CLARKSON FIGURE 215 SLIDE GATE VALVE

INSTALLATION AND MAINTENANCE INSTRUCTIONS

Before installation these instructions must be fully read and understood

WARNING

The user is responsible for correct directional

installation.

On select applications, greater performance

may be realized by installing a unidirectional

valve in the reverse flow position, contact

factory for details.

Packing assembly: the packing gland bolts

should be checked and adjusted to obtain a

first time packing seal. Packing gland bolts

may become slightly loose when valve is

shipped. Field adjustment is expected and

desired. (Tighten just enough to stop any

leakage. Overtightening may increase valve

operating torque and shorten packing life.)

The Figure 215 is equipped with two packing

assemblies.

GENERAL INFORMATION

Thank you for purchasing a Figure 215 slide

gate valve from Emerson. With proper care it

should provide you a long service life.

Valve types: standard Figure 215 is

UNIDIRECTIONAL (one-way shut-off). UniDirectional valves have a preferred shut-off

direction, however, they will handle flow in

both directions without concern.

WARNING

Care must be taken in valve installation with

respect to direction of flow.

Uni-Directional valves have the preferred

direction of shut-off indicated by the word

"SEAT" stamped on the upper right hand

corner of the gate on the seat side or a flow

arrow (pointing toward the preferred direction).

A unidirectional valve is normally installed with

the seat side (preferred direction) downstream,

with the line pressure pushing the gate toward

the seat.

Operators: standard manual handwheels

are shipped loose for field installation. It

is necessary to use a pipe wrench or large

crescent wrench to properly tighten the

handwheel retaining nut. Be sure to fully

tighten.

If valve is supplied with other than standard

handwheel operator, additional support may

be required, especially if valve is other than

vertical. See page 6 for further details.

Bolting: the mating line flanges must be

properly aligned. Slip on or weld flanges can be

used. Never try to make up for misaligned pipe

flanges by the line bolting. Pipe supports and/

or expansion joints should be used to minimize

pipe loads on valves.

Most Figure 215 valves are suitable for use in

either vertical or horizontal lines. If operator

is other than vertical, additional support may

be required if valve is not handwheel operated.

For horizontal pipes with valves mounted with

the stem horizontal, additional wear strips may

be required. Consult factory.

VCIOM-08489-EN 19/09Emerson.com/FinalControl © 2018 Emerson. All Rights Reserved.

CLARKSON FIGURE 215 SLIDE GATE VALVE

INSTALLATION AND MAINTENANCE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Please take note of the specific installation tags

provided with each valve.

The mating line flanges must be properly

aligned. Slip on or weld flanges can be used.

Never try to make up for misaligned pipe

flanges by the line bolting. Pipe supports and/or

expansion joints should be used to minimize

pipe loads on valves.

Most Figure 215 valves are suitable for use in

either vertical or horizontal lines. If operator

is other than vertical, additional support may

be required if valve is not handwheel operated.

For horizontal pipes with valves mounted with

the stem horizontal, additional wear strips may

be required. Consult factory.

Bolting and installation instructions for

standard slide gates

(Valves with drilled and tapped flange mounting

holes)

All standard Class 150 Figure 215 valves

are “flanged” design. The port flanges of the

valves NPS 2 to 24 are drilled and tapped to

ASME B16.5/150. The valves are normally

provided in the MSS standard face-to-face with

the port flange bolt holes drilled and tapped.

The bolt holes in the chest or upper flange

area are blind tapped, see Figure 1.

WARNING

Care must be taken when installing studs or bolts

in the tapped holes of the flange in the valve chest

area to prevent damage.

Cap screws or bolts that are too long can

pinch the valve body, thereby forcing it into

the gate and springing the gate out of line.

Additional damage can occur on the gate face,

such as scoring or scratching of the gate. This

type of damage normally requires the valve

be returned to our shop for repair. To avoid

damage, it is recommended that studs be used

on all tapped bolt holes, especially the upper

chest holes. If cap screws are used, be sure

that they do not enter beyond the depth of the

tapped hole when fully tightened. See Table

A for flange thicknesses of MSS face-to-face

knife gate valves.

