D400DUO D400DUOWS D500DUO D500DUOWS

G400DUO G400DUOWS G500DUO G500DUOWS

Undercounter

Warewasher

User Manual

CAUTION: Read these instructions before operating the warewasher

Classeq Under Counter Range - User Manual

2

Dear Customer,

Thank you for choosing Classeq, the warewasher you have selected has been designed to

give you lasting service.

Please read these instructions before installing, commissioning and operating this

warewasher.

Make sure all users understand the controls prior to using your warewasher.

Please keep these instructions in a safe place for future reference.

If you have any questions, or are not sure about any information contained in this manual

please contact either your distributor or Classeq. Contact details can be found in the ‘Useful

contact details’ section of this manual (►14).

Please record the Model number and Serial number of your warewasher. You will need these

if you need to contact Classeq for support or to make a claim under the warranty. You will

find these on the warewasher rating plate which can be found low down on one side of your

warewasher.

Model number:

Serial number:

Classeq Under Counter Range - User Manual

3

TABLE OF CONTENTS

1. SAFETY ................................................................................................ 5

1.1 Symbols Used in this Manual ................................................................ 5

1.2 Danger Warnings ................................................................................... 6

1.3 Warnings ............................................................................................... 6

1.4 Cautions ................................................................................................ 7

2. KNOW YOUR WAREWASHER ........................................................... 9

2.1 Warewasher Layout............................................................................... 9

2.2 Intended Use ....................................................................................... 11

2.3 Designation of the Warewasher .......................................................... 12

2.4 Warewasher Controls .......................................................................... 13

3. UNPACKING THE WAREWASHER.................................................. 15

3.1 Accessories Supplied .......................................................................... 15

4. INSTALLATION ................................................................................. 17

4.1 Recommended Hand Tools ................................................................. 17

4.2 Warewasher Placement ...................................................................... 17

4.3 Site Requirements ............................................................................... 19

4.4 Electrical Connection ........................................................................... 23

4.5 Water Supply and Connection ............................................................. 25

4.6 Waste Water and Connection ............................................................. 30

4.7 Attaching Chemical Bottles ................................................................. 34

5. COMMISSIONING .............................................................................. 36

5.1 Commissioning Interface ..................................................................... 36

5.2 Commissioning Mode .......................................................................... 37

5.3 Setting the Chemical Dosage Rate ..................................................... 38

5.4 Priming the Chemical Pumps .............................................................. 39

5.5 Integral Water Softener (if fitted) ......................................................... 41

5.6 Wash and Rinse Tank Temperatures.................................................. 44

6. OPERATION ...................................................................................... 45

6.1 Operation Interface .............................................................................. 45

6.2 Turning on the Warewasher ................................................................ 46

6.3 Warewasher Ready to Operate ........................................................... 46

6.4 Changing Temperature Units .............................................................. 47

Classeq Under Counter Range - User Manual

4

6.5 Selecting a Wash Program .................................................................. 47

6.6 Loading a Dishwasher Basket ............................................................. 48

6.7 Loading a Glasswasher Basket ........................................................... 50

6.8 Starting a Cycle ................................................................................... 51

6.9 Draining Down the Warewasher .......................................................... 52

6.10 Warewasher Malfunction ..................................................................... 54

7. MAINTENANCE AND SERVICING ................................................... 55

7.1 Prior to Cleaning .................................................................................. 55

7.2 Daily Cleaning ..................................................................................... 56

7.3 Limescale Build Up .............................................................................. 58

7.4 Regular Maintenance .......................................................................... 59

7.5 Descaling ............................................................................................. 61

8. TROUBLESHOOTING ....................................................................... 62

9. DECOMMISSIONING ......................................................................... 69

9.1 Flush Out Chemical Dosing Systems .................................................. 69

9.2 Drain the Warewasher ......................................................................... 69

9.3 Disconnect the Warewasher ............................................................... 69

9.4 Drain the Rinse Tank / Boiler .............................................................. 70

10. WAREWASHER SPECIFICATIONS ................................................. 72

11. ORDERING ACCESSORIES AND SUPPLIES ................................. 75

12. PARTS AND LABOUR WARRANTY ................................................ 76

13. NOTES ............................................................................................... 77

14. USEFUL CONTACT DETAILS .......................................................... 80

Classeq Under Counter Range - User Manual

5

1. Safety

1.1 Symbols Used in this Manual

The following symbols are used in this Manual:

DANGER!

Warning against potential serious or fatal injuries to persons if the

described precautionary measures are not taken.

Warning!

Warning against potential minor injuries to persons or potential

material damage if the described precautionary measures are not

taken.

Caution

Warning against defects in or destruction of the product if the

described precautionary measures are not taken.

Recycling instructions.

►

This symbol refers to a chapter with more detailed information

For safety reasons the warewasher MUST be bonded to adjacent

metalwork or earthed so that it is at the same potential (i.e. voltage).

For safety reasons, two persons are required for the task.

Classeq Under Counter Range - User Manual

6

1.2 Danger Warnings

For safety reasons your warewasher MUST be bonded to adjacent metalwork or

earthed so that it is the same potential (i.e. voltage).

A means for disconnection that has all poles separation of more than 3mm must

be incorporated in the fixed wiring in accordance with wiring rules (►4.3).

If a mains supply cable is damaged, it must be replaced by a cable supplied by

Classeq, its service agents or similar qualified persons, in order to avoid hazards.

All mains electrical work must be carried out in accordance with local and

national regulations, and by a qualified electrician (►4.4.1).

The warewasher MUST be disconnected from its power source during cleaning,

servicing or when replacing parts (►7).

Ensure the base of the warewasher is never submerged or standing in water

when operating the warewasher (►7).

1.3 Warnings

The warewasher should only be operated at or within the voltage specified on

the rating plate (►2.3).

If Classeq warewashers are used outside the designation for the appliance, you

invalidate your warranty and make the appliance unsafe.

Maximum inlet water pressure is 400 kPA and minimum inlet water pressure is

200 kPA.

For water inlet pressures >400 kPA – a pressure reducing valve is required.

Use only the hose supplied with your warewasher to connect it to the water

supply. Old existing, defective or damaged water supply hoses MUST NOT be

used (►4.5.3).

The installer and user are responsible for ensuring the installation and operation

of this warewasher are in accordance with this Manual and local and national

regulations (►4).

DO NOT use electrical extension lead(s) to supply power to your warewasher

(►4.4.1).

Classeq Under Counter Range - User Manual

7

Children should be supervised to ensure that they do not play with, or operate

the warewasher (►6).

Be aware that wares may be hot when removed from the warewasher (►6.8).

Before cleaning the Wash Chamber, ensure all sharp items, such as broken glass

or other items which could cause injury, are removed carefully.

DO NOT use cleaning agents that contain CHLORINE, BLEACH or

HYPOCHLORITE.

Wear the correct Personal Protective Equipment, e.g., gloves and goggles, when

handling chemicals and observe all safety notes and dosing recommendations

printed on the packaging. (►4.7) (►7.5) (►9.1).

If the warewasher is being drained immediately after use, water draining from

the ‘Boiler drainage hose’ may be hotter than 95°C (►9.4).

1.4 Cautions

Damage to the warewasher caused by limescale or poor water quality will NOT

be covered by the Manufacturer’s Warranty (►7.3).

In hard water areas (>3°dH), DO NOT run the warewasher without the use of

either an internal or external water softener as this could result in damage to

the warewasher. Failure to observe this warning will invalidate the warranty.

Warewashers with WS in the model type are fitted with an internal water

softener.

DO NOT run the warewasher without salt in the Salt Reservoir as this will allow

limescale to build up. Limescale deposits in the warewasher will invalidate the

warranty (►5.5) (►7.4.1).

Only use granulated salt (max. grain size 5 – 7 mm). Salt tablets are not suitable

(►5.5) (►7.4.1).

DO NOT add any chemicals, such as detergent or rinse aid to the Salt Reservoir.

These will cause damage to the warewasher (►5.5) (►7.4.1).

Only use commercial grade detergents and rinse aids in your warewasher

(►4.7).

If the Salt Reservoir Cap is not properly secured, water and/or chemicals can

leak in or out of the unit causing damage to the warewasher (►5.5) (►7.4.1).

Classeq Under Counter Range - User Manual

8

Always remove excess food / debris from any dishes / glasses to be washed. DO

NOT use your warewasher as a waste disposal unit (►6.8).

It is very important that the warewasher is drained down at the end of each

working day (►6.9).

DO NOT use STEEL WOOL, WIRE BRUSHES or any other abrasive materials.

De-scale chemical must not remain in the warewasher for more than 2 hours

(►7.5).

Items placed on the open door of the warewasher must not exceed 20kg (►7).

DO NOT spray the exterior or interior of the warewasher and the surrounding

area (panels, base) using a water jet, steam cleaner or high pressure cleaner.

The function of this warewasher is the washing of dishes, plates, glassware,

cutlery and similar articles only. No other activity is permitted with this

warewasher.

Authorised spare parts only must be used in the event of a breakdown.

Classeq Under Counter Range - User Manual

9

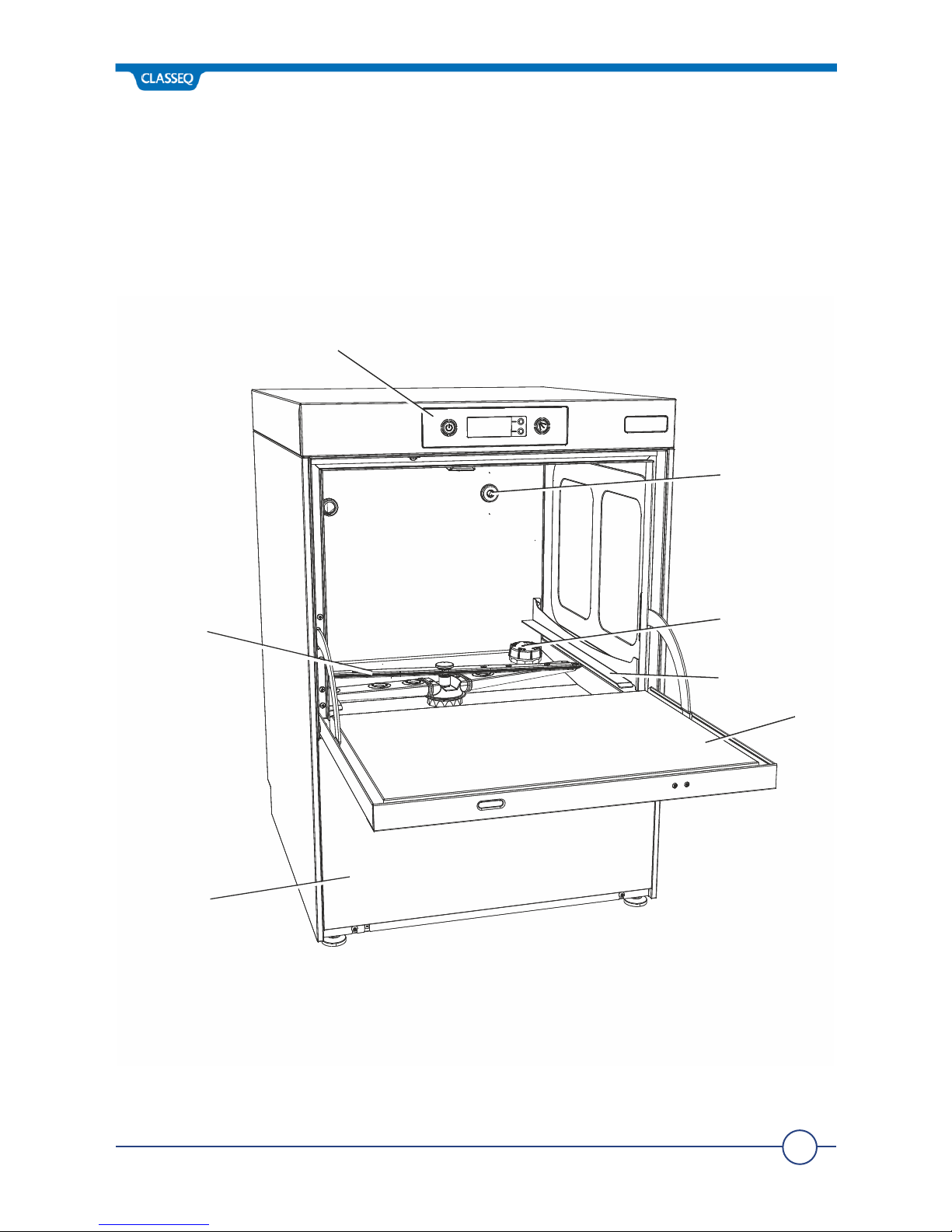

2. Know Your Warewasher

Before installing your warewasher you should familiarise yourself with the various

components shown below.

