Page 1

INSTALLATION / OPERATION / MAINTENANCE

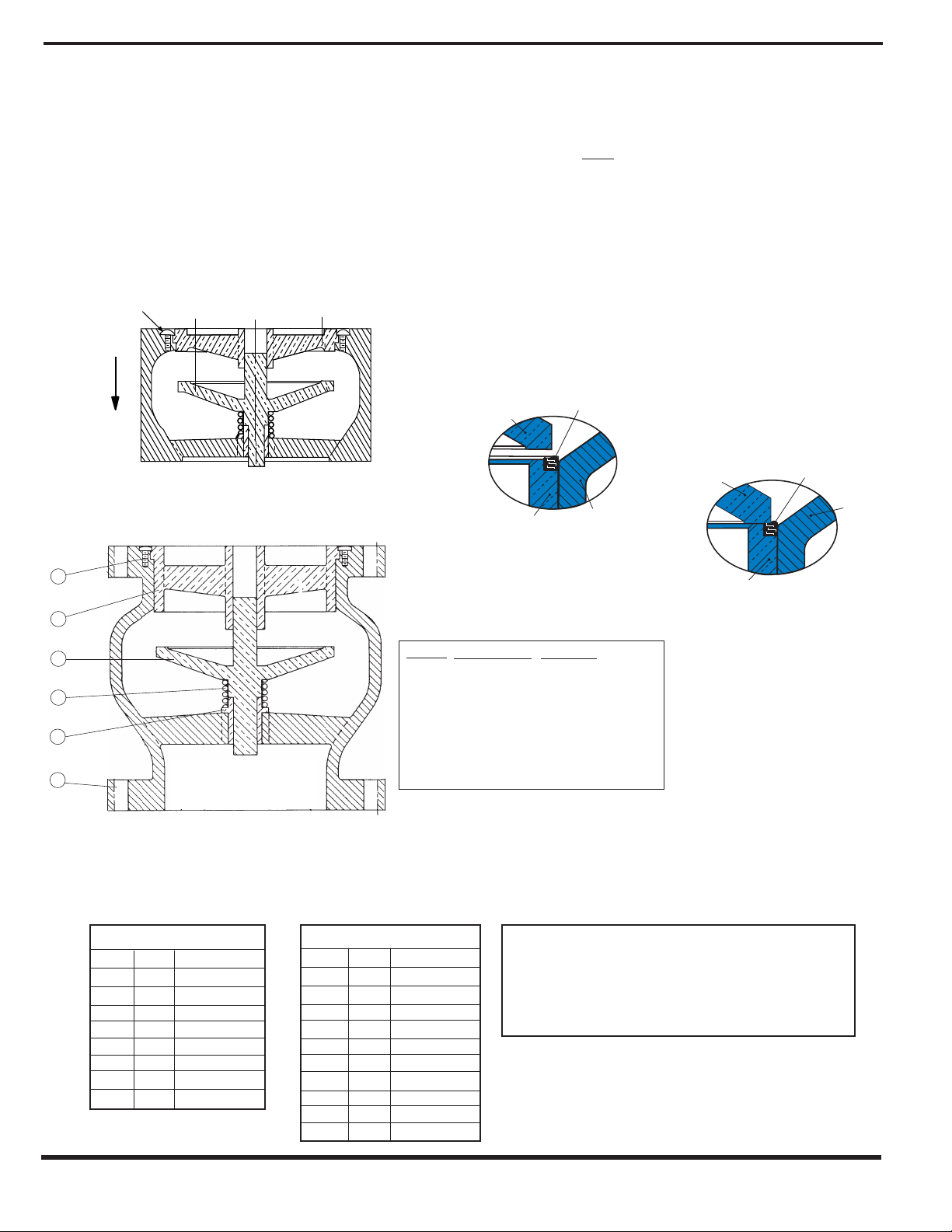

FLOW OPEN

See

Note 2

SERIES 580

WAFER STYLE CHECK VALVE

2" THRU 10"

1

2

6

3

4

5

Y

WAFER & GLOBE SILENT CHECK VALVES

OPERATION:

Cla-Val Silent Check Valves operate automatically, to open...

when pump flow starts and close silently ...when pump flow

stops.

INSTALLATION:

Silent Check Valves, Wafer and Globe style must be

installed between flat faced iron or steel flanges per ANSI

B16.5 or Awwa 207, utilizing a full faced gasket to bridge the

joint between the seat O.D. (2) and the body (1) flange face.

In this manner a pressure seal at this joint is made (see

Note 1). Install the valve so that the nameplate data is plainly read and the flow arrow points in the flow direction.

MAXIMUM ALLOWABLE INSIDE

DIAMETER OF FLANGE

(SEE NOTE No. 1)

VALV E

SIZE

21⁄2 2.940 14 14.140

3 3.570 16 16.160

4 4.570 18 18.180

5 5.660 20 20.200

6 6.720 24 24.250

8 8.720 30 30.250

10 10.880 36 36.250

12 12.880 42 42.250

Val ve

Size

21⁄2 2.875 4.875 5.125 14 14.000 17.750 19.125

3 3.50 5.375 5.875 16 16.000 20.250 21.250

4 4,50 6.875 7.125 18 18.00 21.625 23.500

5 5.562 7.750 8.500 20 20.00 23.875 25.750

6 6.625 8.75 9.875 24 24.000 28.250 30.500

8 8.625 11.000 12.125 30 30.000 34.750 37.500

10 10.750 13.375 14.250 36 36.000 41.250 44.000

12 12.750 16.125 16.625 42 42.000 48.000 50.750

MAINTENANCE:

Cla-Val Silent Check Valves are ruggedly designed for years of trouble-free

VALV E

A

SIZE

STANDARD RING GASKET DIMENSIONS (SEE NOTE No. 2)

I.D. For

125 Lb.

and

250 Lb.

Gasket

A

O.D. for

125 Lb.

Gasket

MAXIMUM ALLOWABLE INSIDE

(1/16" Maximum Thickness)

Note No. 1 - The mating companion flange I.D. must overlap the Valve seat.

