Page 1

52-03/652-03 4in

Page 2

Page 3

Page 4

Page 5

Page 6

Page 7

Page 8

Description

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Installation

1. Before valve is installed, pipe lines should be flushed of all

chips, scale and foreign matter.

2. It is recommended that either gate or block valves be

installed on both ends of the 100-01 Hytrol Valve to facilitate

isoIating the valve for preventive maintenance and repairs.

3. Place the valve in the line with flow through the valve in the

direction indicated on the inlet nameplate. (See “Flow Direction”

Section)

4. Allow sufficient room around valve to make adjustments and

for disassembly.

5. CIa-VaI 100-01 Hytrol Valves operate with maximum efficiency

when mounted in horizontal piping with the cover UP, however,

other positions are acceptable. Due to size and weight of the

cover and internal components of 8 inch and πlarger valves,

installation with the cover UP is advisable. This makes internal

parts readily accessible for periodic inspection.

6. If a pilot control system is installed on the 100-01 Hytrol Valve,

use care to prevent damage. If it is necessary to remove fittings

or components, be sure they are kept clean and replaced

exactly as they were.

7. After the valve is installed and the system is first pressurized,

vent air from the cover chamber and pilot system tubing by

loosening fittings at all high points.

Tight Closing Operation

When pressure from the valve inlet (or

an equivalent independent operating

pressure) is applied to the diaphragm

chamber the valve closes drip-tight.

Full Open Operation

When pressure in diaphragm chamber

is relieved to a zone of lower pressure

(usually atmosphere) the line pressure

(5 psi Min.) at the valve inlet opens the

valve.

Modulating Action

Valve modulates when diaphragm pressure is held at an intermediate point

between inlet and discharge pressure.

With the use of a Cla-Val. "modulating

control," which reacts to line pressure

changes, the pressure above the

diaphragm is varied, allowing the valve

to throttle and compensate for the

change.

Principles of Operation

Three Way

Pilot Control

Three Way

Pilot Control

Restriction

Modulating

Control

100-01

Hytrol Valve

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Page 9

2

Flow Direction

The flow through the 100-01 Hytrol Valve can be in one of two

directions. When flow is “up-and-over the seat,” it is in “normal”

flow and the valve will fail in the open position. When flow is “overthe seat-and down,” it is in “reverse” flow and the valve will fail in

the closed position. There are no permanent flow arrow markings.

The valve must be installed according to nameplate data.

BRIDGEWALL INDlCATOR

Normal Flow Reverse Flow

Troubleshooting

The following troubleshooting information deals strictly with the

Model 100-01 Hytrol Valve. This assumes that all other components of the pilot control system have been checked out and are

in proper working condition. (See appropriate sections in

Technical Manual for complete valve).

Three Checks

The 100-01 Hytrol Valve has only one moving part (the diaphragm

and disc assembly). So, there are only three major types of problems to be considered.

First: Valve is stuck - that is, the diaphragm assembly is not free

to move through a full stroke either from open to close or vice

versa.

Second: Valve is free to move and can’t close because of a worn

out diaphragm.

Third: Valve leaks even though it is free to move and the

diaphragm isn’t leaking.

Closed isolation valves in control system, or in main line.

Lack of cover chamber pressure.

Diaphragm damaged. (See Diaphragm Check.)

Diaphragm assembly inoperative.

Corrosion or excessive scale build up on valve stem.

(See Freedom of Movement Check)

Mechanical obstruction. Object lodged in valve.

(See Freedom of Movement Check)

Worn disc. (See Tight Sealing Check)

Badly scored seat. (See Tight Sealing Check)

Closed upstream and/or downstream isolation

valves in main line.

Insufficient line pressure.

Diaphragm assembly inoperative. Corrosion or excessive

buildup on valve stem. (See Freedom of Movement Check)

Diaphragm damaged. (For valves in "reverse flow" only)

After checking out probable causes and remedies, the following three checks can be used to diagnose the nature of the

problem before maintenance is started. They must be done in the order shown.

Open Isolation valves.

Check upstream pressure, pilot system, strainer, tubing, valves, or needle

valves for obstruction.

Replace diaphragm.

Clean and polish stem. Inspect and replace any damaged or badly eroded

part.

Remove obstruction.

Replace disc.

Replace seat.

Open isolation valves.

Check upstream pressure. (Minimum 5 psi flowing line pressure differential.)

Clean and polish stem. Inspect and replace any

damaged or badly eroded part.

Replace diaphragm.

Fails to Close

Fails to Open

CAUTION:

Care should be taken when doing the troubleshooting checks on

the 100-01 Hytrol Valve. These checks do require the valve to

open fully. This will either allow a high flow rate through the

valve, or the downstream pressure will quickly increase to the

inlet pressure. In some cases, this can be very harmful. Where

this is the case, and there are no block valves in the system to

protect the downstream piping, it should be realized that the

valve cannot be serviced under pressure. Steps should be

taken to remedy this situation before proceeding any further.

(cast into side of valve body)

SYMPTOM PROBABLE CAUSE REMEDY

Recommended Tools

1. Three pressure gauges with ranges suitable to the installation to be put at Hytrol inlet, outlet and cover connections.

2. Cla-Val Model X101 Valve Position Indicator. This provides visual indication of valve position without disassembly

of valve.

3. Other items are: suitable hand tools such as screwdrivers, wrenches, etc. soft jawed (brass or aluminum) vise,

400 grit wet or dry sandpaper and water for cleaning.

All trouble shooting is possible without removing the valve from the

line or removing the cover. It is highly recommended to permanently

install a Model X101 Valve Position Indicator and three gauges in

unused Hytrol inlet, outlet and cover connections.

Page 10

Diaphragm Check (#1 )

1. Shut off pressure to the Hytrol Valve by slowly closing upstream

and downstream isolation valves. SEE CAUTION.

2. Disconnect or close all pilot control lines to the valve cover and

leave only one fitting in highest point of cover open to atmosphere.

3.With the cover vented to atmosphere, slowly open upstream

isolation valve to allow some pressure into the Hytrol Valve body.

Observe the open cover tapping for signs of continuous flow. It is

not necessary to fully open isolating valve. Volume in cover chamber capacity chart will be displaced as valve moves to open position. Allow sufficient time for diaphragm assembly to shift positions. If there is no continuous flow, you can be quite certain the

diaphragm is sound and the diaphragm assembly is tight. If the

fluid appears to flow continuously this is a good reason to believe

the diaphragm is either damaged or it is loose on the stem. In

either case, this is sufficient cause to remove the valve cover and

investigate the leakage. (See “Maintenance” Section for procedure.)

Freedom of Movement Check (#2)

4. Determining the Hytrol Valve’s freedom of movement can be

done by one of two methods.

5. For most valves it can be done after completing Diaphragm

Check (Steps 1, 2, and 3). SEE CAUTION. At the end of step 3

the valve should be fully open.

6. If the valve has a Cla-Val X101 Position Indicator, observe the

indicator to see that the valve opens wide. Mark the point of maximum opening.

7. Re-connect enough of the control system to permit the application of inlet pressure to the cover. Open pilot system cock so

pressure flows from the inlet into the cover.

8. While pressure is building up in the cover, the valve should

close smoothly. There is a hesitation in every Hytrol Valve closure,

which can be mistaken for a mechanical bind. The stem will

appear to stop moving very briefly before going to the closed position. This slight pause is caused by the diaphragm flexing at a

particular point in the valve’s travel and is not caused by a

mechanical bind.

9. When closed, a mark should be made on the X101 Valve position indicator corresponding to the “closed” position. The distance

between the two marks should be approximately the stem travel

shown in chart.

10. If the stroke is different than that shown in stem travel chart

this is a good reason to believe something is mechanically restricting the stroke of the valve at one end of its travel. If the flow does

not stop through the valve when in the indicated “closed” position,

the obstruction probably is between the disc and the seat. If the

flow does stop, then the obstruction is more likely in the cover. In

either case, the cover must be removed, and the obstruction located and removed. The stem should also be checked for scale buildup. (See “Maintenance, section for procedure.)

11. For valves 6” and smaller, the Hytrol Valve’s freedom of movement check can also be done after all pressure is removed from

the valve. SEE CAUTION. After closing inlet and outlet isolation

valves and bleeding pressure from the valve, check that the cover

chamber and the body are temporarily vented to atmosphere.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness. The

diaphragm assembly should move smoothly throughout entire

valve stroke. The tool is fabricated from rod that is threaded on

one end to fit valve stem and has a “T” bar handle of some kind

on the other end for easy gripping. (See chart in Step 4 of

“Disassembly” Section.)

12. Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance

between the two marks should be approximately the stem travel

shown in stem travel chart. If the stroke is different than that

shown, there is a good reason to believe something is mechanically restricting the stroke of the valve. The cover must be

removed, and the obstruction located and removed. The stem

should also be checked for scale build-up. (See “Maintenance”

Section for procedure.)

Tight Sealing Check (#3)

13. Test for seat leakage after completing checks #1 & #2 (Steps

1 to 12). SEE CAUTION. Close the isolation valve downstream of

the Hytrol Valve. Apply inlet pressure to the cover of the valve, wait

until it closes. Install a pressure gauge between the two closed

valves using one of the two ports in the outlet side of the Hytrol.

Watch the pressure gauge. If the pressure begins to climb, then

either the downstream isolation valve is permitting pressure to

creep back, or the Hytrol is allowing pressure to go through it.

Usually the pressure at the Hytrol inlet will be higher than on the

isolation valve discharge, so if the pressure goes up to the inlet

pressure, you can be sure the Hytrol is leaking. Install another

gauge downstream of isolating valve. If the pressure between the

valves only goes up to the pressure on the isolation valve

discharge, the Hytrol Valve is holding tight, and it was just the isolation valve leaking.

