SECTION: C1.50.130

CAUTION

CL0032

®

®

3649 Cane Run Road . Louisville, KY 40211-1961

1-800-928-7867 . Fax: 502-774-3624

www.clarusenvironmental.com

0314

Supersedes

0212

Centrifugal STEP Systems

OWNER'S MANUAL

Congratulations on the purchase of the Clarus Environmental

Centrifugal STEP System. This system will provide years of

trouble-free service when installed according to the manufacturer's

recommendations.

Table of Contents

Safety Instructions .......................................................................... 1

Limited Warranty.............................................................................2

Preinstallation Information .............................................................. 2

System Installation Instructions ................................................... 2-4

Pump Performance Data ................................................................ 5

Operation ........................................................................................ 6

Replacement Parts ......................................................................... 7

Maintenance & Troubleshooting ..................................................... 8

Please read and review this manual before installing the product.

The instructions contained herein, when followed correctly, will not

only ensure a long and problem-free life for the system, but also

save time and money during installation. Should further assistance

be necessary please call Clarus Environmental at 1-800-928-7867.

Safety Instructions

TO AVOID SERIOUS OR FATAL PERSONAL INJURY OR MAJOR

PROPERTY DAMAGE, READ AND FOLLOW ALL SAFETY

INSTRUCTIONS IN MANUAL AND ON THE PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE INSTALLATION

AND OPERATION OF THIS UNIT AND SHOULD BE KEPT WITH

THE SYSTEM.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or in the

manual, look for one of the following signal words

and be alert to the potential for personal injury or

property damage.

Owner’s Information

Model Number: ______________________ Date Code: _________________

Job Name: ______________________________________________________

Dealer: _________________________________________________________

Date of Purchase: _______________________________________________

Contractor: _____________________________________________________

Date of Installation: _______________________________________________

System Readings During Operation: Voltage __________ Amps _________

© Copyright 2014. All rights reserved.

Warns of hazards that WILL cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause serious personal

injury, death or major property damage.

Warns of hazards that CAN cause personal injury

or property damage.

INDICATES SPECIAL INSTRUCTIONS WHICH ARE

VERY IMPORTANT AND MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND WARNINGS

PRIOR TO PERFORMING ANY WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

REFER TO WARRANTY ON PAGE 2.

Limited Warranty

CAUTION

CAUTION

CAUTION

CAUTION

Manufacturer warrants, to the purchaser and subsequent owner during the warranty

period, every new product to be free from defects in material and workmanship under

normal use and service, when properly used and maintained, for a period of one year

from date of purchase by the end user, or 18 months from date of original manufacture

of the product, whichever comes rst. Parts that fail within the warranty period, one

year from date of purchase by the end user, or 18 months from the date of original

manufacture of the product, whichever comes rst, that inspections determine to be

defective in material or workmanship, will be repaired, replaced or remanufactured at

manufacturer's option, provided however, that by so doing we will not be obligated to

replace an entire assembly, the entire mechanism or the complete unit. No allowance

will be made for shipping charges, damages, labor or other charges that may occur

due to product failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for any material or

product that has been disassembled without prior approval of manufacturer, subjected

to misuse, misapplication, neglect, alteration, accident or act of God; that has not

been installed, operated or maintained in accordance with manufacturer's installation

instructions; that has been exposed to outside substances including but not limited to

the following: sand, gravel, cement, mud, tar, hydrocarbons, hydrocarbon derivatives

(oil, gasoline, solvents, etc.), or other abrasive or corrosive substances, wash towels

or feminine sanitary products, etc. in all pumping applications. The warranty set out in

Lifetime Warranty: Every Clarus Environmental lter is guaranteed to be free from defects in materials and workmanship for the lifetime of the homeowner/purchaser. Free repair

or replacement, excluding labor, will be made on return of the lter prepaid to the factory. This warranty is limited to product proven to be free from abuse or improper installation.

the paragraph above is in lieu of all other warranties expressed or implied; and we do

not authorize any representative or other person to assume for us any other liability in

connection with our products.

Contact manufacturer at, 3649 Cane Run Road, Louisville, Kentucky 40211,

Attention: Customer Service Department to obtain any needed repair or replacement

of part(s) or additional information pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES OR BREACH OF EXPRESSED

OR IMPLIED WARRANTY; AND ANY IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE AND OF MERCHANTABILITY SHALL BE LIMITED TO

THE DURATION OF THE EXPRESSED WARRANTY

Some states do not allow limitations on the duration of an implied warranty, so

the above limitation may not apply to you. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion

may not apply to you.

