Dmbttjd!Pshbo!Xpslt!

CMK-1

Classic MIDI Keyboard

User Manual

Version 1.00.05

Div. of:

ARTISAN CLASSIC ORGAN INC.

CLASSIC MIDI KEYBOARD

CMK-1

TABLE OF CONTENTS

LIMITED WARRANTY ............................................................................................... 9

INTRODUCTION ...................................................................................................... 11

Description....................................................................................................................................11

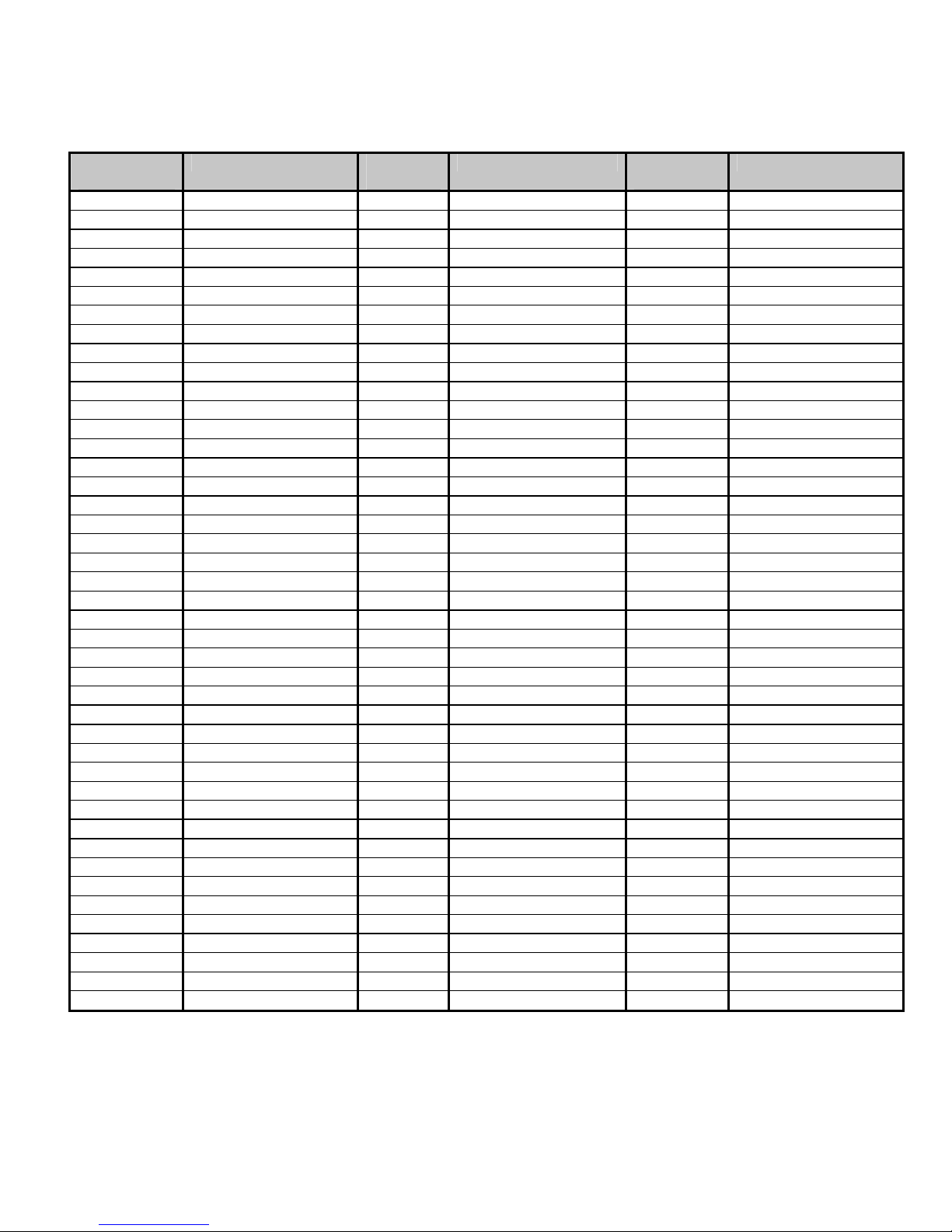

Table 1: Parts/Components List ...............................................................................................................................12

Figure 1: CMK components ..................................................................................................................................... 12

Figure 2: CMK connections .....................................................................................................................................13

INSTALLATION ....................................................................................................... 15

Springs ..........................................................................................................................................15

Figure 3: Steps in replacing a dislocated spring...................................................................................................... 15

Mounting .......................................................................................................................................15

Figure 4: Single-manual stand-alone....................................................................................................................... 16

Figure 5: Single-manual with wooden case............................................................................................................. 16

Figure 6: Two manual setup .................................................................................................................................... 16

Figure 7: Three manual setup.................................................................................................................................. 17

Figure 8: Two/Three-manual setup mounted level .................................................................................................. 17

Figure 9: Two/Three-manual setup mounted ‘tilt-up’ ............................................................................................... 18

Figure 10: Accessing keyboard electronics ............................................................................................................. 18

Connections..................................................................................................................................18

Power....................................................................................................................................................................... 18

Figure 11: Connecting Multiple CMK Keyboards, Rear View, Using Parallel Wiring and Included Power Supply . 19

MIDI .........................................................................................................................................................................19

Figure 12: MIDI Connection Jacks, Rear View........................................................................................................ 19

Analog Inputs........................................................................................................................................................... 20

Figure 13: Wiring Schematic for Analog input ......................................................................................................... 20

Table 2: Connection Chart........................................................................................................................................ 20

Software Installation (Windows users only)............................................................................................................. 21

MIDI SPECIFICATION ............................................................................................. 22

MIDI Sound Sets ...........................................................................................................................22

General MIDI............................................................................................................................................................22

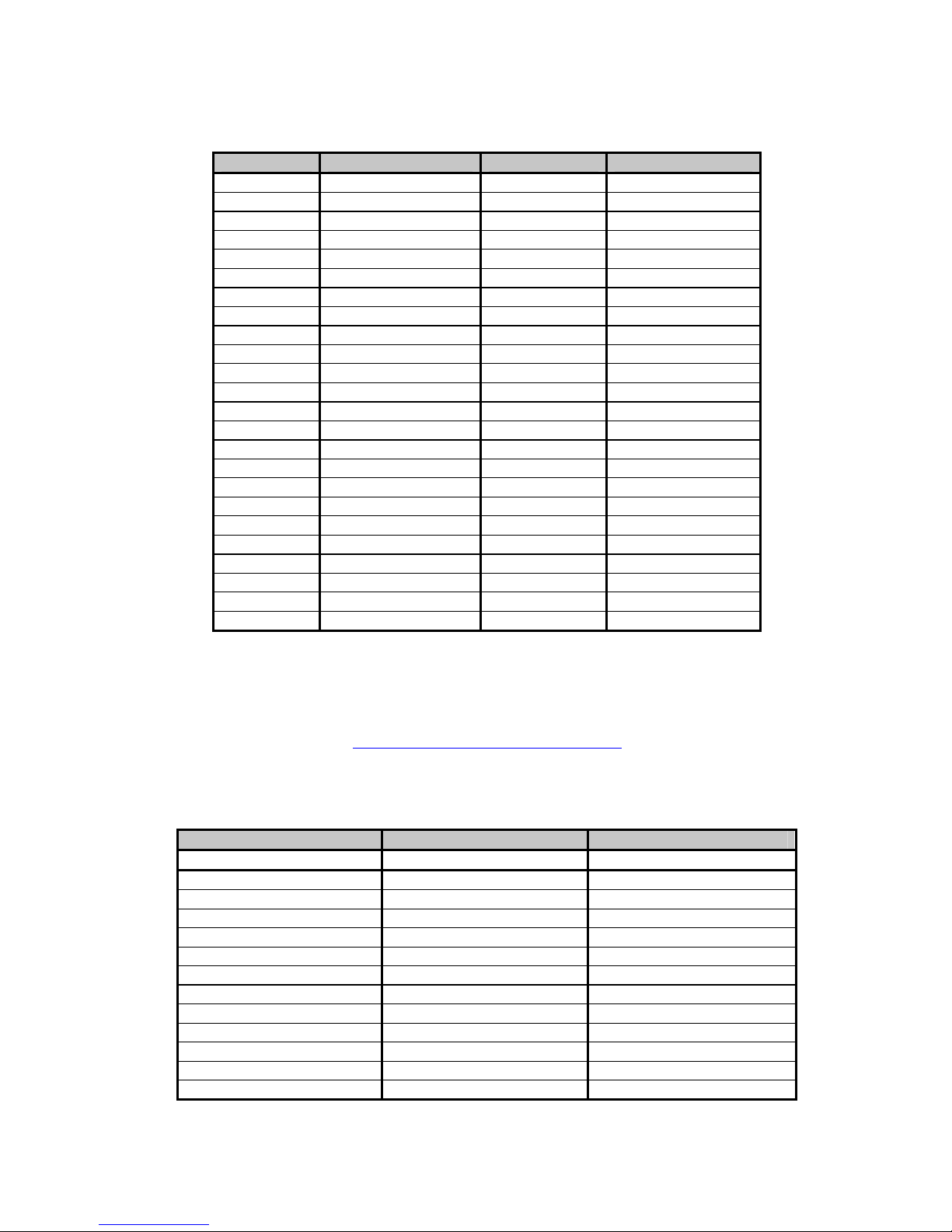

Table 3: Sound Set Groups ...................................................................................................................................... 23

Table 4: General MIDI Program Numbers for MIDI Channels 1-9 and 11-16.......................................................... 24

Table 5: General MIDI Percussion Key Map for MIDI Channel 10........................................................................... 25

Ahlborn..................................................................................................................................................................... 25

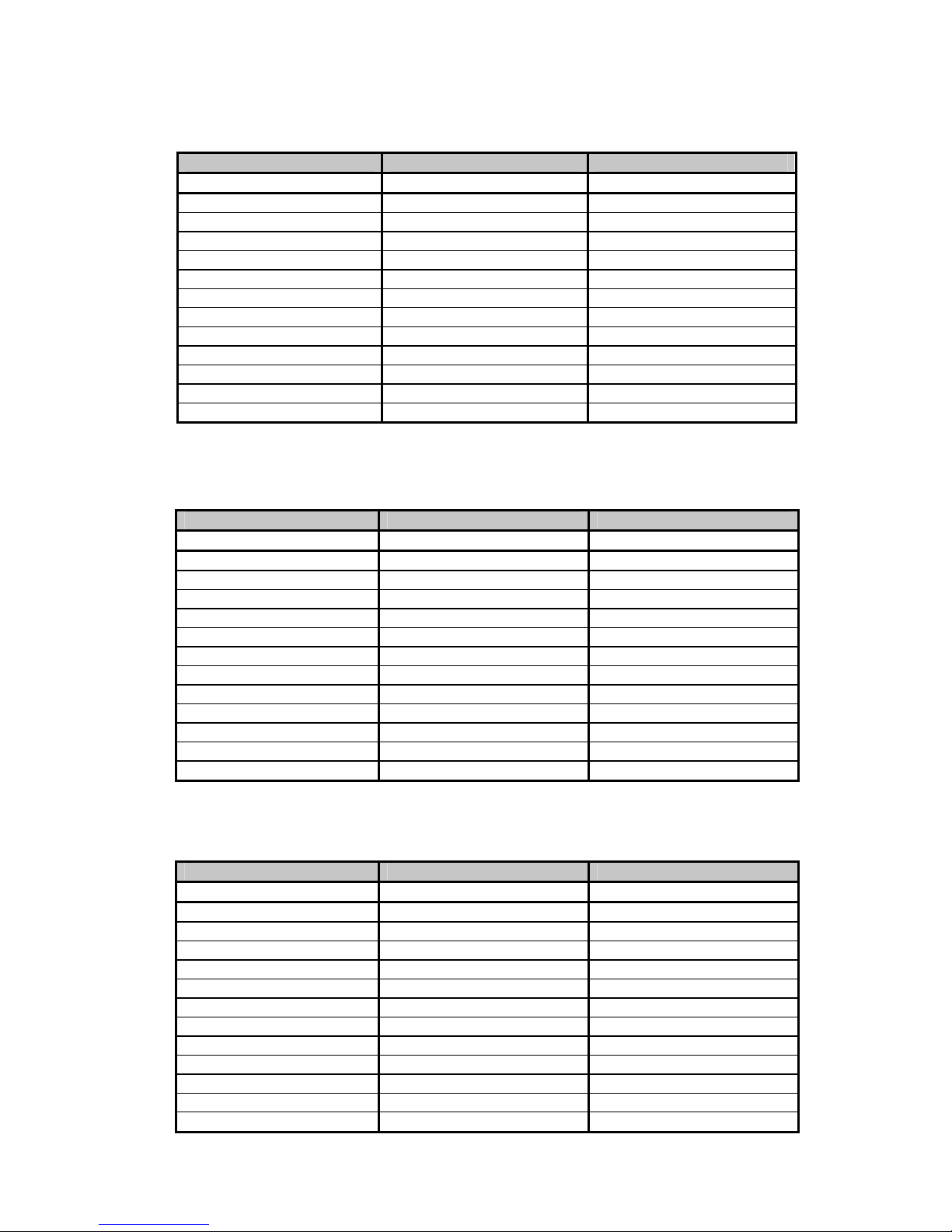

Table 6: Classic Module ...........................................................................................................................................25

