®

®

3649 Cane Run Road . Louisville, KY 40211-1961

877-244-9340 . Fax: 877-414-4316

www.clarusenvironmental.com

SECTION: C1.20.130

CL0020

0911

Supersedes

New

Turbine STEP Systems

OWNER'S MANUAL

Congratulations on the purchase of the Clarus Environmental Turbine

STEP System. This system will provide years of trouble-free service

when installed according to the manufacturer recommendations.

This manual incorporates the installation, operation, maintenance,

and service instructions into one document to aid in the ownership

of a Clarus Environmental onsite wastewater product. Please read

and review this manual before installing the product. Many items

contained within, when followed correctly, will not only ensure a long

and problem-free life for the system, but also save time and money

during installation. Should further assistance be necessary please call

Clarus Environmental at 1-877-244-9340.

Table of Contents

Safety Instructions ............................................................................ 1

Limited Warranty...............................................................................2

General Instructions ......................................................................... 2

Typical Filtered STEP System ..........................................................3

Discharge Pipe & Pump Installation ................................................. 4

Floats and Float Tree Installation ..................................................4-6

Final Assembly ................................................................................. 7

System Wiring Instructions ............................................................... 7

Junction Box Wiring .......................................................................... 8

Startup .............................................................................................. 8

Operation ......................................................................................... 9

Maintenance ..................................................................................... 9

Replacement Parts ......................................................................... 10

Engineered Systems ...................................................................... 11

Owner’s Information

GENERAL

The Turbine STEP System is designed to be an easily installed dropin pump vault that does not require an additional pump chamber.

However, it can be installed in a secondary pumping chamber. By

utilizing a turbine efuent pump, high head pressures are achieved.

Designed for convenience, the lters, as well as the oat tree, are

easily removed for servicing. The lter has 924 linear feet of 1/16"

ltration. This large surface area ensures adequate ltering and a

longer interval between servicing.

Safety Instructions

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND FOLLOW ALL SAFETY INSTRUCTIONS IN MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE INSTALLATION

AND OPERATION OF THIS UNIT AND MUST BE KEPT WITH

THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or in the

manual, look for one of the following signal words

and be alert to the potential for personal injury or

property damage.

Warns of hazards that WILL cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause personal injury

or property damage.

Indicates special instructions which are very

important and must be followed.

Model Number: ______________________ Date Code: _________________

Job Name: ______________________________________________________

Dealer: _________________________________________________________

Date of Purchase: _______________________________________________

Contractor: _____________________________________________________

Date of Installation: _______________________________________________

System Readings During Operation: Voltage __________ Amps _________

© Copyright 2011. All rights reserved.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND WARNINGS

PRIOR TO PERFORMING ANY WORK ON THIS SYSTEM.

MAINTAIN ALL SAFETY DECALS.

According to the state of California (Prop 65), this product contains chemicals known to

the state of California to cause cancer and birth defects or other reproductive harm.

REFER TO WARRANTY ON PAGE 2.

Limited Warranty

Manufacturer warrants, to the purchaser and subsequent owner during

the warranty period, every new product to be free from defects in material and workmanship under normal use and service, when properly

used and maintained, for a period of one year from date of purchase

by the end user, or 18 months from date of original manufacture of the

product, whichever comes rst. Parts that fail within the warranty period,

one year from date of purchase by the end user, or 18 months from

the date of original manufacture of the product, whichever comes rst,

that inspections determine to be defective in material or workmanship,

will be repaired, replaced or remanufactured at manufacturer's option,

provided however, that by so doing we will not be obligated to replace

an entire assembly, the entire mechanism or the complete unit. No

allowance will be made for shipping charges, damages, labor or other

charges that may occur due to product failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for

any material or product that has been disassembled without prior approval of manufacturer, subjected to misuse, misapplication, neglect,

alteration, accident or act of God; that has not been installed, operated

or maintained in accordance with manufacturer's installation instructions; that has been exposed to outside substances including but not

limited to the following: sand, gravel, cement, mud, tar, hydrocarbons,

hydrocarbon derivatives (oil, gasoline, solvents, etc.), or other abrasive

or corrosive substances, wash towels or feminine sanitary products,

etc. in all pumping applications. The warranty set out in the paragraph

above is in lieu of all other warranties expressed or implied; and we do

not authorize any representative or other person to assume for us any

other liability in connection with our products.

Contact manufacturer at, 3649 Cane Run Road, Louisville, Kentucky

40211, Attention: Customer Service Department to obtain any needed

repair or replacement of part(s) or additional information pertaining to

our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES OR BREACH

OF EXPRESSED OR IMPLIED WARRANTY; AND ANY IMPLIED

WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE AND

OF MERCHANTABILITY SHALL BE LIMITED TO THE DURATION

OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty, so the above limitation may not apply to you. Some states do not

allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights and you may also have

other rights which vary from state to state.

