ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 1 of 48

Revision: C

CST Machines

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 2 of 48

Revision: C

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 3 of 48

Revision: C

Contents

1. Introduction ................................................................................................................................. 4

2. Recommended Tool Kit .............................................................................................................. 5

3. Machine Specifications ............................................................................................................... 6

4. Installation Instructions ............................................................................................................... 7

5. Know your unit ............................................................................................................................ 7

6. Warning and safety information .................................................................................................. 9

7. Site requirements ...................................................................................................................... 10

8. Commissioning Instructions ...................................................................................................... 14

9. Water Systems ......................................................................................................................... 18

10. Electrical Component Data ....................................................................................................... 19

11. Changing orientation ................................................................................................................. 20

12. Speed setting ............................................................................................................................ 24

13. Setting basket arm .................................................................................................................... 26

14. Machine wiring and layout ........................................................................................................ 27

15. Dryer unit wiring and layout ...................................................................................................... 41

16. Trouble shooting ....................................................................................................................... 46

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 4 of 48

Revision: C

1. Introduction

Introduction:

Prior to reading this manual, it is essential that you are familiar with the contents and subject matter

covered within the ‘Installation & Operators Manual’ or ‘Installation instruction’.

Installation:

Installation should only be carried out by a Classeq approved technician, in accordance with current

regulations and within our instructions.

Repairs and spare parts:

The appliance must only be repaired by a Classeq approved technician, using genuine Classeq

spare parts, failure to do so could invalidate any warranty and relieve the manufacture of all liability.

Modification:

Classeq reserves the right to modify either the appliance or the contents of these instructions without

notice.

CAREFULLY READ THESE INSTRUCTIONS, BEFORE INSTALLING AND OPERATING OR REPAIRING

THIS APPLIANCE.

INCORRECT INSTALLATION, ADAPTATIONS OR ALTERATIONS COULD RESULT IN INJURY OR

DAMAGE TO PROPERTY.

MALICIOUS DAMAGE, DAMAGE DUE TO NEGLIGENCE, OR FAILURE TO COMPLY WITH THESE

INSTRUCTIONS AND LOCAL LEGISALTION, OR UNAUTHORISED TAMPERING WILL INVALIDATE

ANY WARRANTY AND RELIEVE THE MANUFACTURER OF ALL LIABILITY

DAMAGE CAUSED DUE TO THE LACK OF, OR INCORRECT USE OF A WATER SOFTNER, OR

LIMESCALE DAMAGE WILL NOT BE COVERED BY THE MANUFACTURES WARRANTY

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 5 of 48

Revision: C

2. Recommended Tool Kit

Recommended hand tools

Specification

5.5mm - Spanner / nut runner / socket

7.0mm - Spanner / nut runner / socket

8.0mm - Spanner / nut runner / socket

10.0mm - Spanner / nut runner / socket

13.0mm – Spanner / nut runner / socket

24.0mm - Spanner / nut runner / socket

32.0mm - Spanner / nut runner / socket

10mm to 18mm - Adjustable spanner

Pliers

2.5mm Hex key

3mm Hex key

No. 2 - Pozi screw driver

Electric screw driver (small)

Flat bladed screw driver (large)

Wire cutters

Wire crimpers

Multi meter capable of measuring:

Volts (10V ~ 240V AC)

Amps (0 ~ 50 Amps)

Ohms (0 ~ 30MΩ)

Continuity

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 6 of 48

Revision: C

3. Machine Specifications

Door opening angle

180°

Maximum clear entry height

492mm

Operating noise level*

<70dB

Net weight

180kg

Gross weight

268kg

Built in air gap (WRAS Approved)

Yes

Rinse booster pump

Yes

Built in Detergent dispenser

No

Built in Rinse aid dispenser

No

Auto timer

Yes

Racks per hour

100 - 130

Water connection

G¾” (¾” BSP)

Water inlet height from floor level

170 - 240mm

Required water pressure

2 – 4 bar

Maximum drain height from floor

270 – 320mm

Drain size

Ø40

Amps required – 3 phase

Water fed @ 40°C

32A

Water fed @ 10°C

45A

Total connected load

Water fed @ 40°C

13.74kW

Water fed @ 10°C

25.74kW

Operating voltage

380-415V

Wash tank element

2x6kW

Rinse boiler element

4x6kW

Rinse boiler capacity

7Lts

Wash pump power

1.1kW

Wash tank capacity

80Lts

Wash water operating temperature

55°C – 60°C

Rinse pump power

0.25kW

Rinse water operating temperature

>82°C

Rinse water consumption

4.7Lts/min

Drive motor

0.37kW

Dryer air temperature

60°C

Blower power

0.5kW

Dryer tunnel amps

+12A

Dryer tunnel connected load

+4.5kW

Water consuption

282Ltrs/hour

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 7 of 48

Revision: C

4. Installation Instructions

The site:

Ensure that there is sufficient space for the installation, servicing and easy access to

all mains isolator switches / valves (i.e. electricity and water).

Ensure that the surface the appliance is going to be installed onto is adequately stable

and capable of supporting the appliance during normal operation (see site

requirements).

Once installed ensure the appliance is stable, with its weight being distributed equally

and does not tilt more than 3° in any direction.

Adjuster feet:

After removing the machine from the transport pallet ensure all the feet are adjusted to suit the

surface where the appliance is being installed.

For further instructions see installation and operation manual.

5. Know your unit

Machine layout

* Take note of safety information regarding these components (►6)

Wash pump

Rinse boiler

Rinse pump

Control panel (dryer

controls on rear)

Wash arms and

fitting tubes

Rinse arms

Curtain

Gear box &

Drive motor*

Cassette

assembly

Filter

Fascia and controls

Serial number /

Electrical rating plate

Wash tunnel*

Thermostats

Curtain

bracket

Dryer terminal

block (TB3)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 8 of 48

Revision: C

Dryer unit layout

Dryer cassette

Blower unit

Dryer element*

Dryer thermostat

Blower terminal block (TB4)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 9 of 48

Revision: C

6. Warning and safety information

The machine should only be operated at or within the voltage specified on the rating plate (►5). The

installer and user are responsible for ensuring the installation and operation of this machine are in

accordance with local and national regulations.

The machine is not fitted with a heat interlock but should be allowed to fully heat to the correct

temperatures before use.

Only use commercial grade detergents and rinse-aids within your machine.

DO NOT use electrical extension lead(s) to supply power to your machine.

Damage to the machine caused by lime scale, or poor water quality will NOT be covered by the

Manufacturer’s Warranty.

Children should be supervised to ensure that they do not play with, or operate the machine.

When disconnecting your machine from the mains electrical supply:

Machines hard wired (i.e. no plug), this must be disconnected in accordance with local and national

regulations; Classeq recommends this is performed by a qualified electrician.

Always remove excess food from the dishes before loading.

Caution

DO NOT use the machine

as a waste disposal unit.

Do not insert any items or parts of your body between moving components, as this could cause injury.

Beware of touching or placing items onto the wash tunnel of the machine, as this can get hot during use.

The drive motor and gearbox assembly weighs over 15kg. When removing these items care must be

taken to ensure that the weight is supported correctly.

The dryer unit weighs more than 50kg and should be handled with care. When installing the unit a lifting

trolley should be used.

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 10 of 48

Revision: C

7. Site requirements

Machine dimensions:

Dishwashers

CST

With dyer

Machine

(mm)

A = width

(mm)

1300

2000

B = depth

Closed (mm)

810

Open (mm)

1490

C = height

(mm)

1380-1440

1730-1790

Basket size (mm) (square basket)

500

Load capacity (dishes)

18

Load capacity (pint glass)

30

Basket rate (Baskets/hour)

100 / 130

Rinse running water temperature

82°C

Rinse standby water temperature

60°C

Wash water temperature

55°C

B C A

B

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 11 of 48

Revision: C

Electric Supply:

Electrical connection:

Electrical connections MUST be carried out by an authorized technician and in accordance with local

and national regulations.

As a minimum Classeq recommends the following standards are maintained:

All appliances are connected via a residual current device (R.C.D.) or earth leakage protection device.

EN60204:

Supply isolator switch has all pole separation of more than 3mm.

EN60335:

Connect to an equi-potential conductor, connection stud located at bottom of the appliance to the rear;

this is in addition to the earthed electrical supply.

Prior to connecting the appliance, ensure voltage and supply fuse comply with rating plate.

Electrical rating:

Note: Electrical supply can be

either side of the appliance. The

appliance not supplied with the

electrical plugs.

If the supply cable is damaged ,

it must be replaced by a cable or

cord assembly supplied by

Classeq or its service agents or

to the following minimum

specification.

Cable type

Temperature

rating

Length of cable

Confirm to /

standard

H07RN-F

5G10

80°C minimum

5m

IEC 60335-2-58

&

IEC 60227 types

56 & 57

Electrics

CST

Dryer unit

Volts

380 – 415V (3

Phase)

380 – 415V (3

Phase)

Amps

Hot fill

32A per phase

+12A per phase

Cold Fill

45A per phase

Max total load

Hot fill

13.74kW

+4.5kW

Cold Fill

25.74kW

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 12 of 48

Revision: C

Water Inlet and Waste out let:

Water connection:

The appliance comes with a water supply hose requiring

a G¾” (¾” BSP) male threaded connection at the mains

water supply, upon installation and commissioning all

water joints must be checked for leaks.

