Classeq Duo 750, Duo 3, Duo 2, Hydro 750, Duo 400 Installation & Operator's Manual

...

Installation & Operators Manual

Installation & Operators Manual

Part number 902.0011

Revision F Jan 2012

Language English

The Classeq Under Counter Range

The Classeq Under Counter Range

Glasswashers

Glasswashers

Dishwasher

Dishwasher

Eco 1

Eco 2

Eco 3

Hydro 400

Hydro 700

Hydro 750

Duo 2

Duo 3

Duo 400

Duo 750

www.classeq.co.uk

Service

℡

0844 2245 245

service@classeq.co.uk

Spares

℡

0844 2245 252

spares@classeq.co.uk

Sales

℡

0844 2245 249

sales@classeq.co.uk

Installation and Operation instructions

Installation and Operation instructions

For under counter range of commercial glass & dishwashers.

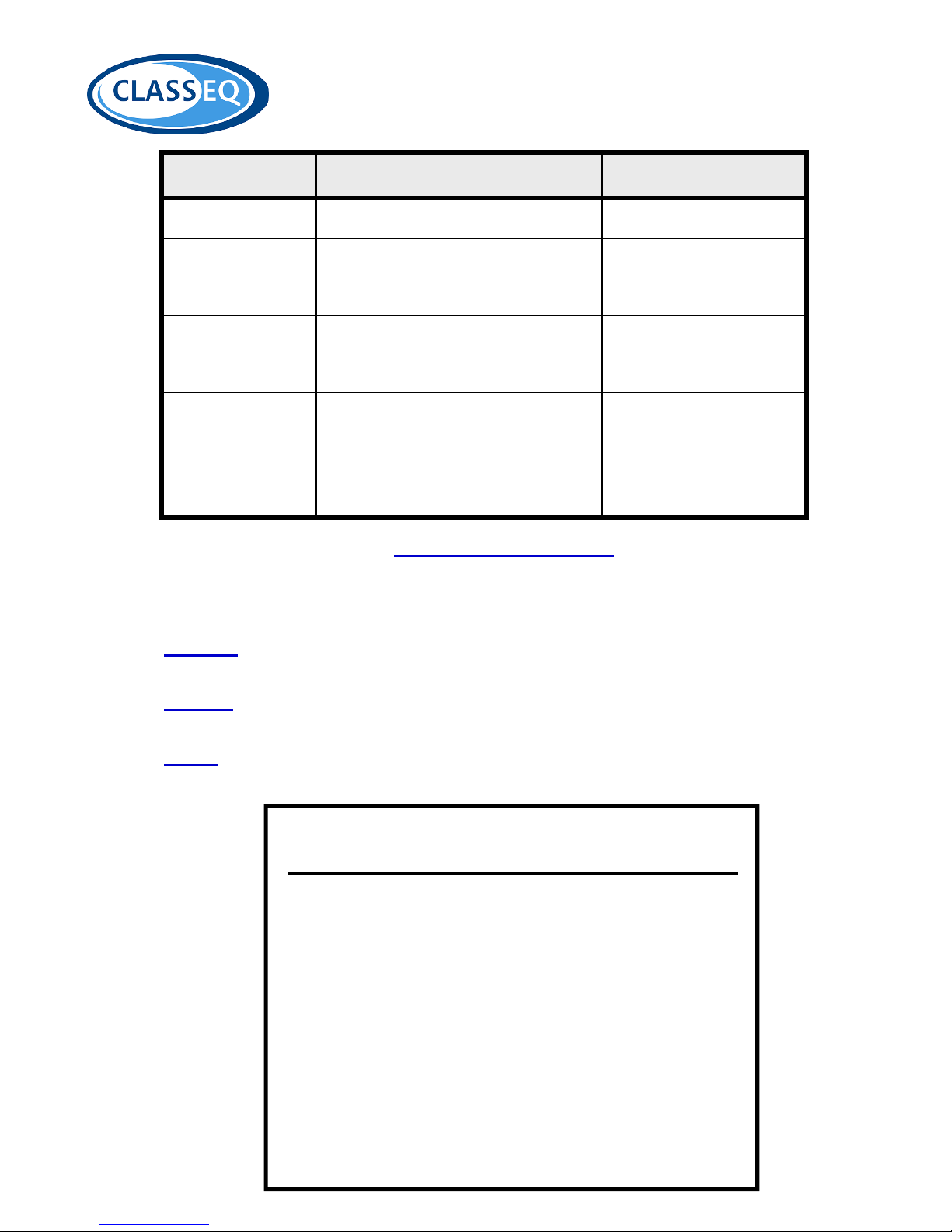

Section Title Page(s)

1

Safety instructions

1

2

Your Classeq appliance

2

3

Installation

2 - 5

4

Commissioning

6 - 7

5

Operation

8 - 10

6

Cleaning

11 - 12

8

Decommissioning

15

7

Trouble shooting

12 - 14

TO HELP WHEN CONTACTING PLESE QUOTE THIS

SERIAL NUMBER

Useful Contact Details

www.classeq.co.uk

Service

℡

0844 2245 245

service@classeq.co.uk

Spares

℡

0844 2245 252

spares@classeq.co.uk

Sales

℡

0844 2245 249

sales@classeq.co.uk

CAREFULLY READ THESE INSTRUCTIONS, BEFORE INSTALLING

AND OPERATING THIS APPLIANCE

INCORRECT INSTALLATION, ADAPTATIONS OR ALTERATIONS

COULD RESULT IN INJURY OR DAMAGE TO PROPERTY

MALICIOUS DAMAGE, DAMAGE DUE TO NEGLIGENCE, OR FAILURE

TO COMPLY WITH THESE INSTRUCTIONS AND LOCAL LEGISALTION,

OR UNAUTHORISED TAMPERING WILL INVALIDATE ANY WARRANTY

AND RELIEVE THE MANUFACTURER OF ALL LIABILITY