This warranty gives you specic legal rights and you may also have other rights

which vary from state to state.

Preinstallation Information

1. Inspect your unit. Occasionally, products are damaged during shipment.

If the unit is damaged, contact your dealer before using.

2. Carefully read the literature provided to familiarize yourself with specic

details regarding installation and use. These materials should be retained

for future reference.

3. Do not lift, carry, or hang pump by the electrical

cables. Damage to the electrical cables can cause shock, burns or

death.

4. For your protection, make certain the pump

ground wire is properly connected to the ground wire with the

incoming power line. Test for ground at the junction box using

an Underwriters Laboratory listed circuit analyzer which will indicate if the

power, neutral and ground wires are correctly connected. If in doubt, call a

qualied licensed electrician.

5. Make certain that the receptacle is within

the reach of the pump’s power supply cord. DO NOT USE AN

EXTENSION CORD. Extension cords that are too long or too light

do not deliver sufcient voltage to the pump motor. But, more important, they

could present a safety hazard if the insulation were to become damaged

or the connection end were to get wet.

6.

the voltage requirements of the motor, as indicated on the pump nameplate.

Check to be sure your power source is capable of handling

7. Make sure the pump electrical supply circuit is

equipped with fuses or circuit breakers of proper capacity. A sepa-

rate branch circuit is recommended, and sized according to the

“National Electrical Code” for the current shown on the pump

nameplate.

8.

The installation of pumps using auxiliary variable level

oat switches is the responsibility of the installing party and care should

be taken that the tethered oat switch will not hang up on the pump ap-

paratus or pit peculiarities and is secured so that the pump will shut off.

9. Water hammer creates momentary high pressure surges.

These surges can cause severe damage to check valves and the piping

system. Consideration for water hammer must be included in the piping system design. Reference ASPE Data Book, Chapter 2.33. Some

systems may require external spring or lever weighted check valves or

other engineered solutions.

10. In cold climates the discharge pipe may be subject to

freezing. If the riser on the septic tank is above the frost line, it will be

necessary to protect the system from freeze up. The discharge pipe can

be insulated or the check valve can be removed. If the check valve is

removed, the “on-off” cycle must be adjusted for any back-ow from the

discharge line.

System Installation Instructions

1. Clarus Environmental Centrifugal STEP Systems are designed for

installation in septic tanks through the riser on the discharge end

of the tank. See Fig. 1. If a complete system has been purchased,

all the components will be included except external pipe, ttings,

and riser. Check your Local Code for alarm requirements.

2. All installations must comply with all applicable electrical and

plumbing codes, including, but not limited to, National Electrical

Code, local, regional, and/or state plumbing codes, etc.

3. If the Clarus Environmental Centrifugal STEP System is being

retrotted into an existing septic system, it will be necessary

to pump and clean out the septic tank before installing. Before

pumping, measure down to the liquid level in the septic tank (not

the scum layer) from the septic tank lid and record. The septic

tank lid becomes the reference point for measuring to correctly

© Copyright 2014. All rights reserved.

install your system. Take the proper measurements before attempting

to install the new ltered pump system.

4. The outlet pipe is typically 3” below the inlet on a conventional gravity

system. Check the dimensions from the top of septic tank to the

bottom of the inlet and outlet pipe. Each individual system varies

therefore do not assume your system is 3”.

5. An 18” hole is required in the top of the septic tank to install the STEP

system. If the hole in your septic tank is less than 18”, provisions

must be made to open the hole up to 18”. (You may have to change

the lid of the septic tank.)

6. If your system is not equipped with a riser, install a new Clarus

Environmental 24” or 30” diameter riser. Follow the installation

instructions provided with the riser.

2

System Installation Instructions, continued

7. Bring piping from the lateral eld to the outside of the riser on the

septic tank. Note: If installing a system using a control panel follow

the instructions included with the panel and skip steps 11-12 and 15.

8. Disconnect Clarus Environmental exible pipe assembly at union

on ball valve. Install pipe seal through the riser wall (2” hole saw

required) to prevent ground water intrusion. Install exible pipe

through pipe seal with union ball valve on inside of riser as shown

in Figure 1A. Solvent weld exible pipe to lateral eld piping using

PVC pipe cement.