General Instructions

1. Installation must comply with all applicable electric codes, plumbing

codes and health department regulations, including, but not limited

to, the National Electrical Code, local, regional and/or state plumbing

codes, etc.

2. If the Clarus Environmental Turbine STEP System is being retrotted

into an existing septic system, it will be necessary to pump and clean

out the septic tank prior to installing. Before pumping, measure down

from the top of the septic tank to the liquid level (not the scum layer)

and record in the chart (see page 4). The top of the septic tank will

become the reference plane for measuring to correctly install your

system.

3. The inlet pipe is typically 3" above the outlet pipe. On a conventional

gravity system, once the system is pumped and cleaned, check the

dimensions from the top of the septic tank to the bottom of the inlet

and outlet pipes. Record in the chart (see page 4). Each system

varies! Therefore, don't assume a 3" difference between the inlet

and outlet.

4. An 18" hole is required in the top of the septic tank to install the STEP

system. If the hole in your septic tank is less than 18", provision must

be made to enlarge the hole to 18" (you may have to change the lid

of the septic tank).

5. If your system is not equipped with a riser, install a new Clarus

Environmental 24" or 30" diameter riser on the outlet end of the

septic tank. Follow the installation instructions provided with the

riser.

6. Unpack the STEP system from the carton. Remove everything

from the pump vault: lter pack, oat tree, discharge assembly and

instructions/hardware pack.

7. If necessary, cut a single inlet hole in the tank inlet tube (see page

11).

8. Install the two 16" long 1" schedule 80 PVC hanger pipes through

the rim holes in the pump vault and lower the pump system through

the riser and into the septic tank opening (see Fig. 1). In most cases,

the pump vault will be suspended in the septic tank by the pipe

hangers. If the septic tank is shallow, the pump vault may rest on

the tank oor. The system is designed to operate properly in either

case.

9. Install the piping from the lateral eld to the outside of the riser on

the septic tank.

© Copyright 2011. All rights reserved.

2

Typical Clarus Environmental Turbine STEP System

Clarus Environmental Turbine STEP Systems are designed for installation in septic tanks. The system should be installed through the riser

on the discharge end of the septic tank. A complete system should include: 1) Filter and pump vault, 2) Filter cartridges, 3) Float tree/ switch

assembly, 4) Efuent rated turbine pump, 5) Discharge pipe assembly, 6) Control/alarm system, 7) Junction box, 8) Prewired conduit, 9) Riser

and lid.

* * * * * * *

STATE OR LOCAL CODES

WITH NEC AND ANY OTHER

ALL WORK IN ACCORDANCE

* * * * * * *

* * * * * * * * * * * * * * * * * * * * * * * *

* * * * * * * * * * * * * * * * * * * * * * * *

55 1/2"

NOTE: BLANK TANKS ARE ALSO

INSTALLED INLET HOLE.

AVAILABLE FOR FIELD

SK2418

K

JGFEDC

H

BFLOAT CONFIGURATION

A

29"

------

---

30.5"

2.5"

---

PUMP ON PUMP OFF

---

31.5"

31.5"

---

---

---

---

---

---

30.5"

30.5"

2.5"

2.5"

2.5"

2.5"

PUMP OFF

PUMP OFF

PUMP ON

PUMP ON

ALARM

ALARM

40"

41"

---

30.5"

---

CLARUS 24 OR 30 INCH ACCESS RISER & LID

---

REDUNDANT OFF

26.5"

25.5"

8"

8"

5"

5" 5"

LOW LEVEL CUTOUT

LOW LEVEL CUTOUT

TIMER OVERRIDE

TIMER OVERRIDE

ALARM

ALARM

CLARUS 12" RISER AND LID

FROM PUMP TO SNUB OUTSIDE RISER

CLARUS DISCHARGE PIPE ASSEMBLY

SECURE EXCESS CORDAGE

(FOR FILTER REMOVAL)

CLARUS J-BOX

18" MIN. OR

(INCLUDES FLEXIBLE PVC PIPE, UNION, BALL VALVE,

AND PIPE SEAL)

4 1/2"

LOCAL CODES

PER STATE AND

FILTERED EFFLUENT

HANGER PIPES

8 1/8"

TOP OF FILTER TANK

TOP OF FLOAT TREE

"D" MIN.

33"

"F" MAX.

ALARM "A"

(BELOW, OR EVEN WITH, THE INLET HEIGHT)

"B"

SCUM LAYER

"C"

"E" MIN.

"J" MAX.

CLEAR EFFLUENT

STANDARD 4" INLET

TYPICAL

INLET LEVEL

"G"

"H" MIN.

