CLASSEQ HYDRO-857 Installation Manual

Dishwashers

HYDRO 857

HYDRO 957

HYDRO 957AS

Installation & Operation Instructions

The Classeq pass through range

www.classeq.net

Accessories and Extras

Glasswashing

Dishwashing

Salt

Detergents and Hygiene Products

Product

Application

Products

Products

Stands

Baskets

Product Name Order Code

Eco 1 glass 400SBG-P

Eco 2, Duo 2 glass, Hydro cup 500GBP

Eco 3, Duo 3 glass, Hydro 750, Hydro 857-957 cup 700GBP

Alto cup, Hydro 400 plate 500P RP

Hydro 750 plate, Alto plate 700DRP

Product Name Quantity Order

Super clean glasswashing detergent 2x5l GW2-5

G3 glass rejuvenator 1x10kg G3/10

Super shine glasswashing rinse aid 2x5l GWRA5-5

Glasswasher starter pack glasswasher detergent 2x5l

Glasswasher starter pack rinse aid 2x5l

Super clean dishwashing detergent 2x5l DW2-5

Super clean dishwashing detergent 1x20l DW1-20

Super shine dishwashing rinse aid 2x5l DWRA2-5

Super shine dishwashing rinse aid 1x20l DWRA1-20

Dishwashing starter pack detergent 2x5l

Dishwashing starter pack rinse aid 2x5l

Super descaler 2x5l DE 2-5

Table Salt DuoMatik 25kg SALT T

Granulated 25kg SALT

Product Name Order

Eco 1-2, Hydro 400 stainless steel 457(w) x 497(d) x 410(h) SS-400

Duo 2, Duo 400 stainless steel 575(w) x 552(d) x 421(h) SS-400D

Eco 3 Hydro 750 stainless steel 555(w) x 550(d) x 410(h) SS-500

Duo 3, Duo 750 stainless steel 575(w) x 552(d) x 421(h) SS-500D

Steel coated stand ( Eco 1-2, Duo 2, Hydro 400) BWS400

Steel coated stand ( Eco 3, Duo 3, Hydro 700, Hydro 750,

Duo 750)

Code

SPG

SPG

Code

BWS500

Page 1

Basket Inserts

Product Name Order Code

Wire plate holder Eco 2, Duo2, Hydro WS8-SK

Hydro, 8 Compartment cutlery CBP

Basket Inserts

Description Order code

Eco, Duo and Hydro

ranges

Hydro ranges 20 litre WS20-SK

Alto ranges Automatic – DuoMatik 51-01-206

Viso ranges Automatic WSAUTO

8 litre WS8-SK

12 litre WS12-SK

16 litre WS16-SK

20 litre WS20-SK

Automatic WSAUTO

Automatic WSAUTO

Automatic hot water WSHC10

Automatic hot water WSHC10

Accessories

Description Order

Code

Boostermatic Pressure Pump (where water pressure is below 45psi/3bar) 99-05-039

Fixing Bracket For Pump 99-32-002

Mixer Valve For hot water installations 99-32-001

Service and Maintenance Contracts

Enjoy complete peace of mind with Classeq’s range of tailored service contracts. We will

be happy to discuss your requirements and provide a proposal which will cater for all your

warewashing service needs.

Four Star

Five Star

Break down cover only. Call out and labour included. All

replacement parts will be charged.

Break down cover with call out, labour and parts included

Page 2

Dear Customer

Thank you for choosing Classeq, the machine you have selected has

been designed to give you lasting service.

Please read these instructions before installing, commissioning and

operating this machine.

The information contained herein is provided to avoid accidental risks

and/or damage to either yourself or your machine.

Make sure you and any other users understand the controls prior to using

your machine.

Please keep these instructions in a safe place for future reference.

If you have any questions, or are not sure about any information contained

in this manual please contact either your distributor or Classeq, details are

provided inside the back cover.

