Page 1

50-49/650-49

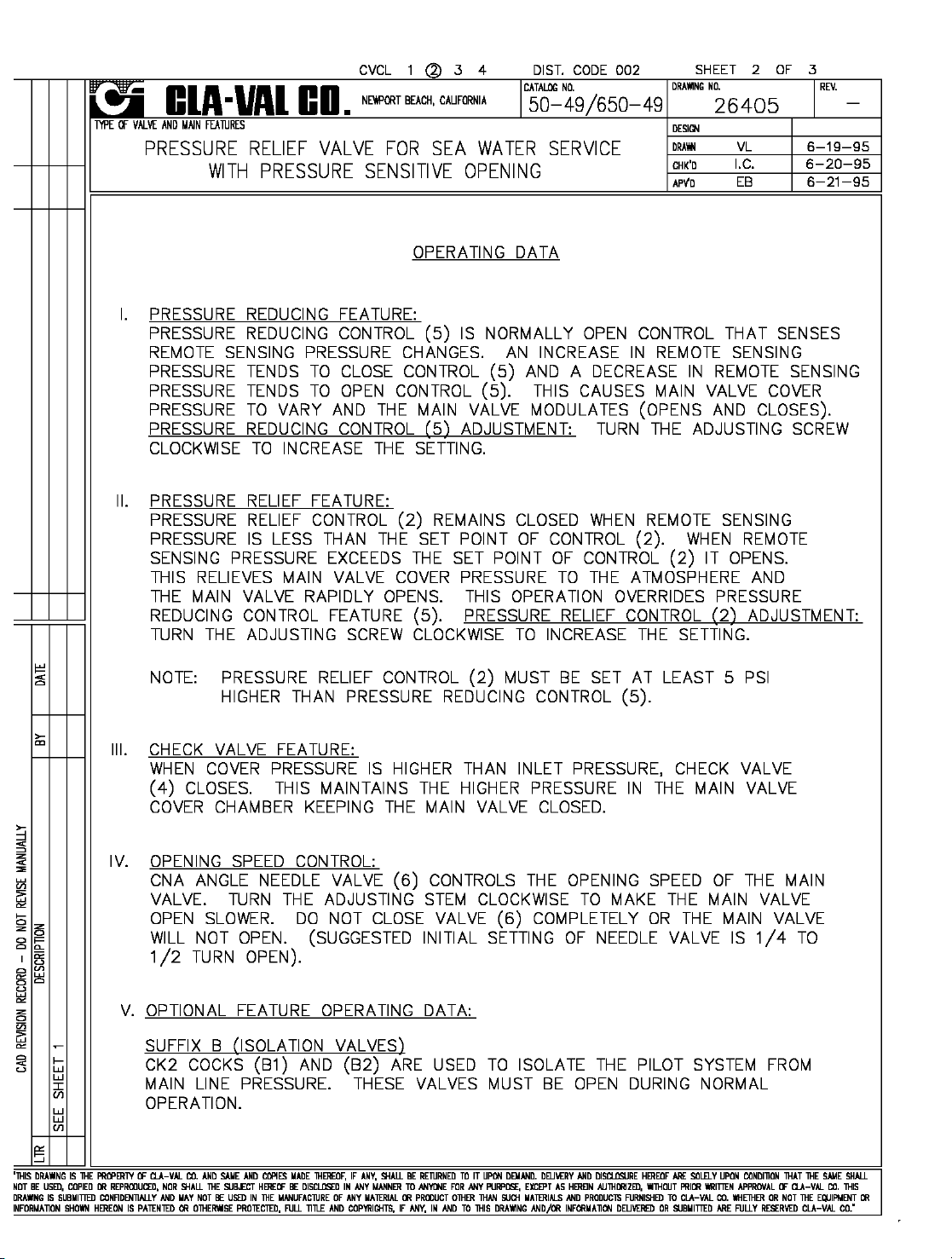

Page 2

Page 3

Page 4

Page 5

• Drip - tight, positive seating

• Service without removal from line

• Screwed or flanged ends

• Globe or angle pattern

• Every valve factory-tested

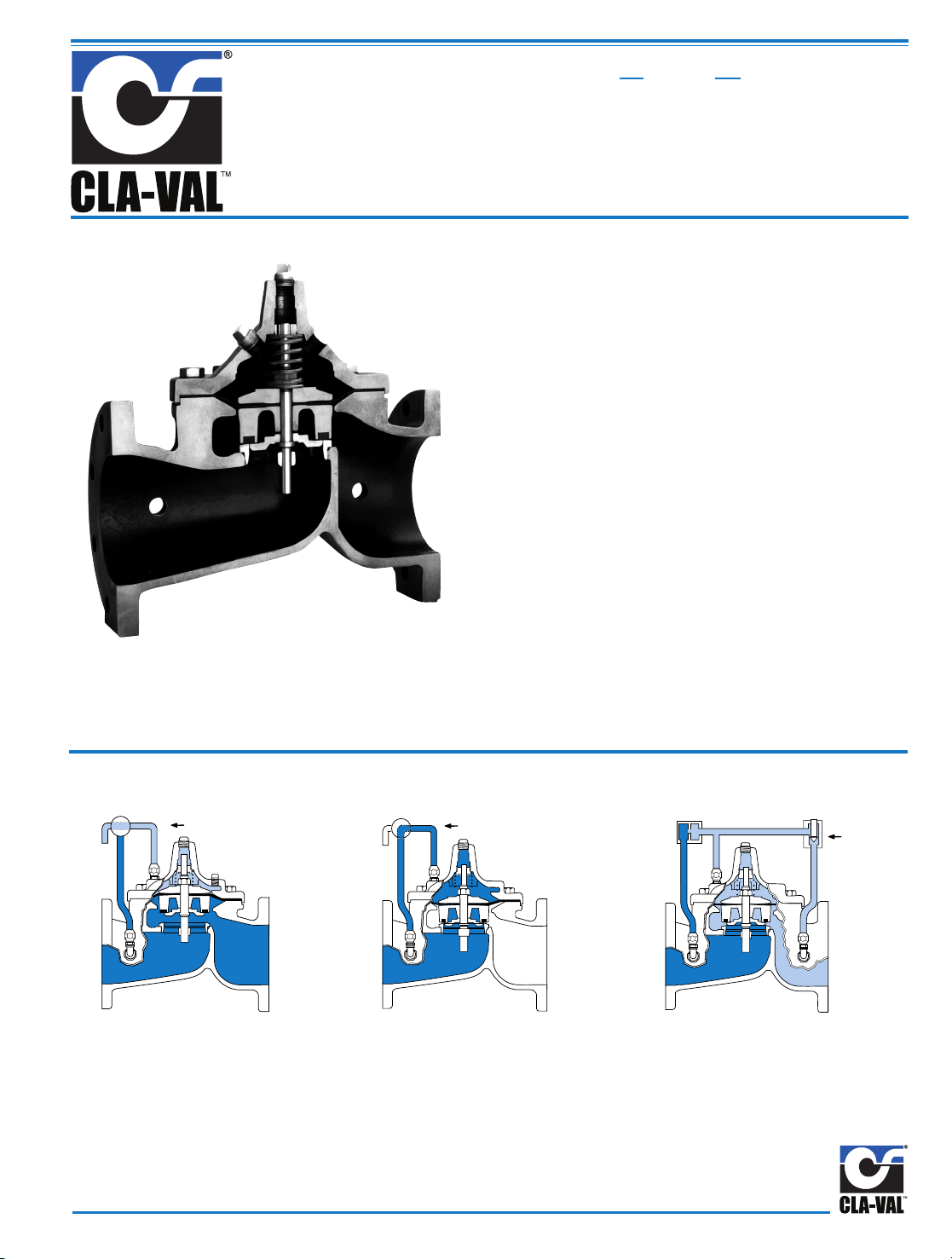

The Cla-Val Model 100S/2100S Seawater Service Hytrol Valve

is a hydraulically operated, diaphragm actuated, globe or

angle pattern valve. It consists of three major components:

body, diaphragm assembly and cover. The diaphragm assembly is the only moving part.

The body (ductile iron or cast steel) is epoxy coated and contains

a removable seat insert. The diaphragm assembly is guided top

and bottom by a precision machined stem. It utilizes a non-wicking diaphragm of nylon fabric bonded with synthetic rubber. A

resilient synthetic rubber disc retained on three and one half sides

by a disc retainer forms a drip-tight seal with the renewable seat

when pressure is applied above the diaphragm.

The Model 100S/2100S Seawater Service Hytrol Valve is the

basic valve used for seawater applications. It is the valve of

choice for system applications requiring deluge, pressure regulation, pressure relief, solenoid operation, rate of flow control, liquid level control or check valve operation. The rugged simplicity

of design and packless construction assure a long life of

dependable, trouble-free operation. It is available in various

materials and in a full range of sizes, with either screwed or

flanged ends. Its applications are unlimited.

Modulating Action

The valve holds any intermediate position

when operating pressures are equal above

and below the diaphragm. A Cla-Val “modulating” pilot control will allow the

valve to automatically compensate for line pressure changes.

Principle of Operation

Full Open Operation

When pressure in the

cover chamber

is relieved to a zone of lower pressure, the line pressure at the valve

inlet opens the valve, allowing full flow.

Tight Closing Operation

When pressure from the valve inlet

is applied to the cover chamber, the

valve closes drip-tight.

Seawater Service Hytrol Valve

100S

2100S

MODEL

On-Off Control

Modulating

Control

On-Off Control

Page 6

Specifications

When Ordering, Please Specify:

1. Model No. 100S or No. 2100S

2. Valve Size

3. Pattern - Globe or Angle

4. Pressure Class

5. Screwed or Flanged

6. Temperature and fluid to be handled.

7. Static and Flowing Line Pressure.

8. Body & Trim Material

9. Desired Options

10. When Vertically Installed

Purchase Specifications

The Model 100S/2100S shall be a hydraulically operated, diaphragm-actuated, globe or

angle pattern valve. It shall contain a resilient, synthetic rubber disc, having a rectangular

cross-section, contained on three and one-half sides by a disc retainer and disc guide,

forming a tight seal against a single removable seat insert. The diaphragm assembly, containing a valve stem, shall be fully guided at both ends by a bearing in the valve cover and

an integral bearing in the valve seat. This diaphragm assembly shall be the only moving

part and shall form a sealed chamber in the upper portion of the valve, separating operating pressure from line pressure. The diaphragm shall consist of nylon fabric bonded with

synthetic rubber and shall not be used as a seating surface. Packing glands or stuffing

boxes are not permitted and there shall be no pistons operating the valve or its pilot controls. All necessary repairs shall be possible without removing the valve from the line. All

materials shall be compatible with seawater.

Valve shall be Model 100S/2100S manufactured by Cla-Val, Newport Beach, CA 92659-0325

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact our Regional Sales Office or Factory.

Available Sizes

Pattern Threaded Flanged Grooved End

Globe3⁄8" - 3" 11⁄2" - 36" 11⁄2"-2"- 3"- 4"- 6"

Angle 11⁄2" - 3" 2" - 16" 2" - 3" - 4"

Operating Temp. Range

Fluids

-40° to 180° F

Valve Body & Cover

Pressure Class

Flanged Threaded

Material

Material

Specifications

ANSI

Standards**

150 Lb. 300 Lb.

End***

Details

Ductile Iron* ASTM-A536 B16.42 250 400 400

Cast Steel* ASTM A216 B16.5 285 400 400

Naval Bronze ASTM B61 B16.24 225 400 400

Stainless Steel

Type 316

ASTM A743-CF-8M B16.5 285 400 400

NI.AL.Bronze ASTM B148 B.16.24 225 400 400

Super Duplex

Stainless Steel

B16.5 285 400 400

Note: *Fusion Bonded Epoxy Coated Internal and External.

