Page 1

Spray Gun

Färgspruta

Malingssprøyte

Maaliruisku

Important!

Read the entire instruction manual carefully

and make sure that you fully understand

it before you use the equipment. Keep the

manual for future reference.

Viktig information:

Läs hela bruksanvisningen noggrant och

försäkra dig om att du har förstått den innan

du använder utrustningen och spara den för

framtida bruk.

Viktig informasjon:

Les disse anvisningene nøye og forsikre deg

om at du forstår dem før du bruker enheten

og oppbevar dem for senere bruk.

Tärkeätä tietoa:

Lue nämä ohjeet huolellisesti ja varmista

että olet ymmärtänyt ne, ennen kuin alat

käyttää laitetta. Säilytä ohjeet myöhempää

tarvetta varten.

ENGLISHSVENSKANOR SKSUOMI

Art.no Model

18-3056 FL-999-UK

30-9579 FL-999

Ver. 200802

Page 2

Page 3

Spray Gun

Art.no: 18-3056 Model: FL-999-UK

30-9579 FL-999

Please read the entire instruction manual before using and save it for future use.

We apologise for any text or photographic errors and any changes in technical data.

If you have any questions concerning technical problems please contact our Custo-

mer Service Department (see address on reverse.)

Table of Contents

Description

Safety

Before starting

Use

Cleaning

Care and Maintenance

Troubleshooting Guide

Disposal

Technical Specications

ENGLISH

3

Page 4

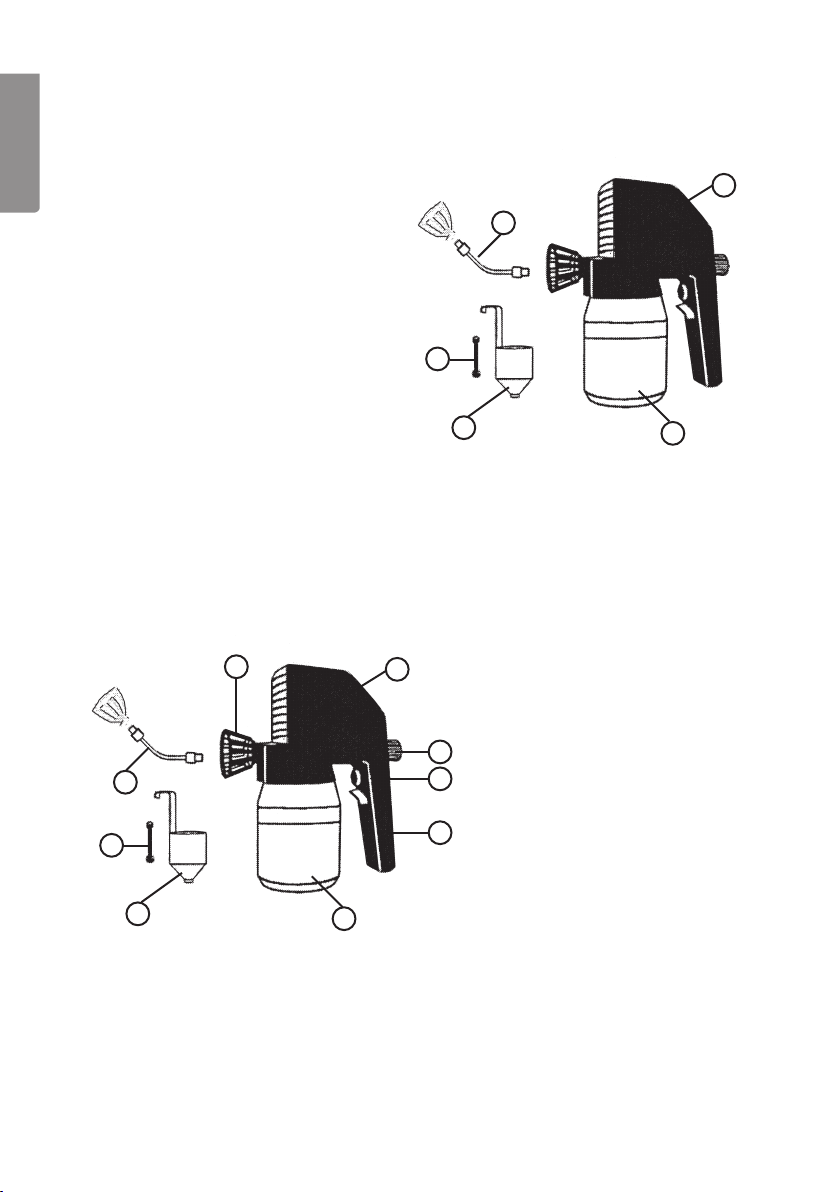

Description

Contents

ENGLISH

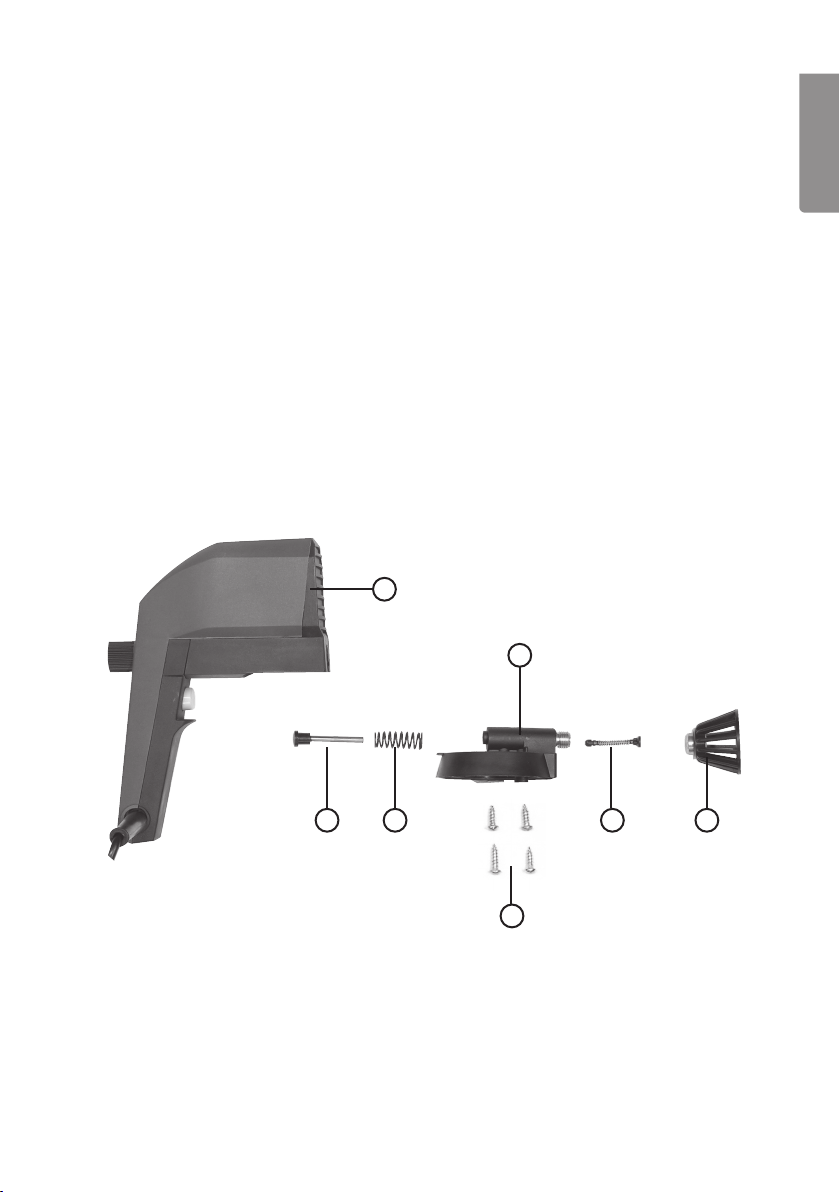

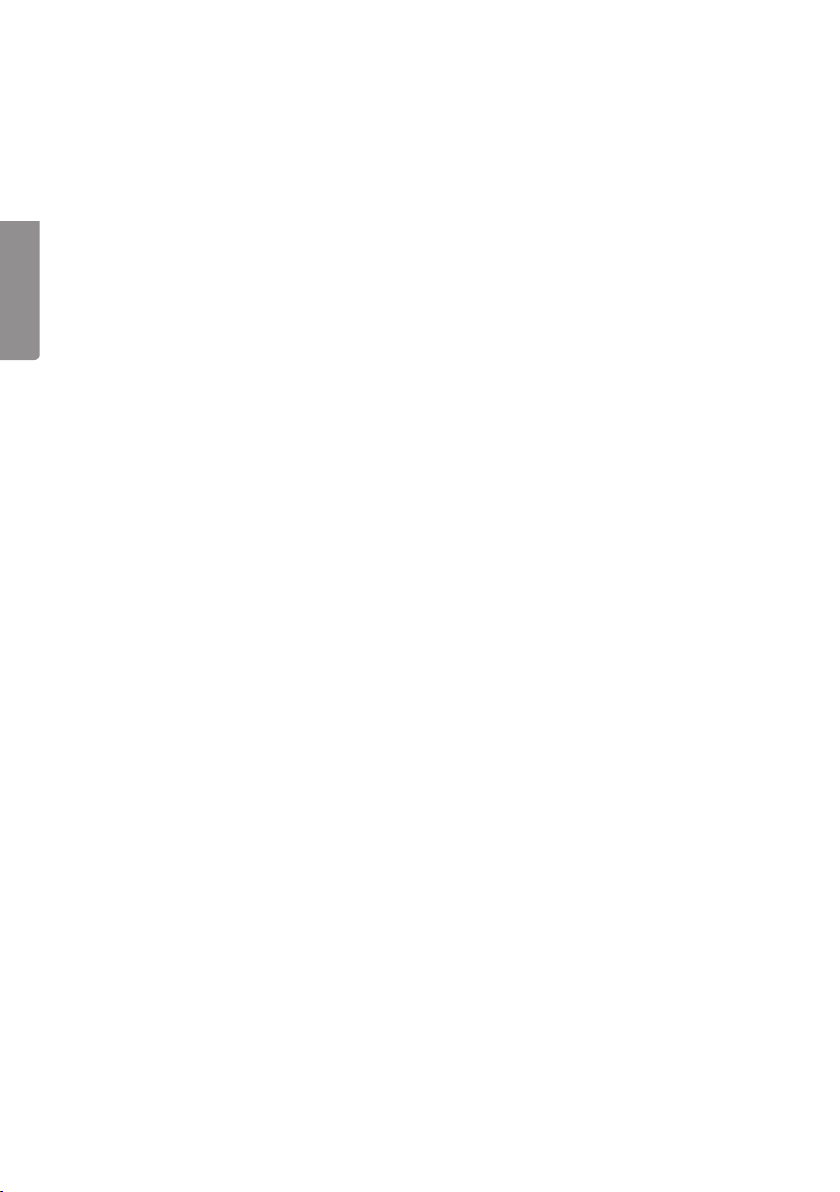

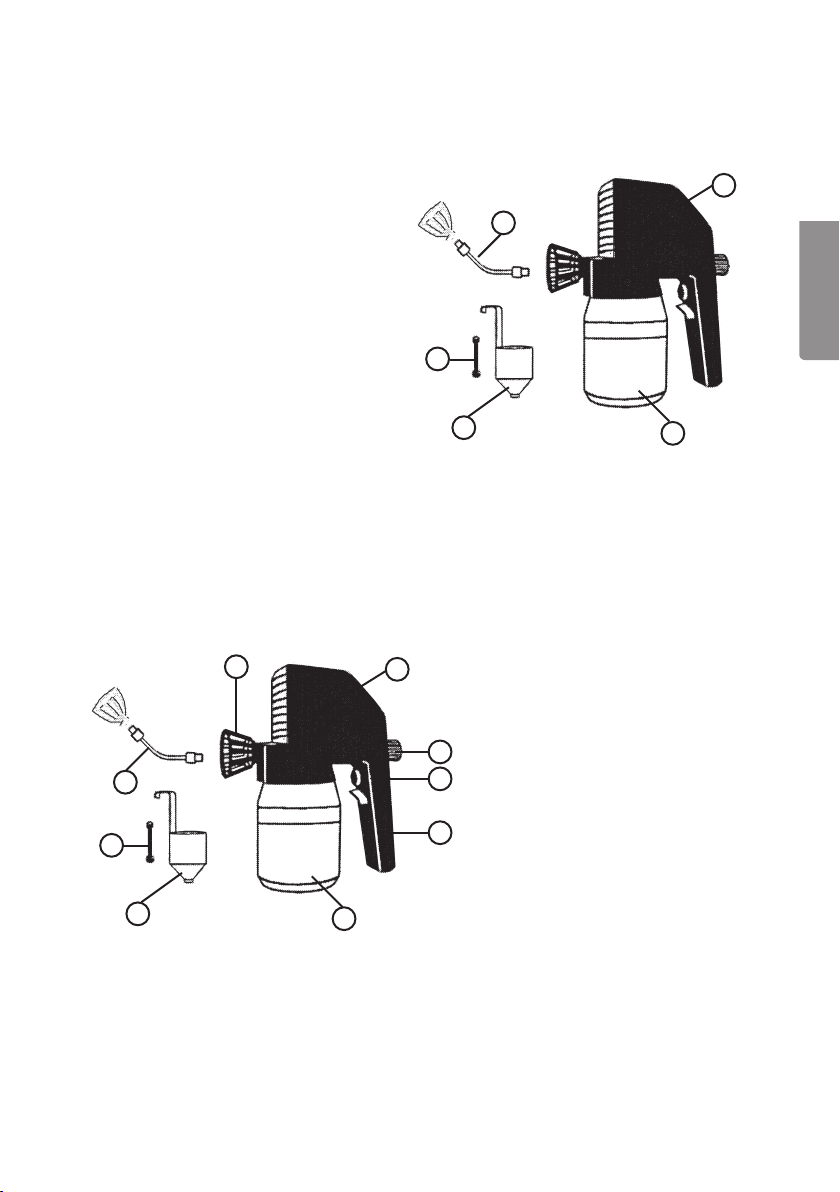

1. Spray Gun

2. Flexible Extension

3. Viscosity Cup

4. Non-Return Valve

5. Paint Container with Suction Tube

and Filter

1

2

4

3

5

Parts Guide

6

7

8

9

1

2

3

4

5

1. Motor Housing

2. Output Control Knob

3. Trigger

4. Handle

5. Paint Container

6. Nozzle

7. Flexible Extension

8. Non-Return Valve

9. Viscosity Meter

4

Page 5

General Safety Instructions

Warning: Read all the instructions. Failing to adhere to the following instructions

may lead to electric shocks, res and/or serious injury. The term “electrical hand

tools” in the warning text below is referring to your mains operated or battery

operated hand tool. Save the instructions.

1) The Work Area

a) Keep the work space clean and well illuminated. Cluttered and poorly lit

areas invite accidents.

b) Do not use electrical hand tools in explosive environments, i.e. nearby

ammable liquids, gas or dust. Electrical hand tools generate sparks that

could easily ignite dust or fumes.

c) Keep away from children and other spectators while using the electrical

hand tool. Disturbances can cause you to lose your concentration and control.

2) Electrical Safety

a) The electrical hand tool’s plug must t correctly into the wall socket. Never

modify the plug in any way. Never use an adaptor together with earthed

electrical hand tools. Unmodied plugs and suitable wall sockets decrease the

risk of electric shock.

b) Avoid physical contact with earthed objects, such as pipes, radiators,

ovens or refrigerators. There is an increased risk of electrical shock if your

body is earthed.

c) Do not expose the electrical hand tool to rain or other wet conditions.

If water gets inside an electrical hand tool it increases the risk of electrical

shock.

d) Do not abuse the lead. Never use the lead to carry the tool, drag or pull the

plug out of the wall socket. Keep the lead away from heat, oil, sharp edges

and movable parts. Damaged or tangled leads increase the risk of electrical

shock.

e) When you use an electrical hand tool outdoors; use an extension cord

suitable for this purpose. Use of an extension cord for outdoor use decreases

the risk of electrical shock.

ENGLISH

5

Page 6

3) Personal Safety

a) Pay attention to what you do and use common sense when using electrical

hand tools. Never use an electrical hand tool if you are tired or under

ENGLISH

the inuence of drugs, alcohol or medication. One moment of not paying

attention while using an electrical hand tool may result in serious injury.

b) Use protective equipment.

clothing such as a face mask, non-slip safety shoes, a helmet and ear defenders

when needed decreases the risk of injury.

c) Avoid accidental starts.

before you connect the device to the wall socket. Never carry an electrical

hand tool with one nger on the trigger or never connect the hand tool to a wall

socket when the switch is set to ON, since it may result in injury.

d) Remove all service tools/keys before switching on the hand tool.