2.1 Warewasher Layout

3

6

8

7

1

5

12

Classeq Under Counter Range - User Manual

10

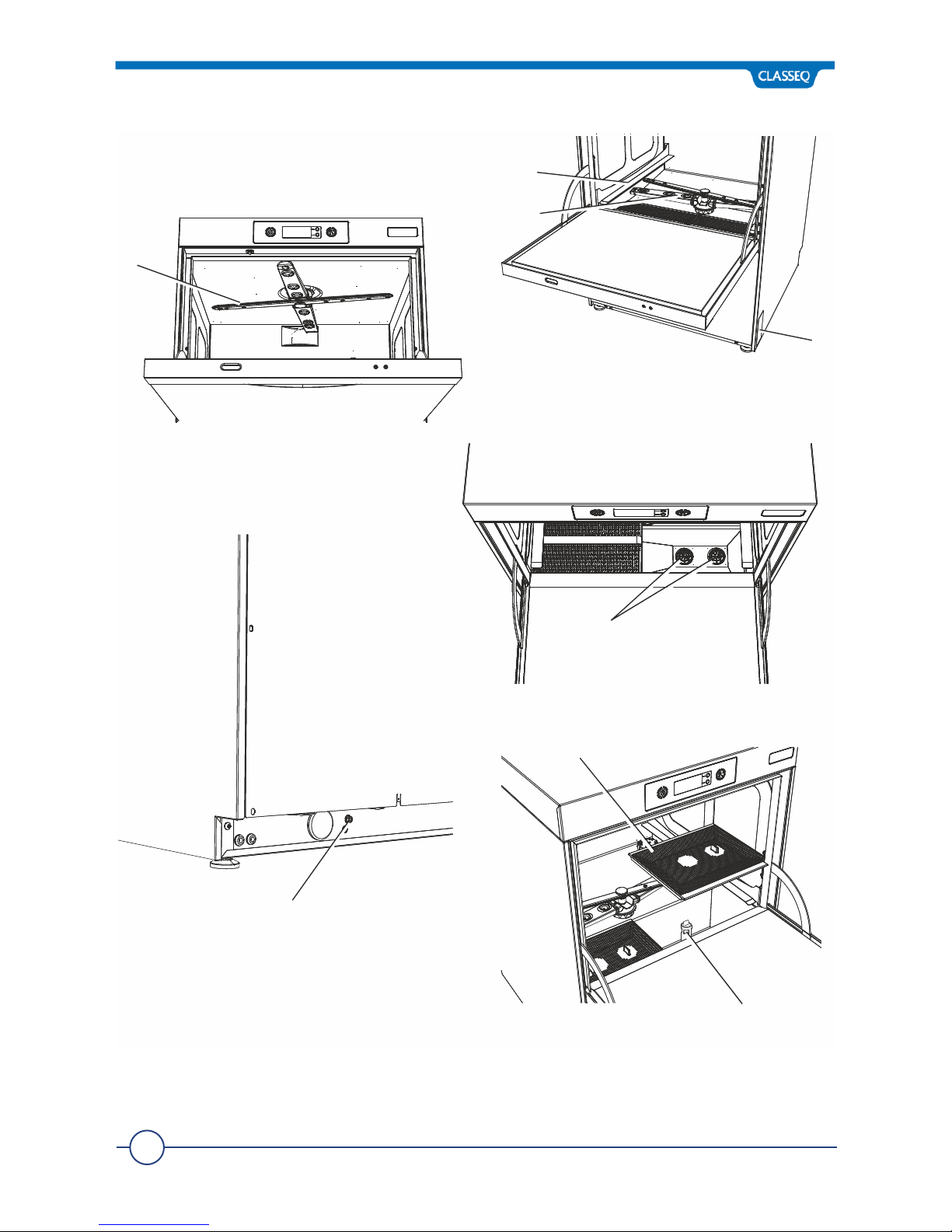

3

4

7

2

11

9

13

10

Classeq Under Counter Range - User Manual

11

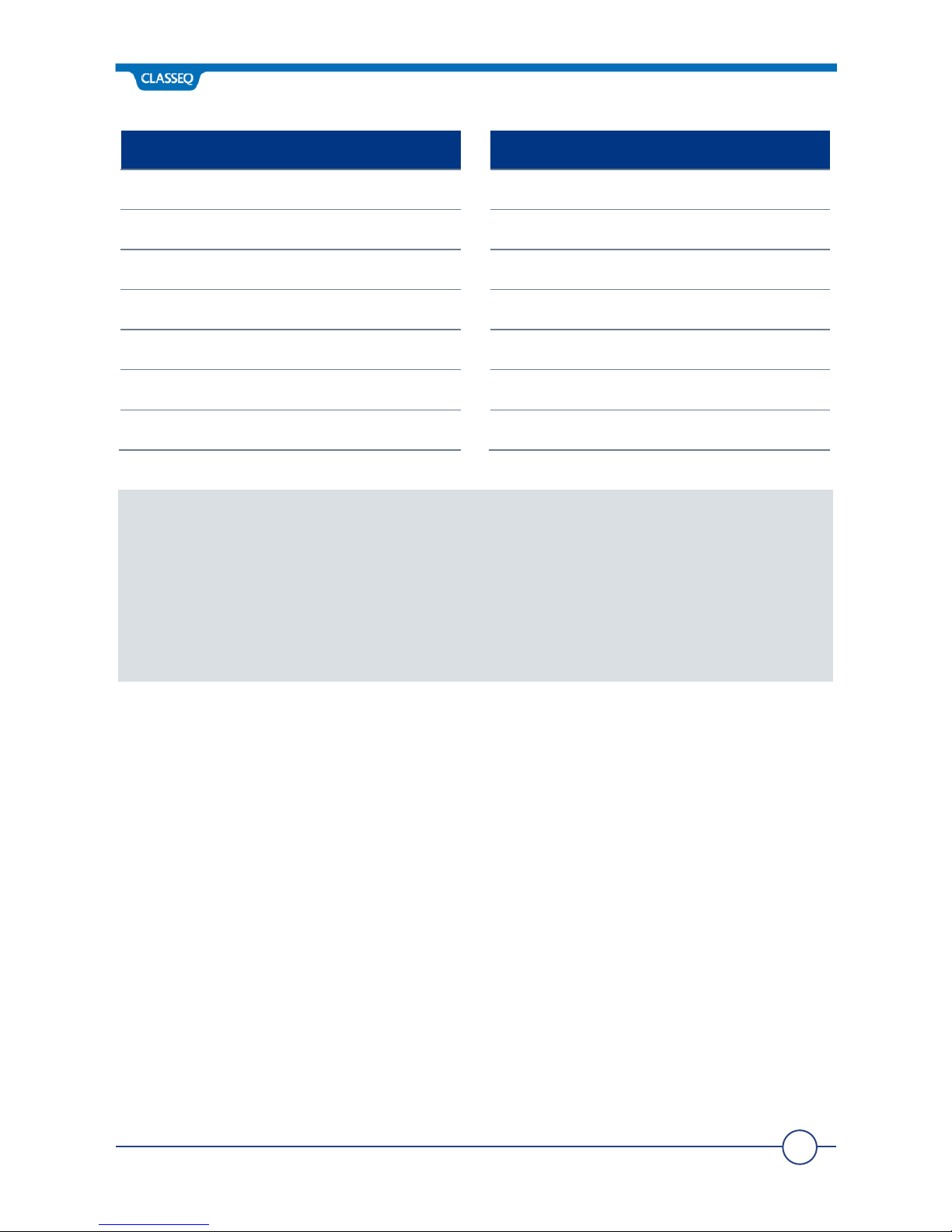

Item

Description

Item

Description

1

Door (Note 1)

8 Salt Reservoir Cap (Note 3)

2

Primary Filters

9 Rating Plate

3

Bottom Wash and Rinse Arms

10

Secondary Filters

4

Top Wash and Rinse Arms

11

Drain Plug (Note 4)

5

Control Panel

12

Removable Lower Front Panel

6

Anti-syphon device (Note 2)

13

Earth bonding stud

7

Basket Ramp

Notes:

1. The Door of the warewasher should never be used as a step or seat.

2. Fitted to pumped drain warewashers only.

3. Fitted to warewashers with a Water Softener only.

4. Fitted to gravity drain warewashers only.

2.2 Intended Use

2.2.1 Glasswasher

The intended use is the washing of glasses.

2.2.2 Dishwasher

The intended use is the washing of kitchen and tablewares.

Classeq Under Counter Range - User Manual

12

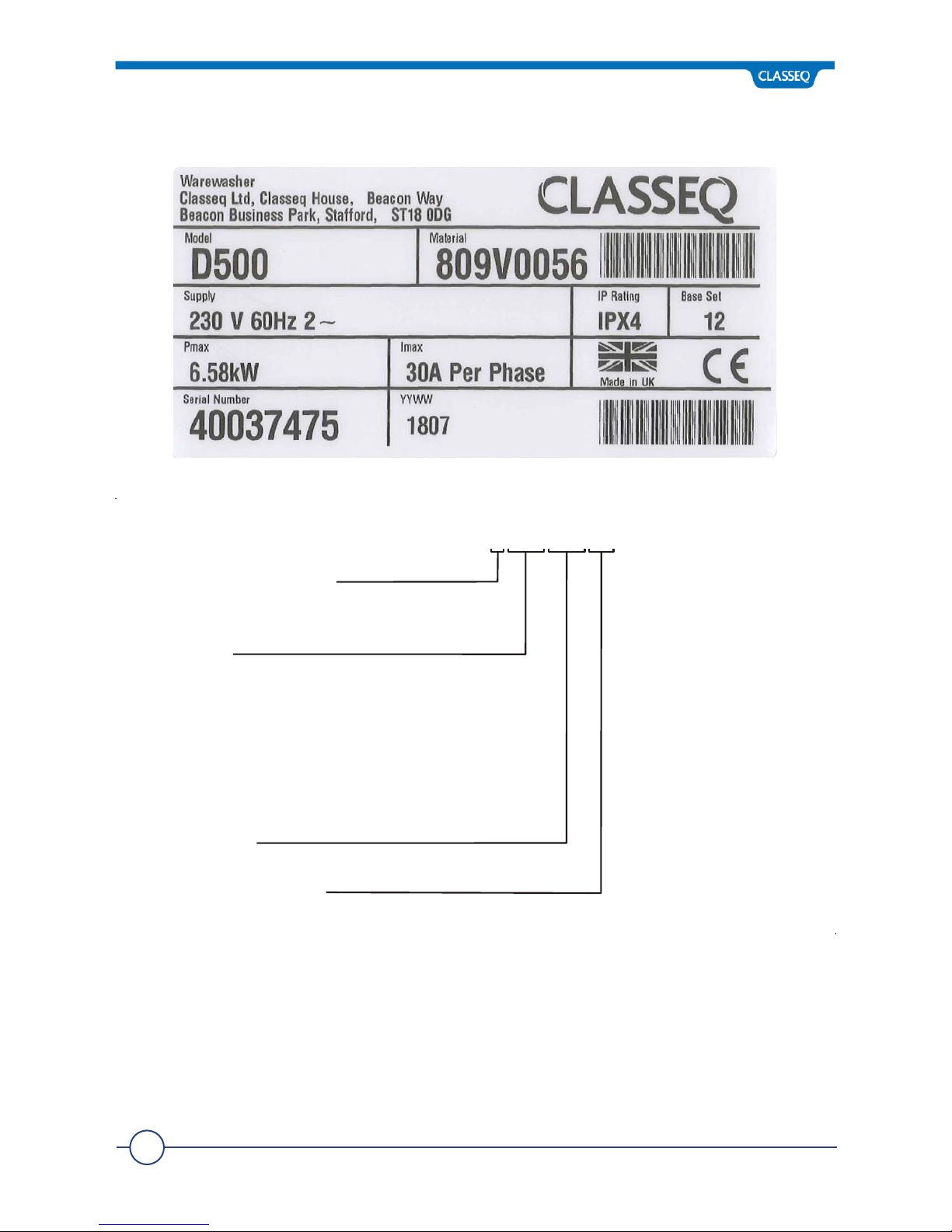

2.3 Designation of the Warewasher

X XXX XXX XX - PREMIUM MACHINES

X XXX - STANDARD MACHINES

Basic machine function:

G = glasswasher

D = dishwasher

Range definer:

DUO = Premium

Water softener option:

WS = water softener option installed

Basket size:

STANDARD MACHINES

G350 = 350mm

G400 / D400 = 400mm

G500 / D500 = 500mm

PREMIUM MACHINES

= 400mm

= 500mm

G400 / D400

G500 / D500

Classeq Under Counter Range - User Manual

13

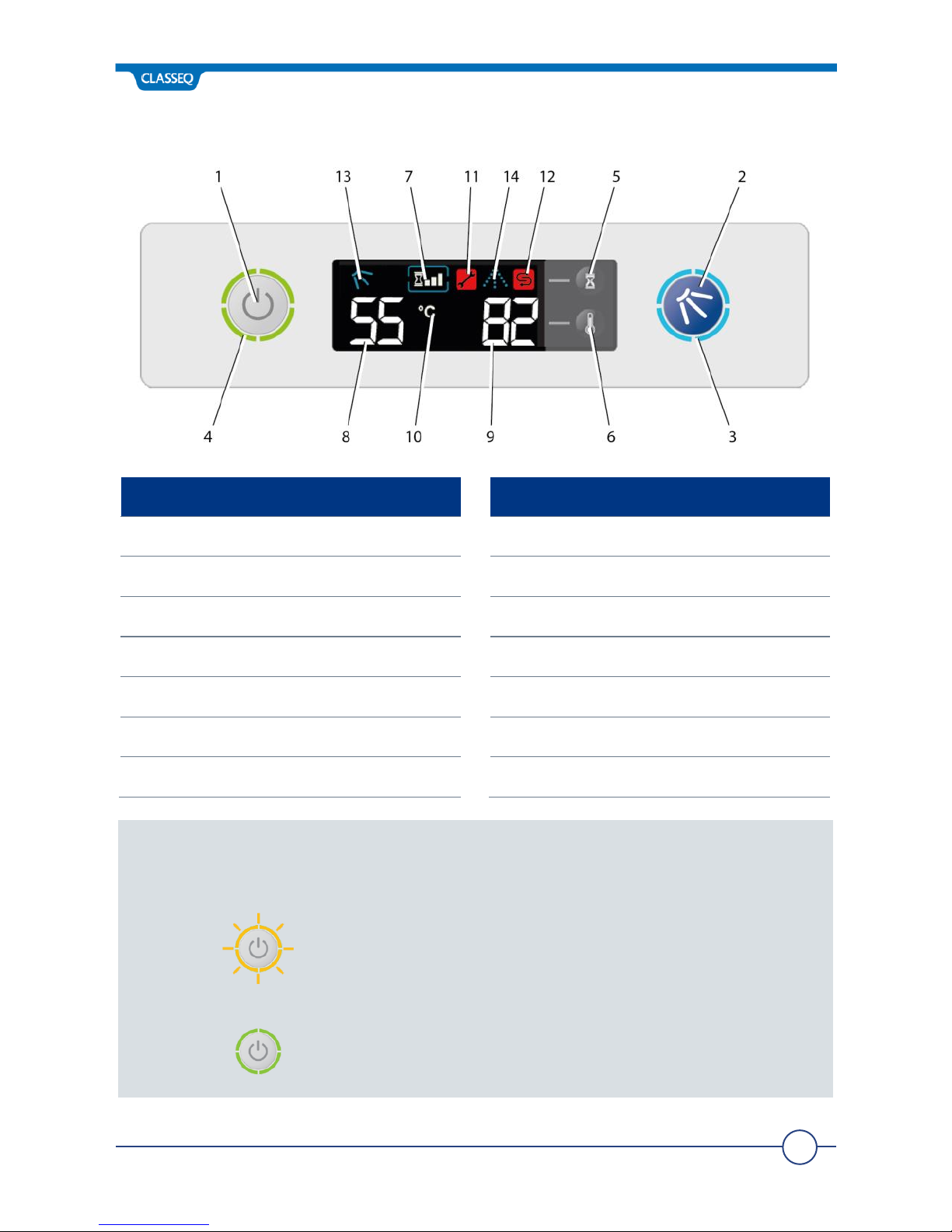

2.4 Warewasher Controls

Item

Description

Item

Description

1

On/Off button

8 Wash temperature display

2

Cycle button

9 Rinse temperature display

3

Cycle indicator (Note 2)