9. Connect other part of 1 ¼” discharge pipe assembly to pump outlet

with pump setup outside the pump tank.

10. Tie off power cord by strapping to the discharge pipe. Make certain

the cord cannot become entangled or obstruct the movement

of the floats.

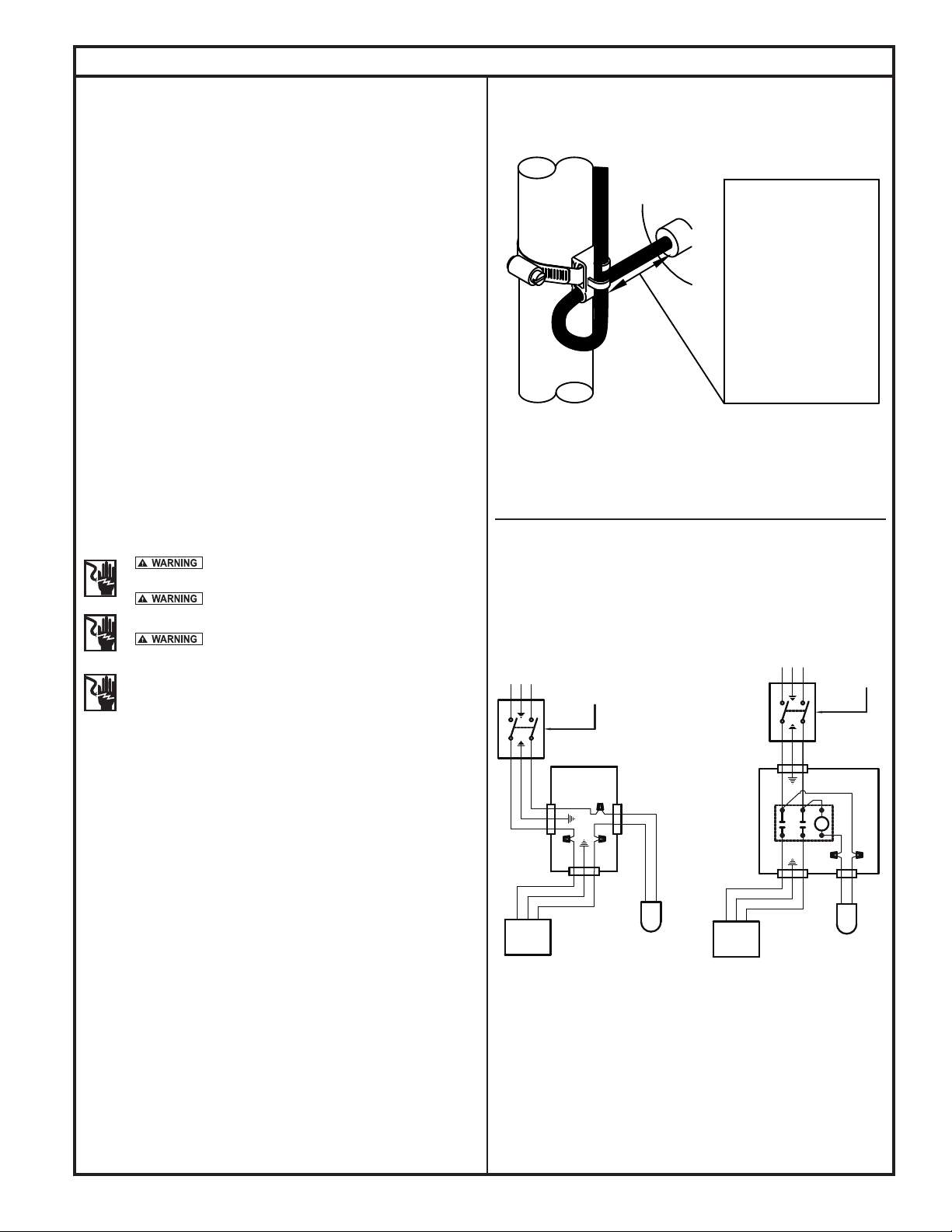

11. Install wire from power source and the alarm. See Fig. 1A or 1B. If

a junction box is being used, Fig. 1A, install inside the septic tank

riser. If a Qwik Box System is being used, Fig. 1B, install outside of

septic tank riser as shown in Fig. 1B or inside of septic tank riser.

Note: Some codes require the junction box to be outside the riser.

12. Install pump switch on discharge pipe using the included band clamp.

Place the band clamp as low on the discharge pipe as possible.