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-3 October 20, 2004

Table 7: Romantic Module........................................................................................................................................ 26

Table 8: 201 Module ................................................................................................................................................. 26

Table 9: 202 Module ................................................................................................................................................. 26

HAUPTWERKTM.......................................................................................................................................................27

Table 10: MIDI messages relevant to Hauptwerk ....................................................................................................27

SCPOPTM.................................................................................................................................................................27

MIDI Hardware Specification .......................................................................................................28

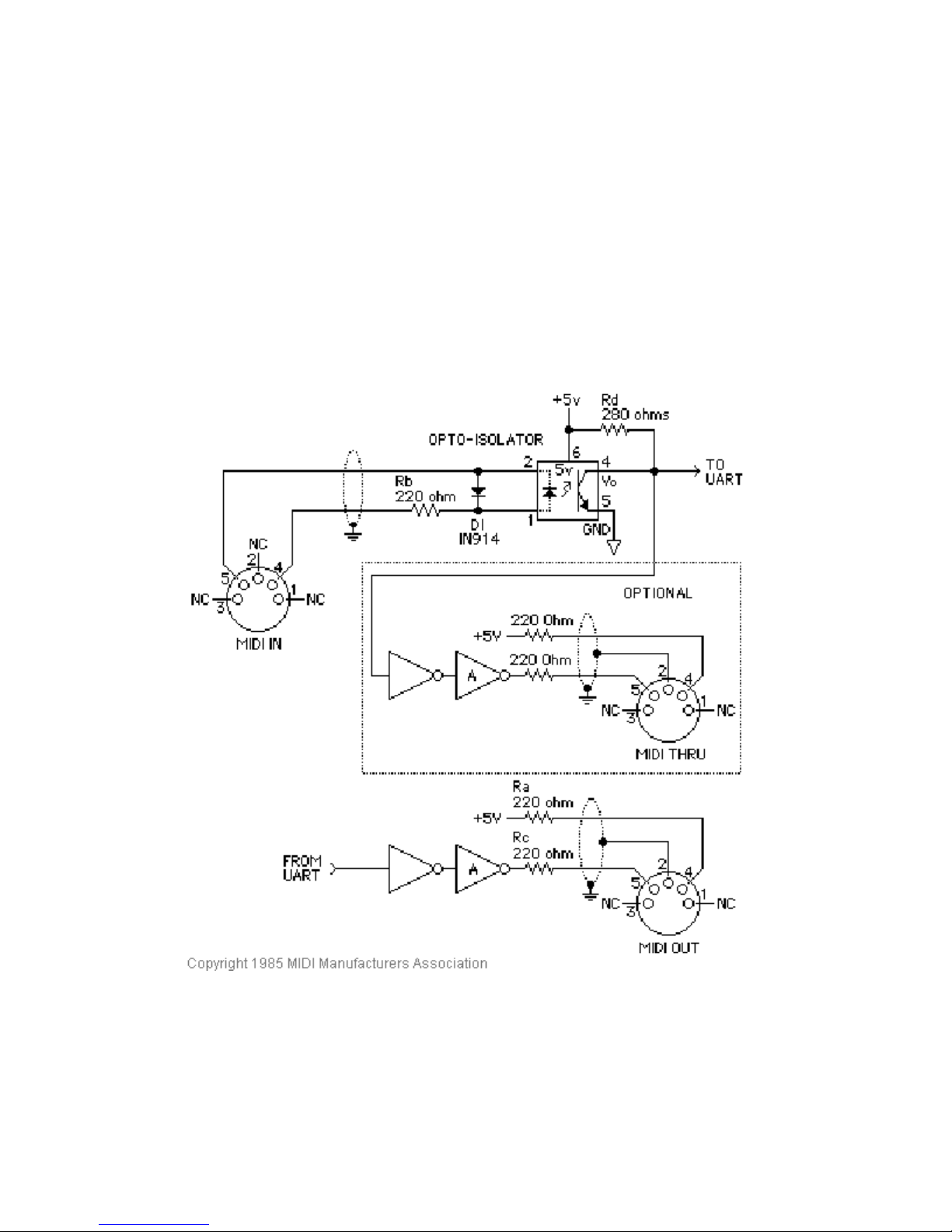

Figure 14: Schematic of 5-pin DIN connector.......................................................................................................... 28

CMK HARDWARE CONFIGURATION.................................................................... 29

Introduction...................................................................................................................................29

Power-On Self Test.......................................................................................................................29

Analog Input Pins ......................................................................................................................... 29

MIDI Crescendo ....................................................................................................................................................... 29

MIDI Volume ............................................................................................................................................................ 29

MIDI Expression.......................................................................................................................................................29

Programming ................................................................................................................................30

Table 11: Piston programming functions .................................................................................................................. 30

CMK SOFTWARE CONFIGURATION..................................................................... 32

Introduction...................................................................................................................................32

Software Installation.....................................................................................................................32

Figure 15: Upon clicking on the ‘CMK_Setup.exe’ file, the above window will appear. .......................................... 33

Figure 16: Allows the user to select a directory to install the CMK program file .....................................................33

Figure 17: Setup adds an icon to the start menu for convenient access.................................................................34

Figure 18: Setup provides the option of creating an icon on the Windows desktop................................................ 34

Figure 19: Confirmation window .............................................................................................................................. 35

Figure 20: Setup progress window .......................................................................................................................... 35

Figure 21: Confirms installation was successful...................................................................................................... 36

Software Startup ...........................................................................................................................37

Figure 22: CMKConfig software startup screen....................................................................................................... 37

Figure 23: CMKConfig software main menu............................................................................................................ 37

Configure a CMK from scratch....................................................................................................38

Figure 24: CMKConfig software attempting to connect with the CMK ....................................................................38

Figure 25: CMKConfig software unable to connect................................................................................................. 38

Figure 26: CMKConfig software successfully connected to the CMK. .................................................................... 38

Figure 27: Successful connection between CMKConfig software and CMK........................................................... 39

Figure 28: Window confirms the loading of pre-configuration data from the CMK to the PC.................................. 39

Load a previously saved CMK configuration .............................................................................40

Figure 29: Configuration File selection window. ...................................................................................................... 40

Figure 30: Program window..................................................................................................................................... 40

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-4 October 20, 2004

Functions of the Toolbars............................................................................................................41

Figure 31: Toolbars in CMKConfig software............................................................................................................ 41

1. File Menu ............................................................................................................................................................ 41

Figure 32: Loading Program Data From File Window ............................................................................................. 41

Figure 33: Save Program Data to File Window ....................................................................................................... 42

Figure 34: Confirm replacing of file window............................................................................................................. 42

Figure 35: Software attempting to make a connection with the CMK...................................................................... 43

Figure 36: Software unable to make a connection with the CMK............................................................................ 43

Figure 37: Software detecting number of keyboards............................................................................................... 43

Figure 38: Successful connection between CMK and PC software ........................................................................ 44

Figure 39: Confirms loading of configuration into CMKConfig software.................................................................. 44

Figure 40: Software attempting to communicate with CMK ...................................................................................44

Figure 41: Successful Software connection to the CMK ......................................................................................... 45

Figure 42: Confirms configuration written to CMK from CMKConfig software. .......................................................45

2. Options Menu...................................................................................................................................................... 45

Figure 43: MIDI Input Output Setup window............................................................................................................ 45

2. Help Menu...................................................................................................................................................... 46

Figure 44: Help Menu .............................................................................................................................................. 46

Keyboard Functions .....................................................................................................................46

Figure 45: Clicking on the keys of the keyboard invokes a MIDI Channel select menu.......................................... 47

Figure 46: Clicking on an individual piston invokes the Piston function select drop-down menu. ..........................47

Table 12: Customizable Functions for each piston ..................................................................................................48

Configuring Multiple Keyboards .................................................................................................49

REFERENCES ......................................................................................................... 51

APPENDIX A: .......................................................................................................... 53

DIP SWITCH CONFIGURATION TABLE ................................................................ 53

Table 13: DIP Switch settings and their corresponding Configuration numbers...................................................... 53

APPENDIX B: .......................................................................................................... 56

MIDI PROTOCOL SPECIFICATION ........................................................................ 56

MIDI Protocol Specification .........................................................................................................56

Channel Messages ..................................................................................................................................................56

System Messages.................................................................................................................................................... 57

Running Status ........................................................................................................................................................ 57

Table 14: MIDI 1.0 Specification Message Summary ..............................................................................................58

Table 15: Expanded Status Bytes List...................................................................................................................... 61

Table 16: Control Changes and Mode Changes ...................................................................................................... 64

Table 17: Registered Parameter Numbers...............................................................................................................67

APPENDIX C: .......................................................................................................... 69

SYSTEM EXCLUSIVE MESSAGE LAYOUTS ........................................................ 69

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-5 October 20, 2004

Messages common to all products............................................................................................. 69

General Information Identity Request...................................................................................................................... 69

General Information Identity Reply .......................................................................................................................... 69

CMK -- Special layouts .................................................................................................................69

APPENDIX D: .......................................................................................................... 71

AHLBORN MESSAGES .......................................................................................... 71

Table 18: Note On/Off MIDI functions to control Ahlborn Archive sound modules ..................................................71

Table 19: Ahlborn Archive ‘ROMANTIC’ sound module commands for stops and couplers ................................... 72

Table 20: Ahlborn Archive ‘CLASSIC’ sound module commands for stops and couplers on.................................. 73

Table 21: Ahlborn Archive ‘202’ sound module commands for stops and couplers................................................. 74

Table 22: Ahlborn Archive ‘201’ sound module commands for stops and couplers................................................. 75

Table 23: Ahlborn Archive sound module Piston and Crescendo input functions for all four units.......................... 76

Table 24: Ahlborn Archive sound module additional Piston input commands .........................................................77

Table 25: Ahlborn Archive and other MIDI sound modules analog input function commands................................. 77

APPENDIX E:........................................................................................................... 79

SCPOP MESSAGES................................................................................................ 79

Table 26: General MIDI Pipe Organ Emulation Upper Manual for SCPOP ............................................................. 79

Table 27: General MIDI Pipe Organ Emulation Lower Manual SCPOP ..................................................................81

Table 28: General MIDI Pipe Organ Emulation Pedals SCPOP .............................................................................. 84

APPENDIX F:........................................................................................................... 85

CIRCUIT BOARD SCHEMATICS ............................................................................ 85

Figure 47: CMK1-1 Classic MIDI Keyboard Circuit board 1 Silk Screen................................................................. 85

Figure 48: CMK1-1 Classic MIDI Keyboard Circuit board 1 schematic................................................................... 86

Figure 49: CMK1-2 Classic MIDI Keyboard Circuit board 2 Silk Screen................................................................. 87

Figure 50: CMK1-2 Classic MIDI Keyboard Circuit board 2 schematic................................................................... 88

Figure 51: CMKPR1-1 Classic MIDI Keyboard Piston Rail board 1 Silk Screen..................................................... 89

Figure 52: CMKPR1-1 Classic MIDI Keyboard Piston Rail board 1 schematic....................................................... 90

Figure 53: CMKPR1-2 Classic MIDI Keyboard Piston Rail board 2 Silk Screen..................................................... 91

Figure 54: CMKPR1-2 Classic MIDI Keyboard Piston Rail board 2 schematic....................................................... 92

APPENDIX G: .......................................................................................................... 93

MECHANICAL DRAWINGS..................................................................................... 93

Figure 55: Two-manual CMK mounted level ........................................................................................................... 93

Figure 56: Two-manual CMK mounted tilted-up...................................................................................................... 94

Figure 57: Three-manual CMK mounted level......................................................................................................... 95

Figure 58: Three-manual CMK mounted ‘tilt-up’...................................................................................................... 96

Figure 59: CMK Piston Rail front panel mechanical drawing .................................................................................. 97

Figure 60: CMK Piston Rail Mounting rail mechanical drawing............................................................................... 98

Figure 61: CMK Piston Rail circuit board mounting rail mechanical drawing.......................................................... 99

Figure 62: CMK Side mounting bracket mechanical drawing (treble end) ............................................................ 100

Figure 63: CMK Side mounting bracket mechanical drawing (bass end)..............................................................101

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-6 October 20, 2004

Figure 64: CMK End clamp mechanical drawing................................................................................................... 102

Figure 65: CMK two-manual mounting bracket mechanical drawing .................................................................... 103

Figure 66: CMK three-manual mounting bracket mechanical drawing.................................................................. 104

DISCLAIMER ......................................................................................................... 105

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-7 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

LIMITED WARRANTY

Classic Organ Works warrants the Classic MIDI Keyboard (CMK) to be free from defects in materials and

workmanship under normal use for a period of ONE YEAR from the delivery date. This warranty applies

only if the product is owned by the original purchaser who has the bill of sale.