STEM TRAVEL

(Fully Open to Fully Closed)

Valve Size (inches) Travel (inches)

Inches MM Inches MM

1 1/4 32 0.4 10

1 1/2 40 0.4 10

2 50 0.6 15

2 1/2 65 0.7 18

3 80 0.8 20

4 100 1.1 28

6 150 1.7 43

8 200 2.3 58

10 250 2.8 71

12 300 3.4 86

14 350 4.0 100

16 400 4.5 114

24 600 6.5 165

36 900 8.5 216

COVER CHAMBER CAPACITY

(Liquid Volume displaced when valve opens)

Valve size (inches) Displacement

Gallons Liters

1 1/4 .020 .07

1 1/2 .020 .07

2 .032 .12

2 1/2 .043 .16

3 .080 .30

4 .169 .64

6 .531 2.0

8 1.26 4.8

10 2.51 9.5

12 4.00 15.1

14 6.50 24.6

16 9.57 36.2

24 29.00 109.8

36 90.00 340.0

3

Page 11

Maintenance

Preventative Maintenance

The Cla-Val Co. Model 100-01 Hytrol Valve requires no lubrication or

packing and a minimum of maintenance. However, a periodic inspection schedule should be established to determine how the operating

conditions of the system are affecting the valve. The effect of these

actions must be determined by inspection.

Disassembly

Inspection or maintenance can be accomplished without removing

the valve from the line. Repair kits with new diaphragm and disc are

recommended to be on hand before work begins.

WARNING: Maintenance personnel can be injured and equipment

damaged if disassembly is attempted with pressure in the valve. SEE

CAUTION.

1. Close upstream and downstream isolation valves and independ-

ent operating pressure when used to shut off all pressure to the

valve.

2. Loosen tube fittings in the pilot system to remove pressure from

valve body and cover chamber. After pressure has been released

from the valve, use care to remove the controls and tubing. Note and

sketch position of tubing and controls for re-assembly. The schematic in front of the Technical Manual can be used as a guide when

reassembling pilot system.

3. Remove cover nuts and remove cover. If the valve has been in

service for any length of time, chances are the cover will have to be

loosened by driving upward along the edge of the cover with a dull

cold chisel.

On 6” and smaller valves block and tackle or a power hoist can be

used to lift valve cover by inserting proper size eye bolt in place of

the center cover plug. on 8” and larger valves there are 4 holes (5/8”

— 11 size) where jacking screws and/or eye bolts may be inserted

for lifting purposes. Pull cover straight up to keep from damaging

the integral seat bearing and stem.

4. Remove the diaphragm and disc assembly from the valve body.

With smaller valves this can be accomplished by hand by pulling

straight up on the stem so as not to damage the seat bearing.

On large valves, an eye bolt of proper size can be installed in the

stem and the diaphragm assembly can be then lifted with a block and

tackle or power hoist. Take care not to damage the stem or bearings.

The valve won't work if these are damaged.

5. The next item to remove is the stem nut. Examine the stem

threads above the nut for signs of mineral deposits or corrosion.

If the threads are not clean, use a wire brush to remove as much

of the residue as possible. Attach a good fitting wrench to the nut

and give it a sharp “rap” rather than a steady pull. Usually

several blows are sufficient to loosen the nut for further removal.

On the smaller valves, the entire diaphragm assembly can be held

by the stem in a vise equipped with soft brass jaws before

removing the stem nut.

The use of a pipe wrench or a vise without soft brass jaws scars

the fine finish on the stem. No amount of careful dressing can

restore the stem to its original condition. Damage to the finish of

the stem can cause the stem to bind in the bearings and the valve

will not open or close.

6. After the stem nut has been removed, the diaphragm assembly

breaks down into its component parts. Removal of the disc from

the disc retainer can be a problem if the valve has been in service for a long time. Using two screwdrivers inserted along the outside edge of the disc usually will accomplish its removal. Care

should be taken to preserve the spacer washers in water, particularly if no new ones are available for re-assembly.

7. The only part left in the valve body is the seat which ordinarily

does not require removal. Careful cleaning and polishing of inside

and outside surfaces with 400 wet/dry sandpaper will usually

restore the seat’s sharp edge. If, however, it is badly worn and

replacement is necessary, it can be easily removed.

Seats in valve sizes 1 1/4” through 6” are threaded into the valve

body. They can be removed with accessory X109 Seat Removing

Tool available from the factory. On 8” and larger valves, the seat

is held in place by flat head machine screws. Use a tight-fitting,

long shank screwdriver to prevent damage to seat screws. If upon

removal of the screws the seat cannot be lifted out, it will be necessary to use a piece of angle or channel iron with a hole drilled

in the center. Place it across the body so a long stud can be inserted through the center hole in the seat and the hole in the angle

iron. By tightening the nut a uniform upward force is exerted on

the seat for removal.

NOTE: Do not lift up on the end of the angle iron as this may force

the integral bearing out of alignment, causing the stem to bind.

VALVE STEM THREAD SIZE

Valve Size Thread Size (UNF Internal)

1 1/4"

—2 1/2" 10—32

3"—4" 1/4—28

6"—14" 3/8—24

16" 1/2—20

24" 3/4-16

36” 3/4-16

COVER CENTER PLUG SIZE

Valve Size Thread Size (NPT)

1 1/4"

—1 1/2" 1/4"

2"—3" 1/2"

4"—6" 3/4"

8"—10" 1"

12" 1 1/4"

14" 1 1/2"

16" 2"

24" 2"

36” 2”

NUT

ANGLE OR CHANNEL IRON

LONG STUD OR BOLT

NUT OR BOLT HEAD

DO NOT

LIFT

VALVE SEAT

VALVE BODY

4

Page 12

Lime Deposits

One of the easiest ways to remove lime deposits from the valve

stem or other metal parts is to dip them in a 5-percent muriatic

acid solution just long enough for the deposit to dissolve. This

will remove most of the common types of deposits. CAUTlON:

USE EXTREME CARE WHEN HANDLING ACID. Rinse parts in

water before handling. If the deposit is not removed by acid, then

a fine grit (400) wet or dry sandpaper can be used with water.

Reassembly

1. Reassembly is the reverse of the disassembly procedure. If a

new disc has been installed, it may require a different number of

spacer washers to obtain the right amount of “grip” on the disc.

When the diaphragm assembly has been tightened to a point

where the diaphragm cannot be twisted, the disc should be compressed very slightly by the disc guide. Excessive compression

should be avoided. Use just enough spacer washers to hold the

disc firmly without noticeable compression.

2. MAKE SURE THE STEM NUT IS VERY TIGHT. Attach a good

fitting wrench to the nut and give it a sharp “rap” rather than a

steady pull. Usually several blows are sufficient to tighten the

stem nut for final tightening. Failure to do so could allow the

diaphragm to pull loose and tear when subjected to pressure.

Test Procedure After Valve Assembly

There are a few simple tests which can be made in the field to

make sure the Hytrol Valve has been assembled properly. Do

these before installing pilot system and returning valve to

service. These are similar to the three troubleshooting tests.

1. Check the diaphragm assembly for freedom of movement

after all pressure is removed from the valve. SEE CAUTlON.

Insert fabricated tool into threaded hole in top of valve stem, and

lift the diaphragm assembly manually. Note any roughness,

sticking or grabbing. The diaphragm assembly should move

smoothly throughout entire valve stroke. The tool is fabricated

from rod that is threaded on one end to fit valve stem (See chart

in Step 4 of “Disassembly” section.) and has a “T” Bar handle of

some kind on the other end for easy gripping.

Place marks on this diaphragm assembly lifting tool when the

valve is closed and when manually positioned open. The distance between the two marks should be approximately the stem

travel shown in stem travel chart. (See “Freedom of Movement

Check” section.) If the stroke is different than that shown, there

is a good reason to believe something is mechanically restricting

the stroke of the valve. The cover must be removed, the obstruction located and removed. (See “Maintenance” Section for

procedure.)

Inspection of Parts

After the valve has been disassembled, each part should be

examined carefully for signs of wear, corrosion, or any other

abnormal condition. Usually, it is a good idea to replace the rubber parts (diaphragm and disc) unless they are free of signs of

wear. These are available in a repair kit. Any other parts which

appear doubtful should be replaced. WHEN ORDERlNG

PARTS, BE SURE TO GIVE COMPLETE NAMEPLATE DATA,

ITEM NUMBER AND DESCRlPTlON.

NOTE: If a new disc isn’t available, the existing disc can be

turned over, exposing the unused surface for contact with the

seat. The disc should be replaced as soon as practical.

3. Carefully install the diaphragm assembly by lowering the stem

through the seat bearing. Take care not to damage the stem or

bearing. Line up the diaphragm holes with the stud or bolt holes

on the body. on larger valves with studs, it may be necessary to

hold the diaphragm assembly up part way while putting the

diaphragm over the studs.

4. Put spring in place and replace cover. Make sure diaphragm

is Iying smooth under the cover.

5. Tighten cover nuts firmly using a cross-over pattern until all

nuts are tight.

6. Test Hytrol Valve before re-installing pilot valve system.

Due to the weight of the diaphragm assembly this procedure is

not possible on valves 8” and larger. on these valves, the same

determination can be made by carefully introducing a low

pressure-less than five psi) into the valve body with the cover

vented. SEE CAUTION. Looking in cover center hole see the

diaphragm assembly lift easily without hesitation, and then

settle back easily when the pressure is removed.

2. To check the valve for drip-tight closure, a line should be

connected from the inlet to the cover, and pressure applied at the

inlet of the valve. If properly assembled, the valve should hold

tight with as low as ten PSI at the inlet. See “Tight Sealing

Check” section.)

3. With the line connected from the inlet to the cover, apply full

working pressure to the inlet. Check all around the cover for any

leaks. Re-tighten cover nuts if necessary to stop leaks past the

diaphragm.

4. Remove pressure, then re-install the pilot system and tubing

exactly as it was prior to removal. Bleed air from all high

points.

5. Follow steps under “Start-Up and Adjustment” Section in

Technical Manual for returning complete valve back to service

.