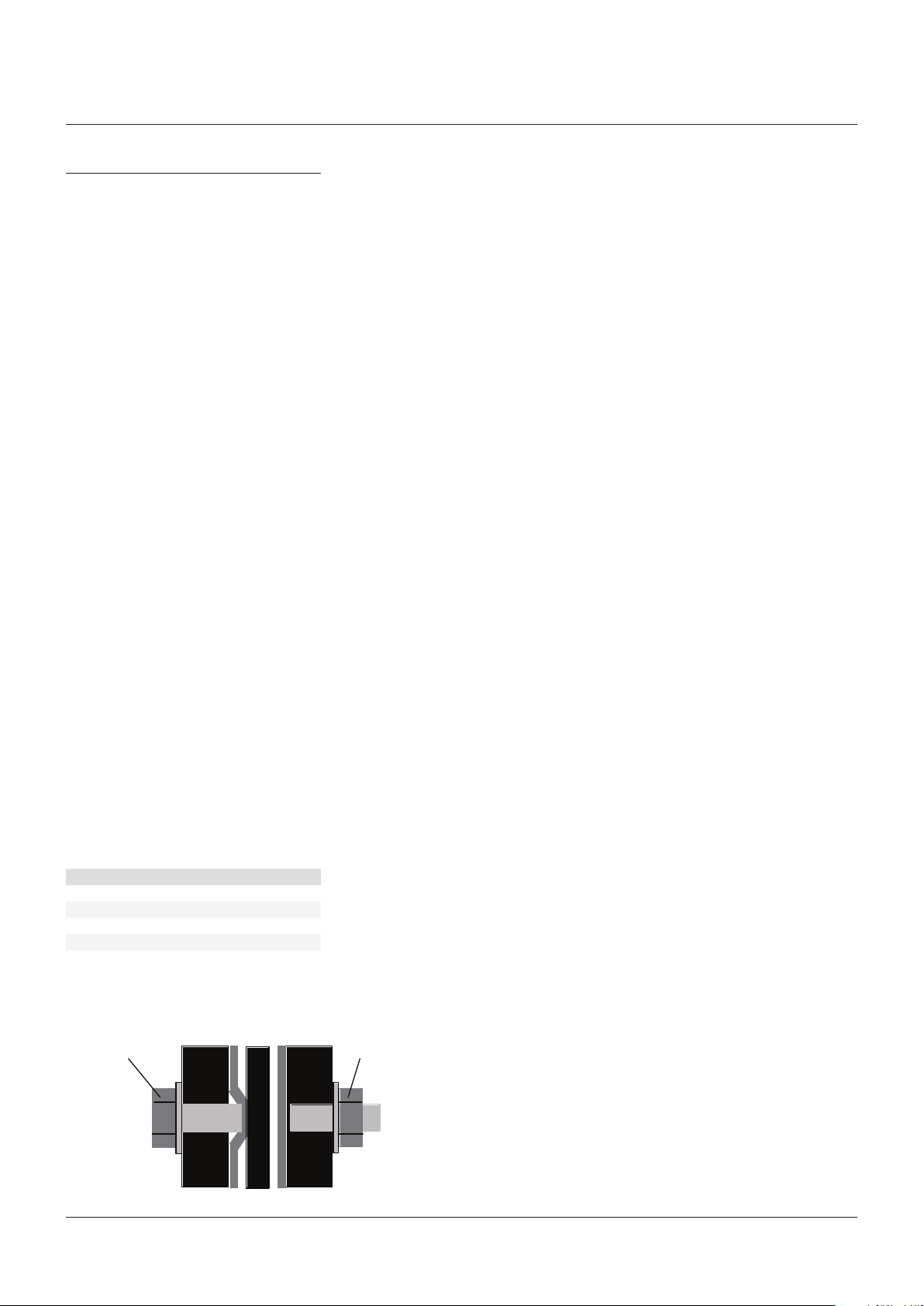

MAXIMUM FLANGE BOLT TORQUES (ft·lbs)