10

Temperature unit display

4

Heating indicator (Note 1)

11

Error indicator

5

Program Select button

12

Refill Salt indicator (Note 3)

6

Temperature Units button

13

Wash indicator

7

Program indicator

14

Rinse indicator

Notes:

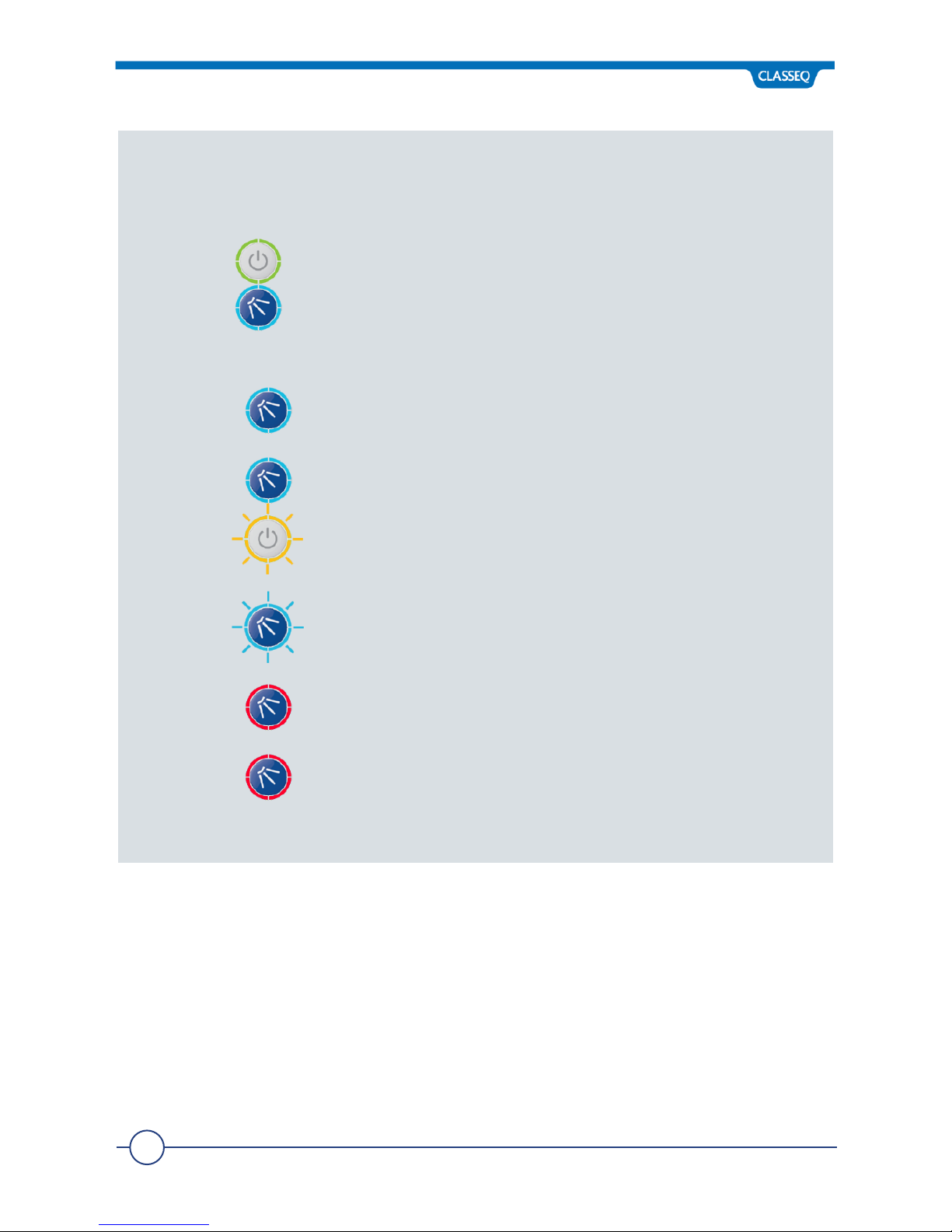

1. Heating indicator:

FLASHING AMBER - warewasher not ready (Wash Tank not full /

Rinse Tank not full / Wash Tank still heating / Rinse Tank still

heating).

GREEN - warewasher is ready / in standby (Wash Tank full /

Rinse Tank full / Wash Tank at operating temperature / Rinse

Classeq Under Counter Range - User Manual

14

Tank at operating temperature).

Note that Tank full interlocks always apply. Operating

temperature interlocks can be altered as required (►5.6).

GREEN plus Cycle indicator BLUE - warewasher will start the

selected wash cycle.

2. Cycle indicator:

BLUE - warewasher is in a wash cycle.

BLUE plus Heating indicator FLASHING AMBER - a wash cycle

has been selected but not started.

FLASHING BLUE - warewasher is draining down (pumped

drain warewashers only).

RED - indicates that warewasher is in Commissioning Mode.

RED plus warewasher turned off - a serious error condition

has occurred.

3. Fitted to warewashers with a Water Softener only.

Classeq Under Counter Range - User Manual

15

3. Unpacking the Warewasher

After unpacking your warewasher, check it for any transport damage. Never install and use a

damaged warewasher. If your warewasher is damaged contact your retailer immediately.

Make sure the water and electricity connections of your warewasher comply with the

specifications given in this Manual.

Remove all outer packaging and the protective film from your warewasher before positioning

it.

Remove any accessories shipped inside the warewasher and unpack them carefully.

Ensure all packaging materials are disposed of in accordance with local and national

regulations.

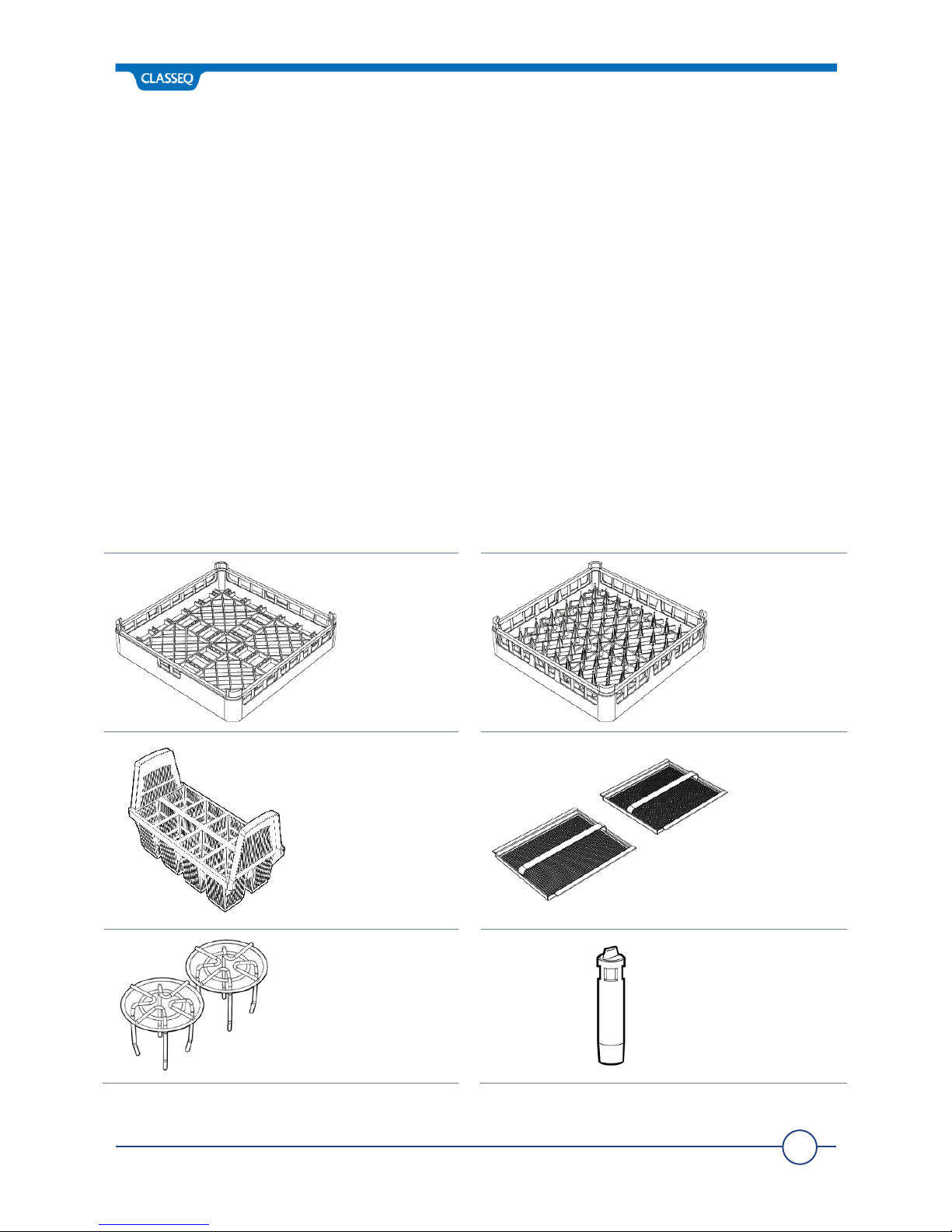

3.1 Accessories Supplied

The warewasher is supplied with the following accessories (Note 1):

Open

Basket

x2

Glasswasher

x1

Dishwasher

Plate

Basket

x1

Dishwasher

only

Cutlery

Basket

x1

Dishwasher

only

Primary

Filters

x1 Left hand

filter

x1 Right

hand filter

(Note 2)

Secondary

Filters

x2 (Note 3)

Drain Plug

x1 (Note 4)

Classeq Under Counter Range - User Manual

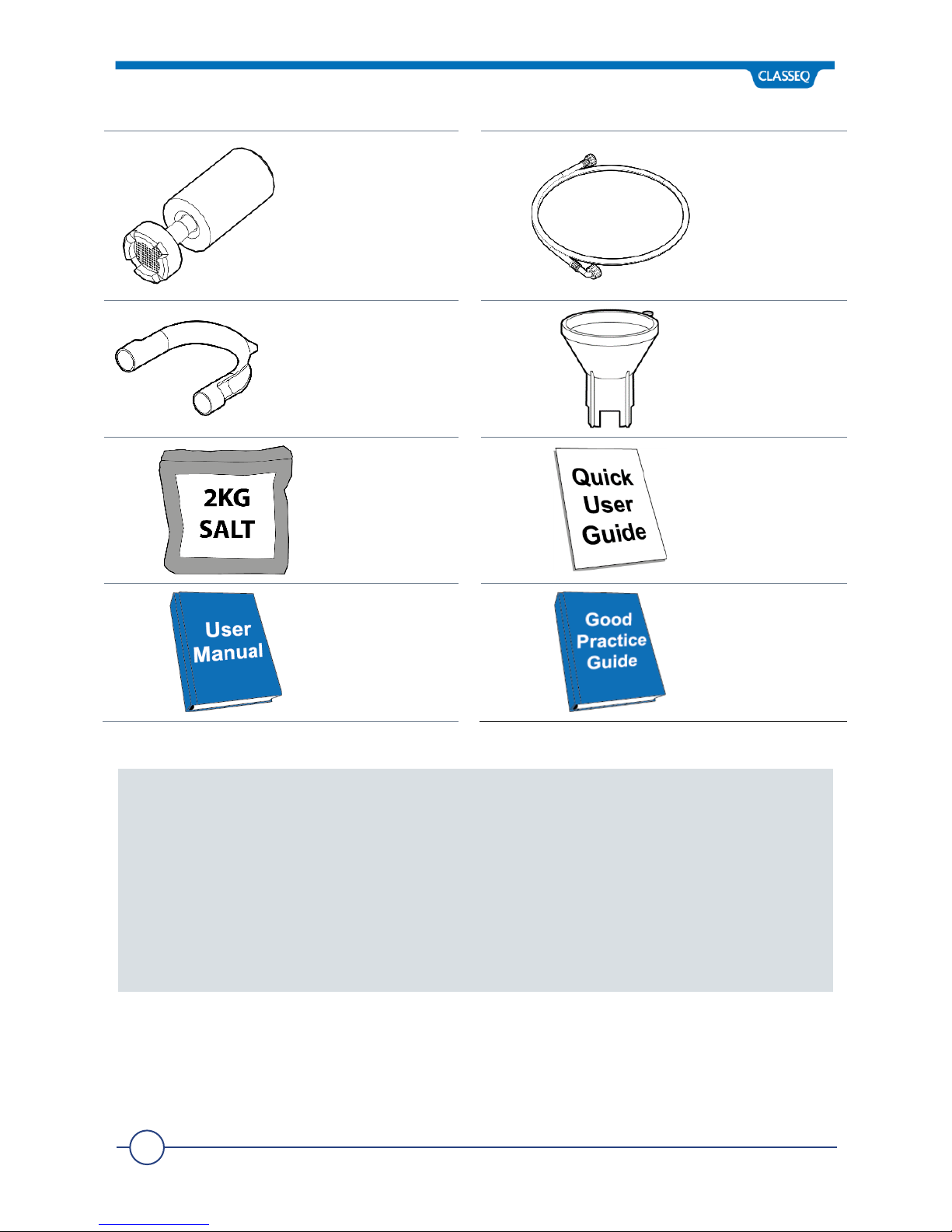

16

Bottle

Weights

x2

Water Inlet

Hose

x1

Waste

Hose Hook

x1

Water

Softener

Funnel

x1 (Note 5)