TEE OR BAFFLE

CLARUS PUMP VAULT

TURBINE PUMP

CLARUS EFFLUENT

3 1/2" OF TETHER

LENGTH FROM CLAMP

CLARUS FILTER ASSEMBLY

17 1/8

8' 0" MIN.

FLOAT SWITCH DETAIL

SLUDGE LAYER

Fig. 1

4 FLOAT TIMED DOSING PANEL

3 FLOAT SIMPLEX CONTROL PANEL

2 FLOAT SWITCH CONTROL W/ALARM

2 FLOAT SWITCH CONTROL

3 FLOAT TIMED DOSING PANEL

OR ALARM SYSTEM

(MOUNTED ON HOUSE)

CLARUS CONTROL PANEL

RISERS FOR DRAINAGE

SLOPE GROUND AWAY FROM

4" MIN.

INLET

SIMPLEX PUMP

APPLICATION

CONDUIT

CLARUS PREWIRED

© Copyright 2011. All rights reserved.

3

"K" MIN.

1" x 16" SCH80

HANGER PIPES

3" MIN.

DUPLEX PUMP

APPLICATION

Discharge Pipe and Pump Installation

Do not lower the pump by the power cord.

10. If supplied or required, attach the check valve to the pump outlet.

Disconnect the Clarus Environmental exible pipe discharge assembly at the union on the ball valve. Connect the long part of the

discharge assembly to the pump outlet or check valve with the pump

set up outside the pump vault. If check valve is used, weephole

should be below check valve.

11. Tie off the power cord by strapping it to the upper end of the discharge

pipe. Make certain the cord cannot become entangled or obstruct

the movement of the oats. Lower the pump by the discharge pipe

into the right or left pump well of the pump vault (see Fig. 1).

Fig. 2

DISCHARGE PIPE

ASSEMBLY

1" 1¾"

1¼" 2"

2" 3"

HOLE SAW

REQUIRED

12. Reconnect the union loosely to see approximately where to install the

pipe seal through the riser wall. Remove the pump by the discharge

assembly. Drill the appropriate hole through the riser wall (see Fig.

2). Install the pipe seal through the riser wall to prevent ground

water intrusion. Disconnect the union on the discharge assembly

and install the exible pipe through the pipe seal with the union

ball valve on the inside of the riser (see Fig. 3). Solvent weld the

exible pipe to the lateral eld piping using PVC pipe cement.

13. Lower the pump by the discharge assembly back into the appropriate

pump well in the pump vault. Adjust the piping using the threaded

elbows and exible piping of the discharge assembly to achieve

proper t. Securely connect the union on the ball valve. Repeat

steps 9-12 for a second pump in a dual pump system.

Fig. 3

LID

CLARUS ACCESS RISER (24" SHOWN)

SINGLE UNION BALL VALVE

PIPE SEAL

FILTERED EFFLUENT

HANGER PIPE

Float Tree Assembly

Top of septic tank to liquid level (bottom of outlet).

Top of septic tank to bottom of inlet.

Top of septic tank to inside oor

STEP system pump vault inlet height (to the center of the inlet).

The alarm must be activated at or before the point when the efuent level reaches the bottom of the inlet pipe. If the STEP

system is being installed in an existing septic tank, the outlet pipe must be plugged.

Fig. 4

14"

TOP OF THE FLOAT TREE

10 1/2"

EXAMPLE:

14 - 3 1/2 = 10 1/2

(SO THE ALARM FLOAT SHOULD

BE SET LOWER THAN 10 1/2"

FROM THE TOP OF THE FLOAT

ROD)

3 1/2"

Fig. 5

1 2

3

4

5

6

7

8 9 10

11

12

1

13

14

16 15

17

18

20 19

22 21

DISCHARGE

FROM PUMP

13"

TOP OF THE FLOAT TREE

51"

EXAMPLE:

51 - 13 = 38

52 1/2 - 38 = 14 1/2

(SO THE ALARM FLOAT SHOULD

BE SET LOWER THAN 14 1/2"

FROM THE TOP OF THE FLOAT

ROD)

14 1/2

52 1/2"

SK1833

1

2

3

4

5

6

7

10 9 8

11

12

1

13

14

15 16

17

18

19

20

21

22

SK2435A

© Copyright 2011. All rights reserved.

4

SK2435B

Float Tree Assembly (continued)

Transferring oat locations if the pump vault is hung from the top

of the tank:

When the pump vault is hung, the top of the oat tree is 3½" below the

top of the septic tank. Therefore, any distance measured from the top

of the septic tank, minus 3½", will transfer to the top of the oat tree

(see Fig. 4 for example).

Double Piggyback Application

Fig. 6

TOP OF FLOAT TREE

30.5" MAX.

(1" ADDED FOR SAFETY)

DOUBLE PIGGY BACK

2.5" MIN.

3.5" MIN.