Old existing, defective or damaged water supply hoses

are NOT to be used when installing the appliance.

Commercial appliance wash results will be affected by

external conditions such as incoming water

temperature, pressure, harness and choice of

chemicals.

For the longevity of any water related devices and to

ensure you get consistently good results it is essential your machine is either fed from a soft water

supply , or your Classeq appliance is connected to an appropriate water softener.

Note: Water supply can be either side of the machine.

IMPORTANT:

All supplier warranties are void if lime scale is present within an appliance

If the above requirements are not adhered to, the performance of the appliance will be impaired

CST 100 / 130

Temperature range

5-55°C

Pressure

0~2 bar

Booster pump required

2~4 bar

No modification

4~6 bar

Flow restrictor required

6 bar +

Pressure reducing valve

required

Flow rate

4.7 Lts / min

Water connection

G ¾” (¾” BSP)

Inlet valve

Waste outlet / Drain hose

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 13 of 48

Revision: C

Waste outlet:

The CST is a gravity drain machine, upon installation the

waste must be configured as stated in this manual.

All installations should be fitted with a running ‘P’ trap to

ensure hygiene.

Ø40mm (1 ½”) standpipe required, must be lower than

the baseline of the wash tank.

Drain hose must be a close / tight fit into the drain pipe

to reduce odours from the drain system.

To ensure correct drainage, the height the sites drain is from the floor / surface the machine sits

upon MUST be within the following

Waste hose must flow down from the waste outlet to the drain.

Joint between standpipe and waste hose must be water tight.

If you have any doubts about the drainage system on the machine, please contact either Classeq or

your dealer/agent.

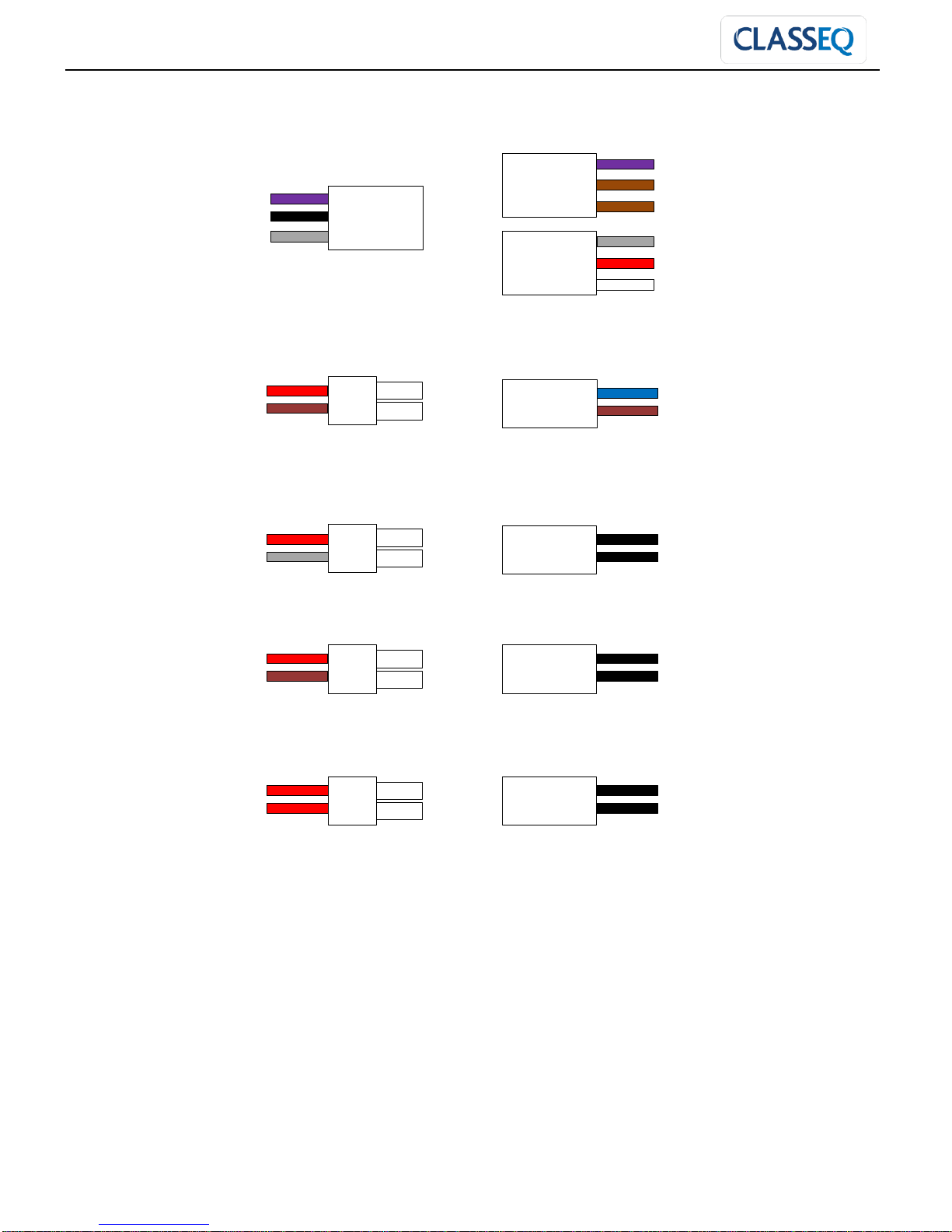

Terminal block layout

Terminal block (TB1) configuration (Mains supply):

Drainage dimensions

(mm)

CST

Drain stand pipe diameter

Ø40

Maximum drain pipe

height (Gravity drain)

(Depending on height

adjustment)

270 - 330mm

4mm² wires for heating

10mm² incoming mains cable

0.75mm² cable to pumps

0.5mm² neutral cable to Filter

4A

1.5mm² cable to control

harness and pumps

1.5mm² earth cable

0.75mm² cable to dryer

unit (if fitted)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 14 of 48

Revision: C

8. Commissioning Instructions

Rinse aid & Detergent:

The CST is not fitted with internal chemical dosing pumps, these will need to be fitted during the

installation.

A terminal block is provided on right hand side of the wash tank for connecting the electrics of the

chemical pumps.

Note: Isolate the machine prior to the access and connection of the chemical pump terminal block.

WARNING: Only rinse aids and detergents developed for commercial glass and

dishwashers are to be used, rinse aids must be suitable for water temperatures down to

40°C.

Terminal block configuration (Chemical pumps):

Yellow/green

Blue

orange

Purple

Brown

Earth

Neutral

Running

WT full

Live

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 15 of 48

Revision: C

Machine temperature settings:

The water temperatures on ’Classeq’ range of machines are adjustable, but have been pre-set to:

Thermostat positions

Rinse thermostat –

standby (ST1)

Rinse thermostat –

Running (ST2)

Wash thermostat

(ST3)

60ºC

82ºC

55ºC – 60°C

Dryer temperature setting

The air temperature on the ’Classeq’ dryer range is adjustable, but have been pre-set to:

Dryer air temperature

(ST4)

60ºC

The manual reset safety thermal trips on the machine are set to the following values and cannot be

adjusted:

Wash tank – 85°C

Rinse boiler – 95°C

Air blower – 85°C

Table end limit switch

It is very important that the table end limit switch be installed at the end of the exit table and the arm

adjusted so that it is activated by the basket before it reaches the end of the table. The cable should

be routed through the small cable gland at the rear of the machine and plugged into the harness at the

connector near the small terminal block. The switch should be wired on the normally closed circuit.

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 16 of 48

Revision: C

This switch will stop the machine when activated allowing the operator time to remove the clean

baskets before more baskets are pushed through the machine.

