Page 1

750B-4KG1

Page 2

Page 3

Page 4

Roll Seal

®

TM

750B - 4KG1

ROLL SEAL FIRE PUMP RELIEF VALVE

INTRODUCTORY INFORMATION

This manual is primarily intended for use as a manual for the UL listed and FM

approved Roll Seal 750B-4KG1 Fire Pump Relief Valves. Certain sections may contain

information that would be useful for the care installation and maintenance of other

Roll Seal products and Valve sizes. This extra data is intended as additional reference

information for the Roll Seal product line.

The product literature for the Roll Seal 750B - 4KG1 Fire Pump Relief Valve notes the

particular Valve Sizes and configurations that are UL listed or FM approved. Consult

the factory or your nearest sales representative if further clarification is required.

UL listed and FM approved products are identified by the appropriate nameplate on

the Valve. Drawings of the UL & FM nameplates are enclosed for reference.

The UL nameplate drawing number 86060. The FM nameplate drawing number is 94777.

This manual contains information regarding care, installation and maintenance of

the Roll Seal Main Valve (100-42) as well as information about the fully piloted product (750B-4KG1 Fire Pump Relief Valve). 100-42 is the identifying nomenclature for

the Main Valve. 750B-4KG1 is identifying nomenclature for the fully piloted Fire Pump

Relief Valve Assembly. See Schematic Drawing No. 29868 for clarification of the component nomenclature and for a description of Valve Operation.

A capacity flow curve for Valve sizes 3" through 10" is included that shows the flow

capacity in the full open valve condition.

Cla-Val recommends that 750B-4KG1 Valves be tested after installation to verify the

Relief pressure set point.

