Installation

Installation

&&

Operators Manual

Operators Manual

C200G, C300G

C200G, C300G

C500U, C750U & C850P

C500U, C750U & C850P

Part number 902.0002

Revision C

DISHWASHERS, COMMERCIAL

51GA

Installation and Operation instructions

Installation and Operation instructions

For ‘Classeq Inc.’ under counter range of glass and dishwashers.

Section Title Page(s)

1

Safety instructions

1

2

The appliance

1

3

Installation

2 - 4

4

Commissioning

4 - 5

5

Operation

6 - 7

6

Cleaning

8

7

Trouble shooting

8 - 10

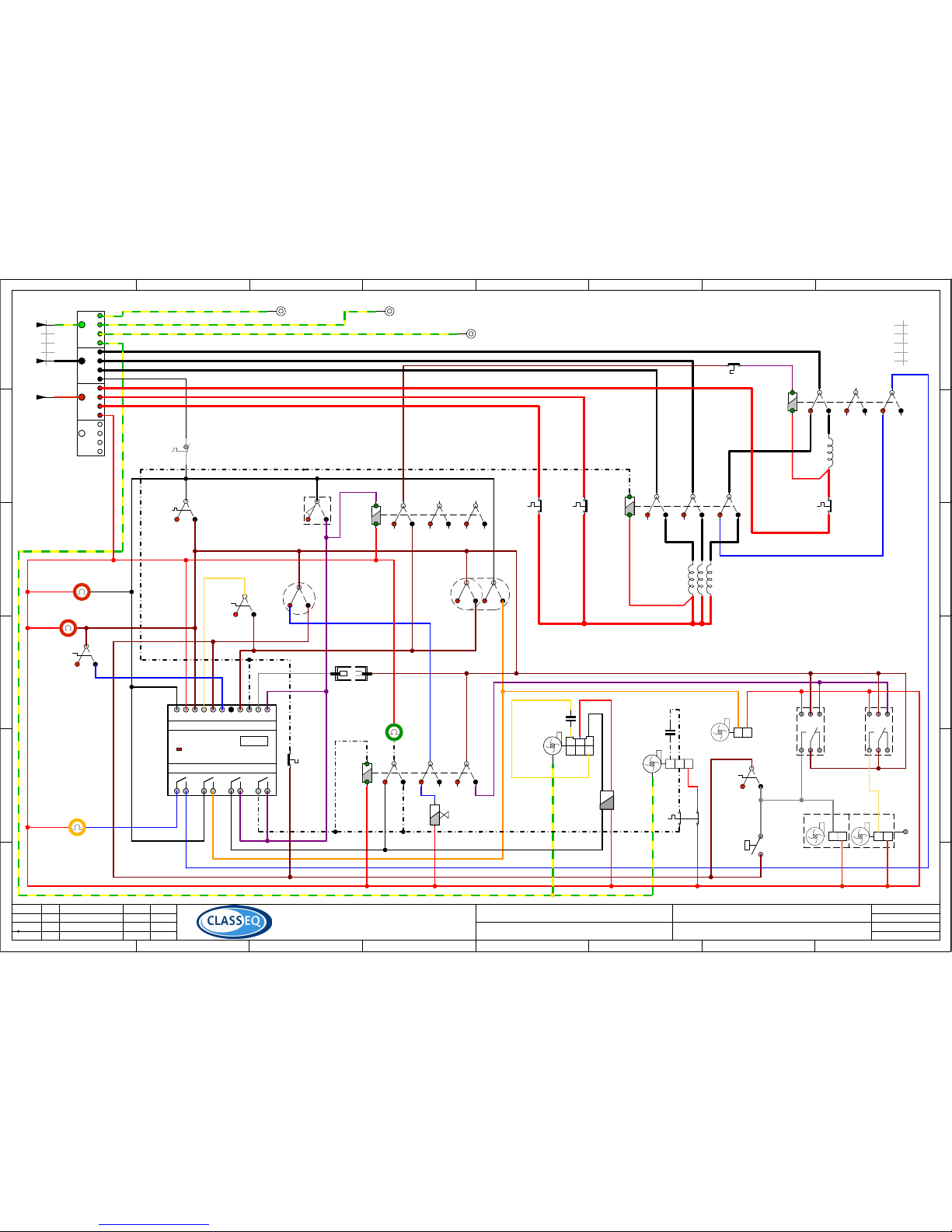

LM-C200G

Wiring diagram - C200G & C500U

11

LM-C750U

Wiring diagram - C300G & C750U

12

LM-C850P

Wiring diagram - C850P

13

CAREFULLY READ THESE INSTRUCTIONS, BEFORE INSTALLING AND

OPERATING THIS APPLIANCE.