**ANSI Standards are for flanged dimensions only.

Flanged Valves are available faced but not drilled

***End Details machined to ANSI B2.1 specifications

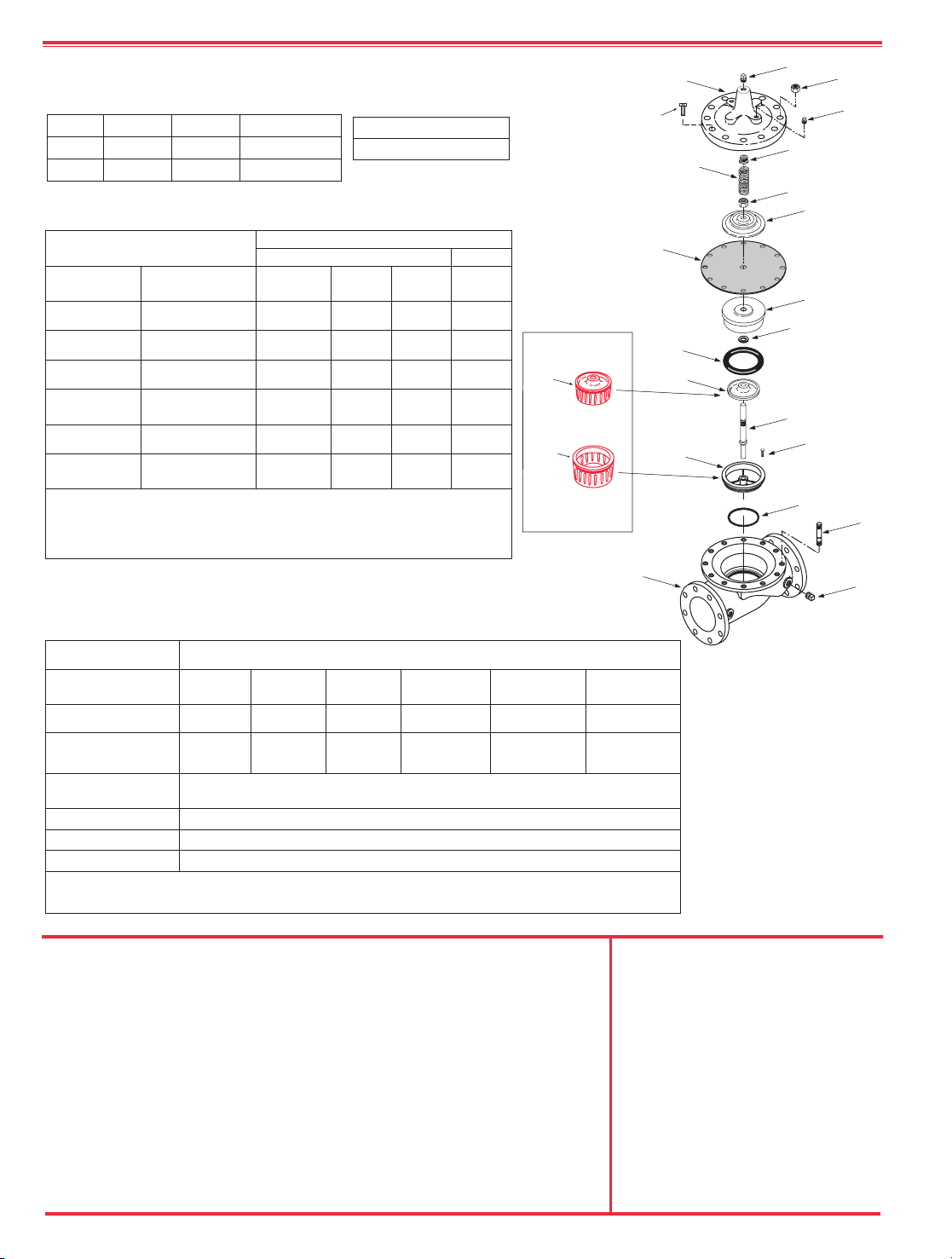

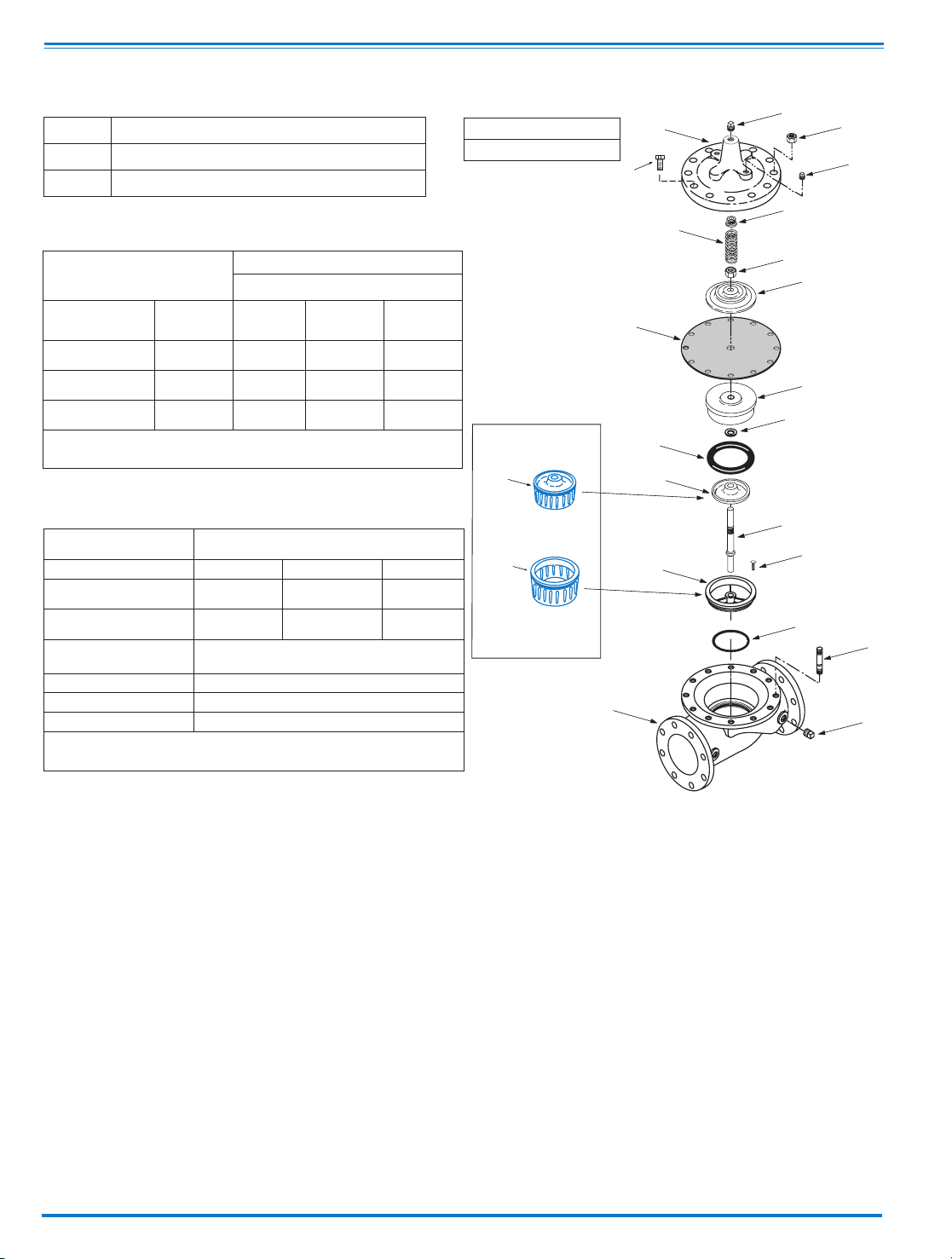

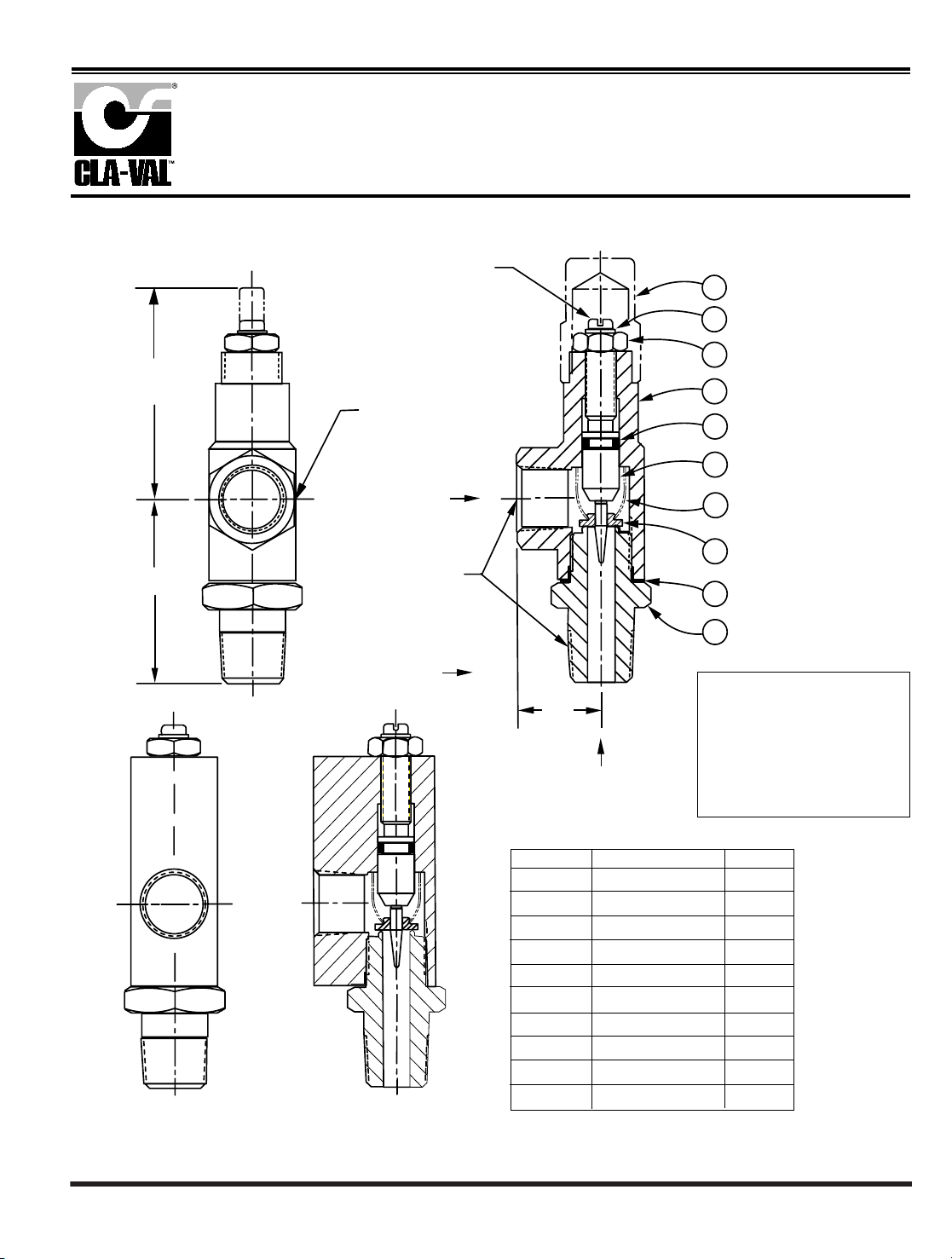

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

8" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

8" and Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

8" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

(Patent Pending)

KO Anti-Cavitation Trim

can be added to any

standard Hytrol Valve

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Stainless Steel

Type 316

NI. AL. Bronze

Super Duplex

Stainless Steel

Available Sizes 11⁄4" - 36" 11⁄4" - 16" 11⁄4" -16" 11⁄4" -16" 11⁄4" -16" 11⁄4" -16"

Disc Retainer &

Diaphragm Washer

Cast Iron Cast Steel Bronze Bronze Monel

Super Duplex

Stainless Steel

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Pressure Ratings

(Recommended Maximum Pressure - psi)

Page 7

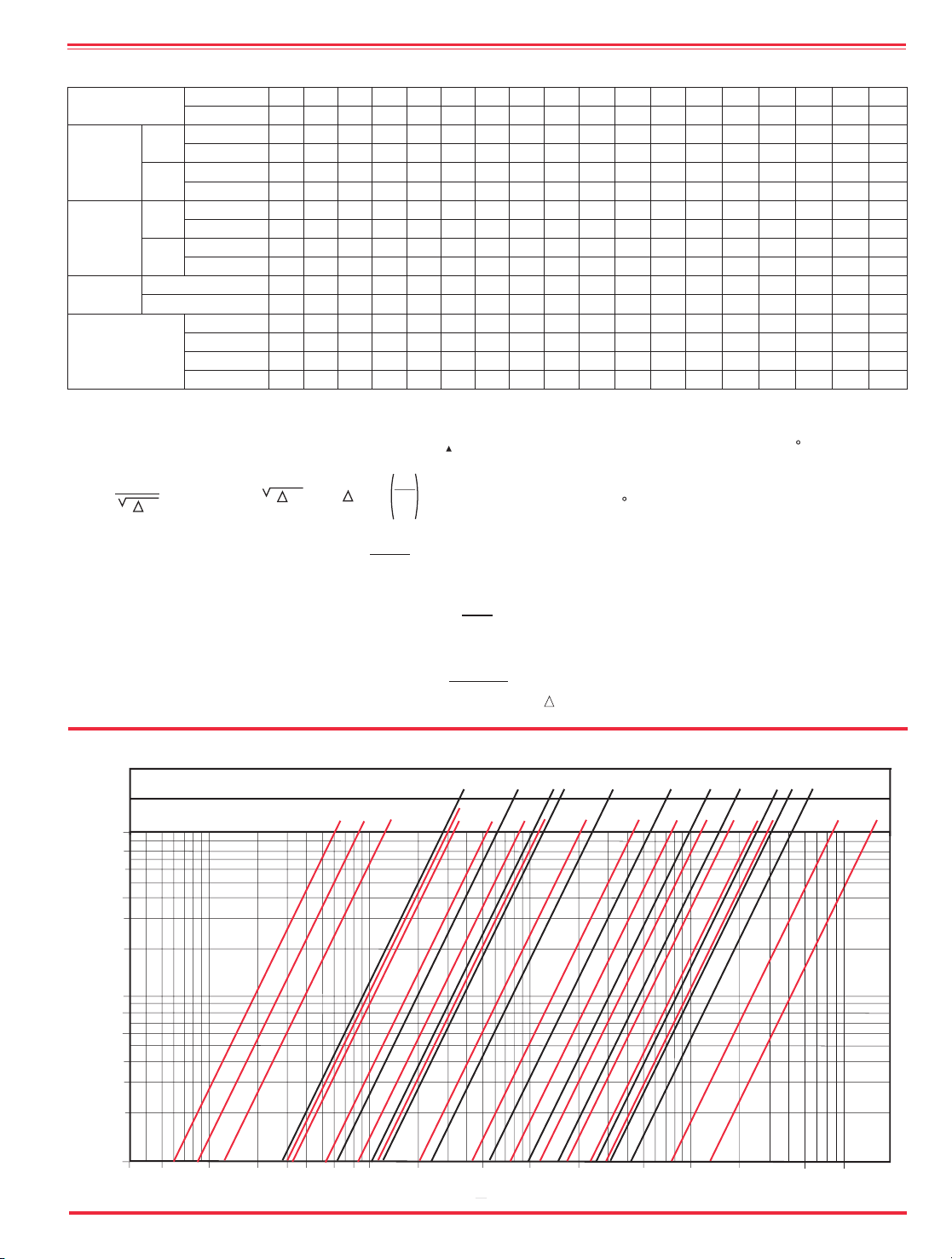

Model 100S/2100S Flow Chart (Based on normal flow through a wide open valve)

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

( P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

Functional Data Model 100S/2100S

*Estimated

Valve Size

Inches

3⁄81⁄23

⁄4 1 11⁄4 11⁄2 2 21⁄2 3 4 6 8 10 12 14 16 24 36

mm.