Page 5

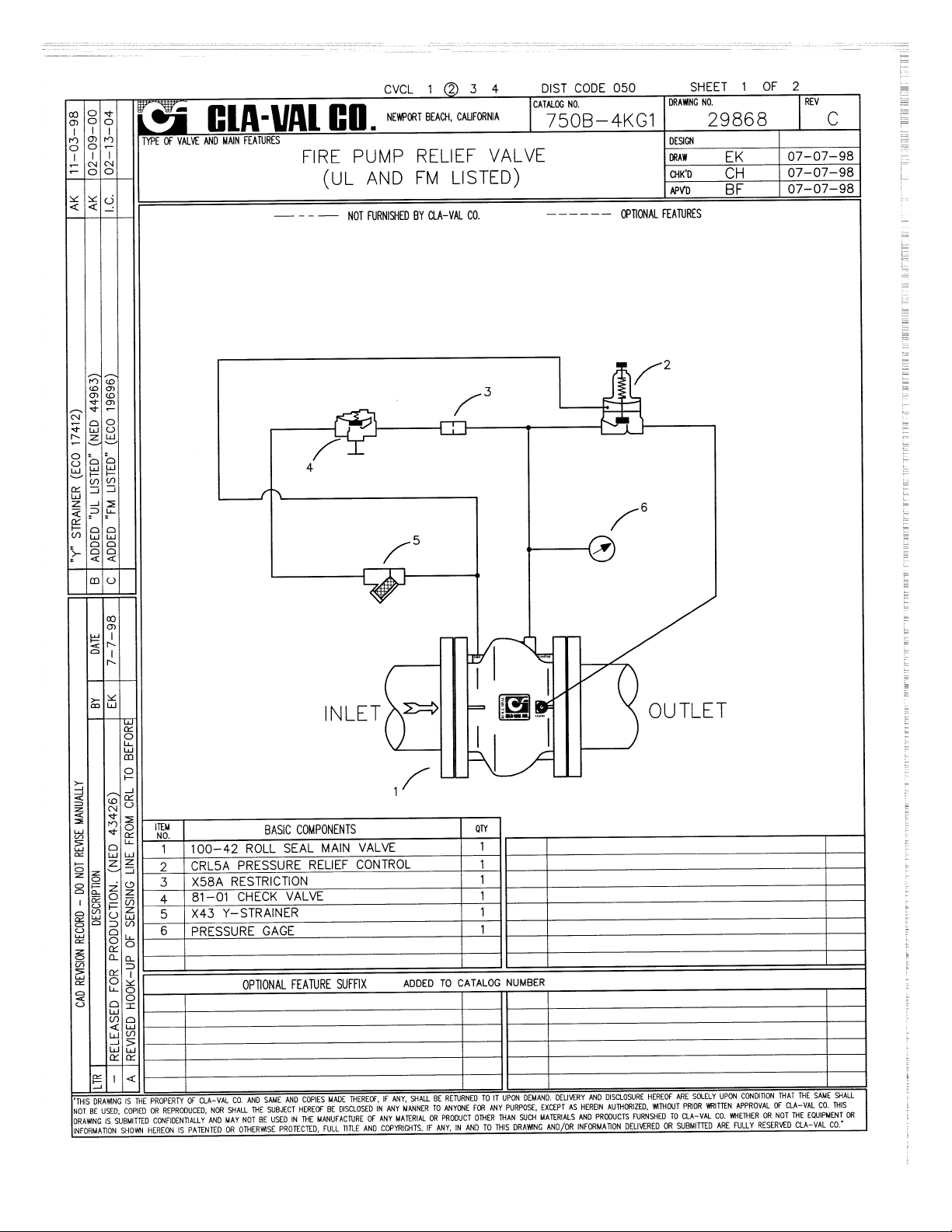

2

3

4

5

6

1

INLET

OUTLET

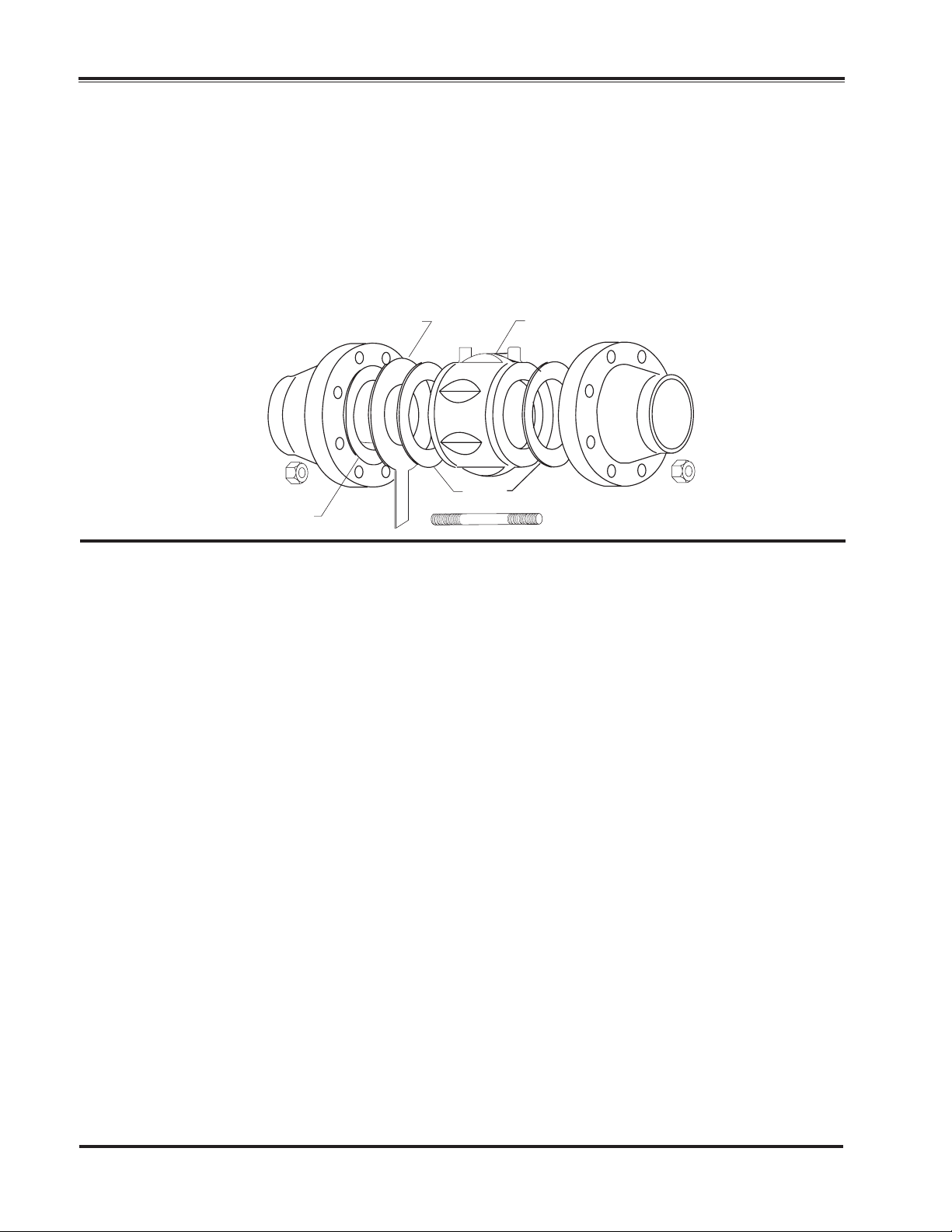

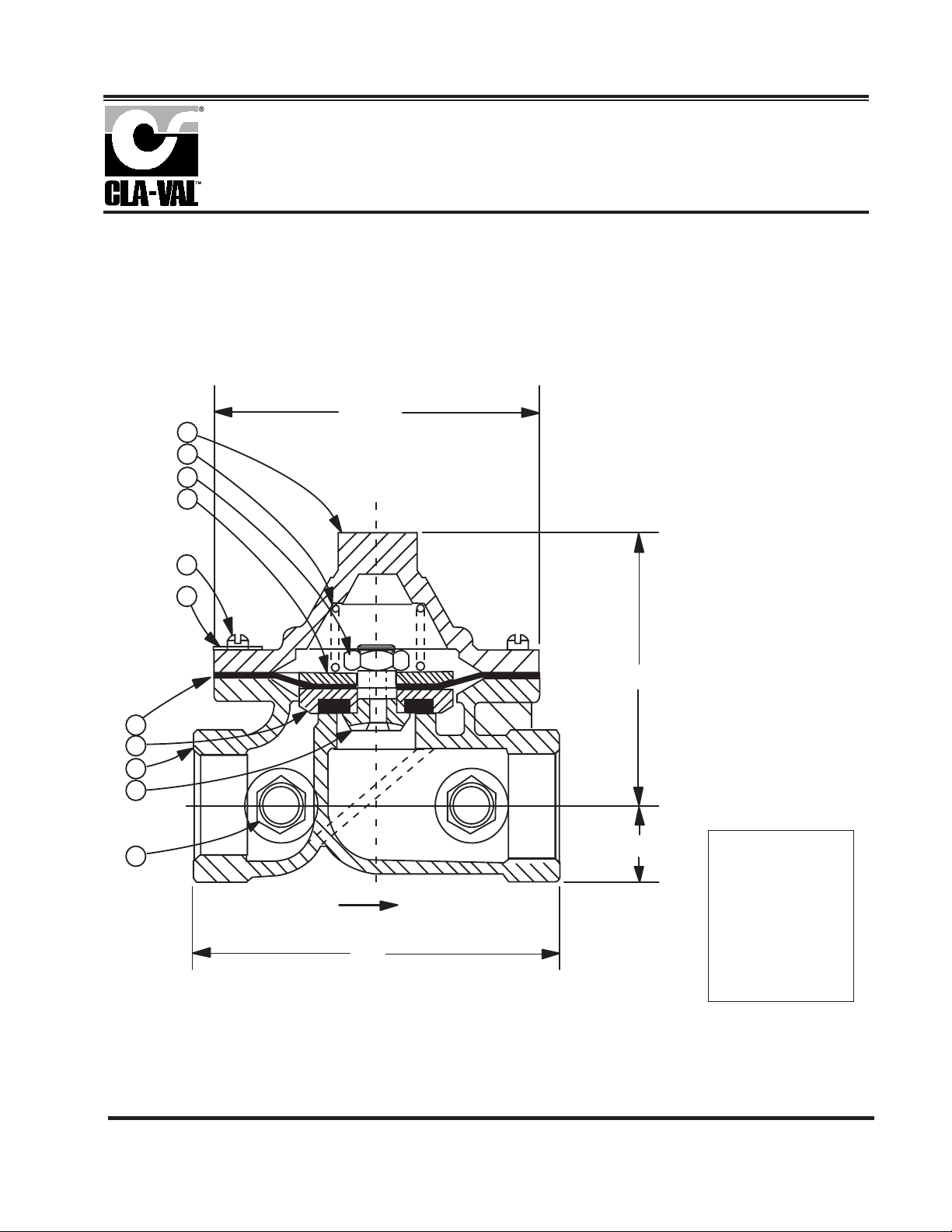

750B-4KG1 Basic Components

Fire Protection Pressure Relief Valve

750B-4KG1

Description

The Cla-Val Model 750B-4KG1 Pressure Relief Valve is a hydraulically

operated pilot actuated automatic control valve designed specifically to

automatically relieve excess pressure in fire protection pumping systems.

Pilot co ntrol led, it maintains consta nt system pressure at the

pump discharge within very close limits as demands change. The main

valve consists of a stainless steel body and only one moving part, an

elastomeric liner or control element.

Cla-Val Model 750B-4KG1 will control from no flow, to full open flow, without any chattering or slamming. For this reason, there is never a region

of control instability. There is no slip-type friction because the valve has

no bearings. Cla-Val Model 750B-4KG1 valves have excellent resistance to cavitation with a Cffactor of 0.9.

Pilot controls are fully piped at the factory and the Cla-Val Model 750B-4KG1

is shipped complete, ready for installation.

Material Specification

Body: 316L Stainless Steel

Liner: Nitrile, 70 durometer

Liner Retainer: 316 Stainless Steel

Pilot

Body: ASTM B62 Bronze*

Spring Cover: ASTM B62 Bronze*

Wetted Parts: Bronze/Stainless Steel*

Buna-N

®

Accessories

Check Control: Brass*

Control Piping: Copper*

“Y” Strainer: Bronze*

Control Fittings: Brass*

*

316 stainless steel available

Item Description

1 100-42 Roll Seal Main Valve

2 CRL5A Pressure Relief Control

3 X58A Restriction

4 81-01 Check Valve (125 psid max. reverse pressure)

5 X43 Y-Strainer

6 Pressure Gauge

FM

PENDING

At pump start, the Cla-Val Pressure Relief Valve modulates

to relieve excess pump capacity, maintaining positive system pressure at the pump discharge.

When fire demand slows or ceases, the main valve opens,

diverting the entire pump output to discharge, allowing the

fire pump to be stopped without causing surging in the lines.

(Please note that when the Model 750B-4KG1 is to be used

on a continuous duty basis to maintain fire-system pressure,

suitable back pressure must be provided on the valve to prevent cavitation damage. Consult the factory for details.)