Min. 50mm

Adjustable 20-70mm

Cable gland

Terminal

block

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 17 of 48

Revision: C

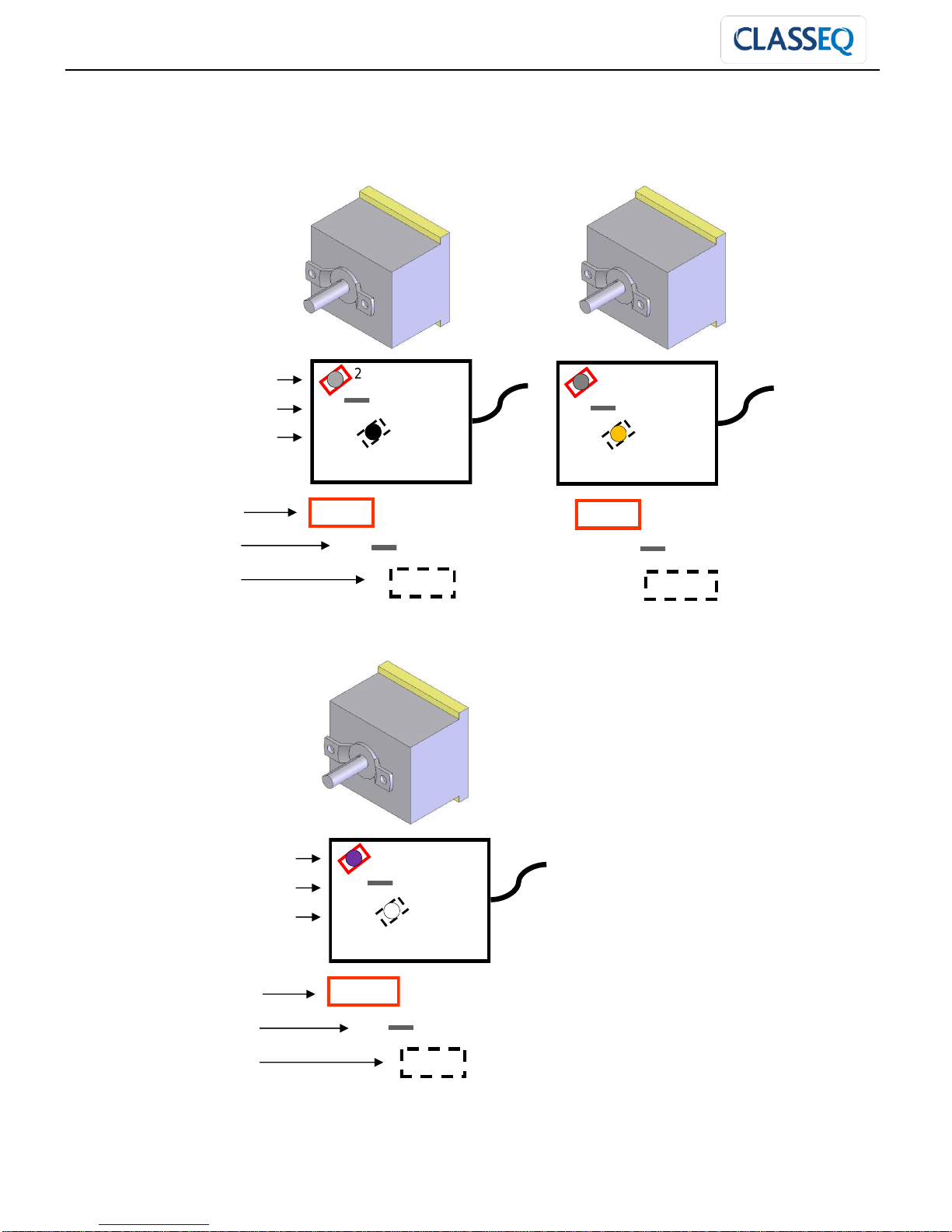

Electrical supply setup

If the machine is fitted to a hot water supply (maximum temperature of 55°C) then the electrical supply

to the machine can be changed (►7). This is done by turning off CB2, this turns off one of the banks

of elements used in the rinse boiler and reduces the current required.

Cold fill (45A per phase)

Hot fill (32A per phase)

Installing the splash guard (only if not dryer fitted)

Once the machine has been installed and all tabling has been aligned the splash guards should be

fitted to the exit of the machine.

Remove the 3x M5 screws on either side of the exit and use these to fasten the splash guard in place.

Align the splash guard to the front of the machine and the side of the exit as best as possible. Once

fitted the splash guards should be sealed against the tabling.

CB2 OFF

CB2 ON

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 18 of 48

Revision: C

9. Water Systems

Rinse system (Also used for filling the wash tank):

Wash system:

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 19 of 48

Revision: C

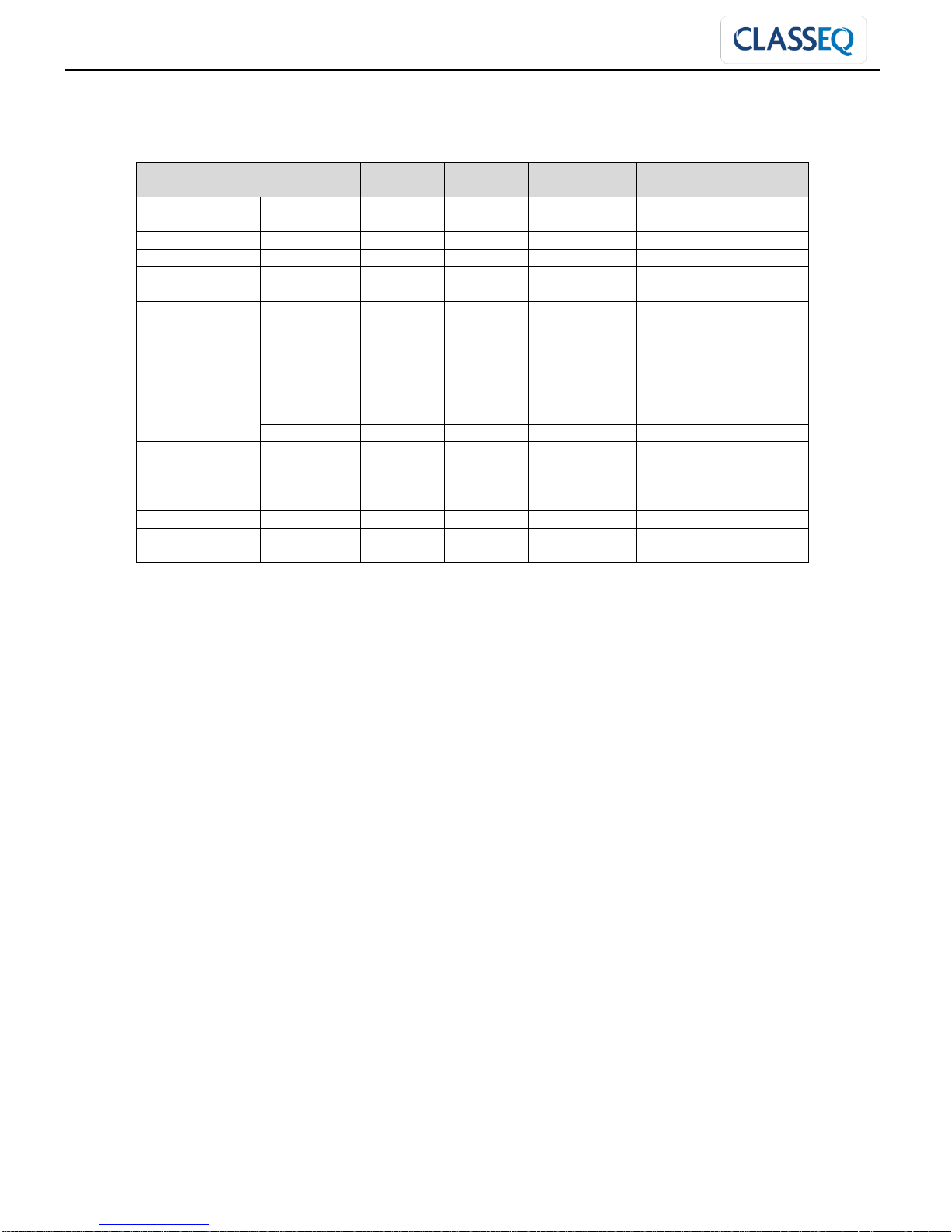

10. Electrical Component Data

Component

Voltage

(V)

Frequancy

(Hz)

Current

(A)

Power

(W)

Resistance

(Ω)

Inlet solenoid

valve

220 ~ 240

50 ~ 60

- - -

Rinse elements

4 x (3x2kW)

230

50 ~ 60

8.7 / leg

2000 / leg

26.42 / leg

Wash elements

2 x (3x2kW)

230

50 ~ 60

8.7 / leg

2000 / leg

26.42 / leg

Rinse pump

220 ~ 240

50

1.2 (Running)

250

Wash pump

380 ~ 415

50

2.8

1100

Drive motor

380 ~ 415

50

1.23

370

Contactors

220 ~ 240

50

Timer

220 ~ 240

50

Relays - (Finder)

220 ~ 240

50

Indicator lamps

White (LED)

220 ~ 240

50 ~ 60

Amber

220 ~ 240

50 ~ 60

Blue

220 ~ 240

50 ~ 60 Red

220 ~ 240

50 ~ 60

Air pressure

switches

220 ~ 240

50 ~ 60

Temperature

display

220 ~ 240

50 ~ 60

Blower unit

380 ~ 415

50

1.05

500

Air heater

element

3x 2kW

230

50 ~ 60

8.7

2000

26.42

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 20 of 48

Revision: C

11. Changing orientation

CST is designed to allow adaption to a change in direction of travel during the commissioning of the

machine.

Ensure the machine is fully drained prior to commencing any changes.

Remove all the curtains and the cassette assembly from the machine.

Danger

For safety reason turn

off all electrical

supplies to your

machine before

following these steps.

Remove rear top and rear bottom panels in order to get access to wash and rinse hoses.

When changing the direction of the CST care must be taken not to misplace or damage the sealing Orings.

11.1 Changing wash and rinse arms system.

Remove the wash arms and cassette from the machine.

