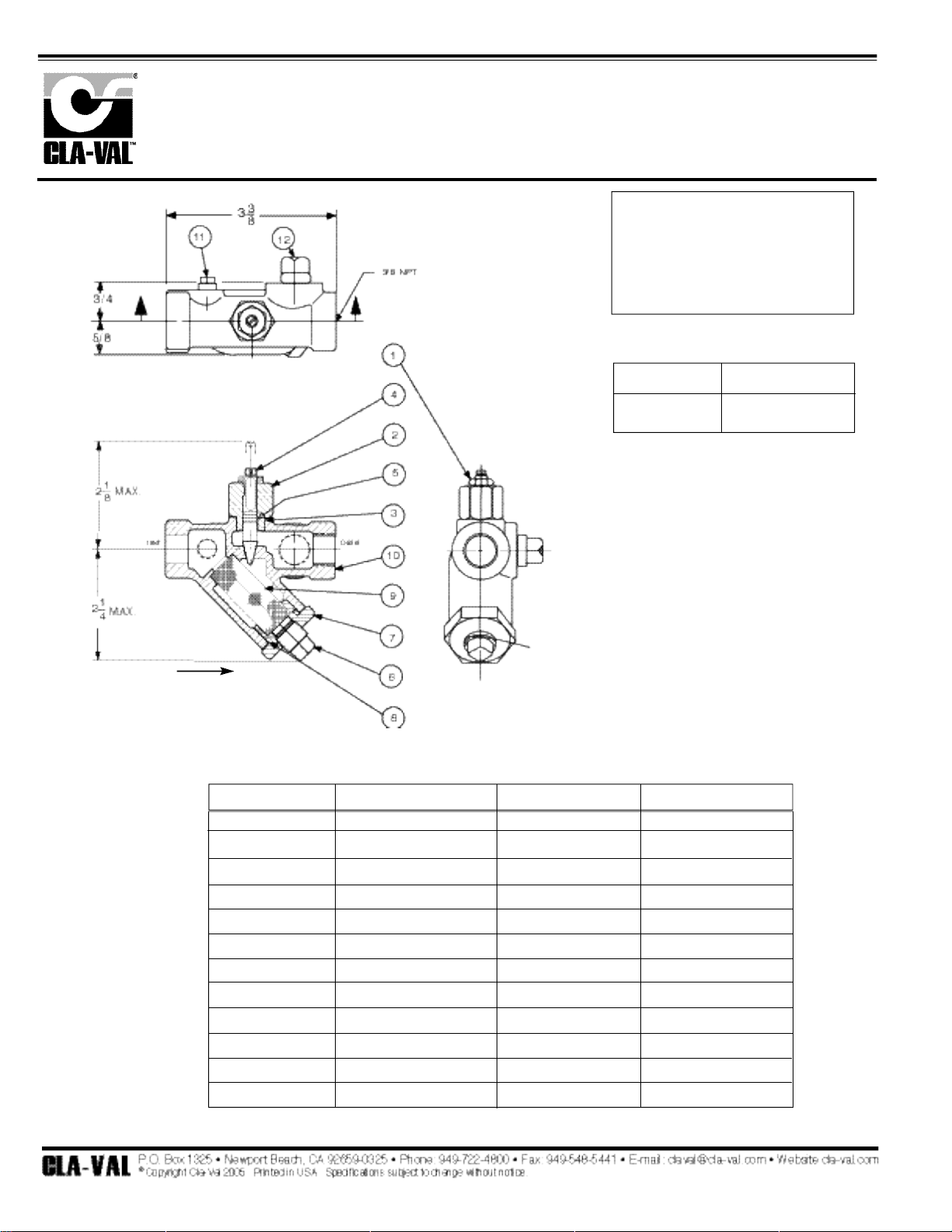

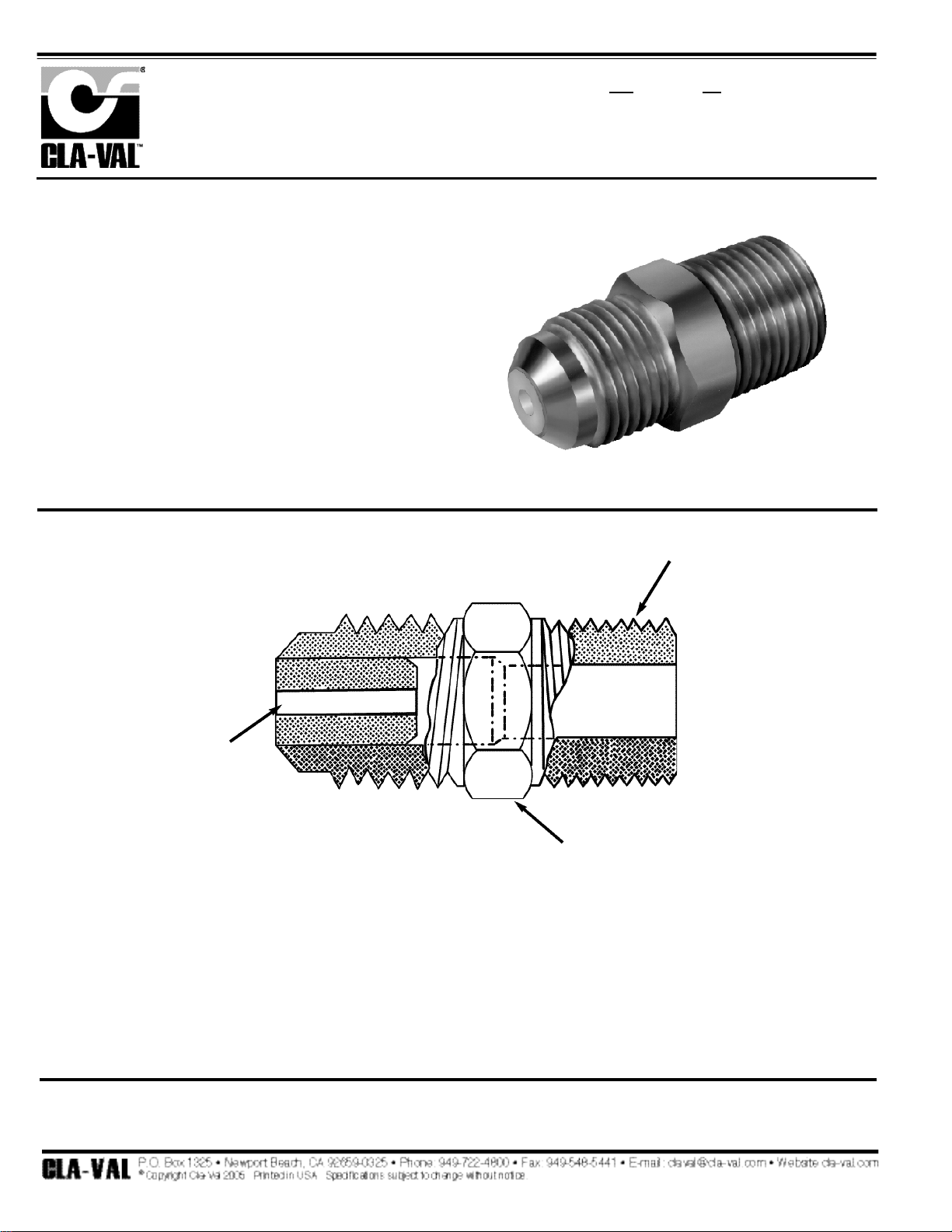

DESCRIPTION

The Cla-Val Model CRD Pressure Reducing Control automatically reduces

a higher inlet pressure to a lower outlet pressure. It is a direct acting, spring

loaded, diaphragm type control that operates hydraulically or pneumatically. It may be used as a self-contained valve or as a pilot control for a ClaVal main valve. It will hold a constant downstream pressure within very

close pressure limits.

OPERATION

The CRD Pressure Reducing Control is normally held open by the force of

the compression spring above the diaphragm; and delivery pressure acts

on the underside of the diaphragm. Flow through the valve responds to

changes in downstream demand to maintain a pressure.

INSTALLATION

The CRD Pressure Reducing Control may be installed in any position.

There is one inlet port and two outlets, for either straight or angle installation. The second outlet port can be used for a gage connection. A flow

arrow is marked on the body casting.

ADJUSTMENT PROCEDURE

The CRD Pressure Reducing Control can be adjusted to provide a delivery

pressure range as specified on the nameplate.

Pressure adjustment is made by turning the adjustment screw to vary the

spring pressure on the diaphragm. The greater the compression on the

spring the higher the pressure setting.

1. Turn the adjustment screw in (clockwise) to increase

delivery pressure.

2. Turn the adjustment screw out (counter-clockwise) to

decrease the delivery pressure.

3. When pressure adjustment is completed tighten jam nut on

adjusting screw and replace protective cap.

4. When this control is used, as a pilot control on a

Cla-Val main valve, the adjustment should be made

under flowing conditions. The flow rate is not critical,

but generally should be somewhat lower than normal

in order to provide an inlet pressure several psi higher

than the desired setting

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open

when deliver

pressure lowers

No spring compression Tighten adjusting screw

Spring guide (8) is not in

place

Assemble properly

Yoke dragging on inlet

nozzle

Disassemble and reassemble

properly (refer to Reassembly)

Fails to close

when delivery

pressure rises

Spring compressed solid Back off adjusting screw

Mechanical obstruction

Disassemble and reassemble

properly (refer to Reassembly)

Worn disc

Disassemble remove and

replace disc retainer assembly

Yoke dragging on inlet

nozzle

Disassemble and reassemble

properly (refer to Reassembly)

Leakage from

cover vent hole

Damaged diaphragm Disassemble and replace

Loose diaphragm nut Remove cover and tighten nut

Damaged spring Disassemble and replace

CRD

MAINTENANCE

Disassembly

To disassemble follow the sequence of the item numbers assigned to

parts in the sectional illustration.

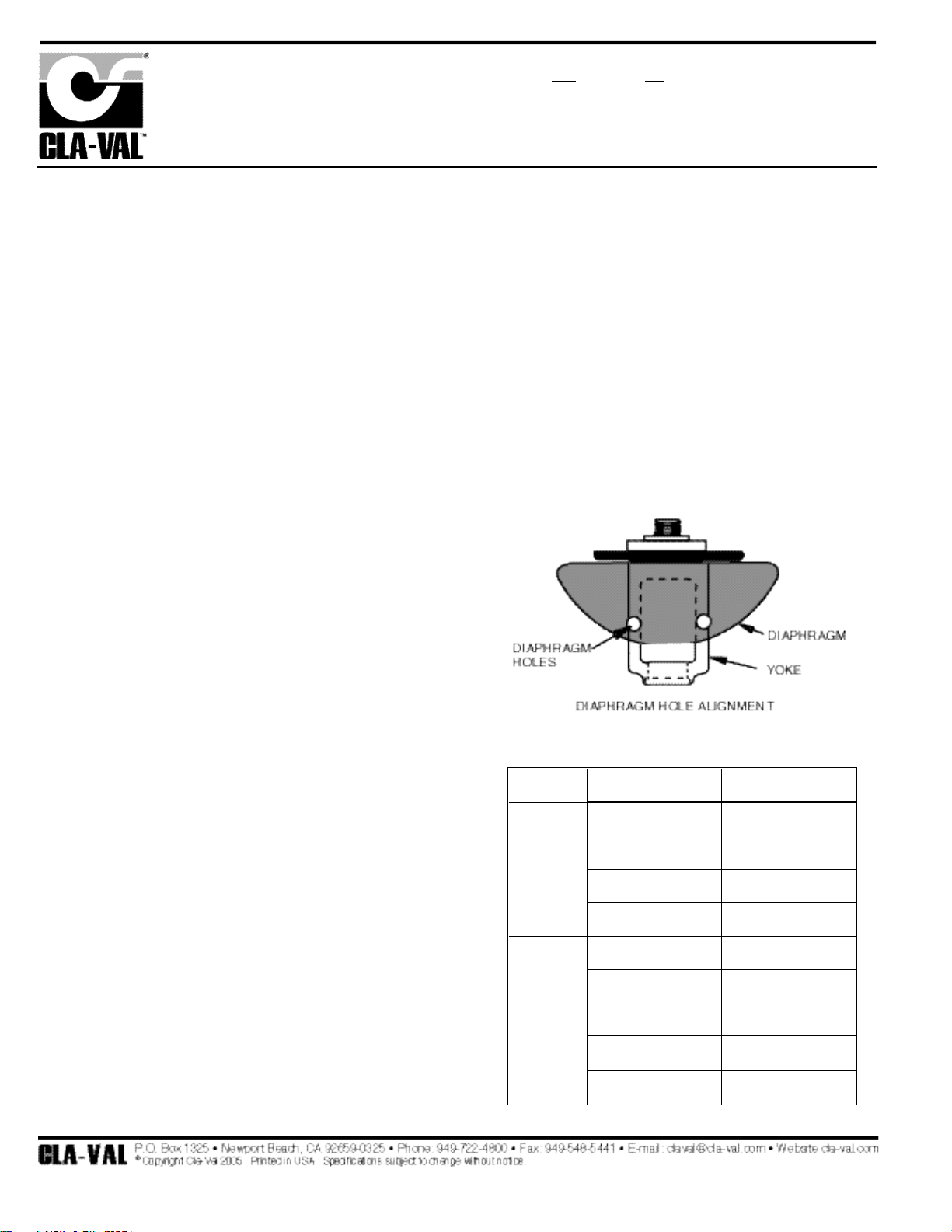

Reassembly

Reassembly is the reverse of disassembly. Caution: must be taken to

avoid having the yoke (17) drag on the inlet nozzle of the body (18).

Follow this procedure:

1. Place yoke (17) in body and screw the disc retainer

assembly (16) until it bottoms.

2. Install gasket (14) and spring (19) for 2-30 and 2-6.5 psi

range onto plug (13) and fasten into body. Disc retainer

must enter guide hole in plug as it is assembled. Screw

the plug in by hand. Use wrench to tighten only.

3. Place diaphragm (12) diaphragm washer (11) and belleville

washer (20) on yoke. Screw on hex nut (10).

4. Hold the diaphragm so that the screw holes in the

diaphragm and body align. Tighten diaphragm nut with

a wrench. At the final tightening release the diaphragm

and permit it to rotate 5° to 10°. The diaphragm holes

should now be properly aligned with the body holes.

To check for proper alignment proceed as follows:

Rotate diaphragm clockwise and counterclockwise as far as possible.

Diaphragm screw holes should rotate equal distance on either side of

body screw holes ±1/8".

Repeat assembly procedure until diaphragm and yoke are properly

aligned. There must be no contact between yoke and body nozzle during its normal movement. To simulate this movement hold body and

diaphragm holes aligned. Move yoke to open and closed positions.

There must be no evidence of contact or dragging.

5. Install spring (9) with spring guide (8).

6. Install cover (5), adjusting screw (2) and nut (3), then cap (1).

Pressure Reducing Control

The approximate minimum flow rates given in the table are for the main valve

on which the CRD is installed.

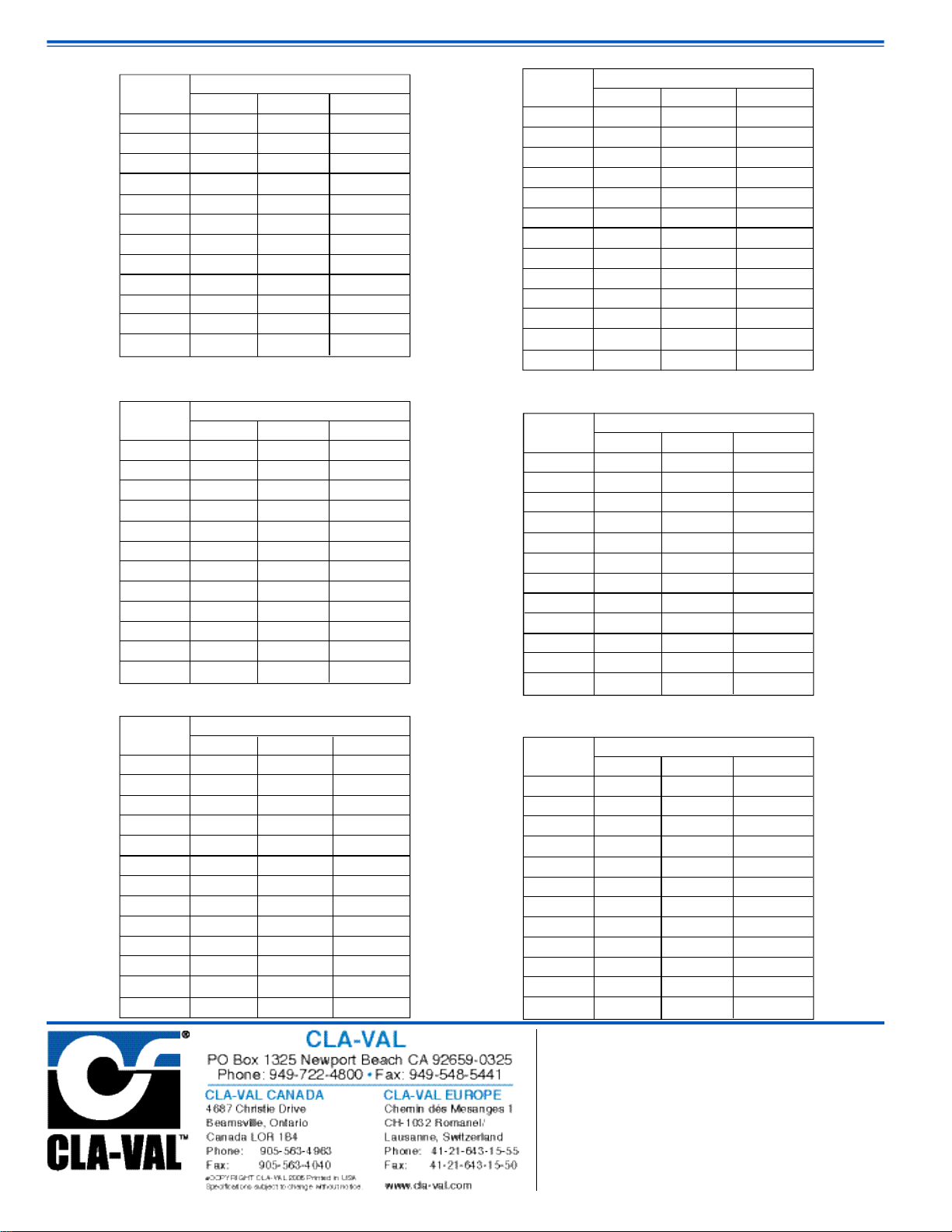

Valve Size

Minimum Flow GPM

1 1/4" -3" 4"-8" 10"-16"

15-30 50-200 300-650

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

N-CRD (R-5/05)

2

–

1

Page 5

84

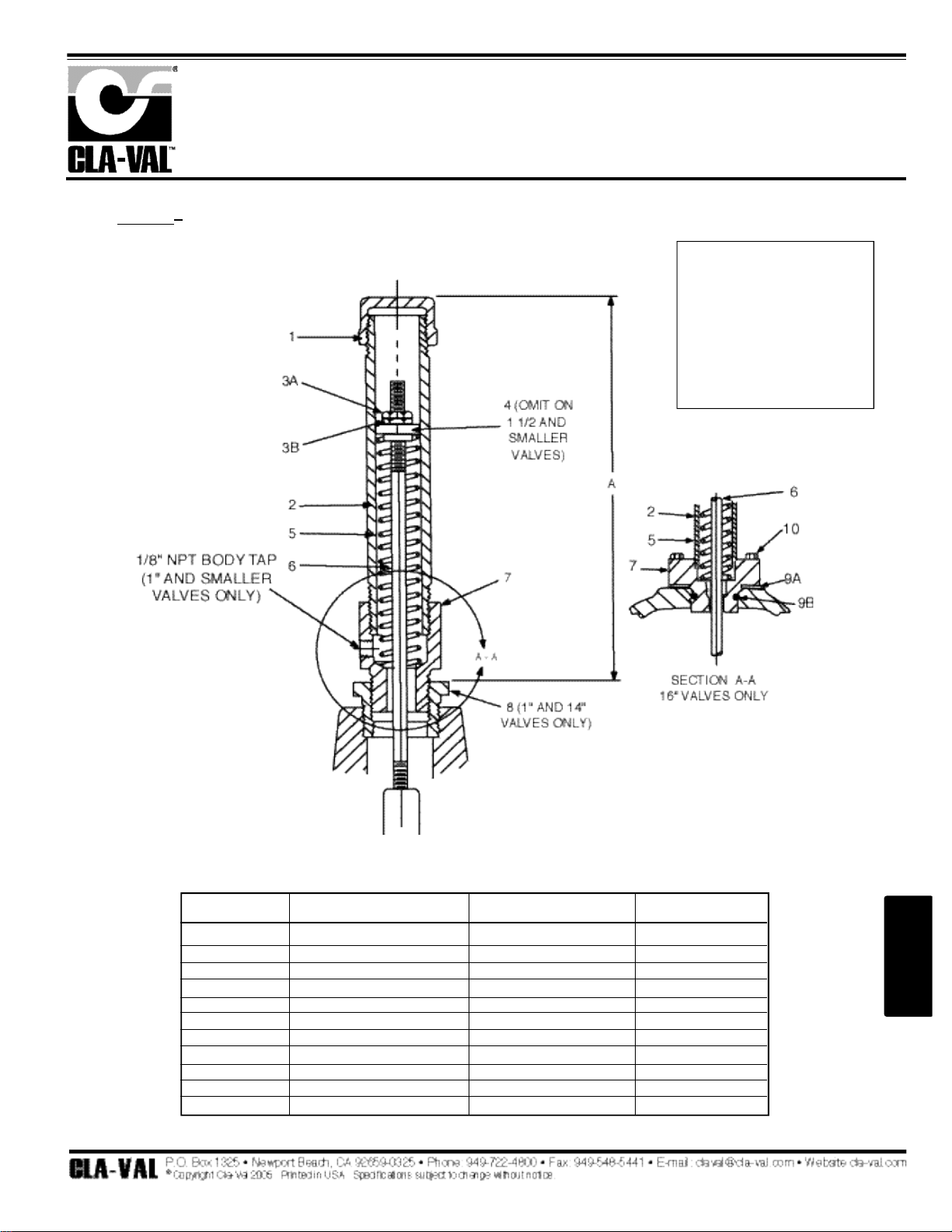

*SUGGESTED REPAIR PARTS

CRD

Pressure Reducing Control

When ordering parts specify:

• All nameplate data

• Item Description

• Item number

PL-CRD (R-12/06)

PARTS LIST

Size

(inch)

Stock

Number

Adjustment Range

psi Ft of Water

3/8 71943-07A 2 - 6.5 4.5 - 15

3/8 71943-08J 2 - 30 4.5 - 69

3/8 71943-03K 15 - 75 35 - 173

3/8 71943-11C 20 - 105 46 - 242

3/8 71943-04H 30 - 300 69 - 692

Factory Set Pressure

PSI per Turn

2 - 6.5 set @ 3.5 psi .61

2 - 30 set @ 10 psi 3.0

15 - 75 set @ 20 psi 9.0

20 - 105 set @ 60 psi 12.0

30 - 300 set @ 60 psi 27.0

*Approximate-Final Adjustment should be

with a pressure gauge and with flow.