Tether the pump switch so that 3.5" of cord exists between the oat

and the clamp. This will yield a 7" drawdown cycle. Additional

tethers can be used if state, local and regional codes permit.

supply cord and strain relief or connect conduit directly to the pump.

hardware should be performed by a qualied licensed electrician.

ground wire is properly connected to the ground wire with the

incoming power line. Test for ground at the junction box using

an Underwriters Laboratory listed circuit analyzer which will indicate

if the power, neutral and ground wires are correctly connected. If in

doubt, call a qualied licensed electrician.

13. Measure length of hanger pipes by measuring inside the riser. Cut and

install hanger pipes in lter tank and lower the assembly into the septic

tank opening. Tie off power cords by strapping to discharge pipe. Make

certain cords cannot become entangled or obstruct the movement of the

oats. See Fig. 1. Lower pump with discharge pipe and oat assemblies

into lter tank.

14. Adjust piping using threaded elbows and exible piping provided to achieve

proper t. Connect union on ball valve.

15. Install the alarm inside the house or in a weather protected location per

installation instructions with alarm kit, making sure the alarm is plugged into

a different circuit than the pump circuit. Complete the wiring connections. If

a junction box is being used, Fig. 1A, wire per diagram in Fig. 4. If a Qwik

Box outside connection is being used, wire according to the installation

instruction provided with the Qwik Box unit. All wiring, from the power

source to the pump, must conform to the National Electrical Code. Be

sure to leave a sufcient amount of cord so the lter can be serviced

without disconnecting the cordage from the junction box or Qwik box.

See Maintenance section on back page.

16. Fill the septic tank with water and check the alarm level before placing

the system into service. See operation and start-up areas of this manual.

“Risk of electrical shock” Do not remove power

Installation and checking of electrical circuits and

For your protection make certain the pump

Figure 3 - Tethered Pump Switch

3.5 INCH

TETHER LENGTH

FOR DOUBLE

FLOAT

3.5 INCH

MINIMUM

TETHER LENGTH

FOR PUMP

SWITCH

SK1301

Figure 4 - J-Box Wiring Diagram

DISCONNECT

VARIABLE

LEVEL

SWITCH

R

BLACK

WHITE

SK306

DISCONNECT

SWITCH

WHITE

PUMP

WATERTIGHT

JUNCTION BOX

L1L2

GREEN

BLACK

VARIABLE

LEVEL

PUMP SWITCH

WHITE

BLACK

WHITE

PUMP

GREEN

BLACK

L2 L1

CONTROL SWITCH

SWITCH

Note: Some codes require the junction box to be outside the riser.

© Copyright 2014. All rights reserved.

3

Note: All on/off alarm

settings must comply

with all state and local

codes.

Note: Some codes require

the junction box to be outside

the riser.

Figure 1A - Typical Installation Centrifugal STEP System - J-Box

J-BOX

SECURE EXCESS CORDAGE

(FOR FILTER REMOVAL)

FILTERED EFFLUENT

INLET

TO POWER SOURCE AND ALARM

3" MIN.

2"

18" TYP.

CONSULT LOCAL

CODE

LIQUID LEVEL

PUMP "ON"

PUMP "OFF"

18" MIN.

ALARM "ON"

10"

8"

RELATIVELY

CLEAR

EFFLUENT

4"

Figure 1B - Typical Installation Centrifugal STEP System - Qwik Box

ABOVE GRADE APPLICATION

QWIK BOX

2" PVC CONDUIT

SUPPLIED BY OTHERS

BELOW GRADE APPLICATION

SK1686

INLET

Note: All on/off alarm

settings must comply with

all state and local codes.

2"

18" TYP.

CONSULT LOCAL

CODE

3" MIN.

LIQUID LEVEL

TO ALARM

TO POWER SOURCE

PUMP "ON"

PUMP "OFF"

ALARM "ON"

10"

8"

RELATIVELY

CLEAR

EFFLUENT

4"

FILTERED EFFLUENT

Figure 2 - Elevation View Centrifugal STEP System

45 7/8"

42 5/8"

24 3/8"

PUMP "ON"

PUMP "OFF"

ALARM "ON"

10"

8"

4"

Note: It is the responsibility

of the installer & designer

to assure all state and local

codes are met.

ALARM FLOAT/PUMP FLOAT

(TETHERED ON OPPOSITE

SIDE OF OTHER)

8 3/4" REF.