This warranty explicitly excludes any cables provided with the CMK, which may become defective as a

result of normal wear and tear. The DC power adaptor is included in the warranty however.

In the event of a defect in materials or workmanship, please contact Classic Organ Works immediately. In

particular, defects due to shipping should be reported within 15 days for insurance claim purposes. For all

other defects, Classic Organ Works agrees to repair or replace all defective parts of said products which are

returned, transportation prepaid, for inspection at its service centre within the period of the warranty.

In the event that Classic Organ Works determines the product requires repair because of user misuse or

regular wear, it will assess a fair repair or replacement fee. The customer will have the option to pay this fee

and have the unit repaired and returned, or not pay this fee and have the unit returned un-repaired.

Classic Organ Works will not be liable for consequential, special, indirect, or similar damages or claims

including loss of profit or any other commercial damage, and in no event will Classic Organ Works’ liability

for any damages to the purchaser or any other person exceed the price paid for the product, regardless of any

form of the claim. Classic Organ Works specifically disclaims all other warranties, expressed or implied.

Specifically, Classic Organ Works makes no warranty that the product is fit for any particular purpose.

This warranty shall be interpreted, and governed by applicable laws in the province of Ontario, Canada. If

any provision of this warranty is found void, invalid or unenforceable, it will not affect the validity of the

balance of the warranty, which shall remain valid and enforceable according to its terms. In the event any

remedy hereunder is determined to have failed of its essential purpose, all limitations of liability and

exclusion of damages set forth herein shall remain in full force and effect.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-9 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

INTRODUCTION

Description

Congratulations! You are now the proud owner of the CMK (Classic MIDI Keyboard). The CMK combines

technology and classical church organ ideas into an innovative MIDI device. With the CMK, MIDI sound modules

may be controlled as if they were part of the organ. Designed as a portable unit, it features a ‘stackable’ feature so that

users may customize a complete practice organ to their specification. With a quality construction, various structural

and electronic design elements, and user-friendly configuration software, the CMK will provide many years of worryfree musical enjoyment for all users.

The CMK is designed for organists, organ enthusiasts, and MIDI users. Key-switch information from the keyboard

and pistons is converted into MIDI control data by the on-board micro-controller. For instance, a MIDI message

defines whether a key was pressed or released, the MIDI channel that the information should be transmitted on and the

key number pressed or released. As many as three CMK keyboards may be daisy-chained.

Each CMK keyboard also has 20 pistons to control features such as coupling and effects. The CMK can

simultaneously drive up to four Ahlborn Archive Series™ modules that generate pipe-organ voices. In addition, any

MIDI-controlled sound module or PC-based synthesizer software may be connected. These pistons are also used for

programming the CMK. Combinations of pistons and keyswitches are used for functions such as a reboot, setting the

MIDI output channel, turning on and off velocity sensing, and setting the volume output.

There are two analog inputs which can be configured as volume/expression and crescendo inputs. By adjusting the

analog device, a unique voltage reading is produced on the analog input pin which is interpreted by the

microprocessor. In the case of a volume adjustment, a MIDI message will send to the MIDI-controlled device the

loudness level of the stop or sound. MIDI messages are also sent for a crescendo adjustment which will gradually add

stops to a registration.

The CMK is completely customizable using the included ‘CMKConfig’ software. Up to 128 configurations may be

programmed into the CMK. As many as three keyboards each with twenty pistons and two analog inputs may be

configured for Ahlborn Archive

software. The software is capable of customizing the CMK for use with organ computer simulation software such as

Hauptwerk and the Sound Canvas Pipe Organ Project (SCPOP).

Configurations are saved as computer files which may be stored in the user’s home computer, or in the CMK.

Configurations that are saved on the CMK will not be lost when power is turned off because the memory is nonvolatile. These configurations may be selected using DIP-switches on the CMK. Eventually, users may inexpensively

upgrade their software as well as configurations by visiting the Classic Organ Works website at

http://www.organworks.com

modules, General MIDI sound modules, and MIDI-controlled PC-based synthesizer

.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-11 October 20, 2004

The following is a list of parts for each CMK setup.

Table 1: Parts/Components List

Setup Items

A B C D E F

Manual(s) 2-Manual

Side Bracket

set (sold

separately)

One Manual 1 - 1 1

One Manual and

Wood Case

Two Manuals 2 2 1 2 4

Three Manuals 3 - 2 1 3 6

1 - 1 1

3-Manual

Side Bracket

set (sold

separately)

12V DC

adaptor

MIDI

Cable(s)

Mounting

Screws

A B C

D E F

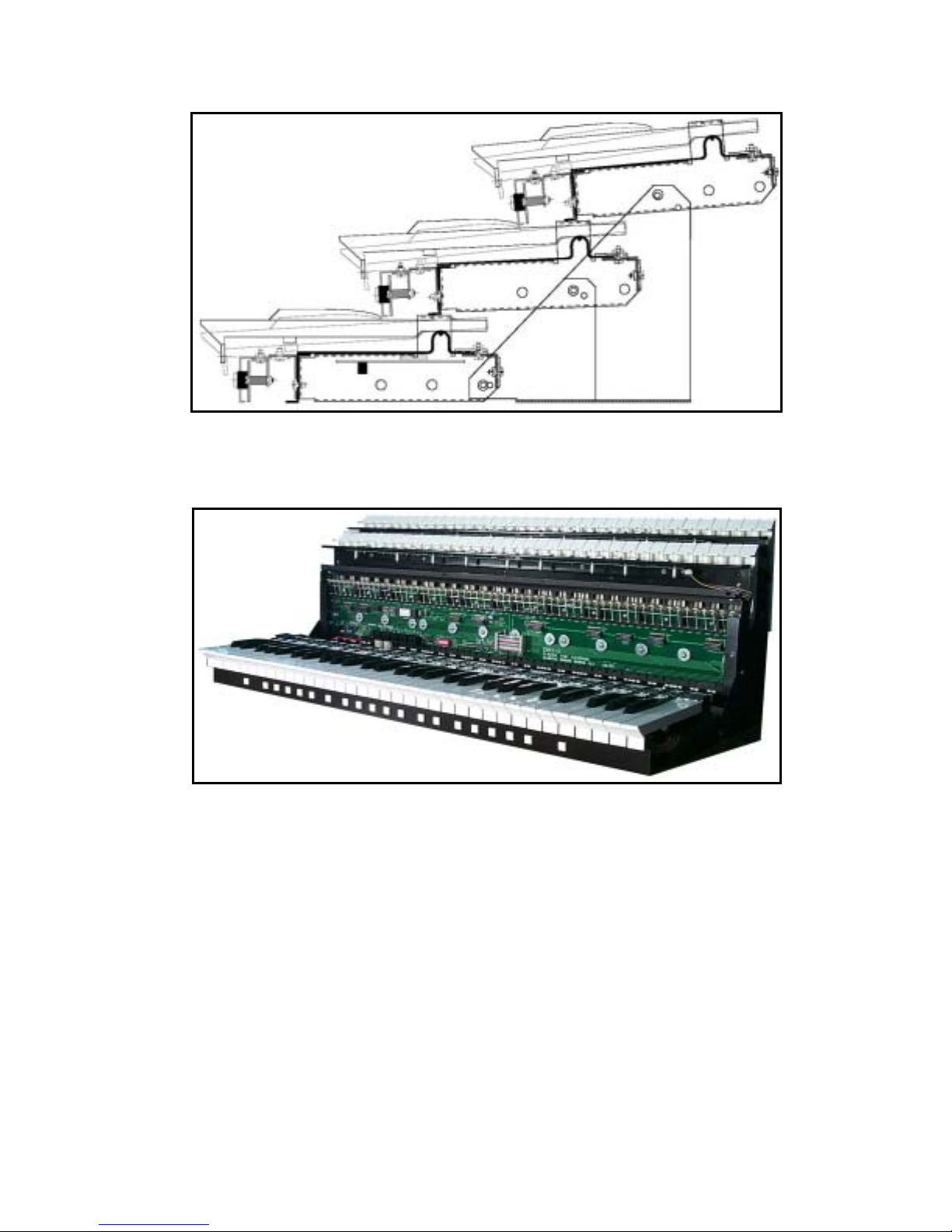

Figure 1: CMK components (from L-R, Top to Bottom):

A) Keyboard

B) 2-manual side mounting brackets (sold separately)

C) 3-manual side mounting brackets (sold separately)

D) 12V DC wall adaptor

E) 6-Ft. MIDI cable

F) Mounting screw.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-12 October 20, 2004

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

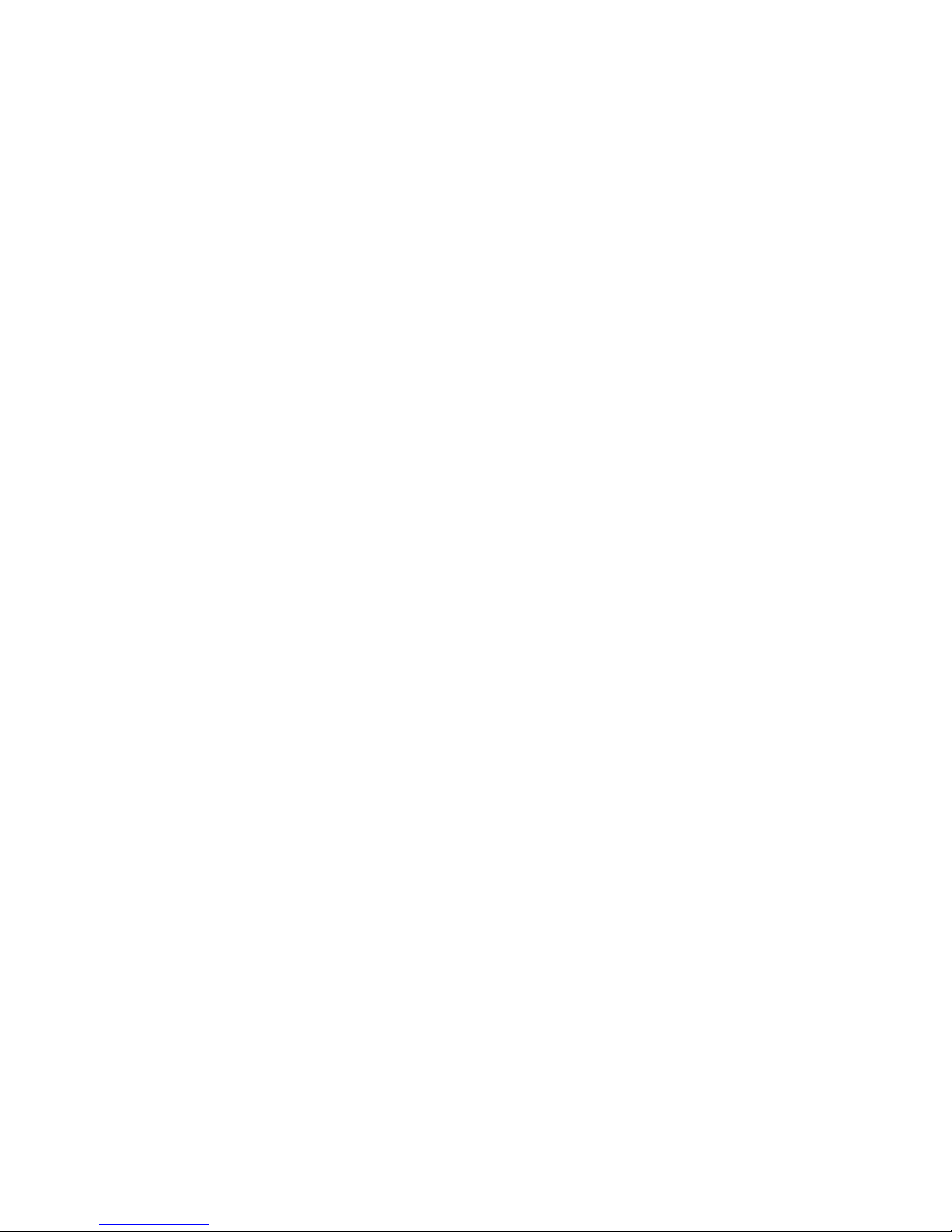

Figure 2: CMK connections

Page-13 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

INSTALLATION

IMPORTANT

READ THIS DOCUMENT BEFORE INSTALLATION

Upon receiving this unit, remove any packing material inside the unit that may have been included to

prevent movement of components or wiring during shipping.