Item Description Material Part Number List Price

1 Cap PL 67628J

2 Adjusting Screw BRS 7188201D

3 Jam Nut (3/8-16) SS 6780106J

4* Machine Screw (Fil.Hd.) 8 Req'd 303 6757821B

5 Cover BRS C2544K

6 Nameplate Screw SS 67999D

7 Nameplate BRS C0022001G

8 Spring Guide 302 71881H

9 Spring (15-75 psi) CHR/VAN 71884B

Spring (2 - 6.5 psi) SS 82575C

Spring (2 - 30 psi) SS 81594E

Spring (20 - 105 psi) CHR/VAN 20561901H

Spring (30 - 300 psi) CHR/VAN 71885J

10 Hex Nut 303 71883D

11 Diaphragm Washer 302 71891G

12 Diaphragm NBR C6936D

13 Plug, Body BRS V5653A

14* Gasket Fiber 40174F

15 Plug BRS 6766003F

16* Disc Retainer Assy. (15 - 75 psi) BZ/Rub C5256H

Disc Retainer Assy. (2 - 30 psi) BZ/Rub C5255K

Disc Retainer Assy. (20 - 105 psi) BZ/Rub 20561901H

Disc Retainer Assy. (30 - 300 psi) BZ/Rub C5256H

17 Yoke VBZ V6951H

18 Body & 1/4" Seat Assy BR/SS 8339702G

19* Bucking Spring (2 - 30 psi) 302 V0558G

20 Belleville Washer STL 7055007E

* Repair Kit (No Bucking Spring)

Buna®-N

9170003K

* Repair Kit (with Bucking Spring)

Buna®-N

9170001D

Page 6

85

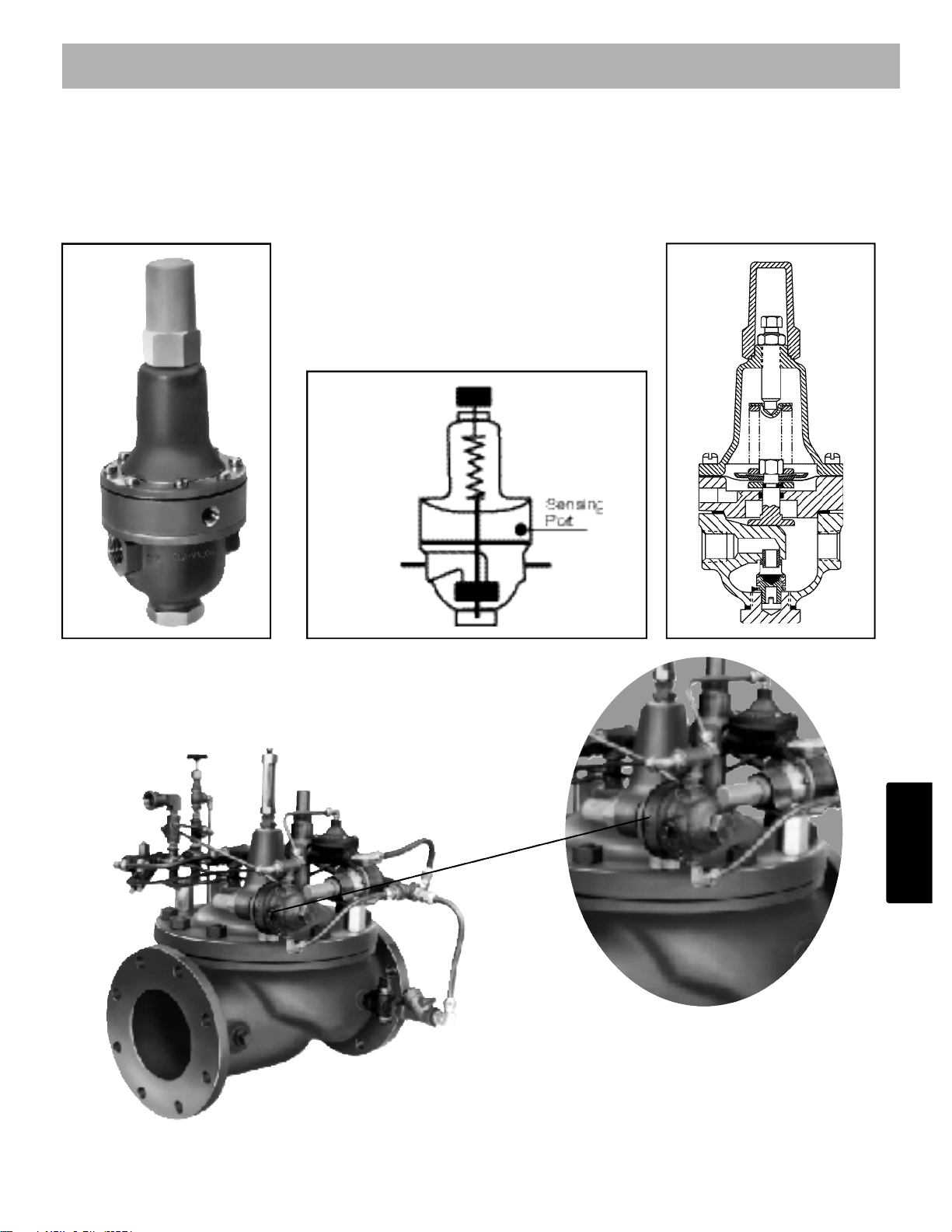

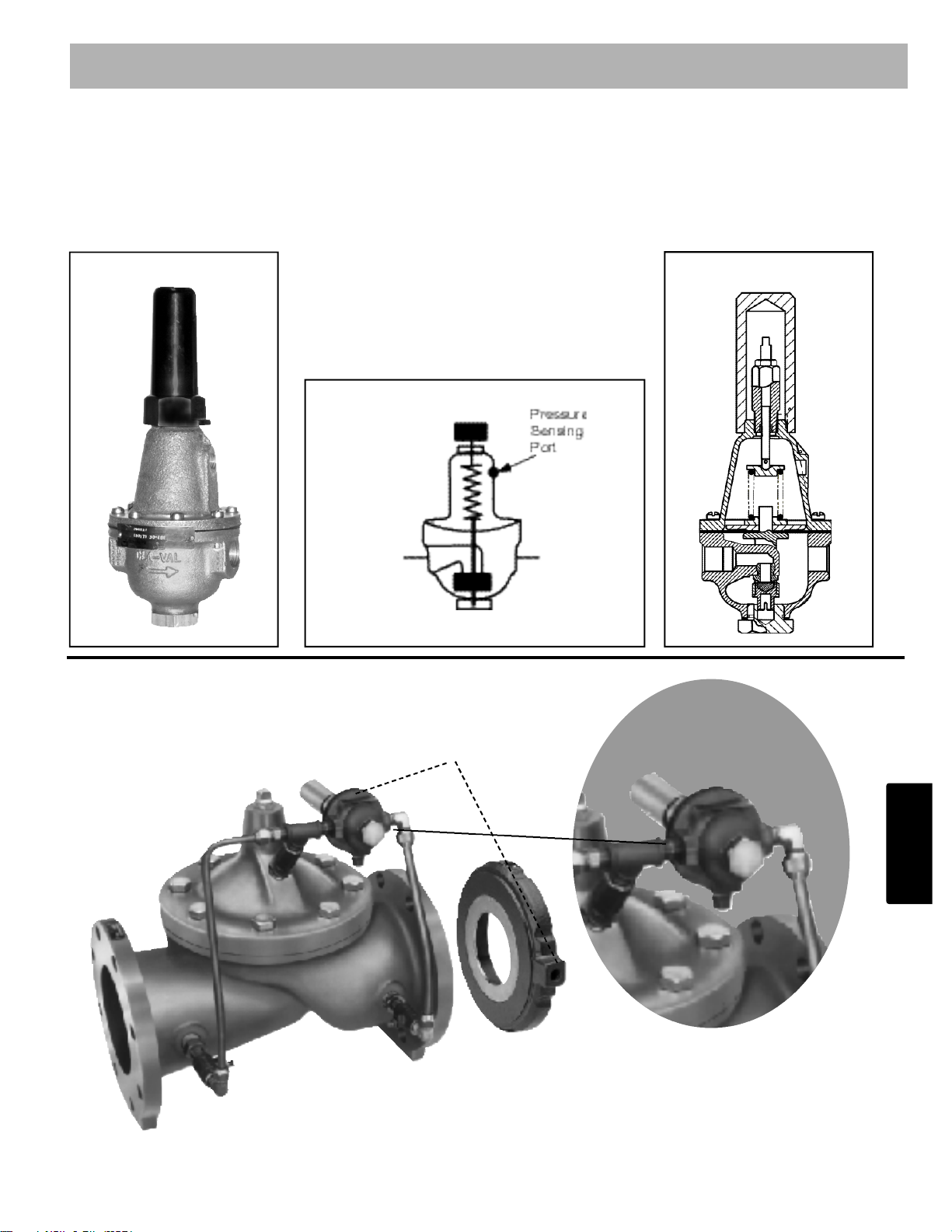

CRA – Cla-Val Reducing Pilot with a remote sensing port

The CRA is similar to a CRD but it also has an extra feature; it has a remote sense port. The CRA

is a Normally Open pilot and will shift to close on rise in pressure. The CRA pilot is used for pressure reducing applications where a remote pressure needs to be sensed.

Normally Open – Shifts to close on rise in

sensed pressure.

Adjustment Ranges – 2-35, 15-75, 30-300 psi

Maximum Working Pressure 400 PSI

OUT

IN

CRA

CRA

CRA

CRA

52-03

2

–

1

Schematic Symbol

Pilot Controls

Page 7

86

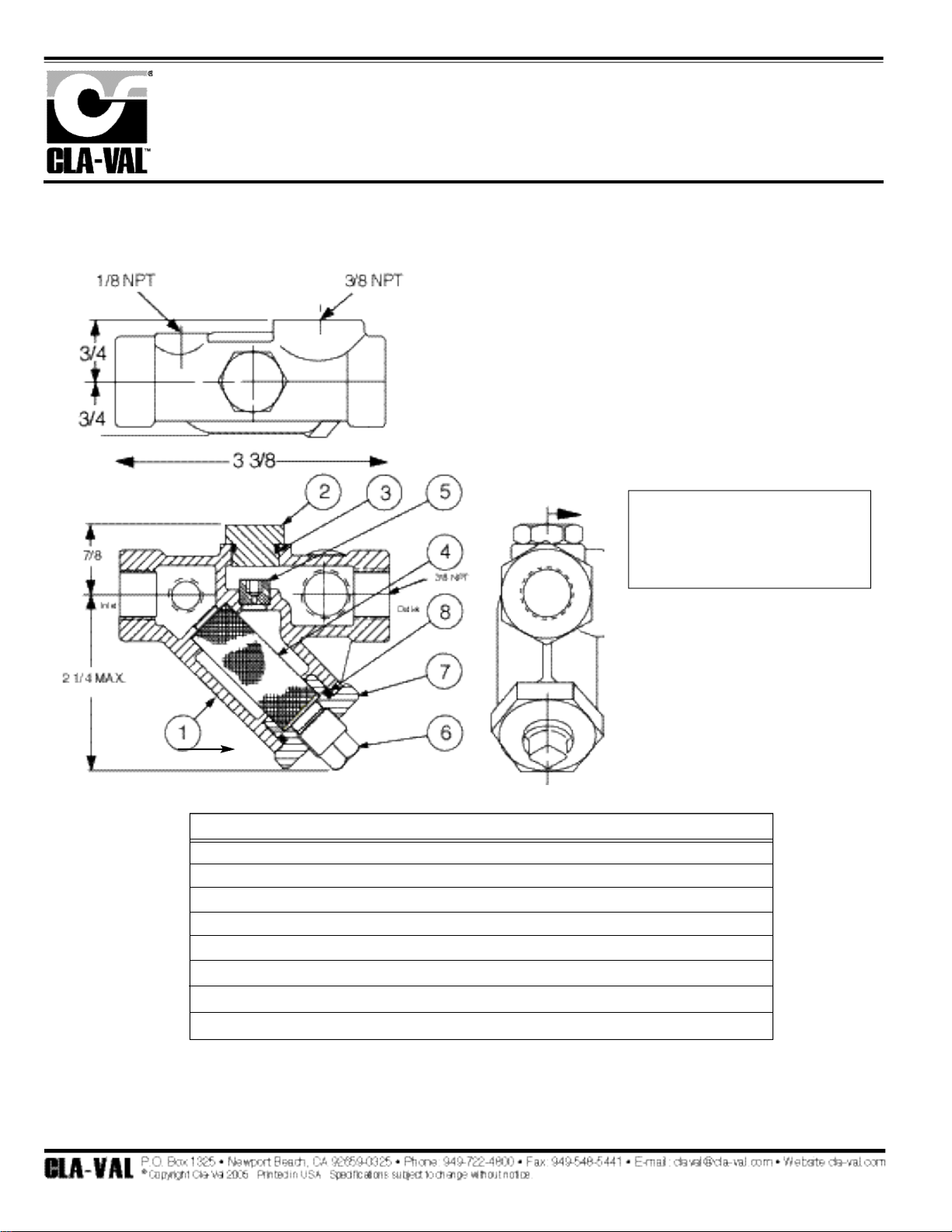

DESCRIPTION

The CRA Pressure Reducing Control automatically reduces a higher inlet

pressure to a lower outlet pressure. It is a direct acting, spring loaded,

diaphragm type valve that operates hydraulically or pneumatically and is

designed to sense pressure from a remote point. It may be used as a selfcontained valve or as a pilot control for a Cla-Val main valve. It will hold a

constant downstream pressure at the remote sensing point within very

close pressure limits.

OPERATION

The CRA Pressure Reducing Control is normally held open by the force

of the compression spring above the diaphragm; delivery pressure acts on

the underside of the diaphragm. Flow through the valve responds to

changes in pressure at the the sensing point.

INSTALLATION

The CRA Pressure Reducing Control may be installed in any position.

There is one inlet port and two outlets, for either straight or angle installation. The second outlet port can be used for a gauge connection. A flow

arrow is marked on the body casting.

ADJUSTMENT PROCEDURE

The CRA Pressure Reducing Control can be adjusted to provide a delivery pressure range as specified on the nameplate.

Pressure adjustment is made by turning the adjustment screw to vary the

spring pressure on the diaphragm. The greater the compression on the

spring the higher the pressure setting.

1. Turn the adjustment screw in (clockwise) to increase delivery

pressure.

2. Turn the adjustment screw out (counter-clockwise) to decrease

the delivery pressure. When pressure adjustment is completed,

tighten jam nut on adjustment screw and replace protective cap.

Flow rates are not critical during pressure setting. The approximate min imum flow rates given in the table are for the main valve on which the CRA

is installed.

Valve Size 1 1/4"-3" 4"-8" 10"-16"

Minimum Flow GPM 15-30 50-200 300-650

MAINTENANCE

Disassembly

To disassemble follow the sequence of the item numbers assigned to

parts in the sectional illustration.

Reassembly

Reassembly is the reverse of disassembly. Caution must be taken to

avoid having the yoke (17) drag on the inlet nozzle of the body (18).

Follow this procedure:

1. Place yoke (17) in body and screw the disc retainer assembly

(16) until it bottoms.

2. Install gasket (14) and spring (19) for 2-30 psi range onto plug

(13) and screw into body. Disc retainer must enter guide hole in

plug as it is assembled. Screw the plug in by hand. Use wrench

to tighten only.

3. Place gasket (25) and powertrol body (21) on yoke extension

(17). Refer to sectional view for proper reassembly of (21) onto

body (18).

4. Place lower diaphragm washer (24), "O" ring (22), diaphragm

(12), upper diaphragm washer (11), and belleville washer (20) on

yoke extension (17). Screw on diaphragm nut (10) finger tight.

5. Place two machine screws (4) through (21) (25) and screw into

body (18). Do not include the diaphragm (12) in this operation.

This holds parts aligned for next step, and allows the diaphragm

to move and be properly located during tightening of nut (10).

6. Hold the diaphragm so that screw holes in the diaphragm (12)

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open when

pressure lowers

No spring compression Tighten adjusting

screw

Mineral buildup on yoke

extension (17)

Disassemble and

clean part,

Replace "O" rings

(22) and (23).

Damaged spring Disassemble and

replace.

Spring guide (8) is not in

place

Disassemble and

place guide (8) on

top of spring (9).

Yoke dragging on inlet

nozzle

Disassembled

and reassemble

use procedure.

Fails to close when

delivery pressure rises

Spring compressed

Back off adjusting

screw

Mineral deposit on yoke

extension (17)

Disassemble and

clean part.

Replace "o" rings

(22) and (23).

Mechanical obstruction

Disassemble and

remove obstruction

Worn disc

Disassemble,

remove and

replace disc

retainer assembly. (16)

Yoke dragging on inlet

nozzle

Refer to paragraph 6

Damaged diaphragm (12)

Disassemble and

replace

Loose diaphragm nut (10)

Remove cover

and tighten nut

REMOTE SENSING TYPE

CRA

Leakage from cover

vent hole

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

N-CRA (R-5/05)

and powertrol body (21) align. Tighten diaphragm nut (10) with a wrench.

At the final tightening release the diaphragm and permit it to rotate

approximately 5° to 10°. The diaphragm holes should now be properly

aligned with the body holes.

To check for proper alignment proceed as follows:

Rotate diaphragm clockwise and counterclockwise as far as possible.

Diaphragm screw holes should rotate equal distance on either side of

powertrol body screw holes ±1/8".

Repeat assembly procedure until diaphragm and yoke are properly

aligned. There must be no contact between yoke and body nozzle during

its normal opening and closing movement. To simulate this movement

hold powertrol body and diaphragm holes aligned. Move yoke to open

and closed positions. There must be no evidence of contact or dragging.