Remove wash arm brackets and fixing tubes. Take note shorter fixing tubes used at bottom and

longer fixing tube used at top.

Remove rinse arm hose from rinse bush.

Remove rinse arms and associated brackets.

Loosen and remove the top wash manifold.

Remove the blanking covers from the remaining holes

Loosen the jubilee clips for the bottom wash manifold.

Rotate the bottom wash manifold 180° to the new position and fasten using long fixing tubes.

C= CST Middle wash hose

C

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 21 of 48

Revision: C

Tighten jubilee clips

Replace wash top wash hose with the hose required for the direction of travel.

Fit top manifold and wash arm. Fasten into place using short fixing tubes and tighten jubilee clips.

Fit rinse arms into outer most holes. Align holes to face directly vertical and fasten into place.

Fit rinse hose to rinse bushes and tighten jubilee clips.

Fit blanking covers into remaining holes.

Fit rinse and wash arm brackets. Note fixing ring orientation.

Fit wash arms.

Move curtain bracket to front edge of entry side of machine (►5).

The below image shows the orientation of the wash arms, rinse arms and blanking covers for both

directions of travel.

Caution

Classeq recommend that

any changes to the

machine be carried out by

trained field technician.

A B

A= Right hand CST Top wash hose

(PN)

B= Left hand CST Top wash hose

(PN)

Wash

Rinse

Blanking

Right to left

Left to right

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 22 of 48

Revision: C

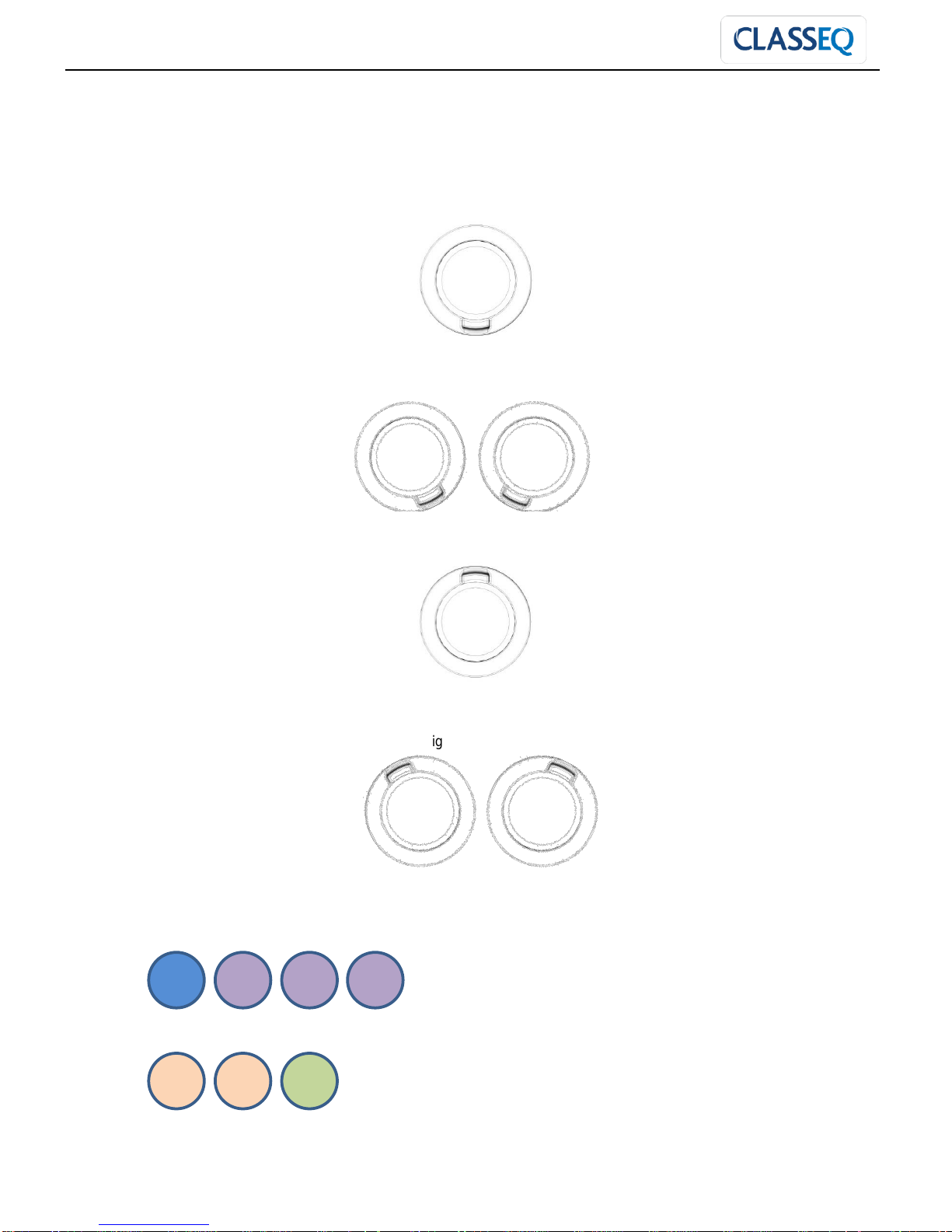

11.2 Setting orientation of the wash arms

Note the orientation of the locating ring for the wash arms. These are fitted in different orientations in

the machine as show below

Orientation 1:

Pointing directly down

Orientation 2:

Tilted slightly inward from entrance

Orientation 3:

Pointing directly up

Orientation 4:

Tilted slightly outward towards entrance

The above orientations are used in the assembly of the wash arms as below:

Top wash arms shown with entrance to the left:

Bottom wash arms shown with entrance to the left:

Left to right Right to left

Left to right Right to left

2 1 1

1

3 3 4

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 23 of 48

Revision: C

Top wash arms shown with entrance to the right:

Bottom wash arms shown with entrance to the right:

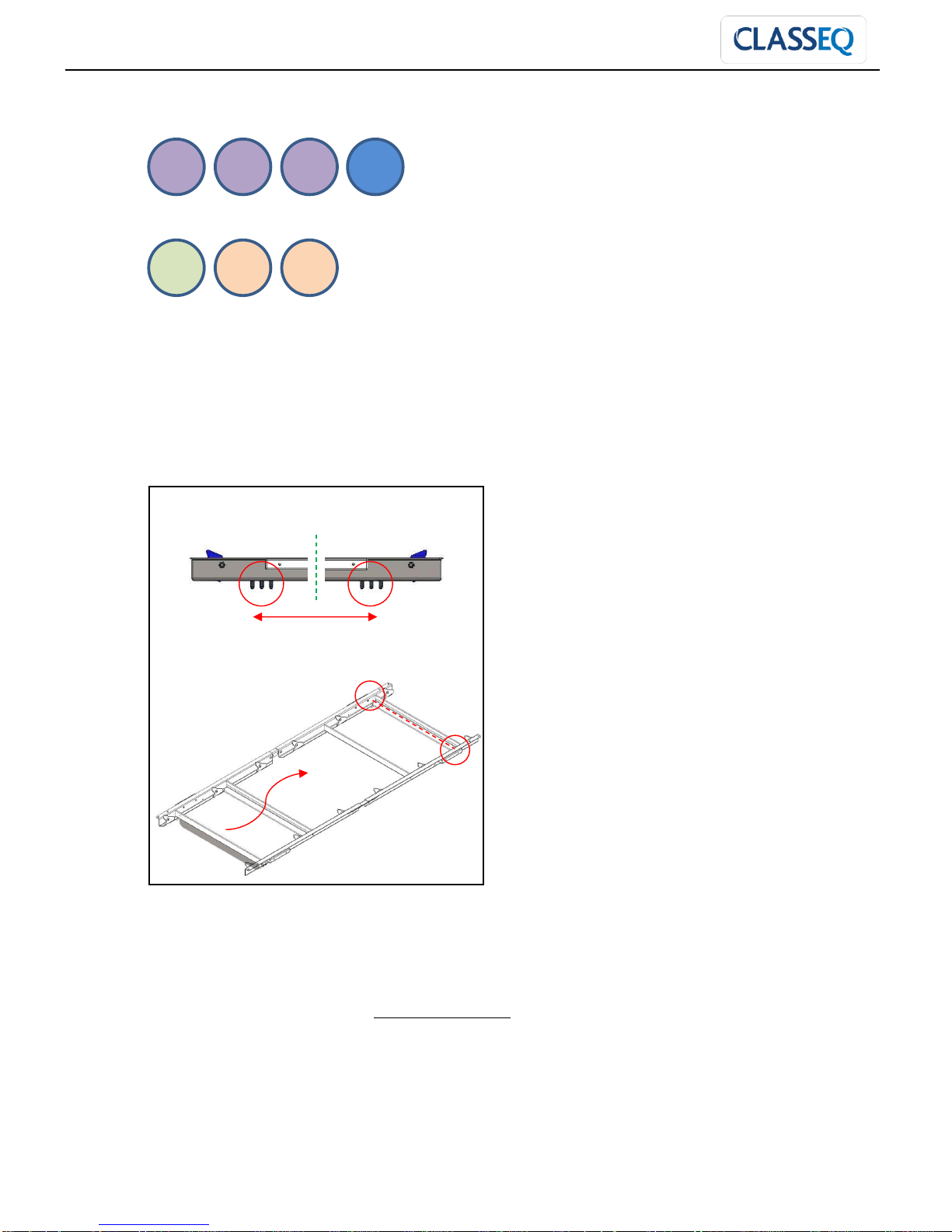

11.3 Changing cassette assembly setting.

Once CST’s hoses have been changed, the cassette assembly needs to be rotated to move the

baskets in the required direction.

