Clarus Environmental 450, 600, 800 User Manual

®

®

3649 Cane Run Road . Louisville, KY 40211-1961

877-244-9340 . Fax: 877-414-4316

www.clarusenvironmental.com

Fusion® Series Treatment Systems

OWNER'S MANUAL

Thank you for choosing a Fusion® Series Treatment System. High quality

workmanship and easy maintenance have been incorporated into the

Fusion® system. The system will provide years of trouble-free service

when maintained according to the manufacturer’s recommendations.

Please read this manual in its entirety before using the Fusion®, and

follow all instructions to ensure proper operation. Keep this manual for

future reference along with other important onsite documents. Should

further assistance be necessary, please contact Clarus Environmental

at 1-877-244-9340.

Warning Labels

You will nd warning labels on the Fusion®, riser lids, blower, and the

alarm control panel. It is very important to follow the information on

these labels to ensure your safety. Please do not remove these labels.

SEE LIST AT RIGHT FOR WARNINGS

SECTION: C3.10.140

CL0056

0612

Supersedes

New

1. DO NOT attempt to service the Fusion

authorized maintenance provider for all service related issues.

2. There are buried electrical cables and piping near and around the

Fusion®. Please consult your authorized maintenance provider to

locate these utilities before excavation.

3. DO NOT bury or cover the Fusion® lids with soil or other debris.

This is necessary to allow access for operation and maintenance

of the unit.

4. The Fusion® blower must be unobstructed and vented for

proper operation. Care must be taken that no grass clippings or

other materials accumulate on or around the blower and block

ventilation.

5. DO NOT place heavy objects over the Fusion® or drive heavy

equipment over the Fusion®, as damage may occur. Damage of

this kind is not covered by the warranty.

6. DO NOT plant trees within 15 feet (4.6 m) of the Fusion

Treatment System.

®

unit yourself. Contact your

®

Series

TABLE OF CONTENTS

Limited Warranty ......................................1

Process Description.................................... 3

System Components and Care ...........................4

Excavation and Installation .............................. 6

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Blower Timer Setting .................................. 11

Operation and Maintenance ............................12

Aeration Chamber Cleaning ............................14

Fusion® Pumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting ...................................... 16

LIMITED WARRANTY

Manufacturer warrants, to the purchaser and subsequent owner during

the warranty period, every new product to be free from defects in material

and workmanship under normal use and service, when properly used and

maintained, for a period of two years from date of purchase by the end

user. No allowance will be made for shipping charges, damages, labor or

other charges that may occur due to product failure, repair or replacement.

This warranty does not apply to and there shall be no warranty for any

material or product that has been disassembled without prior approval of

Manufacturer, subjected to misuse, misapplication, neglect, alteration,

accident or act of God; that has not been installed, operated or maintained

in accordance with Manufacturer's installation instructions; that has been

exposed to outside substances including but not limited to the following:

sand, gravel, cement, mud, tar, hydrocarbons, hydrocarbon derivatives (oil,

gasoline, solvents, etc.), or other abrasive or corrosive substances, wash

towels or feminine sanitary products, etc. in all pumping applications. The

warranty set out in the paragraph above is in lieu of all other warranties

expressed or implied; and we do not authorize any representative or other

person to assume for us any other liability in connection with our products.

The Fusion® Series Treatment Systems represent a collaboration with Fuji Clean Co., Ltd.

© Copyright 2012. All rights reserved.

Fusion® Model: ZF-450 ZF-600 ZF-800

Serial No. ____________________________________

Installing Contractor ____________________________________

Phone Number ____________________________________

Installation Date ____________________________________

Maintenance Provider’s Name _____________________________

Phone Number ____________________________________

Contact Manufacturer at, 3649 Cane Run Road, Louisville, Kentucky 40211,

Attention: Customer Support Department to obtain any needed repair or

replacement of part(s) or additional information pertaining to our warranty.

MANUFACTURER EXPRESSLY DISCLAIMS LIABILITY FOR

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES OR

BREACH OF EXPRESSED OR IMPLIED WARRANTY; AND ANY

IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

AND OF MERCHANTABILITY SHALL BE LIMITED TO THE DURATION

OF THE EXPRESSED WARRANTY.

Some states do not allow limitations on the duration of an implied warranty,

so the above limitation may not apply to you. Some states do not allow

the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

This warranty gives you specic legal rights and you may also have other

rights which vary from state to state.