10 15 20 25 32 40 50 65 80 100 150 200 250 300 350 400 600 900

C

V

Factor

Globe

Pattern

Gal./Min. (gpm.)

1.8 6 8.5 13.3 30 32 54 85 11 5 200 440 770 1245 1725 2300 2940 7655 13320

Litres/Sec. (l/s.)

.43 1.44 2.04 3.2 7.2 7.7 13 20.4 27.6 48 105.6 184.8 299 414 552 706 1837 3200

Angle

Pattern

Gal./Min. (gpm.)

— — — — — 29 61 101 139 240 541 990 1575 2500* 3060* 4200* — —

Litres/Sec. (l/s.)

— — — — — 7 14.6 24.2 33.4 58 130 238 378 600 734.4 1008 — —

Equivalent

Length

of

Pipe

Globe

Pattern

Feet (ft.)

25 7 16 23 19 37 51 53 85 116 211 291 347 467 422 503 628 1866

Meters (m.)

7.6 2.2 4.8 7.1 5.7 11.4 15.5 16.0 25.9 35.3 64.2 88.6 105.8 142.4 128.6 153.6 191.6 569

Angle

Pattern

Feet (ft.)

— — — — — 46 40 37 58 80 139 176 217 222* 238* 247* — —

Meters (m.)

— — — — — 13.9 12.1 11.4 17.8 24.5 42.5 53.6 66.1 67.8 72.7 75.2 — —

K

Factor

Globe Pattern

16.3 3.7 5.7 6.1 3.6 5.9 5.6 4.6 6.0 5.9 6.2 6.1 5.8 6.1 5.0 5.2 4.0 7.1

Angle Pattern

— — — — — 7.1 4.4 3.3 4.1 4.1 4.1 3.7 3.6 2.9 2.8 2.6 — —

Liquid Displaced from

Cover Chamber When

Valve Opens

Fl. Oz

.12 .34 .34 .70 — — — — — — — — — — — — — —

U.S. Gal.

— — — — .02 .02 .03 .04 .08 .17 .53 1.26 2.51 4.0 6.5 9.6 29 42

ml

3.5 10.1 10.1 20.7 75.7 75.7 121 163 303 643 — — — — — — — —

Litres

— — — — — — — — — — 2.0 4.8 9.5 15.1 24.6 36.2 109.8 159

10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

1

2

3

4

6

8

10

20

30

40

60

80

100

5 3

Angle Valve Sizes (Inches)

Globe Valve Sizes (Inches)

1/2 1

2

3 4

6

8 10

12

12

24

3/4

11/2

21/2

11/2

2 3

4 6 8 10

14

16

16

1

1/4

21/2

Pressure Drop — psi

14

Flow Rate gpm (water)

1

36

100,000

Page 8

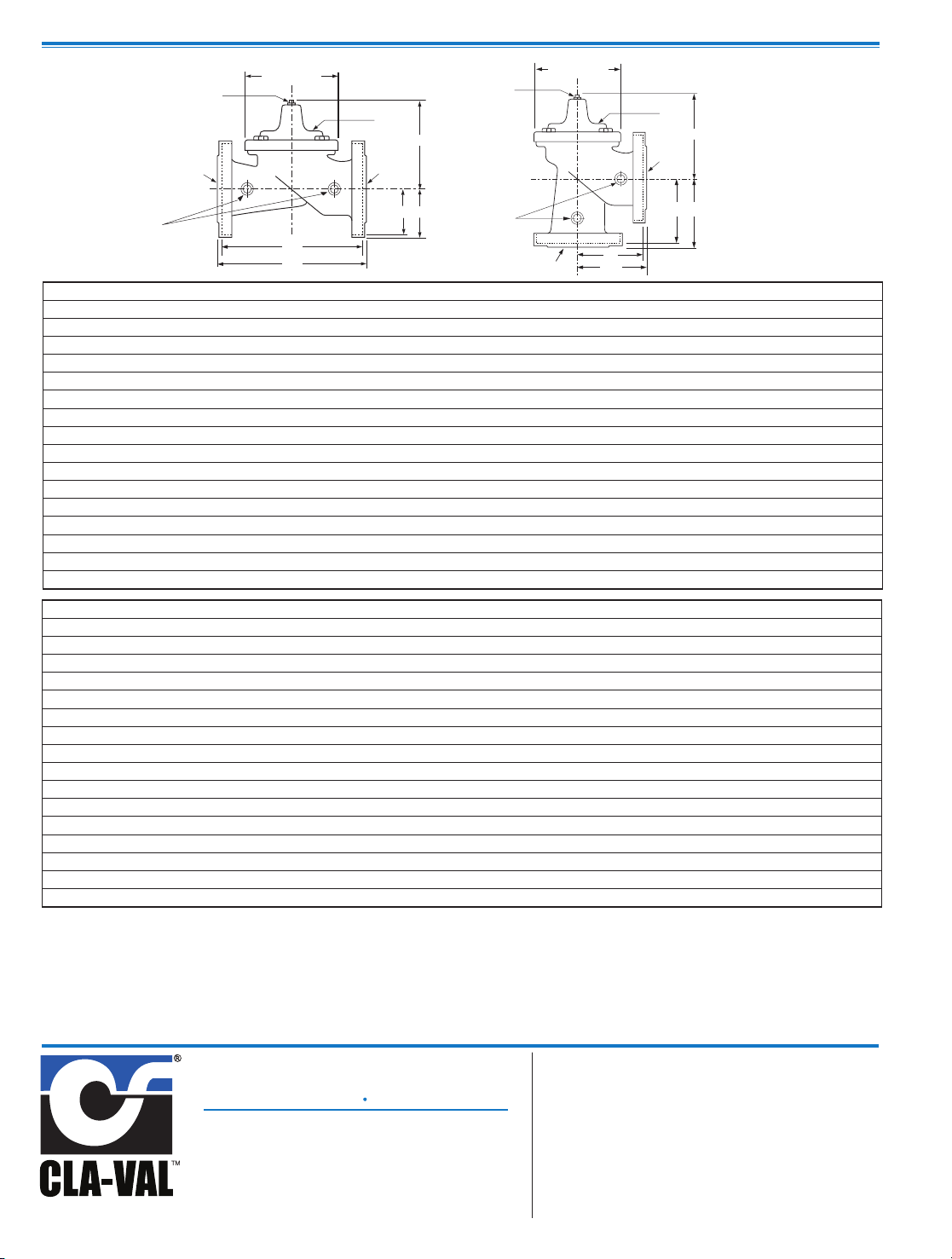

OUTLET

A

AA

AAA

E

INLET

H

J

B (DIAMETER)

K

FF

F

C

DDD

DD

INLET

OUTLET

C

H

B (DIAMETER)

K

GG

GGG

G

D

J

(MAX)

100S (Globe) 2100S (Angle) 100S Grooved (Globe) 2100S Grooved (Angle)

Dimensions

Model 100S

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

E-100S/2100S (R-8/06)

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other positions are acceptable. Due to

component size and weight of 8 inch and larger valves, installation with cover UP is advisable. We recommend isolation valves be installed on inlet and outlet for maintenance.

Adequate space above and around the valve for service personnel should be considered essential. A regular maintenance program should be established based on the specific

application data. However, we recommend a thorough inspection be done at least once a year. Consult factory for specific recommendations.

*11⁄2"Size Only

*40mm Size Only

Valve Size (Inches)

3⁄81

⁄2 - 3⁄4 1 11⁄4-11⁄2 2 21⁄2 3 4 6 8 10 12 14 16 24 36

A Threaded

2.75 3.50 5.12 7.25 9.38 11.00 12.50 — — — — — — — — —

AA 150 ANSI

— — — 8.50* 9.38 11.00 12.00 15.00 20.00 25.38 29.75 34.00 39.00 41.38 61.50 76.00

AAA 300 ANSI

— — — 9.00* 10.00 11.62 13.25 15.62 21.00 26.38 31.12 35.50 40.50 43.50 63.24 78.00

AAAA Grooved End

— — — 8.50 9.00 11.00 12.50 15.00 20.00 25.38 — — — — — —

B Dia.

2.50 3.12 4.38 5.62 6.62 8.00 9.12 11.50 15.75 20.00 23.62 28.00 32.75 35.50 53.16 66.00

C Max.

2.00 3.00 2.75 5.50 6.50 7.56 8.19 10.62 13.38 16.00 17.12 20.88 24.19 25.00 43.93 61.50

CC Max. Grooved End

— — — 4.75 5.75 6.88 7.25 9.62 12.12 14.62 — — — — — —

D Threaded

— — — 3.25 4.75 5.50 6.25 — — — — — — — — —

DD 150 ANSI

— — — 4.00* 4.75 5.50 6.00 7.50 10.00 12.75 14.88 17.00 19.50 20.81 — —

DDD 300 ANSI

— — — 4.25* 5.00 5.88 6.38 7.88 10.50 13.25 15.56 17.75 20.25 21.62 — —

DDDD Grooved End

— — — — 4.75 — 6.00 7.50 — — — — — — — —

E

1.25 0.88 1.63 1.12 1.50 1.69 2.56 3.19 4.31 5.31 9.25 10.75 12.62 15.50 17.75 24.56

EE Grooved End

— — — 2.00 2.50 2.88 3.12 4.25 6.00 7.56 — — — — — —

F 150 ANSI

— — — 2.50 3.00 3.50 3.75 4.50 5.50 6.75 8.00 9.50 10.50 11.75 19.25 28.00

FF 300 ANSI

— — — 3.06 3.25 3.75 4.13 5.00 6.25 7.50 8.75 10.25 11.50 12.75 — —

G Threaded

— — — 1.88 3.25 4.00 4.50 — — — — — — — — —

GG 150 ANSI

— — — 4.00* 3.25 4.00 4.00 5.00 6.00 8.00 8.62 13.75 14.88 15.69 — —

GGG 300 ANSI

— — — 4.25* 3.50 4.31 4.38 5.31 6.50 8.50 9.31 14.50 15.62 16.50 — —

GGGG Grooved End

— — — — 3.25 — 4.25 5.00 — —

— — — — — —

H NPT Body Tapping

—

1

⁄8

1

⁄4

3

⁄8

3

⁄8

1

⁄2

1

⁄2

3

⁄4

3

⁄4

1 1 1 1 1 1 2

J NPT Cover Center Plug

1

⁄

8

1

⁄

8

1

⁄

4

1

⁄

4

1

⁄

2

1

⁄

2

1

⁄

2

3

⁄

4

3

⁄

4

1 1

1

1

⁄

4

1

1

⁄

2

2

1

1

⁄

2

2

K NPT Cover Tapping

—

1

⁄8

1

⁄4

3

⁄8

3

⁄8

1

⁄2

1

⁄2

3

⁄4

3

⁄4

1 1 1 1 1 1 2

Valve Stem Internal

Thread UNF

— — — 10-32 10-32 10-321⁄4-281⁄4-283⁄8-243⁄8-243⁄8-243⁄8-243⁄8-241⁄2-203⁄4-163⁄4-16

Stem Travel

— — —

0.4 0.6 0.7 0.8 1.1 1.7 2.3 2.8 3.4 4.0 4.5 6.75 10.12

Approx. Ship Wt. Lbs.

3 3 8 15 35 50 70 140 285 500 780 1165 1600 2265 6200 11470

Valve Size (mm) 10 15-20 25 32-40 50 65 80 100 150 200 250 300 350 400 600 900

A Threaded

70 89 130 184 238 279 318 — — — — — — — — —

AA 150 ANSI

— — — 216* 238 279 305 381 508 645 756 864 991 1051 1562 1930

AAA 300 ANSI

— — — 229* 254 295 337 397 533 670 790 902 1029 1105 1606 1981

AAAA Grooved End

— — — 216 228 279 318 381 508 645 — — — — — —

B Dia.

64 80 111 143 168 203 232 292 400 508 600 711 832 902 1350 1676

C Max.

51 76 70 140 165 192 208 270 340 406 435 530 614 635 111 6 1562

CC Max. Grooved End

— — — 120 146 175 184 244 308 371 — — — — — —

D Threaded

— — — 83 121 140 159 — — — — — — — — —

DD 150 ANSI

— — — 102* 121 140 152 191 254 324 378 432 495 528 — —

DDD 300 ANSI

— — — 108* 127 149 162 200 267 337 395 451 514 549 — —

DDDD Grooved End

— — — — 121 — 152 191 — — — — — — — —

E

32 23 42 29 38 43 65 81 110 135 235 273 321 394 451 624

EE Grooved End

— — — 52 64 73 79 108 152 192 — — — — — —

F 150 ANSI

— — — 64 76 89 95 114 140 171 203 241 267 298 489 711

FF 300 ANSI

— — — 78 83 95 105 127 159 191 222 260 292 324 — —

G Threaded

— — — 48 83 102 11 4 — — — — — — — — —

GG 150 ANSI

— — — 102* 83 102 102 127 152 203 219 349 378 399 — —

GGG 300 ANSI

— — — 102* 89 11 0 111 135 165 216 236 368 397 419 — —

GGGG Grooved End

— — — — 83 — 108 127 — — — — — — — —

H NPT Body Tapping

—

1

⁄8

1

⁄4

3

⁄8

3

⁄8

1

⁄2

1

⁄2

3

⁄4

3

⁄4

1 1 1 1 1 1 2

J NPT Cover Center Plug

1

⁄8

1

⁄8

1

⁄4

1

⁄4

1

⁄2

1

⁄2

1

⁄2

3

⁄4

3

⁄4

1 1

1

1

⁄4 11⁄2

2

1

1

⁄2

2

K NPT Cover Tapping

—

1

⁄8

1

⁄4

3

⁄8

3

⁄8

1

⁄2

1

⁄2

3

⁄4

3

⁄4

1 1 1 1 1 1 2

Valve Stem Internal

Thread UNF

— — — 10-32 10-32 10-321⁄4-281⁄4-283⁄8-243⁄8-243⁄8-243⁄8-243⁄8-241⁄2-203⁄4-163⁄4-16

Stem Travel

— — —

10 15 18 20 28 43 58 71 86 102 114 171 257

Approx. Ship Wt. Kgs.

