Page 1

INSTALLATION / OPERATION / MAINTENANCE

U

¤

L

The Cla-Val 90-21 Pressure Reducing Valve is a pilot-operated

regulator, capable of holding downstream pressure to a predetermined pressure.

1. Special Note: For system protection, a pressure relief valve is

to be installed downstream (system side) of the 90-21 Pressure

Reducing Valve. Adequate drainage of the relief valve discharge

must be provided. The relief valve should be set above the “no

flow” or “dead end” shutoff pressure which will be 5 to 8 psi higher

than the set pressure.

2. Allow sufficient room around the valve assembly to make adjustments and for disassembly.

3. It is recommended that isolation valves be installed on both

ends of the 90-21 valve to facilitate isolating the valve for start-up,

testing and preventative maintenance.

4. BEFORE THE VALVE IS INSTALLED, PIPE LINES SHOULD

BE FLUSHED OF ALL CHIPS, SCALE, AND FOREIGN MATTER.

5. Place the 90-21 valve in the line with flow through the valve in

the direction indicated on the inlet nameplate mounted on inlet

flange or by arrow on nameplate mounted on side of threaded

ends valves. Check all fittings and hardware for proper makeup

and that no apparent damage is evident.

6. Cla-Val valves operate with maximum efficiency when mounted

in horizontal piping with the cover UP; however, other positions

are acceptable. Due to size and weight of cover and internal components of six inch and larger valves, installation with the cover up

is advisable. This makes periodic inspection of internal parts readily accessible.

Start-Up and Adjustment

1. Upon initial start-up and after any valve servicing, it is necessary

to follow these steps.

2. Prior to pressurizing the valve make sure the necessary gauges

to measure pressure are installed. Gauges should be installed

upstream (inlet) and downstream (outlet) of the valve. Unused

ports on main valve body can be used for this purpose.

Caution: During start-up and test procedures a large volume of

water may be discharged downstream. Check to make sure that

the downstream venting is adequate to prevent damage to personnel and equipment.

3. Close upstream and downstream isolation valves.

4. Slowly open the upstream isolation valve enough to allow the

valve and pilot control system to fill with liquid.

5. Bleed air from the main valve (1) cover and pilot system by

slightly loosening fittings or plugs at all high points until a steady

flow of water is observed retighten. It may be necessary to do this

more than once.

6. Open fully the upstream isolation valve.

7. Slowly open the downstream isolation valve part way to establish a low flow rate.

There must be liquid flowing through the valve during

pressure adjustments. Optimum valve performance occurs when

pressure setting is done with flow rate as low as practical.

8. Adjust the CRD Control (3) to desired pressure. To change pressure setting, turn the adjusting screw in (clockwise) to increase

delivery pressure. Turn the adjusting screw out (counterclockwise)

to decrease delivery pressure. The pressure should change

approximately 27 psi per turn. Only slight changes in adjustment

should be made to avoid damage to equipment. When the desired

setting has been made, tighten jam nut and replace cover.

MODEL

90-21 UL

UL Listed Pressure Reducing Valve

NOTE: The “no flow” or “dead end” shutoff pressure will be 5 to 8

psi above the set pressure.

9. Open downstream isolation valve fully.

Maintenance

1. The Cla-Val 90-21 Pressure Reducing Valve requires no lubrication or packing and a minimum of maintenance. However, a periodic inspection schedule should be established to determine how

the fluid handled is affecting the efficiency of the valve.

Minimum of once per year.

2. When servicing the pilot control system, use care to prevent

damage. If it is necessary to remove fittings or components, be

sure they are kept clean and replaced exactly as they were.

3. Repair and maintenance procedures of the Cla-Val Hytrol Main

Valve and pilot control components are included in a more detailed

IOM manual. It can be downloaded from our web site (www.claval.com) or obtained by contacting a Cla-Val Regional Sales

Office.

4. When ordering parts always refer to the catalog number

and stock number on the valve nameplate.

SYMPTOM PROBABLE CAUSE REMEDY

Main valve

fails to open

Main valve

fails to close

Fails to

Regulate

No pressure at valve inlet

Main valve diaphragm assembly

inoperative

Pilot Valve (CRD) not opening:

1. No. spring compression

2. Damaged spring

3. Spring guide not in place

4. Yoke dragging on inlet nozzle

Foreign matter between disc

and

seat or worn disc. Scale on stem

or Diaphragm ruptured

Flow Clean Strainer plugged

CK2 (isolation valves) closed

Pilot Valve (CRD) remain open:

1. Spring compressed solid

2. Mechanical obstruction

3. Worn disc

4. Yoke dragging on inlet nozzle

diaphragm nut. Leakage from

vent hole in cover

5. Diaphragm damaged or loose

diaphragm nut. Leakage from

vent hole in cover

Air in main valve cover and/or

tubing

Pilot Valve (CRD) yoke dragging

on inlet nozzle

Pilot Valve (CRD) spring not in

correct range to control

Check inlet pressure

Disassemble, clean and polish

stem, replace detective parts

1. Tighten adjusting screw

2. Disassemble and replace

3. Assemble properly.

4. Assemble properly

Disassemble main valve,

remove matter, clean parts and

replace defective parts

Remove and clean or replace

Open isolation valves

1. Back off adjusting screw

2. Disassemble and remove

obstruction

3. Disassemble remove and

replace disc retainer assembly

4. Assemble properly

5. Disassemble. replace

diaphragm and/or tighten nut

Loosen top cover plug and fittings and bleed air

Assemble properly

Check outlet pressure requirements

Page 2

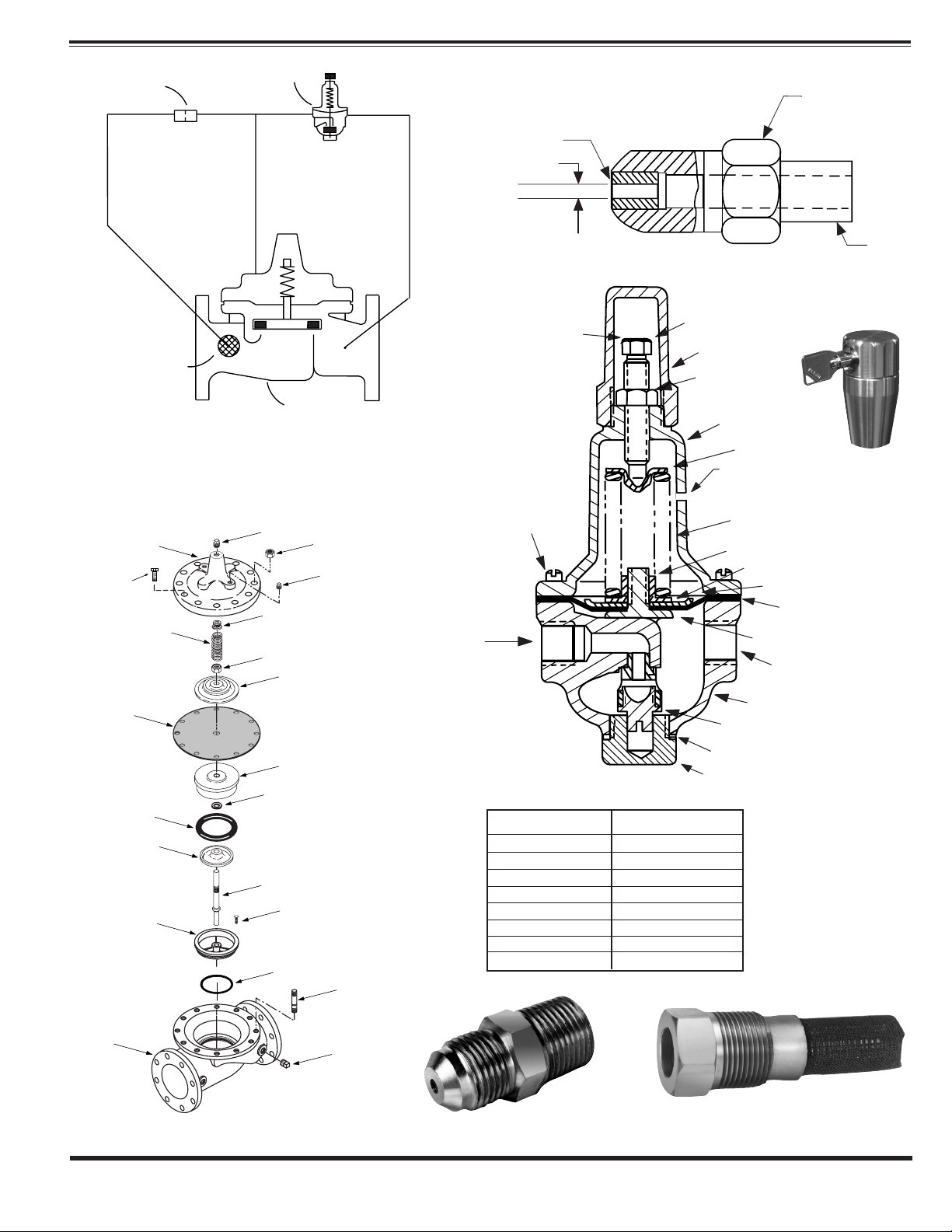

90-21 UL SCHEMATIC

inlet

Cover vent

(3/8" NPT)

Cap

Adjusting Screw

Jam Nut

Cover

Spring

Hex Nut

Belleville Washer

Diaphragm Washer

Diaphragm*

Yoke

Body and Seat Assy

Disc Retainer Assy

Gasket*

Plug, Body

*Machine Screw

(Fil.Hd) 8 Req’d

Spring Guide

Pressure Setting

Adjusting Screw

(Turn Clockwise to

Increase Setting)

Tube Connector

(NPT)

Restriction

Plug

Orifice

2

3

X58C

2.

INLET

4

BASIC COMPONENTS

1 100-01 Hytrol (Main Valve)

2 X58C Restriction Fitting

3 CRD Pressure Reducing Control

4 X46A Flow Clean Strainer

1.

HYTROL MAIN VALVE

COVER

Cover Bolt

6" and Smaller

SPRING

*

DIAPHRAGM

1

PIPE PLUG

COVER BEARING

STEM NUT

DIAPHRAGM WASHER

HEX NUT

8" and Larger

PIPE PLUG

OUTLET

CRD

3.

X140-1

Security Cap

Option

BODY

(Globe

For a more detailed IOM Manual go to www.cla-val.com or contact a Cla-Val Regional Sales Office.

CLA-VAL

DISC RETAINER

*

*

DISC

DISC GUIDE

SEAT

or

Angle)

SPACER WASHERS

STEM

Seat Screw

8" and Larger

SEAT O-RING

STUD

8" and Larger

PIPE PLUG

Minimum Flow Required When Setting Pressure

Valve Size (inch)

1 1/2

2

2 1/2

3

4

6

8

10

Min. Flow (GPM)

16

26

37

57

100

220

390

620

X58C

2.

X46A

4.

*

Repair Parts

*SUGGESTED REPAIR PARTS

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

N-90-21 UL (R-5/05)

Loading...

Loading...