7. Remove machine screws per step 5.

8. Install spring (9) with spring guide (8) on top of spring.

9. Install cover (5) using eight machine screws (4).

10. Replace adjusting screw (2) and nut (3), then cap (1).

Pressure Reducing Control

Page 8

87

2

–

1

* Suggested Repair Parts

REMOTE SENSING TYPE

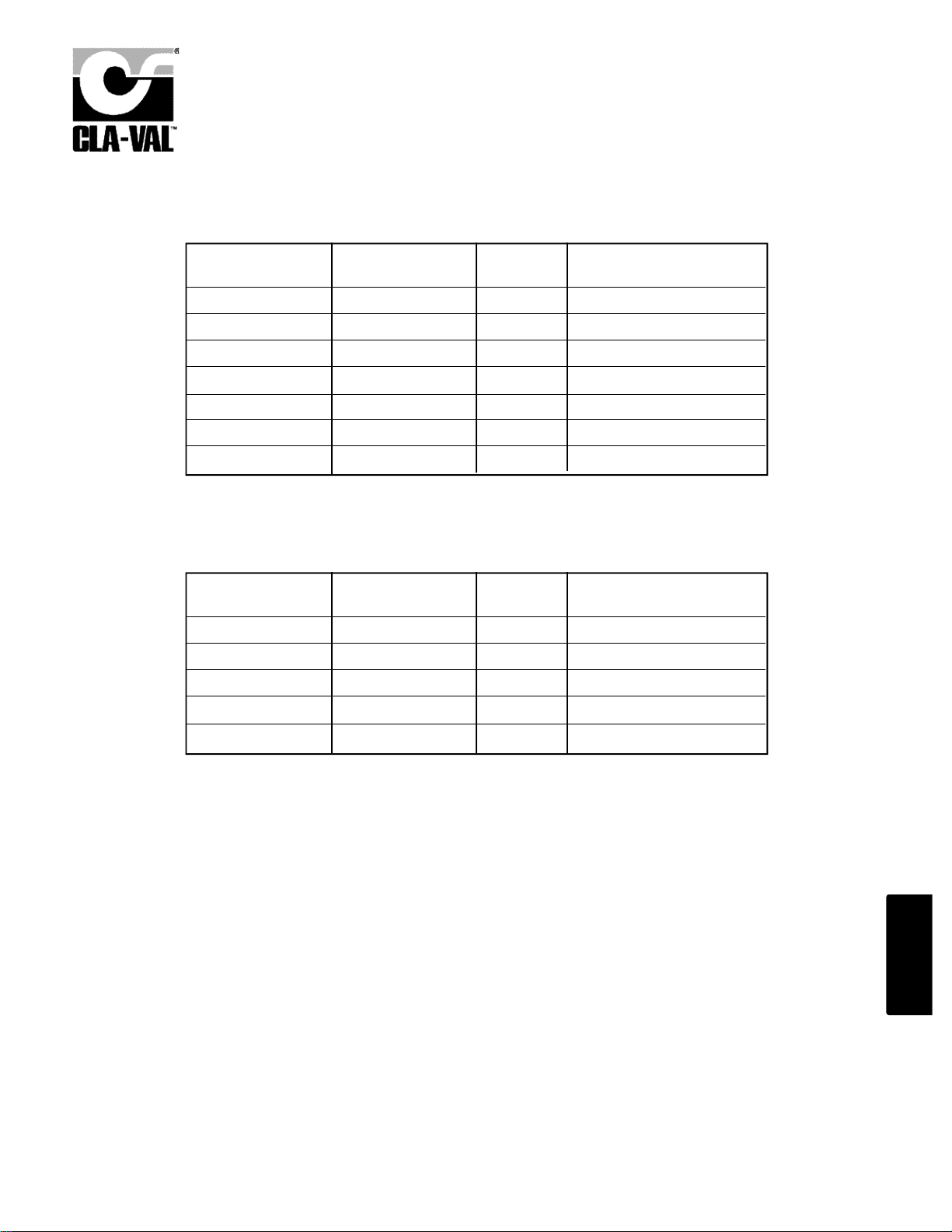

SIZE

(inch)

STOCK

NUMBER

SEAT

DIA

ADJ.

RANGE

(psi)

3/8 79744-04B 1/4 30-300

3/8 79744-06G 1/4 2-30

Factory set pressure:

PSI*per turn

30-300 set @ 60 psi 27.0

2-30@ 10 psi 3.0

3/8 79744-03D 1/4 15-75

Pressure Reducing Control

CRA

When ordering parts specify:

• All nameplate data

• Description

• Item number

* Approximate - Final adjustment should

be made with a pressure gauge and

with flow.

15-75 set @ 20 psi 9.0

1

2

3

4*

5

6

7

8

9

10

11

12*

13

14*

15

16*

17

18

19*

20

21

22*

23*

24

25

*

*

Cap

Adjusting Screw

Jam Nut, 3/8—16

Machine Screw 10-32 x 1-1/4"(Fil.Hd.) (8 required)

Cover

Nameplate Screw

Nameplate

Spring Guide

Spring

(15-75 psi)

(30-300 psi)

(2-30 psi)

Hex Nut 5/16 - 18

Diaphragm Washer (upper)

Diaphragm

Plug, Body

Gasket

Plug, 3/8 NPT

Disc Retainer Assy (15-75 psi & 30-300 psi)

Disc Retainer Assy (2-30 psi)

Yoke

Body & Seat Assy, Seat only 1/4"

Bucking Spring (Required with 2-30 psi)

Belleville Washer

Powertrol Body

O-Ring

O-Ring

Diaphragm Washer (lower)

Gasket

Repair Kit (no Bucking Spring) Item 19

Repair Kit (with Bucking Spring) Item 19

PL

BRS

303

SS

BRS

SS

BRS

302

CHR VAN

CHR VAN

SS

303

302

NBR

BRS

FIB

BRS

BR/RUB

BR/RUB

VBZ

BS

302

STL

BRS

NBR

NBR

BRS

NBC

Buna®-N

Buna®-N

67628J

7188201D

6780106J

6757874A

C2544K

67999D

C002201G

71881H

71884B

71885B

81594E

71883D

71891G

C6936D

V5653A

40174F

6766003F

C5256H

C5255K

C1799A

8339701J

VO5586

7055007E

C3388A

00708J

00746J

C1804J

8059401D

9170003K

9170001D

ITEM DESCRIPTION MATERIAL PART NUMBER LIST PRICE

PL-CRA (R-11/06)

PARTS LIST

Page 9

88

OUT

IN

CRL – Cla-Val Relief Pilot

The Cla-Val CRL pilot is a Normally Closed pilot that shifts to Open on rise in sensed pressure. The

CRL is used for most pressure relief or pressure sustaining applications.

Normally Closed - Shifts to open on rise

in sensed pressure

Adjustment Ranges

0-75, 20-200,100-300 psi

Contact Cla-Val for higher ranges

Maximum Working Pressure 400 PSI

CRL

CRL

CRL

CRL

50-01/650-01

Schematic Symbol

Pilot Controls

Page 10

89

2

–

1

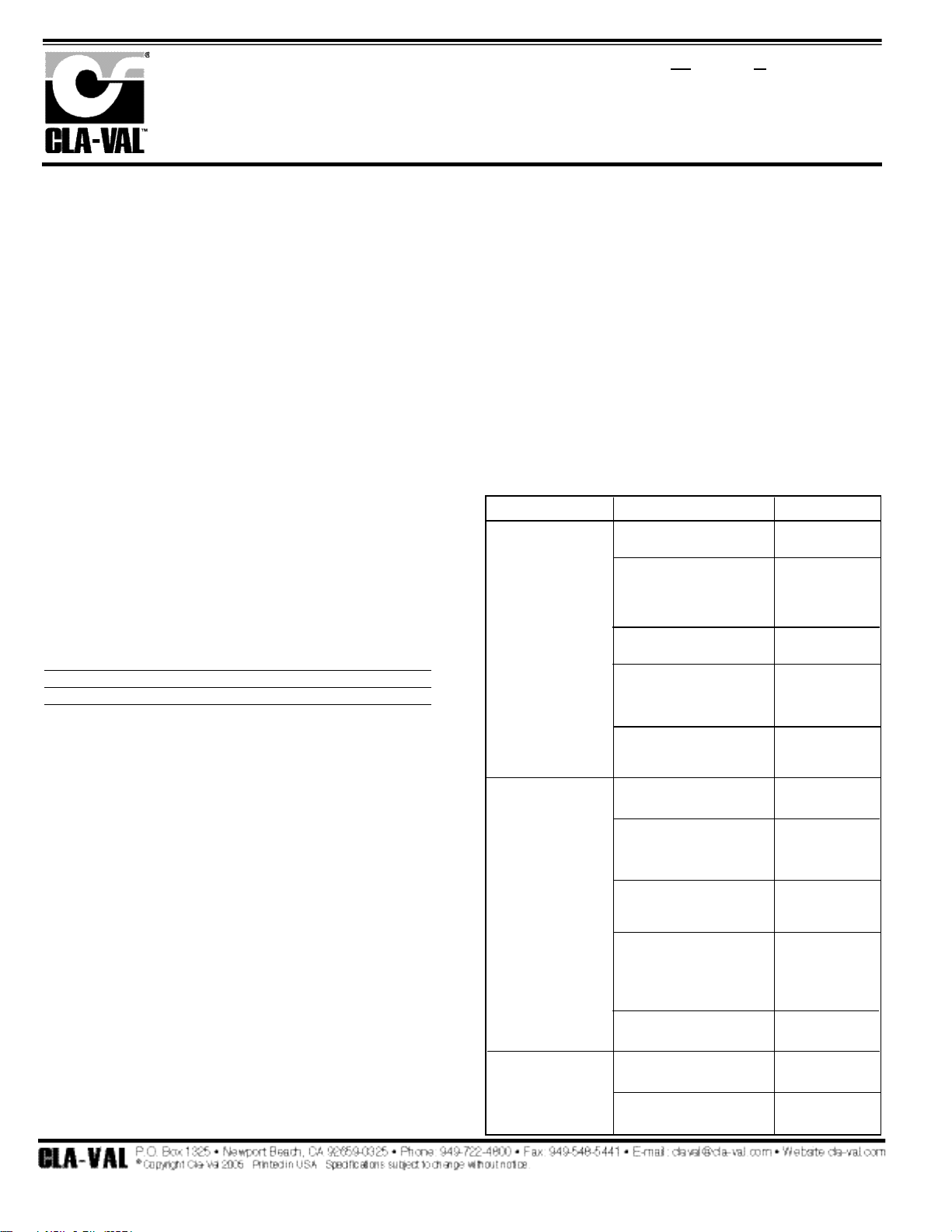

DESCRIPTION

The CRL Pressure Relief Control is a direct acting, spring loaded,

diaphragm type relief valve. It may be used as a self-contained valve or as

a pilot control for a Cla-Val Main valve. It opens and closes within very

close pressure limits.

INSTALLATION

The CRL Pressure Relief Control may be installed in any position. The

control body (7) has one inlet and one outlet port with a side pipe plug (24)

at each port. These plugs are used for control connections or gauge applications. The inlet in the power unit body (6) is the sensing line port. A flow

arrow is marked on the body casting.

OPERATION

The CRL Pressure Relief Control is normally held closed by the force of the

compression spring above the diaphragm; control pressure is applied

under the diaphragm.

When the controlling pressure exceeds the spring setting, the disc is lifted

off its seat, permitting flow through the control.

When controlling pressure drops below spring setting, the spring returns

the control to its normally closed position.

ADJUSTMENT PROCEDURE

The CRL Pressure Relief Control can be adjusted to provide a relief setting

at any point within the range found on the nameplate.

Pressure adjustment is made by turning the adjustment screw (9) to vary

the spring pressure on the diaphragm. Turning the adjustment screw clockwise increases the pressure required to open the valve. Counterclockwise

decreases the pressure required to open the valve.

When pressure adjustments are complete the jam nut (10) should be tightened and the protective cap (1) replaced. If there is a problem of tampering, lock wire holes have been provided in cap and cover. Wire the cap to

cover and secure with lead seal.

DISASSEMBLY

The CRL Pressure Relief Control does not need to be removed from the

line for disassembly. Make sure that pressure shut down is accompanied

prior to disassembly. If the CRL is removed from the line for disassembly

be sure to use a soft jawed vise to hold body during work.

Refer to Parts List Drawing for Item Numbers.

1. Remove cap (1), loosen jam nut (10) and turn adjusting

screw counterclockwise until spring tension is relieved.

2. Remove the eight screws (4) holding the cover (3) and

powerunit body (6). Hold the cover and powerunit together

and place on a suitable work surface.

See NOTE under REASSEMBLY.

3. Remove the cover (3) from powerunit body (6). The spring

(12) and two spring guides (11).

4. Remove nut (13) from stem (19) and slide off the belleville washer

(14), the upper diaphragm washer (15) and the diaphragm (16).

5. Pull the stem (19) with the disc retainer assembly (21) through the

bottom of powerunit. The lower diaphragm washer (17) will slide off

of stem top.

6. Remove jam nut (23) and disc retainer assembly (21) from stem.

Use soft jawed pliers or vise to hold stem. The polished surface of

stem must not be scored or scratched.

7. The seat (22) need not be removed unless it is damaged. If removal

is necessary use proper size socket wrench and turn counterclockwise.

Note: Some models have an integral seat in the body (7).

INSPECTION

Inspect all parts for damage, or evidence of cross threading. Check

diaphragm and disc retainer assembly for tears, abrasions or other da mage. Check all metal parts for damage, corrosion or excessive wear.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using 400 grit wet or dry

sandpaper fine emery or crocus cloth. Replace all O-rings and any damaged parts.

When ordering replacement parts, be sure to specify parts list item number and all nameplate data.

REASSEMBLY

In general, reassembly is the reverse of disassembly. However, the following steps should be observed:

1. Lubricate the O-Ring (18) with a small amount of a good grade of

waterproof grease, (Dow Corning 44 medium grade or equal).

Use grease sparingly and install O-ring in powerunit body (6).

2. Install stem (19) in powerunit body (6). Use a rotating motion with

minimum pressure to let stem pass through O-ring.

Do Not Cut O-Ring.

3. Install O-ring (5) at top of stem (19). Place lower diaphragm

washer (17) on the stem with the serrated side up. Position

diaphragm (16), upper diaphragm washer (15), with serration down,

and belleville washer (14) with concave side down.

4. Position powerunit body (6) as shown on parts list drawing (top view).

5. Continue reassembly as outlined in disassembly steps 1 through 3.

Pressure Relief Control

CRL

Note: Item (4) Screw will have a quantity of 8 for the 0-75 and 20-200psi

design and a quantity of 4 for the 100-300psi design. Item (25) Screw is

used on the 100-300psi design only. Install item (25), before item (4) for

preload of item (12) spring.

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open. Controlling pressure

too low.

Back off adjusting

screw until valve

opens.

Fails to open with

spring compression

removed.

Mechanical obstruction, corrosion, scale

build-up on stem.

Disassemble,

locate,and remove

obstruction, scale.

Leakage from cover

vent hole when controlling pressure is

applied.

Diaphragm Damage Disassembly replace

damaged

diaphragm.

Fails to close with

spring compressed.

Mechanical obstruction.

Disassemble, locate

and remove

obstruction.

Fails to close. No spring compres-

sion.

Re-set pressure

adjustment.

Loose diaphragm

assembly.

Tighten upper

diaphragm washer.

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

N-CRL (R-8/05)

Page 11

90

1/2" & 3/4" PRESSURE RELIEF CONTROL

CRL

When ordering parts please specify:

1. All Nameplate Data

2. Item Part Number

3. Item Description

CRL

RANGE PSI

A

PPROX

. I

NCREASE

FOR EACH CLOCK

-

WISE TURN OF

ADJUSTING SCREW

0 to 75 8.5 PSI

20 to 200 28.0 PSI

100 to 300 18.0 PSI

SIZE

1/2"

1/2"

1/2"

3/4"

3/4"

3/4"

SPRING

RANGE

0-75 PSI

20-200 PSI

100-300 PSI

0-75 PSI

20-200 PSI

100-300 PSI

PART

NUMBER

79222-01E

79222-02C

82809-01D

79229-01K

79229-02H

86005-01E

For 100-450 PSI Contact Factory

Body with

integral Seat

1

1A

2

3

4*

5*

6

7

8*

9

10

11

12

13

14

15

16*

17

18*

19

20*

21*

22

23

24

25*

Cap

Cap 100 to 300 psi Design

Nameplate

Cover

Screw Fil.Hd.10-32 x 1.88

0-Ring

Body, Powerunit

1/2" Body

3/4" Body

0-Ring, Seat

Screw, Adjusting

Nut Hex (Locking)

Guide, Spring

Spring,

Nut, Stem, Upper

Washer, Belleville

Washer, Diaphragm (upper)

Diaphragm

Washer, Diaphragm (lower)

0-Ring, Stem

Stem

0-Ring, Body

Retainer Assembly, Disc

Seat

Nut, hex, Stem, Lower

Pipe Plug

Screw Fil.Hd, 10-32 x 2.25 (Qty 4 on 100-300 psi)

FACTORY SET POINT

REPAIR KIT*

Plastic

Plastic

Brass

Bronze

303 SS

Rubber

Bronze

Bronze

Bronze

Rubber

Brass

303 SS

303 SS

CHR/VAN

Bronze

Steel

303 SS

Rubber

303 SS

Rubber

303 SS

Rubber

303 SS

303 SS

Bronze

Bronze

303 SS

0-75

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71884B

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

50 PSI

9170007A

20-200

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71885J

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

60 PSI

9170007A

100-300

1257601D

1257601D

--

44587E

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

1630301J

1630201A

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

100 PSI

9170007A

Item Material Part Number

Part Number

Part Number

Description

PL-CRL (R-12/05)

PARTS LIST

Page 12

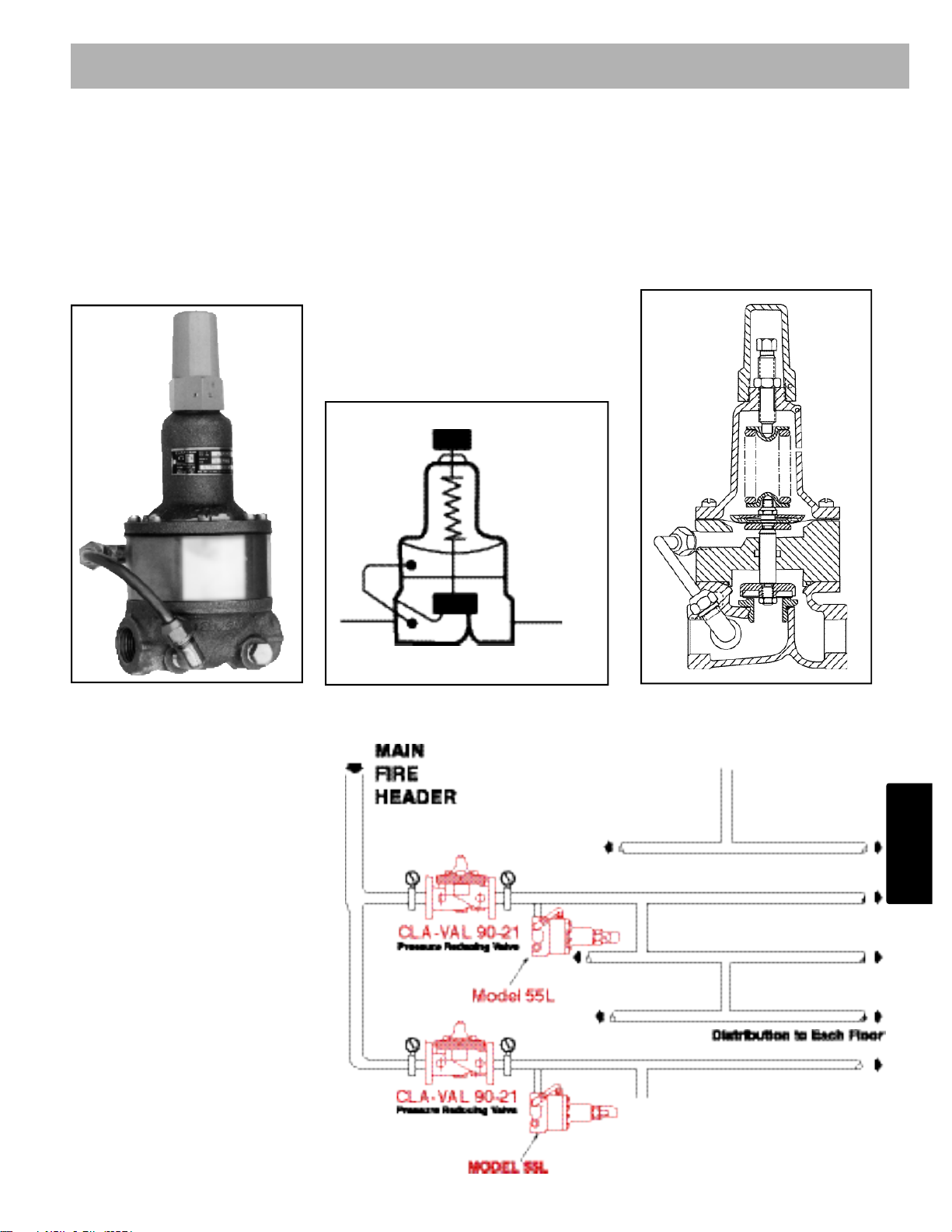

91

55F – Cla-Val Relief Pilot with external mounted sense line

The Cla-Val 55F pilot is a Normally Closed pilot that shifts to Open on rise in sensed pressure. It is

like the CRL but has an extra feature; sense tubing is connected from the inlet of the pilot to the

sensing port of the pilot. The 55F is often used as a stand-alone direct acting pressure relief valve.