Operation Sequence

MODEL

For Seawater Service Options See 750-20 E-sheet

For other than standard ANSI flanges consult factory

Din drilling available on all sizes

Page 6

C

LA-VAL

PO Box 1325 Newport Beach CA 92659-0325 Phone: 949-722-4800

Fax: 949-548-5441

Web Site: cla-val.com E-mail: claval@cla-val.com

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

E-Mail: sales@cla-val.ca

Chemin des M

é

sanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

E-Mail: cla-val@cla-val.ch

Copyright

CLA-VAL 2005 Printed in USA Specifications subject to change without notice.

CLA-VAL UK

Dainton House, Goods Station Road

GB - Tunbridge Wells

Kent TN1 2 DH England

Phone: 44-1892-514-400

Fax: 44-1892-543-423

E-Mail: info@cla-val.co.uk

©

E-750B-4KG1 (R-8/06)

Represented By:

When Ordering

Please Specify

1. Catalog No. 750B-4KG1

2. Valve Size

3. Fluid Being Handled

4. Fluid Temperature Range

5. Inlet Pressure Range

Purchase Specification

The Fire Pump Pressure Relief Valve shall modulate to relieve

excess pressure in a fire protection system. It shall maintain

constant pressure in the system regardless of demand changes.

It shall be pilot controlled and back pressure shall not affect its set

point. It shall be actuated by line pressure through a pilot control

system and open fast in order to maintain steady system pressure

as system demand decreases. It shall close gradually to control

surges and shall re-seat drip-tight within 5% of its pressure setting. This valve shall be UL Listed and Factory Mutual approved.

The control valve shall be constructed of a 316L stainless steel

body and only one moving part, an elastomeric liner or control

element. Minimum rangeability shall be 500:1 based on capacity

at flowing pressure conditions. Cf shall be greater than or equal

to 0.9. Valve and control system shall be similar in all respects to

Cla-Val Model 750B-4KG1 as manufactured by Cla-Val, Newport

Beach, California.

3/8" N.P.T.

3 PORTS

"A" TYP.

"BB"

DIA.

FLOW

"CC"

2", 3", 4" and 6" Wafer Style

"E" N.P.T.

"E" N.P.T.

"E" N.P.T.

"D"

DIA.

"B"

DIA.

"C"

6", 8",10" and 12" Flanged Style

Dimensions (100-42 Main Valve)

Performance Specification

Capacity: See Technical Data Sheet

CfFactor: 0.9

Cavitation: See Technical Data Sheet

Rangeability: 500:1

Bearing Friction: No friction from slip-type

bearings

Design Specification

Sizes: 2, 3, and 6 inch wafer style

6, 8, 10, and 12 inch flanged

End Detail Wafer: Fits ANSI B16.5 class 125,150,

250, and 300 flanges

End Detail Flanged: ANSI B16.5 class 150

(fits class 125) or

ANSI B16.5 class 300

(fits class 250)

Maximum Relief Pressure: 3" thru 10" 150 lb. class - 200 psi

3" thru 10" 300 lb. class - 300 psi

Approvals: U.L. Listed.........Sizes 3" thru 10"

FM Approved....Sizes 3" and 4"

Not UL or FM.... Sizes 2" and 12"

Maximum Differential: 150 psid continuous,

225 psid intermittent*

Reverse Pressure

: 125 psid maximum

Temperature Range: 32 to 160 degrees F*

Flange Operating Pressure: Class 125-175 psi maximum

Class 150-275 psi maximum

Class 250-300 psi maximum

Class 300-720 psi maximum

*Temperature range depends on liner material. Higher differential pressure

ratings available.

6. Outlet Pressure Range

7. Maximum Differential Pressure

8. Minimum Differential Pressure

9. Maximum Flow Rate

10. Pilot Set Point

Valve Size (Inches) 2 3 4 6 8 10 12

A 27Ú8 39Ú16 41Ú8 51Ú4 -- -- --

B -- -- -- 107Ú8 143Ú8 18 215Ú8

BB 43Ú8 57Ú8 73Ú8 913Ú16 -- -- --

C -- -- -- 9 11 13 151Ú4

CC 21Ú2 31Ú4 4 51Ú2 -- -- --

D (ANSI 150) -- -- -- 11 131Ú2 16 19

D (ANSI 300) -- -- -- 121Ú2 15 171Ú2 201Ú2

E (Ports) NPT -- -- --

3

Ú8

3

Ú8

1

Ú2

1

Ú2

Approx. Wt. (150 lbs.) 4 71Ú2 14 58 115 190 290

Approx. Wt. (300 lbs.) 4 71Ú2 14 87 155 250 375

Max. Continuous Flow (gpm) 224 469 794 1787 3177 4964 7148

Valve Size (mm for ANSI) 50 80 100 150 200 250 300

A 73 90 105 133 -- -- -B -- -- -- 276 356 457 549

BB 111 149 187 249 -- -- -C -- -- -- 229 279 330 387

CC 64 83 102 140 -- -- -D (ANSI 150) -- -- -- 279 343 406 483

D (ANSI 300) -- -- -- 318 381 445 521

E (Ports) NPT -- -- --

3

Ú8

3

Ú8

1

Ú2

1

Ú2

Approx. kg. (150 lbs.) 1.81 3.63 6.35 30 54.43 89 151.5

Approx. kg. (150 lbs.)with Studs & Nuts 2.72 4.54 10 -- -- -- -Approx. kg. (300 lbs.) 1.81 3.63 6.35 41.73 72.57 116.57 191