THE DOOR OF ANY APPLIANCE MUST NEVER BE USED TO STAND

ON

DAMAGE TO THE MACHINE CAUSED DUE TO LIMESCALE WILL NOT

BE COVERED BY THE MANUFACTURES WARRANTY

EACH DAY ALLOW MACHINE TO HEAT BEFORE FIRST WASH CYCLE

CHILDREN SHOULD BE SUPERVISED TO ENSURE THAT THEY DO

NOT PLAY WITH, OR OPERATE THE APPLIANCE

1.0 Safety instructions

1.0 Safety instructions

1.1 Warning :

1.2 Installation :

Installation should only be carried out by a ‘Classeq’ approved technician,

and in accordance with current regulations and within our instructions.

1.3 Modification :

‘Classeq’ reserves the right to modify either the appliance or the contents of

these instructions without notice.

1.4 Operation :

The appliance should only be used by a trained operator as instructed in

section 5 of this manual.

1.5 Failure / malfunction :

In the event of a failure / malfunction, the mains electrical and water supplies

MUST be isolated at the wall and not just at the machine.

1.6 Repairs and spare parts :

The appliance must only be repaired by a ‘Classeq’ approved technician,

using genuine ‘Classeq’ spare parts.

Page 1

Please contact :

Service

℡

0844 2245 245

service@classeq.co.uk

Spares

℡

0844 2245 252

spares@classeq.co.uk

2.0 Your Classeq appliance

2.0 Your Classeq appliance

2.1 Unpacking :

Use suitable means and protective equipment to avoid injury whilst unpacking

and handling the appliance. Remove all outer packaging and the protective

film from the outer panels of the appliance prior to installation.

Ensure all packing materials are disposed of in accordance with local and

national regulations.