3 1/2" OF TETHER

LENGTH FROM STRAP

ALARM FLOAT

SK1685

Note: It is the responsibility

of the installer & designer

to assure all state and local

codes are met.

15 3/8"

© Copyright 2014. All rights reserved.

4

PUMP FLOAT

SK1684

Performance Data

TOTAL DYNAMIC HEAD/FLOW PER MINUTE EFFLUENT AND DEWATERING

MODEL

Meters

Feet

1.55

10 3.0

15 4.6

20 6.1

25 7.6

30 9.1

40 12.2

506015.2

18.3

Shut-off Head:

51

Gal. Liters

18

68

13

50

8

32

2

8

-

-

-

-

-

-

-

-

-

-

21 ft.(6.4m)

FEET

METERS

75

22

70

20

65

60

18

55

16

50

14

45

40

12

35

10

30

TOTAL DYNAMIC HEAD

8

25

53

Gal. Liters

43

163

34

129

19

72

-

-

-

-

-

-

-

-

-

-

-

19.25 ft.(5.9m)

-

98

Gal. Liters

-

-

-

-

45

170

25

95

-

-

-

-

-

-

-

-

-

-

23 ft.(7.0m)

PUMP PERFORMANCE

CURVE

51,53,98,142,145,151,

152,153

145

142

153

152

142

Gal. Liters

18

68

18

68

18

68

17

64

16

61

14

53

7

26

1

-

62 ft.(18.9m)

4

-

145

Gal. Liters

-

-

-

-

49

186

45

171

35

133

26

99

16

74 ft.(22.6m)

61

-

-

-

-

151

Gal.

Liters

50

189

45

170

38

144

29

110

16

61

-

-

-

-

-

-

- - - - - -

30 ft. (9.1m)

152

Gal.

-

-

44

34

-

-

38 ft. (11.6m)

Electrical Data

Model HP Volts Phase HZ FLA

N51 0.3 115 1 60 9.5

N53 0.3 115 1 60 9.7

N98 0.5 115 1 60 9.4

N142 1.0 115 1 60 13.0

N145 0.75 11 5 1 60 13.0

N151 0.3 115 1 60 6.0

N152 0.4 115 1 60 8.5

N153 0.5 115 1 60 10.5

Liters

-

-

167

129

8723

-

-

153

Gal.

Liters

-

-

-

-

42

159

12533

22

11

44 ft. (13.4m)

151976B

-

-

-

-

85

42

151976A

20

6

15

4

10

2

5

0

GALLONS

LITERS

51

10 20 30 40 50

0

80 160

FLOW PER MINUTE

98

151

53

189

© Copyright 2014. All rights reserved.

5

Timed Dosing Applications

Clarus Environmental Centrifugal STEP Systems are adaptable for

Timed Dosing Applications using the following recommendations.

• Refer to Clarus Environmental Centrifugal STEP Systems catalog

sheet (CL0031) and Clarus Environmental Timed Dosing Panels

catalog sheet (CL0107) for ordering the correct panel part number.

• If the system is dosing a collection system, draineld, sand lter,

wetland, or some other secondary wastewater treatment system,

the ideal dosing pattern should be known and applied.

Operation

GENERAL

The centrifugal septic tank effluent pumping (STEP) system is

designed to be an easily installed, drop in pump basin that does

not require an additional pump chamber. However it can be

installed in a secondary pumping chamber. By using a submersible

pump, high head pressures are achieved. The system was

designed for convenience. The filters are easily removed for servicing.

The filter has 528 linear feet of 1/16” filtration. This large surface

area ensures adequate filtering, and a longer interval between

necessary servicing.

SHORT TERM STORAGE

If unit is to be stored for six months or longer:

• Store system inside whenever possible or cover with some type of

protective covering

• Store unit upright in original shipping container

• Ideal storage temperatures are 45 to 90 degrees

• Tape or seal in a plastic bag the terminal ends of the wire leads

• The alarm must be activated before the efuent level reaches the

bottom of the existing outlet pipe. The alarm can be set higher, up

to the bottom of the inlet pipe, if the existing outlet pipe has been

plugged. This can be determined by measuring the location and

elevation of the discharge pipe.

• Filling the septic tank with water after completion of the installation

must be done in order to check the pump and alarm.

the pump and check valve to insure the pump will not airlock

• If a control panel is used, the panel must be dry and securely installed

Fill the septic tank with water and check the system operation before

placing into service.