Approx. kg. (300 lbs.)with Studs & Nuts 5 6.35 11.8 -- -- -- --

Max. Continuous Flow (l/s.) 14 30 50 113 200 301 451

Page 7

INSTALLATION / OPERATION / MAINTENANCE

Model 100-42 Valve

in Closed Position

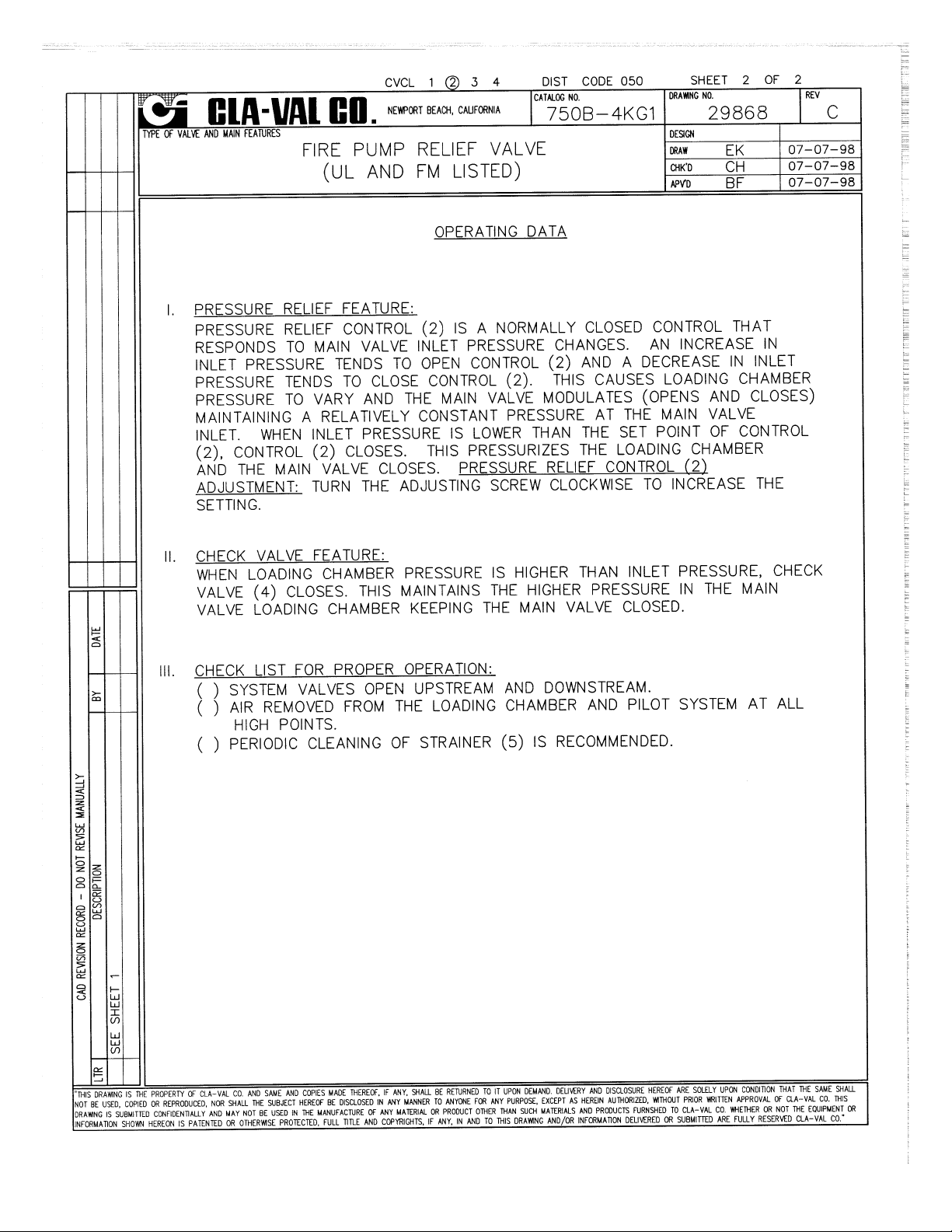

Upstream pressure is introduced to the

control chamber (the chamber formed

behind the liner) through the control

piping and restrictor. When the pilot is

closed, full inlet pressure is supplied to

the control chamber, thus balancing the

force developed by inlet pressure acting on the upstream face on the liner.

Under these conditions, the liner

remains in the fully closed position.

Since the operating pressure in the

control chamber is greater than the outlet pressure, an additional closing force

is developed across the liner, pressing

the liner against the surrounding slotted

grillwork area and seating surface.

Model 100-42 Valve

in Partially Open Position

As loading pressure is lowered slightly

below inlet pressure, the central portion

of the liner is forced to invert and come

to rest against the tip of the control

chamber cavity. Reducing the loading

pressure further (but still higher than

outlet pressure) causes the liner to

drape over the cone shaped portion of

the control chamber cavity. This action

causes the outer section of the liner to

roll off the seating surface and a portion

of the grillwork to partially open the

valve.

Model 100-42 Valve

in Fully Open Position

The valve is fully opened when loading

pressure is sufficiently reduced to allow

the liner to roll back completely and

expose the full slot area. Restoring

loading pressure reverses the liner

rolling action to return the liner to the

fully closed position.

DESCRIPTION

PRINCIPLE OF OPERATION

PILOT

CONTROL

VALVE

RESTRICTOR

SEATING AREA

CONTROL CHAMBER

INLET

Pilot

Control

Valve

RESTRICTOR

SEATING AREA

CONTROL CHAMBER

INLET

PILOT

CONTROL

VALVE

RESTRICTOR

SEATING AREA

INLET

CONTROL CHAMBER

100-42

The Cla-Val Model 100-42 Roll Seal valve

is a hydraulically operated valve used to

control liquid flow by means of a flexible

control element, the liner.

The basic valve consists of only two parts:

a one piece, investment cast body and an

elastomeric liner. The valve body is constructed with internal ribs and slots forming

a grillwork which surrounds the liner to provide support. A normally closed type valve

is formed by the installed liner which covers

the grillwork and seats against the raised

seating surface in the valve body.

Upstream pressure actuates the valve to

produce valve opening by rolling the liner off

the seating surface and the slotted grillwork.

The valve is actuated by upstream pressure

as the loading pressure (pressure supplied

to the control chamber) is varied by an

external pilot control system.

A typical pilot control system used to operate the Model 100-42 valve consists of a

restriction and a suitable pilot connected to

the valve.

700 Series Roll Seal

SERIES

Page 8

The Model 100-42 valve in 6" through

12" sizes are constructed with separable "slip-on" style flanges. Furnished

standard in either class 150 or 300

raised face type, the flanges are

removable and interchangeable. The

class 150 flange may be bolted up to

class 125 pipeline flanges and the

class 300 flange may be mated

against a class 250 flange.

Locate pilot system port connections

at the top of valve in pipeline to allow

easy air venting. A line size strainer is

recommended, mounted on the valve

inlet.

The valve should be given a visual inspection before installation to be sure no foreign

materials have collected inside the valve

during shipment or storage.

Pipelines should be flushed out before the

valve is installed in the system. New systems, especially, should be cleaned as contaminates such as welding beads, scale,

rocks, etc. are commonly contained within

the pipeline.

The valve should be installed in a location

allowing sufficient working space around

the valve to provide easy access for maintenance and removal for servicing.

For 2", 3", and 4" sizes only. Insert the lower

half pattern of stud bolts through the bolt

holes of the upstream and downstream

pipeline flanges.

For 2" & 3" valves only. The 125 and 150

series flanges use a different number of

bolts than the 250 and 300 series flanges.

Hence, the wafer valve body configuration

is inherently self centering regardless of the

flange used.

Install the valve between the flanges being

sure to include the appropriate flange gaskets between each end of the valve and the

mating pipe flange.

Note: The valve must be installed with the

flow arrow on side of body pointing to the

downstream piping section. Cla-Val 700

Series valves may be installed in any position in either vertical or horizontal installations without any effect on valve operation.

Insert the remaining stud bolts and nuts and

tighten evenly using a diagonal cross-over

type pattern.

For the 4'' valve, ANSI pipe flanges use an

8 bolt pattern regardless of pressure ratings, although the 250 and 300 series use

larger bolts on a larger bolt circle. The 4"

valve can be centered in the larger 250 and

300 class flanges by rotating the valve body

into full radial contact with the bolt studs

prior to tightening.

INSTALLATION

PROCEDURE

2.

3.

4.

4a.

6.

7.

1.

Gasket

Gasket

Recommended Strainer

Model 100-42 Roll Seal Valve

The Cla-Val Model 100-42 Roll Seal

valve in 2", 3", and 4" sizes are

designed to mount between standard

pipe flanges (ANSI 125, 150, 250, and

300 series) as a wafer type valve. The

outer portion of the valve body is constructed with fluted (recessed) sections to provide clearance for the class

125 and 150 flange bolt pattern while

the basic outside diameter of the body

centers within the class 250 and 300

flange bolt pattern.

If an inline basket type strainer is to be

included in the installation, insert the strainer into the upstream pipe, making sure a

gasket is placed between the strainer and

the upstream flange.

4b.

5.

Page 9

Liner Retainer Removal 2"-12" Sizes

1

3

5

7

9

2

4

6

8

10

The 2" and 3" liner retainer is secured to the valve with an Allen

screw. Loosen the Allen screw, pull the locking pin back towards

center of retainer, and remove the retainer from valve.

To install, insert the retainer, (do not block inlet feed hole), push

locking pin into position and tighten Allen screw.

The 4"-12" liner retainers are secured with a snap ring. Remove

the snap ring and retainer.