(For internal access, ensure the unit is disconnected from all power sources.)

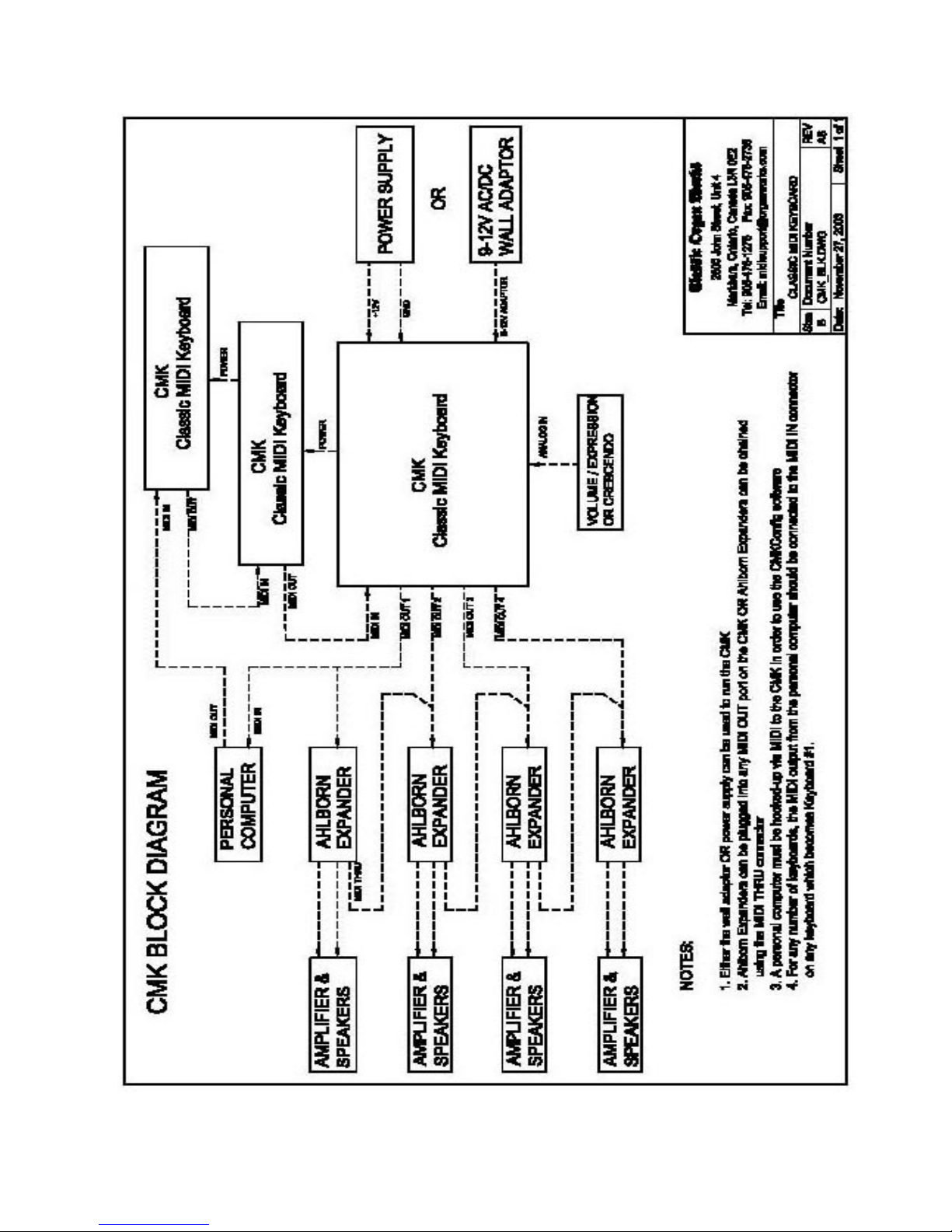

Springs

The keyboard contact springs are installed at Classic Organ Works. However, the nature of these contacts makes them

sensitive to movements during shipping. A visual inspection of the keyboard should be performed upon receiving to

determine if any of these springs have become displaced. A package of five spare springs is included with every

keyboard. To replace the missing springs you will need tweezers and gloves/paper towel. Then follow these

directions:

NOTE: DO NOT HANDLE THE SPRINGS WITH YOUR BARE FINGERS. THE SPRINGS ARE COATED WITH

A LAYER OF SILVER WHICH CAN DETERIORATE IF HANDLED.

1. Pick up the spring using tweezers to gently grip the middle of the spring.

2. Feed one end of the spring in between the two bus bars. Then slide the other end of the spring into the

upper hole (with the keyboard circuit board facing up) of the keyboard keys plastic actuator.

3. With one end of the spring firmly positioned, use the tweezers to grasp the other end of the spring roughly

0.5cm from the end of the spring.

4. SLOWLY stretch this end and position it into the metal spring holder on the circuit board. THE

SPRINGS DEFORM EASILY. USE EXTREME CAUTION TO AVOID OVER-STRETCHING

THE SPRINGS.

1 2 3 4

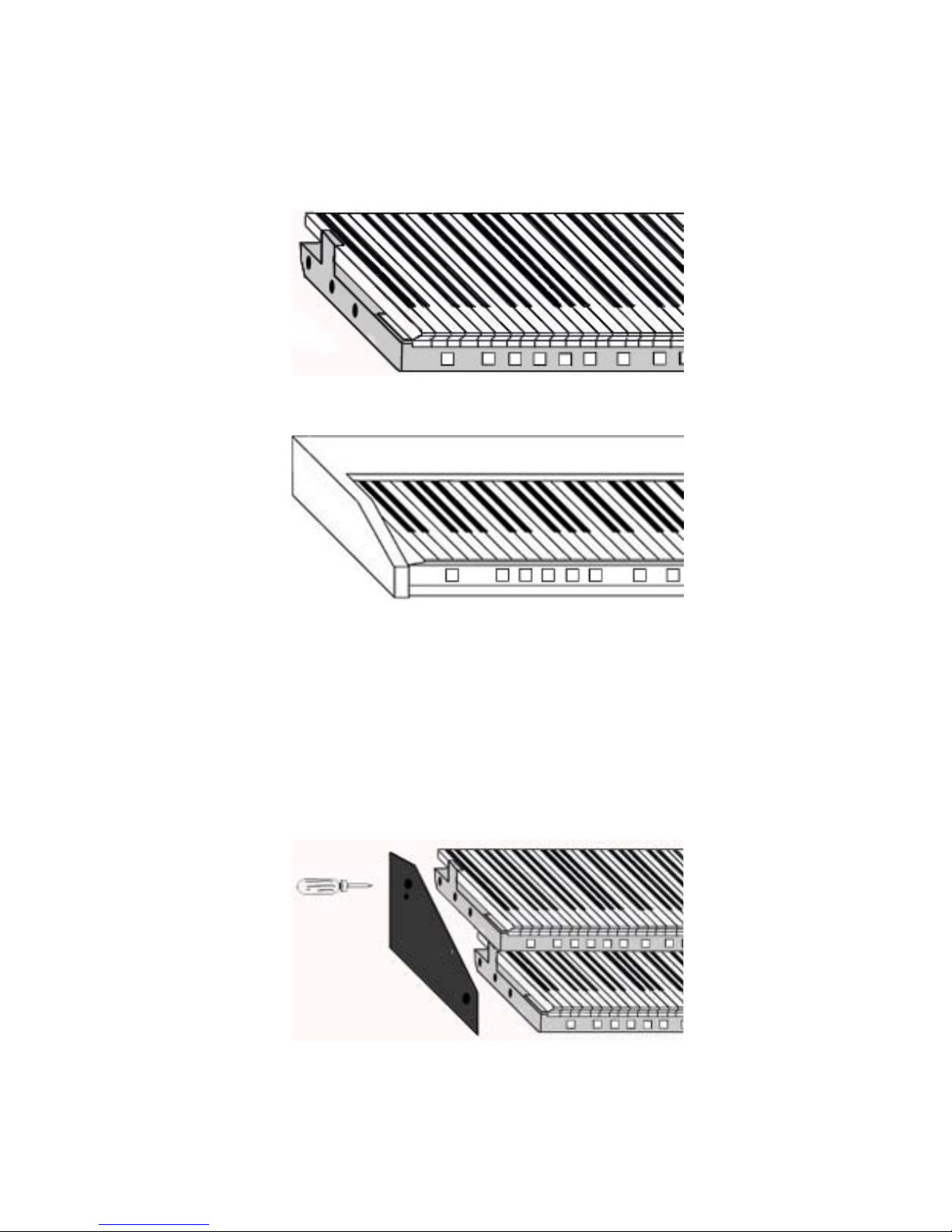

Mounting

Mounting of the CMK is specific to each customized setup. It can be mounted into a wooden case, into an existing

console, or using metal brackets. In the single keyboard configuration, the CMK is a stand-alone unit. In this

configuration, the keyboard is mounted using metal brackets. However, for a professional finish, an optional wooden

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 3: Steps in replacing a dislocated spring

Page-15 October 20, 2004

mounting box may be purchased. When mounted in the wooden mounting box, the electronics may be accessed by

removing four screws on the bottom of the wooden case. The CMK keyboard then slides out easily. In both the single

manual and wooden mounting box versions, the CMK is a ready-to-play keyboard requiring only power and MIDI

connections.

Figure 4: Single-manual stand-alone

Figure 5: Single-manual with wooden case

If the CMK is to be mounted into an existing console, the metal pieces at the ends of the keyboard have holes of 0.156

inch diameter to allow the CMK to be fastened to wooden end cheeks using #6 screws.

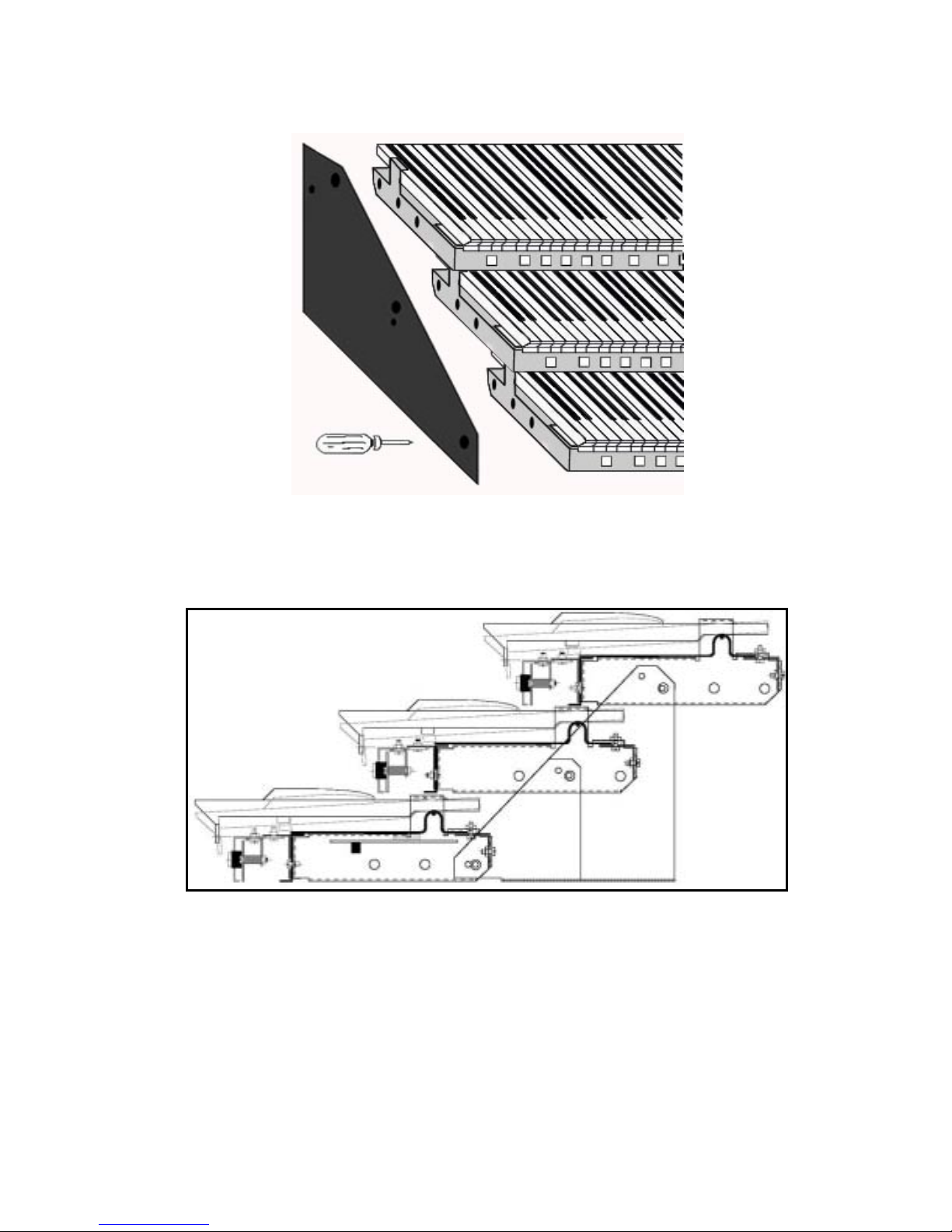

In the two-keyboard and three keyboard configurations, a separate mounting bracket may be purchased. There are

three threaded holes on the sides of the keyboards for mounting purposes. The holes permit mounting of the keyboards

into the brackets either level or tilted as shown in Figures 8 and 9. The entire two/three keyboard configuration with

mounting brackets may be installed in a console using #6 screws. The electronics are accessible by flipping the

keyboards as shown in Figure 10.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 6: Two manual setup