A service tool forgotten on a rotating part of the electrical hand tool may result in

injury.

e) Do not overreach.

times. This gives better control in unexpected situations.

f) Wear suitable clothing. Do not wear loose tting clothes or jewellery. Keep

hair, clothes and gloves away from movable parts. Loose tting clothes,

jewellery or long hair could get caught in movable parts.

g) If the equipment for suctioning or collecting dust is available make sure

it is connected and used properly. Using technical aids may decrease dust

related hazards.

Make sure you stand steady and well balanced at all

Always use safety glasses. Using protective

Make sure that the power switch is set to OFF

4) Use and maintenance of the electrical hand tool.

a) Do not force the hand tool. Use a hand tool suitable for the work you are to

perform. The correct electrical hand tool will perform the task better and safer if

used at the correct feed rate.

b) Never use the electrical hand tool if the power switch does not switch the

tool on and off properly. All electrical hand tools that cannot be controlled by

the power switch are dangerous and must be repaired.

c) Unplug the lead from the wall socket before making any adjustments,

changing accessories or storing the electrical hand tool away. These

precautions reduce the risk of the electrical hand tool starting unexpectedly.

d) Store electrical hand tools that are not being used out of the reach of

children. Do not allow people who are unfamiliar with the tool or its

functions to operate the tool. Electrical hand tools can be dangerous if they

get into the hands of inexperienced users.

6

Page 7

e) Maintenance of electrical hand tools. Check if anything is incorrectly set,

if moving parts are catching, if anything is broken or if there is anything

which could cause the electrical hand tool to malfunction. If something

is damaged it must be repaired before use. Many accidents are caused by

poorly maintained electrical hand tools.

f) Keep the tools sharp and clean.

blades are less likely to jam and are easier to control.

g) Use the electrical hand tool, accessories and such according to the

instructions and in a way suitable for the type of electrical hand tool

used. Using the electrical hand tool for work other than suitable work could

result in a dangerous situation.

Properly maintained cutting tools with sharp

5) Service

a) Repairs and service should only be performed by qualied persons, and

only with original spare parts. This guarantees the safety of the electrical

hand tool.

ENGLISH

7

Page 8

Safety Instructions Specific to Spray Guns

• Do not use the spray gun for easily ignitable* paints or substances.

ENGLISH

• Do not use the spray gun with liquids containing particles or bres such as

metallic paint, re-retardant paint and paints containing asbestos.

• Do not clean the spray gun using easily ignitable solvents.

• Be aware of any possible hazards due to the nature of the material being

painted.

• Carefully read all the instructions and warning texts for the product to be used

in the spray gun including any requirements for protective clothing.

• Do not use any paint product without knowing how dangerous it is.

• Always pull the plug out of the power point when you stop working

(to prevent unexpected starts).

• Never point the spray gun at yourself or anyone else.

* Substances/liquids having a ash point above 55 °C.

Safety Symbols

Read the entire instruction manual

Safety glasses or a visor, a face mask

and ear protectors must be worn.

8

Page 9

Before Starting

Practice

When using the spray gun for the rst time it

is advisable to practice spraying on a piece of

waste chipboard or similar to get a feel for the

spray gun.

1. Make sure that the suction tube is securely

fastened onto the front tube in the lid of the

paint container. Make sure that the nonreturn valve is in place and that the nozzle is

screwed on.

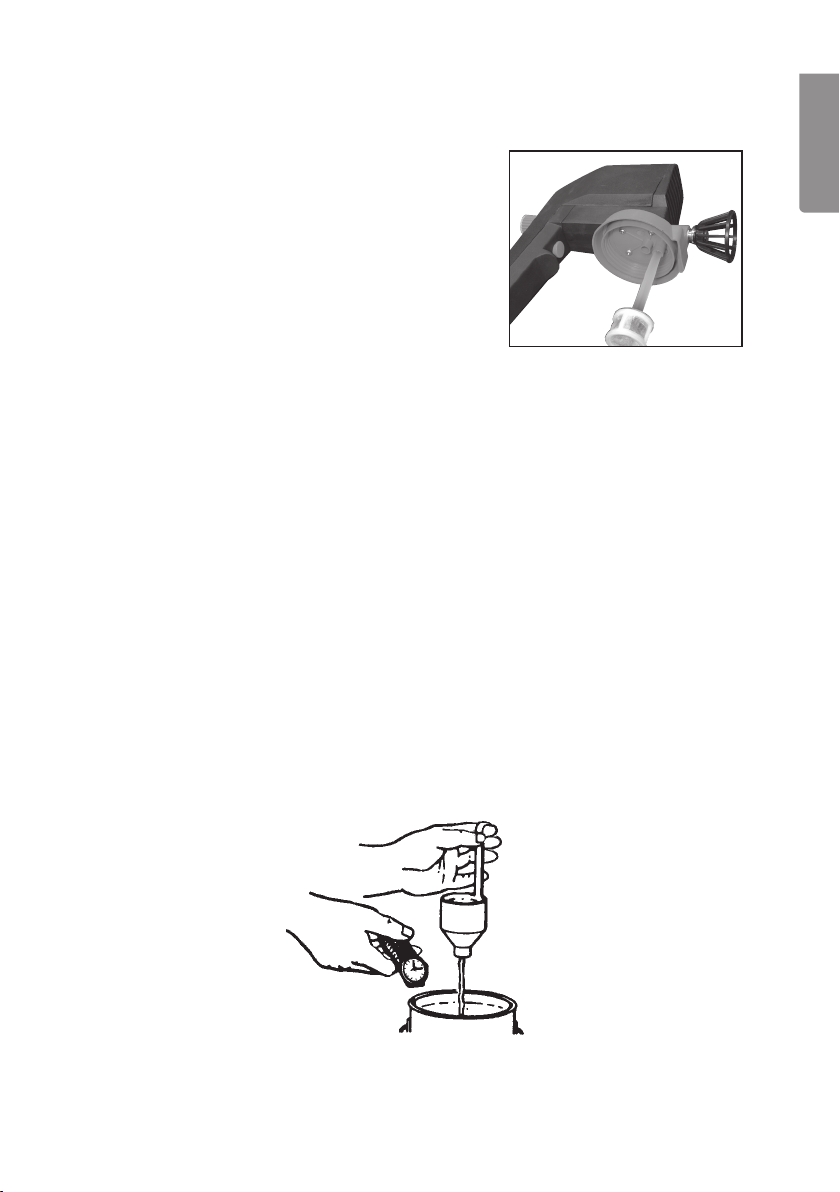

2. The pressure can be adjusted using the knob

on the handle. Set the pressure to medium

before starting to spray and then adjust whilst

spraying.

Viscosity

The viscosity cup and a clock or watch are all that are needed to check the

viscosity of the paint.

1. Fill the measuring cup by dipping it into the paint (stir the paint rst if

it is lumpy).

2. Lift the cup above the surface of the paint and time how long it takes for the

paint to run through the hole at the bottom of the cup. (The longer it takes,

the higher the viscosity (thickness) of the paint.)

