Page 1

81-07

MODEL

(Full Internal Port)

681-07

(Reduced Internal Port)

Non-Slam Dual Speed Control Check Valve

• Simple Proven Design

• No-Slam Operation

• Drip-Tight Shut-Off

• Dual Speed Control

• No Packing Glands or Stuffing Boxes

• Available in a Variety of Materials

The Cla-Val Model 81-07/681-07 Non-Slam Dual Speed Control Check

Valve is a hydraulically operated No-Slam Check Valve with dual speed

controls. This valve opens when the pressure at the inlet exceeds the discharge pressure. A gradual rate of opening prevents sudden opening

surges. When a pressure reversal occurs, the higher downstream pressure

is applied to the cover chamber through the control tube lines, and the valve

closes drip tight.

This valve is ideally suited for use where a positive shutoff is required. The

rubber disc assures tight sealing even if the fluid contains grit or other smallsize particles. The simple packless design insures reliable operation and

freedom from leaks.

Schematic Diagram

Item Description

1 Hytrol (Reverse Flow Main Valve)

2 CV Flow Control (Opening)

3 CSC Swing Check Valve

4 CGA Ange Valve (Closing)

Optional Features

Item Description

P X141 Pressure Gauge

V X101 Valve Position Indicator

Typical Applications

Pump

CLA-VAL 81-07

Check Valve

Discharge To

Atmosphere

CLA-VAL 61-02

Pump Control Valve

Discharge To

Atmosphere

CLA-VAL 52-03/652-03

Surge Anticipator Valve

Pressure Sensing Line

Discharge To System

Note: The effectiveness of this valve is related to pipeline velocity. We recommend a maximum flow based on pipeline velocity of 6 feet per second.

If pipeline velocities exceed 6 feet per second, consideration should be

given to adding a Cla-Val Model 50-01 Pressure Relief Valve or a Cla-Val

Model 52 Series Surge Control Valve to the system.

CLA-VAL

50-01/650-01

Surge Relief Valve

TAN K

Isolation

Valve

Pump

81-07/681-07

Booster Pump

Check Valve

Deep Well Pump

This valve should be an integral part of any well designed pumping

system. It is used to prevent damaging and sometimes expensive

flow reversal.

Booster Pump

Install on the discharge of booster pumps to prevent return flow into tank when pump is off. Relief valve as shown

is good practice to minimize

surges when pump stops.