2.2 Items included within appliance:

•

2 x Baskets

•

1 x Cutlery basket

(Dishwashers only)

•

1 x Water inlet hose

•

2 x Primary filters

•

2 x Secondary filters

(Only 1 on Gravity drain machines)

•

1 x Drain plug

(Gravity drain machines only)

•

2 x Bottle weights

(for Rinse Aid and Detergent tubes)

•

1 x Installation and Operation Instructions

(Must be left with the customer)

•

1 x Warranty card

(Must be left with the customer)

Page 2

F

E

D

C

B

A

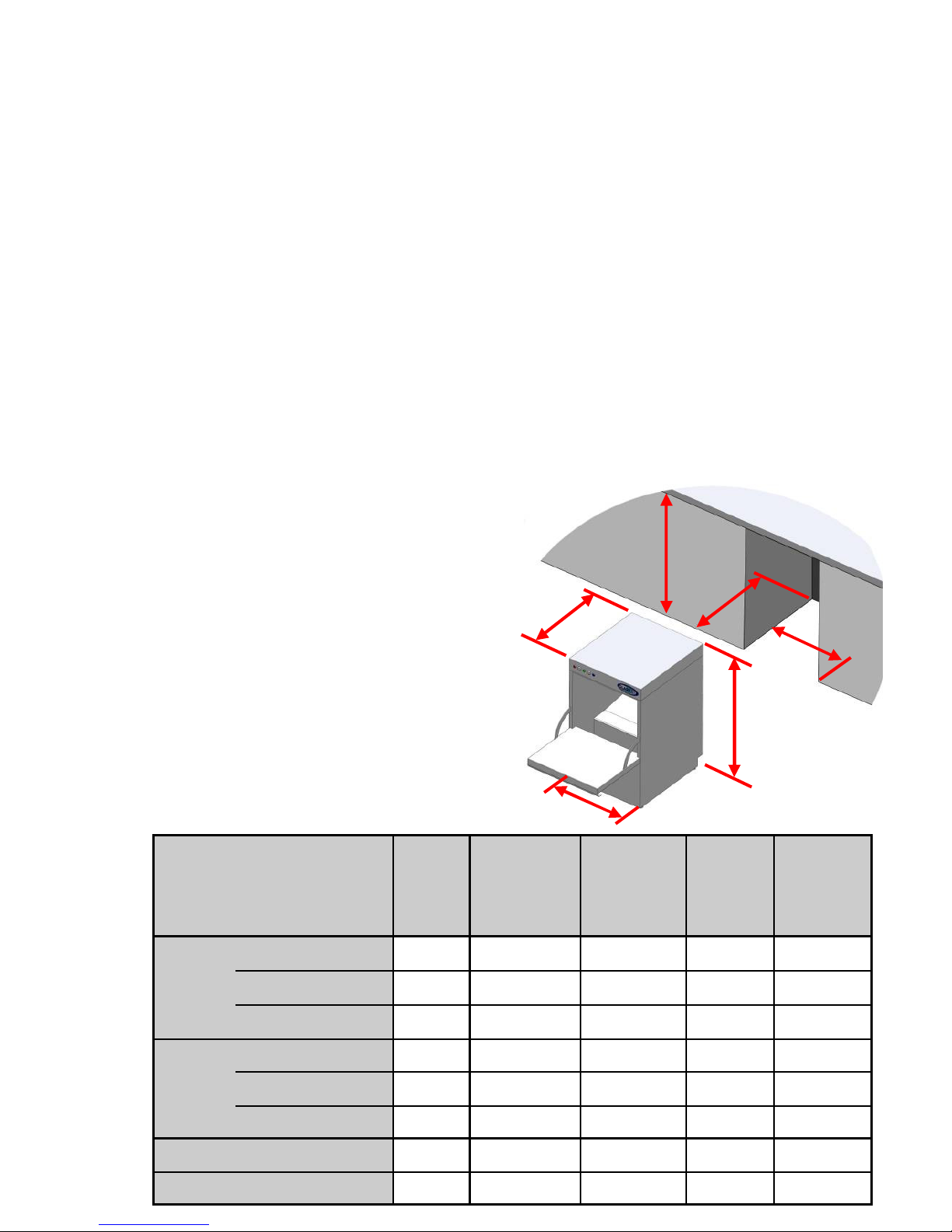

3.0 Installation

3.0 Installation

3.1 The site :

Ensure there is sufficient space for

installation, servicing and easy access

to all mains isolator switches / valves

(i.e. electricity and water). The surface

your appliance will be installed onto

MUST be adequately stable and

capable of supporting the appliance

during normal operation.