TABLE OF CONTENTS

1. KNOW YOUR MACHINE .......................................................................................... 5

2. WARNING AND SAFETY INFORMATION .................................................................. 8

3. PRE - INSTALLATION ............................................................................................... 9

4. INSTALLATION ...................................................................................................... 12

5. COMMISSIONING ................................................................................................. 13

7. SERVICING & MAINTENANCE................................................................................ 18

8. TROUBLE SHOOTING ............................................................................................ 20

9. DECOMMISSIONING ............................................................................................. 22

10. APPENDIX A ....................................................................................................... 23

11. APPENDIX B ....................................................................................................... 24

12. APPENDIX C ....................................................................................................... 27

13. PARTS AND LABOUR WARRANTY TERMS ........................................................... 28

Page 3

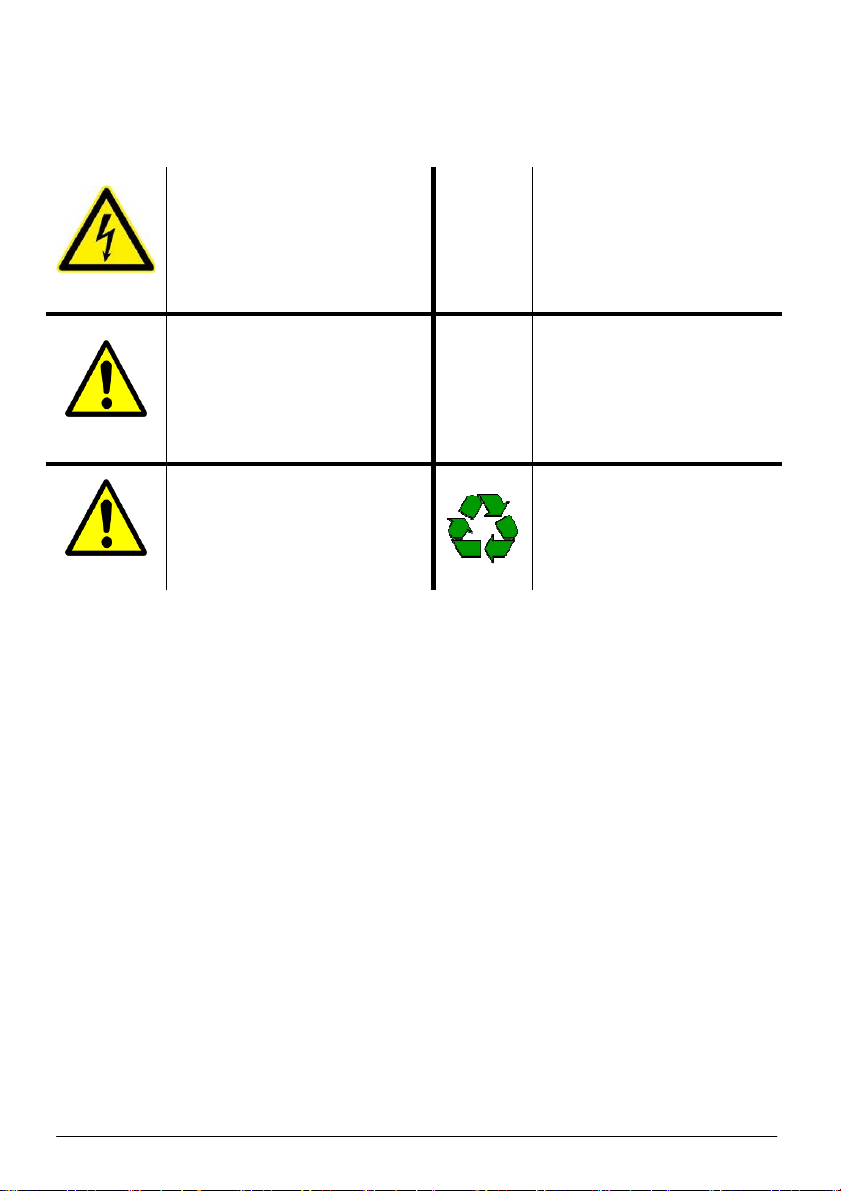

EXPLANATION OF SYMBOLS USED

The following symbols have been used in this manual

Warning against potential

serious or fatal injuries to

persons if the described

precautionary measures are

Danger

Warning!

Caution

not taken.

Warning against potential

minor injuries to persons or

potential material damage if

the described precautionary

measures are not taken

.

Warning against defects in or

destruction of the product if

the described precautionary

measures are not taken.