ENGLISH

9

Page 10

Viscosity Table

Note: These viscosities are only recommendations. Test the spray gun on

a surface with the same texture and incline as that to be sprayed before spraying

the real object if you are the least bit unsure as to which viscosity is suitable.

ENGLISH

Plastic and latex paint 24-28 seconds

Water based paint 20-25 seconds

Primer 24-26 seconds

Varnish 20-25 seconds

Oil based paint 18-22 seconds

Enamel paint 18-22 seconds

Aluminium paint 22-25 seconds

Car underseal 25-35 seconds

Wood sealant 28-35 seconds

Anti-corrosive paint No thinning required

Wood stain No thinning required

Use

Preparations

Note: Never start the spray gun without liquid in the container; it can shorten

the life of the pump.

1. Make sure that the power supply that you are using is compatible with the

rated power of the tool.

2. Pour the liquid to be sprayed into the container.

3. Thin the liquid if necessary and check its viscosity.

4. Place the container on a level surface; cover the surface with paper to catch

any drops.

5. Hold the spray gun over the container and attach the container by screwing the

container anticlockwise.

6. The spray gun is now ready for use.

10

Page 11

Operating Instructions

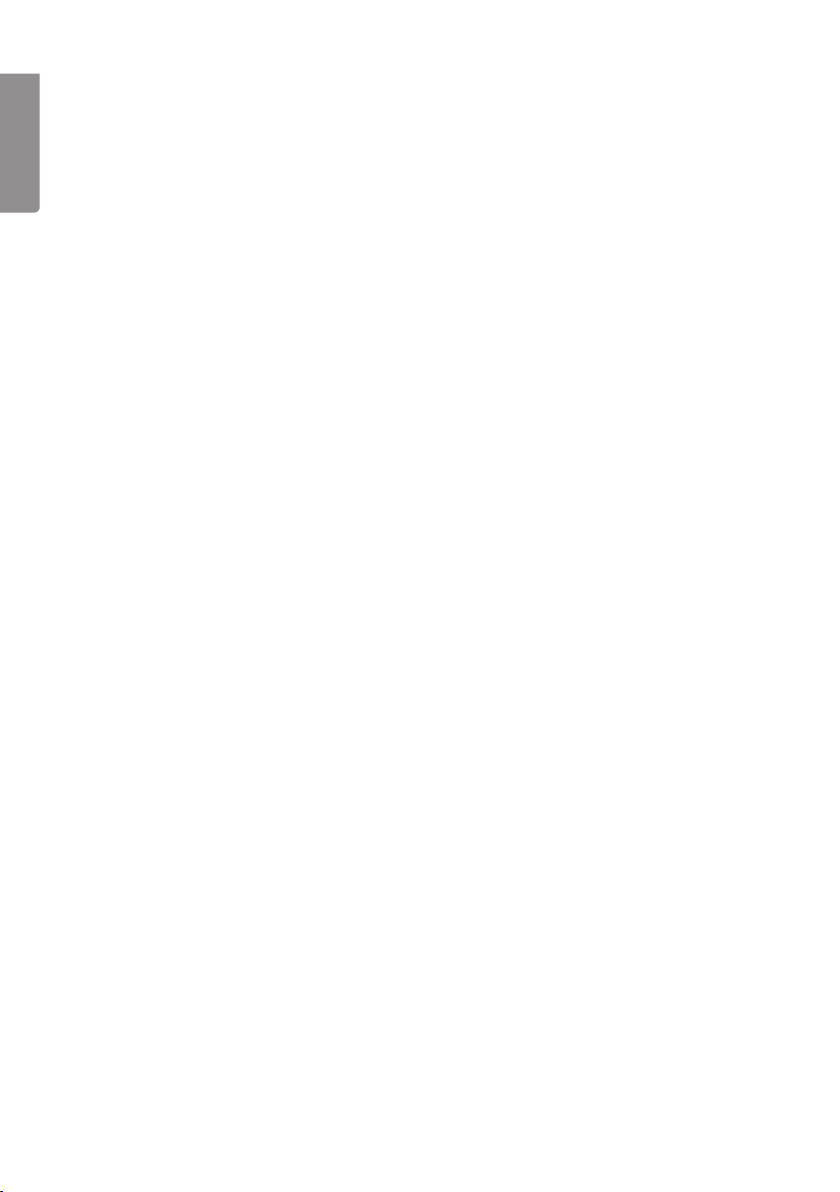

Adjust the paint flow using the control knob (2):

Reduce the ow by turning the knob clockwise (B)

or increase the ow by turning it anticlockwise (A).

Spraying

• As a rule, 30 cm is the ideal distance between the nozzle and the surface to

be sprayed. A greater distance can produce too widespread a spray pattern

and a lesser distance can create too thick a layer of paint.

ENGLISH

• Practice on a piece of scrap material if you are unsure.

• Keep the spray gun level and parallel to the surface at all times.

• For best results, sweep the spray gun in a smooth motion using the whole arm.

Do not direct the spray by exing your wrist.

Right Wrong

11

Page 12

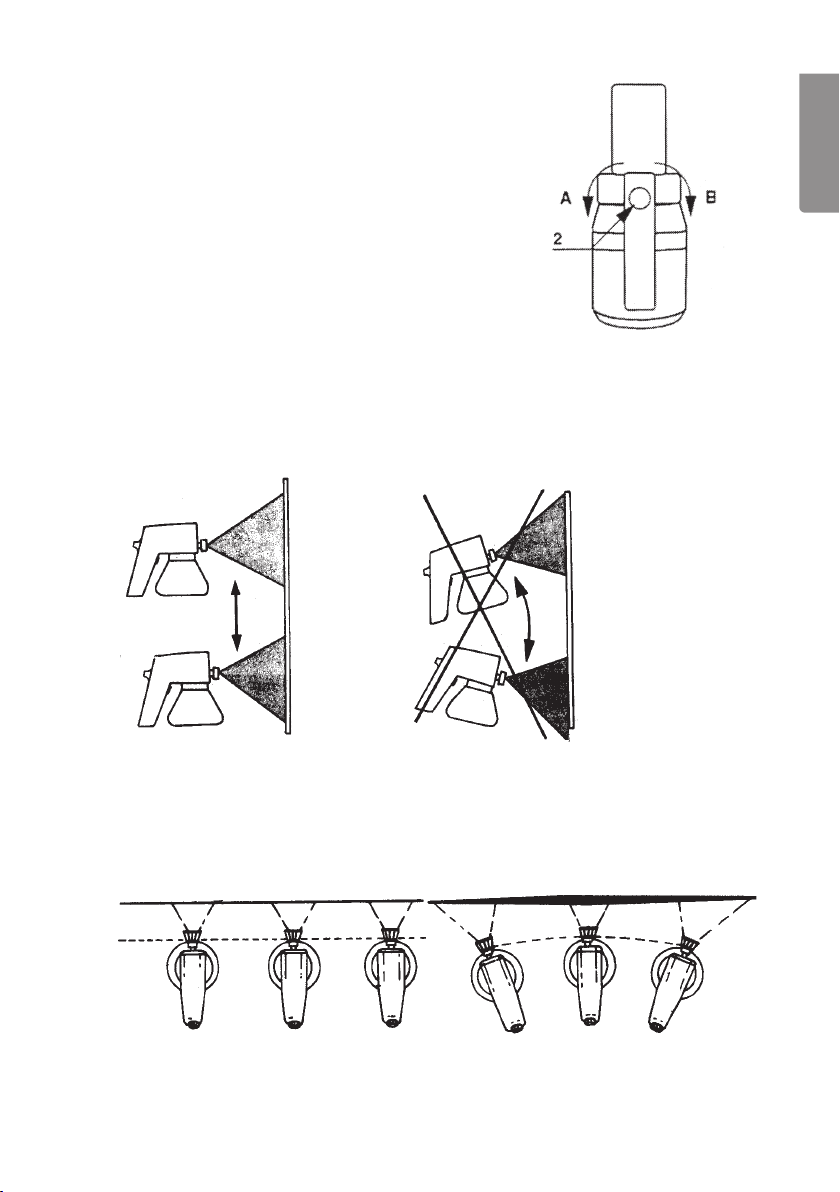

• Sweep the spray gun from side to side and

up and down. For best results, start spraying

a little outside the actual spray area.

• When spraying large areas, use a criss-

ENGLISH

cross pattern.

• To prevent running when painting vertical surfaces, rst cover the surface with

a thin coat by spraying a ne spray from a greater distance and not spraying

too much paint on each sweep. The nal coat can be made from a closer

distance.

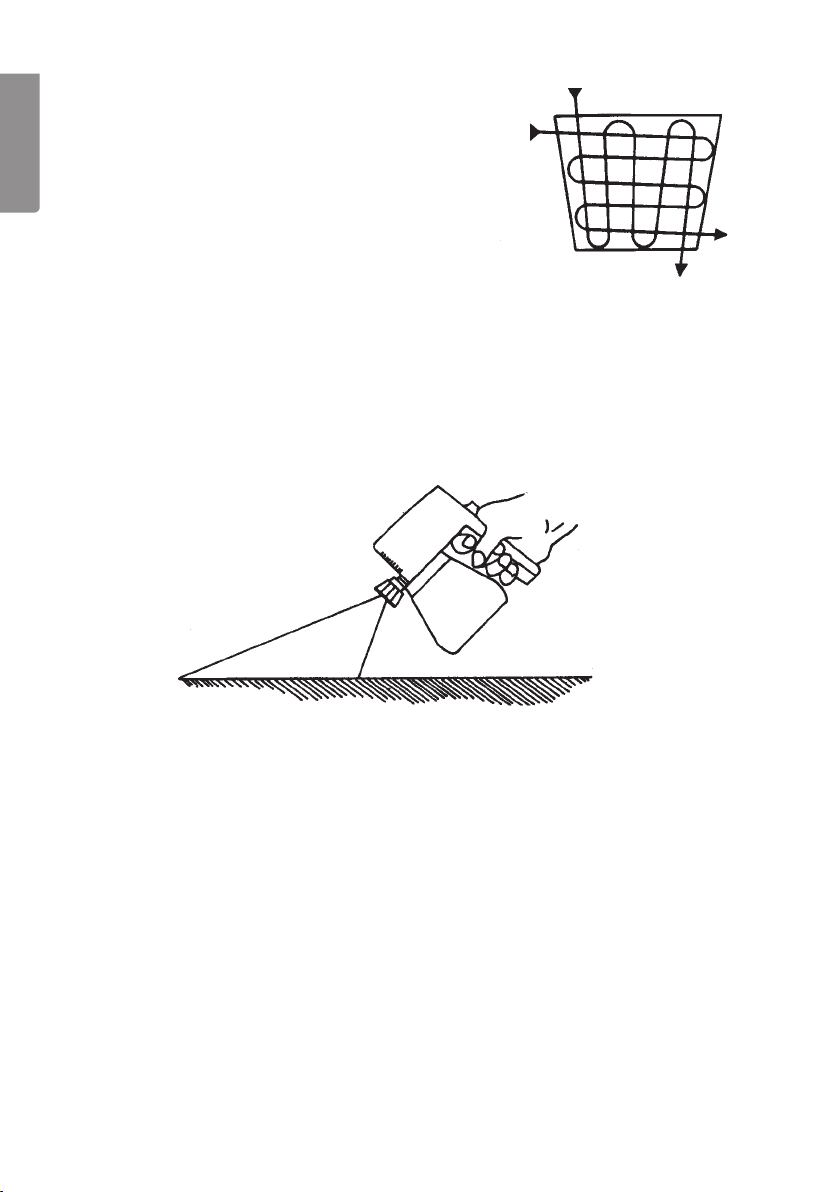

• On horizontal surfaces the spray gun should be angled at 45° and pointed

away from you.

• If the spraying is interrupted it is advisable to restart spraying on a piece

of paper before resuming.