Page-16 October 20, 2004

Figure 7: Three manual setup

Figure 8: Two/Three-manual setup mounted level

(Note the pivoting screw positions on each end bracket are different)

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-17 October 20, 2004

Figure 9: Two/Three-manual setup mounted ‘tilt-up’

Figure 10: Accessing keyboard electronics

Connections

Power

The user must connect Power and MIDI for each keyboard. There are several ways to provide power to the CMK

which will depend on the application. The CMK requires between +9V and +15V DC power at a minimum current of

400mA. If the CMK is to be used as a standalone unit, the most convenient method of providing power would be to

use the supplied 2.1mm Co-axial DC adaptor.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-18 October 20, 2004

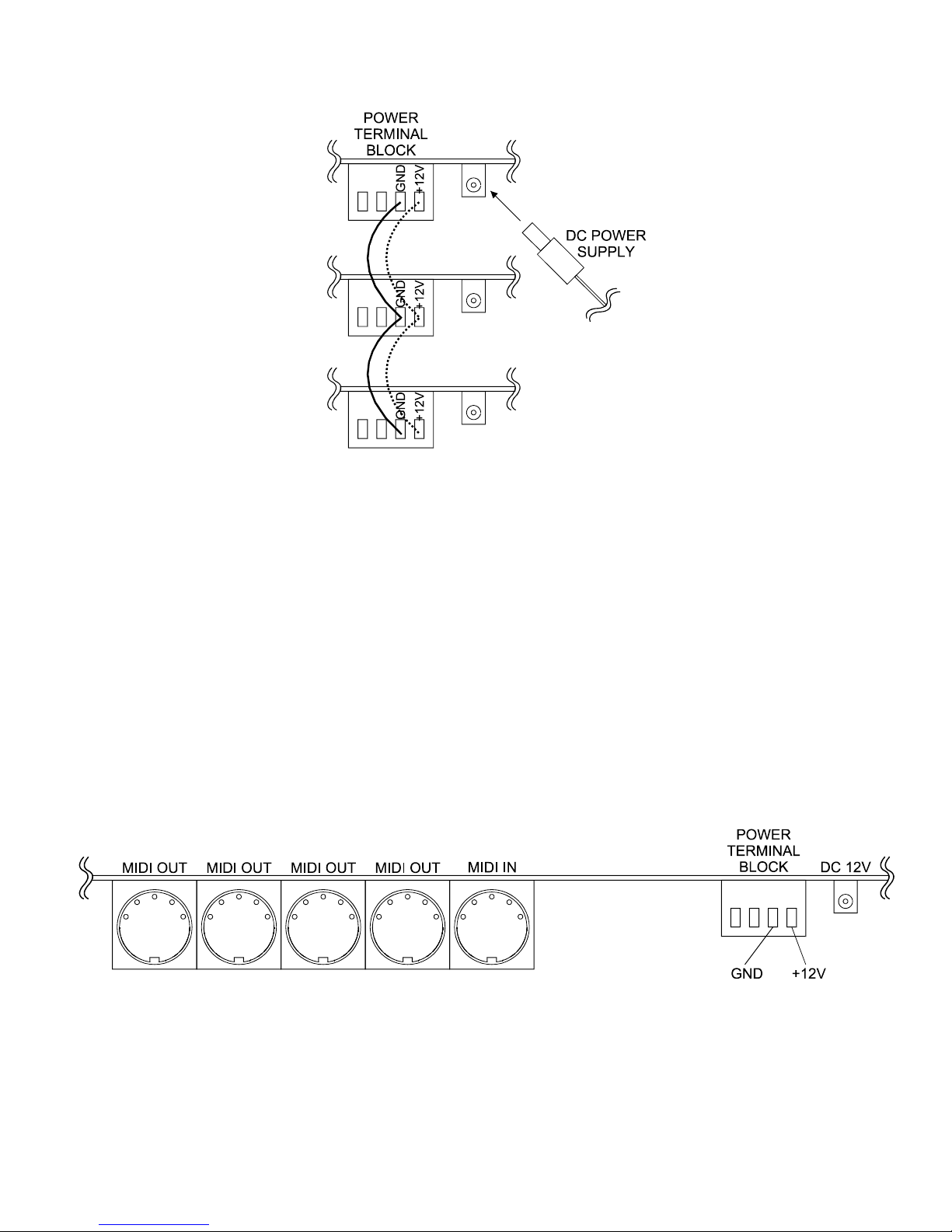

Figure 11: Connecting Multiple CMK Keyboards, Rear View, Using Parallel Wiring and Included Power Supply

However, if multiple keyboards are used or if the CMK is to be mounted inside an organ console, the 4-input terminal

block can be connected to an existing organ power supply. Power and ground are connected to terminal block inputs 1

and 2 respectively. Terminal block inputs 3 and 4 are for grounding the case. One power supply can power up to three

CMK keyboards by paralleling the terminal block connections.

The CMK has a number of safety features. For easy operation, an isolated +12 Volt, DC adaptor of either positive or

negative polarity may be used. It must have a 2.1mm co-axial power jack. A bridge-rectifier is present within the

CMK to ensure the proper polarity. A 500mA self-resetting Polyfuse provides over-current protection from the

common power supply.

MIDI

The CMK has one MIDI input and four paralleled MIDI outputs so that it can be connected to several MIDI devices

and/or a personal computer. All four MIDI OUT connectors produce the same messages and can be used for long

distance applications. The MIDI IN connector allows another MIDI source to be merged with the MIDI signal from

this unit.

The CMK has the capability to simultaneously drive up to four different Ahlborn Archive Series

can be controlled through the general pistons on the CMK. Thus, additional stops and sounds on multiple Ahlborn

Archive modules may be controlled as though they were part of the organ.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 12: MIDI Connection Jacks, Rear View

Page-19 October 20, 2004

TM

modules. These

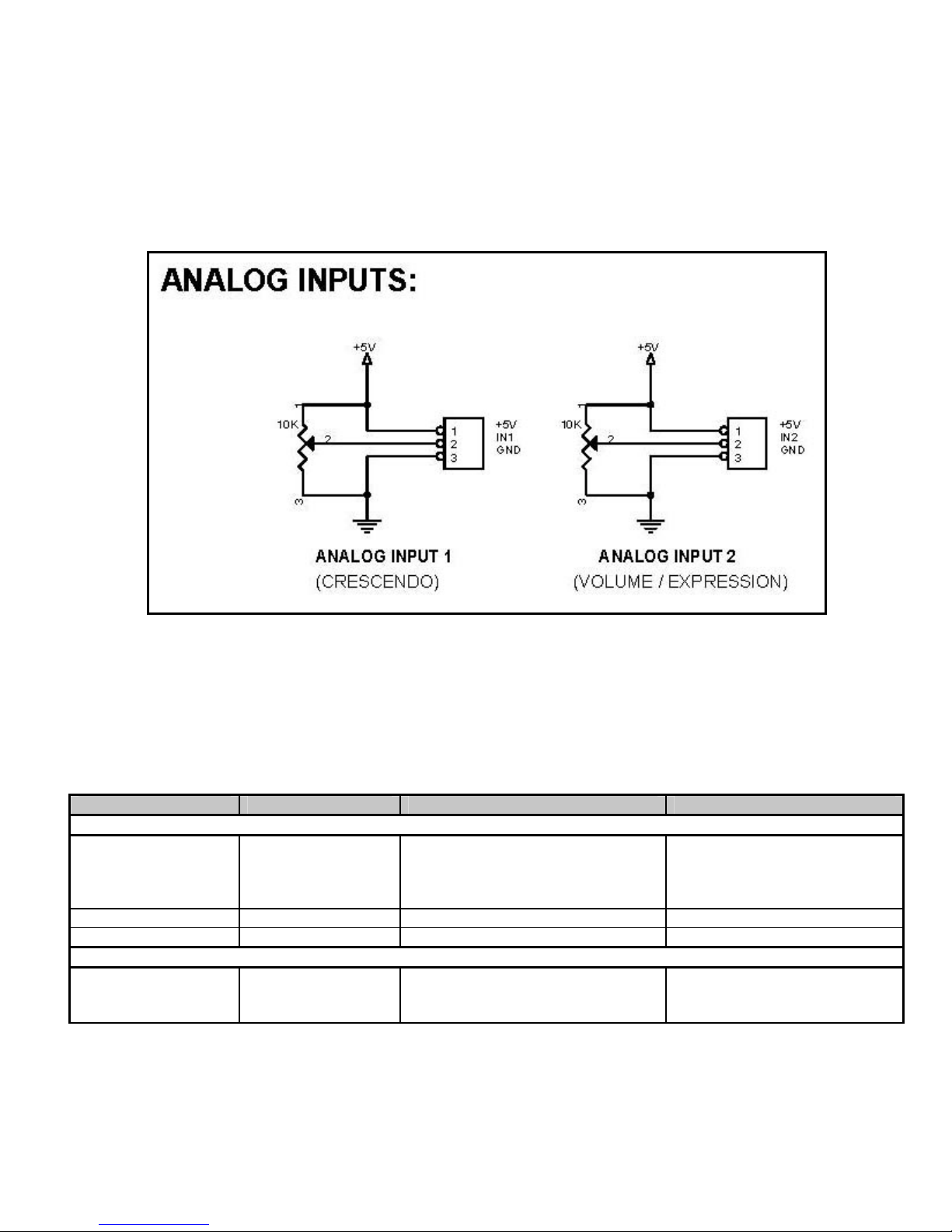

Analog Inputs

Two analog inputs are present on the CMK. The user must ensure that there is one connection to Ground on pin ‘3’,

one connection to an appropriate positive voltage (usually +5V) on pin ‘1’, and one connection to an analog input pin.

Analog inputs are used for crescendo and volume/expression adjustment as shown in Figure 13.

Figure 13: Wiring Schematic for Analog input

The CMK has provision for up to four extra input functions on the circuit board. These inputs are reserved for future

use.

Table 2: Connection Chart

Connection Name Connection Type Hardware Description

Required Connections

Power Input 1. Co-ax 2.1mm (either polarity)

OR

2. 4-input Terminal Block

Input 1 for +12V, Input 2 for GND

MIDI IN Input DIN 5-pin socket 180° Standard MIDI signals

MIDI OUT 1-4 Output DIN 5-pin socket 180° Standard MIDI signals

Optional Connections

Analog Input

Pins, 0.025” Square,

0.3” long, 0.1” pitch

9-12V, 400mA minimum

‘Analog Input 1’ is used for

crescendo and ‘Analog Input 2’ is

used for volume/expression.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-20 October 20, 2004

Software Installation (Windows1 users only)

Software installation instructions are described in the ‘CMK Configuration Software’ section of the manual.

Note: To use the software, the CMK must be connected to a computer via MIDI. If a MIDI port is not available on

your computer, a commercial MIDI adapter for the game port, USB port, or parallel port may be used.

1

Windows is a registered Trademark of the Microsoft Corporation.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-21 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

MIDI SPECIFICATION

MIDI (Music Instrument Digital Interface) is a communication system between computer-controlled music

instruments and describes all the actions of a musical performance. It was originally developed for music synthesizers

but, a few years ago, organ-builders began adding MIDI capabilities to pipe organs. However, as MIDI was not

designed for a complex musical instrument such as the organ, its standards are subject to organ-builders preferences.