5

Page 13

1

5

8

10

14

16

6

17

7

9

OUTLETINLET

GLOBE PATTERN

9

26

27

12

15

14

16

INLET

OUTLET

ANGLE PATTERN

22

23

13

12

14

10

11

15

15

TOP VIEW

8" - 24" SEAT DETAIL

1 1/4" - 6" SEAT DETAIL

16" COVER DETAIL

4

24

2

25

13

31

28

30

29

5

14

3

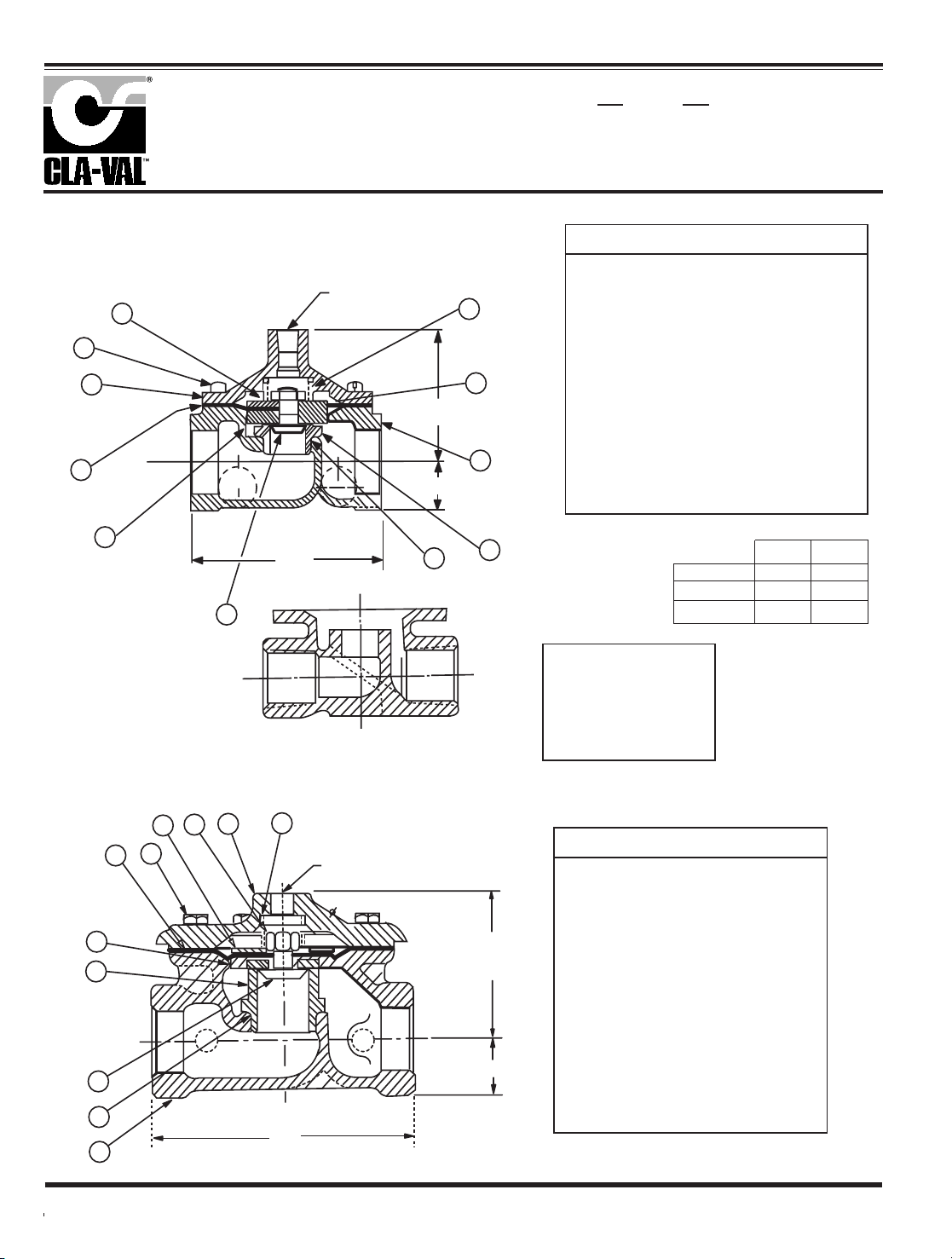

Item Description

1. Pipe Plug

2. Drive Screws (for nameplate)

3. Hex Nut (8” and larger)

4. Stud (8” and larger)

5. Cover Bearing

6. Cover

7. Stem Nut

8. Diaphragm Washer

9. Diaphragm

10. Spacer Washers

11. Disc Guide

12. Disc Retainer

13. Disc

14. Stem

15. Seat

16. Body

17. Spring

22. Flat Head Screws (8” and larger)

23. Seat O-Ring

24. Hex head Bolt (1 1/4” thru 4”)

25. Nameplate

26. Upper Spring Washer (Epoxy coated valves only)

27. Lower Spring Washer (Epoxy coated valves only)

28. Cover Bearing Housing (16” only)

29. Cover O-Ring (16’” only)

30. Hex Bolt (16” only)

31. Pipe Cap (16” only)

PARTS LIST

6

Page 14

100-01

Hytrol Valve Service Data

MODEL

INSTALLATION / OPERATION / MAINTENANCE

Description 100-01 Hytrol Valve

The CIa-VaI Model 100-01 Hytrol Valve is a main valve for

CIa-VaI Automatic Control Valves. It is a hydraulically operated,

diaphragm-actuated, globe or angle pattern valve.

This valve consists of three major components; body, diaphragm

assembly, and cover. The diaphragm assembly is the only

moving part. The diaphragm assembly uses a diaphragm of nylon

fabric bonded with synthetic rubber. A synthetic rubber disc,

contained on three and one half sides by a disc retainer and disc

guide, forms a seal with the valve seat when pressure is applied

above the diaphragm. The diaphragm assembly forms a sealed

chamber in the upper portion of the valve, separating operating

pressure from line pressure.

Description 100-20 600 Series Hytrol Valve

The CIa-VaI Model 100-20 Hytrol Valve (600 Series main valve)

have only one part -the body- that is different from standard 100

Series Cla-Val main valve parts. The remaining parts of the 600

series main valve are standard Cla-Val main valve parts. All serv-

ice and maintenance information for the standard 100 Series

main valves also apply to the 600 series main valves.

The most important thing to remember when ordering main

valve repair kits and replacement parts, except for the body, all

other parts are going to be for a smaller size main valve. Cla-

Val identifies main valve parts with the flange size of the stan-

dard 100 Series main valve. Refer to the "Main Valve Sizes”

chart below.

1”

1 1/4”

1 1/2”2”2 1/2”

3”4”6”

8”

10”

12”

14”

16”

24”

2532405065

80

100

150

200

250

300

350

400

600

100-01

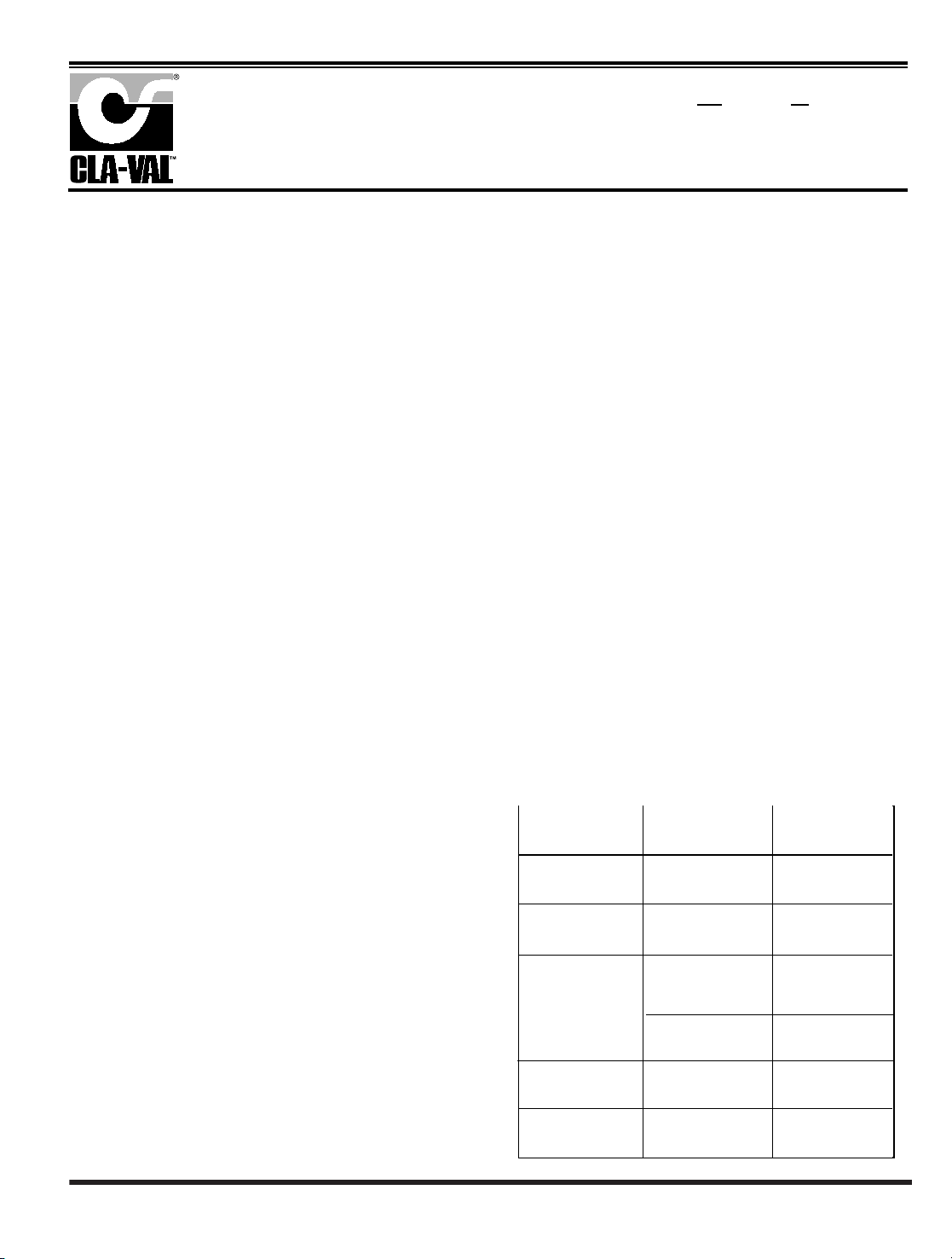

HYTROL SIZE Stem

Travel

Cover Capacity

Displacement

Valve Stem

Thread

UNF-Internal

Cover

Center

Plug NPT

4”6”8”

10”

12”

16”

20”,24”

100

150

200

250

300

400

600

0.3

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

2.8

3.4

3.9

4.5

6.5

8

1010151820234358718699

114

165

0.020

0.020

0.032

0.043

0.080

0.169

0.531

1.26

2.51

4.0

6.5

9.5

29.0

0.07

0.07

0.12

0.16

0.30

0.64

2.00

4.80

9.50

15.10

24.60

36.20

108.80

1/4”

1/4”

1/4”

1/2”

1/2”

1/2”

3/4”

3/4”

1”

1”

