Installation

Installation

&&

Operators Manual

Operators Manual

Eco, Hydro and Duo

Eco, Hydro and Duo

under counter range

under counter range

Part number 902.0001

Revision E

Installation and Operation instructions

Installation and Operation instructions

For ‘Classeq’ under counter range of glass and dishwashers.

Section Title Page(s)

1

Safety instructions

1

2

The appliance

2

3

Installation

2 - 5

4

Commissioning

5 - 8

5

Operation

8 - 11

6

Cleaning

12,13

7

Trouble shooting

13 - 15

CAREFULLY READ THESE INSTRUCTIONS, BEFORE

INSTALLING AND OPERATING THIS APPLIANCE.

INCORRECT INSTALLATION, ADAPTATIONS OR

ALTERATIONS COULD RESULT IN INJURY OR DAMAGE TO

PROPERTY.

MALICIOUS DAMAGE, DAMAGE DUE TO NEGLIGENCE, OR

FAILURE TO COMPLY WITH THESE INSTRUCTIONS AND

LOCAL LEGISALTION, OR UNAUTHORISED TAMPERING

WILL INVALIDATE ANY WARRANTY AND RELIEVE THE

MANUFACTURER OF ALL LIABILITY

1.0 Safety instructions

1.0 Safety instructions

1.1 Warning :

1.2 Installation :

Installation should only be carried out by a ‘Classeq’ approved technician,

and in accordance with current regulations and within our instructions.

1.3 Modification :

‘Classeq Limited’ reserves the right to modify either the appliance or the

contents of these instructions without notice.

1.4 Operation :

The appliance should only be used by a trained operator as instructed in

section 5 of this manual.

1.5 Failure / malfunction :

In the event of a failure / malfunction, the mains electrical

and water supplies MUST be isolated at the wall and not

just at the machine.

1.6 Repairs and spare parts :

The appliance must only be repaired by a ‘Classeq’ approved technician,

using genuine ‘Classeq’ spare parts.

Page 1

2.0 The appliance

2.0 The appliance

2.1 Unpacking :

Use suitable means and protective equipment to avoid injury whilst

unpacking and handling the appliance. Remove all outer packaging and

the protective film from the outer panels of the appliance prior to

installation.

Ensure all packing materials are disposed of in accordance with local

regulations.

2.2 Items included :

The following items are included within the appliance

• 2 x Baskets

• 1 x Cutlery basket (Dishwashers only)

• 1 x Water inlet hose

• 2 x Primary filters

• 2 x Secondary filters (Only 1 on Gravity drain machines)

• 1 x Drain plug (Gravity drain machines only)

• 2 x Bottle weight kits (for Rinse Aid and Detergent tubes)

• 1 x Installation and Operation Instructions (Must be left with the

customer)

• 1 x Warranty card (Must be left with the customer)

3.0 Installation

3.0 Installation

3.1 The site :

Ensure that there is sufficient space for the installation, servicing and easy

access to all mains isolator switches / valves (i.e. electricity and water).

Ensure that the surface the appliance is going to be installed onto is

adequately stable and capable of supporting the appliance during normal

operation, listed below are the approximate machine weights when fully

laden during normal operation.

Once installed ensure that the appliance is stable and secure, with its

weight being distributed equally and does not tilt more than 3° in any

direction.