OUTIN

55F/55L

55F

55F/55L

Fire Protection System Service

Using the Model 55L in a fire protection system or other closed type

system, prevents pressure build-up

whenever line pressure exceeds the

setting of the spring. The valve will

relieve excess pressure to atmosphere preventing damage to the

distribution network.

Typical Applications

2

–

1

Normally Closed - Shifts to open

on rise in sensed pressure

Adjustment Ranges

0-75,20-200,100-300 psi

Maximum Working Pressure 400 PSI

Schematic Symbol

Pilot Controls

Section 2 - 1

Page 13

92

CRL & 55F

Pressure Relief Valves

Dimensions

(In Inches)

55F Model

MODELS

• Direct Acting - Precise Pressure Control

• Positive Dependable Opening

• Drip Tight Closure

• No Packing Glands or Stuffing Boxes

• Sensitive to Small Pressure Variations

The Cla-Val Model CRL and 55F Pressure Relief Valves are direct-acting, spring loaded, diaphragm type relief valves. Often used as pilot controls for Cla-Val Hytrol valves, they can also be used as self-contained

pressure relief valves. These valves may be installed in any position and

open and close within very close pressure limits.

The Model CRL and 55F are normally held closed by the force of the

compression spring above the diaphragm. Control pressure is applied

under the diaphragm. When the controlling pressure exceeds the spring

setting, the disc is lifted off its seat, permitting flow through the control.

When control pressure drops below the spring setting, the spring forces

the control back to its normally closed position. The controlling pressure

is applied to the chamber beneath the diaphragm through an external

tube on the Model 55F and a sensing port on the CRL.

Pressure adjustment is simply a matter of turning the adjusting screw to

vary the spring pressure on the diaphragm. The CRL & 55F

are available in three pressure ranges: 0 to 75 psi, 20 to 200 psi, and

100 to 300 psi. To prevent tampering, the adjustment cap can be wire

sealed by using the lock wire holes provided in the cap and cover.

Note: Also Available in Seawater Service Material

Page 14

93

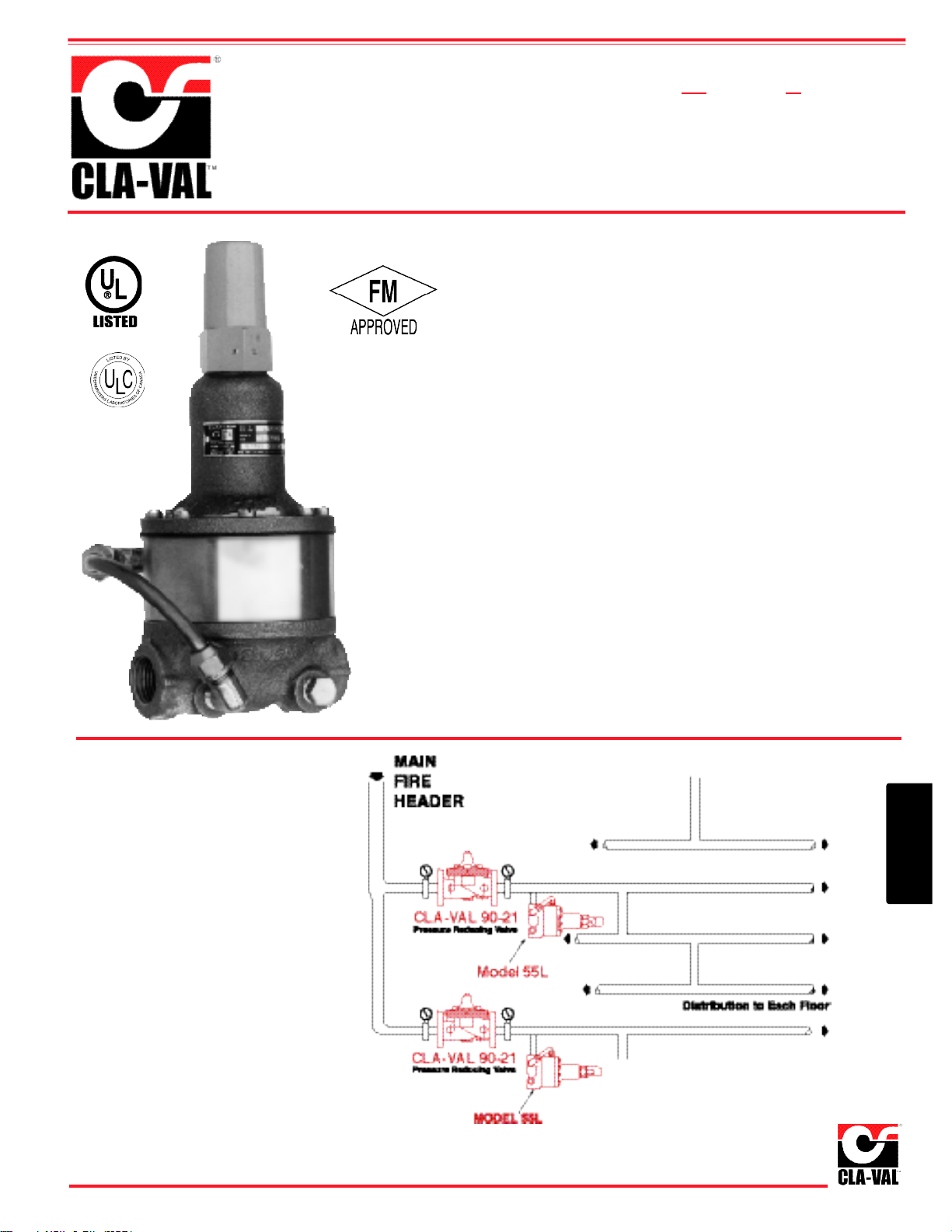

Fire Protection System Service

Using the Model 55L in a fire protection system or other closed type

system, prevents pressure build-up

whenever line pressure exceeds the

setting of the spring. The valve will

relieve excess pressure to atmosphere preventing damage to the

distribution network.

55L

Pressure Relief Valve

Typical Applications

• UL Listed

• Factory Mutual Approved

• Direct Acting - Precise Pressure Control

• Positive Dependable Opening

• Drip Tight Closure

• No Packing Glands or Stuffing Boxes

• Sensitive to Small Pressure Variations

The Cla-Val Model 55L (UL Listed FM approved) Pressure Relief Valve

is a direct-acting, spring loaded, diaphragm type relief valve. The valve

may be installed in any position and will open and close within very close

pressure limits.

The Model 55L is normally held closed by the force of the compression

spring above the diaphragm. When the controlling pressure applied

under the diaphragm exceeds the spring setting, the disc is lifted off its

seat, permitting flow through the control. When control pressure drops

below the spring setting, the spring forces the control back to its normally closed position. The controlling pressure is applied to the chamber

beneath the diaphragm through an external tube on the 55L.

Pressure adjustment is simply a matter of turning the adjusting screw to

vary the spring load on the diaphragm. The 55L is available in two pressure ranges; 0 to 75 psi, 20 to 200 psi. To prevent tampering, the adjustment cap can be wire sealed by using the lock wire holes provided in the

cap and cover.

Note: Also Available in Seawater Service Material

MODEL

2

–

1

Page 15

94

Note:

See E-X140 Locking Security Cap

S i z e 1/2" & 3/4" T h r e a d e d

Temperature Range Wa t e r , Air: to 180°F Max.

M a t e r i a l s

Body & Cover: Cast Bronze ASTM B62

Cast Aluminum 356-T6

Stainless Steel ASTM A 7 4 3 C 7 - 1 6 7 A

Tr i m : Brass & Stainless Steel 303

R u b b e r : B u n a - N®Synthetic Rubber

Pressure Ratings Cast Bronze 400 psi Max.

Cast Aluminum 275 psi Max.

Stainless steel 400 psi Max.

Other Materials Available on special order

Adjustment Ranges 0 t o 75 psi

2 0 t o 200 psi

1 0 0 t o 300 psi

When Ordering, Please Specify

1. Catalog No. CRL & 55F 2. Valve Size 3. Adjustment Range Desired 4. Optional Materials 5.Optional Security Cap

Specifications

Flow Loss Chart (Full Open Valve)

CRL Basic Valve Dimensions

(In Inches)

100 to 300 psi Design

CRL & 55F Approximate Increase

Range For Each Clockwise Turn

PSI Of Adjusting Screw

0 to 75 8.5 psi

20 to 200 28.0 psi

100 to 300 18.0 psi

5 10 15 20 30

1/2" 6 0.7 2.7 6 11

3/4" 8.5 0.3 1.4 3.1 5.5

Valve

Size

C

v

Factor

Flow of Water - gpm

E-CRL/55F (R-6/06)

Represented By:

0 to 75 and 20 to 200 psi Design

X140-1

Locking

Security

Cap

OPTIONAL X140 SECURITY CAP

• Controlled Security for Pilot Control Adjustment

• Long Life Stainless Steel Construction

• Tamper-Resistant Design

• X140 Customer Supplied Padlock

• X140-1 Key and Six Pin Cylinder Lock Supplied

Page 16

95

OUTIN

CDHS18

CDHS18

CDHS18

CDHS-18 Differential Control Valve

is a normally open, spring loaded, diaphragm type valve that operates hydraulically and is designed

to close on a rising differential pressure. When used as a pilot control with Cla-Val Valves, it acts as a

flow limiting control.

CDHS18

40-01/640-01

2

–

1

Sensing Line

Schematic Symbol

Pilot Controls

Normally Closed - Shifts to open

on rise in sensed pressure

Adjustment Ranges

30-480 psi differential

Page 17

96

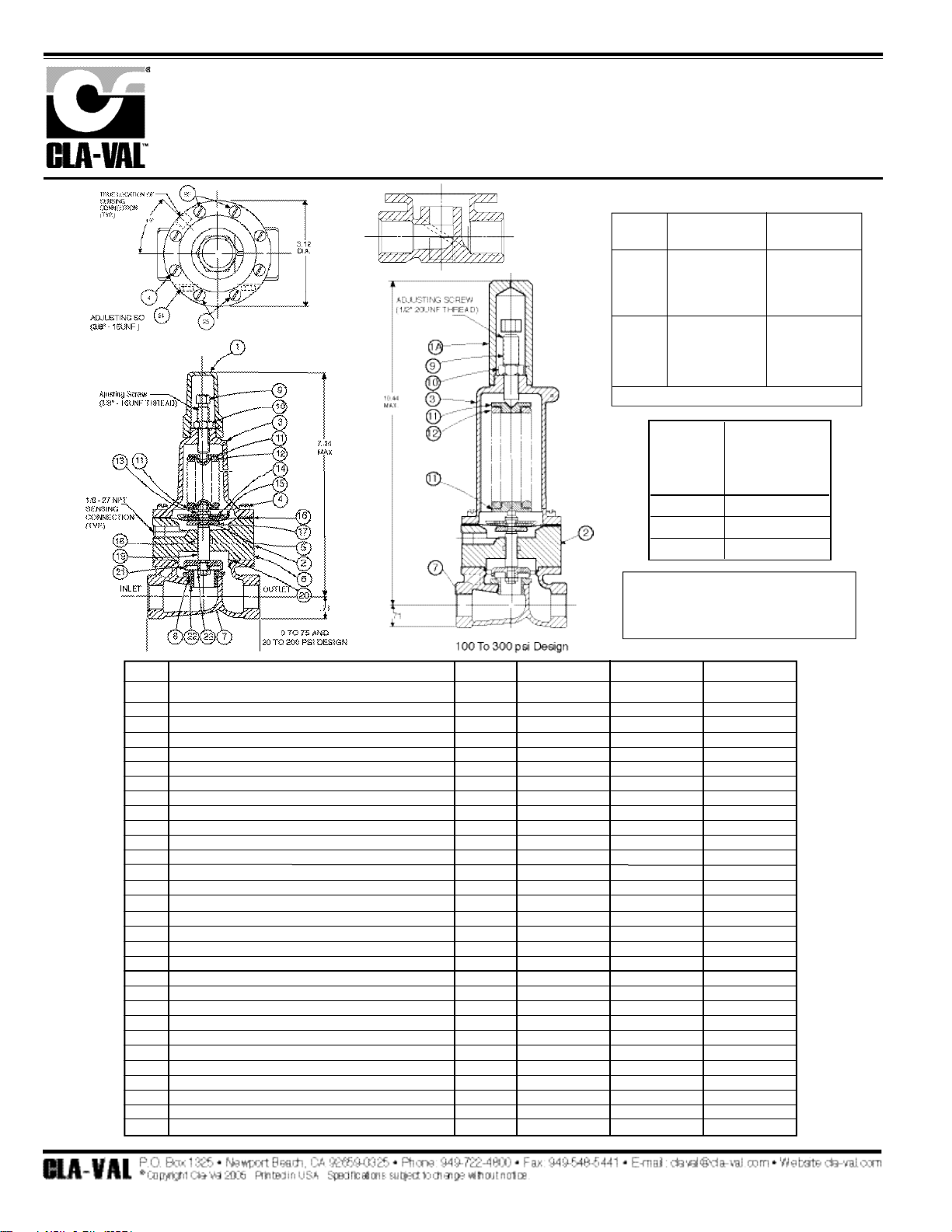

DESCRIPTION

The Cla-Val CDHS-18 Differential Control Valve is a normally open, spring

loaded, diaphragm type valve that operates hydraulically and is designed

to close on a rising differential pressure. When used as a pilot control with

Cla-Val Valves, it acts as a flow limiting control.

INSTALLATION

The Differential Control may be installed in any position. There is one in l e t

port and two outlet ports in the body for either straight or angle ins t a l l a t i o n .

The outlet port senses the high pressure or inlet to the differential p r o d u c i n g

device. One of the outlet ports can be used for a gauge connection.

The port above the diaphragm (located in the control cover) is used to

sense the low pressure or outlet side of the differential producing device. A

flow arrow is marked on the body casting.

OPERATION

The Differential Control is normally held open by the compression spring

and the sensing pressure above the diaphragm. When the rate of flow

through the main valve increases, the sensing pressure above the

diaphragm of the control decreases and the higher pressure at the outlet

port closes the control; which, in turn, closes the main valve. When the

rate of flow through the main valve decreases, the sensing pressure

above the diaphragm increases. This opens the control and in turn opens

the main valve. This action causes the main valve to modulate, limiting the

flow rate to the setting of the control.

ADJUSTMENT

The Differential Control Valve can be adjusted to limit the rate of flow as

specified on the data plate. Rate of flow adjustment is made by turning the

adjustment screw to vary the spring pressure on the diaphragm. The

greater the compression on the spring the higher the flow rate.

1. Turn the adjustment screw in (clockwise) to increase flow rate.

2. Turn the adjustment screw out (counterclockwise) to decrease flow rate.

DISASSEMBLY

The Differential Control Valve should be removed from the Hytrol Valve

assembly. Make sure that pressure shutdown is accomplished prior to disconnecting assembly. During disassembly inspect all threads for damage

or evidence of cross-threading.

NOTE: A bench vice equipped with soft brass jaws should be used to hold

the valve body during disassembly and reassembly. DO NOT t i ghten vice

jaws more than enough to hold unit firmly. Excessive pressure may spring

or crack casting

1. Remove adjusting screw cap (16).

2. Loosen lock nut on adjusting stem assembly (9) and turn

adjusting screw counterclockwise to relieve tension on spring.

3. Remove bottom plug (8) and gasket (6).

4. Remove disc retainer assembly (5) and inspect sealing surface for

damage or wear. Replace if necessary.

5 Remove 8 screws (12) and carefully Iift off cover (2) spring guide (10)

and spring (13) can now be removed.

6. Remove diaphragm assembly.

7. Remove diaphragm nut (7) and diaphragm washer (4).

8. Remove diaphragm (3), inspect for damage and replace if necessary.

9. Inspect all parts for damage, corrosion, wear, foreign particles, and

cleanliness.

10. Repair minor nicks and scratches, these may be polished out

using a fine grade of emery or crocus cloth.

REASSEMBLY

Prior to reassembly replace all parts which are damaged or worn. When

ordering replacement parts be sure to specify item, part number, and all

nameplate data.

1. Place diaphragm (3) on top of yoke (11) place diaphragm

washer (4) over diaphragm with rounded edges down or next

to diaphragm. Screw on diaphragm nut (7) with the spring

guide shoulder in up position. The nut is not tightened at this time.

2. Align diaphragm flange holes with and folding diaphragm as

shown. Tighten diaphragm nut, retaining alignment shown.

3. Place yoke assembly in body (1) and screw the disc retainer

assembly (5) in until it bottoms.

4. Screw in plug (8).

NOTE: The yoke arms can be viewed through the 3/8" NPT

high pressure sensing outlet. There should be even spacing

between the yoke arms and the 3/8' NPT inlet boss seat

assembly. There must be no drag or friction between these

parts. If there is drag, repeat step 2.

5. Align diaphragm flange holes with the body holes and position

spring and spring guide (13) (10).

6. Replace cover (2) and secure with 8 screws (12).

7. Remove plug (8) and turn adjusting screw clockwise until the

disc retainer assembly moves down.

8. Replace gasket (6) and plug (8).

9. Replace cap (16).

3/8" Differential Control

CDHS-18

F

AILS TOOPEN

C

ONTROLLING DIFFERENTIAL

NOT CHANGING

C

HECK WITH GAUGE OR

MANOMETERS

D

IAPHRAGM ASSEMBLY STUCK

CLOSED

D

ISASSEMBLE AND FREE

F

OREIGN OBJECT UNDER

DISC RETAINER

D

ISASSEMBLE AND REMOVE

F

AILS TOCLOSE

I

NSUFFICIENT CONTROLLING

DIFFERENTIAL

I

NCREASE DIFFERENTIAL

F

OREIGN OBJECT UNDER

DISC

D

ISASSEMBLE AND REMOVE

DISPHRAGM ASSEMBLY STUCK

OPEN

D

ISASSEMBLE AND FREE

D

AMAGED DIAPHRAGM

D

ISASSEMBLE AND REPLACE

S

PRING COMPRESSED SOLIDBACK OFF ADJUSTING STEM

SYMPTOM PROBABLE CAUSE REMEDY

N

O SPRING COMPRESSIONSCREW IN ADJUSTING STEM

SERVICE SUGGESTIONS

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

N-CDHS-18 (R- 1/06)

Page 18

97

CDHS-18

3/8" Differential Control

I

TEM

DESCRIPTION MATERIALS PART NUMBER LIST PRICE

1 Body & Seat Assembly BFR/SS 83397-02G

2 Cover BRZ C6657F

3 Diaphragm Buna N

®

C6936JD

4 Diaphragm Washer BRS C1803A

5 Disc Retainer Assembly BRS/RB C5256H

6 Gasket FIB 40174F

7 Diaphragm Nut BRS V5911C

8 Plug, Body BRZ V5653A

9 Adj. Stem Assembly BZ/SS C2002J

10 Spring Guide 303 C1510B

11 Yoke BRZ V6951H

12 Mach. Screw Fil. Hd. (8) SS 67578-21B

13 Spring 316SS 36773A

14 Nameplate BRS C002201G

15 Nameplate Screw — —

16 Cap, Adj. Screw PLS 12576-01D

MATERIAL: BRONZE BODY

B

ODY

S

IZE

S

EAT

S

IZE

S

TOCK

N

UMBER

3/8" 1/4 68017

3/8" 1/4 69597*

*Same as 68017 except cover at 90°

STAINLESS TRIM

*

*

*

*

Repair Parts Kits*

Standard

High Temp.

