Page 1

MODEL

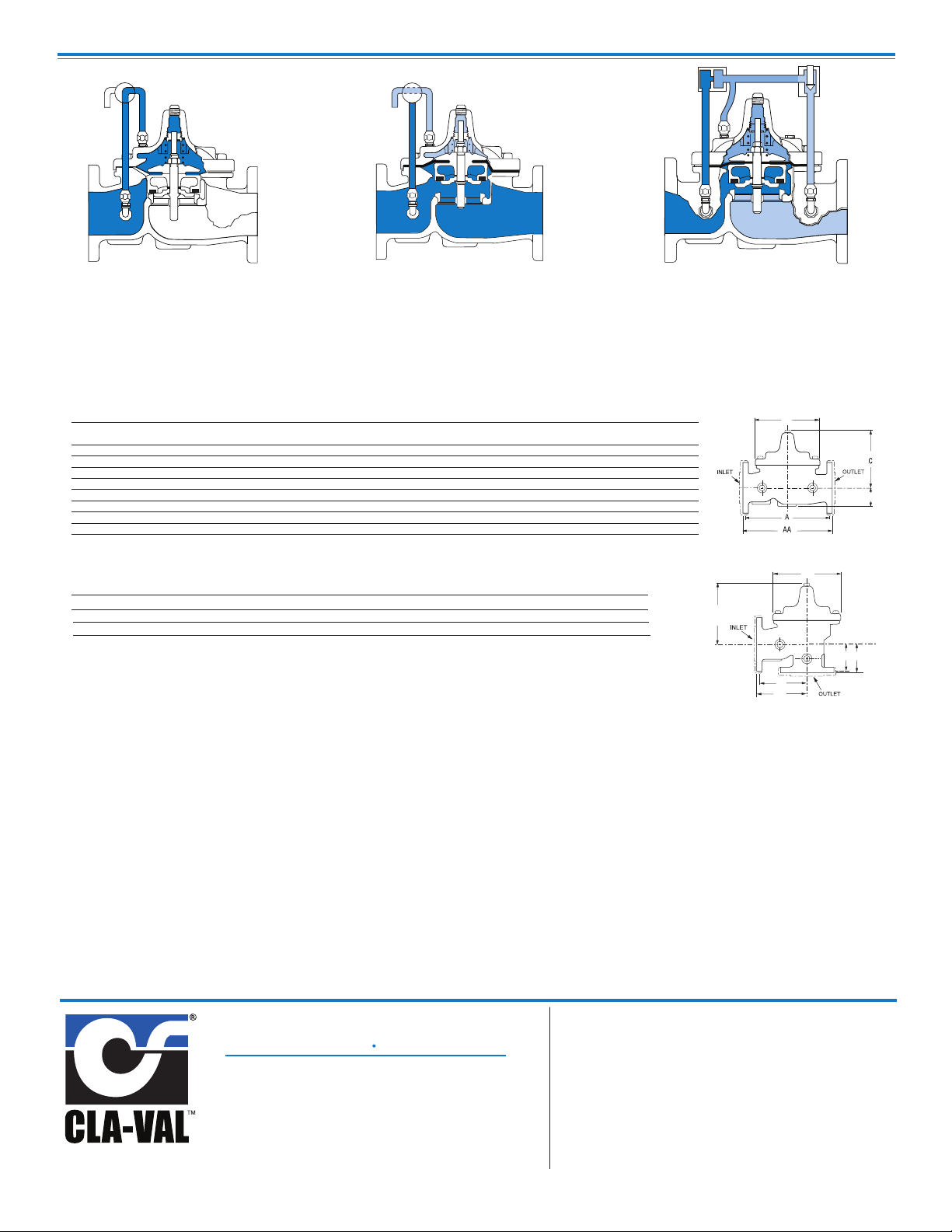

90AF4A-3

Pressure Reducing Valve

• Maintains constant downstream pressure

• Closes quickly to prevent downsream surge when flow is

stopped suddenly

• Deadman control

• Surge control prevents damage to refuelers

• Used in conjunction with Cla-Val Bottom-Loading Pantograph

• Fail-safe operation

The Cla-Val Model 90AF-4A-3 Hytrol Valve is used as the basic unit in almost

all Cla-Val automatic control valves for petroleum applications. The 90AF-4A-3

is a hydaulically-operated, diaphragm actuated, globe or angle pattern valve. It

is available in various materials and full range of sizes. It consists of three major

components: body, diaphragm assembly and cover. The diaphragm assembly

is the only moving part. The rugged simplicity of design and packless

construction assure a long life dependable, trouble-free operation. Should the

diaphragm become damaged the valve will close tight, providing “fail safe”

operation. The 90AF-4A-3 Hytrol Valve is used in many types of piping system

requiring control, flow regulation, rate of flow control, or check valve operation.