O.D. for

250 Lb.

Gasket

A

DIAMETER OF FLANGE

(SEE NOTE NO. 1 )

ANSI B16.5 COMPANION

FLANGE WITH FLAT FACE

Ring or Full Faxe Gasket

This is required to achieve a seal between the seat O.D. and

The Body I.D. Interface area.

Val ve

Size

I.D. For

125 Lb.

250 Lb.

service. Therefore, regular maintenance is not required. However, during

initial start-up period the following problems may surfa ce (due to mis-application)

that can be easily resolved:

A. No Flow thru Valve:

1. Observe that the flow arrow name plate, on the

valve body, is pointing in the direction of flow.

2. Check that the down stream shut-off valve is full open.

B. Valve Chatters:

1. Confirm that the flow velocity is a minimum 3’/Sec.

2. Check that there is a minimum of 3 diameters of

straight pipe installed up stream of the silent check valve.

C. Valve Leakage:

1. Confirm a full face gasket is installed per Note 1.

and

Gasket

VALVE SEAT

VALVE DISC

Silent Check Valve - Flanged or Wafer Style

O.D. for

125 Lb.

Gasket

Series 581

Globe Style

Check Valve

2” thru 42”

Note 1: flanged gasket

must bridge this joint

for pressure seal

VALVE BOD

(Flanged Style Shown)

O.D. for

250 Lb.

Gasket

SERIES

580 & 581

Installed with name plate here

6

Detail

1

2

3

4

5

6

2

Description

Body

Seat*

Disc*

Spring*

Bushing*

Screw*

34

Note 2: All size 2” and 2 1/2” valves have

threaded seats in liev of screws

* Recommended Spare Part Kit

5

Material

Cast Iron

Bronze or SS

Bronze or SS

(Optional Buna-N

Stainless Steel

Bronze

Stainless Steel

(3” & larger valves)

1

®

)

Page 2

TO REMOVE VALVE FROM PIPELINE FOR INSPECTION:

DOWN STREAM

SIDE

UP STREAM

SIDE

REMOVE

CAP SCREWS

DISC

SEAT

FLOW

Plug

Seat

Body

Buna-N Seal

Open

®

Plug

Seat

Body

Buna-N Seal

Closed

®

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

1. Shut off pump and pressure upstream and shut off isolation valve downstream

to completely isolate check valve. A skilled pipe fitter should be used for

this work.

2. Lay valve to rest on its downstream side and remove cap screws as

shown in Fig. 3. Note that 2" and 2-1/2" valves threaded seats in lieu of

cap screws.

3. Grip seat spokes by hand to pull out seats or push down the disc and

release quickly to allow force of the spring to pop out the seat.

4. With seat removed, check that all internal parts are freely removable from

valve body.

5. Examine all parts for wear/damage and order replacement PARTS KITS

as shown below.

Valve Open

Unseated

FIG. 3

6

UP STREAM

SIDE

Pressure

Silent Check Valve

Buna-N® Seating Detail

(Optional)

PROVIDES DROP-TIGHT SEATING

AT L OW

The unique seating action begins with the initial contact

between the metal valve disc and the Buna-N® Seal.

As pressure increases, Buna-N® seal is slightly compressed and allows the disc to make contact with the

metal portion of the valve seat. This metal-to-metal

contact prevents any further compression of the

Buna-N® seal. (Over compression of the synthetic

seal can lead to its destruction and cause potential

leakage.)

PRESSURES WITHOUT DAMAGE TO

BUNA-N

®

SEAL AT HIGHER PRESSURE

Valve Closed

Seated

with Pressure

2

3

4

5

1

Series 580 Wafer Style

Model Size Kits

580

580

580

580

580

580

580

580

2”

1/2”

2

3”

4”

5”

6”

8”

10”

DOWN STREAM

SIDE

A B C D

A B C D

A B C D

A B C D

A B C D

A B C D

A B C D

A B C D

Detail

Description

1

Body

2

Seat*

3

Plug*

4

Spring*

5

Bushing*

6

Screw*

Note 2: All size 2” and 2 1/2” valves have

threaded seats in liev of screws

* Recommended Spare Part Kit

Silent Check Valve Spare Part Kits

Series 581 Globe Style

Model Size Kits

2”

A

B

C

581

581

581

581

581

581

581

581

581

581

2

1/2”

3”

4”

5”

6”

8”

10”

12”

14”

A

A

A

A

A

A

A

A

A

D

B

C

D

B

C

D

B

C

D

B

C

D

B

C

D

B

C

D

B

C

D

B

C

D

B

C

D

Material

Cast Iron

Bronze or SS

Bronze or SS

(Optional Buna-N

Stainless Steel

Bronze

Stainless Steel

(3” & larger valves)

A- Kit Includes Detail 2 Bronze Seat & Detail 3 Disc

B- Kit Includes Detail 2 Stainless Steel Seat & Detail 3 Disc

C-Kit Includes Detail 2 Stainless Steel Seat, Detail 3

Disc, Detail 4 Spring, & Detail 5 Bronze Bushing

D-Kit Includes Detail 2 Stainless Steel Seat, Detail 3

Disc, Detail 4 Spring, & Detail 5 Stainless Steel Bushing

®

)

N-580/581 (R-3/2011)

Loading...

Loading...