Viton

®

9170003K

9170009G

Part Number

Buna-N

®

PL-CDHS-18 (R-5/05)

PARTS LIST

2

–

1

Page 19

98

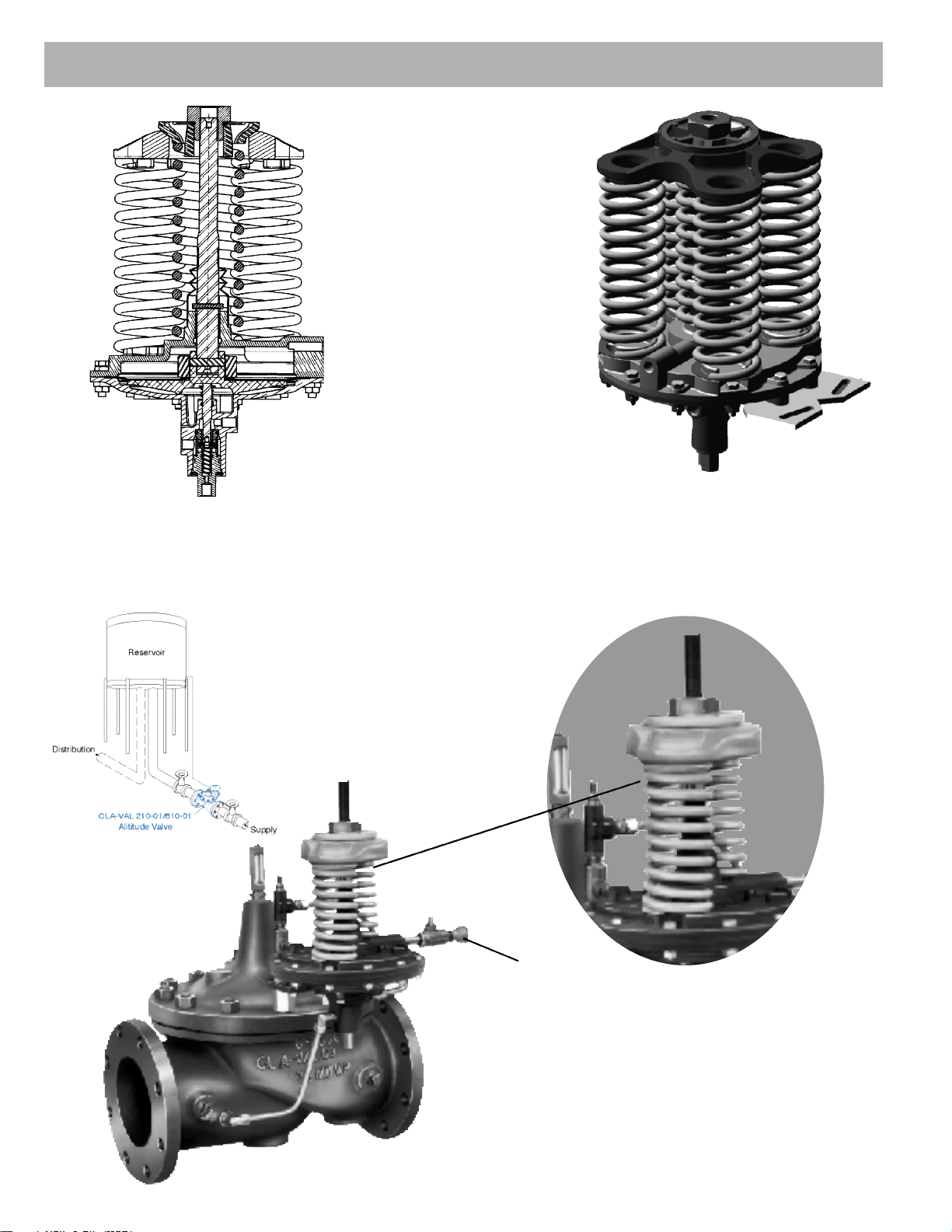

CDS6 Altitude Pilot Control

is a spring-loaded, three-way, diaphragm-actuated control that provides high-level shutoff for Cla-Val

210 Series Altitude Control Valves. The CDS6 controls the high water level in a reservoir or tank without the need for floats or other devices.

CDS6

CDS6

Connection to tank

210-01

Pilot Controls

Section 2 - 1

CDS6

Assembly

Drawing

Altitude Range

5-40 Ft

30-80 Ft

70-120 Ft

110-160 Ft

150-200 Ft

Spring Ranges

5-40 Ft

30-80 Ft

70-120 Ft

110-160 Ft

150-200 Ft

Page 20

99

INTRODUCTION

The Cla-Val Model CDS6 Altitude Control is a spring loaded, 3-way,

diaphragm-actuated control that provides high-level shut-off for Cla-Val

Altitude Control Valves. It remotely senses pressure in the reservoir or

tank. There are five altitude ranges available, 5 to 40 feet, 30 to 80 feet,

70 to 120 feet, 110 to 160 feet and 150 to 200 feet. The spring adjusting

nut can be set to stop flow into the reservoir within these ranges.

INSTALLATION

The CDS6 Altitude Pilot Control is normally supplied mounted on a

Cla-Val 210 Series Altitude Valve which should be installed in a horizontal run of pipe with the main valve cover up. Two line block valves are

recommended for valve servicing. If the CDS6 is mounted from the main

valve by a few feet, then it must be installed with adjustment springs up

for ease of adjustment and servicing. Consult factory for recommendations.

After the Cla-Val 210 Series Altitude Valve is installed in the pipeline

close to the reservoir, install the required remote sensing line from the

CDS6 to the reservoir or tank. The sensing line allows the CDS6 to

sense the static pressure head of the reservoir. The sensing line should

not be installed in the flowing line between the valve and the reservoir or

into turbulent flow area. These locations do not reflect the true static

head of the reservoir.

The remote sensing line should be 3/4" or larger copper tubing or

Schedule 40 PVC pipe. Galvanized pipe is not recommended. The sensing line should slope (minimum 2 degrees) upward from the CDS6

toward the reservoir to self -purge air out of the line. The sensing line

should have no high points to entrap air. A shutoff valve at the reservoir

connection is recommended. For above ground reservoirs, the connecting point for the sensing line should be a minimum of 12" to 18" above

reservoir bottom (if filling from bottom) or at fill pipe connection (if filling

from side). Minimum high-level set-point adjustment is approximately

five feet above the remote sensing point of connection.

OPERATION, START-UP AND ADJUSTMENT

When the reservoir pressure (head) is lower than the set point of the

spring on the CDS6 Altitude Control ports "1" and "D" are interconnected. This relieves the main valve cover pressure to atmosphere. Line

pressure then opens the main valve to start filling the reservoir.

Reservoir sensing pressure increases as the liquid level rises in the

reservoir. When the sensing pressure increases to the set point of the

CDS6 control spring, the control shifts interconnecting port "S" and port "1".

This pressurizes the main valve cover chamber and the main valve closes.

By turning the adjusting nut the liquid level shutoff point will be changed.

Turn the adjusting nut clockwise to raise the liquid level shutoff point;

counterclockwise to lower the liquid level shutoff point. Follow the general operation and start-up instructions regarding purging air from the

valve control system.

MAINTENANCE AND INSPECTION

Under normal operating conditions the CDS6 Altitude Control will be

trouble free. There is a visual check possible to determine if there is

damage to the diaphragm in the control. The Lower Cover/Pilot (a) is

vented to atmosphere by means of a small hole in the wall of the casting. If water is discharging out of this opening, the diaphragm should be

inspected for damage.

One other visual check and indication of a problem is continuous discharge from the drain port ("D") at the bottom of the CDS6.

The volume of drained water will vary according to the valve size.

Continuous draining after main valve has fully opened will indicate a

problem. Refer to the service suggestions to check for probable causes

and remedies.

DISASSEMBLY

During preventive maintenance or service to the CDS6 Altitude Control,

all pressure to the control must be shutoff. The CK2 shutoff isolation

valves in the main valve control lines should be closed before starting

disassembly. Main valves 4" and larger have CK2 isolation valves

installed, however main valves smaller than 4" normally do not, therefore

requiring closure of shutoff valves in the main line at the valve inlet and

outlet. The shutoff isolation valve or valve in the sensing line to the reservoir must also be closed.

WARNING: Failure to shutoff and release pressure prior to any

disassembly can result in serious damage to equipment or

injury to personnel.

1. Disconnect tubing at the CDS6 Altitude Control.

2. Remove two mounting caps screws and two lock washers.

3. Remove CDS6 Altitude Control from main valve to work bench or

clean area. Parts must be kept clean.

DISASSEMBLY OF UPPER SPRING SECTION

1. Unscrew adjusting nut (4) from upper stem (5).

NOTE:

Count the number of turns required to remove the nut (4),

record this information for reference when reassembling.

The CDS6 Altitude Control can then be approximately reset for the

same reservoir liquid level shut-off point.

2. Remove the thrust washer (3), swivel retainer (2) and spring

retainers if applicable.

3. Remove Spring(s) (6), bellows (7) and set-screw (8)

4. Remove twelve hex nuts (33), and twelve bolts (32), and set

mounting bracket (29) aside.

Note:

Assembly contains two (of twelve) longer bolts

which are used for the mounting bracket.

ALTITUDE CONTROL

CDS6

29330-06F

29330-07H

29330-08K

29330-09B

29330-10D

CDS6 STOCK

NUMBER

2" SIZE

CDS6 STOCK

NUMBER

2 1/2" SIZE &

LARGER

29330-01E

29330-02G

29330-03J

29330-04A

29330-05D

ALTITUDE

RANGE

(FT H20)

5 - 40

30 - 80

70 - 120

110 - 160

150 - 200

NUMBER

OF

SPRINGS

1

2

3

4

5

0.32

0.64

0.96

1.28

1.60

0.75

1.50

2.20

3.00

3.70

ALTITUDE

CHANGE

PER TURN

PSI

CHANGE

PER TURN

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

2

–

1

Page 21

100

SERVICE SUGGESTIONS

UPPER (SPRING) SECTION

SYMPTOM PROBABLE CAUSE REMEDY

Vent leaks in Diaphragm (14) damaged Replace diaphragm

lower cover (17) Diaphragm nut (12) loose Tighten nut (12)

O-ring (20) damaged Replace O-ring (20)

Leakage past stem O-ring (10) damaged Replace O-ring

stem (5)

Stem (5) move- *Sand or silt in sensing Remove foreign matter

ment restricted chamber above from sensing chamber

or erratic diaphragm

Sensing line clogged Clean line

Sensing line valve closed Open valve fully

Sensing line sagging or Straighten and

bent collecting sediment support sensing line

to reservoir

Sensing line has high Straighten sensing line.

point trapping air in Must slope upward

the line from altitude control

to the reservoir

*NOTE: if this problem occurs, a sand trap should be

installed in the sensing line, or the line moved to a point

on the reservoir where sand or silt cannot enter this line.

SERVICE SUGGESTIONS

LOWER (PILOT VALVE) SECTION

SYMPTOM PROBABLE CAUSE REMEDY

Vent in lower O-ring (20) worn or Replace O-ring (20)

cover (17) leaks damaged. See Upper Spring

Section service suggestion

Flow from supply Clogged strainer screen (25) Remove screen and

port to clean

valve cover port Silt packed in seat (24) Clear area of blockage

restricted and lower stem (21)

Continuous Seat (24) damaged Inspect and replace

drain leak. Main

valve closed Disc in poppet assembly Inspect and replace

(22) damaged poppet assembly

(22)

Foreign object between Remove object

disc and seat (24)

O-ring (20) in poppet Replace O-ring

guide (28) damaged

Continuous Main valve Service main

drain leak. diaphragm worn valve. Replace

Main valve or stem nut loose diaphragm or

open tighten stem nut

5. Thread and securely fasten poppet guide assembly into lower cover

(recommended 200-250 in/lbs.)

6. Turnover lower cover, and assemble as an assembly lower stem

(21) retainer (18) and spring (19) into lower cover, being careful not

damage o-ring (20).

COMPLETING ASSEMBLY

1. Reassembly of twelve nuts (33) and bolts (32) should be torqued to

200-250 in/lbs. Note: assembly contains two longer bolts (item 32)

for the support bracket. These two bolts are to be assembled with

bracket (29) on the two larger support flats located on the lower

cover located 90 degrees from common/supply ports.

3. Install CDS6 Altitude Control assembly on main valve.

4. Replace tube lines and fittings exactly as removed.

5. Remove upper cover (13) from lower assembly, and push stem

assembly through.

6. Remove diaphragm washer nut (12), diaphragm nut washer (16) and

diaphragm (14)

7. Separate upper stem from diaphragm washer by removing stem

retaining pin. (11)

8. Inspect all parts for damage, wear and mineral deposits.

Check O-ring (10) for wear, inspect and remove any deposit in O-ring

area. Also inspect diaphragm for wear or cracks. Clean parts

thoroughly and replace damaged parts as necessary. If, upon

disassembly, sand and silt are found in the CDS6 Altitude Control,

every effort must be made to eliminate this problem. Filters, or

relocating the reservoir sensing line may be required if deposits are

found in the sensing chamber of the control.

REASSEMBLY OF UPPER SPRING ASSEMBLY

1. Reassembly is in general, the reverse of disassembly. NOTE: A light

coating of Dow Corning 33 grease, or equivalent, should be

applied to CDS6 Altitude Control stems (5), before reassembly.

2. When replacing adjusting nut (4) tighten the same number of

turns as referred to in note in paragraph (1) of "Disassembly Of

Upper Spring Section".

DISASSEMBLY OF LOWER PILOT VALVE SECTION

1. Disassemble control per steps 1 through 5 in "Disassembly of upper

section", to work on lower (pilot) cover (17)

2. Remove lower stem (21) spring (19) and retaining ring (18) as an

assembly, inspect stem for damage.

3. Remove Poppet guide (28) and o-ring (27) from lower cover (17).

4. Remove Poppet (22-1) and poppet spring (26) and inspect poppet

and disc for damage.

5. Remove Strainer screen (25)

6. Remove seat (24), Note: be sure not to nick or ding exposed sealing

surface. To prevent binding and damage, use a wood dowel to

evenly tap out the seat from TOP of lower cover (area from which

lower stem was removed).

7. Inspect all parts for damage, wear and mineral deposits. If there

has been discharge from vent hole, remove o-ring (20) from lower

cover (17) and poppet guide (28). Inspect o-rings for wear or

damage and o-ring groove for material build-up. Clean and/or

replace as necessary. Inspect seat (24) and disc poppet assembly

(22) for wear or damage. If poppet and/or disc are damaged they

must be replaced as an assembly (item 22). Otherwise clean and

polish surfaces of moving parts with 600 wet/dry sandpaper. Also

clean strainer screen (25) of any deposits

REASSEMBLY OF LOWER PILOT VALVE SECTION

1. Reassembly is in general, the reversal of disassembly. Note: A light

coating of Dow Corning 33 grease, or equivalent should be applied

to all o-rings and moving part surfaces (20,21,22-1 23 and 27).

2. Lay lower cover (17) on its top (do not damage serrated surface),

insert the seat (24) with o-ring (23) in lower (pilot) cover with finger.

Use a wood dowel to push the seat in fully with hand pressure

ONLY. Note: damage to the seat can compromise the sealing

ability of the control, and careful efforts must be applied on

reassembly of this component.

3. Insert strainer (25).

4. Install poppet guide, o-ring, spring and poppet assembly.

(See Note #1 for greasing)

N-CDS6 (R-5/05)

Page 22

101

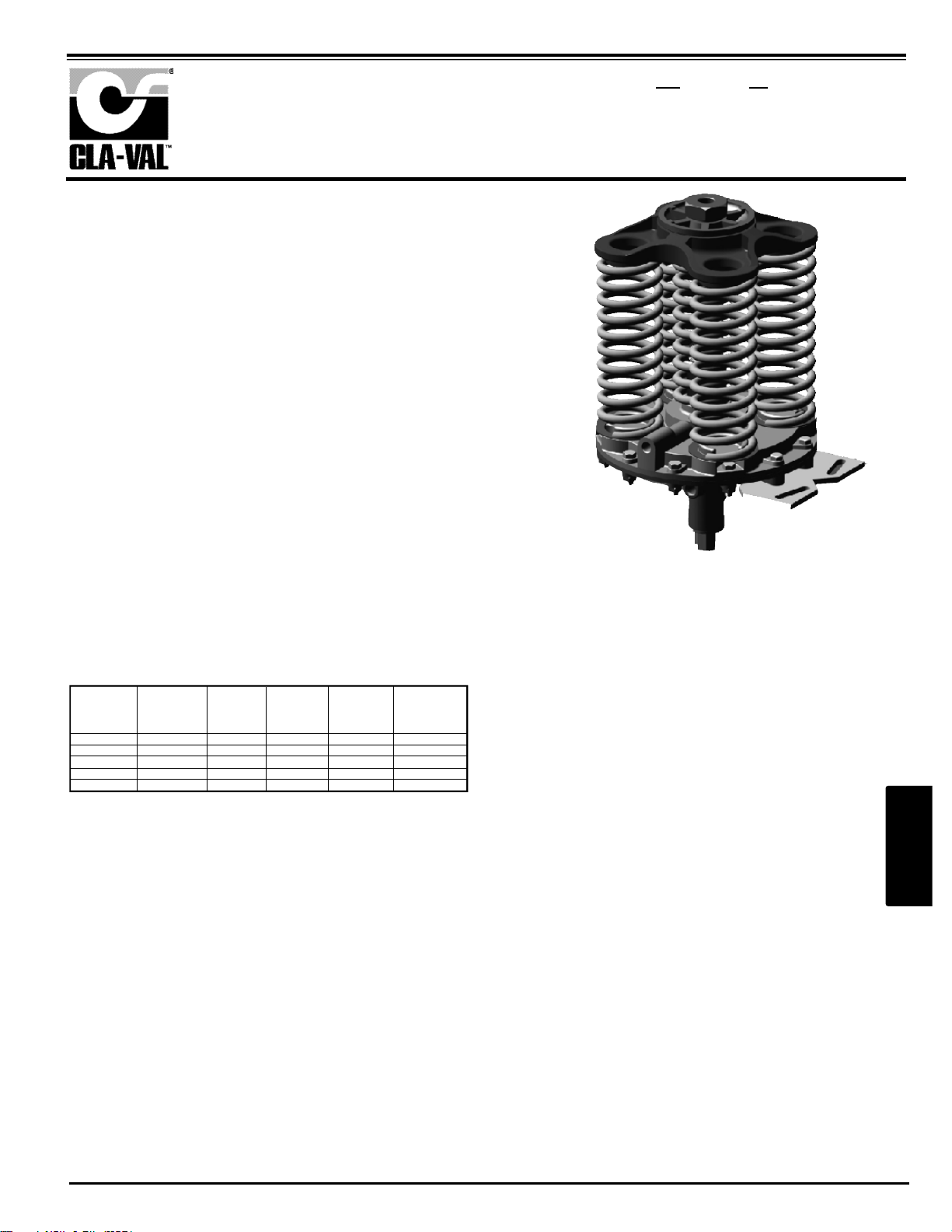

CDS6 Improvements

Recently, our Engineering Department redesigned a few internal parts of the CDS6 Pilot Control

used on 210 Series Altitude Valves. These new parts improve its sensitivity at high differential pressures and allow it to work with inlet supply pressures up to 300 psi (previous maximum recommended pressure was 150 psi). The new control is identified as CDS6A and new part numbers are

assigned to distinguish it from the original CDS6. Adjustment ranges remain the same.

New parts inside the CDS6A are a) stem seals, b) disc and poppet assembly, c) lower stem, d)

lower cover, e) poppet guide, and f) poppet spring. The CDS6A uses new low-friction seals on the

lower stem and the disc and poppet assembly. Also, the new stem and poppet have a special lowfriction nickel-Teflon coating and are dimensionally interchangeable with CDS6 parts. The new

lower cover and poppet guide have larger internal dimensions for the new seals and are not interchangeable with CDS6 parts. Also, the poppet spring has a heavier load and is not interchangeable. All other parts remain the same.

All bills of material for top assemblies using the CDS6 have been changed to the new control. It will

take some time for us to change assembly drawings and deplete existing parts before we begin

using the CDS6A. We plan to finalize the change during first quarter of 2003.

A new CDS6A repair kit is p/n 20349401C and will not work with existing CDS6 controls. The repair

kit will include instructions and tools to install new stem seals. When servicing existing CDS6 controls the current repair kit p/n 20119301A should be used.

A modification kit consisting of all new parts and instructions is p/n 20354801G. Field modification is

recommended only for installations where it is determined to be necessary.