Thinning

If the paint forms a stream instead of a mist it needs to be thinned further. Water

based paints are thinned using water, oil based paints use thinners such as white

spirits.

12

Page 13

Cleaning

Note: Never immerse the entire spray gun into cleaning uid.

After each use

1. Remove the container and pull out the suction tube.

2. Unscrew the four screws (13) under the container lid (12).

3. Detach the container lid from the motor housing (19) by pulling it downwards.

4. Remove the pump assembly from the motor housing. Take the pump apart and

clean all the components using a suitable paint thinner.

5. When reassembling the pump, make sure that the piston (11), piston spring

(10), non-return valve (8) and nozzle (6) are correctly aligned.

6. Plug the spray gun into a 230 V power point and hold it upside down. Pour a

little thin oil into the hole for the suction tube and pull the trigger. This will coat

the piston and cylinder with oil and prevent rust.

1

12

ENGLISH

11 10

13

Note: Insufcient or incorrect cleaning can lead to the piston jamming in the

cylinder. If a faint humming sound can be heard whilst spraying, release the

trigger immediately. Otherwise the motor can overheat and become damaged.

13

8 6

Page 14

Care and Maintenance

Remember to check the parts that wear out such as the nozzle, piston, spring, etc

after having sprayed 20–40 litres of paint. Be extra vigilant when using latex paint

as it wears out the parts more quickly than other types of paint.

ENGLISH

When to replace worn parts

1. Nozzle (6): When the paint no longer forms a ne spray and starts spitting out

instead.

2. Piston (11): Inspect regularly, change if necessary.

3. Non-return valve (8): Inspect the size of the three holes in the valve and the

evenness of the front surface. A worn valve that has scratches and damaged

holes must be replaced.

Disposal

Follow local ordinances when disposing of this product.

If you are unsure about how to dispose of this product

contact your municipality.

Specifications

Power Supply: 230 V AC, 50 Hz

Power: 75 W

Container Volume: 900 ml

Flow Rate: 200 ml/min

Cable Length: 3 m

Weight: 1.45 kg

Vibration X axis: 1.94 m/s²

Y axis: 4.94 m/s²

Z axis: 13.19 m/s²

Sound Pressure: LpA: 87.7 dB

Sound Power: LwA: 100.7dB

14

Page 15

Troubleshooting Guide

Problem Cause Remedy

Atomizing. Nozzle too far away. Hold it 30 cm away.

Paint too thin.

Use thicker paint.

ENGLISH

Overheated

motor.

Motor hums but

does not spray.

Motor runs but

does not spray.

The motor does

not start.

Paint “spits”

and motor

sounds strange.

Paint leaking

from the back

of the pump

assembly.

Pressure too high. Turn the output control

Worn nozzle Replace nozzle.

Spraying too long. Allow spray gun to cool for

Motor runs but does not spray. Check lter and non-return

Output control set wrong. Adjust setting.

Piston worn from acrylic paint spraying. Remove pump unit and

Faulty motor. Lubricate the piston and

Paint too thick Thin the paint.

Nozzle blocked Thoroughly clean.

Non-return valve missing. Replace it.

Non-return valve worn or blocked. Clean or change it.

Output control needs adjusting. Adjust it.

Suction lter is clogged. Clean or change it.

No mains power supply. Check fuse.

Faulty motor.

Output control set wrong. Adjust control knob.

Worn non-return valve or worn nozzle. Replace worn part.

Nozzle aperture too large. Change to a smaller one.

Paint too thick. Thin the paint.

Spray gun held at too high an angle,

no paint can enter the suction tube.

Gun pointed upwards when spraying. Hold gun level.

Scratched piston or cylinder. Replace worn part.

clockwise.

a few minutes.

valve.

Thin the paint.

thoroughly clean all parts.

cylinder.

Hold the gun upright or add

an extension to the tube.

15

Page 16

Färgspruta

Art.no: 18-3056 Model: FL-999-UK

30-9579 FL-999

Läs igenom hela bruksanvisningen före användning och spara den sedan

för framtida bruk. Vi reserverar oss för ev. text- och bildfel samt ändringar

av tekniska data. Vid tekniska problem eller andra frågor, kontakta vår kundtjänst

(se adressuppgifter på baksidan).

SVENSKA

Innehållsförteckning

Beskrivning 4

Säkerhet 5

Innan du börjar 9

Användning 10

Rengöring 13

Skötsel och underhåll 14

Avfallshantering 15

Tekniska specikationer 16

Felsökningsschema 14

16

Page 17

Beskrivning

Förpackningen innehåller

1. Färgspruta

2. Böjbar förlängning

3. Viskositetsbägare

4. Backventil

5. Färgbehållare med sugrör och lter

1

2

SVENSKA

4

3

5

Färgsprutans delar

6

7

8

9

1

2

3

4

5

1. Motorenhet

2. Mängdratt

3. Strömbrytare

4. Handtag

5. Färgbehållare

6. Munstycke

7. Böjbar förlängning

8. Backventil

9. Viskositetsmätare

17

Page 18

Generella säkerhetsinstruktioner

Varning! Läs alla instruktioner. Om nedanstående instruktioner inte följs kan detta

leda till elektrisk stöt, brand och/eller allvarlig skada. Termen ”elektriskt handverktyg” i varningstexten nedan refererar till ditt nätanslutna eller batteridrivna handverktyg. Spara dessa instruktioner!

1) Arbetsutrymmet

a) Håll arbetsutrymmet rent och väl upplyst. Belamrade och mörka utrymmen

SVENSKA

inbjuder till olyckor.

b) Använd inte elektriska handverktyg i explosiva miljöer, som i närheten av

lättantändliga vätskor, gaser eller damm. Elektriska handverktyg genererar

gnistor som kan antända damm eller ångor.

c) Håll undan barn och åskådare medan du använder det elektriska

handverktyget. Störningsmoment kan göra att du tappar kontrollen.

2) Elektrisk säkerhet

a) Det elektriska handverktygets stickpropp måste passa i vägguttaget.

Modiera aldrig stickproppen på något vis. Använd aldrig adapter

tillsammans med jordade elektriska handverktyg. Omodierade stickproppar

och passande vägguttag minskar risken för elektrisk stöt.

b) Undvik kroppskontakt med jordade föremål, som rör, element, köksspis

eller kylskåp. Det nns ökad risk för elektrisk stöt om din kropp är jordad.

c) Utsätt inte det elektriska handverktyget för regn eller våta förhållanden.

Om vatten tränger in i ett elektriskt handverktyg ökar det risken för elektrisk

stöt.

d) Misshandla inte nätsladden.

rycka stickproppen ur vägguttaget. Håll nätsladden undan från värme, olja,

vassa kanter och rörliga delar. Skadade eller trassliga nätsladdar ökar risken

för elektrisk stöt.

e) När du använder ett elektriskt handverktyg utomhus, använd en

skarvsladd anpassad för detta ändamål. Användning av en skarvsladd för

utomhusbruk minskar risken för elektrisk stöt.

Använd aldrig nätsladden för att bära, dra eller

18

Page 19

3) Personlig säkerhet

a) Var uppmärksam på vad du gör och använd sunt förnuft när du använder

ett elektriskt handverktyg. Använd inte ett elektriskt handverktyg om du

är trött eller påverkad av droger, alkohol eller medicinering. Ett ögonblicks

ouppmärksamhet när du använder ett elektriskt handverktyg kan resultera

i allvarlig personskada.

b) Använd skyddsutrustning.

skyddsutrustning som andningsskydd, halksäkra skyddsskor, hjälm och

hörselskydd vid behov minskar risken för personskada.

c) Undvik oavsiktlig start.

ansluter stickproppen till vägguttaget. Att bära ett elektriskt handverktyg

med ett nger på strömbrytaren/avtryckaren eller att ansluta ett elektriskt

handverktyg till elnätet när strömbrytaren är i läge ”ON” inbjuder till olyckor.

d) Tag bort alla serviceverktyg/nycklar innan du slår på det elektriska

handverktyget. Ett kvarglömt serviceverktyg på en roterande del av det

elektriska handverktyget kan reslutera i personskada.

e) Sträck dig inte för långt.

tiden. Detta möjliggör bättre kontroll i oväntade situationer.

f) Bär lämplig klädsel.

kläder och handskar undan från rörliga delar. Lösa kläder, smycken eller långt

hår kan fastna i rörliga delar.

g) Om utrustning för utsugning och uppsamling av damm nns tillgängligt,

se till att denna är ansluten och används ordentligt. Användning av dessa

hjälpmedel kan minska dammrelaterade faror.

Bär alltid skyddsglasögon. Användning av

Se till att strömbrytaren är i läge ”OFF” innan du

Se till att du står stadigt med god balans hela

Bär inte löst sittande kläder eller smycken. Håll hår,

SVENSKA

4) Användning och underhåll av det elektriska handverktyget

a) Pressa inte det elektriska handverktyget. Använd ett elektriskt handverktyg

som är avsett för det arbetsmoment du utför. Korrekt elektriskt handverktyg gör

jobbet bättre och säkrare med avsedd matningshastighet.

b) Använd inte det elektriska handverktyget om strömbrytaren inte slår

på och stänger av verktyget. Alla elektriska handverktyg som inte kan

kontrolleras med strömbrytaren är farliga och måste repareras.

c) Tag stickproppen ur vägguttaget innan du utför några justeringar, byter

tillbehör eller lägger undan det elektriska handverktyget för förvaring.

Dessa åtgärder i förebyggande syfte minskar risken för att starta det elektriska

handverktyget oavsiktligt.

19

Page 20

d) Förvara elektriska handverktyg som inte används utom räckhåll för

barn och låt inte personer som inte är förtrogna med det elektriska

handverktyget eller dessa instruktioner använda det. Elektriska

handverktyg är farliga om de kommer i händerna på ovana användare.

e) Underhåll elektriska handverktyg.

rörliga delar kärvar, om delar har gått sönder eller något annat som kan

påverka funktionen av det elektriska handverktyget. Om något är skadat

måste det repareras före användning. Många olyckor beror på dåligt

underhållna elektriska handverktyg.

SVENSKA

f) Håll verktygen vassa och rena.

vassa eggar är mindre benägna att kärva och lättare att kontrollera.

g) Använd det elektriska handverktyget, tillbehör och liknande enligt

instruktionerna och på det sätt som är ämnat för just den typen av

elektriskt handverktyg, och ta även hänsyn till arbetsförhållandena

och den typ av arbete som ska utföras. Användning av det elektriska

handverktyget för arbeten andra än vad det är ämnat för kan resultera

i en farlig situation.

Kontrollera om något är felinställt, om

Ordentligt underhållna skärverktyg med

5) Service

a) Låt behörig personal utföra service och reparationer, endast med

originalreservdelar. Detta garanterar att säkerheten på det elektriska

handverktyget behålls.

20

Page 21

Särskilda säkerhetsföreskrifter

för färgspruta

• Använd inte färgsprutan till lättantändliga* färger eller ämnen.

• Använd inte färgsprutan till vätskor som innehåller partiklar eller brer som

t.ex. metalliclacker, brandhämmande färger och färger som innehåller

asbestbrer.

• Rengör inte färgsprutan med lättantändliga* lösningsmedel.

• Uppmärksamma eventuella faror som kan uppstå beroende på materialet

som målas.

• Läs noggrant instruktionerna och varningstexten på produkten som

du ska använda i färgsprutan, inklusive eventuella krav på personlig

skyddsutrustning för produkten.

• Måla inte med någon produkt där farorna är okända.

• Dra alltid ur stickproppen ur vägguttaget när du slutar spruta (för att förhindra

oavsiktlig start).

• Rikta aldrig sprutan mot dig själv eller andra.

* Ämnen/vätskor som har en ampunkt över 55 °C.

SVENSKA

Produktmärkning med säkerhetssymboler

Läs hela bruksanvisningen!

Använd alltid skyddsglasögon eller visir och

andningskydd och hörselskydd.