Remove the nuts holding centre plate.

Relocate the centre plate to opposite side of cassette assembly and fasten it with nuts. Ensure centre

plate is fitted to the correct speed setting (►10).

Place cassette assembly back into machine and fasten into place with the fixing screws.

Fit the curtains back into machine

Turn on all electrical supplies to your machine.

Damage to the machine caused by failure to follow steps will NOT be covered by the Manufacturer’s

Warranty.

Symmetric

℄

1 1 1 2 4 3 3

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 24 of 48

Revision: C

12. Speed setting

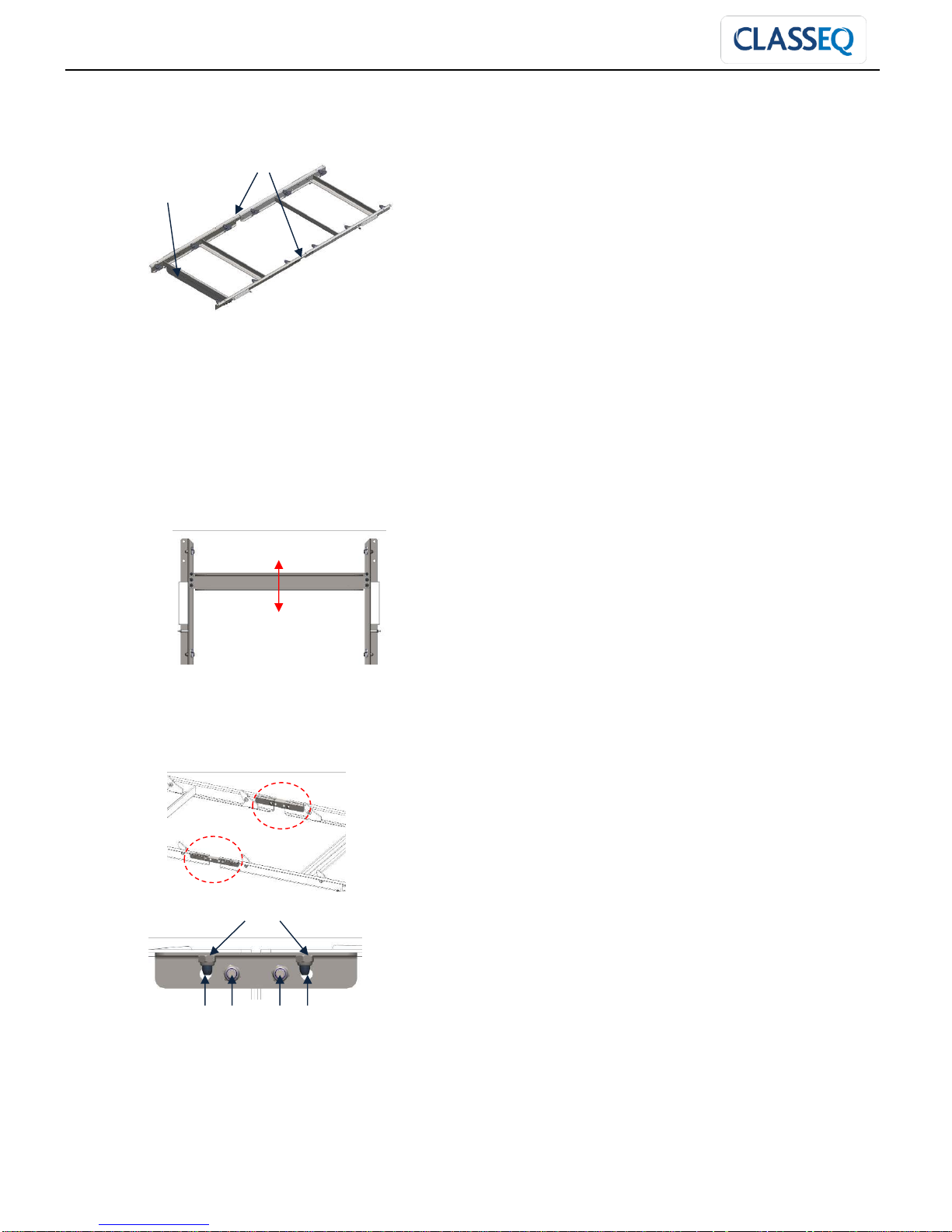

F = 1 x Centre plate

G = 2 x Speed variable plate

The CST is available at two speed settings of 100 or 130 baskets per hour. In order to change the

setting, remove cassette assembly from the machine and follow the steps below:

Step 1: Remove 4x M5 nuts holding centre plate (F) then re-locate centre plate (F) to the correlating

stud and tighten it back with the 4 x M5 nuts.

Step 2: Loosen the 2 nuts attached to the slot of speed adjustment plate (G) on each side. Then

remove socket button head screws (M5x12) and M5 nuts from the hole and re-locate it to required

speed hole of symmetrically on each side.

F

130

100

100

130

Nuts

100

130

130

100

G

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 25 of 48

Revision: C

Step 3: Remove bolt attaching rotating cap (I) to drive plate (J) in the machine and re-locate rotating

cap (I) to require speed setting onto drive plate (J) and tighten the bolt.

I = Rotating cap

J = Drive plate

Step 4: Place cassette assembly back into the machine as follow. Ensure centre plate (F) fits onto

rotating cap (I) and plastic guides (H) sit into the drive rail (K) properly.

K = Drive rail

Caution

It is very important to follow the

steps; failure to it will lead to

potential damage to the cassette

assembly.

If in doubt then contact Classeq or your local dealer.

I J K

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 26 of 48

Revision: C

13. Setting basket arm

The basket arm is factory set to work with all Classeq baskets and should not need to be adjusted.

However should baskets from a different manufacturer be used that is not being picked up by the

machine or are causing the machine to stop in the cylce then the arm can be adjusted to suite these.

At the right hand side of the basket arm is a bracket to allow for adjustment.

1. Isolate the machine.

2. Insert the off sized basket into the centre of the machine

3. Remove the M3 screw and nylock nut.

4. Rotate the magnet arm so that the hooked end is in line with the bend in the cabinet.

5. Find a matching pair of holes for the fastener and tighten in place.

6. Turn on machine, fill and test operation. Readjust if required.

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 27 of 48

Revision: C

14. Machine wiring and layout

Machine control panel layout

Rinse heater contactors

(CT1 & CT2)

Wash heater contactors

(CT3 & CT6)

Rinse heater contactors

(CT4 & CT5)

Three phase

breakers (1-3) 25A

Three phase

breaker (4) 6A

Breaker (5) 6A

Timer (TM1)

On/Off relay (RL1)

Door relay (RL2)

Wash pump relay (RL3)

Machine full relay (RL4)

Basket present relay (RL5)

Drive motor relay (RL6)

Wash heater relay (RL7)

Timer (TM2)

Control Panel

RC Filter

Timer (TM3)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 28 of 48

Revision: C

Front panel

Z

On/Off switch

On/Off lamp (L1)

Double

Red

Double

Blue

Pump running lamp (L2)

Heating lamp (L3)

Error lamp (L4)

Purple

Brown

Double

Blue

Double

Blue

Brown

Brown

Double

Blue

Orange

L

N

Wash temperature

Double

Double

L

N

Rinse temperature

Double

Double

Orange

Brown

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 29 of 48

Revision: C

Machine breakers and timer wiring

Type

Breaker

size

Breaker

number

Wire colour / Connection configuration

6A

Circuit

breaker 5

Incoming wire from Filter 4A (P1)

Out going wire to On/Off switch

6A

Breaker 4

(3 phase

breaker)

Incoming wire from Terminal block (TB1)

Out going wire to Drive motor relay (RL6)

Incoming wire from Terminal block (TB1)

Out going wire to Drive motor relay (RL6)

Incoming wire from Terminal block (TB1)

Out going wire to Drive motor relay (RL6)

25A

Breaker 1

Incoming wire from terminal block (TB1)

Out going wire to heating contactor (CT1)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT1)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT1)

Breaker 2

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT2)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT2)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT2)

Breaker 3

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT3)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT3)

Incoming wire from Terminal block (TB1)

Out going wire to heating contactor (CT3)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 30 of 48

Revision: C

Motor timer (TM1)

A2

Neutral from Terminal block (TB1)

A1

From timer (TM2)

B1

Incoming wire from Door relay (RL2)

18

To Drive motor (DM1)

15

Incoming wire from Door relay (RL2)

Time segment

Select time

segment to

be used

Default:

2m (2 minutes)

Time

Adjust time

within time

segment

Default:

20 (Full)