To install, insert retainer and install snap ring into the groove of

valve. Be sure snap ring is completely inserted into groove.

Liner Removal 2"-12" Sizes

The tool used for removal should be free of sharp edges to prevent damage to the liner, the valve body seat or control chamber surfaces. A motorcycle tire iron or similar tool works well.

1. Insert the tool between the liner and the valve body as

deeply as possible.

2. Using the seat edge as a fulcrum, rock the end of the tool

away from the valve in a manner to pull the liner bead out of the

body. Grasp the liner and remove from the valve body.

Liner Installation 2", 3", 4" Sizes

Thoroughly clean out the interior of the valve body control chamber cavity.

Liberally apply glycerine inside the control chamber cavity and

around the seal bead area of the liner.

DO NOT USE ANY HYDROCARBON OR SILICONE BASED

LUBRICANTS ON LINERS AS THESE COMPOUNDS CAN

SEVERELY ATTACK THE LINER MATERIAL.

3. Fold the liner as shown and install into the valve body control chamber as deeply as possible.

4. Continuing to force the liner into the control chamber cavity,

again fold the liner as shown to insert the liner seal bead section

under the valve body seat surface.

5. Work the folded section of the liner into place by pushing

against the folded area to slide the seal bead down the conical

face of the control chamber.

Liner Seating Instructions 2", 3", 4" Sizes

After installing the liner, it must be seated over the manifold ring

in the valve body. The objective of this seating procedure is to

place the inside lip of the liner over the outside lip of the manifold ring.

6. 4" valve with liner installed.

7. Pinch, pull and knead the liner 360° around to seat the liner

on the manifold ring.

8. Using a dull tool or hammer handle, pry the outer part of the

liner towards the center to help "seat" the liner.

9. Now push the liner down into the valve, holding your hand

on the depressed liner, seal off the loading port with your finger.

10. Remove your hand from liner and continue holding your finger over the loading port. If liner is seated, it will be held in the

open position as long as your finger is over the loading port.

When you release your finger, the liner will popup. If not seated,

repeat with Step 7.

Install liner retainer into body.

Page 10

Liner Installation

1

3

5

7

9

2

4

6

8

10

6", 8", 10", 12" sizes

1. Tools required: Bottle of drugstore glycerine,

30" crowbar, double headed plastic hammer

with 14" handle, rubber mallet and large flat

blade screwdriver.

2. Liberally wipe glycerine on the inside of the

valve and on the outer edge of the liner. Fold

liner in half and insert into valve body.

3. Push liner in as far as possible forcing it out side

ways.

4. Place the crowbar at the upper 25% point of the

liner. Take your other hand and push on nose of liner

to bend the liner over the crowbar. The less material

folded over, the easier it will go into the valve. If too

much is folded over, it will be difficult to complete

liner installation.

5. Continue bending liner nose down into the valve.

Use your hands and/or hammer handle to continue

forcing it down into valve. It is important to keep the

"V" of the bend near the 25% point. If it goes over

the center, The liner won't go in, and it will be necessary to start over at Step 3.

6. Use the hammer to force the liner down and out into

the valve body.

7. Use the hammer handle for the final insertion.

Sometimes it is helpful to beat on the liner with the

hammer for the final step.

8. To seat the liner on the manifold ring use the hammer handle to push down on the liner near bore of

valve inlet and pry handle and liner towards the center. Continue this prying action for 360° around the

liner for proper seating.

9. To test for liner seating, push down on the center of

liner and close the loading port shut-off cock, or

block it with your hand. When you release your hand

from the liner, it should remain in the down position

until the loading port is opened.

10. If liner appears seated, open loading port cock and

liner should pop-up to the closed position. Repeat

Steps 6-10 if liner is not seated.

When the liner is fully seated, the inside diameter of

the liner will be seated over the outside diameter of

the manifold ring. The manifold ring is a raised circular ridge at the bottom of the open cavity which provides for even distribution of the fluid coming in and

going out the loading port.

Install liner retainer into body.

Page 11

PLACING VALVE INTO OPERATION

In most instances, the 700 Series Cla-Val

Control valves will be shipped complete

with a pilot control system mounted on the

Model 100-42 valve. Consult the appropriate start up and operation instructions for

the pilot control used before pressurizing

the system.

START-UP INSTRUCTIONS

Pressure Reducing

790 Series Valves

Important Procedure for All Installations:

IT IS IMPORTANT THAT THE PRESSURIZATION AND DEPRESSURIZATION OF ALL

INSTALLATIONS BE CARRIED OUT IN A MANNER TO PREVENT IMPOSING A REVERSE

PRESSURE CONDITION ON THE CLA-VAL

MODEL 100-42 VALVE. PRESSURIZATION OF

THE SYSTEM SHOULD BE ACCOMPLISHED

BY PRESSURIZING THE INLET SIDE FIRST.

Back Pressure Control

750 Series Valves

DEPRESSURIZATION OF THE SYSTEM SHOULD BE ACCOMPLISHED BY

DEPRESSURIZING THE OUTLET SIDE

FIRST. FAILURE TO FOLLOW THIS

PROCEDURE COULD RESULT IN DISLODGEMENT AND/OR DESTRUCTION

OF THE RUBBER LINER.

Relief Valve Applications 750

Series Valves

The following instructions are for

valves equipped with a Model CRD

Pressure Reducing Pilot Control.

1.

Remove the adjustment cap and back

off adjustment screw setting (turn

counterclockwise) of the CRD

Pressure Reducing Pilot Control to fully

relieve all loading on the range spring.

Slowly open the upstream main line

2.

block valve to pressurize the inlet section of the valve.

3.

Bleed any entrapped air from the control chamber of the valve and tubing

sections by loosening fittings at the

highest points. Retighten fittings.

Install gauge on downstream port of

CRD.

4.

Slowly increase tension on the range

spring, by means of the adjustment

screw (turn clockwise) until the desired

downstream pressure is attained. Use

a gauge.

5.

Open the downstream main line block

valve.

If required, reset the pilot adjustment

6.

screw setting to obtain the downstream

pressure desired.

7.

Tighten the adjustment screw lock nut

and replace the adjustment cap.

The following instructions are for

valves equipped with a Model CRL

Back Pressure Pilot Control.

1.

Remove the adjustment cap and

increase tension on the range spring,

by means of the adjustment screw

(turn clockwise) until maximum

spring load is attained.

2.

Slowly open the upstream main line

block valve to pressurize the inlet

section of the valve.

Bleed any entrapped air from the

3.

control chamber of the valve and tubing sections by loosening fittings at

the highest points. Retighten fittings.

4.

Open the downstream main line

block valve.

5.

Gradually decrease tension on the

range spring by means of the adjustment screw (turn counterclockwise)

until upstream pressure decreases to

the desired setpoint.

6.

Tighten the adjustment screw lock

nut and replace the adjustment cap.

The following instructions are for valves

equipped with a Model CRL Pressure

Relief Pilot Control.

Due to the nature of intended use, the

system being protected with the relief

valve will most likely not be able to furnish the pressure source needed to

establish the proper setpoint of the pilot

control. Due to this fact, in most

instances, the relief valve setting procedures will either have to be carried out at

other locations or an auxiliary pressure

source will have to be supplied at the

site in order to carry out the following

procedure.

1.

Remove the adjustment cap and

increase tension on the range spring by

means of the adjustment screw (turn

clockwise) until maximum spring load is

attained.

2.

Slowly introduce inlet pressure to the

valve at the desired setpoint value.

Bleed all air.

3.