NYLON CABLE TIE

PUMP ON

PUMP OFF

Transferring oat locations if the pump vault is placed on the

septic tank oor:

When the pump vault is placed on the oor, the top of the oat tree is

52½" from the oor. Measure the depth of the tank and record above.

Subtract any distance measured from the depth of the tank, then sub-

tract that number from 52½" and the answer will transfer to the top of

the oat tree (see Fig. 5 for example).

If using the double piggyback oat switch option, the oats should be

set as follows (see Fig. 6).

Clarus Environmental recommends an auxiliary high water alarm

when using the double piggyback oat switch option. The alarm

should be plugged into a different circuit than the pump circuit. Follow

the installation instructions provided with the alarm (see Fig. 7).

The alarm must be activated at or before the point when the efuent

level reaches the bottom of the inlet pipe.

Record the actual settings measured from the top of the oat tree in

the table provided for future reference.

Float switch distance from top of the oat tree w/o alarm.

Pump on - Gray (below the bottom of the inlet.)

Pump off - Black (maximum 30½")

Fig. 7

30.5" MAX.

SEPTIC TANK MIN. INLET HEIGHT 29"

TOP OF FLOAT TREE

2.5" MIN.

3.5" MIN.

(1" ADDED FOR SAFETY)

SIMPLEX

2.5" MIN.

TOP OF FILTER HOLDER

Float switch distance from top of the oat tree with alarm.

Alarm - Black (below or even w/ bottom of inlet)

Pump on - Gray (varies)

SK2434G

Pump off - Black (maximum 30½")

Simplex Control Panel Applications

If using a simplex control panel, the oats should be set as follows

(see Fig. 7).

NYLON CABLE TIE

HIGH WATER ALARM

PUMP ON

PUMP OFF

The alarm must be activated at or before the point when the efuent

level reaches the bottom of the inlet pipe.

Record the actual settings measured from the top of the oat tree in

the table provided for future reference.

Float switch distance from top of the oat tree.

Alarm - Black (below or even w/ bottom of inlet)

Pump on - Black (varies)

Pump off - Black (maximum 30½")

TOP OF FILTER HOLDER

SEPTIC TANK MIN. INLET HEIGHT 31.5"

SK2434D

© Copyright 2011. All rights reserved.

5

Timed Dosing Applications

Fig. 8

26.5" MAX.

TOP OF FLOAT TREE

8" MIN.

7.5" MIN.

(1" ADDED FOR SAFETY)

SEPTIC TANK MIN. INLET HEIGHT 40"

TIMED DOSING

5" MIN.

NYLON CABLE TIE

HIGH WATER ALARM

TIMER OVERRIDE

LOW LEVEL CUTOUT

TOP OF FILTER HOLDER

SK2434E

If using a timed dosing panel, the oats should be set as follows:

Timed dosing without redundant off (see Fig. 8). Timed dosing with

redundant off (see Fig. 9).

If the system is dosing a collection system drain eld, media lter,

wetland or some other secondary wastewater treatment system, the

ideal dosing pattern should be known and applied.

The alarm must be activated at or before the point when the efuent

level reaches the bottom of the inlet pipe.

Record the actual settings measured from the top of the oat tree in

the table provided for future reference.

Float switch distance from top of the oat tree w/o redundant off.

Alarm - Black (below or even w/ bottom of inlet)

Timer override - Gray (varies)

Low level cutout - Gray (maximum 26½")

Float switch distance from top of the oat tree with redundant off.

Alarm - Black (below or even w/ bottom of inlet)

Timer override - Gray (varies)

Low level cutout - Gray (varies - maximum 25½")

Redundant off - Black (maximum 30½")

Fig. 9

TOP OF FLOAT TREE

30.5" MAX.

5" MIN.

(1" ADDED FOR SAFETY)

TIMED DOSING WITH REDUNDANT OFF

5" MIN.

8" MIN.

3.5" MIN.

SEPTIC TANK MIN. INLET HEIGHT 41"

NYLON CABLE TIE

HIGH WATER ALARM

TIMER OVERRIDE

LOW LEVEL CUTOUT

REDUNDANT OFF

TOP OF FILTER HOLDER

SK2434F

Fig. 10

NOTE: IN ALL CASES. THE LOOSE CORD ABOVE

FLOAT CORD HOLDER MUST BE ATTACHED

TO THE FLOAT TREE USING TAPE OR

NYLON WIRE TIES.

NOTE: FLOATS ARE 90° OPPOSED AND

LOCATED OPPOSITE THE INSIDE

WALL OF THE PUMP VAULT.

13. Measure and mark all oat locations on the oat tree. Install the

cord holders on the oat tree. Place one at each marked location

rotating them approximately 90° apart in two quadrants (see Fig.

10).