2kg Bag of

Salt

x1 (Note 5)

Quick User

Guide

x1

User

Manual

Good

Practice

Guide

Notes:

1. Images are for reference only, actual parts supplied may differ.

2. Differs depending on drain type.

3. On gravity drain warewashers x1.

4. On gravity drain warewashers only.

5. Fitted to warewashers with a Water Softener only.

Classeq Under Counter Range - User Manual

17

4. Installation

Warning!

The installer and user are responsible for ensuring the installation and

operation of this warewasher are in accordance with this manual and

with local and national regulations.

4.1 Recommended Hand Tools

The following hand tools are required when installing the warewasher:

Spirit level

8mm spanner

Multimeter or voltmeter

Insulated No. 2 Posi screw driver

Drill with 8mm bit

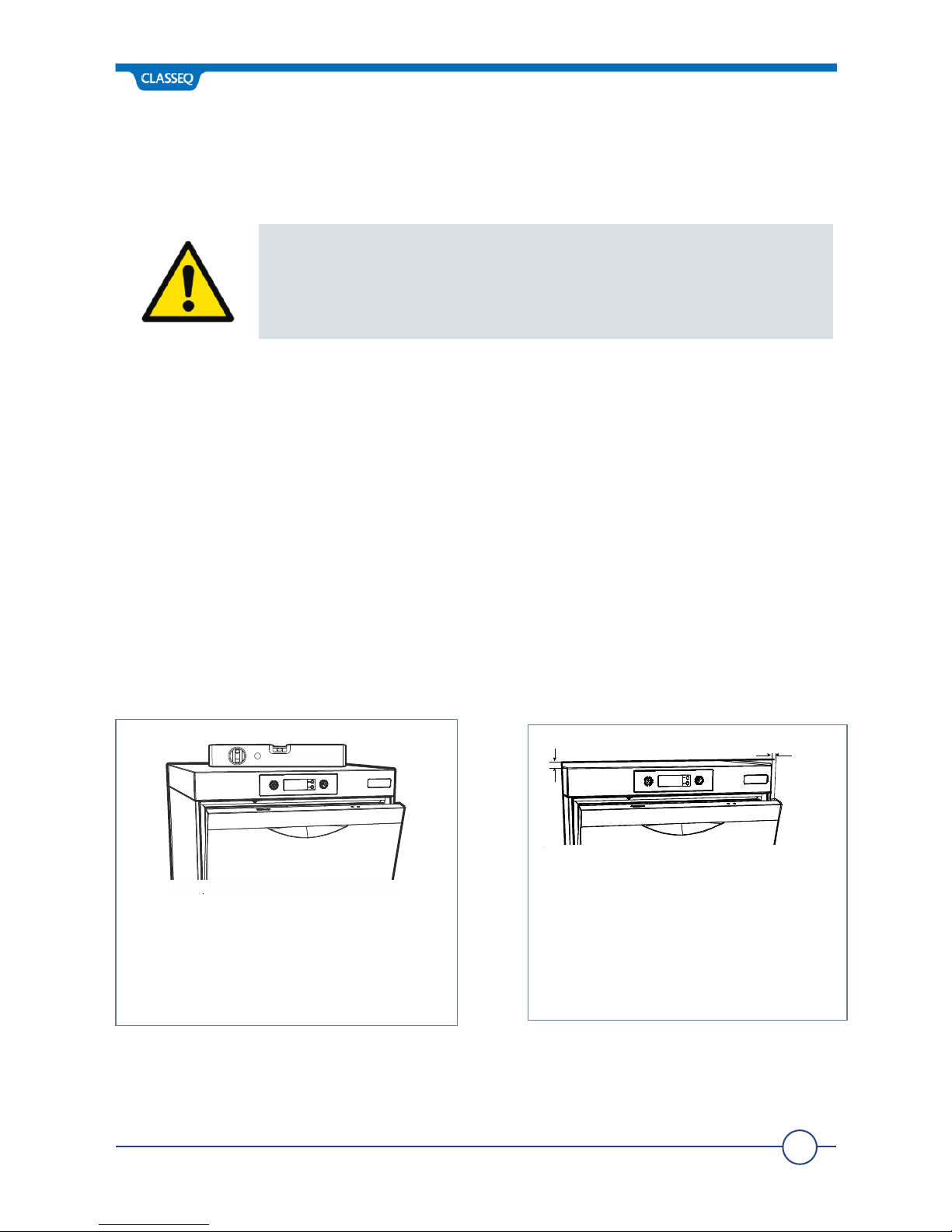

4.2 Warewasher Placement

Your warewasher should be installed on

a flat, stable surface that is capable of

holding the full weight of the filled

warewasher and withstanding the

vibration of regular use.

Ensure there is a minimum of 10mm

clearance on each side of your

warewasher and 20 mm clearance at

the top and rear of the warewasher

(►4.3).

20mm

10mm

Classeq Under Counter Range - User Manual

18

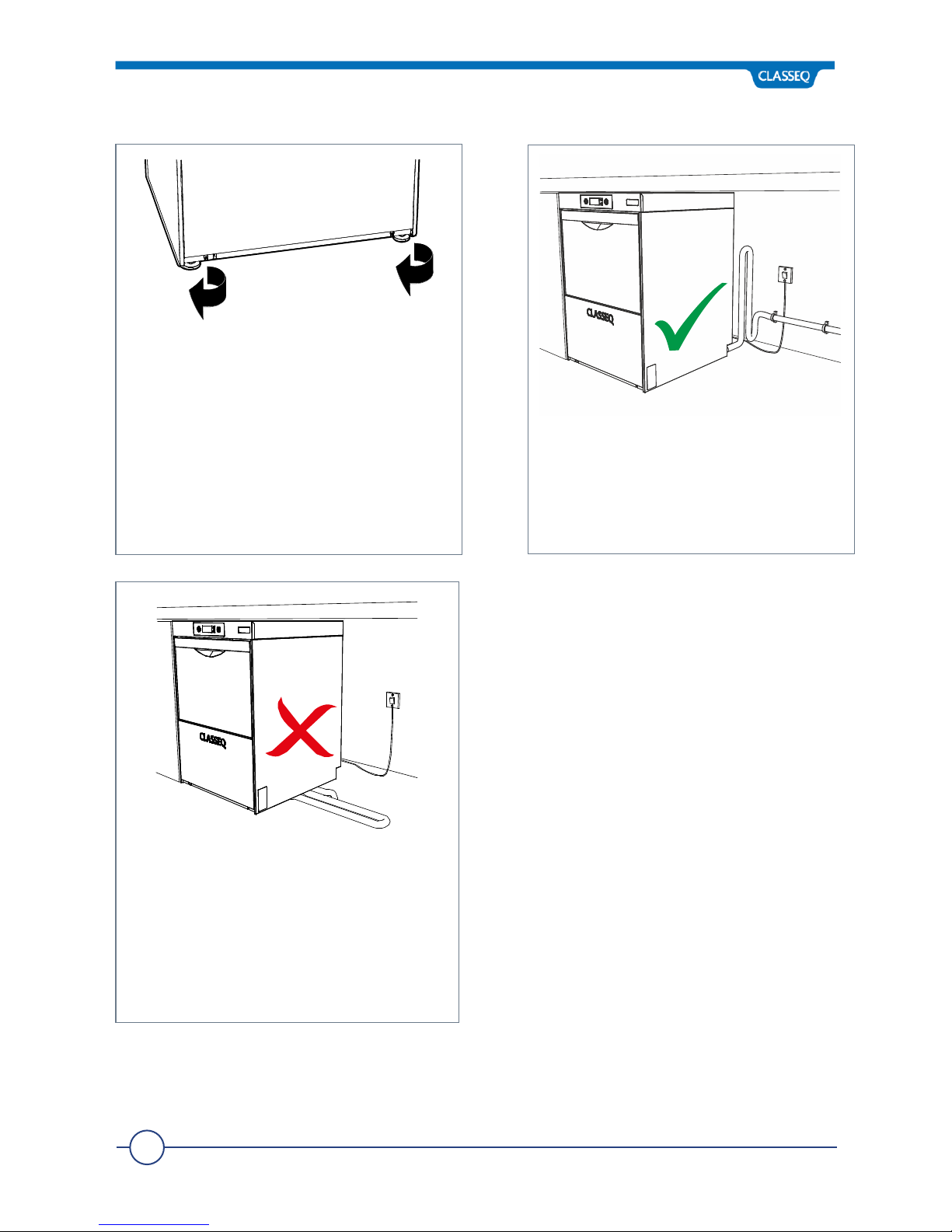

Once your warewasher is in its final

position, adjust the adjustable feet to

ensure the warewasher is stable, its

weight is being distributed equally, and it

does not tilt more than 2 degrees in any

direction.

Your warewasher should be placed in a

location that allows the electrical,

supply water and waste water

connections to be fitted (►4.3).

When positioning your warewasher,

ensure that the water inlet, chemical

tubes and drain hoses are not kinked or

squashed. Care must also be taken to

ensure the warewasher does not rest on

any of its supply hoses / leads.

Classeq Under Counter Range - User Manual

19

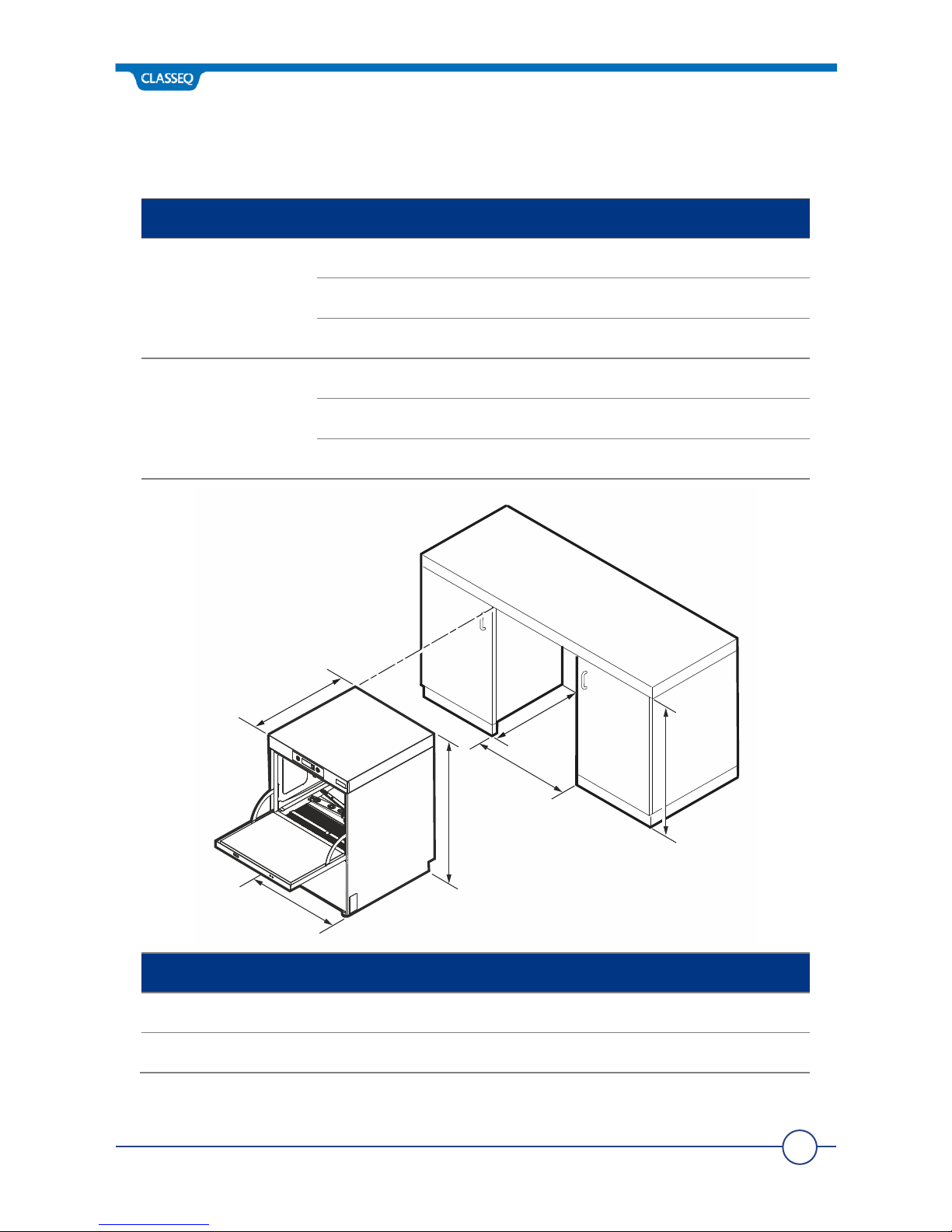

4.3 Site Requirements

Overall Warewasher and Clearance Dimensions

Dimensions (mm)

D400 / G400

D500 / G500

Warewasher

A = width

470

570

B = depth

517

605

C = height (min)

760

830

Recess

D = width

490

590

E = depth

557

645

F = height

790

860

Weights (kg)

D400 / G400

D500 / G500

Empty

40.3

54.7

Fully Loaded

46.8

75.2

B

F

E

D

A

C

Classeq Under Counter Range - User Manual

20

Electrical Supply

Electrical connections MUST be carried out in accordance with local regulations. As a

minimum Classeq recommends the following are maintained:

All warewashers are connected via a residual current device (RCD) or earth leakage

protection device.