Range (ft) size p/n size p/n

5 - 40 2 _" & larger 20354701K 2" & smaller 20354706E

30 - 80 2 _" & larger 20354702J 2" & smaller 20354707D

70 - 120 2 _" & larger 20354703H 2" & smaller 20354708C

110 - 160 2 _" & larger 20354704G 2" & smaller 20354709B

150 - 200 2 _" & larger 20354705F 2" & smaller 20354710J

Technical Bulletin

2

–

1

April 2 2003

Page 23

102

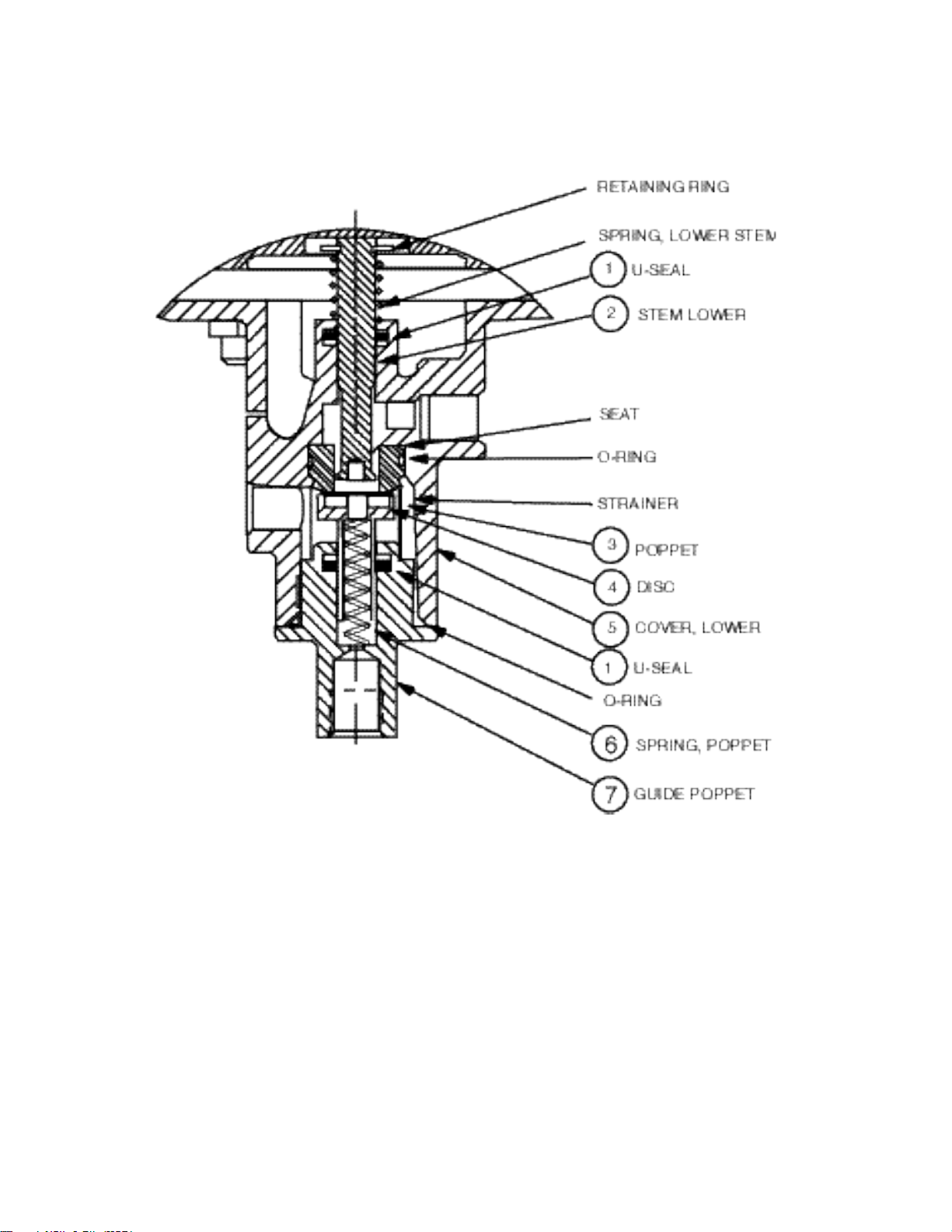

NEW CDS6A PARTS ARE ABOVE NUMBERED ITEMS.

A) All other parts are the same as current CDS6 parts.

B) Two new low-friction U-Seals, Item 1, will not fit into O-ring grooves of CDS6 lower cover and

poppet guide. The machined groove dimensions are different between the O-ring version and the

new U-seal version parts. New Lower Cover, Item 5, and Poppet Guide, Item 7, have proper

dimensions for U-Seal.

C) Lower Stem, Item 2, and Poppet, Item 3, are dimensionally interchangeable with CDS6 parts

that are now obsolete. These new parts have a special low-friction coating which may enhance

CDS6 performance.

D) Poppet Spring, Item 6, has a heavier load rating and is not interchangeable with CDS6 poppet

spring. Sensitivity will be greater than a 12" differential, if used in CDS6 controls.

Page 24

103

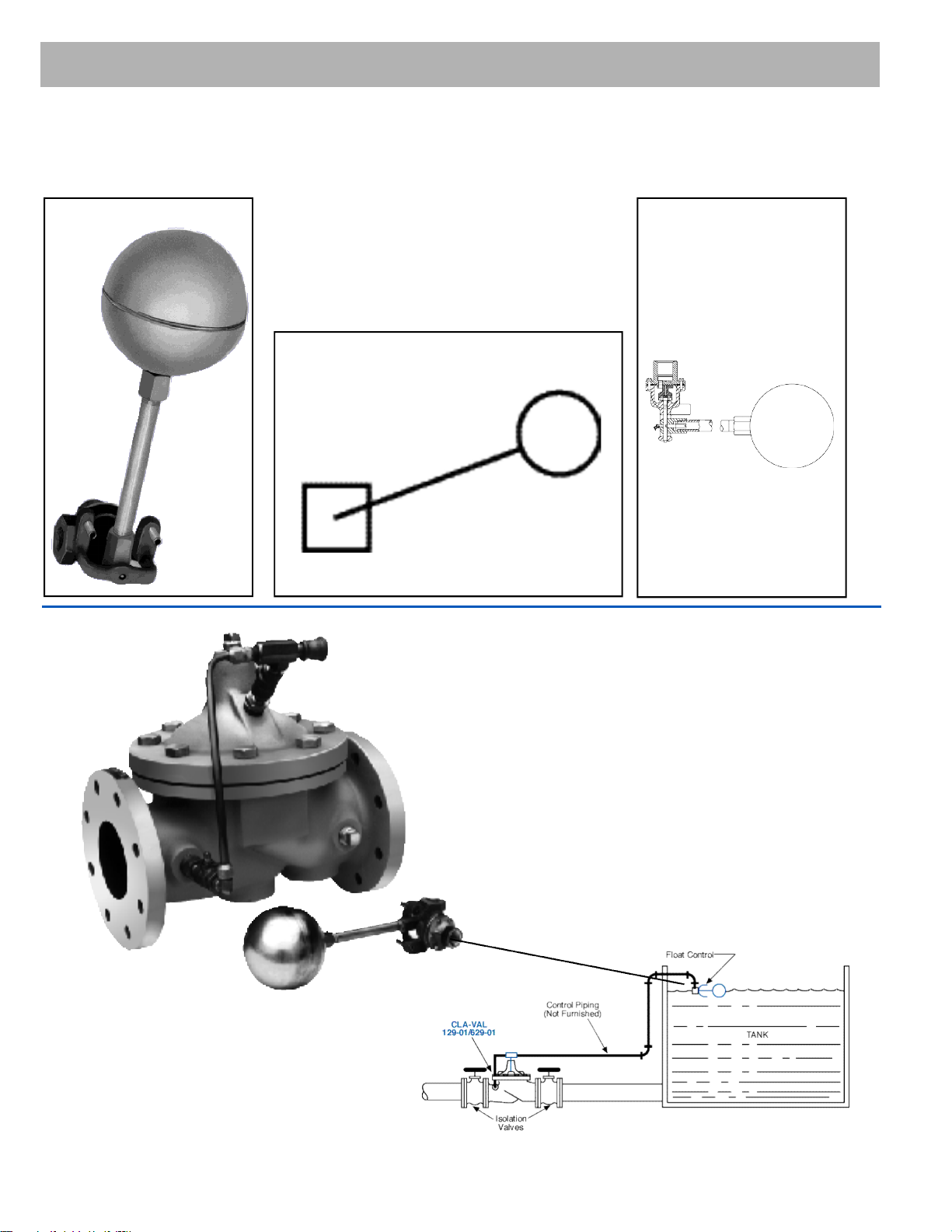

CF1-C1

CF1-C1

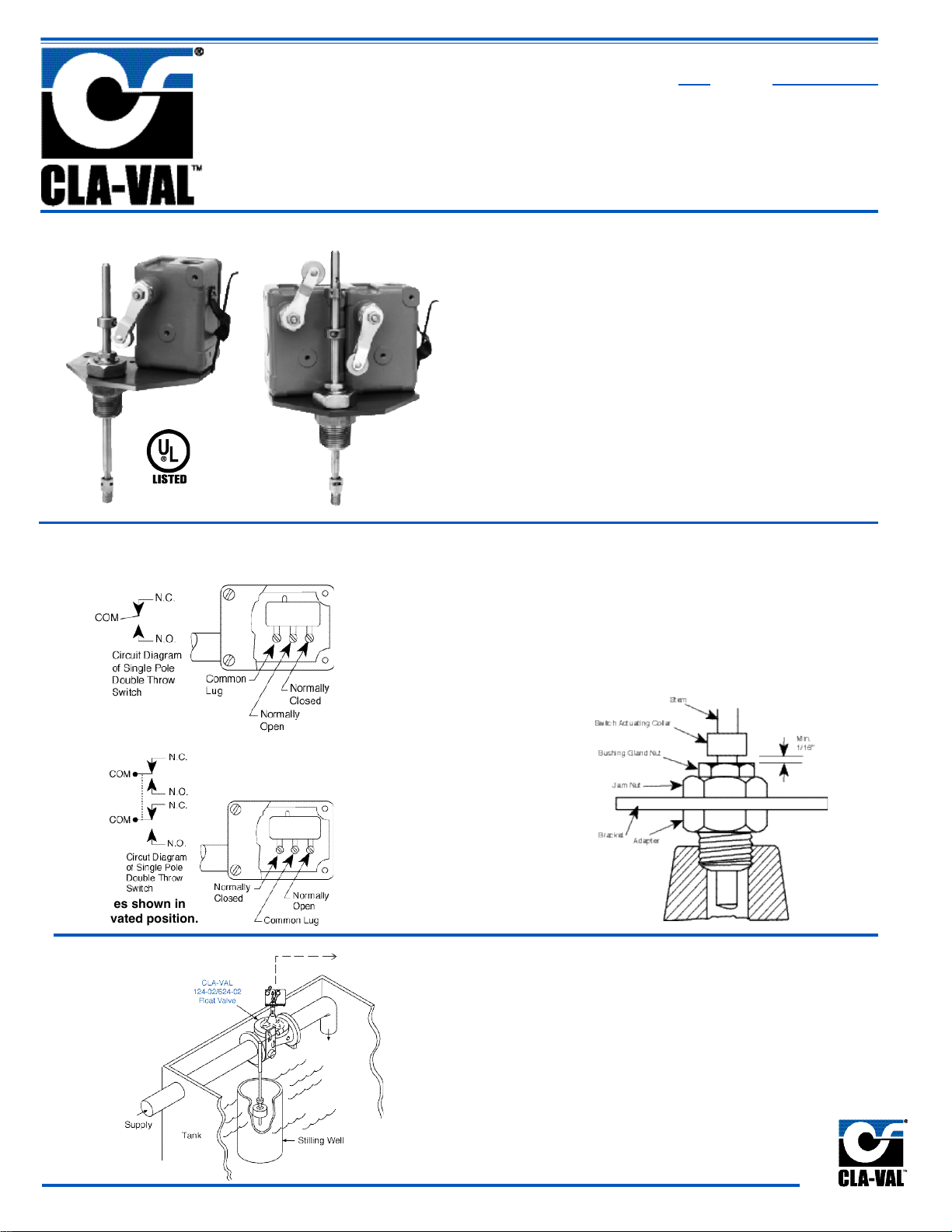

CF1-C1

CF1-C1

CF1-C1 Float Control

is a float-actuated multiport pilot control which provides non-modulating, two-position, on-off operation. It is used primarily to operate remotely located Cla-Val valves requiring three-way or four-way

pilot valve operation for level control. Control can be remotely located.

CF1-C1

124-01/624-01

Schematic Symbol

2

–

1

Page 25

104

CF1 Series Float Controls

CF1 Series

INSTALLATION / OPERATION / MAINTENANCE

Initial Adjustment CF1 Series Float Controls

Check installation to be sure that liquid surface is not subject to wind or currents, if so, a stilling well should be

installed around the float and rod assembly. A short section of 8" pipe (PVC) mounted vertically in the tank

around the float and rod is suggested.

1. See parts sheet (other side of this sheet) for proper assembly of the float rod, float, and stop collars and for

threading into the Link Assembly of the CF1-C1.

2. Balance the Float Rod Assembly. This compensates for the buoyancy of the float rod in the water.

Temporarily remove float by removing float rod and float from the link assembly. Remove float from float rod,

reinstall rod assembly (leave stop collars on float rod) back into link assembly.

Adjust counterweight on rod to balance the weight of the float rod assembly less the float. Loosen setscrew on

counterweight and move weight in or out round rod remains horizontal without shifting. Tighten setscrew.

Check by pushing up or down on float rod assembly and seeing that entire assembly returns to balanced position. Replace float between the stop collars. The counterweight size changes as float rod is lengthened.

Consult factory for more information.

3. Set Float High Level Shut-Off. Move float rod to "up" position. Adjust the upper stop collar on the float rod

assembly approximately three inches above the desire high water level. Move float rod to "down" position.

Adjust the lower stop collar on the float rod assembly approximately three inches below the desired low water

level. Tighten collar set screws.

4. If the closing level is too high, allowing tank to overflow, then the top stop collar on the float rod should be

lowered. If the opening level is too low, then the bottom stop collar should be raised.

If the counterweight has been properly adjusted the float will move freely on the float rod, without causing the

pilot arm to raise or lower, until the float actually contacts one of the stop collars.

5. For reference: with a new control and supply pressure less than 40 psi the maximum level differential available will be: 18 to 20 inches with PVC float and rod assembly and 48 to 50 inches with Stainless Steel or Brass

float and rod assembly.

Installation Data

The float control is mounted above the

high water level in the tank. The valve is

installed in the line leading to the tank

and is connected to the float control

pilot by tubing. (Min. 3/8" tubing)

When line pressure is used to operate

the valve, tubing connections are made

from the float control pilot to the valve

cover, and also to the inlet side of the

valve. An X43 “Y” Strainer or X46 Flow

Clean Strainer must be installed in the

inlet side of the valve. The control may

be installed at any elevation above the

valve, providing that the flowing line

pressure in psi is equal to, or greater

than, the vertical distance in feet

between the valve and the float control.

An independent source of air or water

may be used to operate the valve. The

pressure from this independent source

must constantly be equal to or greater

than pressure at the valve inlet. The

independent source is connected to the

float control pilot in place of the supply

line connected to the inlet side of the

valve. If the Model 100-01 under the

control of the CF1-C1 is 8" or larger,

auxiliary Hytrols may be required.

Consult factory for details.

N O T E :

A stilling well (Min. 8" I.D.) must be provided around the float if the liquid su r f a c e

is subject to turbulence, ripples or wind.

Note: We recommend protecting Float Control tubing and valve from freezing temperatures.

Page 26

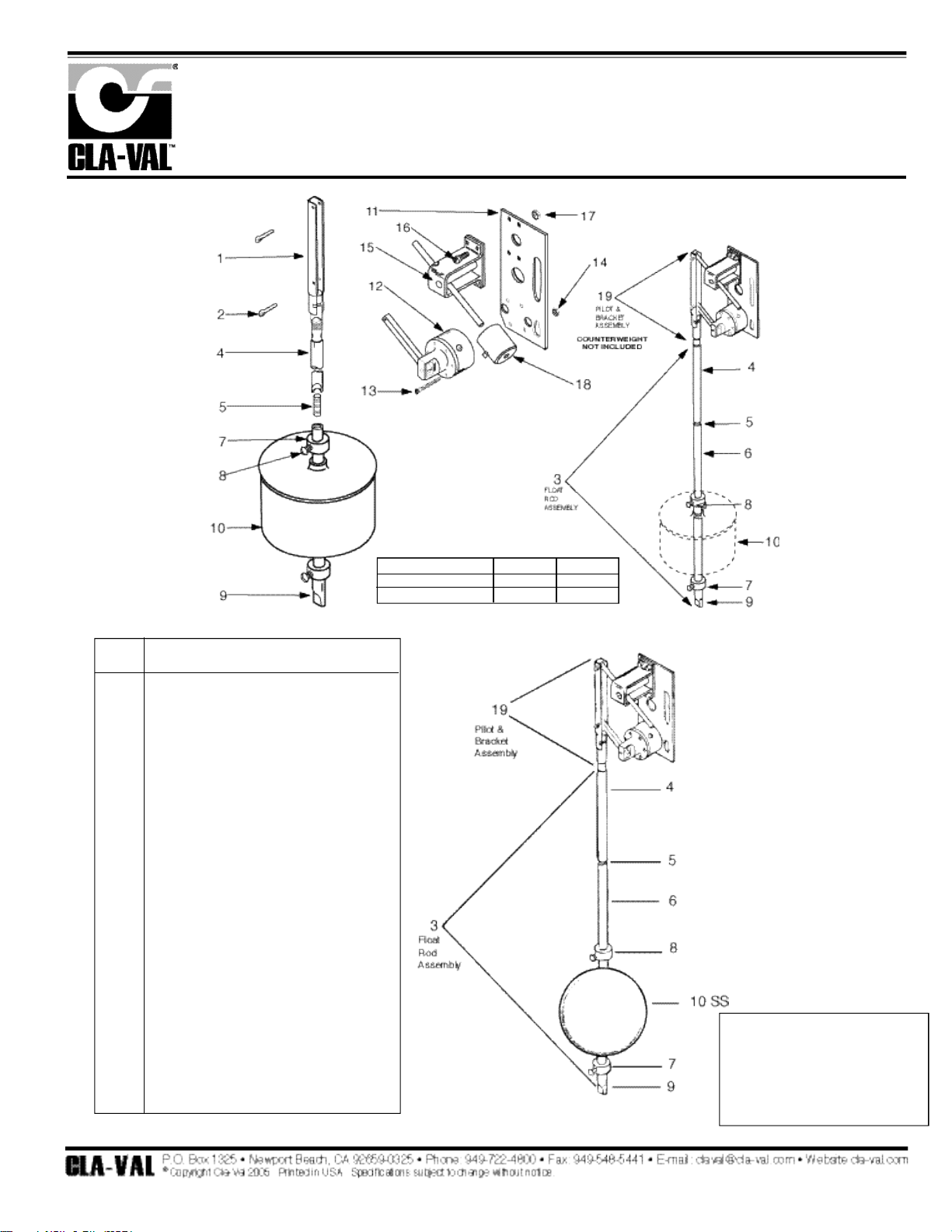

105

When ordering parts,

please specify:

• All nameplate data

• Description

• Item Number

ITEM DESCRIPTION

1 Link Assembly

2 Cotter Pins (2 req'd)

3 Float Rod Assembly (2 ft. )

FLOAT ROD ASSY. BREAKDOWN ITEMS 4 - 9

4 Upper Float Rod (1 ft.)

Upper Float Rod (2 ft.)

5 Stud (Req. for connecting upper and lower rods

and one for each extension rod)

6 Extension Float Rod (1 ft.)

Extension Float Rod (2 ft.)

7 Stop Collar (2 req'd)

8 Set Screw (1 ea. stop collar)

9 Lower Float Rod (1 ft.)

Lower Float Rod (2 ft.)