After installing the pump into the containment area with adequate

submergence, open the discharge valve fully. Start the unit using manual

controls. If ow is appreciably less than rated performance, pump may

be air locked. To expel trapped air, jog the unit several times, using

the manual controls.

Have a qualied electrician take voltage and current measurements on the

black wire of single phase. Record these readings in the space provided

in the “Owner’s Information” section of this manual for future reference.

Be sure to complete all items such as installing the lid on the riser,

securely closing the control panel, and checking the system operation

have been completed before placing the system into service.

If panel is to be stored for more than six months, the following is advised:

• Store the panel inside whenever possible and leave in the shipping box

• All openings must be sealed

• Store in an upright position

• Do not stack anything on top of panel

START-UP

Before placing the equipment into operation the following must

be checked:

• Septic tank should be pumped and cleaned prior to installation in

existing system

• Installation needs to be according to instructions

• Installation should include an easy access riser and tamper resistant lid

• Filter assembly needs to be in place and secure

• Floats need to be in place, secure and adjusted for proper cycling

• Make sure oat switches are free to move within the basin

•

Be sure electrical connections are watertight and conform to uniform

building codes

• When a check valve is used, drill a 3/16” vent hole in pipe, between

© Copyright 2014. All rights reserved.

OPERATION

• If the system is dosing a collection system, draineld, sand lter,

wetland, or some other secondary wastewater treatment system,

the ideal dosing pattern should be known and applied.

• The high water alarm will indicate the system needs maintenance.

However, regular maintenance by trained professionals is a necessary

part of operation.

• During operation, the system owner must continue to use proper

septic tank ownership practices. Ground garbage, hair, grease, and

non-ushable paper products should be prevented from entering any

septic system. These materials will be prevented from entering the

draineld by the lter apparatus, but abuse of the system will result

in the need for more frequent servicing.

6

Replacement Parts

SERVICE PARTS LIST FOR CENTRIFUGAL STEP SYSTEM

5040-0001

SYSTEM

7

2

1

5

2

SK1687

1 Check Valve 30-0181

Discharge Assembly with Check Valve 170-0084

2

Discharge Assembly without Check Valve 170-0083

3 Tank 011300

Pump, N51, Nonautomatic (Pump Only) 51-0002

Pump, BN51, Automatic (Pump and Switch) 51-0006

Pump, N53, Nonautomatic (Pump Only) 53-0002

Pump, BN53, Automatic, (Pump and Switch) 53-0029

Pump, N98, Nonautomatic (Pump Only) 98-0002

Pump, BN98, Automatic, (Pump and Switch) 98-0005

Pump, N142, Nonautomatic (Pump Only) 142-0002

Pump, BN142, Automatic (Pump and Switch) 142-0006

4

Pump, N145, Nonautomatic (Pump Only) 145-0002

Pump, BN145, Automatic (Pump and Switch) 145-0005

Pump, N151, Nonautomatic (Pump Only) 151-0002

Pump, BN151, Automatic (Pump and Switch) 151-0005

Pump, N152, Nonautomatic (Pump Only) 152-0002

4

3

6

Pump, BN152, Automatic (Pump and Switch) 152-0005

Pump, N153, Nonautomatic (Pump Only) 153-0002

Pump, BN153, Automatic (Pump and Switch) 153-0005

Piggyback Pump Switch (Switch Only) 10-0063

5 Filter Cartridge Assembly 011303

Indoor Alarm Pak (Alarm Box and Switch) 10-1494

6

Outdoor Alarm Pak (Alarm Box and Switch) 10-0623

Mechanical Float Switch, 15' cord (Float Switch Only) 10-0743

7 Qwik Box 10-0579

thru

5040-0025

1/00 thru Current

The above parts lists are provided for ordering service parts. Please have pump model number and date code for immediate service.

© Copyright 2014. All rights reserved.

7

Maintenance

For your personal safety and health, a high quality

pair of rubber gloves are recommended while servicing this unit. For

your personal health, always wash your hands with antibacterial

soap after servicing this unit.

Always disconnect pump and panel from its power source

before servicing

GENERAL

Clarus Environmental Centrifugal STEP Systems require periodic maintenance

to remain in operational condition. A qualied service technician should carry

out the required maintenance. These technicians will not only service the pump

unit, but can assess the health of the septic tank.