21

Page 22

3. Innan du börjar

Övning

Om det är första gången du använder färgspruta, spruta gärna vatten mot en masonitskiva eller

liknande för att få in känslan för sprutan.

1. Se till att sugröret är säkert fastsatt

i främre röret i behållarlocket. Kontrollera

SVENSKA

att backventilen sitter på plats och att

munstycket är fastskruvat.

2. Du kan justera trycket med mängdratten bak

på handtaget. Ställ in trycket i ett mellanläge

innan du börjar spruta och justera ytterligare

under sprutningen.

Färgblandning

Viskositetsbägaren och en klocka är det enda du behöver för att kunna bedöma

viskositeten.

1. Fyll mätbägaren helt genom att doppa ner den i färgen (rör om färgen först

om den har klumpar).

2. Lyft upp den ovanför ytan och kontrollera hur lång tid det tar för färgen att

rinna ut genom bottenhålet. (Ju längre tid det tar, desto högre är viskositeten

(tjockleken) hos färgen.)

22

Page 23

Tabell över lämplig viskositet

Obs! Detta är endast rekommendationer, prova färgsprutan mot en yta med

samma struktur och lutning som den som ska sprutas, innan du påbörjar den

verkliga sprutmålningen om du är det minsta osäker vilken viskositet som

är lämplig.

Plast och latexfärg 24-28 sekunder

Vattenbaserad färg 20-25 sekunder

Grundfärg 24-26 sekunder

Fernissa 20-25 sekunder

Oljebaserad färg 18-22 sekunder

Emaljlack 18-22 sekunder

Aluminiumfärg 22-25 sekunder

Flytande rostskyddsmassa 25-35 sekunder

Trä förseglare 28-35 sekunder

Rötskyddsfärg Oförtunnat

Bets Oförtunnat

Användning

Förberedelser

Obs! Starta aldrig färgsprutan utan vätska i behållaren, det kan reducera

pumpens livslängd.

1. Kontrollera att nätspänningen i eluttaget är lika som märkskylten.

2. Häll vätskan som ska sprutas i behållaren.

3. Förtunna vätskan vid behov och kontrollera viskositeten.

4. Placera behållaren på ett plant underlag, lägg på ett papper som

kan suga upp ev. spill.

5. Placera färgsprutan över behållaren, vrid behållaren motsols till det tar stopp.

6. Färgsprutan är nu klar för användning.

SVENSKA

23

Page 24

Arbetsgång vid användning

Justera färgmängden med mängdratten (2)

Minska ödet genom att vrida medsols (B) eller öka

ödet genom att vrida motsols (A).

SVENSKA

Håll sprutan rätt

• Observera att 30 cm i regel är det bästa avståndet mellan mynning och yta.

Större avstånd kan ge för stor spridning och mindre avstånd kan ge ojämn

påläggning och för tjockt färgskikt.

• Prova innan sprutningen påbörjas om du är osäker.

• Håll alltid sprutan upprätt och spruta parallellt med ytan som ska sprutas.

• För sprutan i ett jämnt svep med hela armen för att få en jämn fördelning.

Vrid inte sprutan med handleden.

Rätt Fel

24

Page 25

• Svep med sprutan från vänster till höger och

tillbaka, från toppen till botten och tillbaka.

För bästa resultat, börja spruta lite utanför

själva sprutytan.

• På stora ytor kan man ibland med fördel

spruta både lodrätt och vågrätt.

• För att undvika att färgen rinner på lodräta ytor kan du försöka täcka sprutytan

med en n dimma på större sprutavstånd och inte spruta så tjockt i varje svep.

Spruta sedan sista lagret på något närmare håll.

• På vågrät yta riktar du sprutan i ungefär 45° vinkel mot ytan och sprutar bort

från dig.

SVENSKA

• Om du gör en paus i sprutningen är det bra att börja med att spruta mot en bit

papper innan du börjar spruta riktigt igen.

Förtunning

Om färgen bildar en stråle istället för att nfördelas måste du späda färgen ytterligare. Vattenburen färg förtunnas med vatten, och oljebaserad färg förtunnas med

färgförtunning, t.ex. lacknafta.

25

Page 26

Rengöring

Obs! Sänk aldrig ned hela färgsprutan i vätska för rengöring.

Efter varje sprutning

1. Ta bort behållaren och drag ur sugröret med silen.

2. Skruva ur dom fyra skruvarna (13) under behållarlocket (12).

3. Tag loss behållarlocket från motorenheten (1) genom att dra det nedåt.

SVENSKA

4. Tag isär delarna och rengör alla komponenter med lämplig färgförtunning.

5. När du sätter ihop aggregatet igen, se till att kolv (11), kolvfjäder (10),

backventil (8) och munstycke (6) blir rätt monterade.

6. Anslut stickproppen till ett 230 V vägguttag och håll aggregatet upp och ned.

Häll lite tunn olja i hålet för sugröret och tryck kort in avtryckaren.

Då rostskyddas kolv och cylinder.

1

12

11 10

13

Obs! Otillräcklig eller felaktig rengöring kan leda till att kolven skär (fastnar)

i cylindern. Om du hör ett svagt brummande ljud när du sprutar, släpp genast

avtryckaren. Annars riskerar motorn att överhettas med skador som följd.

26

8 6

Page 27

Skötsel och underhåll

Kom ihåg att kontrollera slitdelar som munstycke, backventil, kolv, kolvfjäder, etc.

när du har sprutat 20-40 liter färg. Var speciellt noga om du sprutat mycket latexfärg, eftersom den angriper delarna som då slits många gånger snabbare än om

man använder andra färger.

Byt ut slitdelarna i följande fall

1. Munstycke (6): När du märker att färgen inte längre nfördelas riktigt och

kanske börjar spottas ut.

2. Kolv (11): Kontrolleras regelbundet, byt vid behov.

3. Backventil (8): Undersök storleken på de tre hålen i ventilhuvudet och

ytjämnheten på framdelen. En sliten ventil har repor och förstorade hål

och måste bytas.

Avfallshantering

När du ska göra dig av med produkten ska detta ske enligt

lokala föreskrifter. Är du osäker på hur du ska gå tillväga,

kontakta din kommun.

Tekniska specifikationer

Strömförsörjning AC, 230 V, 50 Hz

Effekt 75 W

Storlek färgbehållare 900 ml

Spruteffekt 200 ml / min

Kabellängd 3 m

Vikt 1,45 kg

Vibration X led: 1,94 m/s2

Y led: 4,94 m/s2

Z led: 13,19 m/s2

Ljudtryck: LpA: 87.7 dB

Ljudeffekt: LwA: 100.7dB

SVENSKA

27

Page 28

Felsökningsschema

Problem Orsak Åtgärd

Dimbildning. Du håller sprutan för långt ifrån. Håll den ca 30 cm ifrån.

För tunn färg. Spruta med tjockare färg.

För högt tryck. Vrid mängdratten medurs.

Utslitet munstycke Byt munstycke.

Överhettad

SVENSKA

motor.

Motorn brum

mar, men det

sprutar inte.

Du har sprutat för länge. Låt sprutan vila efter några

minuters sprutning.

Motorn går, men det sprutar inte. Kolla ltret och att backventi-

len är isatt.

Färgen kan vara för tjock.

Mängdratten står fel. Justera inställningen.

Kolven har skurit efter akrylmålning. Tag ur drivenheten och

rengör alla delar noga.

Defekt motor. Smörj kolv och cylinder.

Motorn går

riktigt, men

sprutar inte.

Motorn går inte. Ingen ström i uttaget. Åtgärda.

Sprutan spottar

färg och motorn

låter konstigt.

Det läcker in

färg i pump

huset baktill.

För tjock färg. Förtunna.

Munstycket igensatt. Rengör det noga.

Backventil ej isatt. Sätt i den.

Backventil utsliten eller igensatt. Rengör eller byt ut den.

Mängdratten behöver justeras. Ställ in den riktigt.

Insugningsltret är igensatt. Rengör eller byt ut.

Defekt motor.

Mängdratten står fel. Justera.

Sliten atomiseringsventil eller slitet munstycke.

För stort hål i munstycket. Byt till ett mindre.

För tjock färg. Förtunna.

Du håller sprutan snett så att det inte kommer någon färg in i sugröret.

Du pekar sprutan uppåt när du sprutar. Håll den upprätt.

Det är repor i kolv eller cylinder. Byt ut sliten del.

Byt ut slitna delar.

Håll sprutan upprätt eller sätt

på en förlängning på röret.

28

Page 29

Malingssprøyte

Art.no: 18-3056 Model: FL-999-UK

30-9579 FL-999

Les nøye igjennom hele bruksanvisningen og ta vare på den til senere bruk.

Vi reserverer oss mot ev. tekst- og bildefeil, samt forandringer av tekniske data.

Ved tekniske problemer eller andre spørsmål, ta kontakt med vårt kundesenter

(se opplysninger på baksiden).

Innholdsfortegnelse

Beskrivelse 18

Sikkerhet 19

Før du begynner 23

Bruk 24

Rengjøring 27

Vedlikehold 28

Avfallshåndtering 29

Tekniske spesikasjoner 30

Feilsøkingsskjema 28

NOR SK

29

Page 30

Beskrivelse

Forpakningen inneholder

1. Malingssprøyte

2. Fleksibel forlengelse

3. Viskositetsmålebeger

4. Ventil

5. Malingsbeholder med sugerør

og lter

1

2

4

3

NOR SK

5

Malingssprøytens

6

7

8

9

1

2

3

4

5

deler

1. Motorenhet

2. Mengderegulator

3. Strømbryter

4. Håndtak

5. Malingsbeholder

6. Munnstykke

7. Fleksibel forlengelse

8. Ventil bak

9. Viskositetsmåler

30

Page 31

Generelle sikkerhetsinstruksjoner

Advarsel! Les alle instruksjonene grundig. Dersom instruksjonene ikke følges, kan

dette lede til brann, elektrisk støt og/eller alvorlig skade. Med begrepet ”elektriske

håndverktøy” i teksten under, menes strømtilkoblede håndverktøy. Ta vare på

denne instruksjonen.

1) Arbeidsplassen

a) Hold arbeidsplassen ren, ryddig og godt opplyst. Rotete arbeidsplass eller

dårlig opplyste områder kan føre til ulykker.

Bruk ikke elektriske håndverktøy i omgivelser med eksplosjonsfare, som

b)

for eksempel i nærheten av lettantennelige væsker, gasser eller støv.

Elektrisk håndverktøy kan danne gnister som igjen kan antenne støv eller

trespon.

c) Hold barn og andre tilskuere unna mens du bruker elektriske håndverktøy.

Du kan lett miste kontrollen dersom du blir forstyrret mens du arbeider.

2) Sikkerhet ved bruk av elektrisk strøm

a) Strømkabelens støpsel, til det elektriske verktøyet, må passe i vegguttaket.

Støpselet må ikke forandres på. Bruk aldri adapter sammen med elektrisk

håndverktøy som krever jording. Ved bruk av originale kontakter og støpsler

minskes faren for elektrisk støt.

b) Unngå kroppskontakt med jordede gjenstander som rør, ovner, komfyrer

og kjøleskap. Kroppskontakt med disse øker faren for elektrisk støt.

c) Elektrisk håndverktøy bør ikke utsettes for regn eller fuktighet.

kommer vann inn i et elektrisk håndverktøy, øker faren for elektrisk støt.

Håndter strømkabelen med forsiktighet. Den må ikke bli brukt til å bære

d)

verktøyet med. Dra ikke i kabelen når du skal ha stikket ut av kontakten. Hold

kabelen unna varme, olje, skarpe kanter og bevegelige deler. Skadde eller

deformerte støpsler kan øke faren for elektrisk støt.

e) Ved bruk av elektrisk håndverktøy utendørs, skal det benyttes skjøtekabel

som er beregnet til dette formålet. Når skjøtekabel som er beregnet for

utendørs bruk benyttes, minsker faren for elektrisk støt.