14. Unpack variable level oat switches from system. Remove and

discard any oat holders/clamps attached to oat switch cords. Cut

any piggyback plugs from any oat switches. Measure 3½” from the

oat switch on the cord and mark this spot. Using the appropriate

Fig. 11

FLOAT TREE

CORD HOLDER

FLOAT

3 1/2" TETHER

SK2415

oat diagram section (see Figs. 6, 7, 8 & 9), assemble each oat

cord through the oat holder and hand tighten (see Fig. 11).

15. Secure oat cords to top of the oat tree to prevent hang-ups (see

Fig. 10).

Small dimension oat switches are recommended

in all applications to prevent hang-ups.

SK2504

© Copyright 2011. All rights reserved.

6

Final Assembly

16. Place the lter holder assembly down in the pump vault, tilting it

toward the pump well side to allow the handle to be placed into the

anti-otation pocket (see Fig. 1 & 13).

17. Place the oat tree assembly down into the pump vault. The bottom

of the oat tree must go into the top of the lter holder. Snap the

top of the oat tree to the lter holder handle (see Fig. 1 & 12).

Fig. 12

TILT FILTER HOLDER TO LOCATE

IN ANTI-FLOTATION POCKET

ATTACH FLOAT TREE RIGHT BELOW

THE FILTER HOLDER FITTING

FILTER HOLDER

FILTER TANK

HP Volts Ph Hz S.F.

1/2 115 1 60 1.6 12 970 64.4 R 30 15 1.0 - 1.3

1/2 230 1 60 1.6 6 970 32.2 R 15 8 4.2 - 5.2

3/4 230 1 60 1.5 8 1325 40.7 N 20 10 3.0 - 3.6

1 230 1 60 1.4 9.8 1600 48.7 N 25 11 2.2 - 2.7

1 1/2 230 1 60 1.3 13.1 2250 56.8 L 35 15 1.5 - 1.9

2 230 1 60 1.25

3 230 1 60 1.15

SK2416

Electrical Data for Clarus Environmental Turbine Efuent Pumps

18. Connect the pump, oats, alarms and control panels. Follow installation instructions and wiring diagrams supplied with each.

19. After wiring, ll the septic tank with water. This must be done to

check the pump, oat operating levels and the alarm. Be sure the

oats do not hang up during operation! Do not fully empty

the septic tank of water to help prevent oat-out.

Maximum

Amps Watts Std. Delay

Locked

Rotor

Amps

KVA

Code

Y 13.2

B 11.9

2650 51.0 G 30 15

R 2.6

Y 14.0

B 14.5

3650 82.0 G 45 20

R 4.5

Fuse/Circuit

Breaker Amps

Winding

Resistance

Line to Line

1.6 - 2.3 M

5.2 - 7.15 S

.9 - 1.5 M

3.0 - 4.9 S

Wiring Instructions

"Risk of electrical shock" Do not remove

the power supply cord and strain relief or connect conduit directly to the pump. Installation and checking of electrical cir-

cuits and hardware should be performed by a qualied and licensed

electrician.

For your protection, make certain that the

pump ground wire is properly connected to the ground

wire in the incoming power line. Test for ground at the junc-

tion box using an Underwriters Laboratory listed circuit analyzer which will indicate if the power, neutral and ground wires are correctly connected.

In 230 VAC pump installations, one side of

the line going to the pump is always hot. This condition exists

if the switch is on or off. Install a double pole disconnect on all

230 VAC pump circuits.

Double Piggyback Float Switch Installations

120 VAC

G

G

N

G N L1

L1

BLACK

WHITE

RED

L1 N

115V

POWER

SOURCE

LIQUID-TIGHT

CONNECTOR

G

115V

SWITCH

GENERAL WIRING RECOMMENDATIONS

• Follow the correct wiring diagram for your system.

• Use an auxiliary alarm with the double piggyback oat switch op-

tion or any other control method that does not include a high water

alarm. Install the alarm inside the house or in a weather protected

location per installation instructions with the alarm kit. Make sure

the alarm is plugged into a different circuit than the pump circuit.

• If a junction box is being used, follow the installation instructions

and wiring directions with the junction box or follow the directions

below. All wiring, from the power source to the pump, must conform

to the National Electrical Code.

• Be sure to leave a sufcient amount of cord so the lter can be

serviced without disconnecting the cordage from the junction box

(see maintenance section).

L1

L2

230 VAC

G

230V

POWER

SOURCE

L1

G

L2

BLACK

G

WHITE

RED

G

L2

L1

LIQUID-TIGHT

CONNECTOR

230V

SWITCH

JUNCTION BOX

115V

PUMP

SK1837A

© Copyright 2011. All rights reserved.

7

JUNCTION BOX

230V

PUMP

SK1837B

Watertight Junction Box Wiring

The preferred location of the junction box is inside the riser. Some

codes require the junction box to be outside the riser. Check with your

local health department and electrical inspector before deciding upon

the location.