►

This symbol refers to a

chapter with more detailed

information

Refer to foot note at bottom

of page

Recycle

Page 4

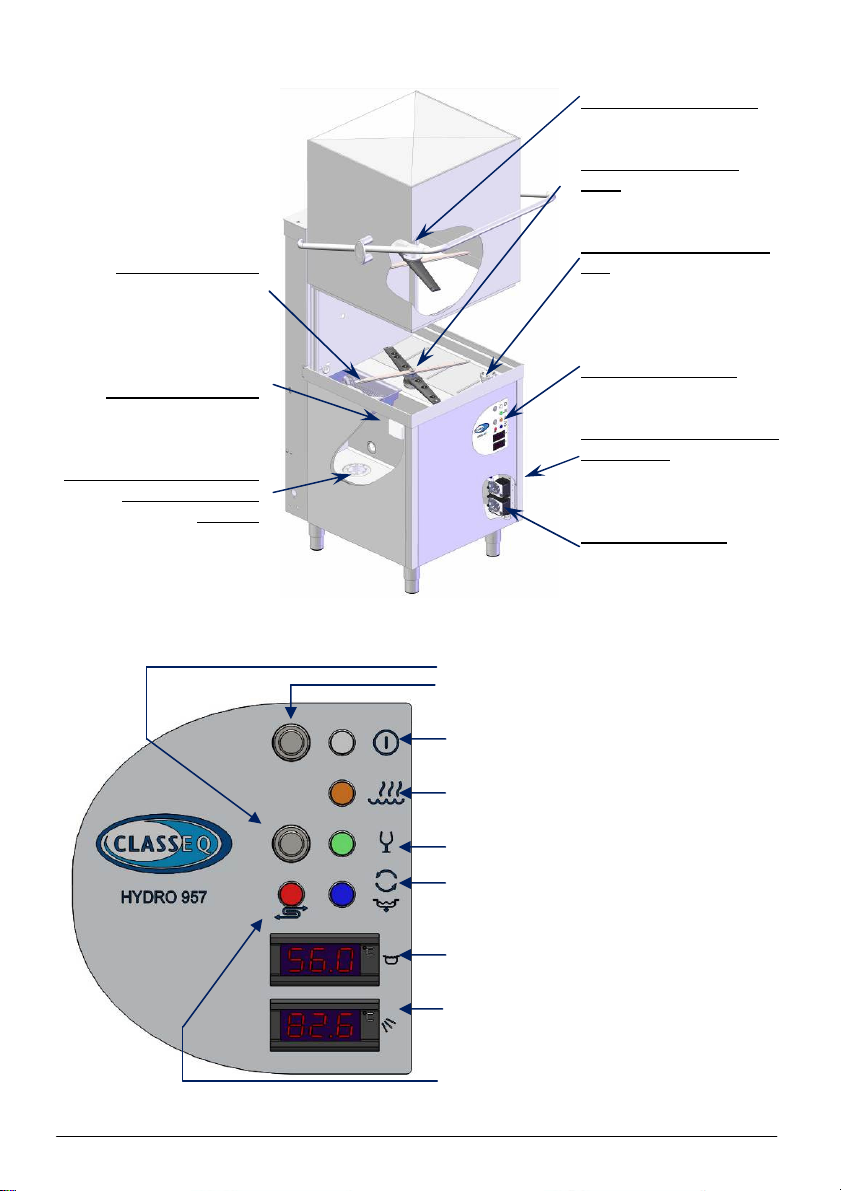

1. Know Your Machine

Rear primary filter

(front filter not shown)

Air pressure vessel

Secondary filters, and or

gravity drain plug

position

1.1 Fascia and Controls

Top wash / rinse arms

Bottom wash / rinse

arms

Water softener salt refill

cap

(only on machines with

integral water softeners)

Fascia and controls

Serial number / electrical

rating plate

(on side of machine)

Chemical pump(s)

(detergent pump is

optional)

Short cycle button

On / Off button

On / Off lamp

Machine heating (if Amber in colour)

Short cycle lamp

Cycle / Drain lamp

Wash Temperature Thermometer

(optional)

Rinse Temperature Thermometer

(optional)

Refill salt warning lamp

(only on machines with integral water

softeners)