INCORRECT INSTALLATION, ADAPTATIONS OR ALTERATIONS COULD RESULT IN

INJURY OR DAMAGE TO PROPERTY.

MALICIOUS DAMAGE, DAMAGE DUE TO NEGLIGENCE, OR FAILURE TO COMPLY

WITH THESE INSTRUCTIONS AND LOCAL LEGISLATION, OR UNAUTHORIZED

TAMPERING WILL INVALIDATE ANY WARRANTY AND RELIEVE THE

MANUFACTURER OF ALL LIABILITY

1.0 Safety instructions

1.0 Safety instructions

1.1 Warning :

1.2 Installation :

Installation should only be carried out by a ‘Classeq’ approved technician, and in accordance with

current regulations and within our instructions.

1.3 Modification :

‘Classeq Inc.’ reserves the right to modify either the appliance or the contents of these instructions

without notice.

1.4 Operation :

The appliance should only be used by a trained operator as instructed in section 5 of this manual.

1.5 Failure / malfunction :

In the event of a failure / malfunction, the main electrical and water supplies MUST

be turned off at the source and not just at the machine.

1.6 Repairs and spare parts :

The appliance must only be repaired by a ‘Classeq’ approved technician, using genuine ‘Classeq’

spare parts.

2.0 The appliance

2.0 The appliance

2.1 Unpacking :

Use suitable means and protective equipment to avoid injury when unpacking and handling the

appliance. Remove all outer packaging and the protective film from the outer panels of the appliance

prior to installation.

Ensure all packing materials are disposed of in accordance with local regulations.

2.2 Items included :

The following items are included within the appliance

• 2 x Baskets

• 1 x Cutlery basket (Dishwashers only)

• 1 x Drain hose (C850P only, all other machines drain hose permanently attached)

• 2 x Bottle weight kits (for Rinse Aid and Detergent tubes)

• 1 x Installation and Operation Instructions (Must be left with the customer)

Page 1

3.0 Installation

3.0 Installation

3.1 The site :

Ensure that there is sufficient space for the installation, servicing and easy access to all main

breaker switches / valves (i.e. electricity and water).

Ensure that the surface the appliance is going to be installed onto is adequately stable and capable

of supporting the appliance during normal operation, listed below are the approximate machine

weights when fully laden during normal operation.

C200G, C300G, C500U and C750U must be installed onto a metal stand in accordance with CSA

168, clause 5.10 (Canadian Standards Association)

Once installed ensure that the appliance is stable and secure, with its weight being distributed

equally and does not tilt more than 3° in any direction.

If the appliance is being installed onto a stand or table, ensure it is capable of withstanding the ‘Fully

loaded’ weight for the appliance stated below.

3.2 Electrical connection :

All electrical connections MUST be carried out by an authorized technician and in accordance with

local regulations.

As a minimum ‘Classeq’ recommends that the following standards are maintained :

• All appliances must be connected via a circuit breaker or some other protective device,

for the rating of the device refer to either the rating plate on the appliance or the last

page of this manual.

• Supply breaker switch must have all pole separation of more than 1/8 inch (3mm).

• The cabinet of the appliance must be grounded, the connection stud is located at the rear of the

appliance (a suitable ring terminal shall be required), this is in addition to the main electric ground.

3.2.1 Electrical rating :

For the electrical rating details, please refer to either the rating plate on the appliance or the last

page of this manual.

Each appliance is designed to run at either 208v or 240v AC, without any modifications, please note

that the ratings between the two voltages do change.

3.2.2 Connection :

The main electrical connection must be made via the field terminal block, which is located :

• C200G, C500U, C300G and C750U - Under the top panel, front right hand side of the

appliance.

• C850P - Behind the front lower panel, located at the bottom of the control panel.

For supply connections, use copper wires suitable for at least 194ºF (90ºc ), of the following sizes

• C200G and C500U minimum wire gauge = 14 AWG (2.5mm²) minimum gauge

• C300G, C750U and C850P = 8 AWG (10mm²) minimum gauge

Machine sizes Weight (fully loaded) Weight (transport / shipping)

C200G & C500U

198 lbs (90 Kgs) 165 lbs (75 Kgs)

C300G & C750U

298 lbs (135 Kgs) 198 lbs (90 Kgs)

C850P

386 lbs (175 Kgs) 287 lbs (130 Kgs)

Page 2

Page 3

3.3 Water connection :

The appliance comes with a water supply hose requiring a ¾” NTP male threaded connection at the

main water supply, upon installation and commissioning all water joints must be checked for leaks.

3.3.1 Water supply restrictions :

Water supply constraints must be adhered to.