1.4 1.4 4 7 16 23 32 64 129 227 354 528 726 1027 2812 5200

Page 9

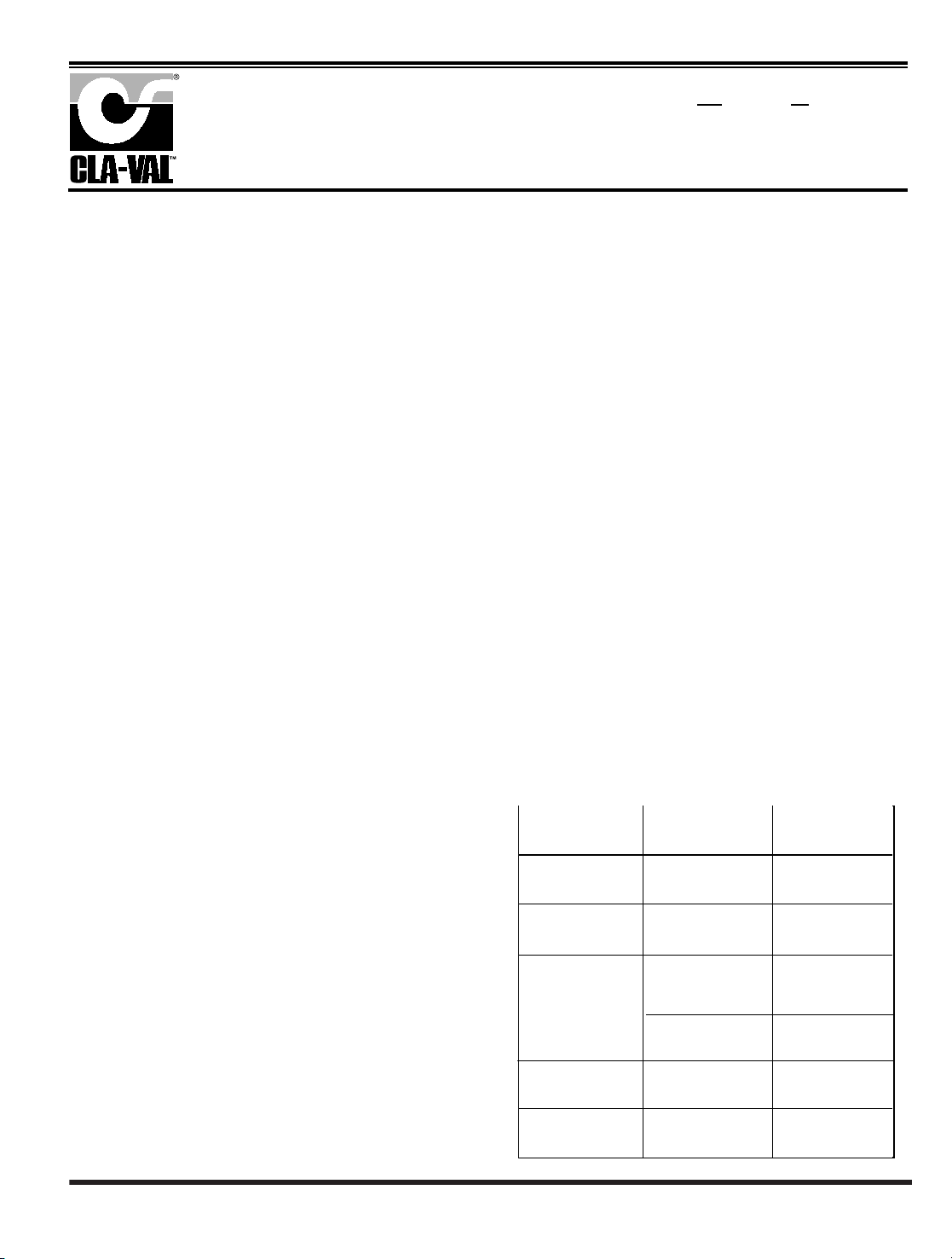

MODEL

• Reduced Cavitation Design

• Drip-Tight, Positive Seating Action

• Service Without Removal From Line

• Globe or Angle Pattern

• Every Valve Factory Tested

The Cla-Val Model 100-20 Hytrol Valve is a hydraulically operated,

diaphragm actuated, globe or angle pattern valve. It consists of

three major components: body, diaphragm assembly and cover.

The diaphragm assembly is the only moving part.

The diaphragm assembly is guided top and bottom by a precision

machined stem which utilizes a non-wicking diaphragm of nylon

fabric bonded with synthetic rubber. A resilient synthetic rubber

disc, retained on three and one-half sides by a disc retainer, forms

a drip-tight seal with the renewable seat when pressure is applied

above the diaphragm.

The reduced cavitation characteristics of the 100-20 Hytrol Valve is

the basis for the Cla-Val 600 Series. The rugged simplicity of

design and packless construction assure a long life of dependable,

trouble-free operation. It's smooth flow passages and fully guided

disc and diaphragm assembly assure optimum control when used

in piping systems requiring remote control, pressure regulation,

solenoid operation, rate of flow control or check valve operation.

Available in various materials and in a wide range of sizes. It's

applications are unlimited.

100-20

600 Series

Hytrol Valve

Principle of Operation

Full Open Operation

When pressure in the

cover chamber

is relieved to a zone of lower

pressure, the line pressure at the

valve inlet opens the valve, allowing

full flow.

Modulating Action

The valve holds any intermediate

position when operating pressure is

equal above and below the

diaphragm. Using a Cla-Val

“Modulating” Control will allow the

valve to automatically compensate

for line pressure changes.

Tight Closing Operation

When pressure from the valve inlet

is applied to the cover chamber, the

valve closes drip-tight.

On-Off Control

On-Off Control

Modulating

Control

(Reduced Internal Port)

Page 10

Options

Specifications

Model 100-20

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Body & Cover

Pressure Class

Flanged

Grade Material

ANSI

Standards*

150 lb. 300 lb.

ASTM A536 Ductile Iron B16.42 250 400

ASTM A216-WCB Cast Steel B16.5 285 400

ASTM B62 Bronze B16.24 225 400

Note: *ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

Component Standard Material Combinations

Body & Cover Ductile Iron Cast Steel Bronze

Available Sizes 3" - 48" 3" - 16" 3" - 16"

Disc Retainer &

Diaphragm Washer

Cast Iron Cast Steel Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is optional

Disc Buna-N®Rubber

Diaphragm Nylon Reinforced Buna-N®Rubber

Stem, Nut & Spring Stainless Steel

For material options not listed consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

Operating Temp. Range

Available Sizes

Pattern Flanged

Globe 3", 4", 6", 8", 10", 12", 14", 16", 18", 20", 24", 30"

Angle 4", 6", 8"

Fluids

-40° to 180° F

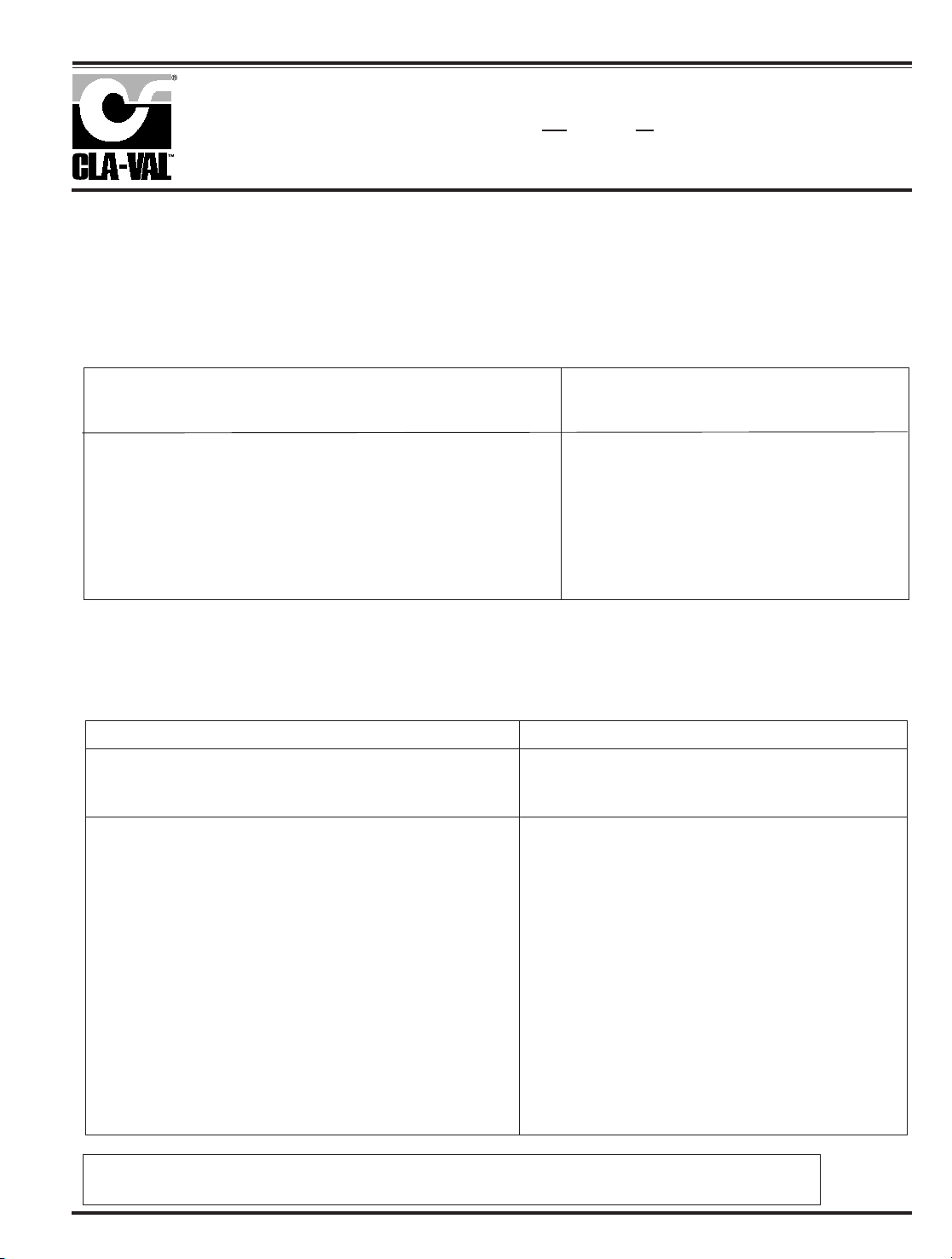

COVER

PIPE PLUG

COVER BEARING

SPRING

STEM NUT

DIAPHRAGM WASHER

DISC RETAINER

BODY

*

SPACER WASHERS

DISC GUIDE

SEAT

PIPE PLUG

STEM

SEAT O-RING

STUD

10" and Larger

*

DIAPHRAGM

*

DISC

*

Repair Parts

Seat Screw

10" annd Larger

(Globe

or

Angle)

PIPE PLUG

HEX NUT

10" and Larger

Cover Bolt

6" and Smaller

KO

DISC GUIDE

KO

SEAT

KO Anti-Cavitation

Trim Option

(Patent Pending)

KO Anti-Cavitation Trim

can be added to any

standard Hytrol Valve

Viton®Rubber Parts- suffix KB

Optional diaphragm, disc and o-ring

fabricated with Viton

®

synthetic rubber.

Viton

®

is well suited for use with mineral

acids, salt solutions, chlorinated

hydrocarbons, and petroleum oils; and is

primarily used in high temperature

applications up to 250° F.

Do not use with

epoxy coatings above

175° F.

Epoxy Coating - suffix KC

An FDA approved fusion bonded epoxy

coating for use with cast iron, ductile iron

or steel valves. This coating is resistant to

various water conditions, certain acids,

chemicals, solvents and alkalies.

Epoxy

coatings are applied in accordance with

AWWA coating specifications C116-03.

Do not use with temperatures above

175° F.

Dura-Kleen® Stem - suffix KD

This stem is designed for applications

where water supplies containing dissolved

minerals create deposits that build-up on a

standard stem and hamper valve

operation. A patented, self-cleaning

design on the stem allows all valve sizes

to operate freely in the harshest

conditions.

Delrin

®

Sleeved Stem- suffix KG

The Delrin

®

sleeved stem is designed for

applications where water supplies contain

dissolved minerals which can form

deposits that build up on the valve stem

and hamper valve operation. Scale buildup will not adhere to the Delrin

®

sleeve

stem. Delrin

®

sleeved stems are not

recommended for valves in continuous

operation where differential pressures are

in excess of 80 psi (2" and larger Hytrol valves).