Page 5

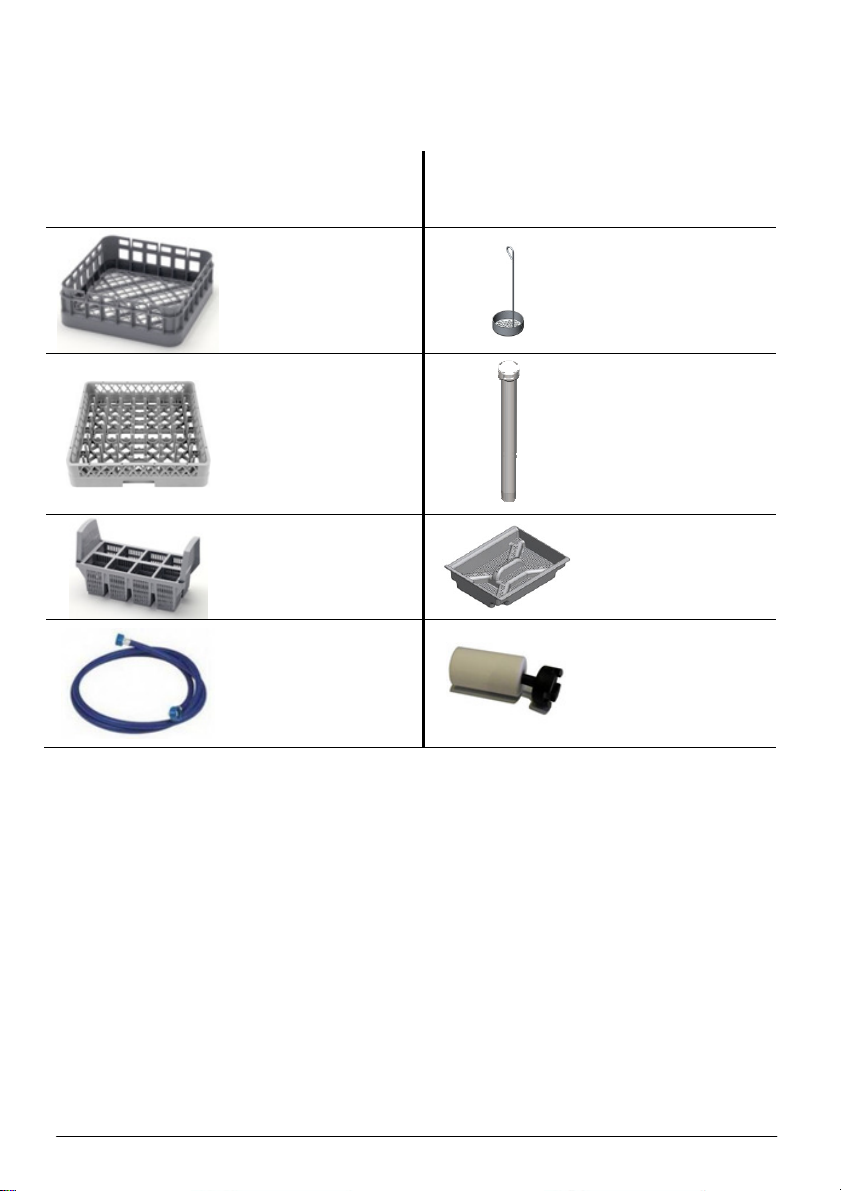

1.2 Contents of Your Machine

Items included within machine

1 x Installation

and Operation

Instructions

1 x Open basket

1 x Good

Practice Guide

1 x Secondary

filters

(only on drain

pump machines)

1 x Sectioned

basket

1 x Drain plug

(only on gravity

drain machines)

1 x Cutlery

basket

2 x Primary

filters

2 x Bottle

1 x Water inlet

hose

weights

(for Rinse Aid

and Detergent

tubes)