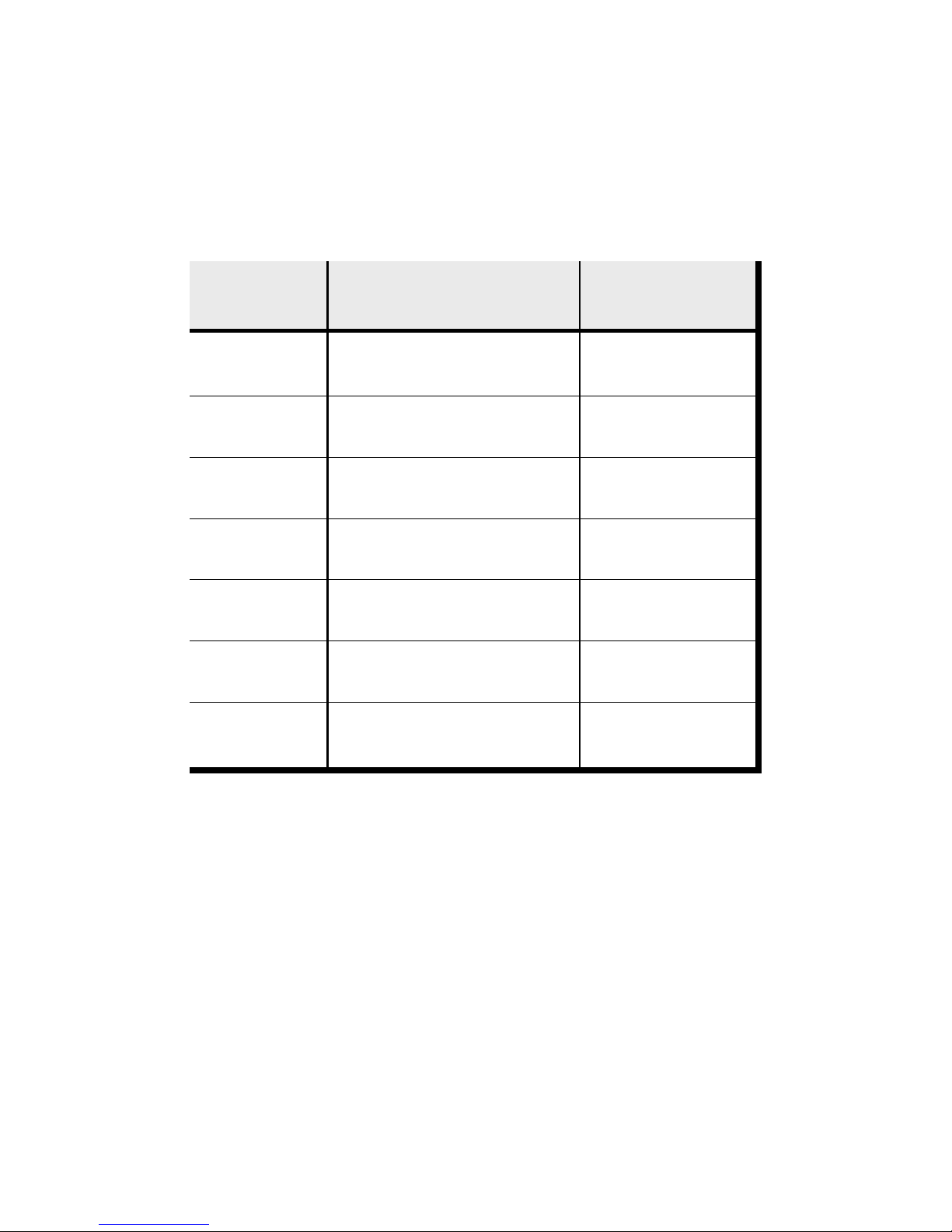

Machine sizes Weight

400mm² basket 90 Kgs

500mm² basket 135 Kgs

Page 2

3.2 Electrical connection :

All electrical connections MUST be carried out by an authorised

technician and in accordance with local regulations.

As a minimum ‘Classeq’ recommends that the following standards are

maintained :

• All appliances are connected via a residual current device

(R.C.D.) or earth leakage protection device.

• EN 60204

Supply isolator switch must have all pole separation of more

than 3mm.

• EN 60335

The appliance must be connected to a equi-potential

conductor, the connection stud is located at the rear of the

appliance (a suitable ring terminal shall be required), this is in

addition to the earthed electrical supply.

Prior to connecting the appliance, ensure that the voltage and the supply

fuse complies with the rating plate on the appliance.

3.2.1 Electrical rating :

Within the ‘Classeq’ range several of the 500mm² basket appliances can

be either down rated or up rated electrically, such a procedure MUST be

carried out by a ‘Classeq’ approved technician.

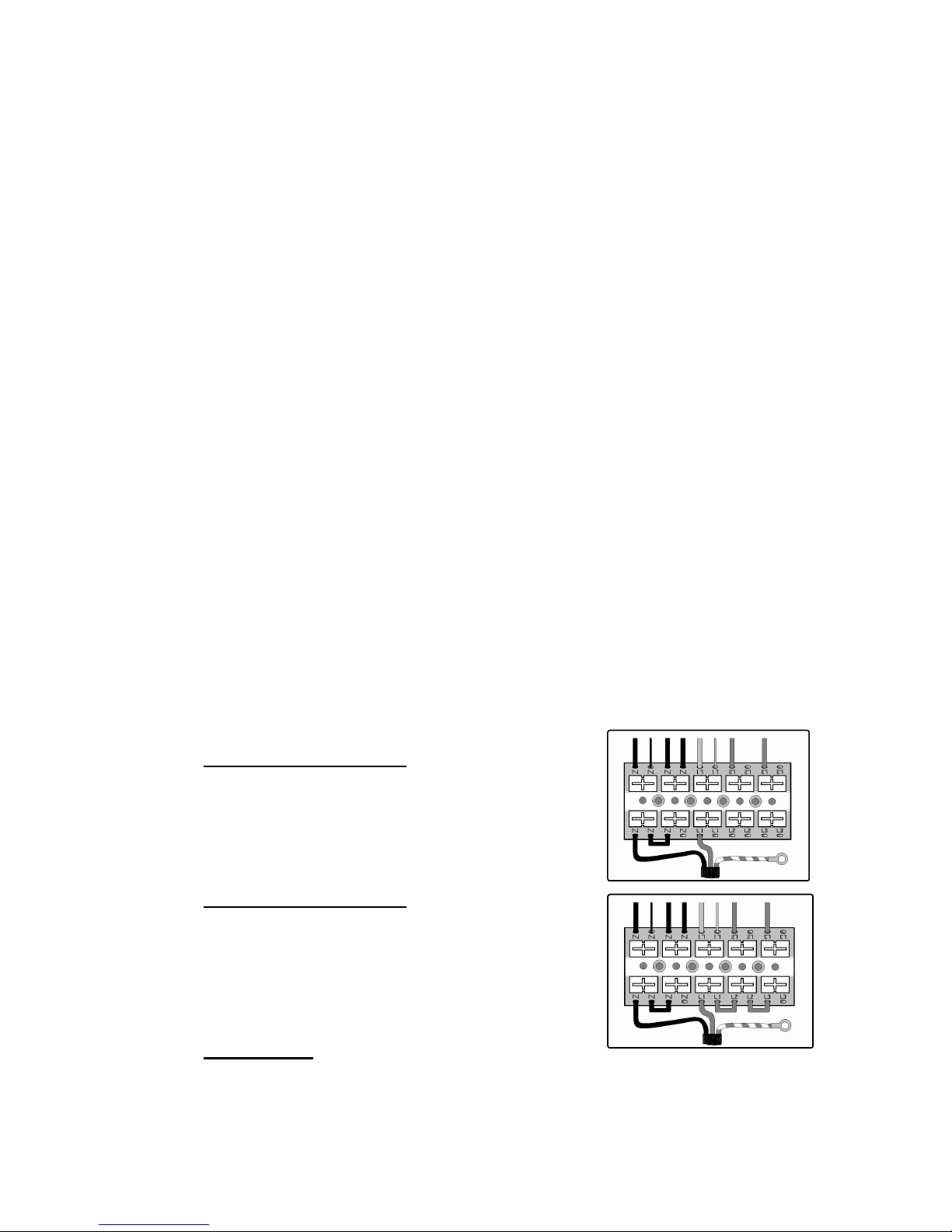

The down / up rating of the machine is carried out by configuring the

terminal block within the appliance to the following

13 Amp – Single phase

• Links removed between L1, L2 and L3

• Ensure link remains between neutrals (N)