10 Float Ball (Standard Plastic)

10 SS Float Ball (Optional Stainless Steel)

11 Base and Mounting Plate

12 Pilot Valve Assembly CF1-Cl

13 Machine Screw 6/32 x 1 1/2" (6 req'd.)

14 Hex Nut 6/32 (6 req)

15 Counter Balance Bracket Assy.

16 Machine Screw 10/32 x 9/16" (4 req'd.)

17 Hex Nut 10/32 (4 req'd.)

18 Counterweight (varies with rod

length, includes set screw)

19 Pilot & Bracket Assembly CF1-Cl

COUNTERWEIGHT NOT INCLUDED

OPERATION

FLOAT POSITION PORT 1 PORT 2

Up Pressure Drain

Down Drain Pressure

Float Control

CF1-C1

Optional Stainless Steel Float

N- CF1-C1 (R-8/05)

PARTS LIST

Page 27

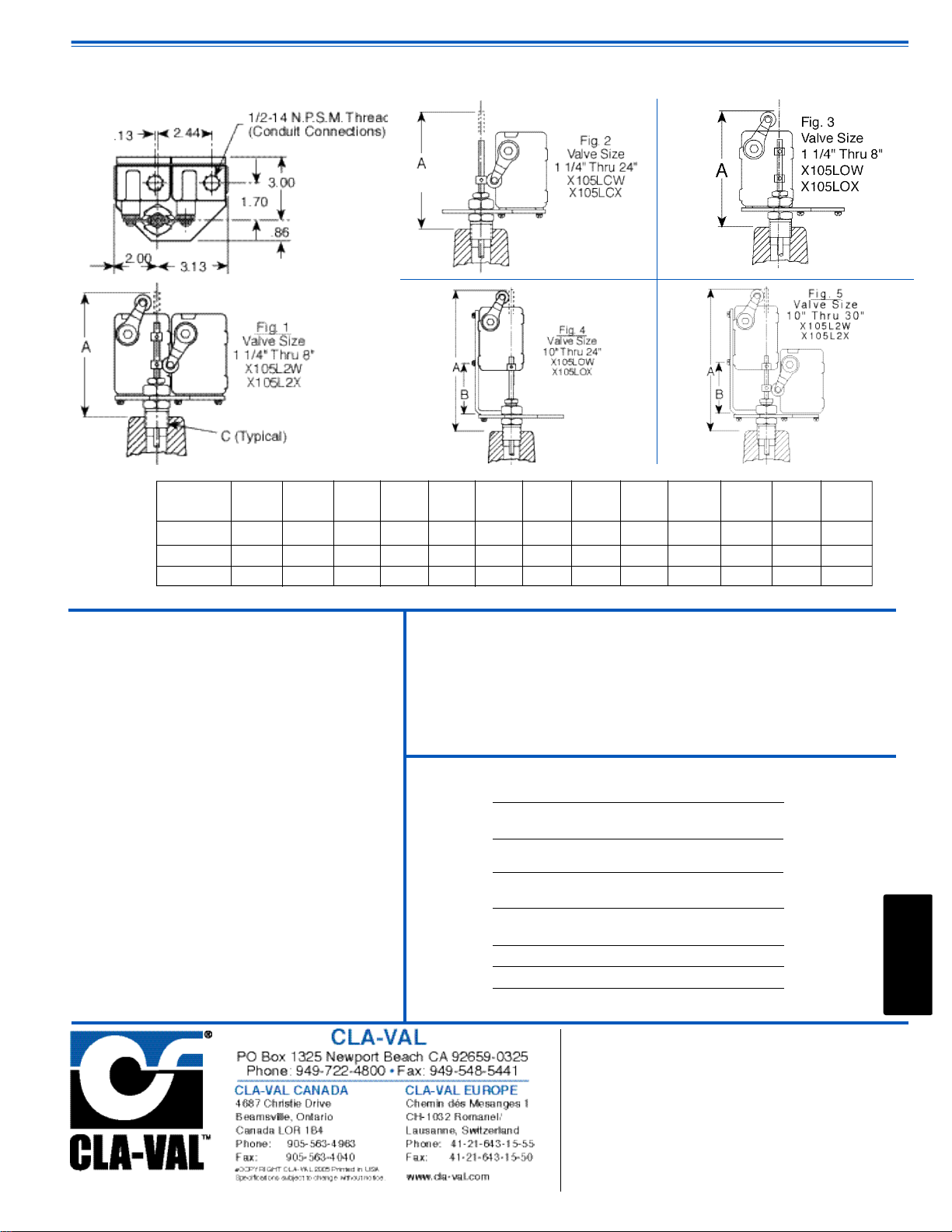

106

CFC2 Float Control

is a float-actuated multiport pilot control which provides non-modulating, two-position, on-off operation.

It is used primarily to operate remotely located Cla-Val Main Valves requiring three-way or four-way pilot

valve operation.

CFC2

CFC2

CFC2

CFC2

Schematic Symbol

Pilot Controls

Section 2 - 1

Page 28

107

CFC2

Float Control For Closed Tanks

Specifications

• Accurate Liquid Level Control

• Fully Hydraulic Operation

• Simple Design, Easy Maintenance

• No Lubrication Necessary

• No Gears, No Mechanical Linkage Between

Valve and Control

The Cla-Val Model CFC2 Float Control is a float-actuated multiport

pilot control which provides non-modulating, two-position, on-off

operation. It is used primarily to operate remotely located Cla-Va l

Valves requiring three-way or four-way pilot valve operation.

Designed for use in closed tanks, this control operates on a minimum level change of approximately 1". Maximum level change of

5

1 / 2

" is needed for full capacity.

Note: We recommend protecting the control tubing and valve from

freezing temperatures.

Dimensions

(In Inches)

Control Piping

C o n n e c t i o n s

1 / 8

" NPT

R e s e r v o i r

C o n n e c t i o n s 1" NPT

Pressure Rating 0-300 psi

Te m p e r a t u r e

R a t i n g Water: to 180°F.

M a t e r i a l s In contact with operating fluid:

Brass, stainless steel, monel, with

B u n a - N®S e a l s

Float chamber:

Cast Iron

Pilot valve housing:

B r o n z e

Materials in contact with operating fluid:

Brass, Stainless Steel, Monel with

B u n a - N®S e a l s

Float ball:

Stainless Steel

Float arm:

B r a s s

Other material available:

Cast steel or aluminum chamber and

pilot valve housing. A l l

stainless steel

Level Differential Approximately 1" minimum required to

change pilot valve operation. 5 5 / 1 6"

required to develop full capacity.

Operating Fluids Clean liquids or gases compatible with

specified materials.

Shipping We i g h t 12 Lbs.

MODEL

2

–

1

Page 29

108

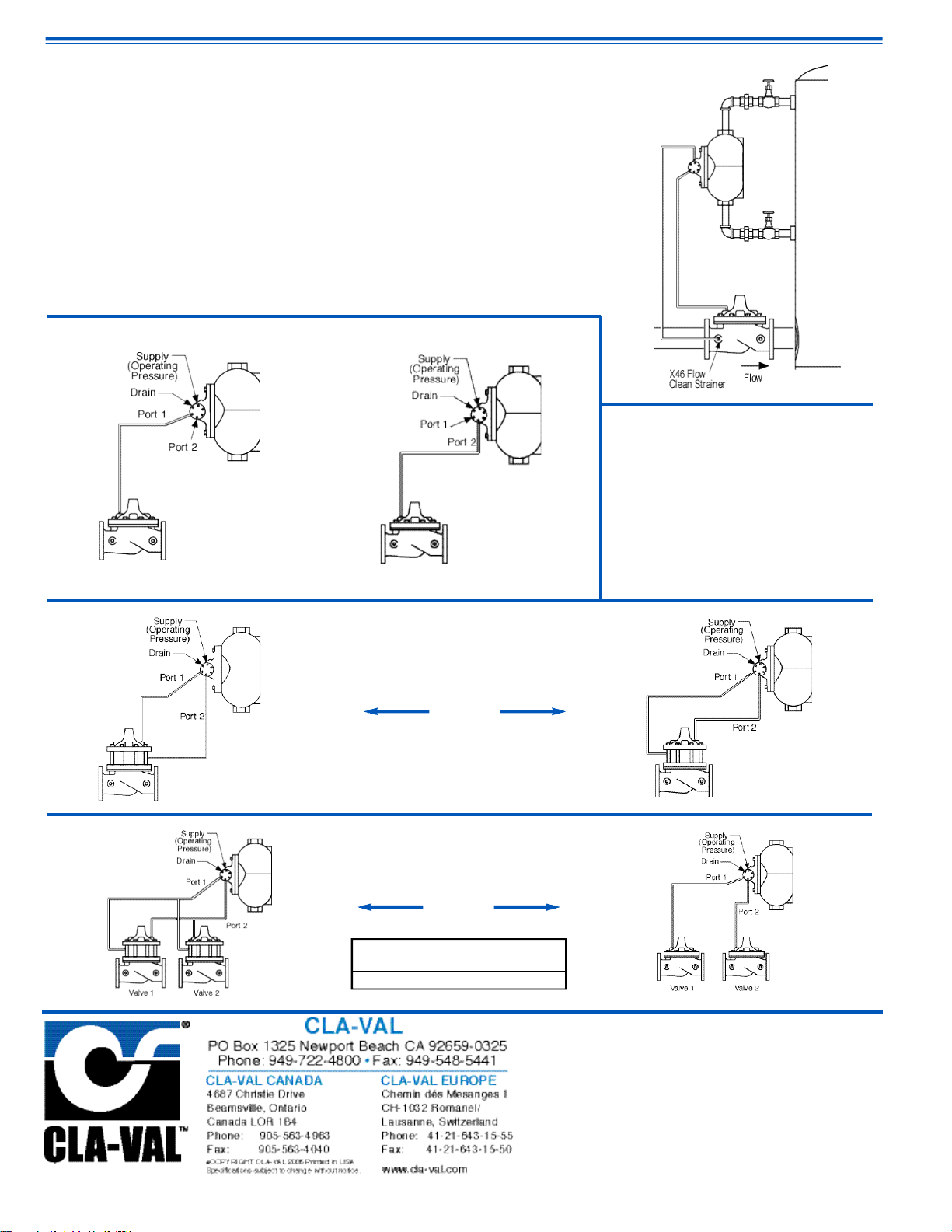

Installation Data

For Controlling Hytrol Valve

The float control is mounted at the high water

level in the tank. The remote Cla-Val valve is

installed in the line leading to the tank and is

connected to the float control pilot by tubing.

(Min. 3⁄8" for valves 6" and smaller,3⁄4" or larger

for valves 8" or larger.)

When line pressure is used to operate the valve,

tubing connections are made from the float control pilot to the valve cover, and also to the inlet

side of the valve. An X46 Flow Clean Strainer

must be installed in the inlet side of the valve.

The control may be installed at any elevation

above the valve, providing that the flowing line

pressure in psi is equal to, or greater than, the

vertical distance in feet between the valve and

the float control.

An independent source of air or water may be

used to operate the valve. The pressure from

this independent source must constantly be

equal to or greater than pressure at the valve

inlet. The independent source is connected to

the float control pilot in place of the supply line

connected to the inlet side of the valve. If the

Model 100-01 under the control of the CFC2 is

8" or larger, auxiliary Hytrols may be required.

Consult factory for details.

Note: We recommend protecting the control tubing and valve from freezing temperatures.

For Controlling

Powertrol Valves

Float Up Float Up

Closes Valve Opens Valve

When Ordering, Please

S p e c i f y

1 . Catalog No. CFC2-C1

2 . Size and type of Valve to be

c o n t r o l l e d .

3 . Materials if different from standard

4 . Specify gravity of fluid if other than

w a t e r .

Float Up Closes Va l v e Float Down Closes Va l v e

Float Position Valve 1 Valve 2

UP CLOSED OPEN

DOWN OPEN CLOSED

Operation

For Controlling

Two Valves Simultaneously

E-CFC2 (R-5/05)

Represented By:

Page 30

109

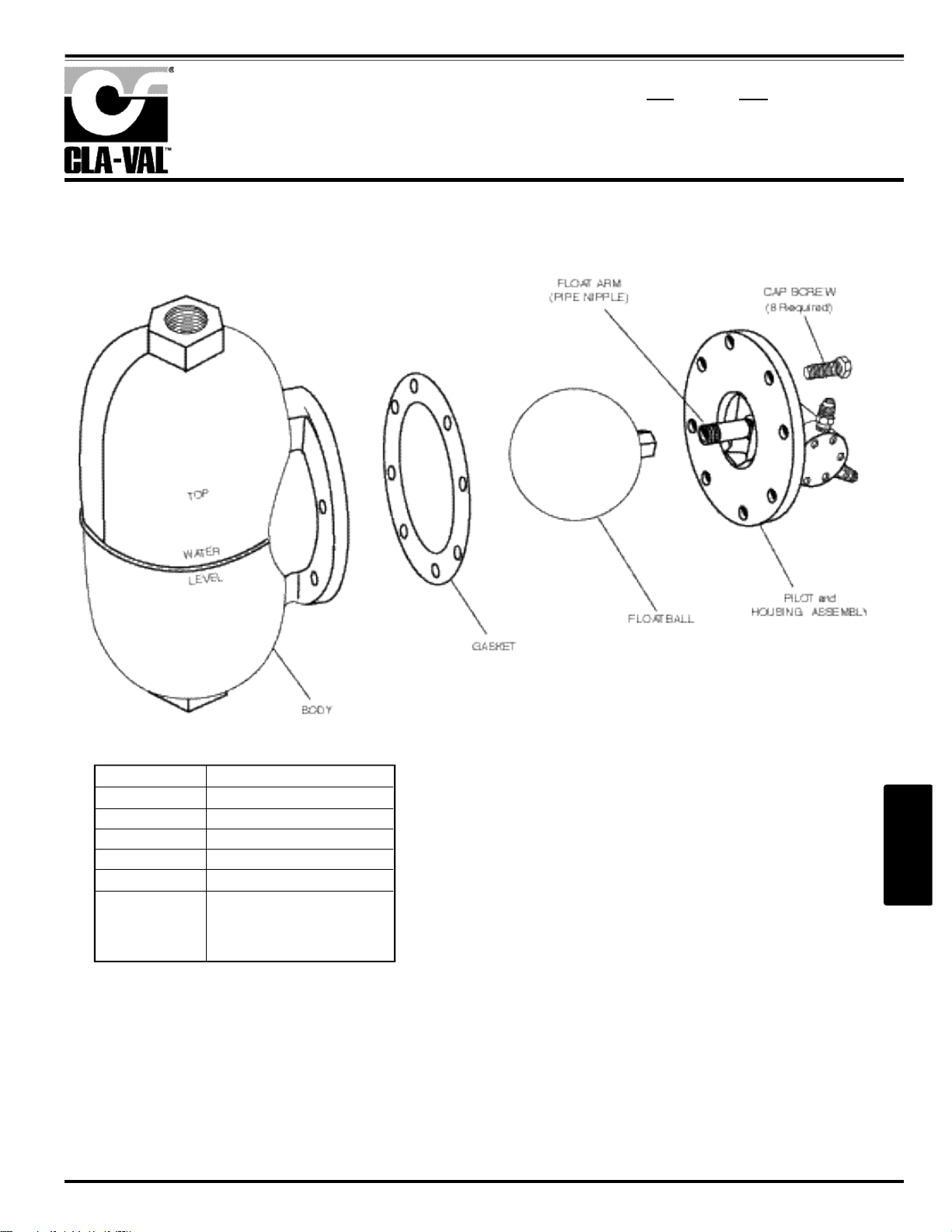

PARTS LIST

C F C 2

Float Chamber Control

M O D E L

Description

Float Ball

*Gasket

Cap Screws

3/8-16 x 7/8

Body

Float Arm

Pipe Nipple

1/4"x1/2" npr

Material

Stainless Steel

Neoprene

Steel Cad.

Plated

Iron

Bronze/Stainless Steel

2

–

1

Page 31

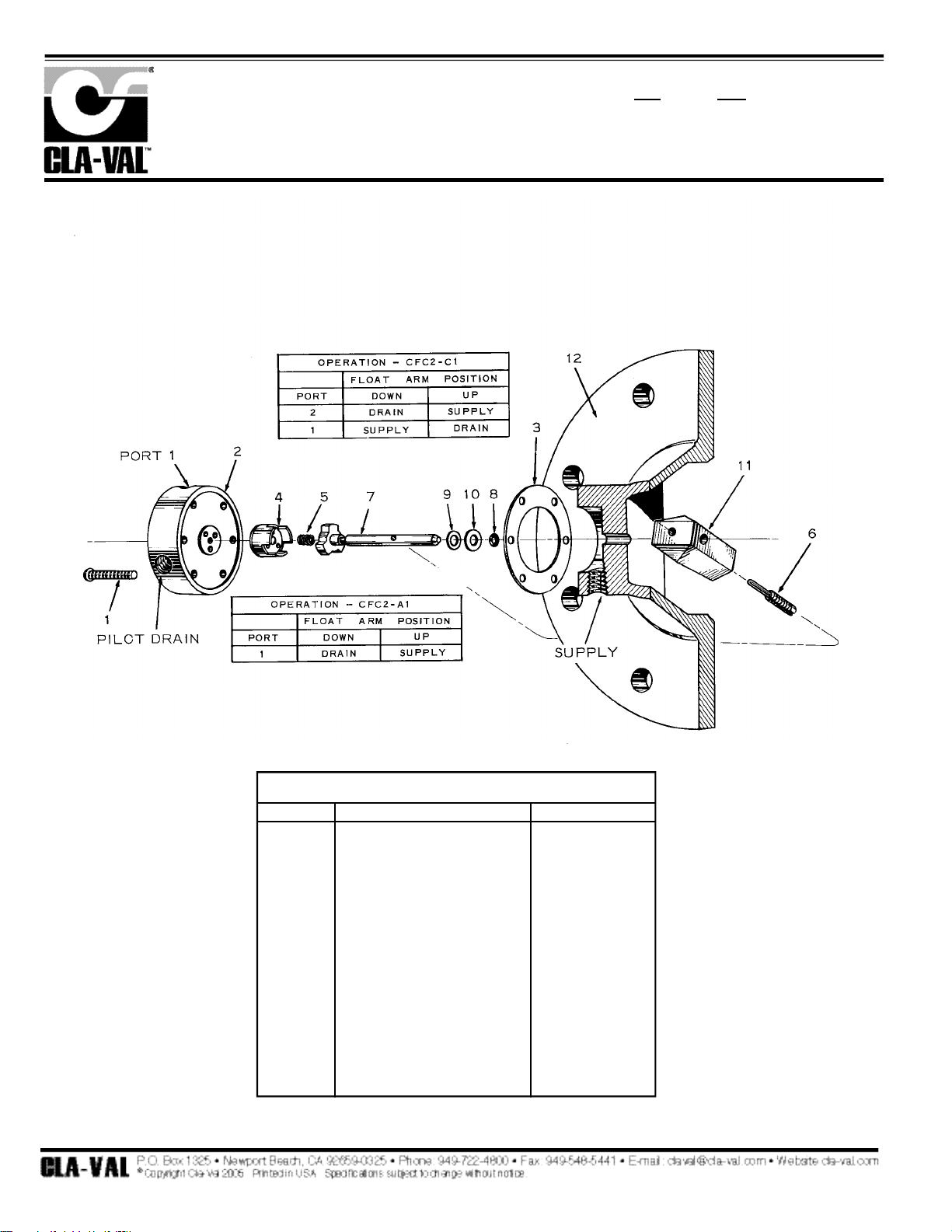

110

PL-CFC2 (R-5/05)

PARTS LIST

C F C 2

Pilot & Housing Assembly For Float Chamber Control

M o d e l

PILOT & HOUSING ASSEMBLY (BRONZE W/STAINLESS STEEL)

ITEM

1

*2

*3

*4

*5

6

7

*8

9

10

11

12

DESCRIPTION

Machine Screw, Rd. Hd.,

6/32 x 1", 6 Required

Distributor for C426-1

Distributor for C-2035

Distributor for C-2149-1

Gasket

Disc Assembly

Spring

Pin, Lock

Stem Assembly

“O" Ring

Washer

Washer, Thrust

Arm, Float

Housing

MATERIAL

Brass

S.S.

S.S.

S.S.

Buna-N

®

S.S.

S.S.

S.S.

S.S.

Brass - S.S.

Buna-N

®

Brass

Brass

Brass

Bronze

* Repair Kit Parts

OBSOLETE REFERENCE ONLY

Page 32

111

CFC2-A1-3 Float Chamber Control CONVERSION

(also CFC2-A2-3 Float Chamber Control)

This control is obsolete and is replaced by the CFC2-C1 Float Chamber Control. The diff e r e n c e s

between these controls are few. Refer to E-CFC2-C1 data sheet.

A. The pilot housing assembly is now installed on the float chamber so that the distributor is on

the right of the vertical centerline of the control. The word "top" is cast into the pilot housing

flange. There is an "O" ring seal between the pilot housing and the float chamber instead of earlier flat gasket.

B. The disc and distributor are the same as those of the CF1-C1 Float Pilot Control.

C. The CFC2-C1 has 4 ports. "Supply" is found on the housing. "Port 1", "Port 2" and "Drain"

are located and marked on the Distributor. Port 2 is for special applications and will have a pipe

plug in it. "Supply" port on the distributor is not used and has an Allen socket plug in it.

1. When service is required for the CFC2-A1-3 (or CFC2-A2-3) Control, then conversion to

CFC2-C1 is recommended.

2. For converting to the current design control, use Repair Parts Kit for the CFC2-C1 control.

Order Kit P/N 2674701E (in standard materials). Also, use this kit for maintenance or servicing

the CFC2-C1 control after conversion. This kit includes new disc, distributor, ‘O’ rings, gasket,

spring and screws. Spare Parts Kit P/N 9696630E had only 'O' ring, gasket and spring and is

obsolete and no longer available.