• Junction boxes must be watertight. All wiring that passes through

the wall of the box must use watertight connectors and be sealed

properly.

• NOTE: See CL0625B for a list of suggested junction boxes and

CL0620B for prewired conduit assemblies. Junction boxes for the

Startup

Before placing the equipment into operation the following must be

checked:

• Septic tank or pump chamber should be pumped and cleaned prior

to installation in existing system.

• Septic tank or pump chamber must be watertight.

• Installation needs to be according to instructions.

• Installation should include an easy access riser and tamper

resistant lid.

• Filter assembly needs to be in place and secure.

• Float tree needs to be in place, secure and adjusted for

proper cycling.

• Make sure oat switches are free to move within the basin.

• Be sure electrical connections are watertight and

conform to the Uniform Building Code and the National Electrical

Code (NEC).

• Fill the septic tank with water and check the system for operation.

After installing the pump into the containment area with adequate

high head lter system are fully assembled and are provided with a

3/4” PVC conduit attachment and the appropriate number of cord

seals for the pump and oats.

• For junction boxes that are not fully assembled or predrilled, drill

a 1-1/8” hole in the box for the 3/4” PVC conduit tting. Install with

washer on the outside of box. Silicone is recommended around the

opening for the best seal. Drill a 7/8” hole in the box for each cord

seal. Install with washer on the outside of box. Silicone is recommended around each opening for the best seal.

submergence, open the discharge valve fully. Start the unit using manual

controls. If ow is appreciably less than rated performance, pump may

be air locked. To expel trapped air, jog the unit several times, using

the manual controls. If your system has a check valve, make sure the

weep hole is clear.

Check oat levels during operation and adjust accordingly as

needed.

Have a qualied electrician take voltage and current measurements

on the black wire of single phase. Record these readings in the space

provided in the “Owner’s Information” section on the front this manual

for future reference.

Be sure to complete all items such as installing the lid on the riser,

securely closing the control panel, and checking the system operation

have been completed before placing the system into service.

© Copyright 2011. All rights reserved.

8

Operation

• If the system is dosing a collection system, draineld, sand lter,

wetland, or some other secondary wastewater treatment system,

the ideal dosing pattern should be known and applied.

• The high water alarm will indicate the system needs maintenance.

However, regular maintenance by trained professionals is a necessary part of operation.

Maintenance

For your personal safety and health, a high quality pair of rubber gloves are recommended while servicing this unit. For your

personal health, always wash your hands with antibacterial soap after servicing this unit.

Always disconnect pump and panel from its power source before servicing.

GENERAL

Clarus Environmental Turbine STEP Systems require periodic mainte-

nance to remain in operational condition. A qualied service technician

should carry out the required maintenance. These technicians will not only

service the pump unit, but can assess the health of the septic tank.

SERVICE FREQUENCY

• The system contains an efuent lter. This lter will prevent solids larger than 1/16” from entering the pump compartment. The

lter will require cleaning. The cleaning interval is determined by

household use patterns. For example, a low water use household

with no children may need a lter cleaning and inspection on yearly

intervals, but a larger family may require lter maintenance every

six months, or sooner. The pump tank and pump should be serviced at a minimum each time the septic tank is pumped. Annual

inspections by trained professionals are recommended.

• Continual alarm indicator activation between service intervals is a

clear indicator that the system is not being serviced often enough.

The alarm indicates a high liquid level and service is required

immediately to avoid ooding and back up into the house.

SERVICING THE UNIT

During lter maintenance, the service technician must perform the

following:

• Check the sludge level of the septic tank. If the sludge level approaches 50% of the pump basin inlet height then, the septic tank

needs to be pumped.

• The pump should be removed, cleaned, and inspected. Any defective components should be replaced. Inspect and remove any

sand, debris, or mud present in the pump vault.

• Inspect the panel for any presence of moisture in enclosure, loose

connections, and general component condition.

• Check for proper location and unobstructed oat operation.

To remove the lter pack only:

1. The lter pack can be removed on a periodic basis for inspection

and servicing without disturbing the pump and piping. Remove the

riser cover only after disconnecting power to both the pump

and alarm.

• During operation, the system owner must continue to use proper

septic tank ownership practices. Ground garbage, hair, grease, and

non-ushable paper products should be prevented from entering

any septic system. These materials will be prevented from entering

the draineld by the lter apparatus, but abuse of the system will

result in the need for more frequent servicing.

2. Remove the oat tree assembly. Remove lter pack from pump

tank by pulling the handle on the lter pack towards the pump(s)

and through the opening on the top of tank. Place each component

over the septic tank opening and hose down thoroughly. The cord-

age from the junction box to the oat tree should be of sufcient

length to avoid the necessity of disconnecting the electrical wiring

in the junction box. Do not disturb wiring connection unless oats

or pump is being replaced or repaired.