Hvis det

NOR SK

31

Page 32

3) Personlig sikkerhet

a) Vær våken og bruk sunn fornuft når du bruker et elektrisk verktøy. Ikke

bruk elektriske håndverktøy når du er trett eller påvirket av rusmidler,

alkohol eller sterke medisiner. Når du bruker elektrisk håndverktøy, kan et lite

øyeblikk med uoppmerksomhet resultere i store personskader.

Bruk verneutstyr. Benytt alltid vernebriller. Bruk av verneutstyr som

b)

støvmaske, sklisikre såler på skoene, hjelm og hørselsvern, ved behov, minsker

faren for personskade.

Unngå uønsket oppstart. Påse at strømbryteren står i posisjon ”OFF” før

c)

du kobler til strømmen. Det å bære et elektrisk håndverktøy med en nger på

avtrekkeren/strømbryteren, eller å koble til strømmen når strømbryteren står

i posisjon ”ON”, kan forårsake ulykker.

d) Fjern alle nøkler/serviceverktøy før du starter det elektriske håndverktøyet.

Et gjenglemt serviceverktøy på en roterende del, kan forårsake personskader.

e) Strekk deg ikke for langt.

NOR SK

tiden. Da er du bedre forberedt når uventede situasjoner oppstår.

Benytt fornuftige arbeidsklær. Ikke bruk løstsittende klær og smykker.

f)

Hold klær, hansker og smykker unna bevegelige deler. Løstsittende klær,

smykker eller langt hår, kan sette seg fast i bevegelige deler.

g) Hvis det er mulig å koble til en støvsamler/støvsuger, bør dette gjøres.

Ved bruk av sådanne hjelpemidler, kan en minske faren for støvrelaterte skader

og ulykker.

Påse at du står støtt og har god balanse hele

4) Bruk og vedlikehold av elektrisk håndverktøy

a) Ikke press et elektrisk håndverktøy. Bruk elektriske håndverktøy som er

beregnet til den arbeidsoperasjonen du skal utføre. Riktig innmatingshastighet

er viktig for å utføre bedre og sikrere arbeide.

b) Ikke bruk det elektriske håndverktøyet dersom ikke strømbryteren virker

og verktøyet kan skrues av. Alle elektriske håndverktøy, som ikke kan

kontrolleres med en strømbryter, er farlige og må repareres.

c) Dra ut støpselet før du utfører justeringer, bytter tilbehør eller legger det

elektriske håndverktøyet fra deg. Dette for å unngå at elektrisk håndverktøy

får en ukontrollert start.

d) Oppbevar elektrisk håndverktøy utilgjengelig for barn.

elektrisk håndverktøy er utilgjengelig for personer som ikke har fått tilstrekkelig

opplæring på eller er fortrolig med verktøyet. Elektrisk håndverktøy kan være

farlige dersom de kommer i hendene på ukyndige.

32

Påse også at

Page 33

e) Vedlikehold av elektrisk håndverktøy. Påse at verktøyet ikke er feilinnstilt,

at bevegelige deler ikke beveger seg usymmetrisk, at ingen deler er skadet

eller at det elektriske håndverktøyet har andre feil, som kan påvirke verktøyets

funksjon. Dersom noe er skadet må dette repareres før verktøyet tas i bruk.

Mange ulykker skyldes dårlig eller manglende vedlikehold.

f) Hold verktøyet rent. Påse også at det elektriske verktøyet holdes skarpt.

Godt vedlikeholdt skjæreverktøy, med skarpe egger, er lettere å kontrollere.

g) Følg instruksjonen, ta hensyn til arbeidsforholdene og den type arbeide

som skal utføres. Bruk av elektrisk håndverktøy til andre arbeidsoperasjoner

enn det det er beregnet til, kan skape farlige situasjoner.

5) Service

a) La profesjonelle fagfolk utføre service og reparasjoner. Benytt kun

originale reservedeler. Dette for å opprettholde sikkerheten ved bruk av

det elektriske håndverktøyet.

NOR SK

33

Page 34

Spesielle sikkerhetsforskrifter

for malersprøyte

• Malingssprøyten må ikke brukes til lettanntennelig* maling eller emner.

• Bruk ikke malingssprøyten til væsker som inneholder partikler eller bere

som f.eks. metallic lakk, brannhemmende maling eller maling som inneholder

asbestbere.

• Malingssprøyten må ikke rengjøres med lettanntennelige* løsemidler.

• Vær oppmerksom på ev. farer som kan oppstå avhengig av materiale som

males.

• Les instruksene og varselteksten på produktet grundig før bruk. Følg ev. krav

om bruk av verneutstyr.

• Bruk ikke maling med ukjent innhold, der farene er ukjente.

• Dra alltid stikkontakten ut fra vegguttaket når du er ferdig med å male.

NOR SK

(Dette for å forhindre uønsket start).

• Rett aldri sprøyten mot deg selv eller andre.

* Emner og væsker som har ammepunkt over 55 °C.

Produktmerkning med sikkerhetssymboler

Les bruksanvisningen!

Bruk alltid vernebriller eller visir og beskyttelse mot innånding

av giftige gasser og hørselsbeskyttelse.

34

Page 35

Før du begynner

Innøving

Hvis det er første gangen du skal bruke malingssprøyten, så sprut gjerne vann mot en plate, hvor

du kan observere hvor du har sprutet hen, til du

har blitt kjent med sprøyten.

1. Påse at sugerøret er godt festet i det fremre

røret i beholderlokket. Kontroller at ventilen

bak sitter på plass og at munnstykket er

skrudd fast.

2. Du kan justere trykket med mengderegulatoren bak på håndtaket. Still inn trykket

til en mellomposisjon før du starter å sprute,

og juster det underveis.

Blanding av maling

Viskositetsmålebegeret og en klokke er det eneste du trenger for å kunne

bedømme viskositeten.

1. Fyll målebegeret ved å dyppe det ned i malingen (rør om i malingen først, hvis

den inneholder klumper).

2. Ta den opp over overaten og kontroller hvor lang tid det tar for malingen å

renne ut gjennom hullet i bunnen av begeret. (Jo lengre tid det tar, desto høyere

er viskositeten (tykkelsen) på malingen.)

NOR SK

35

Page 36

Tabell over anbefalt viskositet

Obs! Dette er kun en anbefaling. Prøv malingssprøyten mot en overate med

samme struktur og helling som den som skal males, før du starter den egentlige

malingen, dersom du er det minste i tvil om hvilken viskositet malingen har.

Plast og latexmaling: 24-28 sekunder

Vannbasert maling: 20-25 sekunder

Grunnmaling: 24-26 sekunder

Lakk: 20-25 sekunder

Oljebasert maling: 18-22 sekunder

Emaljelakk: 18-22 sekunder

Aluminiumsmaling: 22-25 sekunder

Flytende rustbeskyttende masse: 25-35 sekunder

NOR SK

Treforsegler: 28-35 sekunder

Rötskyddsfärg: Ufortynnet

Beis: Ufortynnet

Bruk

Forberedelser

Obs! Start aldri malingssprøyten uten væske i beholderen. Det kan redusere

pumpens levetid.

1. Kontroller at nettspenningen på strømuttaket er den samme som sprøyten

krever (se merkeskilt).

2. Hell væsken som skal sprutes i beholderen.

3. Fortynn væsken ved behov og kontroller viskositeten.

4. Plasser beholderen på et plant underlag. Legg på et papir, som kan

suge opp ev. spill.

5. Plasser malingssprøyten over beholderen. Vri beholderen motsols

til den stopper.

6. Produktet er nå klart til bruk.

36

Page 37

Arbeidsgangen ved bruk

Juster malingsmengden med

mengderegulatoren (2)

Reduser yten ved å vri medsols (B) eller øk den

ved å vri motsols (A).

Hold malingssprøyten riktig

• 30 cm er som regel den beste avstanden mellom munningen og overaten, som

skal males. Større avstand kan gi for stor spredning, og mindre kan gi ujevne og

for tykke lag.

NOR SK

• Hvis du er usikker, så prøv deg fram før du starter sprøyting av ditt

arbeidsstykke.

• Hold alltid sprøyten oppreist og sprut parallelt med overaten som skal males.

• For å få en jevn fordeling bør sprøyten føres med en jevn bevegelse. Ikke vri

sprøyten med hendelen.

Riktig Galt

37

Page 38

• Beveg sprøyten fra venstre til høyre og

tilbake, eller fra toppen til bunnen og

tilbake. Best resultat oppnås hvis du starter

sprøytingen litt utenfor overaten som skal

males.

• På store ater kan man som regel med fordel

sprøyte både loddrett og vannrett på.

• For å unngå at fargen renner på loddrette ater, kan du forsøke å sprøyte med

en n tåke og med en større sprøyteavstand, og ikke sprøyte så tykke lag av

gangen. Siste laget kan legges på med mindre avstand.

• På vannrette ater retter du sprøyten i ca. 45° vinkel mot overaten og sprøyter

bort fra deg.

NOR SK

• Hvis du tar deg pauser i sprøytingen, er det best å starte med å sprøyte på en

papirbit før du går løs på arbeidsemnet igjen.

Fortynning

Dersom malingen lager en stråle i stedet for en sprøyt, må du spe malingen ytterligere. Maling som er vannbasert fortynnes med vann, og oljebasert maling fortynnes

med malingsfortynner som f.eks. whitesprite.

38

Page 39

Rengjøring

Obs! Senk aldri hele malingssprøyten ned i væske når du rengjør den.

Etter hver gangs bruk

1. Ta bort beholderen og dra ut sugerøret.

2. Skru ut de re skruene (13) under beholderlokket (12).

3. Ta beholderlokket fra motorenheten (1) ved å dra det nedover.

4. Dra pumpeenheten ut av aggregatet. Ta delene fra hverandre og rengjør alle

komponenter med malingsfortynner.

5. Når du setter sammen aggregatet igjen må du se til at stempelet (11),

stempelfjærer (10), ventil bak (8) og munnstykke (6) blir riktig montert.

6. Plasser stikkontakten i et vegguttak med 230 V, og hold aggregatet opp ned.

Hell litt tynn olje i hullet for sugerøret, og trykk kort inn avtrekkeren. Dette er

med på å rustbeskytte sprøyten.

1

12

NOR SK

11 10

13

Obs! Mangel på eller feil rengjøring kan føre til at stempelet fester seg i sylinderen.

Dersom du hører en svak brummende lyd når du sprøyter, slipp da opp avtrekkeren

snarest. Hvis ikke kan motoren bli overopphetet og skades.

39

8 6

Page 40

Vedlikehold

Husk på å kontrollere slitedelene som munnstykke, ventil, stempel, fjærer, etc. med

jevne mellomrom. Vær spesielt nøye hvis du bruker mye latexmaling, fordi den

angriper delene i sprøyten og de slites mange ganger raskere enn om men bruker

andre malingstyper.

Skift ut slitedelene ettersom disse slites

1. Munnstykke (6): Når du merker at malingen ikke lengre kommer ut nfordelt

og kanskje kommer mer i kladder.

2. Stempel (11): Kontrolleres regelmessig, skift ved behov.

3. Ventil bak (8): Undersøk størrelsen på de tre hullene i ventilhodet og framdelens

jevnhet. En slitt ventil har riper og ødelagt hull og må skiftes.

NOR SK

Når du skal kvitte deg med produktet, skal dette skje i henhold

til lokale forskrifter. Er du usikker på hvordan du går fram, ta kontakt

med lokale myndigheter.

Spesifikasjoner

Strømforsyning: AC, 230 V, 50 Hz

Effekt: 75 W

Størrelse på fargebeholdere: 900 ml

Sprøyteeffekt: 200 ml/min

Kabellengde: 3 m

Vekt: 1,45 kg

Vibrasjon X led: 1,94 m/s2

Y led: 4,94 m/s2

Z led: 13,19 m/s2

Lydtrykk: LpA: 87,7 dB

Lydeffekt: LwA: 100,7 dB

Avfallshåndtering

40

Page 41

Feilsøkingsskjema

Problem Årsak Tiltak

Tåkeopphop

ning.