Timer type

Select type

of timer

Default:

BE (On delay)

DO NOT CHANGE

Delay timer (TM2)

A2

Neutral from Terminal block (TB1)

A1

Incoming wire from Door relay (RL2)

B1

Incoming wire from Basket switch

(Sw4)

18

To Basket pressent relay (RL5)

15

From timer (TM2)

Time segment

Select time

segment to

be used

Default:

2m (2 minutes)

Time

Adjust time

within time

segment

Default:

10 (Half)(1 minute)

Timer type

Select type

of timer

Default:

BE (On delay)

DO NOT CHANGE

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 31 of 48

Revision: C

Delay timer (TM3)

A2

Neutral from Terminal block (TB1)

A1

From CB5

B1

From on/off switch

18

To Basket pressent relay (RL5)

16

To Control circuit

15

From timer (TM2)

Time segment

Select time

segment to

be used

Default:

20s (20 seconds)

Time

Adjust time

within time

segment

Default:

5 (Quarter)(5 Seconds)

Timer type

Select type

of timer

Default:

BE (On delay)

DO NOT CHANGE

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 32 of 48

Revision: C

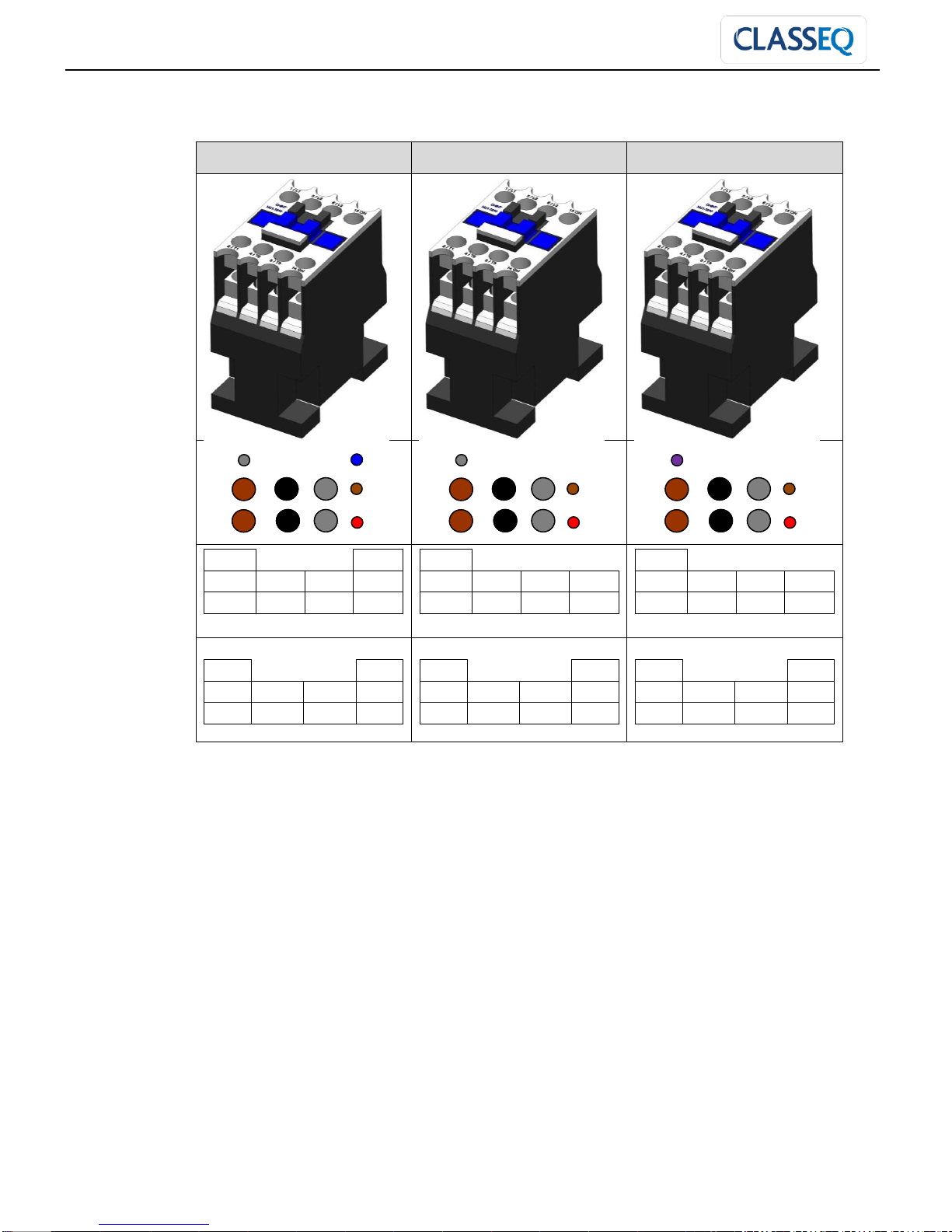

Machine contactors

Rinse heating contactor (CT1)

Rinse heating contactor (CT2)

Wash heating contactor (CT3)

Red

Blue

Brown

Black

Grey

Brown

Black

Grey

Red

Blue

Brown

Black

Grey

Brown

Black

Grey

Red

Blue

Brown

Black

Grey

Brown

Black

Grey

A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 33 of 48

Revision: C

Machine contactors

Rinse heating contactor (CT4)

Rinse heating contactor (CT5)

Wash heating contactor (CT6)

Grey

Blue

Brown

Black

Grey

Brown

Brown

Black

Grey

Red Grey

Brown

Black

Grey

Brown

Brown

Black

Grey

Red Purple

Brown

Black

Grey

Brown

Brown

Black

Grey

Red

A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO

A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO

A1

A2

2T1

4T2

6T3

14NO

1L1

3L2

5L3

13NO

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 34 of 48

Revision: C

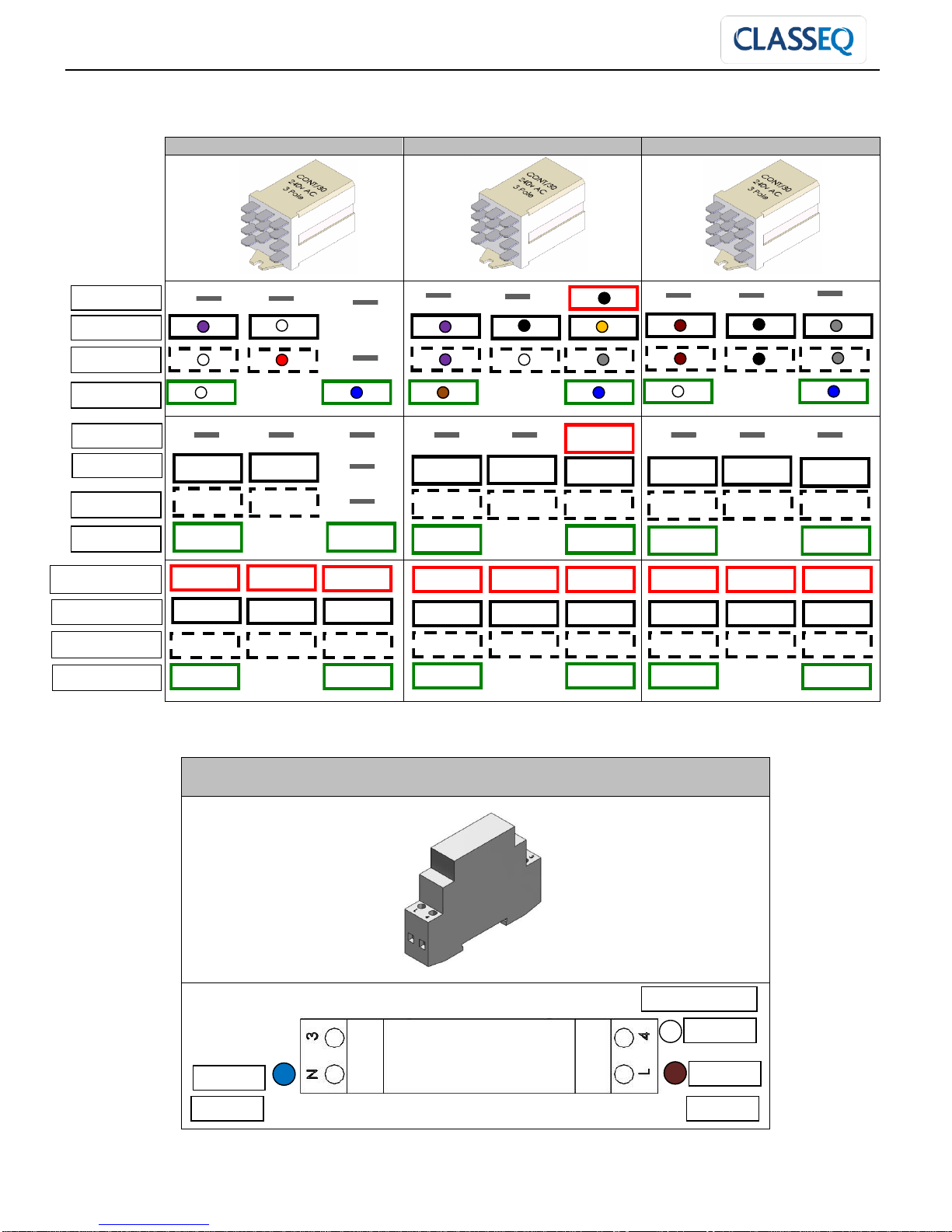

Machine relays

Wash heater Relay (RL7)