30 Amp – Single phase

• Ensure all link remains between lives

terminals (L1, L2 and L3)

• Ensure link remains between neutrals (N)

Three phase

Only Eco3, H750, Duo3 and Duo750 appliances can be converted to three phase,

such conversion must be carried out in accordance with instructions WI-PROD-001A

Page 3

3.3 Water connection :

The appliance comes with a water supply hose requiring a ¾” BSP male

threaded connection at the mains water supply, upon installation and

commissioning all water joints must be checked for leaks).

3.3.1 Water supply restrictions :

Water supply constraints must be adhered to :

• Incoming water temperature

• 4°c minimum

• 55°c maximum

• Supply water dynamic pressure (air break machines, minimum water pressure

0.25 bar, all other parameters apply).

• 0 to 2 bar Rinse booster pump required

• 2 to 4 bar No modifications required

• 4 to 6 bar Flow restrictor required

• 6 bar plus Pressure reducing valve required

If the above requirements are not adhered to, the performance of the appliance

will be impaired

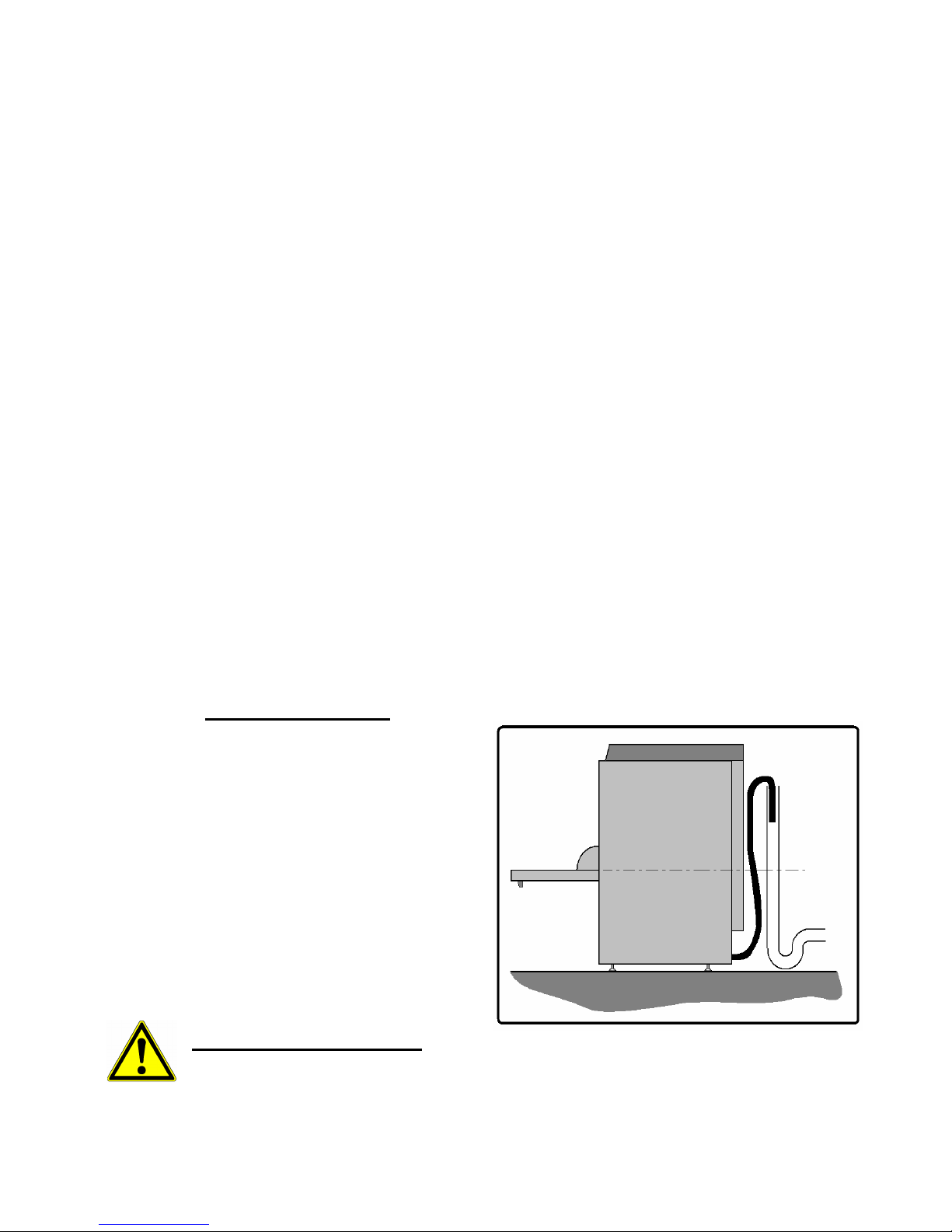

3.3.2 Drainage systems

Appliances are available as either gravity drain or pumped drain, upon

installation the waste hose and stand pipe must be configured as shown within

this manual, also all installations must be with a running / ‘P’ trap to ensure

hygiene, to identify your appliance see page 9 of this manual :

Drain pump machine

• Ø40mm (Ø1 ½”) standpipe required

• Standpipe must be 100 to 150mm

(4” to 6”) below the top of the

appliance.