MIDI is composed of three components which are the language (protocol), hardware (MIDI connector), and

distribution format (MIDI file) [1]. The MIDI language is in binary format and is a uni-directional asynchronous

stream of bits at 31.25 Kbits per second with 10 bits transmitted per byte. The 10 bits per byte consist of a start bit, 8

data bits, and a stop bit. In the hardware domain, the MIDI 1.0 Specification (maintained by the MIDI Manufacturers

Association) recommends the 5-pin DIN 180° connector. The 5-pin DIN connector is standard and allows MIDI

equipment from differing manufacturers to be connected together. MIDI cables transmit information in a unidirectional manner so connectors are designated as either input or output. MIDI files are the standard distribution

format. They capture all the details of MIDI onto a hardcopy medium. MIDI files are similar to the MIDI language

except that they add a time-stamp for each event so that MIDI equipment can replicate the timing required to generate

accurate performances. [1] MIDI Message information can be found in Appendix B and Appendix C.

MIDI Sound Sets

General MIDI [2]

The MIDI Manufacturers Association (MMA) developed General MIDI (GM) to provide a standard relationship

between commands and sounds generated by synthesizers. A serious problem developed as the number of MIDI

device manufacturers grew. Every manufacturer associated different commands with different sounds. Users were

confused when they used a command to play a piano sound but ended up with some other instrument. To alleviate the

confusion, the MIDI Manufacturers Association dictated that commands termed ‘Patch numbers’ would be the

standard reference to a sound. A ‘Patch Map’ shows Patch numbers and their respective sounds. In addition, since

MIDI transmits using MIDI channels, every MIDI sequence begins by assigning a MIDI channel for each sound that is

transmitted. This assignment is termed ‘Program Change’.

In addition to standardizing the mapping of patch numbers to their respective sounds, the General MIDI protocol

defines a set of capabilities for General MIDI instruments. Included are a General MIDI Sound Set (patch map), a

General MIDI Percussion map (maps percussion sounds to note numbers), and a set of General MIDI performance

capabilities (number of voices, MIDI messages recognized, etc.).

MIDI channels 1-9 and 11-16 are used for chromatic instrument sounds, while MIDI channel 10 is used for ‘keybased’ percussion sounds. Furthermore, the 128 program numbers are grouped into 16 related sets. For example,

program numbers 1-8 are for piano sounds, 25-32 are guitar sounds, etc. (a chart is shown on the next page). The pitch

of the sound is indicated by a note number. Note numbers on the ‘key-based’ percussion sounds of MIDI Channel 10

represent different percussion instruments. It should be noted that although sounds may have the same label, they may

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-22 October 20, 2004

not necessarily produce the same sound. The sound output depends on the recorded sound source which is not

standard (an ‘Acoustic Grand Piano’ will sound different depending on the instrument used to produce the sound).

Only the patch numbers and their labels are standardized.

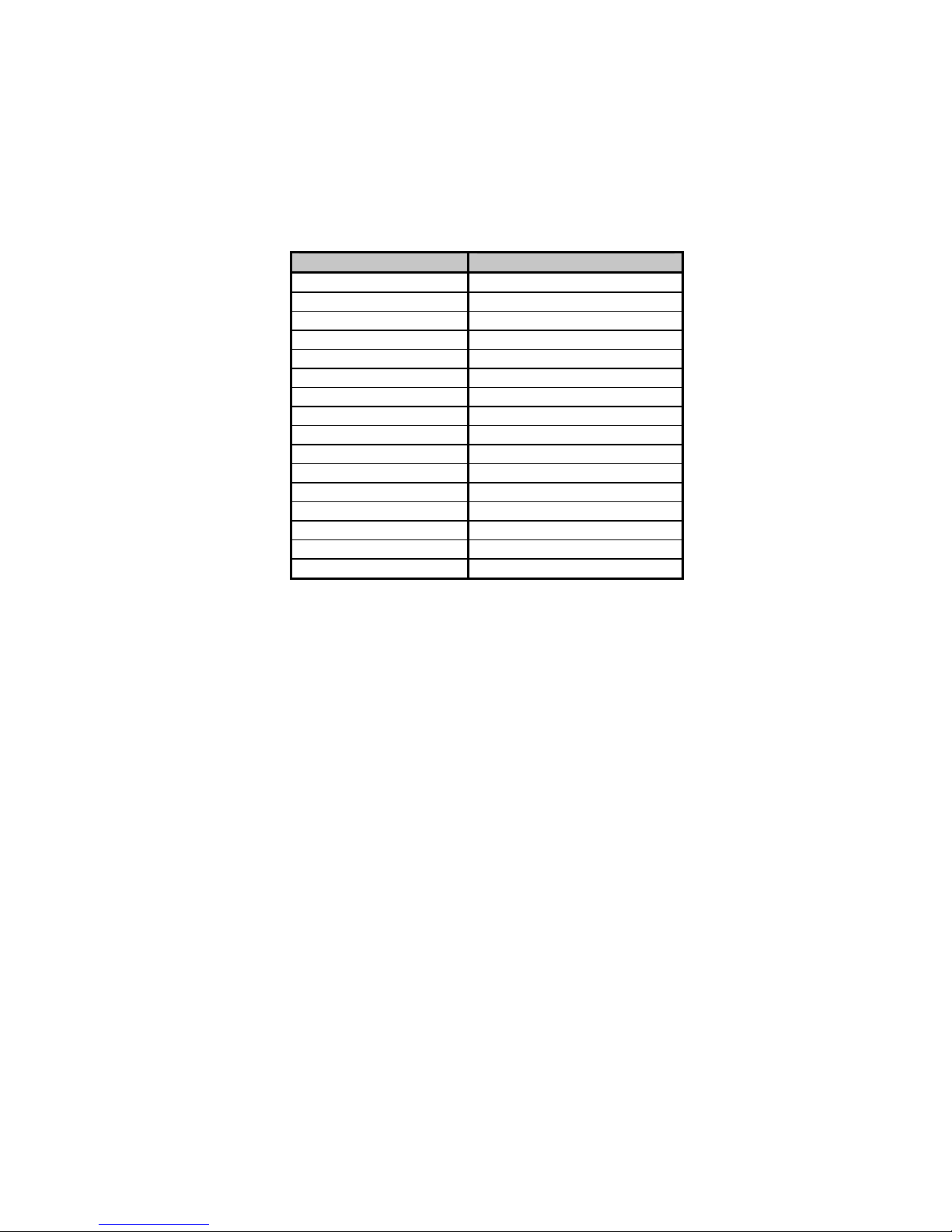

Table 3: Sound Set Groups [3]

Set Sound

1-8 Piano

9-16 Chromatic Percussion

17-24 Organ

25-32 Guitar

33-40 Bass

41-48 Strings

49-56 Ensemble

57-64 Brass

65-72 Reed

73-80 Pipe

81-88 Synthesizer Lead

89-96 Synthesizer Pad

97-104 Synthesizer Effects

105-112 Ethnic

113-120 Percussive

121-128 Sound Effects

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-23 October 20, 2004

Table 4: General MIDI Program Numbers for MIDI Channels 1-9 and 11-16

Patch

Number

1 Acou Grand Piano 44 Contrabass 87 Lead 7 (fifths)

2 Bright Acou Piano 45 Tremolo Strings 88 Lead 8 (bass+lead)

3 Electric Grand Piano 46 Pizzicato Strings 89 Pad 1 (new age)

4 Honky-tonk Piano 47 Orchestral Harp 90 Pad 2 (warm)

5 Electric Piano 1 48 Timpani 91 Pad 3 (polysynth)

6 Electric Piano 2 49 String Ensemble 1 92 Pad 4 (choir)

7 Harpsichord 50 String Ensemble 2 93 Pad 5 (bowed)

8 Clavinet 51 SynthStrings 1 94 Pad 6 (metallic)

9 Celesta 52 SynthStrings 2 95 Pad 7 (halo)

10 Glockenspiel 53 Choir Aahs 96 Pad 8 (sweep)

11 Music Box 54 Voice Oohs 97 FX 1 (train)

12 Vibraphone 55 Synth Voice 98 FX 2 (soundtrack)

13 Marimba 56 Orchestra Hit 99 FX 3 (crystal)

14 Xylophone 57 Trumpet 100 FX 4 (atmosphere)

15 Tubular Bells 58 Trombone 101 FX 5 (brightness)

16 Dulcimer 59 Tuba 102 FX 6 (goblins)

17 Drawbar Organ 60 Muted Trumpet 103 FX 7 (echoes)

18 Percussive Organ 61 French Horn 104 FX 8 (sci-fi)

19 Rock Organ 62 Brass Section 105 Sitar

20 Church Organ 63 Synth Brass 1 106 Banjo

21 Reed Organ 64 Synth Brass 2 107 Shamisen

22 Accordion 65 Soprano Sax 108 Koto

23 Harmonica 66 Alto Sax 109 Kalimba

24 Tango Accordion 67 Tenor Sax 110 Bagpipe

25 Acoustic Guitar (nylon) 68 Baritone Sax 111 Fiddle

26 Acoustic Guitar (steel) 69 Oboe 112 Shanai

27 Electric Guitar (jazz) 70 English Horn 113 Tinkle Bell

28 Electric Guitar (clean) 71 Bassoon 114 Agogo

29 Electric Guitar (muted) 72 Clarinet 115 Steel Drums

30 Overdriven Guitar 73 Piccolo 116 Woodblock

31 Distortion Guitar 74 Flute 117 Tailo Drum

32 Guitar Harmonics 75 Recorder 118 Melodic Drum

33 Acoustic Bass 76 Pan Flute 119 Synth Drum

34 Electric Bass (finger) 77 Blown Bottle 120 Reverse Cymbal

35 Electric Bass (pick) 78 Shakuhachi 121 Guitar Fret Noise

36 Fretless Bass 79 Whistle 122 Breath Noise

37 Slap Bass 1 80 Ocarina 123 Seashore

38 Slap Bass 2 81 Lead 1 (square) 124 Bird Tweet

39 Synth Bass 1 82 Lead 2 (sawtooth) 125 Telephone Ring

40 Synth Bass 2 83 Lead 3 (calliope) 126 Helicopter

41 Violin 84 Lead 4 (chiff) 127 Applause

42 Viola 85 Lead 5 (charang) 128 Gunshot

43 Cello 86 Lead 6 (voice)

Name Patch

Number

Name Patch

[3]

Name

Number

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-24 October 20, 2004

Table 5: General MIDI Percussion Key Map for MIDI Channel 10

MIDI Key Drum Sound MIDI Key Drum Sound

35 Acoustic Bass Drum 59 Ride Cymbal 2

36 Bass Drum 1 60 Hi Bongo

37 Side Stick 61 Low Bongo

38 Acoustic Snare 62 Mute Hi Conga

39 Hand Clap 63 Open Hi Conga

40 Electric Snare 64 Low Conga

41 Low Floor Tom 65 High Timbale

42 Closed Hi-Hat 66 Low Timbale

43 High Floor Tom 67 High Agogo

44 Pedal Hi-Hat 68 Low Agogo

45 Low Tom 69 Cabasa

46 Open Hi-Hat 70 Maracas

47 Low-Mid Tom 71 Short Whistle

48 Hi-Mid Tom 72 Long Whistle

49 Crash Cymbal 1 73 Short Guiro

50 High Tom 74 Long Guiro

51 Ride Cymbal 1 75 Claves

52 Chinese Cymbal 76 Hi Wood Block

53 Ride Bell 77 Low Wood Block

54 Tambourine 78 Mute Cuica

55 Splash Cymbal 79 Open Cuica

56 Cowbell 80 Mute Triangle

57 Crash Cymbal 2 81 Open Triangle

58 Vibraslap

[4]

Ahlborn [5]:

The Ahlborn Archive modules allow additional pipe organ sounds to be played on an existing organ. There are four

separate Ahlborn Archive modules of 20 different stops each over three separate divisions. For more information on

Ahlborn Archive modules, please visit: http://www.ahlbornorgans.com/archive

Archive modules can be found in Appendix D. The stop list for each module is shown below.

Table 6: Classic Module [6]

Division A Division B Pedal

Description Description Description

Gemshorn 8’ Principal 8’ Contre Basse 32’

Gemshorn Celeste 8’ Holzgedackt 8’ Contre Gambe 16’

Flûte à cheminée 8’ Flûte Harmonique 8’ Contre Bombarde 32’

Koppelflöte 4’ Flûte Octaviante 4’ Bombarde 16’

Plein Jeu IV-V Octave 2’ Div. A to Ped.

Bombarde 16’ Cymbale III Div. B to Ped.

Harmonic Trumpet 8’ Tremulant

Corno di Bassetto 8’ Div. A to Div. B

Festival Trumpet 8’

Clarion 4’

Tremulant

Div. B to Div. A

. The messages for controlling Ahlborn

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-25 October 20, 2004

Table 7: Romantic Module

Division A Division B Pedal

Description Description Description

Cello 8’ Open Diapason 8’ Contre Violone 32’

Cello Celeste 8’ Flauto Mirabilis 8’ Contre Gambe 16’

Cornet des Bombardes IV Concert Flute 4’ Contre Bassoon 32’

Cornopean 16’ Quint Flute 2 2/3’ Ophicleide 16’

Clarinet 8’ Piccolo 2’ Div. A to Ped.