Gradually decrease tension on the

range spring by means of the adjustment screw (turn counterclockwise) until

flow is initiated through the valve.

4.

Reduce system pressure back to normal

value. Tighten the adjustment screw

lock nut and replace the adjustment cap.

The valve is now ready for service.

Taking Valve Out of Service

The following procedure should be followed

when taking the Model 100-42 valve out of

service.

1.

Close the upstream main line block valve

first. Then close the downstream main line

block valve.

2.

Vent the downstream section to fully relieve

pressure in the outlet section of the valve.

Vent the upstream section to fully relieve

3.

pressure in the inlet section and control chamber of the Model 100-42 valve.

If the valve liner is to be inspected or

4.

replaced, remove the valve from the main line.

Page 12

2

T

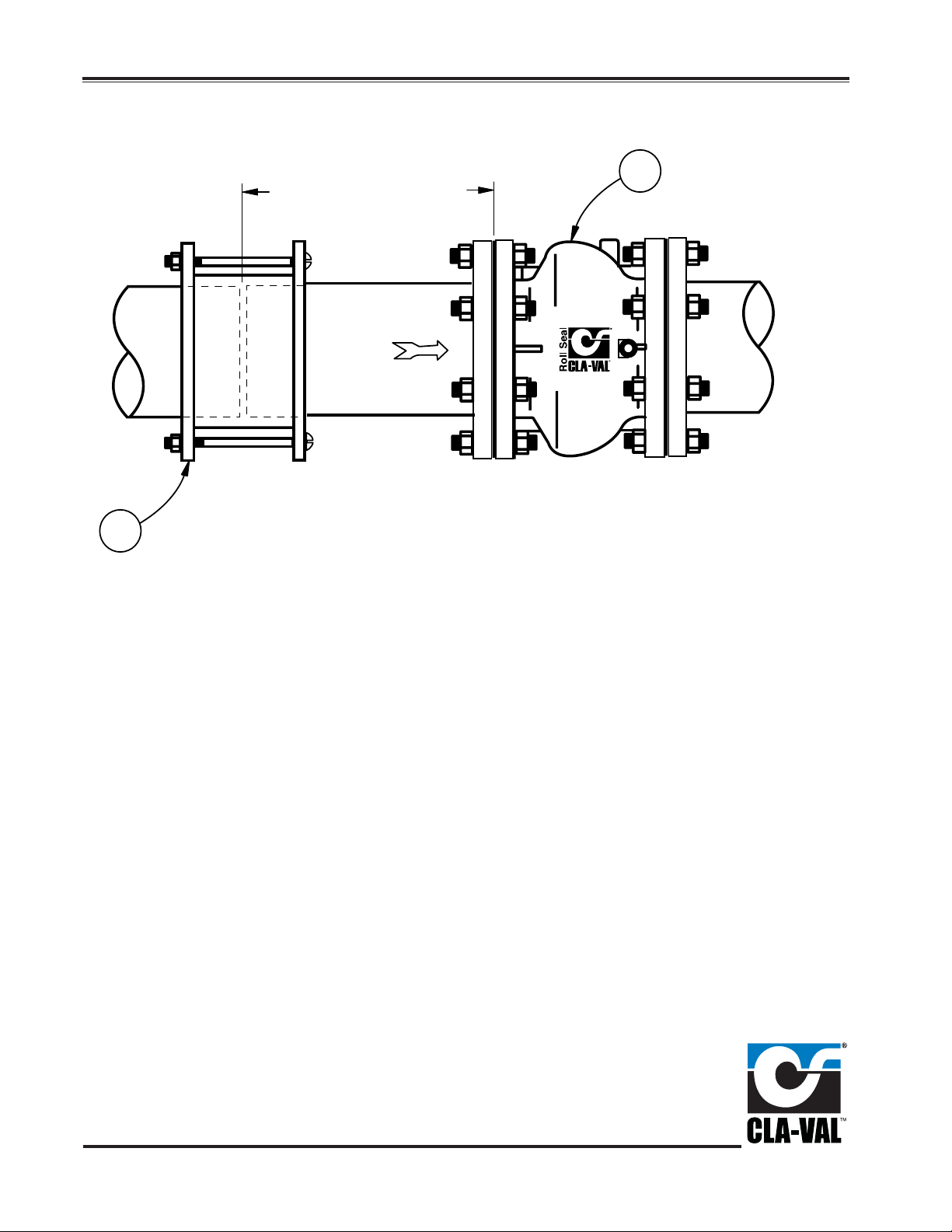

Recommended Pipe layout

6" - 12" Flange style 100-42

2 Pipe Coupling (Rubber Gasket Type)

1 100-42 Main Valve, Flange X Flange

2 1/2 Pipe Diameters

1

Min Recomended

Length Spool

OUTLE

Page 13

2 1/2 PIPE DIAMETERS

MIN RECOMENDED

LENGTH SPOOL

INLET

INLET

®

™

Roll Seal

3

®

™

Roll Seal

4

OUTLET

OUTLET

2

1

Recommended Pipe layout

6" - 12" Grooved style 100-42

1 COUPLER FOR GROOVED PIPE

2 SPOOL STRAINER ASSEMBLY (WITH CONE)

3 100-42 MAIN VALVE, GROOVE X FLANGE

4 100-42 MAIN VALVE, GROOVE X GROOVE

Page 14

1

When ordering

please specify:

• All nameplate data

• Description

• Part Numbers

• Item Number

• Material

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-100-42 (R-1/08)

Item

No.

Description

No.

Req'd

Material

(Standard)

1

2*

3

4

5

6

7

8

Body

Liner

Nameplate

Drive Screw

Liner Retainer

Retaining Ring

Slip-on Flange

Flange Retainer Ring

*Recommended Spare Part

5

1

1

1

2

1

1

2

2

1

7

8

316L Stainless Steel "L"

Natural Rubber

Aluminum

316L Stainless Steel

316L Stainless Steel

316L Stainless Steel

Steel-Cad. Pl.

Steel-Cad. Pl.

2

6

5

4

3

5

6

4

3

2

4" Wafer Style Valve 2-3" Wafer Style Valve 6"-12" Flanged Valve

Page 15

Page 16

Capacity Information

700 Series

MODEL

1

1

However, the above stated relationship only remains valid if the flowing conditions are both turbulent

(non-viscous) and non-cavitating. Fortunately, these conditions are the most common encountered in

liquid flow applications. In those cases where viscous or cavitating

(1)

flow conditions are possible,

consult factory for guidance in selection of valve size.

Example:

Determine the maximum flow rate capability of a 4" Cla-Val Roll Seal valve in fresh water service with

an upstream pressure of 90 psi and downstream pressure of 77 psi. From table, a 4" Cla-Val 700

Series valve has a full open C

v

factor of 128; hence:

Valve Sizing Coefficient - Cv

A very useful expression often used in determining the head loss and/or flow rate capacity of control

valves is the Cvfactor. Commonly referred to as the flow coefficient or valve sizing coefficient, this

empirically determined factor describes the flow capacity of a valve.

The C

v

factor is defined as the number of U.S. gallons per minute of water (at 60°F flowing temperature)

discharged through a flow restriction with a head loss of one psi. In the case of a control valve, the C

v

value is normally stated for the valve in the fully open position. For conditions other than full open, (i.e.

modulating valves), contact Cla-Val Technical Services.

Cla-Val 700 Series Valves - Full Open C

v Factors

Liquid Flow Equation

The basic flow to pressure drop relationship for liquid service is expressed by the formula:

Q = 128 = 128 (3.61) = 462 GPMx

13

or

Q = Flow rate in U.S. gallons per minute (GPM).