Overopphetet

motor.

Motoren går,

men det kommer

ikke noe maling.

Motoren går

riktig, men spru

ter ikke.

Motoren går

ikke.

Sprøyten spytter

ut malingen og

motoren låter

rart.

Det lekker

maling inn

i pumpehuset

bakfra.

Du holder sprøyten for langt fra. Hold den ca. 30 cm fra.

For tynn farge. Bruk tykkere malingsblanding.

For høyt trykk.

Utslitt munnstykke. Skift munnstykke.

Du har sprutet for lenge. La sprøyten hvile etter noen

Motoren går, men det kommer ikke

noe maling.

Mengderegulatoren er galt innstilt. Juster innstillingen.

Stempelet har skjært seg etter bruk

av akrylmaling.

Defekt motor. Smør stempel og sylinder.

For tykk maling. Fortynn malingen.

Munnstykket tett. Rengjør det grundig.

Ventilen bak er ikke satt i. Sett den i.

Ventilen bak er utslitt eller tett. Rengjør eller skift den ut.

Mengderegulatoren trenger justering. Still den inn riktig.

Tett lter. Rengjør eller skift ut.

Ingen strøm i uttaket. Tiltak.

Defekt motor.

Mengderegulatoren er galt innstilt. Juster.

Utslitt venlil eller munnstykke. Skift ut slitte deler.

For stort hull i munnstykket. Skift til et mindre.

For tykk maling. Fortynn malingen.

Du holder sprøyten skjevt slik at

det ikke kommer noe maling inn i

sugerøret.

Du peker oppover med sprøyten når

du sprøyter.

Stempel eller sylinder er ripet opp. Skift ut slitte deler.

Vri justerrattet medurs.

minutters sprøyting.

Sjekk lteret og at ventilen

bak er satt i.

Malingen kan være for tykk.

Ta ut drivenheten og rengjør alle

deler nøye.

Hold sprøyten riktig eller sett på en

forlenging på røret.

Hold den rett.

41

NOR SK

Page 42

Maaliruisku

Art.no: 18-3056 Model: FL-999-UK

30-9579 FL-999

Lue käyttöohjeet ennen tuotteen käyttöönottoa. Säilytä käyttöohjeet tulevaa tarvetta varten. Pidätämme oikeuden teknisten tietojen muutoksiin. Emme vastaa

mahdollisista teksti- tai kuvavirheistä.

Sisällysluettelo

Kuvaus 32

Turvallisuus 33

Ennen kuin aloitat 37

Käyttö 38

Puhdistus 41

Huolto ja ylläpito 42

Kierrätys 43

Tekniset tiedot 44

Vianhakutaulukko 42

SUOMI

42

Page 43

Kuvaus

Pakkauksen sisältö

1. Maaliruisku

2. Taivutettava jatkokappale

3. Viskositeettiastia

4. Takaiskuventtiili

5. Värisäiliö, imuputki ja suodatin

1

2

4

3

5

SUOMI

Maaliruiskun osat

6

7

8

9

1

2

3

4

5

1. Moottori

2. Maalimäärän nuppi

3. Virtakytkimet

4. Kahva

5. Maalisäiliö

6. Suutin

7. Taivutettava jatkokappale

8. Takaiskuventtiili

9. Viskositeettimittari

43

Page 44

Yleisiä turvallisuusohjeita

Varoitus! Lue kaikki ohjeet. Seuraavien ohjeiden noudattamatta jättäminen

saattaa johtaa sähköiskuun, tulipaloon ja/tai vakavaan onnettomuuteen. Varoitustekstien termi ”sähkökäyttöinen käsityökalu” tarkoittaa sinun verkkovirralla tai

paristoilla/akulla toimivaa käsityökaluasi. Säästä nämä ohjeet!

1) Työtila

a) Pidä työtilat puhtaina ja hyvin valaistuina. Täynnä tavaraa olevat ja pimeät

tilat ovat avoin kutsu onnettomuudelle.

b) Älä käytä sähkökäyttöisiä käsityökaluja räjähdysherkässä ympäristössä,

kuten helposti syttyvien nesteiden, kaasujen tai pölyn lähellä.

Sähkökäyttöiset käsityökalut muodostavat kipinöitä, jotka saattavat sytyttää

pölyn tai höyryt.

c) Pidä lapset ja vierailijat loitolla, kun käytät sähkökäyttöisiä käsityökaluja.

Häiriötekijät saattavat johtaa laitteen hallinnan menettämiseen.

2) Sähköturvallisuus!

a) Sähkökäyttöisen käsityökalun pistokkeen tulee sopia pistorasiaan.

SUOMI

Älä muuta tuotetta millään tavalla. Älä käytä adapteria maadoitettujen

sähkökäyttöisten sähkötyökalujen kanssa. Pistokkeet, joita ei ole muutettu

sekä sopivat pistorasiat pienentävät sähköiskun vaaraa.

b) Vältä koskettamasta maadoitettuja esineitä, kuten putkia,

lämpöpattereita, hellaa tai jääkaappia. Sähköiskun riski kasvaa, mikäli

kehosi on maadoitettu.

c) Älä altista sähkökäyttöistä käsityökalua sateelle, äläkä käytä sitä

kosteissa olosuhteissa. Veden joutuminen sähkökäyttöiseen käsityökaluun

lisää sähköiskun vaaraa.

d) Käsittele sähköjohtoa varoen.

äläkä irrota pistoketta pistorasiasta johdosta vetämällä. Älä altista virtajohtoa

kuumuudelle, öljyille, teräville reunoille tai liikkuville osille. Vioittuneet tai

sotkeutuneet virtajohdot lisäävät sähköiskun vaaraa.

e) Kun käytät sähkökäyttöistä käsityökalua ulkona, käytä ainoastaan

ulkokäyttöön sopivia jatkojohtoja. Ulkokäyttöön sopivan jatkojohdon

käyttäminen pienentää sähköiskun vaaraa.

Älä käytä sähköjohtoa laitteen kantamiseen,

44

Page 45

3) Oma turvallisuutesi

a) Ole huolellinen ja käytä tervettä järkeä kun työskentelet sähkökäyttöisellä

käsityökalulla. Älä käytä sähkökäyttöistä käsityökalua, mikäli olet väsynyt

tai huumeiden, lääkkeiden tai alkoholin vaikutuksen alaisena. Lyhyenkin

hetken kestävä tarkkaavaisuuden herpaantuminen saattaa johtaa vakavaan

loukkaantumiseen.

b) Käytä suojavarusteita.

hengityssuojaimen, liukuestekenkien, kypärän ja kuulosuojaimien käyttäminen

vähentää loukkaantumisvaaraa.

c) Vältä tahatonta käynnistystä.

”OFF” ennen kuin liität pistokkeen seinäpistorasiaan. On äärimmäisen

vaarallista kantaa sähkökäyttöistä käsityökalua sormi liipaisimella tai liittää

sähkökäyttöinen käsityökalu pistorasiaan virtakytkimen ollessa ”ON”asennossa.

d) Poista kaikki huoltotyökalut/avaimet ennen kuin käynnistät

sähkökäyttöisen käsityökalun. Sähkökäyttöisen käsityökalun liikkuvan osan

päälle unohdettu työkalu saattaa johtaa onnettomuuteen.

e) Älä kurota liian kauas.

työn jokaisessa vaiheessa. Näin olet paremmin varustautunut mahdollisen

onnettomuuden sattuessa.

f) Käytä sopivia vaatteita.

vaatteet ja käsineet loitolla liikkuvista osista. Löysät vaatteet, korut tai pitkät

hiukset saattavat juuttua liikkuviin osiin.

g) Jos käytössäsi on pölynpoistojärjestelmä, käytä sitä.

apuvälineiden käyttö saattaa vähentää pölyyn liittyviä vaaroja.

Käytä aina suojalaseja. Suojavarusteiden, kuten

Varmista, että virtakytkin on asennossa

Varmista, että työasentosi on tasapainoinen

Älä käytä löysiä vaatteita tai koruja. Pidä hiukset,

Näiden

SUOMI

4) Sähkökäyttöisten käsityökalujen käyttäminen

ja huoltaminen.

a) Älä pakota sähkökäyttöistä käsityökalua. Käytä sähkökäyttöistä

käsityökalua, joka soveltuu suunnittelemaasi työtehtävään. Sopiva

sähkökäyttöinen käsityökalu tekee työn paremmin ja turvallisemmin oikealla

nopeudella.

b) Älä käytä sähkökäyttöistä käsityökalua, mikäli virtakytkin ei käynnistä

ja sammuta laitetta. Kaikki sähkökäyttöiset käsityökalut, joita ei voida hallita

virtakytkimellä, ovat vaarallisia ja ne tulee korjata.

c) Irrota pistoke pistorasiasta ennen kuin teet sähkökäyttöiseen

käsityökaluun säätöjä tai ennen kuin vaihdat sen varusteita tai ennen

kuin asetat sen säilytykseen. Nämä ennaltaehkäisevät toimenpiteet

vähentävät sähkökäyttöisen käsityökalun tahatonta käynnistymistä.

45

Page 46

d) Säilytä sähkökäyttöisiä käsityökaluja lasten ulottumattomissa. Älä

luovuta sähkökäyttöistä käsityökalua henkilöille, jotka eivät tunne

sitä tai sen käyttöohjetta. Sähkökäyttöiset käsityökalut ovat vaarallisia

tottumattomien käyttäjien käsissä.

e) Huolla sähkökäyttöisiä käsityökaluja.

kunnossa, että liikkuvat osat liikkuvat esteettä, että osat ovat ehjiä, ja että

sähkökäyttöisessä käsityökalussa ei ole muita seikkoja, jotka vaikuttavat

laitteen toimintaan. Jos jokin osa on vioittunut, se tulee korjata ennen

käyttöä. Monet onnettomuudet johtuvat väärin hoidetuista sähkökäyttöisistä

käsityökaluista.

f) Pidä työkalut puhtaina ja terävinä.

se on oikein hoidettu ja sen terät ovat teräviä.

g) Käytä sähkökäyttöistä käsityökalua, sen varusteita tms. ohjeiden

mukaisesti ja sellaisella tavalla, joka sopii kyseiselle sähkökäyttöiselle

käsityökalulle ja ota myös huomioon työskentelyolosuhteet ja

suoritettava työ. Sähkökäyttöisen käsityökalun käyttäminen muihin kuin sille

tarkoitettuihin työtehtäviin saattaa johtaa vaaratilanteeseen.

Tarkasta, että säädöt ovat

Terätyökalun hallinta on helpompaa, kun

5) Huolto

a) Laitteen saa huoltaa ja korjata ainoastaan ammattihenkilö ja huollossa

SUOMI

tulee käyttää ainoastaan alkuperäisosia. Näin taataan sähkökäyttöisen

käsityökalun turvallisuus.

46

Page 47

Maaliruiskua koskevia turvallisuusohjeita

• Älä ruiskuta helposti syttyviä* maaleja tai aineita.

• Älä ruiskuta nesteitä, jotka sisältävät hiukkasia tai kuituja, esim. metallicmaaleja, hitaasti palavia maaleja tai maaleja, jotka sisältävät asbestikuituja.

• Älä puhdista maaliruiskua helposti syttyvillä liuotusaineilla.

• Ota huomioon maalattavan materiaalin aiheuttamat mahdolliset vaarat.

• Lue maaliruiskussa käytettävän tuotteen ohjeet ja varoitustekstit ennen kuin

käytät maaliruiskua. Lue tuotteesta myös, mitä henkilökohtaisia suojavarusteita

tarvitset.

• Älä maalaa tuotteella, jonka vaarat eivät ole tiedossa.