In hard water areas, Classeq advises that a external water softener is fitted to the supply of the

appliance, please consult your agent or Classeq for more information.

Do not connect to hot water supply exceeding a temperature of 131ºF (55°c).

• 15 to 60 p.s.i. No modifications required, maximum temperature of 105ºF (40ºc)

• 60 to 90 p.s.i. Flow restrictor required, maximum temperature of 67ºF (20ºc)

• 90 p.s.i. + Pressure reducing valve required, maximum temperature of 50ºF (10ºc)

3.2.2 Connection (cont.):

For all appliances, the field terminal block must be wired in accordance with the instructions

located near the field terminal block on the appliance.

Field terminal block

Hot 1 (Live 1)

Hot 2 (Live 2)

Hot 3 (3ph units only)

Ground (Earth)

3.3.2 Drainage systems

To ensure that the appliance correctly drains, ensure the correct configuration is true for the

appliance.

All installations must be with a running ‘P’ trap to ensure hygiene :

C200G, C300G, C500U and C750U

• Diameter 1 ½” (40mm) standpipe required

• Standpipe must be 4” to 6” (100 to 150mm)

below the top of the appliance.

• The end of the waste outlet hose in the stand-

pipe must not be lower than the bottom of the

door.

• The waste outlet hose must be a loose fit within

the standpipe.

Bleeding of drain system on C200G, C300G, C500U and C750U

After installation once the tank is partially filled and before the 1st wash cycle the drain system

MUST be ‘BLED’, simply lower the drain hose into an empty bucket and allow approximately 1/2

gallon of water to flow out of the hose, carefully return the hose to the stand pipe as shown above.

Ensure any spillage is cleaned before leaving the appliance

Page 4

C850P (only)

• Flexible waste hose must be securely attached to

the waste outlet elbow on the rear of the machine.

• The waste hose must flow down from the waste

outlet elbow to the drain.

• Diameter 1 ¼” (35mm) standpipe required, must be

lower than the baseline of the appliance

• C850P standpipe must be a minimum of 3” (75mm)

below the baseline of the appliance.

• Hose to be a close / tight fit into the drain pipe to

reduce odors from the drain system

4.1.2 Detergent / Soap prime :

The detergent / soap pump system on these appliances are self priming.

4.1.3 Chemical dosage :

Chemical doses are pre-set to the following nominal values, however, these values should be

calibrated to suit individual sites requirements

4.1.1 Rinse aid prime :

• Switch machine ON and allow to fill

• There are two prime switches on the

machine one on the front lower panel

and the other inside the machine,

Classeq would recommend that the

external switch is used for priming the

chemical.

• Depress and hold switch.

• To fully prime, this will take approx 1 ½

minutes (90 seconds).

4.1 Rinse aid & detergent :

Ensure PVC chemical hoses are attached correctly to the individual chemical pumps (pumps located behind front lower panel of the appliance).

At the bottle end of the PVC chemical hoses, slide the rigid plastic tube over each hose then push

the brass bottle weight onto the end of each hose, now place the hose , tube and bottle weight

into the correct chemical bottle.

Ensure the correct chemical tubes now go to the corresponding chemical bottles.

WARNING : Only rinse aids and detergents developed for commercial glass and dishwashers are

to be used, rinse aids must be suitable for water temperatures of 104°f or higher.

4.0 Commissioning

4.0 Commissioning

Internal prime switch located

on the chemical pump

bracket, Classeq recommends

that this is only used by qualified service engineers

Page 5

4.2 Rinse & wash tank temperatures :

To ensure NSF compliance, the water temperatures on ’Classeq’ range of appliances must be set to

the following.

Machine type

Temperatures (minimum)

Rinse water Wash water

180ºF (82°c) 150ºF (66°c)

C200G, C300G, C500U, C750U & C850P

4.3 Machine ready status :

All the appliances are designed to allow a cycle to commence once the wash tank and rinse boiler

are full, not taking into account the temperature of their associated water.

To ensure NSF compliance, the temperatures must be set as stated in section 4.2 of this manual

and the ‘Machine ’GREEN ’ lamp is illuminated, then and then only should a cycle be selected.

To adjust the amount of chemical, rotate the centre dial on the timers , the timers are located

C200G, C500U, C300G and C750U - Under the top panel of the appliance.

C850P - Behind the front lower panel on the control panel

Machine sizes

Rinse aid

Cycle

Deter-

gent

Cycle

C200G 5 10

C300G 5 10

C500U 5 10

C750U 5 10

C850P 5 10

Pre-set values (in seconds)

4.4 Demonstration :

‘Classeq’ recommends that prior to leaving the site / installation, the installer demonstrates the

following to the end user, as this will ensure the appliance is correctly used

• What to do in case of an emergency, i.e. how to turn the appliance off at the source (see

section 1).