Size Torque Size Torque

⅝ 55 +/-5 1⅛ 150 +/-5

¾ 65 +/-5 1¼ 200 +/-5

⅞ 110 +/-5 1½ 250 +/-5

1 135 +/-5

FIGURE 1

Cap screw Stud with nut

Incorrect

Correct

2

CLARKSON FIGURE 215 SLIDE GATE VALVE

INSTALLATION AND MAINTENANCE INSTRUCTIONS

TABLE A - MSS-SP81 DIMENSIONS

Valve

size

Flange

outside dia.

[1]

Raised

face o.D.

[1]

Bolt circle

[1]

dia.

Bolting dimensions

No. of bolts Tap size

[1,3]

Face to

face

thickness

2 6 3⅝ 4¾ 4 ⅝ - 11 NC 1⅞ ½

3 7½ 5 6 4 ⅝ - 11 NC 2 ½

3

4 9 6

5 10 7

/

16 7½ 8 ⅝ - 11 NC 2 ½

5

/

16 8½ 8 ¾ - 10 NC 2¼ ⅝

6 11 8½ 9½ 8 ¾ - 10 NC 2¼ ⅝

8 13½ 10⅝ 11¾ 8 ¾ - 10 NC 2¾ ⅝

10 16 12¾ 14¼ 12 ⅞ - 9 NC 2¾ ¾

12 19 15 17 12 ⅞ - 9 NC 3 ¾

14 21 16¼ 18¾ 12 1 - 8 NC 3

16 23½ 18½ 21¼ 16 1 - 8 NC 3½ ⅞

18 25 21 22¾ 16 1⅛ - 7 NC 3½

20 27½ 23 25 20 1⅛ - 7 NC 4½ 1

24 32 27¼ 29½ 20 1¼ - 7 NC 4½ 1

NOTES

For larger size valves, refer to the customer drawing.

1. These dimensions duplicate Class 150 of ASME B16.5 to facilitate mating.

1

2. Flange thickness includes

/

16" raised face.

3. Hole size dimensions for through bolting shall conform to Class 150 of ASME B16.5.

4. All dimensions are in inches.

Flange

13

/

16

15

/

16

[2]