A means for disconnection that has all poles separation of more than 3 mm must

be incorporated in the fixed wiring in accordance with wiring rules.

Connect to an equipotential conductor, connection stud located at rear of the

warewasher, this is in addition to the earthed electrical supply.

Prior to connecting the warewasher, ensure voltage and supply fuse comply with

rating plate.

Electrics

D400 / G400

D500 / G500

Supply 1

220-240V (1-phase)

13A

2.85 kW

Supply 2

380-415V (3-phase)

13A

6.25 kW

6.58 kW

Supply 3

220-240V (1-phase)

30A

6.25 kW

6.58 kW

Supply 4

220-240V (1-phase)

12A

2.58 kW

Classeq Under Counter Range - User Manual

21

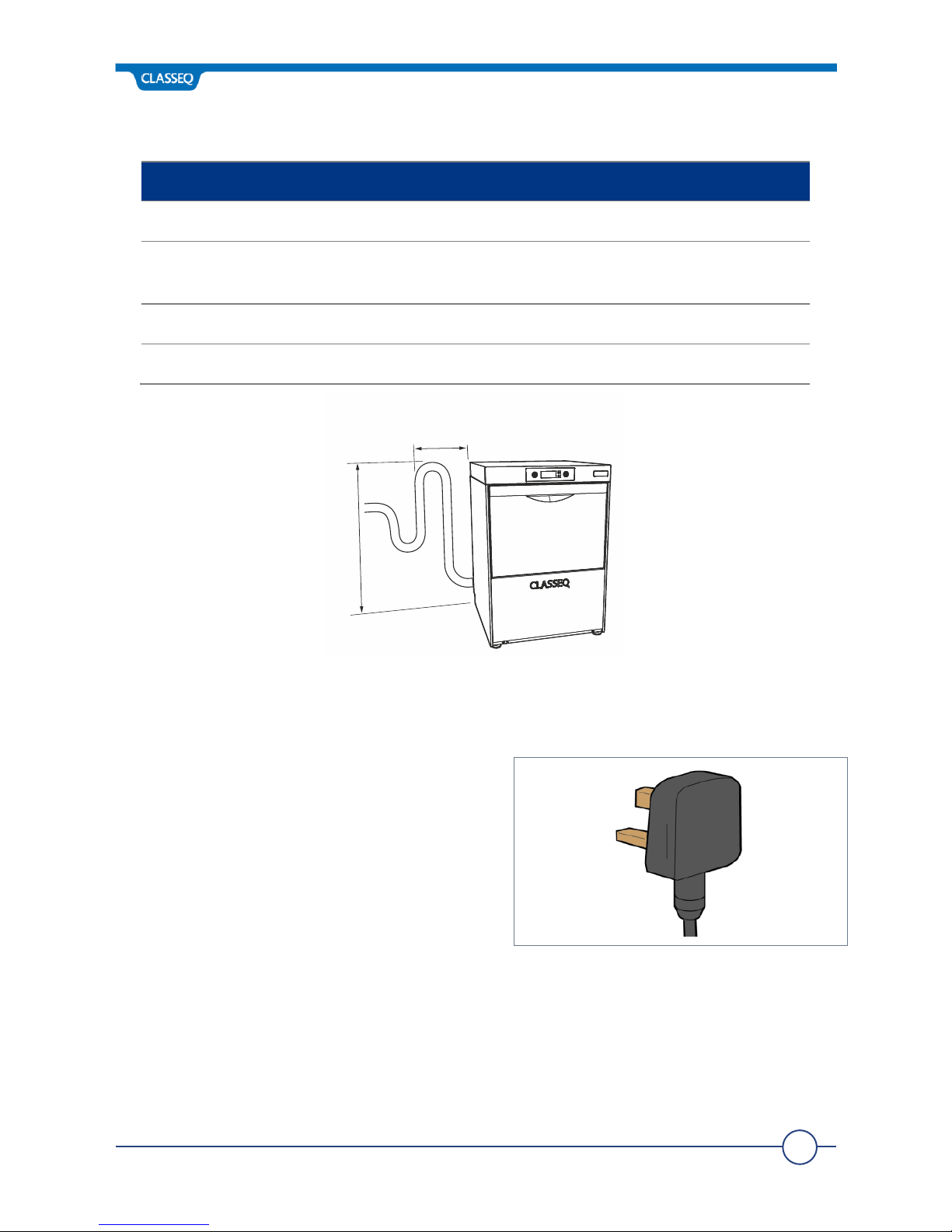

Supply Socket (mm)

D400 / G400

D500 / G500

Max position of

electrical supply

socket (mm)

W = width

950

700

H = height (max)

1500

1550

H

W

Classeq Under Counter Range - User Manual

22

Water Inlet

D400 / G400

D500 / G500

Temperature range

4 - 55°C

Pressure

0 - 2 bar

Booster pump required

2 - 4 bar

No modification

4 bar +

Pressure reducing valve required

Flowrate

without softener

11 l/min

with softener

4 l/min

Water connection

G¾” (¾” BSP)

Maximum

position of water

supply (mm)

W = width

650

600

H = height

700

650

H

W

Classeq Under Counter Range - User Manual

23

Waste Outlet

Drainage Dimensions (mm)

D400 / G400

D500 / G500

Drain standpipe diameter

35

W = maximum distance from

warewasher

750

400

H = Drain pipe height (gravity drain)

0 - 40

Drain pipe height (drain pump)

0 - 390

0 - 600

4.4 Electrical Connection

4.4.1 Mains cable connection

Prior to connecting the warewasher, ensure that

the available electrical outlet voltage and the

supply fuse comply with the rating of the

warewasher. For the electrical rating of your

warewasher refer to the rating plate.

Contact your distributor, a qualified electrician,

or Classeq if you are unsure how to check this.

The electrical supply must incorporate a

disconnection device (circuit breaker / fuse) that complies with local and national regulations.

Your warewasher must be connected directly to the mains electricity using the mains

electrical cable provided. DO NOT use electrical extension lead(s) to supply power to your

warewasher.

H

W

Classeq Under Counter Range - User Manual

24

DANGER!

All mains electrical work must be carried out in accordance with local

and national regulations by a qualified electrician.

4.4.2 Electrical connection specification

Depending on the specification of your warewasher it may be supplied with or without a

moulded mains electrical plug.

When hard wiring the warewasher into the mains outlet, use a multimeter or voltmeter to

ensure that the connection point is electrically isolated before attempting to make the

connections.

4.4.3 Electrical cable specification

If the mains electrical supply cable is damaged or has deteriorated, it MUST be replaced by a

cable or cord assembly supplied by Classeq, its service agents or suitably qualified persons in

order to avoid hazards, and be to the following minimum specifications.

Warewasher rating

(Volts / Phase / Amps)

Cable size

Temperature

rating

Length

of cable

Conforms to

220-240V / 1N~/30A

3G 4.0

60°C min.

3m

H07RN-f

380-415V / 3N~/12A

5G 2.5

380-415V / 3N~/16A

5G 2.5

380-415V / 3N~/22A

5G 4.0

For electrical rating of your warewasher refer to the rating label (►2.3).

4.4.4 Equipotential bonding

DANGER!

For safety reasons your warewasher MUST be bonded to adjacent

metalwork or earthed so that it is at the same potential (i.e. voltage).

Consult your distributor, Classeq or a qualified electrician if you are unsure how to do this.

Classeq Under Counter Range - User Manual

25

The equipotential bonding stud is located at the

rear of the warewasher and is fitted with an M5

nut. Use the 8mm spanner to connect the

bonding wire terminal to this location and

ensure the nut is securely fastened.

4.5 Water Supply and Connection

4.5.1 Water supply restrictions

Commercial warewasher wash results may be affected by external conditions such as

incoming water temperature, pressure, hardness and choice of chemicals.

Supply water temperature:

4°C minimum

55°C maximum

Supply water dynamic pressure:

The dynamic pressure of the water supply will determine whether your warewasher needs

additional equipment to be installed in the water supply system, as follows:

Measured water pressure

Consequence

0 to 2 bar (0 to 200 kPa)

An external rinse booster pump must be

installed to increase the pressure of the water

supply to the warewasher.

2 to 4 bar (200 to 400 kPa)

No modifications required - warewasher can be

installed with a direct hose connection to the

existing water supply.

>4 bar (400 kPa)

A pressure reducing valve must be installed to

reduce the pressure of the water supply to the

warewasher - maximum allowable pressure is 4

bar.

Classeq Under Counter Range - User Manual

26

Minimum supply flow rate:

Without Water Softener: 11 litre/minute.

With Water Softener: 4 litre/minute.

Water hardness:

Caution

Damage to the warewasher d caused by limescale will NOT be covered

by the manufacturer’s warranty (►12).

For the longevity of your warewasher, and to ensure you get consistently good washing

results, your warewasher must wash with soft water, ie water that contains a low

concentration of ions, in particular ions of calcium and magnesium. There are three ways to

achieve this:

The supply water must be naturally soft.

Your warewasher is specified to be fitted with an internal Water Softener (models

D400DUOWS and D500DUOWS).

Your water supply to the warewasher is from a suitable external water softener unit.

4.5.2 Water hardness explained

Water hardness occurs because certain chemicals in the rocks through which the water

passes on its way to the consumer slowly leach out into the water.

The problem shows itself in two forms:

1. When hard water is heated the chemicals come out of solution and appear as solid

particles (limescale) that are carried round the warewasher. These particles are formed

most quickly at the hottest part of the warewasher – typically, the rinse element and the

Rinse Tank. This is why the Rinse Tank is the best place to look to judge if limescale is

being formed in a warewasher.

2. Most commercial washing chemicals operate much less efficiently in hard water, and

this will often show as poor results, failure to remove tannin stains or condensation on

glasses. Tannin stains appear to cling to the hard water film in the drink, which then

clings to the surface of the cup or saucer. With soft water this is not the case.

Some types of hard water do not produce limescale when heated, but still reduce the

performance of washing chemicals, as mentioned above. This is known as permanent

hardness. Temporary hardness is when the hardness can be largely removed by conversion

into limescale by boiling.

Classeq Under Counter Range - User Manual

27

If limescale is produced inside a warewasher it will cause a

number of maintenance problems, for example:

Coating of heating elements leading to slow heating

and eventually, element failure.

Blockage of rinse jets, showing as poor results.

Wear of bushes in the centre boss, showing as poor

results and possibly wash water passing backwards

into the rinse system.

Blockage of the rinse aid injection point in the boiler.

White marks appearing on glasses, dishes and cutlery.

Dishes or cups may appear dirty even after a wash.

Especially coffee or tea cups.

Discolouration of the inside of the warewasher,

making cleaning difficult.

Blockage of hoses due to limescale deposits “furring

up” the inside of the hoses.

When limescale is found, it must be removed with commercial de-scaling chemicals, used

with care in accordance with the instructions on the product.

The descaling instructions in this manual should always be followed.

The Rinse Tank is difficult to de-scale and a service engineer may be required to carry this

out.

Your local water board / water supply company should be able to tell you if the water in your

area is hard or soft.

Alternatively you can establish the hardness of your water supply yourself using a simple

water hardness testing kit.

Classeq Under Counter Range - User Manual

28

Water Softener settings:

Your Water Softener needs to be set up to soften the water supply depending on the water

hardness, according to the following table:

Water

Softener

Setting

Hardness

Water

Volume

(litres)

No. of

cycles

°dH

°e/°clark

°fh

ppm

h00

---- Water Softener deactivated ----

---------

---------

h01

1

1.3

1.8

18

48.1

16

h02

2

2.5

3.6

36

45.7

15

h03

3

3.8

5.4

54

43.4

14

h04

4

5.0

7.2

71

41.2

14

h05

5

6.3

9.0

89

39.0

13

h06

6

7.5

10.7

107

36.9

12

h07

7

8.8

12.5

125

34.9

12

h08

8

10.0

14.3

143

32.9

11

h09

9

11.3

16.1

161

31.0

10

h10

10

12.5

17.9

179

29.2

10

h11

11

13.8

19.7

196

27.4 9 h12

12

15.0

21.5

214

25.7

9

h13

13

16.3

23.3

232

24.1

8

h14

14

17.5

25.1

250

22.5

7

h15

15

18.8

26.9

268

21.0 7 h16

16

20.0

28.6

286

19.5

7

h17

17

21.3

30.4

303

18.2

6

h18

18

22.5

32.2

321

16.9

6

h19

19

23.8

34.0

339

15.9

5

Classeq Under Counter Range - User Manual

29

Water

Softener

Setting

Hardness

Water

Volume

(litres)

No. of

cycles

°dH

°e/°clark

°fh

ppm

h20

20

25.0

35.8

357

14.4

5

h21

21

26.3

37.6

375

13.3

4

h22

22

27.5

39.4

393

12.3

4

h23

23

28.8

41.2

411

11.3 4 h24

24

30.0

43.0

428

10.4

3

h25

25

31.3

44.8

446

9.6

3

h26

26

32.5

46.5

464

8.8

3

h27

27

33.8

48.3

482

8.1 3 h28

28

35.0

50.1

500

7.4

2

h29

29

36.3

51.9

518

6.8

2

h30

30

37.5

53.7

536

6.3

2

4.5.3 Water supply hose connection

Classeq recommend installing a shut off valve in the mains water supply line near the

warewasher such that it is easily accessible.