3. Reinstall assemblies back in pump tank.

4. Follow Startup procedures located in CL0140E to get system

running again.

To remove the entire system:

1. The pump and pump tank must be removed for cleaning and

servicing of the septic tank. This provides an opening for pumping out the septic tank. Remove the riser ring cover only after

disconnecting power to both the pump and alarm.

2. Remove the oat tree assembly. Remove lter pack from pump

tank by pulling the handle on the lter pack towards the pump(s)

and through the opening on the top of pump tank. Hose off each

assembly as it is being removed to avoid any spillage of sewage

or efuent outside the septic tank.

3. Disconnect the pipe union in the discharge pipe to remove the

pump from pump vault. The cordage from the junction box to the

pump should be of sufcient length to avoid the necessity of disconnecting the electrical wiring in the junction box. Do not disturb

wiring connection unless pump is being replaced or repaired.

4. Lift the pump vault out of the riser and stand upright on ground or

level working surface.

5. Place each component over the septic tank opening and hose

down thoroughly. Also hose down the inside and outside of pump

tank.

6. Reinstall pump tank and related assemblies back in septic tank in

reverse order.

7. Follow Start-up procedures located in CL0140E to get system

running again.

© Copyright 2011. All rights reserved.

9

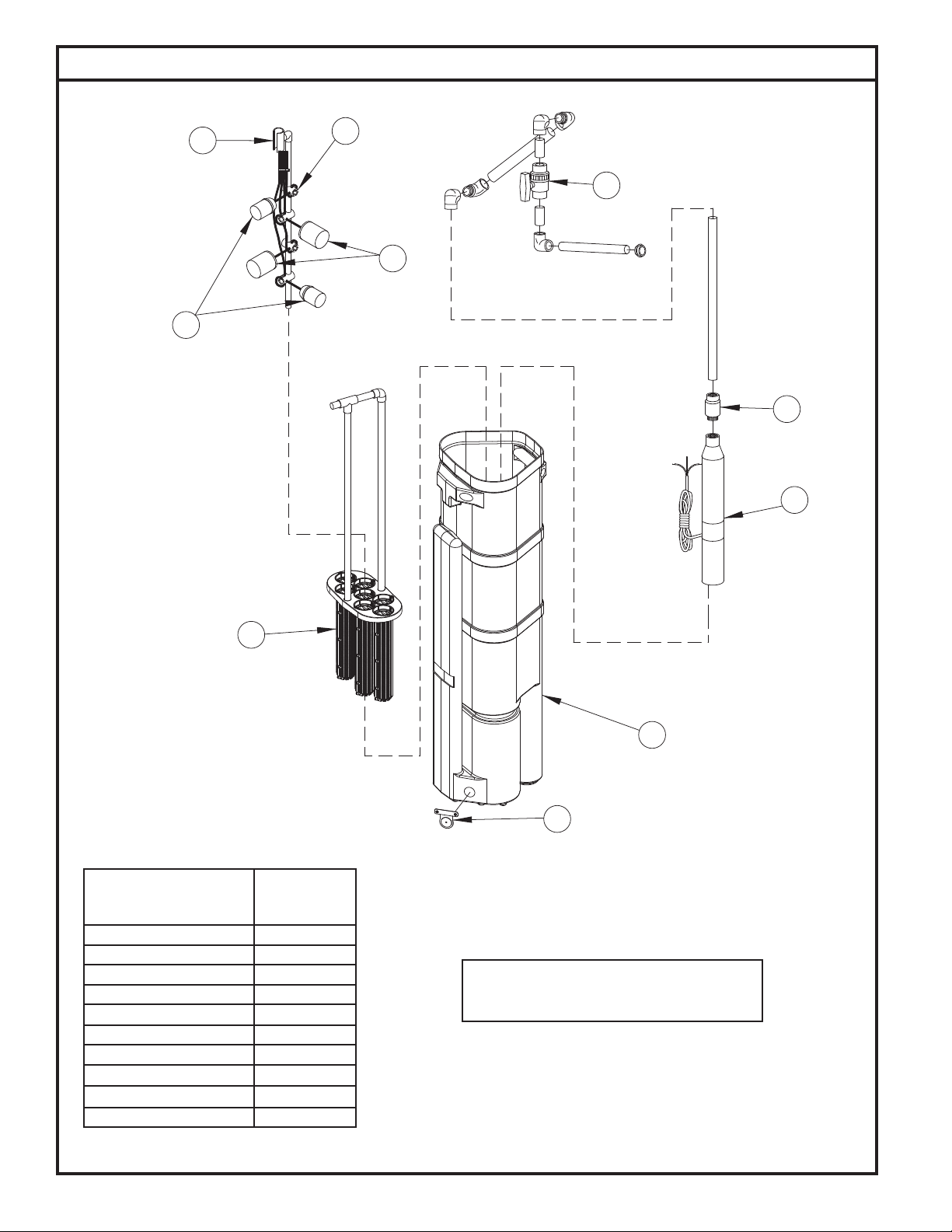

Replacement Parts for Clarus Environmental Turbine STEP System

3

4

6

5

2

7

8

1

SERVICE PARTS LIST TURBINE

EFFLUENT STEP SYSTEM

PART NUMBER

PART NAME 4/04 THRU

CURRENT

1 FILTER ASSEMBLY 016140

2 FLOAT (NARROW ANGLE) 011833

3 FLOAT TREE (TEE ONLY) 10-1681

4 FLOAT HOLDER 013940

5 FLOAT (WIDE ANGLE) 004066

6 DISCHARGE ASSEMBLY 170-0082

7 EXTERNAL CHECK VALVE 30-0187

8 PUMP consult factory

9 PUMP TANK* 016452

10 FLAPPER ASSEMBLY 016141

9

10

The accompanying parts list is provided for ordering

service parts. Please have pump model number and

date code ready for immediate service.

SK2417

*NOTE: Replacement tank will require eld cutting of the inlet.

© Copyright 2011. All rights reserved.

10

Covered by US Patent No.

5,985,139; others pending.