• Switching the appliance on.

• Operating the appliance.

• Draining down.

• Switch the appliance off.

• Clean the appliance, including removal and replacement of all filters.

• Replenishing and priming of rinse aid and detergent.

Upon completion of the installation and commissioning of the appliance, this manual MUST be left

with the end user.

Page 6

5.0 Operation

5.0 Operation

5.1 Machine description :

The design of commercial glass and dishwashing machines differ from their domestic versions as

they are designed to run nearly continually for many hours.

Commercial appliances, wash results can be effected by external considerations such as incoming

water temperature, pressure, hardness and choice of chemicals, ‘Classeq’ recommends that your

appliance is either connected to a water softener or a softened water supply, for further details on

water softeners please contact the supplier of your appliance.

5.2 Controls :

Prior to switching the machine ON, ensure that you are familiar with the controls on the front fascia

of the appliance and the location of the isolator for mains electricity and water supply.

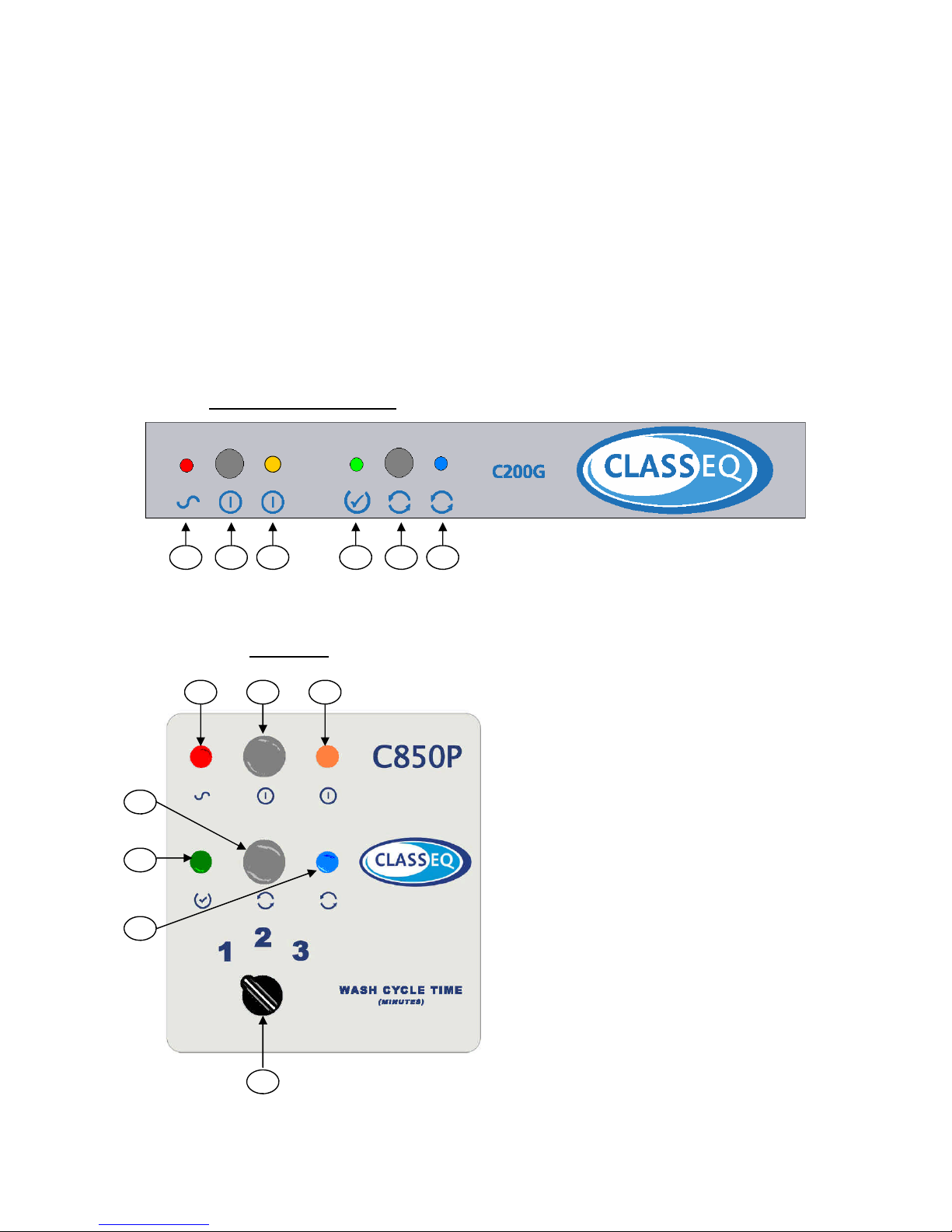

C200G, C500U, C300G, C750U

1. Power lamp (Red)

2. ON / OFF Button

3. ON / OFF Lamp (Yellow)

4. Machine Ready lamp (Green)

5. Wash Button

6. Cycle lamp

7. Selector switch (optional on C850P only)

In addition to these switches there are two further

switches on the front of the appliance

• Rinse Aid Prime button

• Refer to section 4.1.1 of this manual

• Continual wash button (optional)

• The function of this button will only work

when the machine is full and switch ON.