Your warewasher is supplied with a new UK Water Regulations Advisory Scheme (WRAS)

approved water inlet hose, requiring a G¾” (¾” BSP) male threaded connection at the mains

water outlet.

Warning!

Use only the hose supplied with your warewasher to connect it to the

water supply. Old existing, defective or damaged water supply hoses

MUST NOT be used.

Connect the 90 degree bend connector of the water supply hose to the inlet on the back of

your warewasher and the straight connector to the mains water supply.

Classeq Under Counter Range - User Manual

30

Ensure the rubber seals are in place in the connectors.

Hand tighten the connectors only.

Ensure all connections are watertight before using your warewasher.

4.6 Waste Water and Connection

4.6.1 Waste water system type

The waste system of your warewasher will vary depending on the variant. You can identify

the type of drain your warewasher has by checking whether there is a Drain Plug, as shown,

present in the Wash Sump.

Warewashers with a Drain Plug are gravity drain type and warewashers without a Drain Plug

are pumped drain type.

Classeq Under Counter Range - User Manual

31

4.6.2 Waste water connection

Gravity drain warewashers:

If your warewasher has a Drain Plug fitted in the Wash Sump the waste hose will fit into

Ø40mm plumbing or over a Ø20mm spigot.

The waste hose for this type of warewasher has to lead away below the base of the

warewasher.

Pumped drain warewashers:

The outlet end of the waste hose of a pumped drain type warewasher can be trimmed to fit a

variety of sizes of pipes / spigots.

The waste plumbing for this type of warewasher can be up to a maximum of the following

heights from the base of the warewasher:

Warewasher size

Max waste height (mm)

470mm (D400/G400)

540

570mm (D500/G500)

600

Classeq Under Counter Range - User Manual

32

Fit the waste hose of your warewasher to the existing waste piping. Ensure that the waste

hose is not kinked. Ensure that the waste hose is fitted in such a way that it will not come off

or out of the existing waste piping during warewasher operation.

Maximum drain

stand pipe height

Max Waste

Height

Classeq Under Counter Range - User Manual

33

The waste water from your warewasher must be disposed of down the foul drains system, i.e.

the drains from sinks and WCs. The waste water from your warewasher must not be

connected to the surface water drainage system.

A form of back flow prevention must be installed into the waste water plumbing in

accordance with local and national regulations.

Ensure that no part of the waste hose from the warewasher is

higher than the mark on the rear of the warewasher (shown),

when the warewasher is in place.

Where the warewasher is fitted to a stand pipe,

the Waste Hose Hook should be used to help

manage the hose.

540mm - 600cm

Min 120mm

Classeq Under Counter Range - User Manual

34

4.7 Attaching Chemical Bottles

Warning!

Wear the correct Personal Protective Equipment, e.g., gloves and

goggles, when handling chemicals and observe all safety notes and

dosing recommendations printed on the packaging.

Caution

Only use commercial grade detergents and rinse aids within your

warewasher.

The chemical bottles should be placed in a safe, stable location that is close to the

warewasher and easily accessible in order to check the levels and replace the bottles as

needed.

A coil of PVC tubing is connected to each of the chemical pumps inside the warewasher.

These tubes exit the rear of the warewasher and should be routed to the chemical bottle

locations. The tubes need to be long enough to allow the bottles to be moved without the risk

of falling over. Excess tubing may be cut off.

Classeq Under Counter Range - User Manual

35

Tubing colour

Chemical

BLUE

Rinse aid

CLEAR

Detergent

4.7.1 Preparing the bottles

1. Remove the cap from the chemical bottle.

2. Using the drill and 8mm bit, carefully drill a hole in the centre of the cap.

3. Feed the tube through the hole.

4. Fit the bottle weight over the tube and then attach the end of the tube to a filter.

5. Feed the filter and bottle weight into the bottle and screw on the cap.

Classeq Under Counter Range - User Manual

36

5. Commissioning

5.1 Commissioning Interface

Item

Description

Item

Description

1

Exit button

5 Up button

2

Enter button

6 Down button

3

Cycle indicator

7 Display

4

Heating indicator

Classeq Under Counter Range - User Manual

37

5.2 Commissioning Mode

With the warewasher turned on at the

mains electrical supply but off on the

Control Panel, press and hold the Exit

(1) and Enter (2) buttons

simultaneously for 3 seconds.

The display (7) will illuminate to show the first

menu item and the Cycle indicator (3) will

illuminate red.

If no buttons are pressed for a period of time the warewasher will cancel the Commissioning

Mode and return to the off state.

Below is the complete menu list:

Display

Description

**

Rinse aid setting (e.g. 15 = 1.5mL/L)

Rinse aid prime

**

Detergent setting (e.g. 33 = 3.3mL/L)

Detergent prime

**

Water softener setting (if fitted)

** The numbers indicated refer to the setting of the chemical dosing and water hardness. For

example, the default setting for rinse aid is 1ml of chemical per 1 litre of water, this will be

displayed as ‘r10’. The default setting for detergent is 3ml of chemical per 1 litre of water, this will

be displayed as ‘d30’.

Classeq Under Counter Range - User Manual

38

5.3 Setting the Chemical Dosage Rate

Your warewasher will be set to the default chemical dosing settings. However, since there are

many different chemicals on the market and each of these have different concentration

requirements, the dosage can be adjusted by following the instructions given below:

Refer to the chemical bottle or contact

the chemical supplier to find the

concentration requirements for the

rinse aid and detergent in millilitres of

chemical per litre of water (ml/L).

Enter Commissioning Mode - press and

hold the Exit (1) and Enter (2) buttons

simultaneously for 3 seconds (►5.2).

Using the Up and Down keys (5 and 6),

scroll to the rinse aid setting menu (r**),

press Enter (2). The display will flash.

Use the Up and Down keys (5 and 6) to

scroll to the required ml/L setting and

press Enter (2).

Using the Up and Down keys (5 and 6),

scroll to the detergent setting menu

(d**), press Enter (2). The display will

flash.

Use the Up and Down keys (5 and 6) to

scroll to the required ml/L setting and

press Enter (2).

Classeq Under Counter Range - User Manual

39

Press Exit (1) until the warewasher exits

Commissioning Mode and returns to

the off state.

5.4 Priming the Chemical Pumps

Before the warewasher can be used the chemical tubes need to be filled with chemicals, in

order to do this you will need to follow the instructions given below to prime the chemical

pumps.

Enter Commissioning Mode - press and

hold the Exit (1) and Enter (2) buttons

simultaneously for 3 seconds (►5.2).

Using the Up and Down keys (5 and 6),

scroll to the rinse aid prime menu (rP0)

and press Enter (2)

The display will flash and will change to

rP1.

This will start and run the Rinse Aid

Pump for a maximum of 12 minutes,

drawing chemical into the warewasher.

When the chemical has reached the

back of the warewasher (the chemical is

visible through the tubing), press Enter

(2) again to stop the Pump.

Classeq Under Counter Range - User Manual

40

The display will stop flashing and revert

to rP0.

Using the Up and Down keys (5 and 6),

scroll to the detergent prime menu

(dP0) and press Enter (2)

The display will flash and will change to

dP1.

This will start and run the Detergent

Pump for a maximum of 2 minutes,

drawing chemical into the warewasher.

When the chemical has reached the

back of the warewasher (the chemical is

visible through the tubing), press Enter

(2) again to stop the Pump.

The display will stop flashing and revert

to dP0.

Press Exit (1) until the warewasher exits

Commissioning Mode and returns to

the off state.

Classeq Under Counter Range - User Manual

41

5.5 Integral Water Softener (if fitted)

5.5.1 Commissioning the water softener unit

To commission the Water Softener unit follow the instructions below:

1. Open the door to the warewasher.

2. Remove the right hand Basket Guide.

3. Remove the Salt Reservoir Cap at the back right hand corner of the Wash Chamber.

4. Fill the Reservoir with fresh water.

5. Using the Water Softener Funnel supplied, fill the Reservoir with approximately

1.5kg of granulated salt.

6. Wipe away any excess or spilt salt from the Wash Chamber and the Reservoir

opening.

7. Refit the Salt Reservoir Cap, ensuring that the Cap is fitted flat and secure.

8. Do not overtighten the Salt Reservoir Cap.

Classeq Under Counter Range - User Manual

42

Caution

DO NOT run the warewasher if there is no salt in the salt reservoir, as

this will allow limescale to build up. Limescale deposits in the

warewasher will invalidate the warranty.

Caution

DO NOT add any chemicals, such as detergent or rinse aid to the

reservoir. These will cause damage to the warewasher.

Caution

Only use granulated salt (max. grain size 5 – 7 mm). Salt tablets are not

suitable.

Caution

If the Reservoir Cap is not properly secured, water and/or chemicals

can leak in or out of the unit causing damage to the warewasher.

Classeq Under Counter Range - User Manual

43

5.5.2 Setting the water softener

Check the hardness of your water supply (°d). You can establish the hardness of your water

supply yourself using a simple water hardness testing kit or you may be able to get this

information from your local Water Supply Company. Once you have this data, complete the

following steps.

Refer to the Water Softener settings

table to find the setting required for

your water hardness.

Enter Commissioning Mode - press and

hold the Exit (1) and Enter (2) buttons

simultaneously for 3 seconds (►5.2).

Using the Up and Down keys (5 and 6),

scroll to the water hardness menu (h**)

and press Enter (2).

The display will flash.

Use the Up and Down keys (5 and 6) to

scroll to the setting you require and

press Enter (2).

Press Exit (1) until the warewasher exits

Commissioning Mode and returns to

the off state.

Classeq Under Counter Range - User Manual

44

5.6 Wash and Rinse Tank Temperatures

The Wash and Rinse Tank (Boiler) temperatures have been factory set to pre-set

temperatures. These temperatures do not normally need to be adjusted by the user.

Please refer to the latest version of the Engineers Manual on the Classeq website for full

information regarding temperatures and interlock settings.

Classeq Under Counter Range - User Manual

45

6. Operation

Before operating the warewasher, ensure that the mains electrical and water supplies are

turned on.

Children must be supervised to ensure that they do not play with, or operate, the

warewasher.

6.1 Operation Interface

Item

Description

Item

Description

1

On/Off button

7 Program indicator

2

Cycle button

8 Wash Temperature display

3

Cycle indicator (Note 1)

9 Rinse Temperature display

4

Heating indicator (Note 2)

10

Temperature Unit display

5

Program Select button

11

Wash indicator

6

Temperature Units button

12

Rinse indicator

Classeq Under Counter Range - User Manual

46

6.2 Turning on the Warewasher

To turn on the warewasher, ensure the door is

closed and press the On/Off button (1) on the

Control Panel. The display will illuminate and the

warewasher will start to fill, as long as the door is

closed.

6.3 Warewasher Ready to Operate

Your warewasher operates a pulse fill function,

this means that it will fill the Rinse Tank, heat this

to a pre-set temperature then transfer this water

to the Wash Tank. During the fill stage the

Heating indicator (4) will flash amber.

Once the Wash Tank is filled and both Tanks are

up to the required temperatures, the Heating

indicator will illuminate green to indicate the

warewasher is ready to run a cycle.

The time required for the warewasher to fill and heat will vary depending on the power rating

of the warewasher, as stated on the rating label (►2.3), and the incoming water temperature.

Below is a guide to these fill and heating times when the incoming water is 16°C.

Rating

Time

220-240V / 1N~ / 13A

50 min

220-240V / 1N~ / 28A

25 min

380-415V / 3N~ / 11A

25 min

Classeq Under Counter Range - User Manual

47

6.4 Changing Temperature Units

The temperature displays (8 and 9) on your

warewasher can be shown in °C or °F (10). Press

the Temperature Units button (6) to cycle

between these options.