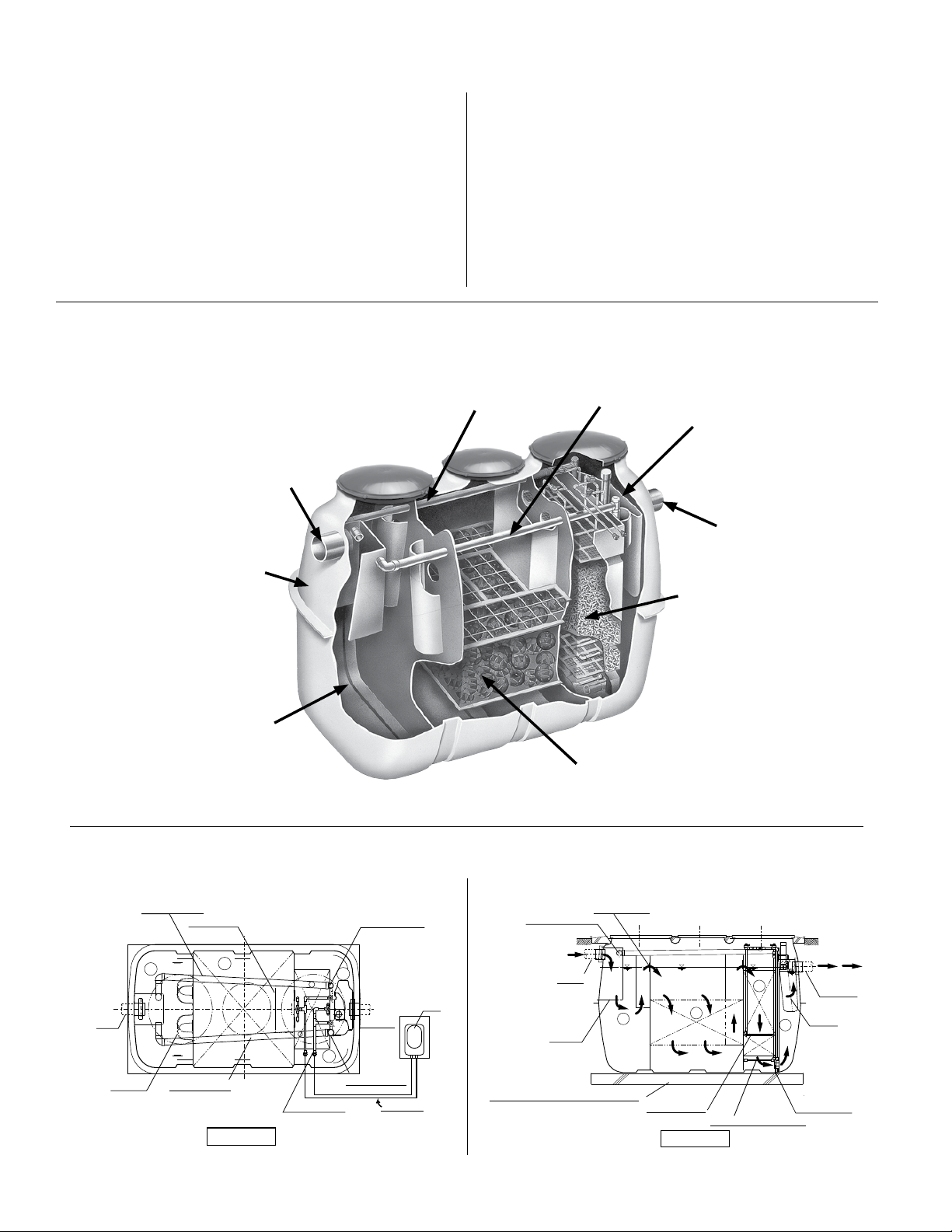

HOW A FUSION® SERIES TREATMENT SYSTEM WORKS

The Fusion® is simple in design, yet advanced in its wastewater

treatment ability. The design has been rened over many years

of intense research and development in an effort to perfect

this superior treatment system. Fusion

®

systems are 90% -

95% efcient at treating wastewater. This is nearly twice as

effective as a traditional septic tank, which is approximately

50% efcient. This high degree of treatment helps to protect

both your personal property and the environment.

The Fusion

oxygen) and aerobic (with oxygen) biological processes to treat

wastewater. As wastewater enters the Fusion

Figure 1 - The following diagram will help you to better understand the process:

®

utilizes a combination of anaerobic (without

®

, it is broken

down and becomes food for biological organisms operating

within the unit. The rst chamber serves to separate grease

and large solids from the liquid. In the second chamber, plastic

media with large surface areas are used to increase contact

between water and benecial bacteria to optimize treatment. A

small linear air blower is used to move air (oxygen) into the third

chamber for the aerobic process. The nal efuent leaving the

system will have been treated to secondary quality efuent and

will average *9 mg/L CBOD5 and 9mg/L TSS.

* Based on NSF Standard 40 testing.

Recirculation Line

Inlet Pipe

4” PVC

SCH 40 (DN 100)

Sludge Return Line

Storage

Chamber

Outlet Pipe

4” PVC

SCH 40

(DN 100)

Tank - Compression

Molded Fiber

Reinforced Plastic

Sedimentation

Chamber -

Separates bulk solid

and grease waste

Figure 2 - Schematic diagram of the Fusion

Re-circulation

Inflow

Baffle

1

Sludge return

Baffle

2

Backwash

Top View

®

Treatment System

Air-lift Pump

4

Effluent

3

Air-lift Pump

Aeration

Blower

Anaerobic Chamber -

Organisms adhere to xed lm

media and digest waste

Recirculation

6 “ (152 mm) stone or concrete pad

Wall opening

G.L.