Heavy Spring

-

suffix KH

The heavy spring option is used in

applications where there is low differential

pressure across the valve, and the

additional spring force is needed to help

the valve close. This option is best suited

for valves used in on-off (non-modulating)

service.

Anti-Cavitation Trim

-

suffix KO

Anti-Cavitation Trim components consist

of a stainless steel radial slotted disc guide

and seat. This system is used when high

differentials are present across the valve.

Water Treatment Clearance

-

suffix KW

This additional clearance is beneficial in

applications where water treatment

compounds can interfere with the closing

of the valve. The smaller outside diameter

disc guide provides more clearance

between the disc guide and the valve seat.

This option is best suited for valves used

in on-off (non-modulating) service.

Page 11

Model 100-20 Flow Chart (Based on normal flow through a wide open valve)

20

24

10 20 30 40 60 80 100 200 500 1000 2000 5000 10,000 20,000 50,000

1

2

3

4

6

8

10

20

30

40

60

80

100

53

Angle Valve Sizes (Inches)

Globe Valve Sizes (Inches)

3

46

8

10 12

68

16

Pressure Drop — psi

4

18

30

14

Flow Rate gpm (water)

K =

894d

4

C

2

v

L =

K

12 f

K Factor (Resistance Coefficient)

The Value of K is calculated from the formula:

(U.S. system units)

Equivalent Length of Pipe

Equivalent lengths of pipe (L) are determined from the formula:

(U.S. system units)

Fluid Velocity

Fluid velocity can be calculated from the following formula:

(U.S. system units)

d

V =

.4085 Q

2

d

C

V

Factor

Formulas for computing C Factor, Flow (Q) and Pressure Drop

V

( P):

C

V

=

Q

P

C

V

=

Q

P

C

V

=

Q

P

2

V

Where:

U.S. (gpm) @ 1 psi differential at 60 F water

(l/s) @ 1 bar (14.5 PSIG) differential

or

at 15 C water

inside pipe diameter of Schedule 40 Steel Pipe (inches)

friction factor for clean, new Schedule 40 pipe

(dimensionless) (from Cameron Hydraulic Data,

18th Edition, P 3-119)

Resistance Coefficient (calculated)

Equivalent Length of Pipe (feet)

Flow Rate in U.S. (gpm) or (l/s)

Fluid Velocity (feet per second) or (meters per second)

Pressure Drop in (psi) or (bar)

=

=

=

=

=

=

=

=

=

P

V

Q

L

K

f

d

C

Functional Data Model 100-20

*Estimated

Valve Size

Inches 3 4 6 8 10 12 14 16 18 20 24 30

mm. 80 100 150 200 250 300 350 400 460 500 600 760

C

V

Factor

Globe

Pattern

Gal./Min. (gpm.) 62 136 229 480 930 1458 1725 2110 2940* 3400* 4020 7900*

Litres/Sec. (l/s.) 15 32.5 55 115 223 350 414 506 705 816 965 1895

Angle

Pattern

Gal./Min. (gpm.) — 135 233 545 — — — — — — — —

Litres/Sec. (l/s.) — 32 56 132 — — — — — — — —

Equivalent

Length

of

Pipe

Globe

Pattern

Feet (ft.) 293 251 777 748 621 654 750 977 983 1125 3005 2130

Meters (m.) 89.3 76.4 237.1 228.1 189.5 199.4 228.7 298.1 299.9 343.2 916.6 649.6

Angle

Pattern

Feet (ft.) — 254 751 580 — — — — — — — —

Meters (m.) — 77.6 229 176.9 — — — — — — — —

K

Factor

Globe Pattern 20.6 12.7 23.1 15.7 10.4 8.5 8.9 10.2 8.4 8.8 19.1 10.5

Angle Pattern — 12.9 22.3 12.2 — — — — — — — —

Liquid Displaced

from Cover Chamber

When Valve Opens

Fl. Oz — — — — — — — — — — — —

U.S. Gal. 0.32 .08 .17 .53 1.26 2.51 4.0 4.0 9.6 9.6 9.6 29.0

ml — — — — — — — — — — — —

Litres .12 .30 .64 2.0 4.8 9.5 15.1 15.1 36.2 36.2 36.2 110

Page 12

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©COPYRIGHT CLA-VAL 2006 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-100-20 (R-8/06)

Represented By:

B (DIAMETER)

J

INLET

H

A

AA

K

C

OUTLET

F

FF

J

B

(DIAMETER)

K

C

OUTLET

E

EE

INLET

D

DD

H

100-20 (Angle)

100-20 (Globe)

Dimensions

Model 100-20

Service and Installation

Cla-Val Control Valves operate with maximum efficiency when mounted in horizontal piping with the main valve cover UP, however, other

positions are acceptable. Due to component size and weight of 10 inch and larger valves, installation with cover UP is advisable. We recommend

isolation valves be installed on inlet and outlet for maintenance. Adequate space above and around the valve for service personnel should be

considered essential. A regular maintenance program should be established based on the specific application data. However, we recommend a

thorough inspection be done at least once a year. Consult factory for specific recommendations.

Valve Size (Inches) 3 4 6 8 10 12 14 16 18 20 24 30

A 150 ANSI 10.25 13.88 17.75 21.38 26.00 30.00 34.25 35.00 42.12 48.00 48.00 63.25

AA 300 ANSI 11.00 14.50 18.62 22.38 27.38 31.50 — 36.62 43.63 49.62 49.75 —

B Dia. 6.62 9.12 11.50 15.75 20.00 23.62 28.00 28.00 35.44 35.44 35.44 53.19

C Max. 7.00 8.62 11.62 15.00 17.88 21.00 20.88 25.75 25.00 31.00 31.00 43.94

D 150 ANSI — 6.94 8.88 10.69 — — — — — — — —

DD 300 ANSI — 7.25 9.38 11.19 — — — — — — — —

E 150 ANSI — 5.50 6.75 7.25 — — — — — — — —

EE 300 ANSI — 5.81 7.25 7.75 — — — — — — — —

F 150 ANSI 3.75 4.50 5.50 6.75 8.00 9.50 11.00 11.75 15.88 14.56 17.00 19.88

FF 300 ANSI 4.12 5.00 6.25 7.50 8.75 10.25 — 12.75 15.88 16.06 19.00 —

H NPT Body Tapping

3

⁄8

1

⁄2

3

⁄4

3

⁄4 1 1 1 1 1 1 1 1

J NPT Cover Center Plug

1

⁄2

1

⁄2

3

⁄4

3

⁄4 1 1 11⁄4 11⁄4 2 2 2 2

K NPT Cover Tapping

3

⁄8

1

⁄2

3

⁄4

3

⁄4 1 1 1 1 1 1 1 1

Valve Stem Internal Thread UNF 10-321⁄

4-28

1

⁄

4-28

3

⁄

8-24

3

⁄

8-24

3

⁄

8-24

3

⁄

8-24

3

⁄

8-24

1

⁄

2-20

1

⁄

2-20

1

⁄

2-20

3

⁄

4-16

Stem Travel 0.6 0.8 1.1 1.7 2.3 2.8 3.4 3.4 3.4 4.5 4.5 6.5

Approx. Ship Wt. Lbs. 45 85 195 330 625 900 1250 1380 1500 2551 2733 6500

Valve Size (mm) 80 100 150 200 250 300 350 400 450 500 600 750

A 150 ANSI 260 353 451 543 660 762 870 889 1070 1219 1219 1607

AA 300 ANSI 279 368 473 568 695 800 — 930 1108 1260 1263 —

B Dia. 168 232 292 400 508 600 711 711 900 900 900 1351

C Max. 178 219 295 381 454 533 530 654 635 787 787 1116

D 150 ANSI — 176 226 272 — — — — — — — —

DD 300 ANSI — 184 238 284 — — — — — — — —

E 150 ANSI — 140 171 184 — — — — — — — —

EE 300 ANSI — 148 184 197 — — — — — — — —

F 150 ANSI 95 114 140 171 203 241 279 298 403 370 432 505

FF 300 ANSI 105 127 159 191 222 260 — 324 403 408 483 —

H NPT Body Tapping

3

⁄8

1

⁄2

3

⁄4

3

⁄4 1 1 1 1 1 1 1 1

J NPT Cover Center Plug

1

⁄2

1

⁄2

3

⁄4

3

⁄4 1 1 11⁄4 11⁄4 2 2 2 2

K NPT Cover Tapping

3

⁄8

1

⁄2

3

⁄4

3

⁄4 1 1 1 1 1 1 1 1

Valve Stem Internal Thread UNF 10-321⁄4-281⁄4-283⁄8-243⁄8-243⁄8-243⁄8-243⁄8-241⁄2-201⁄2-201⁄2-203⁄4-16

Stem Travel 15 20 28 43 58 71 86 86 86 114 114 165

Approx. Ship Wt. Kgs. 20 39 89 150 284 409 568 627 681 1157 1249 2951

For assistance in selecting appropriate valve options or valves manufactured with special design requirements, please contact our Regional Sales Office or Factory.

Page 13

DESCRIPTION

The CRL Pressure Relief Control is a direct acting, spring loaded,

diaphragm type relief valve. It may be used as a self-contained valve or as

a pilot control for a Cla-Val Main valve. It opens and closes within very

close pressure limits.

INSTALLATION

The CRL Pressure Relief Control may be installed in any position. The

control body (7) has one inlet and one outlet port with a side pipe plug (24)

at each port. These plugs are used for control connections or gauge applications. The inlet in the power unit body (6) is the sensing line port. A flow

arrow is marked on the body casting.

OPERATION

The CRL Pressure Relief Control is normally held closed by the force of the

compression spring above the diaphragm; control pressure is applied

under the diaphragm.

When the controlling pressure exceeds the spring setting, the disc is lifted

off its seat, permitting flow through the control.

When controlling pressure drops below spring setting, the spring returns

the control to its normally closed position.

ADJUSTMENT PROCEDURE

The CRL Pressure Relief Control can be adjusted to provide a relief setting

at any point within the range found on the nameplate.

Pressure adjustment is made by turning the adjustment screw (9) to vary

the spring pressure on the diaphragm. Turning the adjustment screw clockwise increases the pressure required to open the valve. Counterclockwise

decreases the pressure required to open the valve.

When pressure adjustments are complete the jam nut (10) should be tightened and the protective cap (1) replaced. If there is a problem of tampering, lock wire holes have been provided in cap and cover. Wire the cap to

cover and secure with lead seal.

DISASSEMBLY

The CRL Pressure Relief Control does not need to be removed from the

line for disassembly. Make sure that pressure shut down is accompanied

prior to disassembly. If the CRL is removed from the line for disassembly

be sure to use a soft jawed vise to hold body during work.

Refer to Parts List Drawing for Item Numbers.

1. Remove cap (1), loosen jam nut (10) and turn adjusting

screw counterclockwise until spring tension is relieved.

2. Remove the eight screws (4) holding the cover (3) and

powerunit body (6). Hold the cover and powerunit together

and place on a suitable work surface.

See NOTE under REASSEMBLY.

3. Remove the cover (3) from powerunit body (6). The spring

(12) and two spring guides (11).

4. Remove nut (13) from stem (19) and slide off the belleville washer

(14), the upper diaphragm washer (15) and the diaphragm (16).

5. Pull the stem (19) with the disc retainer assembly (21) through the

bottom of powerunit. The lower diaphragm washer (17) will slide off

of stem top.

6. Remove jam nut (23) and disc retainer assembly (21) from stem.

Use soft jawed pliers or vise to hold stem. The polished surface of

stem must not be scored or scratched.

7. The seat (22) need not be removed unless it is damaged. If removal

is necessary use proper size socket wrench and turn counterclockwise.

Note: Some models have an integral seat in the body (7).

INSPECTION

Inspect all parts for damage, or evidence of cross threading. Check

diaphragm and disc retainer assembly for tears, abrasions or other damage. Check all metal parts for damage, corrosion or excessive wear.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using 400 grit wet or dry

sandpaper fine emery or crocus cloth. Replace all O-rings and any damaged parts.

When ordering replacement parts, be sure to specify parts list item number and all nameplate data.

REASSEMBLY

In general, reassembly is the reverse of disassembly. However, the following steps should be observed:

1. Lubricate the O-Ring (18) with a small amount of a good grade of

waterproof grease, (Dow Corning 44 medium grade or equal).

Use grease sparingly and install O-ring in powerunit body (6).

2. Install stem (19) in powerunit body (6). Use a rotating motion with

minimum pressure to let stem pass through O-ring.

Do Not Cut O-Ring.

3. Install O-ring (5) at top of stem (19). Place lower diaphragm

washer (17) on the stem with the serrated side up. Position

diaphragm (16), upper diaphragm washer (15), with serration down,

and belleville washer (14) with concave side down.

4. Position powerunit body (6) as shown on parts list drawing (top view).

5. Continue reassembly as outlined in disassembly steps 1 through 3.

Pressure Relief Control

CRL

Note: Item (4) Screw will have a quantity of 8 for the 0-75 and 20-200psi

design and a quantity of 4 for the 100-300psi design. Item (25) Screw is

used on the 100-300psi design only. Install item (25), before item (4) for

preload of item (12) spring.

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open. Controlling pressure

too low.

Back off adjusting

screw until valve

opens.

Fails to open with

spring compression

removed.

Mechanical obstruction, corrosion, scale

build-up on stem.

Disassemble,

locate,and remove

obstruction, scale.

Leakage from cover

vent hole when controlling pressure is

applied.

Diaphragm Damage Disassembly replace

damaged

diaphragm.

Fails to close with

spring compressed.

Mechanical obstruction.

Disassemble, locate

and remove

obstruction.

Fails to close. No spring compres-

sion.