1 1/4”

1 1/2”

2”

3/4”

1/4” - 20 (B)

5/16” - 18 (B)

5/16” - 18 (B)

3/8” - 16 (B)

7/16” - 14 (B)

1/2” - 13 (B)

3/4” - 10 (B)

3/4” - 10 (B)

3/4” - 10

7/8” - 9

1-1/8” -7

1-1/4” -7

1-1/4” -7

1-1/2” -12

10-32

10-32

10-32

10-32

1/4 - 28

1/4 - 28

3/8 - 24

3/8 - 24

3/8 - 24

3/8 - 24

3/8 - 24

1/2 - 20

3/4 - 16 *

100-20

Thread

(Bolt)

7/16”

1/2”

1/2”

9/16”

5/8”

3/4”

1 1/8”

1 1/8”

1 1/4”

1 7/16

1 13/16

2”

2”

2 3/8”

Socket

5/8” - 11

3/4” - 10

3/4” - 10

1” - 8

1” - 8

1-1/8” 7

Cover

Lifting

Holes UNC

Liters

8888888

12162020202024

Qty

3/8”

1/2”

1/2”

3/4”

3/4”

1”1”1”1”1”

1”

Thread

3/8” - 24

7/16” 20

7/16” 20

1/2” - 20

5/8” - 18

5/8” - 18

3/4” - 16

7/8” - 14

1 1/8” - 12

1 1/2” - 12

1 1/2” - 12

1 1/2” - 12

2” - 16

3” - 12

Thread

3/4”

15/16”

15/16”

1 1/16”

1 5/16”

1 13/16”

1 7/8”

2 1/2”

2 1/2”

3”

Special

Socket

(Long)

7/16”

9/16”

9/16”

5/8”

5/8”

13/16”

13/16”

13/16”

13/16”

13/16”

13/16”

Socket

488

122030

110

110

110

160

390

545

545

800

ft. Lbs.

489696

in. Lbs.

466

1021214085

125

250

270

280

500

1350

Lubed

6

1010153030

60

125

185

375

400

420

750

N/R

DRY

Gallonsmmmm mm inchesinches inches

Cover Nut or Bolt Cover Plug Cover Torque Stem Nut ** Stem Nut Torque

(ft Lbs)

Grade 5 Bolts

“Heavy” Grade Nuts

Tighten cover nuts in a “star” cross-over pattern

* Adapter p/n 2594101E

inside 1/4” - 28

**Must Use ONLY

Cla-Val Supplied part

HYTROL Service Data

Page 15

CLA-VAL

Copyright Cla-Val 2007 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-100-01 (R-3/07)

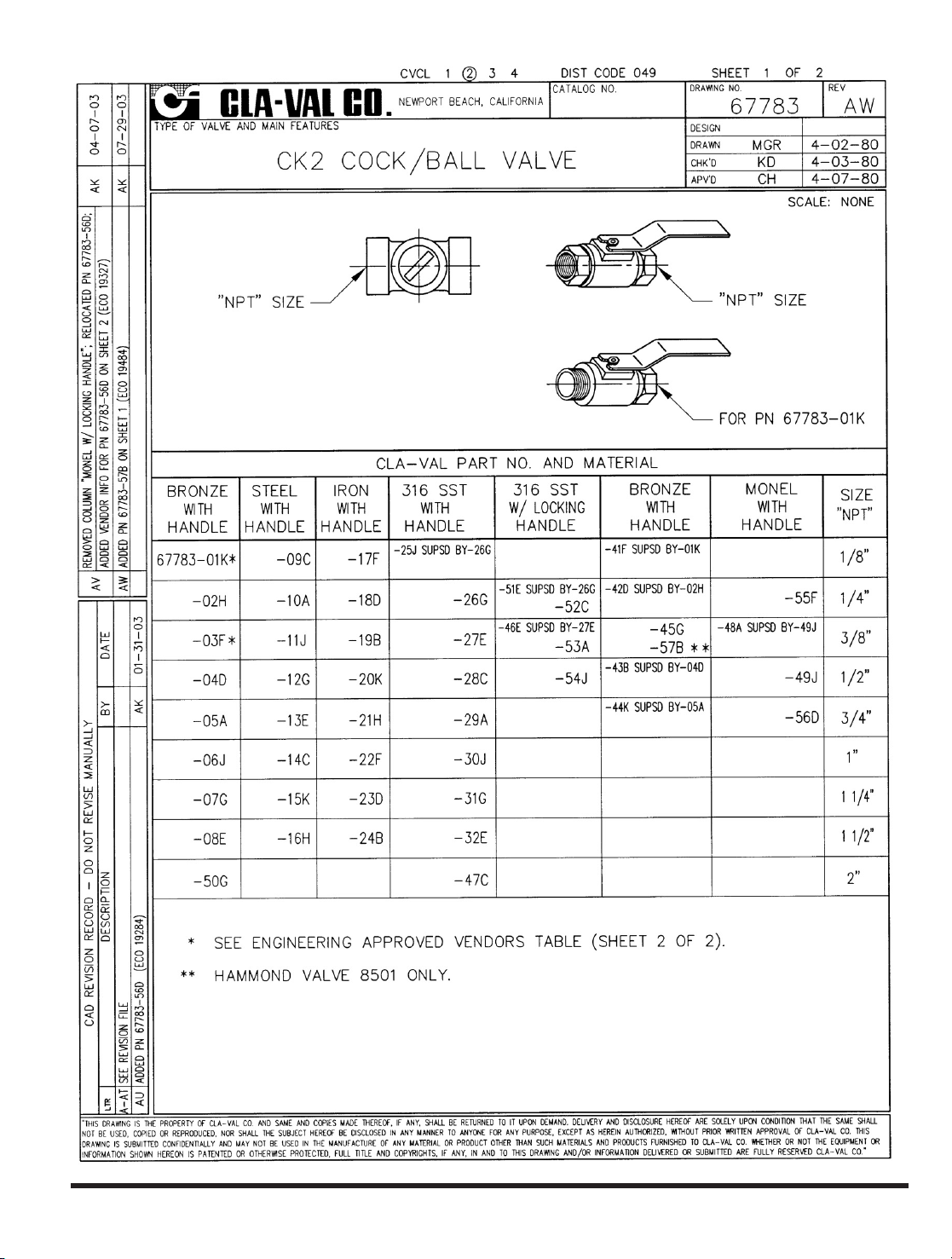

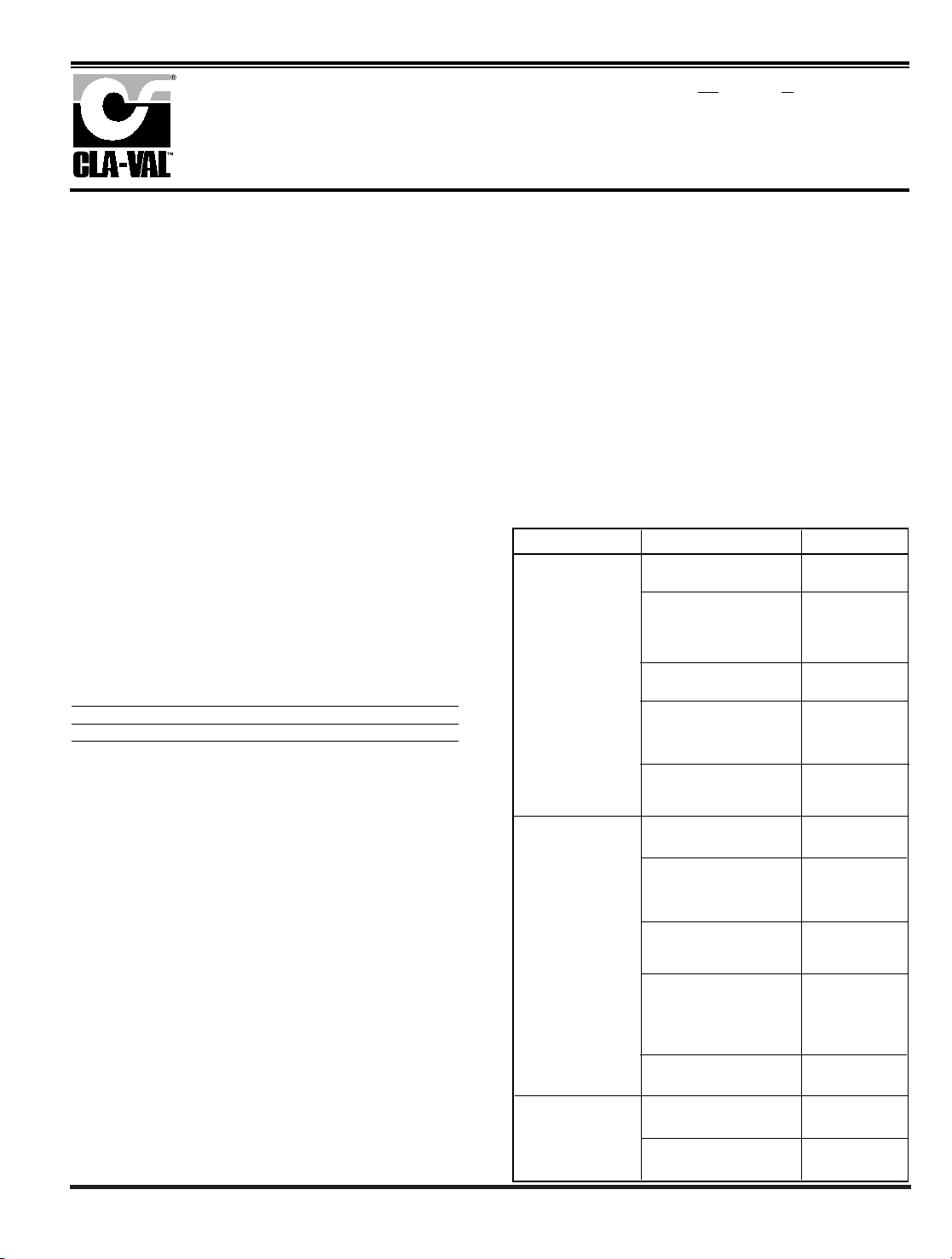

BOLT/NUT TORQUING PROCEDURES ON VALVE COVERS

4

BOLTS

6

BOLTS

8

BOLTS

12

BOLTS

16

BOLTS

20

BOLTS

4

3

2

1

65

4

3

2

1

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

Follow this procedure when reassembling MAIN Valve:

1. Tightens bolts/nuts in a “Star” or “Cross-Over” Pattern following the

numbers shown above to insure that cover seats evenly on the diaphragm

material and body.