Orchestral Oboe 8’ Vox Humana 8’ Div. B to Ped.

French Horn 8’ Tremulant

Cor Anglais 8’ Div. A to Div. B

Tuba Mirabilis 8’

Clarion 4’

Tremulant

Div. B to Div. A

[6]

Table 8: 201 Module [6]

Division A Division B Pedal

Description Description Description

Bourdon 16’ Gedackt 8’ Subbass 16’

Principal 8’ Gamba 8’ Octave 8’

Flûte à cheminée 8’ Nachthorn 4’ Bourdon 8’

Unda Maris 8’ Cymbale III Posaune 16’

Octave 4’ Cornet III Div. A to Ped.

Spitzflöte 2’ Oboe 8’ Div. B to Ped.

Nasard 2 2/3’ Tremulant

Superoctave 2’ Div. A to Div. B

Mixture IV

Trompete 8’

Tremulant

Div. B to Div. A

Table 9: 202 Module

[6]

Division A Division B Pedal

Description Description Description

Contregambe 16’ Bourdon 8’ Soubasse 32’

Diapason 8’ Flûte harmonique 8’ Violone 16’

Quintadena 8’ Flûte octaviante 4’ Contrebombarde 32’

Terz 1 3/5’ Larigot 1 1/3’ Bombarde 16’

Septime 1 1/7’ Corno di bassetto 8’ Div. A to Ped.

Scharff III Clarion 4’ Div. B to Ped.

Bombarde 16’ Tremulant

Trompette 8’ Div. A to Div. B

Tuba Mirabilis 8’

Chimes

Tremulant

Div. B to Div. A

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-26 October 20, 2004

HAUPTWERK

TM

[7]

Hauptwerk (German for ‘Great Organ’) is a computer simulation of a pipe organ. It produces a realistic organ sound

by use of a ‘virtual sampler’ technique. Traditionally, synthesizers used a small number of samples by recording keys

at intervals across the keyboard. In order to simulate all the keys, the samples were time-stretched. Hauptwerk uses a

three-to-five second sample of every pipe in the organ. To accommodate the intensive requirement for memory, a

high-speed personal computer must be used. With current technology, thousands of individual sample sounds can be

stored and recalled when a key is pressed. Thus, the software is able to capture many different and customizable organ

configurations and sounds which can be loaded via ‘.organ’ files. The ‘.organ’ file contains information regarding

number of stops, pistons, and keyboards in addition to other organ-related details.

Hauptwerk was initially designed for use with one MIDI keyboard which would be connected to the personal computer

through the sound card game port. If numerous keyboards were required, a MIDI merge box would have to be

purchased. However, the CMK not only performs the MIDI merge function but, also provides an interface for volume

controls, expression controls, and pistons. MIDI messages will then be sent through the MIDI out port to the personal

computer where Hauptwerk software will translate the MIDI message commands into actions on the organ. A table

listing the types of messages sent for the individual functions is shown below.

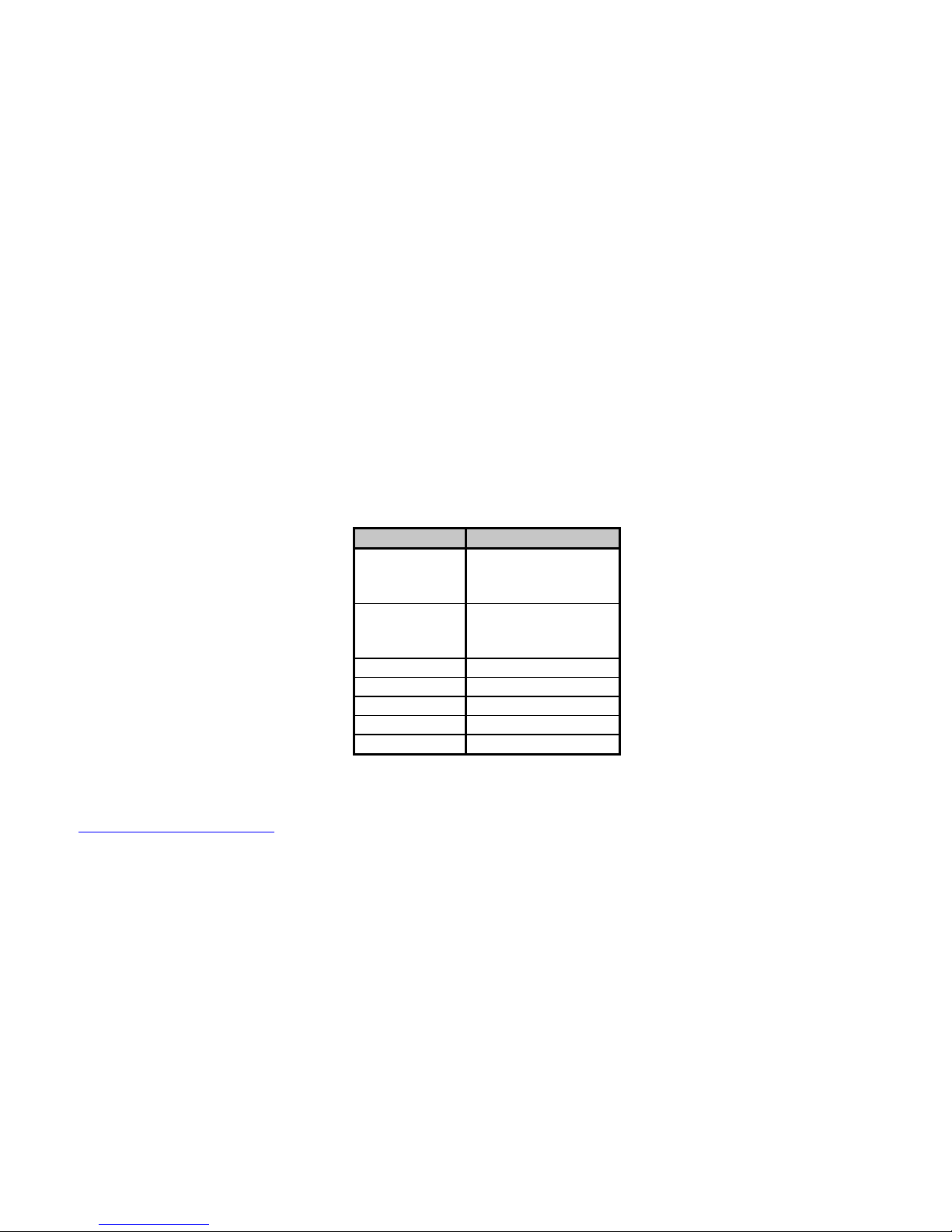

Table 10: MIDI messages relevant to Hauptwerk

Function MIDI command

Keyboards 1. Note on/off

2. Channel number

3. Key number

Pedalboard 1. Note on/off

2. Channel number

3. Key number

Stops Note on/off

Pistons Program change

Volume Program change

Expression Program change

Crescendo Program change

For more information or to download a shareware version of Hauptwerk software, please visit:

http://www.hauptwerk.co.uk

SCPOP

TM

(not supported on the current version of the CMK)

Sound Canvas Pipe Organ Project (SCPOP) is a computer program that emulates organ features like stop changes,

keyboard coupling, tremolo, assignable memories, temperament changes, and the ability to choose different reverb

settings. All of the features can be accessed using the computer keyboard’s keys like a true organ console. [8]

SCPOP requires a Roland Sound Canvas MIDI Expander module and is only compatible with Roland hardware

containing the ‘Sound Canvas’ label [9]. The messages used to control SCPOP can be found in Appendix E.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-27 October 20, 2004

MIDI Hardware Specification [1]

The only MIDI connector approved by the MIDI Manufacturers Association is a 5-pin 180º DIN connector. There are

other ways of connecting devices to send MIDI messages but, it is easier to have compatibility between different MIDI

devices if there is a standard connector. In connecting a MIDI device to a personal computer, the simplest way is

through the MIDI ports of a computer (MIDI connectors are uni-directional from the ‘OUT’ connector to the ‘IN’

connector). Due to space limitations of computer circuit boards, most computers are not equipped with a MIDI port.

Thus, adapters must be used which connect the MIDI device to another port. The most common port is the computer’s

game port which is found on most soundcards. Adapters are also available for the serial port, parallel port, and USB

port.

A schematic of the 5-pin DIN connector typical interface is shown below:

Figure 14: Schematic of 5-pin DIN connector

MIDI Hardware NOTES:

1. Opto-isolator shown is Sharp PC-900. HP 6N138 or other types can be used with changes.

2. Gates "A" are Integrated Circuit or transistor; Resistors are 5%.

3. Maximum cable length is fifty feet (15 meters), terminated at each end by a 5-pin 180º DIN male plug (e.g. SWITCHCRAFT

05GM5M).

4. Cable is shielded twisted-pair, with shield connected to pin 2 at both ends.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-28 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

CMK HARDWARE CONFIGURATION

Introduction

The CMK is customizable to suit many organ applications. Up to three CMK keyboards may be stacked level or tilted

if the optional mounting brackets are purchased. Each keyboard has 61-keys which serve programming purposes as

well as musical purposes. Two analog inputs are available (for volume/expression and crescendo adjustment).

Power-On Self Test

The CMK has a built-in self test that executes upon power up. This power-on self test serves to detect the presence of

hardware for velocity sensing. The test also checks that all 61 key-switch contacts are functioning properly. If

hardware is not present or is malfunctioning, velocity sensing is automatically disabled. The user can also disable

velocity sensing manually by pressing any keyboard key before connecting power.

Analog Input Pins

There are two analog inputs which can be configured for volume/expression and crescendo. Analog devices must be

connected to the analog input pin, a positive voltage (+5V) on pin ‘1’, and ground potential (0V) on pin ‘3’.

Depending on the position of the analog device, a unique voltage will be read by the processor which will determine

the setting. In the case of a volume control, the position of the analog device will determine the loudness level. See

Figure 13.

MIDI Crescendo

A MIDI program change message is sent to gradually add stops to a registration. ‘Analog Input 1’ is used for

Crescendo.

MIDI Volume

A MIDI program change message is sent to change the loudness level of the stop or sound. The MIDI volume analog

input must be configured to transmit on one or more MIDI channels as outlined in Table 11. ‘Analog input 2’ is used

for Volume but can also be used for Expression.

MIDI Expression

A MIDI program change message is sent to set the loudness level within the preset volume range. ‘Analog Input 2’ is

used for Expression but can also be used for Volume. Expression messages adjust the loudness within a range not

exceeding the maximum set by volume. The MIDI Expression analog input must be configured to transmit on one or

more MIDI channels as outlined in Table 11. In multi-manual CMK setups, the range for the Expression control can

be set by attaching a Volume control to one of the keyboards and attaching an Expression control to another keyboard.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-29 October 20, 2004

If the volume and expression controls are set to produce messages on the same MIDI channels, the volume control will

set the maximum range while the expression control will change the loudness level in the volume range.

Programming

The following chart lists different functions achievable using the piston pushbuttons and keyboard key-switches.

Table 11: Piston programming functions

Name Steps Function

SOFT

REBOOT

SET MIDI

CHANNELS

FOR THE

KEYBOARD

CLEAR MIDI

CHANNELS

FOR THE

KEYBOARD

Press the 1st piston

from the left (SET)

st

and 1

piston from

the right

(CANCEL)

simultaneously

Hold the 1st piston

from the left (SET)

and the 1

st

black

key from the left

(C#1). Then select

any combination of

the 1

st

16 white

keys from the left

(C1 to D3).

Afterwards, release

the SET piston.

Hold 1st piston from

the left (SET) and

nd

2

black key from

the left (D#1).

Afterwards, release

the SET piston.

Performs a soft reboot. This will restart the keyboard

and reload configuration data from the on-board

EEPROM.

Sets the output MIDI channels for the keyboard. For

example, if we configure the keyboard to output on

channels 1, 3 and 5, then all MIDI events originating

from that keyboard will produce MIDI messages

transmitted on these three channels.

Clears the output MIDI channels for the keyboard.

DEFAULT

VELOCITY

(if keyboard is

in non-velocity

mode)

Hold the 1st piston

from the left (SET)

rd

and 3

from the left (F#1).

Then press one of

the white keys and

release the SET

piston.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

black key

If the keyboard is set to non-velocity mode, the

default velocity output of the keyboard can be

selected. This is accomplished by using the white

keys select a velocity level between 0 (bass end:

softest) and 127 (treble end: loudest). Keys pressed

in between will produce a velocity level between 0

and 127 depending on the location of the key

relative to the extremes. The change in velocity level

between adjacent white keys is approximately 3.