Door Relay (RL2)

Wash pump Relay (RL3)

Red cover

Black cover

White cover

Green cover

Purple

Purple

Red

Blue

White

Black

Orange

Red

Purple

Purple

Brown

Orange

Blue

Black

Grey

Grey

Black

Purple

Purple

Grey

Blue

22

32

24

34

21

31

12

14

11

A1

A2

22

32

24

34

21

31

12

14

11

A1

22

32

24

34

21

31

12

14

11

A1

A2

Normally closed

Normally open

Common

Coil

A2

Red cover

Black cover

White cover

Green cover

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 35 of 48

Revision: C

Machine relays

Machine full Relay (RL4)

Basket present Relay (RL5)

Drive motor Relay (RL6)

Machine relays

ON / OFF Relay (RL1)

Purple

Purple

Brown

Blue

White

Grey

Orange

Black

Black

Brown

Brown

White

Blue

Black

Grey

Grey

Black

Purple

White

White

Blue

Red

White

22

32

24

34

21

31

12

14

11

A1

A2

22

32

24

34

21

31

12

14

11

A1

22

32

24

34

21

31

12

14

11

A1

A2

Normally closed

Normally open

Common

Coil

A2

Red cover

Black cover

White cover

Green cover

Red cover

Black cover

White cover

Green cover

Blue

Brown

White

From SW3

From CB5

To control unit

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 36 of 48

Revision: C

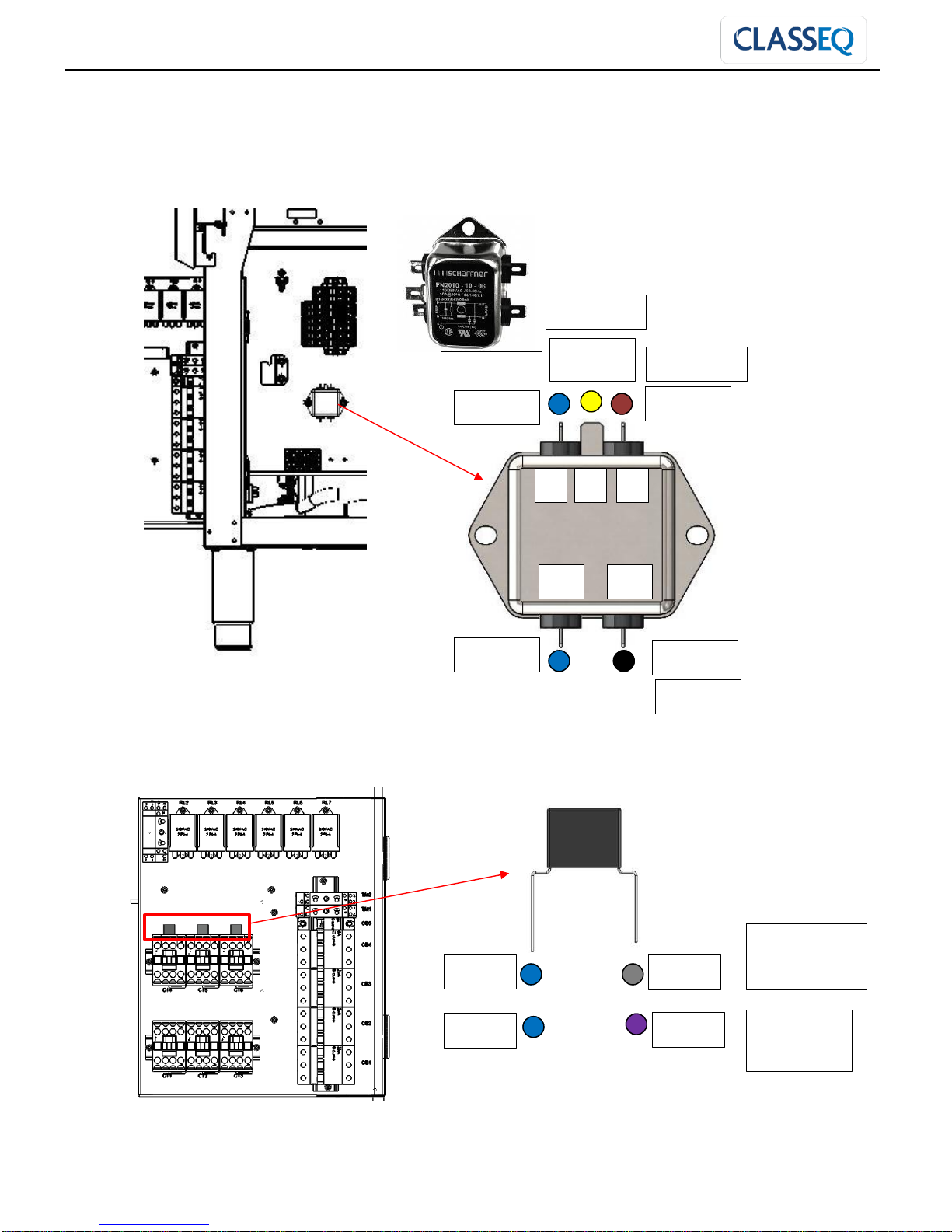

Machine Filters

1) Suppression filter (4 Amp)

2) RC Filters

Brown

Blue

Black

Blue

P

P1

N1

N

E

Yellow -

Earth

CT4 & CT5

Rinse heating

contactor

CT6 Wash

heating

contactor

Grey

Purple

Blue

Blue

To CB5

From TB1

From TB1

From TB1

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 37 of 48

Revision: C

Machine thermostat wiring

Rinse standby thermostat (ST1) Rinse run thermostat (ST2)

Wash thermostat (ST3)

Grey

Orange

2 1 2

Grey

Black

Red cover / Normally Closed

Black cover / Normally Open

White cover / Common

1

Red cover

Black cover

White cover

Red cover

Black cover

White cover

2

1

Red cover / Normally Closed

Black cover / Normally Open

White cover / Common

Purple

White

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 38 of 48

Revision: C

Machine options / Selection

Table end switch (CC4 and CC5) connector plug

Basket present switch (SW4) connector plug

Motor clutch switch (SW2) connector plug

Door switch (SW3) connector plug

Purple

Black

Grey

Blue

Brown

Red

Red

Red

Brown

Red

Grey

Red

Brown

Common

Air break

Pressurised

Purple

Brown

Brown

Grey

Red

White

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 39 of 48

Revision: C

Note: Connect capacitor terminals with

the wires coming from Rinse pump

Components wiring

Component

Part number &

Description

Wiring configuration

Inlet Solenoid Valve

Rinse safety

Thermostat (95°C)

Wash safety

Thermostat (85°C)