W.L

Inflow

1

Baffle

Aeration Chamber

Floating/Circulating

Filter Media -

“Fluidized Bed”

Invigorates aerobic bacteria

W.L

2

Recirculation

Side View

W.L

3

Backwash Mechanism

G.L.

Baffle

4

Wall opening

Effluent

© Copyright 2012. All rights reserved.

2

P R E L I M I N A RY

PROCESS DESCRIPTION

1. Sedimentation Chamber

This chamber is designed to physically separate solids

from the incoming water. Scum is the oating material

and sludge is the material that has settled at the bottom.

2. Anaerobic Chamber

This chamber contains a spherical skeleton-type lter

media, 4.3 inch diameter (109 mm). Through bacterial

growth processes on the surface of the lter media,

biological anaerobic treatment thrives while suspended

solids are captured. Furthermore, the microorganisms

in this chamber convert nitrates in the recirculated water

returning from the aerobic chamber to gaseous nitrogen.

The gaseous nitrogen then escapes to the atmosphere.

3. Aeration Chamber

The aeration chamber consists of an aerated upper

section and a lter media lower section. The chamber is

lled with hollow, cylindrical lter media 0.6 inch diameter

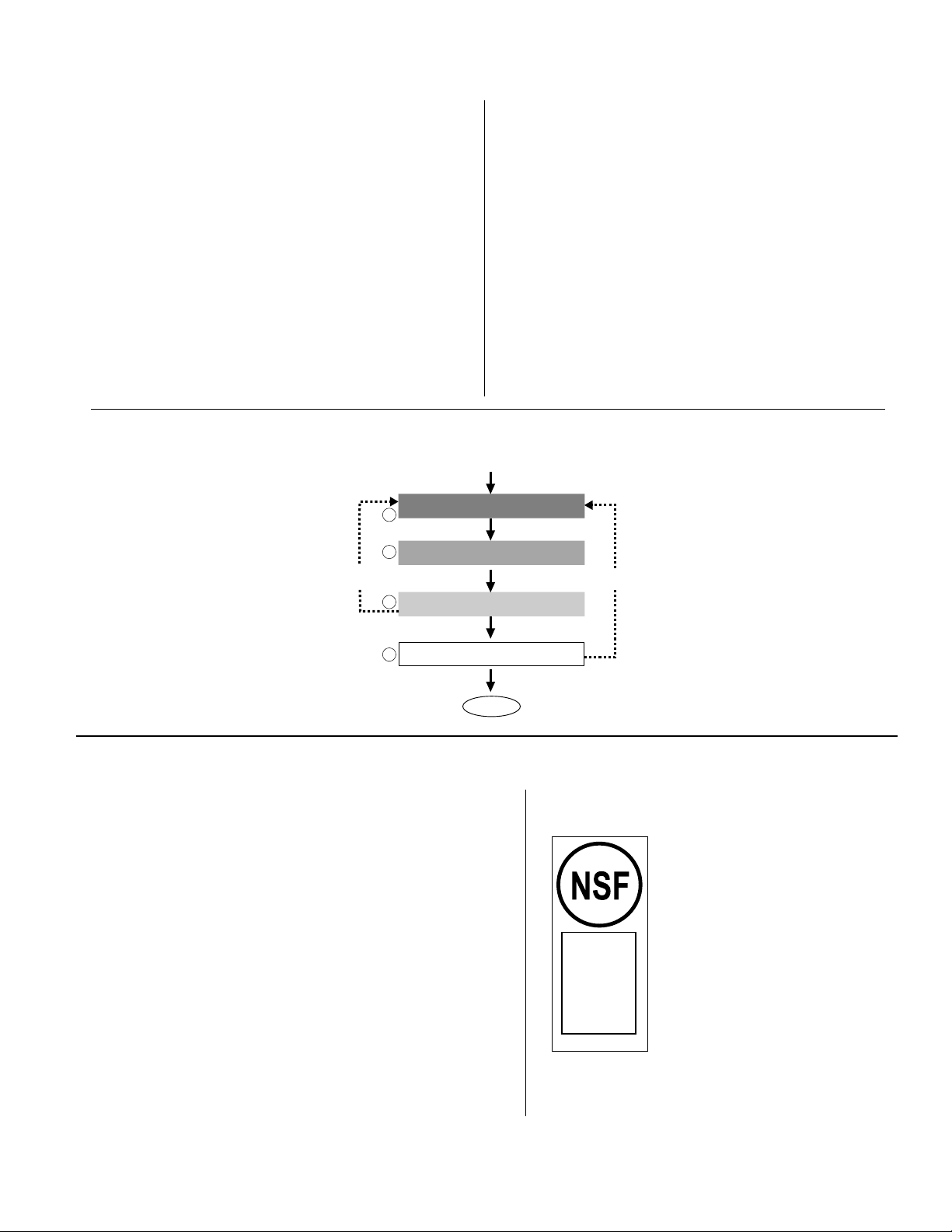

Figure 3 - Treatment Flow of the Fusion® System.

1

2

Back-Wash

3

(15 mm) and 0.55 inches long (14 mm). Biological

treatment takes place on the lter media surface.