2. Torque the bolt/nuts in three stages:

A. To approximately 10% of final torque valve.

B. To approximately 75% of final torque valve.

C. To final required torque valve.

3. Valves that are to be tested to 375 PSI or higher should be retorqued

after 24 hours.

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

(Patent Pending)

KO Anti-Cavitation Trim

can be added to any

standard Hytrol Valve

100-01 Hytrol Main Valve Assembly

Page 16

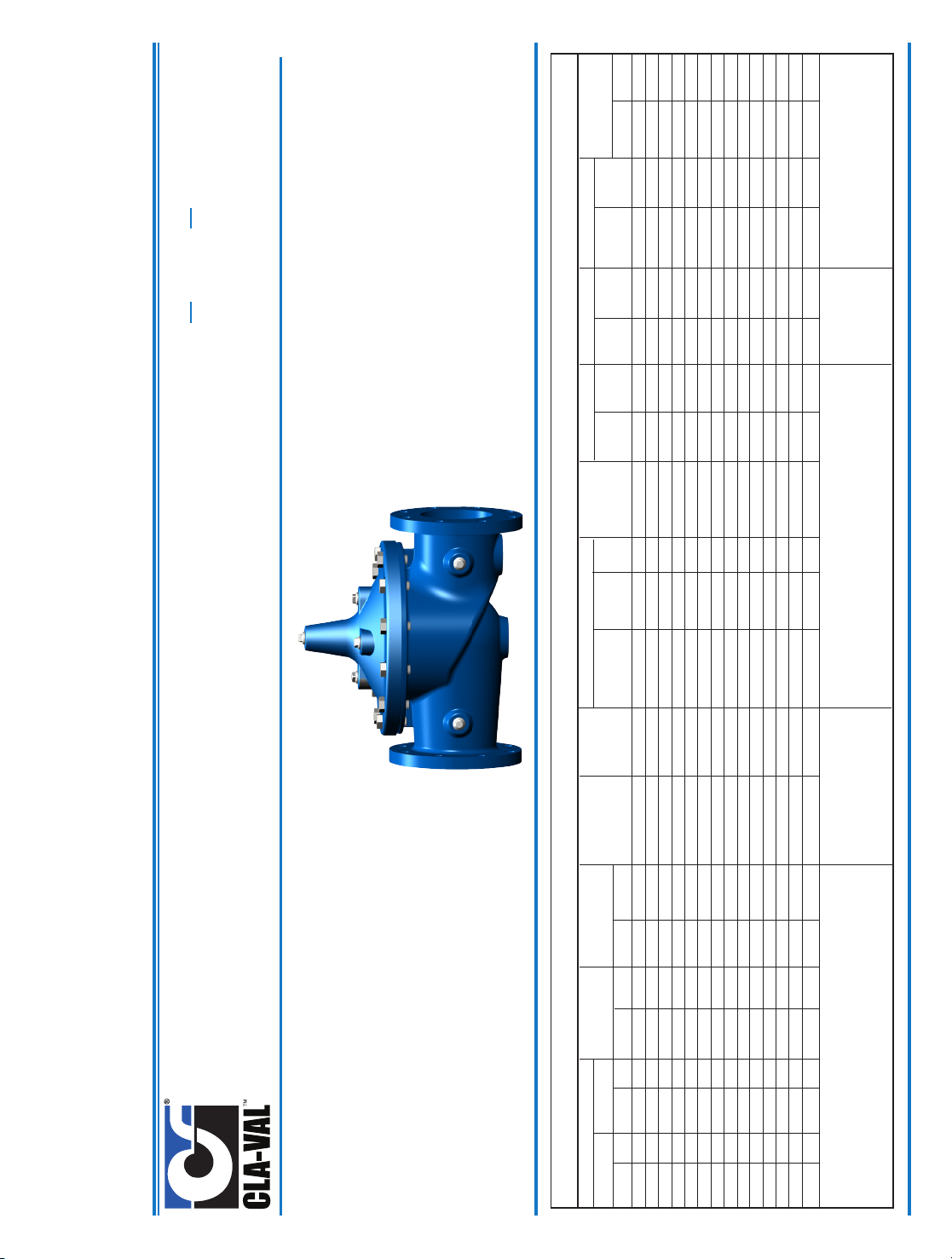

UNDERSTANDING THE 600 SERIES VALVES

In 1987, Cla-Val introduced the Model 100-20 Hytrol as the basic

main valve for the 600 Series of automatic control valves. To

identify all new valves using the 100-20 Hytrol, an existing catalog number is modified. Making a 600 Series catalog number is

simply done by using a "6" in front of the two digit catalog numbers or replacing the "2" with a "6" in three digit catalog numbers. Current schematics reflect both catalog numbers together

separated by a slash ( i.e. - 90-01/690-01, 58-02/658-02, 21001/610-01, etc). Since these two valves 'share' the same catalog

number and schematic, they provide the same function in a system. The only difference between the two valves is the relative

capacity of the two main valve series.

The 100-01 Hytrol is the basic main valve for Cla-Val automatic

control valves. This valve is the current version of the Clayton

Hytrol valve design originated in 1936. The 100-01 Hytrol is

designed as a full flow area valve. This means that the inlet,

seat and outlet openings are the same size. Thus, the pressure

drop is kept to a minimum for this globe style design.

The 100-20 Hytrol valve has all of the basic features and advantages of the original 100-01 Hytrol. Only one part has been

changed - the body. It is designed with different size inlet, seat

and outlet openings. The 100-20 Hytrol has inlet and outlet

flanges one valve size larger than the seat opening size. This

results in what is sometimes called a ''reduced port' main valve.

For example, a 4" 100-20 valve has a 3" seat. Note: valve size

is always determined by the flange size. The following chart

compares the 100-01 and the 100-20 main valves.

Globe Pattern Valves

Flange Size

(inch)

Seat Size

100-01

(100 Series)

100-20

(600 Series)

3 3 2

4 4 3

6 6 4

8 8 6

10 10 8

12 12 10

14 14

16 16 12

20 16

24 24 16

Angle Pattern Valves

Flange Size

(inch)

Seat Size

100-01

(100 Series)

100-20

(600 Series)

4 4 3

6 6 4

8 8 6

600 Series Hytrol Valve

100-20

M O D E L

INSTALLATION / OPERATION / MAINTENANCE

Basic Main Valve Sizes Comparison

SERVICE AND MAINTENANCE OF 600 SERIES

VALVES

The 600 series main valves have only one part -the body- that is

different from standard 100 Series Cla-Val main valve parts. The

remaining parts of the 600 series main valve are standard ClaVal main valve parts. All service and maintenance information

for the standard 100 Series main valves in this manual also

apply to the 600 series main valves.

The most important thing to remember when ordering main valve

repair kits and replacement parts, except for the body, all other

parts are going to be for a smaller size main valve. Cla-Val identifies main valve parts with the flange size of the standard 100

Series main valve. Refer to the "Main Valve Sizes Comparison"

chart. For example, if you are servicing a 6" 100-20 Hytrol and

needed a repair kit, you would order a repair kit for a 4" 100-01

Hytrol. This kit is also suitable for a 6" 100-20 Hytrol. Complete

Technical Manuals include a repair kit data sheet N-RK that

shows this relationship.

When you order repair parts, it is a good idea to include valve

nameplate data (size, catalog number, and part number) and

description of the parts desired. Do this to be sure parts will fit

the valve you are working on and not be too big for it. Pilot controls and repair kits maintenance information remain the same

for 100 or 600 Series valves.

Cla-Val Main Valves

Catalog Number

The 100-20 Hytrol is available only in ductile iron, 150 and 300

pressure class, and Bronze trim standard. Available extra cost

main valve options include stainless steel trim, epoxy coating,

Dura-Kleen stem, Delrin sleeved stem, and high temperature rubber parts. All four basic main valves have a 600 Series version

available with all of the same benefits and size relationships.

The following chart shows the relationship of Cla-Val main valve

catalog numbers.

Catalog Name

Hytrol

Powertrol

Powercheck

Hycheck

Circa 1936

100 (Angle =2100)

100P & 100PA

100PC & 100PCA

181

100-Series

100-01

100-02

100-03

100-04

600 Series

100-20

100-21

100-22

100-23

(Reduced Internal Port)

Page 17

N-100-20 (R-6/06)

100-20

PARTS LIST

NO. DESCRIPTION

1 Pipe Plug

2 Drive Screws (for nameplate)

3 Hex Nut (8" and larger)

4 Stud (8" and larger)

5 Cover Bearing

6 Cover

7 Stem Nut

8 Diaphragm Washer

9 Diaphragm

10 Spacer Washers

11 Disc Guide

12 Disc Retainer

13 Disc

14 Stem

15 Seat

16 Body

17 Spring

22 Flat Head Screws (10" and larger)

23 Seat O-Ring

24 Hex Bolt (3 " Thru 6")

25 Nameplate (Mounted on inlet flange)

26 Upper Spring Washer (Epoxy coated valves

only)

27 Lower Spring Washer (Epoxy coated valves

only)

28 Cover Bearing Housing (20" & 24")

29 Cover Bearing Housing O-Ring (20"& 24")

30 Hex Bolt (20" & 24")

31 Pipe Cap (20" & 24")

11

14

1 24 3 4

5

17

16

26

14

7

8

9

27

10

14

13

22

12

15

31

28

5

30

29

10" — 24" SEAT DETAIL 20" — 24" COVER DETAIL

TOP VIEW

12

13

15

OUTLET

GLOBE

INLET

ANGLE

INLET

6

8

9

2

25

3" — 6" COVER DETAIL

23

11

WHEN ORDERING PARTS, BE SURE TO GIVE COMPLETE

NAMEPLATE DATA, ITEM NUMBER AND DESCRIPTION.

Page 18

Page 19

When Ordering, Please Specify

1. Valve Size

2. Catalog No. X101

3. Valve Series No. (Appears on Valve Nameplate)

4. Optional Material

Stainless Steel

A

Vent Valve

Closed

B

NPT

Sight Tube

Stem

Gasket

Adapter

Bushing

Valve Cover

Stem Adapter

Valve Stem

Housing

Gasket

Vent Valve

X101

MODEL

Valve Position Indicator

& Pilot System Components

Dimensions

Specifications

Installation

Dimension "A" is height added to valve by indicator assembly

Can be installed on any Cla-Val basic main

valve in a few minutes. Simply replace the

fitting on top of the valve cover with the

indicator assembly.