Page 2

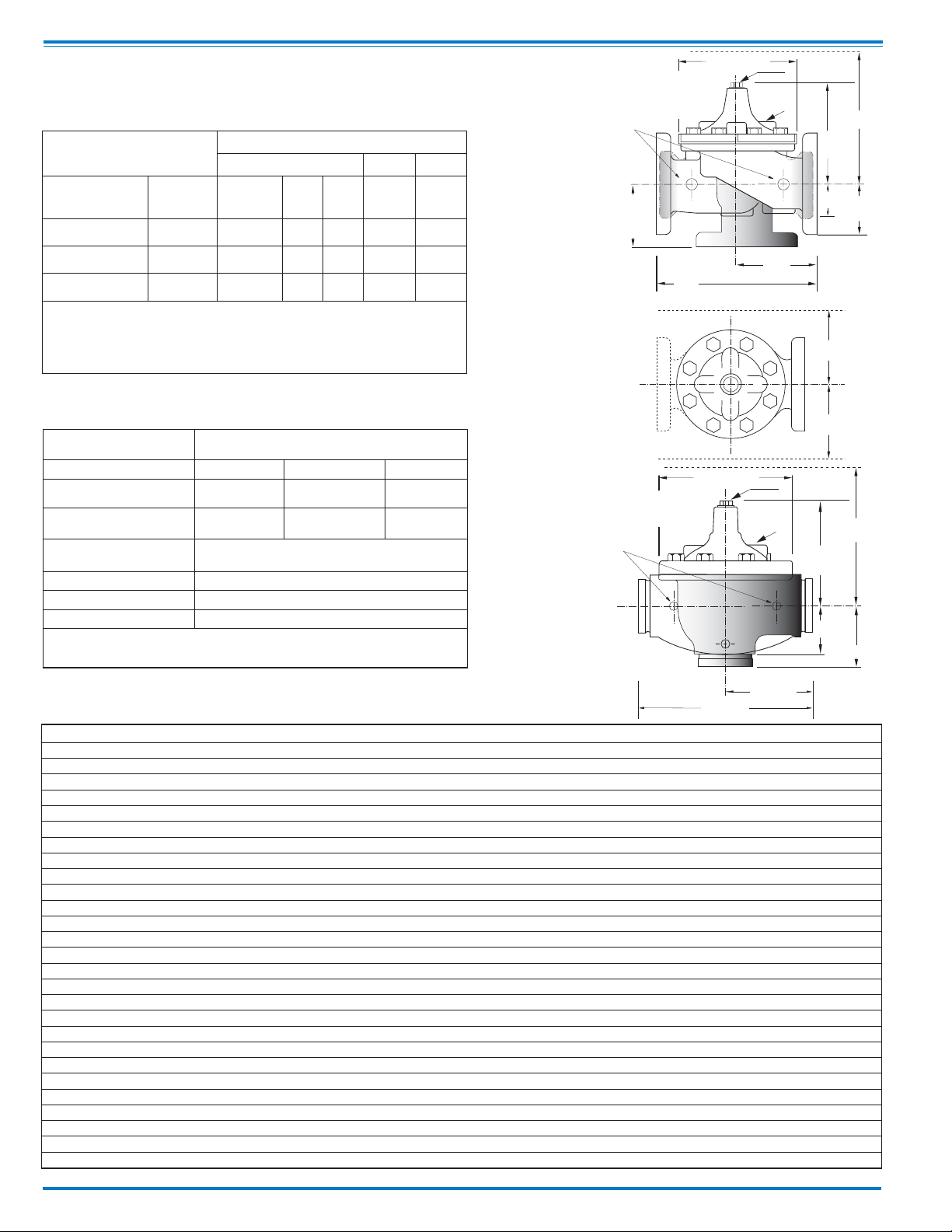

Model 81-07 (Uses Basic Valve Model 100-01)

Pressure Ratings

Valve Body & Cover

Grade Material

ASTM A536 Ductile Iron B16.42 250 400 400 400

ASTM A216-WCB Cast Steel B16.5 285 400 400 400

ASTM B62 Bronze B16.24 225 400 400 400

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

(Recommended Maximum Pressure - psi)

Pressure Class

Flanged Grooved Threaded

ANSI

Standards*

150

Class

300

Class

300

Class

End‡

Details

Dimensions

(In inches)

H

Inlet

G

GG

GGG

100-01

Threaded &

Flanged

A

AA

AAA

B

Inlet

(Diameter)

D

DD

DDD

J

K

C

(MAX)

E

X

Outlet

F

FF

Y

Materials

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes 2" - 24" 2" - 16" 2" - 16"

Disc Retainer &

Diaphragm Washer

Trim: Disc Guide,

Seat & Cover Bearing

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

Cast Iron Cast Steel Bronze

Bronze is Standard

Stainless Steel is Optional

100-01

Grooved

H

Inlet

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Model 81-07 Dimensions (In Inches)

Valve Size (Inches) 22 1/2 3 4 6 8 10 12 14 16 18 20 24

A Threaded

AA 150 ANSI

AAA 300 ANSI

AAAA Grooved End

B Dia.

C Max.

CC Max. Grooved End

D Threaded

DD 150 ANSI

DDD 300 ANSI

DDDD Grooved End

E

EE Grooved End

F 150 ANSI

FF 300 ANSI

G Threaded

GG 150 ANSI

GGG 300 ANSI

GGGG Grooved End

H NPT Body Tapping

J NPT Cover

K NPT Cover Tapping

Stem Travel

Approx. Ship Wt. Lbs.