Once installed ensure the appliance is

stable, with its weight being distributed

equally and does not tilt more than 3°

in any direction.

Dimensions

(mm)

Eco 2 Eco 3 Duo 2 Duo 3

Eco 1 & Hydro 700 & &

Hydro 400 Hydro 750 Duo 400 Duo 750

Machine ‘A’ = Width

410 450 550 470 570

‘B’ = Depth

510 535 625 535 625

‘C’ = Height (min)

640 740 825 750 835

‘D’ = Width (min)

413 453 553 473 573

‘E’ = Depth (min)

530 555 645 545 645

‘F’ = Height (min)

660 760 845 770 855

Machine fully loaded weight

45 kg 61 kg 105 kg 64 kg 110kg

Recess

Operating noise levels <70db <70db <70db <70db <70db

3.3 Electrical connection :

All electrical connections MUST be carried out by an authorised

technician and in accordance with local and national wiring regulations.

As a minimum ‘Classeq’ recommends that the following standards are

maintained :

•

All appliances are connected via a residual current device (R.C.D.)

or earth leakage protection device.

•

EN 60204

Supply isolator switch must have all pole separation of more than 3mm.

•

EN 60335

The appliance must be connected to a equi-potential conductor , the

connection stud is located at the rear of the appliance (a suitable ring

terminal shall be required), this is in addition to the earthed electrical supply.

Prior to connecting the appliance, ensure that the voltage and the supply

fuse complies with the rating plate on the appliance.

If the supply cable is damaged, it must be replaced by a cable or cord

assembly supplied by Classeq, or its service agents, or to the following

minimum specification.