)

J-BOX

RISERS FOR DRAINAGE

SLOPE GROUND AWAY FROM

REMOVAL OF THE FILTER ASSEMBLY.

(INSTALL THE J-BOX IN SUCH A MANNER

THAT IT WILL NOT INTERFERE WITH THE

DISCHARGE PIPE ASSEMBLY

(INCLUDES FLEXIBLE PVC PIPE, UNION,

CLARUS

24 OR 30 INCH ACCESS RISER & LID

SECURE EXCESS CORDAGE

(FOR FILTER REMOVAL)

CLARUS

& LID

CLARUS

24" RISER

BALL VALVE, AND PIPE SEAL)

FILTERED EFFLUENT

TOP OF FILTER TANK

11"

TOP OF FLOAT TREE

ALARM

15"

25"

ON

CUT TO

51"

OFF

3 1/2 MIN.

TOP OF FILTERS

(SEE NOTE)

TOP OF INLET

* * * * * * *

17 1/8"

STATE OR LOCAL CODES

WITH NEC AND ANY OTHER

ALL WORK IN ACCORDANCE

* * * * * * *

* * * * * * * * * * * * * * * * * * * * * * * * *

126"

* * * * * * * * * * * * * * * * * * * * * * * * *

SK2422

CLARUS

(MOUNTED ON HOUSE)

INDOOR/OUTDOOR ALARM

ENGINEERED SYSTEMS

CONTROL PANEL

CLARUS

PERMANENTLY MOUNTED

HAZARD

ELECTRICAL SHOCK

WARNING

!

REV. A

P/N 10-1193

CONDUIT

18" MIN. OR

PER STATE AND

PREWIRED

CLARUS

SLOPE GROUND AWAY FROM

RISERS FOR DRAINAGE

FILTERED EFFLUENT

FLEXIBLE DISCHARGE ASSEMBLY

8"

48"

LOCAL CODES

TIMER OVERRIDE

HIGH WATER ALARM

INLET

JOB SPECIFIC

SECURE EXCESS CORDAGE

(FOR FILTER REMOVAL)

5"

REDUNDANT OFF

LOW LEVEL CUTOUT

(TO BE DETERMINED BY ENGINEER)

5"

TOP OF INLET

(SEE NOTE)

3 1/2"

MIN.

THE INLET HOLE ON ENGINEERED FILTER TANKS ARE FIELD INSTALLED.

NOTES:

ENGINEERED FILTERED STEP SYSTEM

INLET HEIGHT TO BE DETERMINED BY ENGINEER, APPROXIMATELY 40%

BELOW THE EFFLUENT SURFACE.

(SINGLE OR DUAL PUMPS)

DUAL PUMP SHOWN

NON HANGING CUSTOM TANK AVAILABLE IN 51".

HANGING CUSTOM TANKS AVAILABLE IN 60", 66", 72", 84", 90" AND 96".

17 3/8

30 INCH RISER & LID

CLARUS

© Copyright 2011. All rights reserved.

4 1/2"

FILTERED EFFLUENT

91 1/2

SINGLE INLET

CUT 2" X 5"

INLET TUBE

HOLE TO BE

11

Notes

All Clarus Environmental products must be installed and maintained in accordance with all applicable codes.

Product information presented here reects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

Your Peace of Mind is Our Top Priority

3649 Cane Run Rd. • Louisville, KY 40211-1961 • 877-244-9340 • FAX: 877-414-4316

www.clarusenvironmental.com

© Copyright 2011. All rights reserved.

®

Loading...

Loading...