Sizes: 1" thru 24"

Materials: Brass, Pyrex Tube

Pressure Rating: 400 psi

Optional Material: Stainless Steel

• Positive Visual Indicator

• Frictionless

• Leak Proof

• Easy Maintenance and Cleaning

• Protected Indicator Rod

The Cla-Val Model X101 Visual Position Indicator is designed to

display Cla-Val valve position quickly and easily. A solid brass

indicator rod fastened directly to the valve stem moves up and down

inside a pyrex tube. The tube is contained within a brass housing

which is open on two opposite sides to permit clear vision of the

indicator rod.

To purge air that may be trapped in the valve cover, a vent valve in the

top of the housing is provided. Model X101 valve position indicator is

furnished complete for installation on specified size Cla-Val Automatic

Control Valve.

VALVE A B

SIZE INCHES NPT

1" 5.88

1/4"

1

1/4

" 3.21

1/4"

1

1/2

" 3.21

1/4"

2" 3.33

1/2"

2

1/2

" 3.33

1/2"

3" 3.33

1/2"

4" 4.52

3⁄4"

6" 4.52

3⁄4"

8" 5.83 1

"

10" 7.70 1

"

12" 8.20 1

1/4"

14" 8.20 1

1/2"

16" 10.81 2

"

24" 12.04 1"

Page 20

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©COPYRIGHT CLA-VAL 2005 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-X101 (R-5/05)

Represented By:

CSM-11 Solenoid Control

CDS6 Altitude Control

CDC-1 Check Valve CSC Swing Check Valve

CN Series - Needle Valves CK Series - Isolation Valve

Size Body Material Trim Material

3/8"-1" Standard: Bronze Stainless Steel/Teflon

Option: Stainless Steel Stainless Steel/Teflon

Size Body Material Trim Material

1/4"-1" Standard: Bronze Brass

Option: Stainless Steel Stainless Steel

Size

Body Material Trim Material

3/8"-1/2" Brass Delrin

Size Body Material Trim Material

3/8"-1" Brass Brass/Buna N

Wetted Body Material

Standard: Bronze with

Stainless Steel

Trim

Body Material

Standard: Bronze with

Monel Trim

Option: Bronze with

Stainless Steel

Trim

No. of Springs Altitude Ranges

1 5 - 40 ft

2 30 - 80 ft

3 70 - 120 ft

4 110 - 160 ft

5 150 - 200 ft

Page 21

4 Sight Tube

7 Stem

3 Gasket

5 Adapter

6 Bushing

Valve Cover

8 Stem Adapter

Valve Stem

2 Housing

3 Gasket

1 Vent Valve

Valve Position Indicator

X-101

When ordering parts,

please specify:

• All Nameplate data

• Item Number

• Description

• Material

• Part Number

ITEM DESCRIPTION MATERIAL

1 Vent Valve Brass

2 Housing Brass

3 *Gasket

(2 Required) Buna-N

4 *Sight Tube Pyrex

5 Adapter Brass

6 Busing Brass

7 Stem Brass

8 Stem Adapter Brass

COMPLETE X101

1 1/4 - 1 1/2 C2812A

2 C8972G

2 1/2 C2607E

3 C2609A

4 9710001A

6 9710002J

8 C8581F

10 C9187A

12 31420D

14 30256C

16 30251D

SIZE STOCK NO.

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL- X101 (R-5/05)

PARTS LIST

Page 22

CLA-VAL

©Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

PL-CK2 (R-5/05)

Page 23

100-01

PARTS LIST

2.50

A

2.75

OPERATING PRESSURE

1/8 NPT

2

3

1

4

5

6

8

3/8 NPT

3/8 NPT

BOTH ENDS

1.50

1.25

INLET

A

SECTION

AA

100-01 3/8" HYTROL VALVE

7

3/8"-1 Hytrol Valve

PARTS LIST

ITEM DESCRIPTION

1. Cover Screw (8 Required)

2. Cover

3. Spring

4. Diaphragm Washer

5. Diaphragm

6. Disc Retainer Assembly

7. Body Plug (3/8 NPT)

8. Body

*

*

* Recommended Spare Parts

When Ordering parts,

please specify

• All nameplate data

• Description

• Item Number

• Material

MODEL

Page 24

100-01

PARTS LIST

1/2"-3/4"-1” Hytrol Valve

CLA-VAL

©

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

PL-100-01 3/8” - 1” (R-5/05)

MODEL

10

13

3

1

2

6

7

8

A

4

5

9

13

OPERATING PRESSURE

1/8

C

OUTLET

INLET

BODY WITH INTEGRAL SEAT

11

10

14

1

15

16

22

19

26

25

OPERATING PRESSURE

1/4

5.12

2.68

OUTLET

1.03

INLET

PARTS LIST

ITEM DESCRIPTION

1 COVER SCREW

2 COVER

3 SPRING

4 STEM NUT

5 DIAPHRAGM WASHER

6 DIAPHRAGM

7 DISC RETAINER ASSEMBLY

8 DISC GUIDE & STEM

9 BODY

10 SEAT

11 NAMEPLATE

12 BODY PLUG HEX HD.

13 O-RING SEAT

(FOR OLD STYLE BODY ONLY)

*

*

* Recommended Spare Parts

When Ordering parts,

please specify

• All nameplate data

• Description

• Item Number

• Material

1/2 3/4

1-7/16 3-1/2

2-3/8 2-3/8

25/32 29/32

A

C

(MAXIMUM)

D

PARTS LIST

ITEM DESCRIPTION

1 COVER SCREW

2 NAMEPLATE

3 NAMEPLATE SCREW

10 COVER

11 SPRING

13 STEM NUT

14 DIAPHRAGM WASHER

15 DIAPHRAGM

16 DISC RETAINER ASSEMBLY

19 DISC GUIDE

22 SEAT

24 BODY PLUG

25 BODY

26 O-RING, SEAT

* Recommended Spare Parts

100-01 3/4" & 1/2" Hytrol Valve

100-01 1" Hytrol Valve

Page 25

DESCRIPTION

The CRL Pressure Relief Control is a direct acting, spring loaded,

diaphragm type relief valve. It may be used as a self-contained valve or as

a pilot control for a Cla-Val Main valve. It opens and closes within very

close pressure limits.

INSTALLATION

The CRL Pressure Relief Control may be installed in any position. The

control body (7) has one inlet and one outlet port with a side pipe plug (24)

at each port. These plugs are used for control connections or gauge applications. The inlet in the power unit body (6) is the sensing line port. A flow

arrow is marked on the body casting.

OPERATION

The CRL Pressure Relief Control is normally held closed by the force of the

compression spring above the diaphragm; control pressure is applied

under the diaphragm.

When the controlling pressure exceeds the spring setting, the disc is lifted

off its seat, permitting flow through the control.

When controlling pressure drops below spring setting, the spring returns

the control to its normally closed position.

ADJUSTMENT PROCEDURE

The CRL Pressure Relief Control can be adjusted to provide a relief setting

at any point within the range found on the nameplate.

Pressure adjustment is made by turning the adjustment screw (9) to vary

the spring pressure on the diaphragm. Turning the adjustment screw clockwise increases the pressure required to open the valve. Counterclockwise

decreases the pressure required to open the valve.

When pressure adjustments are complete the jam nut (10) should be tightened and the protective cap (1) replaced. If there is a problem of tampering, lock wire holes have been provided in cap and cover. Wire the cap to

cover and secure with lead seal.

DISASSEMBLY

The CRL Pressure Relief Control does not need to be removed from the

line for disassembly. Make sure that pressure shut down is accompanied

prior to disassembly. If the CRL is removed from the line for disassembly

be sure to use a soft jawed vise to hold body during work.

Refer to Parts List Drawing for Item Numbers.

1. Remove cap (1), loosen jam nut (10) and turn adjusting

screw counterclockwise until spring tension is relieved.

2. Remove the eight screws (4) holding the cover (3) and

powerunit body (6). Hold the cover and powerunit together

and place on a suitable work surface.

See NOTE under REASSEMBLY.

3. Remove the cover (3) from powerunit body (6). The spring

(12) and two spring guides (11).

4. Remove nut (13) from stem (19) and slide off the belleville washer

(14), the upper diaphragm washer (15) and the diaphragm (16).

5. Pull the stem (19) with the disc retainer assembly (21) through the

bottom of powerunit. The lower diaphragm washer (17) will slide off

of stem top.

6. Remove jam nut (23) and disc retainer assembly (21) from stem.

Use soft jawed pliers or vise to hold stem. The polished surface of

stem must not be scored or scratched.

7. The seat (22) need not be removed unless it is damaged. If removal

is necessary use proper size socket wrench and turn counterclockwise.

Note: Some models have an integral seat in the body (7).

INSPECTION

Inspect all parts for damage, or evidence of cross threading. Check

diaphragm and disc retainer assembly for tears, abrasions or other damage. Check all metal parts for damage, corrosion or excessive wear.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using 400 grit wet or dry

sandpaper fine emery or crocus cloth. Replace all O-rings and any damaged parts.

When ordering replacement parts, be sure to specify parts list item number and all nameplate data.

REASSEMBLY

In general, reassembly is the reverse of disassembly. However, the following steps should be observed:

1. Lubricate the O-Ring (18) with a small amount of a good grade of

waterproof grease, (Dow Corning 44 medium grade or equal).

Use grease sparingly and install O-ring in powerunit body (6).

2. Install stem (19) in powerunit body (6). Use a rotating motion with

minimum pressure to let stem pass through O-ring.

Do Not Cut O-Ring.

3. Install O-ring (5) at top of stem (19). Place lower diaphragm

washer (17) on the stem with the serrated side up. Position

diaphragm (16), upper diaphragm washer (15), with serration down,

and belleville washer (14) with concave side down.

4. Position powerunit body (6) as shown on parts list drawing (top view).

5. Continue reassembly as outlined in disassembly steps 1 through 3.

Pressure Relief Control

CRL

Note: Item (4) Screw will have a quantity of 8 for the 0-75 and 20-200psi

design and a quantity of 4 for the 100-300psi design. Item (25) Screw is

used on the 100-300psi design only. Install item (25), before item (4) for

preload of item (12) spring.