• The end of the waste outlet hose in

the standpipe must not be lower

than the bottom of the door.

• The waste outlet hose must be a

loose fit within the standpipe.

Page 4

Bleeding of drain pump

After installation and once the tank is partially filled, i.e. before the 1st wash

cycle the drain system MUST be ‘BLED’, simply lower the drain hose into an

empty bucket and allow approximately 4 litres of water to flow out of the hose,

carefully return the hose to the stand pipe as shown above. Ensure any spillage

is cleaned before leaving the appliance.

Gravity drain machine

• Flexible waste hose must

be securely attached to

the waste outlet elbow on

the rear of the machine.

• The waste hose must

flow down from the waste

outlet elbow to the drain.

• Ø35mm (Ø1 ¼”) stand-

pipe required, must be

lower than the baseline

of the appliance

• H800 standpipe must be

a minimum of 75mm (3”)

below the baseline of the

appliance.

4.1 Rinse aid & detergent :

Ensure chemical tubes are attached correctly to the individual chemical

pumps (pumps located behind front lower panel of the appliance).

At the bottle end of the chemical tubes, slide the bottle weight onto the

tube, now place the tube and bottle weight into the correct chemical

bottle.

Ensure the correct chemical tubes now go to the corresponding chemical

bottles.

WARNING : Only rinse aids and detergents developed for commercial

glass and dishwashers are to be used, rinse aids must be suitable for

water temperatures down to 40°c.

4.0 Commissioning

4.0 Commissioning

Page 5

• Hose to be a close / tight fit into the drain pipe to reduce odours from the

drain system

4.1.2 Detergent / Soap prime :

The detergent / soap pump system on these appliances is self

priming.

4.1.3 Chemical dosage :

Chemical doses are pre-set to the following nominal values,

however these values should be calibrated to suit individual sites

requirements

Pre-set values (in seconds)

4.1.1 Rinse aid prime :

• Switch machine ON and allow to fill

• Remove the lower front panel (do not

to touch any wire connections).

• Depress and hold button located on

the chemical pump bracket.

• To fully prime, this will take approx 1 ½

minutes.

• Replace the front lower panel.