Wash Air

pressure Switch

Rinse Air

pressure Switch

Rinse Pump

Wash pump

Drive motor

11 / 14 / 12 22 / 24 / 21

Purple Black

Blue Wire

White Crimp

Grey wire

White Crimp

Blue Wire

White Crimp

Double blue Wire

White Crimp

Blue Wire

White Crimp

Double blue Wire

White Crimp

11 / 14 / 12 22 / 24 / 21

Grey Red

Red Brown

U1

V1

W1

U1

V1

W1

Purple

Black

Grey

Brown

Black

Grey

Brown

Blue

D Purple

Blue

Brown White

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 40 of 48

Revision: C

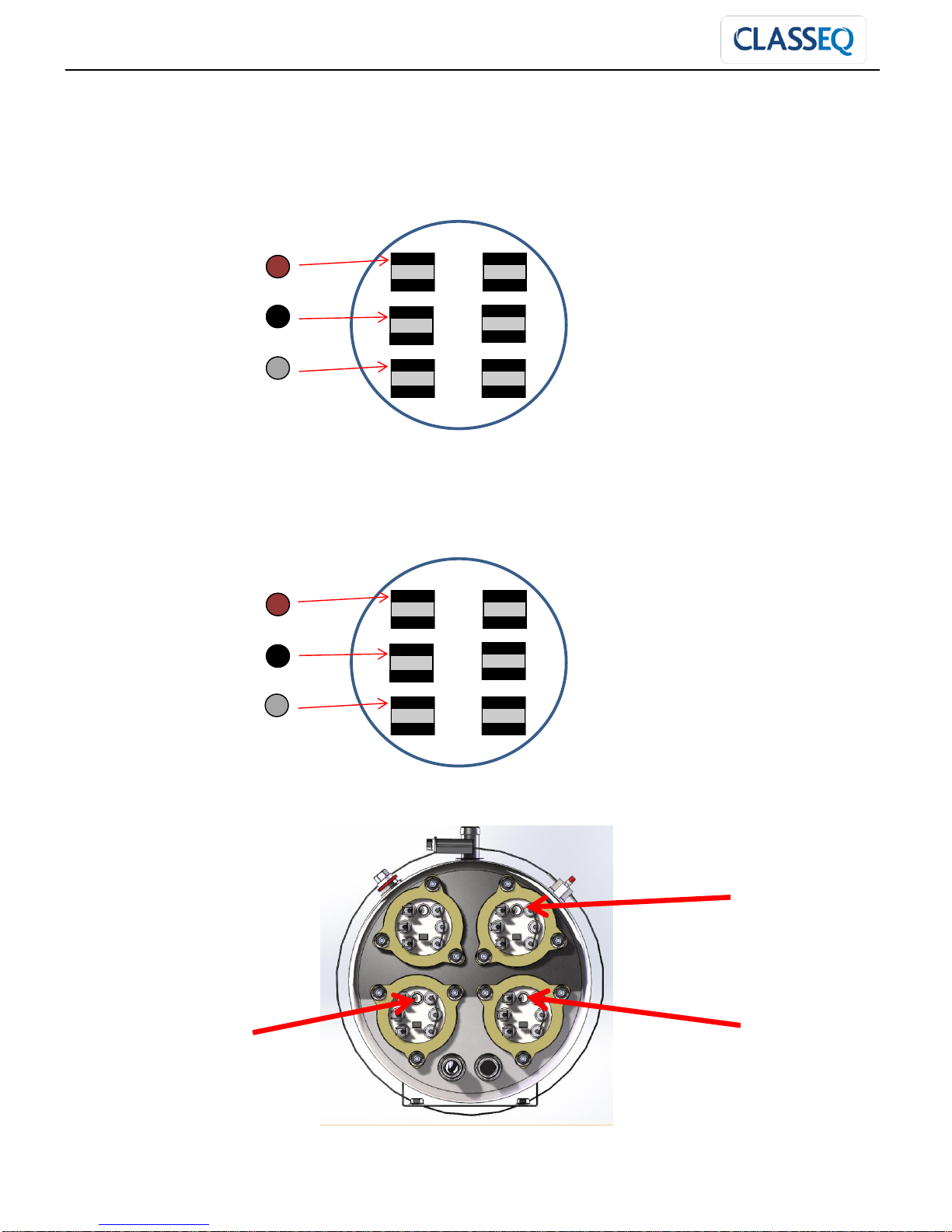

Element wiring

6kW Rinse elements, using LM-CST-HEATING

Element 1, 2, 3 & 4:

6kW Wash elements, using LM-CST-HEATING

Element 5 & 6:

Temperature probes:

Brown wire (Thick)

Black wire (Thick)

Grey wire (Thick)

Brown wire (Thick)

Black wire (Thick)

Grey wire (Thick)

Temperature gauge

Running temperature:

82-85 degrees

Standy Temperature:

55-58 degrees

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 41 of 48

Revision: C

15. Dryer unit wiring and layout

Dryer control panel layout

Tempraure rdfd

Air heater relay (RL8)

Heater safety relay (RL9)

Blower relay (RL10)

Dryer breaker (CB6)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 42 of 48

Revision: C

Dryer terminal block (TB3)

Earth

1.5mm

Black

0.5mm

Orange

0.5mm

White

0.5mm

Grey

0.75mm

Black

0.75mm

Brown

0.75mm

White

1.5mm

Purple

1.5mm

Brown

1.5mm

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 43 of 48

Revision: C

Blower terminal block

From TB3

From thermal

safety trip

To TB3

From TB3

Brown

Black

Grey

White

Red

Earth

Linked

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

Blue

Brown

Black

White

White

Earth

Red

Grey

Orange

To blower motor

Dryer breakers

Type

Breaker

size

Breaker

number

Wire colour / Connection configuration

16A

Breaker 6

(3 phase

breaker)

Incoming wire from Terminal block (TB3)

Out going wire to Drive motor relay (RL8)

Incoming wire from Terminal block (TB3)

Out going wire to Drive motor relay (RL8)

Incoming wire from Terminal block (TB3)

Out going wire to Drive motor relay (RL8)

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 44 of 48

Revision: C

Dryer relays

Air heater relay (RL8)

Heater safety relay (RL9)

Blower relay (RL10)

Dryer thermostat

Red cover

Black cover

White cover

Green cover

Brown

Brown

Black

Blue

Purple

White

White

Purple

Brown

Brown

Black

Blue

Black

Grey

Grey

Black

Brown

Brown

Orange

Blue

Grey

White

22

32

24

34

21

31

12

14

11

A1

A2

22

32

24

34

21

31

12

14

11

A1

22

32

24

34

21

31

12

14

11

A1

A2

Normally closed

Normally open

Common

Coil

A2

Red cover

Black cover

White cover

Green cover

Orange

White

1

Red cover

White cover

2

Purple

Black

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 45 of 48

Revision: C

Dryer safety thermostat

Rinse safety

Thermostat (100°C)

Dryer elements

6kW Delta connection

Red Wire

White Crimp

Black Wire

White Crimp

Dryer Element 2 (E8)

Dryer Element 1 (E7)

White wire

from TB3

Purple wire

from TB3

Brown wire

from TB3

Black wire

Brown wire

Grey wire

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 46 of 48

Revision: C

16. Trouble shooting

I. Machine does not fill:

Check water supply is turned ON.

Check water supply hose is not trapped or kinked.

Check that the machine is switched ON.

Check that door is closed.

Check table end switch has not been activated.

Check there is no obstruction around the drive plate or cassette.

Check that the air pressure switches are switched correctly (see wiring diagram)

Check solenoid valve and rinse pump are getting powered up.

II. Cycle does not start:

Check that the machine is switched ON.

Check wash tank is full.

Check that the error lamp is not illuminated.

Check basket arm rod touching the basket.

Check water supply is turned ON.

Check water supply hose is not trapped or kinked.

Check that the rinse boiler is full.

Check that breaker 4 and 5 are both on.

III. Machine fills slowly:

Check water supply tap is fully open.

Check water supply hose is not trapped or kinked.

Check water supply pressure and remove any pressure regulator or reducer.

Check and clean rinse jets (located on the rinse arms within the machine).

Check drain plug securely fitted and sealing.

Check the correct flow restrictors are fitted:

o Purple (4l/min) in rinse hose

o Orange (8l/min) in solenoid

IV. Machine not heating:

Check machine is ON.

Ensure enough time has been allowed for machine to reach correct temperatures.

Check that the machine is full of water.

Check that breaker 3 is ON.

Check breaker 1 and 2 are on as relivent.

V. Machine not draining:

Check and clean all filters within the machine.

Check that the drain is not clogged / blocked / kinked.

Check waste hight is below the base of the machine.

VI. Poor wash results:

Check and replenish chemicals.

Ensure chemical dosing is corect.

Check and clean wash and rinse jets on the wash and rinse arm assemblies.

Clean filters within machine and check that they are fitted correctly.

Check water supply is ON and fully open.

Rinse dishes of food debris before placing into the dishwasher.

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 47 of 48

Revision: C

VII. Overfilling:

Drain machine fully, then try again to fill the machine.

Check and clean all filters within the machine.

Check drain height is configured correctly.

Check that drain is not clogged / blocked / kinked.

Check and clean drain plug.

Check wash APS is switching correctly.

VIII. Wash water foaming:

Check chemicals are manufactured for use in commercial dishwashers.

Check wash water is up to temperature.

Check chemical dosing is set according to the chemical manufacturers requirements.

Check wash tank thermal trip.

Drain, refill and allow re-heating.

IX. Will not turn ON:

Check and reset circuit breaker within the sites fuse board.

Check and reset breaker 5.

Check on/off relay (RL1).

X. Basket not moving:

Check for obstructions on the drive rail and at the drive plate.

Check cassette is fitted correctly and flat.

Check that machine error lamp is not illuminated.

Check breaker 4 is ON.

Check both timers are opperating.

Check drive motor relay (RL5).

XI. Machine stopping and starting while in a cycle:

Check water supply hose is not trapped or kinked.

Check water supply tap is fully open.

Check dynamic water pressure is above 2 bar.

Check table end switch has not been activated.

Check the correct flow restrictors are fitted:

o Purple (4l/min) in rinse hose or Fitted Flow restrictor

o Brown (5l/min) in solenoid

Check over run timer (TM2) is set and working correctly.

XII. Red (Error) lap illuminated:

Check door is closed.

Check driving cassette is not jammed.

Check table end switch has not been activated.

XIII. Blower unit not blowing air:

Check blower wiring.

Check dryer unit breaker (6).

XIV. Dryer not heating air:

Check dryer unit breaker (6).

Check dryer heater thermal trip.

ENGINEERS MANUAL CST MACHINES AND DRYER UNIT

Drawn up: 05/10/2018

Document number : 30008893

Page 48 of 48

Revision: C

Classeq Ltd

Winterhalter House

Roebuck Way

Knowlhill

Milton Keynes

MK5 8WH

Spares department

0844 225 9252

spares@classeq.co.uk

Service department

0844 225 9245

service@classeq.co.uk

Classeq Ltd

Loading...

Loading...