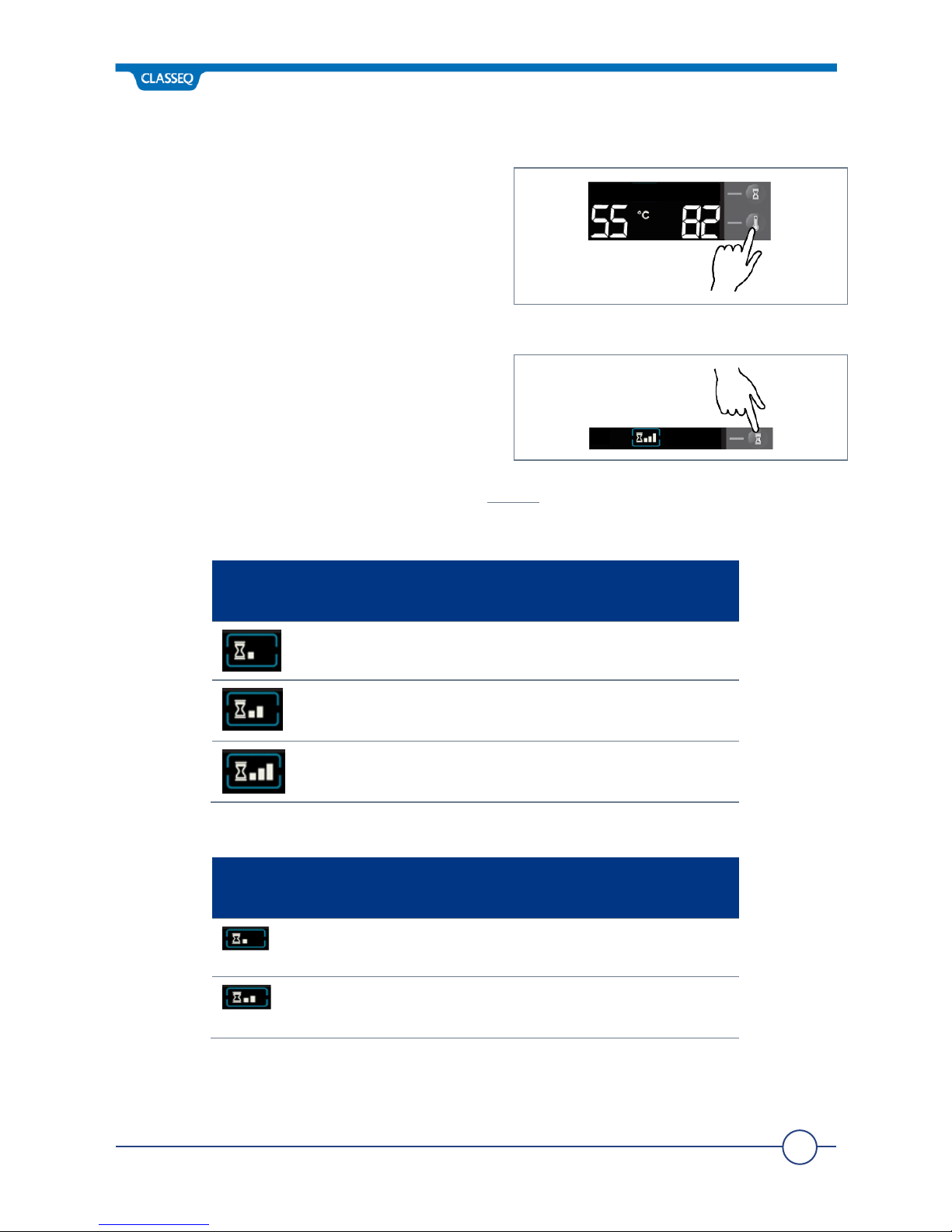

6.5 Selecting a Wash Program

Your warewasher has multiple program times;

these are pre-set to offer the best possible

results. To select a program press the Program

Select button (5) until the Program indicator (7)

shows the selection you require.

When the warewasher is turned on (►6.2) it will always start on the ‘Normal’ program.

6.5.1 Dishwasher program options:

Display

Description

Approximate Time

(min)

Light

2

Standard

3

Intensive

5

6.5.2 Glass washer program options:

Display

Description

Approximate Time

(min)

Light

1.5

Standard

2

Your warewasher has a heat interlock to ensure that the rinse is in accordance with

environmental health requirements. This will extend the wash cycle if the Rinse Boiler has not

Classeq Under Counter Range - User Manual

48

achieved the required temperature within the cycle times given above.

For full information on operating temperatures and the interlock, please refer to the latest

version of the Engineers Manual on the Classeq website for full information regarding

temperatures and interlock settings.

6.6 Loading a Dishwasher Basket

For dishwashers ONLY

Classeq Under Counter Range - User Manual

49

6.6.1 Is it Suitable?

Before loading any item into your dishwasher, check that it is dishwasher compatible.

Pots and pans made of aluminium or stainless steel are normally safe to put in a

dishwasher - but always check for a dishwasher-safe indication on the base of the

pans. If this is not obvious, check the manufacturer’s website or label.

Non-stick pans - many manufacturers state that they are dishwasher safe, however,

always check for a dishwasher-safe indication on the base of the pans. If this is not

obvious, check the manufacturer’s website or label.

Items made of brass, bronze, wood, or china with gold leaf embellishment are not

suitable for washing in a dishwasher. Wash these items by hand.

Large kitchen knives may suffer over time if washed in a dishwasher. Wash these

items by hand.

6.6.2 Preparation

Large chunks of leftover food should be scraped off plates / bowls / pans.

For best results pre-rinse all dirty wares before they go in the dishwasher. Pre-rinse in plain

hot water or water with dishwasher detergent added to it. Do not use handwash detergent as

this may cause foaming when the wares are transferred into the dishwasher.

6.6.3 Service Cutlery

Knives, forks and spoons should be loaded into the Cutlery Basket. Load forks and spoons

handle end down. Load knives handle end up, to prevent cuts when unloading the

warewasher / Basket. Do not overfill the compartments. Do not sort into cutlery types, i.e. do

not fill one compartment in the Basket with all spoons as these may nest with each other and

not wash properly.

Classeq Under Counter Range - User Manual

50

6.6.4 Tableware

Adjust the Plate Basket Inserts to suit your plate / bowl size. Stack plates / bowls so that they

are free-draining. Large platters should be placed face down in the bottom of a Basket.

6.6.5 Preparation / Serving Utensils

Long utensils / cutlery, such as ladles and long knives etc., must be placed horizontally on the

bottom of an Open Basket. This will avoid possible collision with Wash / Rinse Arms.

6.6.6 Pots and Pans

Pots and pans should be placed in an Open Basket face down. Try not to overlap items.

6.7 Loading a Glasswasher Basket

For glasswashers ONLY

Glasses should be placed in the Open Basket open end down.

Always try to fill the Basket - to prevent glasses from clinking against each other during a

wash cycle.

With tall glasses always check carefully that they will fit in the glasswasher when stood

upright in the Open Basket.

Classeq Under Counter Range - User Manual

51

6.8 Starting a Cycle

Always remove excess food / debris from any dishes / glasses to be washed. DO NOT use

your warewasher as a waste disposal unit.

To start a cycle, follow the instructions given below.

Open the Door.

Load the full Basket, ensuring that the

bottom and top Arms rotate freely.

Close the Door.

Press the Cycle button (2). The cycle will

start once the warewasher has achieved

its correct water levels. The cycle will

start when it has completed it’s initial

heat and fill. During the cycle the Cycle

indicator (3) will be illuminated blue.

Do NOT open the door during a cycle.

If the Cycle button is pressed before the

warewasher has reached the required levels and

temperatures the Cycle indicator (3) will

illuminate blue to indicate that a cycle has been

selected, the Heating indicator (4) will flash

amber, and the warewasher will automatically start when the requirements have been met.

Classeq Under Counter Range - User Manual

52

1. At the end of the cycle, the Cycle indicator (3) goes out. Open the Door and remove

the Basket.

2. Reload the warewasher and repeat as required.

Wares in the basket may be wet and will dry in a short time due to evaporation.

Warning!

Wares may be hot when removed from the warewasher.

6.9 Draining Down the Warewasher

Caution

It is very important the warewasher is drained down at the end of each

working day.

During normal operation the warewasher will drain out any excess water.

To fully drain down the warewasher follow the instructions given below.

6.9.1 Draining a gravity drain warewasher

1. Open the Door of the warewasher.

2. Locate and remove the Drain Plug.

Classeq Under Counter Range - User Manual

53

6.9.2 Draining a pumped drain warewasher

Close the Door to the warewasher.

Press the On/Off button (1) to turn off

the warewasher.

Press the Cycle button (2).

The Cycle indicator (3) will flash blue.

The warewasher will drain down the

Wash Tank.

The warewasher will do a self-rinse.

Classeq Under Counter Range - User Manual

54

When the Cycle indicator (3) goes out

the drain cycle is complete.

Notes:

1. Once empty, Classeq recommends that the mains water and electricity supplies

are turned off and the warewasher is cleaned (►7.2).

2. For hygiene reasons it is recommended that once the warewasher has been

drained and cleaned the door is left open to assist in natural drying of the

Wash Chamber.

6.10 Warewasher Malfunction

In the event of a warewasher malfunction:

Switch the warewasher off using the On/Off button.

Isolate the electrical supply to the warewasher.

Turn off the water supply.

Request a service callout.

Classeq Under Counter Range - User Manual

55

7. Maintenance and Servicing

DANGER!

The warewasher MUST be disconnected from its power source during

cleaning, servicing or when replacing parts.

DANGER!

Ensure the base of the warewasher is never submerged or standing in

water when operating the warewasher.

Caution

DO NOT spray the exterior or interior of the warewasher and the

surrounding area (panels, base) using a water hose, steam-jet air ejector

or high pressure cleaner.

Caution

Ensure that the items placed on the open door of the warewasher do

not exceed 20kg in weight.

7.1 Prior to Cleaning

Ensure the warewasher has first been drained down (►6.9).

Turn off the mains electrical supply before cleaning the warewasher.

Warning!

DO NOT use cleaning agents that contain CHLORINE, BLEACH or

HYPOCHLORITE.

Classeq Under Counter Range - User Manual

56

Warning!

Before cleaning the Wash Chamber, ensure all sharp items, such as

broken glass or other items which could cause injury, are removed

carefully.

Caution

DO NOT use STEEL WOOL, WIRE BRUSHES or any other abrasive

materials.

7.2 Daily Cleaning

It is recommended that the warewasher is cleaned daily to ensure good hygiene in the

warewasher.

7.2.1 Interior cleaning

The interior of the warewasher should be cleaned after each service when the warewasher is

drained down.

As a minimum Classeq recommends the following are checked and cleaned:

Remove and clean the top and bottom

Rinse and Wash Arms.

Classeq Under Counter Range - User Manual

57

Remove and clean the primary filters.

Remove and clean the secondary

filters.

Clean the interior of the Wash Tank

with a sponge and/or brush for all

apertures and outlets.

Clean around the door hinge.

Classeq Under Counter Range - User Manual

58

Use a small bottle brush followed by a trigger spray bottle with a jet nozzle, clean the ball

in the anti-syphon device (pumped drain warewashers only).

If required apply food grade grease to the Door Ball Catch.

Ensure all arms and filters are refitted to the warewasher before turning the warewasher on.

7.2.2 Exterior cleaning

Wipe the exterior of the warewasher with a damp (NOT WET) sponge.

Once dry, clean using a STAINLESS STEEL cleaning agent.

7.3 Limescale Build Up

For best results ensure your warewasher is operated with soft water so that limescale does

not build up.

If your warewasher is connected to an external Water Softener, ensure this is routinely

regenerated as per the manufacturer’s instruction manual.

If your warewasher has an internal Water Softener fitted ensure the salt level is maintained

as per the instructions in this manual.

If your warewasher is operated with hard water, without the relevant water treatment, the

internal workings and water lines can become scaled, your washing results will deteriorate

and the warewasher could be damaged. For more information on hard water refer to Water

Supply and Connection (►4.5).

Caution

Damage to the warewasher caused by limescale will NOT be covered

by the manufacturer’s warranty (►12).

Classeq Under Counter Range - User Manual

59

7.4 Regular Maintenance

7.4.1 Water softener salt (if fitted)

When the salt level inside the Salt Reservoir gets low the Refill Salt indicator will illuminate on

the display.

The salt should be replenished as soon as possible to avoid limescale from building up in

your warewasher. To refill the Salt Reservoir follow the instructions below:

1. Open the door to the warewasher.

2. Remove the right hand Basket Guide.

3. Remove the Salt Reservoir Cap at the back right hand corner of the Wash Chamber.

4. Using the Salt Funnel supplied, fill the Reservoir with granulated salt.

5. Wipe away any excess or spilt salt from the Wash Chamber and the Reservoir

opening.

6. Refit the Salt Reservoir Cap, ensuring that the Cap is fitted flat and secure.

7. Do not overtighten the salt reservoir cap.

8. Drain down the warewasher and refill to remove any residual salt water after

refilling the reservoir.

Classeq Under Counter Range - User Manual

60

Note: The Refill Salt indicator may stay illuminated for up to three complete wash

cycles after filling / refilling the Salt Reservoir with salt.

Caution

DO NOT run the warewasher if there is no salt in the Salt Reservoir, as

this will allow limescale to build up. Limescale deposits in the

warewasher will invalidate the warranty.

Caution

DO NOT add any chemicals, such as detergent or rinse aid to the Salt

Reservoir. These will cause damage to the warewasher.

Classeq Under Counter Range - User Manual

61

Caution

Only use granulated salt (max. grain size 5 – 7 mm). Salt tablets are not

suitable.

Caution

If the Salt Reservoir Cap is not properly secured, water and/or

chemicals can leak in or out of the unit causing damage to the

warewasher.

7.5 Descaling

You can de-scale the Wash Tank of your warewasher yourself with the help of the following

notes; to de-scale the Rinse Boiler you will need to contact your service engineer or Classeq.

Warning!

Wear the correct Personal Protective Equipment, e.g., gloves and

goggles, when handling chemicals and observe all safety notes and

dosing recommendations printed on the packaging.

Caution

De-scale chemical must not remain in the warewasher for more than 2

hours.

In order to descale the Wash Tank follow the instructions below:

1. Remove the chemical tubes from the chemical bottles and place the ends of the

tubes into a container of water.

2. Use the commissioning menu to prime the Rinse Aid and Detergent Pump to draw

water all the way into the warewasher.