X Pilot System 13 14 15 17 29 31 33 36 40 40 43 47 68

Y Pilot System 9 10 11 12 20 22 24 26 29 30 32 34 39

Z Pilot System 9 10 11 12 20 22 24 26 29 30 32 34 39

Center Plug

9.38 11.00 12.50 ——————————

9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38 46.00 52.00 61.50

10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50 47.64 53.62 63.24

9.00 11.00 12.50 15.00 20.00 25.38 ———————

6.62 8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50 41.50 45.00 53.16

6.50 7.56 8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00 39.06 41.90 43.93

5.75 6.88 7.25 9.31 12.12 14.62 ———————

4.75 5.50 6.25 ——————————

4.75 5.50 6.00 7.50 10.00 12.69 14.88 17.00 19.50 20.81 — — 30.75

5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75 20.25 21.62 — — 31.62

4.75 — 6.00 7.50 —————————

1.50 1.69 2.06 3.19 4.31 5.31 9.25 10.75 12.62 15.50 12.95 15.00 17.75

2.50 2.88 3.12 4.25 6.00 7.56 ———————

3.00 3.50 3.75 4.50 5.50 6.75 8.00 9.50 10.50 11.75 15.00 16.50 19.25

3.25 3.75 4.13 5.00 6.25 7.50 8.75 10.25 11.50 12.75 15.00 16.50 19.25

3.25 4.00 4.50 ——————————

3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69 — — 22.06

3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50 — — 22.90

3.25 — 4.25 5.00 —————————

.375 .50 .50 .75 .75 11111111

.50 .50 .50 .75 .75 1 1 1.25 1.5 2 1.5 1.5 1.5

.375 .50 .50 .75 .75 11111111

0.6 0.7 0.8 1.1 1.7 2.3 2.8 3.4 4.0 4.5 5.1 5.63 6.75

35 50 70 140 285 500 780 1165 1600 2265 2982 3900 6200

(Diameter)

B

Inlet

AAAA

J

K

DDDD

CC

(MAX)

EE

Z

Outlet

GGGG

X

Page 3

EE

D

E

Inlet

DD

AA

X

100-20

Flanged

F

A

C

(MAX)

K

J

H

Inlet

Outlet

FF

B

(Diameter)

Model 681-07 (Uses Basic Valve Model 100-20)

Dimensions

(In inches)

Pressure Ratings

Valve Body & Cover

Grade Material

ASTM A536 Ductile Iron B16.42 250 400

ASTM A216-WCB Cast Steel B16.5 285 400

ASTM B62 Bronze B16.24 225 400

Note: * ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Valves for higher pressure are available; consult factory for details

(Recommended Maximum Pressure - psi)

Pressure Class

Flanged

ANSI

Standards*

150

Class

Class

Materials

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes 3" - 30" 3" - 16" 3" - 16"

Disc Retainer &

Diaphragm Washer

Trim: Disc Guide,

Seat & Cover Bearing

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Cast Iron Cast Steel Bronze

Bronze is Standard

Stainless Steel is Optional

300

Y

Z

Model 681-07 Dimensions (In Inches)

Valve Size (Inches)

A 150 ANSI

AA 300 ANSI

B Dia.

C Max.

D 150 ANSI

DD 300 ANSI

E 150 ANSI

EE 300 ANSI

F 150 ANSI

FF 300 ANSI

H NPT Body Tapping

J NPT Cover Center Plug

K NPT Cover Tapping

Stem Travel

Approx. Ship Wt. Lbs.