Re-set pressure

adjustment.

Loose diaphragm

assembly.

Tighten upper

diaphragm washer.

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-CRL (R-8/05)

Page 14

1/2" & 3/4" PRESSURE RELIEF CONTROL

CRL

Ajusting Screw

(3/8" - 16UNF THREAD)

9

1

10

3

11

12

14

13

11

8

22

23

7

18

19

21

INLET

1/8 - 27 NPT

SENSING

CONNECTION

(TYP.)

7.44

MAX

.71

OUTLET

20

6

2

0 TO 75 AND

20 TO 200 PSI DESIGN

5

17

16

15

4

1A

9

10

3

11

12

11

7

2

100 To 300 psi Design

.71

ADJUSTING SCREW

(1/2" 20UNF THREAD)

10.44

MAX.

When ordering parts please specify:

1. All Nameplate Data

2. Item Part Number

3. Item Description

CRL

RANGE PSI

APPROX. INCREASE

FOR EACH CLOCK-

WISE TURN OF

ADJUSTING SCREW

0 to 75 8.5 PSI

20 to 200 28.0 PSI

100 to 300 18.0 PSI

25

25

24

4

45º

3.12

DIA.

TRUE LOCATION OF

SENSING

CONNECTION

(TYP.)

ADJUSTING SO

(3/8" - 16UNF )

SIZE

1/2"

1/2"

1/2"

3/4"

3/4"

3/4"

SPRING

RANGE

0-75 PSI

20-200 PSI

100-300 PSI

0-75 PSI

20-200 PSI

100-300 PSI

PART

NUMBER

79222-01E

79222-02C

82809-01D

79229-01K

79229-02H

86005-01E

For 100-450 PSI Contact Factory

Body with

integral Seat

1

1A

2

3

4*

5*

6

7

8*

9

10

11

12

13

14

15

16*

17

18*

19

20*

21*

22

23

24

25*

Cap

Cap 100 to 300 psi Design

Nameplate

Cover

Screw Fil.Hd.10-32 x 1.88

0-Ring

Body, Powerunit

1/2" Body

3/4" Body

0-Ring, Seat

Screw, Adjusting

Nut Hex (Locking)

Guide, Spring

Spring,

Nut, Stem, Upper

Washer, Belleville

Washer, Diaphragm (upper)

Diaphragm

Washer, Diaphragm (lower)

0-Ring, Stem

Stem

0-Ring, Body

Retainer Assembly, Disc

Seat

Nut, hex, Stem, Lower

Pipe Plug

Screw Fil.Hd, 10-32 x 2.25 (Qty 4 on 100-300 psi)

FACTORY SET POINT

REPAIR KIT*

Plastic

Plastic

Brass

Bronze

303 SS

Rubber

Bronze

Bronze

Bronze

Rubber

Brass

303 SS

303 SS

CHR/VAN

Bronze

Steel

303 SS

Rubber

303 SS

Rubber

303 SS

Rubber

303 SS

303 SS

Bronze

Bronze

303 SS

0-75

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71884B

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

50 PSI

9170007A

20-200

67628J

1257601D

--

C2544K

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

71881H

71885J

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

60 PSI

9170007A

100-300

1257601D

1257601D

--

44587E

6757867E

00902H

7920504D

C7928K

C9083B

00718H

7188201D

6780106J

1630301J

1630201A

73034B

7055007E

71891G

C1505B

45871B

00746J

8982401F

00767E

C8964D

62187A

6779806G

6784701C

6757867E

100 PSI

9170007A

Item Material Part Number

Part Number

Part Number

Description

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CRL (R-12/05)

PARTS LIST

Page 15

*This drawing is the property of CLA-VAL and same and copies made thereof, if any, shall be returned to it upon demand. Delivery and disclosure hereof are made solely

upon condition that the same shall not be used, copied ore reproduced, nor shall the subject here of be disclosed in any manner to anyone for any purpose, except as

herein authorized, without prior approval of CLA-VAL. Whether or not the equipment or information shown hereon is patented or otherwise protected, full title and copyrights if any, in and to this drawing and/or information delivered or submitted are fully reserved by CLA-VAL.

Dwg#47117

Regulator Spring Color Coding Chart

THE FOLLOWING CONTROL & SPRING P/N#'S WERE REMOVED, 32656B, 31554K, 44591G, V65695B, & V5695B.

ADDED CRL-13, CRL-5A, CRA, CRA-10A, CHANGED SPRING RANGES TO MATCH CURRENT CONTROLS.

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-47117 AD (R-11/06)

PARTS LIST

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *PSI PER TURN

.080 DIA. C0492D BLUE S.S.

CDB-7

CRL-5A

0-7

0-7

.75

.75

.018 DIA. 82575C -- S.S.

CRD

CRD-10A

1.9-6.5

1.9-6.5

.61

.49

.116 DIA. 81594E -- S.S.

CRD

CRD-10A

2-30

2-30

3.0

2.4

.120 DIA. V5654J GREEN CHR VAN

CRL-5A

CRD

5-25

10-40

4.0

4.0

.162 DIA. 32447F NATURAL S.S.

CDB-7

CRL-5A

CRL-13

10-60

10-60

10-60

12.0

12.0

12.0

.162 DIA. V5695B YELLOW MUSIC WIRE

CDB-7

CRL-5A

CRL-13

20-80

20-80

20-80

14.5

14.5

14.5

.207 DIA. C1124B CAD PLT MUSIC WIRE

CDB-7

CRL-13

CRL-5A

50-150

50-150

50-150

29.5

29.5

29.5

.225 DIA. V6515A RED MUSIC WIRE

CDB-7

CRL-13

CRL-5A

65-180

65-180

65-180

44.0

44.0

44.0

.115 X .218 71884B RED CHR VAN

CRL

CRD

CRD-10A

0-75

15-75

15-75

8.5

9.0

7.2

.118 X .225 71886J GREEN CHR VAN

CRL

CRD

CRD-10A

20-200

30-300

30-300

28.0

27.0

22.4

.225 X .295 1630201A CAD PLT CHR VAN

CRL

CRL-5A

100-300

100-300

18.00

18.00

.440 X .219 48211H CAD PLT STEEL

CRA-18

CRD-22

CRL-4A

200-450

200-450

100-450

17.0

17.0

17.0

.187 20561901H BLACK STEEL CRD 20-105 12.0

WIRE SIZE SPRING NUMBER COLOR WIRE MATERIAL CATALOG NUMBER PSI RANGE *FEET PER TURN

.080 DIA. C0492D BLUE S.S.

CRA

CRD-2

4.5-15

4.5-15

.82

.82

.375 DIA.

87719B

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-5

5-40

30-80

70-120

110-120

150-200

1.0

2.0

3.0

4.0

5.0

.072 DIA. V5097A -- 302SS CVC 1-17 .7

.375 DIA.

2933502H

1 SPRING

2 SPRING

3 SPRING

4 SPRING

5 SPRING

EPOXY

COATED

CHROME SILICON CDS-6

5-40

30-80

70-120

110-120

150-200

.75

1.50

2.20

3.00

3.70

*THESE FIGURES ARE ONLY APPROXIMATE. FINAL ADJUSTMENTS SHOULD BE MADE WITH A PRESSURE GAGE.

Page 16

When ordering parts, please specify:

• All Nameplate Data

• Item Number

• Description

• Recommended Spare Parts

Strainer and Orifice Assembly

X44A

BRONZE BODY — S.S. ORIFICE

1/8 NPT

3/8 NPT

3/4

3/4

3 3/8

2

3

5

4

3/8 NPT

8

7

6

1

2 1/4 MAX.

7/8

Inlet

Outlet

X44A

STOCK NO.

71310-01

-02

-03

-04

-05

-06

* -07

-08

-09

-10

ORIFICE DIA.

.031

.046

.062

.078

.093

.109

.125

.140

.156

.187

ORIFICE PLUG

PART # (ITEM 5)

94132-01

-02

-03

-04

-05

-06

-07

-08

-09

-10

*Standard

3/8" x 3/8"

ITEM

1

2

3

4

5

6

7

8

DESCRIPTION

Body

Plug, Top

"O" Ring, Plug Top

Screen

Orifice Plug

Plug, Pipe

Strainer Plug

"O" Ring, Strainer Plug

MATERIAL

Red Brs.

Brass

Syn. Rub.

Monel

Delrin

Brass

S.S.

Syn. Rub.

QTY.

1

1

1

1

1

1

1

1

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

P-X44A (R-5/05)

PARTS LIST

Page 17

A

2.50

A

2.75

SECTION

AA

3/8 N.P.T.

1.25

1.50

3/8 N.P.T.

BOTH ENDS

6

5

4

1

3

2

8

7

Outlet

Inlet

Flow

1. Cover Screw (8 Required)

2. Cover

*3. Spring

4. Diaphragm Washer

*5. Diaphragm

*6. Disc Retainer Assembly

7. Body Plug (3/8 NPT)

8. Body (Threaded)

ITEM DESCRIPTION

When ordering

parts, please

specify:

• All nameplate data

• Description

• Part Number

• Item Number

• Material

*Recommended Spare Parts

3/8" Check Valve

81-01

PARTS LIST

Page 18

2

10

7

6

9

11

3

5

1

4

8

3.50

.56

2.56

FLOW

OUTLETINLET

3.12 DIA

ITEM DESCRIPTION

When ordering

parts, please

specify:

• All nameplate data

• Description

• Part Number

• Item Number

• Material

*Recommended Spare Parts

1/2" & 3/4 Check Valve

81-01

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-81-01 (R-5/05)

PARTS LIST

1. Body 1

2. Cover 1

*3. Diaphragm 1

4. Guide Disc 1

*5. Disc Retainer Assembly 1

7. Nut Hex 3/8 - 24UNF 28 1

8. Plug Pipe Hex NPT 2

9. Screw, Fil HD 10 32UNF 2 x 2LG 8

10. Spring 1

11. Nameplate 1

Page 19

DESCRIPTION

The CRA Pressure Reducing Control automatically reduces a higher inlet

pressure to a lower outlet pressure. It is a direct acting, spring loaded,

diaphragm type valve that operates hydraulically or pneumatically and is

designed to sense pressure from a remote point. It may be used as a selfcontained valve or as a pilot control for a Cla-Val Co. main valve. It will

hold a constant downstream pressure at the remote sensing point within

very close pressure limits.

OPERATION

The CRA Pressure Reducing Control is normally held open by the force

of the compression spring above the diaphragm; delivery pressure acts on

the underside of the diaphragm. Flow through the valve responds to

changes in pressure at the the sensing point.

INSTALLATION

The CRA Pressure Reducing Control may be installed in any position.

There is one inlet port and two outlets, for either straight or angle installation. The second outlet port can be used for a gauge connection. A flow

arrow is marked on the body casting.

ADJUSTMENT PROCEDURE

The CRA Pressure Reducing Control can be adjusted to provide a delivery pressure range as specified on the nameplate.

Pressure adjustment is made by turning the adjustment screw to vary the

spring pressure on the diaphragm. The greater the compression on the

spring the higher the pressure setting.

1. Turn the adjustment screw in (clockwise) to increase delivery

pressure.

2. Turn the adjustment screw out (counter-clockwise) to decrease

the delivery pressure. When pressure adjustment is completed,

tighten jam nut on adjustment screw and replace protective cap.

Flow rates are not critical during pressure setting. The approximate minimum flow rates given in the table are for the main valve on which the CRA

is installed.

Valve Size 1 1⁄4"-3" 4"-8" 10"-16"

Minimum Flow GPM 15-30 50-200 300-650

MAINTENANCE

Disassembly

To disassemble follow the sequence of the item numbers assigned to

parts in the sectional illustration.

Reassembly

Reassembly is the reverse of disassembly. Caution must be taken to

avoid having the yoke (17) drag on the inlet nozzle of the body (18).

Follow this procedure:

1. Place yoke (17) in body and screw the disc retainer assembly

(16) until it bottoms.

2. Install gasket (14) and spring (19) for 2-30 psi range onto plug

(13) and screw into body. Disc retainer must enter guide hole in

plug as it is assembled. Screw the plug in by hand. Use wrench

to tighten only.

3. Place gasket (25) and powertrol body (21) on yoke extension

(17). Refer to sectional view for proper reassembly of (21) onto

body (18).

4. Place lower diaphragm washer (24), "o" ring (22), diaphragm

(12), upper diaphragm washer (11), and belleville washer (20) on

yoke extension (17). Screw on diaphragm nut (10) finger tight.

5. Place two machine screws (4) through (21) (25) and screw into

body (18). Do not include the diaphragm (12) in this operation.

This holds parts aligned for next step, and allows the diaphragm

to move and be properly located during tightening of nut (10).

6. Hold the diaphragm so that screw holes in the diaphragm (12)

SYMPTOM PROBABLE CAUSE REMEDY

Fails to open when

pressure lowers

No spring compression Tighten adjusting

screw

Mineral buildup on yoke

extension (17)

Disassemble and

clean part,

Replace "O" rings

(22) and (23).

Damaged spring Disassemble and

replace.

Spring guide (8) is not in

place

Disassemble and

place guide (8) on

top of spring (9).

Yoke dragging on inlet

nozzle

Disassembled

and reassemble

use procedure.

Fails to close when

delivery pressure rises

Spring compressed

Back off adjusting

screw

Mineral deposit on yoke

extension (17)

Disassemble and

clean part.

Replace "o" rings

(22) and (23).