Aeration is continuous. Residual suspended solids are

captured by the lter media circulating in this section.

During normal operation, a recirculation line transfers

water back to the sedimentation chamber by way of an air

lift pump.

The lter media in the aeration chamber are backwashed

regularly (twice a day, 5 or 10 minute cycle) by the

backwash system located at the bottom of the chamber.

The accumulated sludge is transferred by an air lift pump

back into the sedimentation chamber for further digestion.

4. Storage Chamber

This chamber is designed to temporarily store treated

water exiting the aeration chamber. This treated water is

ready for discharge.

Inflow

Sedimentation Chamber

Anaerobic Chamber

Recirculation

Aeration Chamber

4

Storage Chamber

Effluent

SYSTEM COMPONENTS

The complete wastewater treatment system will typically consist of

the Fusion

disposal of the liquid efuent. Some states or counties may require

the addition of a septic tank before the Fusion® to increase the

sedimentation chamber capacity and retain more solids. Please see

Figure 11 for a typical Fusion

will be made to suit your particular site and system design needs.

Please contact your authorized Fusion® installer or maintenance

provider for further information about your system design.

The Fusion® treatment unit comes with an electronic, dual-

port blower designed specically for use with this system. The

blower utilizes a linear motor and two diaphragms to generate

the air ow necessary to aerate and recirculate water within the

system. This style of compressor is quieter and more efcient

than traditional rotary vane compressors. Once installed and

adjusted, circuitry within the blower will automatically switch the

unit from normal recirculation mode to backwash mode and back

again when appropriate. In the event of a power outage, the

blower will stop, but a backup battery within the unit will retain

the correct time and backwash settings.

®

treatment components and a soil absorption eld for nal

®

system. Variations to the typical system

®

THE FUSION

DUAL-PORT BLOWER

© Copyright 2012. All rights reserved.

3

Figure 4

Certified to

NSF/ANSI

Standard 40

Class 1

Performance

Designation

NSF STANDARD 40, CLASS 1,

CERTIFICATION MARK

The NSF mark displayed here

will be on all NSF Standard

®

40, Class 1 certied Fusion

systems. The Fusion

ZF-450, ZF-600 and ZF-800 will

have the mark displayed on the

alarm panel. Systems not NSF

Standard 40, Class 1 certied,

will not display the mark.

®

models

®

DATAPLATE

A dataplate similar to the one in Figure 5 is located on the blower

housing and the alarm panel. There is important information about

the Fusion

number, serial number, and hydraulic capacity. Please make a

note of this information for future reference or in case you should

need to contact your Fusion® maintenance provider.

The contracting installer must mark the installed model number

on the dataplate, the blower housing and the alarm control panel.

®

on the dataplate, such as the part number, model

Figure 5

FU SI ON T REA TMEN T SYS TEM

□

ZF 450

ZF 600

□

ZF 800

□

MFG.DATE: 09/07

Manufacturer:

BL OWE R SER VI CE P AR TS

P/N 018860-B

450

GALLONS/DAY

600GALLONS /DAY

800GALLONS /DAY

Clarus Environmental • 3649 Cane Run Road

Louisville, KY 40211•1-877-244-9340

COMPLETE BLOWER: P/N 019617

BLOWER DIAPHRAGM: P /N 018848

BLOWER FILTER: P/N 018849

toll free

Certified to

NSF - ANSI

Standard 40

®

®

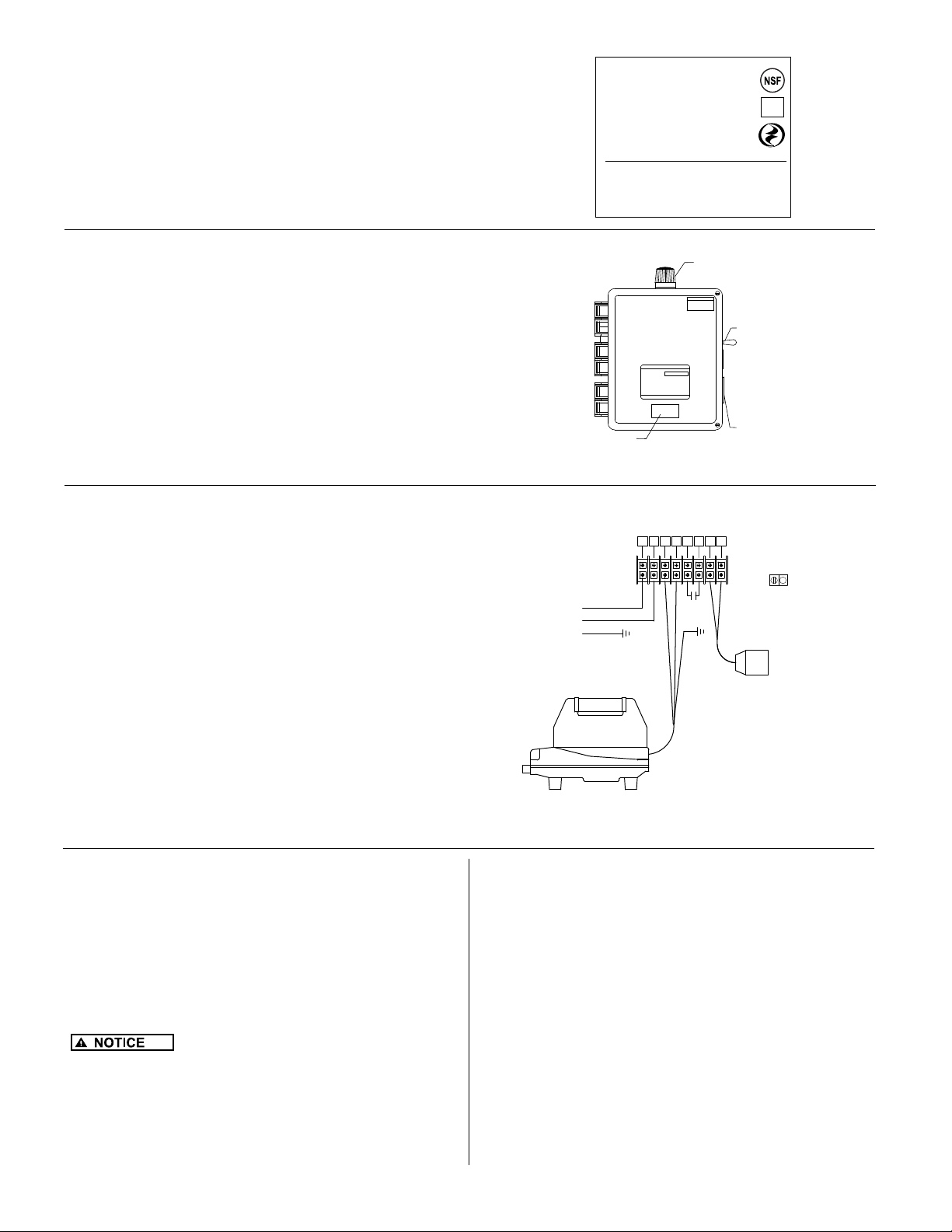

ALARM PANEL

The Fusion® comes with an alarm panel (see Figure 6) that is

designed to activate an audible buzzer and red beacon light on

top of the panel if there is a drop in air pressure, if a high water

alarm condition occurs, or if the blower does not cycle between

recirculation and backwash modes within the preset time. (Note:

Alarm panel can only function as long as there is electrical power

supplied to the panel)

You may from time to time check the proper operation of the

alarm panel by toggling the black switch on the side of the panel

to “test”. The buzzer will sound and the red beacon will light as

long as you hold the switch in the test position. Release the

switch for normal operation.

SYSTEM CARE

®

The Fusion

with little direct maintenance from the owner. Periodically, a check of the

blower area is recommended to ensure no debris obstructs the ventilation

or intake areas of the blower. Also, periodically test the control panel

as outlined under the alarm panel section. The owner should closely

monitor the types and amounts of substances and products used. Water

use should also be closely monitored to ensure proper operation of the

Fusion® system.

Periodically, more extensive maintenance must be performed. Your

authorized Fusion® maintenance provider will oversee this service. The

name of the maintenance provider can be recorded on the front of this

document and should also be located on the alarm panel. For more

information see the Operation and Maintenance section of the manual.

The owner should only perform minimal routine maintenance on the Fusion®

such as clearing debris from around blower housing (leaves, snow, and

grass clippings). The Fusion® should also be protected from excessive

weight such as vehicular trafc. Trees and bushes should not be planted

in close proximity to the Fusion®. The Fusion® should be accessible to

maintenance personnel and the riser lids must never be buried.

system is designed to continuously operate automatically

Figure 6

Figure 7

120 VAC

INCOMING

POWER

L1

N

GND

BLOWER

FUSION

DATAPLATE

TB2

RED BEACON

WARNING!

SILENCE/TEST

SWITCH

P/N

BUZZER

1

2 3 4 5 6 7 8

DISNF

ALARM

HIGH WATER

*FOR ILLUSTRATION PURPOSES ONLY*

REFER TO SCHEMATIC LOCATED IN

PANEL FOR INSTALLATION

sk2649

GND LUG

ALARM

sk2933

HIGH USE WATER DEVICES

The draining of hot tubs and swimming pools into your Fusion® system

could cause hydraulic overloading and may reduce the treatment

efciency. Please drain these devices to another location. Contact

your local regulatory authorities or authorized Fusion® maintenance

provider for more information. The use of large capacity single ll and

drain whirlpool bathtubs may also cause hydraulic overloading of your

Fusion®. Please limit the use of these types of tubs.

FLOODING

If ooding of the Fusion® occurs and the blower

or the alarm panel is submerged, please disconnect power at the

circuit breaker. DO NOT try to reconnect power to either the blower

or alarm panel once it has been submerged. Immediately contact your

authorized Fusion® maintenance provider to inspect the Fusion®, the

blower, and the alarm panel. Your maintenance provider will repair or

replace the components as needed.

© Copyright 2012. All rights reserved.