3. Fill and drain the warewasher to remove any chemical residue.

4. Refill the warewasher.

5. Follow the instructions on the chemical packaging to de-scale the Wash Tank.

6. Once the de-scale process is complete drain the warewasher.

7. Refill and drain the warewasher at least 3 times to remove any chemical residue.

8. Refit the chemical tubes to the bottles and prime the Pumps (►5.4).

9. Do not overtighten the salt reservoir cap.

Classeq Under Counter Range - User Manual

62

8. Troubleshooting

If you believe the warewasher is not behaving as expected or has gone into error mode (Cycle

indicator illuminated red), reset the warewasher by pressing the On/Off button, then follow

the troubleshooting tips before requesting a service callout. The service support number can

be found in the Useful Contact Details section (►14).

Note: In the event of a service call being made under Warranty and it is found that the

fault(s) are due to non-observance of instructions in this manual, the call will be

charged at current rates.

Problem

Possible Cause

Solution / Check

Warewasher does not fill.

The warewasher is still

heating the water in the

Rinse Boiler, indicated by the

Heating indicator flashing

amber.

Wait for heating stage to

complete.

Warewasher has not filled

and Heating indicator has

been flashing amber for

more than 30 minutes.

There is a problem with the

water supply.

Ensure the water supply hose

is connected to the

warewasher and has not

been trapped or kinked.

Ensure the water supply is

turned on.

Check that the site water

supply has not been turned

off.

The warewasher is not

turned on.

Press the On/Off button.

The door is not closed

properly.

Close the door.

Classeq Under Counter Range - User Manual

63

Problem

Possible Cause

Solution / Check

Warewasher will not turn

on.

There is a problem with the

power supply.

Ensure the warewasher is

connected to the mains

power supply.

Check the power supply

outlet is turned on.

On 13A warewasher s check

and replace the fuse in the

plug, ensuring that the

correct rating is used.

On all ratings of warewasher

check and reset the circuit

breaker in the site fuse

board.

If the fuse or breaker keeps

tripping, request a service

callout.

Warewasher fills slowly.

There is a problem with the

water supply.

Ensure the water supply is

turned fully on.

Ensure the water supply hose

has not been trapped or

kinked.

Check that the site water

supply has not been turned

off.

Check that the site water

pressure is adequate

(►4.5.1).

Warewasher is over filling

(too much water in the

Wash Tank - visible with the

Door open, or water spills

out when the Door is

opened).

There is a problem with the

drains system.

Attempt to drain the

warewasher (►6.9). If

warewasher does not drain,

stop the warewasher and

check the site drains system.

There is a problem with the

warewasher’s control

system.

Request a service callout.

Classeq Under Counter Range - User Manual

64

Problem

Possible Cause

Solution / Check

Warewasher is over filling

(pumped drain warewasher

s only).

Drain Pump failure.

Attempt to drain the

warewasher (►6.9). If

warewasher does not drain,

stop the warewasher and

request a service callout.

Warewasher does not heat

up.

Warewasher not turned on.

Check that the indicators and

display on the Control Panel

are illuminated.

Press the On/Off button.

Warewasher not able to fill.

Ensure the water supply is

turned fully on.

Ensure the water supply hose

has not been trapped or

kinked.

Check that the site water

supply has not been turned

off.

Check that the site water

pressure is adequate

(►4.5.1).

Warewasher still going

through fill / heat cycle.

Check that Heating indicator

is flashing amber.

Allow enough time for the

warewasher to fill and heat

(►6.3).

Excessive foam in Wash

Tank.

Wrong type of wash and/or

rinse aid chemicals.

Check that the wash and/or

rinse aid chemicals are

commercial ware washer

grade. Always use the correct

grade of chemicals.

Wash and/or rinse aid

chemical injection rate too

high.

Check / adjust the injection

rates of the wash and rinse

aid chemicals.

Classeq Under Counter Range - User Manual

65

Problem

Possible Cause

Solution / Check

Wash Tank not fully heated.

Check Wash Tank

temperature on Control

Panel display.

Wrong type of Prewash

Do not prewash with soap

based detergent.

Cycle does not start.

(Your warewasher has a

heat interlock that will delay

the start of the wash cycle

until all cycle start criteria

have been met. When the

criteria have been met the

heat indicator will illuminate

green and the cycle should

start. If this is not the case

please check the below

items before requesting a

service callout.)

Warewasher not turned on.

Check that the indicators and

display on the Control Panel

are illuminated.

Press the On/Off button.

Warewasher still going

through fill / heat cycle.

Check that Heating indicator

is flashing amber.

Allow enough time for the

warewasher to fill and heat

(►6.3).

Please refer to the latest

version of the Engineers

Manual on the Classeq

website for full information

regarding temperatures and

interlock settings.

Wash Tank not full.

Ensure the water supply is

turned fully on.

Ensure the water supply hose

has not been trapped or

kinked.

Check that the site water

supply has not been turned

off.

Check that the site water

pressure is adequate

(►4.5.1).

Classeq Under Counter Range - User Manual

66

Problem

Possible Cause

Solution / Check

Cycle runs for a long time.

Rinse water not hot enough.

Your warewasher has a heat

interlock to ensure that the

rinse is in accordance with

UK environmental health

requirements. This will

extend the wash cycle if the

Rinse Boiler has not achieved

the required temperature

If rinse water is not hot

enough Heating indicator will

be flashing amber.

Check Rinse Tank

temperature on Control

Panel display.

Please refer to the latest

version of the Engineers

Manual on the Classeq

website for full information

regarding temperatures and

interlock settings.

Warewasher runs through a

full cycle but does not rinse.

If your warewasher runs

through a full cycle, but does

not rinse, you will need to

request a service callout to

identify the root cause of the

problem.

Warewasher overflowing.

Wrong Drain Plug fitted.

Check that the Drain Plug is

the right one for the

warewasher (►4.6).

Primary / Secondary Filters

blocked.

Check the Primary /

Secondary Filters - if blocked

remove and clean

thoroughly.

Classeq Under Counter Range - User Manual

67

Problem

Possible Cause

Solution / Check

There is a problem with the

drains system.

Check that the warewasher

waste hose is not kinked or

blocked.

Check that the site waste is

not blocked.

If the warewasher continues

to overflow isolate the

warewasher and request a

service callout.

Poor wash results.

Warewasher not being

supplied with soft water.

Check the operation of the

Water Softener (external or

internal) if fitted.

If external, regenerate the

Water Softener.

If internal, check / refill the

Salt Reservoir.

There is a problem with the

wash and rinse aid chemicals

system.

Check the level of chemicals

within the detergent and

rinse aid bottles.

Ensure the bottle weights

and tubes are correctly

positioned.

Check the chemical dosing

rates are correctly set (►0).

Warewasher not properly

cleaned.

Ensure that the warewasher

is regularly cleaned (►7.2).

Check for presence of beige

or black film deposits around

the door and door hinges of

the warewasher indicating a

build up of growing yeast

cells.

Check glasses and renovate if

required.

Classeq Under Counter Range - User Manual

68

Problem

Possible Cause

Solution / Check

Warewasher does not drain.

Wrong Drain Plug fitted.

Check that the Drain Plug is

the right one for the

warewasher (►4.6).

Primary / Secondary Filters

blocked.

Check the Primary /

Secondary Filters - if blocked

remove and clean

thoroughly.

There is a problem with the

drains system.

Check that the warewasher

waste hose is not kinked or

blocked.

Check that the site waste is

not blocked.

Correct drain procedure is

being used for the

warewasher type (►6.9).

Ball in anti-syphon device

dirty / blocked (pumped

drain warewashers only).

Remove the anti-syphon

device cover inside the

warewasher, gently clean the

ball by inserting and agitating

a small bottle brush, flush

using a trigger spray bottle

with a jet nozzle.

Warewasher will not turn off

when the On/Off button is

pressed.

There is a problem with the

warewasher’s control /

electrical system.

Isolate the electrical supply to

the warewasher, turn off the

water supply, and request a

service callout.

Classeq Under Counter Range - User Manual

69

9. Decommissioning

If for any reason you need to remove or decommission your warewasher, do so in

accordance with local and national regulations.

Classeq recommends the following procedures are followed.

9.1 Flush Out Chemical Dosing Systems

Prior to removing any chemicals refer to all safety statements on the chemical bottles for

dealing with any spillage.

Warning!

Wear the correct Personal Protective Equipment, e.g., gloves and

goggles, when handling chemicals and observe all safety notes and

dosing recommendations printed on the packaging.

1. Remove the chemical tubes from the chemical bottles.

2. Place the ends of the tubes into a container of water.

3. Use the commissioning menu to prime the Rinse Aid and Detergent Pumps to draw

water all the way into the warewasher.

4. Fill and drain the warewasher to remove any chemical residue.

5. Ensure the bottles are then capped to prevent any spillage.

9.2 Drain the Warewasher

6. Ensure the warewasher is fully drained (►6.9).

7. Remove the Waste Hose from the drain standpipe; ensure any spilt liquid is dried

prior to advancing to the next stage.

9.3 Disconnect the Warewasher

8. Turn off the mains electrical supply at the socket / isolator / junction box.

When disconnecting the warewasher from the mains electrical supply:

o Warewashers with an electrical plug, always pull the plug. Never pull the cord

itself.

Classeq Under Counter Range - User Manual

70

o Warewashers that are hardwired (i.e. no plug), must be disconnected in

accordance with local and national regulations. Classeq recommends this is

performed by a qualified electrician.

9. Once the electrical supply has been disconnected, disconnect the equipotential wire

from the stud at the rear of the warewasher.

10. Turn off the water supply to the warewasher and disconnect the Water Supply Hose

from the mains water supply, ensuring any spillage is cleared up.

9.4 Drain the Rinse Tank / Boiler

11. Remove the lower Front Panel from the warewasher using a 3mm hex key.

12. Locate the Boiler Drainage Hose. Ensure the Hose protrudes from the front of the

warewasher.

13. Position a container large enough to hold eight litres of water so that the Hose will

drain into it.

Classeq Under Counter Range - User Manual

71

Warning!

If the warewasher is being drained immediately after use, the water

draining from the Boiler Drainage Hose may be as hot as 95°C.

14. Loosen the Jubilee Clip and remove the Drain Plug, ensuring the water flows into

the container. Once fully drained replace the Drain Plug and retighten the Jubilee

Clip.

15. Replace the Front Panel, and ensure all cables and hoses are secured to the

warewasher to prevent tripping hazards. The warewasher is now ready to be

removed.

RECYCLING: If you are recycling or disposing of your warewasher, you

must ensure this is done in accordance with local and national

regulations.

Classeq Under Counter Range - User Manual

72

10. Warewasher Specifications

Model No.

D400DUO

D400DUOWS

D500DUO

D500DUOWS

A. Width (mm)

470

470

570

570

B. Depth - door

closed (mm)

517

517

605

605

C. Height (mm)

min/max

760/790

760/790

830/870

830/870

D. Depth - door open

(mm)

865

865

987

987

E. Height to open

door (mm)

338

338

375

375

B

D

E

A

C

Classeq Under Counter Range - User Manual

73

Model No.

D400DUO

D400DUOWS

D500DUO

D500DUOWS

Water supply

connection

G¾” (¾”BSP)

G¾” (¾”BSP)

G¾” (¾”BSP)

G¾” (¾”BSP)

Water pressure - min

(bar)

0.5 bar

2.0 bar

0.5bar

2.0 bar

Water flow rate - min

(L/min)

11 4 11

4

Water temperature min/max (°C)

4/55

4/55

4/55

4/55

Drain height - gravity

(mm)

40

40

40

40

Drain height pumped (mm)

540

540

600

600

Drain size (mm)

Ø40

Ø40

Ø40

Ø40

Current - standard (A)

13 (1 phase)

13 (1 phase)

30 (1 phase)

30 (1 phase)

Voltage - standard (V)

220-240

/1N~/50Hz

220-240

/1N~/50Hz

220-240

/1N~/50Hz

220-240

/1N~/50Hz

Power consumption standard (kW)

2.85

2.85

6.58

6.58

Current - option 1 (A)

13 (3 phase)

13 (3 phase)

13 (3 phase)

13 (3 phase)

Voltage - option 1 (V)

380-415

/3N~/50Hz

380-415

/3N~/50Hz

380-415

/3N~/50Hz

380-415

/3N~/50Hz

Power consumption option 1 (kW)

6.58

6.58

6.58

6.58

Current - option 2 (A)

30 (1 phase)

30 (1 phase)

12 (1 phase)

12 (1 phase)

Voltage - option 2 (V)

220-240

/1N~/50Hz

220-240

/1N~/50Hz

220-240

/1N~/50Hz

220-240

/1N~/50Hz

Power consumption option 2 (kW)

6.58

6.58

2.58

2.58

Classeq Under Counter Range - User Manual

74

Model No.

D400DUO

D400DUOWS

D500DUO

D500DUOWS

Wash Tank element

rating (kW)

2.00

2.00

2.00

2.00

Rinse Tank element

rating (kW)

2.60

2.60

6.00

6.00

Wash Tank capacity

(litres)

9.77

9.77

14.33

14.33

Rinse Tank capacity

(litres)

6.5

6.5

7.5

7.5

Rinse water

consumption @3bar

(L/cycle)

3.00

3.00

3.00

3.00

Wash Tank

temperature (°C)

55

55

55

55

Rinse Tank

temperature (°C)

82

82

82

82

Noise level (dB)

<70

<70

<70

<70

Weight - empty (kg)

40.3

40.3

54.7

54.7

Weight - fully loaded

(kg)

46.8

46.8

75.2

75.2

Weight - packed (kg)

49.8

51.9

66.6

68.7

Rinse

Aid

Tube

Inlet

Solenoid

Valve