C

v

= Valve sizing coefficient.

∆P = Head loss across valve in psi.

G = Specific gravity of liquid at flowing temperature referred to

water (1.0) at standard conditions (60°F).

Where:

(1) Note: For further information on cavitation, see technical data sheet "RS-Cavitation".

Q = C

v

Q = C

v

x

∆P

G

∆P

or

1

G

Valve Size 2" 3" 4" 6" 8" 10" 12"

Cv Factor

48 84 128 451 764 1443 2048

Page 17

N-RS-Capacity (R-8/00)

Specific Gravity Correction Table

Maximum Continuous Flow (U.S. GPM)

Specific

Gravity

"G"

Correction

Factor 1

G

0.75 0.80 0.85 0.90 0.95 1.00 1.05 1.10 1.15 1.20 1.30 1.40

1.15 1.12 1.08 1.05 1.03 1.00 0.98 0.95 0.93 0.91 0.88 0.85

To obtain flow capacity of a liquid other than water (specific gravity of 1.00), multiply water flow capacity obtained by the

appropriate specific gravity correction factor.

NOTE: The flow rate vs. head loss data presented here is based on a fully open valve condition. The maximum

recommended velocity is 20 ft./sec.

Valve Size

Maximum

Continuous

Flow

2" 3" 4" 6" 8" 10" 12"

224 469 794 1787 3177 4964 7148

3"

4"

10000100010010

1

10

100

2" THRU 12" ROLL SEAL FLOW CURVES

STANDARD VERSION WITH LINER RETAINER

(COVER TO ATMOSPHERE)

FLOW (GPM)

PRESSURE DROP (PSI)

10"8"6"

2"

12"

Page 18

*This drawing is the property of CLA-VAL and same and copies made thereof, if any, shall be returned to it upon demand. Delivery and disclosure hereof are made solely

upon condition that the same shall not be used, copied ore reproduced, nor shall the subject here of be disclosed in any manner to anyone for any purpose, except as

herein authorized, without prior approval of CLA-VAL. Whether or not the equipment or information shown hereon is patented or otherwise protected, full title and copyrights if any, in and to this drawing and/or information delivered or submitted are fully reserved by CLA-VAL.

Dwg#47117

Regulator Spring Color Coding Chart

THE FOLLOWING CONTROL & SPRING P/N#'S WERE REMOVED, 32656B, 31554K, 44591G, V65695B, & V5695B.

ADDED CRL-13, CRL-5A, CRA, CRA-10A, CHANGED SPRING RANGES TO MATCH CURRENT CONTROLS.

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-47117 AF (R-1/08)

PARTS LIST

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *PSI PER TURN

.080 DIA. C0492D BLUE S.S.

CDB-7

CRL-5A

0-7

0-7

.75

.75

.018 DIA. 82575C -- S.S.

CRD

CRD-10A

1.9-6.5

1.9-6.5

.61

.49

.116 DIA. 81594E -- S.S.

CRD

CRD-10A

2-30

2-30

3.0

2.4

.120 DIA. V5654J GREEN CHR VAN

CRL-5A

CRD

5-25

10-40

4.0

4.0

.162 DIA. 32447F NATURAL S.S.

CDB-7

CRL-5A

CRL-13

10-60

10-60

10-60

12.0

12.0

12.0

.162 DIA. V5695B YELLOW MUSIC WIRE

CDB-7

CRL-5A

CRL-13

20-80

20-80

20-80

14.5

14.5

14.5

.207 DIA. C1124B CAD PLT MUSIC WIRE

CDB-7

CRL-13

CRL-5A

50-150

50-150

50-150

29.5

29.5

29.5

.225 DIA. V6515A RED MUSIC WIRE

CDB-7

CRL-13

CRL-5A

65-180

65-180

65-180

44.0

44.0

44.0

.115 X .218 71884B RED CHR VAN

CRL

CRD

CRD-10A

0-75

15-75

15-75

8.5

9.0

7.2

.118 X .225 71885J GREEN CHR VAN

CRL

CRD

CRD-10A

20-200

30-300

30-300

28.0

27.0

22.4

.225 X .295 1630201A CAD PLT CHR VAN

CRL

CRL-5A

100-300

100-300

18.00

18.00

.440 X .219 48211H CAD PLT STEEL

CRA-18

CRD-22

CRL-4A

200-450

200-450

100-450

17.0

17.0

17.0

.187 20632101E BLACK 316 SST

CRD

CRL

20-105

20-105

13.0

13.0

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *FEET PER TURN

.080 DIA. C0492D BLUE S.S.

CRA

CRD-2

4.5-15

4.5-15

.82

.82

.375 DIA.

87719B

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-5

5-40

30-80

70-120

110-120

150-200

1.0

2.0

3.0

4.0

5.0

.072 DIA. V5097A -- 302SS CVC 1-17 .7

.375 DIA.

2933502H

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-6A

5-40

30-80

70-120

110-160

150-200

.75

1.50

2.20

3.00

3.70

*THESE FIGURES ARE ONLY APPROXIMATE. FINAL ADJUSTMENTS SHOULD BE MADE WITH A PRESSURE GAGE.

Page 19

THREADED 3/8" 18 NPT

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-X58A (R-1/08)

PARTS LIST

(TYP. BOTH ENDS)

X58A

Restriction Pipe Fitting

"A" DIA.

When ordering parts,

please

specify:

• All Nameplate Data

.69

HEX

(Stock)

• Description

• Size

Part No. Material "A"

Orifice Dia.

74894-07C Brass 3/32" (.093)

74894-06E 303 SS 1/16" (.062)

74894-05G Brass 1/16" (.062)

74894-04K 303 SS 1/8" (.125)

74894-03B Brass 1/8" (.125)

Page 20

2.50

PARTS LIST

A

A

81-01

3/8" Check Valve

ITEM DESCRIPTION

1. Cover Screw (8 Required)

2. Cover

*3. Spring

4. Diaphragm Washer

*5. Diaphragm

*6. Disc Retainer Assembly

7. Body Plug (3/8 NPT)

8. Body (Threaded)

*Recommended Spare Parts

2

1.50

1.25

Outlet

3/8 N.P.T.

Flow

2.75

SECTION

AA

3/8 N.P.T.

BOTH ENDS

Inlet

3

1

4

5

6

When ordering

8

7

parts, please

specify:

• All nameplate data

• Description

• Part Number

• Item Number

• Material

Page 21

10

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-81-01 (R-1/08)

PARTS LIST

1. Body 1

2. Cover 1

*3. Diaphragm 1

4. Guide Disc 1

*5. Disc Retainer Assembly 1

7. Nut Hex 3/8 - 24UNF 28 1

8. Plug Pipe Hex NPT 2

9. Screw, Fil HD 10 32UNF 2 x 2LG 8

10. Spring 1

11. Nameplate 1

81-01

1/2" & 3/4 Check Valve

ITEM DESCRIPTION

3.12 DIA

2

7

6

9

*Recommended Spare Parts

11

2.56

3

5

1

4

OUTLETINLET

8

.56

When ordering

parts, please

specify:

FLOW

3.50

• All nameplate data

• Description

• Part Number

• Item Number

• Material

Page 22

ITEM DESCRIPTION MATERIAL

1 Pipe Plug Steel

2 Strainer Plug Brass

3 Gasket Copper

4 Screen SST

5 Body Brass

1

2

3

4

5

3/8 NPT

2.06

2.72

SIZE STOCK NUMBER

3/8 x 3/8 33450J

Strainer

X43

No parts available. Rreplacement assembly only.