LEAKY FIXTURES

It is very important to monitor all water xtures in the home for leaks

and drips and repair them immediately. Leaks can cause tremendous

water use and use may hydraulically overload your Fusion® system and

reduce its treatment efciency. Excessive water use may also overload

your soil absorption eld and cause failure.

INTERMITTENT USE

The Fusion® system is designed to function even if wastewater does

not enter it for extended periods of time. The power to the blower

must remain on during this time for the system to function properly.

Weekend use will not harm the system as long as the blower is on.

Should seasonal use require a complete shut down of the property,

then it is recommended that the blower be turned off. It is important

to start up the system in advance of actual occupancy to allow for

normal treatment to resume. Please contact your authorized Fusion®

maintenance provider for further information concerning shut down and

startup of the Fusion®. You may also contact your maintenance provider

for the shut down and startup services.

4

P R E L I M I N A RY

HARMFUL SUBSTANCES

The Fusion® is designed to treat household type waste and

can treat most common substances introduced into the

system. However, certain harmful substances may reduce

the efciency or stop the treatment process by reducing or

destroying the benecial bacterial populations responsible for

treatment. In general, if a chemical substance is considered

harmful to humans then it should also be considered harmful

to the Fusion

concerning the use of any of these substances, please contact

your Fusion

substance on the “Do Not List” into the Fusion

the warranty.

DO NOT introduce the following substances into the

Fusion

• Motor oil • Antifreeze

• Brake uid • Paint

• Paint thinner • Gasoline

• Solvents • Pesticides

• Herbicides • Strong disinfectants

• Strong caustic drain • Toilet tank

cleaners in excess disinfection chemicals

• Excess pharmeceuticals • Chemicals & chemical

waste

Not Recommended: Trash and excess food products will

likely increase frequency of pumping.

Trash

• Sanitary napkins and • Condoms

feminine products • Cat litter

• Diapers • Dental oss

• Paper products such as • Cigarette butts

paper towels & baby wipes • Plastic/rubber products

Food Products

• Coffee lters and grounds • Greases or lards

• Fruit and vegetable peels • Seeds

• Meat products • Bones

• Garbage disposal waste • Egg shells

Limited Use Products

Certain products in small or moderate amounts should not

disrupt the Fusion

the minimum quantities of these substances as recommended

by the manufacturer.

• Liquid laundry bleach only as needed per load

• Liquid laundry detergents without added bleach

• Liquid dishwashing detergents

• Household cleaners

®

treatment system. If you have any questions

®

maintenance provider. The introduction of any

- THE DO NOT LIST -

®

treatment system:

®

treatment process. You should always use

®

will void

EFFLUENT QUALITY

®

Fusion

be installed in a typical residential/light commercial environment.

The nal efuent leaving the system will typically be treated to the

secondary quality strength of *9 mg/L CBOD5 and 9 mg/L TSS.

*

If water softners are present in the home, Clarus Environmental

recommends the use of water and salt conservative models

that are installed and operated correctly. If you have questions

about softeners, contact the Water Quality Association at

www.wqa.org. Contact factory for installation details.

Series systems are compact, efcient, and designed to

Based on NSF/ANSI Standard 40 testing.

WATER SOFTENERS

© Copyright 2012. All rights reserved.

INITIAL SERVICE POLICY

The Fusion® models ZF-450, ZF-600, and ZF-800 (NSF

Standard 40, Class 1 certied systems) have a two-year service

policy included in the initial purchase price. The service policy will

include two inspections per year for a total of four inspections.

During these inspections, numerous system checks and

adjustments will be made to ensure proper operation.

EXTENDED MAINTENANCE POLICY

An extended maintenance policy is available for purchase from

your authorized Fusion

policy will include the same system checks, schedule, and

adjustments as the initial maintenance policy. Please contact

your Fusion

information regarding the extended maintenance policy.

®

distributor or maintenance provider for further

®

distributor. The extended maintenance

AUTHORIZED MAINTENANCE PROVIDER

Your authorized maintenance provider will perform many system

checks and adjustments as needed during the maintenance

inspection. Two inspections per year will be made for a total of four

inspections during the initial service policy. Please see the Operation

and Maintenance section of this manual for further details.

Should there be any operational deciencies with your Fusion

the maintenance provider will notify the owner in writing when the

deciencies will be corrected. If the maintenance provider does

not correct the deciencies or the service calls are not completed,

please contact Clarus Environmental at 1-877-244-9340.

INSPECTION AND MAINTENANCE FREQUENCY

Fusion® Series systems are to be inspected and maintained

every six months under normal usage. The inspection and

maintenance are only to be performed by personnel trained and

authorized by Clarus Environmental. A Maintenance & Service

Report (CL0059) is to be completed for each inspection and

maintenance visit.

ALARM CONDITION

If an alarm condition occurs, please check the air intake area

around the blower and make sure no debris blocks the blower

intake. Remove the air lter cap by removing the screw from

the cap and then pulling on the sides of the top of the blower.

Remove the foam lter and gently tap against your other hand.

If it is very clogged wash it in warm, soapy water and dry well

before replacing. Reassemble lter and cap on top of blower.