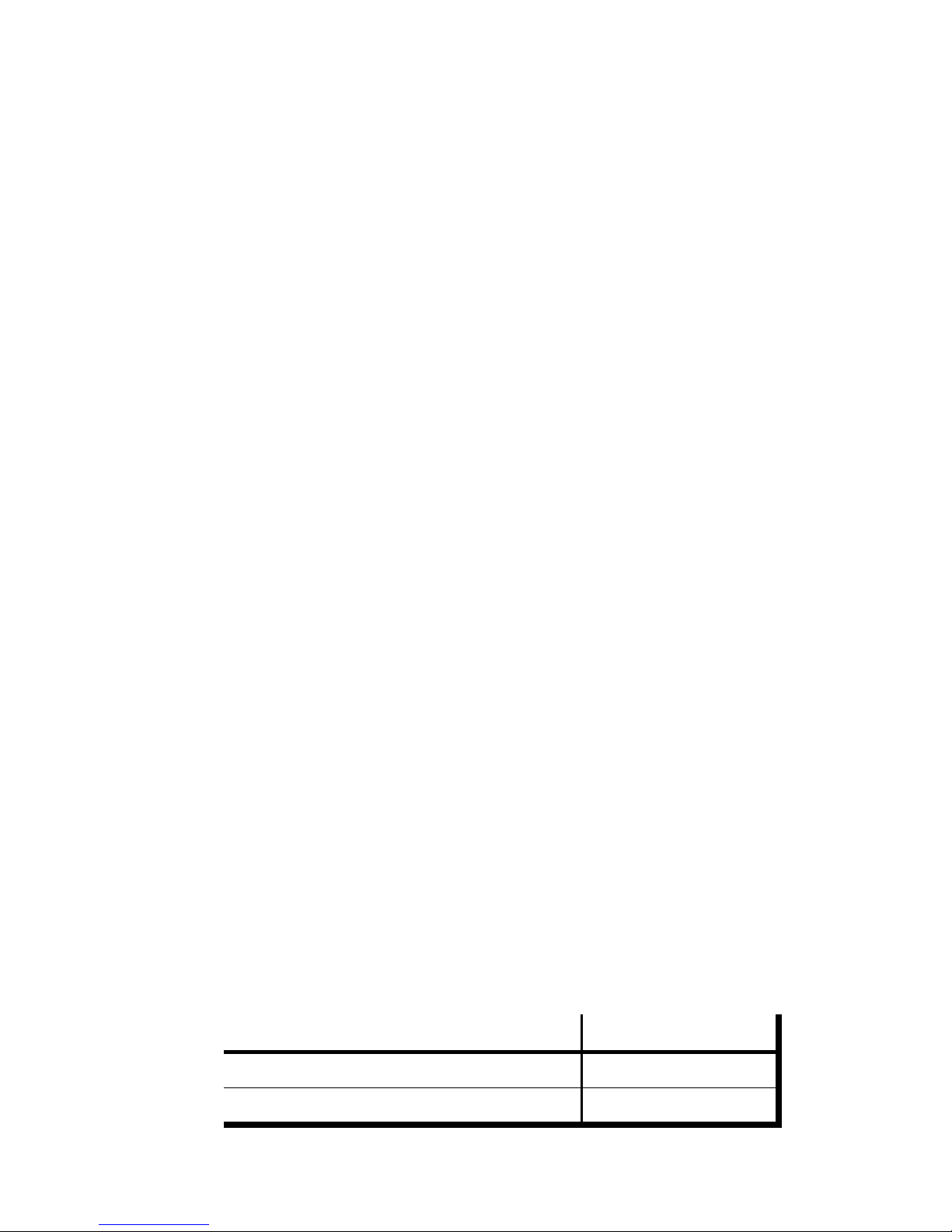

Machine sizes

Rinse aid

Cycle

Detergent

Initial Cycle

Eco 2 & Duo 2 5 40 10

Eco 3 & Duo 3 5 70 10

Hydro500 & Duo 500 5 40 10

Hydro700, Hydro750 & Duo 750 5 45 10

Adjustment of chemical dose is via the timer located under the top

panel of the appliance, the timer allows the following values to be

calibrated to suit the sites requirements

Page 6

Rinse aid pump Soap pump

The chemical timer allows the following dosing to be adjusted

• Cycle rinse aid

• Cycle detergent / soap

• Initial detergent / soap

4.2 Rinse & wash tank temperatures :

The water temperatures on ’Classeq’ range of machines is none adjustable.

Machine type

Temperatures

Rinse water Wash water

Glasswashers 70°c

55°c

Dishwashers 80°c

4.3 Interlock options :

All appliance now have the following three interlock options, to select such an

option remove the front lower panel, towards the centre of the machine you will

find four cables tied together, each wire with a different coloured cover (black,

green, red & white), by connecting different combinations together you will

obtain the appropriate interlock option

• Interlock removed

Will start at any temperature

Connect the Black crimp to the White crimp

• Quick start (default setting)

Will start if the rinse tank is above 55°c

Connect the Green crimp to the White crimp

• Interlock

All tanks must be up to temperature, before a cycle will start

Connect the Red crimp to the White crimp

Page 7

P1 = Detergent / Soap

pump

P2 = Rinse aid pump

4.4 Demonstration :

‘Classeq’ recommends that prior to leaving the site / installation, the installer

demonstrates the following to the end user, as this will ensure the appliance is

correctly used

• What to do in case of an emergency, i.e. how to isolate the mains

electricity and water (see section 1).

• Switching the appliance on.

• Operating the appliance.

• Draining down.

• Switch the appliance off.

• Clean the appliance, including removal and replacement of all filters.

• Replenishing and priming of rinse aid and detergent.

5.0 Operation

5.0 Operation

5.1 Machine description :

The design of commercial glass and dishwashing machines differ from

their domestic versions as they are designed to run nearly continually for

many hours.

Commercial appliances, wash results can be effected by external

considerations such as incoming water temperature, pressure, hardness

and choice of chemicals, ‘Classeq’ recommends that your appliance is

either connected to a water softener or a softened water supply, for

further details on water softeners please contact the supplier of your

appliance.

Upon completion of the installation and commissioning of the appliance,

this manual MUST be left with the end user.