X Pilot System 13 15 27 30 33 36 36 41 40 46 55 68

Y Pilot System 10 11 18 20 22 24 26 26 30 30 30 39

Z Pilot System 10 11 18 20 22 24 26 26 30 30 30 39

*Consult Factory

34681012141618202430

10.25 13.88 17.75 21.38 26.00 30.00 34.25 35.00 42.12 48.00 48.00 63.25

11.00 14.50 18.62 22.38 27.38 31.50 35.75 36.62 43.63 49.62 49.75 63.75

6.62 9.12 11.50 15.75 20.00 23.62 27.47 28.00 35.44 35.44 35.44 53.19

7.00 8.62 11.62 15.00 17.88 21.00 20.88 25.75 25.00 31.00 31.00 43.94

— 6.94 8.88 10.69 CF* CF* CF* CF* CF* CF* CF* —

— 7.25 9.38 11.19 CF* CF* CF* CF* CF* CF* CF* —

— 5.50 6.75 7.25 CF* CF* CF* CF* CF* CF* CF* —

— 5.81 7.25 7.75 CF* CF* CF* CF* CF* CF* CF* —

3.75 4.50 5.50 6.75 8.00 9.50 11.00 11.75 15.88 14.56 17.00 19.88

4.12 5.00 6.25 7.50 8.75 10.25 11.50 12.75 15.88 16.06 19.00 22.00

.375 .50 .75 .75 11111111

.50 .50 .75 .75 1 1 1.25 1.25 2222

.375 .50 .75 .75 11111111

0.6 0.8 1.1 1.7 2.3 2.8 3.4 3.4 4.5 4.5 4.5 6.5

45 85 195 330 625 900 1250 1380 1500 2551 2733 6500

Page 4

C

81-07

Valve

Selection

100-01 Pattern: Globe (G), Angle (A), End Connections: Threaded (T), Grooved (GR), Flanged (F) Indicate Available Sizes

Inches 1 11⁄4 11⁄2

mm 25 32 40

2 2 1⁄2 3 4 6 8 10 12 14 16 18 20 24

50 65 80 100 150 200 250 300 350 400 450 500 600

30 36

750 900

Basic Valve

100-01

Suggested

Flow

(gpm)

Suggested

Flow

(Liters/Sec)

100-01 Series is the full internal port Hytrol. *Globe Grooved Only

681-07

Valve

Pattern

End Detail

Maximum

Maximum

Inches

3 4 6 8 10 12 14 16 18 20 24 30

G, A G, A G, A G, A G, A G, A G, A G, A G, A G, A G G G, A

T , F,GrT , F,

T , F,GrT , F,GrT , F,

Gr*

Gr*

T , F,

Gr*

FFFFFFF

63 90 138 240 550 950 1475 2100 2600 3400 4200 5200 7700

4.0 5.7 8.7 15.1 34.7 60 93 132 164 214 265 328 485

100-20 Pattern: Globe (G), Angle (A), End Connections: Flanged (F) Indicate Available Sizes

36 42 48

Selection

Basic Valve

100-20

Suggested

Flow

(gpm)

mm

Pattern

End Detail

Maximum

80 100 150 200 250 300 350 400 450 500 600 750

GG, AG, AG, AGGGG GGGG

FFFFFFFF FFFF

60 138 240 550 950 1475 2100 2100 3800 3800 3800 8400

900 1000 1200

Suggested

Flow

(Liters/Sec)

100-20 Series is the reduced internal port size version of the 100-01 Series.

Maximum

3.8 8.7 15.1 35 60 93 132 132 239 239 239 529

Pilot System Specifications

Temperature Rating

Water:

to 180°F. Max.

Speed Controls

Opening and closing speed controls are

standard

Note: Advise factory when ordering if valve will

*

not be installed with the main valve stem in a

vertical position.

on the 81-02 and 681-02 Model.

Materials

Standard Pilot System Materials

Fittings: Brass

Tubing

: Copper

Optional Pilot System Materials

Pilot Systems are available with

optional stainless steel or Monel

materials.

LA-VAL

PO Box 1325 Newport Beach CA 92659-0325

E-81-07/681-07 (R-1/2013)

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada L0R 1B4

Phone: 905-563-4963

Fax: 905-563-4040

©COPYRIGHT CLA-VAL 2013 Printed in USA

Specifications subject to change without notice.

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

www.cla-val.com

When Ordering,

Please Specify

1. Catalog No. 81-07 or 681-07

2. Valve Size

3. Pattern - Globe or Angle

4. Pressure Class

5. Threaded or Flanged

6. When Vertically Installed *

Represented By:

Loading...

Loading...