Do not attempt to remove the blower housing or any other

parts from the blower. If the blower is operating properly, there

may be a high water condition within the Fusion

necessary to discontinue water use until the alarm condition

has been resolved. If the buzzer continues to sound or the

red light stays on, please contact your authorized Fusion

maintenance provider. The buzzer may be silenced by toggling

the black switch on the side of the alarm panel to “silence”.

The red beacon light will remain on until the problem has been

resolved.

®

. It may be

POWER OUTAGE

Should you experience a power outage, the blower will not

operate and air (oxygen) will not be supplied to the Fusion

If the blower is off for more than 24 hours, the lack of fresh

air will cause the treatment efciency to decrease. During a

power outage, the Fusion

will not create a backup in the home. You may, however,

have a pump or dose tank with a pump on the outlet of the

®

Fusion

soil absorption eld. If you have a system such as this,

please be aware of this condition and conserve water

accordingly.

5

, which requires power to pump the efuent to the

®

will still allow efuent to ow, and

®

,

®

®

.

EXCAVATION AND INSTALLATION

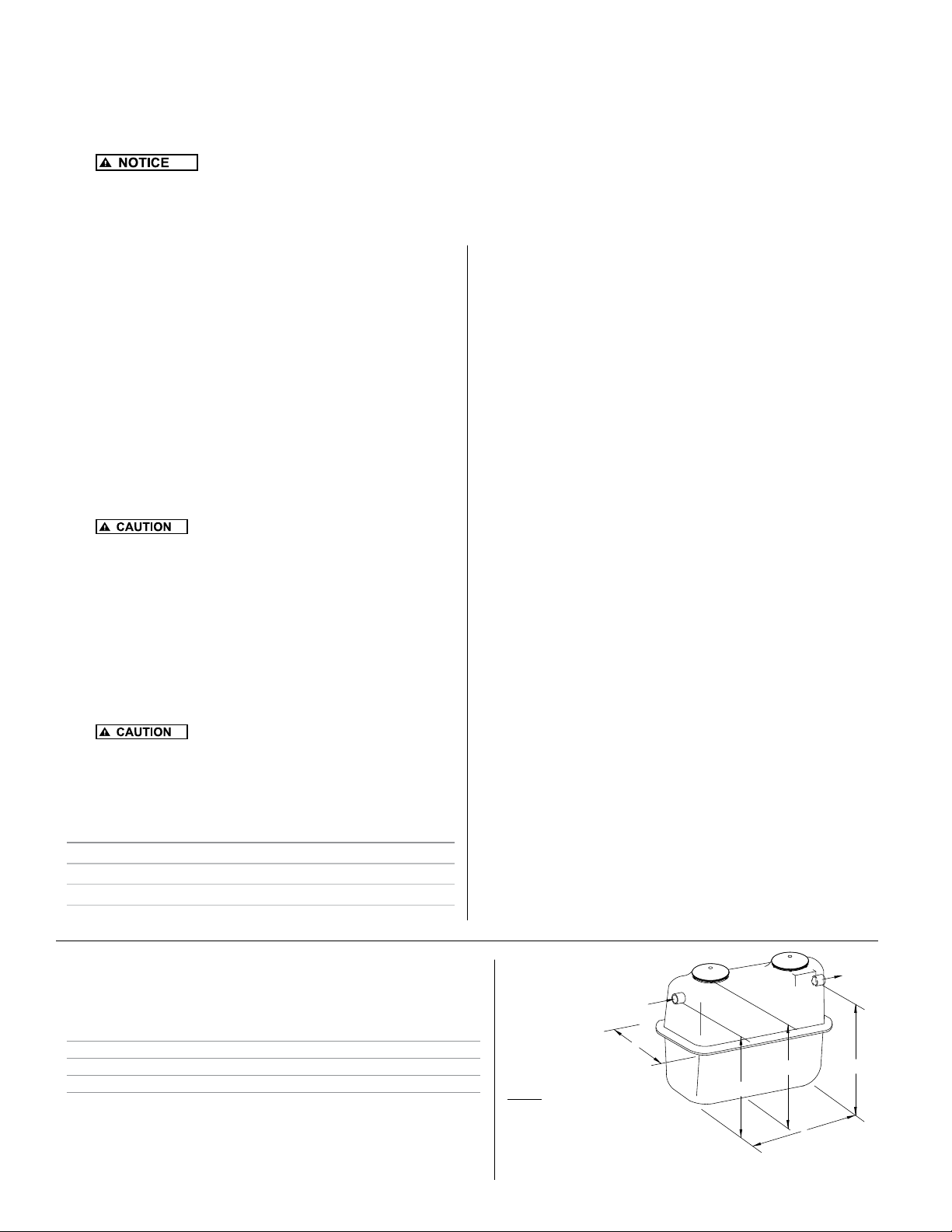

1. Excavate an area large enough for the Fusion® Series unit to be installed. See Figure 8 and Table 3 for the actual dimensions

of the unit. Excavation dimensions are calculated by adding 12-18" (305-457 mm) to the length and width of the Fusion

will allow sufcient room for proper backlling.