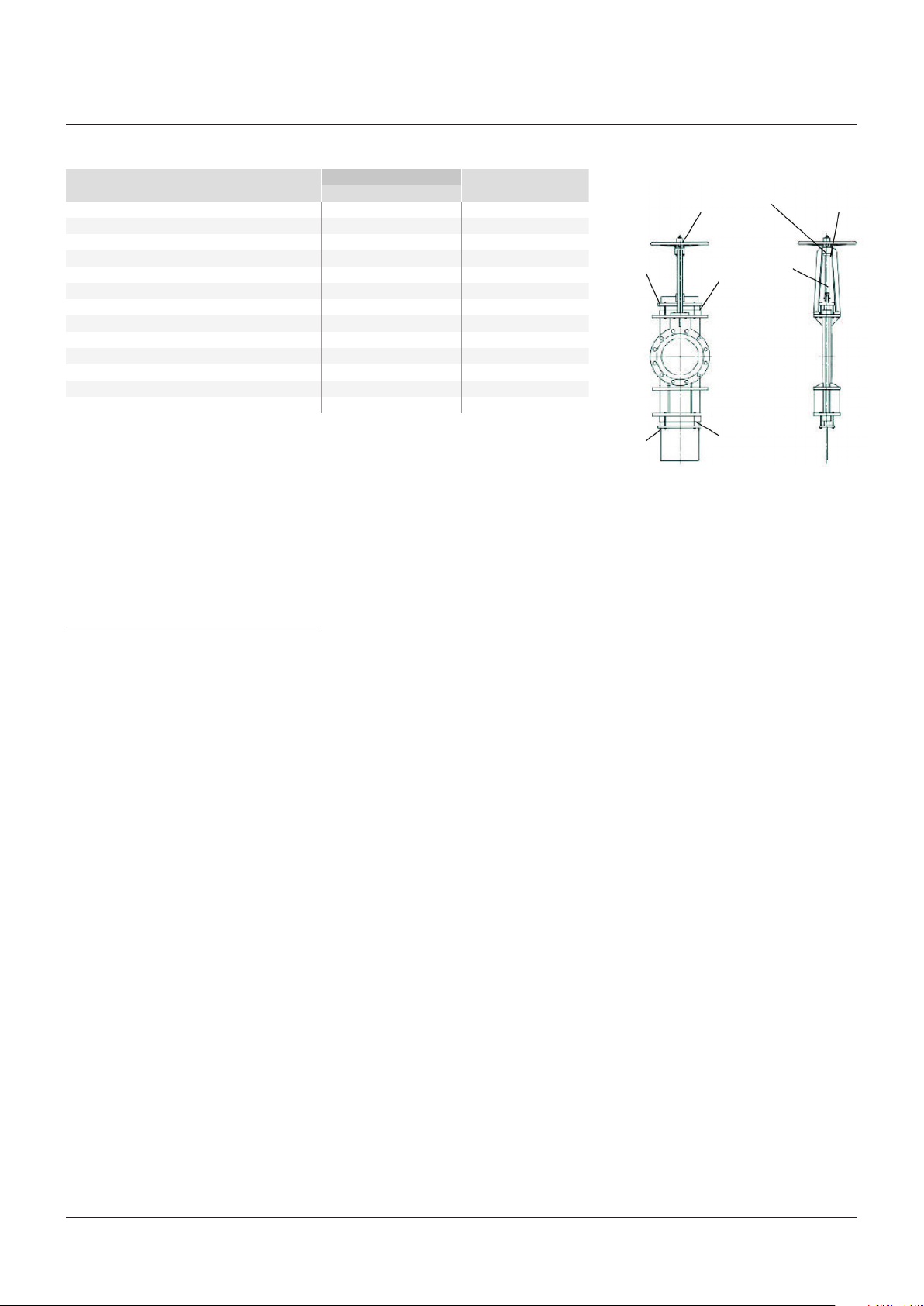

FIGURE 2

Packing

gland

Packing

gland

Umbrella nut

(stop stud)

Packing

Packing

Grease

fitting

Stem

Stem nut

GENERAL MAINTENANCE

The factory recommends that all Figure 215

valves be inspected at least every 60 days.

The following points should be examined and

corrected as required:

1. Valve stems, extension stems, and stem

nut: look for excessive corrosion, galling or

lack of lubrication. If a valve stem requires

lubrication, utilize the grease fitting provided

and pump standard bearing grease through

the yoke hub to lubricate the stem and stem

nut assembly. Additional lubrication may be

applied directly onto stem or stem threads.

(Use material which meets ASTM 4950

GBLB). See Figure 2.

2. Packing glands: check for leaks or worn

packing. If leakage is occurring around the

packing gland, tighten the packing gland

bolts, being careful not to overstress the

bolting. On some valves this will require two

wrenches, one to tighten the nut and the

other to hold the packing bolt from turning.

If the valve requires repacking, you may

use any standard square braided packing

as suitable for your service. See additional

instructions for repacking on page 5 for

bonnetless valves.

3. If possible, stroke the valve through the full

open and closed position to make sure it is

functioning properly.

NOTES

1 Stop all small leaks as soon as possible as

considerable damage can be done to the valve

and the surrounding area if leakage is allowed to

continue to grow.

2. Replacement parts including handwheel and yoke

assemblies, gates, packing glands, and packing

can be provided from our factory. If valve requires

further repair, please contact our office for an

estimate of feasibility and cost of repair.

3

Loading...

Loading...