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open. Controlling pressure

too low.

Back off adjusting

screw until valve

opens.

Fails to open with

spring compression

removed.

Mechanical obstruction, corrosion, scale

build-up on stem.

Disassemble,

locate,and remove

obstruction, scale.

Leakage from cover

vent hole when controlling pressure is

applied.

Diaphragm Damage Disassembly replace

damaged

diaphragm.

Fails to close with

spring compressed.

Mechanical obstruction.

Disassemble, locate

and remove

obstruction.

Fails to close. No spring compres-

sion.

Re-set pressure

adjustment.

Loose diaphragm

assembly.

Tighten upper

diaphragm washer.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-CRL (R-8/05)

Page 26

1/2" & 3/4" PRESSURE RELIEF CONTROL

CRL

Ajusting Screw

(3/8" - 16UNF THREAD)

9

1

10

3

11

12

14

13

11

8

22

23

7

18

19

21

INLET

1/8 - 27 NPT

SENSING

CONNECTION

(TYP.)

7.44

MAX

.71

OUTLET

20

6

2

0 TO 75 AND

20 TO 200 PSI DESIGN

5

17

16

15

4

1A

9

10

3

11

12

11

7

2

100 To 300 psi Design

.71

ADJUSTING SCREW

(1/2" 20UNF THREAD)

10.44

MAX.

When ordering parts please specify:

1. All Nameplate Data

2. Item Part Number

3. Item Description

CRL

RANGE PSI

APPROX. INCREASE

FOR EACH CLOCK-

WISE TURN OF

ADJUSTING SCREW

0 to 75 8.5 PSI

20 to 200 28.0 PSI

100 to 300 18.0 PSI

25

25

24

4

45º

3.12

DIA.

TRUE LOCATION OF

SENSING

CONNECTION

(TYP.)

ADJUSTING SO

(3/8" - 16UNF )

SIZE

1/2"

1/2"

1/2"

3/4"

3/4"

3/4"

SPRING

RANGE

0-75 PSI

20-200 PSI

100-300 PSI

0-75 PSI

20-200 PSI

100-300 PSI

PART

NUMBER

79222-01E

79222-02C

82809-01D

79229-01K

79229-02H

86005-01E

For 100-450 PSI Contact Factory

Body with

integral Seat

1

1A

2

3

4*

5*

6

7

8*

9

10

11

12

13

14

15

16*

17

18*

19

20*

21*

22

23

24

25*

Cap

Cap 100 to 300 psi Design

Nameplate

Cover

Screw Fil.Hd.10-32 x 1.88

0-Ring

Body, Powerunit

1/2" Body

3/4" Body

0-Ring, Seat

Screw, Adjusting

Nut Hex (Locking)

Guide, Spring

Spring,

Nut, Stem, Upper

Washer, Belleville

Washer, Diaphragm (upper)

Diaphragm

Washer, Diaphragm (lower)

0-Ring, Stem

Stem

0-Ring, Body

Retainer Assembly, Disc

Seat

Nut, hex, Stem, Lower

Pipe Plug

Screw Fil.Hd, 10-32 x 2.25 (Qty 4 on 100-300 psi)

FACTORY SET POINT

REPAIR KIT*

Plastic

Plastic

Brass

Bronze

303 SS

Rubber

Bronze

Bronze

Bronze

Rubber

Brass

303 SS

303 SS

CHR/VAN

Bronze

Steel

303 SS

Rubber

303 SS

Rubber

303 SS

Rubber

303 SS

303 SS

Bronze

Bronze

303 SS

0-75

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71884B

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

50 PSI

9170007A

20-200

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71885J

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

60 PSI

9170007A

100-300

1257601D

1257601D

--

44587E

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

1630301J

1630201A

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

100 PSI

9170007A

Item Material Part Number

Part Number

Part Number

Description

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CRL (R-12/05)

PARTS LIST

Page 27

DESCRIPTION

The CRA Pressure Reducing Control automatically reduces a higher inlet

pressure to a lower outlet pressure. It is a direct acting, spring loaded,

diaphragm type valve that operates hydraulically or pneumatically and is

designed to sense pressure from a remote point. It may be used as a selfcontained valve or as a pilot control for a Cla-Val Co. main valve. It will

hold a constant downstream pressure at the remote sensing point within

very close pressure limits.

OPERATION

The CRA Pressure Reducing Control is normally held open by the force

of the compression spring above the diaphragm; delivery pressure acts on

the underside of the diaphragm. Flow through the valve responds to

changes in pressure at the the sensing point.

INSTALLATION

The CRA Pressure Reducing Control may be installed in any position.

There is one inlet port and two outlets, for either straight or angle installation. The second outlet port can be used for a gauge connection. A flow

arrow is marked on the body casting.

ADJUSTMENT PROCEDURE

The CRA Pressure Reducing Control can be adjusted to provide a delivery pressure range as specified on the nameplate.

Pressure adjustment is made by turning the adjustment screw to vary the

spring pressure on the diaphragm. The greater the compression on the

spring the higher the pressure setting.

1. Turn the adjustment screw in (clockwise) to increase delivery

pressure.

2. Turn the adjustment screw out (counter-clockwise) to decrease

the delivery pressure. When pressure adjustment is completed,

tighten jam nut on adjustment screw and replace protective cap.

Flow rates are not critical during pressure setting. The approximate minimum flow rates given in the table are for the main valve on which the CRA

is installed.

Valve Size 1 1⁄4"-3" 4"-8" 10"-16"

Minimum Flow GPM 15-30 50-200 300-650

MAINTENANCE

Disassembly

To disassemble follow the sequence of the item numbers assigned to

parts in the sectional illustration.

Reassembly

Reassembly is the reverse of disassembly. Caution must be taken to

avoid having the yoke (17) drag on the inlet nozzle of the body (18).

Follow this procedure:

1. Place yoke (17) in body and screw the disc retainer assembly

(16) until it bottoms.

2. Install gasket (14) and spring (19) for 2-30 psi range onto plug

(13) and screw into body. Disc retainer must enter guide hole in

plug as it is assembled. Screw the plug in by hand. Use wrench

to tighten only.

3. Place gasket (25) and powertrol body (21) on yoke extension

(17). Refer to sectional view for proper reassembly of (21) onto

body (18).

4. Place lower diaphragm washer (24), "o" ring (22), diaphragm

(12), upper diaphragm washer (11), and belleville washer (20) on

yoke extension (17). Screw on diaphragm nut (10) finger tight.

5. Place two machine screws (4) through (21) (25) and screw into

body (18). Do not include the diaphragm (12) in this operation.

This holds parts aligned for next step, and allows the diaphragm

to move and be properly located during tightening of nut (10).

6. Hold the diaphragm so that screw holes in the diaphragm (12)

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open when

pressure lowers

No spring compression Tighten adjusting

screw

Mineral buildup on yoke

extension (17)

Disassemble and

clean part,

Replace "O" rings

(22) and (23).

Damaged spring Disassemble and

replace.

Spring guide (8) is not in

place

Disassemble and

place guide (8) on

top of spring (9).

Yoke dragging on inlet

nozzle

Disassembled

and reassemble

use procedure.

Fails to close when

delivery pressure rises

Spring compressed

Back off adjusting

screw

Mineral deposit on yoke

extension (17)

Disassemble and

clean part.

Replace "o" rings

(22) and (23).

Mechanical obstruction

Disassemble and

remove obstruction

Worn disc

Disassemble,

remove and

replace disc

retainer assembly. (16)

Yoke dragging on inlet

nozzle

Refer to paragraph 6

Damaged diaphragm (12)

Disassemble and

replace

Loose diaphragm nut (10)

Remove cover

and tighten nut

REMOTE SENSING TYPE

CRA

Leakage from cover

vent hole

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-CRA (R-5/05)

and powertrol body (21) align. Tighten diaphragm nut (10) with a wrench.

At the final tightening release the diaphragm and permit it to rotate

approximately 5° to 10°. The diaphragm holes should now be properly

aligned with the body holes.

To check for proper alignment proceed as follows:

Rotate diaphragm clockwise and counterclockwise as far as possible.

Diaphragm screw holes should rotate equal distance on either side of

powertrol body screw holes ±1/8".

Repeat assembly procedure until diaphragm and yoke are properly

aligned. There must be no contact between yoke and body nozzle during

its normal opening and closing movement. To simulate this movement

hold powertrol body and diaphragm holes aligned. Move yoke to open

and closed positions. There must be no evidence of contact or dragging.

7. Remove machine screws per step 5.

8. Install spring (9) with spring guide (8) on top of spring.

9. Install cover (5) using eight machine screws (4).

10. Replace adjusting screw (2) and nut (3), then cap (1).

Pressure Reducing Control

Page 28

* Suggested Repair Parts

REMOTE SENSING TYPE

4

15

6

7

1/8" NPT

REMOTE

SENSING

CONNECTION

VIEW

C

FOR 20-300 PSI RANGE ONLY

16

SIZE

(inch)

STOCK

NUMBER

SEAT

DIA

ADJ.

RANGE

(psi)

3/8 79744-04B 1/4 30-300

3/8 79744-06G 1/4 2-30

Factory set pressure:

PSI*per turn

30-300 set @ 60 psi 27.0

2-30@ 10 psi 3.0

3/8 79744-03D 1/4 15-75

Pressure Reducing Control

CRA

When ordering parts specify:

• All nameplate data

• Description

• Item number

* Approximate - Final adjustment should

be made with a pressure gauge and

with flow.