Page 8

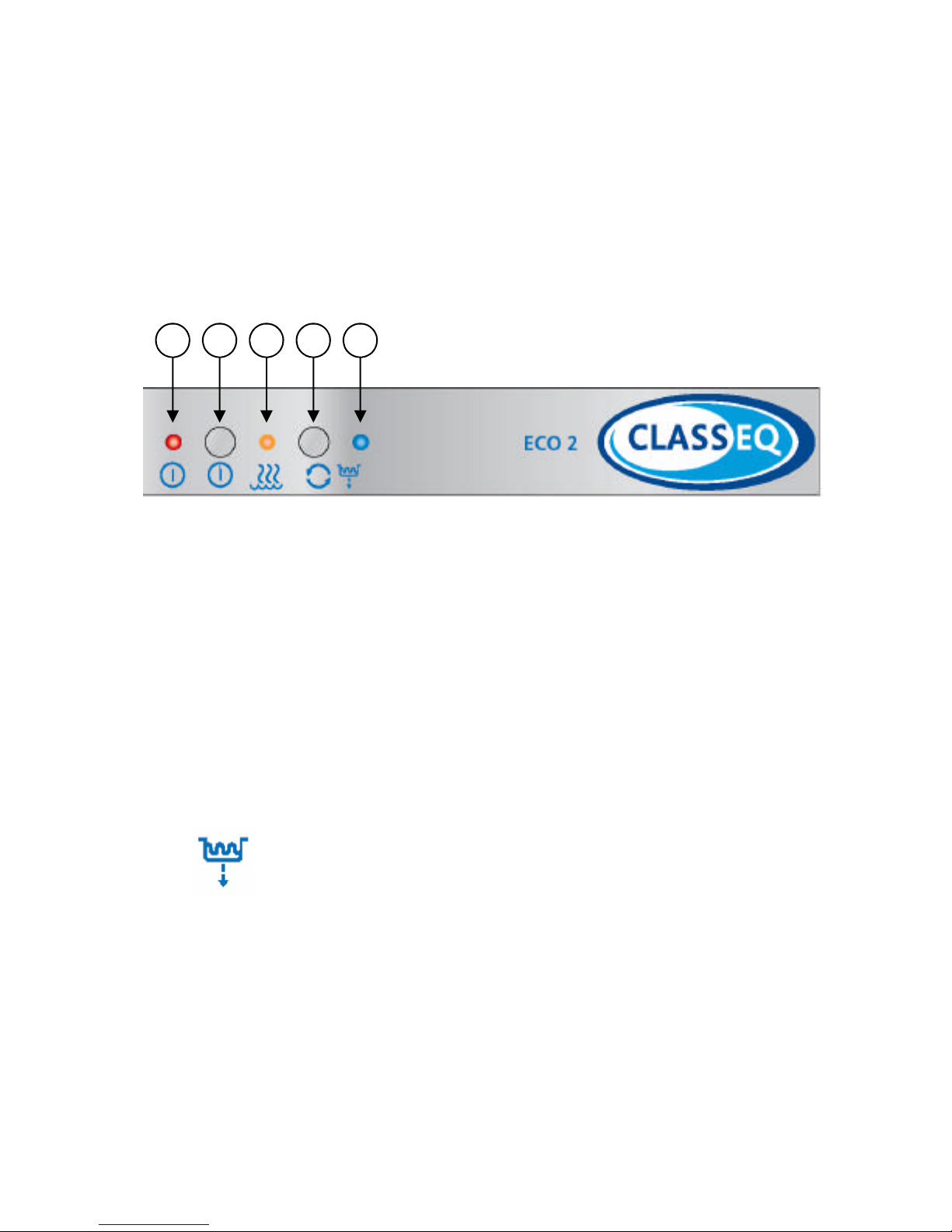

5.2 Controls :

Prior to switching the machine ON, ensure that you are familiar with the

controls on the front fascia of the appliance and the location of the isolator

for mains electricity and water supply.

1. ON / OFF lamp

2. ON / OFF switch

3. Heating lamp

4. Cycle switch

5. Cycle lamp

Page 9

1 2 3 4 5

Note !

Appliances fitted with a drain pump, the Cycle switch and lamp

double as the drain down switch and lamp

Drain pump appliances will have this symbol located below

the Cycle lamp (5), as shown on the above fascia.

If the symbol this is not present, the machine will have been

despatched as a gravity drain machine.

If in doubt please contact ’Classeq’ for advise.

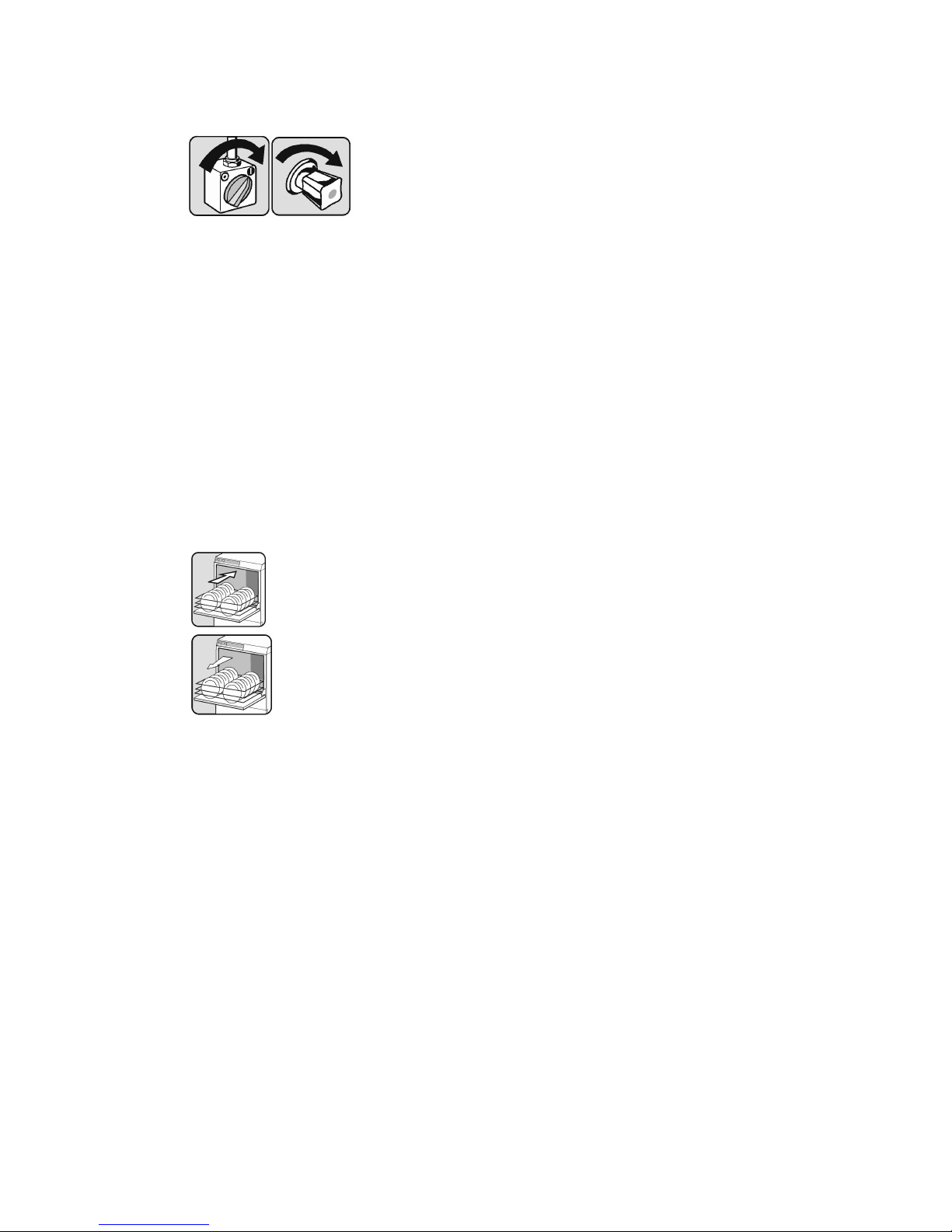

5.3 Switch the machine on :

Ensure that both the water and electrical supply are

connected and switched on, then depress the ‘ON/OFF’

switch located on the fascia of the machine.