Schematic Diagram

Item Description

1 100-34 Hytrol (Reverse Flow)

2 X47A Ejector

3 Bell Reducer

4 CFM2 Float Control

5 X101 Valve Position Indicator

X105L Switch Assembly (Optional)

Optional Features

Item Description

A X46A Flow Clean Strainer

B CK2 Cock (Isolation Valve)

C CV Flow Control (Closing)

G 81-01 Check Valve With Cock

Q Quick Connect Assembly

S CV Flow Control (Opening)

T 55F Thermal Relief Control

Specifications

Sizes

Globe: 1 1/2” - 16” flanged

Angle: 2” - 16” flanged

End Details

Flanged:

Cast Aluminum, 150 ANSI B16.1

Cast Bronze, 150 & 300 ANSI B16.24

Ductile Iron, 150 & 300 ANSI B16.42

Cast Steel, 150 & 300 ANSI B16.5

Temperature Range

Light Petroleum Product -40° to+140°F

Pressure Ratings

150 class 175-PSI Max.

150 class 275-PSI Max.

250 class 300-PSI Max.

300 class 400-PSI Max.

Material

Body & cover:

Cast Aluminum 356-T6

Cast Bronze ASTM B62

Ductile Iron ASTM A-536

Cast Stainless Steel 303

Cast Steel ASTM A216-WCB

Valve trim:

Bronze ASTM B61

Stainless Steel 303

Rubber parts:

Buna-N® Synthetic Rubber

Viton

Other Materials

Available on Special Order

Page 2

Principle of Operation

B

C

Tight Closing Operation

When pressure from the valve inlet (or

an equivalent independent operating

pressure) is applied to the diaphragm

chamber, the valve closes drip-tight.

When pressure in the diaphragm chamber

is relieved to zone of lower pressure under

the valve. Flow in either direction is

permitted.

Full Open Operation

The valve modulates when diaphragm

chamber pressure is held at an

intermediate point between inlet and

discharge pressure changes, the

pressure above the diaphragm is varied

allowing the valve to modulate and

compensate for the changes.

SIZE 1 1/2 2 2 1/2 3 4 6 8 10 12 14 16

A 125 & 150 ANSI 8.50 9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38

AA 250 & 300 ANSI 9.00 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50

B DIAMETER 5.62 6.62 8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50

C MAX. 5.50 6.50 7.56 8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00

D 1.12 1.50 1.69 2.06 3.19 4.31 5.31 9.25 10.75 12.62 15.50

E 125 & 150 ANSI 4.75 5.00 6.00 7.50 10.00 12.75 14.88 17.00 19.50 20.81

EE 250 & 150 ANSI 5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75 20.25 21.62

F 125 & 150 ANSI 3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69

FF 250 & 300 ANSI 3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50

CVFactor

VALVE SIZE 1 1/2 2 2 1/2 3 4 6 8 10 12

100-34 GLOBE PATTERN 26 49 80 107 200 440 771 1151 1600

100-34 ANGLE PATTERN 30 62 100 137

CVfactor is defined as the number of gallons per minute of water at 60˚F. which will flow at a 60˚F. which will flow at a

one pound per square inch differential.

Purchase Specifications

The valve shall be hydraulically-operated, diaphragm-actuated, globe or angle pattern

valve. It shall contain a resilient, synthetic rubber disc, having a rectangular cross

section, contained on three and on-half sides by a disc retainer and disc guide, forming

a tight seal against a single renewable seat. The valve stem shall be guided at both

ends by a bearing in the valve cover and an integral bearing in the valve seat. The

diaphragm assembly shall be the only moving part and shall form a sealed chamber in

the upper portion of the valve, separating operating pressure from line pressure. The

diaphragm consist of nylon fabric bonded with synthetic rubber and shall not be used

as a seating surface. Packing glands and/or stuffing boxes are not permitted and there

shall be no pistons operating the valve. All necessary repairs shall be possible without

removing the valve from the line. If the diaphragm becomes damaged the valve shall

close tight. This valve shall be a Model 100-34 (globe pattern or angle pattern) Hytrol

Valve as manufactured by Cla-Val. Newport Beach, California.

Specify When Ordering

1. Size

2. Model

3. Pressure Class

4. Temperature and fluid to be handled

5. Static and flowing line pressure

6. Operating fluid and pressure

7. Body and trim materials

8. End details

Modulating Action

100AF

B

C

E

EE

90AF-4A-3

Globe or Angle

(if other than line pressure)

D

FFF

E-90AF-4A-3 (R-04/2012)

LA-VAL

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada L0R 1B4

Phone: 905-563-4963

Fax: 905-563-4040

©COPYRIGHT CLA-VAL 2012 Printed in USA

Specifications subject to change without notice.

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

www.cla-val.com

Represented By:

Loading...

Loading...