15-75 set @ 20 psi 9.0

1

2

3

4*

5

6

7

8

9

10

11

12*

13

14*

15

16*

17

18

19*

20

21

22*

23*

24

25

Cap

Adjusting Screw

Jam Nut, 3/8—16

Machine Screw 10-32 x 1-1/4"(Fil.Hd.) (8 required)

Cover

Nameplate Screw

Nameplate

Spring Guide

Spring

(15-75 psi)

(30-300 psi)

(2-30 psi)

Hex Nut 5/16 - 18

Diaphragm Washer (upper)

Diaphragm

Plug, Body

Gasket

Plug, 3/8 NPT

Disc Retainer Assy (15-75 psi & 30-300 psi)

Disc Retainer Assy (2-30 psi)

Yoke

Body & Seat Assy, Seat only 1/4"

Bucking Spring (Required with 2-30 psi)

Belleville Washer

Powertrol Body

O-Ring

O-Ring

Diaphragm Washer (lower)

Gasket

Repair Kit (no Bucking Spring) Item 19

Repair Kit (with Bucking Spring) Item 19

PL

BRS

303

SS

BRS

SS

BRS

302

CHR VAN

CHR VAN

SS

303

302

NBR

BRS

FIB

BRS

BR/RUB

BR/RUB

VBZ

BS

302

STL

BRS

NBR

NBR

BRS

NBC

67628J

7188201D

6780106J

6757874A

C2544K

67999D

C002201G

71881H

71884B

71885B

81594E

71883D

71891G

C6936D

V5653A

40174F

6766003F

C5256H

C5255K

C1799A

8339701J

VO5586

7055007E

C3388A

00708J

00746J

C1804J

8059401D

9170003K

9170001D

ITEM DESCRIPTION MATERIAL PART NUMBER LIST PRICE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CRA (R-5/05)

PARTS LIST

Page 29

*This drawing is the property of CLA-VAL and same and copies made thereof, if any, shall be returned to it upon demand. Delivery and disclosure hereof are made solely

upon condition that the same shall not be used, copied ore reproduced, nor shall the subject here of be disclosed in any manner to anyone for any purpose, except as

herein authorized, without prior approval of CLA-VAL. Whether or not the equipment or information shown hereon is patented or otherwise protected, full title and copyrights if any, in and to this drawing and/or information delivered or submitted are fully reserved by CLA-VAL.

Dwg#47117

Regulator Spring Color Coding Chart

THE FOLLOWING CONTROL & SPRING P/N#'S WERE REMOVED, 32656B, 31554K, 44591G, V65695B, & V5695B.

ADDED CRL-13, CRL-5A, CRA, CRA-10A, CHANGED SPRING RANGES TO MATCH CURRENT CONTROLS.

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-47117 AD (R-11/06)

PARTS LIST

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *PSI PER TURN

.080 DIA. C0492D BLUE S.S.

CDB-7

CRL-5A

0-7

0-7

.75

.75

.018 DIA. 82575C -- S.S.

CRD

CRD-10A

1.9-6.5

1.9-6.5

.61

.49

.116 DIA. 81594E -- S.S.

CRD

CRD-10A

2-30

2-30

3.0

2.4

.120 DIA. V5654J GREEN CHR VAN

CRL-5A

CRD

5-25

10-40

4.0

4.0

.162 DIA. 32447F NATURAL S.S.

CDB-7

CRL-5A

CRL-13

10-60

10-60

10-60

12.0

12.0

12.0

.162 DIA. V5695B YELLOW MUSIC WIRE

CDB-7

CRL-5A

CRL-13

20-80

20-80

20-80

14.5

14.5

14.5

.207 DIA. C1124B CAD PLT MUSIC WIRE

CDB-7

CRL-13

CRL-5A

50-150

50-150

50-150

29.5

29.5

29.5

.225 DIA. V6515A RED MUSIC WIRE

CDB-7

CRL-13

CRL-5A

65-180

65-180

65-180

44.0

44.0

44.0

.115 X .218 71884B RED CHR VAN

CRL

CRD

CRD-10A

0-75

15-75

15-75

8.5

9.0

7.2

.118 X .225 71886J GREEN CHR VAN

CRL

CRD

CRD-10A

20-200

30-300

30-300

28.0

27.0

22.4

.225 X .295 1630201A CAD PLT CHR VAN

CRL

CRL-5A

100-300

100-300

18.00

18.00

.440 X .219 48211H CAD PLT STEEL

CRA-18

CRD-22

CRL-4A

200-450

200-450

100-450

17.0

17.0

17.0

.187 20561901H BLACK STEEL CRD 20-105 12.0

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *FEET PER TURN

.080 DIA. C0492D BLUE S.S.

CRA

CRD-2

4.5-15

4.5-15

.82

.82

.375 DIA.

87719B

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-5

5-40

30-80

70-120

110-120

150-200

1.0

2.0

3.0

4.0

5.0

.072 DIA. V5097A -- 302SS CVC 1-17 .7

.375 DIA.

2933502H

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-6

5-40

30-80

70-120

110-120

150-200

.75

1.50

2.20

3.00

3.70

*THESE FIGURES ARE ONLY APPROXIMATE. FINAL ADJUSTMENTS SHOULD BE MADE WITH A PRESSURE GAGE.

Page 30

Page 31

Page 32

Page 33

Cla-Val Product

Identification

Proper Identification

For ordering repair kits, replacement parts, or for

inquiries concerning valve operation, it is important to

properly identify Cla-Val products already in service

by including all nameplate data with your inquiry.

Pertinent product data includes valve function, size,

material, pressure rating, end details, type of pilot

controls used and control adjustment ranges.

Identification Plates

For product identification, cast-in body markings are

supplemented by identification plates as illustrated on

this page. The plates, depending on type and size of

product, are mounted in the most practical position. It

is extremely important that these identification

plates are not painted over, removed, or in any

other way rendered illegible.

INLET

EINTRITT

ENTREE

ENTRADA

SIZE &

CAT NO.

STOCK

NO.

CODE

MFD. BY CLA-VAL

NEWPORT BEACH, CALIF, U.S.A.

RESERVOIR

END

I

N

L

E

T

I

N

L

E

T

SIZE &

CAT NO.

STOCK

NO.

FLOW

MFD. BY CLA-VAL NEWPORT BEACH, CALIF. U.S.A.

CODE

C

¤

“

SIZE &

CAT NO.

STOCK

NO.

SPRING

RANGE

MFD. BY CLA-VAL NEWPORT BEACH, CALIF. U.S.A.

SIZE &

CAT NO.

STOCK

NO.

CODE

MFD. BY CLA-VAL

NEWPORT BEACH, CALIF.

U.S.A.

C

¤

“

DO NOT REMOVE

THIS VALVE HAS BEEN MODIFIED

SINCE ORIGINAL SHIPMENT FROM

FACTORY. WHEN ORDERING PARTS

AND/ OR SERVICE SUPPLY DATA FROM

THIS PLATE & ALL OTHER PLATES ON

ORIGINAL VALVE.

REDUCED PRESSURE BACKFLOW PREVENTION DEVICE

STK.

NO.

SER.

NO.

CAT.

NO.

RP

-4

CLA-VAL

NEWPORT BEACH, CA.

This brass plate appears on valves sized 21/2" and larger

and is located on the top of the inlet flange.

These two brass plates appear on 3/8", 1/2", and 3/4" size

valves and are located on the valve cover.

These two brass plates appear on threaded valves

1" through 3" size or flanged valves 1" through 2".

It is located on only one side of the valve body.

This brass plate appears on altitude valves only and is

found on top of the outlet flange.

This brass plate is used to identify pilot control valves.

The adjustment range is stamped into the plate.

This tag is affixed to the cover of the pilot control valve.

The adjustment range appears in the spring range section.

This aluminum plate is included in pilot system

modification kits and is to be wired to the new pilot

control system after installation.

This brass plate is used on our backflow prevention

assemblies. It is located on the side of the Number Two

check (2" through 10"). The serial number of the

assembly is also stamped on the top of the inlet flange of

the Number One check.

How to Order

Page 34

HOW TO ORDER

Because of the vast number of possible configurations and

combinations available, many valves and controls are not

shown in published product and price lists. For ordering

information, price and availability on product that are not listed,

please contact your local Cla-Val office or our factory office

located at:

SPECIFY WHEN ORDERING

• Model Number • Valve Size

• Globe or Angle Pattern • Threaded or Flanged

• Adjustment Range • Body and Trim Materials

(As Applicable) • Optional Features

• Pressure Class

UNLESS OTHERWISE SPECIFIED

• Globe or angle pattern are the same price

• Ductile iron body and bronze trim are standard

• X46 Flow Clean Strainer or X43 “Y” Strainer are included

• CK2 Isolation Valves are included in price on 4" and larger

valve sizes (6" and larger on 600 Series)

P. O. Box 1325

Newport Beach, California 92659-0325

(949) 722-4800

FAX (949) 548-5441

LIMITED WARRANTY

Automatic valves and controls as manufactured by Cla-Val are warranted

for three years from date of shipment against manufacturing defects in

material and workmanship that develop in the service for which they are

designed, provided the products are installed and used in accordance

with all applicable instructions and limitations issued by Cla-Val.

We will repair or replace defective material, free of charge, that is returned

to our factory, transportation charges prepaid, if upon inspection, the

material is found to have been defective at time of original shipment. This

warranty is expressly conditioned on the purchaser’s providing written

notification to Cla-Val immediate upon discovery of the defect.

Components used by Cla-Val but manufactured by others, are warranted

only to the extent of that manufacturer’s guarantee.

This warranty shall not apply if the product has been altered or repaired by

others, Cla-Val shall make no allowance or credit for such repairs or

alterations unless authorized in writing by Cla-Val.

DISCLAIMER OF WARRANTIES AND

LIMITATIONS OF LIABILITY

The foregoing warranty is exclusive and in lieu of all other

warranties and representations, whether expressed, implied, oral or

written, including but not limited to any implied warranties or

merchantability or fitness for a particular purpose. All such other

warranties and representations are hereby cancelled.

Cla-Val shall not be liable for any incidental or consequential loss,

damage or expense arising directly or indirectly from the use of the

product. Cla-Val shall not be liable for any damages or charges for

labor or expense in making repairs or adjustments to the product.

Cla-Val shall not be liable for any damages or charges sustained in

the adaptation or use of its engineering data and services. No

representative of Cla-Val may change any of the foregoing or

assume any additional liability or responsibility in connection with

the product. The liability of Cla-Val is limited to material

replacements F.O.B. Newport Beach, California.

TERMS OF SALE

ACCEPTANCE OF ORDERS

All orders are subject to acceptance by our main office at Newport Beach, California.

CREDIT TERMS

Credit terms are net thirty (30) days from date of invoice.

PURCHASE ORDER FORMS

Orders submitted on customer’s own purchase order forms will be accepted only

with the express understanding that no statements, clauses, or conditions contained

in said order form will be binding on the Seller if they in any way modify the Seller’s

own terms and conditions of sales.

PRODUCT CHANGES

The right is reserved to make changes in pattern, design or materials when deemed

necessary, without prior notice.

PRICES