Note that in the event multiple keys are pressed,

only the last one released will be registered by the

software.

Page-30 October 20, 2004

Table 11: Piston programming functions (cont’d)

Name Steps Function

VELOCITY

SENSING

ON/OFF

ANALOG

INPUT –

VOLUME

SETUP

DISABLING

ANALOG

INPUT –

VOLUME

Hold 1st piston from

the left (SET) and 4

black key from the

left (G#1) to turn off

velocity sensing.

st

Hold 1

piston (SET)

th

and 5

black key

from the left (A#1) to

turn on velocity

sensing. Afterwards,

release the SET

piston.

Hold the 1st piston

from the left (SET)

and the 6

th

black key

from the left (C#2).

Then select any

combination of the 1

16 white keys from

the left (C1 to D3).

Afterwards, release

the SET piston.

Hold the 1st piston

from the left (SET)

and the 6

th

black key

from the left (C#2).

Afterwards, release

the SET piston.

th

Velocity sensing produces a different volume level

corresponding to the force with which a key is pressed.

To conform to traditional organ consoles which are not

velocity sensitive, the CMK permits users to disable

velocity sensing in the keyboard.

Sets the output MIDI channels for the volume analog

input. For example, if we configure the analog input to

produce General MIDI volume information on channels

1, 3 and 5, then all MIDI events originating from that

analog input will produce MIDI messages transmitted on

st

these three channels. Please note that the crescendo input

does not require setup because it produces messages for

the Ahlborn Archive modules.

MIDI messages describing volume information from the

analog input will not be transmitted on any MIDI

channel.

ANALOG

INPUT –

EXPRESSION

SETUP

Hold the 1st piston

from the left (SET)

and the 7

th

black key

from the left (D#2).

Then select any

combination of the 1

16 white keys from

the left (C1 to D3).

Sets the output MIDI channels for the expression analog

input. For example, if we configure the analog input to

produce General MIDI expression information on

channels 1, 3 and 5, then all MIDI events originating

from that analog input will produce MIDI messages

st

transmitted on these three channels. Please note that the

crescendo input does not require setup because it

produces messages for the Ahlborn Archive modules.

Afterwards, release

the SET piston.

DISABLING

ANALOG

INPUT -

EXPRESSION

Hold the 1st piston

from the left (SET)

and the 7

th

black key

from the left (D#2).

Afterwards, release

MIDI messages describing expression information from

the analog input will not be transmitted on any MIDI

channel.

the SET piston.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-31 October 20, 2004

CLASSIC MIDI KEYBOARD

CMK-1

CMK SOFTWARE CONFIGURATION

(PC WindowsTM USERS ONLY)

Introduction

Users with access to a personal computer running Windows

(contained in the compact disc) to program additional configurations. These configuration files describe the features

of each keyboard such as output MIDI channel and the function of each piston. The software allows users to create

configuration files, change existing configuration files, and use existing configuration files.

TM 1

operating system can use the ‘CMKConfig’ software

Software Installation

The CMK includes a compact disc (CD) with software allowing users to create custom configurations. To use the

software, the CMK must be connected to a personal computer running Windows operating system software

(Windows 98, 2000, XP). The CMK must be connected to a computer using MIDI. If a MIDI port is not available

on your computer, commercial MIDI adapters for the game port, USB port, and parallel port may be used. When the

installation CD is placed in the optical drive of your computer (CD drive), the software installation wizard should

automatically run. If however, the software installation wizard does not automatically run follow the steps below:

1. Open the ‘Start’ menu and click on ‘Run’.

2. Click on ‘Browse’ and select the optical drive (CD drive) from the ‘Look in:’ drop down menu.

3. Locate and click on a file named ‘CMK_Setup.exe’.

4. Follow the instructions in the software installation wizard (screen captures are shown below).

1

Windows is a registered Trademark of the Microsoft Corporation.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-32 October 20, 2004

Figure 15: Upon clicking on the ‘CMK_Setup.exe’ file, the above window will appear.

Figure 16: Allows the user to select a directory to install the CMK program file

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-33 October 20, 2004

Figure 17: Setup adds an icon to the start menu for convenient access

Figure 18: Setup provides the option of creating an icon on the Windows desktop

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-34 October 20, 2004

Figure 19: Confirmation window

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 20: Setup progress window

Page-35 October 20, 2004

Figure 21: Confirms installation was successful

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-36 October 20, 2004

Software Startup

After installation, a shortcut titled ‘CMKConfig’ will be created in the ‘Classic Organ Works’ folder (Start menu→

Programs→ Classic Organ Works→ CMKConfig). To start using the software, click your left mouse button on this

‘CMKConfig’ shortcut. You should see a screen as shown below:

Figure 22: CMKConfig software startup screen.

Press a key on your computer keyboard or click on any mouse button and the main menu selection will appear:

The main menu allows you to select one of two editing types:

1. Configure a Classic MIDI Keyboard from scratch: This mode allows you to create a new file for storing on

the CMK memory or for generating a file on your PC.

2. Load a previously saved CMK configuration: This mode allows you to edit a file stored on your PC.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 23: CMKConfig software main menu.

Page-37 October 20, 2004

Configure a CMK from scratch

This editing mode allows the user to create a new configuration for the CMK. The user can then choose to save the

new settings on a computer or transfer the file to the CMK memory as a new configuration. When a user selects the

‘Configure a Classic CMK from scratch’ option from the main menu, the software attempts to make a connection to

the CMK as shown below. Note: If this is the first time you run CMKConfig, the software will prompt the user for the

computer’s MIDI configuration. See ‘MIDI I/O Setup’ on page 45.

Figure 24: CMKConfig software attempting to connect with the CMK

If a connection is not made, the following window appears:

Figure 25: CMKConfig software unable to connect

If a connection is made, the CMKConfig software will indicate the number of keyboards connected.

Figure 26: CMKConfig software successfully connected to the CMK.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-38 October 20, 2004

Afterwards, the following window appears. The software defaults to reading the DIP switch. However, the user can

specify another configuration number for the new configuration.

Figure 27: Successful connection between CMKConfig software and CMK.

When the user has specified the configuration number, CMKConfig software will load data from the CMK to start the

configuration process.

Figure 28: Window confirms the loading of pre-configuration data from the CMK to the PC.

The user can then design a custom configuration to the required specification.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-39 October 20, 2004

Load a previously saved CMK configuration

CMK configuration files are saved on a PC in the format: filename.cmk. In this editing type, a configuration file that

exists on your computer may be edited to the new specifications. The user can then choose to save the new settings on

a computer or transfer the file to the CMK memory as a new configuration. When a user selects the ‘Load a

previously saved CMK configuration’ option from the main menu, the software prompts for a filename through the

following window:

Figure 29: Configuration File selection window.

After selecting the appropriate file, click on the ‘Open’ button. A window should appear like the one shown below:

Figure 30: Program window

At this point, the user may customize each of the drop-down menus to their specifications.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-40 October 20, 2004

Functions of the Toolbars

The software has toolbars which contain four main functions:

Figure 31: Toolbars in CMKConfig software

1. File Menu

• Open Program Data File – Loads a configuration file (with a ‘.cmk’ extension) from the PC to the

CMKConfig software. The user may then edit the file to their specifications.

Icon:

Keyboard shortcut: Ctrl+O

To begin loading a configuration go to File → Open Program Data File, or use the Keyboard shortcut,

or icon shown above. A window prompting the user for a filename should appear:

Figure 32: Loading Program Data From File Window

The user can then select the filename and click on the ‘O

• Save Program Data File – Saves a configuration file to be stored on the PC. All configuration files

have a ‘.cmk’ extension.

Icon:

Keyboard shortcut: Ctrl+S

To save a configuration file to the PC, go to File → Save Program Data File, or use the Keyboard

shortcut or icon shown above.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

pen’ button.

Page-41 October 20, 2004

A window prompting the user for a filename should appear:

Figure 33: Save Program Data to File Window

If the configuration uses the same name as a previous configuration, a warning window will ask the

user for confirmation in replacing the old file with the newly revised one.

Icon:

Figure 34: Confirm replacing of file window

• Load Program Data From CMK – Loads a configuration file from the CMK memory chip. A CMK

may contain numerous configuration files which are selectable by changing the DIP-switch so, the

software displays an initial configuration number as set in the DIP-switch. If a configuration number

different from the DIP switch is required, it may be specified by the user.

Keyboard shortcut: Ctrl+L

To load a configuration from the CMK memory chip, the user must ensure that the CMK is connected

to power and to a computer using a MIDI cable (please see software installation for details on

connecting MIDI devices to computers). Then go to File → Load Program Data From CMK, or use

the keyboard shortcut or icon as shown above. A window appears attempting to make a connection

with the CMK as shown in Figure 35.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-42 October 20, 2004

Figure 35: Software attempting to make a connection with the CMK

If a connection is not available, a window will appear as a reminder to make connections to the CMK:

Figure 36: Software unable to make a connection with the CMK

If a connection is made, a window will appear to confirm the communication.

Figure 37: Software detecting number of keyboards

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-43 October 20, 2004

A window will then appear and the program will read the DIP switch to get the configuration number

(see table 12 in Appendix A for DIP switch codes). The user may change the configuration number to

be loaded if desired.

Figure 38: Successful connection between CMK and PC software

After the user has the desired configuration number, pressing ‘OK’ will display a window to confirm

the selection:

Icon:

Figure 39: Confirms loading of configuration into CMKConfig software.

• Write Program Data to CMK – Saves a configuration file to the CMK memory chip. Typical CMK

units will have numerous configuration files so the user should specify the configuration number of

the current file.

Keyboard shortcut: Ctrl+W

To save a configuration to the CMK, go to File → Write Program Data to CMK or, use the keyboard

shortcut or icon as shown above. The Software attempts to make a connection to the CMK.

Figure 40: Software attempting to communicate with CMK

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-44 October 20, 2004

Figure 41: Successful Software connection to the CMK

NOTE: The ‘DIP Switch is set to’ field reflects the current DIP Switch setting. Care must be taken

when choosing a new ‘Configuration Number’. If a ‘Configuration Number’ already contains settings,

writing to the same ‘Configuration Number’ will overwrite this information.

A window should appear to confirm that the contents were written.

2. Options Menu

• MIDI I/O Setup – This function sets the MIDI input and output ports on your PC.

Icon:

Keyboard shortcut: Ctrl+M

Figure 42: Confirms configuration written to CMK from CMKConfig software.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Figure 43: MIDI Input Output Setup window

Page-45 October 20, 2004

2. Help Menu

• View CMKConfig Documentation – This function displays the CMK documentation in a web

• About CMKConfig – This function contains the software title, company and version number.

browser.

Figure 44: Help Menu

Keyboard Functions

The keyboard is a physical representation of the items that a user needs to specify when configuring the CMK. The

user must specify functions for two categories: ‘MIDI channel output’ and ‘Piston function’.

• MIDI Channel output - This function controls the MIDI Channel(s) on which the keyboard can send

messages. To specify the MIDI channel(s), click on the keys of the keyboard and a menu such as the

one shown on the next page will appear. To select the MIDI Channel(s), use the mouse cursor to point

and click on the numbered buttons inside the blue bubble. These numbers correspond to the MIDI

Channels from 1-16 since the keyboard can send on multiple channels. Clicking on a selected

numbered button again will deselect it.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-46 October 20, 2004

Figure 45: Clicking on the keys of the keyboard invokes a MIDI Channel select menu.

• Piston Function – Each piston can be configured for a particular function. To select these functions

from a menu, click on any one of the twenty piston buttons and navigate through the resulting dropdown menus.

Figure 46: Clicking on an individual piston invokes the Piston function select drop-down menu.

_________________________________________________________________________________________________________

CMK-1 Manual (Issue-1)

Page-47 October 20, 2004

Note that configuring these pistons in software does not affect the use of the two end buttons to set keyboard hardware

parameters as discussed on page 29.

Three drop-down menus enable the user to select the MIDI device being controlled, specific functions of these devices,

and the MIDI output channel for the command.

Table 12: Customizable Functions for each piston

Ahlborn Coupler: Allows a keyboard to play stops from another division

A to Pedal B to Pedal B to A A to B A to Aux B to Aux

Ahlborn Tremulant

Swell Tremulant Great Tremulant Choir Tremulant

Ahlborn Cancel

General Cancel Swell

Divisional Cancel

Great

Divisional Cancel

Choir

Divisional Cancel

Ahlborn General: associates a combination of stops to a memory level.

These combinations can be from different divisions.

Memory A

General #1

Memory B

General #1

Memory C

General #1

Memory D

General #1

Memory E

General #1

Memory A

General #2

Memory B

General #2

Memory C

General #2

Memory D

General #2

Memory E

General #2

Memory A

General #3