• Irrota pistoke pistorasiasta kun lopetat maalaamisen (näin estetään tahaton

käynnistyminen).

• Älä suuntaa ruiskua itseäsi tai muita kohti.

• Älä käytä ruiskua kuivana, säiliössä tulee olla nestettä.

* Aineet ja nesteet, joiden leimahduspiste on yli 55 °C.

Tuotteen merkinnät ja turvallisuussymbolit

Lue koko käyttöohje!

Käytä aina suojalaseja tai visiiriä ja hengityssuojainta ja kuulosuojaimia.

SUOMI

47

Page 48

Ennen kuin aloitat

Harjoittele

Mikäli käytät ruiskua ensimmäistä kertaa,

kokeile ensin esim. ruiskuttamalla vettä

kovalevylle saadaksesi tuntuman maaliruiskuun.

1. Varmista, että imuputki on kiinnitetty

kunnolla säiliön kannen etummaiseen

putkeen. Varmista, että takaiskuventtiili on

paikallaan ja että suutin on kiinni.

2. Painetta säädellään kahvan takana olevalla

maalimääränupilla. Aseta paine aluksi

keskikohtaan ja säädä käytön aikana.

SUOMI

Maalin sekoittaminen

Tarvitset viskositeettiastian ja kellon määritelläksesi nesteen viskositeetin.

1. Upota mitta-astia maalipurkkiin täyttääksesi sen kokonaan (sekoita tarvittaessa

maali ensin tasaiseksi).

2. Nosta mitta-astia maalista ja katso kellosta, kuinka nopeasti maali valuu

pohjareiästä. Mitä hitaampi valumisaika, sitä suurempi maalin viskositeetti

(paksuus).

48

Page 49

Viskositeettitaulukko

Huom.! Taulukon arvot ovat suosituksia. Varmista oikea viskositeetti ruiskuttamalla ensin maalia kokeeksi pinnalle, jonka pinta ja maalauskulma vastaavat maalattavaa pinnaa, jos olet epävarma.

Muovi- ja lateksimaali 24–28 sekuntia

Vesiliukoinen maali 20–25 sekuntia

Pohjamaali 24–26 sekuntia

Vernissa 20–25 sekuntia

Öljypohjaiset maalit 18–22 sekuntia

Emalilakka 18–22 sekuntia

Alumiinimaali 22–25 sekuntia

Ruostesuojamaali, nestemäinen 25–35 sekuntia

Viimeistelylakka (puu) 28–35 sekuntia

Homeenesto Ohentamaton

Petsi Ohentamaton

Käyttö

Esivalmistelut

Huom.! Älä koskaan käynnistä maaliruiskua tyhjänä, se saattaa lyhentää

pumpun käyttöikää.

1. Varmista, että arvokyltin jännite on sama kuin pistorasian verkkojännite.

2. Kaada ruiskutettava maali astiaan.

3. Ohenna maalia tarvittaessa ja tarkista viskositeetti.

4. Aseta astia tasaiselle alustalle suojapaperin päälle.

5. Asenna ruiskuosa astiaan kiertämällä vastapäivään.

6. Ruisku on valmis käytettäväksi.

SUOMI

49

Page 50

Työskentelytapa

Säännöstele maalin määrää

maalimääräratilla (2):

Vähennä maalin määrää kääntämällä myötäpäivään

(B) ja lisää kääntämällä vastapäivään (A).

Pidä ruisku suorassa

• Suuttimen ja maalattavan pinnan paras etäisyys on n. 30 cm. Maali jakautuu

suuremmalle alueelle, jos etäisyys on suurempi. Maali jakautuu epätasaisesti

ja liian paksuksi kerrokseksi, jos etäisyys on puolestaan pienempi.

SUOMI

• Maalaa kokeeksi ensin muuta pintaa, jos olet epävarma.

• Pidä ruiskua aina suorassa ja samassa kulmassa kuin maalattava pinta.

• Liikuta ruiskua tasaisesti koko kättä liikuttaen, jotta saat tasaisen maalipinnan.

Älä käännä ruiskua ranteella.

Oikein Väärin

50

Page 51

• Liikuta ruiskua vasemmalta oikealla ja

takaisin, ylhäältä alas ja takaisin. Paras tulos

saadaan, kun ruiskuttaminen aloitetaan jo

hieman ennen maalattavaa pintaa.

• Suuria pintoja voidaan ruiskuttaa sekä vaakaettä pystysuuntaan.

• Maalin valuminen pystysuorilla pinnoilla voidaan estää ruiskuttamalla

hienojakoista sumua suuremmalta etäisyydeltä sen sijaan, että ruiskutetaan

paksu kerros läheltä. Ruiskuta viimeinen kerros hieman lähempää.

• Vaakatasopintoja maalatessa ruiskua kallistetaan noin 45° kulmaan pintaan

nähden. Ruiskuta poispäin itsestäsi.

SUOMI

• Mikäli pidät tauon ruiskutuksessa, kannattaa aloittaa ruiskuttamalla

paperinpalalle ennen varsinaista maalattavaa pintaa.

Maalin ohentaminen

Ohenna maalia enemmän, mikäli maali leviää ruiskuna/säteenä, eikä tasaisena

suihkuna. Vesipohjaisia maaleja ohennetaan vedellä ja öljypohjaisia maaleja

ohennetaan ohenteella, esim. mineraalitärpätillä.

51

Page 52

Puhdistus

Huom.! Älä upota väriruiskua veteen.

Jokaisen maalauskerran jälkeen

1. Poista säiliö ja irrota imuputki.

2. Poista kannen (12) alla olevat ruuvit (13) (4 kpl).

3. Poista säiliön kansi moottoriosasta (1) vetämällä sitä alaspäin.

4. Irrota pumppuyksikkö aggregaatista. Irrota osat ja puhdista kaikki komponentit

sopivalla ohenteella.

5. Kun kokoat laitteen, varmista että mäntä (11), männän jousi (10),

takaiskuventtiili (8) ja suutin (6) tulevat oikein kiinni.

6. Liitä pistoke pistorasiaan (230 V) ja pidä laitetta ylösalaisin. Kaada hieman

ohutta öljyä imuputken reikään ja paina lyhyesti liipaisimesta. Näin estetään

männän ja sylinterin ruostuminen.

SUOMI

11 10

Huom.! Riittämätön tai virheellinen puhdistus saattaa aiheuttaa männän leikkautumisen (juuttumisen) sylinteriin. Päästä liipaisin heti, mikäli ruiskuttaessa kuuluu

heikkoa mörisevää ääntä. Muuten moottori saattaa ylikuumentua ja vioittua.

1

12

8 6

13

52

Page 53

Huolto ja ylläpito

Muista tarkastaa kuluvat osat, kuten suutin, takaiskuventtiili, mäntä, männän jousi

ym. ruiskutettuasi noin 20–40 litraa maalia. Ole erityisen huolellinen lateksivärin

kanssa, sillä se kuluttaa osia hyvin paljon nopeammin kuin muut maalit.

Vaihda kuluneet osat seuraavissa tapauksissa

1. Suutin (6): Mikäli maali ei hajoa hienoksi sumuksi tai tulee ”sylkemällä” ulos.

2. Mäntä (11): Tarkasta säännöllisesti, vaihda tarvittaessa.

3. Takaiskuventtiili (8): Tarkasta venttiilinpään kolmen reiän mitat ja etuosan

pinnan tasaisuus. Kuluneessa venttiilissä on naarmuja ja suurentuneet reiät ja

se tulee vaihtaa.

Kierrätys

Kierrätä tuote asianmukaisesti, kun poistat sen käytöstä. Ota yhteys kuntasi

jäteneuvontaan, mikäli olet epävarma.

Tekniset tiedot

Virtalähde AC, 230 V, 50 Hz

Teho 75 W

Maalisäiliön tilavuus 900 ml

Ruiskuteho 200 ml minuutissa

Kaapelin pituus 3 m

Paino 1,45 kg

Tärinä suunnassa X: 1,94 m/s2

suunnassa Y: 4,94 m/s2

suunnassa Z: 13,19 m/s2

Äänenpaine: LpA 87,7 dB

Äänen teho: LwA 100,7 dB

SUOMI

53

Page 54

Vianhakutaulukko

Ongelma Syy Toimenpiteet

Sumuttuminen Ruisku liian kaukana. Pidä 30 cm:n päässä.

Liian ohutta maalia. Ruiskuta paksumpaa maalia.

Liian kova paine Käännä maalimäärärattia myötäpäivään.

Kulunut suutin Vaihda suutinta.

Moottori ylikuumenee Olet ruiskuttanut liian kauan. Anna ruiskun jäähtyä muutaman

minuutin ruiskutuksen jälkeen.

Moottori käy, mutta maalia ei

tule.

Moottorista kuuluu

ääntä, mutta maalia

ei tule.

Moottori käy oikein,

mutta ei ruiskuta.

SUOMI

Moottori ei käy. Pistorasiassa ei virtaa. Hoida kuntoon.

Ruisku sylkee maalia

ja moottori kuulostaa

oudolta.

Maalia vuotaa pum

pun rungon taakse.

Maalimääräratti väärässä asennossa.

Mäntä on leikannut akryylimaalauksen jäljiltä.

Viallinen moottori. Voitele mäntä ja sylinteri.

Liian paksua maalia. Ohenna.

Suutin tukossa. Puhdista huolella.

Takaiskuventtiili ei paikoillaan. Laita paikoilleen.

Takaiskuventtiili kulunut tai

tukossa.

Väärin säädetty maalimääränuppi.

Imusuodatin tukossa. Puhdista tai vaihda.

Viallinen moottori.

Maalimääräratti väärässä asennossa.

Kulunut takaiskuventtiili tai

kulunut suutin.

Liian suuri reikä suuttimessa. Vaihda pienempään.

Liian paksua maalia. Ohenna.

Ruiskua pidetään vinossa, jolloin

imuputkeen ei tule maalia.

Ruiskua osoitetaan ylöspäin

ruiskutettaessa.

Männässä tai sylinterissä on

naarmuja.

Tarkasta suodatin, varmista että

takaiskuventtiili ei ole tukossa.

Maali voi olla liian paksua.

Säädä.

Irrota moottoriyksikkö ja puhdista kaikki

osat huolella.

Puhdista tai vaihda.

Säädä kunnolla.

Säädä.

Vaihda kuluneet osat.

Pidä ruiskua suorassa tai laita putkeen

pidennin.

Pidä suorassa.

Vaihda kulunut osa.

54

Page 55

Declaration of Conformity

Hereby, Clas Ohlson AB, declares that the machinery:

Electric Spray Gun Cotech

Art. no: 18-3056 Model:FL-999-UK

Art. no: 30-9579 Model:FL-999

Complies with the provisions of the following Directives:

2006/95/EC LOW VOLTAGE EQUIPMENT

89/336/EEC EMC

Insjön, Sweden, February 2008

Klas Balkow

President

Clas Ohlson, 793 85 Insjön, Sweden

Page 56

SVERIGE

KUNDTJÄNST Tel: 0247/445 00

Fax: 0247/445 09

E-post: kundtjanst@clasohlson.se

INTERNET www.clasohlson.se

BREV Clas Ohlson AB, 793 85

INSJÖN

NORGE

KUNDESENTER Tlf.: 23 21 40 00

Faks: 23 21 40 80

E-post: kundesenter@clasohlson.no

INTERNETT www.clasohlson.no

POST Clas Ohlson AS, Postboks 485 Sentrum, 0105 OSLO

SUOMI

ASIAKASPALVELU Puh: 020 111 2222

Faksi: 020 111 2221

Sähköposti: info@clasohlson.fi

INTERNET www.clasohlson.fi

OSOITE Clas Ohlson Oy, Yrjönkatu

23 A, 00100 HELSINKI

UNITED KINGDOM

For consumer contact, please visit

www.clasohlson.co.uk and click on

customer service.

INTERNET www.clasohlson.co.uk

Loading...

Loading...