Standard 60 mesh pilot system strainer for fluid service.

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL- X43 (R-1/08)

PARTS LIST

Page 23

CLA-VAL

©

copyright Cla-Val 2004 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

How to Order

Roll Seal

¤

TM

CLA-VAL

How To Order

There are many valves and controls manufactured by Cla-Val. that

are not listed due to the sheer volume. For information not listed,

please contact your local Cla-Val

representative.

Specify when

ordering

• Model Number

• Adjustment Range

(As Applicable)

• Valve Size

• Optional Features

• Pressure Class

Unless Otherwise

Specified

• X43 “Y” Strainer is

included.

• CK2 Isolation Valves is

included in price on 6" and

larger valve sizes.

Limited Warranty

Automatic valves and controls as manufactured by Cla-Val are

warranted for one year from date of shipment against manufacturing defects in material and workmanship which develop in the

service for which they are designed, provided the products are

installed and used in accordance with all applicable instructions and limitations issued by Cla-Val.

We will repair or replace defective material, free of charge, which

is returned to our factory, transportation charges prepaid, provided that, after inspection, the material is found to have been

defective at time of shipment. This warranty is expressly conditioned on the purchaser’s giving Cla-Val immediate written

notice upon discovery of the defect.

Components used by Cla-Val but manufactured by others, are

warranted only to the extent of that manufacturer’s guarantee.

This warranty shall not apply if the product has been altered or

repaired by others, and Cla-Val. shall make no allowance or

credit for such repairs or alterations unless authorized in writing

by Cla-Val.

750B-4KG1

Product Identification

Proper Identification

For ordering repair kits, replacement parts, or for

inquiries concerning valve operation it is important to

properly identify Cla-Val products already in service.

Include all nameplate data with your inquiry. Pertinent

product data includes valve function, size, material,

pressure rating, end details, type of pilot controls used

and control adjustment ranges.

Identification Plate

For product identification, cast in body markings are

supplemented by the identification plate illustrated on

this page. The plate is mounted in the most practical

position. It is extremely important that this identifi-

cation plate is not painted over, removed, or in any

other way rendered illegible.

N-750B-4KG1 P.I.D.

Terms Of Sale

ACCEPTANCE OF ORDERS

All orders are subject to acceptance by our main office at

Newport Beach, California.

CREDIT TERMS

Credit terms are net thirty (30) days from date of invoice.

PURCHASE ORDER FORMS

Orders submitted on customer’s own purchase order forms will be

accepted only with the express understanding that no statements,

clauses, or conditions contained in said order form will be binding

on the Seller if they in any way modify the Seller’s own terms and

conditions of sales.

PRODUCT CHANGES

The right is reserved to make changes in pattern, design or materials when deemed necessary, without prior notice.

PRICES

All prices are F.O.B. Newport Beach, California, unless expressly

stated otherwise on our acknowledgement of the order. Prices are

subject to change without notice. The prices at which any order is

accepted are subject to adjustment to the Seller’s price in effect at

the time of shipment. Prices do not include sales, excise, municipal,

state or any other Government taxes. Minimum order charge

$75.00.

RESPONSIBILITY

We will not be responsible for delays resulting from strikes, accidents, negligence of carriers, or other causes beyond our control.

Also, we will not be liable for any unauthorized product alterations

or charges accruing there from.

Page 24

Disclaimer Of Warranties And

Limitations Of Liability

The foregoing warranty is exclusive and in lieu of all other

warranties and representations, whether expressed,

implied, oral or written, including but not limited to any

implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations

are hereby cancelled.

Cla-Val shall not be liable for any incidental or consequential

loss, damage or expense arising directly or indirectly from

the use of the product. Cla-Val shall not be liable for any

damages or charges for labor or expense in making repairs

or adjustments to the product. Cla-Val shall not be liable for

any damages or charges sustained in the adaptation or use

of its engineering data and services. No representative of

Cla-Val may change any of the foregoing or assume any

additional liability or responsibility in connection with the

product. The liability of Cla-Val is limited to material replacements F.O.B. Newport Beach, California.

Risk

All goods are shipped at the risk of the purchaser after they have been

delivered by us to the carrier. Claims for error, shortages, etc., must be

made upon receipt of goods.

EXPORT SHIPMENTS

Export shipments are subject to an additional charge for export packing.

RETURNED GOODS

1. Customers must obtain written approval from Cla-Val prior to returning any material.

2. Cla-Val reserves the right to refuse the return of any products.

3. Products more than six (6) months old cannot be returned for credit.

4. Specially produced, non-standard models cannot be returned for

credit.

5. Rubber goods cannot be returned for credit, unless as part of an

unopened repair kit which is less than six months old.

6. Goods authorized for return are subject to a 35% ($75 minimum)

restocking charge and a service charge for inspection, reconditioning, replacement of rubber parts, retesting and repackaging as

required.

7. Authorized returned goods must be packaged and shipped prepaid to

Cla-Val., 1701 Placentia Avenue, Costa Mesa, California 92627-

4475.

N-750B-4KG1 P.I.D.

Page 25

®

INSTALLATION / OPERATION / MAINTENANCE

750B-4KG1

™

Repair Kits

Roll Seal

The Cla-Val 700 Series valve repair kit for the 750B-4KG1 is the only recommended spare part. The valve

series is highly reliable due to fewer parts to create problems.

Valve repair kits are recommended over individual liner sales. Kits offer all essentials for easy installation to

include: liner, lubricant, liner retainer hardware, and instructions.

REPAIR KIT PART NUMBERS:

2" 3" 4" 6" 8" 10" 12"

Natural Rubber

65 Durometer

EPDM

70 Durometer

Nitrile

70 Durometer

Silicone

70 Durometer

Viton

70 Durometer

Natural Rubber

65 Durometer

EPDM

70 Durometer

Nitrile

70 Durometer

Silicone

70 Durometer

Viton

70 Durometer

R2001501A R2001502A R2001503J R2001504G R2001505A R2001506A R2001507K

R2002201J R2002202G R2002203E R2002204C R2002205K R2002206H R2002207F

R2002301G R2002302E R2002303C R2002304A R2002305H R20012306F R2002307D

R2001401F R2001402D R2001403B R2001404K R2001405G R2001406E R2001407C

R2002101A R2002102J R22002103G R2002104E R2002105A R2002106K R2002107H

LINER PART NUMBERS:

2" 3" 4" 6" 8" 10" 12"

R940001 R940101 R940201 R940301 R940401 R940501 R940601

R940006 R940106 R940206 R940306 R940406 R940506 R940606

R940007 R940107 R940207 R940307 R940407 R940507 R940607

R940003 R940103 R940203 R940303 R940403 R940503 R940603

R940005 R940105 R940205 R940305 R940405 R940505 R940605

REPAIR KIT PART NUMBERS:

(FOR UL LISTED 750B-4KG1 VALVE ASSEMBLY

3" 4" 6" 8" 10"

Nitrile

70 Durometer

R2002302E R2002303C R2002304A R2002305H R20012306F

LINER PART NUMBERS:

(FOR UL LISTED 750B-4KG1 VALVE ASSEMBLY

Nitrile

70 Durometer

When ordering, please give complete nameplate data of the valve and/or control being repaired.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

CLA-VAL

©copyright Cla-Val 2000 Printed in USA Specification subject to change without notice.

R940107 R940207 R940307 R940407 R940507

MINIMUM ORDER CHARGE APPLIES.

N-750B-4KG1 RSRK (R-11/99)

Loading...

Loading...