SERVICE FREQUENCY

• The system contains an efuent lter. This lter will prevent solids larger

than 1/16” from entering the pump compartment. The lter will require

cleaning. The cleaning interval is determined by household use patterns.

For example, a single individual may need a lter cleaning and inspection on

yearly intervals, but a family with teenagers may require lter maintenance

every six months, or sooner. The pump tank and pump should be serviced

at a minimum each time the septic tank is pumped. Annual inspections

by trained professionals are recommended.

• Alarm activation between service intervals may be an indication that the

system is not being serviced often enough. The alarm indicates a high

liquid level and service is required immediately to avoid ooding

and sewage back up into the house.

SERVICING THE UNIT

During lter maintenance, the service technician must perform the following:

• Check the sludge level of the septic tank. If the sludge level approaches

the bottom of the STEP vault, the septic tank needs to be pumped.

• The pump should be removed, cleaned, and inspected. Any defective

components should be replaced. Inspect and remove any sand, debris,

or mud present in the pump basin assembly.

• Inspect the panel for any presence of moisture in enclosure, loose

connections, and general component condition.

• Check for proper location and unobstructed oat operation.

To remove the entire system:

1. The pump and lter tank must be removed for cleaning and servicing. This

provides an opening for pumping out the septic tank. Remove the riser

ring cover only after disconnecting power to both the pump and alarm.

2. Disconnect the pipe union in the discharge pipe and remove the entire

pump tank assembly. Hose off assembly as it is being removed to avoid

any spillage of sewage or efuents outside the septic tank.

3. Lift assembly out of the riser and stand upright on ground or level working

surface. Remove one of the 1½” support pipes, and then remove lid, pump/

oat assembly, and discharge pipe. Place over septic tank opening and

hose down thoroughly. The cordage from the junction box to the pump is

of sufcient length to avoid the necessity of disconnecting the electrical

wiring in the junction box. Do not disturb wiring connection unless pump

is being replaced or repaired. If access is required to the junction box,

disconnect power. Power is disconnected in the Qwik Box by unplugging

the connections.

4. With tank & lter over the opening, hose down the inside and outside tank.

Remove lter pack from tank by pushing on lter pack at the bottom of the

tank through opening or pulling from the top side.

5. Reinstall lter in tank. Check oat assemblies for proper operation and

reassemble pump piping and lid on lter tank. Reinstall 1½” support pipe.

Install pump and lter tank back in tank and reconnect union.

6. Fill tank with water and check out the pump system and alarm.

7. Follow Start-up procedures located in the Operation section of this manual

to get system running again.

Service Checklist

ELECTRICAL PRECAUTIONS- Before servicing a pump, always shut off the main power breaker and then unplug the

pump - making sure you are not standing in water and wearing insulated protective sole shoes. Under ooded conditions, contact your

local electric company or a qualied licensed electrician for disconnecting electrical service prior to pump removal.

Submersible pumps contain oils which becomes pressurized and hot under operating conditions - allow 2½ hours after

disconnecting before attempting service.

CONDITION COMMON CAUSES

Check fuse, low voltage, overload open, open or incorrect wiring, open switch, impeller or

A. Pump will not start or run.

Motor overheats and trips overload or

B

.

blows fuse.

C. Pump starts and stops too often.

D. Pump will not shut off.

E. Pump operates but delivers little or no water.

Drop in head and/or capacity after a

F.

period of use.

seal bound mechanically, defective capacitor or relay when used, motor or wiring shorted.

Float assembly held down. Switch defective, damaged, or out of adjustment.

Incorrect voltage, impeller or seal bound mechanically.

Float tether length too short, check valve stuck or not installed in discharge line, overload

open, level switch(s) defective.

Debris under oat assembly, oat or oat rod obstructed, switch defective, damaged

or out of adjustment.

Check strainer housing on pump and discharge pipe must be open. Discharge head

exceeds pump capacity. Low or incorrect voltage. Incoming water containing air or

causing air to enter pump. Filter Clogged.

Increased pipe friction, clogged line or check valve. Abrasive material and/or adverse

chemicals could possibly deteriorate impeller and pump housing. Check discharge line.

Remove base and inspect pump.

If the above checklist does not uncover the problem, consult the factory - Do not attempt to service or otherwise disassemble pump.

All Clarus Environmental products must be installed and maintained in accordance with all applicable codes.

Product information presented here reflects conditions at time of publication. Consult factory regarding discrepancies or inconsistencies.

© Copyright 2014. All rights reserved.

Loading...

Loading...