Page 3

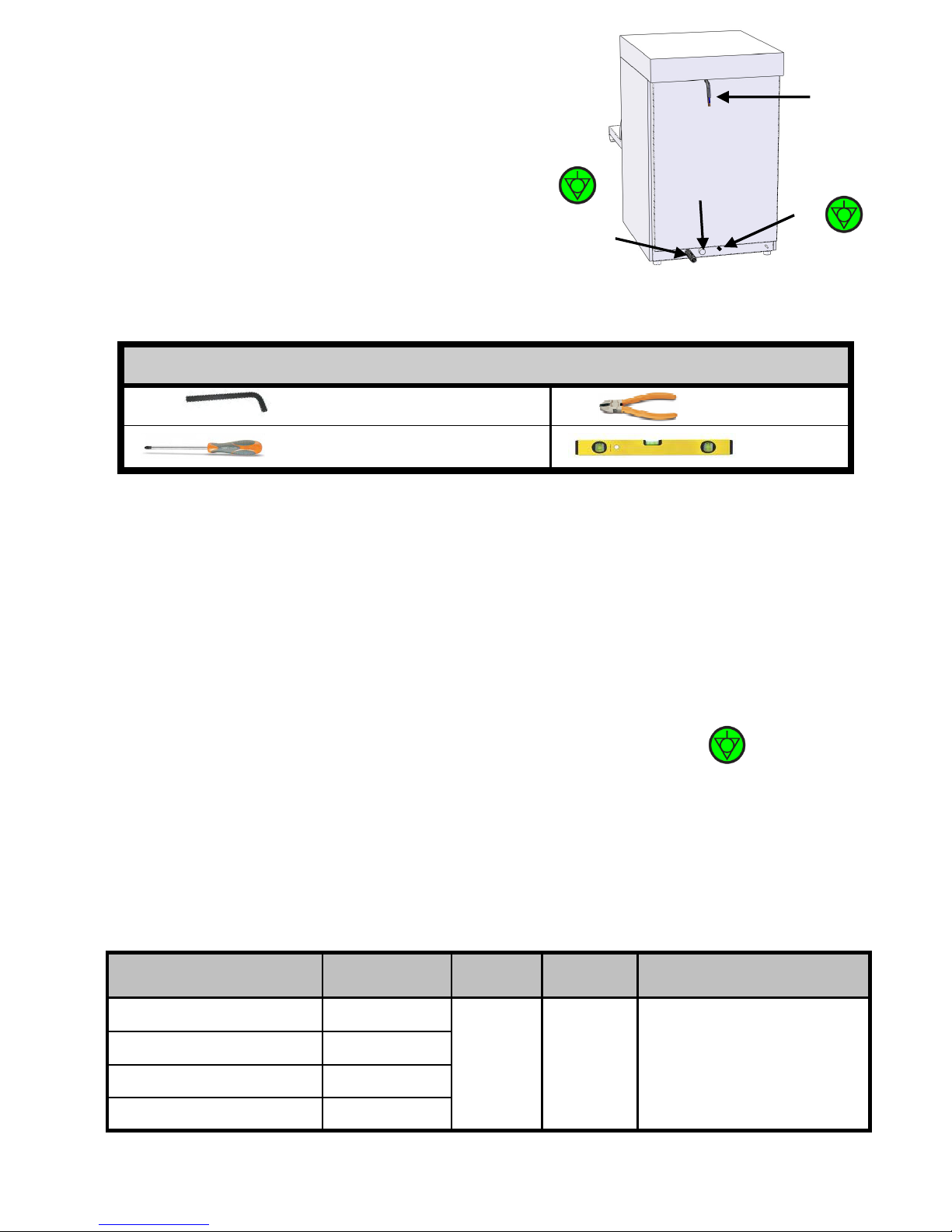

4.0mm - Allen key Wire cutters

Electric screw driver (small) Spirit level

Recommended hand tools

3.2 Connections :

All mains connections are made at the rear of

the appliance

G

= Mains electrical supply lead

H

= Earth bonding / Equi-potential stud

J

= Water supply connector (G 3/4”)

K

= Drain / waste water hose

To aid both installation and connection of the appliance, ‘Classeq’

recommends the following hand tools are used.

For electrical rating of appliance refer to rating plate located on appliance

or in this manual.

Machine rating Cable type Temp.

rating

Length

of cable

Conform to

220-240V / 1N~ / 13A PVC 3G 1.5

80°C

minimum

2.75m

IEC 60335-2-58

&

IEC 60227 types 56 & 57

220-240V / 1N~ / 20A PVC 3G 4.0

220-240V / 1N~ / 32A PVC 3G 4.0

380-415V / 3N~ / 13A PVC 5G 2.5

G

H

J

K

3.4 Water connection :

The appliance comes with a water supply hose requiring a G¾” (¾” BSP) male

threaded connection at the mains water supply, upon installation and

commissioning all water joints must be checked for leaks.

New hoses supplied are to be used. Old existing, defective or damaged water

supply hoses are NOT to be used when installing the appliance.

Commercial appliance wash results will be effected by external conditions such

as incoming water temperature, pressure, harness and choice of chemicals.

For the longevity of any water related devices and to ensure you get consistently

good results it is essential your machine is either fed from a soft water supply , or

your Classeq appliance is connected to an appropriate water softener.

IMPORTANT - All supplier warranties are void if lime scale is present within

an appliance.