2. Construct a 6" (152 mm) thick stone pad of either 1/4" - 1/2" (6-13 mm) diameter stone or concrete pad and level to within 1/8" (3 mm).

3.

If the unit is not level, it will cause uneven water ow as well as unbalanced aeration, which will result in

poor performance.

4. Gently lift the unit at all four lifting points with a harness and install it on leveled stone pad (Figure 9).

5. Check unit to make certain it is level by placing a level at several locations on the riser. (riser covers removed) (Figure 9).

®

. This

BACKFILLING

1. If groundwater is present, anti-otation measures must be

used to stabilize the unit prior to backlling. Please follow

the procedures in the Anti-otation section to properly

anchor the Fusion

2. Fill the unit with clean water to the normal operating depth

prior to backlling. Partition walls between chambers are

water-tight and will ll in succession beginning on the inlet

side of the unit. Therefore, it is best to alternate chambers

when lling with water so the unit remains level. Check for

leakage around the unit.

3. If necessary, install riser extensions on the adapter rings

prior to backlling. See Table 1 for number and size of

access opennings. Riser extensions are available for

deeper burial. Make certain risers are sealed properly and

watertight.

4. Apply two beads of silicone fully around

each riser section prior to securing with supplied screws.

5. Install riser covers.

6. Backll with good quality granular soil around the unit that is

free of organic matter, rock, stone, tree roots, or other debris

that could damage the unit.

7. Tamp soil around perimeter of the unit as it is backlled to

stabilize the unit and to reduce settling.

8. Finalize backll with a mounded contour so that surface

water is shed away from the unit. Under no circumstances

should surface water be allowed to accumulate around unit.

9.

is 36 inches (914 mm).

Table 1

Number aND size of access opeNiNgs iN fusioN

20" (51 cm) Diameter

24" (61 cm) Diameter

®.

MAXIMUM soil burial depth over the unit

®

series

ZF-450 ZF-600 ZF-800

0 1 1

2 2 2

COLD WEATHER INSTALLATION

When installing Fusion® in cold climates, the designer should

specify insulated lids and risers from the factory. These are

available as an option to the standard lids and risers. In addition,

the blower must be protected from snow drifts by installing it

either inside a garage, home, basement, crawlspace or riser. If

installed in a riser, the blower must be protected from inundation

and must have a vent pipe installed to above the maximum

snow depth with a 180 degree angle at the end to prevent snow

and water entry. Also, the top and sides of the Fusion

®

must be

insulated with insulation sheeting or other means to provide a

minimum insulation value of R-8. Please contact the factory for

further information.

ANTI-FLOTATION PROCEDURES

It is necessary to anchor the Fusion® in high ground water

conditions to prevent otation. If groundwater rises above the

rock or concrete pad that the Fusion

required. Please consult a design engineer, soil scientist or other

qualied individual to determine high groundwater conditions.

1. Follow the procedures outlined in the Excavation and

Installation Section items 1-5 to properly prepare and level

the Fusion excavation.

2. Follow the procedures outlined in the Backlling Section

items 1-4 to properly ll the Fusion

risers if needed.

3. Refer to Figure 10, Anchoring Schematic to determine

the minimum amount of backll to be placed around the

®

Fusion

in the excavation. Tamp the ll to prevent settling.

4. Refer to Table 3, Concrete Anchoring Dimensions to

determine the amount of concrete needed for the concrete

anchor collar that is poured around the entire circumference

of the Fusion

®

. Pour concrete to the specied dimensions

to fully engage the mid-seam of the Fusion

anchor it once the concrete cures. Make certain to pour

the concrete in a manor to minimize trapped air within

the concrete. Agitating or lightly mixing the concrete with

a metal rod or other similar device once poured will help

release trapped air.

5. Allow the concrete to harden before nal backlling.

6. Complete the procedures outlined in the Backlling Section,

items 5-8.

®

sits on, anchoring is

®

with water and add

®

, which will

Table 2

FUSION® DIMENSIONS

SYSTEM L W H I E

®

Fusion

450 7'-1" (2.2 m) 3'-8" (1.1 m) 5'-2" (1.6 m) 4'-4" (1.3 m) 3'-10" (1.2 m)

®

Fusion

600 8' (2.4 m) 4'-1" (1.2 m) 5'-6" (1.7 m) 4'-8" (1.4 m) 4'-2" (1.3 m)

®

Fusion

800 8'-3" (2.5 m) 4'-8" (1.4 m) 6'-2" (1.9 m) 5'-4" (1.6 m) 4'-10" (1.5 m)

© Copyright 2012. All rights reserved.

Figure 8- Dimensions

INLET

W

H

NOTES:

1) DIMENSIONS "I" AND "E" ARE TO THE BOTTOM

OF THE INLET/OUTLET PIPE.

2) THE OVERALL HEIGHT DIMENSION "H" IS TO THE

TOP OF THE NARROW ADAPTER RING, NOT THE RISER LID.

3) A RISER COVER COMES STANDARD. ADDITIONAL RISERS ARE

PURCHASED SEPERATELY.

6

I

OUTLET

E

sk2624

L

Loading...

Loading...