Mechanical obstruction

Disassemble and

remove obstruction

Worn disc

Disassemble,

remove and

replace disc

retainer assembly. (16)

Yoke dragging on inlet

nozzle

Refer to paragraph 6

Damaged diaphragm (12)

Disassemble and

replace

Loose diaphragm nut (10)

Remove cover

and tighten nut

REMOTE SENSING TYPE

CRA

Leakage from cover

vent hole

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

N-CRA (R-5/05)

and powertrol body (21) align. Tighten diaphragm nut (10) with a wrench.

At the final tightening release the diaphragm and permit it to rotate

approximately 5° to 10°. The diaphragm holes should now be properly

aligned with the body holes.

To check for proper alignment proceed as follows:

Rotate diaphragm clockwise and counterclockwise as far as possible.

Diaphragm screw holes should rotate equal distance on either side of

powertrol body screw holes ±1/8".

Repeat assembly procedure until diaphragm and yoke are properly

aligned. There must be no contact between yoke and body nozzle during

its normal opening and closing movement. To simulate this movement

hold powertrol body and diaphragm holes aligned. Move yoke to open

and closed positions. There must be no evidence of contact or dragging.

7. Remove machine screws per step 5.

8. Install spring (9) with spring guide (8) on top of spring.

9. Install cover (5) using eight machine screws (4).

10. Replace adjusting screw (2) and nut (3), then cap (1).

Pressure Reducing Control

Page 20

* Suggested Repair Parts

REMOTE SENSING TYPE

4

15

6

7

1/8" NPT

REMOTE

SENSING

CONNECTION

VIEW

C

FOR 20-300 PSI RANGE ONLY

16

SIZE

(inch)

STOCK

NUMBER

SEAT

DIA

ADJ.

RANGE

(psi)

3/8 79744-04B 1/4 30-300

3/8 79744-06G 1/4 2-30

Factory set pressure:

PSI*per turn

30-300 set @ 60 psi 27.0

2-30@ 10 psi 3.0

3/8 79744-03D 1/4 15-75

Pressure Reducing Control

CRA

When ordering parts specify:

• All nameplate data

• Description

• Item number

* Approximate - Final adjustment should

be made with a pressure gauge and

with flow.

15-75 set @ 20 psi 9.0

1

2

3

4*

5

6

7

8

9

10

11

12*

13

14*

15

16*

17

18

19*

20

21

22*

23*

24

25

Cap

Adjusting Screw

Jam Nut, 3/8—16

Machine Screw 10-32 x 1-1/4"(Fil.Hd.) (8 required)

Cover

Nameplate Screw

Nameplate

Spring Guide

Spring

(15-75 psi)

(30-300 psi)

(2-30 psi)

Hex Nut 5/16 - 18

Diaphragm Washer (upper)

Diaphragm

Plug, Body

Gasket

Plug, 3/8 NPT

Disc Retainer Assy (15-75 psi & 30-300 psi)

Disc Retainer Assy (2-30 psi)

Yoke

Body & Seat Assy, Seat only 1/4"

Bucking Spring (Required with 2-30 psi)

Belleville Washer

Powertrol Body

O-Ring

O-Ring

Diaphragm Washer (lower)

Gasket

Repair Kit (no Bucking Spring) Item 19

Repair Kit (with Bucking Spring) Item 19

PL

BRS

303

SS

BRS

SS

BRS

302

CHR VAN

CHR VAN

SS

303

302

NBR

BRS

FIB

BRS

BR/RUB

BR/RUB

VBZ

BS

302

STL

BRS

NBR

NBR

BRS

NBC

67628J

7188201D

6780106J

6757874A

C2544K

67999D

C002201G

71881H

71884B

71885B

81594E

71883D

71891G

C6936D

V5653A

40174F

6766003F

C5256H

C5255K

C1799A

8339701J

VO5586

7055007E

C3388A

00708J

00746J

C1804J

8059401D

9170003K

9170001D

ITEM DESCRIPTION MATERIAL PART NUMBER LIST PRICE

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CRA (R-5/05)

PARTS LIST

Page 21

Globe and Angle Needle Valves—CN Series

1. Body

2. Bonnet

3. Stem

4. Gland

5. Nut

6. Handwheel

7. Nut

8. Packing

Item Description

When ordering parts,

please specify:

• All nameplate data

• Description

• Part Number

• Item Number

• Material

CN

7

6

3

5

8

2

1

3/4" SIZE ONLY

4

CAT. NO. CNB

GLOBE

CAT. NO. CNA

ANGLE

WHEN USED AS A CONTROL

VALVE, HANDWEEL IS

REMOVED AND STEM IS

SLOTTED FOR SCREWDRIVER ADJUSTMENT .

CLA-VAL

copyright Cla-Val 2003 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL- CN (R-9/03)

PARTS LIST

Page 22

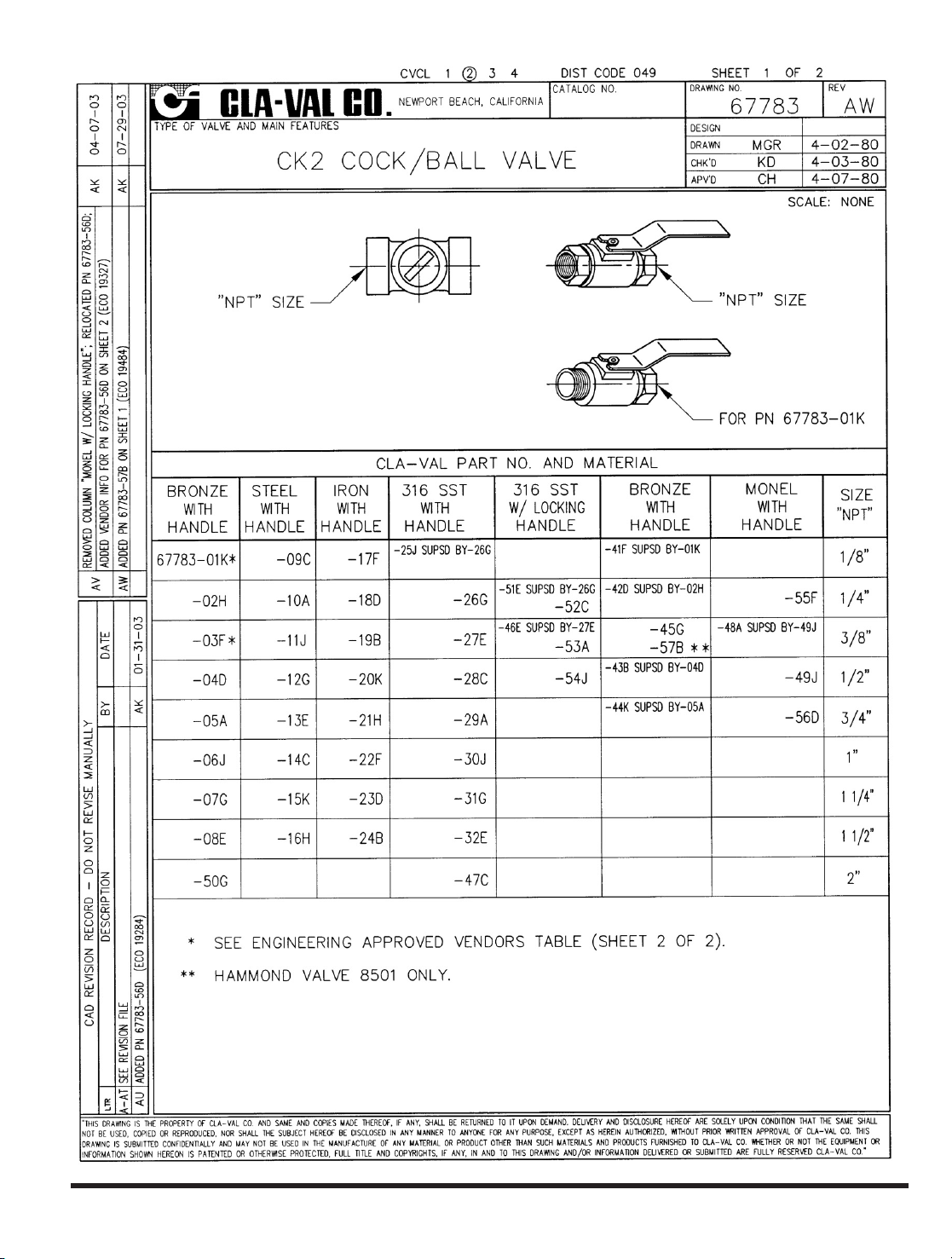

CLA-VAL

©Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

PL-CK2 (R-5/05)

Page 23

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

INSTALLATION / OPERATION / MAINTENANCE

Flow Control

CV

MODEL

N-CV (R-5/05)

DESCRIPTION

The Cla-Val Model CV Flow Control is a simply-designed,

spring-loaded check valve. Rate of flow is full flow in one direction and restricted in other direction. Flow is adjustable in the

restricted direction. It is intended for use in conjunction with a

pilot control system on a Cla-Val Automatic Control Valve.

OPERATION

The CV Flow Control permits full flow from port A to B, and

restricted flow in the reverse direction. Flow from port A to B

lifts the disc from seat, permitting full flow. Flow in the reverse

direction seats the disc, causing fluid to pass through the clearance between the stem and the disc. This clearance can be

increased, thereby increasing the restricted flow, by screwing

the stem out, or counter-clockwise. Turning the stem in, or

clockwise reduces the clearance between the stem and the

disc, thereby reducing the restricted flow.’

INSTALLATION

Install the CV Flow Control as shown in the valve schematic

All connections must be tight to prevent leakage.

DISASSEMBLY

Follow the sequence of the item numbers assigned to the

parts in the cross sectional illustration for recommended

order of disassembly.

Use a scriber, or similar sharp-pointed tool to remove O-ring

from the stem.

INSPECTION

Inspect all threads for damage or evidence of crossthreading. Check mating surface of seat and valve disc for

excessive scoring or embedded foreign particles. Check

spring for visible distortion, cracks and breaks. Inspect all

parts for damage, corrosion and cleanliness.

CLEANING

After disassembly and inspection, cleaning of the parts can

begin. Water service usually will produce mineral or lime

deposits on metal parts in contact with water. These

deposits can be cleaned by dipping the parts in a 5-percent

muriatic acid solution just long enough for deposits to dissolve. This will remove most of the common types of

deposits. Caution: use extreme care when handling

acid. If the deposit is not removed by acid, then a fine grit

(400) wet or dry sandpaper can be used with water. Rinse

parts in water before handling. An appropriate solvent can

clean parts used in fueling service. Dry with compressed air

or a clean, lint-free cloth. Protect from damage and dust

until reassembled.

REPAIR AND REPLACEMENT

Minor nicks and scratches may be polished out using a fine

grade of emery or crocus cloth; replace parts if scratches

cannot be removed.

Replace O-ring packing and gasket each time CV Flow

Control is overhauled.

Replace all parts which are defective. Replace any parts

which create the slightest doubt that they will not afford completely satisfactory operation. Use Inspection steps as a

guide.

REASSEMBLY

Reassembly is the reverse of disassembly; no special tools

are required.

TEST PROCEDURE

No testing of the flow Control is required prior to reassembly

to the pilot control system on Cla-Val Main Valve.

Page 24

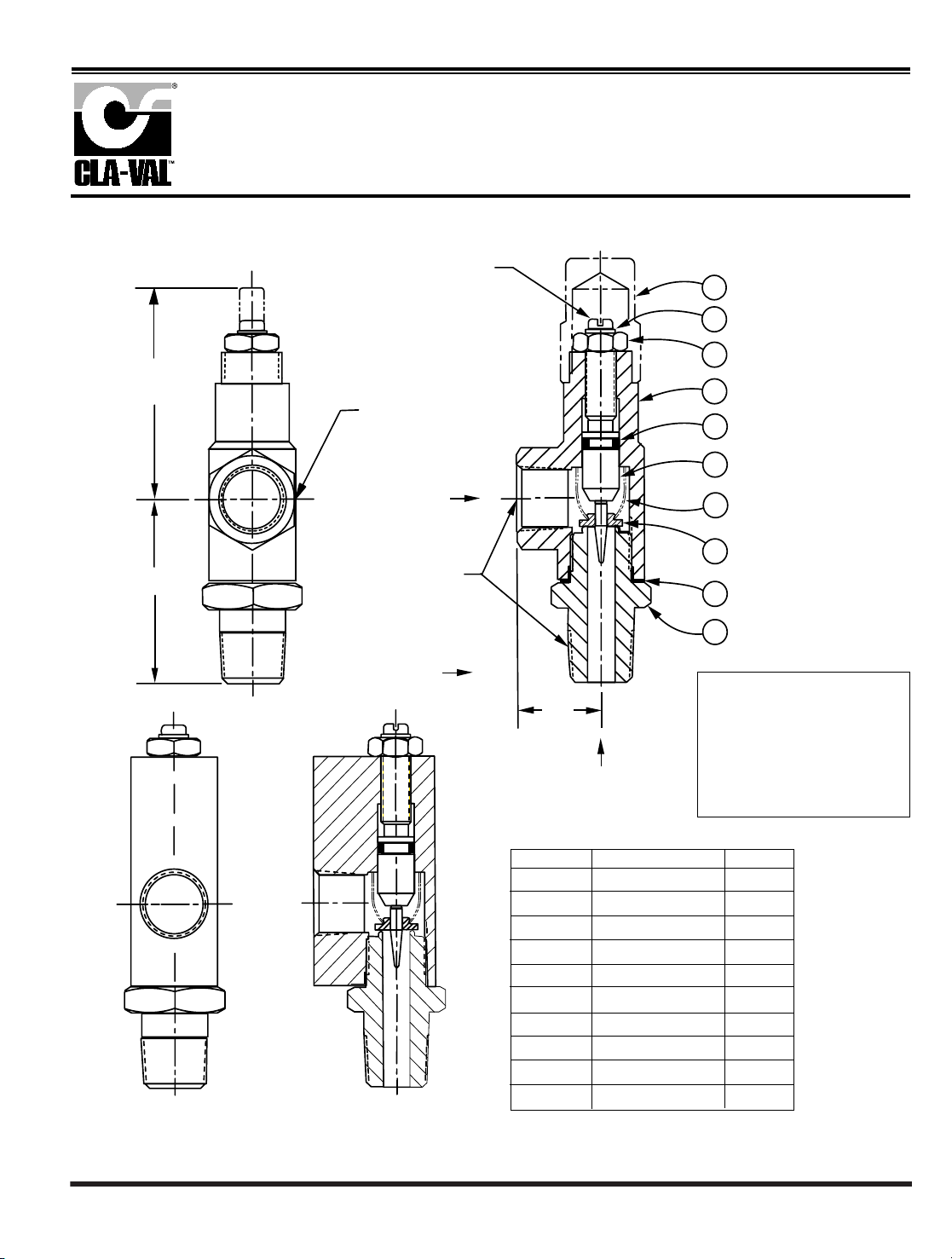

3/8" Flow Control

CV

2.12

MAX

STAMP PART NO. ON

SMOOTH SURFACE

RESTRICTED

FLOW

3/8 - 18 NPT

1.84

ADJUSTING STEM

(TURN CLOCKWISE TO

INCREASE RESTRICTION)