• Once depressed, the wash pump will run

for 10 minutes, during the cycle lamp 6 will

be illuminated.

• At the end of the 10 minutes neither the

rinse or drain pumps will operate

• This button must only be used when using

either lime scale remover or renovate

chemicals are being applied.

• Classeq recommends that once the cycle

has been completed that the machine is

switched OFF and allowed to fully drain

down

1 2 3 4 5 6

C850P (only)

2 1 3

4

5

6

7

Page 7

5.3 Switch the machine on :

Ensure that both the water and electrical supply are connected and turned on, then

depress the ‘ON/OFF’ button located on the front of the machine.

The machine will now automatically fill and heat, during this process the door should remain closed,

allowing the process to be completed quickly.

5.4 Machine ready to operate :

As state section 4.3 of this manual, it will be possible to start a cycle prior to the ‘Machine Green’

lamp being illuminated, to ensure NSF compliance ‘Classeq’ recommends that you wait for the

lamp to be illuminated before requesting a cycle to commence.

Please note for safety reason the wash heating element turns off when the door is opened,

’Classeq’ therefore advise that the door is closed between cycles.

5.5 Starting a cycle :

To start a cycle, open the door / hood, depending upon your appliance, load the first

basket, ensuring that all arms rotate freely.

Close the door, then depress the ‘Cycle’ button, your appliance will now automatically progress

though the cycle, during which time the ‘Cycle’ lamp will be illuminated.

At the end of the cycle open the door and remove the basket, then reload the machine

and repeat as required

5.6 Draining :

During normal operation your appliance will automatically drain away any excess water. ’Classeq’

recommends if your appliance is not being used for a prolonged period of time the machine must be

completely drained down

C200G and C500U

• Switch appliance OFF at the front

• Remove drain plug from wash tank.

• Ensure that door is closed

• Your appliance will now automatically drain down

• Once completed replace the drain plug.

• Now isolate main water and electricity at the wall.

C300G, C750U and C850P

• Switch appliance OFF at the front.

• Ensure the door is closed.

• Your appliance will now automatically drain down

• Once completed, isolate main water and electricity at the wall.

Note !

Once empty ‘Classeq’ recommends that the main water and electricity supplies are

isolated at the wall and the machine be cleaned as instructed in section 6 of this manual

For hygiene reasons it is recommended that once the appliance has been drained that

the door is left open to assist in natural drying of the wash chamber

Page 8

6.0 Cleaning

6.0 Cleaning

6.1 Prior to cleaning :

Switch off and isolate electrical supply before cleaning the appliance

WARNING

DO NOT use cleaning agents that contain CHLORINE, BLEACH or HYPOCHLORITE.

DO NOT use STEEL WOOL, WIRE BRUSHES or any other abrasive materials.

DO NOT jet wash or hose pipe the appliance down either internally or on the exterior

6.2 Internal cleaning :

Remove wash / rinse arms and filters from within the appliance, now remove

the individual wash and rinse jets from each arm and wash in warm soapy

water, ensuring all debris are removed then rinse in clean water before

reassembling and fitting back into the appliance.

WARNING

Before cleaning the wash chamber, ensure all sharp items, such as broken glass or

other items which could cause injury are removed carefully

Now wipe the inside of the wash chamber ensuring any debris are removed

and the chamber is clean, now reassemble all filters and wash arms.

6.3 Exterior cleaning :

Wipe the exterior of the appliance with a damp sponge (NOT WET)

Once dry, clean using a STAINLESS STEEL cleaning agent

Page 9

7.0 Trouble shooting

7.0 Trouble shooting

• Before placing a service call, please check the following:

• Check the appliance is connected to the main water and electricity supply and both are turned

on.

• Check levels of chemicals within the rinse aid and detergent bottles.

• Check the drain / stand pipe is correct for the appliance (refer to section 3.3.2 of this manual).

NOTE

In the event of a service call being made under Warranty, and it is found that the faults are due

to non-observance of instructions in this manual, the call will be charged at current rates.