Page 4

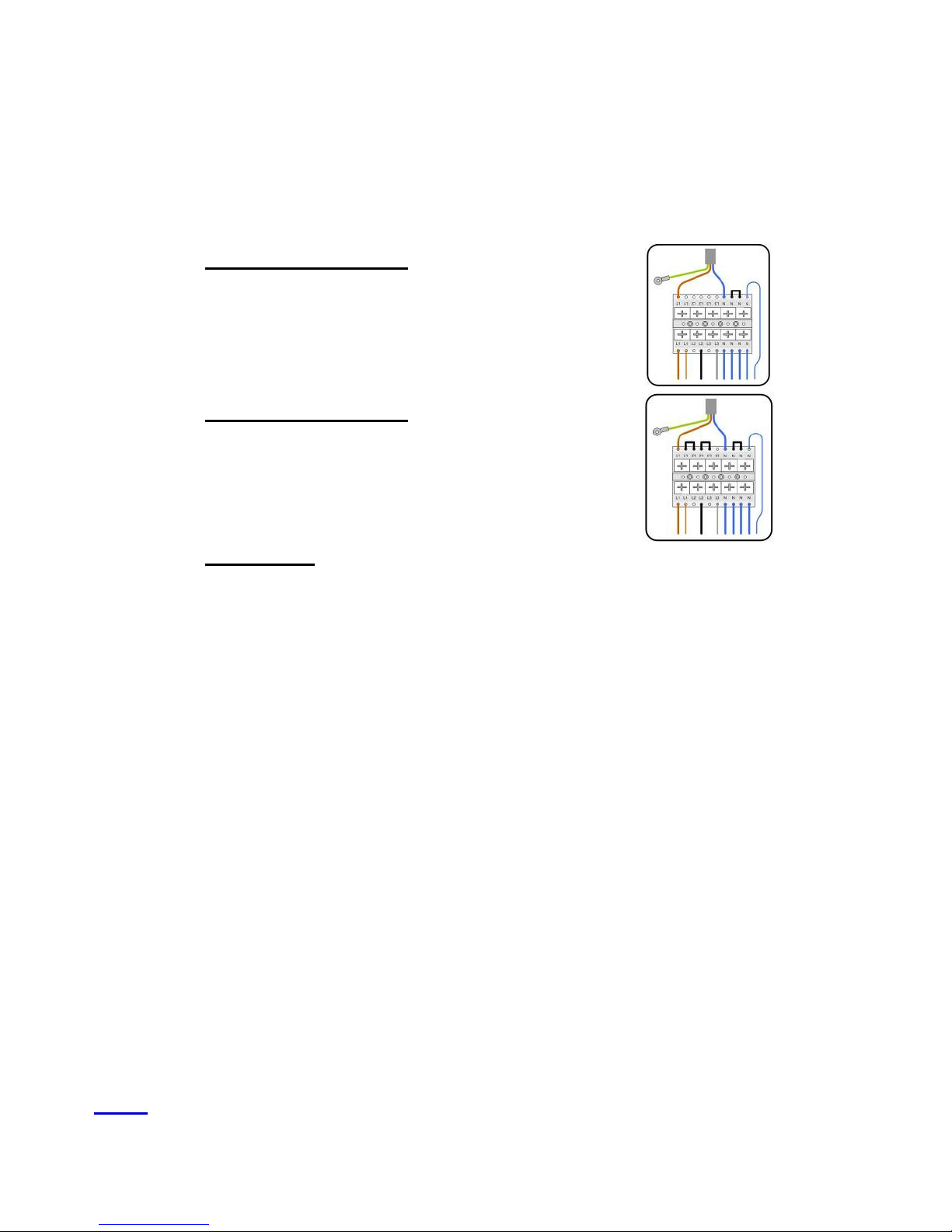

3.3.1 Electrical rating :

Within the ‘Classeq’ range several of the 500mm² basket appliances can

be either down rated or up rated electrically, such a procedure MUST be

carried out by a ‘Classeq’ approved technician.

The down / up rating of the machine is carried out by configuring the

terminal block within the appliance to the following

13 Amp – Single phase

• Links removed between L1, L2 and L3

• Ensure link remains between neutrals (N)

30 Amp – Single phase

• Ensure all link remains between lives

terminals (L1, L2 and L3)

• Ensure link remains between neutrals (N)

Three phase

Only Eco3 and H750 appliances can be converted to three phase, this is performed

by removing electrical links at the terminal between L1 L2 & L3, then installing a new

5 core supply cable, i.e. L1, L2, L3, N and Earth (PE).

FOR ADVISE on water softeners and appropriate chemicals, please contact :

Sales

℡

0844 2245 249

sales@classeq.co.uk

Loading...

Loading...