The machine will now automatically fill and heat, during this process the door

should remain closed, allowing the process to be completed quickly.

5.4 Machine ready to operate :

The appliance is designed to only start a cycle when the correct temperatures

are achieved, so there may be a pause between a cycle being selected and the

cycle starting

5.5 Starting a cycle :

To start a cycle, open the door, load the first basket, ensuring that bottom and

top arms rotate freely.

Close the door, then depress the ‘Cycle’ switch, the cycle will now

start once the appliance has achieved its correct temperatures,

during the cycle the ‘Cycle’ lamp will be illuminated.

Once the ‘Cycle’ lamp has gone out (at the end of the cycle) open the

door and remove the basket, then reload the machine and repeat as

required

5.6 Draining :

During normal operation your appliance will automatically drain away any

excess water.

’Classeq’ recommends if your appliance is not being used for a prolonged period of time the machine must be completely drained down

Page 10

5.6 Draining (cont.) :

Gravity drain (typically Eco1 and Eco2).

• Switch appliance OFF at fascia.

• Remove drain plug from wash tank.

• You appliance should now drain under gravity.

• Once completed replace the drain plug.

• Now isolate mains water and electricity at the wall.

Drain pump appliances (optional on Eco1,Eco2)

• Switch appliance OFF at fascia.

• Close the door.

• Now depress the ‘Cycle’ switch, the ’Cycle’ lamp will now illuminate

to indicate that the drain cycle is in progress..

• Once the ‘Cycle’ lamp goes out, switch the appliance Off at the wall,

DO NOT switch isolate the appliance while in the drain down cycle.

Note !

Once empty ‘Classeq’ recommends that the mains water and

electricity supplies are isolated at the wall and the machine be

cleaned as instructed in section 6 of this manual

For hygiene reasons it is recommended that once the appliance has

been drained that the door is left open to assist in natural drying of the

wash chamber

Page 11

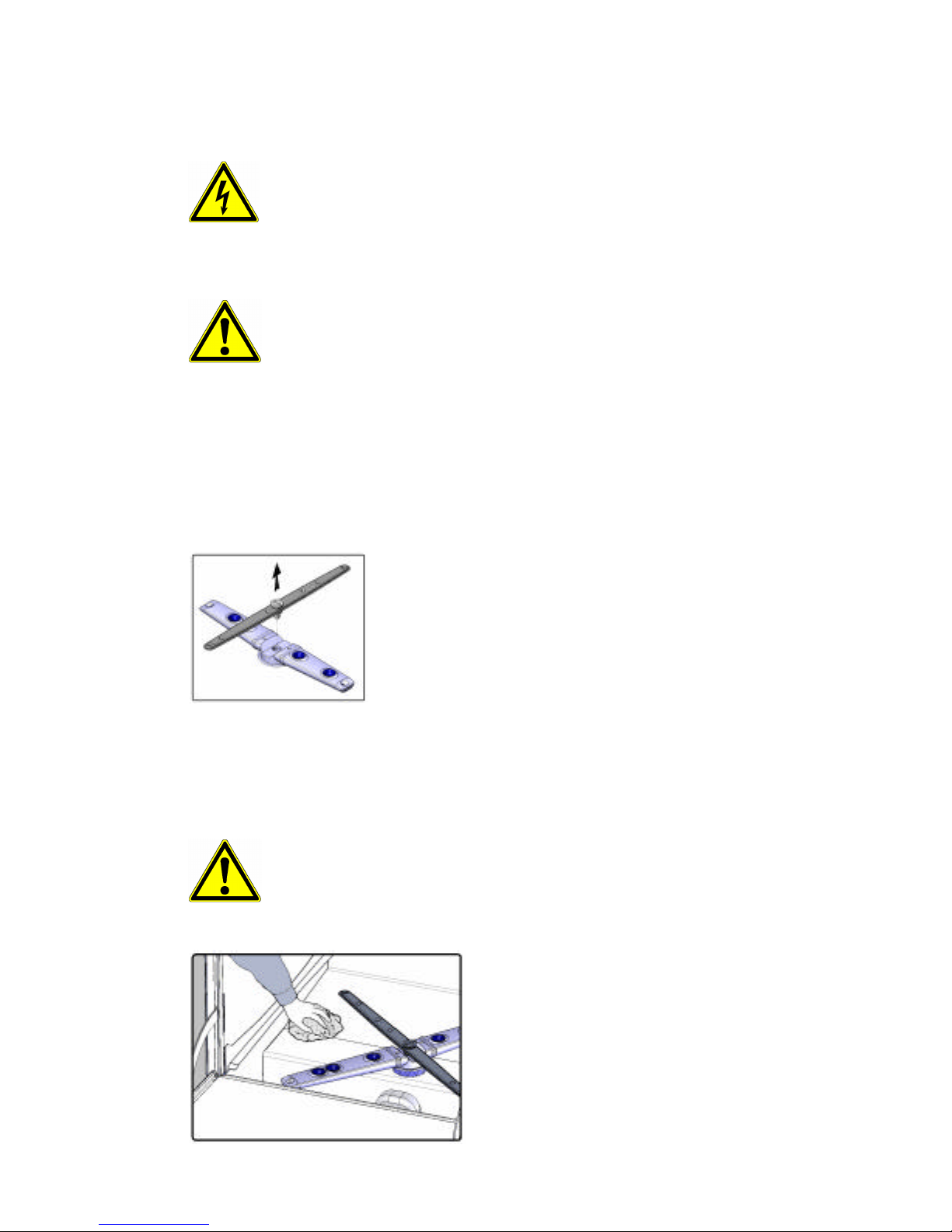

6.0 Cleaning

6.0 Cleaning

6.1 Prior to cleaning :

Switch off and isolated electrical supply before cleaning the

appliance

WARNING

DO NOT use cleaning agents that contain CHLORINE,

BLEACH or HYPOCHLORITE.