7.1 Appliance does not fill :

Appliance does not start :

Appliance does not rinse :

• Check water supply is turned ON.

• Check water supply hose is not trapped or kinked.

• Check that the appliance is turned ON at the source.

• Drain appliance fully, then try again to fill the machine, drain as per instructions 5.6 of this

manual..

7.2 Appliance fills slowly :

• Check water supply valve is fully open.

• Check water supply pressure, should be above 30 lbs per square inch, if not ask your dealer

to install a booster pump to increase water pressure.

• Check and clean rinse jets (located on the wash arms within the appliance).

• Check water supply hose is not trapped or kinked.

• Remove any pressure regulator or reducer from the water supply.

7.3 Appliance not heating :

• Drain appliance fully, then try again to fill the machine, drain as per instructions 5.6 of this

manual.

• Check the temperature of the main water, as variations in water temperature will affect the

heating of the appliance.

• Check that the wash chamber is full of water.

7.4 Appliance not draining :

• Check and clean all filters within the appliance.

• Check that the stand pipe / drain is not clogged / blocked.

Page 10

7.5 Poor wash results :

• Check and replenish chemicals.

• Check and clean wash and rinse jets on wash arm assembly.

• Clean filters within appliance and check that they are fitted correctly.

• Check water supply is ON and fully open.

• Rinse dishes of any food debris before placing into the dishwasher.

• Glasses may need to be refurbished.

• If glasses are ‘Blooming’ you may need a water softener, call your dealer to advise on size of

water softener required.

• If connected to a water softener, replenish the salt within the softener, as per the water

softener instructions.

7.6 Overfilling :

• Drain appliance fully, then try again to fill the machine, drain as per instructions 5.6 of this

manual.

• Check and clean all filters within the appliance.

• Check that the stand pipe / drain is not clogged / blocked.

• If the appliance continues to overfill turn off both the main electricity and water, before call a

service technician.

7.7 Will not switch ON :

• Ensure there is main electrical supply

7.8 Will not switch OFF :

• Isolate at main electricity before calling for a service technician immediately.

E

D

C

B

F

A

E

D

C

B

F

A

87

65

4

3

2

1

87

65

4

3

2

1

of

Sheet

Approved

Drawn

Date

Name

Date

Comment

Revision

any other purpose without writtern permission from Classeq Ltd.

not be disclosed, loaned, copied or used for manufacturing, tendering or

DCN No.

Title

Loom / Dwg No.

This drawing and any information or descriptive matter set out hereon

are the confidential and copywright property of CLASSEQ LTD and must

© Classic Glass & Dishwashing Systems Ltd.

Special Notes

Standards

1

LM-C200G

D

C

B

Production

Production

Production

06/03/06

18/01/06

06/09/05

M.D.

M.D.

M.D.

04/08/05

M. Downing

T. Lovatt

DCN0051

DCN0053

1

UL and NSF

0

1

TCB-1

-SD3

Breaker

ZE-700-4

90

11

12

14

7.12.90

-APS5

Double APS Wash

A2-DP0401

17

21

22

24

11

12 14

-APS6

Rinse APS

Single (Oval)

18

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT10

W Element Cont

46

11

12

A1

A2

14

31

32 34

21

22

24

-CT5

R element Cont

45

7.14.10/1

-Sw17

Door Sw

19

Q1

Q2

Q3

Q4

L1 NI1I2

I3 I4 I5 I6 I7

I8

LOGO!

230RCo

OUTPUT 4xRELAY/10A

INPUT 8xAC/DC

AC/DC 115..240V

RUN/STOP

Classic

Part No. :- ES-06

ES-06

-PLC2

Controller

51,52

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT15

Cycle Latch

Cycle Lamp

49

7.12.6/9

-L9

Mc Ready Lamp

22

A2

A1 B1

1518 16

ES-07

-T5

RA timer

80.01

55

A2

A1 B1

1518 16

ES-07

-T6

Soap timer

80.01

55

Dishwash select

7.12.1/4

-SRS2

Wash trip

76

7.12.12/1

-IS1

Inlet sol. val.