Page 6

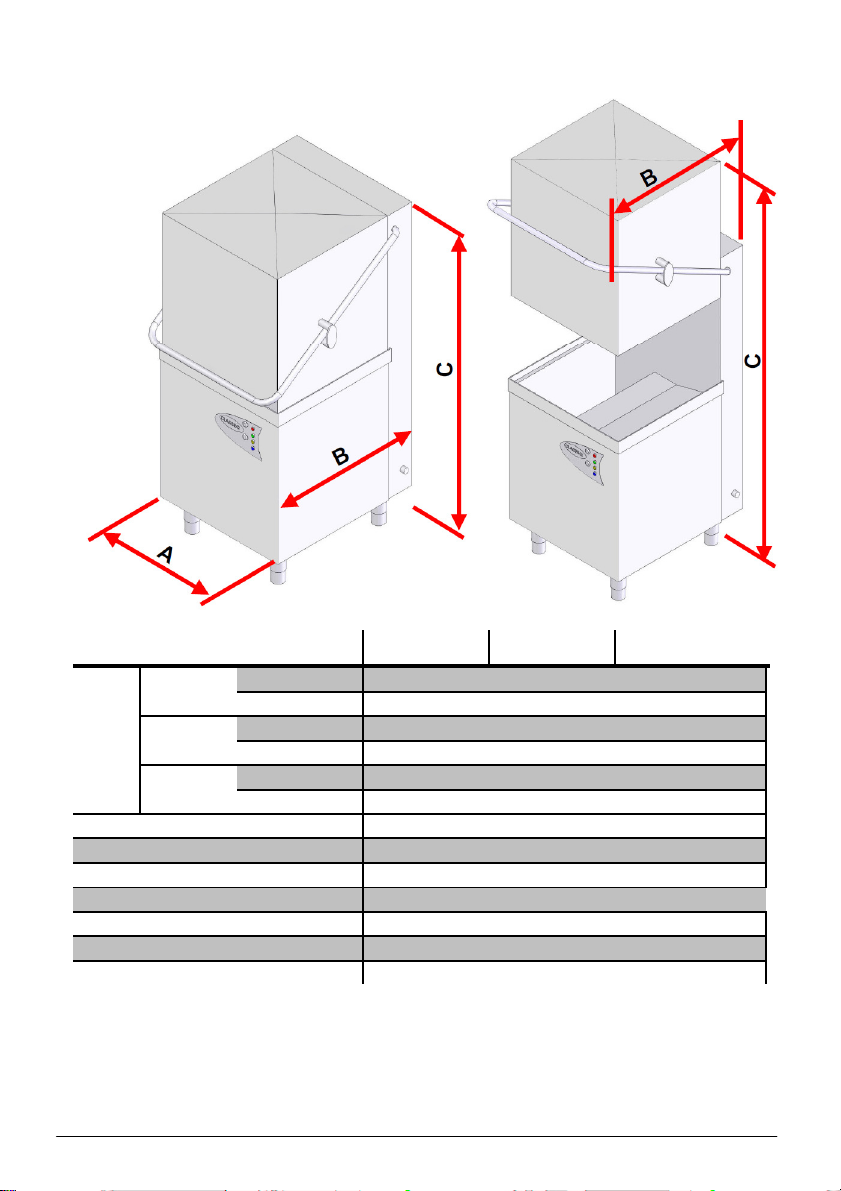

1.3 Machine specification

Dishwashers

A = width Inc. handle 730

Ex. Handle 630

B = depth Inc. handle 950

(mm)

Machine

C = height

(min)

Basket size (mm) (square basket)

Load capacity (pint glasses)

Load capacity (dishes)

Machine fully loaded weight (kg)

Rinse water temperature

Wash water temperature

Operating noise level

Ex. Handle 720

Hood closed 1470 - 1520

Hood open 1890 - 1940

HYDRO 857 HYDRO 957 HDYDRO 957AS

500

30

18

176

82°C

55°C

<70 db

Page 7

2.

The machine should only be operated on

the voltage specified on the rating plate

(►1). The installer and user are

responsible for ensuring the installation and

operation of this machine are in

accordance with local and national

regulations.

Each day allow your machine to heat up

before the first wash cycle (►6.4).

Only use commercial grade detergents and

rinse-aids within your machine.

DO NOT use electrical extension lead(s) to

supply power to your machine.

Damage to the machine caused by lime

scale, or poor water quality will NOT be

covered by the Manufacturer’s Warranty.

Children should be supervised to ensure

that they do not play with, or operate the

machine.

When disconnecting your machine from the

mains electrical supply:

Warning and safety information

• Machines hard wired (i.e. no plug),

this must be disconnected in

accordance with local and national

regulations; Classeq recommends

this is performed by a qualified

electrician.

For Dishwashers ONLY

Long cutlery, such as ladles and long

knives etc, must be placed horizontally on

the open basket (

possible collision with wash / rinse arms.

Always remove excess food from the

dishes before loading.

Caution

►1.2), this will avoid

DO NOT use your

machine as a waste

disposal unit.

Page 8

3. Pre - Installation

After unpacking your machine, check it for

any possible transport damage. Never

install and use a damaged machine. If your

machine is damaged contact your retailer

immediately.

Make sure the water and electricity

connections of your machine are in

compliance with these instructions.

Remove all outer packaging and the

protective film from your machine before

positioning it.

Ensure all packaging materials are

disposed of in accordance with local and

national regulations.

When positioning the machine, ensure that

the water inlet and drain hoses are not

kinked or squashed. Care must also be

taken to ensure your machine does not rest

upon any of its supply hoses / leads.

Once installed use the adjustable feet to

ensure your machine is stable, with its

weight being distributed equally and does

not tilt more than 3° in any direction.

Page 9

Loading...

Loading...