1

7

2

10

9

8

6

5

4

3

.85

FREE FLOW

BAR STOCK

CONFIGURATION

When ordering parts,

please specify:

• Number Stamped on Side

• Description (CV Flow Control)

• Part Description

• Material

ITEM DESCRIPTION QTY

1 Cap (SS only) 1

2 Nut, Jam 1

3 Seat 1

4 Gasket 1

5 Disc 1

6 Spring 1

7 Ring, Retaining 1

8 Stem 1

9 O-Ring 1

10 Housing 1

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CV (R-5/05)

PARTS LIST

Page 25

3/8" Flow Control

CV

2.12

MAX

STAMP PART NO. ON

SMOOTH SURFACE

RESTRICTED

FLOW

3/8 - 18 NPT

1.84

ADJUSTING STEM

(TURN CLOCKWISE TO

INCREASE RESTRICTION)

1

7

2

10

9

8

6

5

4

3

.85

FREE FLOW

BAR STOCK

CONFIGURATION

When ordering parts,

please specify:

• Number Stamped on Side

• Description (CV Flow Control)

• Part Description

• Material

ITEM DESCRIPTION QTY

1 Cap (SS only) 1

2 Nut, Jam 1

3 Seat 1

4 Gasket 1

5 Disc 1

6 Spring 1

7 Ring, Retaining 1

8 Stem 1

9 O-Ring 1

10 Housing 1

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325 • Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: claval@cla-val.com • Website cla-val.com

©

PL-CV (R-5/05)

PARTS LIST

Page 26

Cla-Val Product

Identification

Proper Identification

For ordering repair kits, replacement parts, or for

inquiries concerning valve operation, it is important to

properly identify Cla-Val products already in service

by including all nameplate data with your inquiry.

Pertinent product data includes valve function, size,

material, pressure rating, end details, type of pilot

controls used and control adjustment ranges.

Identification Plates

For product identification, cast-in body markings are

supplemented by identification plates as illustrated on

this page. The plates, depending on type and size of

product, are mounted in the most practical position. It

is extremely important that these identification

plates are not painted over, removed, or in any

other way rendered illegible.

INLET

EINTRITT

ENTREE

ENTRADA

SIZE &

CAT NO.

STOCK

NO.

CODE

MFD. BY CLA-VAL

NEWPORT BEACH, CALIF, U.S.A.

RESERVOIR

END

I

N

L

E

T

I

N

L

E

T

SIZE &

CAT NO.

STOCK

NO.

FLOW

MFD. BY CLA-VAL NEWPORT BEACH, CALIF. U.S.A.

CODE

C

¤

“

SIZE &

CAT NO.

STOCK

NO.

SPRING

RANGE

MFD. BY CLA-VAL NEWPORT BEACH, CALIF. U.S.A.

SIZE &

CAT NO.

STOCK

NO.

CODE

MFD. BY CLA-VAL

NEWPORT BEACH, CALIF.

U.S.A.

C

¤

“

DO NOT REMOVE

THIS VALVE HAS BEEN MODIFIED

SINCE ORIGINAL SHIPMENT FROM

FACTORY. WHEN ORDERING PARTS

AND/ OR SERVICE SUPPLY DATA FROM

THIS PLATE & ALL OTHER PLATES ON

ORIGINAL VALVE.

REDUCED PRESSURE BACKFLOW PREVENTION DEVICE

STK.

NO.

SER.

NO.

CAT.

NO.

RP

-4

CLA-VAL

NEWPORT BEACH, CA.

This brass plate appears on valves sized 21/2" and larger

and is located on the top of the inlet flange.

These two brass plates appear on 3/8", 1/2", and 3/4" size

valves and are located on the valve cover.

These two brass plates appear on threaded valves

1" through 3" size or flanged valves 1" through 2".

It is located on only one side of the valve body.

This brass plate appears on altitude valves only and is

found on top of the outlet flange.

This brass plate is used to identify pilot control valves.

The adjustment range is stamped into the plate.

This tag is affixed to the cover of the pilot control valve.

The adjustment range appears in the spring range section.

This aluminum plate is included in pilot system

modification kits and is to be wired to the new pilot

control system after installation.

This brass plate is used on our backflow prevention

assemblies. It is located on the side of the Number Two

check (2" through 10"). The serial number of the

assembly is also stamped on the top of the inlet flange of

the Number One check.

How to Order

Page 27

HOW TO ORDER

Because of the vast number of possible configurations and

combinations available, many valves and controls are not

shown in published product and price lists. For ordering

information, price and availability on product that are not listed,

please contact your local Cla-Val office or our factory office

located at:

SPECIFY WHEN ORDERING

• Model Number • Valve Size

• Globe or Angle Pattern • Threaded or Flanged

• Adjustment Range • Body and Trim Materials

(As Applicable) • Optional Features

• Pressure Class

UNLESS OTHERWISE SPECIFIED

• Globe or angle pattern are the same price

• Ductile iron body and bronze trim are standard

• X46 Flow Clean Strainer or X43 “Y” Strainer are included

• CK2 Isolation Valves are included in price on 4" and larger

valve sizes (6" and larger on 600 Series)

P. O. Box 1325

Newport Beach, California 92659-0325

(949) 722-4800

FAX (949) 548-5441

LIMITED WARRANTY

Automatic valves and controls as manufactured by Cla-Val are warranted

for three years from date of shipment against manufacturing defects in

material and workmanship that develop in the service for which they are

designed, provided the products are installed and used in accordance

with all applicable instructions and limitations issued by Cla-Val.

We will repair or replace defective material, free of charge, that is returned

to our factory, transportation charges prepaid, if upon inspection, the

material is found to have been defective at time of original shipment. This

warranty is expressly conditioned on the purchaser’s providing written

notification to Cla-Val immediate upon discovery of the defect.

Components used by Cla-Val but manufactured by others, are warranted

only to the extent of that manufacturer’s guarantee.

This warranty shall not apply if the product has been altered or repaired by

others, Cla-Val shall make no allowance or credit for such repairs or

alterations unless authorized in writing by Cla-Val.

DISCLAIMER OF WARRANTIES AND

LIMITATIONS OF LIABILITY

The foregoing warranty is exclusive and in lieu of all other

warranties and representations, whether expressed, implied, oral or

written, including but not limited to any implied warranties or

merchantability or fitness for a particular purpose. All such other

warranties and representations are hereby cancelled.

Cla-Val shall not be liable for any incidental or consequential loss,

damage or expense arising directly or indirectly from the use of the

product. Cla-Val shall not be liable for any damages or charges for

labor or expense in making repairs or adjustments to the product.

Cla-Val shall not be liable for any damages or charges sustained in

the adaptation or use of its engineering data and services. No

representative of Cla-Val may change any of the foregoing or

assume any additional liability or responsibility in connection with

the product. The liability of Cla-Val is limited to material

replacements F.O.B. Newport Beach, California.

TERMS OF SALE

ACCEPTANCE OF ORDERS

All orders are subject to acceptance by our main office at Newport Beach, California.

CREDIT TERMS

Credit terms are net thirty (30) days from date of invoice.

PURCHASE ORDER FORMS

Orders submitted on customer’s own purchase order forms will be accepted only

with the express understanding that no statements, clauses, or conditions contained

in said order form will be binding on the Seller if they in any way modify the Seller’s

own terms and conditions of sales.

PRODUCT CHANGES

The right is reserved to make changes in pattern, design or materials when deemed

necessary, without prior notice.

PRICES

All prices are F.O.B. Newport Beach, California unless expressly stated otherwise on

our acknowledgement of the order. Prices are subject to change without notice. The

prices at which any order is accepted are subject to adjustment to the Seller’s price

in effect at the time of shipment. Prices do not include sales, excise, municipal, state

or any other Government taxes. Minimum order charge $75.00.

RESPONSIBILITY

We will not be responsible for delays resulting from strikes, accidents, negligence of

carriers, or other causes beyond our control. Also, we will not be liable for any

unauthorized product alterations or charges accruing there from.

RISK

All goods are shipped at the risk of the purchaser after they have been delivered by

us to the carrier. Claims for error, shortages, etc., must be made upon receipt of

goods.

EXPORT SHIPMENTS

Export shipments are subject to an additional charge for export packing.

RETURNED GOODS

1. Customers must obtain written approval from Cla-Val prior to returning any

material.

2. Cla-Val reserves the right to refuse the return of any products.

3. Products more than six (6) months old cannot be returned for credit.

4. Specially produced, non-standard models cannot be returned for credit.

5. Rubber goods such as diaphragms, discs, o-rings, etc., cannot be returned for

credit, unless as part of an unopened vacuum sealed repair kit which is less

than six months old.

6. Goods authorized for return are subject to a 35% ($75 minimum) restocking

charge and a service charge for inspection, reconditioning, replacement of

rubber parts, retesting, repainting and repackaging as required.

7. Authorized returned goods must be packaged and shipped prepaid to Cla-Val,

1701 Placentia Avenue, Costa Mesa, California 92627.

PO Box 1325 Newport Beach CA 92659-0325

Phone: 949-722-4800 Fax: 949-548-5441

CLA-VAL

CLA-VAL CANADA CLA-VAL EUROPE

4687 Christie Drive

Beamsville, Ontario

Canada LOR 1B4

Phone: 905-563-4963

Fax: 905-563-4040

Chemin dés Mesanges 1

CH-1032 Romanel/

Lausanne, Switzerland

Phone: 41-21-643-15-55

Fax: 41-21-643-15-50

©COPYRIGHT CLA-VAL 2005 Printed in USA

Specifications subject to change without notice.

www.cla-val.com

E-Product I.D. (R-5/05)

Represented By:

Page 28

Complete Replacement Diaphragm Assemblies for 100-01 and 100-20 Hytrol Main Valves

For:

Hytrol Main Valves with Ductile Iron, Bronze Trim Materials—125/150 Pressure Class Only.

FACTORY ASSEMBLED

Includes: Stem, Disc Guide, Disc, Disc Retainer, Spacer Washers, Diaphragm, Diaphragm Washer

and Stem Nut.

3/8"

1/2" - 3/4"

1"

1 1/4"-1 1/2"

2"

2 1/2"

3"

4"

(Also 81-01 )

(Also 81-01 )

N/A

N/A

N/A

N/A

N/A

N/A

C2524B

C2525J

6"

8"

10"

12"

14"

16"

20"

24"

40456G

45276D

81752J

85533J

89067D

89068B

N/A

N/A

33273E

40456G

45276D

81752J

N/A

85533J

89068B

89068B

Valve

Size

Valve

Size

49097K

C2518D

C2520K

C2522 F

C2524B

C2523D

C2525J

33273E

100-01 100-20

Diaphragm Assembly

Stock Number

100-01 100-20

Diaphragm Assembly

Stock Number

3/8"

1/2" - 3/4"

1"

1 1/4" - 1 1/2"

2"

2 1/2"

3"

4"

6"

8"

10"

12"

14"

16"

20"

24"

(Also 81-01 )

(Also 81-01 )

N/A

N/A

N/A

N/A

N/A

N/A

9169805A

9169812G

9169813E

9169815K

9817901D

9817902B

N/A

9817903K

9817905E

9817905E

3/8"

1/2" - 3/4"

1"

1 1/4” - 1 1/2"

2"

2 1/2"

3"

4"

6"

8"

9169806J

9169807G

9169808E

9169809C

9169810A

9169817F

9169818D

9169819B

9169820K

9169834A

N/A

N/A

N/A

N/A

N/A

N/A

9169810A

9169818D

9169819B

9169820K

Valve

Size

Valve

Size

9169801K

9169802H

9169803F

9169804D

9169805A

9169811J

9169812G

9169813E

9169815K

9817901D

9817902B

9817903K

9817904H

9817905E

N/A

9817906C

100-01 100-20

Repair Kit

Stock Number

100-01 100-20

Repair Kit

Stock Number

Repair Kits for 100-01/100-20 Hytrol Valves

For:

Hytrol Main Valves—125/150 Pressure Class Only.

Includes: Diaphragm, Disc (or Disc Assembly) and spare Spacer Washers.

(Also 81-01 )

(Also 81-01 )

REPAIR KITS

When ordering, please give complete nameplate data of the valve and/or control being repaired.

MINIMUM ORDER CHARGE APPLIES.