DO NOT use STEEL WOOL, WIRE BRUSHES or any other

abrasive materials.

DO NOT jet wash or hose pipe the appliance down either inter-

nally or on the exterior

6.2 Internal cleaning :

Remove the wash and rinse arms from the appliance,

once removed wash in warm soapy water, ensuring

all debris are removed, before reassembling the arm

Remove all the filters from within the appliance and again wash in warm

soapy water, ensuring all debris are removed.

WARNING

Before cleaning the wash chamber, ensure all sharp items,

such as broken glass or other items which could cause injury

are removed carefully

Now wipe the inside of the wash chamber

ensuring any debris are removed and the

chamber is clean, now reassemble all

filters and wash arms.

Page 12

6.3 Exterior cleaning :

Wipe the exterior of the appliance with a damp

sponge (NOT WET)

Once dry, clean using a STAINLESS STEEL

cleaning agent

7.0 Trouble shooting

7.0 Trouble shooting

• Before placing a service call , please check the following:

• Check the appliance is connected to the mains water and electricity

supply and both are turned on.

• Check levels of chemicals within the rinse aid and detergent bottles.

• Check the drain / stand pipe is correct for the appliance (refer to

section 3.3.2 of this manual).

NOTE

In the event of a service call being made under Warranty, and it is

found that the fault(s) are due to non-observance of instructions in

this manual, the call will be charged at current rates.

7.1 Appliance does not fill :

Appliance does not start :

Appliance does not rinse :

• Check water supply is turned ON.

• Check water supply hose is not trapped or kinked.

• Check that the appliance is switched ON.

• Drain appliance fully, then try again to fill the machine, drain as per

instructions 5.6 of this manual..

Page 13

7.2 Appliance fills slowly :

• Check water supply tap is fully open.

• Check water supply pressure, should be above 2 bar, if not ask

your dealer to install a booster pump to increase water pressure.

• Check and clean rinse jets (located on the wash arms within the

appliance).

• Check water supply hose is not trapped or kinked.

• Remove any pressure regulator or reducer from the water supply.

7.3 Appliance not heating :

• Drain appliance fully, then try again to fill the machine, drain as per

instructions 5.6 of this manual..

• Check the temperature of the mains water, as variations in water

temperature will affect the heating of the appliance.

• Check that the wash chamber is full of water.

7.4 Appliance not draining :

• Check and clean all filters within the appliance.

• Check that the stand pipe / drain is not clogged / blocked.

• With drain pump appliance, bleed the pump as stated in section

3.3.2. of this manual.

7.5 Poor wash results :

• Check and replenish chemicals.

• Check and clean wash and rinse jets on wash arm assembly.

• Clean filters within appliance and check that they are fitted

correctly.

Page 14

• Check water supply is ON and fully open.

• Rinse dishes of any food debris before placing into the dish-

washer.

• Glasses may need to be renovated.

• If glasses are ‘Blooming’ you may need a water softener, call your

dealer to advise on size of water softener required.

• If a water softener is fitted, replenish the salt within the softener, as

per the water softener instructions.

7.6 Overfilling :

• Drain appliance fully, then try again to fill the machine, drain as per

instructions 5.6 of this manual.

• Check and clean all filters within the appliance.

• Check stand pipe / drain height is configured correctly shown in

section 3.3.2. of this manual

• Check that the stand pipe / drain is not clogged / blocked.

• With drain pump appliance, bleed the pump as stated in section

3.3.2. of this manual.

• If the appliance continues to overfill isolate both the mains

electricity and water, before call a service technician.

7.7 Will not switch ON :

• On an 13 amp appliance check and replace the fuse in the plug,

ensuring the replacement fuse is of the correct rating.

• On other amperage appliances check and reset circuit breaker

within the sites fuse board, if the circuit breaker continues to trip

call a service technician immediately.

7.8 Will not switch OFF :

• Isolate at mains electricity before calling for a service technician

immediately.

Page 15

Notes

Notes

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

………………………………………………

……………………………………………….

..................................................................

..................................................................

..................................................................

..................................................................

..................................................................

..................................................................

Classeq

Winterhalter House

Roebuck Way

Knowlhill

Milton Keynes

MK5 8WH

'

7

Email

Website

0870 224 7280

0870 224 7255

service@classeq.co.uk

www.classeq.co.uk

"

"

CLASSEQ SERVICE DEPARTMENT

CLASSEQ

WINTERHALTER HOUSE

ROEBUCK WAY

KNOWLHILL

MILTON KEYNES

MK5 8WH

Affix

Stamp

"

"

Thank you for buying a quality ‘Classeq’ product, please complete and post this form without delay

Your new appliance is supplied with a full 12 months

warranty, protecting you against failure due to workmanship

or component failure

The information you supply to ‘Classeq’ is covered by the

DATA PROTECTION ACT. This data will also assist us to

speed up the process, if you require a service visit.

From time to time we may wish to contact you regarding any

future developments, if you do not wish to be contacted please

tick the box . o

AFIX

RATING PLATE

HERE

Rating plate

YOUR DETAILS

SITE

ADDRESS

POST CODE

TELEPHONE

PRODUCT DETAILS

MODEL NO SERIAL NUMBER

GLASSWASHER q DISHWASHER q

DATE OF PURCHASE / INSTALLATION

PURCHASED FROM

SIGNED

POSITION

ARE YOU INTERESTED IN EXTENDED WARRANTIES ?

Please tick the box YES q NO q

Loading...

Loading...