67

Rinse Aid Soap

LN LN

8LPP4DS

-P5

Chemical Pump Assy

61,60

E (PE)

7.12.4/65

-Sw5

R. Aid Prime

1213C BLACK

110

LN

DP2

-P2

Drain Pump

DPS25-091

66

+

-

7.12.102

-C1

W. P. Capacitor

68

+

-

DS400-05-11

-C2

R. P. Capacitor

1274WC34400

68

7.12.1/4

-SRS13

Trip

79

L

N

9.12.17/2.5

-E2

Wash Element

82

7.12.6/8

-L6

Supply lamp

20

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

500.0001

-Sw54

On/Off Switch

10

501.0001

-Sw55

Cycle sw

11

7.12.6/4

-L25

On/Off lamp

21

7.12.6/1A

-L26

Cycle lamp

23

540.0003

-MRS12

WE safety trip

71

540.0003

-MRS13

RE safety trip

70

L

N

7.12.17

-E13

Wash Element

82

CLC

N

E

DS400-05-10

-P6

Rinse Pump

UP60-159

63

1

23

456

C

NL

C

E

DS400-04-10

-P18

Wash Pump

CP50-163

64

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT49

Door cont

40

Ground

Hot (1)

Hot (2)

Neutral

580.0001

-TB11

Terminal Block

1414400

30

Ground

Hot 1

Hot 2

501.0001

-Sw56

De Scale Sw

501.0001

-Sw57

R.Aid Prime

501.0001

Fascia EarthContactor Plate Earth

Cabinet Earth

C200G & C500U - Wiring Diagram (USA)

Disconnect if the m/c

is a glasswasher

39X

15 amp = Grey to terminal 31 of 'RE contactor'

28 amp = Brack to terminal 31 of 'RE contactor'

White

0.50 mm²

White

0.50 mm²

White

0.50 mm²

E

D

C

B

F

A

E

D

C

B

F

A

87

65

4

3

2

1

87

65

4

3

2

1

of

Sheet

Approved

Drawn

Date

Name

Date

Comment

Revision

any other purpose without writtern permission from Classeq Ltd.

not be disclosed, loaned, copied or used for manufacturing, tendering or

DCN No.

Title

Loom / Dwg No.

This drawing and any information or descriptive matter set out hereon

are the confidential and copywright property of CLASSEQ LTD and must

© Classeq Ltd.

Special Notes

Standards

1

LM-C750U

D

C

B

Trip added

Production

Production

06/03/06

18/01/06

06/09/05

M.D.

M.D.

M.S.

04/08/05

M. Downing

T. LovattDCN0051

DCN0053

1

UL and NSF

Ground

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

0

1

TCB-1

-SD3

Breaker

ZE-700-4

90

L

N

HY306

-E1

Rinse Element

80

7.12.12/1

-IS1

Inlet sol. val.

67

LN

DP2

-P2

Drain Pump

DPS25-091

66

Rinse Aid Soap

LN LN

8LPP4DS

-P5

Chemical Pump Assy

61,60

E (PE)

L

N

9.12.17/2.5

-E2

Wash Element

82

7.12.4/65

-Sw5

R. Aid Prime

1213C BLACK

110

12

11

14

22

21

24

7.12.90

-APS5

Double APS Wash

A2-DP0401

17

1

23

456

C

NL

C

E

9.6.0/R

-P1

Wash Pump

H7

64

+

-

7.12.102

-C1

W. P. Capacitor

68

CLC

N

E

DS500-05-10

-P6

Rinse Pump

UP60-159

63

+

-

DS400-05-11

-C2

R. P. Capacitor

1274WC34400

68

7.14.10/1

-Sw17

Door Sw

19

11

12

A1

A2

14

31

32 34

21

22

24

-CT5

R element Cont

45

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT10

W Element Cont

46

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT15

Cycle Latch

49

7.12.6/8

-L6

Supply lamp

20

7.12.6/9

-L9

Mc Ready Lamp

22

11

12 14

-APS6

Rinse APS

Single (Oval)

18

7.12.1/4

-SRS2

Wash trip

76

7.12.1/4

-SRS13

Trip

79

Q1

Q2

Q3

Q4

L1 NI1I2

I3 I4 I5 I6 I7

I8

LOGO!

230RCo

OUTPUT 4xRELAY/10A

INPUT 8xAC/DC

AC/DC 115..240V

RUN/STOP

Classic

Part No. :- ES-06

ES-06

-PLC2

Controller

51,52

A2

A1 B1

1518 16

ES-07

-T5

RA timer

80.01

55

A2

A1 B1

1518 16

ES-07

-T6

Soap timer

80.01

55

Dishwash select

500.0001

-Sw54

On/Off Switch

10

501.0001

-Sw55

Cycle sw

11

7.12.6/4

-L25

On/Off lamp

21

7.12.6/1A

-L26

Cycle lamp

23

540.0003

-MRS12

WE safety trip

71

540.0003

-MRS13

RE safety trip

70

540.0003

-MRS14

RE safety trip

70

L

N

L

N

561.0001

-SS1

SSCF-25

63

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT49

Door cont

40

L

N

TCB05

-TCB1

Breaker

-

91

Ground

Hot (1)

Hot (2)