3. The new CFC2-C1 pilot housing flange seal is redesigned from a flat gasket to a groove for an

'O' ring seal with the chamber. This 'O' ring is in repair parts kit. The flat gasket is still available,

order part number C3580C, it is also in the kit.

4. Be sure to install parts so that the pilot housing is mounted with the distributor located to the

right of the vertical centerline of the control. Pilot tubing and connections will have to be relocated when converting.

5. The repair kit comes with a 1/8" hex-head pipe plug to be installed in pilot port 2. This will

give the ON-OFF operation from Port 1 the same as the previous CFC2-A1. By removing this

plug from Port 2 and installing in Port 1, the operation of the control becomes that of the previous CFC2-A2. By not installing the plug, the operation becomes that of the previous CFC2-C1.

Also, there is a 1/8" Allen socket pipe plug to be installed in the "S" supply port on the distributor.

Once installed THIS PLUG SHOULD NOT BE REMOVED. Supply pressure is to be connected

to the supply port on the pilot housing of the control.

Technical Bulletin

2

–

1

Page 33

112

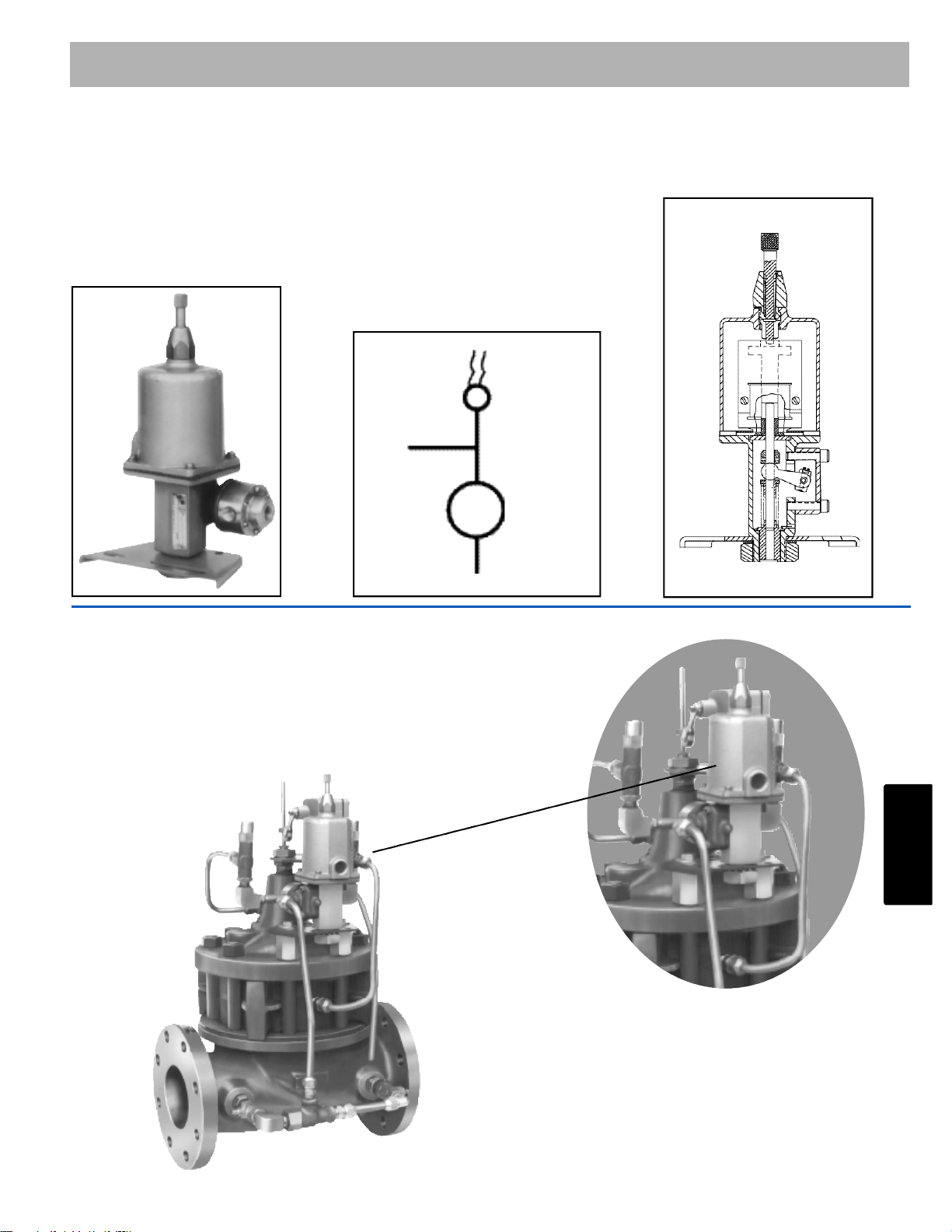

CFM2 Modulating Float Control

is a precision-lapped, rotary-disc, plate-type valve directly operated by the movement of a float ball. It

is designed to control a Cla-Val Hytrol Main valve to maintain level in liquid storage tanks.

Pilot Identification

CFM2

CFM2

CFM2

129-01/629-01

Schematic Symbol

Page 34

113

INSPECTION

Inspect all threads for damage or evidence of cross-threading.

Check float ball for crushing and punctures. Check spring for

visible distortion, cracks and breaks. Inspect distributor and

valve disc for clogged holes.

REPAIR AND REPLACEMENT

Replace O-Ring packing and distributor gasket each time valve

is overhauled. Replace float ball if at all crushed or punctured.

Minor nicks and scratches may be polished out using a fine

grade of emery or crocus cloth.

Replace all parts which are defective, and any which create the

slightest doubt that they may not afford completely satisfactory

operation. Use inspections outlined above as a guide.

Lapping of disc and distributor in the field is not recommended

because of the difficulties involved in getting perfectly flat surfaces. If repair is need on either of these parts, replace the control with a spare, and return defective unit to Cla-Val for repair.

REASSEMBLY

Replace valve disc in the position previously marked to obtain

proper flow pattern through holes.

TEST PROCEDURE

Attach a source of pressure (air or water) to "inlet" port and

check for tight sealing when float is "up".

CFM2

Modulating Float Control

DESCRIPTION

The Type CFM2 Float Control is a precision-lapped, rotary-disc, platetype valve directly operated by the movement of a float ball. It is

designed to control a Cla-Val Hytrol Main valve to maintain level in liquid storage tanks.

OPERATION

Any change in the level of the storage tank is detected instantly by the

ball of the Float Control mounted inside the tank. The float ball is

attached to a lever arm which transmits a turning motion to the valve

disc as the float rises and falls.

In the closed position, the holes in the valve disc do not meet with the

holes in the distributor, and completely prevent all flow through the

Float Control. In the half-open or modulating position, the holes in the

valve disc only partially coincide with the holes in the distributor, permitting a restricted flow through the Float Control. In the open position,

the holes in the valve disc line up completely with the holes in the distributor permitting full flow through the Float Control.

INSTALLATION

The Float Control can be installed to be either fully closed or fully open

when float is in the "up" position. Normal applications require the

Control to be installed so that it is in the closed position when the float

ball is raised.

DISASSEMBLY

Follow the sequence of item numbers assigned to the parts in the

cross-sectional illustration for recommended order of disassembly.

Mark parts so they may be reassembled in their proper position.

CLEANING

Wash all parts with cleaning solvent, Federal specification P-S-661, or

approved equivalent. Dry with compressed air, or a clean, lint-free

cloth. Protect parts from damage and dust until reassembled.

ITEM DESCRIPTION QTY PART NO.

1 FLOAT 1

2 ARM EXTENSION NIPPLE 1

3 LOCK PIN 1

4 SCREW -RD HD MACHINE 6

5 DISTRIBUTOR 1

6 GASKET 1

DISC ASSEMBLY 1

7 DISC 1

8 SKIRT 1

9 SPRING 1

STEM ASSEMBLY 1

10 DRIVER 1

11 STEM 1

12 THRUST WASHER 1

13 O-RING PACKING 1

14 FLOAT ARM 1

15 HOUSING 1

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

N-CFM2 (R-5/05)

2

–

1

Page 35

114

DESCRIPTION

W/COPPER FLOAT BALL,

BRASS ARM AND BRASS

ARM EXTENSION

W/S.S. FLOAT BALL, ARM

& ARM EXTENSION

SIZE

1/2"

1/2"

CFM2

Modulating Float Control

†

Permanently Joined Assembly

PL-CFM2 (R-5/05)

PARTS LIST

Item

1

2

3

4

5*

6*

Description

Float Ball

Arm Extension

1/4" Dia. X 5" Long

Lock Pin

Machine Screw, Fil. Hd.

6.32 x 5/8 (6 Req’d)

Distributor

Gasket

Item

7 & 8*

9*

10 & 11

12

13*

14

15

Description

†

Disc Assembly

(7-Disc / 8-Skirt)

Spring

†

Stem Assembly

(10-Driver)

(11-Stem)

Thrust Washer

“0" Ring 3855-B

Float Arm

Housing

Page 36

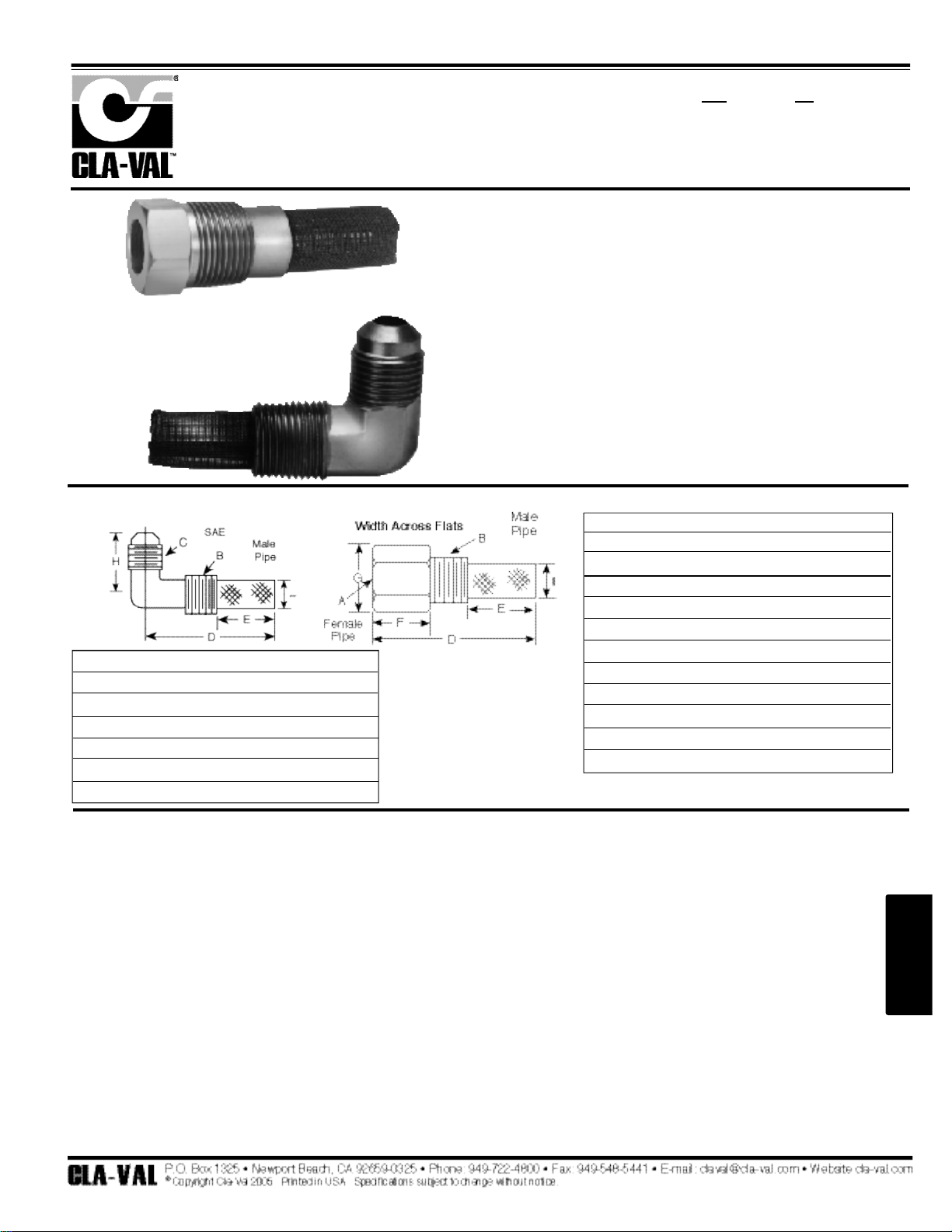

115

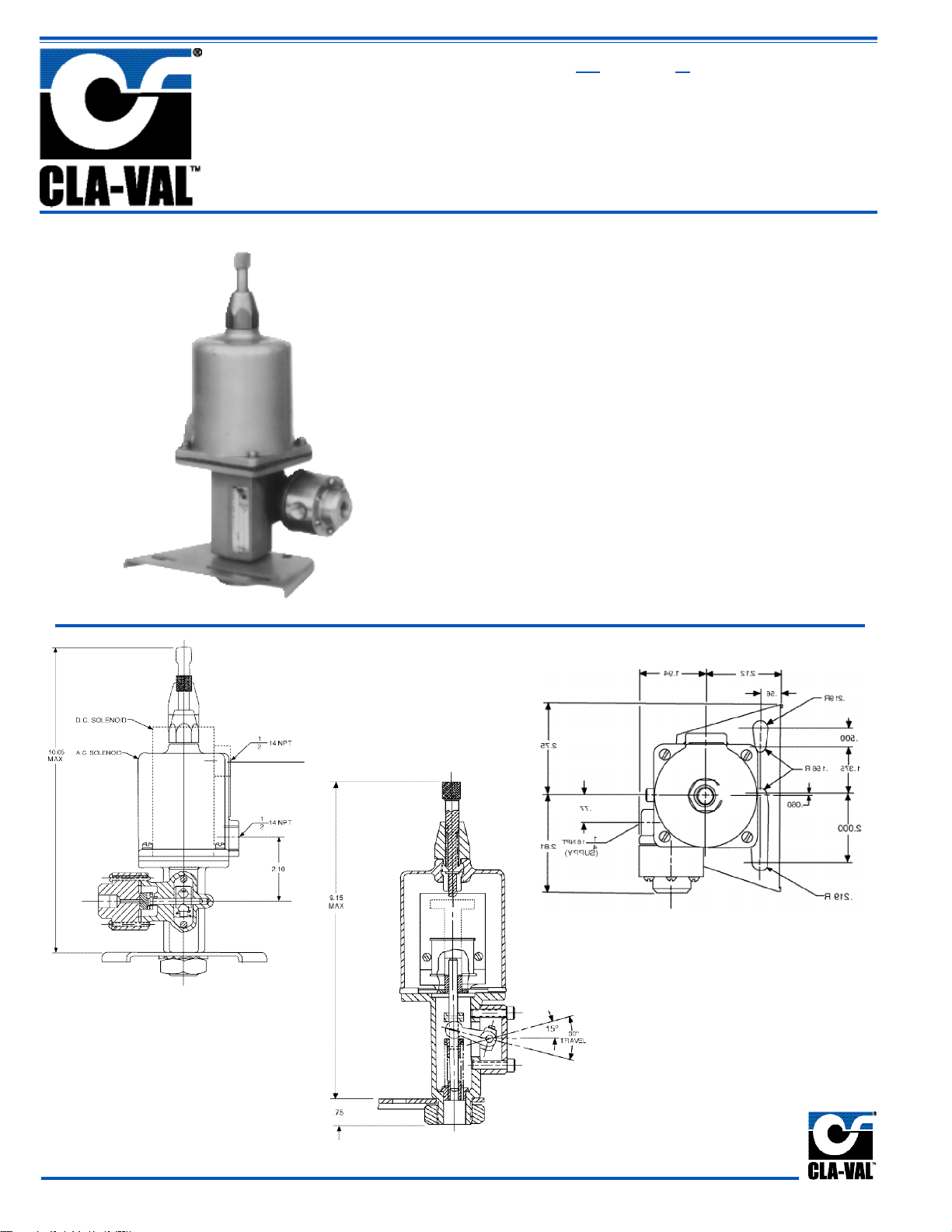

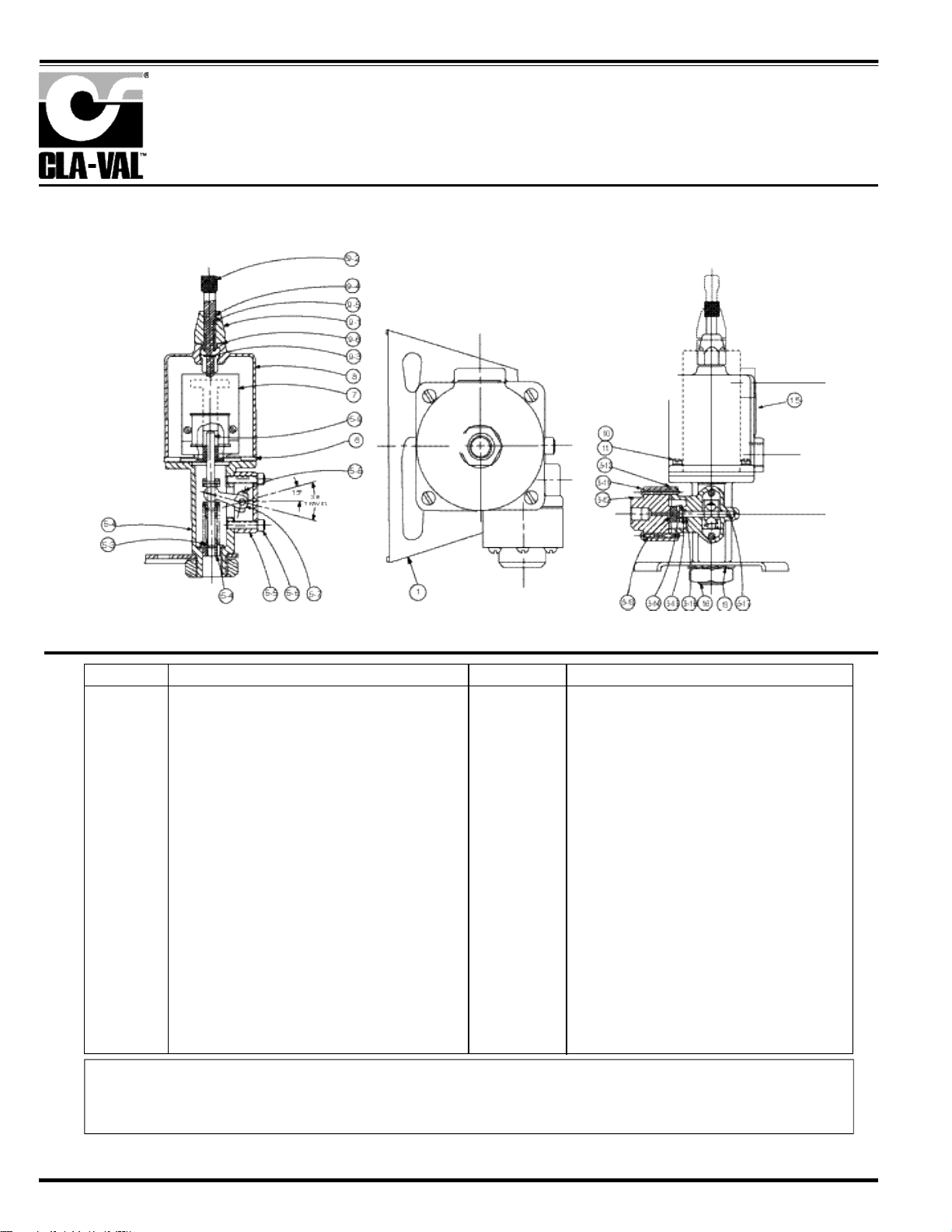

CSM-11 Solenoid Control with Manual Operator

is a direct-acting solenoid valve for use in four-way, three-way, and interceptor service. It is a continuous duty type which assures positive and dependable operation over the entire pressure range.

Cla-Val can refurbish into new condition when needed.

Pilot Identification

CSM11

CSM11

CSM11

CSM-11

60-11/660-11

Schematic Symbol

2

–

1

Page 37

116

Solenoid Control with Manual Operator

CSM-11

• Positive Operation Through Full Pressure Range

• Both Manual and Electrical Operation

• Coil is Protected Against Foreign Matter by Sealtight Gasket Cover

• Moving Parts of Solenoid are Cushioned

• Modular Pilot Assembly Provides for Easy

Replacement and Minimum Down Time

The Cla-Val CSM-11 is a direct-acting solenoid valve for use in

four-way, three-way, and interceptor service. It is a continuous

duty type which assures positive and dependable operation