Neutral

580.0001

-TB11

Terminal Block

1414400

30

Hot 1

Hot 2

501.0001

-Sw56

De Scale Sw

501.0001

-Sw57

R.Aid Prime

Fascia EarthContactor Plate Earth

Cabinet Earth

C300G & C750U - Wiring Diagram (USA)

Disconnect if the m/c

is a glasswasher

39X

White

0.50 mm²

White

0.50 mm²

E

D

C

B

F

A

E

D

C

B

F

A

87

6

5

4

3

2

1

87

6

5

4

3

2

1

of

Sheet

Approved

Drawn

Date

Name

Date

CommentRevision

any other purpose without writtern permission from Classeq Ltd.

not be disclosed, loaned, copied or used for manufacturing, tendering or

DCN No.

Title

Loom / Dwg No.

This drawing and any information or descriptive matter set out hereon

are the confidential and copywright property of CLASSEQ LTD and must

© Classeq Ltd.

Special Notes

Standards

1

LM-C850P

E

G

F

Trip Added

Trip posi

3 Phase

06/03/06

11/09/06

22/08/06

M.D.

M.D.

J.B.

04/08/05

M. Downing

T. Lovatt

DCN-0063

DCN0062

DCN0053

1

UL and NSF

0

1

TCB-1

-SD3

Breaker

ZE-700-4

90

11

12

14

7.12.90

-APS5

Wash APS

A2-DP0401

17

21

22

24

11

12 14

-APS6

Rinse APS

Single (Oval)

18

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT10

W Element Cont

46

11

12

A1

A2

14

31

32 34

21

22

24

-CT5

R element Cont

45

7.14.10/1

-Sw17

Door Sw

19

Q1

Q2

Q3

Q4

L1

NI1I2 I3 I4 I5 I6 I7 I8

LOGO!

230RCo

OUTPUT 4xRELAY/10A

INPUT 8xAC/DC

AC/DC 115..240V

RUN/STOP

Classic

Part No. :- ES-06

ES-06

-PLC2

Controller

51,52

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT15

Cycle Latch

Cycle Lamp

49

7.12.6/9

-L9

Mc Ready Lamp

22

A2

A1 B1

1518 16

ES-07

-T5

RA timer

80.01

55

A2

A1 B1

1518 16

ES-07

-T6

Soap timer

80.01

55

Dishwash select

L

N

HY306

-E1

Wash Element

80

7.12.1/4

-SRS2

Wash op trip

76

7.12.12/1

-IS1

Inlet sol. val.

67

Rinse Aid Soap

LN LN

8LPP4DS

-P5

Chem Pump Assy

61,60

E (PE)

7.12.4/65

-Sw5

R. Aid Prime

1213C BLACK

110

LN

DP2

-P2

Drain Pump

DPS25-091

66

+

-

7.12.102

-C1

W. P. Capacitor

68

CLC

N

E

DS500-05-10

-P6

Rinse Pump

UP60-159

63

+

-

DS400-05-11

-C2

R. P. Capacitor

1274WC34400

68

7.12.1/4

-SRS13

RE op trip

79

7.12.6/8

-L6

Supply lamp

20

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

CR-31

Eyelet Crimp

34

500.0001

-Sw54

On/Off Switch

10

501.0001

-Sw55

Cycle sw

11

7.12.6/4

-L25

On/Off lamp

21

7.12.6/1A

-L26

Cycle lamp

23

1

23

456

C

NL

C

E

9.6.0/R

-P1

Wash Pump

H7

64

540.0003

-MRS13

RE safety trip

70

L

N

9.9.14

-E13

Rinse Element

82

L

N

9.9.14

-E14

Rinse Element

82

540.0003

-MRS15

WE safety trip

71

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT49

Door Cont

40

L

N

TCB05

-TCB1

1.8A breaker

Hot 1

Hot 2

Ground

L

N

TCB05

-TCB3

8A breaker

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT50

40

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT51

40

501.0001

-Sw56

De Scale Sw

501.0001

-Sw57

R.Aid Prime

Ground

Hot (1)

Hot (2)

Neutral

580.0001

-TB11

Terminal Block

1414400

30

IIIIII

IIIIII

502.0001

-Sw58

Selector Sw

3SB400-0C

12

11

12

A1

A2

14

31

32 34

21

22

24

CONT 30

-CT53

40

Fascia Earth

Contactor Plate Earth

Cabinet Earth

C850P - Wiring Diagram (USA)

Disconnect if the m/c

is a glasswasher

39X

White0.50 mm²

White0.50 mm²

White

0.50 mm²

Classeq Inc.

1006 Corporate Lane

Export

PA15632

Tel: 724 733 2391

Fax: 724 733 2491

Notes

Loading...

Loading...